Patents

Literature

57results about How to "Reasonable investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

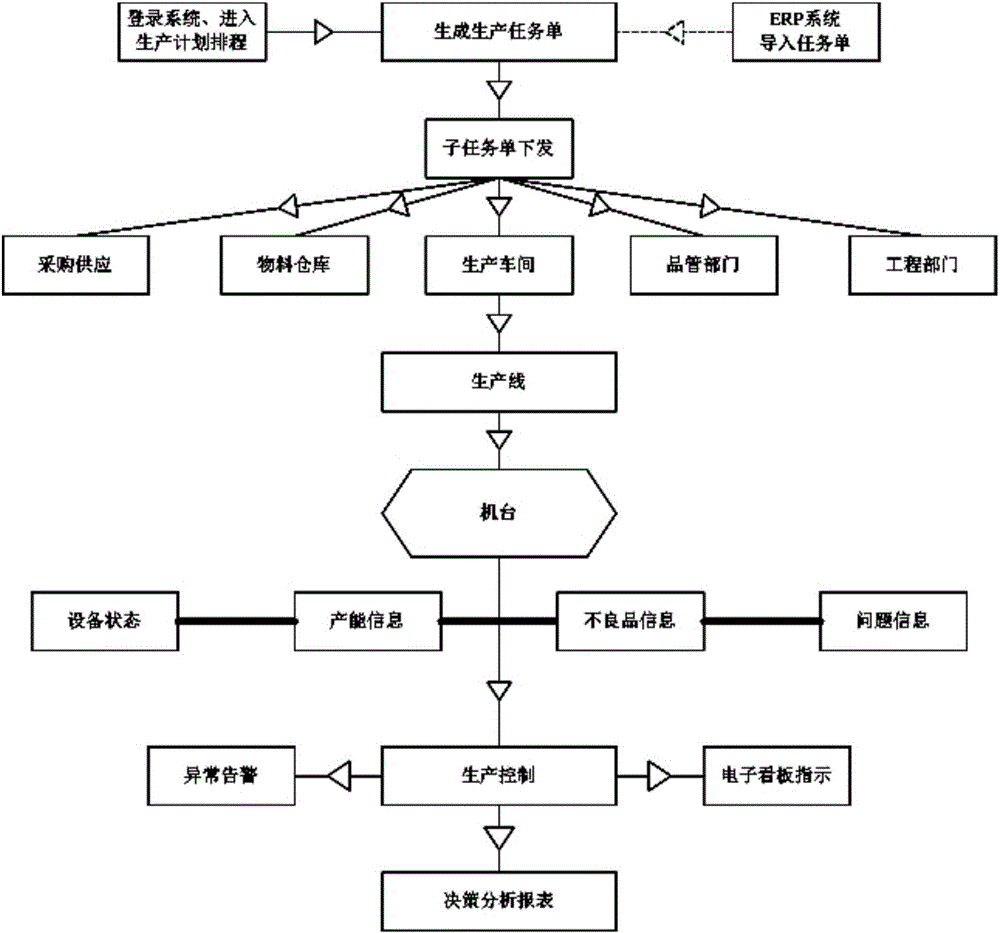

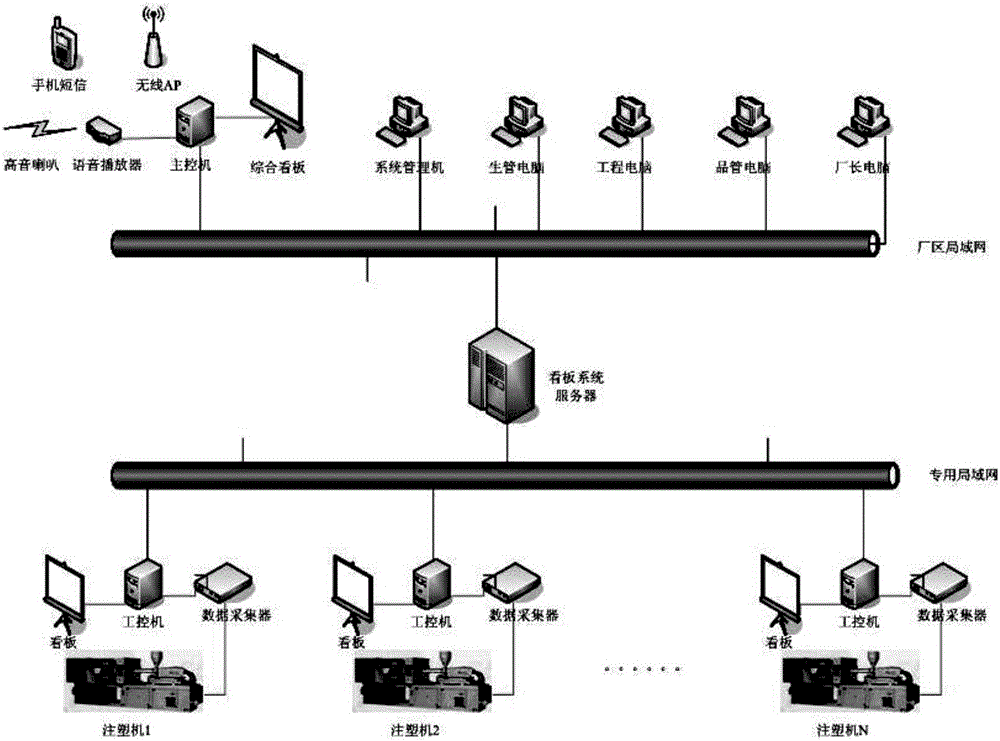

Lean production management kanban system and application method

InactiveCN106779592ASimple designAdvanced architectureOffice automationManufacturing computing systemsData acquisitionPersonal computer

The invention discloses a lean production management kanban system and an application method. The system mainly comprises machine table kanban, comprehensive kanban, a data collector, an industrial personal computer, a server, kanban system software, a call broadcast system, and a special local network. The system has the effects of real-time transmission of production information, transparent management and guarantee of production field work order, and is an effective tool for realizing lean production accurate management.

