Nuclear operation and maintenance robot shaft hole assembling method based on man-machine cooperation

An assembly method and robot technology, applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problems of heavy manual operation tasks, accidental shaft holes, complex working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

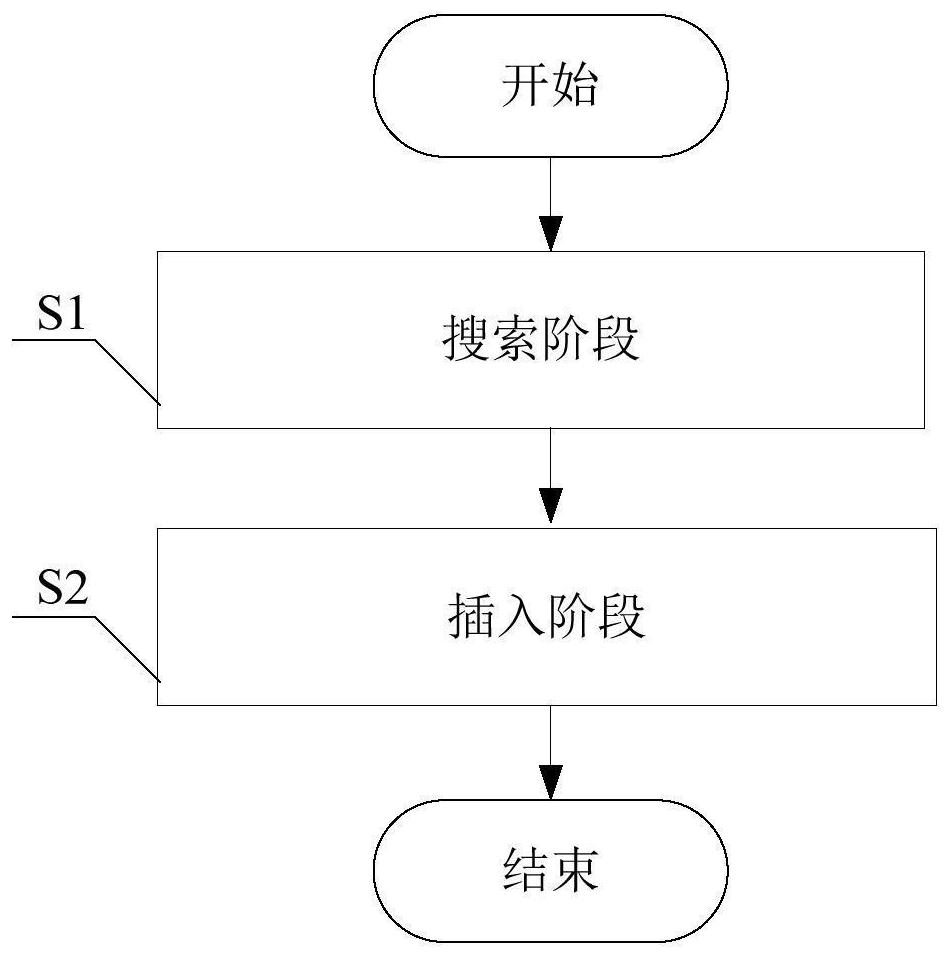

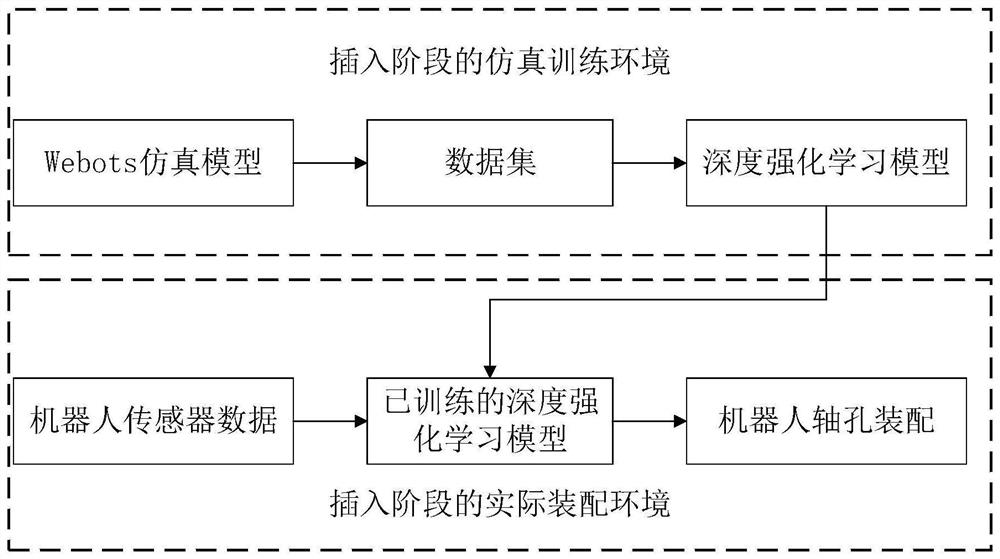

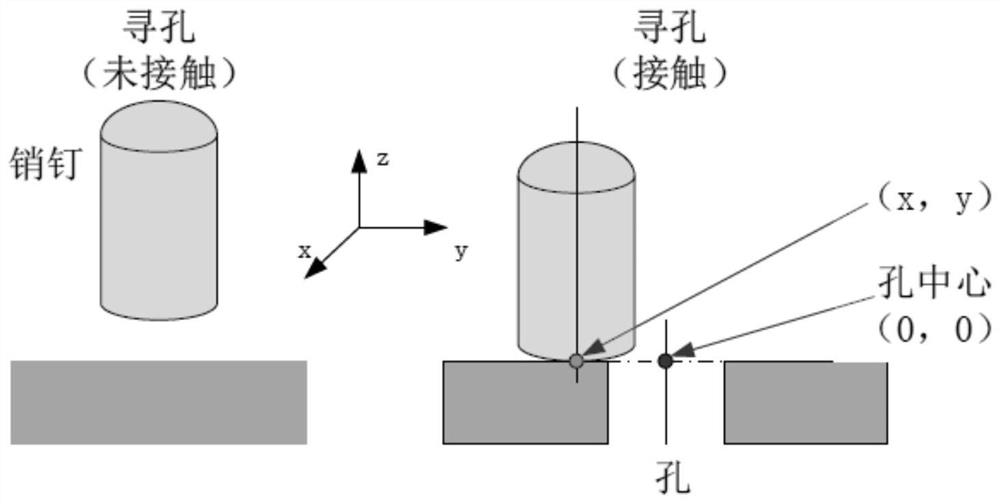

[0064] In order to reduce the radiation dose of the operation and maintenance personnel and improve the efficiency of operation and maintenance, this paper proposes a method for assembling the shaft hole of the nuclear operation and maintenance robot based on human-machine cooperation, and introduces the robot autonomous control technology in the installation process of the nuclear detector outside the reactor. All operations must be carried out under the premise of human monitoring, that is, "teleoperation + partial autonomy". Fully combine robot intelligence with human intelligence: use human experience and knowledge to complete the hole-seeking task of shaft-hole assembly, enhance the reliability of the operation process, and ensure that risks are controllable; at the same time, use the DRL algorithm to enable the robot to complete pins autonomously in local areas Insertion tasks such as figure 1 As shown, the implementation method is as follows:

[0065] S1. Search stage:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com