Patents

Literature

94results about How to "Controllable risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

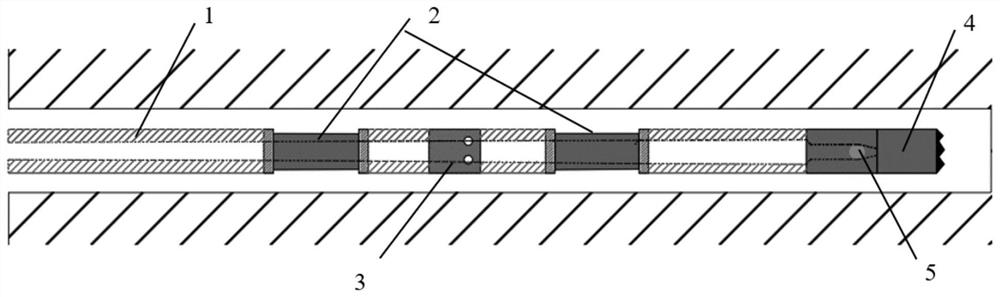

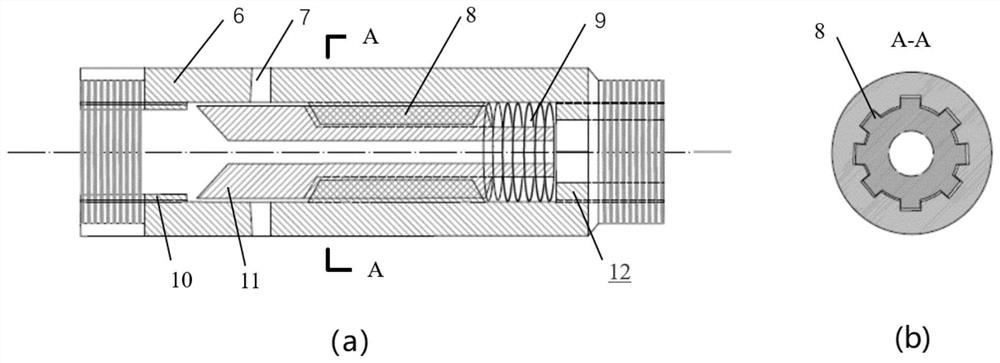

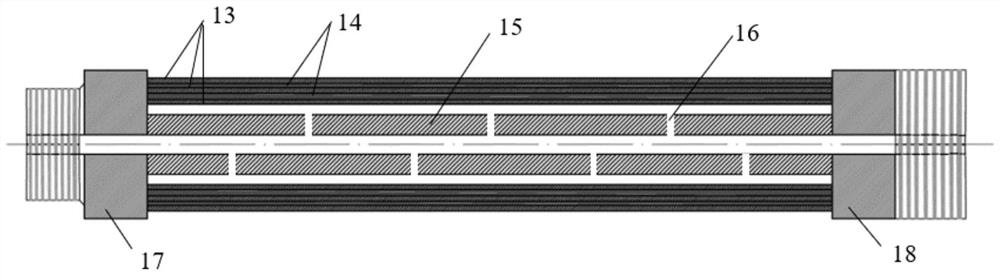

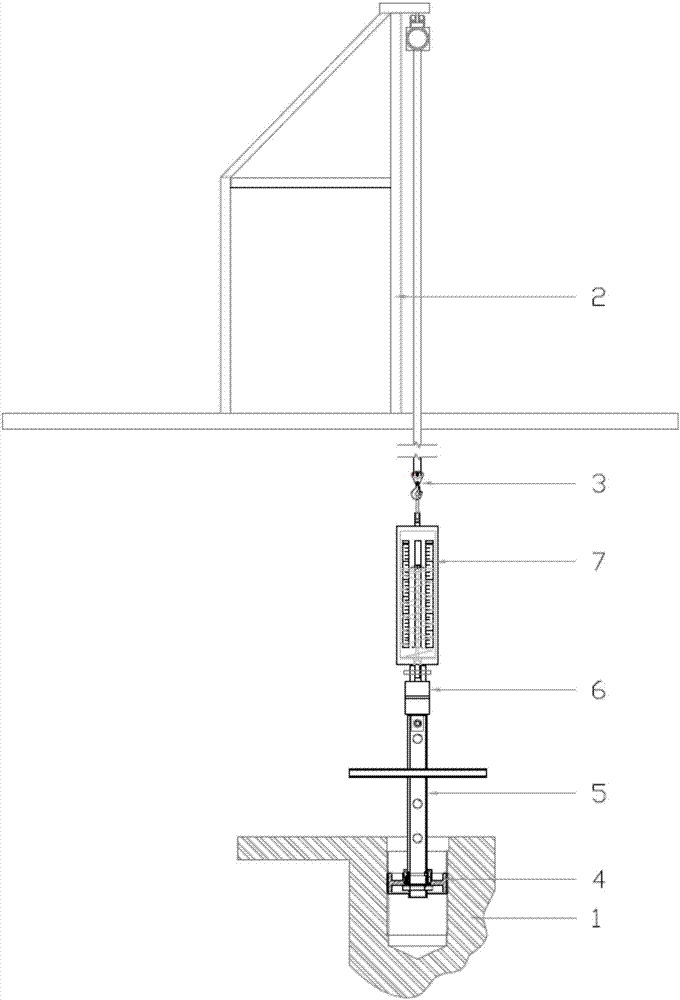

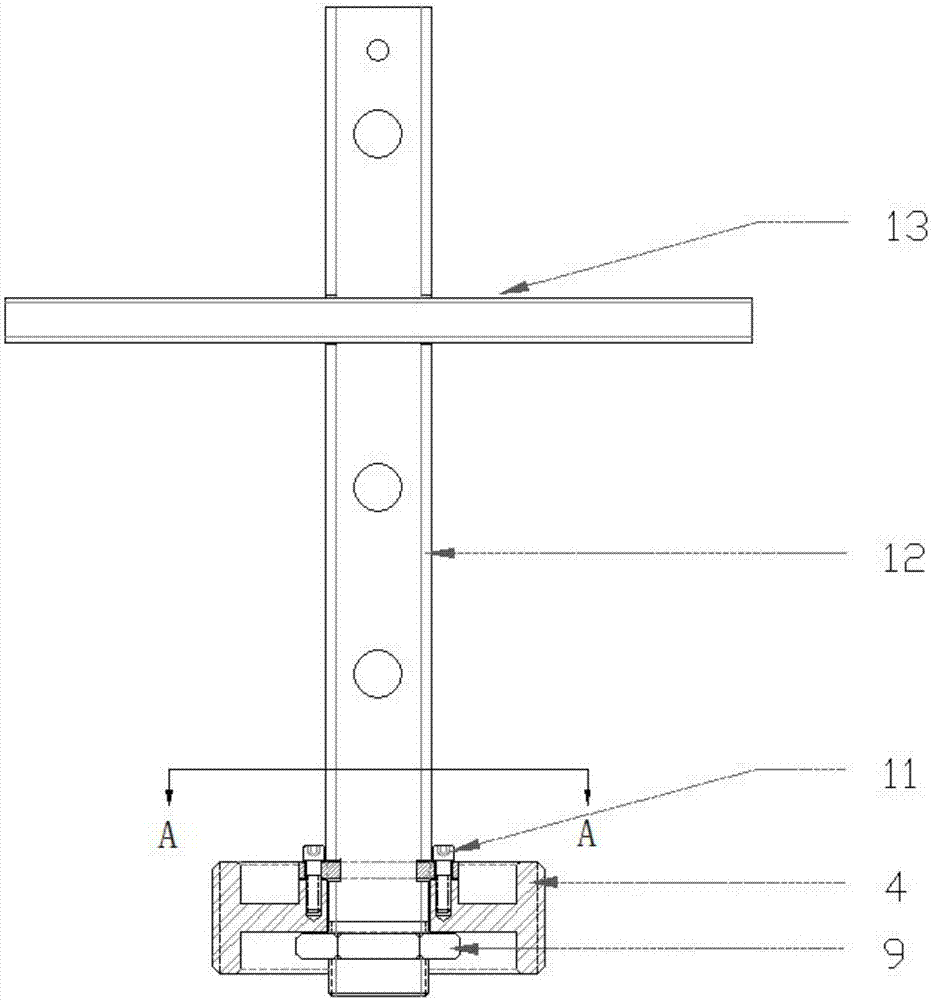

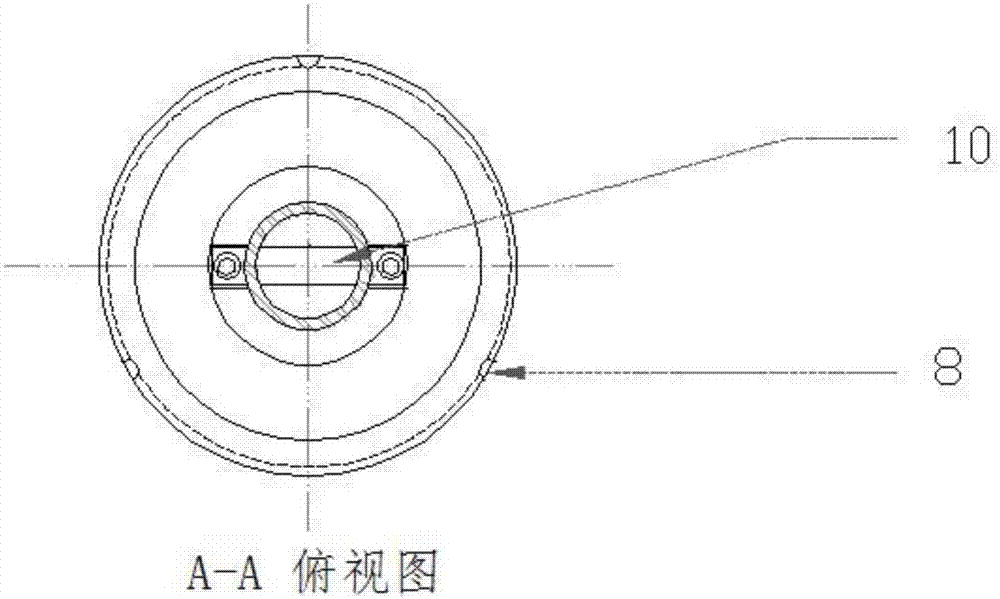

Roller guide rail station-passing construction method of whole shield machine

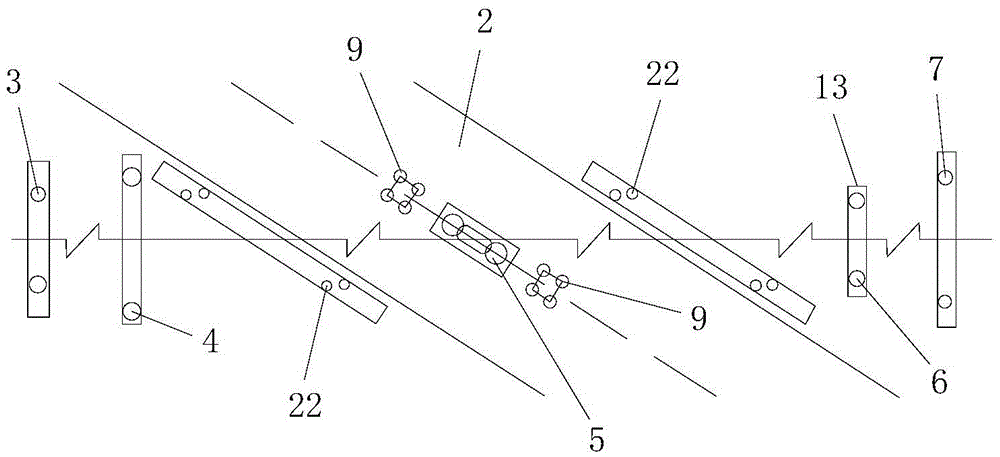

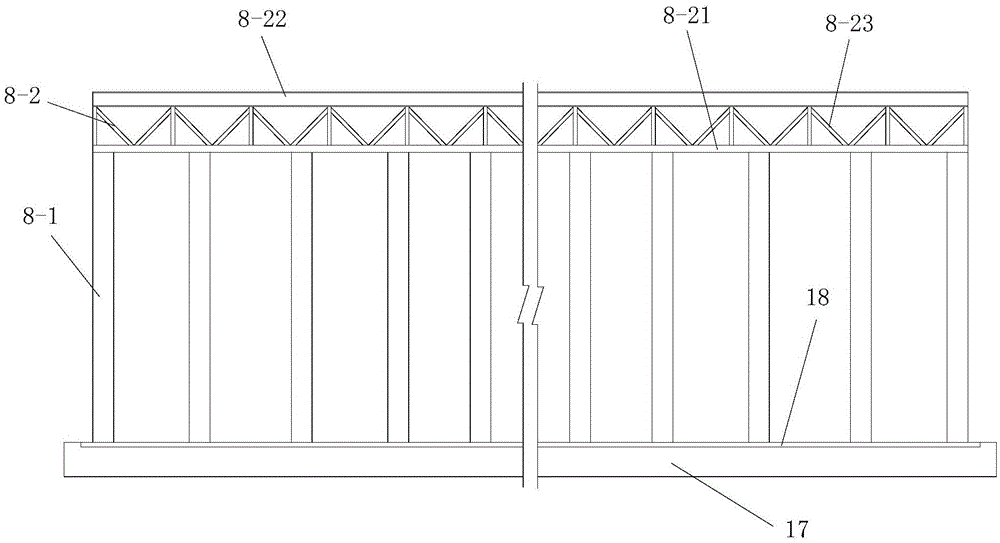

The invention relates to the field of tunneling shield construction, in particular to a roller guide rail station-passing construction method of a whole shield machine and solving the problems of high difficulty, high cost, long construction peroid and the like of the traditional method. The roller guide rail station-passing construction method comprises the following steps of: machining a shieldforward-moving roller, a forward-moving guide rail, a counter-force device and a rear matched track section; determining whether water stop fabric is arranged in a hole, carrying out shield receivingand welding the forward-moving roller while receiving; moving the whole shield machine forwards, cutting a U-shaped groove plate at a shield connecting bridge off, paving the shield forward-moving guide rail, installing the counter-force device, and enabling the shield to move continuously forwards under the actions of the counter-force device and an oil cylinder; cutting the forward-moving roller off in the process of moving the shield to an originated base forwards, arranging the oil cylinder to the originated base and the side wall of an originated wall, starting the oil cylinder so that the shield body and the originated base translate together along the articulation part of the connecting bridge and the shield body and subsequent associated equipment are in the same straight line, and carrying out second originating. The roller guide rail station-passing construction method has the advantages of simple process, short construction peroid, low cost, risk controllability and the like and has favorable economic and social benefits and wide application range.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

A construction method for the communication channel of the broken stratum in the shield tunnel crossing the river

ActiveCN102287198AEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingEnvironmental resistanceGround contact

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

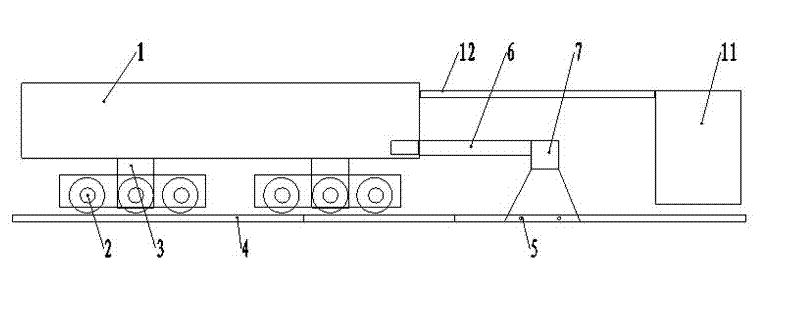

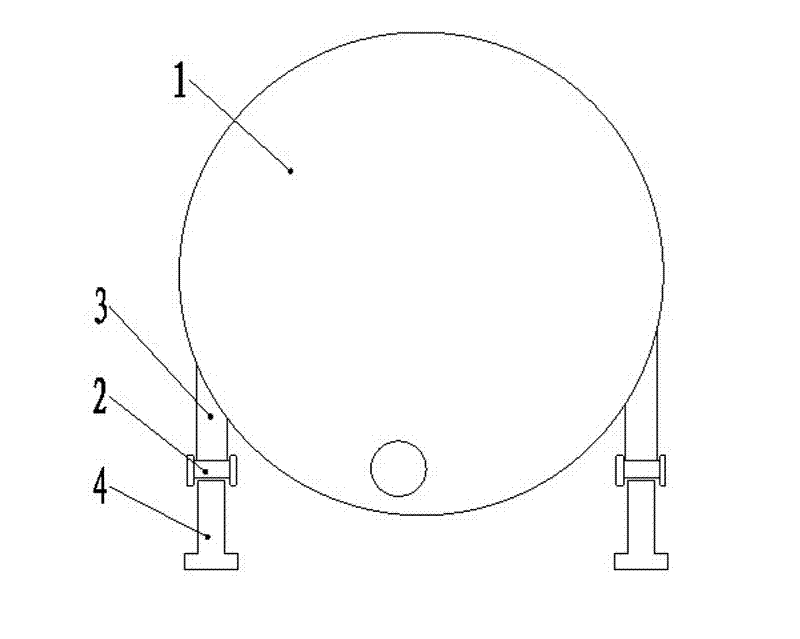

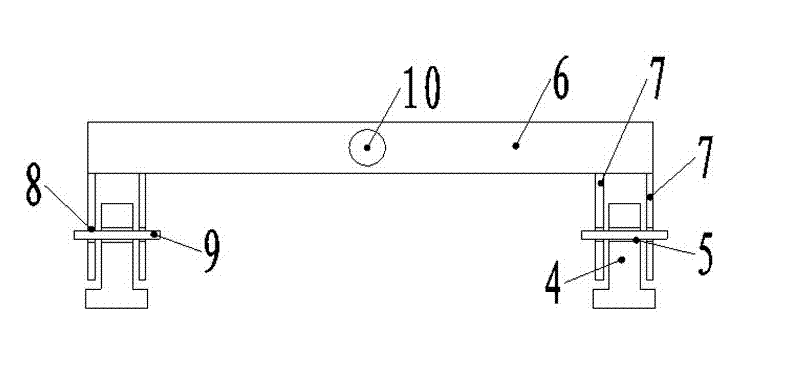

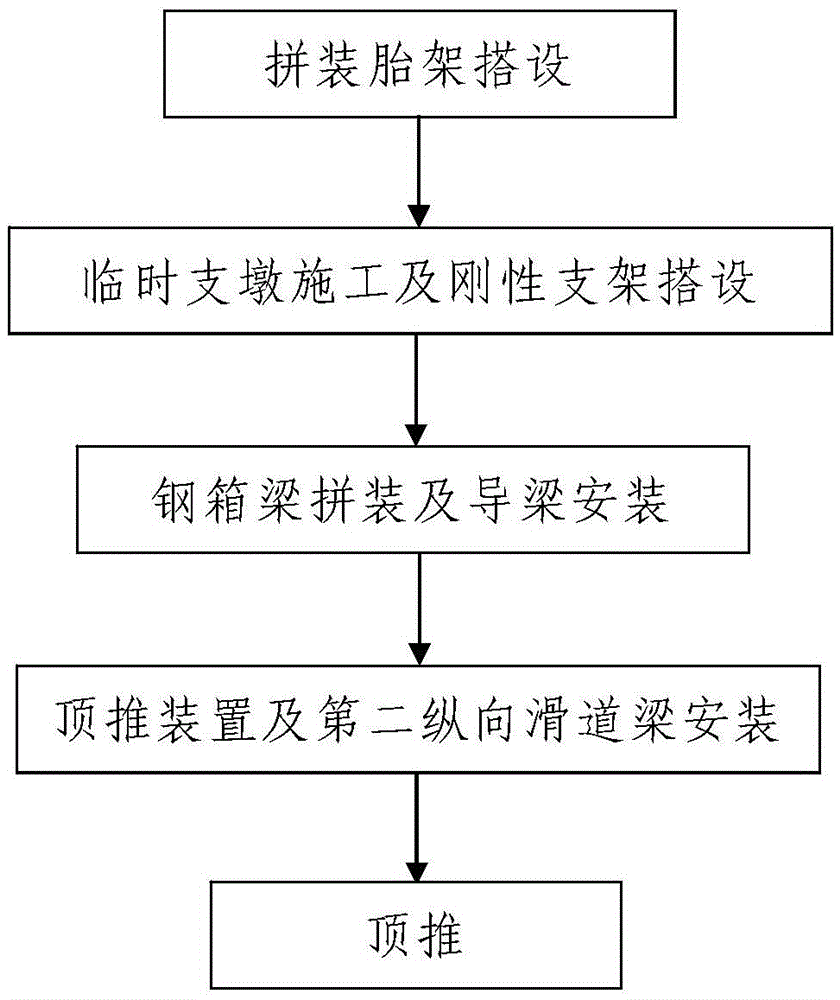

Incremental launching construction method for large-span steel box girder spanning constructed road

ActiveCN105568866AThe method steps are simpleSimple and fast operationBridge erection/assemblyButtressSteel box girder

The invention discloses an incremental launching construction method for a large-span steel box girder spanning a constructed road. An incremental launching steel box girder spans the constructed road, is supported by five permanent buttresses, and is formed by a plurality of steel box girder segments which are spliced back to front; the five permanent buttresses are all uncovered girder double-cylinder pillars; the uncovered girder double-cylinder pillars respectively consist of two cylindrical buttresses which are supported below the left side and the right side of the steel box girder; the incremental launching construction method for the incremental launching steel box girder comprises the following steps: I, splicing jig frames; II, constructing temporary buttresses and rigid brackets; III, splicing the steel box girder and mounting guide beams; IV, mounting an incremental launching device and a second longitudinal slideway beam; V, performing incremental launching. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient to construct and good in use effect, and by constructing the rigid brackets on the outer sides of the buttresses and mounting a longitudinal slideway and a transverse deviation correcting device, the incremental launching construction of the large-span steel box girder can be easily, conveniently and rapidly completed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

