Equipment and process for preparing polymer water source by katalysis deactivation of oilfield sewage

A technology of oilfield sewage and polymerization, applied in the direction of oxidized water/sewage treatment, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the impact and limit the popularization and application of polymer flooding technology, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

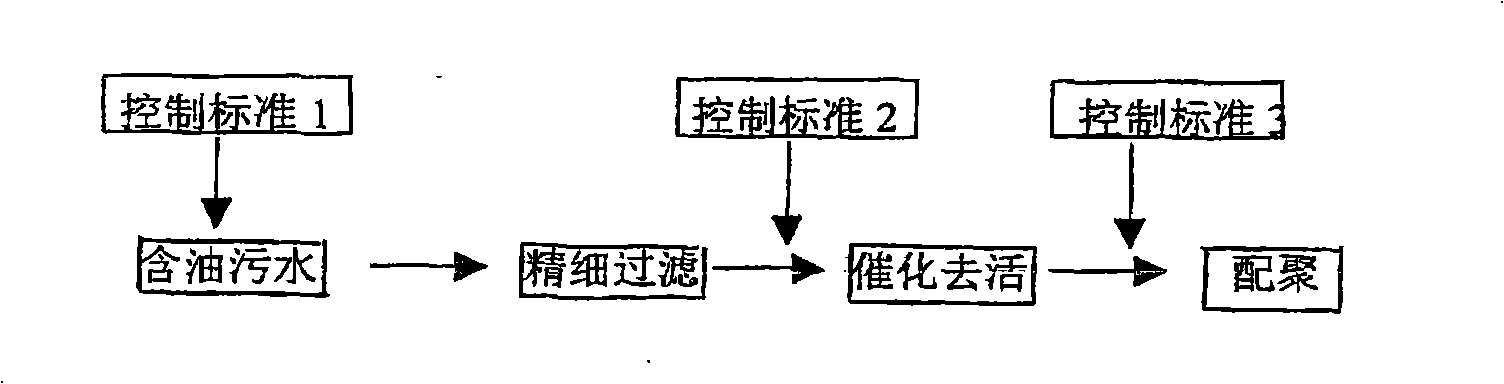

[0029] The preparation process of this scheme is as follows: figure 1 shown. The incoming water that meets the control standard 1 in Table 1 is first filtered through a fine filter, and the filtered water reaches the control standard 2 in Table 1; then it is treated by a catalytic oxidation deactivation device, and the treated sewage reaches the control standard 3 in Table 1. It can be directly used to prepare polymer solution.

[0030] Table 1 Production Process Control Indicators

[0031]