Owner:林冠良

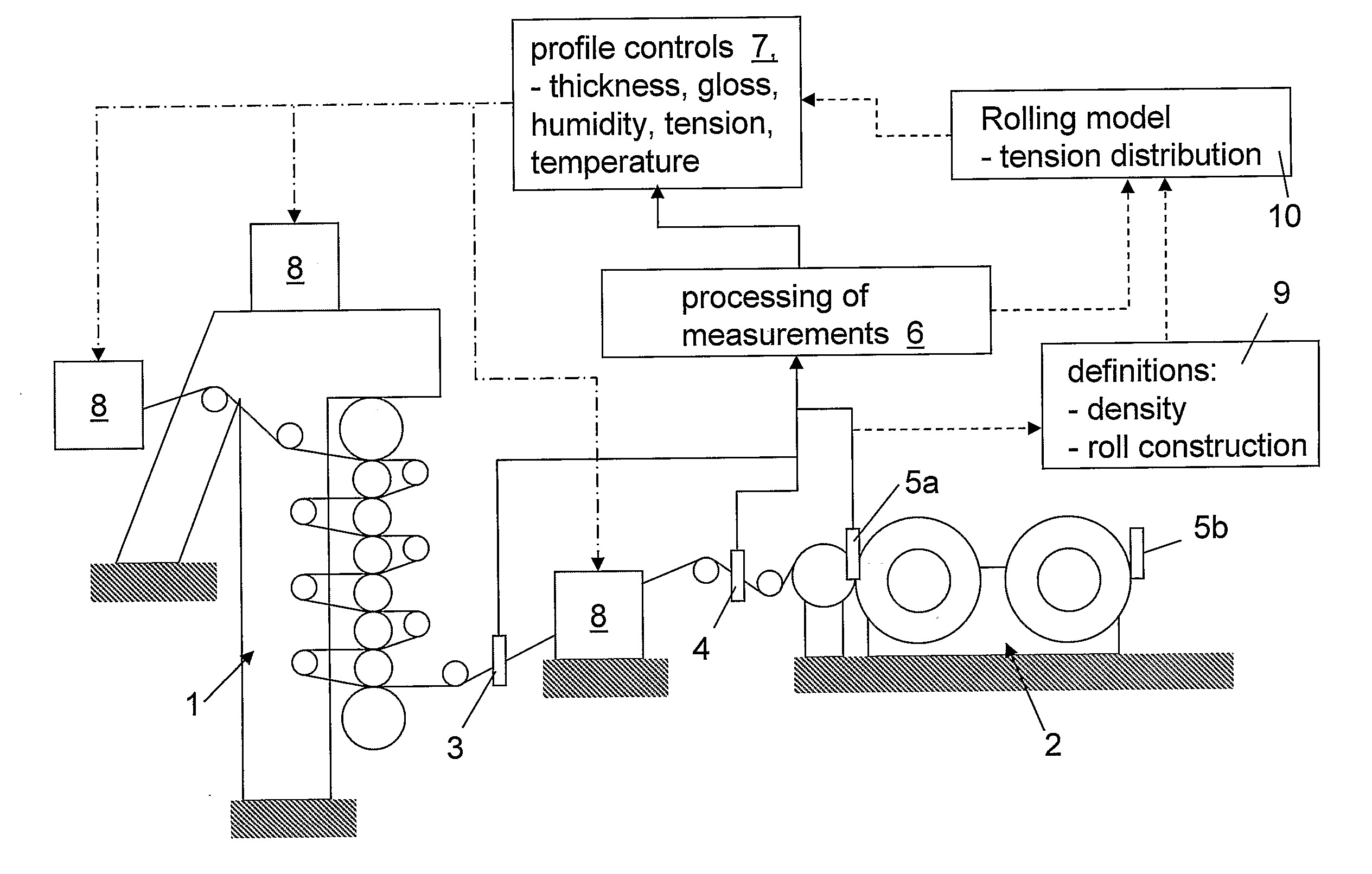

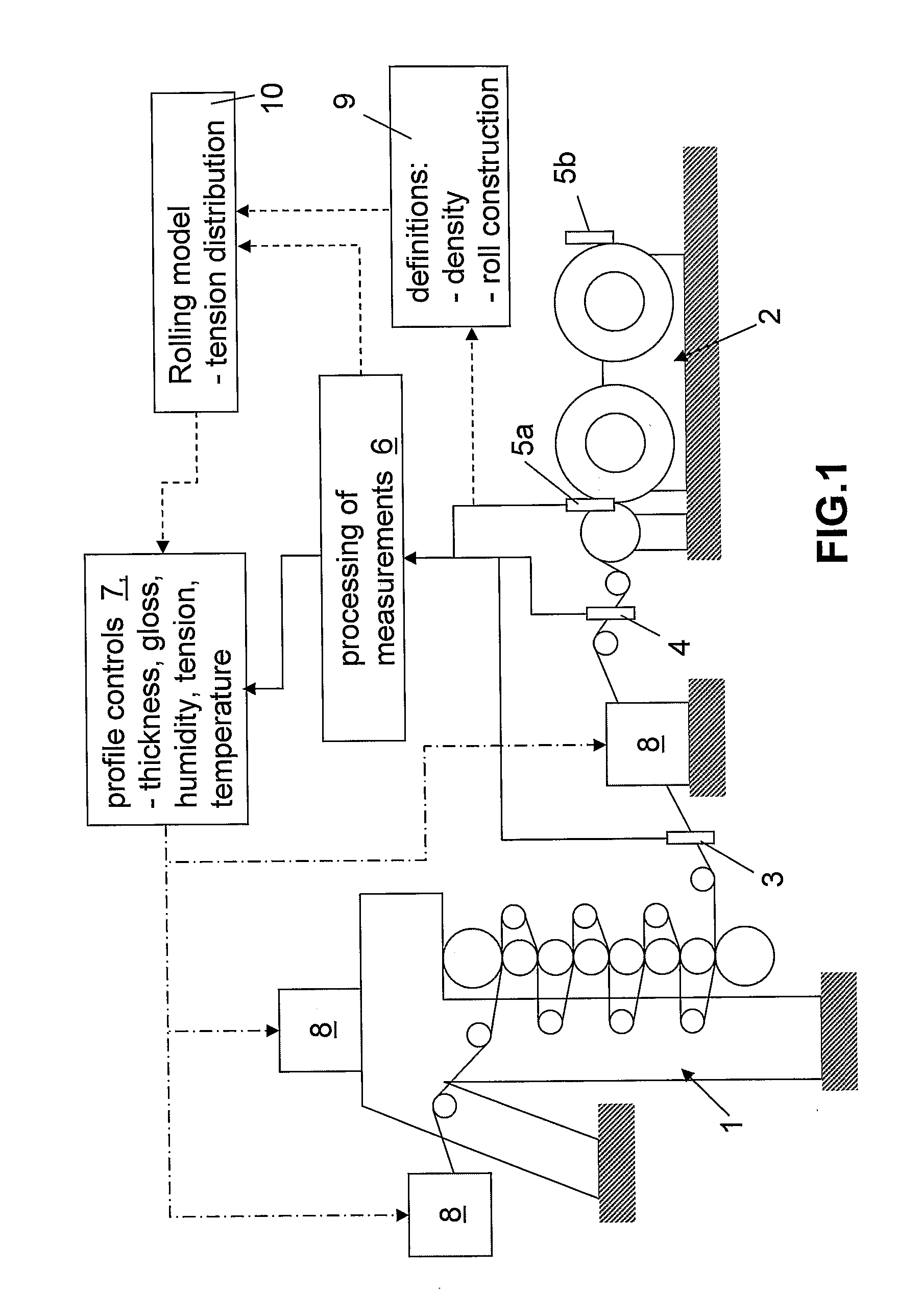

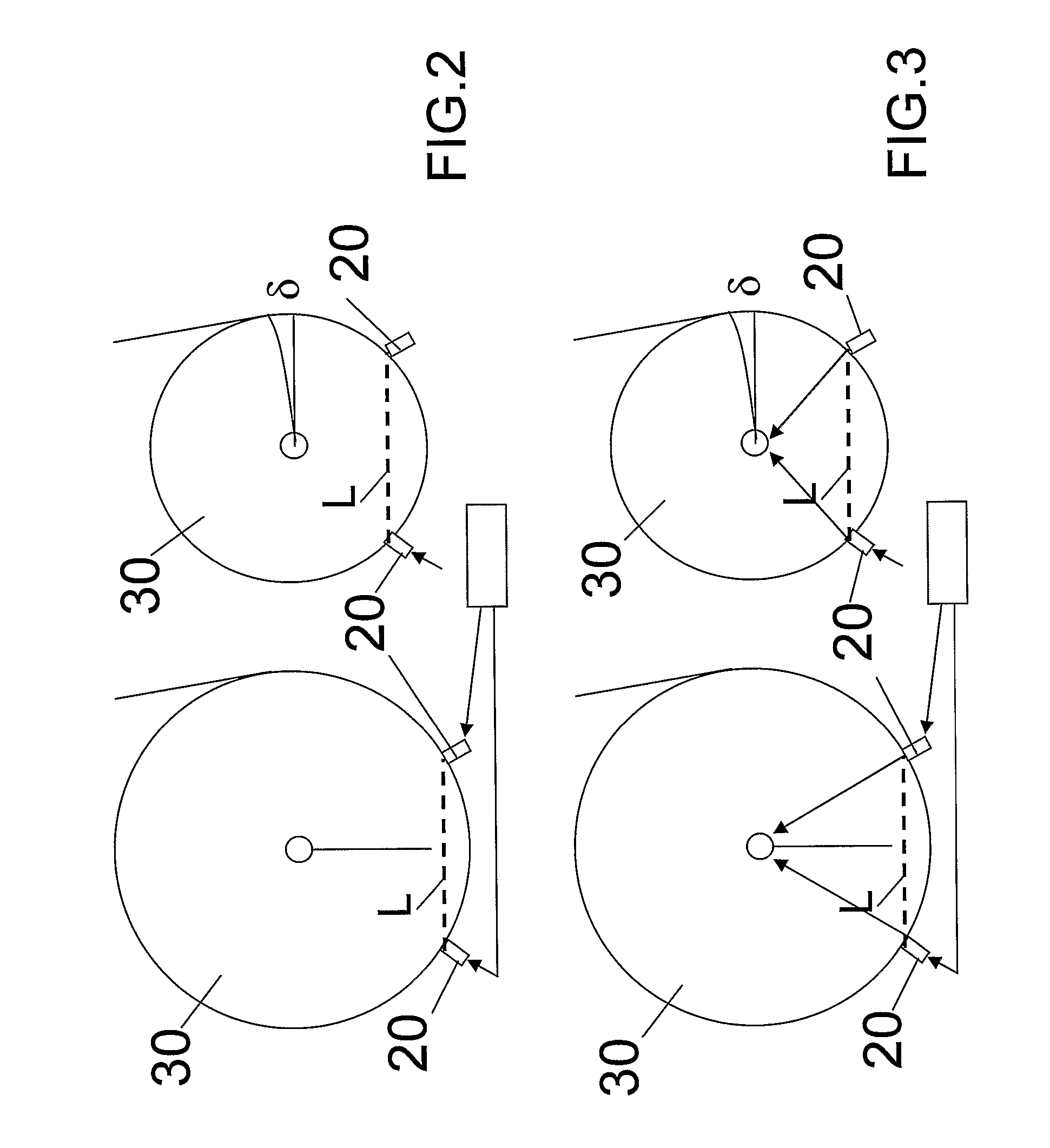

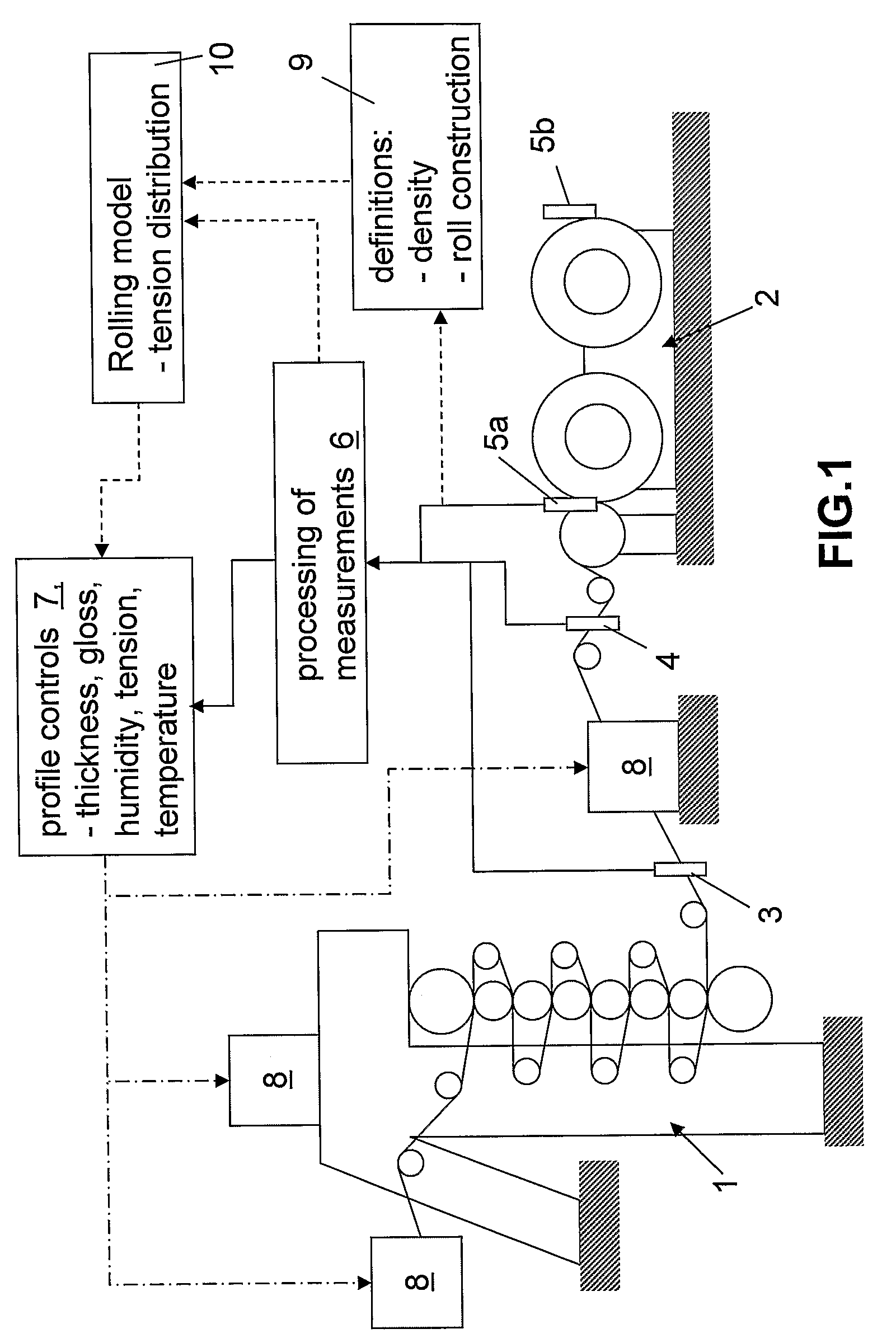

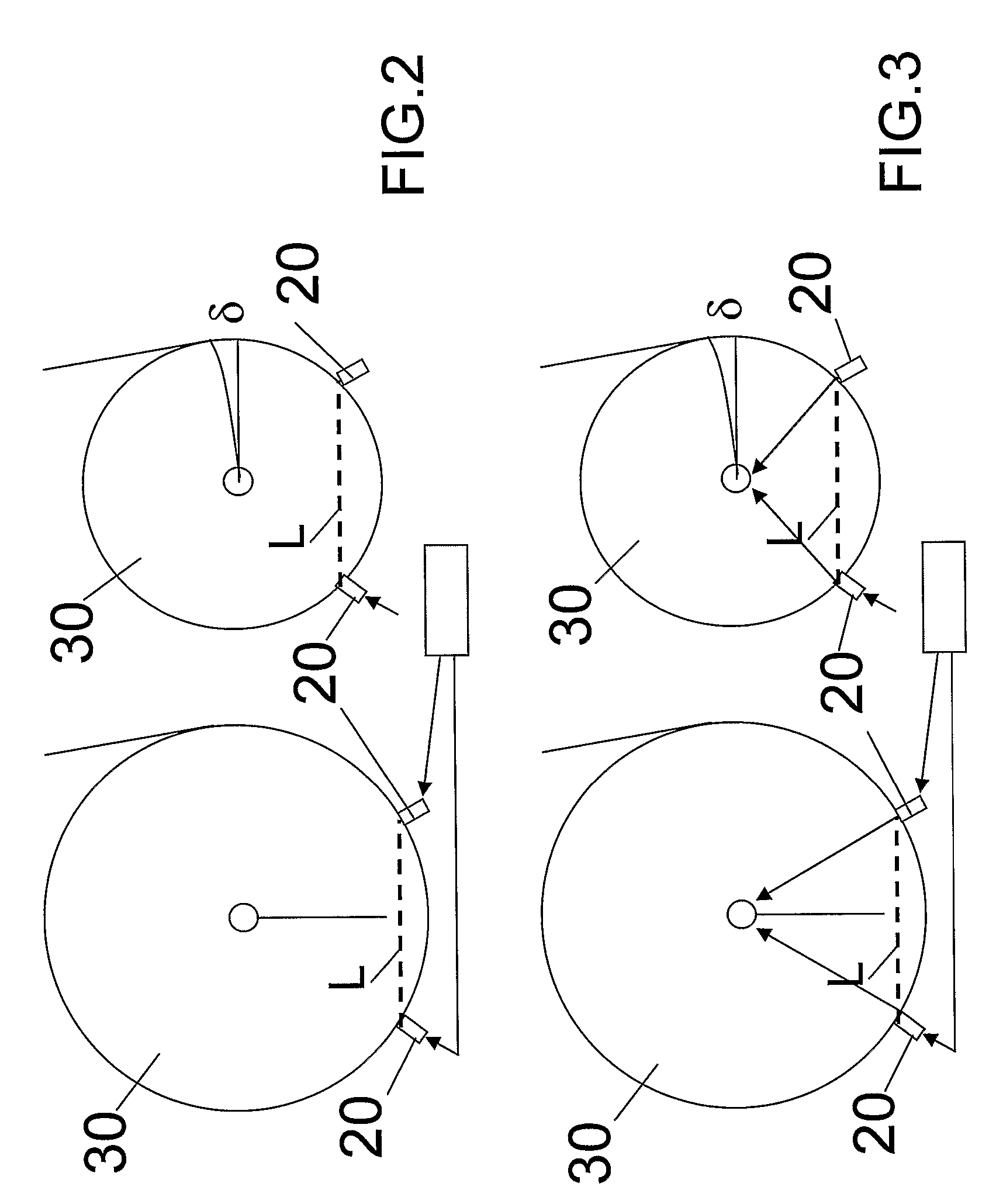

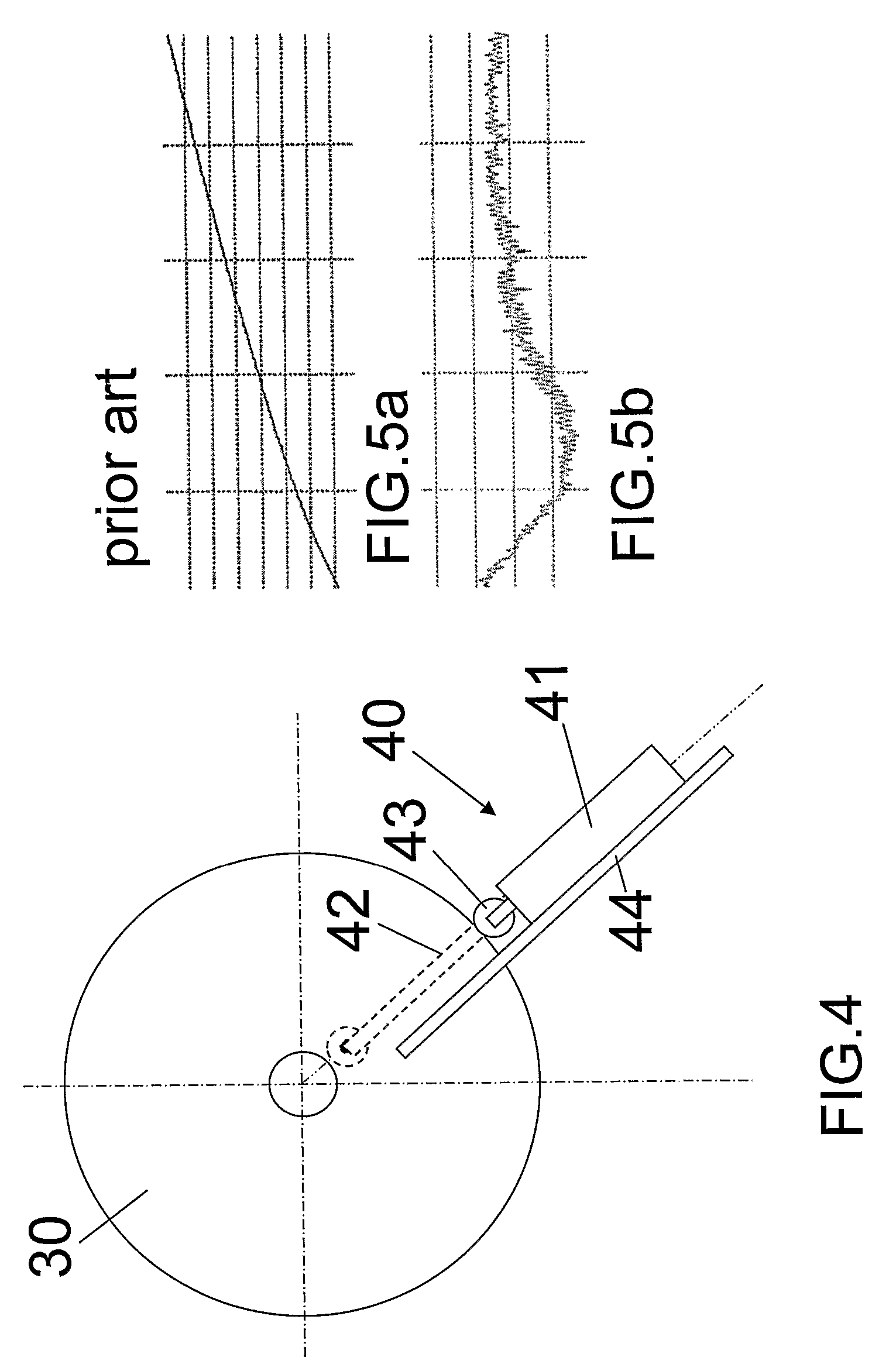

Reeling Method and System as Well as an Measuring Apparatus

ActiveUS20080017341A1Minimize measurement errorCost-effectiveAnalysing solids using sonic/ultrasonic/infrasonic wavesPaper testingPaper sheetMeasurement device

A method and a system to control a reeling profile of a material web reel (30), when, in the forming of a material web reel (30), a web is reeled around a reeling core and when in an adjustment of CD-directional profiles of the web reel, profiling devices (8) have been applied. For adjusting quality profiles and reeling profiles of the web, profiling devices are managed with the help of profile measurings of the roller nip and / or of the profile measurings of the reel (30), which are obtained from the reel-up (2). A measuring device (40) for a measuring of a CD-directional hardness profile of the fiber web reel includes a measuring head (43), which is connected with a loading means (41, 42), which loads the measuring head against the fiber web reel. The motion course of the measuring head is linear.

Owner:VALMET TECHNOLOGIES INC

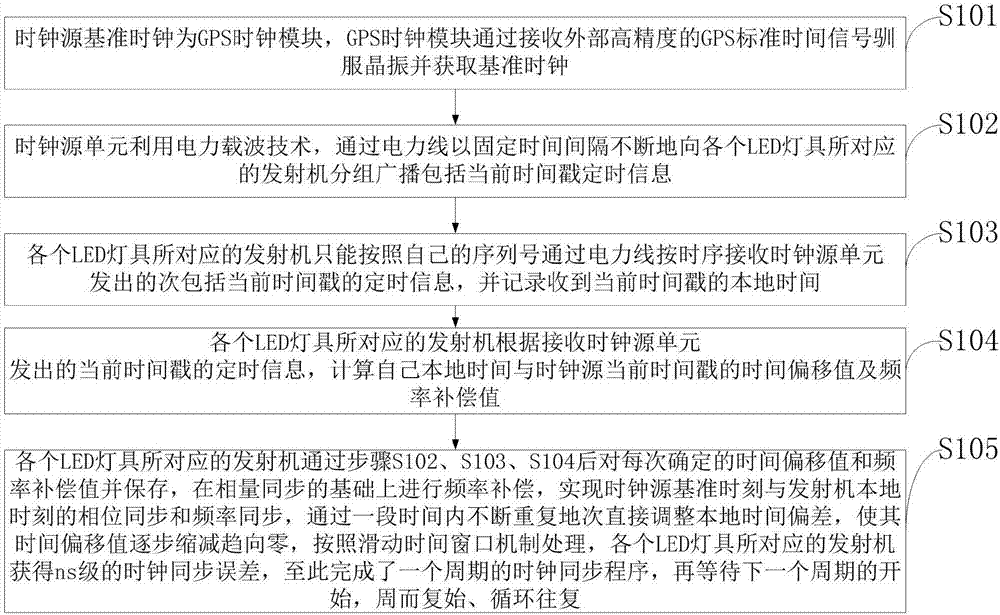

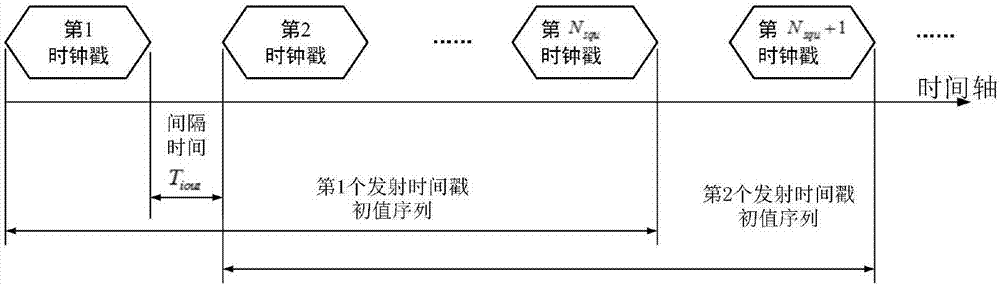

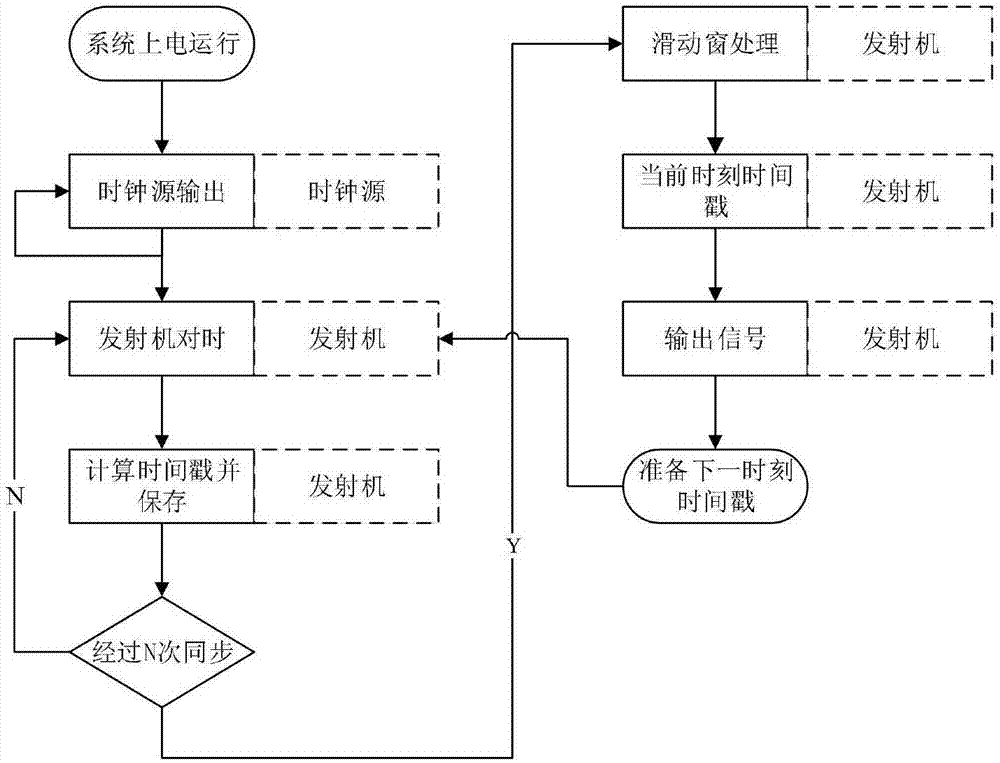

Clock synchronization method and system of LED visible light indoor locating

InactiveCN107196726AConsistent robustnessConsistent convergence ratePower distribution line transmissionPosition fixationTimestampCurrent time

The invention discloses a clock synchronization method and system for indoor positioning of LED visible light. The method and the system select a clock source as the GPS timing reference, and the clock source uses power carrier technology to send packets including The timing information of the current time stamp, the transmitter corresponding to each LED lamp receives the timing information through the power line, and calculates the time offset value and frequency compensation value between its local time and the current time stamp of the clock source, after Nsqu times of phase synchronization and frequency synchronization , so that the time offset value of its local clock gradually decreases towards zero, and it is processed according to the sliding time window mechanism. The invention realizes that the clock synchronization error of LED visible light indoor positioning is controlled within the range of ns level.

Owner:吕志勤

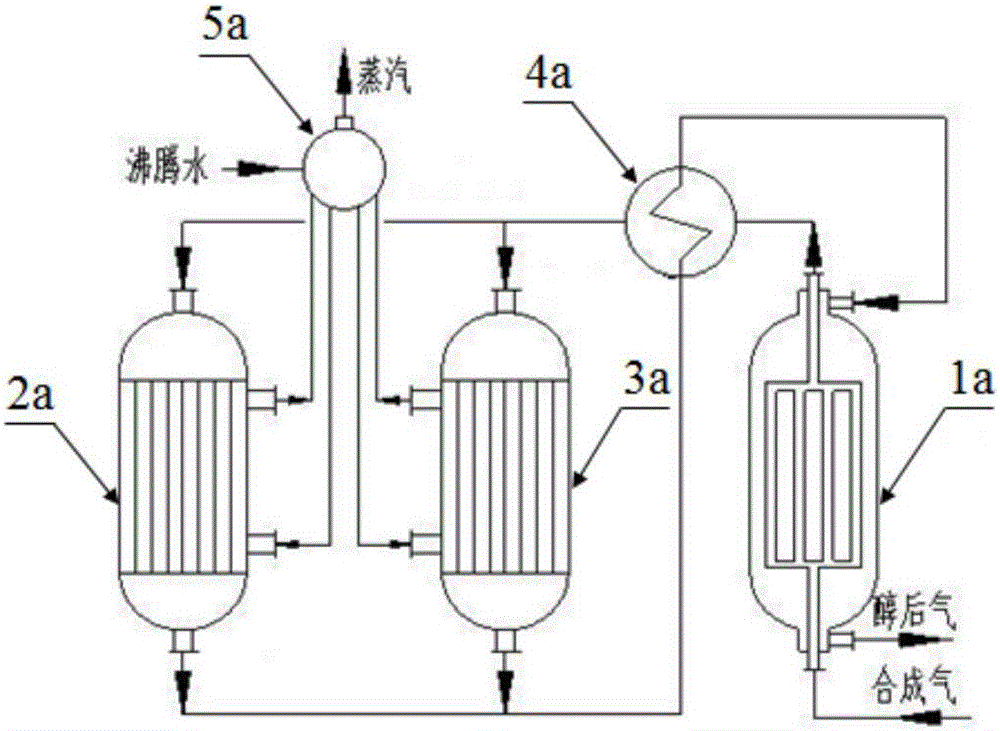

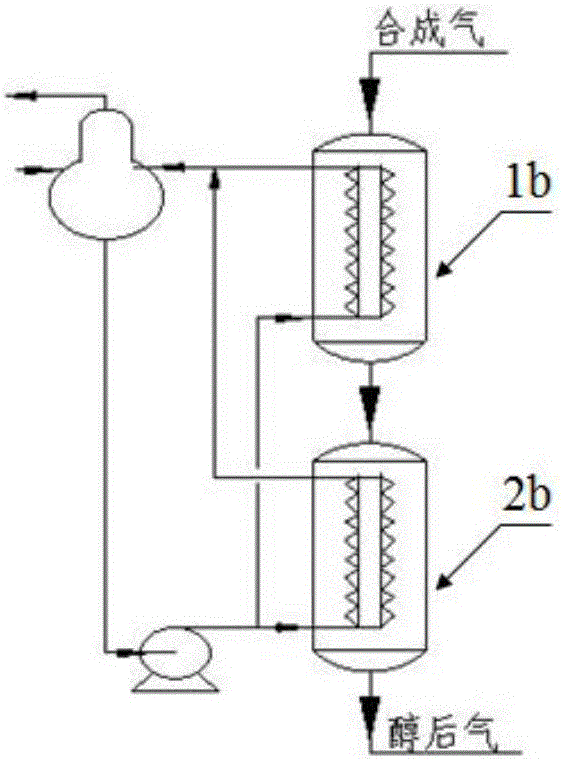

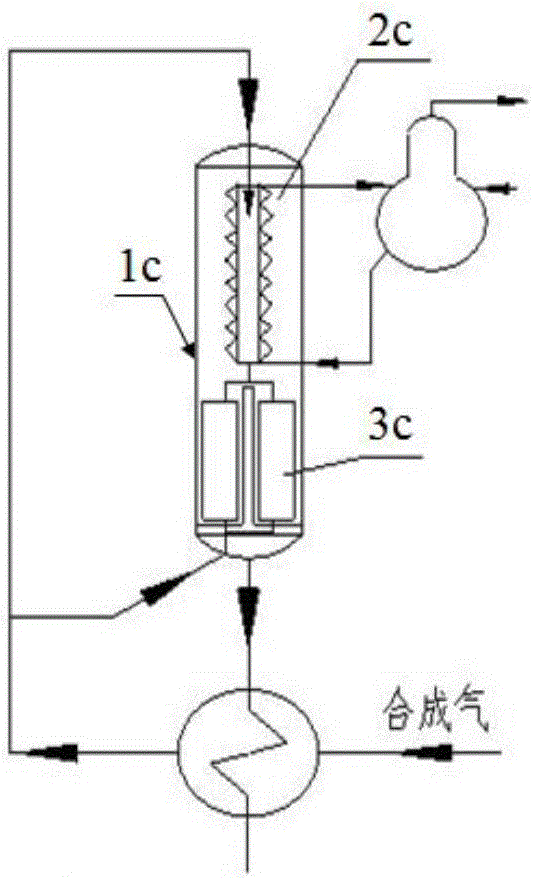

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

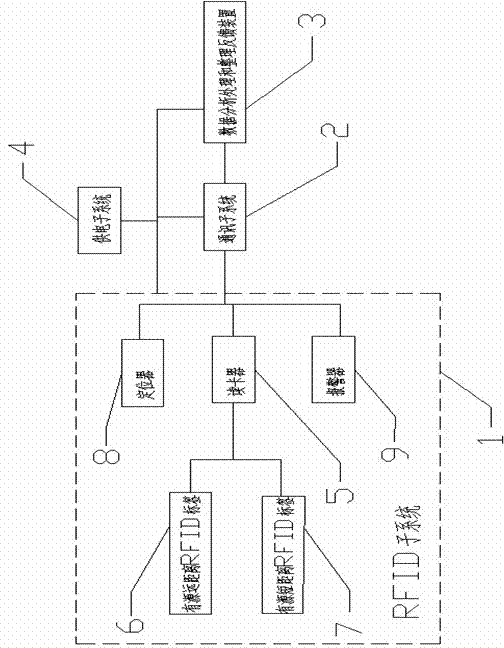

Baby anti-theft system based on radio frequency identification device (RFID) technology

InactiveCN103093577AImprove efficiencyReasonable investmentSensing record carriersAlarmsTelecommunicationsAnti theft

The invention relates to a baby anti-theft system based on radio frequency identification device (RFID) technology. The baby anti-theft system based on the RFID technology is composed of an RFID subsystem, a communication subsystem, a data analysis processing and reduction feedback device, and a power supply subsystem. The baby anti-theft system is characterized in that technologies like RFID and wireless fidelity (WIFI) of the Internet of things are utilized, a baby with an RFID care chip can be automatically identified, and relevant information like the name of the baby, the conditions of the baby, and the conditions of parents of the baby can be obtained directly. At the same time, the positions of the baby are combined with a background system of a nurse station to realize electronic supervision to the anti-theft and anti-miscarrying problems in hospital maternal and infant management.

Owner:QINGDAO ZHONGKE SOFTWARE

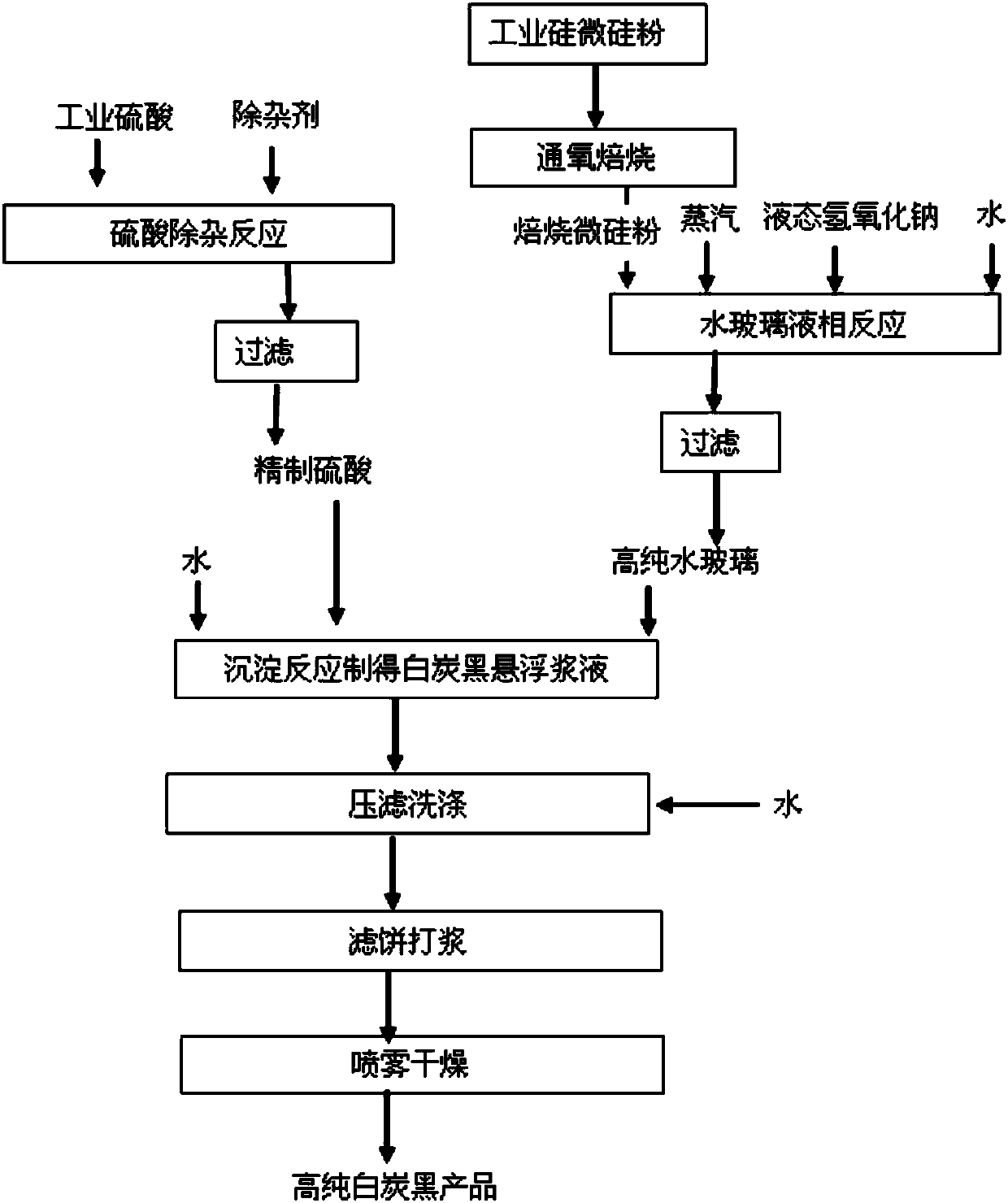

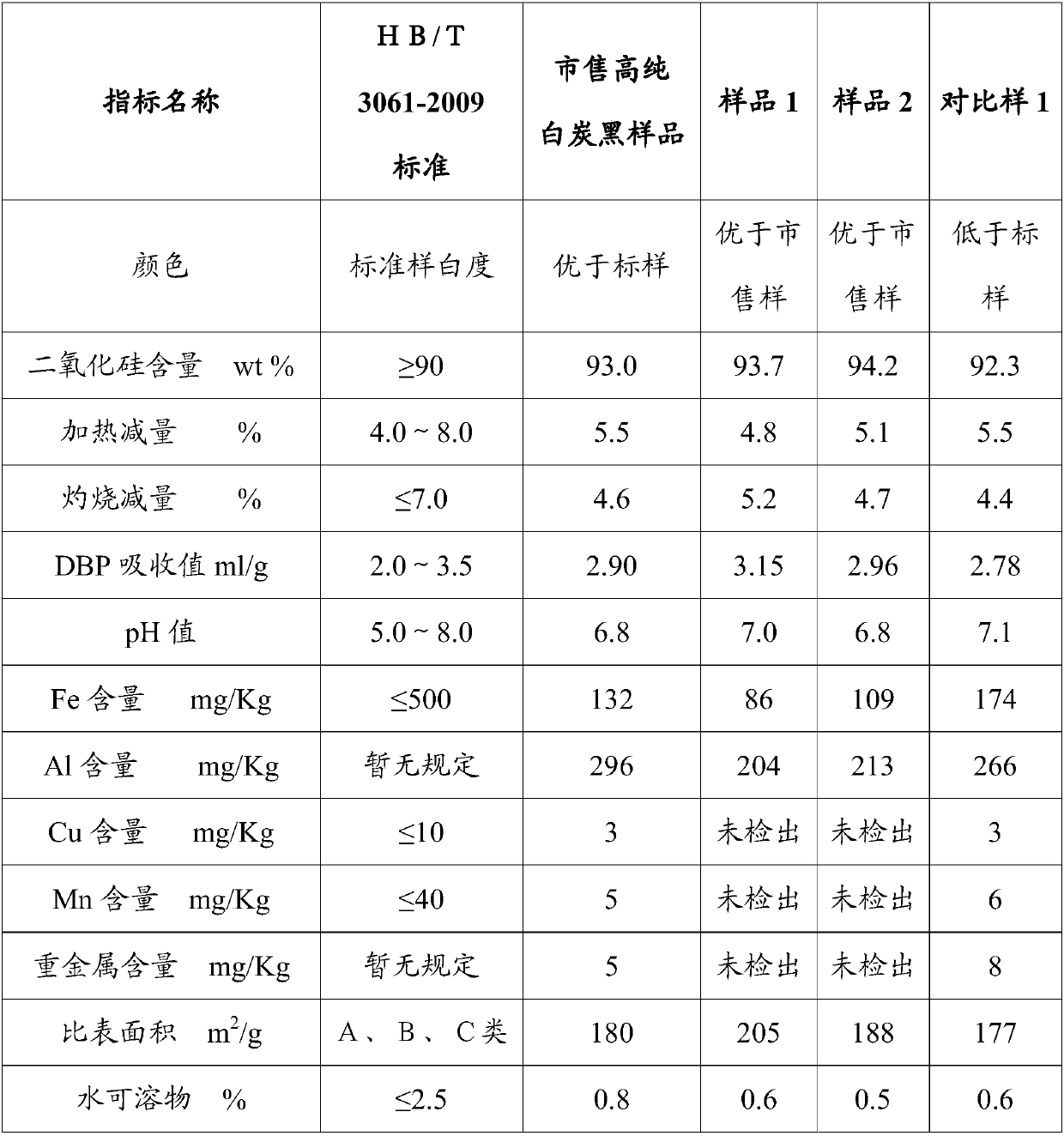

High pure white carbon black produced by utilizing industrial silicon byproduct silica fume and production method of high pure white carbon black

InactiveCN108017066AHigh economic valueReduce production energy consumptionTransportation and packagingSolid waste disposalSlurryImpurity

The invention discloses high pure white carbon black produced by utilizing industrial silicon byproduct silica fume and a production method of the high pure white carbon black. The method comprises the concrete steps of roasting the silica fume to remove organic impurities such as coal tar, reacting with caustic soda liquid to obtain a water glass mother liquor, and filtering to obtain high-pure water glass; adding a sulfuric acid impurity removal agent into sulfuric acid, reacting for precipitating metal and heavy metal in the sulfuric acid, and filtering to obtain refined sulfuric acid; adding water into the high-pure water glass so as to prepare into an alkaline base solution, enabling the water glass and the sulfuric acid to parallelly flow into the base solution, and reacting to obtain suspension slurry; filtering, washing, pulping and drying the suspension slurry to obtain the high pure white carbon black. According to the high pure white carbon black produced by utilizing industrial silicon byproduct silica fume and the production method thereof provided by the invention, the high pure white carbon black is produced by adopting the industrial solid waste silica fume as a silicon source, so that the solid waste is recycled, and the process is simple and reasonable and low-cost, and has better economic and social benefits.