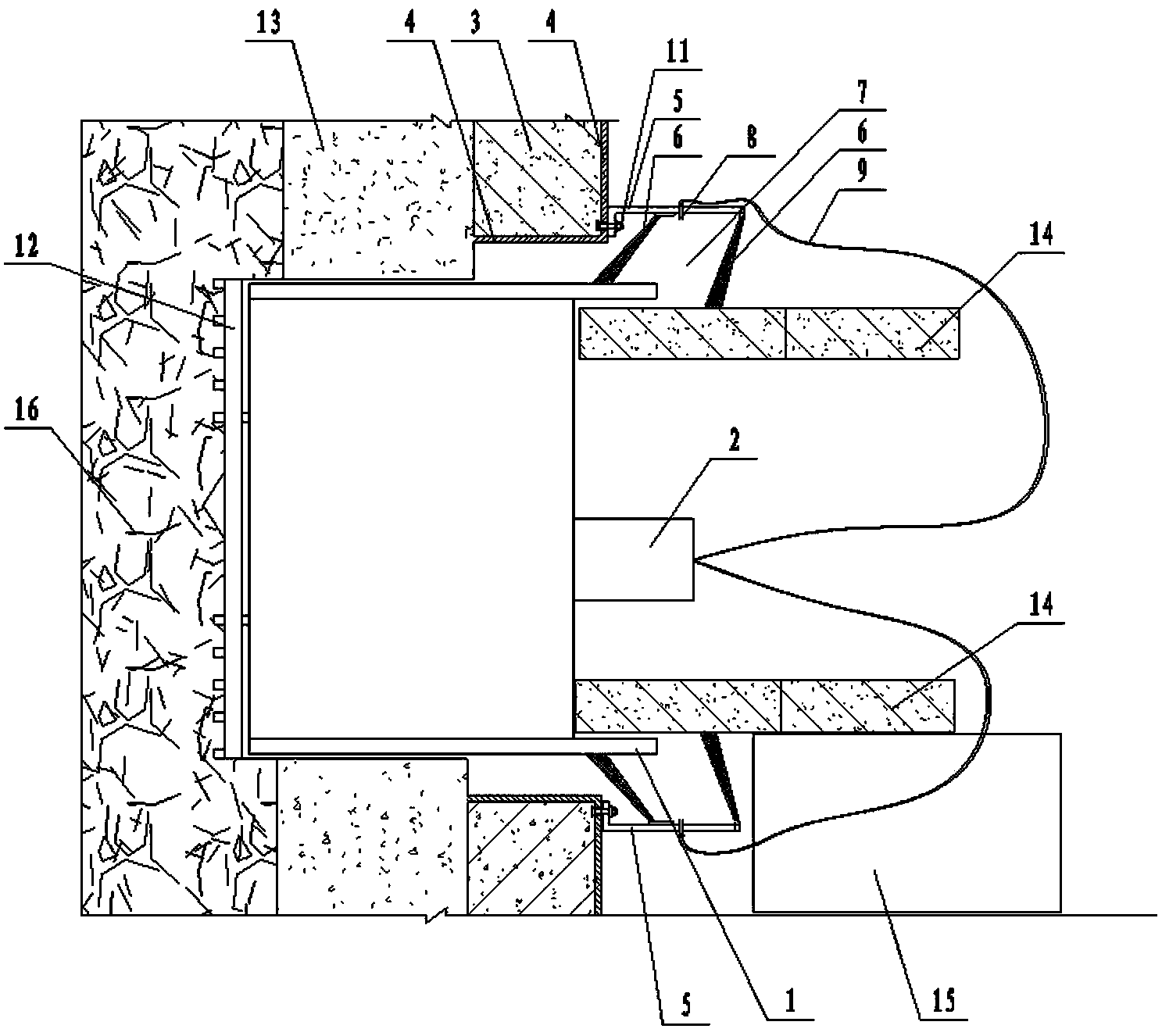

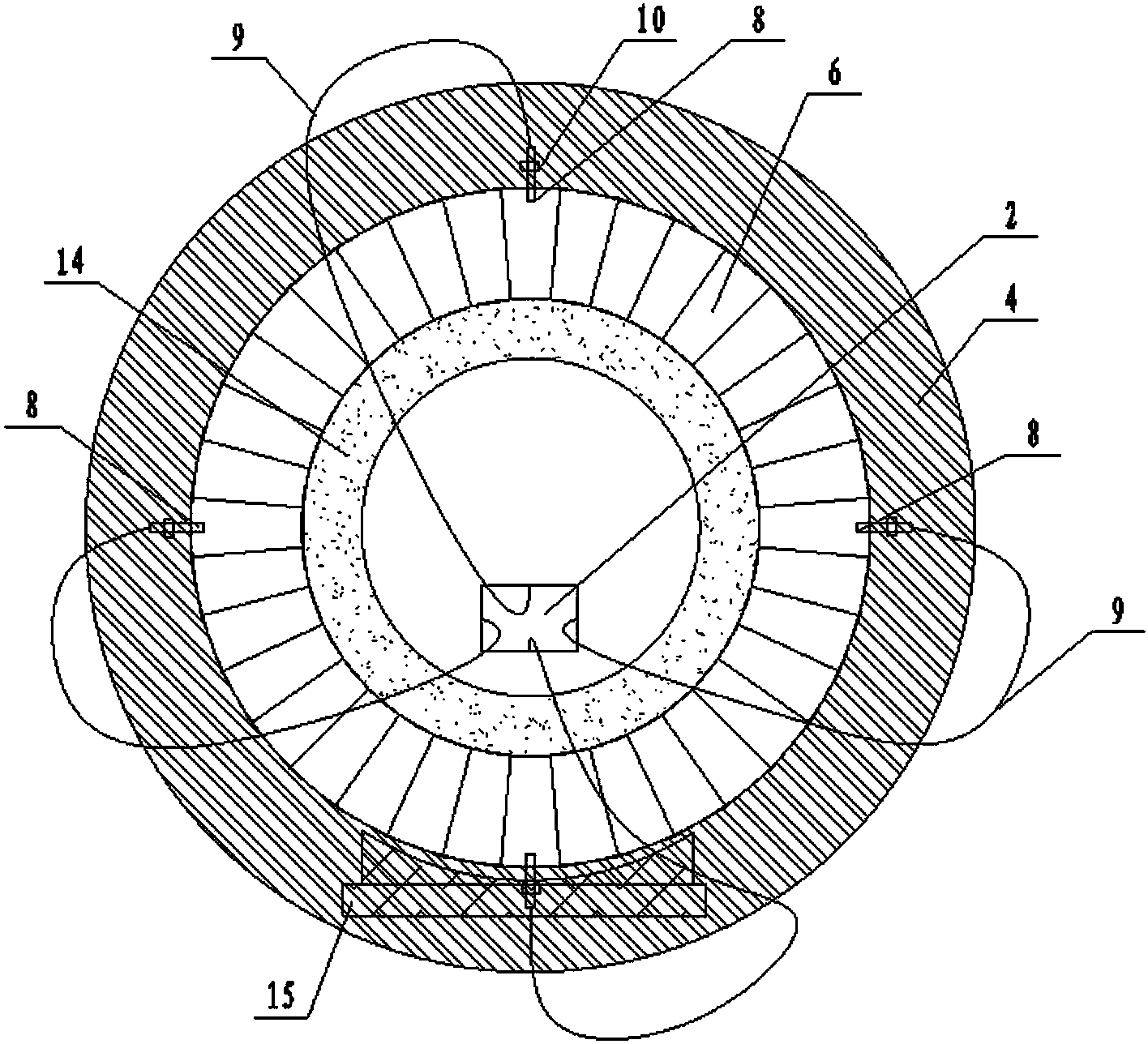

Sealing device for slurry shield starting of water-rich sand layer and sealing control method for starting

The invention relates to the field of tunnel shield construction, in particular to a sealing device for slurry shield starting of a water-rich sand layer and a sealing control method for the starting, and solves the problem that the conventional sealing devices are poor in effect, and high in risk, and water leakage and grout leakage are easy to occur during a shield starting process. Grease distributing valves are additionally arranged on shield tail grease filling pipes; an external steel loop is connected with a tunnel portal steel loop; two wire brushes are arranged in the external steel loop; grease injection holes with gate valves are reserved between the wire brushes; after the shield is assembled on a starting base, grease is smeared on the wire brushes of the external steel loop; a cutter head is pushed to a station space enclosing structure; the grease injection pipes are connected with the grease injection holes reserved in the external steel loop and the grease distributing valves; the grease injection gate valves are opened to enable the grease to be injected between the two wire brushes from the grease injection holes reserved in the external steel loop to fill the interspace; slurry balance is built to conduct shield starting. According to the invention, slurry shield safe starting is realized; slurry shield starting technology is simplified greatly; the technology is simple; the technique is advanced; the practicability is high.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

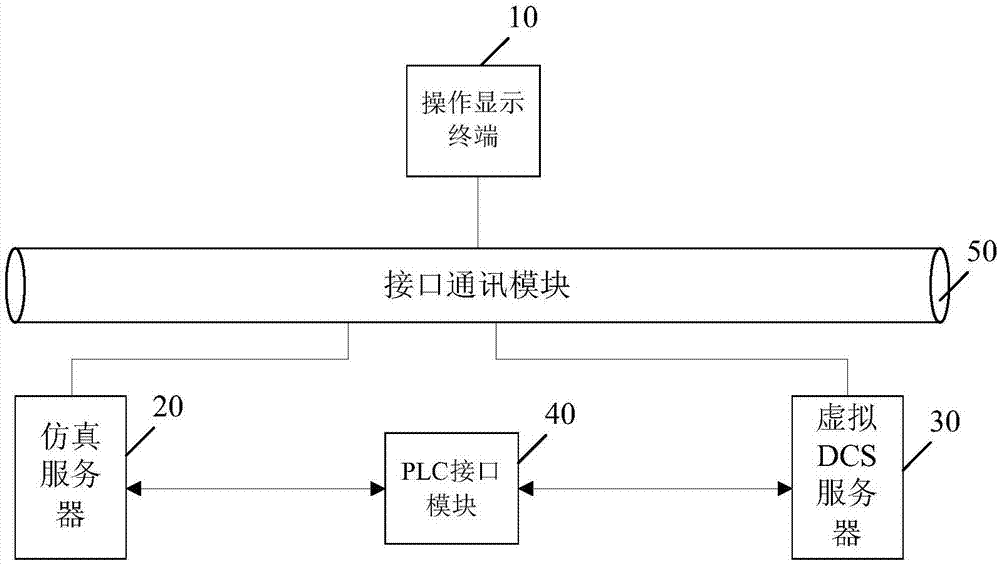

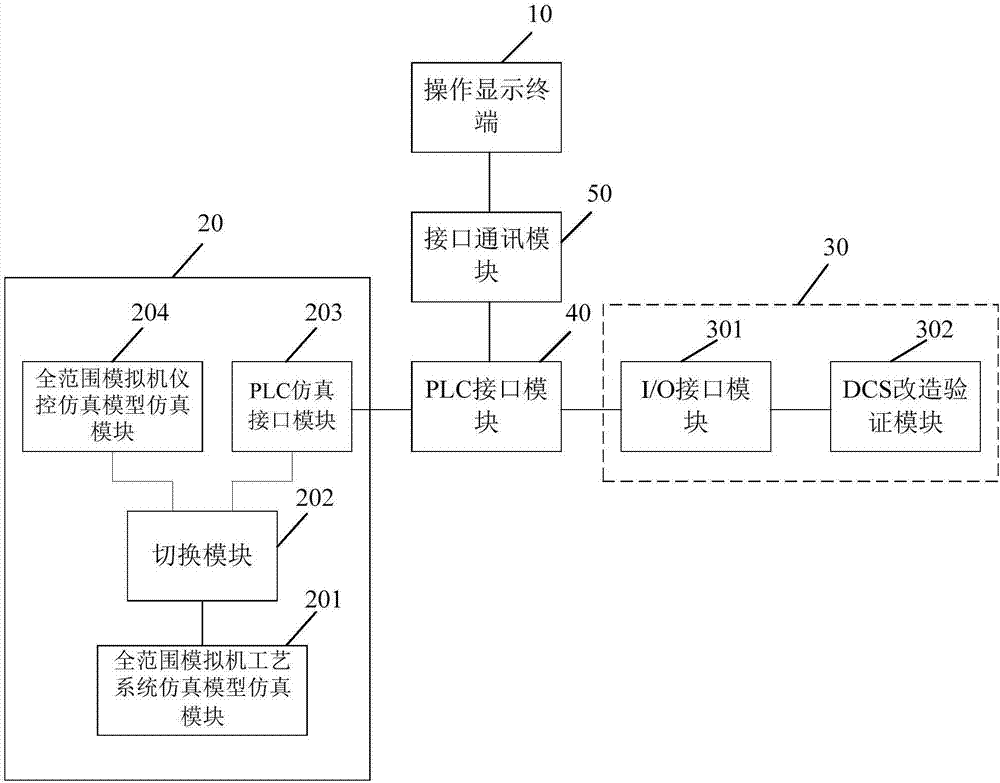

Nuclear power station simulation instrument control system DCS transformation closed-loop verification system and method

ActiveCN107885097AQuality improvementCost controlSimulator controlElectric testing/monitoringProcess systemsComputer architecture

The invention relates to a nuclear power station simulation instrument control system DCS transformation closed-loop verification system and method. The system comprises a simulation server, an operation display terminal and a virtual DCS server which are connected through network communication. The operation display terminal receives the initial condition and verification operation information inputted by the user and transmits the initial condition and verification operation information to the simulation server and displays the simulation result of the simulation server and the DCS verification simulation result of the virtual DCS server. The simulation server simulates the nuclear power station system equipment state and physical parameters according to the initial condition and based on the full scope simulator process system simulation model and outputs the simulation data. The virtual DCS server receives and processes the simulation data and then returns a DCS operation instruction to the simulation server and outputs the DCS simulation result to the operation display terminal to be displayed. Nuclear power station simulation instrument control system DCS transformation closed-loop test verification can be realized so that the major potential problems of digital transformation can be discovered in advance, controllable upgrade implementation risk and controllable construction period can be realized and the requirements of safe and stable operation of the unit can be met.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +4

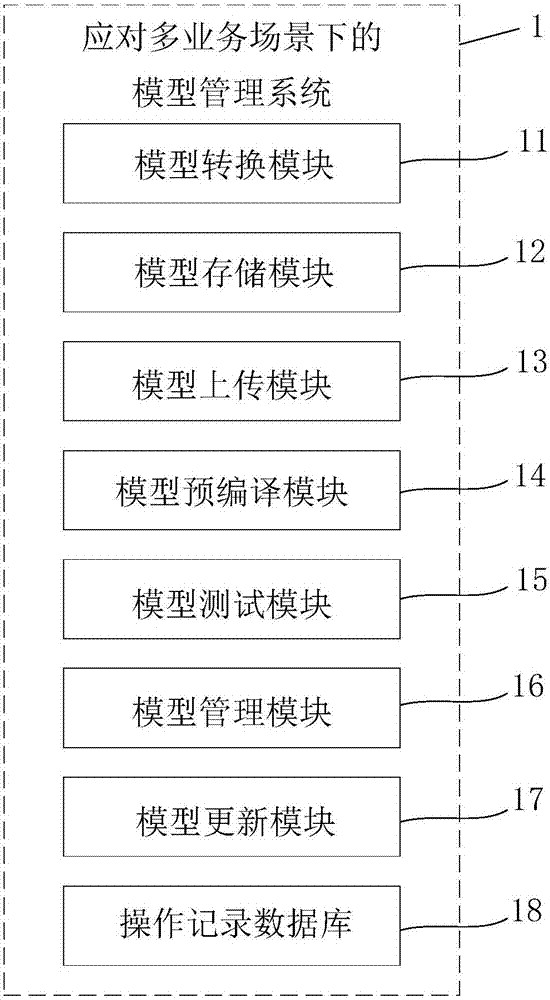

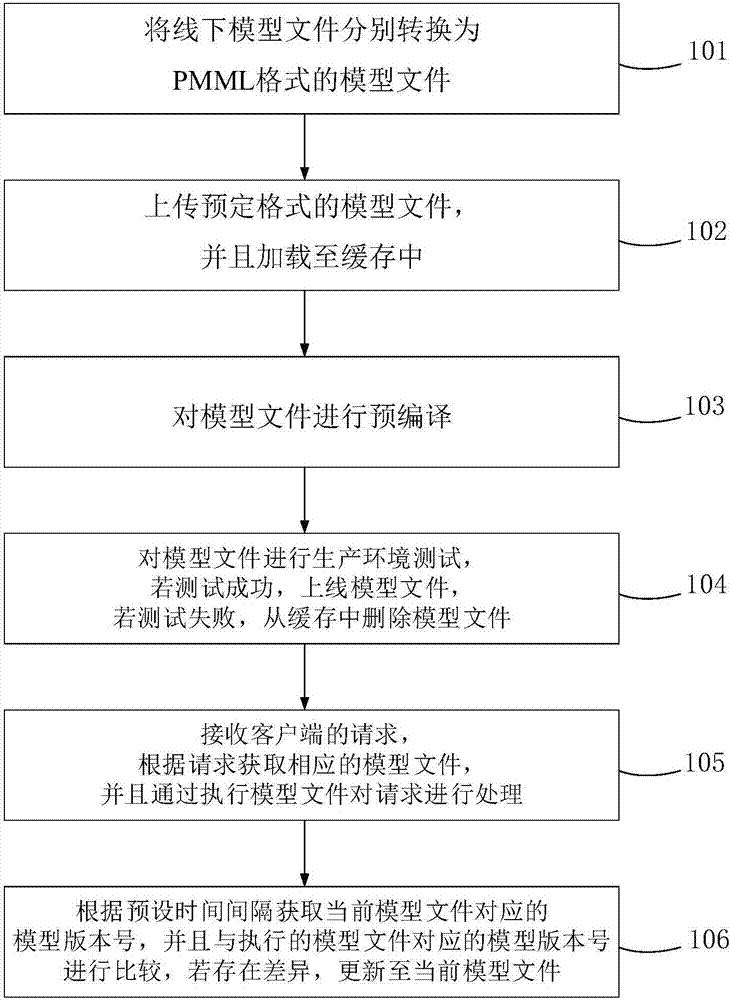

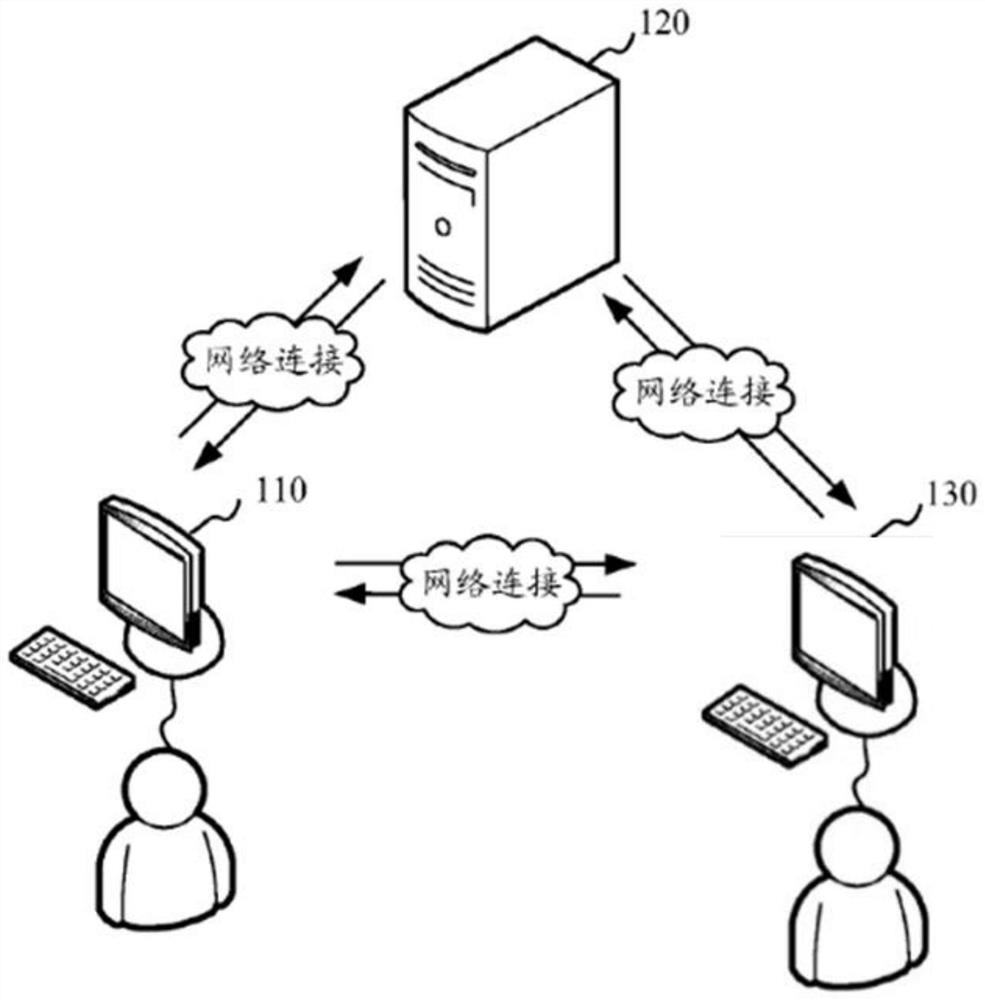

Model management system and method dealing with multiple-business scenarios

ActiveCN107247592APrevent inconsistent resultsControllable riskSoftware maintainance/managementOffice automationModel managementClient-side

The invention discloses a model management system and method dealing with multiple-business scenarios. The model management system comprises a model conversion module, a model uploading module, a model pre-compiling module, a model test module and a model management module; the model conversion module converts offline model files into model files with predetermined formats; the model uploading module uploads the model files and loading the same to cache; the model pre-compiling module pre-compiles the uploaded model files; the model test module performs production environment test on the model files, if succeeds, the model files are uploaded, and if fails, the model files are deleted from the cache; the model management module receives requests of clients, acquire the corresponding model files as required, and processes the requests by executing the model files. The process of models from delivery to uploading is unified, risk controllable is achieved, unified management of the models is facilitated, and the situation about inconsistent model results caused by environment different is effectively prevented.

