Patents

Literature

30results about How to "Ensure normal excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

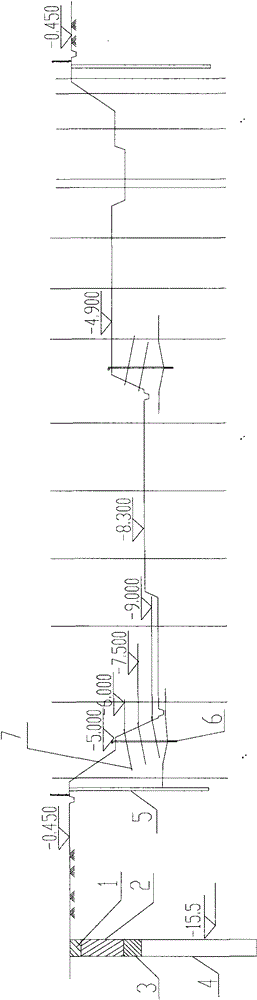

A construction method for the communication channel of the broken stratum in the shield tunnel crossing the river

ActiveCN102287198AEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingEnvironmental resistanceGround contact

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

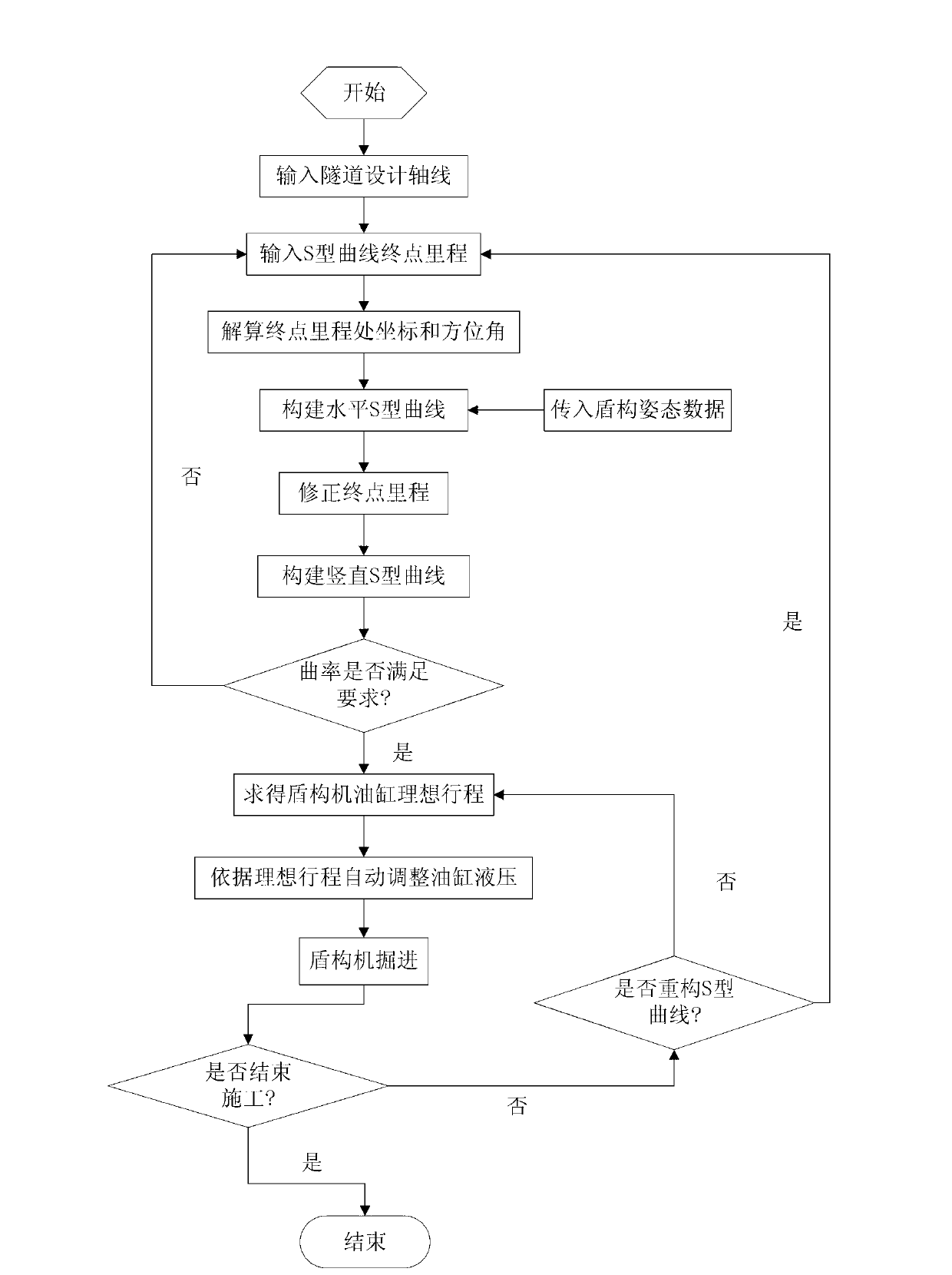

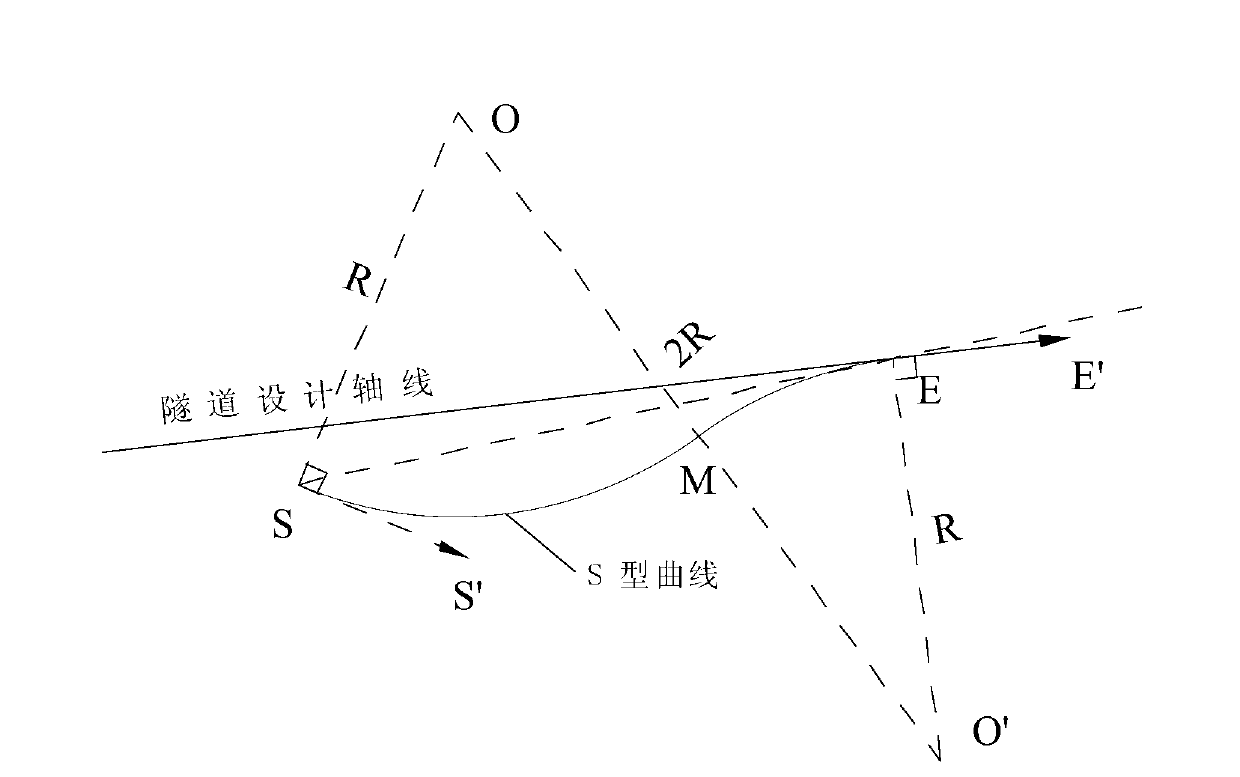

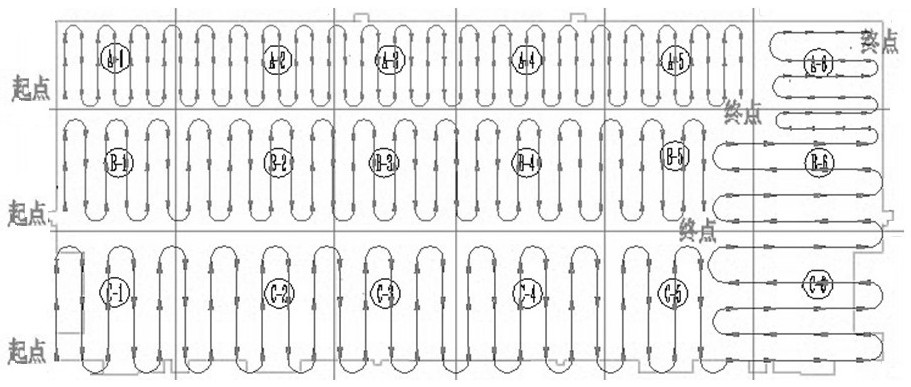

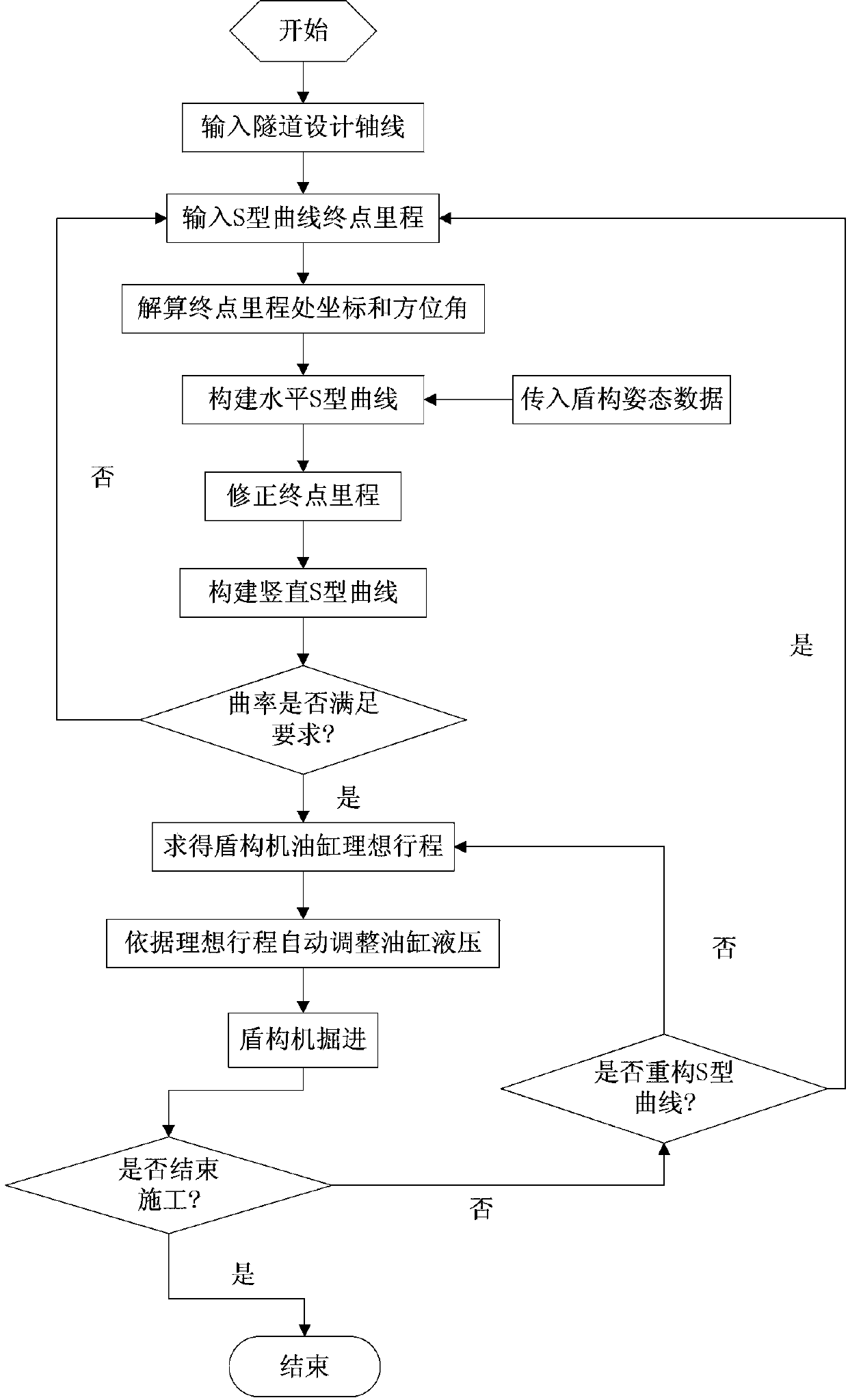

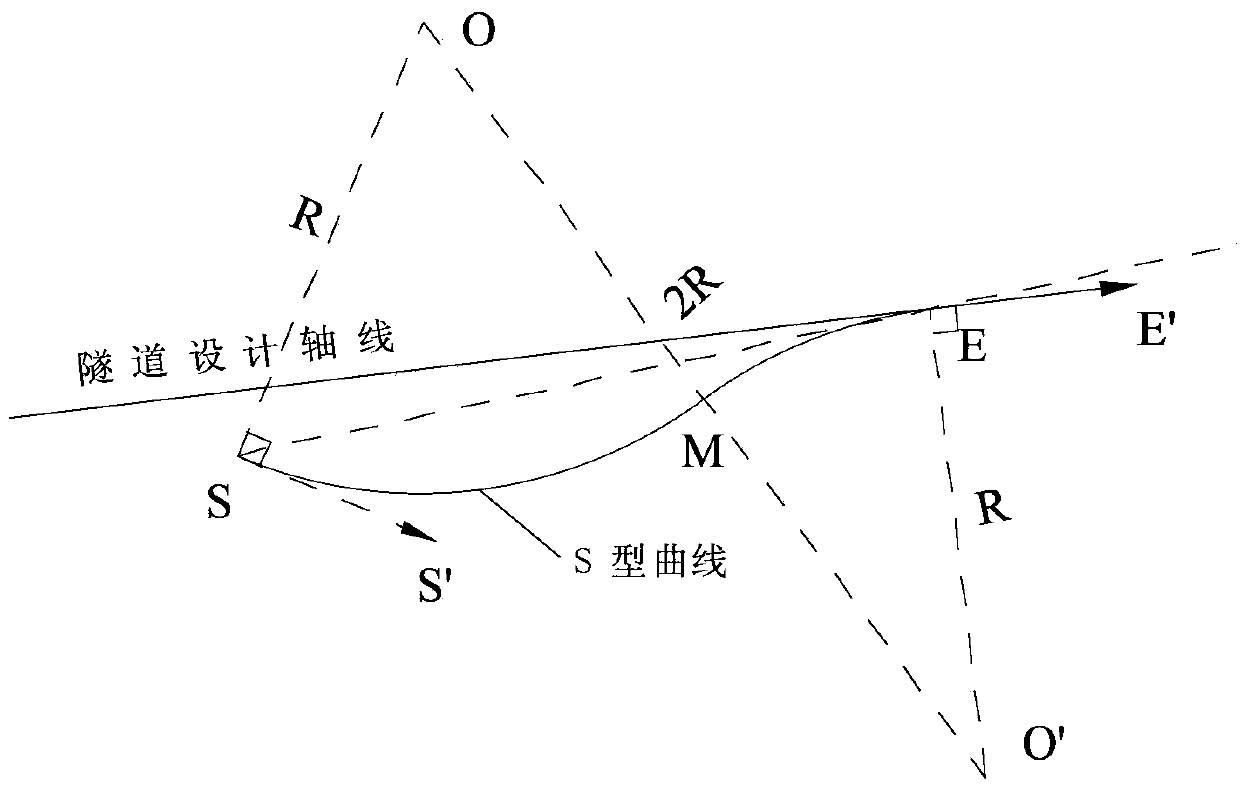

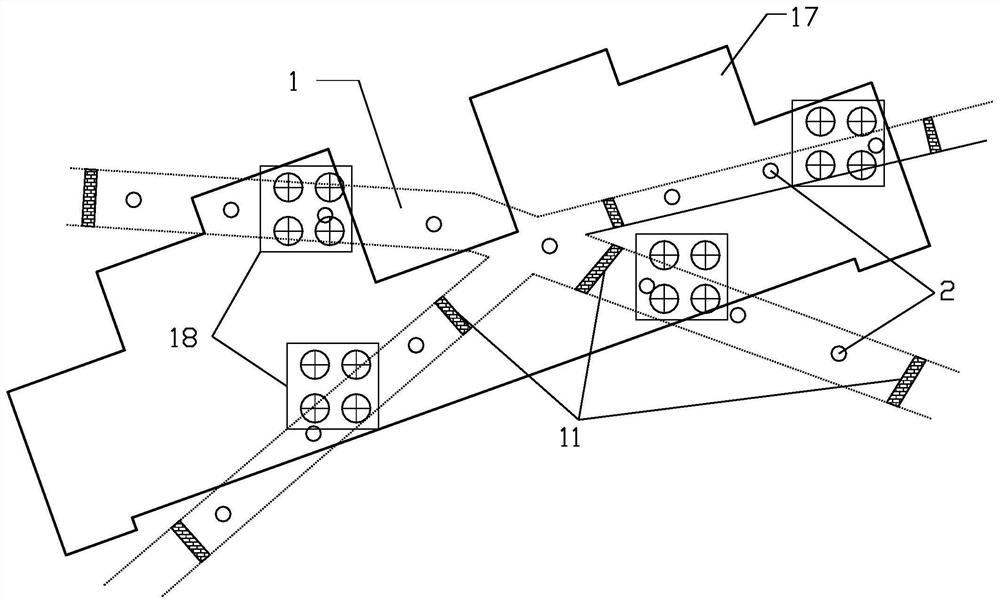

S-shaped curve based method for control track of shield tunneling machine

The invention relates to an S-shaped curve based method for control a track of a shield tunneling machine. The method comprises the steps of obtaining horizontal and vertical curve elements of a tunnel design axis; obtaining mileages of terminal points of S-shaped curves, which are set initially; calculating coordinates and azimuth angles at positions of mileages of terminal points of S-shaped curves; obtaining real-time attitude data of the shield tunneling machine; establishing the horizontal S-shaped curve; correcting mileages of terminal points of S-shaped curves; establishing the vertical S-shaped curve; judging whether the minimum curvature radiuses of S-shaped curves are less than the minimum turning radius of the shield tunneling machine or not, and obtaining mileages of terminal points of S-shaped curves again if the minimum curvature radiuses of S-shaped curves are less than the minimum turning radius of the shield tunneling machine; calculating an ideal stroke of a jack after the shield tunneling machine tunnels one ring along S-shaped curves; converting data of the ideal stroke into the required oil cylinder hydraulic pressure; and transmitting calculation results to the shield tunneling machine by a computer, controlling the shield tunneling machine to tunnel forward, and judging in real time whether S-shaped curves are required to be reconstructed or not. Compared with the prior art, the method has the advantages of being capable of finishing deviation rectification once, high in generality, capable of reducing the fluctuation of the track of the shield tunneling machine and the like.

