A face rockfill dam anti-seepage structure

A face rockfill dam, face plate technology, applied in dams, barrages, water conservancy projects, etc., can solve the problems of prolonging the construction period, increasing investment, increasing engineering costs, etc., to ensure the water stop effect, reduce engineering costs, and improve engineering. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

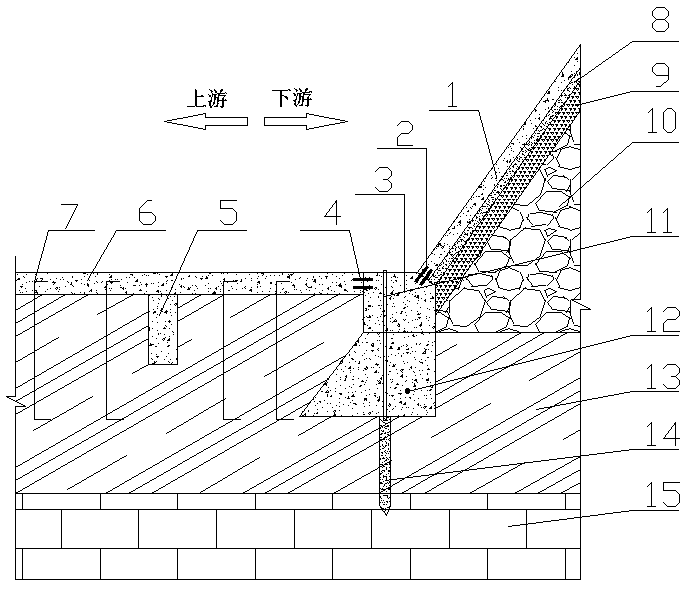

[0024] Such as figure 1 Shown, a kind of concrete face rockfill dam anti-seepage structure, comprises bedrock 15, is positioned at the covering layer 13 on bedrock 15, and described covering layer 13 is provided with dam body, and this dam body comprises rockfill 10, and rockfill 10 Lay the dam transition material 9, the dam cushion material 8, and the panel 1 sequentially from bottom to top on the slope.

[0025] The upstream side of the dam body is located at the lower end of the face plate 1, and a foundation abutment 12 with a trapezoidal cross section is excavated. A toe plate 3 is provided on the foundation abutment 12. The top side of the toe plate 3 is in contact with the face plate 1. Waterstop copper sheet 2.

[0026] An anti-seepage board 6 flush with the toe board 3 is provided on the upstream side of the toe board 3 , and a water-stop copper sheet 4 is provided at the junction of the toe board 3 and the anti-seepage board 6 .

[0027] The cover layer 13 under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com