Owner:CTRIP TRAVEL NETWORK TECH SHANGHAI0

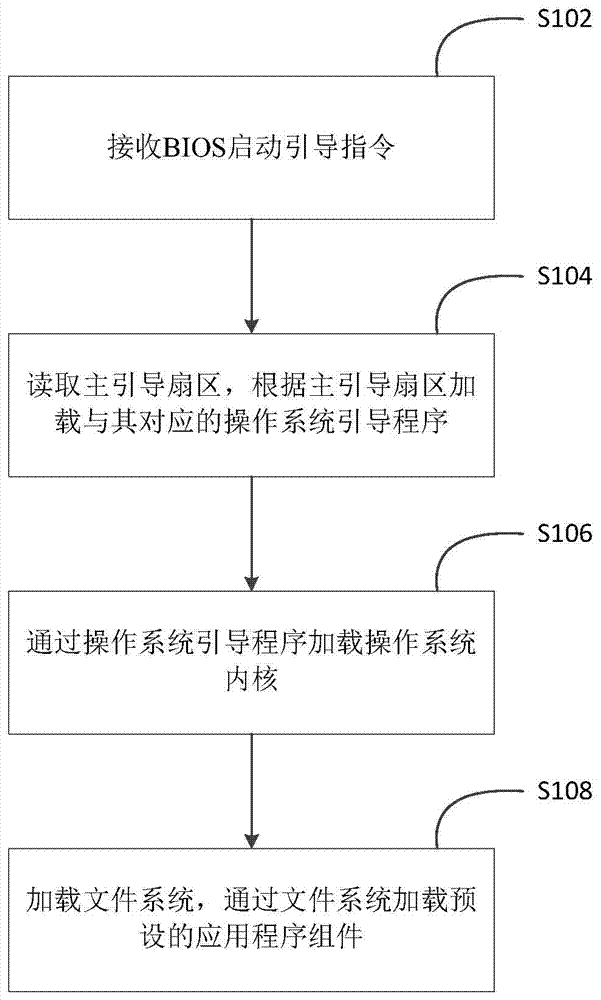

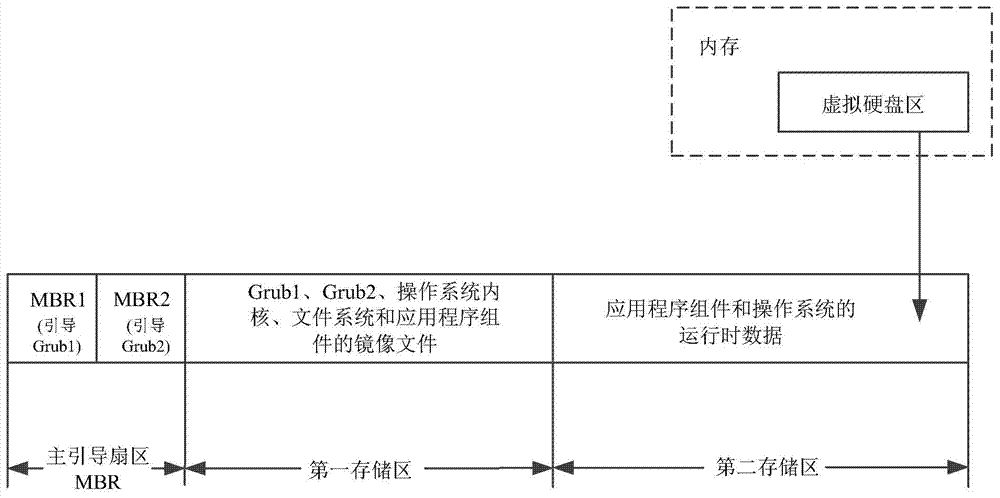

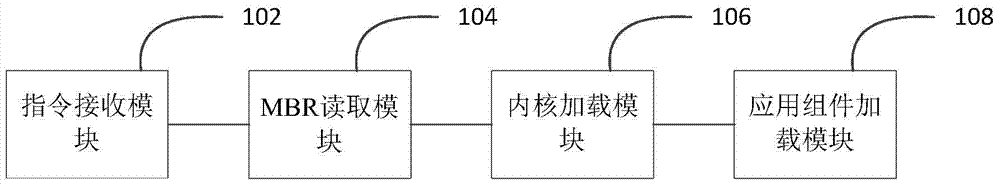

Method and device improving operation system reliability

ActiveCN104751062AImprove reliabilityGuaranteed uptimePlatform integrity maintainanceRedundant operation error correctionOperational systemFile system

The invention relates to a method and device improving operation system reliability. The method includes receiving a BIOS start guidance instruction; reading a main guidance section, and loading a corresponded operation system guidance program according to the main guidance section; loading an operation system kernel; loading a file system, and loading a preset application program component according to the file system; storing the operation system guidance program, the operation system kernel, the file system and the application program component in a first storage region, which is a read-only one, in an image manner; storing data in a second storage region, which is a read and write one, during the operation of the application program component and operation system kernel. The data include at least one of the generated files, logs and database records. By the aid of the method, the reliability of the operation system can be improved.

Owner:深圳市研祥智慧科技股份有限公司

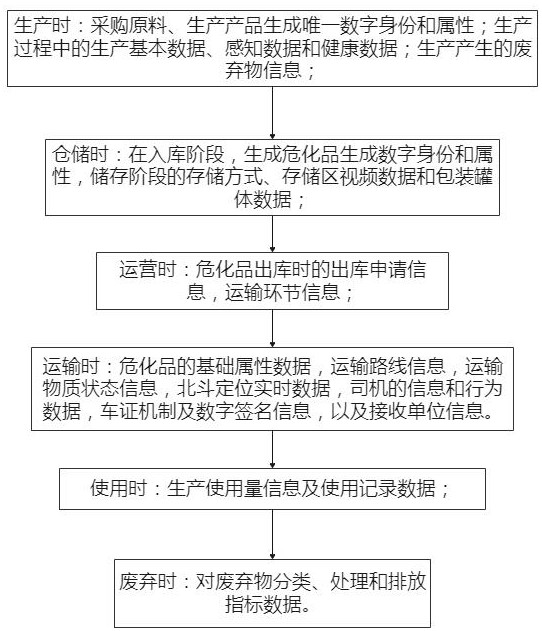

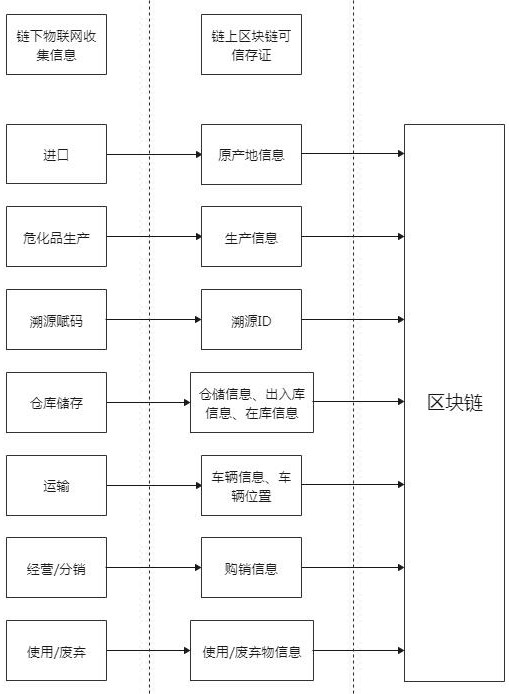

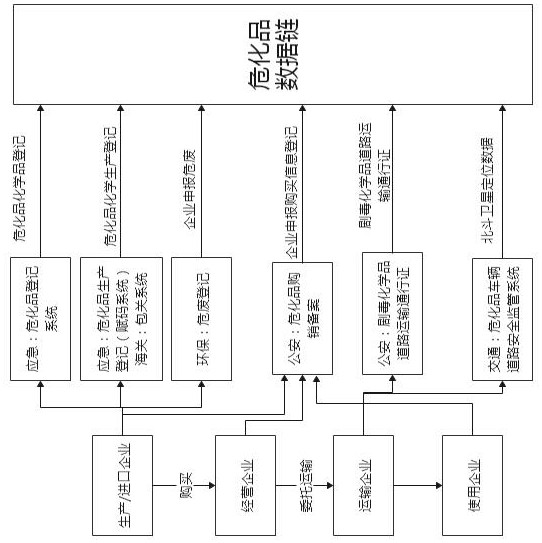

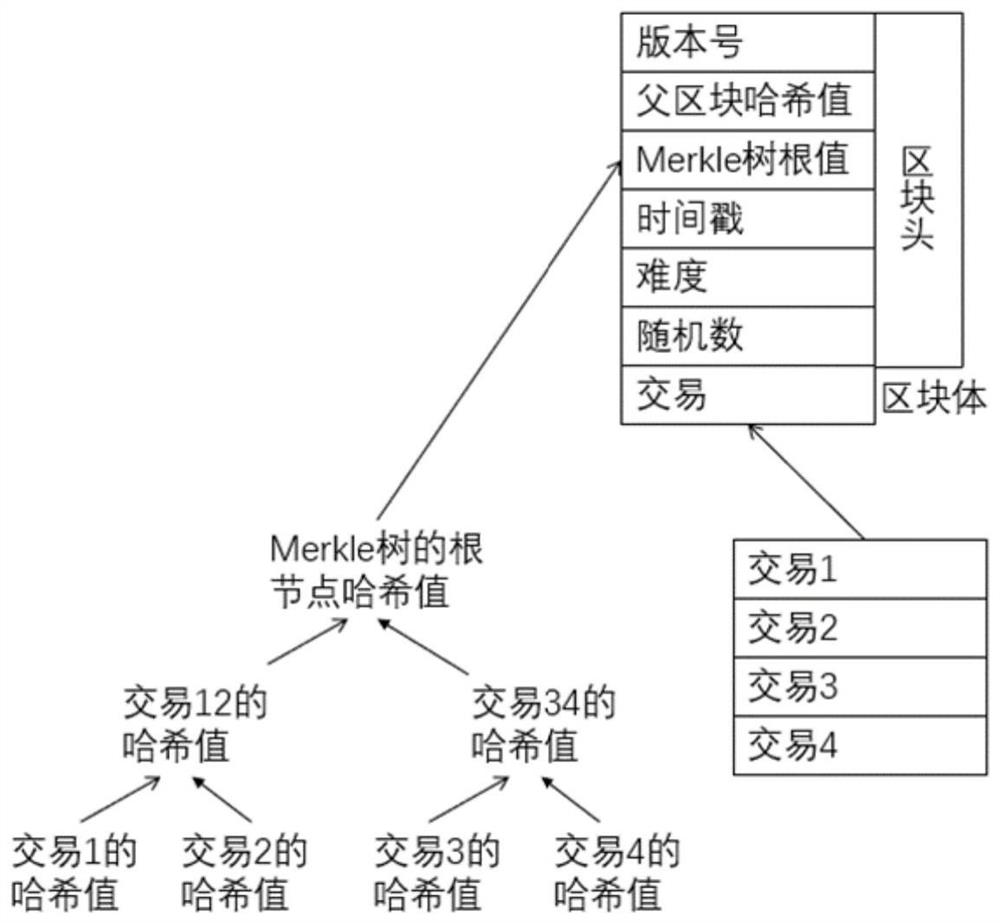

A block chain-based hazardous chemical substance whole-process supervision method and system

ActiveCN114037228AControllable riskRaise the emergency levelSustainable waste treatmentVisual data miningInformatizationData acquisition

The invention discloses a block chain-based hazardous chemical substance whole-process supervision method and system, and aims to solve the problem that a complete informatization system capable of covering the whole chain, the whole life cycle, the whole functional department and the whole process of hazardous chemical substances does not exist in the prior art. Many platforms are built before several years and cannot be in butt joint with new technologies, only serve as information recording type software and have no supporting effect on actual operation and safety supervision of enterprises. According to the scheme provided by the invention, the method specifically comprises the steps of constructing a hazardous chemical substance whole-process platform based on a block chain; on the basis of a hazardous chemical substance whole-process platform, forming comprehensive monitoring of data in a data interconnection and intercommunication mode. The objective of the invention is to construct a hazardous chemical substance informatization platform and realize a plurality of functions such as basic data acquisition service, analysis and decision, monitoring and supervision, and public service; and a hazardous chemical innovation platform and a scientific emergency production guidance platform are constructed to support hazardous chemical emergency scientific research and scientific hazardous chemical production guidance.

Owner:四川易链科技有限公司

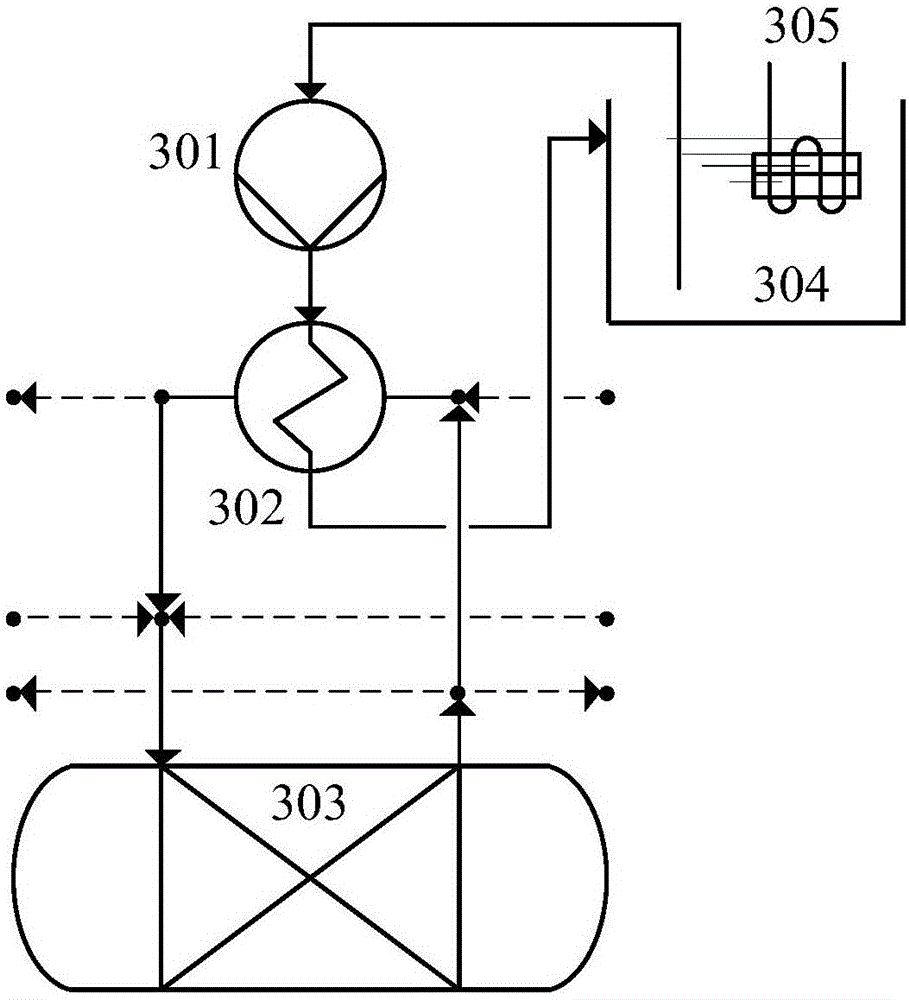

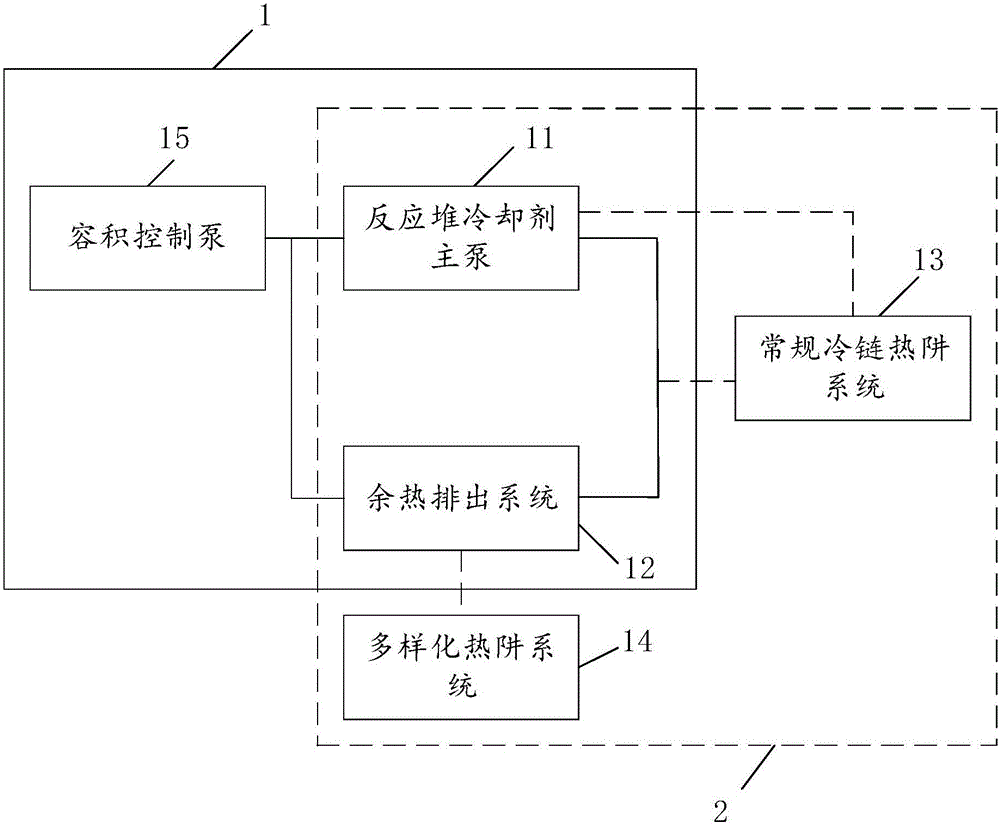

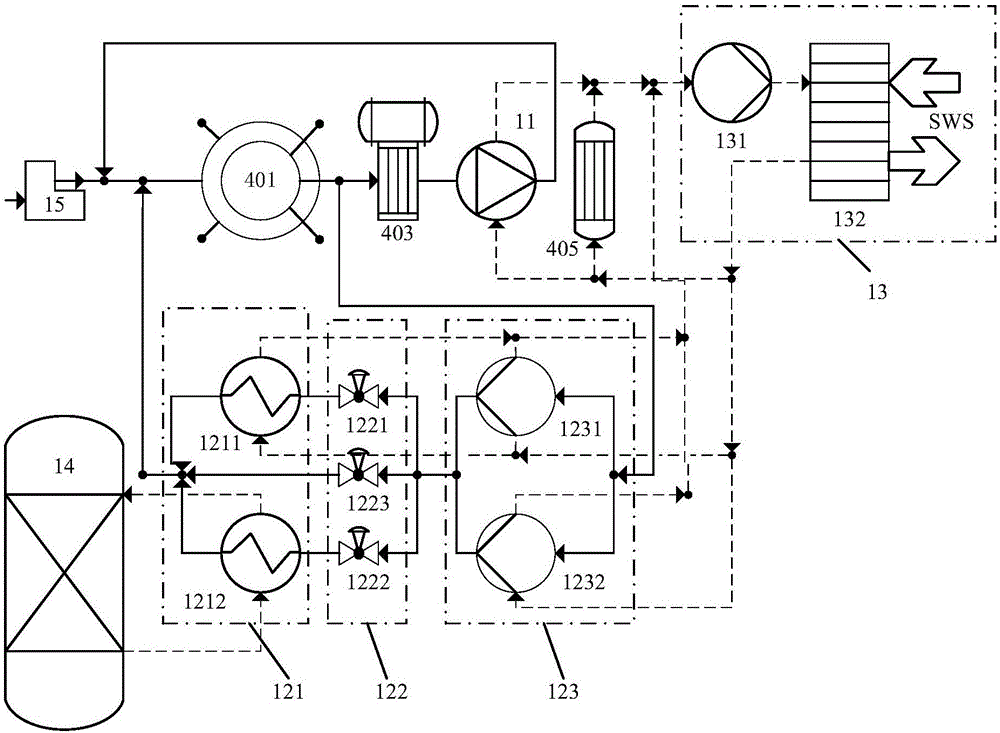

Test system and method for heat transfer performance of diversified hot-well system in nuclear power plant

ActiveCN107180657AEnsure safetyEasy to operateNuclear energy generationNuclear monitoringCold chainNuclear power

The invention discloses a test system for heat transfer performance of a diversified hot-well system in a nuclear power plant. The test system for heat the transfer performance of the diversified hot-well system in the nuclear power plant comprises a reactor coolant circulation loop and a heat derived circulation loop, the reactor coolant circulation loop comprises: a reactor coolant main pump communicating with the reactor coolant circulation loop and a hot side of a waste heat discharge system communicating with the reactor coolant recirculation loop; the heat derived circulation loop comprises a cooler of the reactor coolant main pump, a cold side of the waste heat discharge system, a conventional cold chain hot-well system, and a diversified hot-well system, wherein the conventional cold chain hot-well system is communicated with the cooler of the reactor coolant main pump and the cold side of the waste heat discharge system, and the diversified hot-well system communicates with the cold side of the waste heat discharge system. The test system for heat transfer performance of the diversified hot-well system in the nuclear power plant realizes the performance test of the diversified hot-well system without adding additional equipment, the operation method is simple and the risk is controllable. In addition, the invention also discloses a test method for heat transfer performance of the diversified hot-well system in the nuclear power plant.