Owner:SHANGHAI TONGYAN CIVIL ENGINEERING TECHNOLOGY CORP LTD

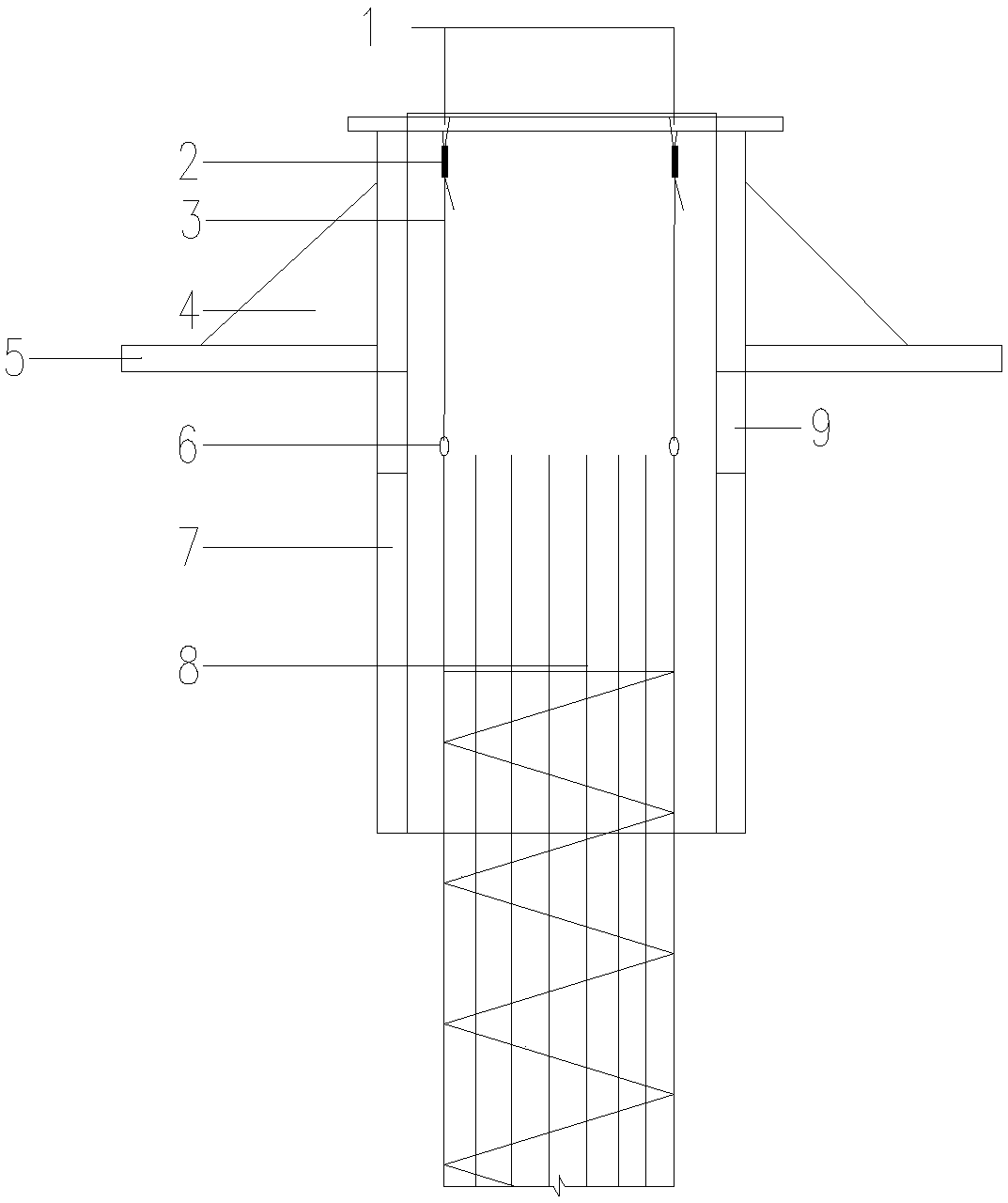

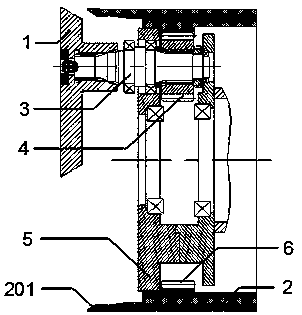

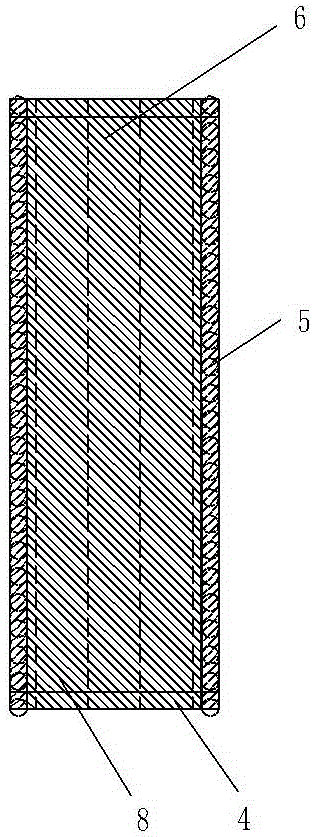

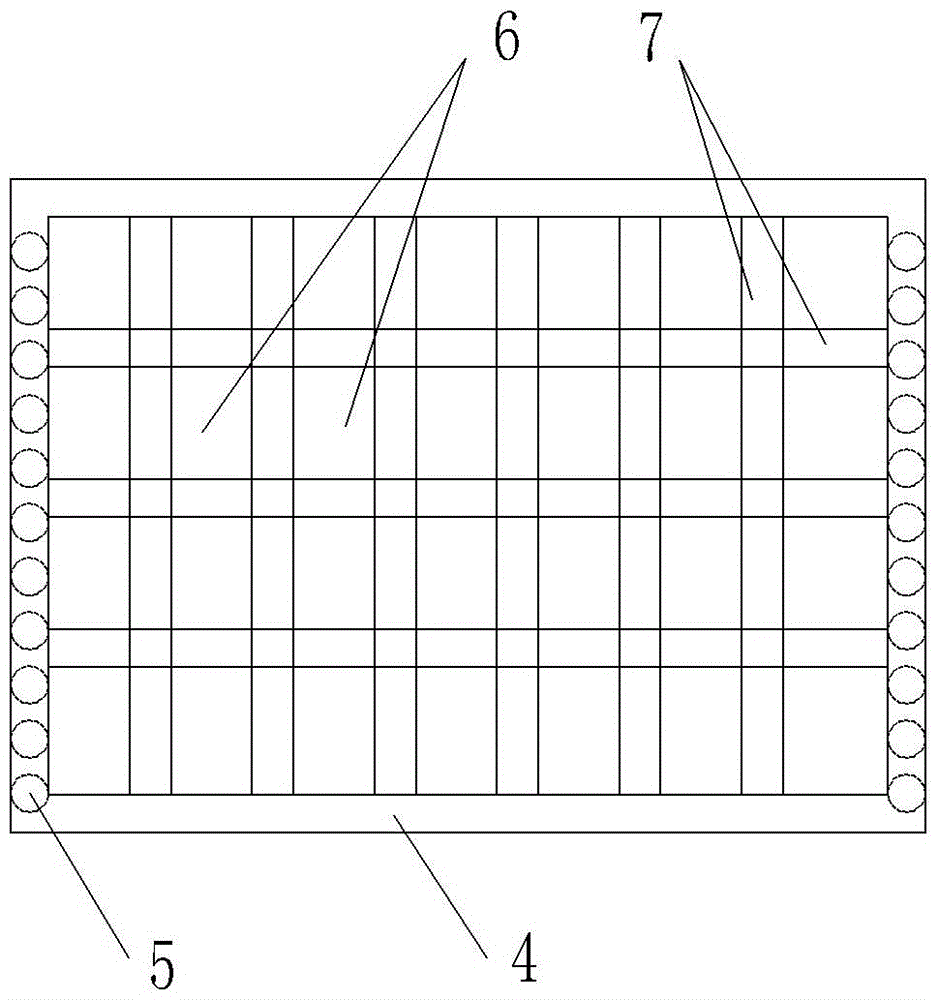

Method for preventing sinking of hole opening protective cylinder of slurry retaining wall hole forming cast-in-place pile

The invention discloses a method for preventing sinking of a hole opening protective cylinder of a slurry retaining wall hole forming cast-in-place pile. The method comprises the specific processes that two cylinder protecting flanges are arranged on the upper portion of the outer wall of the hole opening protective cylinder, and a gap is reserved between the cylinder protecting flanges; a groovefor storing a reinforcement cage hanging device is formed in the top end of the hole opening protective cylinder; and slurry overflow ports are formed in the side wall of the hole opening protective cylinder and formed corresponding to the gap between the two cylinder protecting flanges. According to the method, the accuracy that the top elevation of the hole opening protective cylinder is adoptedas control over the temporary pile hole depth and the reinforcement cage elevation on site is guaranteed, and at the same time, it is guaranteed that the protective cylinder can be normally pulled upand move; and meanwhile the situation that subsequent concrete guide pipe putting-down arrangement is influenced by steel pipe hanging is avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

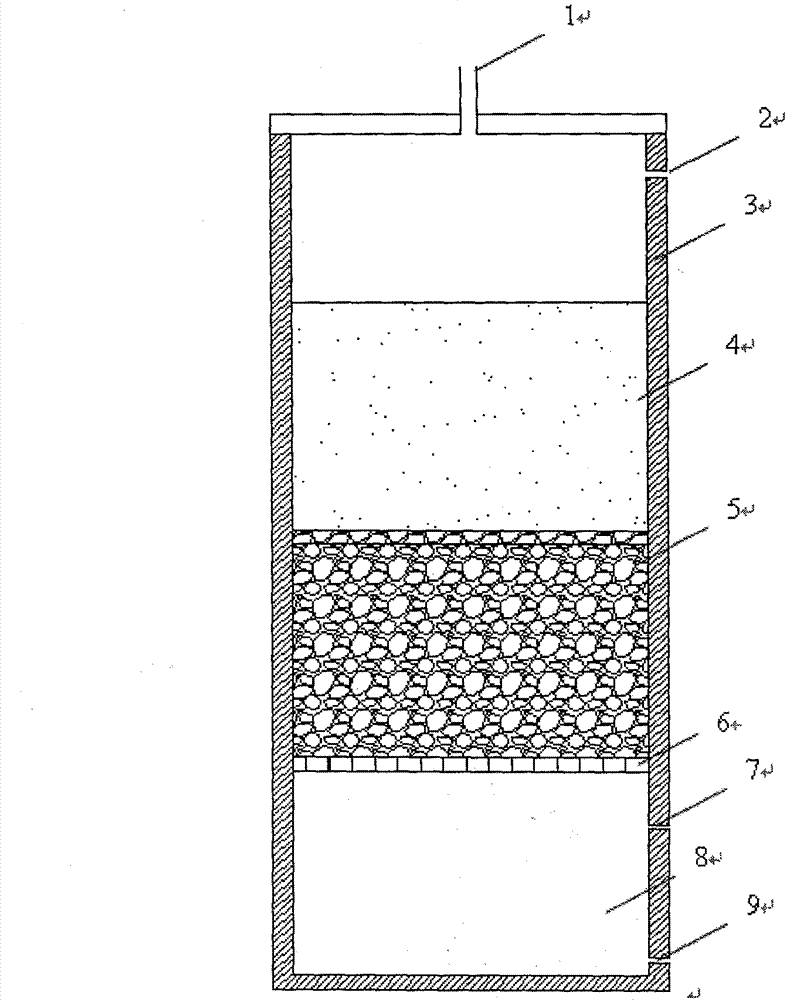

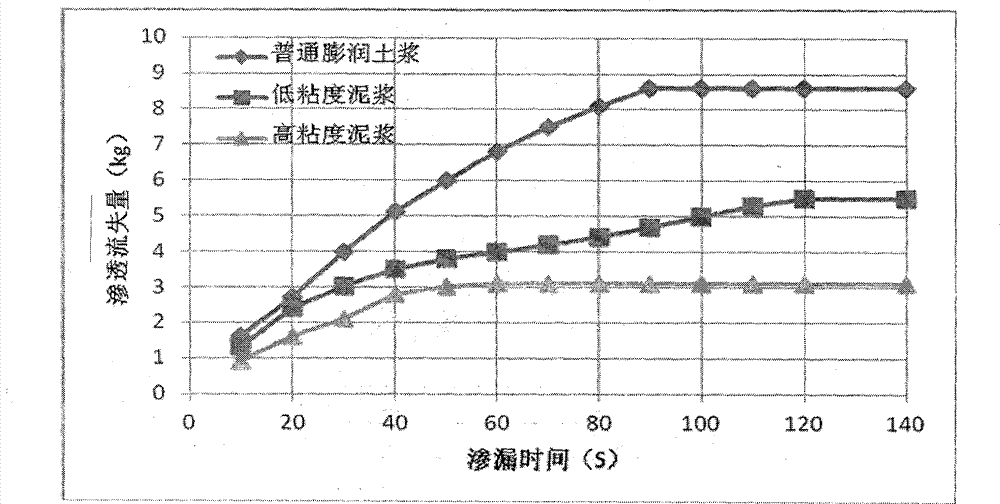

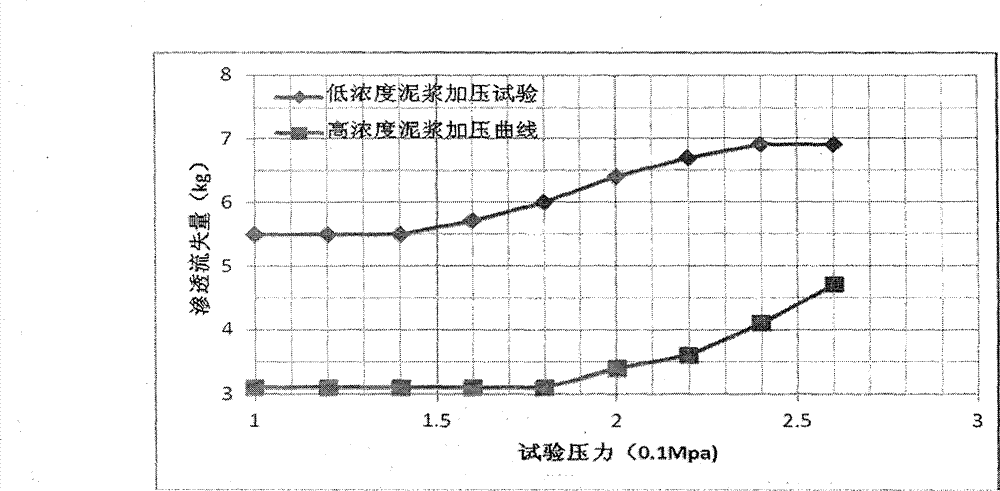

High viscosity slurry for water-rich sandy gravel stratum slurry shield construction

The invention relates to high viscosity slurry for water-rich sandy gravel stratum slurry shield construction. 12 parts of bentonite and a proper quantity of water are jointly added into a slurry preparing pool, the bentonite turns into even paste after 15 minutes of full agitation, then 1 part of I type slurrying agent is added into the slurry preparing pool and then stirred so as to form I type slurry, the specific gravity of the I type slurry is detected, the specific gravity of the I type slurry is required to be controlled between 1.05 and 1.15g / cm3, 20 parts of II type slurrying agent and 2 parts of III type slurrying agent are added into the slurry preparing pool and then stirred for 10 minutes so as to form high viscosity slurry, the marsh funnel viscosity of the high viscosity slurry is detected and is required to be controlled between 30-35s, and the marsh funnel viscosity of the high viscosity slurry is twice that of common bentonite slurry, so that the high viscosity slurry can be effectively mixed with excavated muck, the muck is prevented from depositing in a cutter cabin, and the shield is ensured to tunnel normally.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

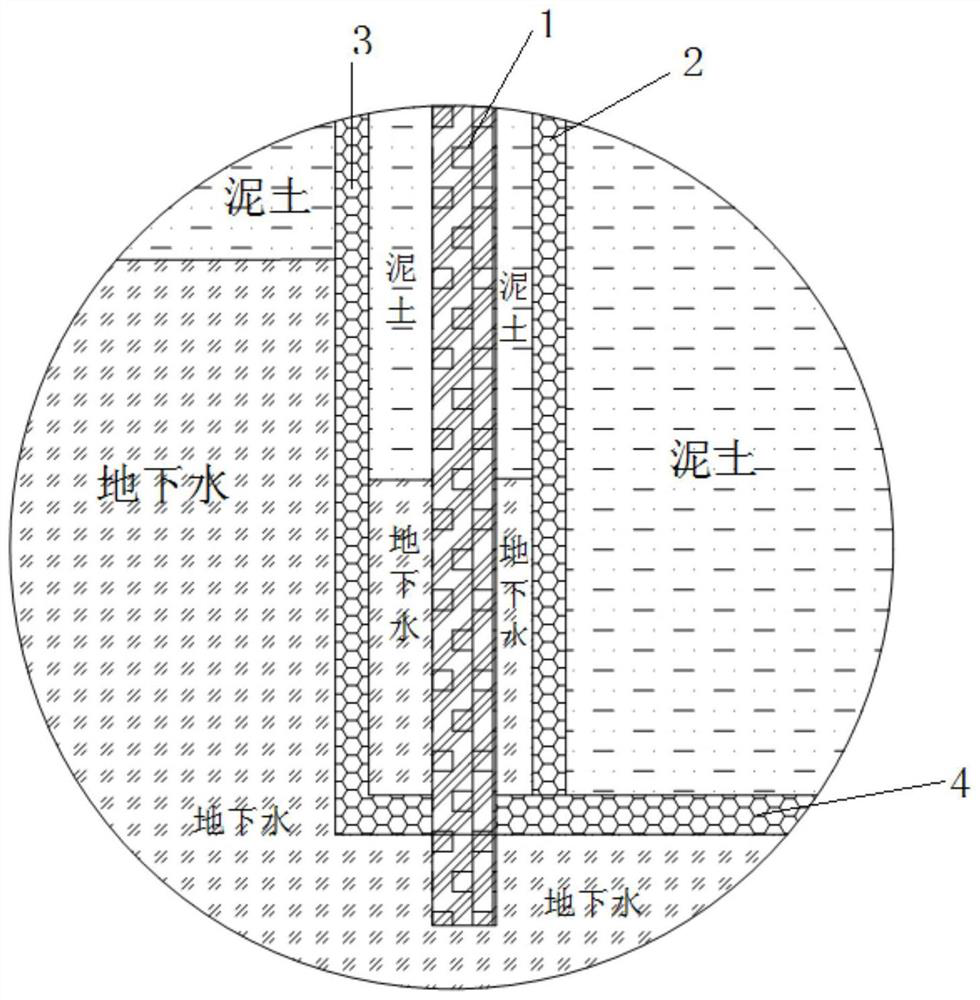

In-rock deep foundation pit rock-socketed water-stop curtain construction method

InactiveCN103850261AGuarantee the effect of anti-seepage treatmentEnsure anti-seepage treatment effectExcavationsGranolithicHigh pressure

The invention relates to a deep foundation pit, in particular to a deep foundation pit water-stop curtain construction method. An in-rock deep foundation pit rock-socketed water-stop curtain construction method comprises the following steps: 1) stopping water in a highly permeable layer above a rock layer by using three-axis cement mixing piles; 2) clearly exploring the situations of distribution and elevations of sand-containing coral debris, highly-weathered granite layers and medium-weathered granite layers by adopting a preliminary hole prospecting technology, and guiding the construction of the three-axis cement mixing piles and high-pressure jet grouting piles through information; 3) performing fully-closed water interception on the rock layer and an interface between the rock layer and the sand-containing coral debris by adopting the high-pressure jet grouting piles. The in-rock deep foundation pit rock-socketed water-stop curtain construction method has the advantages that two structural geological layer enclosure structures are bonded into an integral body, the seepage problem of the seeping interface is treated very well, the foundation pit excavation and the foundation construction are guaranteed to be performed in a waterless state and the foundation pit safety is also guaranteed.

Owner:CHINA MCC20 GRP CORP

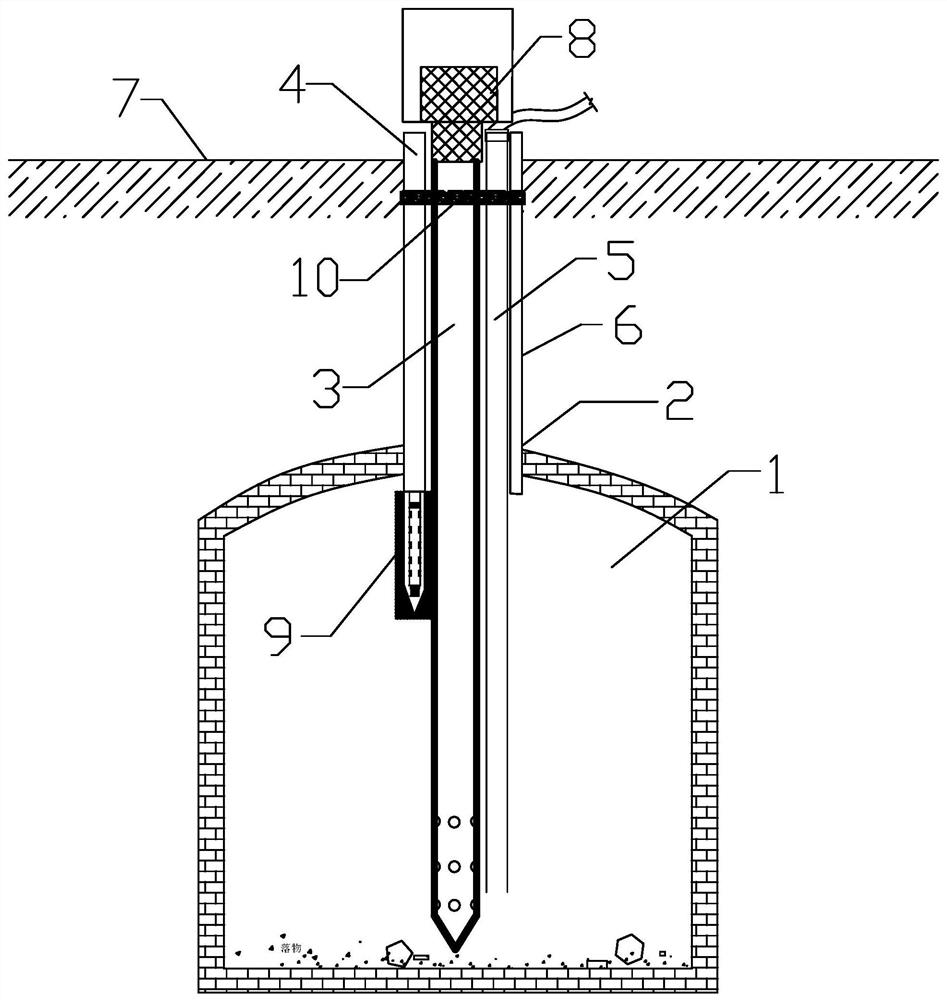

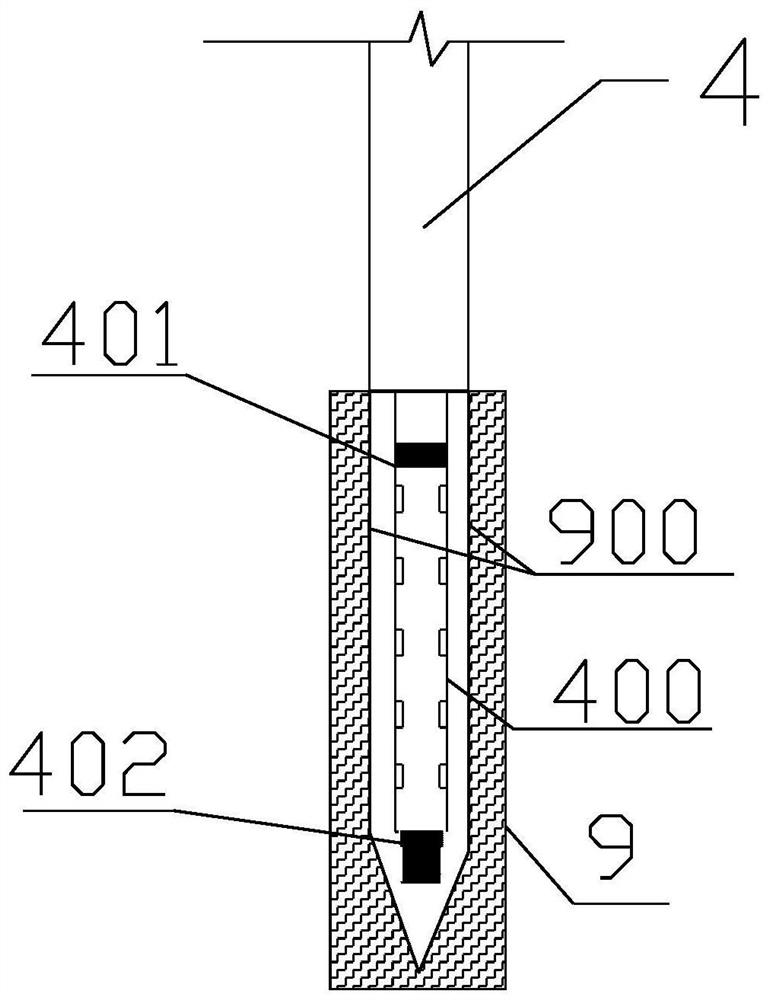

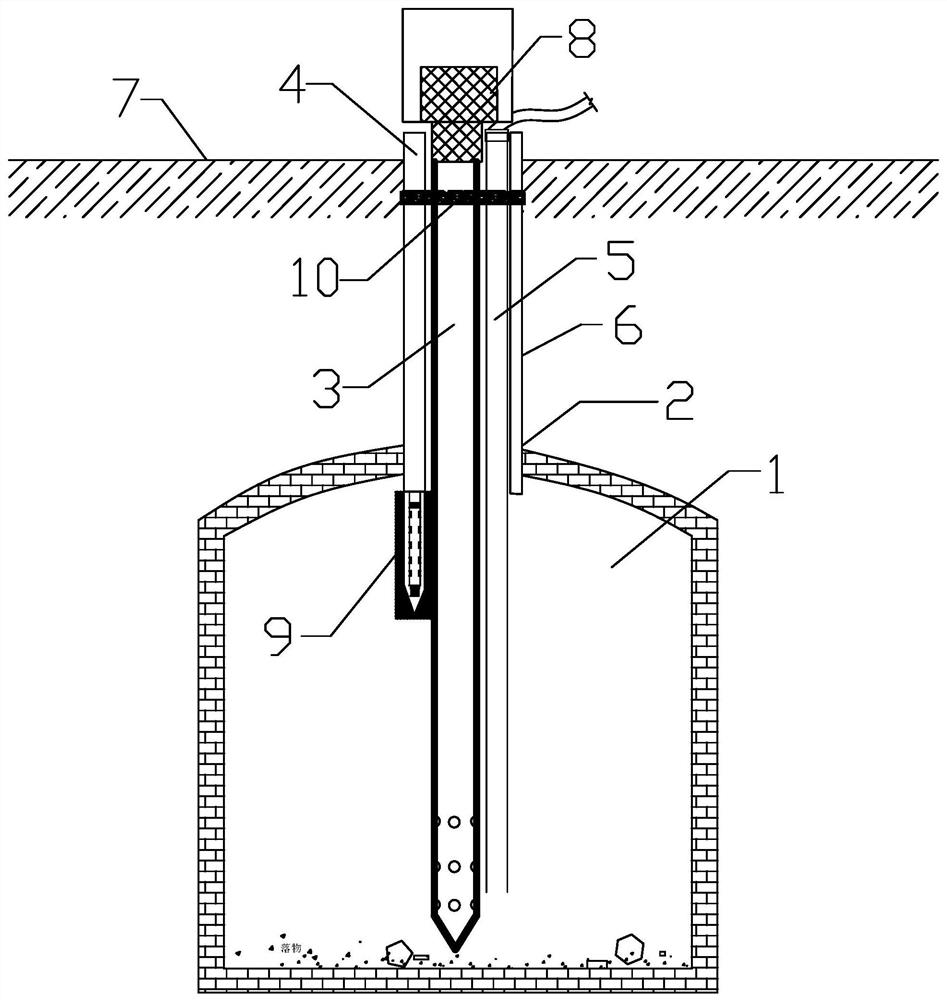

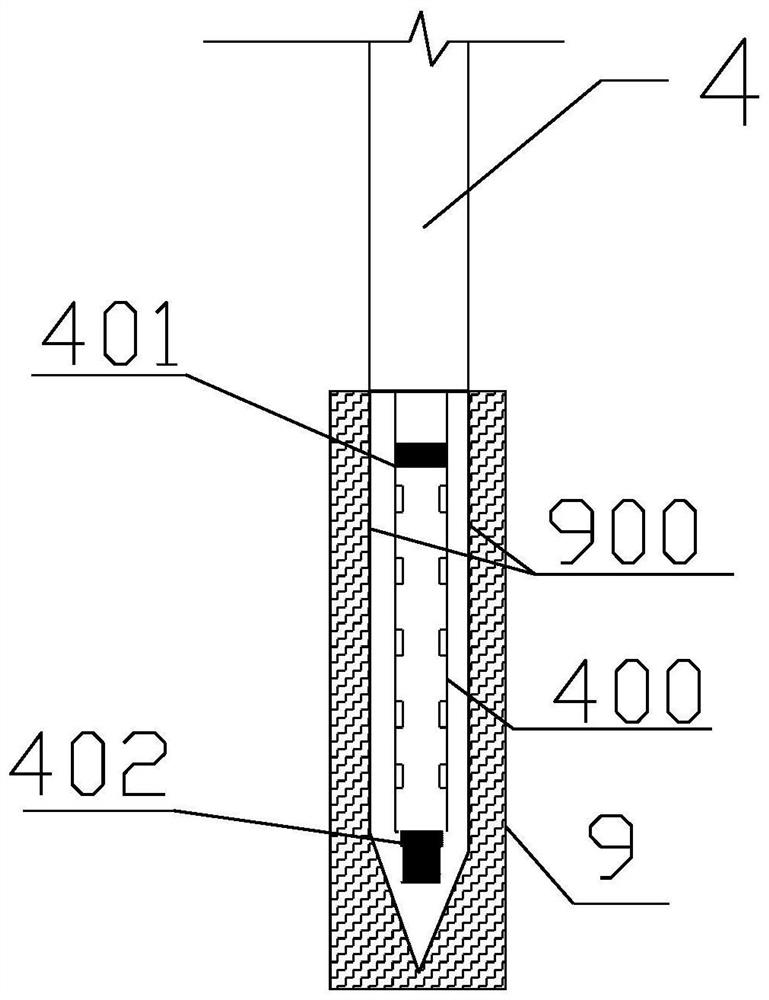

Filling device and method for waste air-raid shelter of pile foundation construction site

