Method for extracting olefin carbon, enriching rare earth and separating inorganic materials by solid waste liquid waste three-phase method

An inorganic material, olefin-carbon enrichment technology, applied in the field of solid waste liquid waste three-phase extraction of olefin carbon enrichment rare earth separation inorganic materials, can solve the problems of low operability, high energy consumption, high material consumption, low extraction rate, etc. Achieve the effects of broad application prospects, easy risk control, and product diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

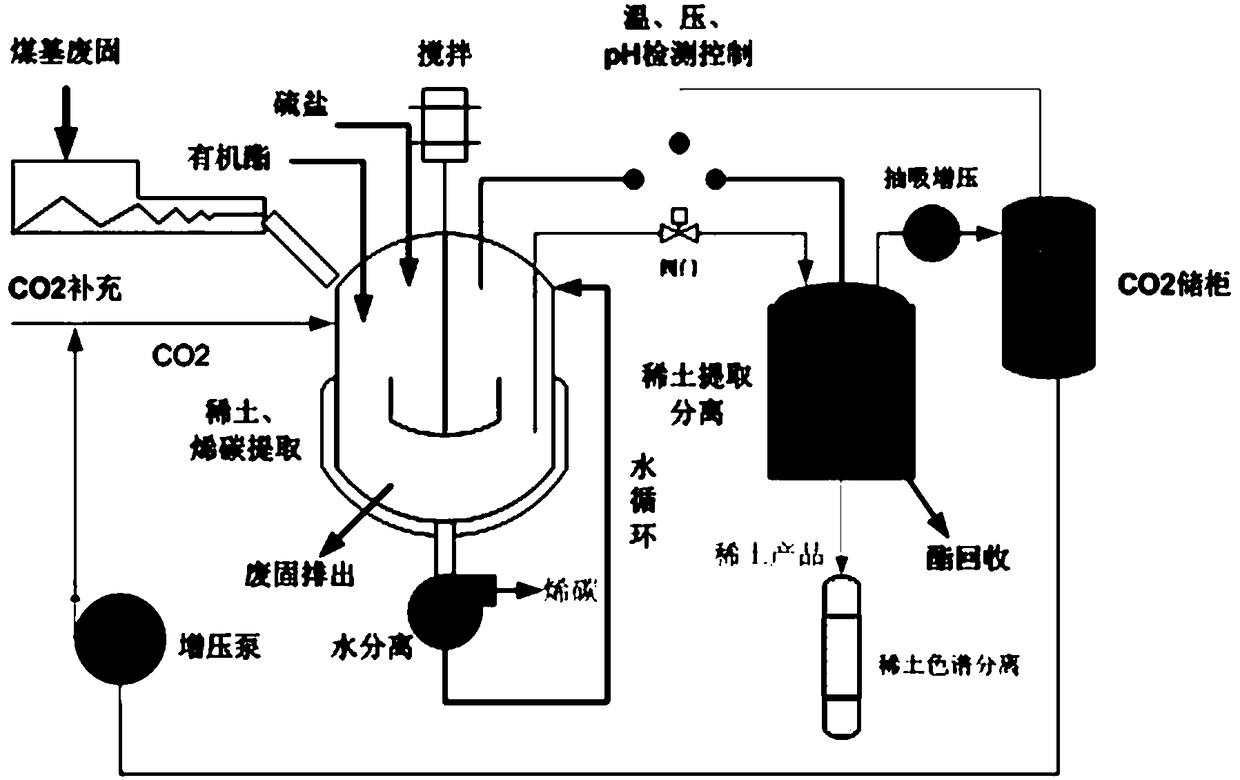

[0030] like figure 1 As shown, the method for extracting olefinic carbon, enriching rare earths, and separating inorganic materials by the three-phase method of solid waste and liquid waste is carried out according to the following steps:

[0031] Step 1) Mix raw materials (coal-based solid waste materials or liquid waste, solid waste and liquid waste in the iron and steel non-ferrous smelting industry, and rare earth concentrate or slag or liquid waste) into water, and then add to supercritical CO 2 In the reaction kettle, maintain the temperature of the reaction kettle at 283K-423K, and the pressure at 3.5MPa-35MPa, extract rare earth elements from the added raw materials, and strip off the carbon at the same time;

[0032] Step 2) performing solid-liquid separation on the reacted solution, and the separated solid is bulk silicon-aluminum solid material;

[0033] Step 3) Reduce and maintain the temperature of the reactor at 283K-373K, and the pressure at 0.1MPa-10MPa, add s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com