Owner:中广核工程有限公司 +1

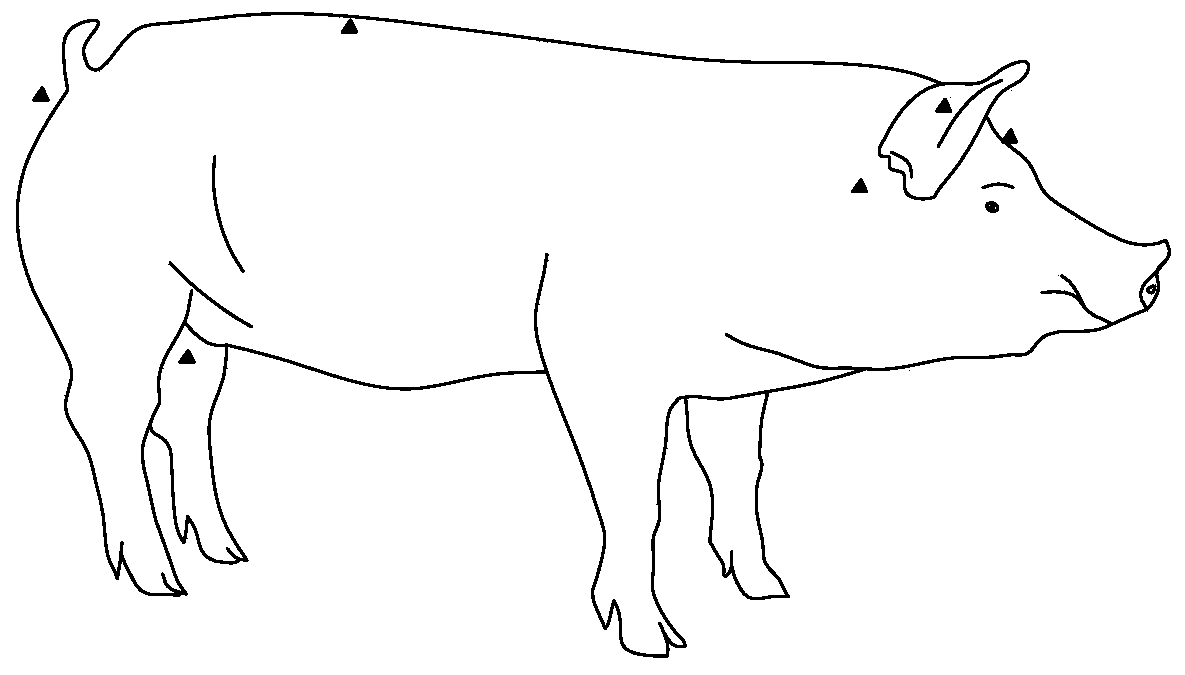

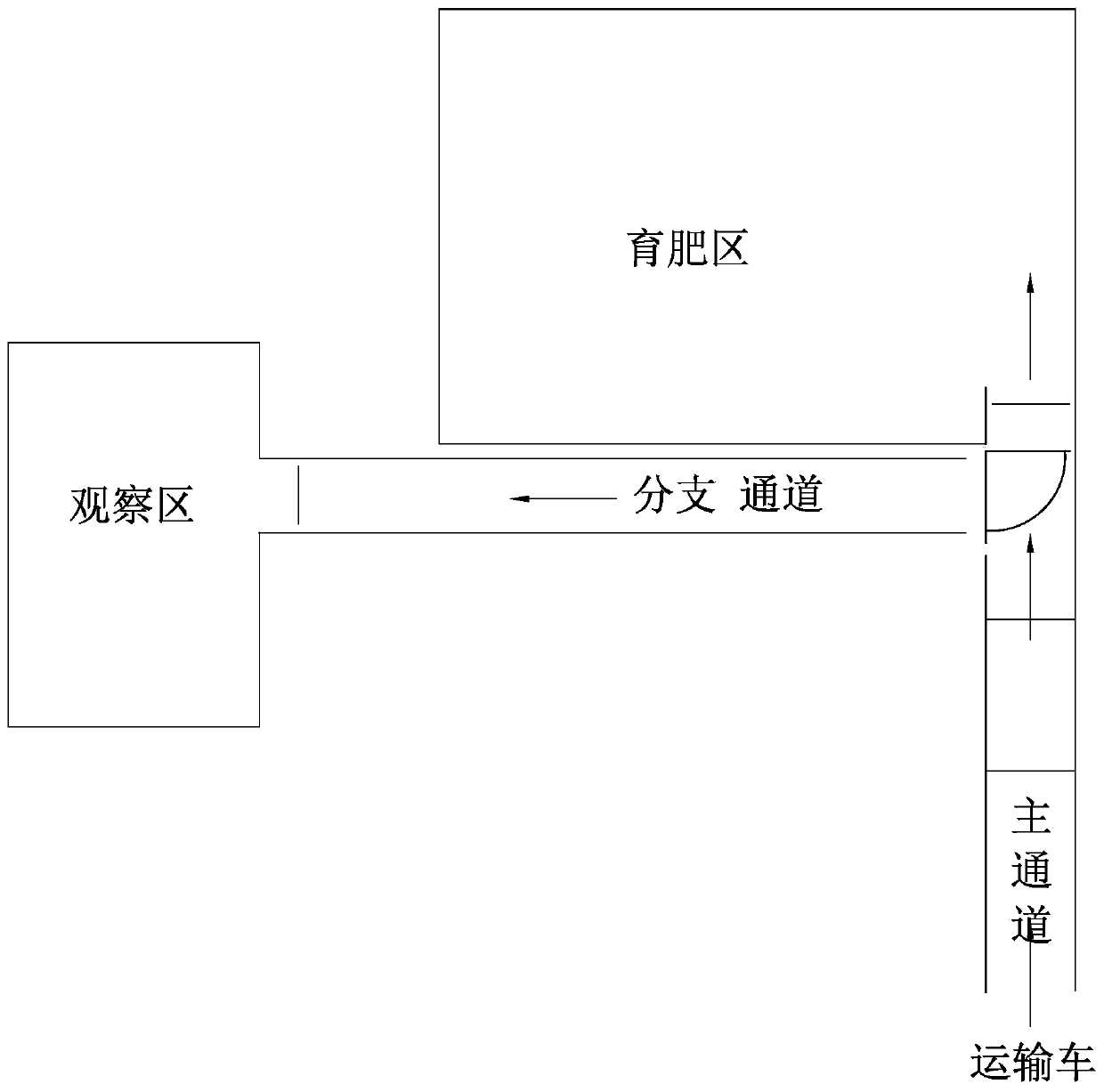

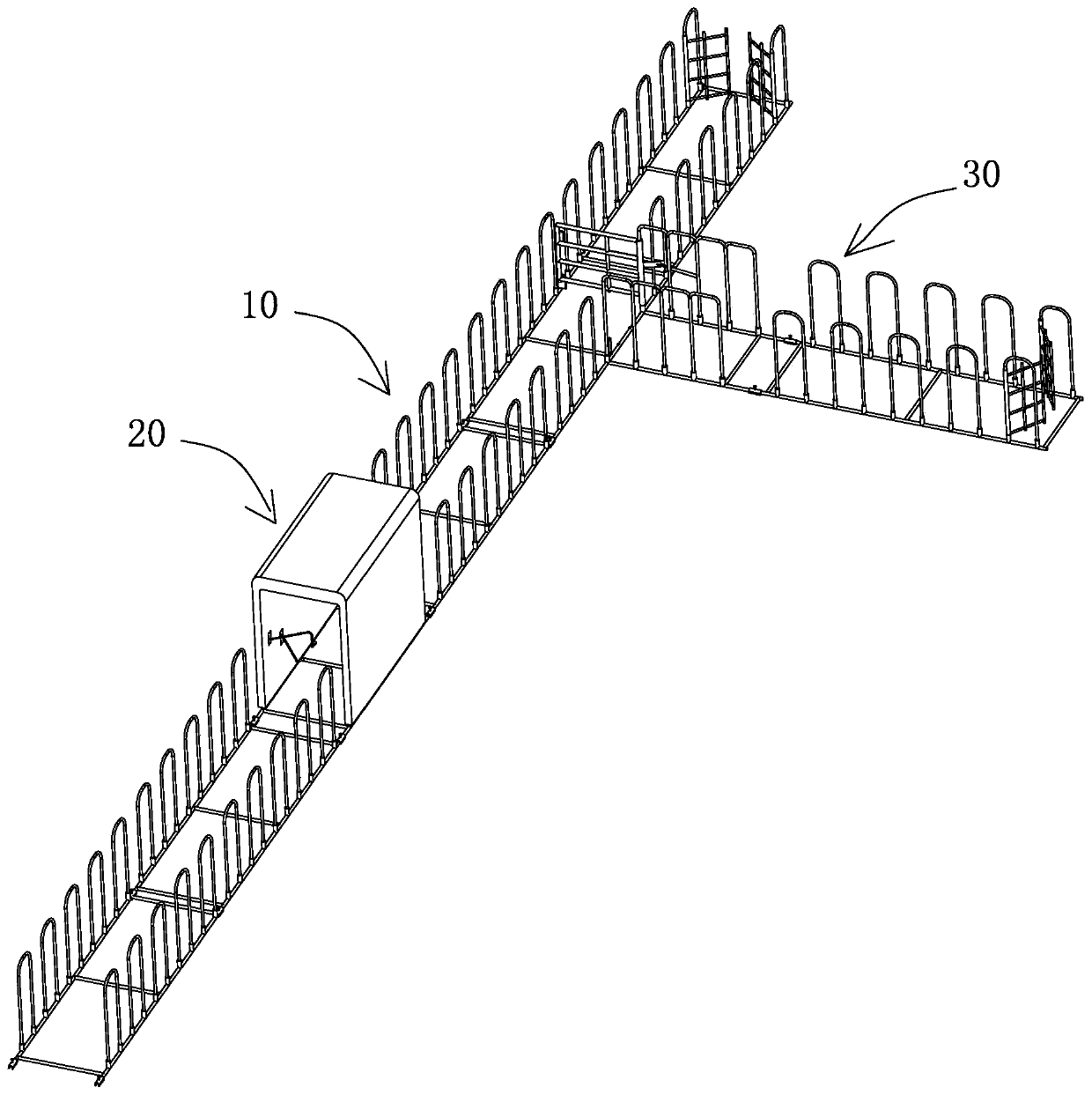

Infrared fast temperature measuring device and temperature measuring method for live pig body temperature monitoring

InactiveCN110200596AAccurate temperature measurementAvoid inaccurate monitoringDiagnostic recording/measuringSensorsInfraredMeasurement precision

The invention discloses an infrared fast temperature measuring device and temperature measuring method for live pig body temperature monitoring, and is used for solving the problem that conventional live pig body temperature measuring accuracy is not high. The method comprises the steps: allowing live pigs to enter a portal frame along a main channel, making each live pig do arm rocking action, reading the pig identity identification information through an electronic identification device and reading probes, and measuring the temperature and recording, if all temperatures measured by all temperature measuring probes do not reach an overtemperature point, forming a body temperature electronic record and storing in a database, and rushing pigs with normal body temperature to a fattening area; and when temperatures measured by one or more temperature probes exceeds the overtemperature point, rushing pigs with abnormal body temperature to an observation area. Through the implementation ofthe temperature measuring device and the temperature measuring method, the flowing and industrialized body temperature monitoring can be realized, and with adopting of the multi-point temperature monitoring, the problem of inaccurate monitoring can be effectively solved and a high-efficiency and risk-controllable temperature monitoring system is achieved.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

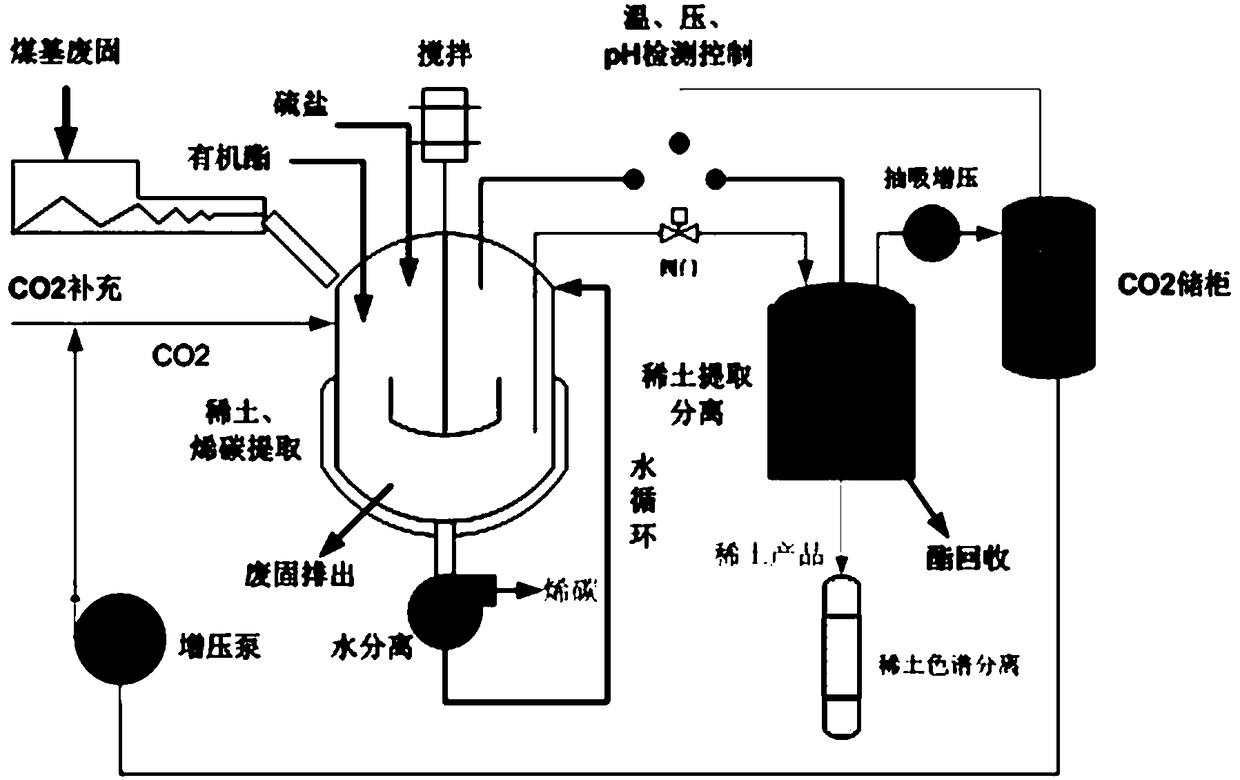

Method for extracting olefin carbon, enriching rare earth and separating inorganic materials by solid waste liquid waste three-phase method

ActiveCN108546825AAbundant supplyPlay a protective effectCarbon preparation/purificationProcess efficiency improvementRare-earth elementLiquid waste

The invention particularly discloses a method for extracting olefin carbon, enriching rare earth and separating inorganic materials by a solid waste liquid waste three-phase method. The method is mainly based on supercritical ScCO2 / H2O / organic fat three-phase extraction system, and the means, such as stirring, microwave, ultrasonic or heating or moderately adding acid and enhanced extraction and enhanced mass transfer, are used in an supplementary mode. When necessary, high-speed ball milling and other mechanical forces are used for stripping and enhancing the breakage and re-bonding of chemical bonds. ScCO2 phase is cooperated with H2O phase to form supercritical and acidic environment to dissolve and separate rare earth and carbon in solid waste. Complexation is carried out on safe and environmental-friendly organic lipid additives and the rare earth to extract the rare earth soluble in the H2O phase, the porous carbon or graphene carbon is basically retained in H2O, and the rare earth is transferred to CO2 phase when an organic ester is the same to form a stable CO2 extended solution phase, so that the distribution coefficient of solute in the two phases is changed, and the separation and extraction of rare earth elements and olefin carbon are completed.

Owner:山西中谱能源科技有限公司

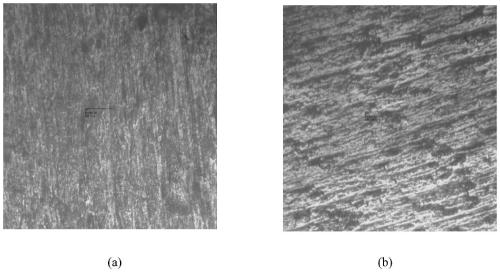

Copper surface treatment liquid and copper surface treatment method for multilayer printed circuit board manufacturing

ActiveCN110029336AAvoid the problem of excessive roughnessPromote growthMetallic material coating processesAlkali hydroxidePrinted circuit board

The invention relates to copper surface treatment liquid and a copper surface treatment method for multilayer printed circuit board manufacturing, and belongs to the technical field of printed circuits. According to the copper surface treatment liquid and the copper surface treatment method, copper surface roughening and medium layer performance optimization for improving interlayer bonding forceare carried out in two stages, wherein the treatment liquid used for the copper surface roughening comprises alkali metal peroxide, alkali metal hydroxide, alkali metal silicate, polyhydroxylated polymer, a metal complexing agent, a copper metal corrosion inhibitor and a molybdate additive with mass concentrations being 20-50g / L, 30-60g / L, 30-60g / L, 3.5-10g / L, 30-60g / L, 3-8g / L and 6-30g / L respectively; and the treatment liquid used for the medium layer optimization comprises alkali metal sulfide, alkali metal phosphate and a silane coupling agent with the mass concentrations being 10-30g / L, 40-160g / L and 7.5-30g / L respectively. The copper surface treatment liquid has better compatibility with the prior art, the low roughness modification of the copper surface can reach the IPC standard, and the copper surface treatment liquid and the copper surface treatment method are favorable for a multilayer board manufacturing technology to meet the challenge brought by the high frequency of transmission signals of a printed circuit board.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

