Large-section and small clear spacing dark excavation construction method through combined supporting of MJS construction method and pipe curtain method

A combined support and large-section technology, applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems of poor economy, difficult construction, limited usable places, etc., and achieve the effect of ensuring safety and controlling risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

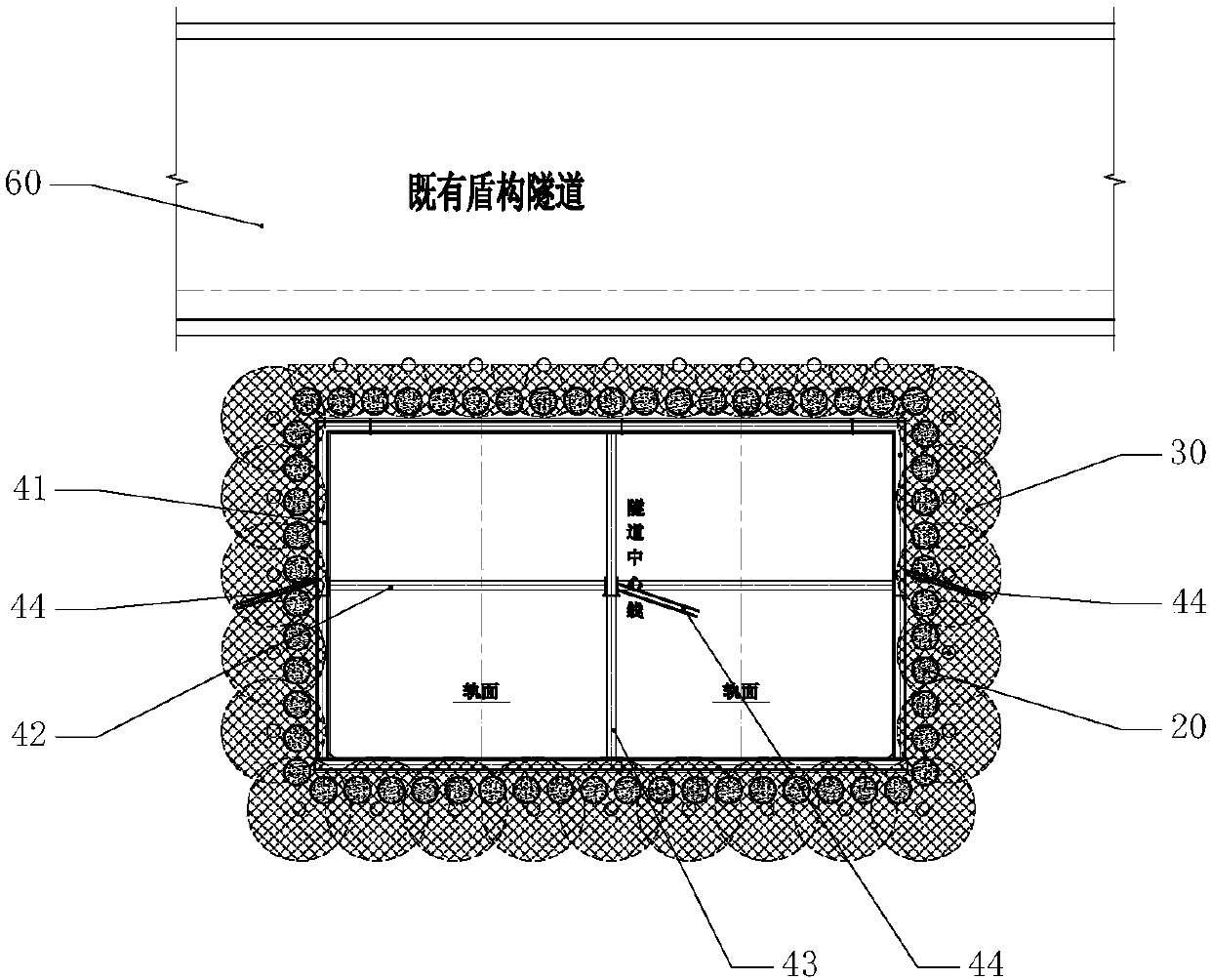

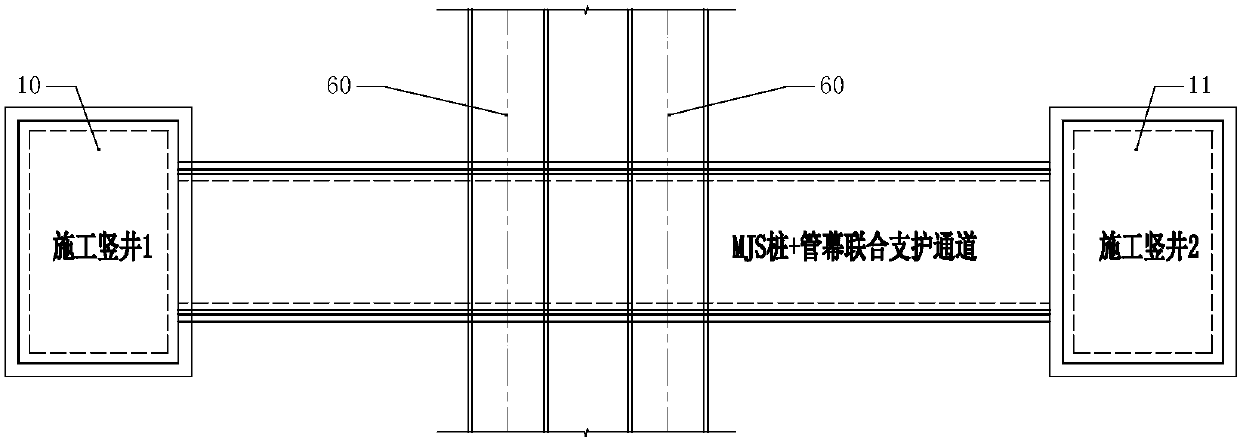

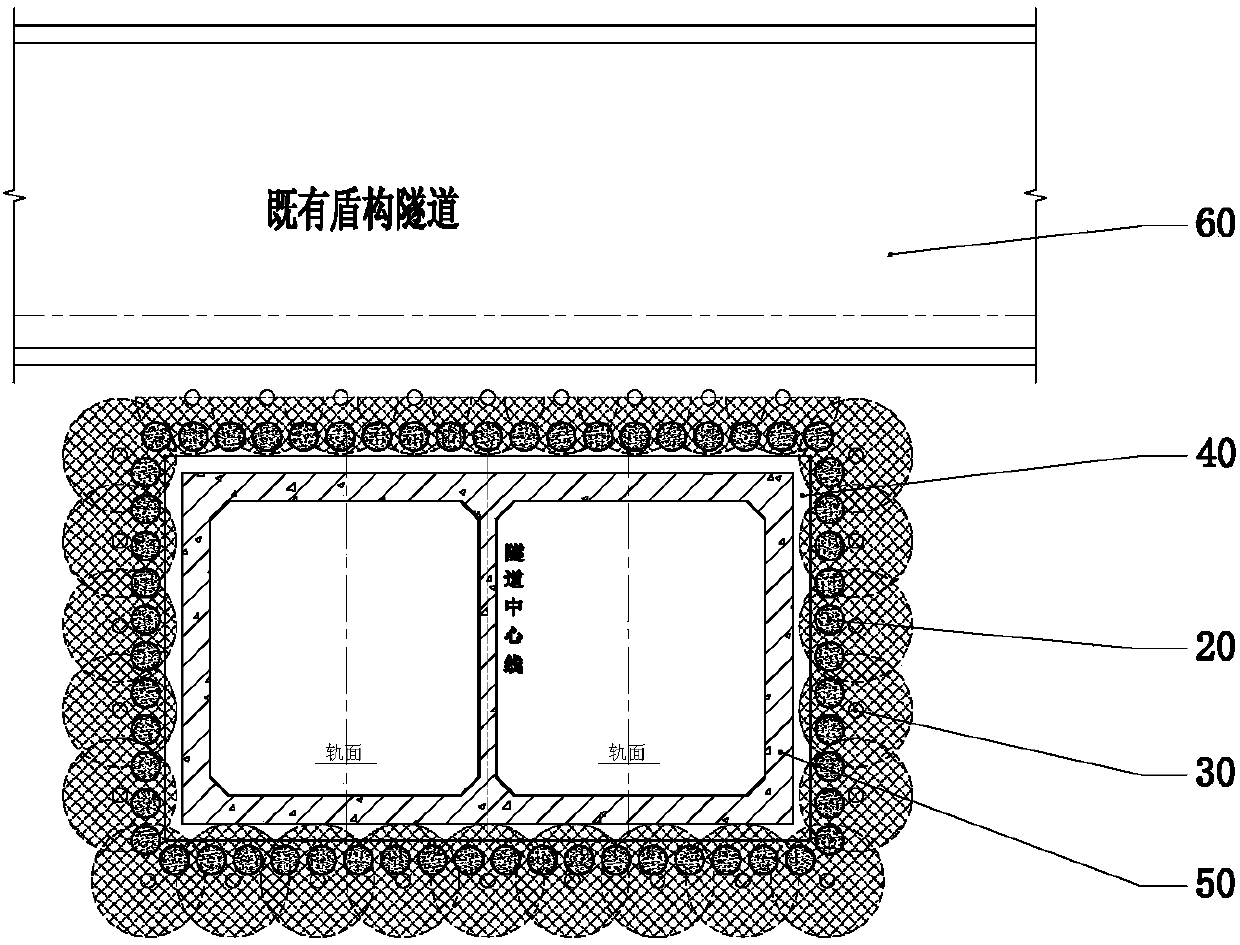

[0025] Reference Figure 1 to Figure 4 In this embodiment, under the existing shield tunnel 60, the MJS method and the tube-screen method combined support method are used to excavate a large-section and small-distance tunnel, and complete the construction of the internal structure 50 of the tunnel. The specific steps are as follows:

[0026] a. Set up working shafts 10 at both ends of the proposed tunnel. The cross-section of the proposed small clearance tunnel is rectangular. The pipe curtain is formed by steel pipes 20 evenly distributed along the outer contour of the tunnel and horizontally passing through the soil. Section and length, the clear distance between the tunnel and the existing shield tunnel 60, and the actual situation of the site geology, design the number and diameter of the steel pipe 20, the location of the steel pipe 20, the spray range and spray angle of the MJS pile 30, and the MJS pile 30 The position arrangement, as well as related parameters such as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com