ActiveCN112323823ASmooth Construction MeasuresGuaranteed cycleEmbankmentsFoam concreteArchitectural engineering

The invention provides a filling device and method for a waste air-raid shelter of a pile foundation construction site. The filling method comprises the steps that a grouting drill hole is drilled above a waste air-raid shelter to be filled, a primary grouting pipe, a secondary grouting pipe, an air supply pipe and an air exhaust pipe are installed in the drill hole, the primary grouting pipe andthe air supply pipe vertically extend into the bottom of the air-raid shelter, the secondary grouting pipe and the air exhaust pipe vertically extend to the top of the air-raid shelter, firstly, the primary grouting pipe is connected with a grouting pump, the air supply pipe is connected with an air compressor, foam concrete grouting slurry is injected in a layered mode, the primary grouting pipeand the air supply pipe are pulled up all the way to the top of the air-raid shelter after grouting of each layer is completed, then the secondary grouting pipe is connected to inject the foam concrete grouting slurry for the second time, and air is not supplied during secondary grouting. The filling problem of the deep-buried air-raid shelter can be solved under the condition that excavation is not conducted, normal construction of a cast-in-situ bored pile can be guaranteed on a filled construction site, and the problems that when a rotary drilling rig constructs a cast-in-situ pile foundation, normal construction cannot be conducted on the deep-buried air-raid shelter, the site collapses and the like are solved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

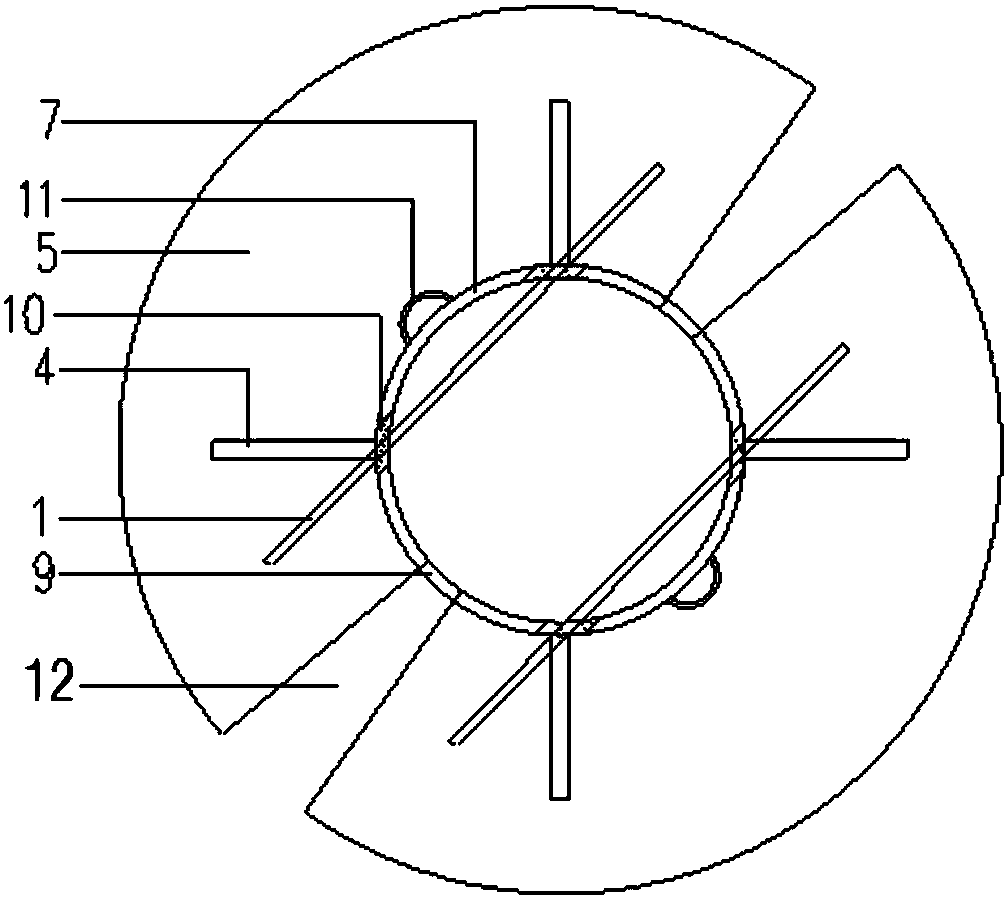

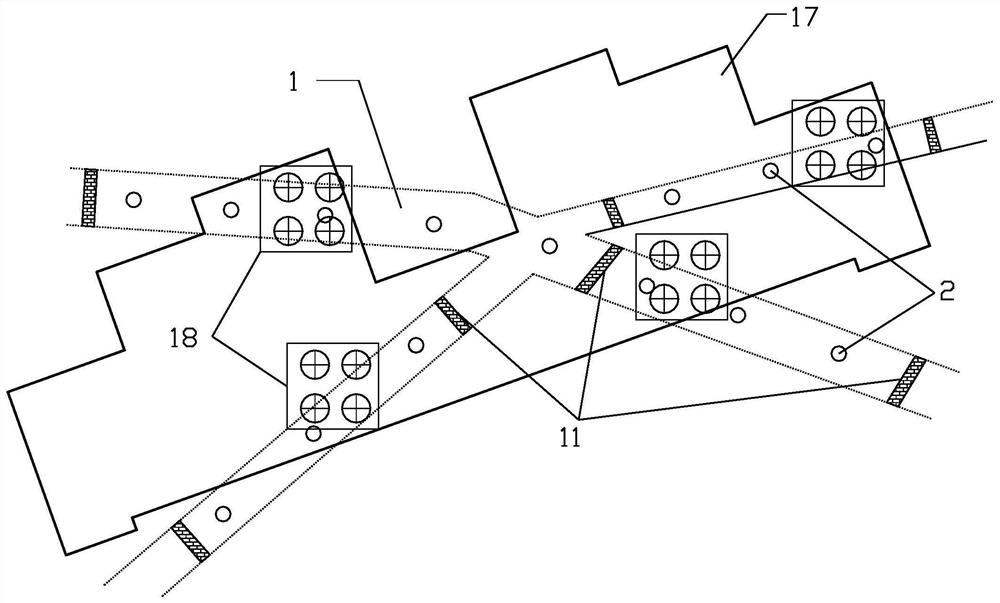

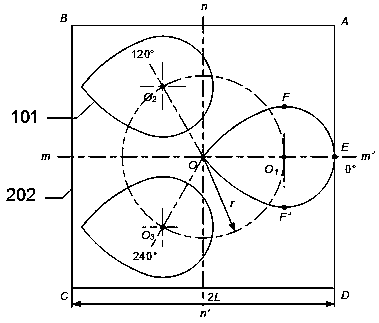

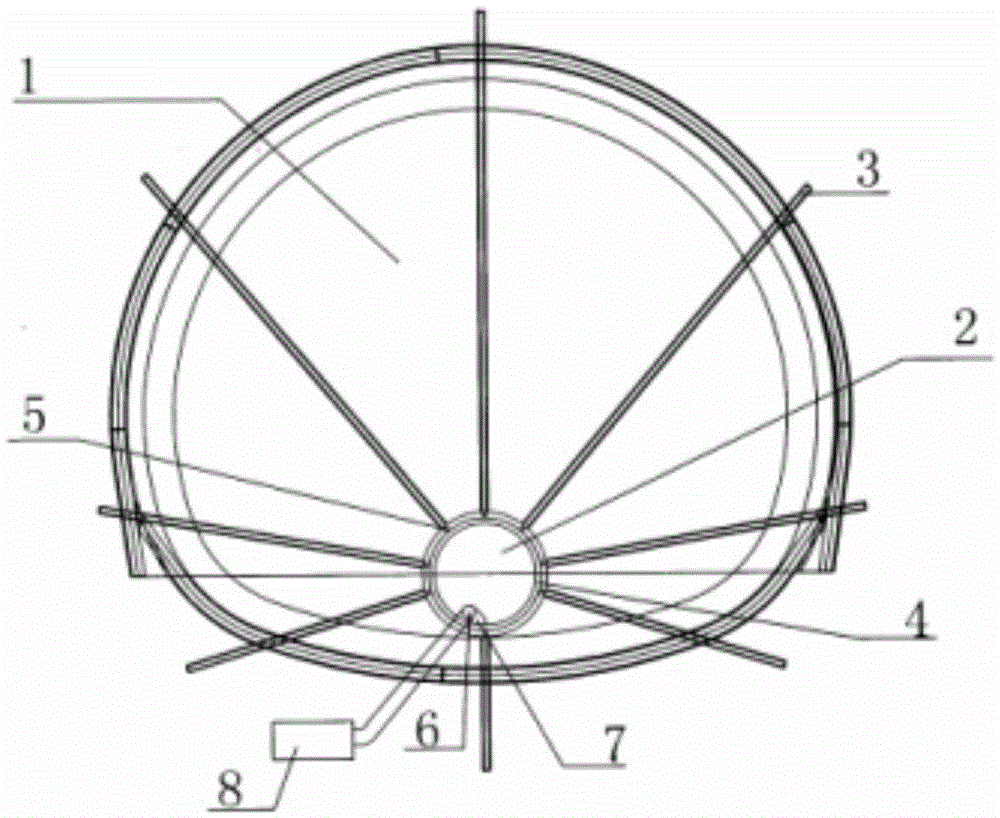

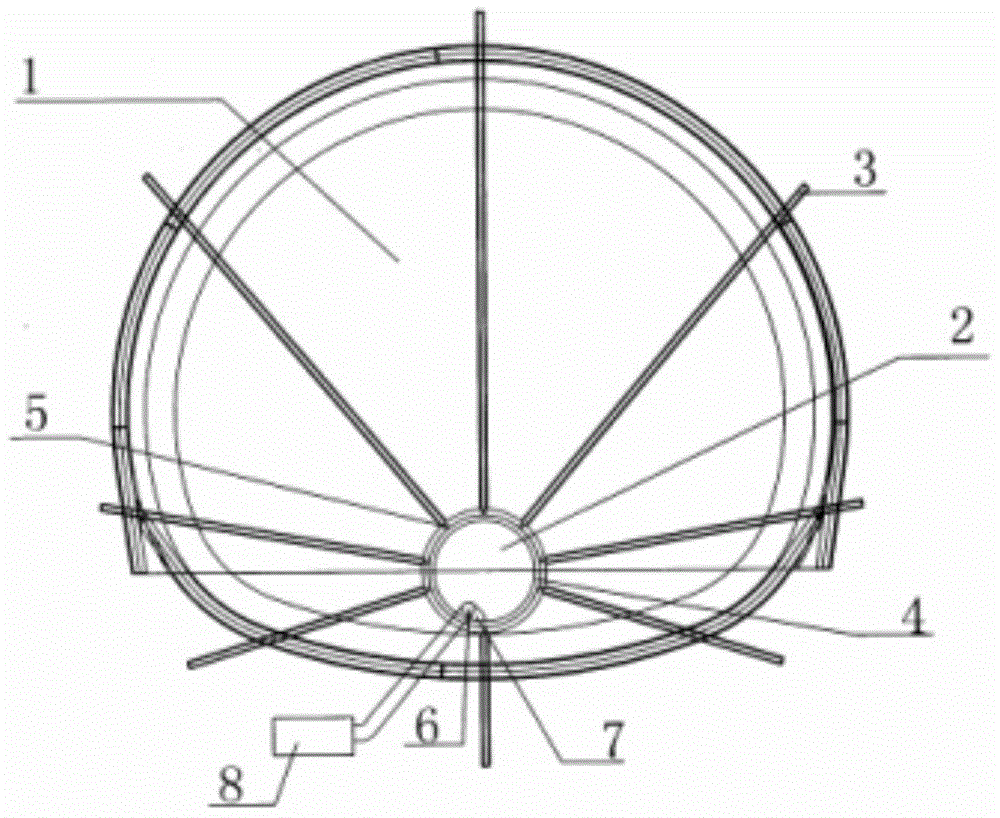

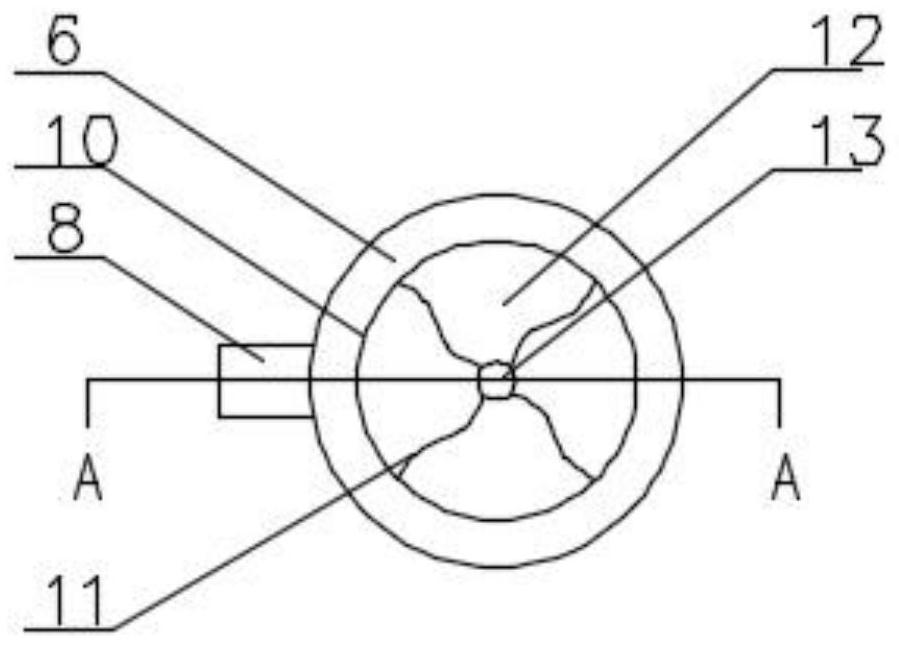

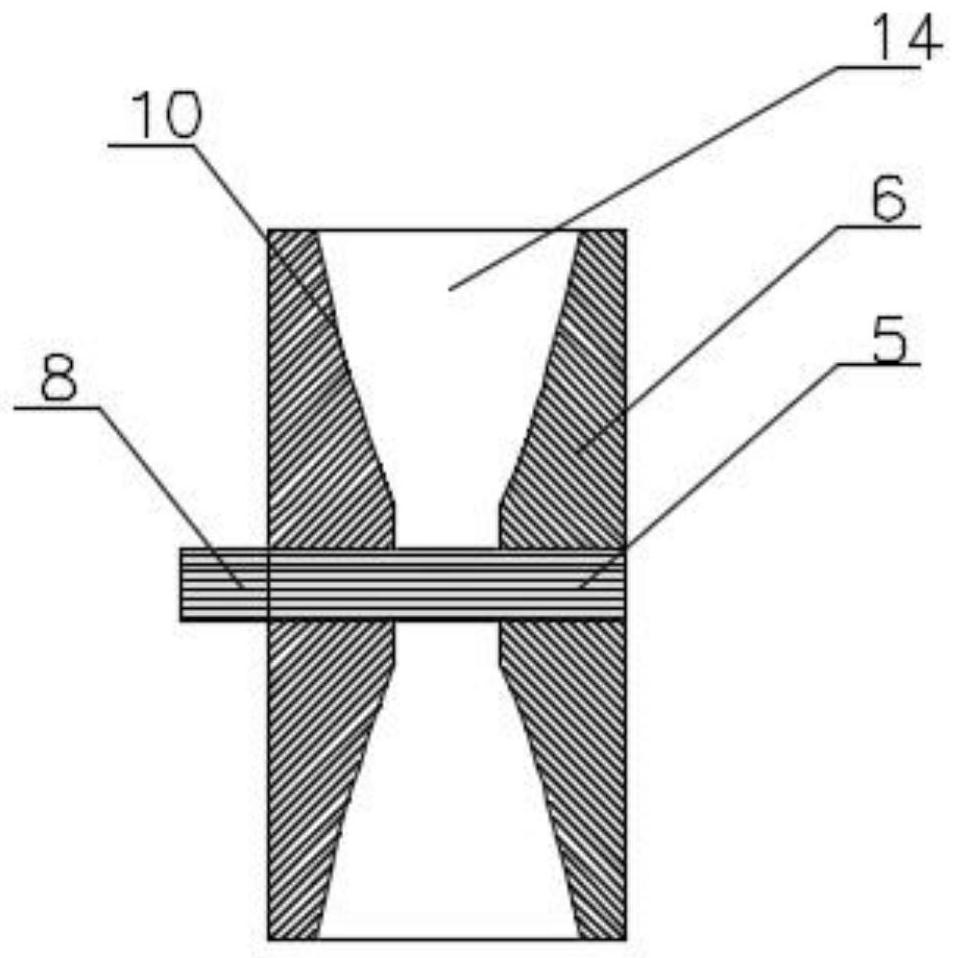

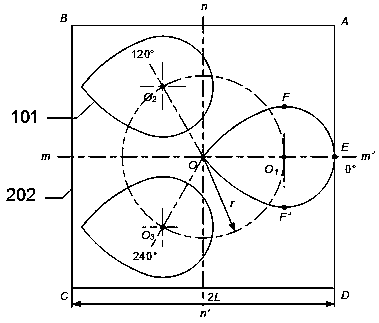

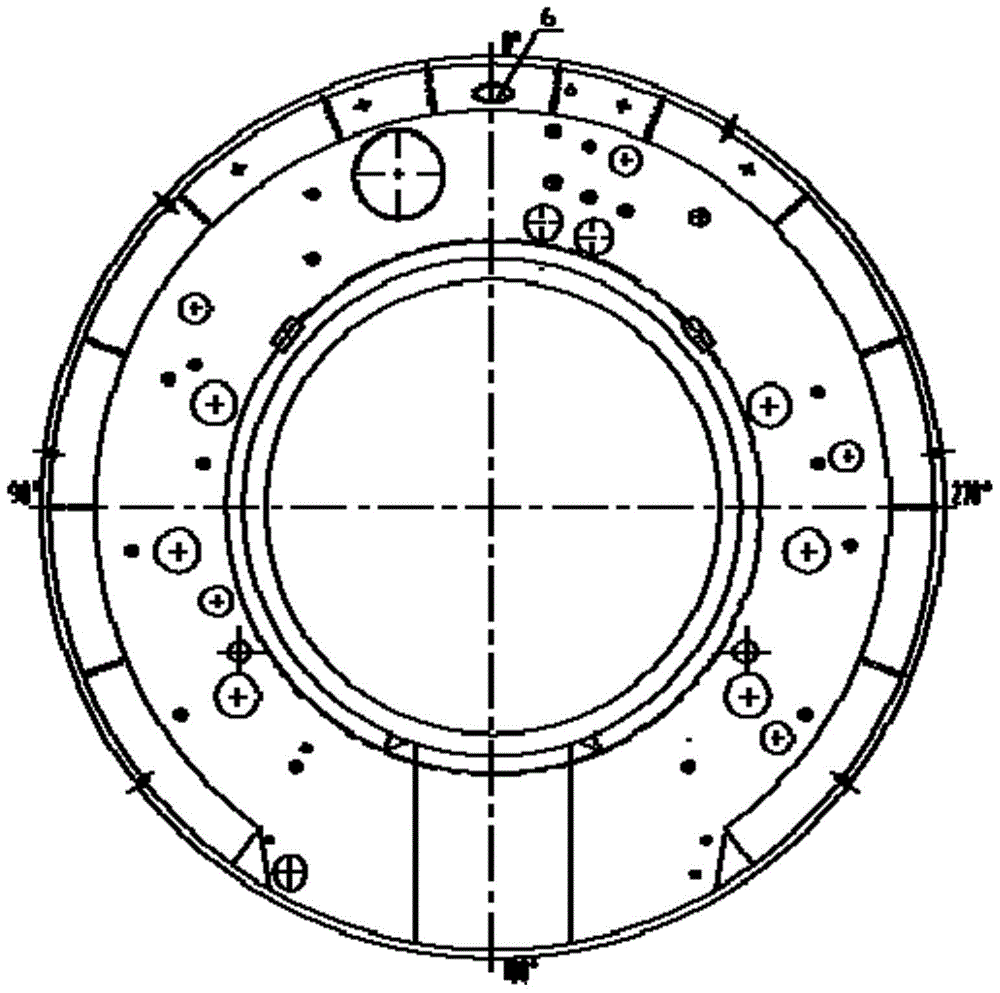

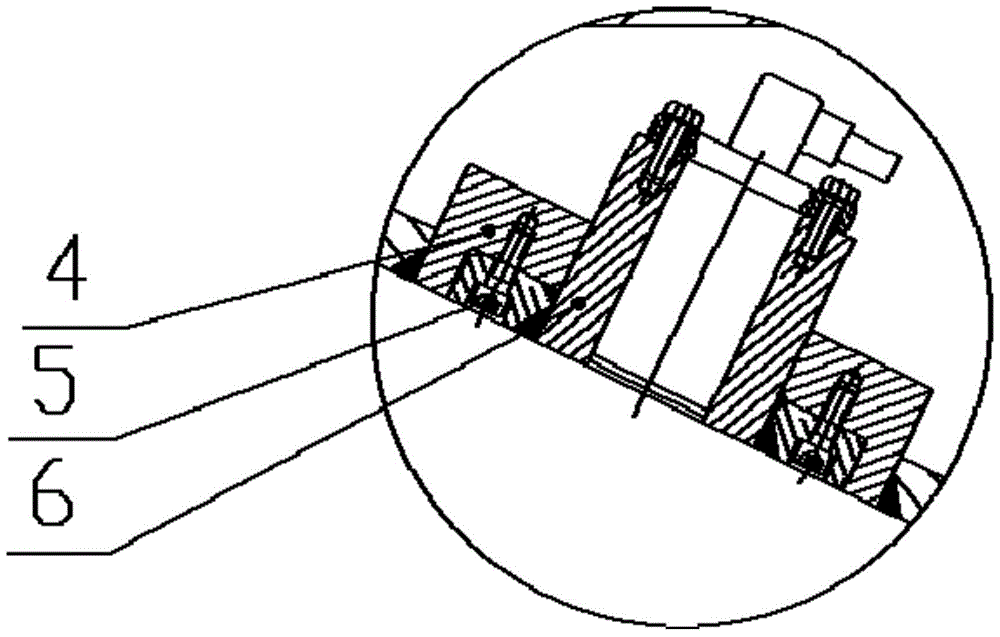

Planet wheel type profiling excavation device for construction of rectangular-cross-section tunnel