Owner:CHANGJI JISHENG NEW BUILDING MATERIALS CO LTD

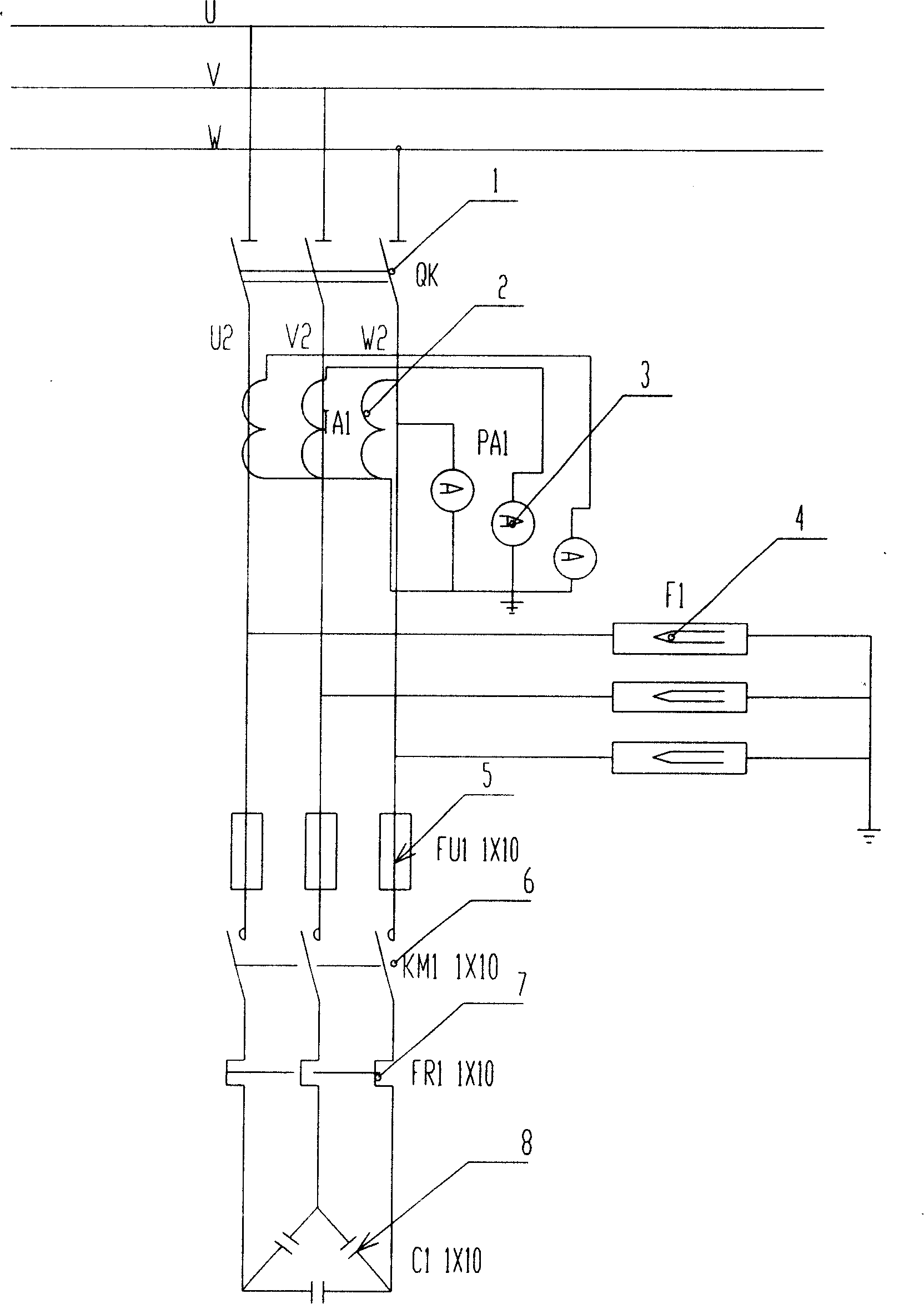

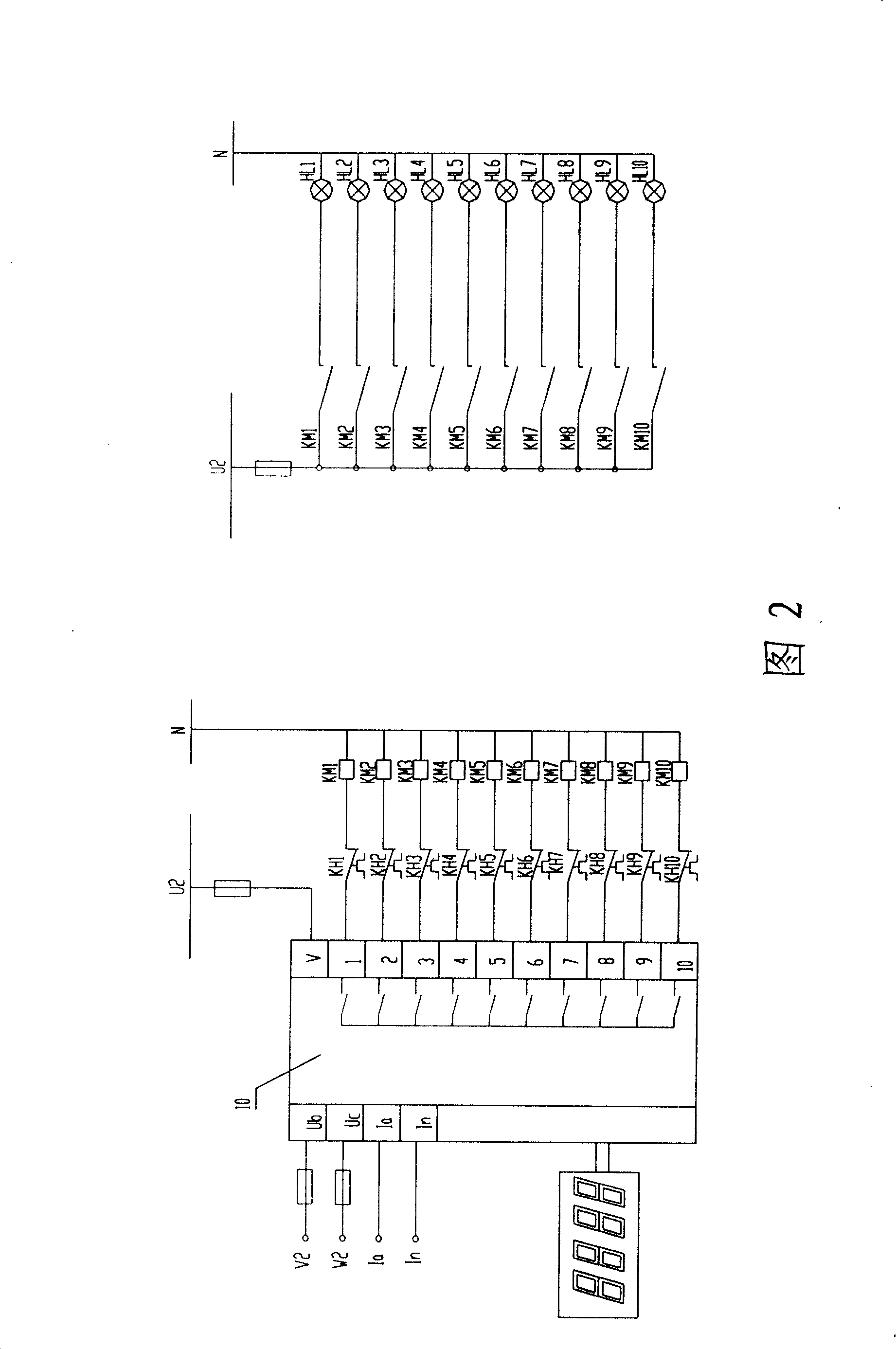

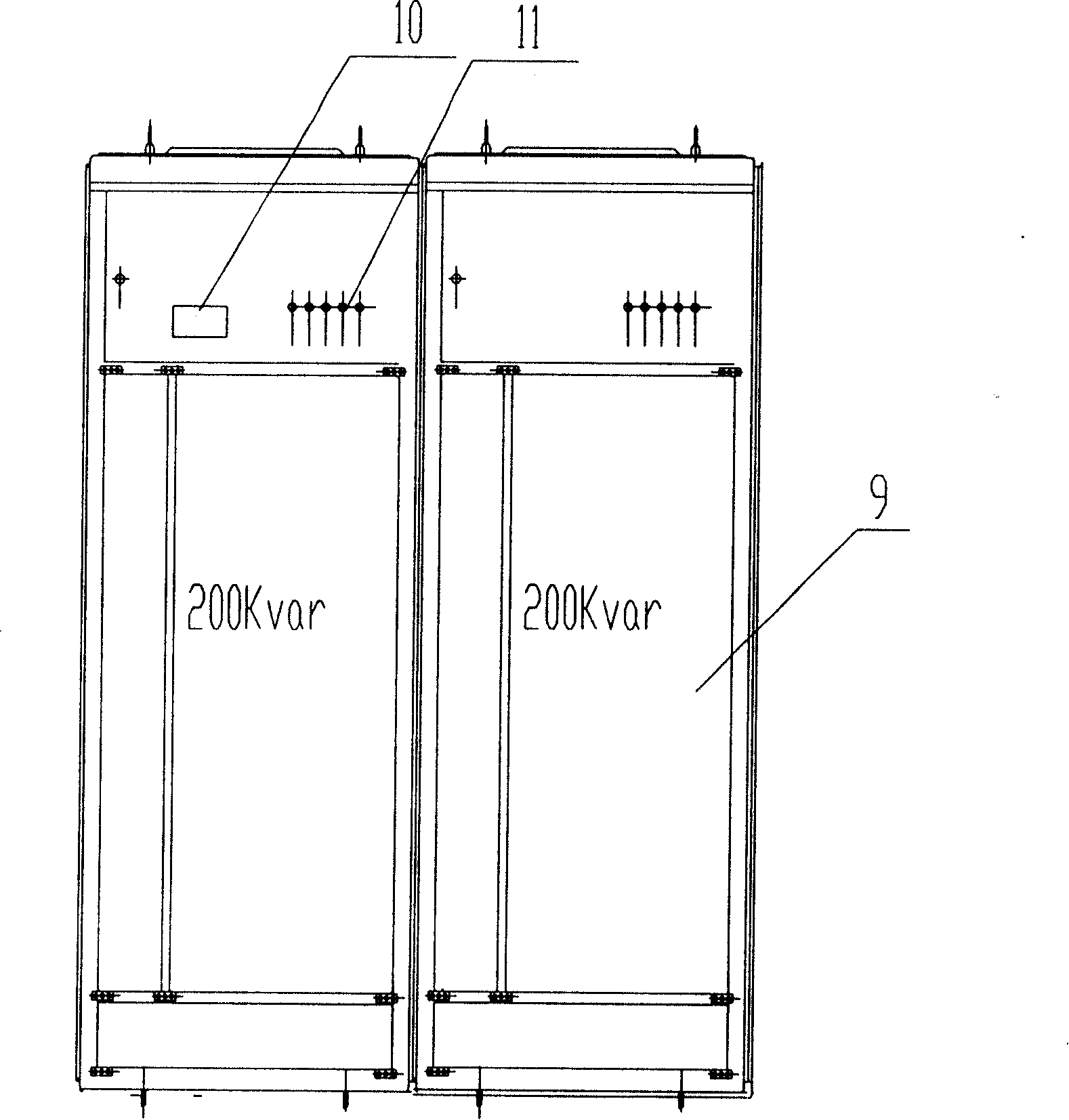

Numerically-controlled forging hydraulic press capable of realizing reactive power compensation

InactiveCN101164719AImprove power factorReduce active power lossForging press drivesContactorCapacitance

The present invention relates to a numerically-controlled forging hydraulic press capable of implementing reactive power compensation, belonging to the field of hydraulic press technology. It includes the following several portions: hydraulic press machine frame, movable transverse beam, working table, display, electric controller and power mechanism. The electric controller can be used for controlling power mechanism to drive hydraulic press machine frame and movable transverse beam, the electric controller is connected with display. It is characterized by that the hydraulic press possesses a reactive power compensator and a reactive power compensation controller. The structure of said reactive power compensator is a three-phase power supply main circuit capable of making the compensation capacitance be connected into the oil pump motor by means of contactor, the reactive power compensation controller is connected with the control contactor.

Owner:TIANJIN TIANDUAN PRESS CO LTD

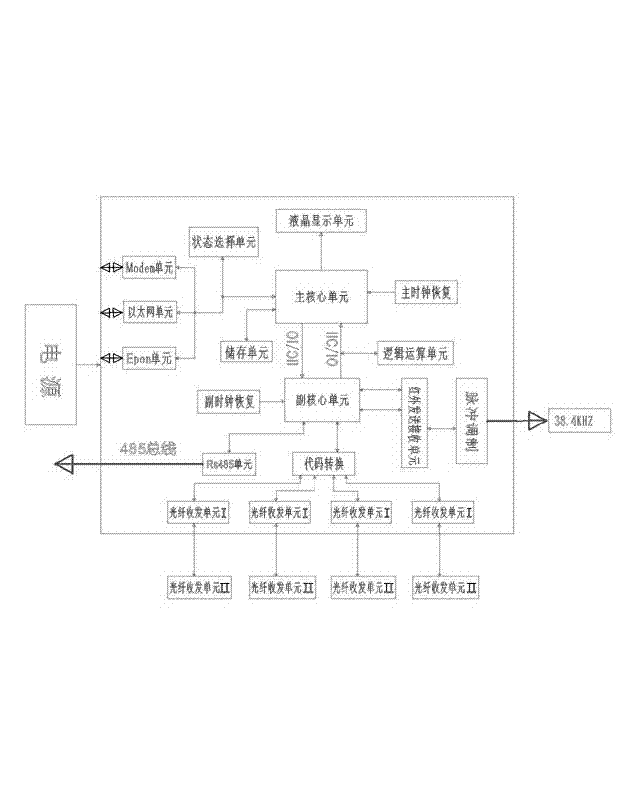

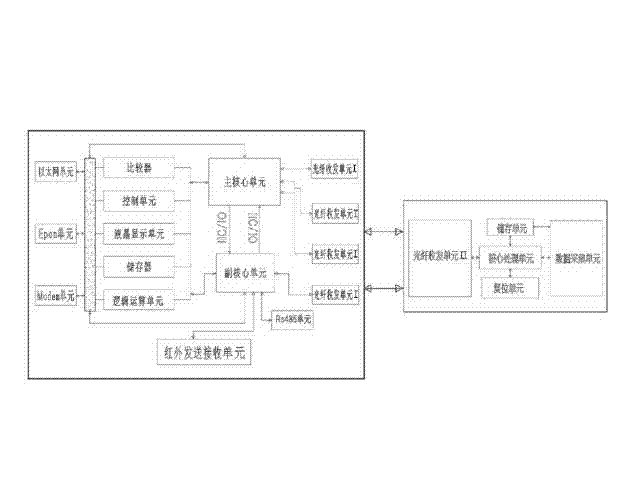

Real time remote optical fiber meter reading system

InactiveCN102867405AIncrease profitReasonable investmentNon-electrical signal transmission systemsCommunications systemData acquisition

The invention discloses a real time remote optical fiber meter reading system which is designed in modularization, flexibly matched and compatible with existing topologic structures, has the characteristics of high utilization rate of a communication channel, rational communication system investment, reduction of repeat constructions, relatively simple arrangement of wires, wide cover area and the like; the system has no subsequent operating cost, is low maintaining cost, and is capable of adapting to the existing remote meter reading wiring structure so far furthest, so as to fundamentally eliminate the problems of insufficient bandwidth caused by lower bandwidth, bad instantaneity and the like. The meter reading system disclosed by the invention comprises a power utilization information intelligent communication terminal module and a power utilization information intelligent photoelectric module, wherein the power utilization information intelligent communication terminal module at the near end sends a command through an optical fiber to control the power utilization information intelligent photoelectric module at the far end to collect data; the collected data are transmitted back to the power utilization information intelligent communication terminal module through the optical fiber, so as to be processed and finally uploaded to a client use end. The real time remote optical fiber meter reading system disclosed by the invention is applicable to the area of meter reading of power utilization information.

Owner:珠海市康定电子股份有限公司

Reeling method and system as well as a measuring apparatus

ActiveUS7799171B2Better CD-profileCost-effectivelyAnalysing solids using sonic/ultrasonic/infrasonic wavesPaper testingFiberHardness

A method and a system to control a reeling profile of a material web reel (30), when, in the forming of a material web reel (30), a web is reeled around a reeling core and when in an adjustment of CD-directional profiles of the web reel, profiling devices (8) have been applied. For adjusting quality profiles and reeling profiles of the web, profiling devices are managed with the help of profile measurings of the roller nip and / or of the profile measurings of the reel (30), which are obtained from the reel-up (2). A measuring device (40) for a measuring of a CD-directional hardness profile of the fiber web reel includes a measuring head (43), which is connected with a loading means (41, 42), which loads the measuring head against the fiber web reel. The motion course of the measuring head is linear.

Owner:VALMET TECH INC

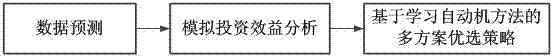

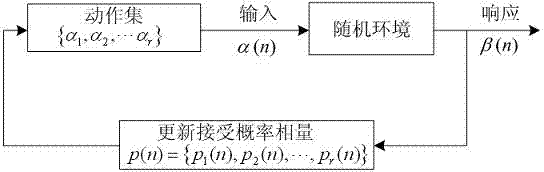

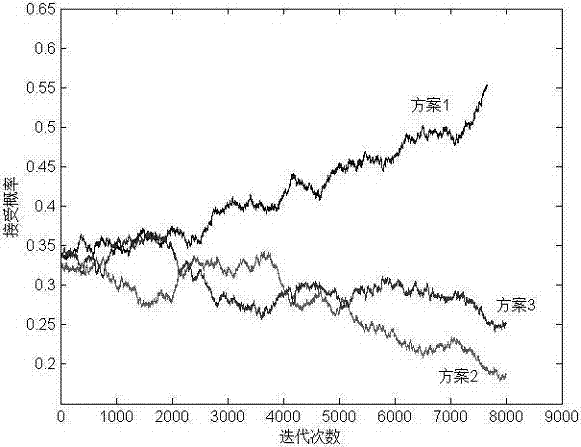

Power grid investment optimization method based on simulation investment benefit analysis and learning automatons

InactiveCN103886393AOptimize investmentInvestment objectiveForecastingSystems intergating technologiesLearning automataElectric power system

The invention relates to the technical field of electric power system planning, in particular to a power grid investment optimization method based on simulation investment benefit analysis and learning automatons. The method comprises the following steps that first, a grey prediction model is used for conducting data prediction on power grid development data; second, related indexes in an investment benefit index system are calculated according to prediction schemes of various obtained investment data through data prediction for the coming year, and then the simulation investment benefit analysis is carried out to obtain simulation investment comprehensive score results; third, the score results obtained through different schemes are optimized based on a multi-scheme optimization strategy of a learning automaton method, and finally the optimal investment scheme is obtained. The power grid investment optimization method based on the simulation investment benefit analysis and the learning automatons is beneficial to optimizing power grid investment and good in using effect.

