Movable water stop system of final connector and application method

A water stop and water stop technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems such as difficult water stop, poor water stop effect, short service life, etc., to ensure water stop, strengthen water stop Water effect, the effect of prolonging the water stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

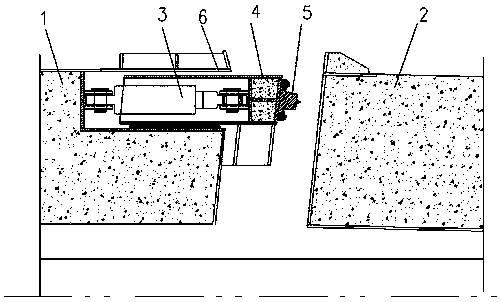

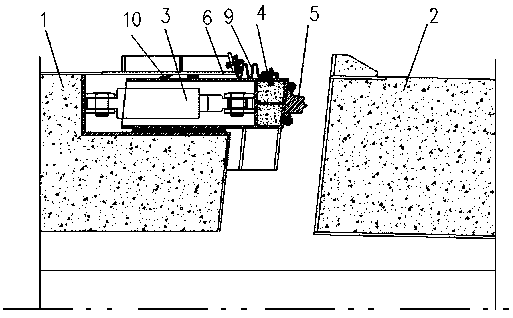

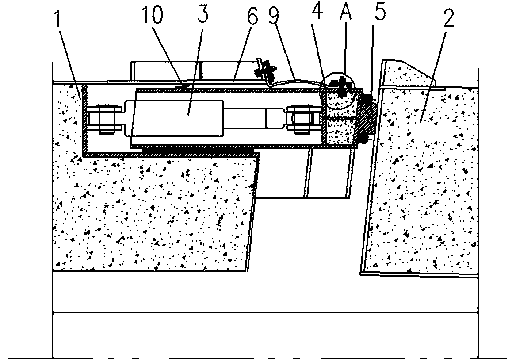

[0050] Such as figure 2 and image 3 As shown in the mobile water stop system of the final joint, the final joint 1 and the push beam 4 are equipped with an external water stop device 9 that makes the annular cavity relatively sealed from the outside water flow, and the external water stop device 9 includes a flexible Waterstop, one end of the flexible waterstop is connected to the final joint 1, and the other end is connected to the push beam 4, the extension length of the flexible waterstop corresponds to the length of the outward movement of the push beam 4, and the ring An internal water stop device 10 is also installed in the cavity of the cavity.

[0051] The external water stop device uses a flexible water stop, and the two ends of the flexible water stop are respectively connected with the final joint 1 and the push beam 4 to complete the sealing. When the push beam 4 moves relatively, the flexible water stop follows the The push beam 4 moves to the adjacent pipe jo...

Embodiment 2

[0071] Such as figure 2 and image 3 As shown, the method of using the mobile water stop system for the final joint includes the following steps:

[0072] a. Install the internal water stop device 10, and install the internal water stop device 10 at the design position of the push beam 4;

[0073] b. Push the pushing beam 4 into the inner cavity of the final joint 1, so that the pushing beam 4 is at the initial position before pushing;

[0074] c. Install the jack 3, and use the jack 3 to connect the pushing girder 4 and the final joint 1;

[0075] d. Install the external water stop device 9, and connect the two ends of the flexible water stop belt to the pushing girder 4 and the final joint 1, so that an independent closed space is formed between the external water stop device 9 and the internal water stop device 10.

[0076] Through the above method, a mobile water-stop structure is formed between the pushing girder and the final joint to achieve the effect of sealing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com