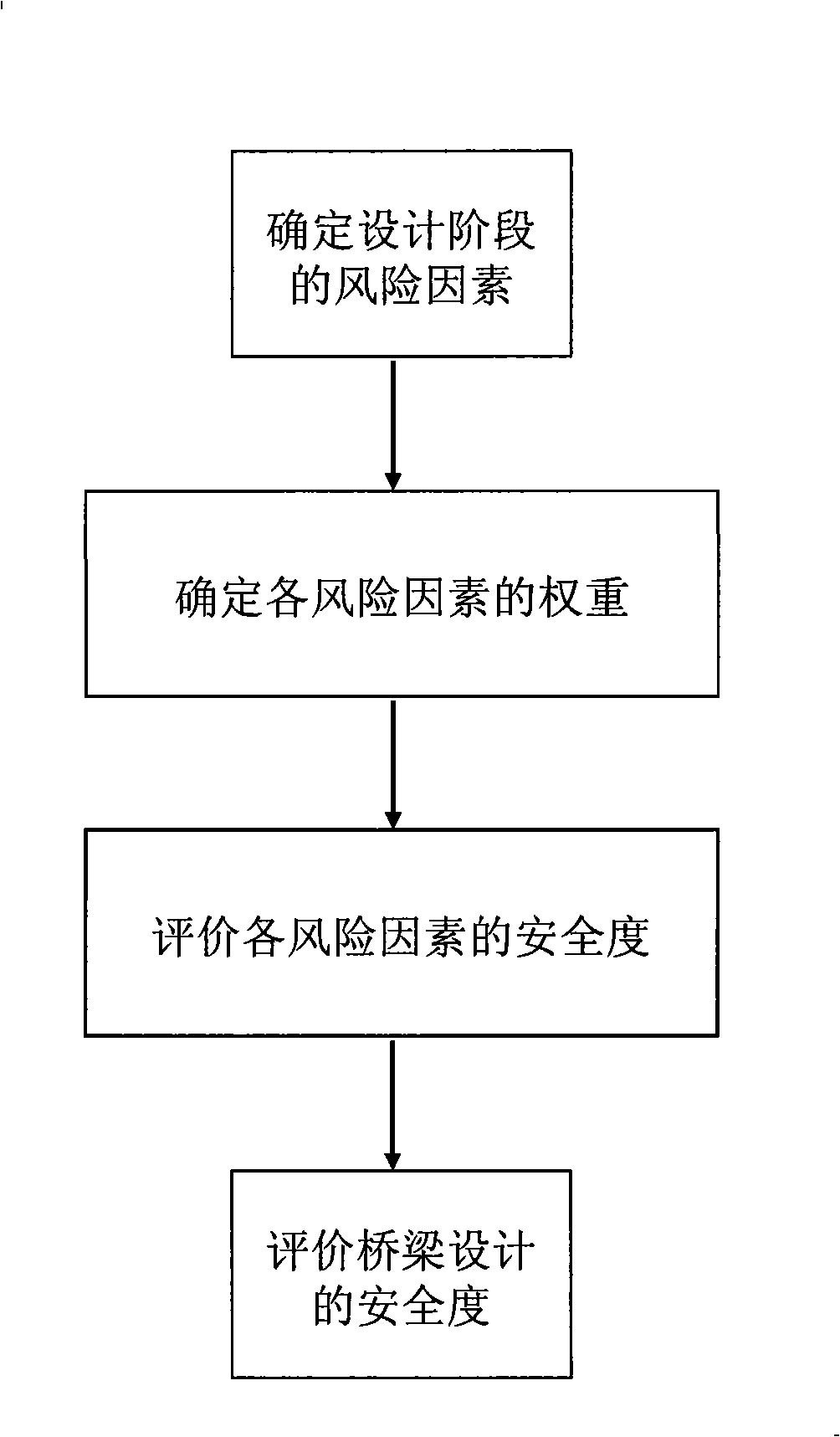

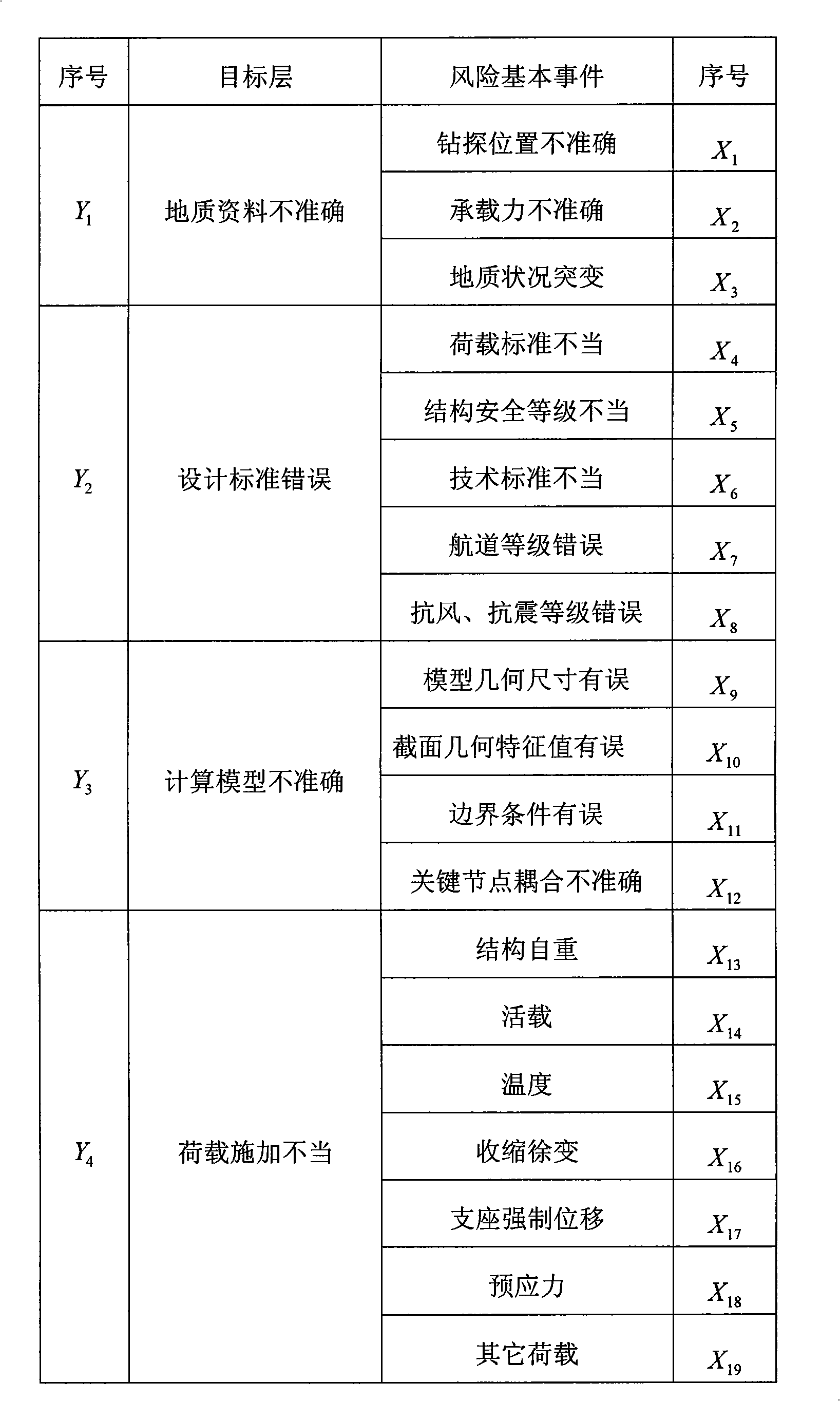

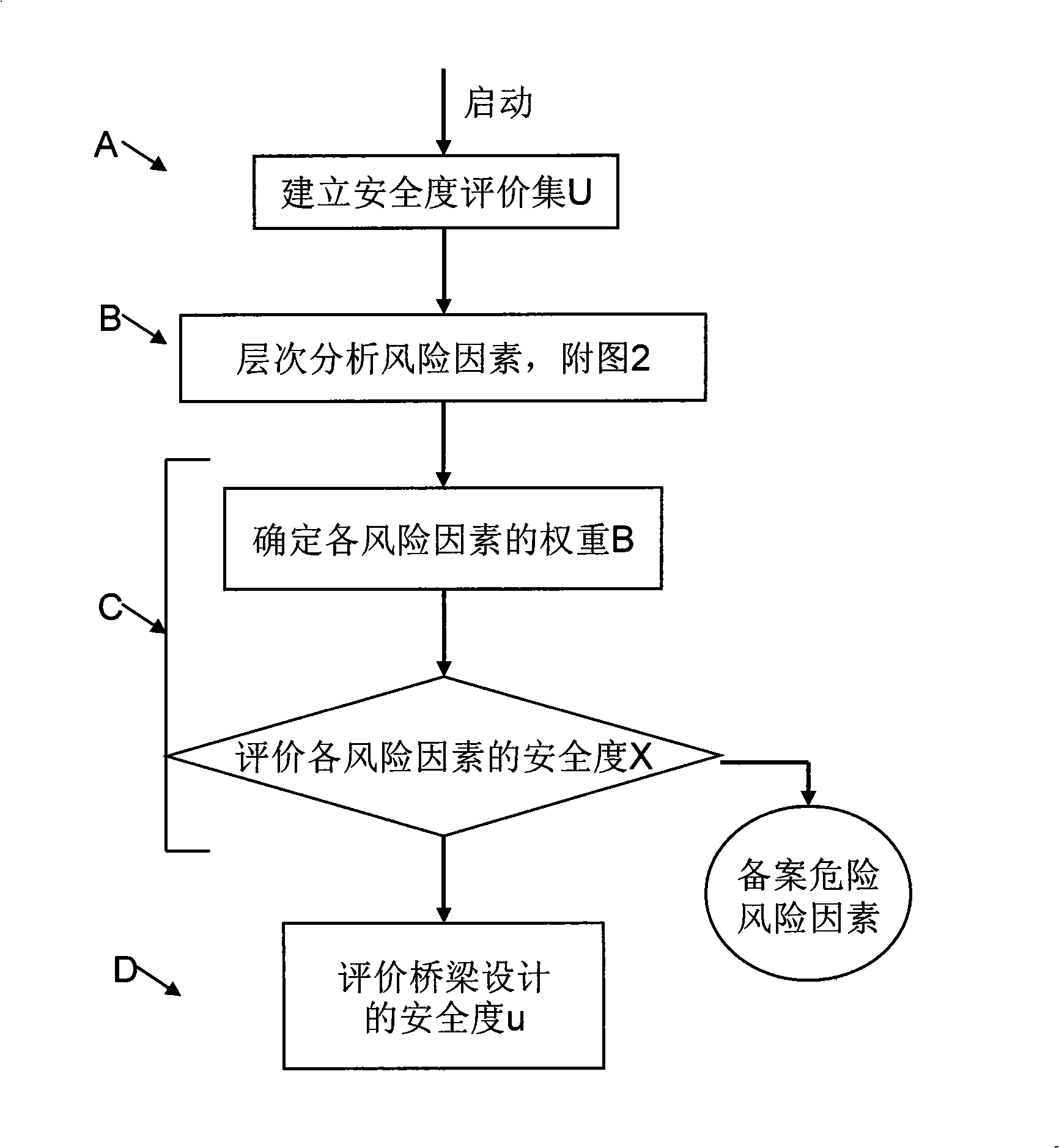

Risk evaluation method of bridge design

InactiveCN101527029AControllable riskEliminate design pitfallsData processing applicationsStatistical analysisDesign phase

The invention discloses a risk evaluation method of bridge design. The risk evaluation method comprises the following steps: qualitatively and quantitatively analyzing risk factors during a bridge design phase; qualitatively analyzing the existing risk factors by an analytic hierarchy process and quantitatively describing weight and safety degree of various risk factors by a mathematical means; and finally solving weighted average of the safety degree which is a risk evaluation result of the bridge design by a statistical analysis method. The risk evaluation method can provide a quantitative answer for risks of a bridge design result, which is simple and visual. Meanwhile, the risk evaluation method of the bridge design can help locate the risk factors causing risks in the case of the risks of the bridge design result, which provides a basis for design modification and realizes that the bridge design risks can be controlled.

Owner:辛太康

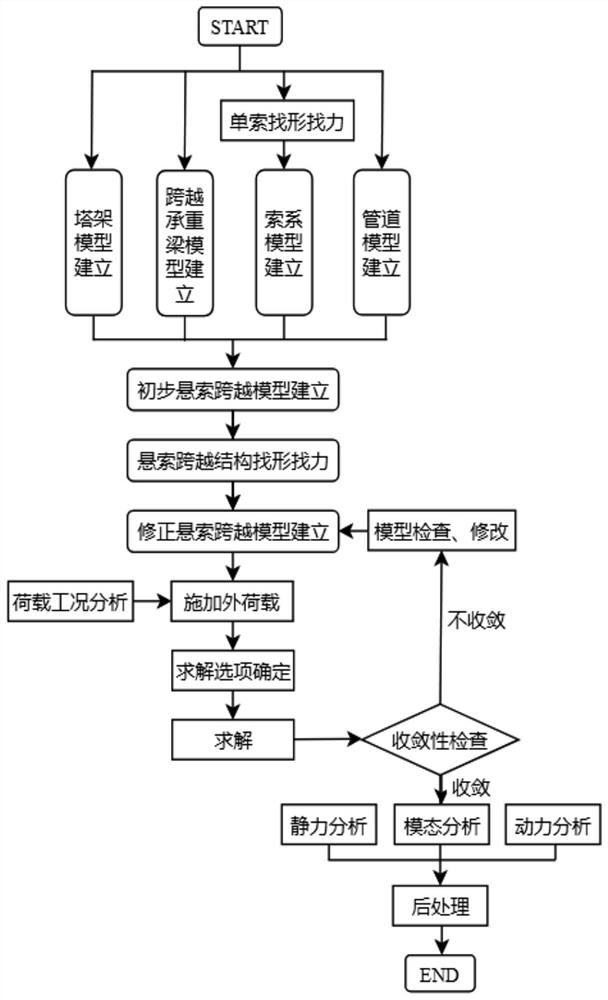

Oil and gas pipe suspension cable crossing simulation analysis method

ActiveCN112395797AControllable riskDesign optimisation/simulationConstraint-based CADEngineeringNon linear behavior

The invention provides an oil and gas pipe suspension cable crossing simulation analysis method. The method comprises the following steps that an oil and gas pipe suspension cable crossing simulationanalysis model is built; for different stages of the actual construction process, load working condition analysis is carried out, an external load is applied to the oil and gas pipe suspension cable crossing simulation analysis model by utilizing an analysis result, and simulation calculation of each construction stage of the suspension cable crossing structure is carried out; each influence factor in the construction process of the suspension cable spanning structure is comprehensively considered, static analysis and / or modal analysis and / or dynamic analysis is carried out on the analogue simulation calculation result of each construction stage of the suspension cable spanning structure, and displacement change and stress change of each component of the suspension cable spanning structureis obtained; and the simulation calculation result forms a dynamic tower stabilizing load calculation technology so as to guide all components to be dynamically adjusted in the construction process of the suspension cable spanning structure, and a construction scheme is generated. The nonlinear behavior of the suspension cable spanning structure in actual construction can be analyzed, and reference is provided for construction design of the suspension cable spanning structure.

Owner:SICHUAN GASOLINEEUM CONSTR ENG

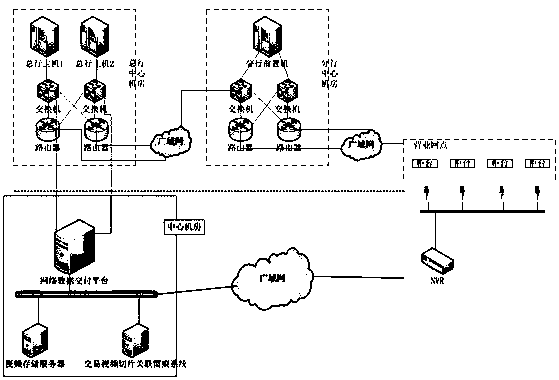

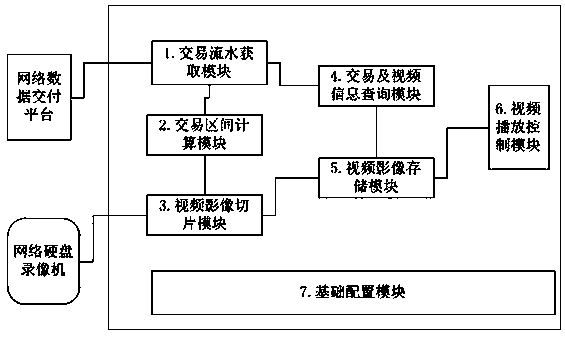

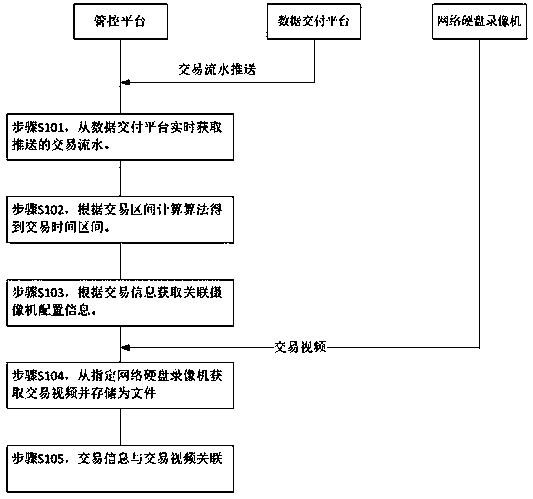

Service data and service video association method and service data and service video management system

InactiveCN108093212AImprove processing efficiencyControllable riskTelevision system detailsColor television detailsVideo monitoringStart time

The invention discloses a service data and service video association method and a service data and service video management system, wherein the association method comprises the following steps: acquiring service data key element information, wherein the key element information contains an involved service handling time and an involved service terminal serial number; according to the involved service handling time and a service type time, calculating a starting time and an ending time of a service video through a period of time distinguishing algorithm, wherein the service type time is the timeneeded for handling a special service; according to the involved service terminal serial number, gradually finding out a hard disc video recorder and a channel serial number corresponding to the terminal; according to the starting time and the ending time of the involved service video, the hard disc video recorder and the channel serial number, associating the key element information of the involved service data with a sliced service video record. The service data and the video are associated in time, and after risks happen, checking and controlling can be executed through consulting video monitoring real-time images or video records, thus, processing efficiency is improved, and overall risk is controllable.