Owner:STATE GRID CORP OF CHINA +3

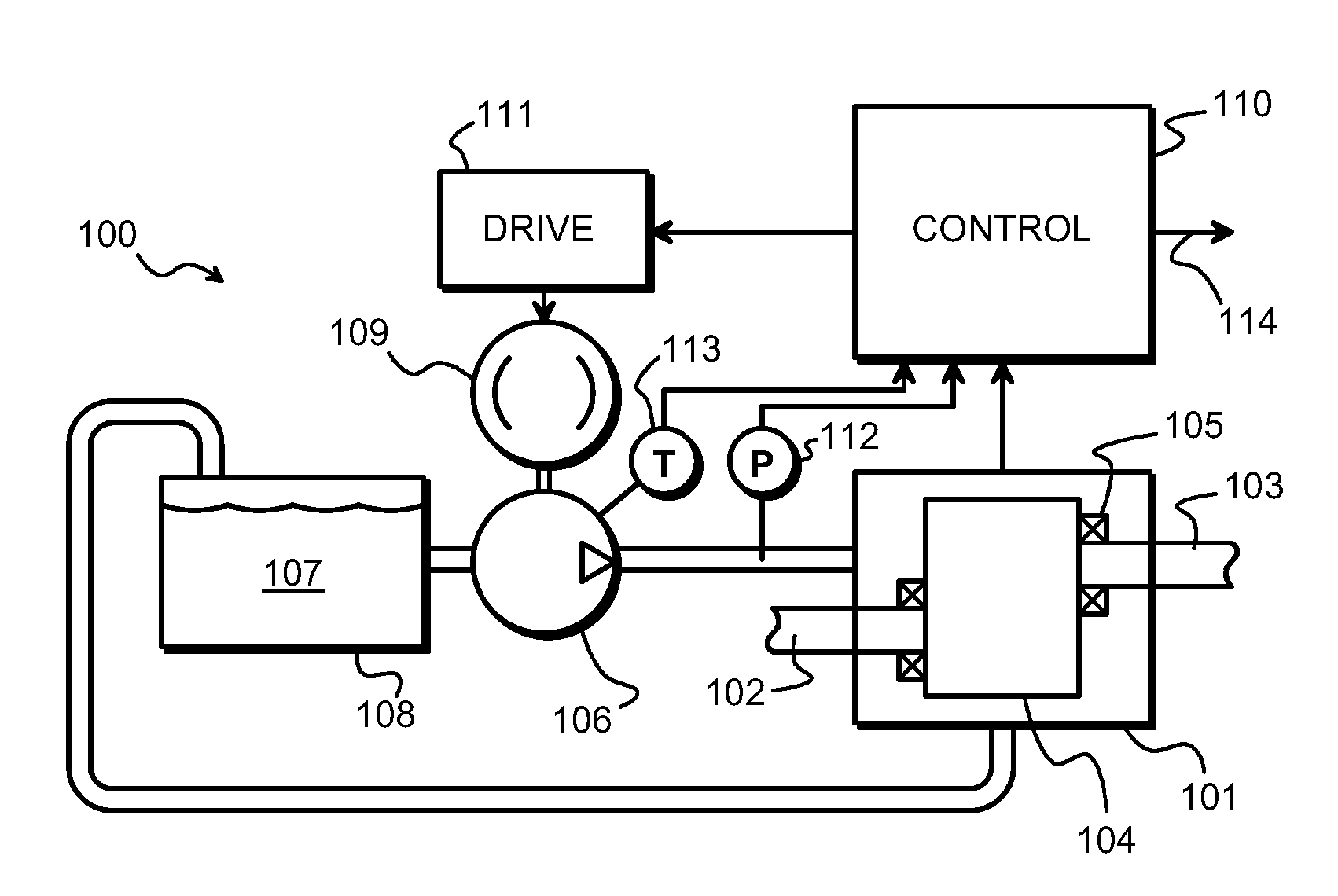

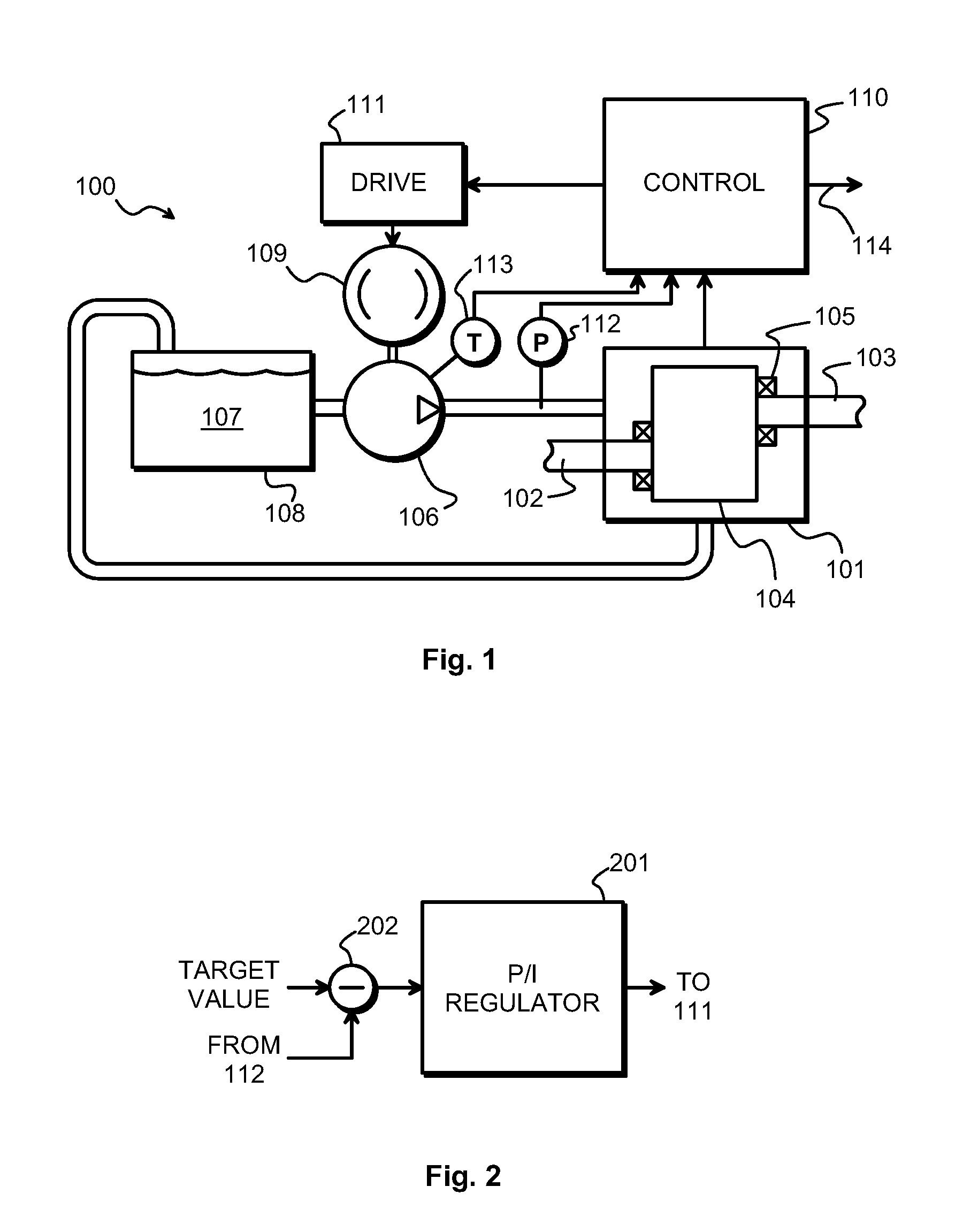

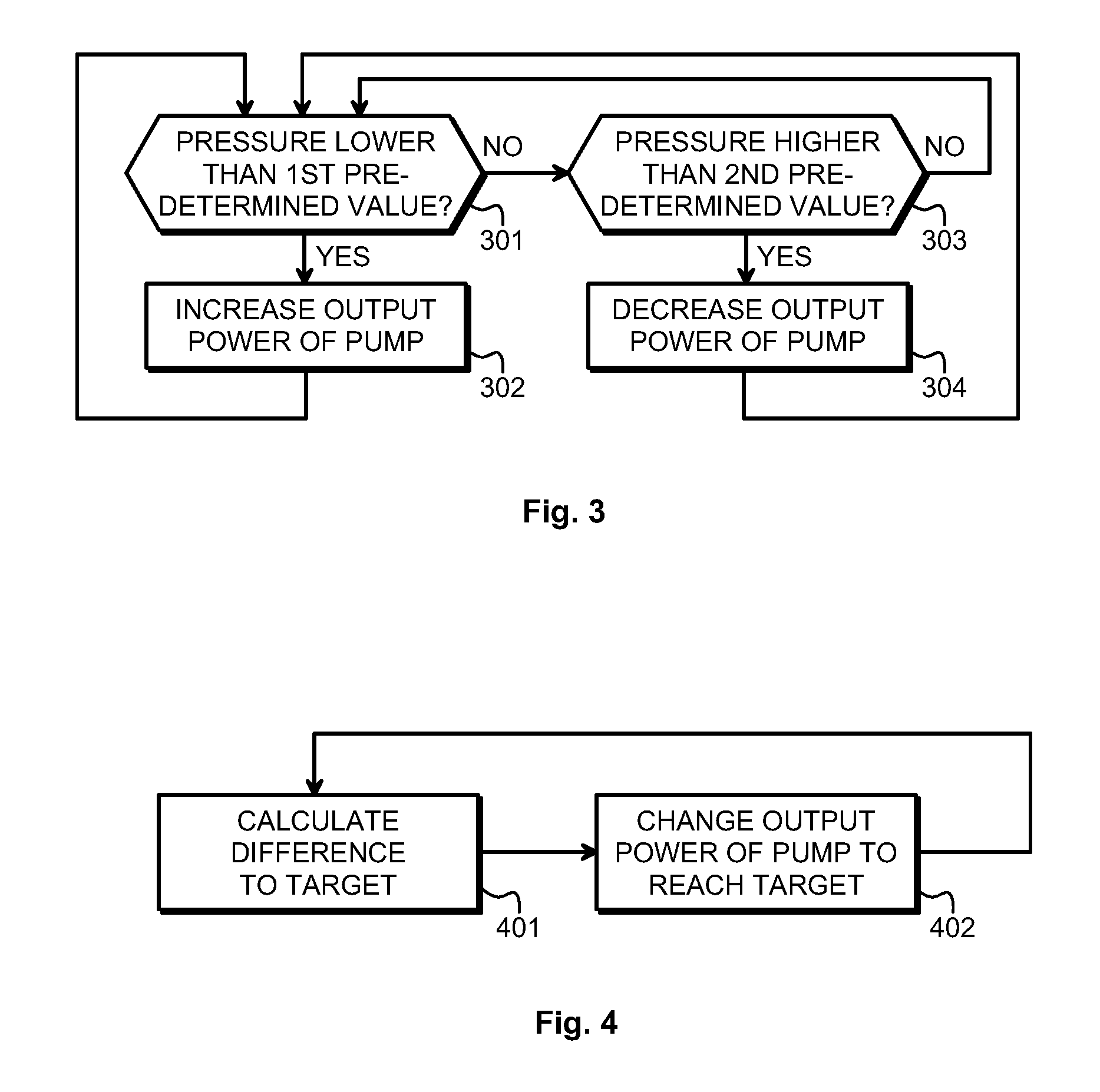

Method and arrangement for controlling the lubrication of a gear system

ActiveUS9353849B2Easy to integrateEasily scaledGear lubrication/coolingGearing controlGear systemEngineering

Owner:MOVENTAS GEARS

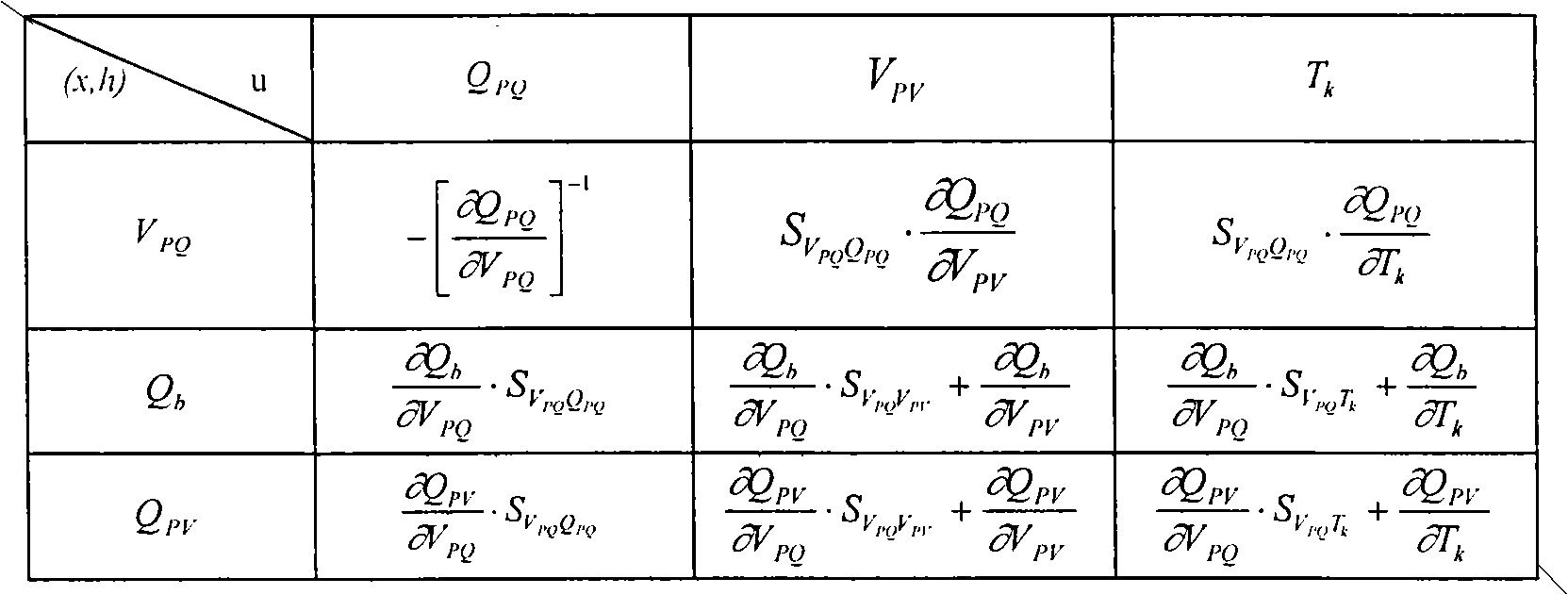

Selecting method of discrete reactive equipment based on weighting operation factors

InactiveCN102055192AAchieving automatic voltage control goalsImprove robustnessReactive power adjustment/elimination/compensationAc network voltage adjustmentElectric power systemControl objective

The invention relates to a selecting method of discrete reactive equipment based on weighting operation factors, belonging to the technical field of automatic voltage control of power systems. The method comprises the following steps of: quantizing various constraints for restricting the reactive equipment from being put into operation or cut off and effects for putting the reactive equipment into operation or cutting off the reactive equipment in a numerical way according to different importance, defining each equipment to have 7 operation factors, and calculating the corresponding intermediate variables of the values of the 7 operation factors and the corresponding weighting coefficient of each operation factor; summing by multiplying the calculated value of each operation factor by the corresponding weighting coefficient, and finally selecting the equipment with a maximum weighting operation factor X as the discrete reactive equipment for realizing the control target. By selecting the equipment with the maximum weighting operation factor, the invention better realizes the optimization and the rationalization for selection of the discrete reactive equipment.

Owner:NORTHWEST CHINA GRID +1

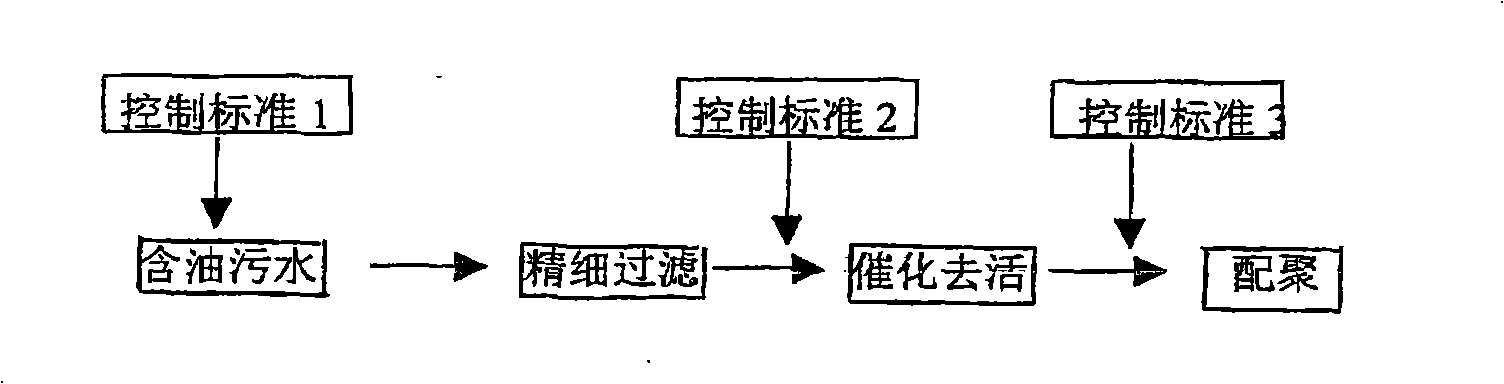

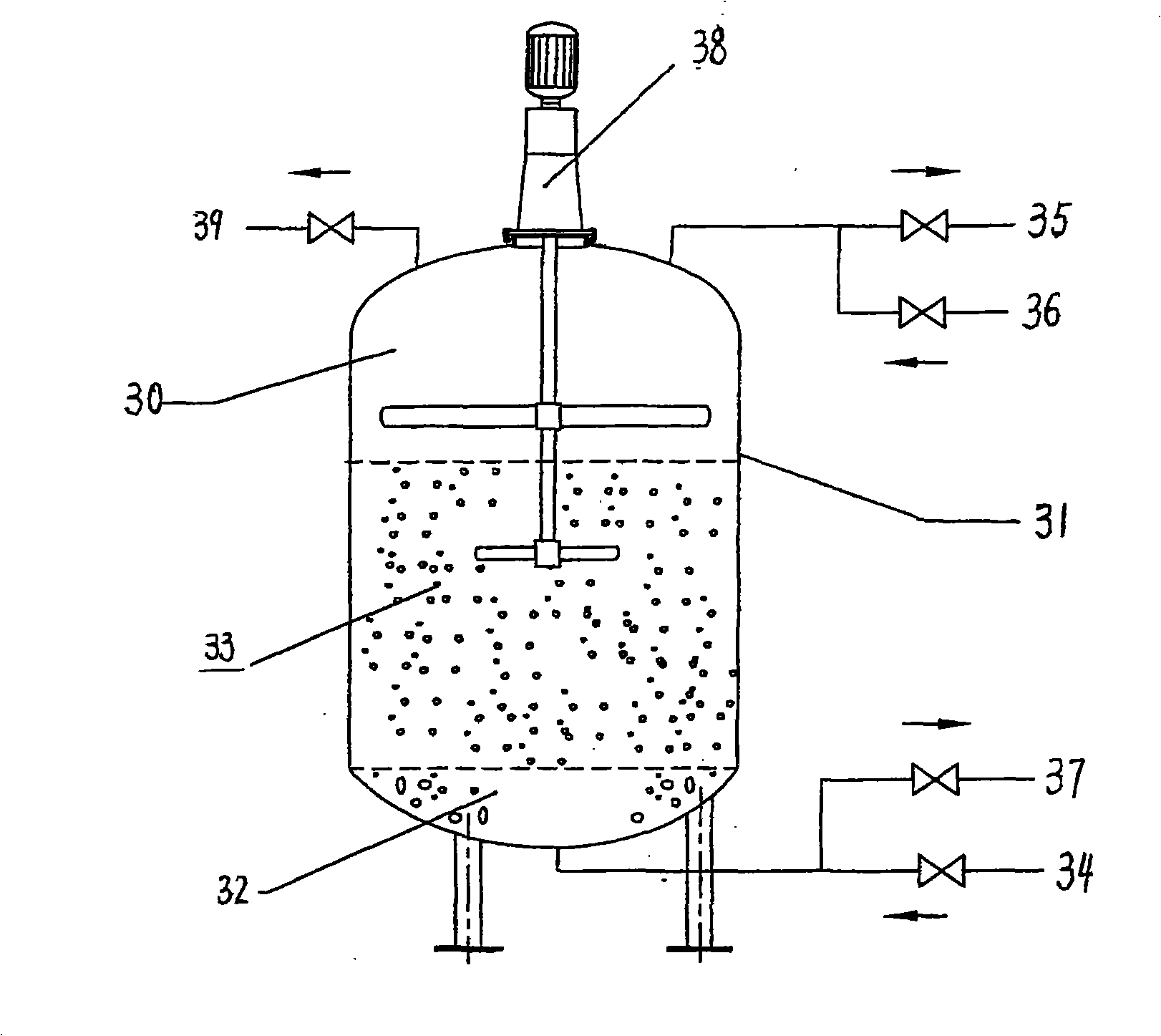

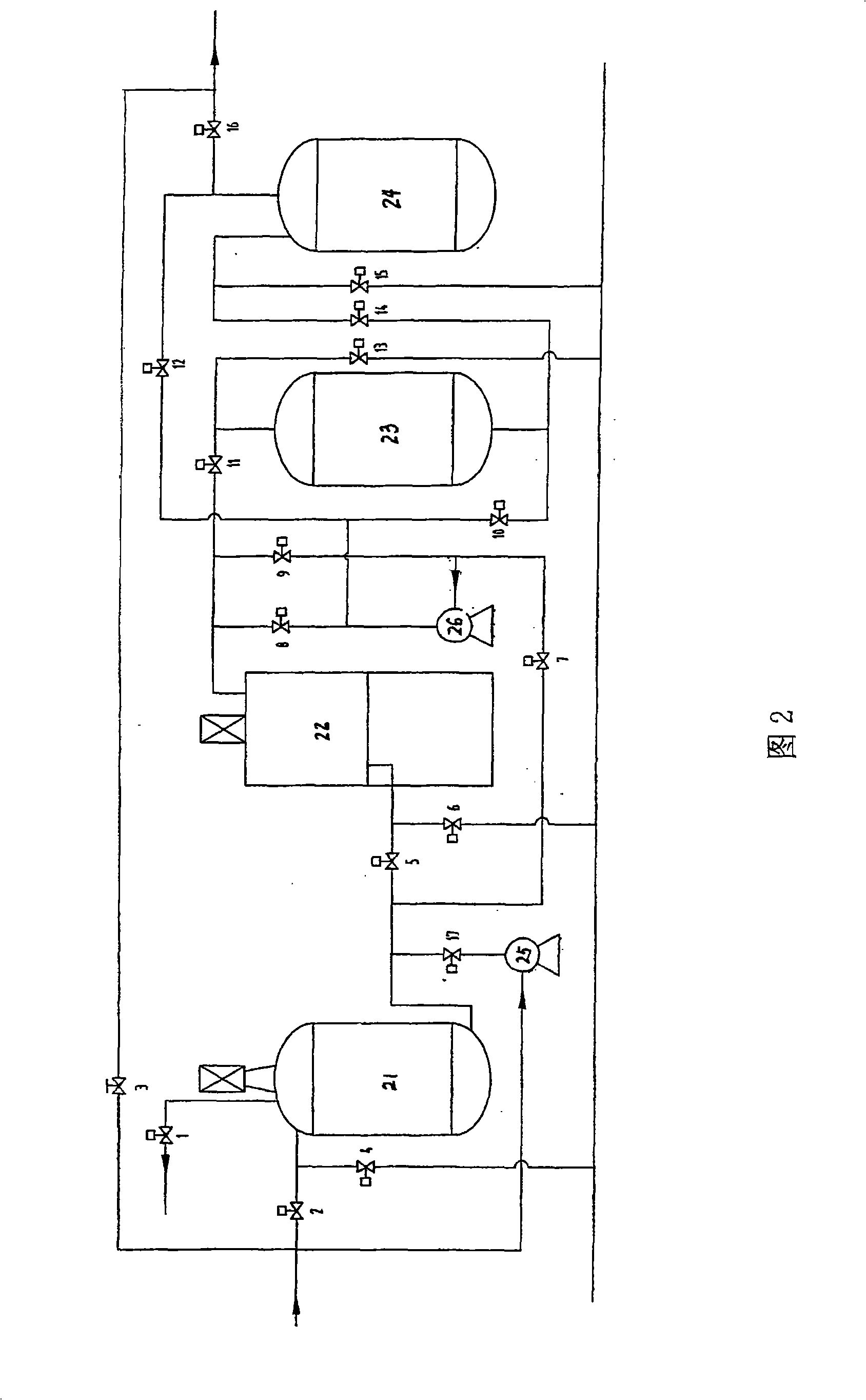

Equipment and process for preparing polymer water source by katalysis deactivation of oilfield sewage

ActiveCN101274797AMeet the protection requirementsHigh viscosityWaste water treatment from quariesMetal/metal-oxides/metal-hydroxide catalystsWater sourceWastewater

The invention provides equipment and a technique for preparing confecting polymer water sources by catalyzing wastewater in oil fields for deactivation. The equipment consists of a walnut shell filter, in which cobbles and walnut shell fillings are filled, a TCLW filter, in which fibrous bundles are filled, an iron removing tank, in which manganese sand and quartz sand fillings are filled, a catalyzing reaction tank, the structure of which is a maze and in which a catalyzer MnO2-ZnO-CeO2 / Al2O3 is filled, connecting pipelines and valves between the walnut shell filter, the TCLW filter, the iron removing tank and the catalyzing reaction tank. The lower part outlet of the walnut shell filter is connected with the lower part inlet of the TCLW filter through a pipeline, the upper outlet of the TCLW filter is connected with the top inlet of the iron removing tank through a pipeline and the bottom outlet of the TCLW filter is connected with the top inlet of the catalyzing reaction tank. The technique has stable and safe operation, simple operation, convenient management, reasonable investment, being economic and high efficient, and complies with environmental protection requirements. After catalysis and deactivation, the viscosity of wastewater confecting polymer solution is improve by over 100 percent and the rate of utilization of wastewater confecting polymer is up to 100 percent.

