Quantized quenching apparatus in metal heat treatment and the quantized quenching method using same

A technology for metal heat treatment and quenching equipment, applied in heat treatment equipment, heat treatment process control, quenching device and other directions, can solve the problem of no major progress in the research and development of quenching and cooling equipment, and achieve the effect of eliminating potential safety hazards, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

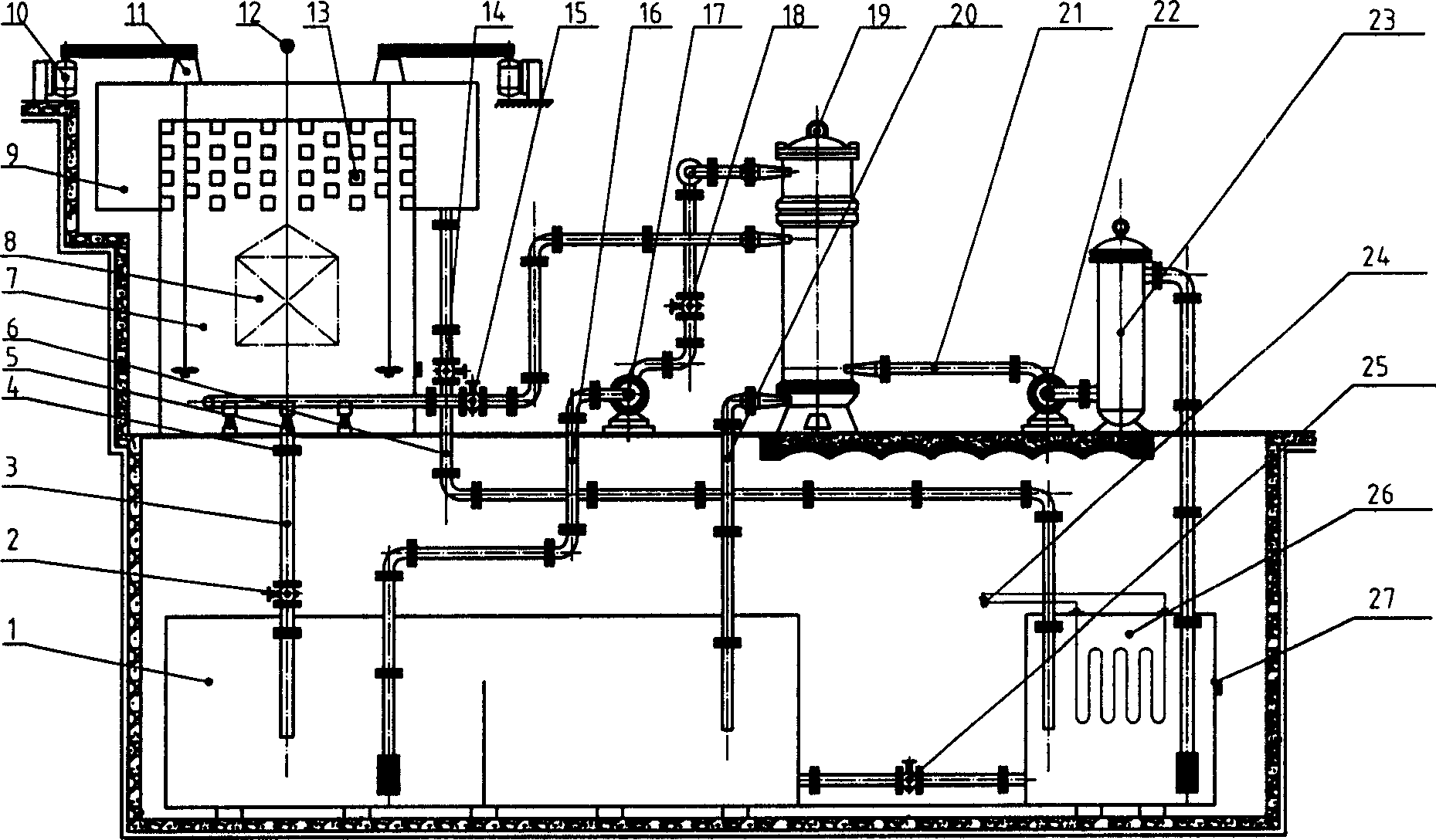

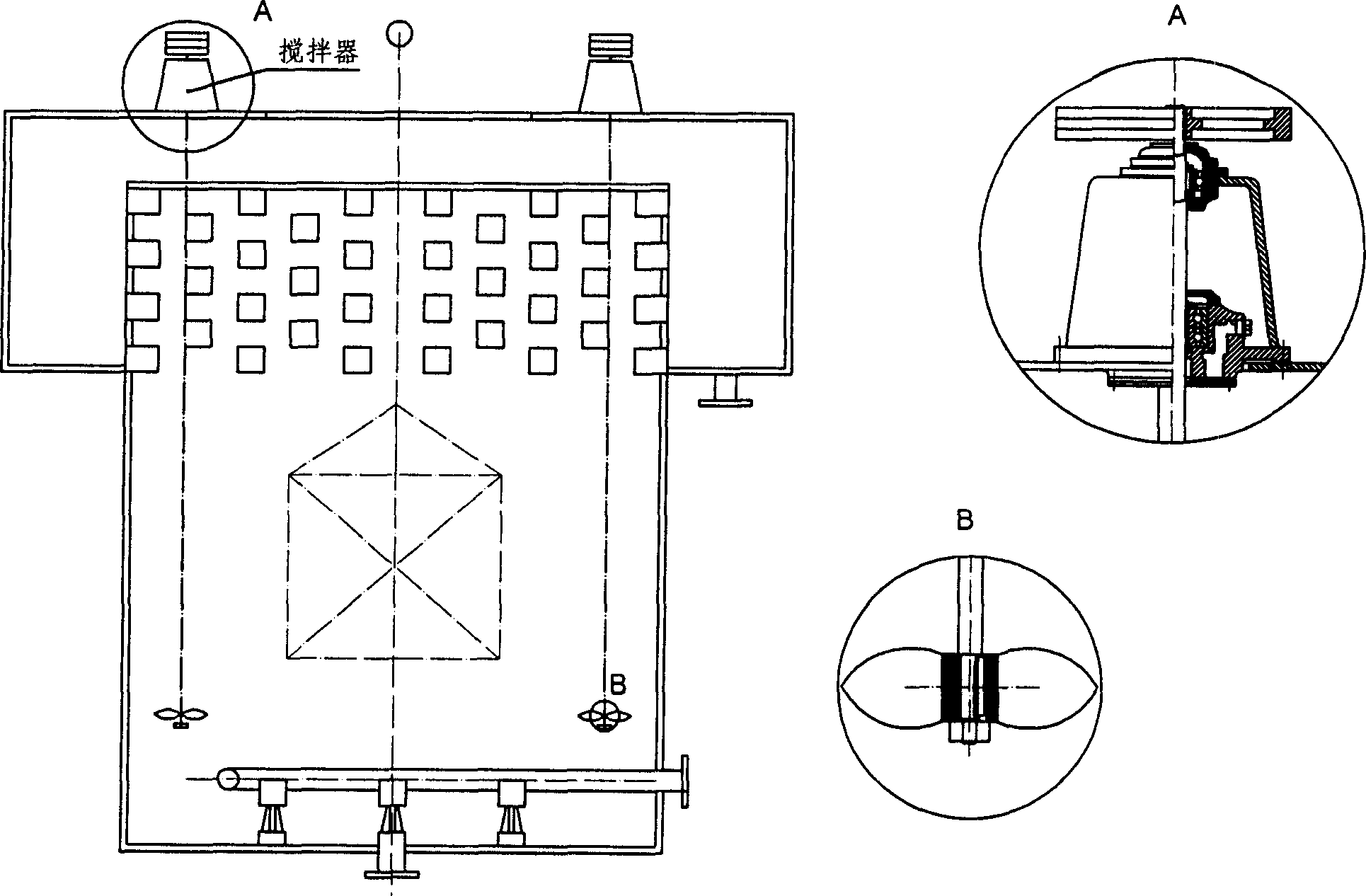

[0025] Such as figure 1 As shown, the quantitative quenching equipment for metal heat treatment of the present invention includes a quenching tank 7, and the liquid collecting tank 1 is connected with the quenching tank 7 through a cooling liquid inlet pipe 16, a pump 17, and a valve 18 through a cooler 19 and a flow control valve 15. The tank 26 is connected to the quenching tank 7 through the filter 23, the pump 22, the quenching liquid inlet pipe 21 and the cooler 19 and the flow control valve 15. A heater 24 is arranged in the blending tank 26 , a material basket 8 for containing workpieces is arranged in the quenching tank 7 , and an overflow tank 9 and an overflow hole 13 are arranged on the quenching tank 7 .

[0026] The quenching tank 7 is provided with a liquid discharge pipe 3 connected to the liquid collection tank 1 and controlled by a valve 2 , and the liquid discharge pipe 3 communicates with the pipeline at the bottom of the quenching tank 7 through the flange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com