The invention provides a planet wheel type profiling excavation device for construction of a rectangular-cross-section tunnel which is used for solving the problems that an excavation bland area is large, a cutting effect of soil mass is poor, the structure is complex, the adaptability of the cross section is poor existing in an existing excavation device. The plant wheel type profiling excavationdevice comprises a cutter disc, a planet wheel, a planet wheel shaft, a planet carrier, a large gear ring and a shield body. The cutter disc is in a water-drop shape, and the rear portion of the cutter disc is engaged with the planet wheel shaft. The planet wheel shaft is connected with the planet carrier through a bearing, and the rear portion of the planet carrier is connected with an externaldriving device. The planet wheel is arranged on the planet wheel shaft, the planet wheel is arranged in the large gear ring, the planet wheel is engaged with the large gear ring, and the outer side ofthe large gear ring is fixed to the shield body. The planet wheel type profiling excavation device ensures full-section excavation, different excavation sections can be formed, excavation of rectangular-cross-section tunnels in various specifications can be achieved, and the good economical efficiency, adaptability and reliability are achieved. Meanwhile, the planet wheel type profiling excavation device has a good soil mass cutting effect and good cross section adaptability.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

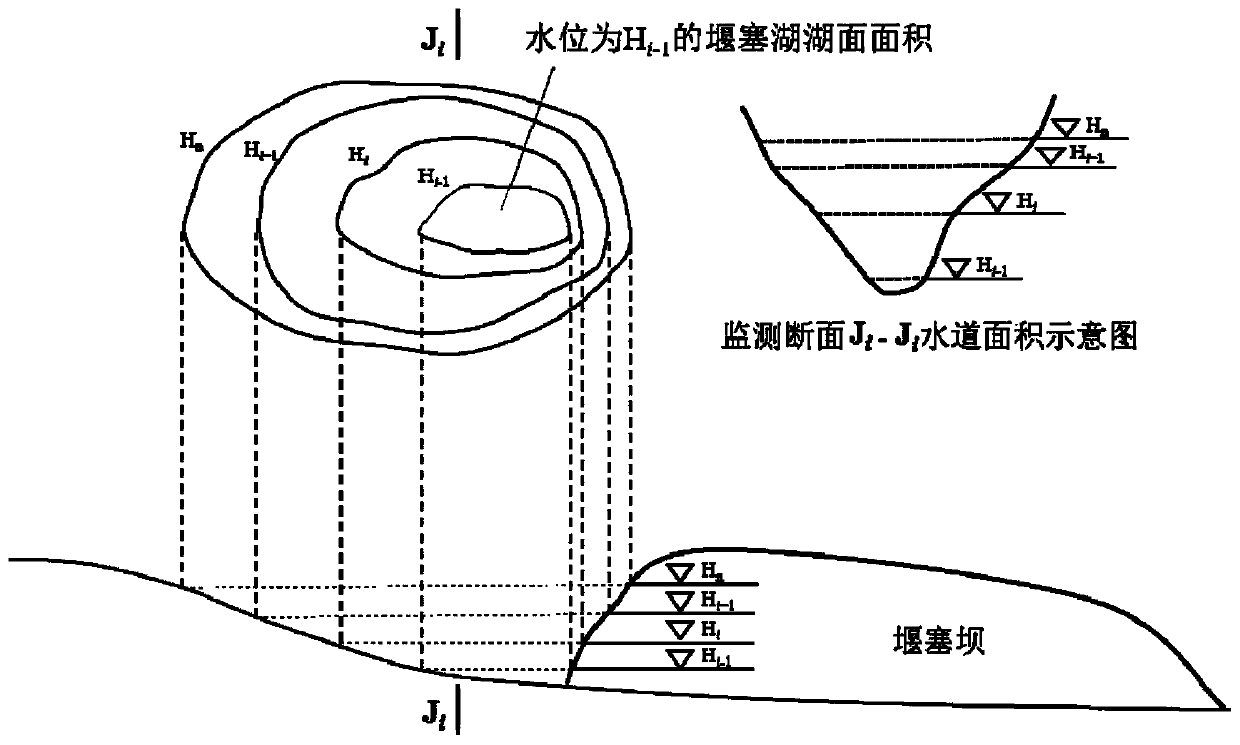

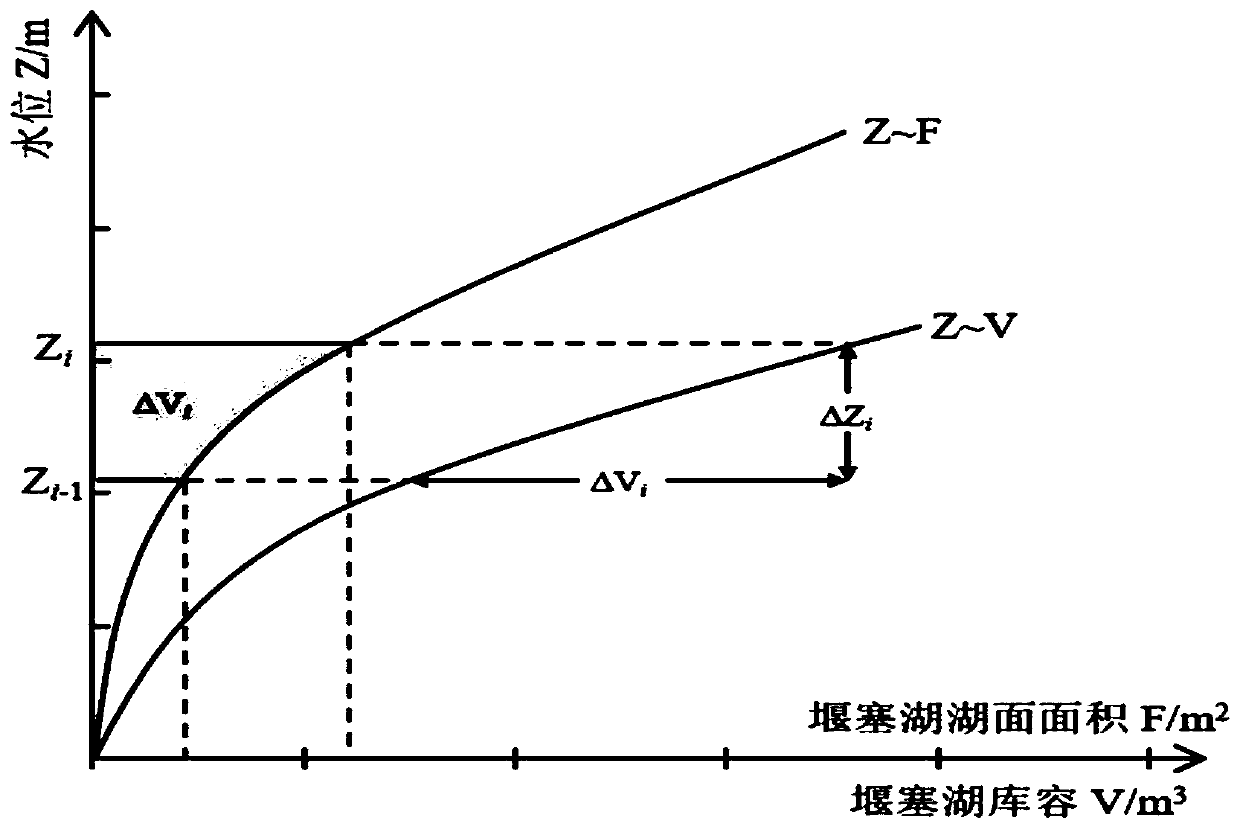

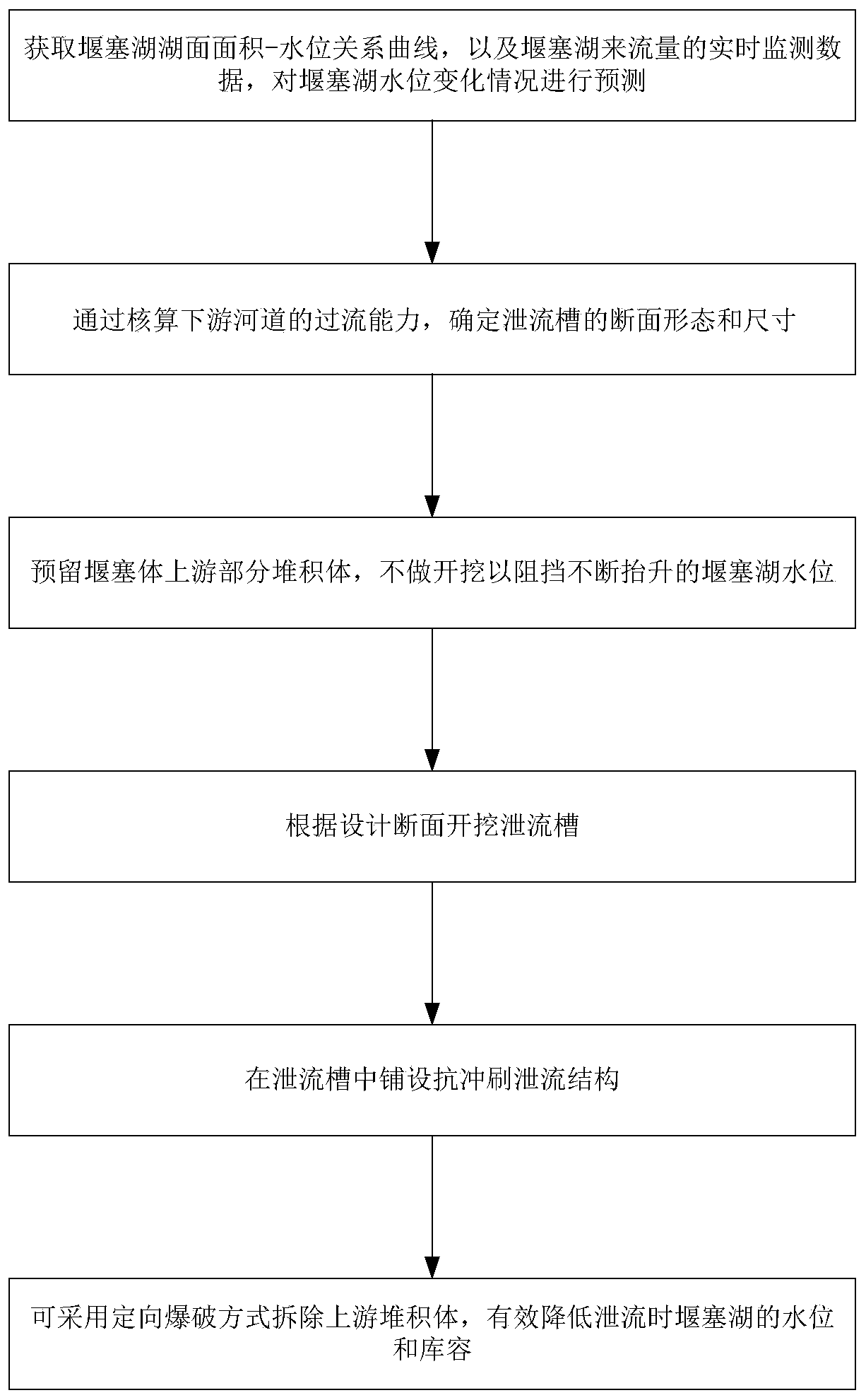

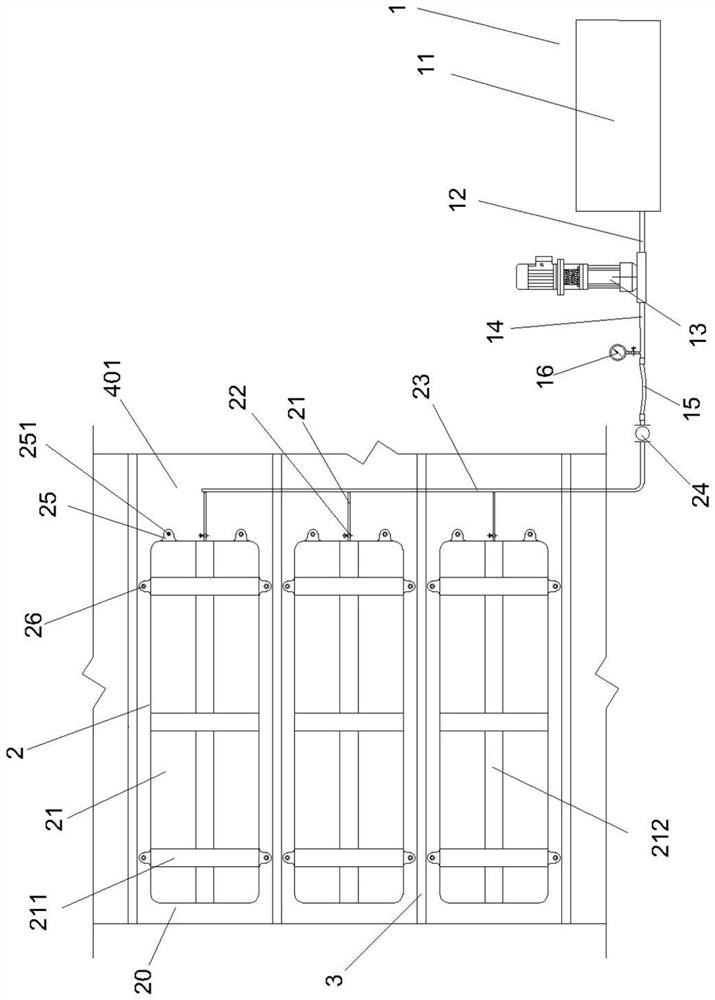

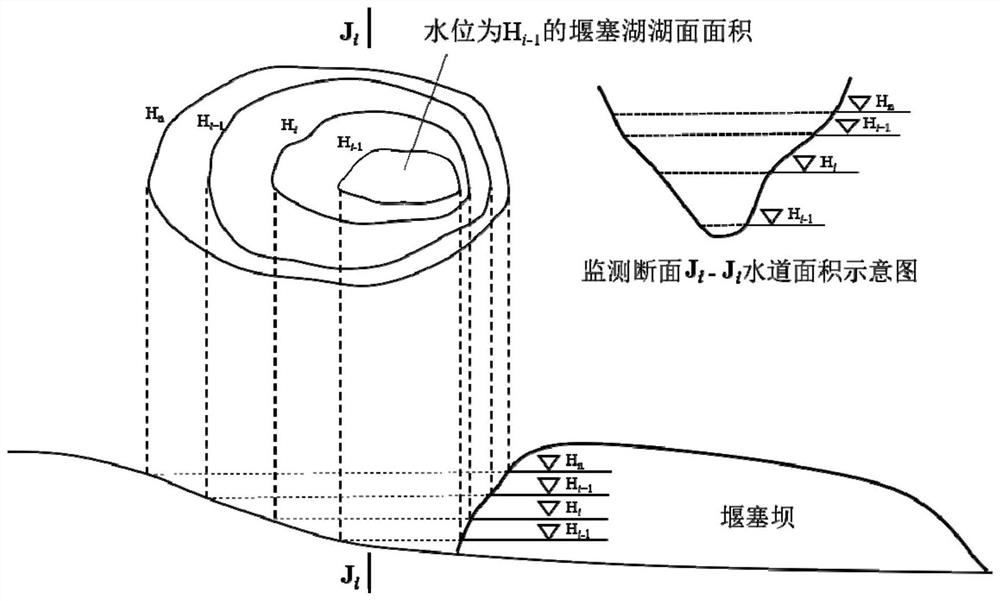

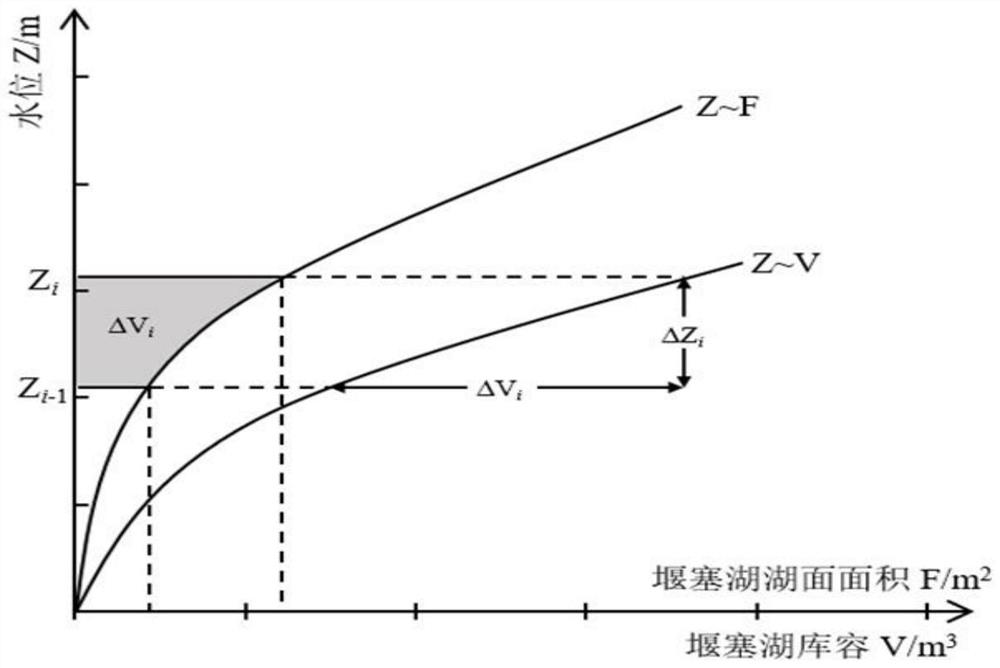

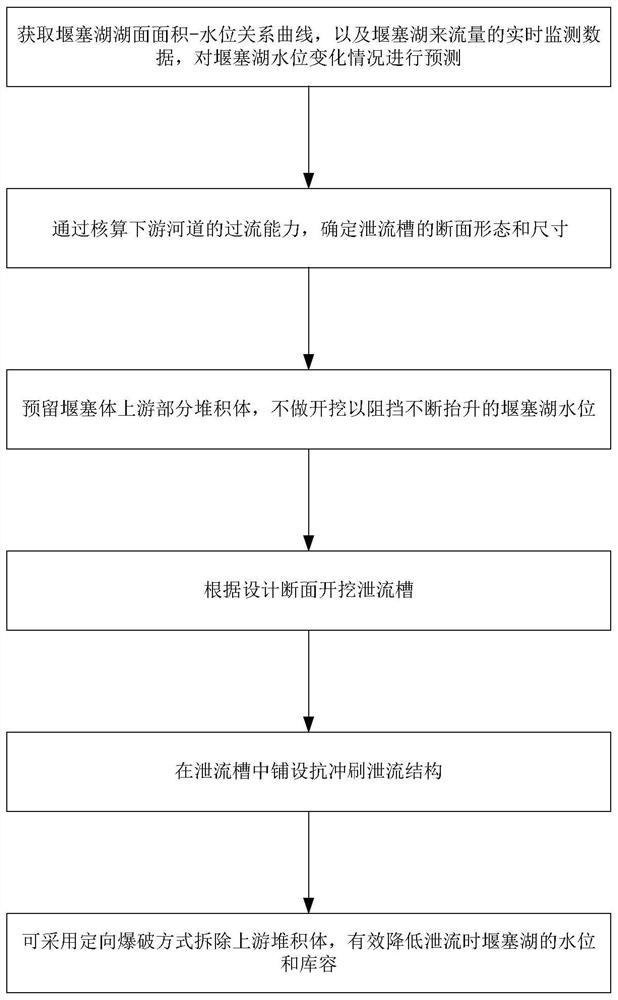

Construction method of anti-scouring flood relief channel of barrier lake

ActiveCN111455943AEnsure normal excavationGuaranteed to workBarrages/weirsHydraulic engineering apparatusGeomembraneLandslide dam

The invention discloses a construction method of an anti-scouring flood relief channel of a barrier lake. Slope steel wire meshes are laid on slopes on the two sides of the flood relief channel, a reinforced geomembrane is laid at the bottom of the flood relief channel, reinforcing steel bar gabions are arranged at the bottoms of the slopes on the two sides, multiple rows of prefabricated pier stones are arranged in the flood relief channel, each row of prefabricated pier stones are arranged in the width direction of the flood relief channel, each prefabricated pier stone is fixed to the bottom of the flood relief channel through a first anchor rod, every two adjacent prefabricated pier stones are connected through a second anchor rod, and the second anchor rods close to the slopes are fixedly connected to the slopes on the two sides. The flood relief channel constructed through the construction method can effectively reduce the scouring strength and flow speed of water flow, the anti-scouring capacity of the slopes on the two sides and the bottom of the flood relief channel is enhanced, and the damage and loss to the downstream are reduced. According to the construction method, the construction time is relatively short, the emergency preparation time can be shortened as much as possible, excavation and channel body reinforcement work of the flood relief channel can be guaranteed within a short time, and various geotechnical materials adopted in the construction process are low in price.