Owner:PETROCHINA CO LTD

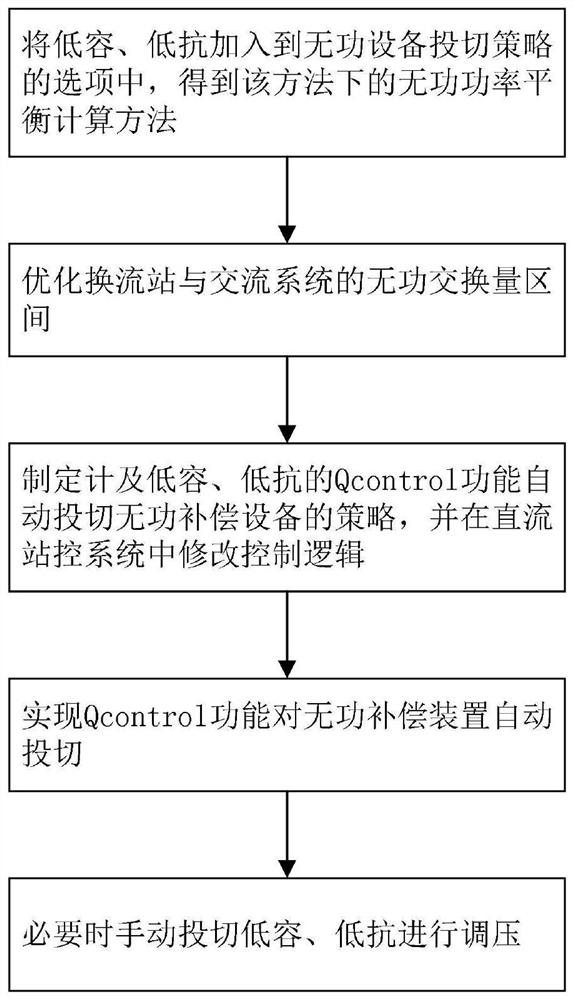

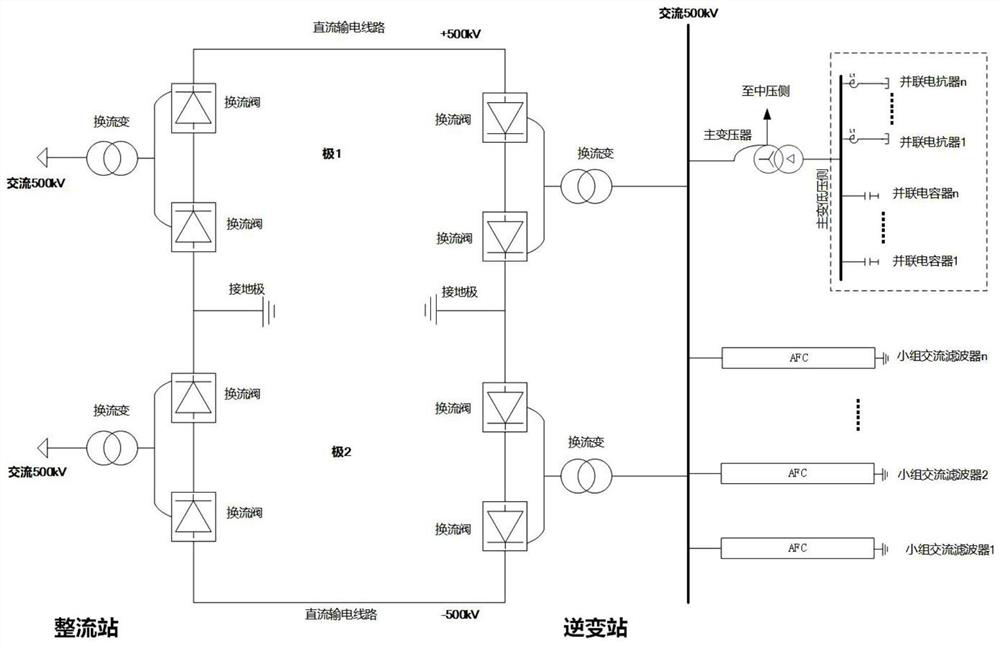

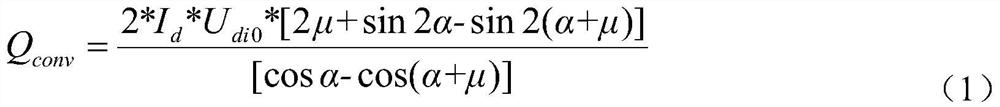

Converter station reactive power optimization method considering main transformer low-voltage side reactive power compensation device

ActiveCN111835020AReduce the number of input groupsImprove stabilityElectric power transfer ac networkReactive power adjustment/elimination/compensationVoltage regulationCapacitance

The invention discloses a converter station reactive power optimization method considering a main transformer low-voltage side reactive power compensation device, and the method comprises the steps: adding a low capacitor and a low reactor into an option of a reactive power equipment switching strategy, and obtaining a reactive power balance calculation method under the method; optimizing a reactive exchange capacity interval between the converter station and the alternating current system; formulating a strategy of automatically switching reactive power compensation equipment considering a Qcontrol function of low capacitance and low reactance, and modifying control logic in a direct current station control system; realizing the automatic switching of the reactive power compensation device by the Qcontrol function; and when necessary, manually switching low capacity and low reactance for voltage regulation. According to the invention, reactive compensation capabilities of reactive compensation devices with low capacitance, low reactance and the like are utilized in reactive adjustment of the high-voltage direct current system, the reactive adjustment gradient is reduced, and meanwhile, by adjusting the reactive exchange capacity interval of the converter station and the alternating current system, the input group number of alternating current filters is reduced, the resource configuration is optimized, and the voltage control capability is improved.

Owner:中国南方电网有限责任公司超高压输电公司柳州局

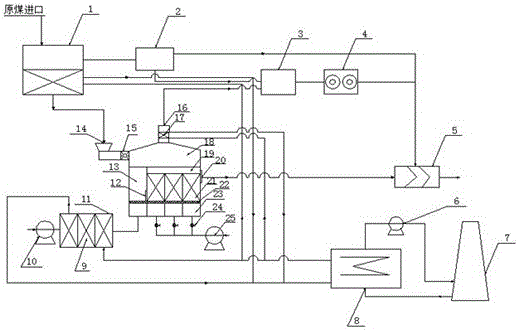

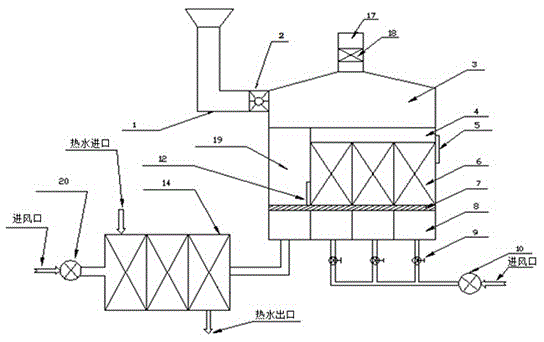

Clean and efficient gradient screening internal thermal fluidized bed coal moisture control process

InactiveCN105733635AWide adaptability to humidityReliable operation regulationCoke ovensScreening proceduresHeat carrier

The invention discloses a clean and efficient gradient screening internal thermal fluidized bed coal moisture control process.An internal thermal fluidized bed dryer serves as a main device; in the coal moisture control procedure, a coal particle diameter gradient screening procedure, a selective smashing procedure and a coal fly ash recovering and pelleting procedure are included; step-by-step screening of coal particle diameters is realized in the mode of mechanical screening through a low-temperature variable speed fluidized bed, orderly control over coal particle smashing and drying and coal dust is ensured, repeated processing of coal materials is reduced, and energy is reasonably input in the technological process.Air with strong moisture carrying capacity and high-temperature hot water with high thermal capacity are selected as a fluidizing medium and a heat transfer medium respectively according to the physical properties of the air and the high-temperature hot water.Compared with a traditional fluidized bed coal moisture control process, the functions of a heat carrier, a moisture carrier and the fluidizing medium in the coal moisture control process are separated, flexible control and precise processing can be achieved in terms of control and regulation, and the process is particularly suitable for moisture control over dryness of high-humidity coal materials.

Owner:WUXI YIEN TECH

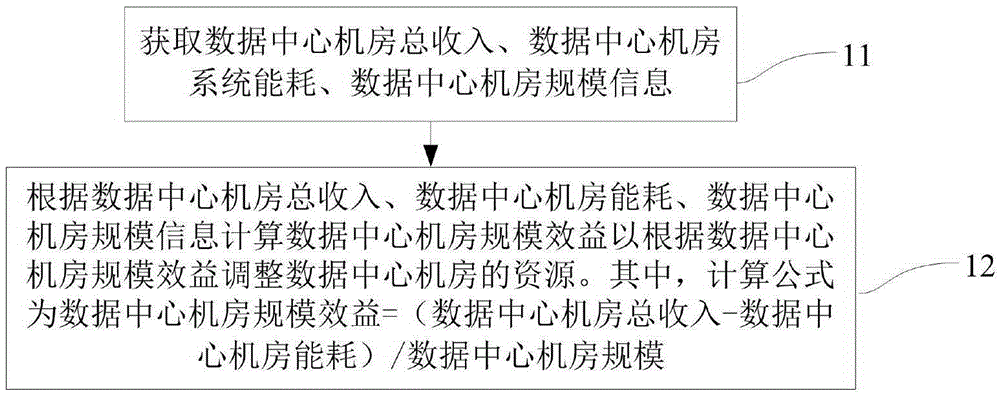

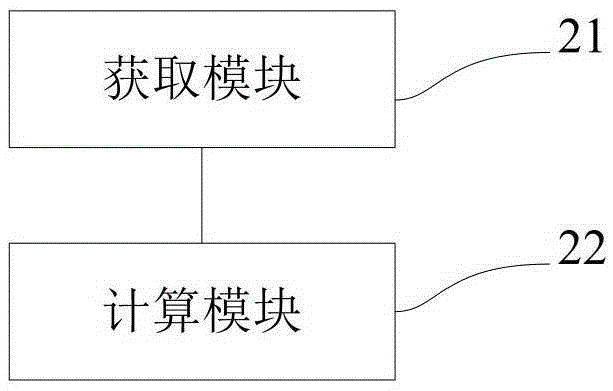

Method and apparatus for measuring and calculating energy utilization efficiency of data center

InactiveCN105825287AImprove accuracyReasonable investmentForecastingEnergy consumptionEconomic benefits

The present invention provides a method and device for measuring and calculating the energy utilization efficiency of a data center. The method includes: obtaining the total income of the data center computer room, the energy consumption of the data center computer room, and the scale information of the data center computer room; according to the total income of the data center computer room, the According to the energy consumption of the data center computer room and the scale information of the data center computer room, the scale benefit of the data center computer room is calculated to adjust the resources of the data center computer room according to the scale benefit of the data center computer room, wherein the scale benefit of the data center computer room=(the data center Total income of the computer room - energy consumption of the computer room of the data center) / scale of the computer room of the data center. The present invention comprehensively considers the influence of factors such as energy consumption costs, business income, and computer room scale on energy consumption benefits, improves the accuracy of energy consumption benefit calculation of data center computer rooms, and helps operators find inefficient and loss-making computer rooms and take rectification measures in a timely manner. Improve the economic benefits of the data center computer room.

Owner:GUANGDONG ESHORE TECH

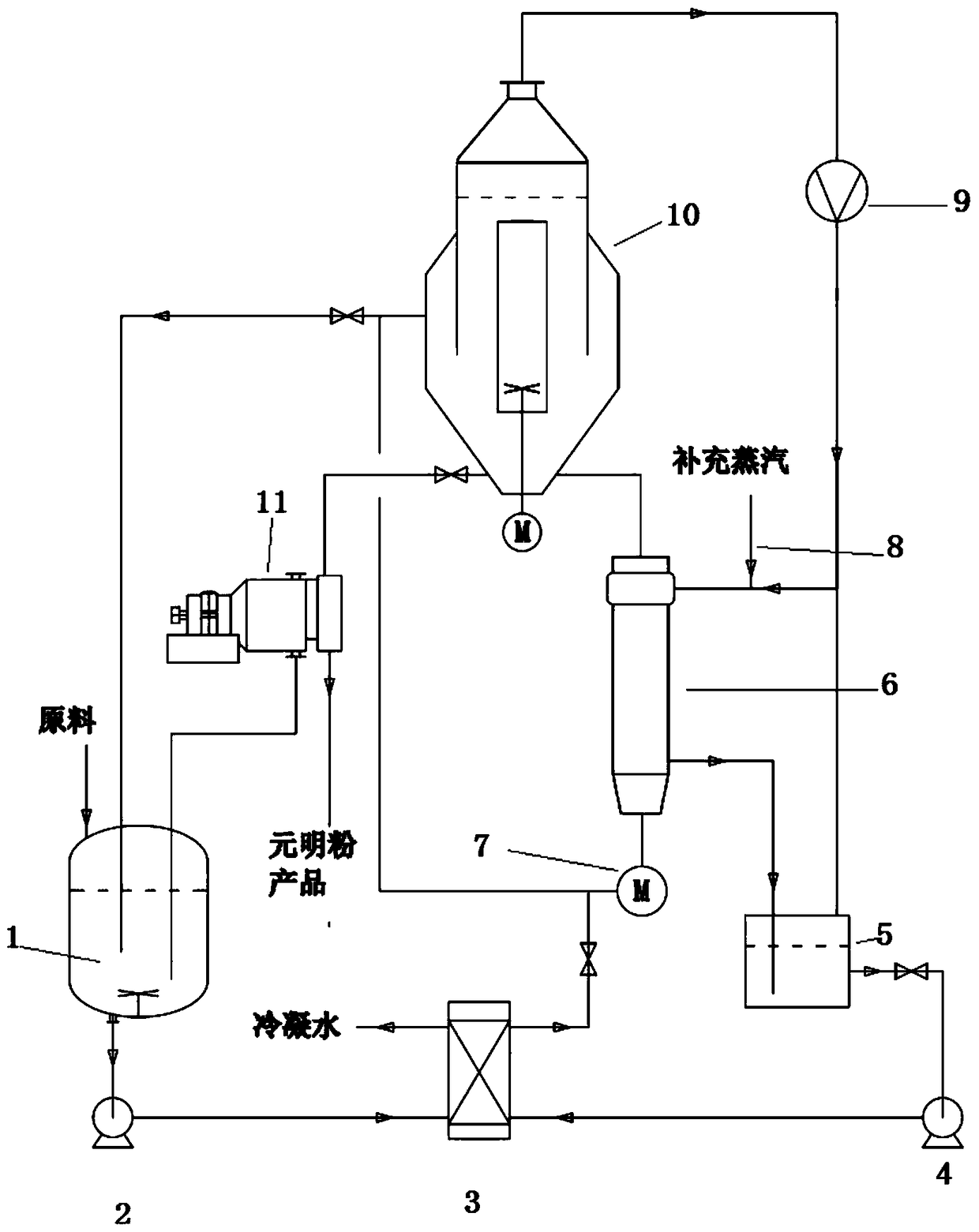

Anhydrous sodium sulfate production equipment

InactiveCN109502610AAvoid easy cloggingReduce pollutionAlkali metal sulfite/sulfate dehydrationEvaporationCondensate pump

The invention provides anhydrous sodium sulfate production equipment which comprises a nitrate dissolving tank, a feed pump, a first heat exchanger, a circulating pump, a second heat exchanger, a condensate pump, a centrifugal machine, a DTB evaporation crystallizer, an MVR (Mechanical Vapor Recompression) compressor and a steam supplementing pipeline. According to the anhydrous sodium sulfate production equipment disclosed by the invention, the nitrate dissolving energy consumption is reduced by utilizing heat of the feed liquid discharged by the DTB evaporation crystallizer and the mother liquor discharged by the centrifugal machine, the anhydrous sodium sulfate production equipment is simple in technical process, compact in equipment arrangement and reasonable in energy utilization, andmultiple advantages of saving investment, shortening the process flow, reducing the cost, comprehensively utilizing resources, protecting the environment and the like are fully achieved; moreover, the anhydrous sodium sulfate production equipment has the advantages that the product liquidity is excellent, the stock bin is difficult to block, the stored material is difficult to agglomerate, the drying energy consumption is reduced, the dust pollution is reduced, the product cost is low.

Owner:ENG TECH INST CO LTD OF CNSIC

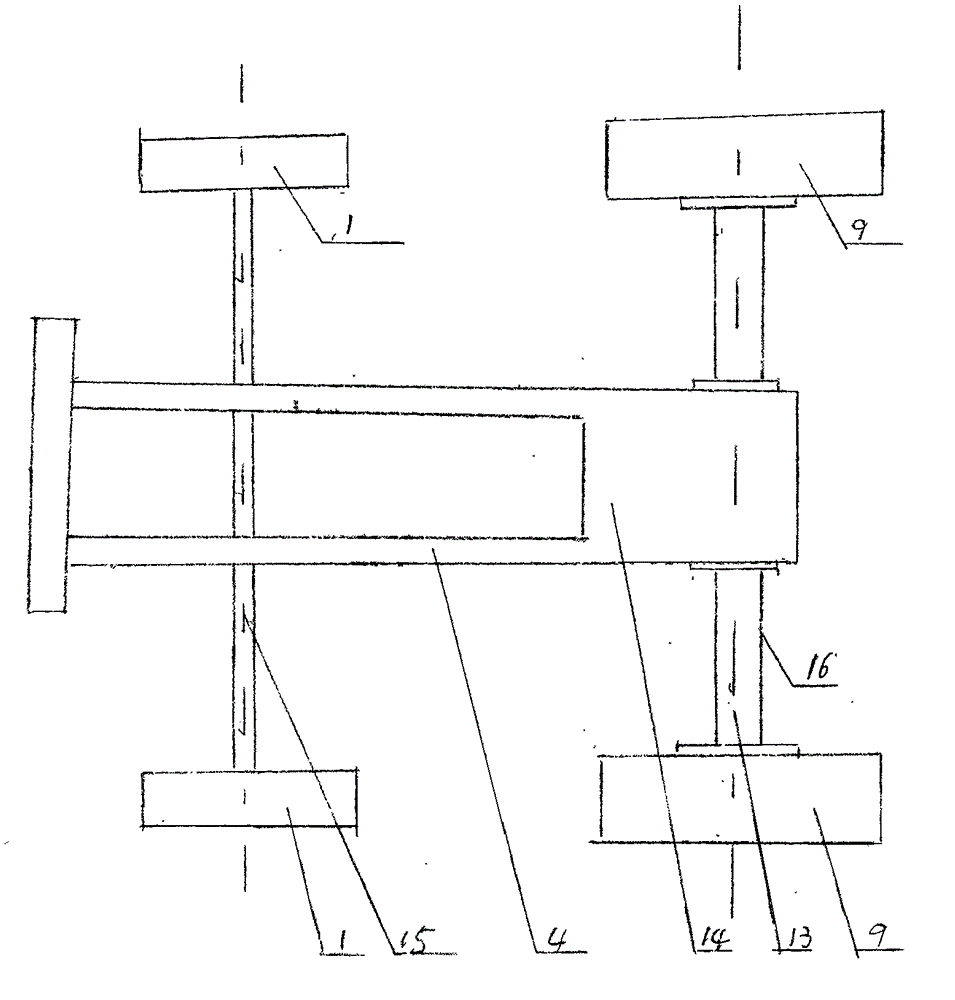

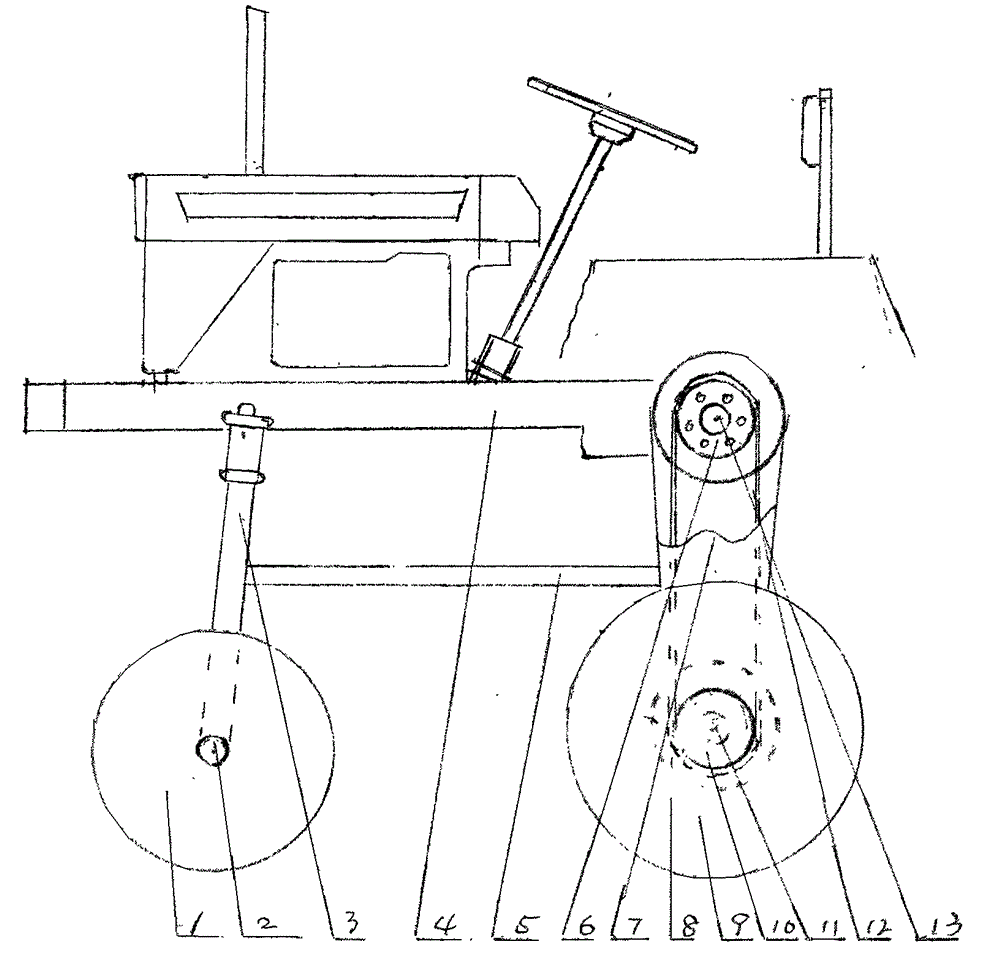

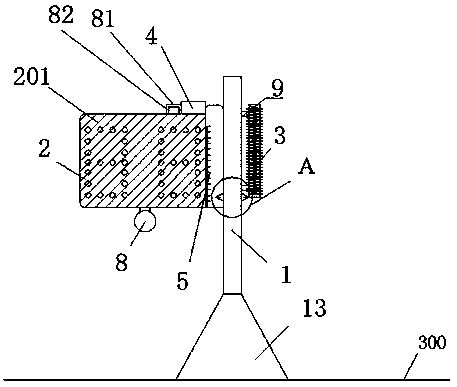

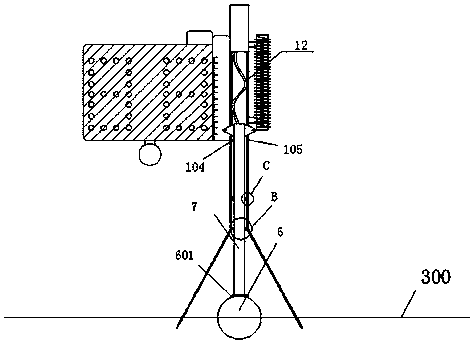

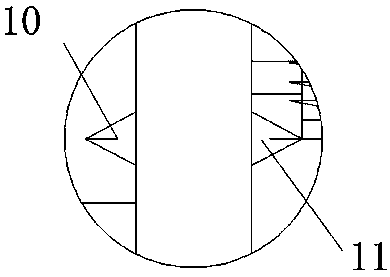

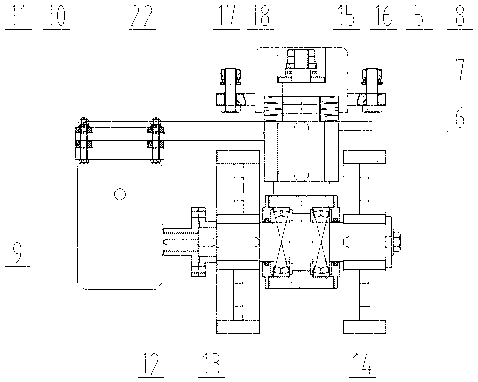

High-clearance double-shaft wheel tractor

The invention provides a high-clearance double-shaft wheel tractor which fills the blank that no applicable mechanisms are provided for later field management of dry crops. The high-clearance double-shaft wheel tractor can perform a plurality of middle and later working processes in a dry land, such as fertilizing and chemicals spraying, and has the characteristics of being high in mechanical efficiency, low in cost, advanced, applicable, practical, and high in social benefit and economic benefit. The high-clearance double-shaft wheel tractor is featured in the proposing of a high-clearance concept, the breakthroughs in technology of the tractor, as well as the core technologies of front and rear axis assemblies. The high-clearance double-shaft wheel tractor is characterized by comprising a (1) front wheel, a (2) front wheel shaft, a (3) front heightening upright arm, a (4) main rack, a (5) fixing connecting arm, a (6) chain wheel, a (7) rear heightening upright arm, a (8) brake assembly, a (9) rear wheel, a (10) lower chain wheel, a (11) driven shaft, a (12) chain, a (13) power driving shaft, a (14) gear box, a (15) front shaft and a (16) semi-axis outer sleeve. The high-clearance double-shaft wheel tractor has the features that the labor and material input can be decreased, and a management method is optimized; the efficiency of the materials and mechanisms can be improved, and the crop quality can be improved; the income is increased while the input is decreased; the pollution of an existing mode on the soil and underwater can be greatly reduced; extremely high social benefit and economic benefit are brought.