Owner:西安优卓软件有限公司

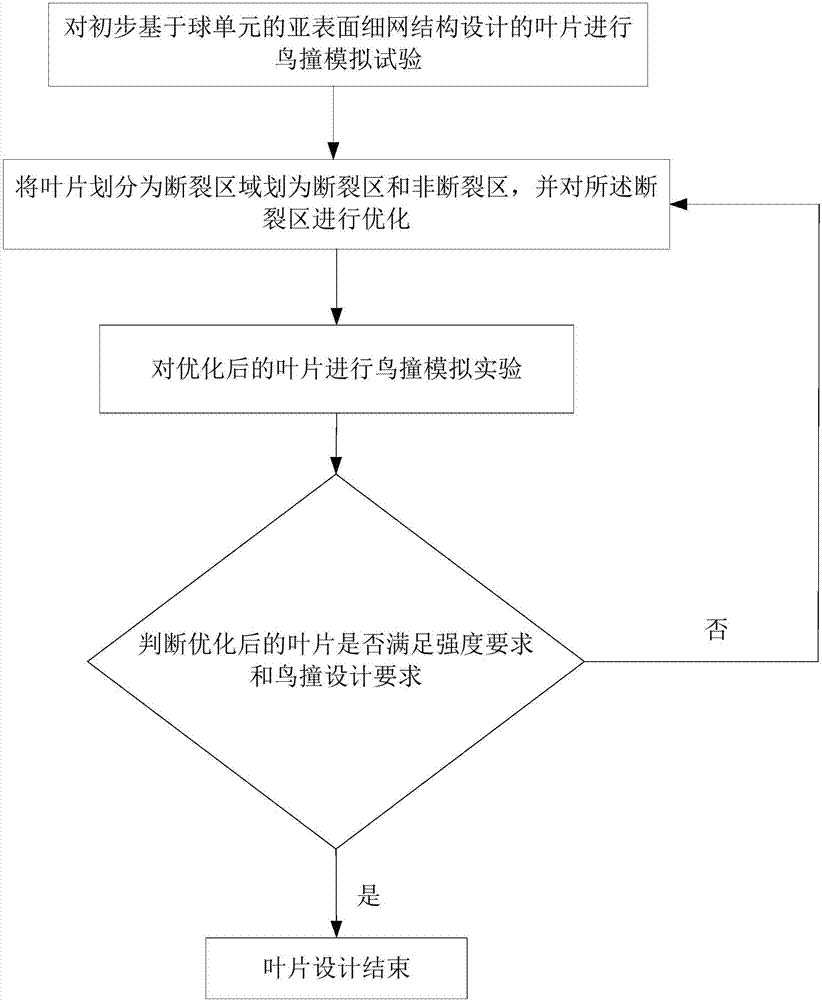

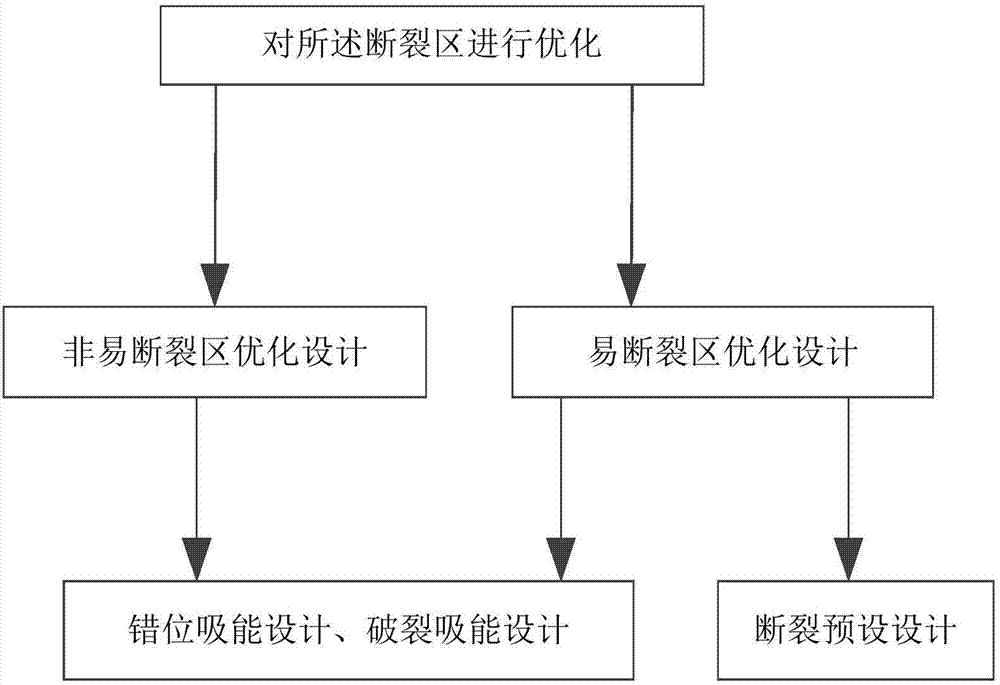

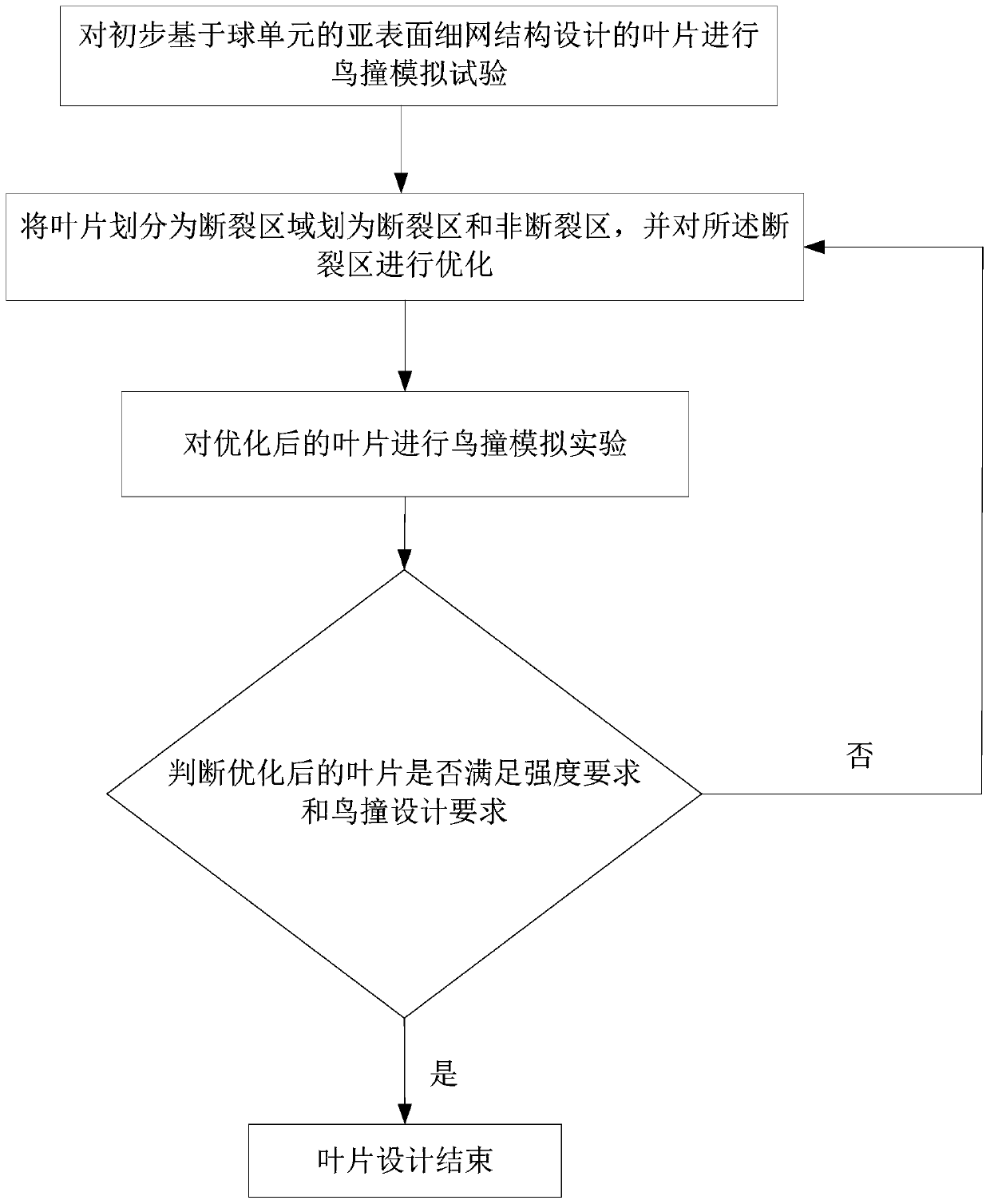

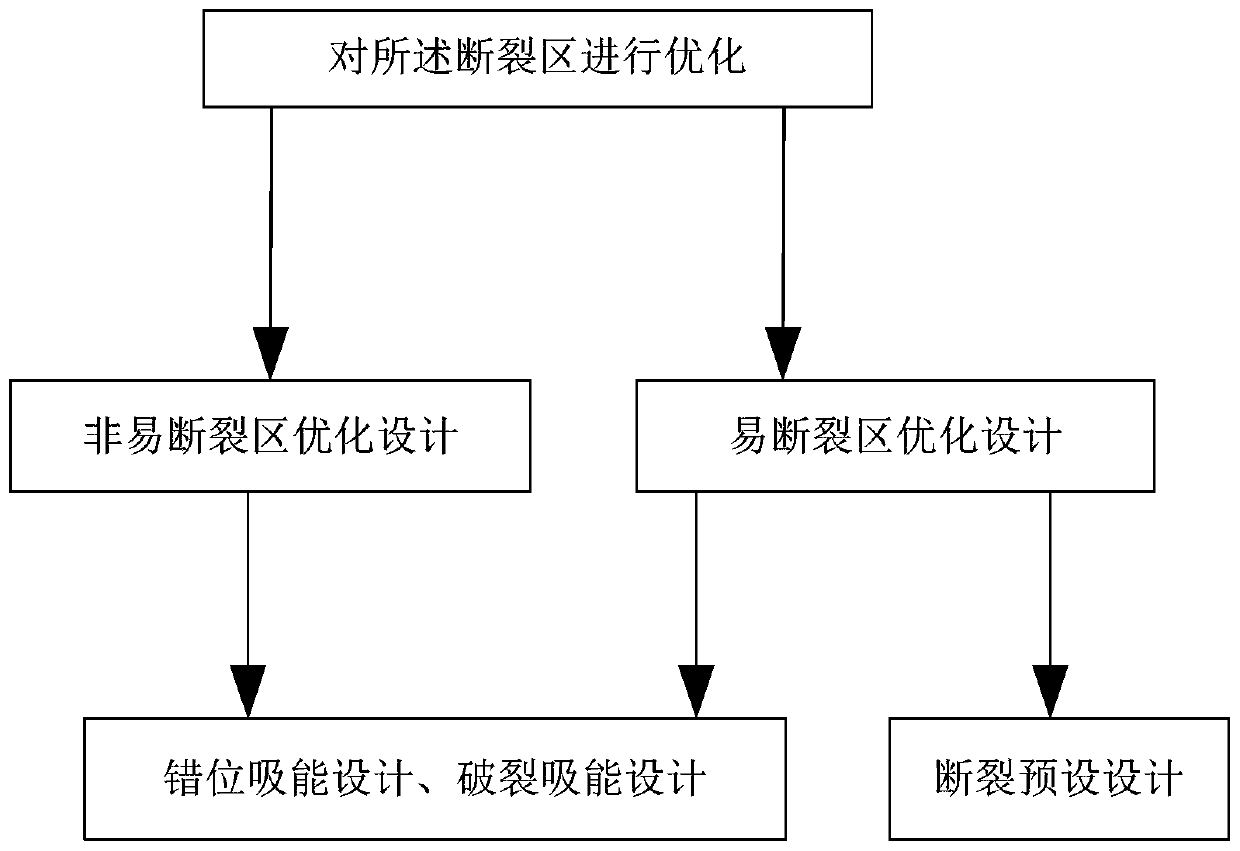

Bird impact design method for fan blade

ActiveCN107061353AImprove securityIncrease job securityGeometric CADEngine manufactureForeign matterEngineering

The invention relates to a bird impact design method for a fan blade, belongs to the technical field of aviation and provides a bird impact design method for a fan blade. The sub-surface fine net structural design is conducted on the blade, elastic deformation of the fan blade due to bird impacts or foreign matter collisions is controlled, the effects of inner structure dislocation energy absorbing and breaking energy absorbing are achieved, and the purpose that the blade is greatly deformed but not fractured is achieved to the maximum degree. Even though the blade is fractured, the fracture position and trend can be controlled through the design method, risk controllability is achieved, and the safety of the fan blade is improved to the maximum degree. Through the inner design, effective control and prediction over blade fracture during bird impacts can be achieved, and the work safety of an aero-engine is improved.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

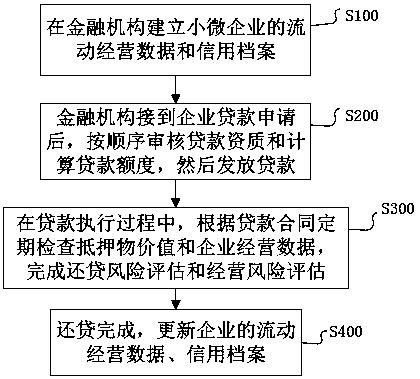

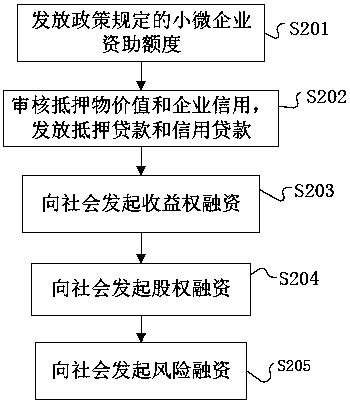

Big data based small- and mini-size enterprise small financial transaction method

The invention discloses a big data based small financial transaction method for a small- and mini-size enterprise. Circulating operation data and a credit file of the small- and mini-size enterprise are established in a financial mechanism. After the financial mechanism receives enterprise loan application, loan qualification is checked in sequence and loan limit is calculated, and then financingfunds including multiple forms of small- and mini-size enterprise fund, mortgage loan, credit loan, gains right based raised fund, stock based raised fund and risk based raised fund and the like are delivered. In a loan execution process, the guarantee value and enterprise operation data are checked regularly according to a loan contract and loan repayment risk evaluation and operation risk evaluation are implemented. After loan payment is completed, the circulating operation data and the credit file of the enterprise are updated. Therefore, a technical aim of reducing check and evaluation period and realizing quick loan delivery through comprehensively employing multiple financial means including mortgage, credit, venture investment, stock and the like and fully utilizing internet and bigdata means at the same time during the loan process of the small- and mini-size enterprise is achieved.

Owner:NANJING NANYOU INST OF INFORMATION TECHNOVATION CO LTD

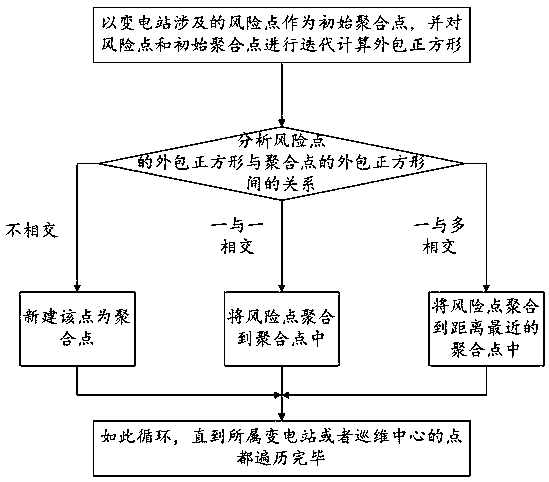

On-site operation safety risk management and control method based on geographic information aggregation

InactiveCN108090701ADisplay clearEasy to controlResourcesInformation technology support systemDecompositionPower grid

The invention relates to the technical field of power grid risk management and control, in particular to an on-site operation safety risk management and control method based on geographic informationaggregation. The method comprises the steps that upward aggregation and downward decomposition of risks of risk points of the whole power grid on an electric map are performed by adopting a point aggregation algorithm based on the combination of grids and distance and levels of the risks. According to the method, multiple points are upwardly aggregated to be marking points of a map by means of thepoint aggregation algorithm of the map, the number of markers of the map is greatly reduced, the risk points on the map do not cover a base map of the electric map, an overall risk condition of a specific zone can be checked by users clearly, and therefore management and control of a global safety and production risk are achieved; the method has the advantages that resource overhead of a front end can be relieved, and loading performance of the map and interaction performance of the users are improved.

Owner:ZHUHAI POWER SUPPLY BUREAU GUANGDONG POWER GIRD CO

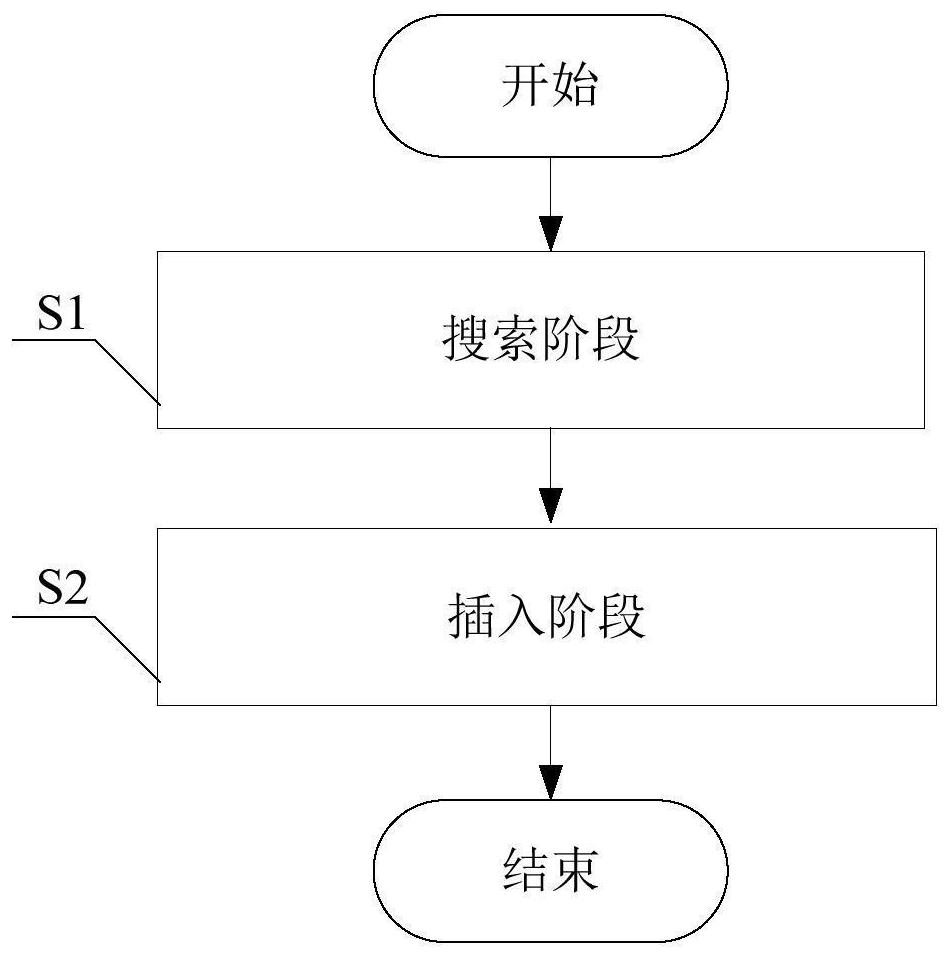

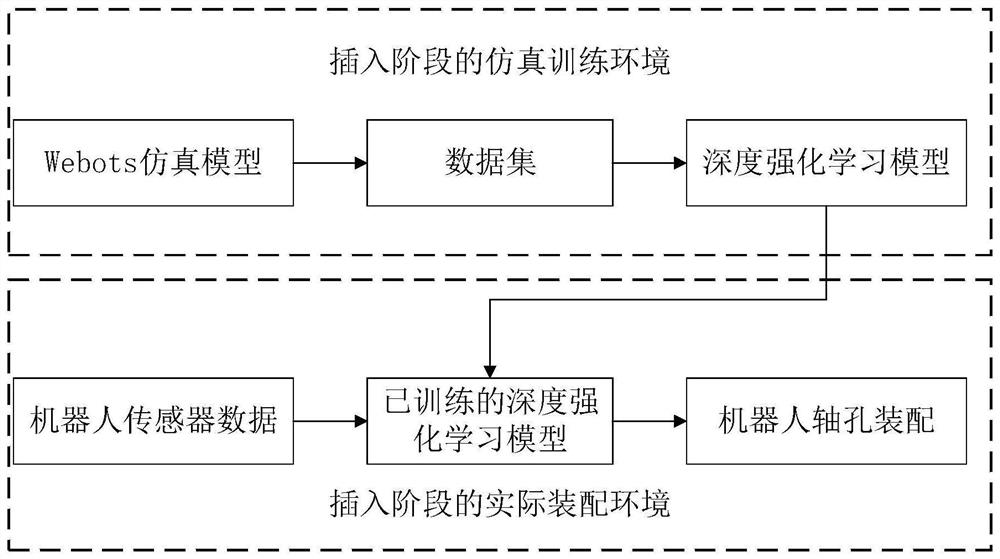

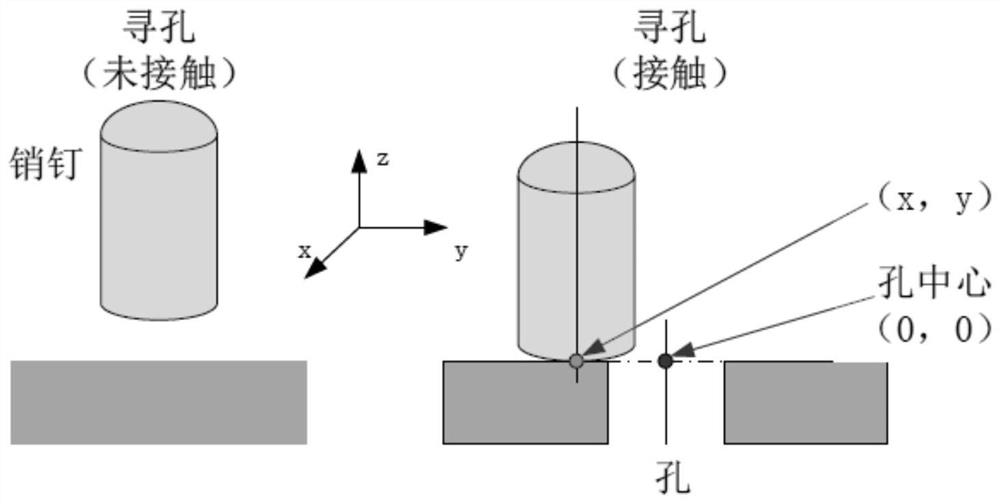

Nuclear operation and maintenance robot shaft hole assembling method based on man-machine cooperation

InactiveCN112192614AGuaranteed safe operationReduce radiation doseMetal working apparatusManipulatorMachineIndustrial engineering

The invention provides a nuclear operation and maintenance robot shaft hole assembling method based on man-machine cooperation, and belongs to the technical field of industrial robots. A slave end mechanical arm is controlled by a master end mechanical arm to rotate a pin in a gap area of the center of a hole; the pin at the tail end of the slave end mechanical arm makes contact with a plane wherethe hole is located, and adjusting is carried out on the pose of the pin through data returned by a torque sensor in real time; and pose information of the pin and information of the torque sensor are acquired, and the pin is pushed to be inserted into the hole by utilizing a depth deterministic strategy gradient network of continuous action, and then nuclear operation and maintenance robot shafthole assembly based on man-machine cooperation is finished. In order to reduce the radiation dosage borne by operation and maintenance personnel and improve the operation and maintenance efficiency,robot intelligence and human intelligence are fully combined through the method; the reliability of the operation process is enhanced by utilizing experience knowledge of people, and it is guaranteedthat the risk is controllable; and meanwhile, the robot autonomously acts in a local area by utilizing an artificial intelligence algorithm.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Foundation reinforcement and connector combination of integral floating water taking head and construction method

The invention discloses a foundation reinforcement and connector combination of an integral floating water taking head and a construction method. The foundation reinforcement and connector combination comprises a water taking head foundation. The water taking head foundation is reinforced by the aid of rock-socketed cast-in-place piles and is excavated, and rubble is filled back into the water taking head foundation; pile sleeves are arranged at the bottom of the water taking head, underwater concrete is filled into gaps of the pile sleeves of the rock-socketed cast-in-place piles via reserved grout pipes, and the rock-socketed cast-in-place piles are nested in the water taking head. The construction method includes a, reasonably arranging the rock-socketed cast-in-place piles according to actual conditions of the water taking head and computation results and reinforcing the foundation; b, excavating a foundation region of the water taking head and filling the rubble into the foundation region; c, arranging the pile sleeves for sleeving the rock-socketed cast-in-place piles at the bottom of the water taking head and reserving the grout pipes when the water taking head is manufactured; d, temporarily plugging the reserved grout pipes of the water taking head; e, filling the underwater concrete from the tops of the reserved grout pipes into the nesting gaps of the rock-socketed cast-in-place piles nested in the water taking head.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