Owner:NANJING HYDRAULIC RES INST

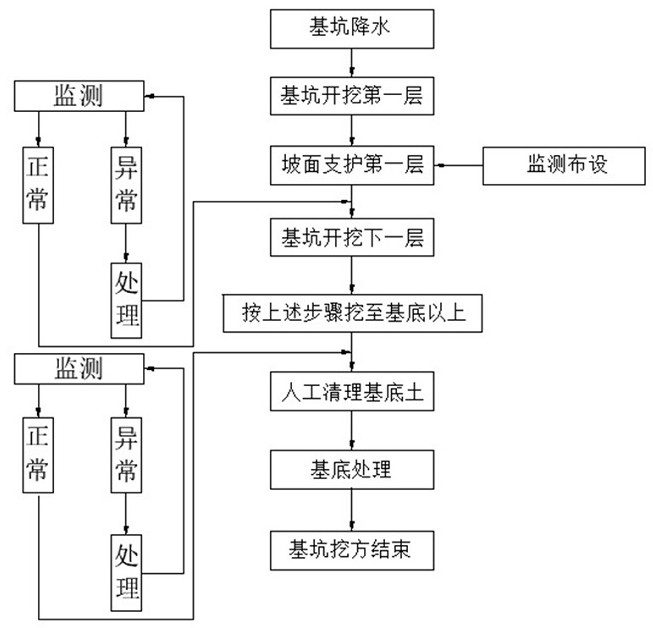

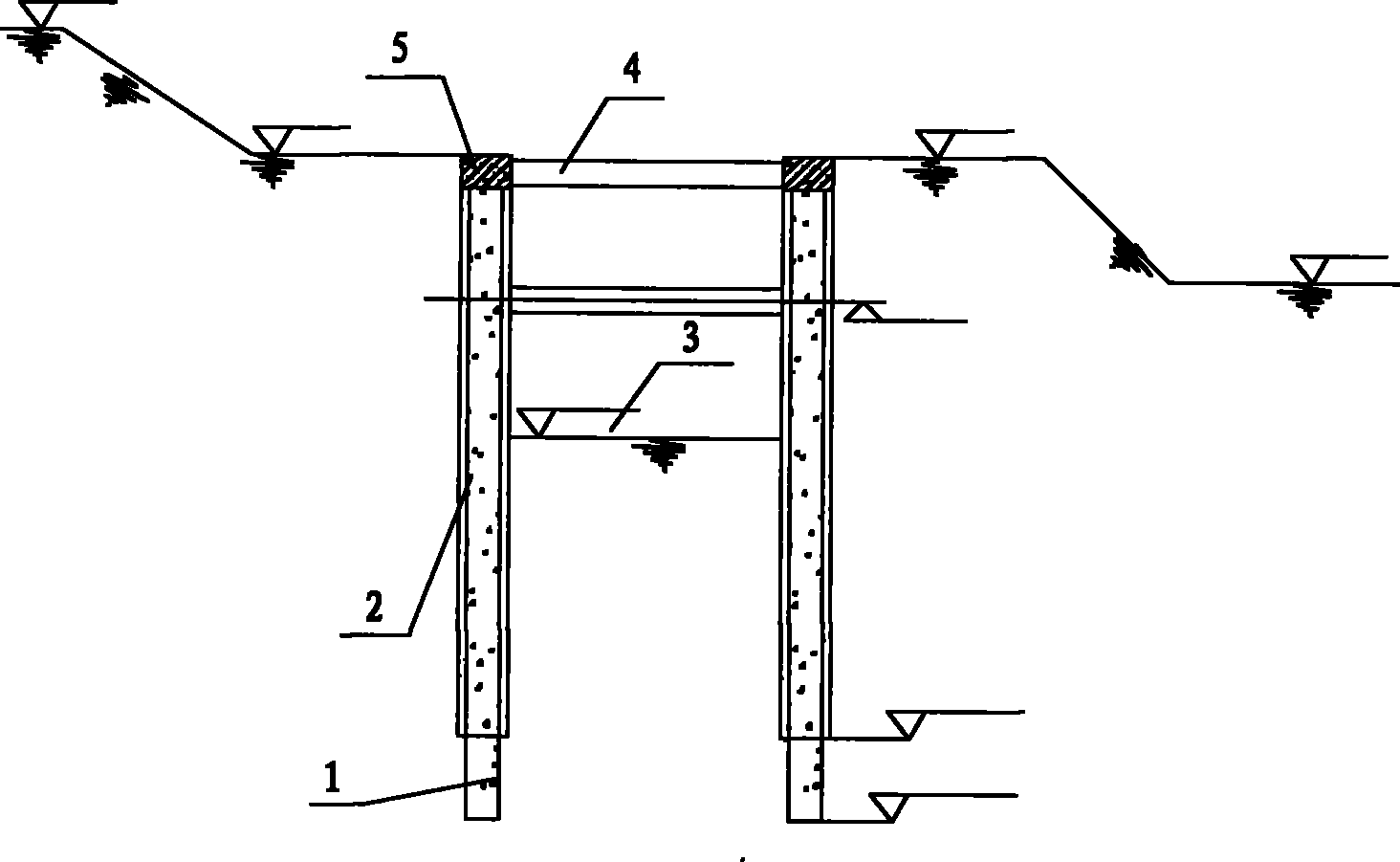

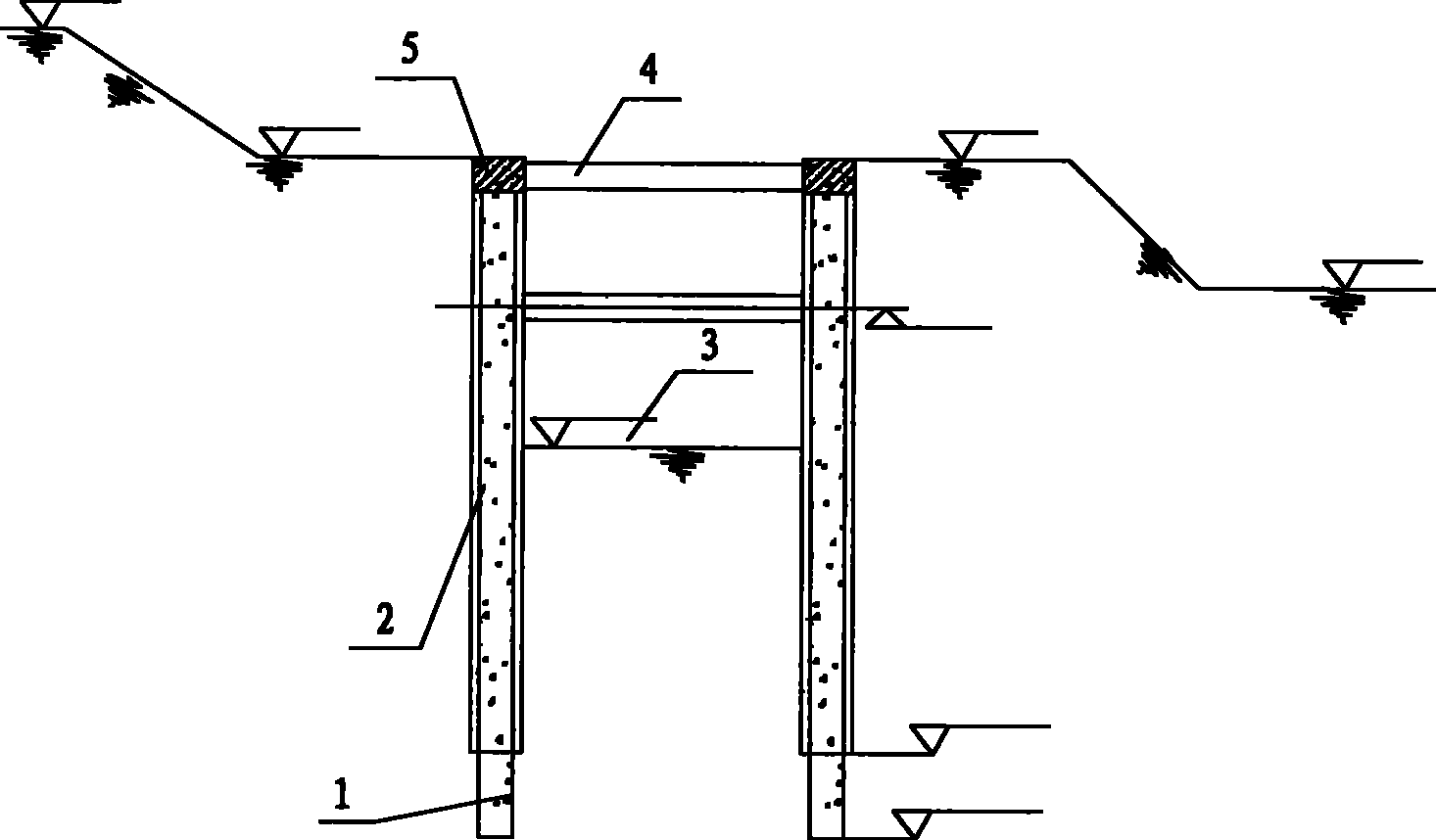

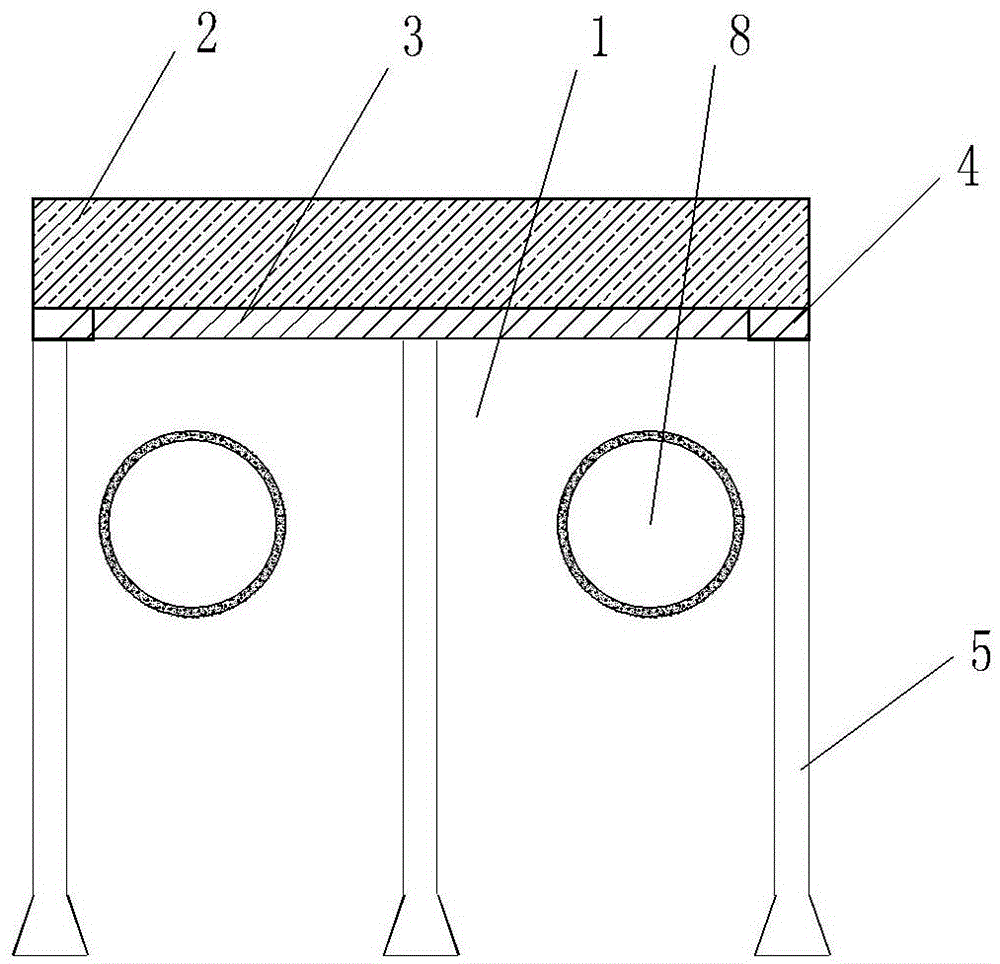

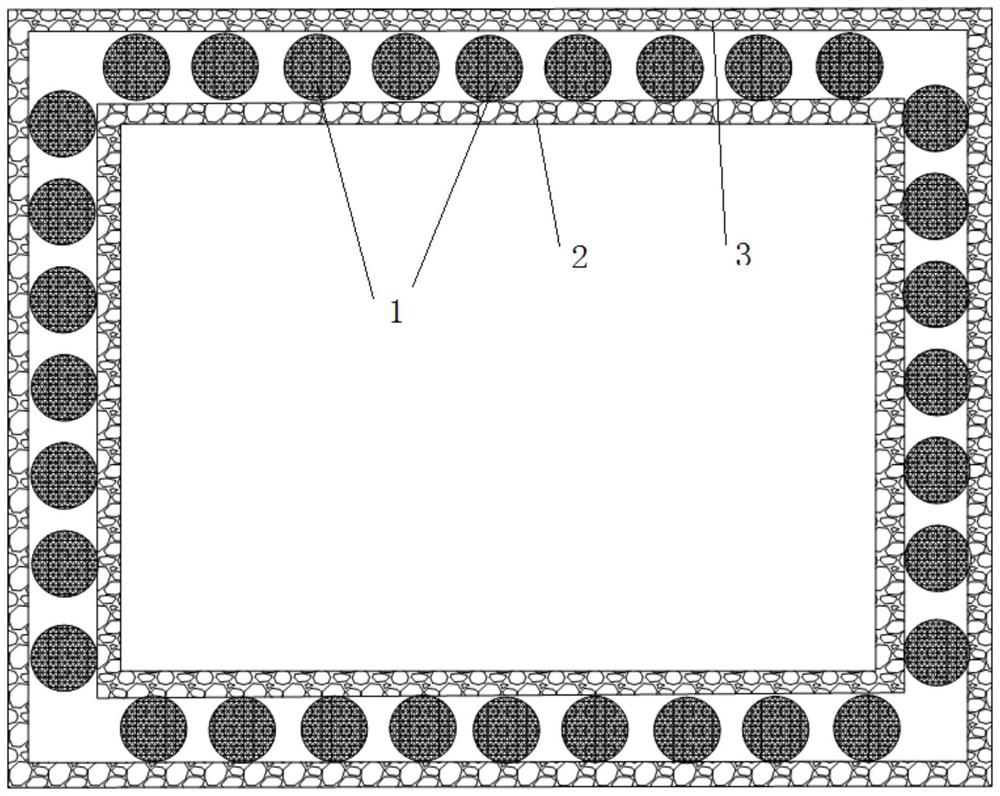

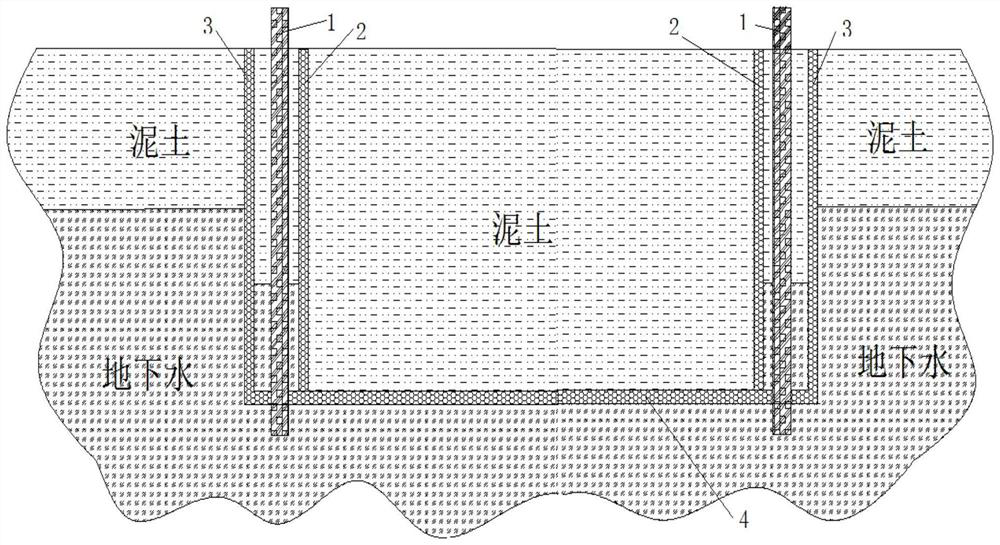

Shield receiving well foundation pit excavation and supporting non-precipitation construction method

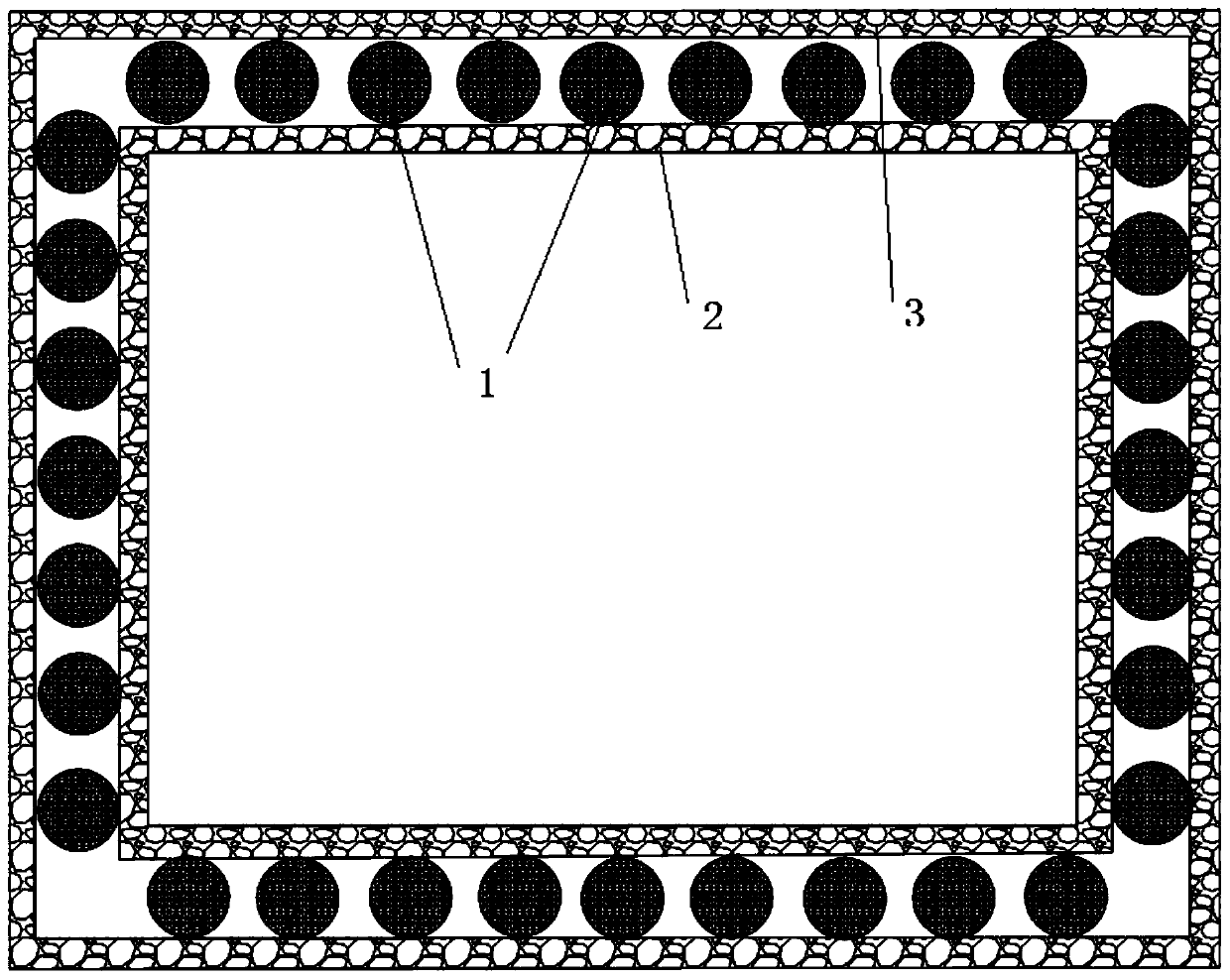

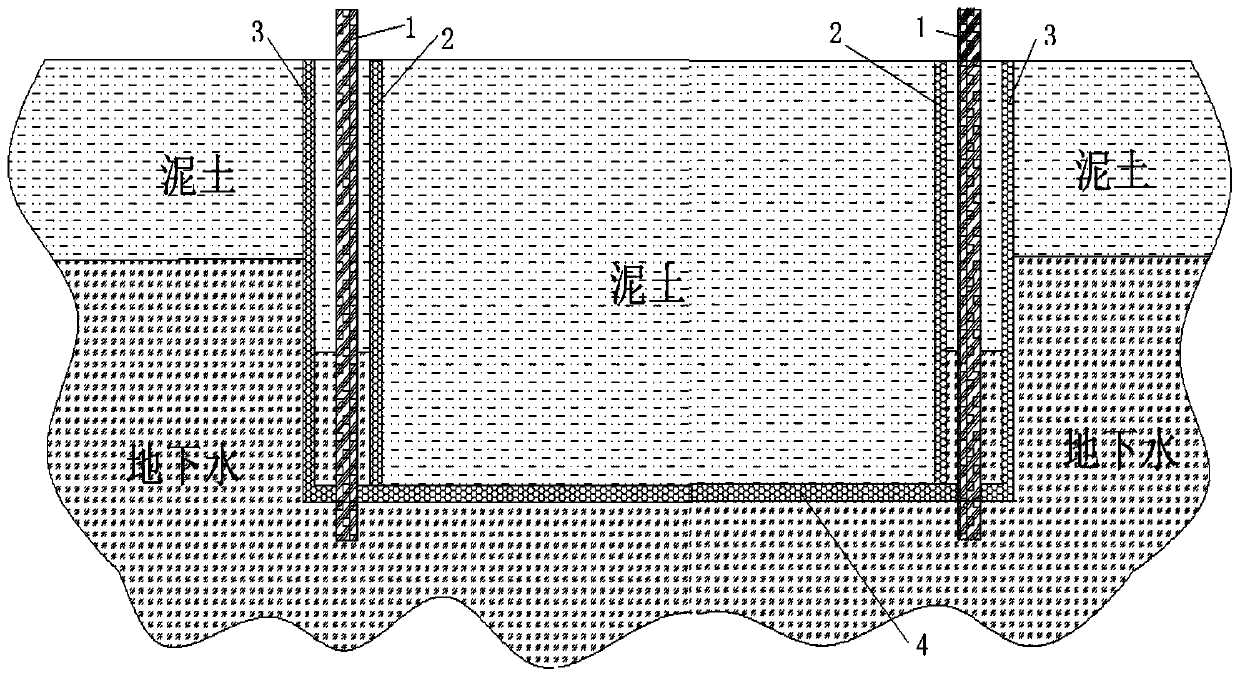

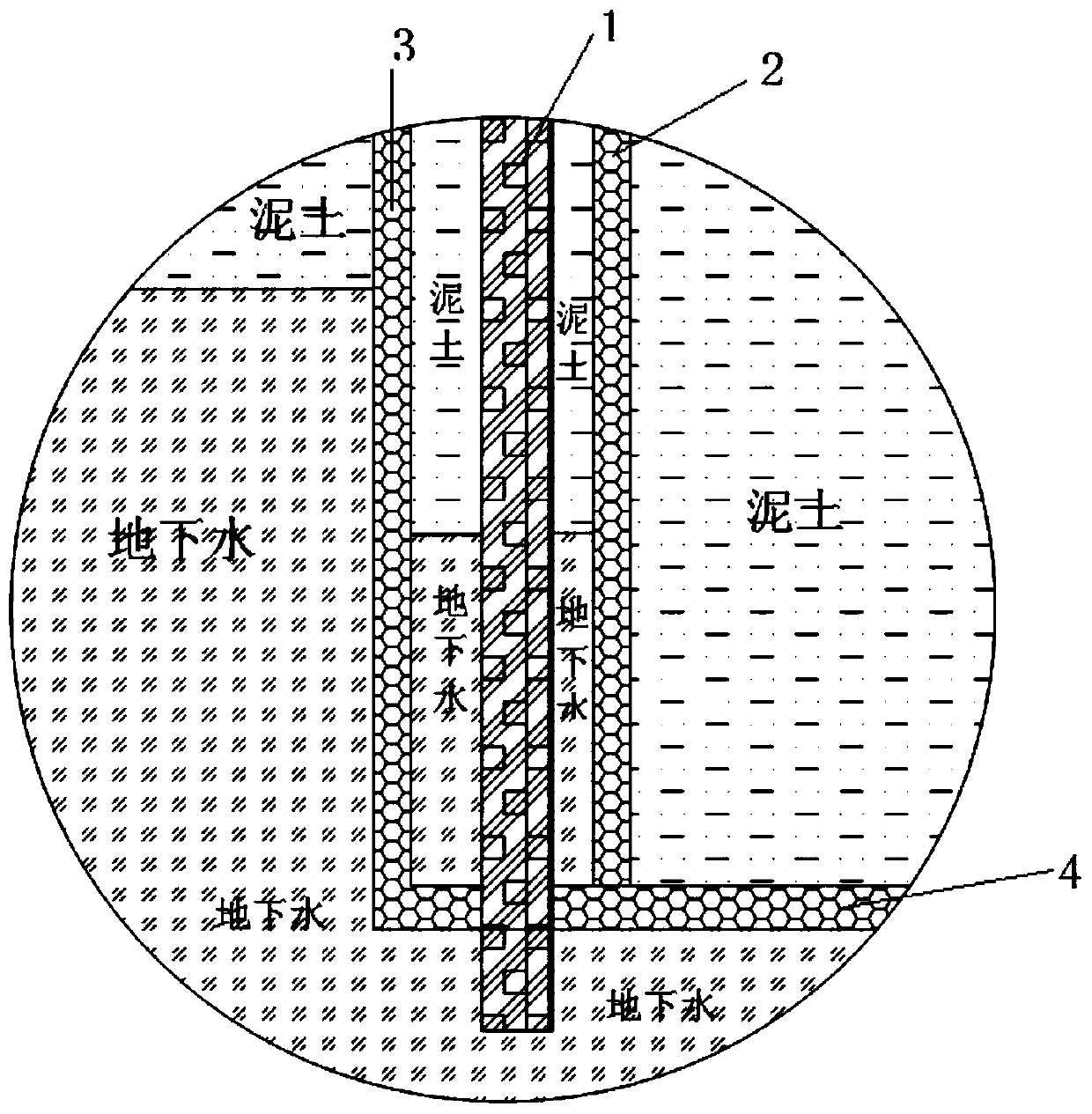

ActiveCN111560957AEnsure normal excavationEnsure that the support does not fall in the constructionExcavationsBulkheads/pilesWater stopArchitectural engineering

The invention discloses a shield receiving well foundation pit excavation and supporting non-precipitation construction method. The method includes the steps that multiple bored cast-in-place piles distributed in an annular array are arranged in a shield receiving well foundation pit excavation region, and the side wall of a shield receiving well foundation pit is defined by the bored cast-in-place piles; the bottom face of the foundation pit and the inner side and the outer side of the side wall of the foundation pit are subjected to grouting water stop, a bottom water stop curtain, an innerwater stop curtain and an outer water stop curtain are formed, the water stop curtains are integrally formed, and a gap groove is formed between the water stop curtains on the inner side and the outerside of the side wall of the foundation pit; water in the foundation pit is extracted away, part of water in the gap groove is extracted, the horizontal plane in the gap groove is located at the position between the underground horizontal plane and the bottom face of the foundation pit, and then a crown beam and a ground water retaining wall are arranged; and the foundation pit is excavated and driven from top to bottom layer by layer, and multiple supports are arranged on all the layers for supporting. By means of the method, the problem about safety construction under the non-precipitationcondition in the shield receiving well foundation pit excavation and supporting construction process is solved.