Owner:郝忠双

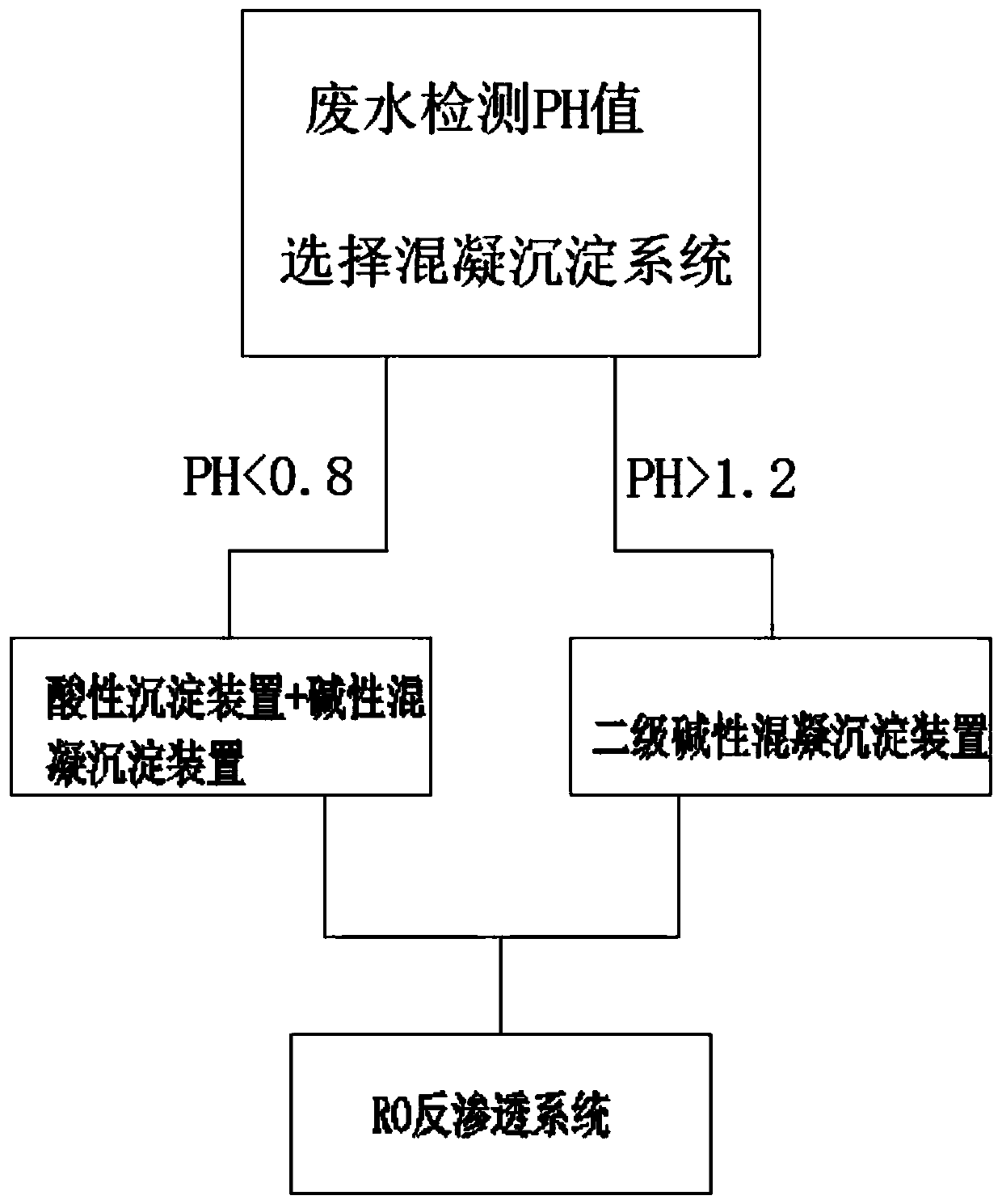

Treatment method and device for stainless steel electrolytic polishing wastewater

PendingCN109987752AImprove degradation efficiencyImprove stabilityWater treatment parameter controlWater contaminantsElectrolysisReverse osmosis

The invention discloses a treatment method and device for stainless steel electrolytic polishing wastewater. The method comprises the following steps: detecting the pH value of the wastewater, performing classification according to different pH values, and putting the classified wastewater into different coagulation sedimentation systems; selecting an acidic sedimentation device + an alkaline coagulation sedimentation device for the electrolytic wastewater with original wastewater water quality acidity pH of < 0.8; selecting a two-stage alkaline coagulation sedimentation device for the electrolytic wastewater with original wastewater water quality acidity pH of > 1.2; and performing solid-liquid separation in the coagulation sedimentation system, performing advanced treatment on the treated wastewater by using an reverse osmosis (RO) system, and performing discharge or performing recycling. The treatment method and device for the stainless steel electrolytic polishing wastewater provided by the invention have scientific and reasonable design, effectively treat the stainless steel electrolytic polishing wastewater, realizes recycling, rationally select the combined process and a coagulating agent according to different wastewater characteristics, emission limit values and resource requirements, and achieve a plurality of targets such as reasonable investment, simple and convenient management, high environmental benefits and low costs.

Owner:广州长晟环保有限公司

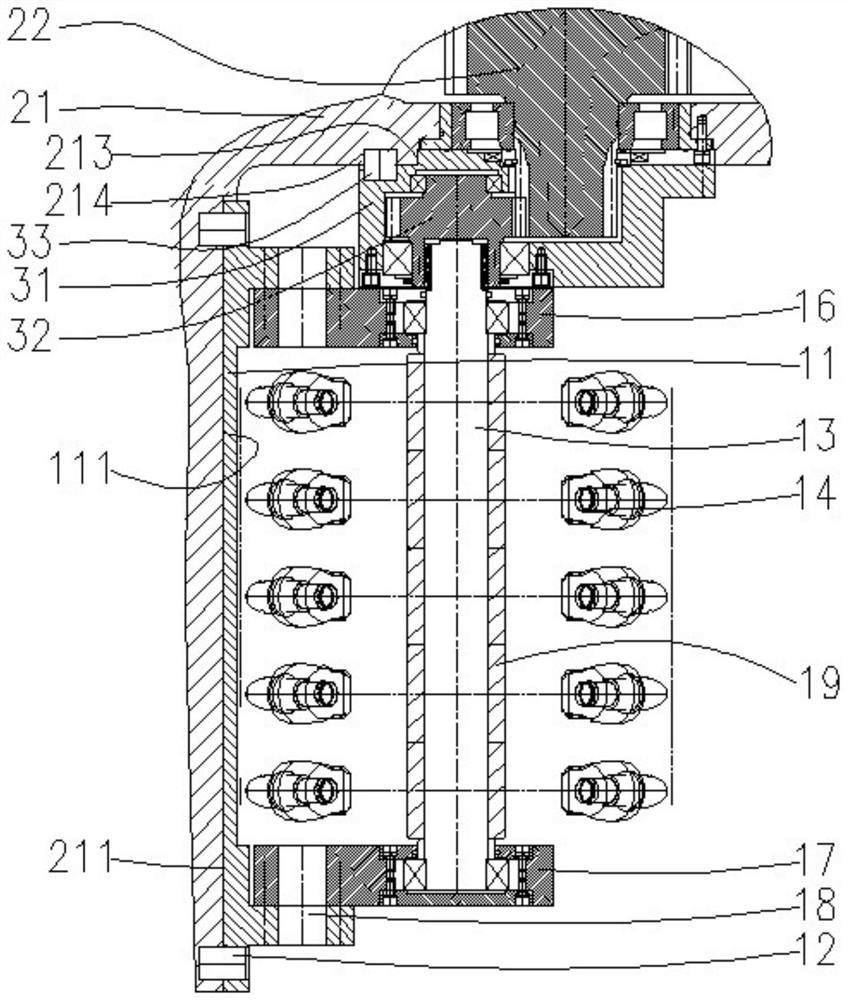

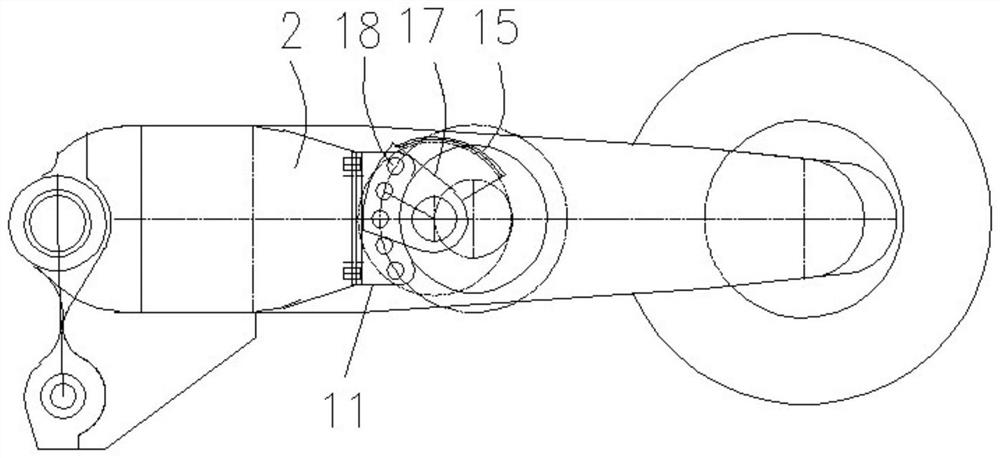

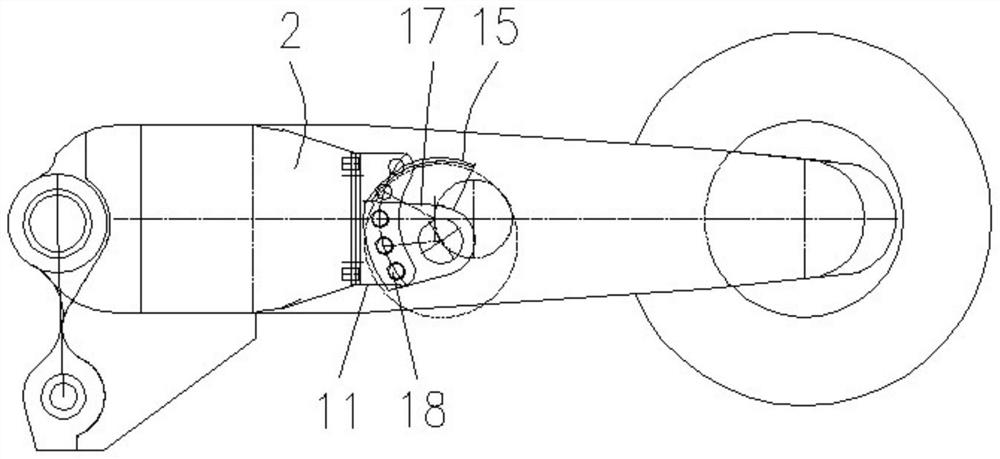

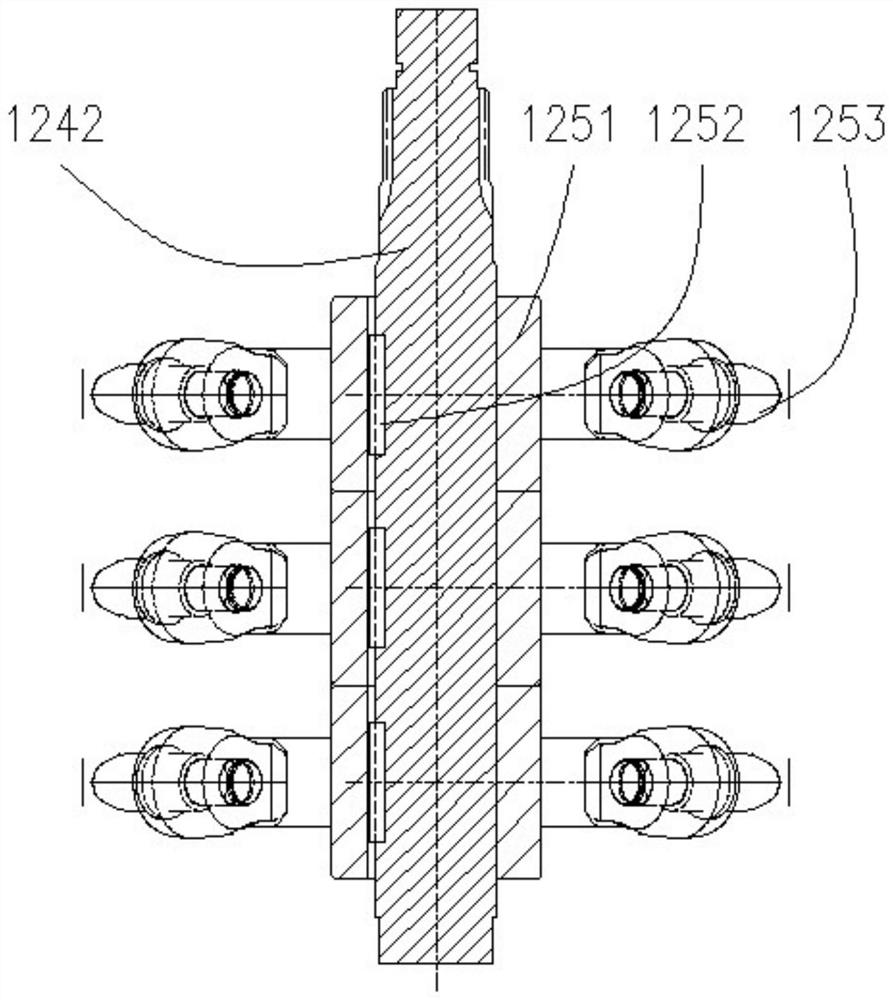

Split type crushing mechanism with rocker arm power

PendingCN112879006ASimple structureReduce space consumptionSlitting machinesGear wheelClassical mechanics

The invention relates to a split type crushing mechanism with rocker arm power. The split type crushing mechanism comprises a support, a connecting seat, a crushing tooth assembly and a mining machine rocker arm, wherein the support comprises a base, a front supporting plate and a rear supporting plate; the base and the connecting seat are fixed on the rocker arm; the crushing tooth assembly comprises a rotating shaft, a plurality of shaft sleeves and crushing teeth; the shaft sleeves sleeve the rotating shaft side by side; the crushing teeth are arranged on the shaft sleeves; the front part and the rear part of the rotating shaft are respectively supported on the front supporting plate and the rear supporting plate in a rotating manner; the front end of the rotating shaft penetrates through the front supporting plate and is positioned in an inner cavity of the connecting seat; the rear end of a transmission gear in the rocker arm extends out of the rocker arm and is positioned in the inner cavity of the connecting seat; the rear end of the transmission gear is in transmission connection with the front end of the rotating shaft through a transmission system; the front supporting plate and the rear supporting plate can be arranged at different positions of the base; and the connecting seat can also be arranged at different positions of the rocker arm. The split type crushing mechanism can be used for a mining machine for mining a thin ore bed or a high-grade thin ore bed, and rocks are effectively crushed, so that the rocks can smoothly pass through the lower part of the mining machine rocker arm, and accumulation is avoided.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

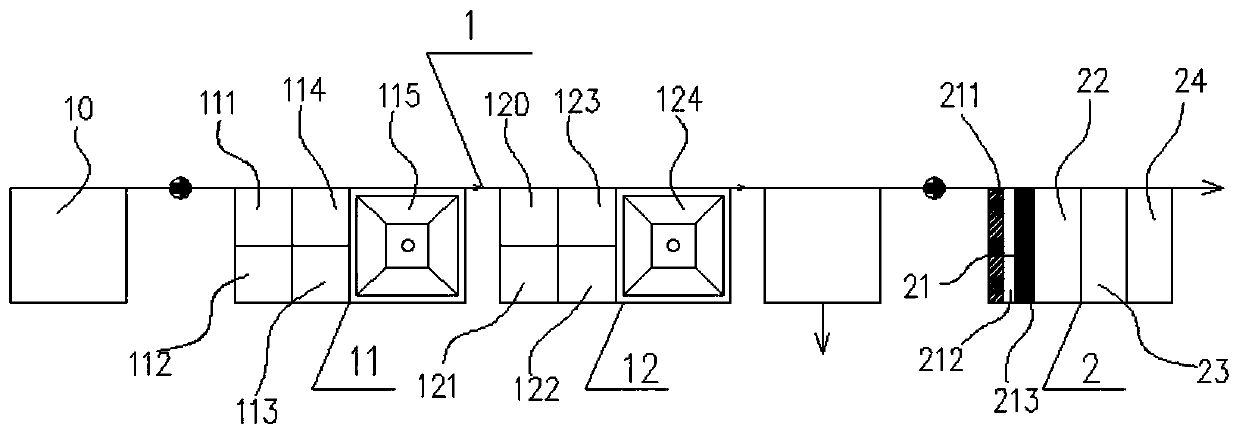

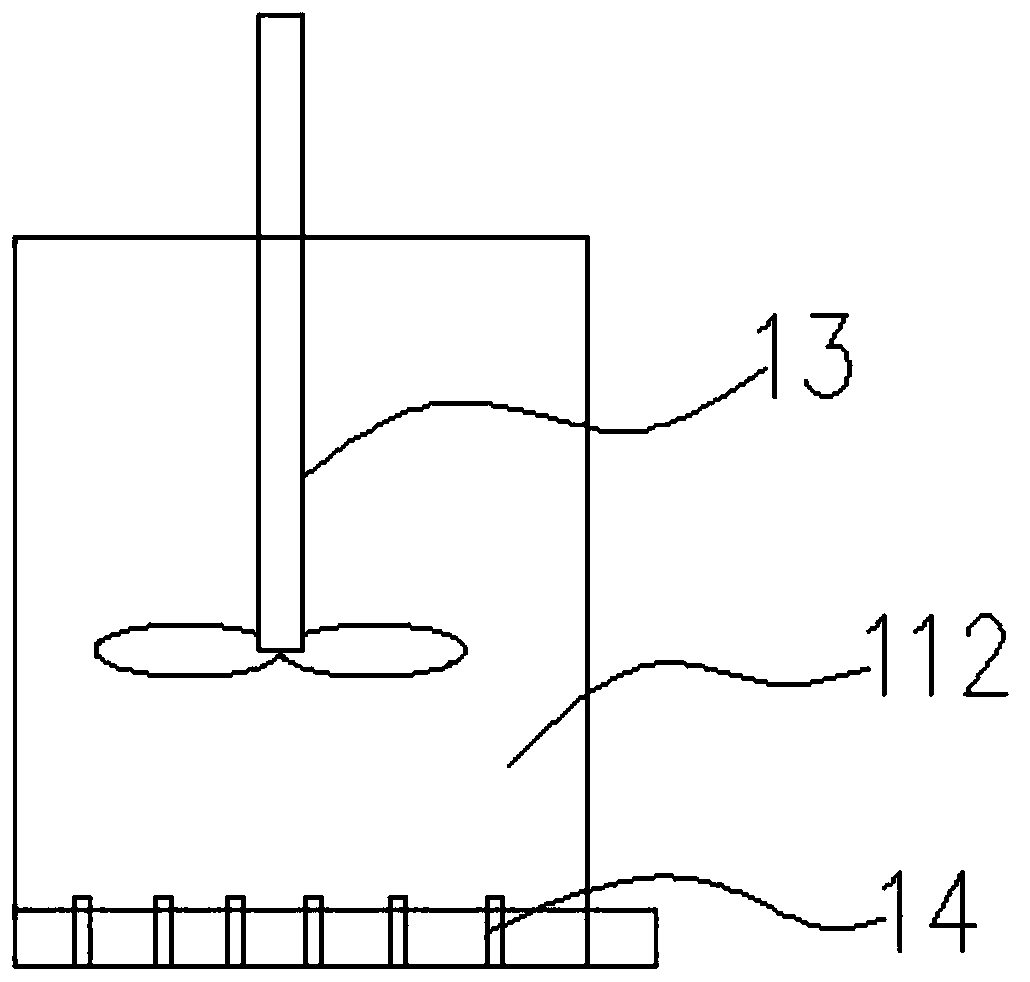

Novel sewage treatment device

The invention discloses a novel sewage treatment device which comprises a main pipe. The main pipe is arranged in a sewage treatment pond, a transverse plate is fixedly mounted on the lower portion ofthe rear end of the main pipe and is fixedly provided with a mounting plate which is positioned at the other end of the main pipe, an electronic screen is arranged on the left side of the outer surface of the main pipe and is close to the top of the left side of the outer surface of the main pipe, a meter scale is arranged on the right side of the front end surface of the electronic screen, a controller is arranged on the right side of the top of the electronic screen, a waterproof lamp is arranged in the middle of the bottom of the electronic screen, two connecting arms are symmetrically arranged on the right side of the main pipe in the up-down directions and are close to the top of the right side of the main pipe, and a slide rheostat is fixedly arranged at the end, which is far away from the main pipe, of each connecting arm. The novel sewage treatment device has the advantages that the novel sewage treatment device is simple in integral structure and low in manufacturing cost, and accurate numerical values can be automatically displayed by the electronic screen according to the heights of sewage top surfaces.

