Online repairing method for main screw holes of reactor pressure vessel flanges

A pressure vessel and repair method technology, which is applied in the field of on-line repair of the main screw hole of the reactor pressure vessel flange, can solve the problems of restricting the critical path of refueling overhaul, damage to the main bolt or screw hole thread, and seizure, so as to achieve optimal online repair Effect of selection and prevention of overgrinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

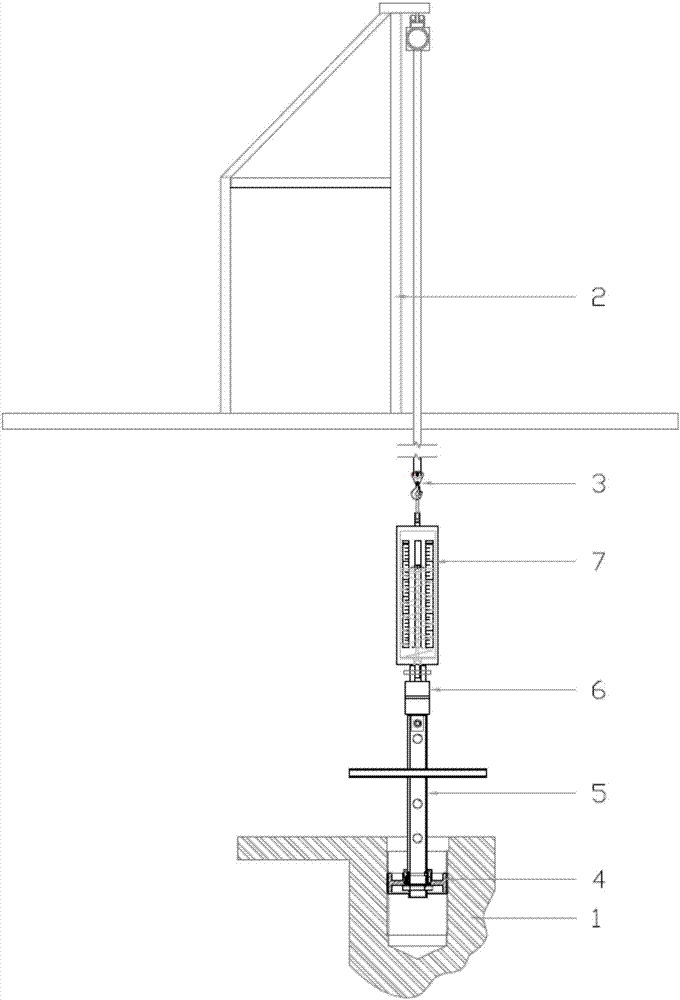

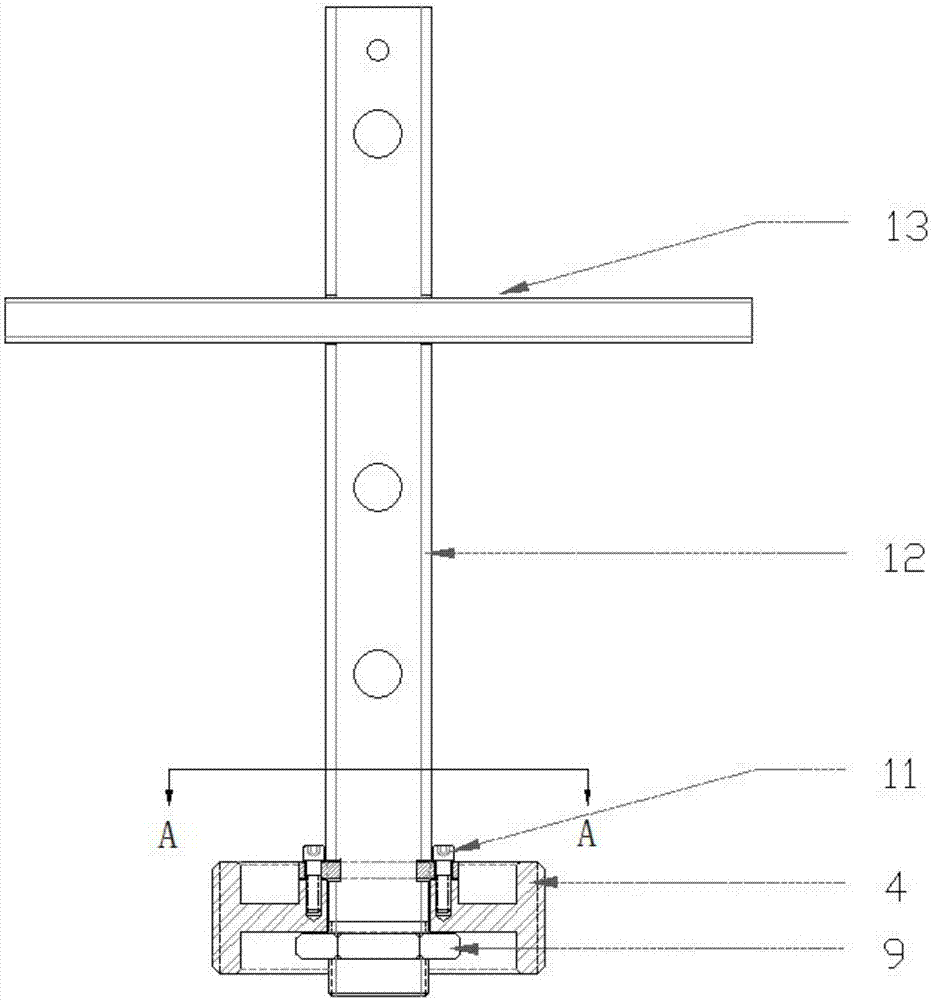

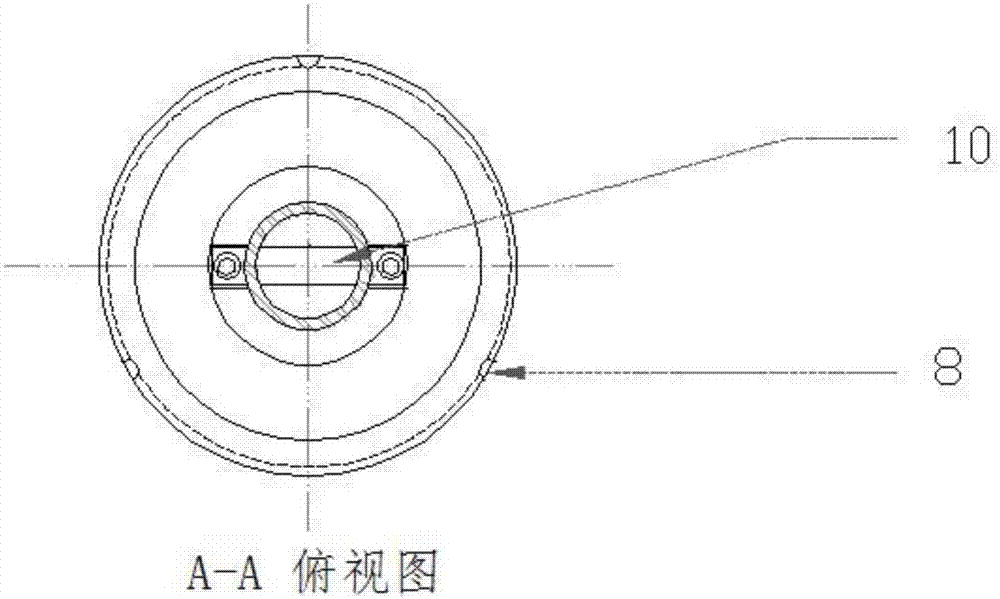

[0050] as attached figure 1 , 2 As shown in and 3, a reactor pressure vessel flange main screw hole online grinding and repairing device provided by the present invention, the device includes a grinding thread mold 4, a rotating operating handle 5 (composed of a connecting pipe 12 and an operating handle 13) , Swivel device 6, spring balancer 7, lock nut 9, positioning plug 10 and positioning screw 11.

[0051] Among them, the external thread of the paired thread tire 4 refers to the thread specification of the main bolt, and the middle diameter is processed according to the standard thread diameter of the main bolt by 0.01 mm. The material is 45# steel and has been quenched, tempered and hardened. The hardness requirement of the tool 4 thread should not be lower than the thread of the main screw hole 1; the thickness of the research thread mold 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com