Owner:RANKEN RAILWAY CONSTR GROUP

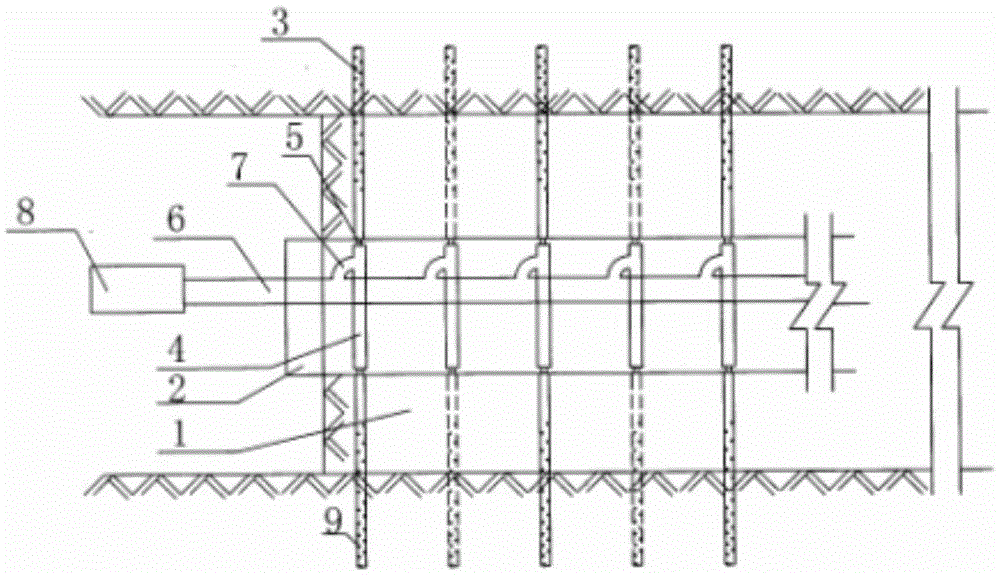

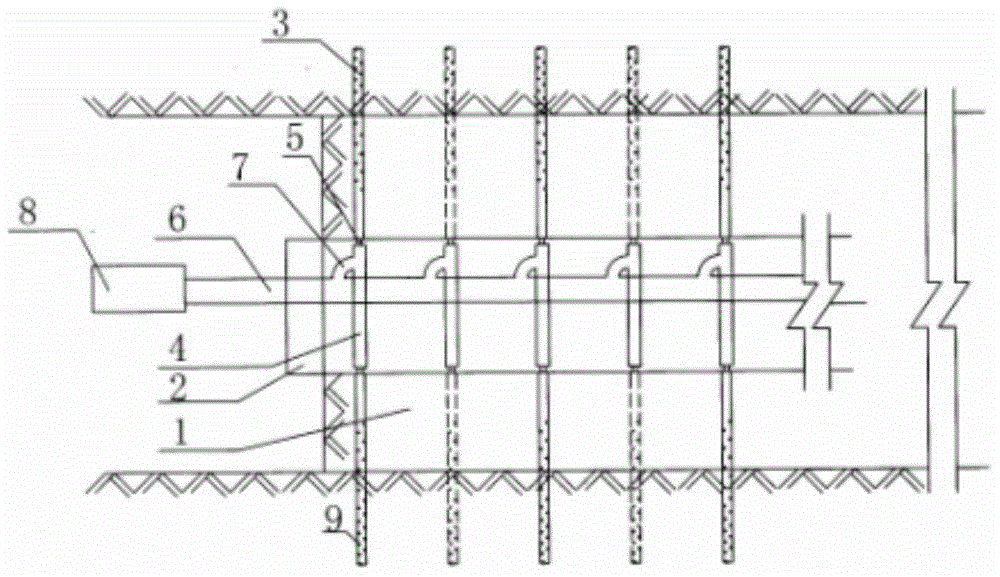

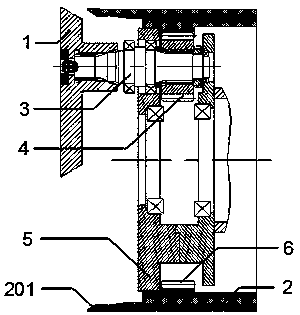

Advanced Radial Precipitation Channel System and Advanced Radial Precipitation Method

ActiveCN104532864BImprove precipitation effectEasy to implement on siteFoundation engineeringEngineeringWater level

The invention relates to the technical field of tunnel construction, in particular to an advanced radial water lowering channel system and an advanced radial water lowering method. The advanced radial water lowering channel system comprises a horizontal water lowering channel, a communication ring pipe, a vacuum filter pipe, an evacuated water lowering main pipe and a vacuum water lowering pump, the horizontal water lowering channel is arranged in a tunnel surrounding rock to be excavated, the vacuum filter pipe is inserted into the tunnel surrounding rock outside the horizontal water lowering channel, water in the tunnel surrounding rock enters the vacuum filter pipe under the action of the vacuum water lowering pump, enters the communication ring pipe through a joint, enters the evacuated water lowering main pipe through a communication short pipe and finally is drained through the vacuum water lowering pump, water lowering effects are obvious, field implementation is easy, characteristics of weak surrounding rocks are improved, saturated water level is reduced below an excavation line, and excavation of a subsequent tunnel is ensured.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

Vacuum preloading film pressing groove extension construction method

Owner:NO 4 ENG CO LTD OF CCCC FIRST HARBOR ENG CO LTD

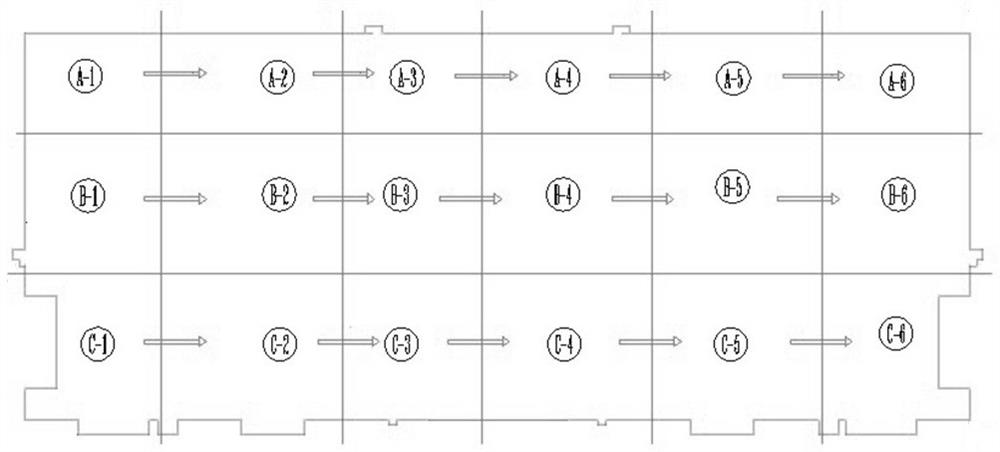

Foundation pit earthwork construction method for civil air defense engineering

PendingCN113235603AAvoid destructionAccurate locationExcavationsBulkheads/pilesArchitectural engineeringStructural engineering

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

S-shaped curve based method for control track of shield tunneling machine

The invention relates to an S-shaped curve based method for control a track of a shield tunneling machine. The method comprises the steps of obtaining horizontal and vertical curve elements of a tunnel design axis; obtaining mileages of terminal points of S-shaped curves, which are set initially; calculating coordinates and azimuth angles at positions of mileages of terminal points of S-shaped curves; obtaining real-time attitude data of the shield tunneling machine; establishing the horizontal S-shaped curve; correcting mileages of terminal points of S-shaped curves; establishing the vertical S-shaped curve; judging whether the minimum curvature radiuses of S-shaped curves are less than the minimum turning radius of the shield tunneling machine or not, and obtaining mileages of terminal points of S-shaped curves again if the minimum curvature radiuses of S-shaped curves are less than the minimum turning radius of the shield tunneling machine; calculating an ideal stroke of a jack after the shield tunneling machine tunnels one ring along S-shaped curves; converting data of the ideal stroke into the required oil cylinder hydraulic pressure; and transmitting calculation results to the shield tunneling machine by a computer, controlling the shield tunneling machine to tunnel forward, and judging in real time whether S-shaped curves are required to be reconstructed or not. Compared with the prior art, the method has the advantages of being capable of finishing deviation rectification once, high in generality, capable of reducing the fluctuation of the track of the shield tunneling machine and the like.

Owner:SHANGHAI TONGYAN CIVIL ENGINEERING TECHNOLOGY CORP LTD

Construction method for river-crossing shield tunnel crushed stratum communication channel

ActiveCN102287198BEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingUnderground tunnelHigh intensity

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Protective construction method of excavating large area deep foundation pit in running sand confined water soil layer

ActiveCN102162250BEnsure normal excavationReduce construction difficultyExcavationsBulkheads/pilesSoil nailingConfined water

Owner:CHINA MCC20 GRP CORP

Advanced radial water lowering channel system and advanced radial water lowering method

ActiveCN104532864AImprove precipitation effectEasy to implement on siteFoundation engineeringEngineeringWater level

The invention relates to the technical field of tunnel construction, in particular to an advanced radial water lowering channel system and an advanced radial water lowering method. The advanced radial water lowering channel system comprises a horizontal water lowering channel, a communication ring pipe, a vacuum filter pipe, an evacuated water lowering main pipe and a vacuum water lowering pump, the horizontal water lowering channel is arranged in a tunnel surrounding rock to be excavated, the vacuum filter pipe is inserted into the tunnel surrounding rock outside the horizontal water lowering channel, water in the tunnel surrounding rock enters the vacuum filter pipe under the action of the vacuum water lowering pump, enters the communication ring pipe through a joint, enters the evacuated water lowering main pipe through a communication short pipe and finally is drained through the vacuum water lowering pump, water lowering effects are obvious, field implementation is easy, characteristics of weak surrounding rocks are improved, saturated water level is reduced below an excavation line, and excavation of a subsequent tunnel is ensured.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

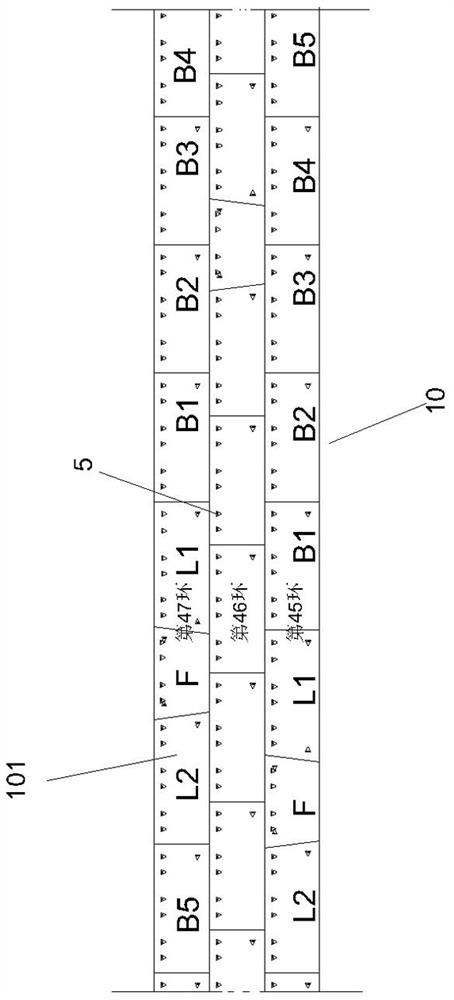

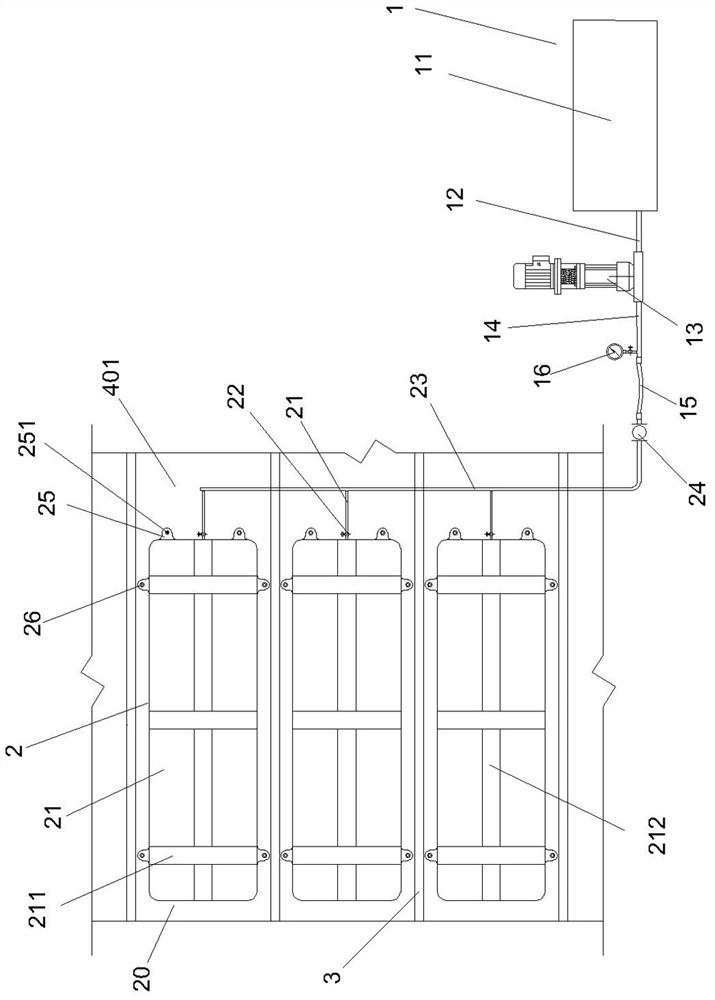

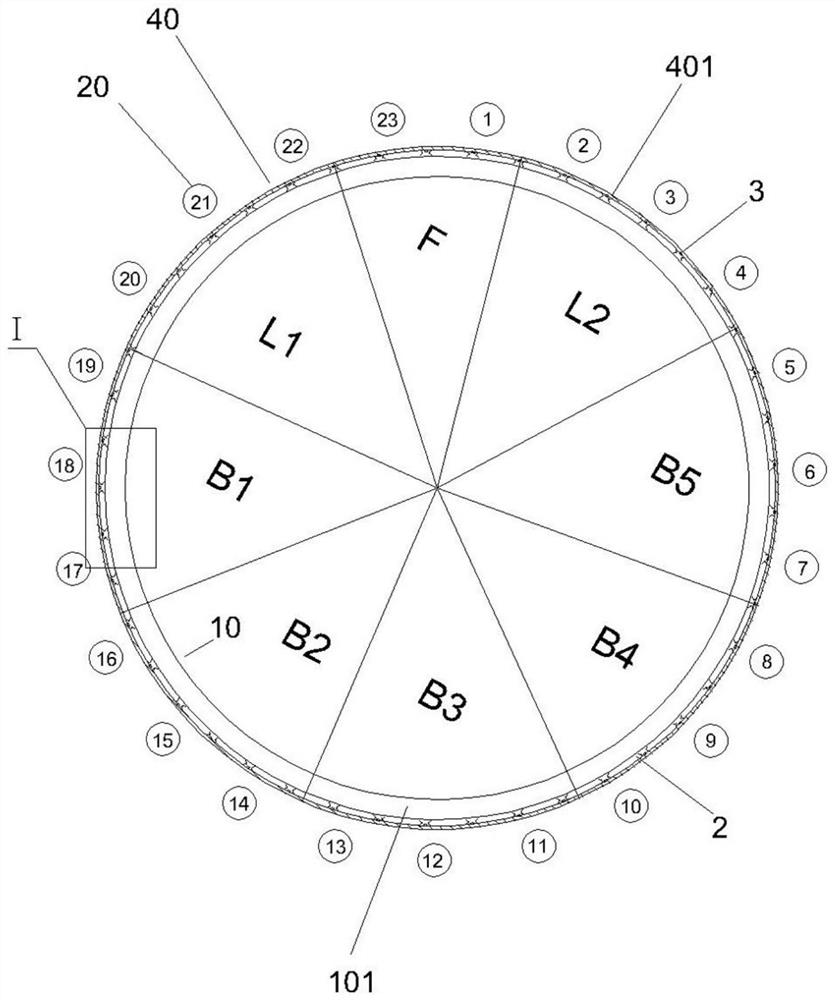

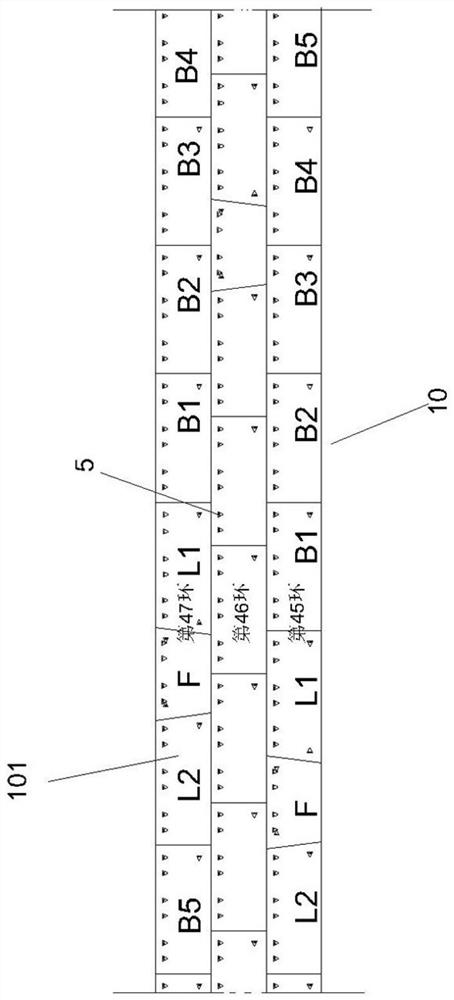

Underwater large-diameter shield continuous tunneling construction tool with deformed tail shield and construction method

ActiveCN113446014AEnsure normal excavationReduce breakageUnderground chambersHydro energy generationMarine engineeringStructural engineering

The invention discloses an underwater large-diameter shield continuous tunneling construction tool with a deformed tail shield. The underwater large-diameter shield continuous tunneling construction tool comprises a water conveying unit, a plurality of high-pressure water bags and a plurality of guide strips, wherein the high-pressure water bags are fixed to the inner wall of a tail shield shell and located between the inner wall of the tail shield shell and the peripheral faces of segment rings, the water conveying unit comprises an industrial water tank, an input water pipe, a high-pressure water pump, an output water pipe and a tail end hose, the input water pipes of the high-pressure water bags in one group are connected in parallel to form a main input water pipe, and one end of the tail end hose of the water conveying unit is connected to the multiple high-pressure water bags in one group through quick connectors and the main input water pipe, the construction method comprises the following steps that (1) the high-pressure water bags are installed and connected to the water conveying unit; (2) the segment rings are assembled; (3) water injection and pressurization of the high-pressure water bag units in the segment rings are completed in sequence. and (4) shield driving and monitoring are conducted. According to the underwater large-diameter shield continuous tunneling construction tool with the deformed tail shield and the construction method, the deformed inner wall of the tail shield shell can be prevented from extruding segment pieces, damage to the segment pieces in a formed tunnel is reduced, the construction efficiency is improved, and the construction cost is reduced.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

Construction tool and construction method for continuous excavation of underwater large-diameter shield with deformed tail shield

ActiveCN113446014BEnsure normal excavationReduce breakageUnderground chambersHydro energy generationStructural engineeringHigh pressure water

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

A construction method of anti-scour discharge channel for barrier lake

ActiveCN111455943BEnsure normal excavationGuaranteed to workBarrages/weirsHydraulic engineering apparatusGeomembraneLandslide dam

Owner:NANJING HYDRAULIC RES INST

Method for supporting bored filling pile driven by stirring pile in foundation pit, group pit and middle pit

ActiveCN101545260BEnsure normal excavationEnsure safetyExcavationsBulkheads/pilesBrickReinforced concrete

The invention discloses a method for supporting a bored filling pile driven by a stirring pile in a foundation pit, a group pit and a middle pit, which comprises the following steps: selecting a suitable stirring pile and a filling pile for preparing a curing agent mortar on a natural ground surface, wherein the construction intermittent time for lapping constructions of adjacent piles by the stirring pile is not more than 6 to 12 hours; setting the depth and reinforcing bars of the bored filling pile according to a pit-in-pit requirement, adopting a round steel suspension method to release areinforcing cage on an excavation part in the upper foundation pit, and constructing the filling pile in 3 to 7 days after the construction of the stirring pile is ended; mounting a temporary steel support in the process of excavation by an excavator; mounting a reinforced concrete cap beam on the top of the filling pile to form an entire body; and building a brick wall or plastering mortar on the outer side of the stirring pile as a structural external mold. The method carries out a variable parameter process of the same stirring pile, achieves pit-in-pit supporting on the natural ground surface, sets the depths of the bored filling pile and the stirring pile according to an excavation height mark of the foundation pit, the group pit and the middle pit, effectively controls the deformation and the water seal of a deep foundation pit, a deep group pit and a deep middle pit, and ensures the earthwork excavation and the structure construction safety of a large-area deep foundation pit group.