Owner:罗志江

Device for coking coal stage drying step humidify regulating process

ActiveCN105647557AGuaranteed installation and maintenanceGuarantee normal productionDrying solid materials with heatCoke ovensAir preheaterProcess engineering

The invention discloses a device for a coking coal stage drying step humidify regulating process. The device comprises a first-stage humidify regulating process loop and a second-stage humidify regulating process loop, wherein the first-stage humidify regulating process loop comprises a first-stage fluidization air chamber (19), an air preheater (14) and a first fluidization fan (20), wherein no coiled pipe heating module is arranged in the first-stage fluidization air chamber (19), and a layer of bed materials with the thickness being 500 to 600mm is arranged at the bottom; the second-stage humidify regulating process loop comprises a second-stage fluidization air chamber (6) and a second fluidization fan (10); the second-stage fluidization air chamber (6) mainly consists of a plurality of humidify regulating modules; a coiled pipe heater is arranged in each humidify regulating module. The device has the advantages that the stage drying step humidify regulation is realized through two stages of humidify regulating process loops, so that the device has wide coal humidify applicability; the coal dust generation and elutriation can be orderly controlled; energy can be fed in a step way according to the technological process; the system operation regulation is reliable and flexible; the energy saving performance is high.

Owner:WUXI YIEN TECH

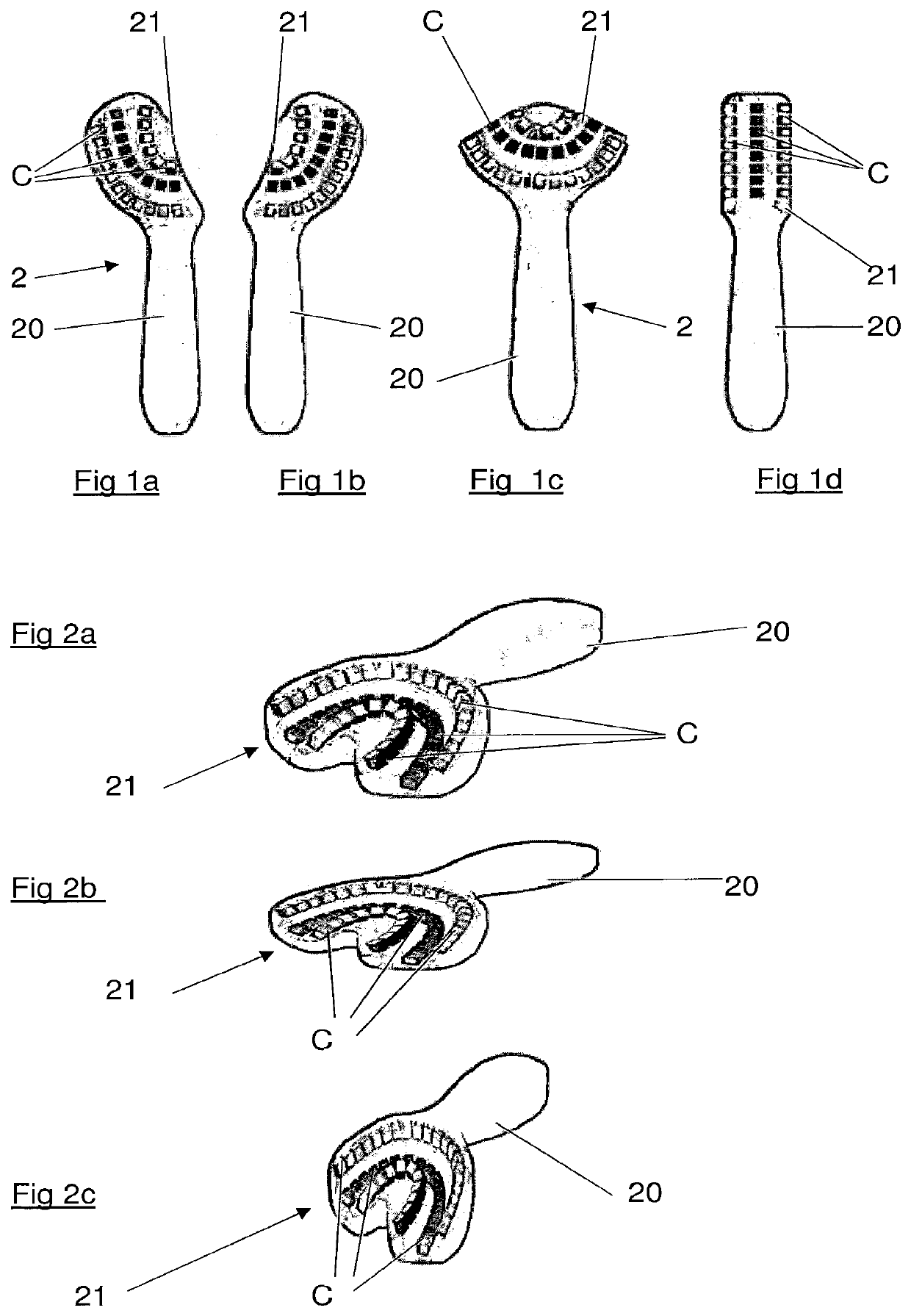

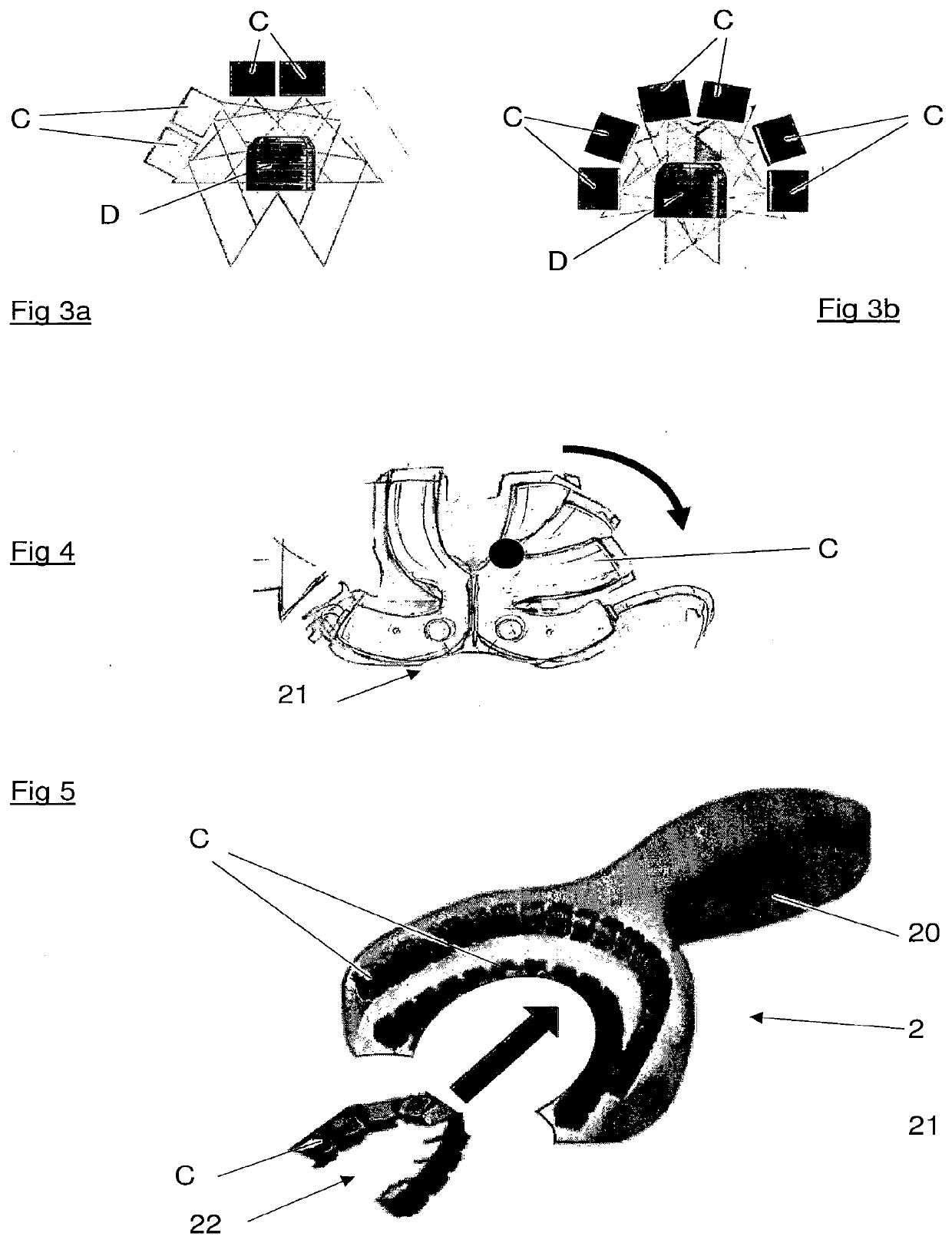

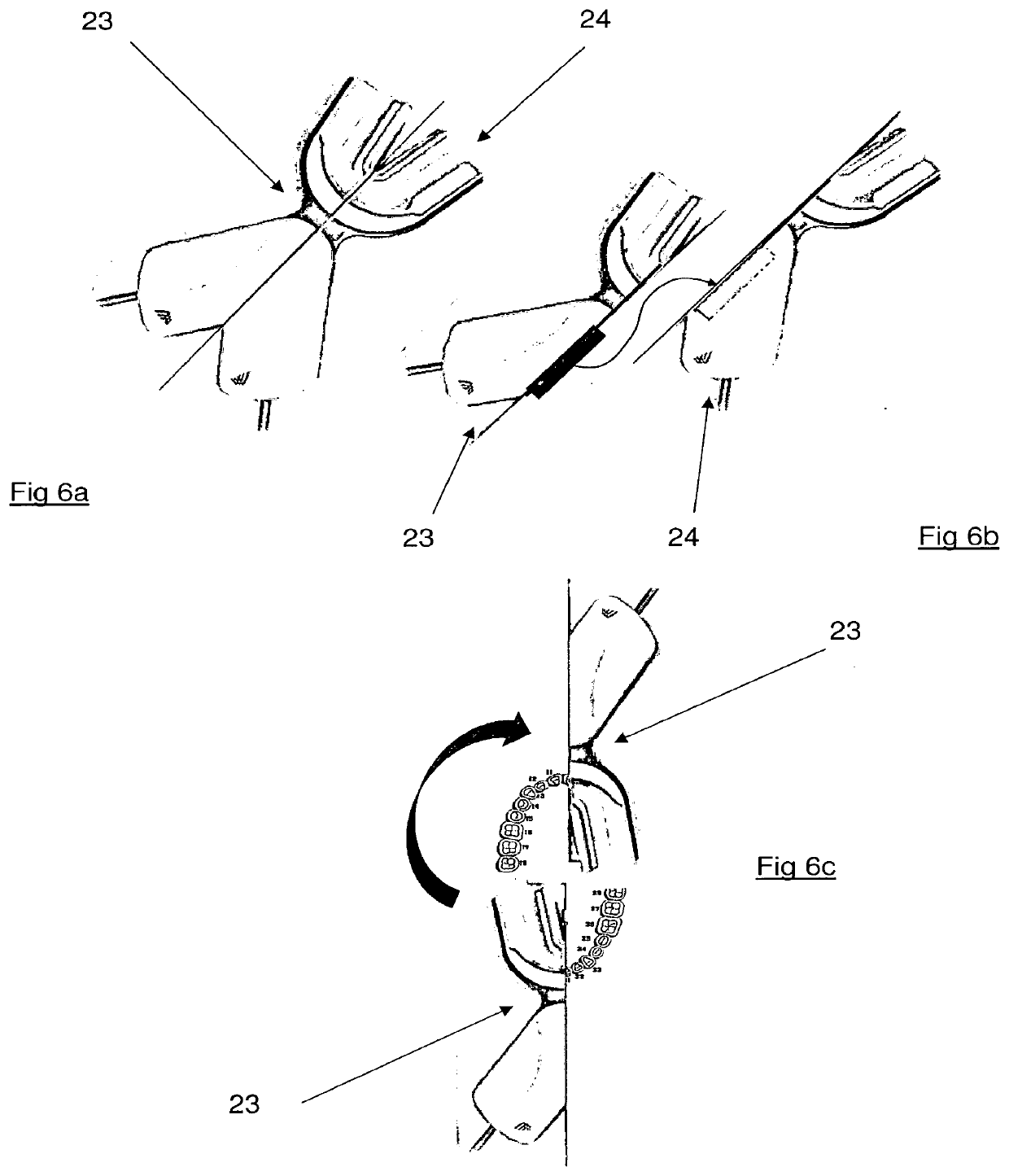

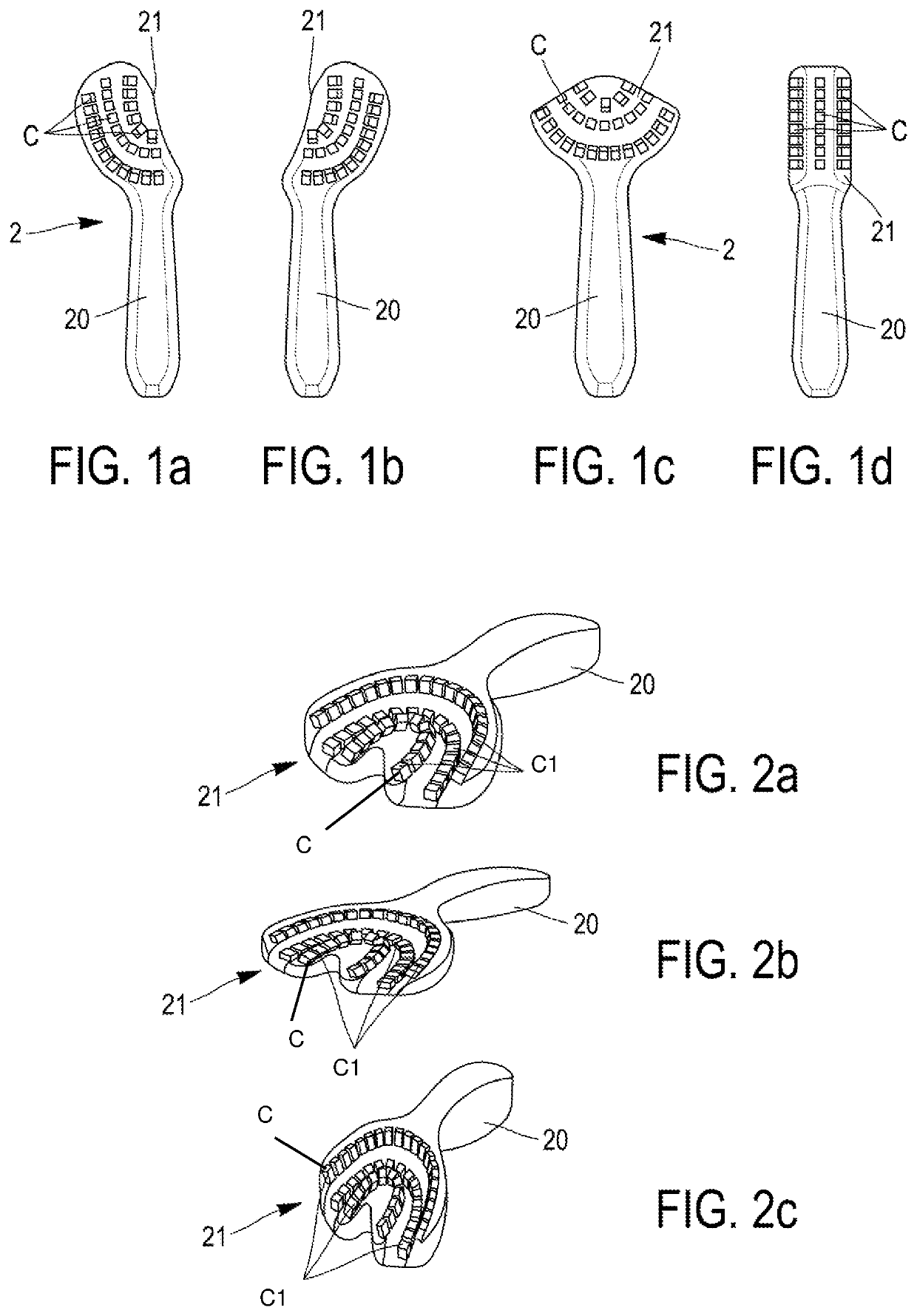

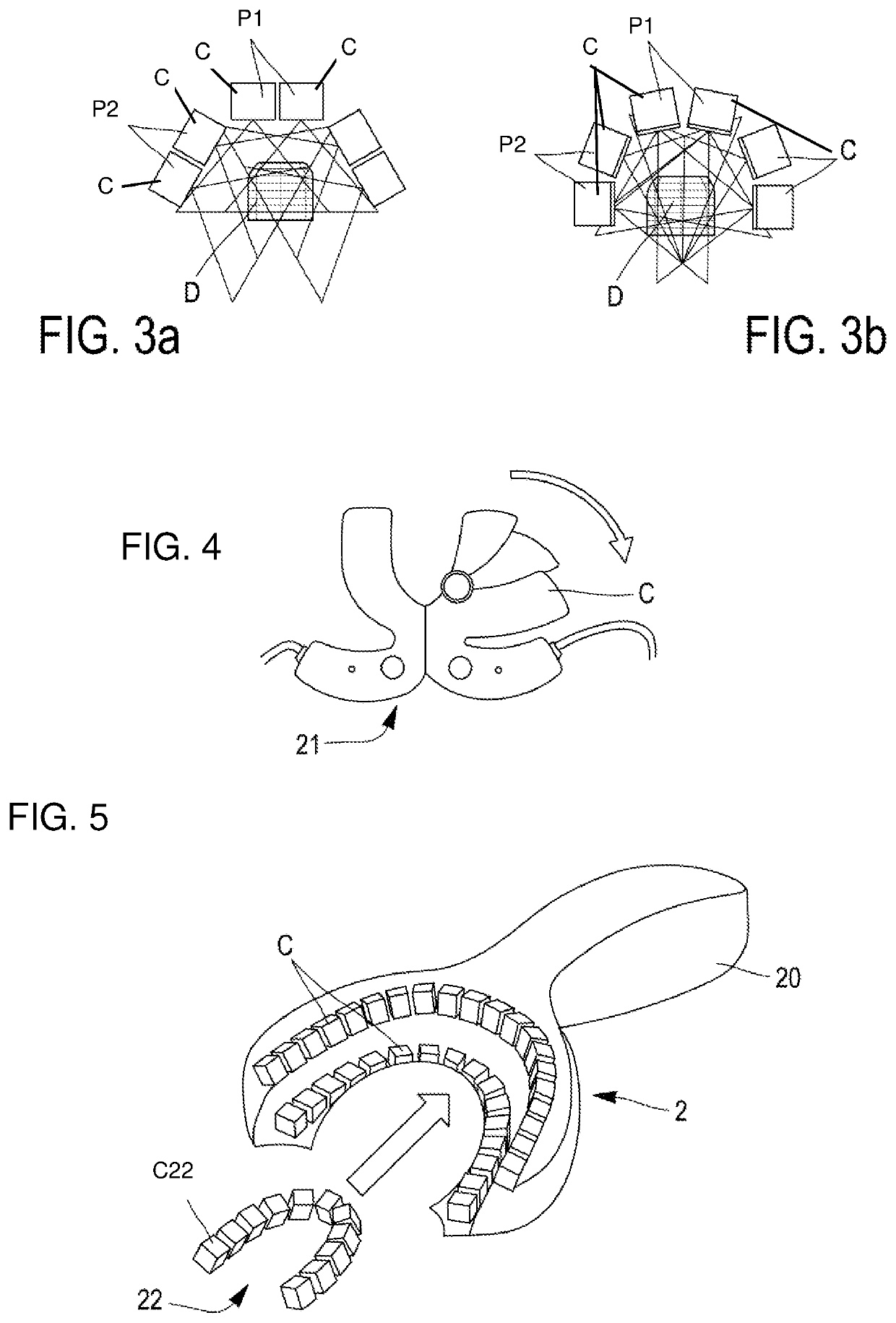

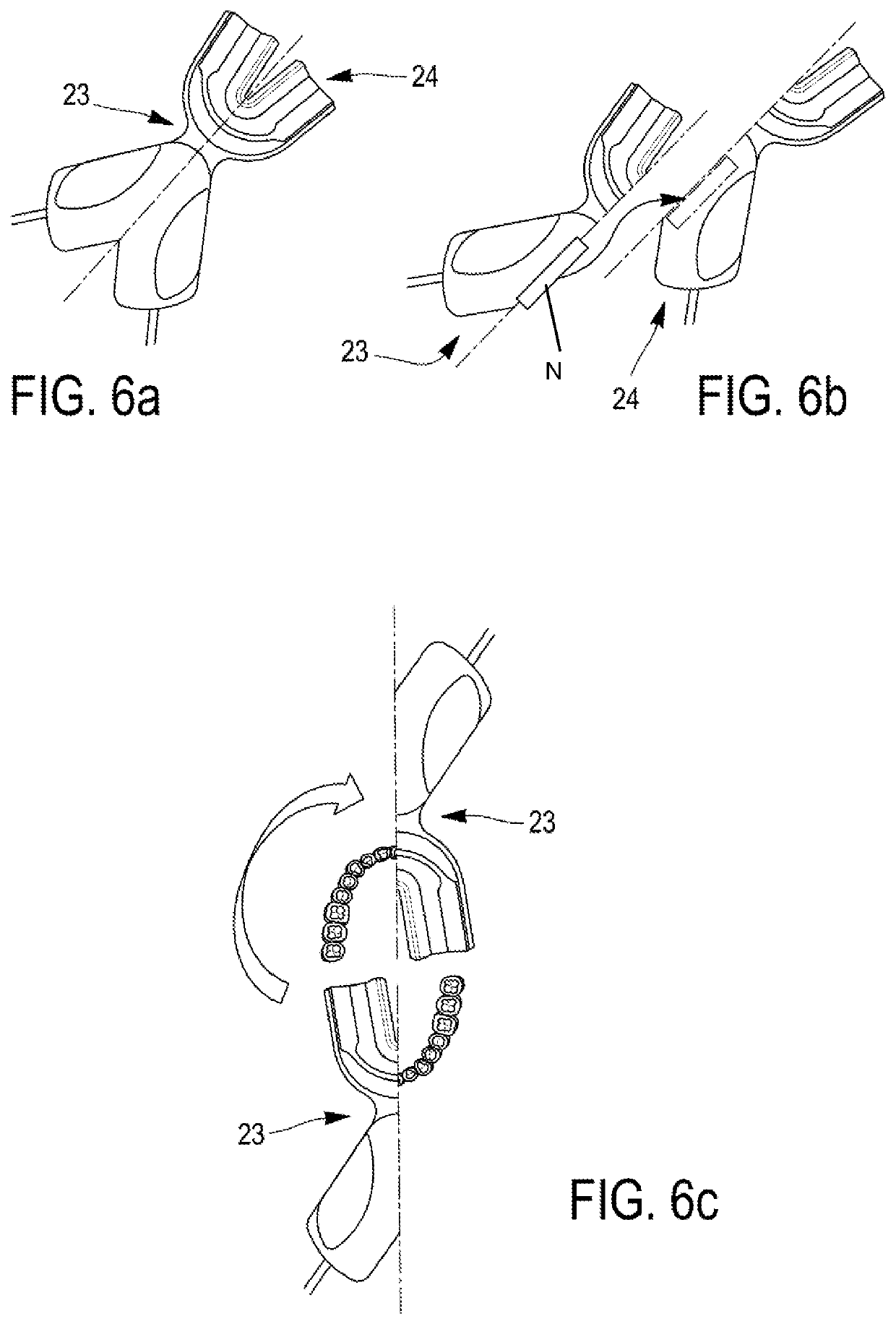

Electronic impression tray for obtaining dental information

ActiveUS20210045851A1Low costReasonable investmentImpression capsTooth rinsingElectronic systemsImpression trays

An electronic impression tray can be used to obtain three-dimensional and temporal measurements in dentistry. There is a device having optical measurement sensor system, and an electronic system including a central management unit capable of collecting, storing and ordering the data obtained by the sensor systems distributed over all or part of the impression tray. An optical impression of all or part of a dental arch can be obtained with a single or multiple impressions. The tray includes a part having the shape of all or part of a dental arch, and the part can change by virtue of its ability to deform and / or a structure formed by multiple elements that are hinged to one another and / or reversibly assembled and secured to one another, such as to provide the optimal shape.