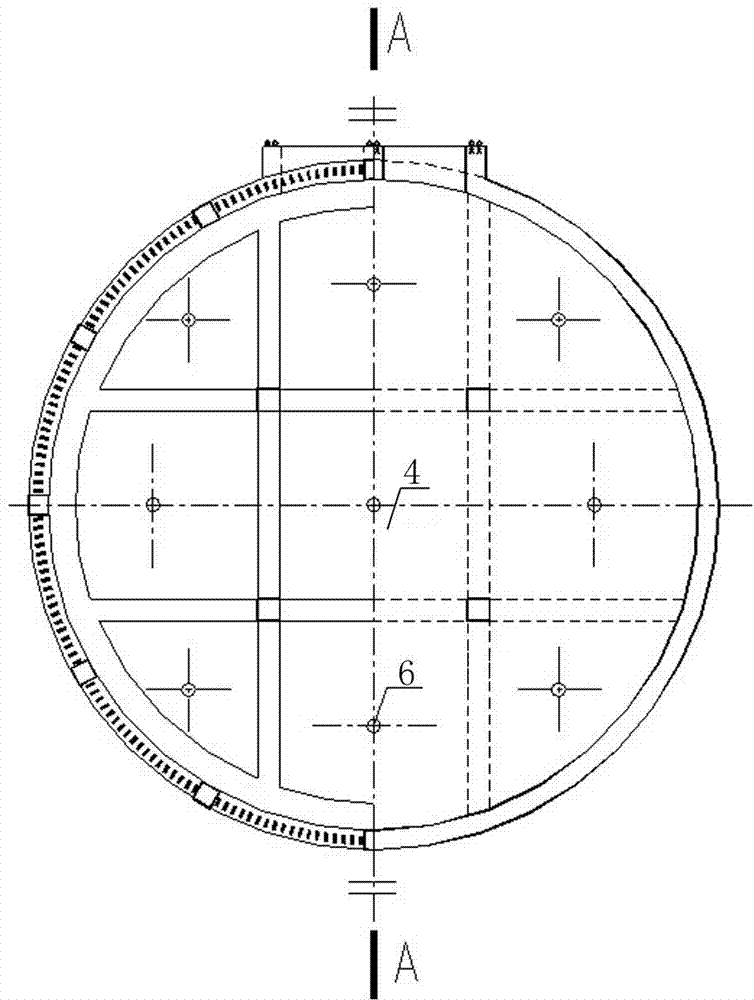

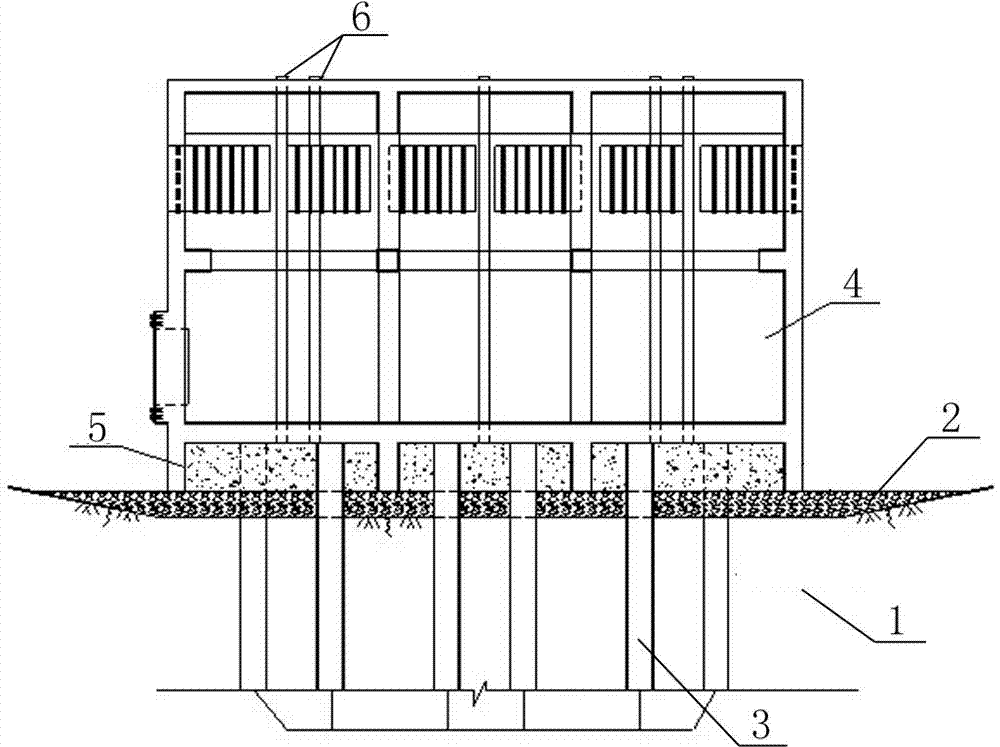

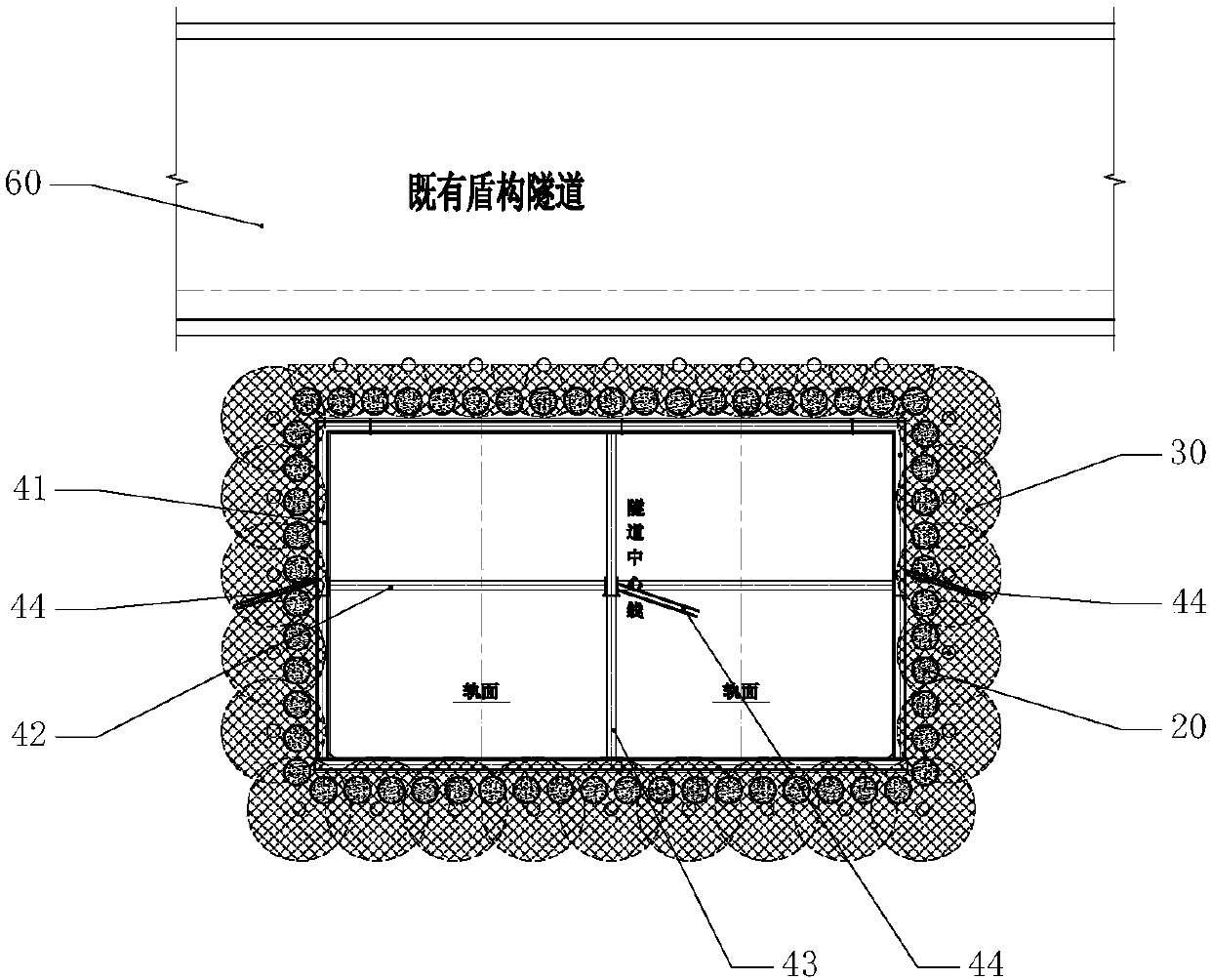

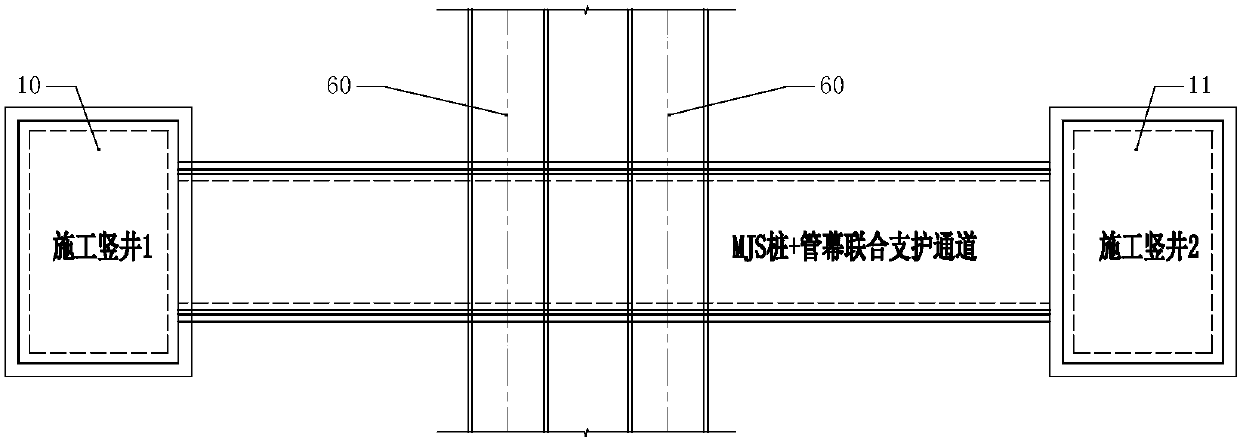

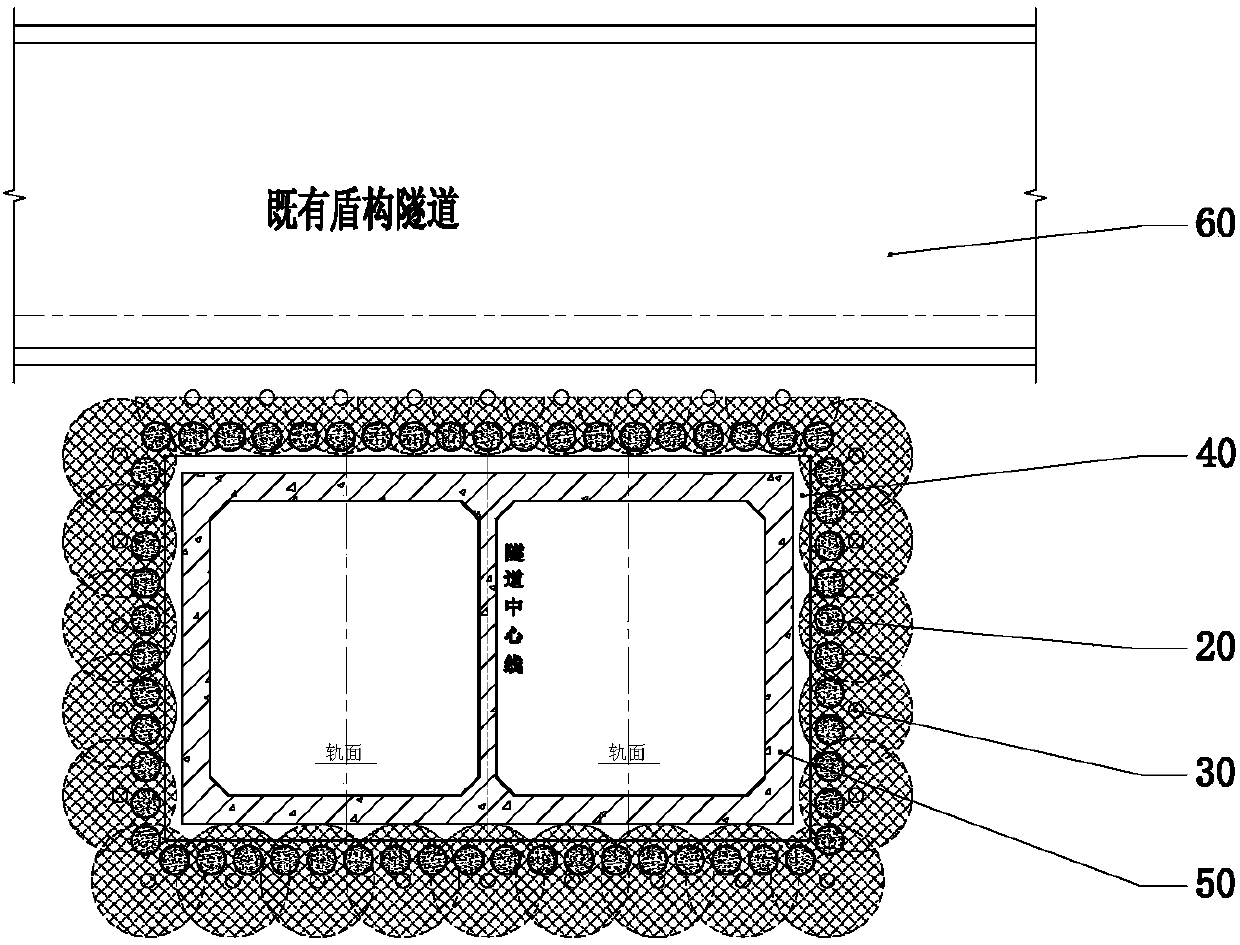

Large-section and small clear spacing dark excavation construction method through combined supporting of MJS construction method and pipe curtain method

InactiveCN107620600ARealize water stopSafe excavationUnderground chambersTunnel liningSteel tubeBuilding construction

The invention discloses a large-section and small clear spacing dark excavation construction method through combined supporting of an MJS construction method and a pipe curtain method. The large-section and small clear spacing dark excavation construction method comprises the following steps that according to requirements and the actual situation of site geology, relevant parameters of steel pipes, position arrangement of the steel pipes and relevant parameters of MJS piles are designed; working vertical shafts are arranged at the two ends of a planned large-section and small clear spacing tunnel; the steel pipes are horizontally jacked into along the outer contour of the planned large-section and small clear spacing tunnel, so that a pipe curtain is formed; the interior of the pipe curtain is densely filled with concrete; the MJS piles are constructed along the periphery of the pipe curtain; and excavation is conducted, and construction of the inner structure of the planned large-section and small clear spacing tunnel is completed. The interior of the pipe curtain is densely filled with concrete, so that pipe curtain enclosure with the sufficient rigidity is formed; and the MJS piles are constructed around the periphery of the pipe curtain, so that water stop between gaps of the steel pipes is achieved, safety of excavation of the planned large-section and small clear spacingtunnel is ensured fundamentally, and risks can be controlled.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

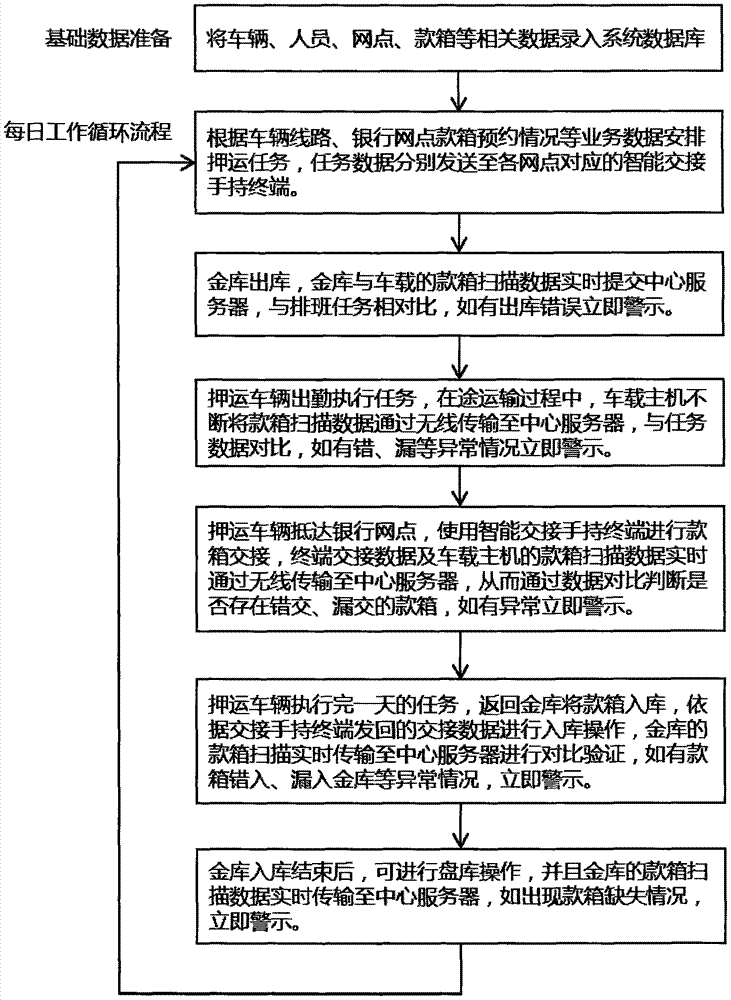

Safety monitoring system and safety monitoring method based on escort transportation cash box circulation service

The invention discloses a safety monitoring system based on an escort transportation cash box circulation service. The safety monitoring system comprises a central server, vault cash box scanning equipment, on-vehicle cash box scanning equipment and an intelligent handover handheld terminal. The central server is used for storing related data in an escort transportation operation and has a related service logic function. The vault cash box scanning equipment is used for scanning cash boxes in a vault in real time and transmits a scanning result to the central server. The vault cash box scanning equipment is used for transmitting the scanned cash box information to the central server every certain time period. The intelligent handover handheld terminal is used for a cash box handover operation between escort personnel and bank outlet personnel. The safety monitoring system performs real-time monitoring for scanning data of all cash boxes in a working flow and performs verification and comparison according to cash box change in each delivering out of the vault and each storing into the vault and handover completion. When an abnormity occurs, the system can perform in-time alarming, thereby preventing an accident risk.

Owner:深圳市众能泰科智能技术有限公司

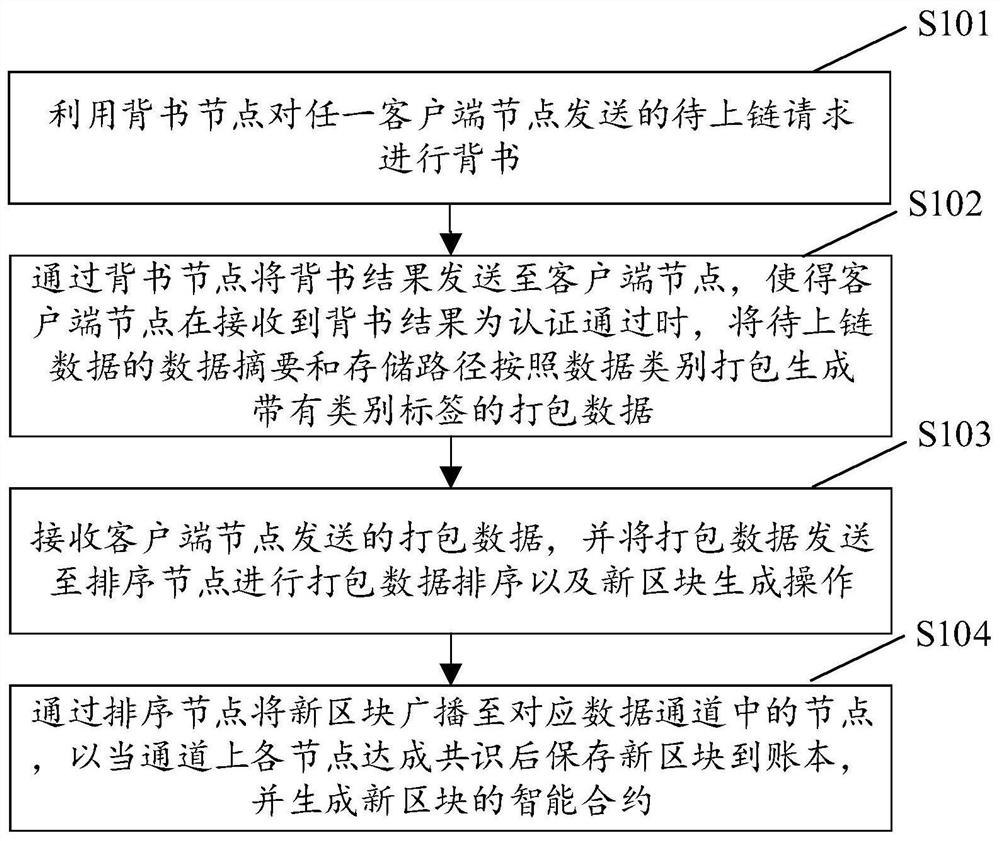

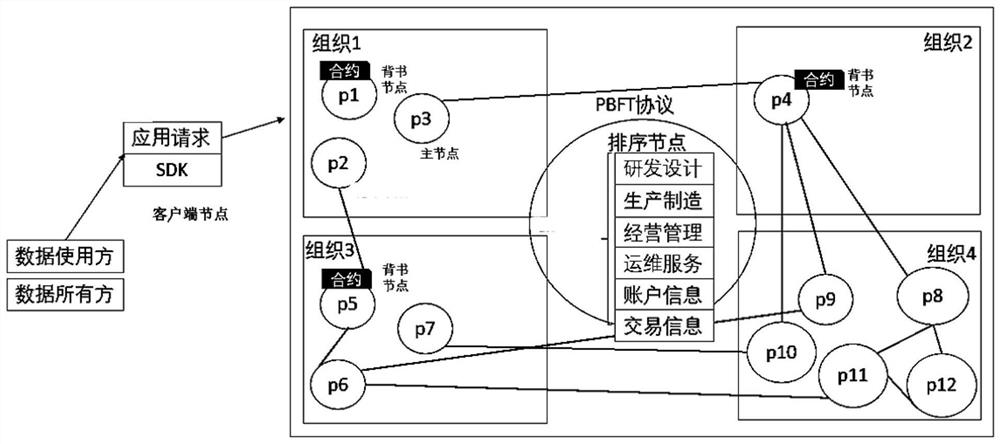

Industrial data asset management method, system and equipment

PendingCN113779607AImprove management abilityPrevent leakageDigital data protectionThe InternetIndustrial Internet

The invention discloses an industrial data asset management method, which is realized based on a block chain. The block chain comprises a plurality of data channels, different data channels are used for storing different types of information. The method comprises the following steps: endorsing a to-be-linked request sent by any client node by using an endorsing node; then the endorsement result is sent to the client node, so that when the client node receives the endorsement result that authentication is passed, the data abstract and the storage path of the to-be-linked data are packaged according to the data category to generate packaged data with a category label; sending the packaged data to a sorting node for sorting the packaged data and generating a new block; and broadcasting the new block to the nodes in the corresponding data channels through the sorting nodes, storing the new block to an account book after the nodes on the channels reach a consensus, and generating an intelligent contract of the new block. According to the technical scheme provided by the invention, the problems of safety and credibility of industrial internet edge data right confirmation, sharing and transaction are solved.

