Treatment method and device for stainless steel electrolytic polishing wastewater

An electrolytic polishing and wastewater treatment technology, which is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as endangering the health of surrounding residents, destroying regional ecosystems, and clogging of reverse osmosis membranes. Low, improve the degradation efficiency, reduce the effect of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

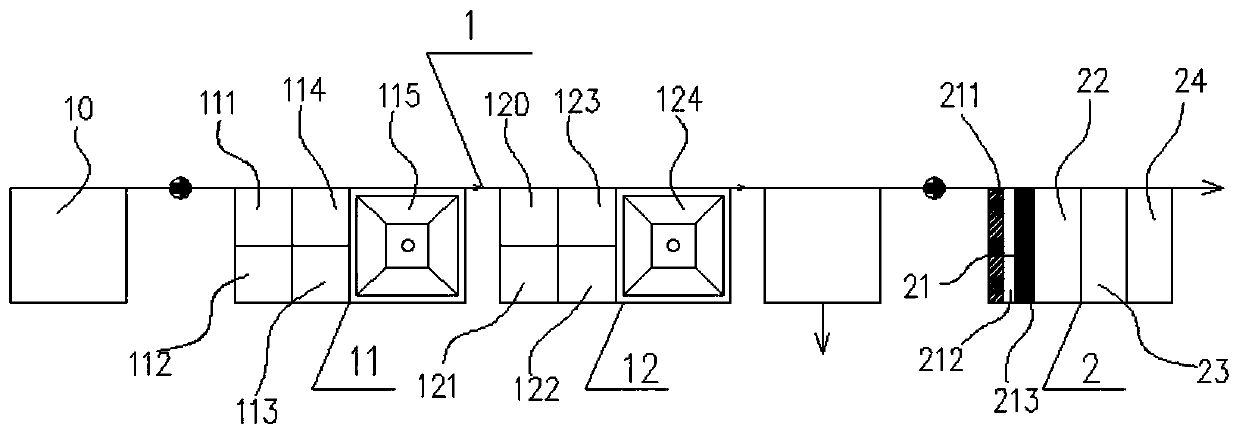

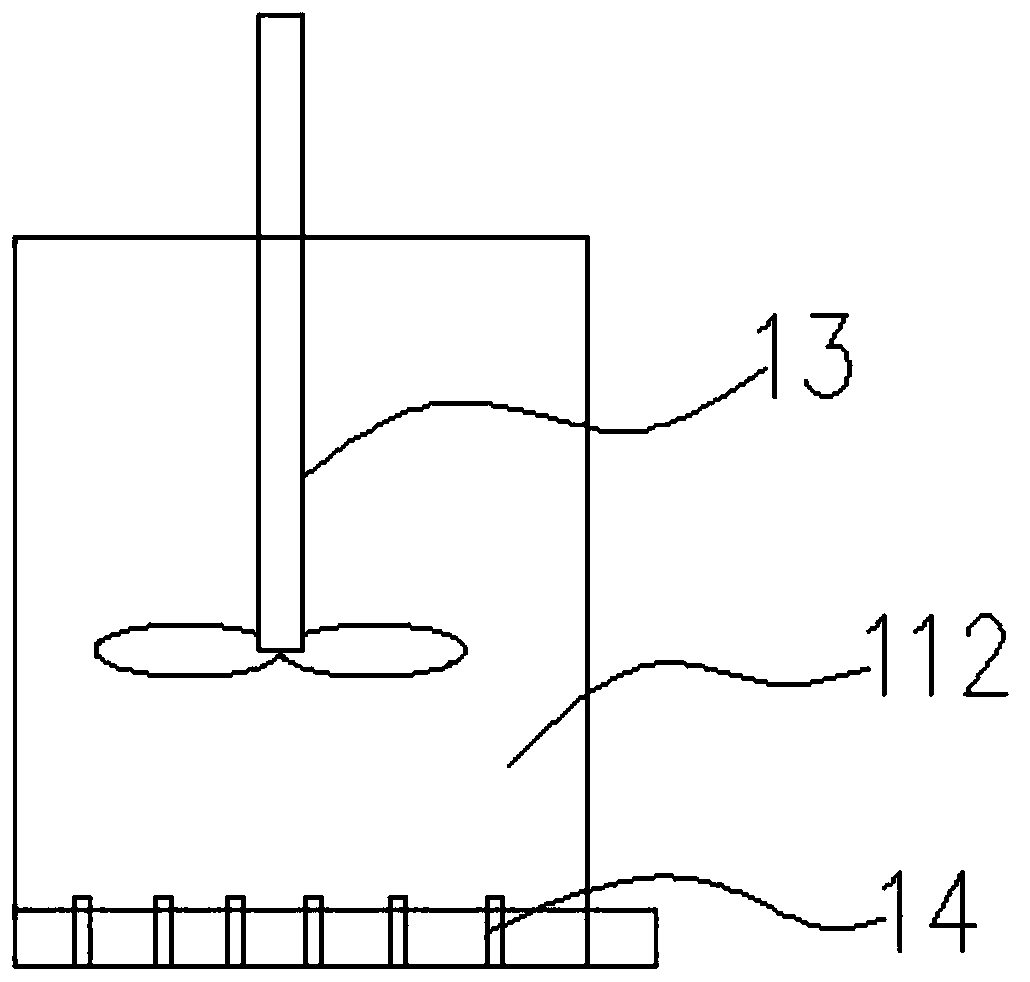

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

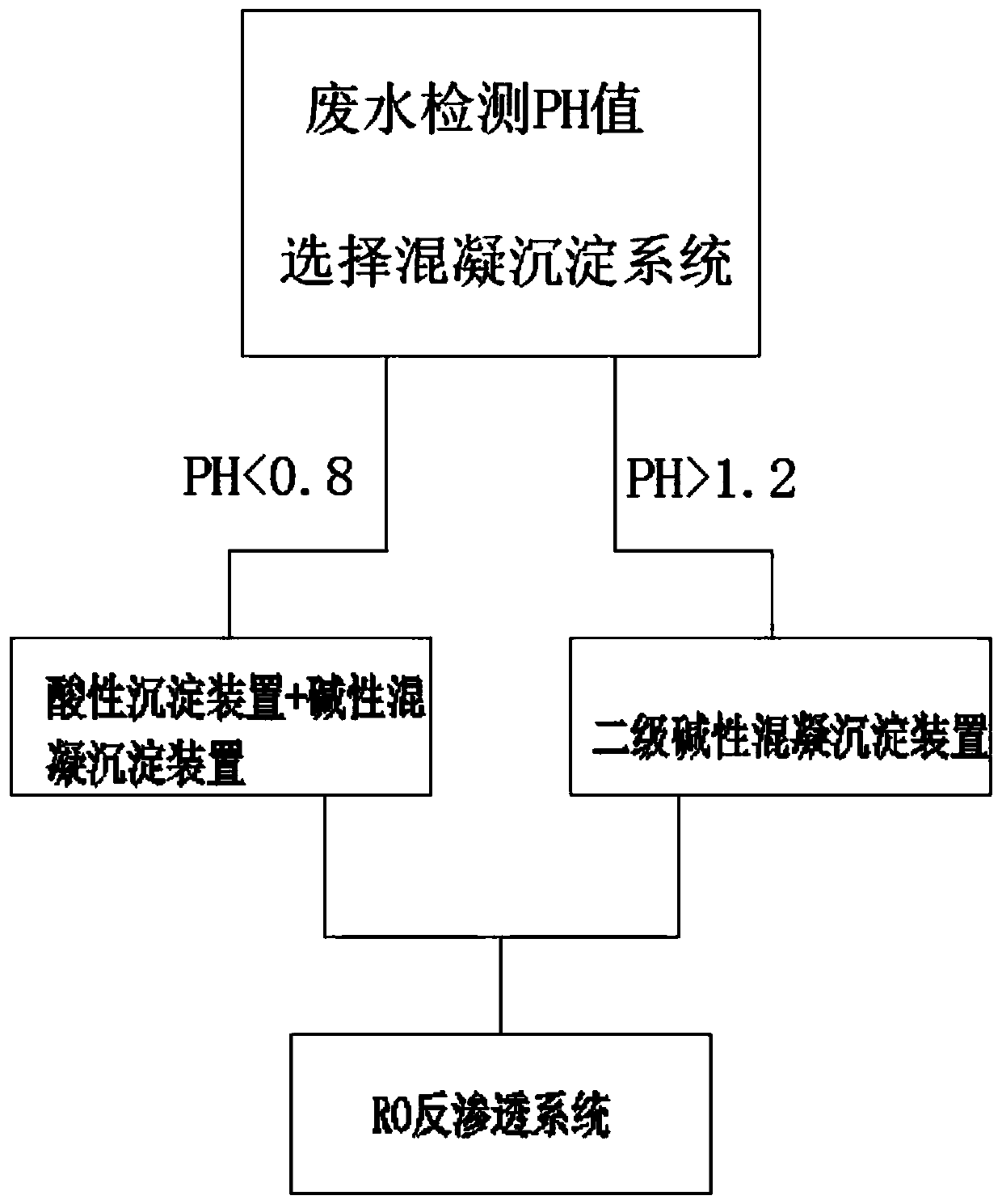

[0031] Such as figure 1 , figure 2 and image 3 Shown, a kind of stainless steel electropolishing wastewater treatment method comprises the following steps,

[0032] The two-stage coagulation-sedimentation system can be divided into two types. The first type uses acid precipitation device + alkaline coagulation-sedimentation device, and the second type uses two-stage alkaline coagulation-sedimentation device. For electrolytic wastewater with high raw water acidity (pH1.2), the second type of secondary coagulation sedimentation system is preferred system. Reasonable selection of the type of coagulation and sedimentation system can effectively improve the degradation efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com