Owner:CHINA MCC20 GRP CORP

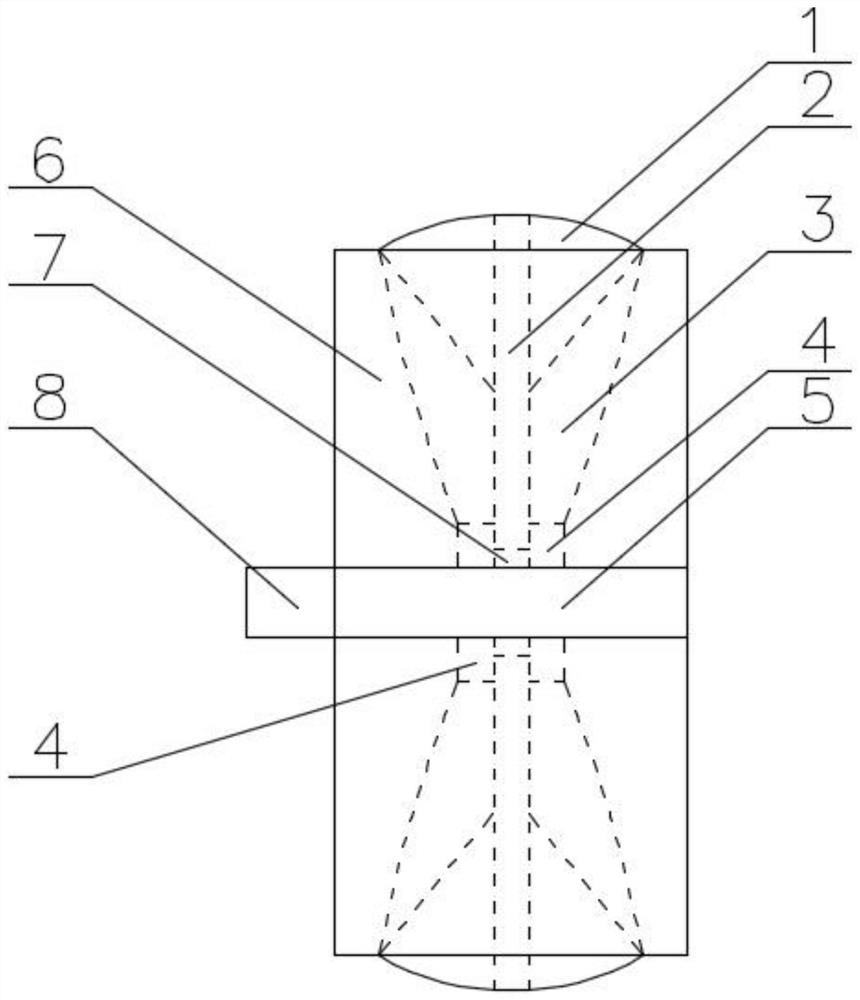

Device for rapidly testing water burst pressure of bedrock fracture in magmatic rock tunnel

ActiveCN112857657AEnsure normal excavationEnsure lining constructionFluid pressure measurementHydro energy generationConvertersClassical mechanics

The invention discloses a device for rapidly testing the water burst pressure of a bedrock fracture in a magmatic rock tunnel. The device comprises a light hard material retaining ring and a pressure receiving converter, the pressure receiving converter is arranged at the bottom of the light hard material retaining ring, and a movable cavity is defined by the pressure receiving converter and an inner concave part. The pressure receiving converter, a wireless transmitter, a sensitive pressure conversion circular ring, a sensitive pressure conversion cylinder, a sensitive pressure sensing column, a sensing column cap, a sensitive compression sensing body, a flexible sensing body and a flexible sensing protective surface are arranged in the movable cavity to form a sensing testing device. The device can quickly test the water burst pressure of the bedrock fracture.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

A planetary wheel type profiling excavation device for tunnel construction with rectangular section

ActiveCN108150185BImprove cutting effectImprove cutting performanceTunnelsDrop-shapedMechanical engineering

The invention provides a planet wheel type profiling excavation device for construction of a rectangular-cross-section tunnel which is used for solving the problems that an excavation bland area is large, a cutting effect of soil mass is poor, the structure is complex, the adaptability of the cross section is poor existing in an existing excavation device. The plant wheel type profiling excavationdevice comprises a cutter disc, a planet wheel, a planet wheel shaft, a planet carrier, a large gear ring and a shield body. The cutter disc is in a water-drop shape, and the rear portion of the cutter disc is engaged with the planet wheel shaft. The planet wheel shaft is connected with the planet carrier through a bearing, and the rear portion of the planet carrier is connected with an externaldriving device. The planet wheel is arranged on the planet wheel shaft, the planet wheel is arranged in the large gear ring, the planet wheel is engaged with the large gear ring, and the outer side ofthe large gear ring is fixed to the shield body. The planet wheel type profiling excavation device ensures full-section excavation, different excavation sections can be formed, excavation of rectangular-cross-section tunnels in various specifications can be achieved, and the good economical efficiency, adaptability and reliability are achieved. Meanwhile, the planet wheel type profiling excavation device has a good soil mass cutting effect and good cross section adaptability.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Strata reinforcement system of shield tunneling in shallow overburden area and its construction method

ActiveCN104712341BReduce adverse effectsBlock uplift deformationArtificial islandsUnderground chambersEngineeringEarth surface

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

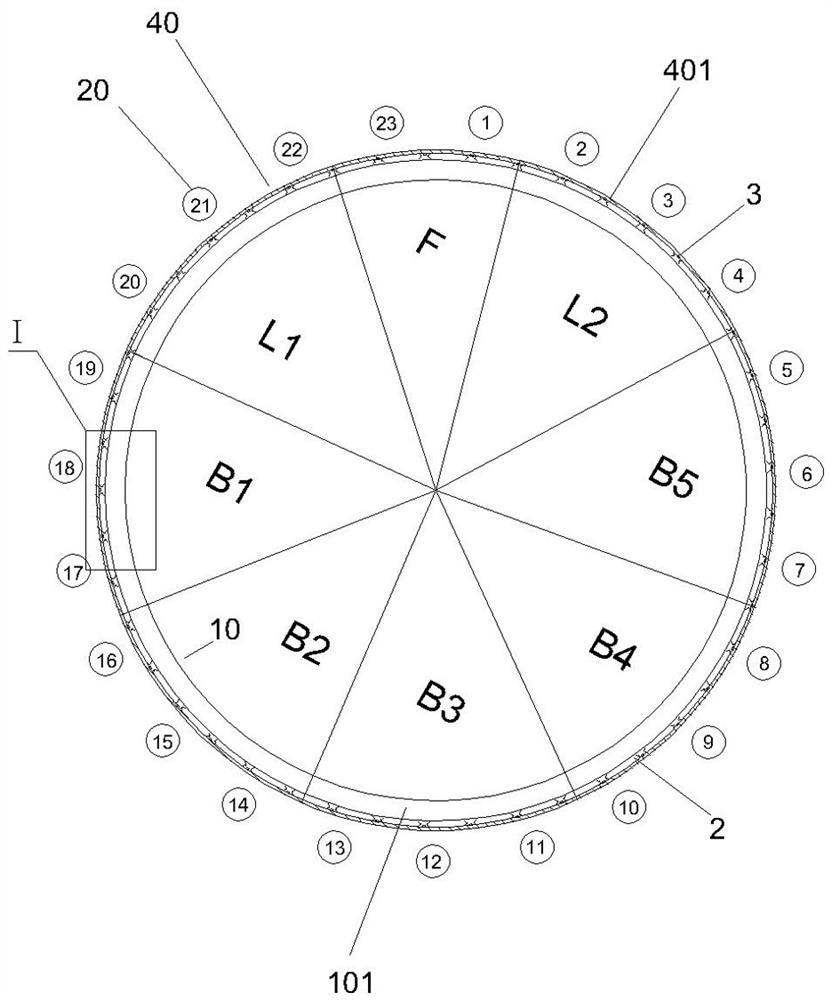

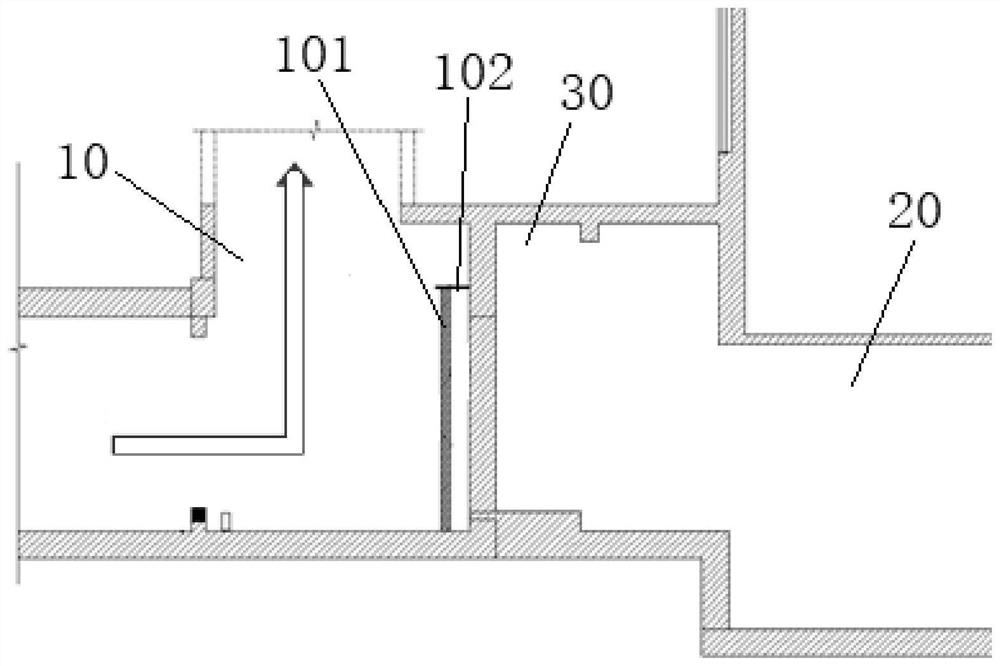

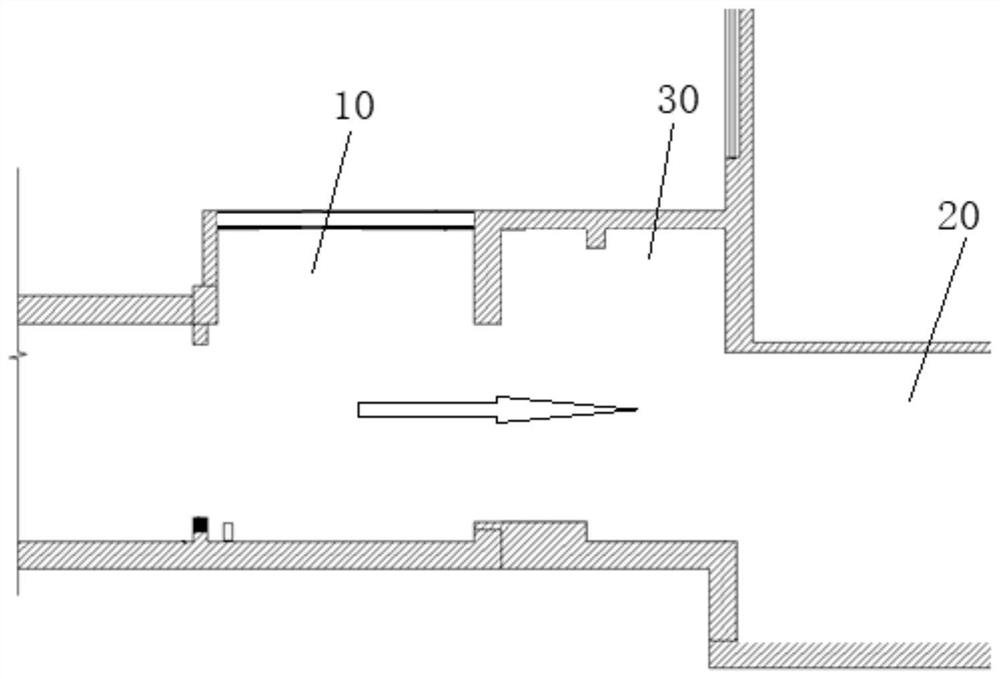

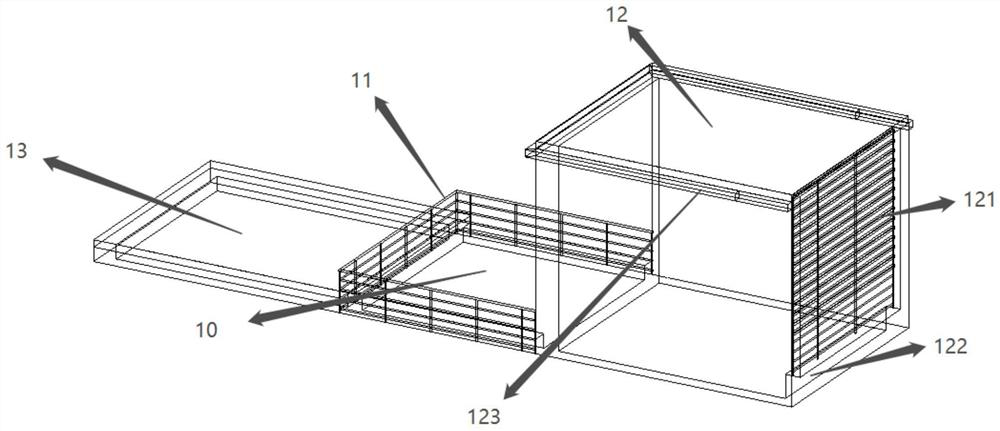

Air duct transformation and communication construction method for subway air shaft

PendingCN114483144AEasy to useEnsure normal excavationMining devicesTunnel/mines ventillationArchitectural engineeringFresh air

The invention discloses an air duct transformation and communication construction method for a subway air shaft. The method comprises the following steps: 1, cutting a part of an overground structure of an original air shaft (10); 2, an original air shaft is partially closed, and a top ventilation structure (11) and a side ventilation structure (12) are arranged; 3, a fresh air shaft (20) is constructed, and an air shaft communication area (30) is reserved between the fresh air shaft (20) and the original air shaft; 4, completely covering the communicating part of the original air shaft and the air shaft communicating area through a retaining wall (101) and an isolating plate (102) in the original air shaft; 5, constructing an air shaft communicating area and a communicating part of the air shaft communicating area and the original air shaft; 6, the retaining wall is dismantled, the original air shaft, the air shaft communication area and the fresh air shaft are communicated, and the original air shaft is completely sealed; and 7, removing the overground part of the original air shaft, and constructing upper waterproof and earthwork backfilling. By reserving part of the structure and ventilation function of the original air shaft, safe construction of the fresh air shaft and the air shaft communication area is guaranteed, the air duct communication transformation construction period is shortened, and subway operation is not affected.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

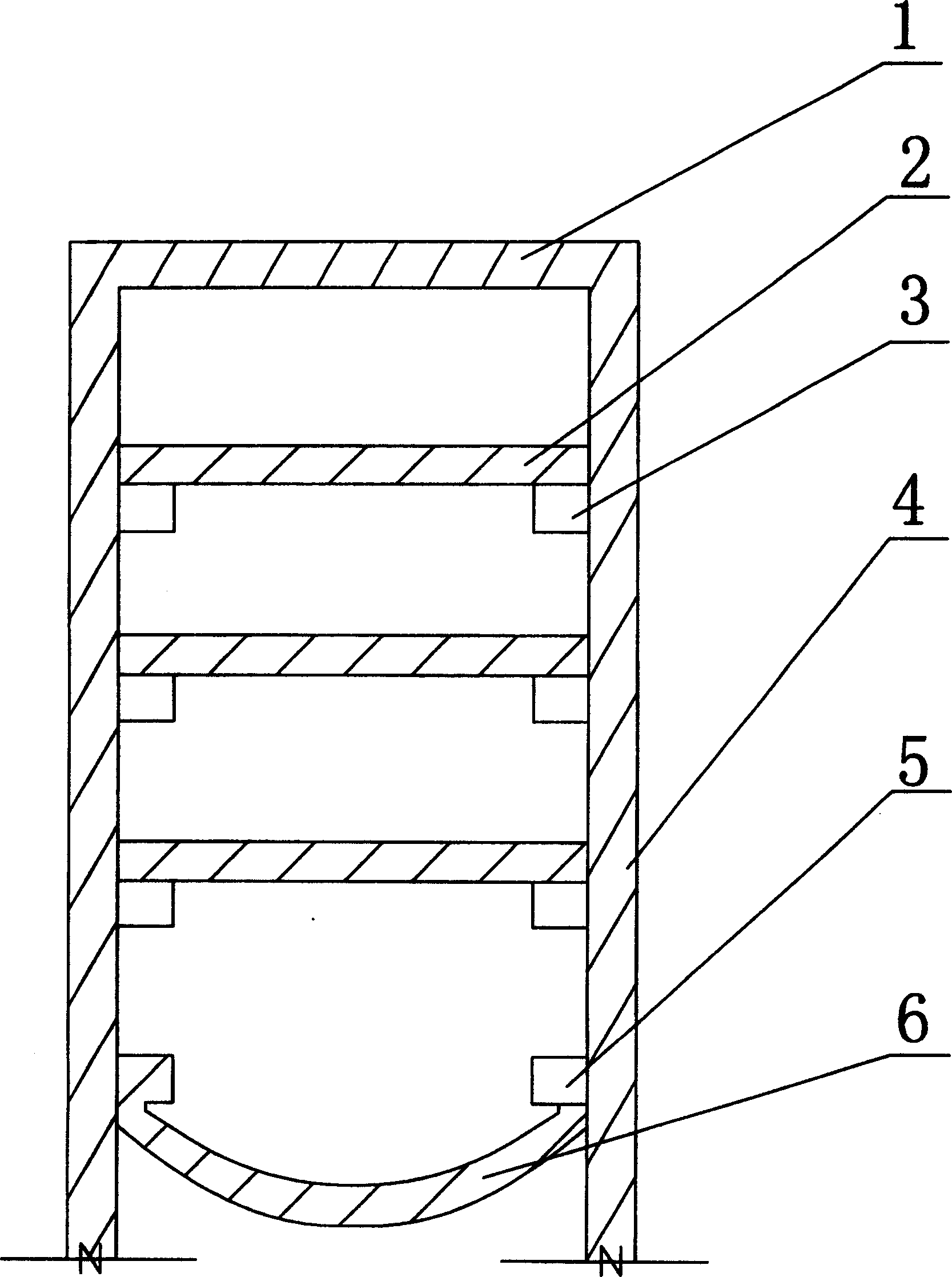

Subway station construction method

InactiveCN1274915CImprove carrying capacityIncrease stiffnessArtificial islandsUnderwater structuresSlurry wallButtress

A subway station construction method belongs to underground build technology field. The method includes subway station enclosing and protection, the construction of load carrying structure-underground continue wall, executing deep layer high-pressure grouting for the ground base soil layer in the continue wall, casting-in-place ferroconcrete to the top of the continue wall to form the top plate of the subway station, casting-in-place ferroconcrete counterfort moving beam or mounting prefabricated counterfort moving beam on the low side of the first layer floor plate under the top plate and the periphery of the continue wall and proceeding the construction of the floor plate of the layer, proceeding the following layer construction by the passages among layers, constructing the reverse arched bottom plate. The invention adopts inverse construct method, the construction quantity is small, the construction efficiency is high and the construction quality is good.