Owner:BEIJING E HUALU INFORMATION TECH

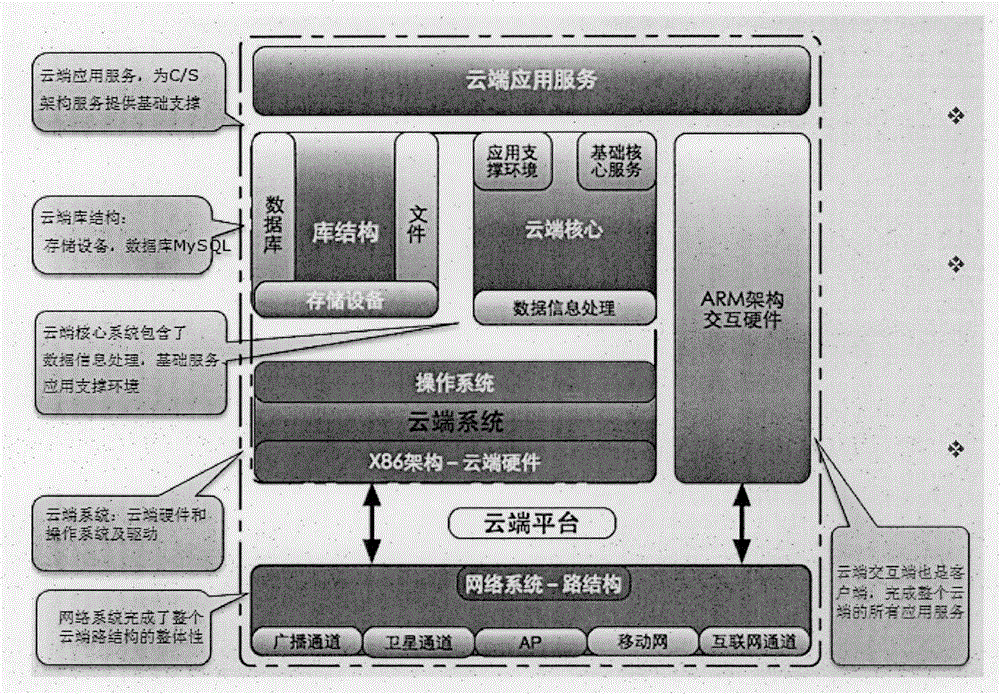

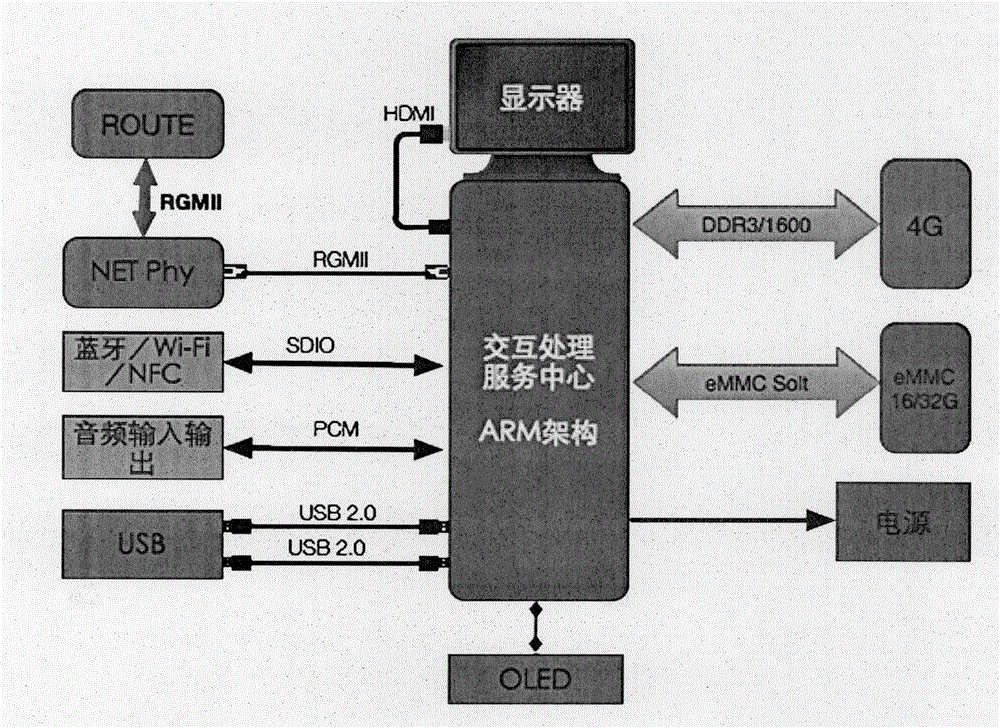

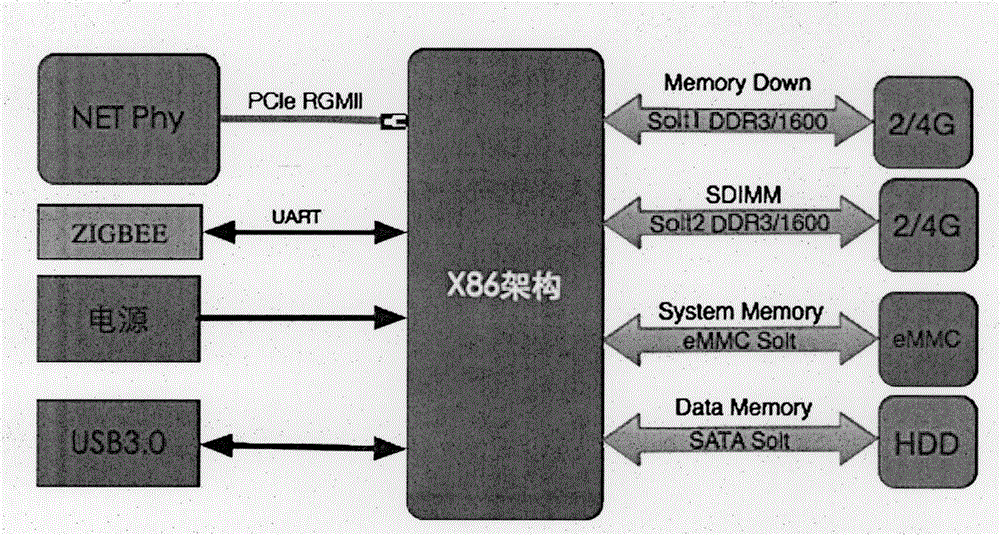

Novel heterogeneous fusion platform

InactiveCN105933418ASmooth experienceReduce couplingMultiprogramming arrangementsTransmissionCouplingGNU/Linux

The invention relates to the technical field of a network and especially relates to a novel heterogeneous fusion platform. The platform comprises a man-machine interaction system, a core service system and a cloud platform. The man-machine interaction system and the core service system are in communication connection with the cloud platform. The man-machine interaction system is responsible for UI user interactive processing; the core service system is responsible for core service processing, finishing a cloud platform-cloud end-client whole data play and storage processing process, and providing data service capable of being provided by the cloud end to a mobile end device. Through the structure above, each system operates independently, thereby reducing coupling degree and improving stability of the whole device; a Linux system finishes core processing of the whole system service; besides, portability, safety and stability are higher; and an Android system finishes user interaction of the whole cloud, so that smooth user experience is realized, man-machine interaction is human friendly, cost and risk are controllable, product development period is shorter, and hardware and application selection range is wider.

Owner:BEIJING DAYOU ZHONGCHENG TECH CO LTD

Water injection fracturing device and method while drilling

PendingCN113513294AEasy to operateControllable riskFluid removalMining engineeringHydraulic fracturing

The invention relates to a water injection fracturing device and method while drilling, belongs to the field of coal mine underground drilling and fracturing engineering, and particularly relates to the water injection fracturing device and method while drilling. The water injection fracturing device and method while drilling solve the problems that in a traditional hydraulic fracturing technology, drilling and fracturing construction are conducted step by step, the working procedures of repeated drilling up and down and drilling tool replacement are complex, and stability is affected by repeated disturbance of drilling before fracturing. By means of the water injection fracturing device while drilling and a matched technological method, water injection fracturing of layer penetrating or bedding drilling can be conducted in time in the position next to drilling construction, the working procedures of additional drilling up and down, drilling tool replacement and the like are not needed, equipment is simple, operation is convenient, risks are controllable, and the field application effect is remarkable.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Online repairing method for main screw holes of reactor pressure vessel flanges

The invention relates to an online repairing method for screw holes and threads, in particular to the online repairing method for the main screw hole of reactor pressure vessel flanges. The repairingmethod comprises the following steps of 1, defects of the main screw holes and the threads are inspected and repair preparation is carried out; 2, manually repairing is carried out by a scraper; 3, manual slight grinding is carried out by a metallographic abrasive paper; 4, screw tap repairing method is adopted; and 5, online grinding and repairing are adopted. According to the online repairing method, common defects of the main screw holes and the threads are covered, so that fine, efficient and reliable online repairing is realized.

Owner:SANMEN NUCLEAR POWER CO LTD

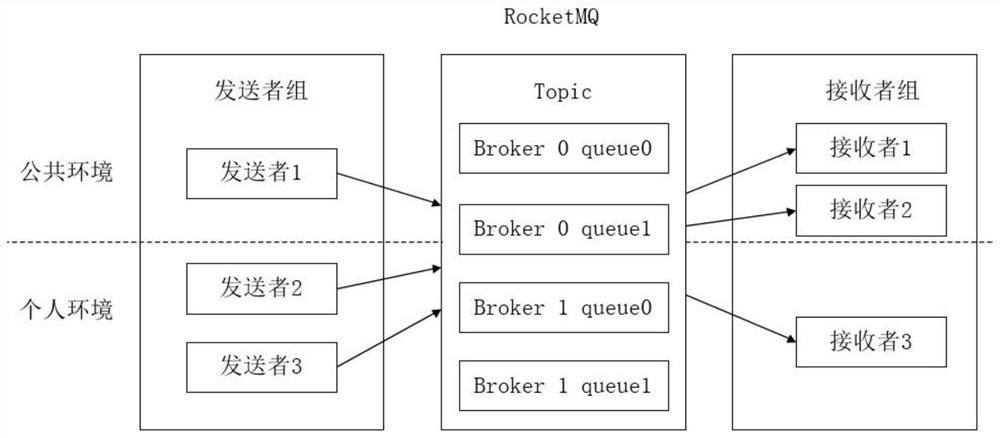

Message passing method and device under multii-test environment

PendingCN113254235AMeet needsImprove test efficiencyInterprogram communicationSoftware testing/debuggingMessage deliveryMiddleware

The invention relates to the technical field of computers, and discloses a message passing method in a multi-test environment, the multi-test environment comprises a first test environment and a second test environment, and the first test environment and the second test environment comprise at least one sender and at least one receiver. The message is forwarded between the sender and the receiver through the message middleware; the sender sends the message, and the message comprises a first mark used for indicating the sender; the message middleware receives the message, and determines a receiver as a message destination from receivers connected with the message middleware according to the first mark; and a receiver serving as a destination obtains the message through the message middleware. According to the invention, each developer or tester can realize simultaneous testing of multiple services in own testing environment, so that the testing efficiency is greatly improved, the requirements of the developers and testers are practically met, and the invention is convenient, quick and efficient.

Owner:行吟信息科技(武汉)有限公司

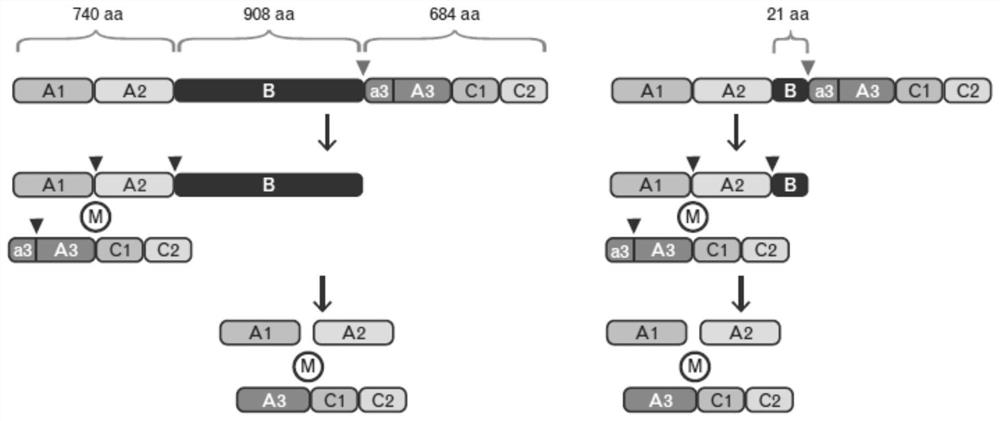

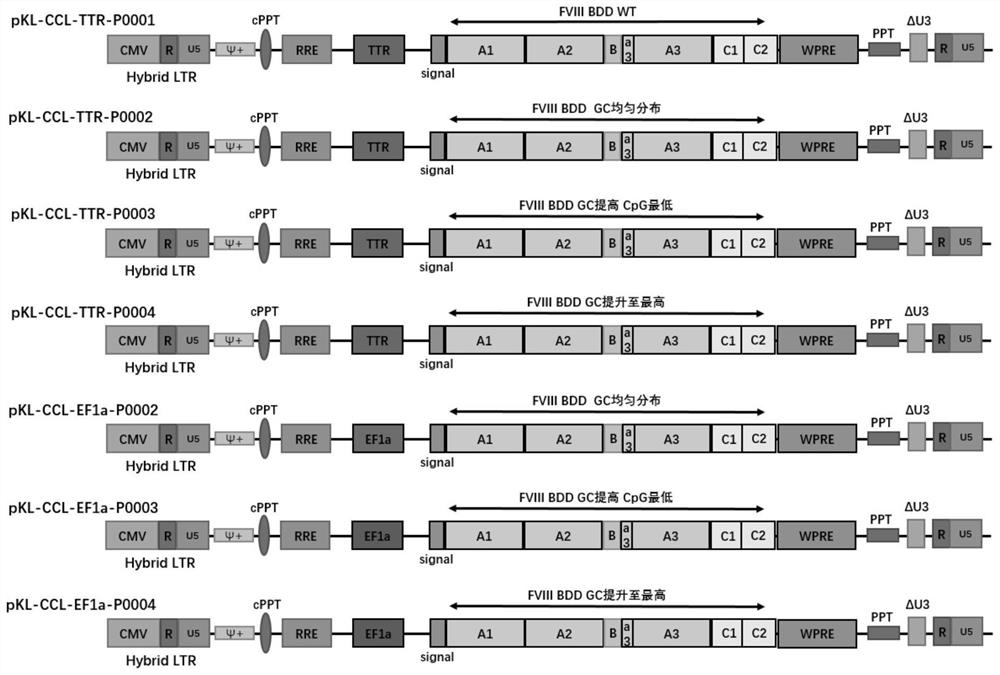

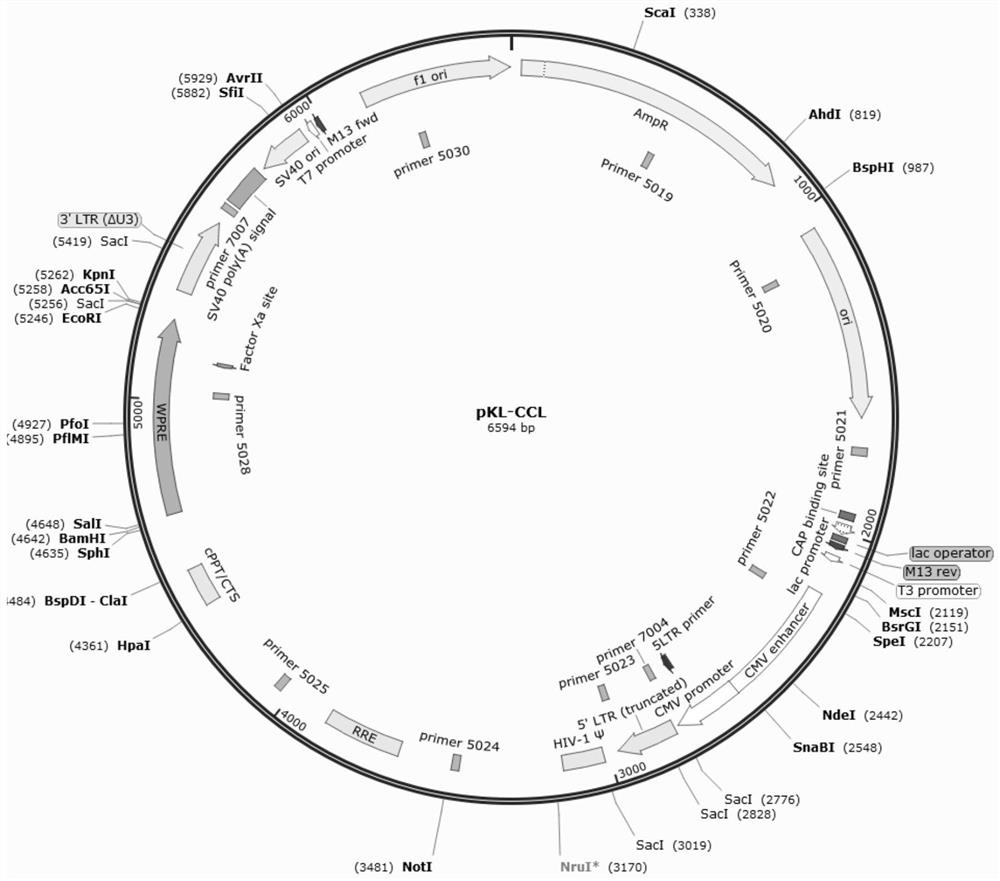

Codon-optimized blood coagulation factor VIII gene and construct comprising codon-optimized blood coagulation factor VIII gene

ActiveCN111808863AHigh expressionHigh GC contentFactor VIIPeptide/protein ingredientsBlood coagulation factor VIIIBlood coagulations

The invention relates to the field of biological medicine, in particular to a codon-optimized blood coagulation factor VIII gene and a construct comprising the codon-optimized blood coagulation factorVIII gene. The codon-optimized blood coagulation factor VIII gene is provided, a GC content in a sequence of the blood coagulation factor VIII gene is at least 54%, a CpG island number is at least 122, and a gene sequence of a B domain in the codon-optimized blood coagulation factor VIII gene is a truncated sequence. The nucleic acid construct is further provided, and the nucleic acid construct comprises the codon-optimized blood coagulation factor VIII gene. The codon-optimized blood coagulation factor VIII gene and the construct comprising the codon-optimized blood coagulation factor VIII gene have the following beneficial effects that the expression quantity of a blood coagulation factor VIII is significantly improved; the activity level of the blood coagulation factor VIII is significantly raised; and a dosage is low, immunoreaction and the immunogenicity are reduced, and risks are relatively controllable.

Owner:KANGLIN BIOTECHNOLOGY (HANGZHOU) CO LTD

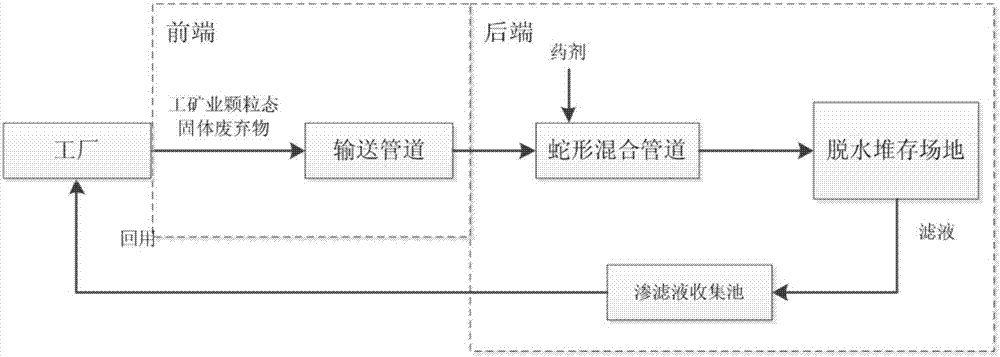

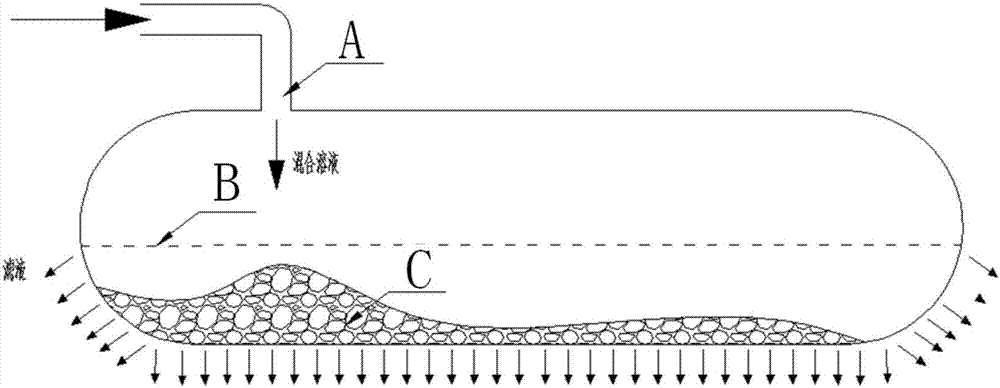

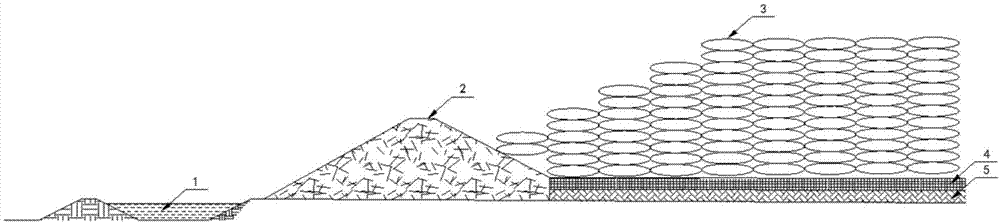

Dewatering and safe stockpiling integrated system and method for industrial and mineral industry particulate solid waste

InactiveCN107350262AHigh safety and stability of the yardReduce shipping costsSolid waste disposalEmbankmentsEnvironment effectLandslide

The invention discloses a dewatering and safe stockpiling integrated system and method for industrial and mineral industry particulate solid waste. The dewatering and safe stockpiling integrated system comprises a front end transporting unit, a rear end transporting unit and a dewatering and stockpiling site. The rear end transporting unit comprises a mixing pipeline with the input end being connected to the front end transporting unit. The dewatering and stockpiling site comprises a water permeable rock-fill dam, a geotextile tube stockpiling body arranged on one side of the water permeable rock-fill dam and a leachate gathering tank arranged on the other side of the water permeable rock-fill dam. A plurality of geotextile tubes are stacked on the geotextile tube stockpiling body in a stack-up mode. Solid waste mud is transported to the geotextile tubes of the geotextile tube stockpiling body through the mixing pipeline, and a leachate guide discharging system is arranged at the bottom of the geotextile tube stockpiling body. According to the dewatering and safe stockpiling integrated system and method, the transporting and disposition cost of the solid waste is low, a large part of waste water can be recovered, the environmental influence is reduced, the stacking site for stacking the capsule-state solid waste is high in safety and stability, and the problems of safety risks such as stacking site side slope unstability, collapse, landslide and debris flow are not prone to occurring.

Owner:上海胜义环境科技有限公司

A Bird Strike Design Method for Fan Blades

ActiveCN107061353BImprove securityIncrease job securityGeometric CADEngine manufactureForeign matterAviation

The invention relates to a bird impact design method for a fan blade, belongs to the technical field of aviation and provides a bird impact design method for a fan blade. The sub-surface fine net structural design is conducted on the blade, elastic deformation of the fan blade due to bird impacts or foreign matter collisions is controlled, the effects of inner structure dislocation energy absorbing and breaking energy absorbing are achieved, and the purpose that the blade is greatly deformed but not fractured is achieved to the maximum degree. Even though the blade is fractured, the fracture position and trend can be controlled through the design method, risk controllability is achieved, and the safety of the fan blade is improved to the maximum degree. Through the inner design, effective control and prediction over blade fracture during bird impacts can be achieved, and the work safety of an aero-engine is improved.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com