Numerically-controlled forging hydraulic press capable of realizing reactive power compensation

A technology of power compensation and power compensator, applied in the field of numerical control forging hydraulic press, can solve the problems of energy waste and increase cost, and achieve the effect of reducing production cost, improving power factor and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

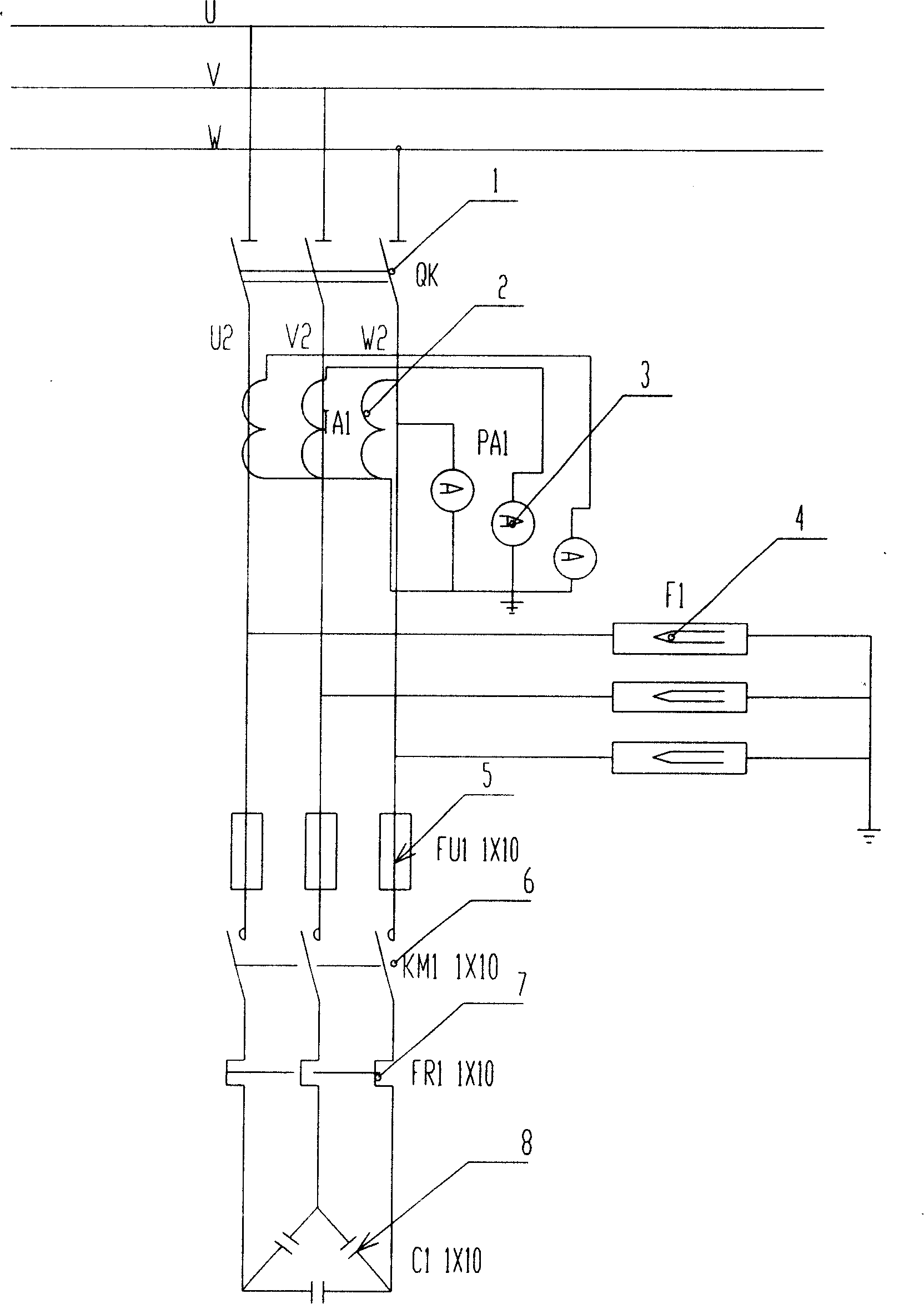

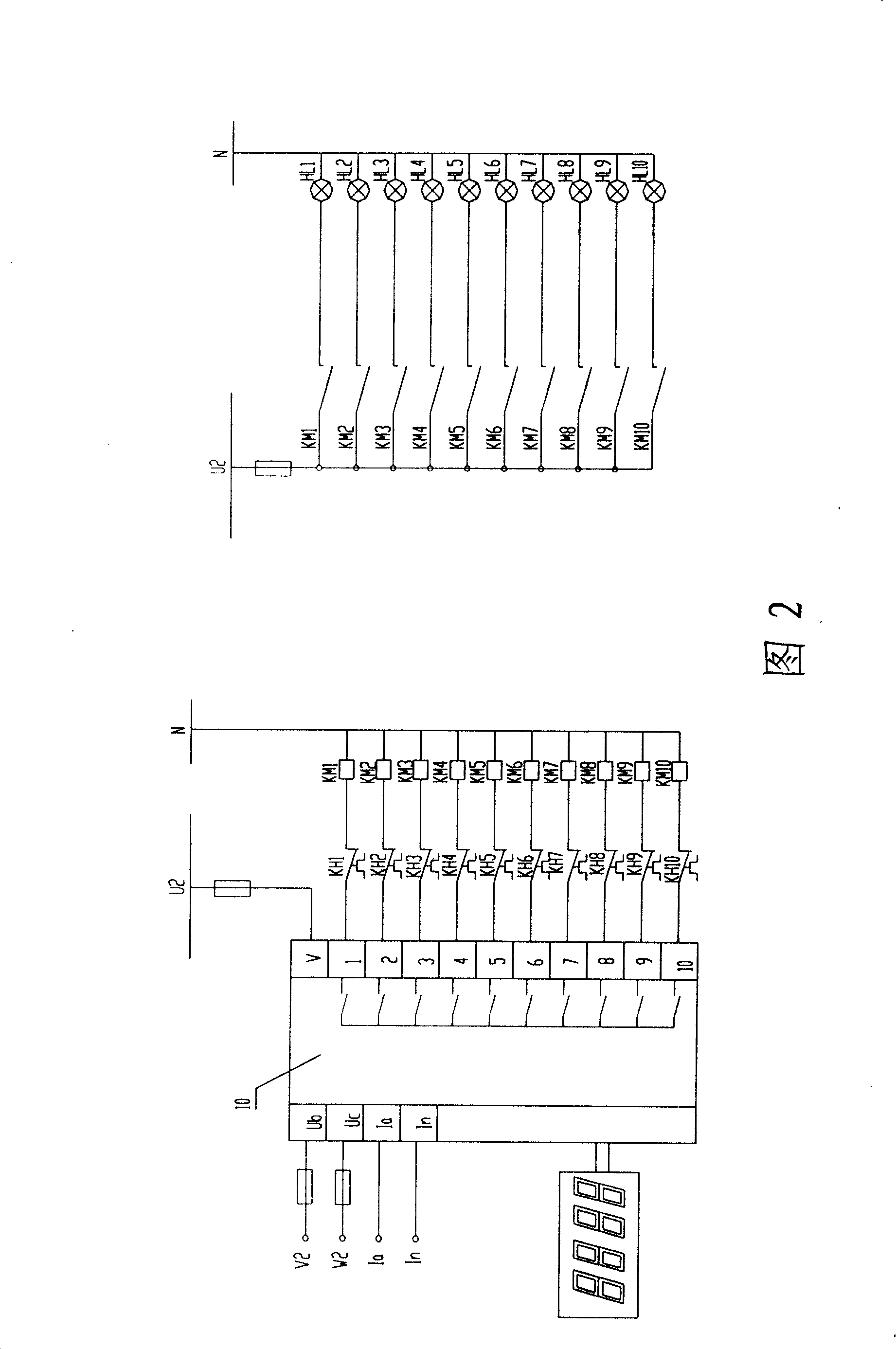

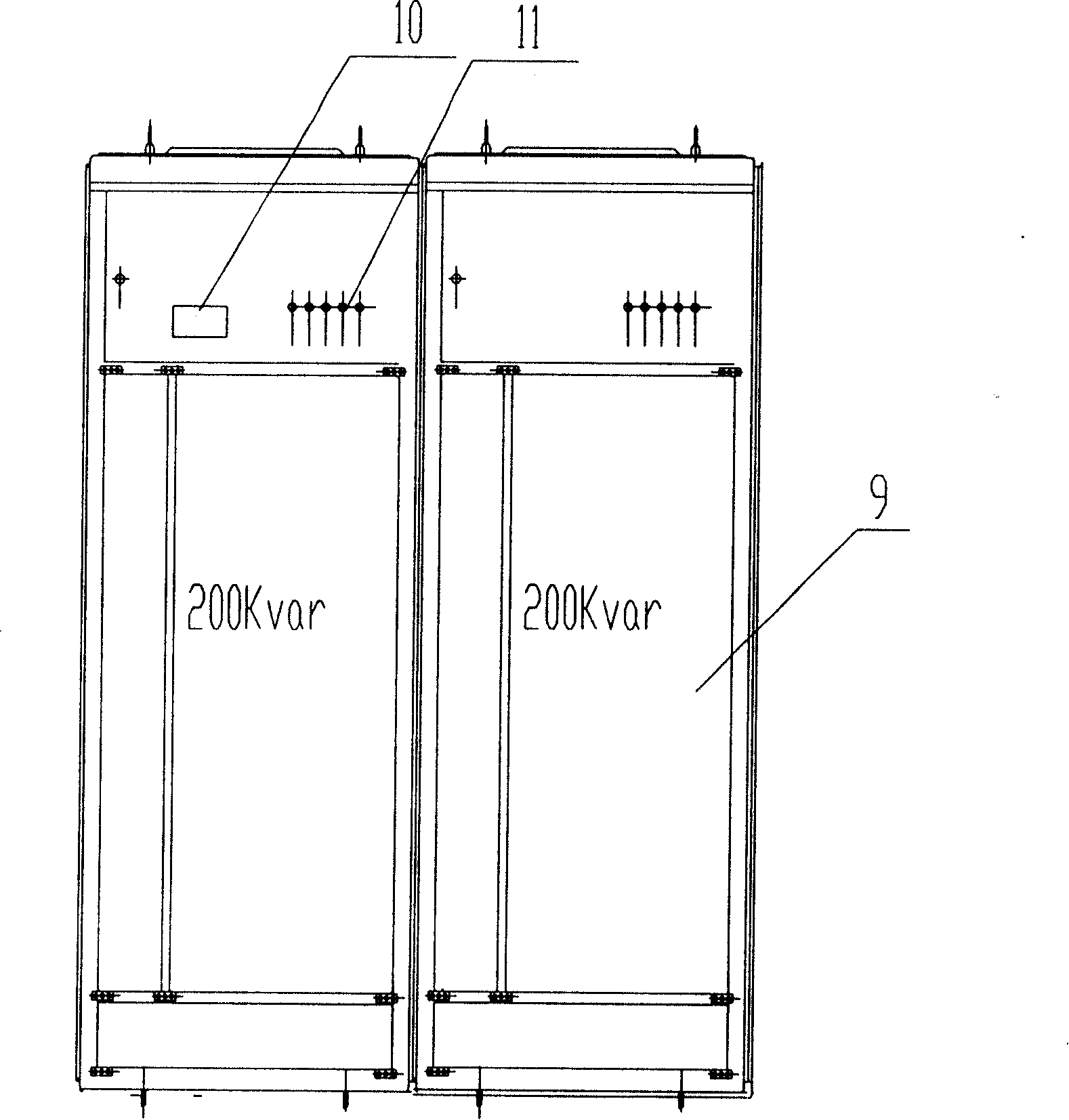

[0025] Refer to attached figure 1 , Figure 2 and image 3 .

[0026] The CNC forging hydraulic press that can realize reactive power compensation includes a hydraulic frame, a movable beam, a workbench, a display, an electrical controller and a power mechanism. The electrical controller controls the power mechanism to drive the hydraulic frame and the movable beam, and the electrical controller is connected to the display. The hydraulic press is equipped with a reactive power compensator and a reactive power compensation controller. The structure of the reactive power compensator consists of a knife switch 1 and an AC contactor 6. The compensation capacitor 8 is connected to the main circuit of the three-phase power supply of the oil pump motor. The reactive power There are 10 groups of compensators, and the reactive power compensation controller is connected to control the AC contactor of the reactive power compensator to realize the connection of one group, multiple groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com