[0032] Option II

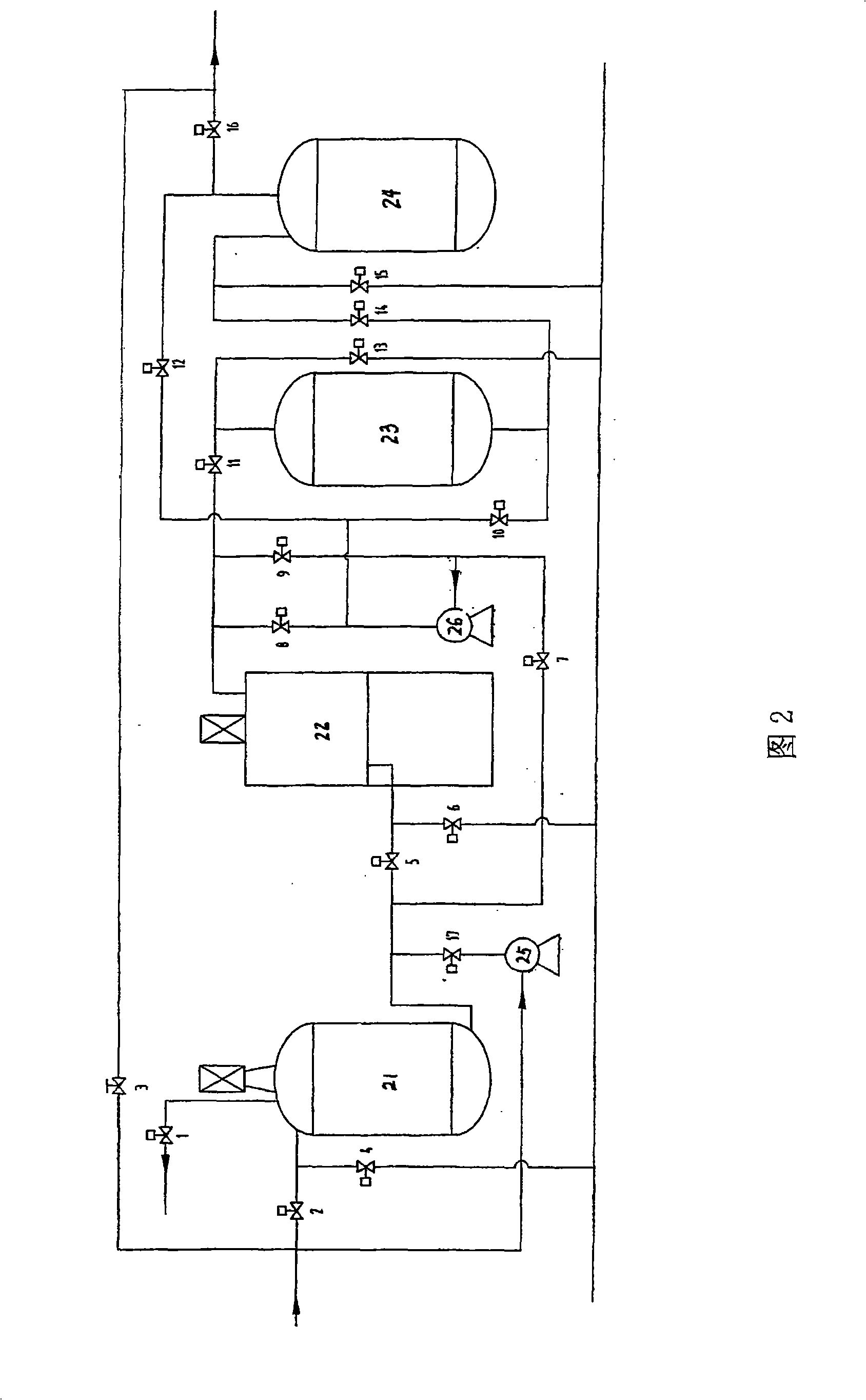

[0033] The flow of this program is shown in Figure 2. On the basis of scheme 1, a preliminary filtration step through a walnut shell filter is added before the fine filtration step, and a preliminary iron removal step is performed with an iron removal filter device filled with manganese sand and quartz sand before the catalytic oxidation deactivation step. The valve actions are shown in Table 2. Valve 1 is the oil discharge valve, valve 2 is the electric valve of...

Embodiment 1

[0110] MnO 2 -ZnO-CeO 2 / Al 2 O 3 Preparation of catalyst

[0111] The diameter is 1.6mm and the specific surface area is 150m 2 / g Al 2 O 3 The carrier is in Mn(NO 3 ) 2 , Zn(NO 3 ) 2 and Ce(NO 3 ) 3 The molar concentrations of the three nitrates in the solution are shown in Table 4. After drying at 150°C for 4 hours, it was calcined at 650°C for 3 hours. That is to get MnO 2 -ZnO-CeO 2 / Al 2 O 3 catalyst.

[0112] Table 4 Nitrate solution molarity

[0113] Mn(NO 3 ) 2 (mol / L)

Embodiment 2

[0115] Catalytic deactivation unit to treat fresh flowing sewage in Hanan Oilfield

[0116] The fresh flowing sewage from Hanan Oilfield was treated with preliminary oil removal to meet the requirements of control standard 1 in Table 1 above. The process and equipment of the first solution of the present invention are used for treatment. The catalyst 1 prepared in Example 1 was used as the filler in the catalyst tank.

[0117] The polymer HPAM (molecular weight: 25 million) was added to the water before and after the treatment to prepare a polymer solution with a concentration of 1 g / L.

[0118] See the test results Figure 7 and Figure 8 , Obviously, the viscosity of the polymer solution prepared by the catalytic deactivation technology to treat the fresh flowing sewage of Hanan Oilfield is about 300% higher than that of the untreated sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com