Owner:DURET +1

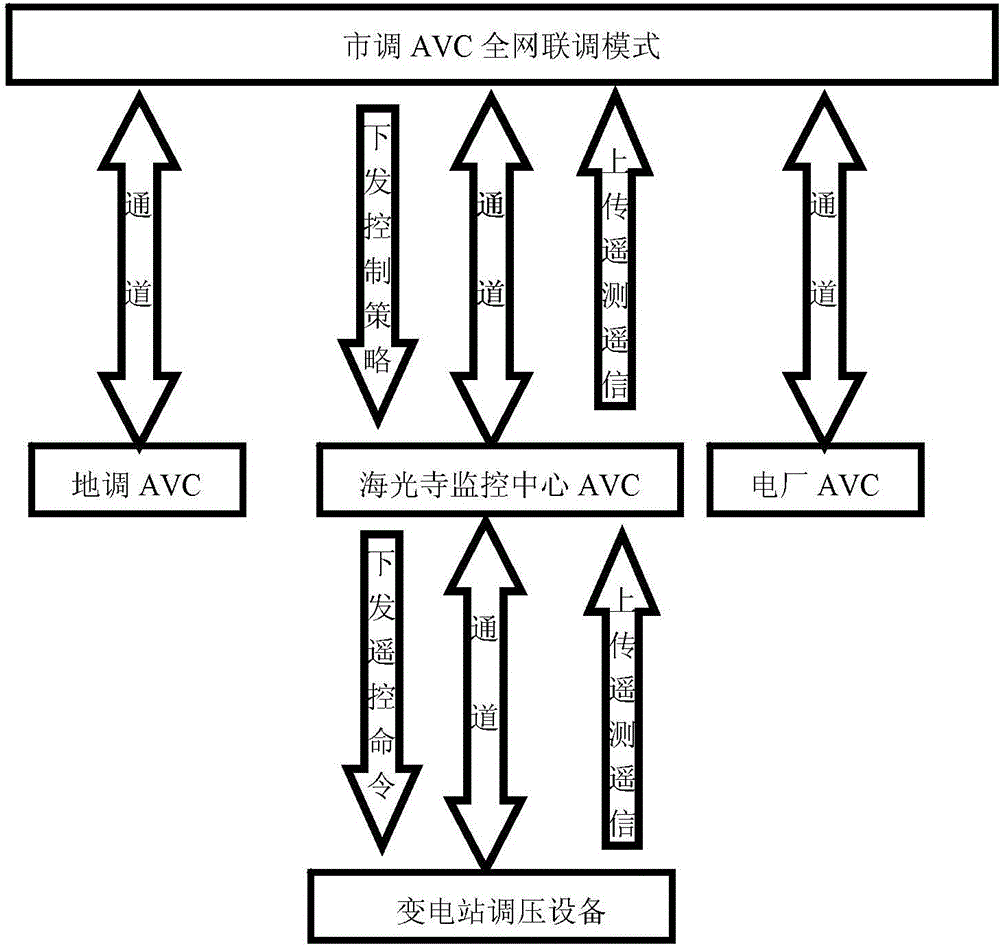

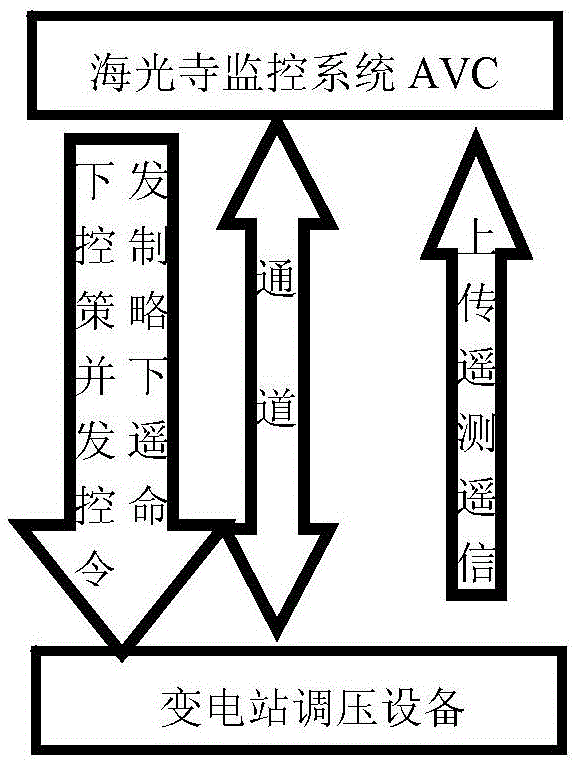

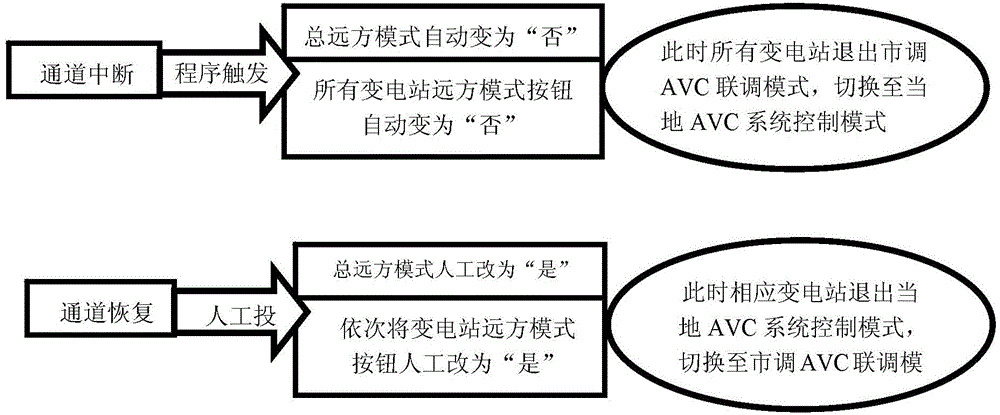

Voltage reactive automatic control system channel switching method

ActiveCN104065078AVoltage Stability and SafetyThe main grid voltage is stableAc network voltage adjustmentReactive power compensationAutomatic controlControl system

The invention discloses a voltage reactive automatic control system channel switching method. The method comprises the system normal operation stage, the scanning period running stage, the stage for judging whether a first exit condition is satisfied, the stage for judging whether a second exit condition is satisfied, the channel abnormal condition processing stage, the scanning period joint debugging recovery stage, the stage for judging whether the channels are recovered, the municipal dispatching joint debugging setting recovery stage, the stage for a substation to be input into municipal dispatching joint debugging, etc. According to the invention, automatic closed-loop control and real-time adjustment can be realized, the voltage stability and safe operation of the grid can be ensured; the misoperation caused by unreasonable manual adjustment and artificial omissions can be avoided; the gate reactive change can be adjusted on a real-time basis and tracked timely, the main grid voltage can be effectively supported, and the main grid voltage stability can be facilitated; and the control has the advantage of foreseeability, the time of unnecessary equipment actions can be reduced, and misoperation or frequent adjustment can be avoided.

Owner:STATE GRID CORP OF CHINA +1

Establishment of electric power engineering cost database system

The establishment of the power project cost database system includes analyzing and determining the key technical and economic indicators of power project investment control, and establishing a project cost data collection model; establishing a historical project cost experience database to provide reference data for reviewing project cost; intelligently selecting historical projects to realize historical Automatic comparison between projects and pending projects to improve review efficiency. The establishment of this database system is safe and reliable, with advanced technology, environmental protection, reasonable investment, unified standards, and efficient operation, and promotes the construction of power grids to better cooperate with social and economic development, avoiding the risk of investment waste becoming a bottleneck in economic development. On the other hand, under the premise of ensuring the safe and reliable operation of the power grid and the social demand for electricity, reasonably reduce the project investment cost, minimize the operating cost of the power grid enterprise, and realize the sustainable development of the company, thereby proposing safe, reliable and high-quality solutions for social development. , Low-cost electricity supply.

Owner:国网上海市电力公司经济技术研究院

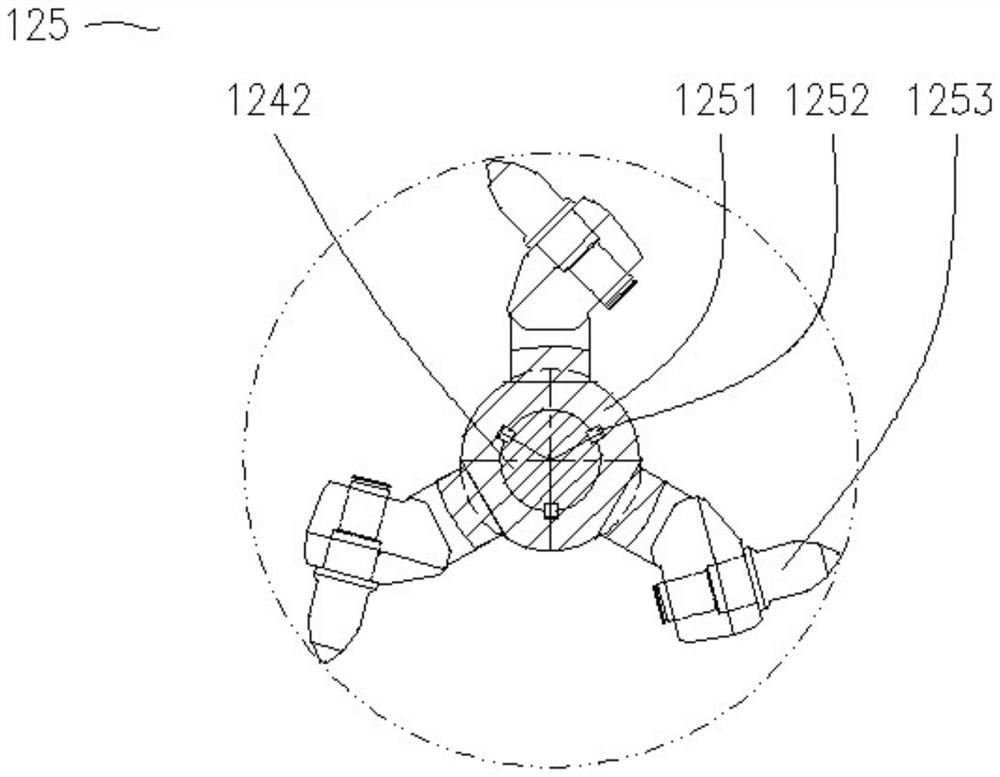

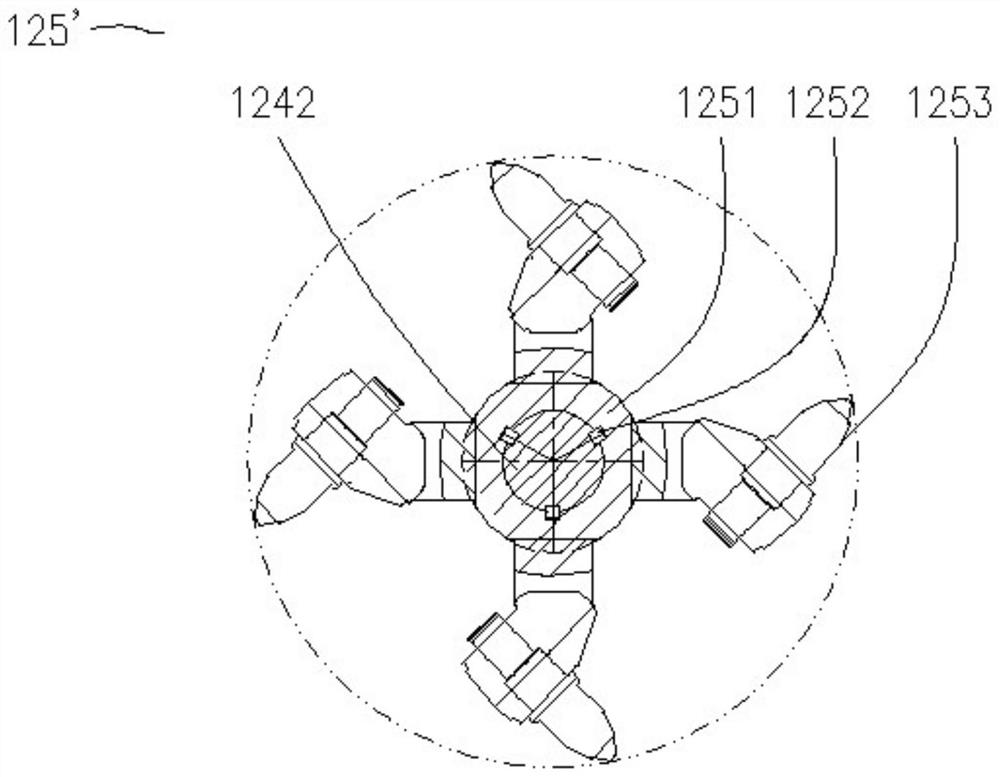

Crushing tooth assembly and crusher

PendingCN112892770ASimple structureEasy maintenanceGrain treatmentsRocker armManufacturing engineering

The invention discloses a crushing tooth assembly and a crusher. The crushing tooth assembly comprises a connecting shaft and a plurality of crushing tooth sets, each crushing tooth set comprises a shaft sleeve and a plurality of crushing teeth fixed to the periphery of the shaft sleeve, and the multiple crushing tooth sets are arranged side by side in a sleeving mode and fixed to the connecting shaft in the circumferential direction. The crusher comprises a mining machine rocker arm, a fixing base, a swinging arm and a crushing tooth assembly, wherein the fixing base is fixed to the rocker arm, a tubular structure extending front and back is arranged at one end of the swinging arm and hinged to the fixing base, the front end and the rear end of a rotating shaft are rotationally supported at the front end and the rear end of an inner cavity of the tubular structure respectively, the front end and the rear end of the connecting shaft are rotationally supported on a front arm frame and a rear arm frame at the other end of the swing arm respectively, and the front portion of the rotating shaft is in transmission connection with the front portion of the connecting shaft through a transmission system located in an inner cavity of the front arm frame. The crushing teeth can be partially replaced, so that the use cost can be reduced, and the crusher is compact in structure and can be used for an alumina mining machine for exploiting a thin ore bed.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

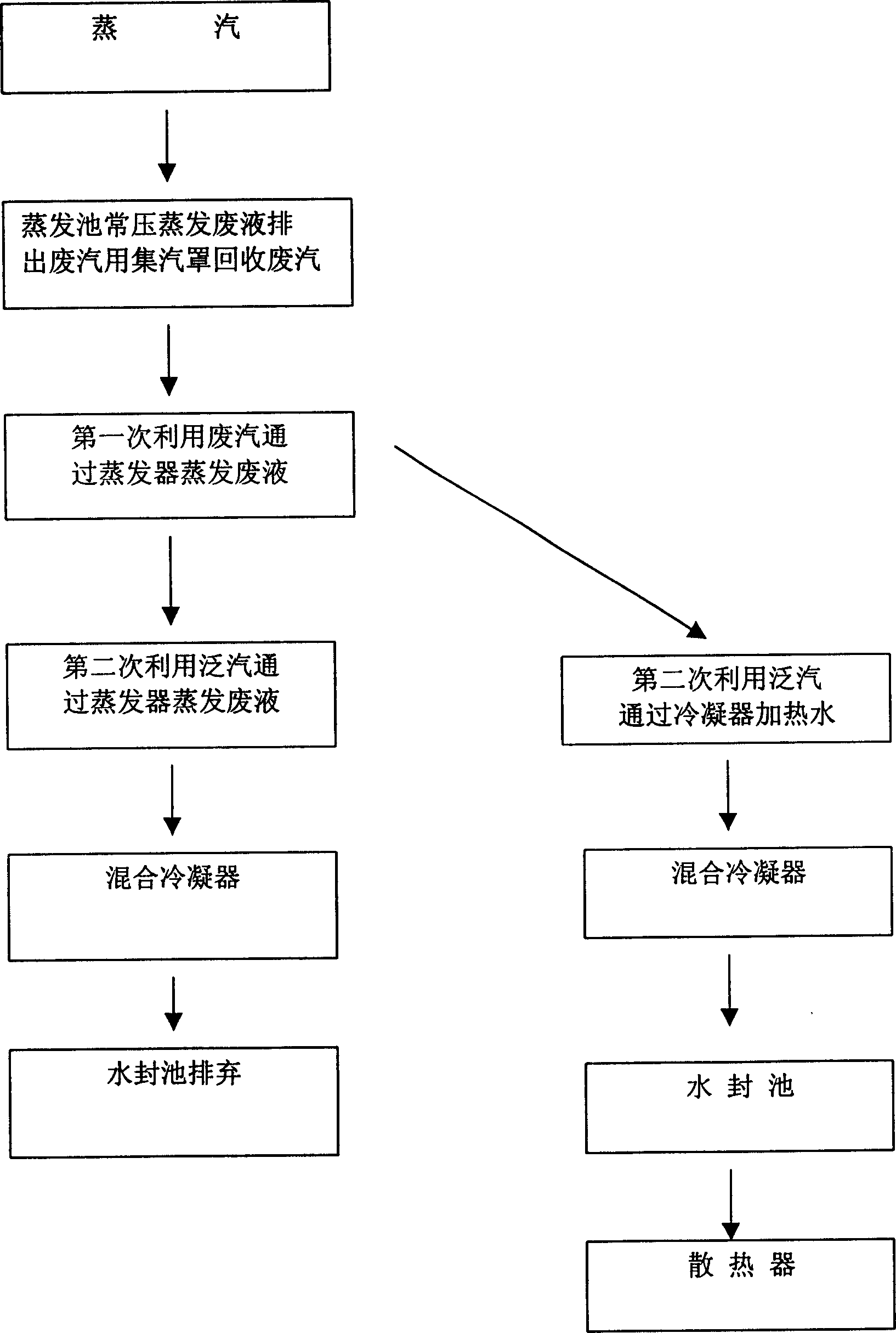

Waste steam recovering and utilziing method for atmospheric evaporation in imine puling process

InactiveCN1185035CReduce energy consumptionBig investmentEvaporationSpent liquor concentrationLiquid wasteEvaporation

The waste steam recovering and utilizing method includes recovering waste steam with one steam collecting hood, evaporating waste liquor and heating water for warming with the recovered waste steam. The present invention has the features of reasonable investment-to-power consumption ratio, no pressure container and no environmental pollution. The present invention can reduce the production cost of waste liquid feed, fertilizer and industrial product greatly.

Owner:赵时来 +2

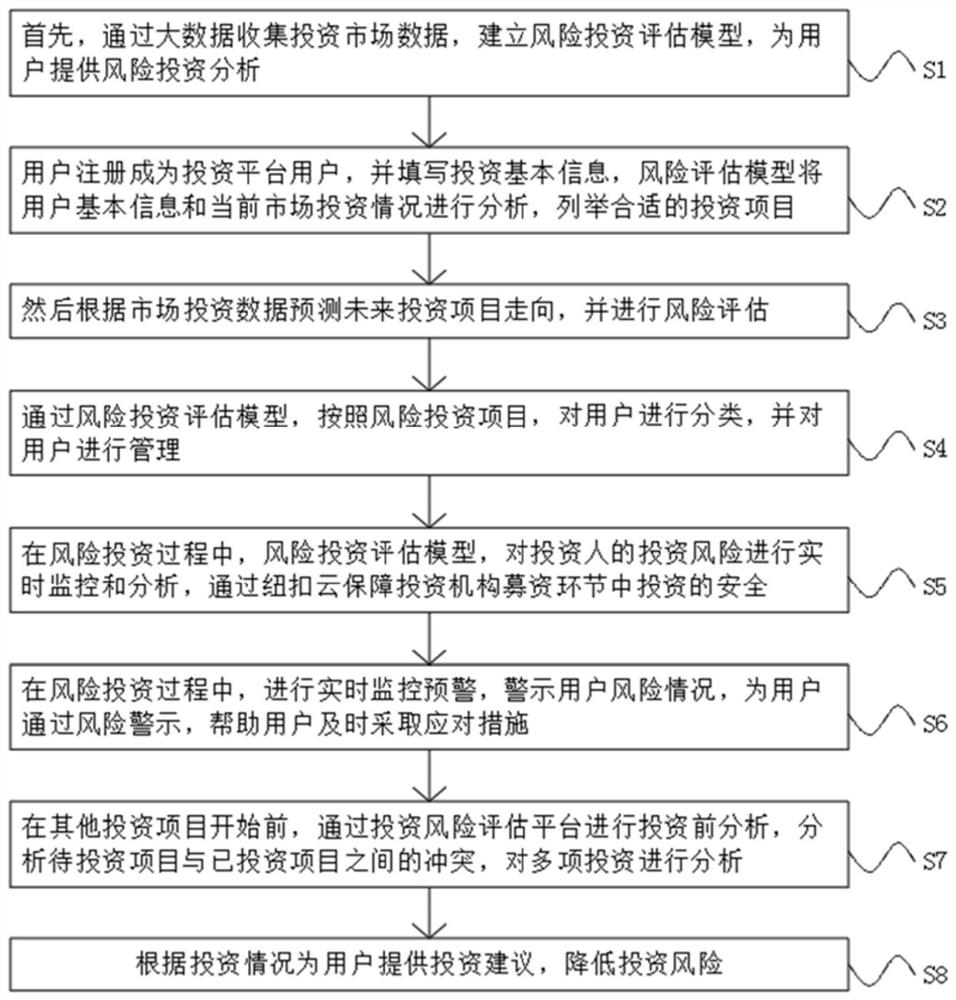

Investment risk assessment method based on big data and artificial intelligence technology

PendingCN113408873AMaster quicklyEarly warning is timely and intuitiveFinanceOffice automationRisk levelInvestment analysis

The invention discloses an investment risk assessment method based on big data and an artificial intelligence technology, and the method comprises the following assessment steps: S1, collecting investment market data through big data, building a risk investment assessment model, and providing risk investment analysis for a user; and S2, enabling the user to register as an investment platform user, and filling basic investment information. The investment project is monitored in real time through the investment risk assessment model, the risk early warning level is set, monitoring and analysis are performed according to the cycle, when the investment encounters the risk, the risk is analyzed and the risk level is assessed in time through big data, the controllable risk and the uncontrollable risk are distinguished, the fluctuation range between the risk and the expectation is determined, the user can master the risk and know the specific level and fluctuation amplitude of the risk more quickly, so that the user can know early warning of the risk timely and intuitively, and when the early warning occurs, reasonable measures are given for reference to the user, and the investment loss is reduced.

Owner:南京超募数字科技有限公司

Electronic impression tray for obtaining dental information

ActiveUS11357601B2Low costReasonable investmentImpression capsTooth rinsingElectronic systemsImpression trays

An electronic impression tray can be used to obtain three-dimensional and temporal measurements in dentistry. There is a device having optical measurement sensor system, and an electronic system including a central management unit capable of collecting, storing and ordering the data obtained by the sensor systems distributed over all or part of the impression tray. An optical impression of all or part of a dental arch can be obtained with a single or multiple impressions. The tray includes a part having the shape of all or part of a dental arch, and the part can change by virtue of its ability to deform and / or a structure formed by multiple elements that are hinged to one another and / or reversibly assembled and secured to one another, such as to provide the optimal shape.

Owner:DURET FRANCOIS +1

Trackless transport vehicle for heavy-load logistics system

The invention discloses a trackless transport vehicle for a heavy-load logistics system. The trackless transport vehicle comprises a vehicle body (1), and is characterized in that a plurality of pairsof wheel groups (2) are arranged at the bottom of the vehicle body (1); each pair of the wheel group (2) comprises two sets of wheel group assemblies which are symmetrically arranged; four vehicle body jacking oil cylinders (3) are arranged in the middle of the vehicle body (1); each two vehicle body jacking oil cylinders (3) are used as one group; the two groups of vehicle body jacking oil cylinders (3) are symmetrically arranged; meanwhile, the stretching directions of working shafts of the vehicle body jacking oil cylinders (3) are downward; heavy-load jacking oil cylinders (4) are also symmetrically arranged at the front part and rear part of the vehicle body (1); the stretching directions of working shafts of the heavy-load jacking oil cylinders (4) are upward. The trackless transport vehicle for the heavy-load logistics system is simple in structure, ingenious in design and low in cost; tracks do not need to be paved and the trackless transport vehicle for the heavy-load logistics system can be directly used for transporting heavy loads on the ground.

Owner:大连壹海科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com