Owner:ZHENGZHOU MUNICIPAL ENG CORP

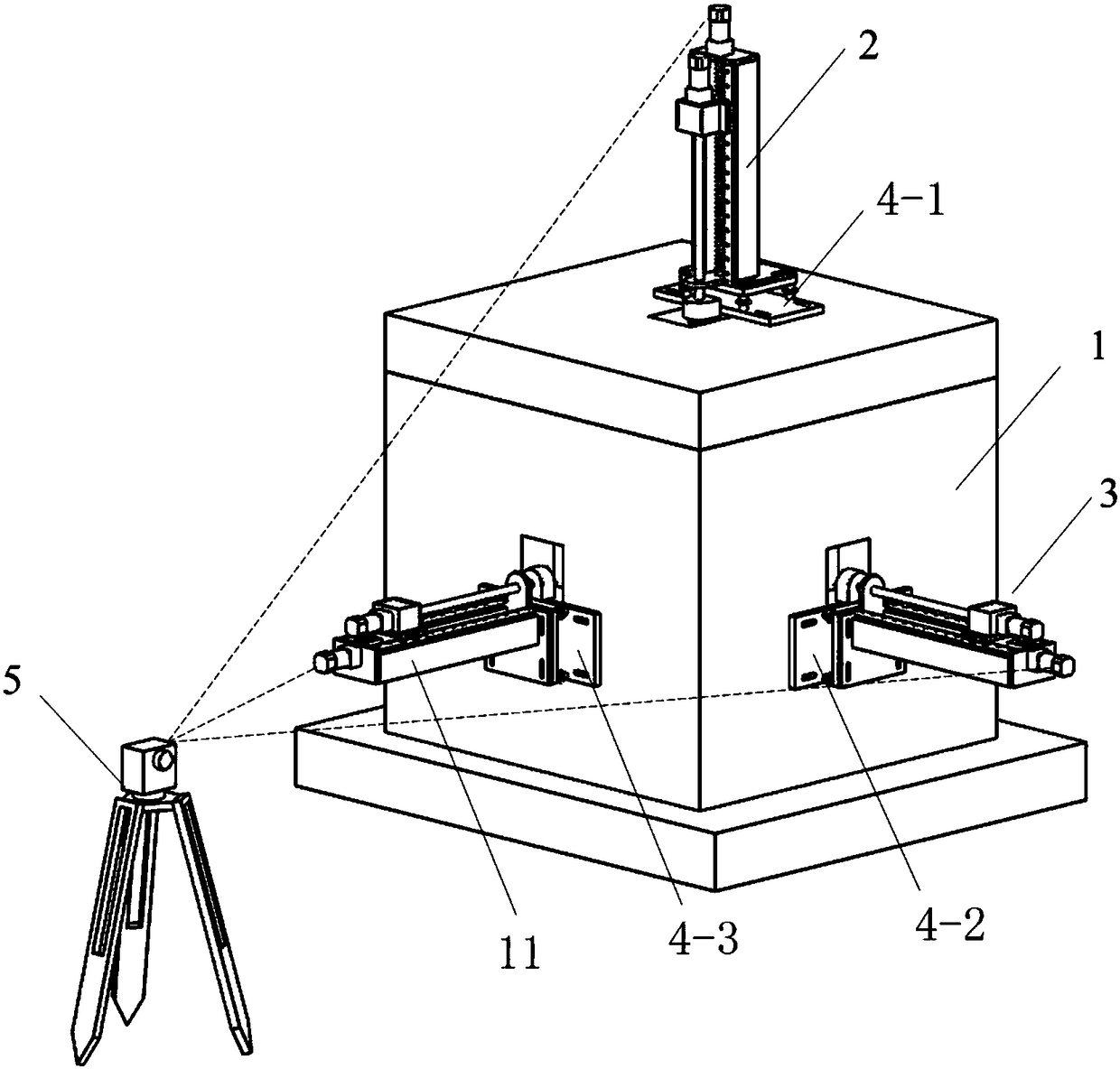

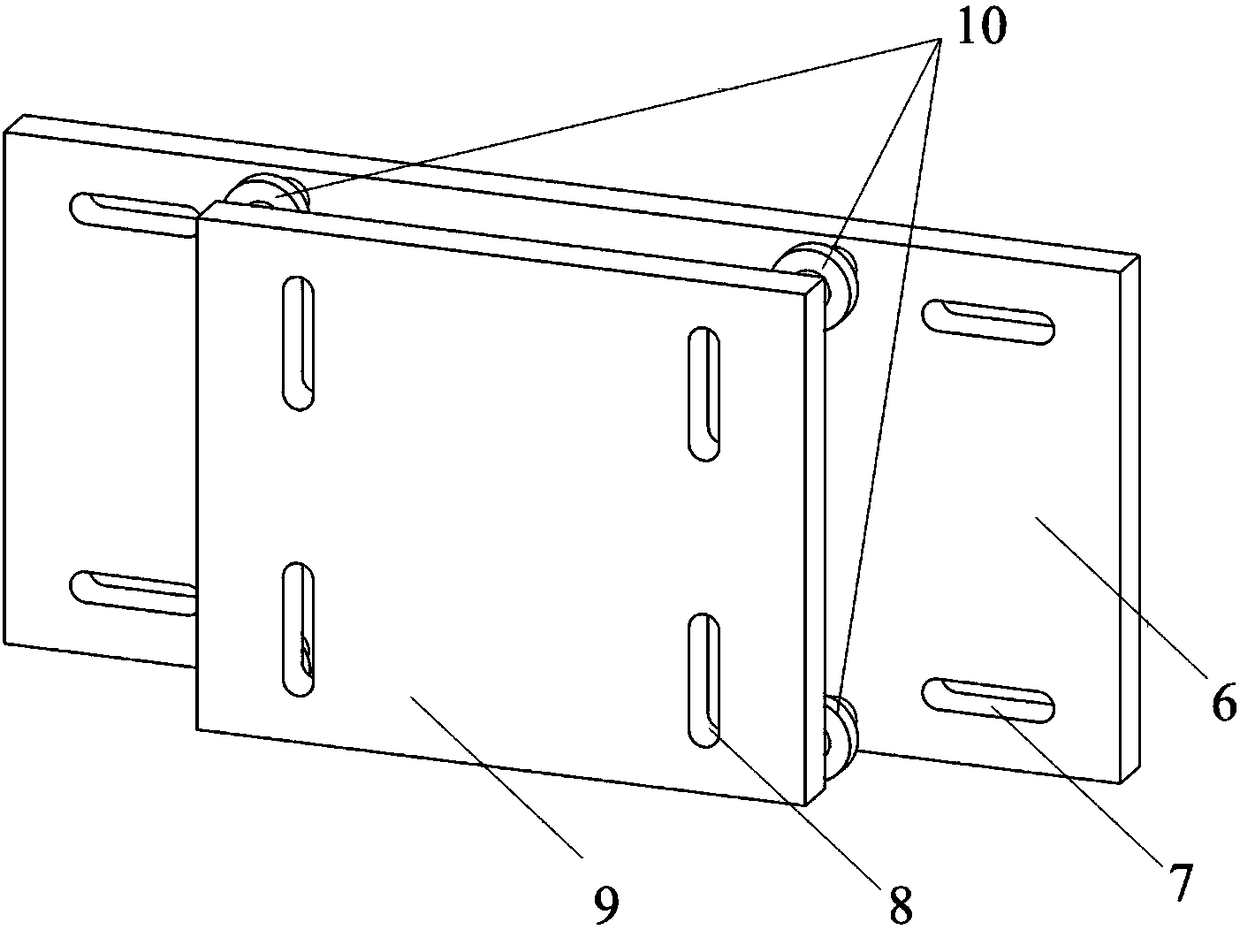

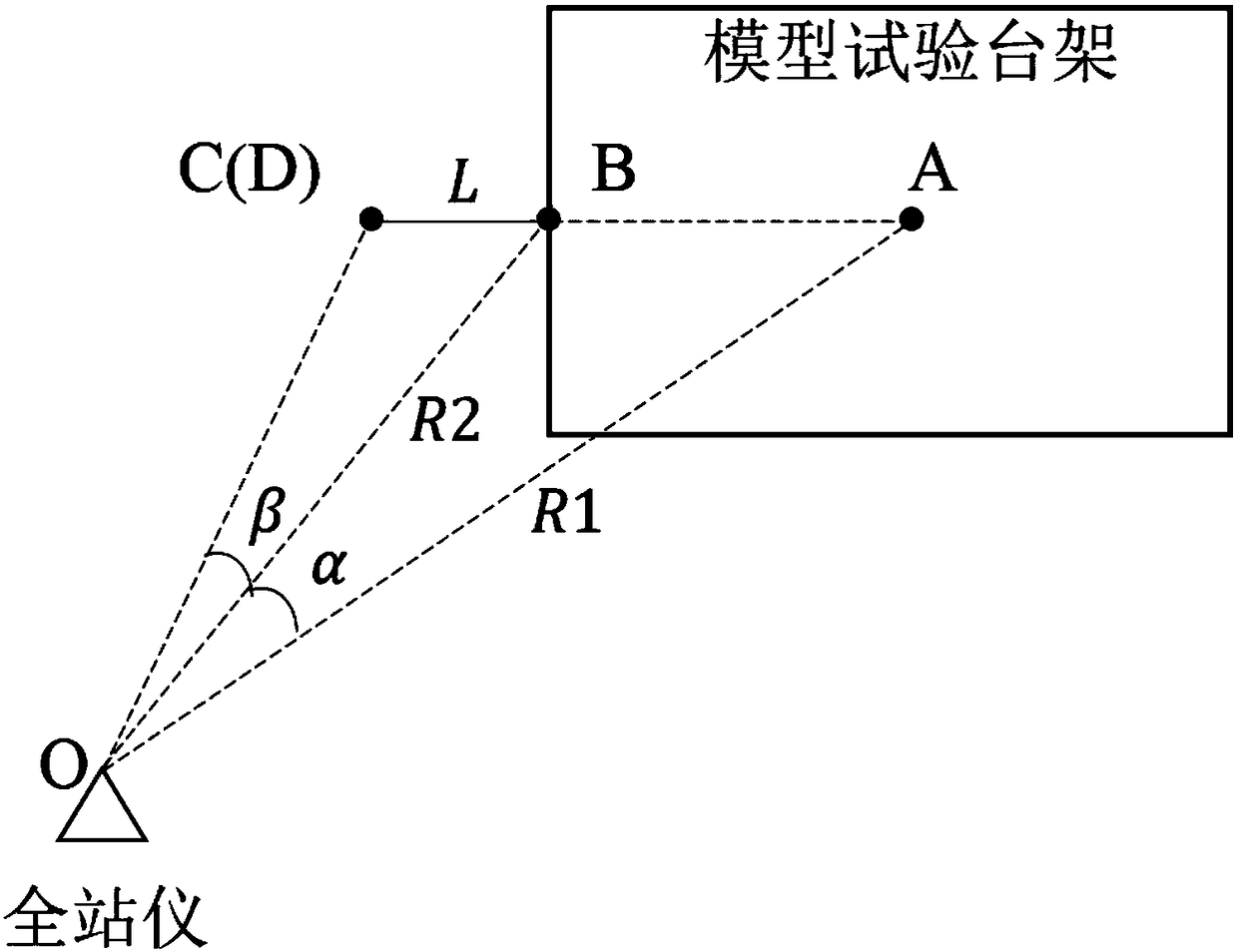

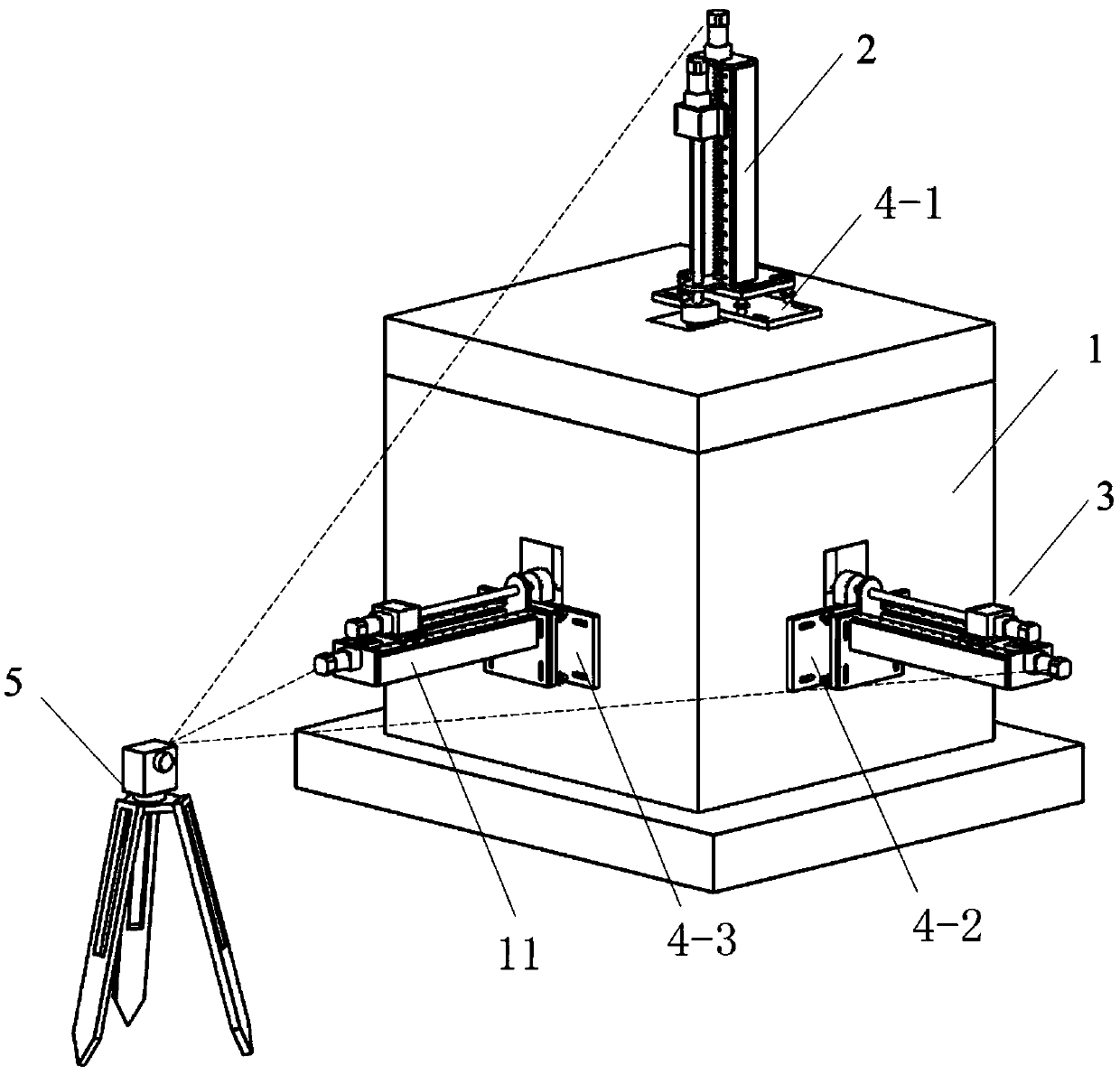

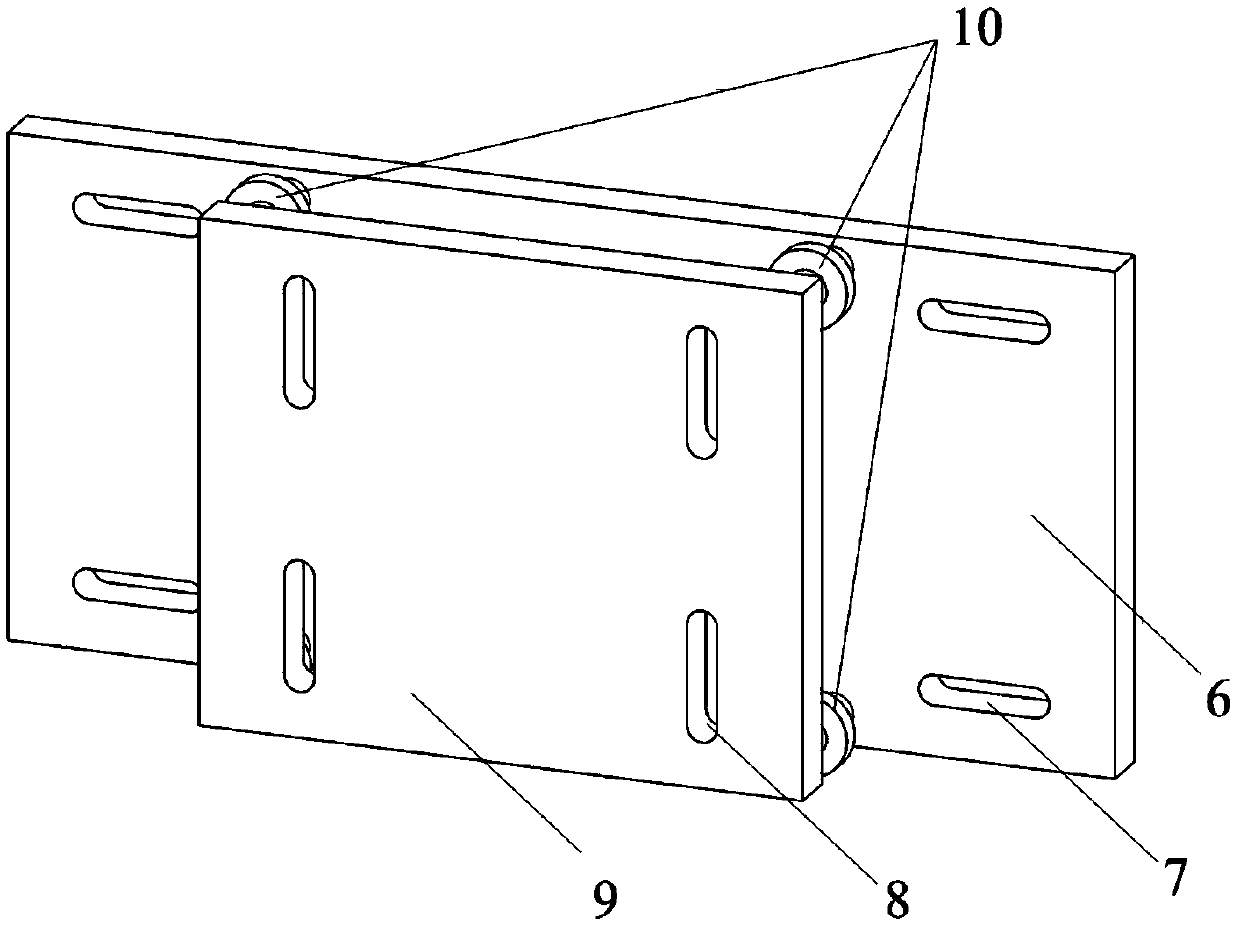

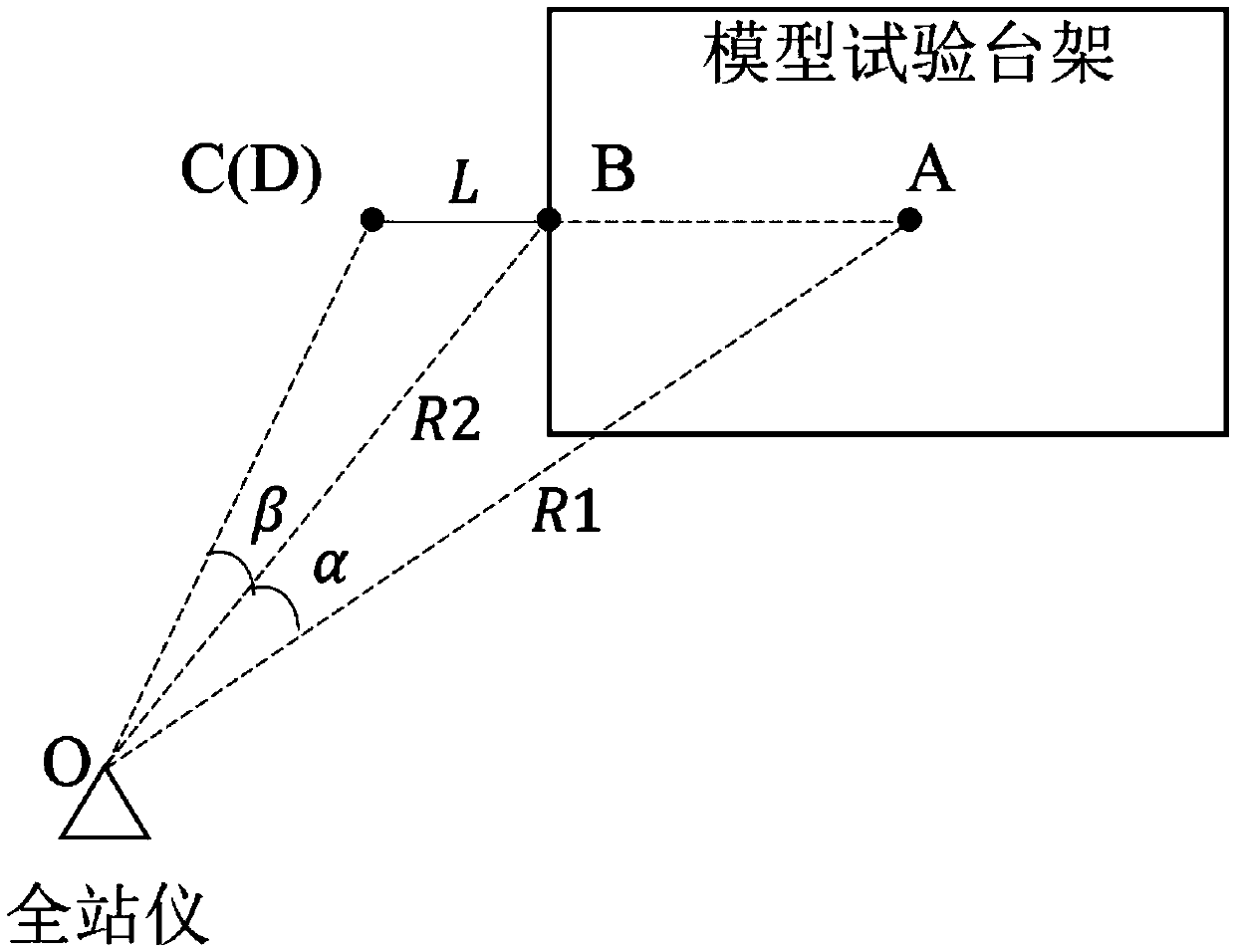

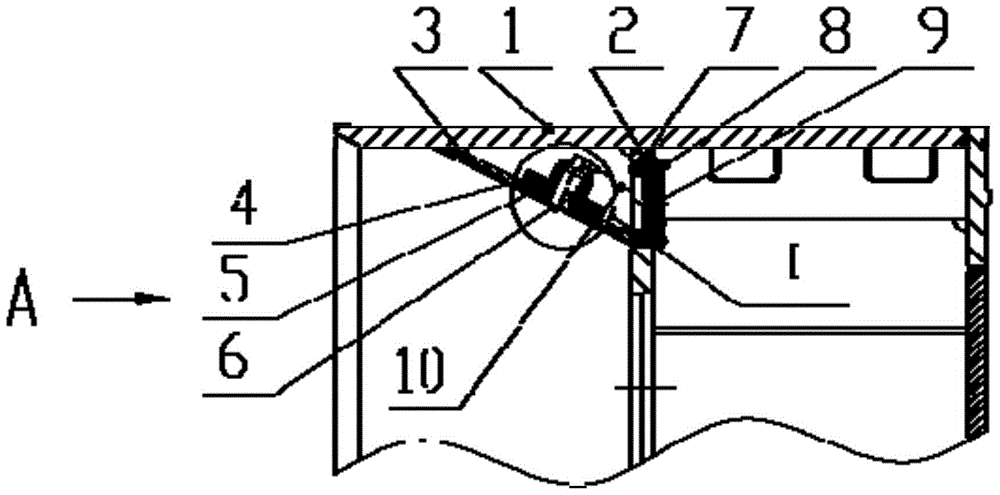

Geomechnical model test complex structure cavern group excavating positioning device and method

ActiveCN108278118AHigh positioning accuracySimple and efficient operationMining devicesTunnelsTotal stationEnvironmental geology

The invention discloses a geomechnical model test complex structure cavern group excavating positioning device and method. The geomechnical model test complex structure cavern group excavating positioning method comprises the main steps that (1) an excavation initial point is positioned, specifically, through transverse and vertical positioning groove holes in excavation positioning plates, the position of a tool bit of an excavation device is accurately and finely adjusted, and positioning of the excavation initial point is completed; (2), the excavation orientation is positioned, specifically, through combination of a total station and software, the excavation orientation is determined, by adjusting foot screws on the excavation positioning plates, the orientation of the exaction deviceis accurately adjusted, and positioning of the excavation orientation is completed; and (3), deviation rectifying monitoring is conducted in the excavation process, specifically, after excavation positioning is completed, the position and angle of the total station are kept to be unchanged, andthe deviation of the excavation orientation is monitored in real time through a laser indicator lamp of the total station, and rectified in time. The geomechnical model test complex structure cavern group excavating positioning device and method have the following advantages that (1) the excavation positioning accuracy is high; (2) operation is easy and convenient, and disturbance to a model frame is small; and (3) the excavation orientation can be monitored in real time and rectified in time in theexcavation process.

Owner:SHANDONG UNIV

A Construction Method for Excavating and Supporting the Foundation Pit of a Shield Receiving Shaft without Precipitation

ActiveCN111560957BEnsure normal excavationGuaranteed dry tank working environmentExcavationsBulkheads/pilesArchitectural engineeringRetaining wall

Owner:RANKEN RAILWAY CONSTR GROUP

Filling device and method for abandoned air-raid shelter in pile foundation construction site

ActiveCN112323823BSmooth Construction MeasuresGuaranteed cycleEmbankmentsFoam concreteArchitectural engineering

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Excavation positioning device and method for complex structure cavern group in geomechanics model test

ActiveCN108278118BExcavation positioning accuracy is highPrecise control of excavation starting pointMining devicesTunnelsTotal stationModel test

The invention discloses a geomechnical model test complex structure cavern group excavating positioning device and method. The geomechnical model test complex structure cavern group excavating positioning method comprises the main steps that (1) an excavation initial point is positioned, specifically, through transverse and vertical positioning groove holes in excavation positioning plates, the position of a tool bit of an excavation device is accurately and finely adjusted, and positioning of the excavation initial point is completed; (2), the excavation orientation is positioned, specifically, through combination of a total station and software, the excavation orientation is determined, by adjusting foot screws on the excavation positioning plates, the orientation of the exaction deviceis accurately adjusted, and positioning of the excavation orientation is completed; and (3), deviation rectifying monitoring is conducted in the excavation process, specifically, after excavation positioning is completed, the position and angle of the total station are kept to be unchanged, andthe deviation of the excavation orientation is monitored in real time through a laser indicator lamp of the total station, and rectified in time. The geomechnical model test complex structure cavern group excavating positioning device and method have the following advantages that (1) the excavation positioning accuracy is high; (2) operation is easy and convenient, and disturbance to a model frame is small; and (3) the excavation orientation can be monitored in real time and rectified in time in theexcavation process.

Owner:SHANDONG UNIV

A device for judging whether the earth pressure balance shield earth bin is full

ActiveCN103912279BEnsure normal excavationReduce the risk of landslidesTunnelsEngineeringShield tunneling

The invention discloses a device judging whether or not an earth pressure balance shield earth chamber is full. The device comprises a pressure detector disposed on the upper portion of a front shield earth chamber of the earth pressure balance shield; the signal output end of a pressure sensor is connected with an upper computer; the upper computer judges whether or not the chamber is full; if not, a warning signal is sent to an alarm unit. The device has the advantages that whether or not the earth chamber is full can be judged anytime during earth pressure balance shield tunneling, full-chamber shield tunneling can be ensured and the application of full-chamber tunneling decreases the danger of collapse ahead.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com