Subway station construction method

A technology for subway stations and earthwork, applied in construction, underwater structures, infrastructure engineering, etc., can solve the problems of poor operating conditions, large equipment consumption, poor safety, etc. Reasonable effect of structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

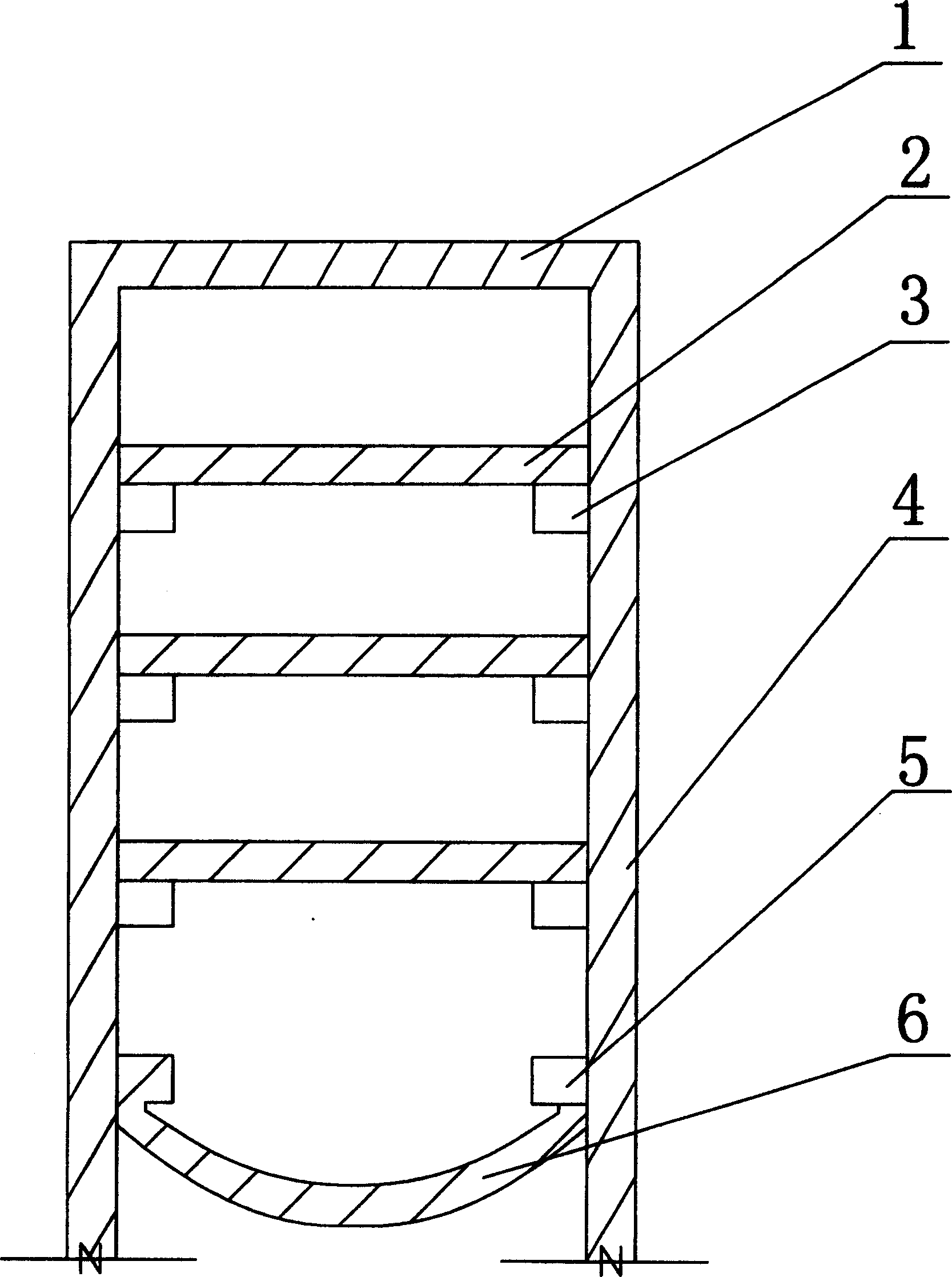

[0014] Embodiment, subway station construction method comprises the following procedures: (1) after the location of the subway station, at first carry out the subway station enclosure and the construction of the underground reinforced concrete diaphragm wall of the load-bearing structure, 4 is the underground diaphragm wall, and pre-buried in relevant positions pieces. (2) After the construction of the diaphragm wall is completed, the local deep high-pressure grouting of the soil layer in the wall is carried out. The purpose is to cut off the underground seepage and prevent seepage deformation when the earthwork in the station is excavated layer by layer. (3) On-site open excavation treatment of the soil layer (top soil) above the roof elevation of the subway station (no need to remove the earthwork for backfilling after roof construction). (4) Carry out the construction of the flat roof and arched roof of the underground diaphragm wall, 1 is the roof, and the construction en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com