Process for production of biological degradable chewing gum

A technology of biodegradation and production method, applied in confectionary, confectionary industry, food science, etc., can solve the problem of unsatisfactory gum base of chewing gum, and achieve the effect of preventing and treating oral diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

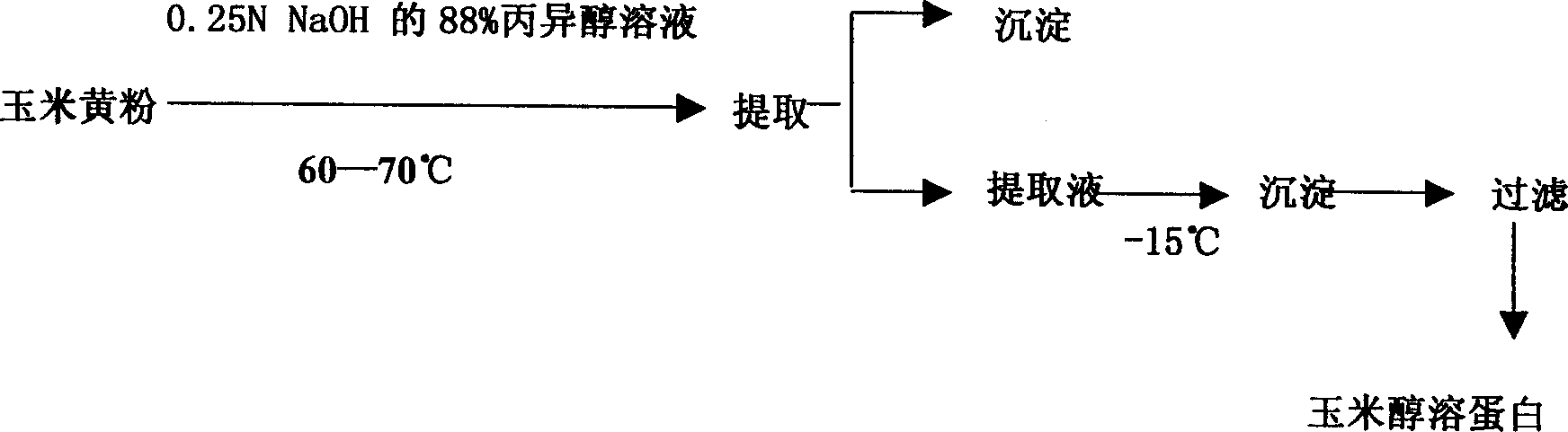

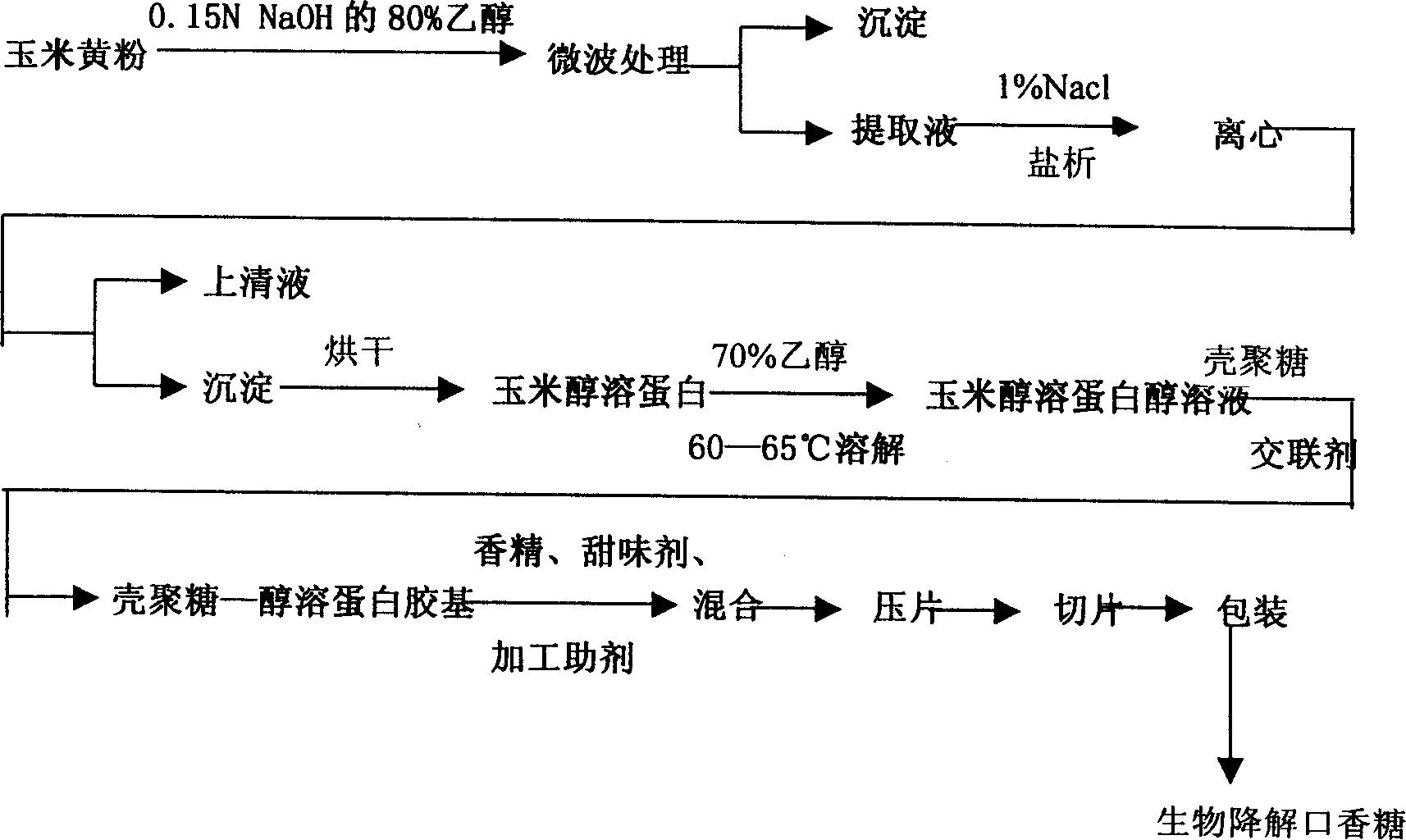

Method used

Image

Examples

Embodiment 1

[0019] Mix 100 grams of corn yellow powder and 800 ml of 70% ethanol in a glass container with a volume of 2000 ml, heat in microwave for 6 minutes (microwave condition: 915MHz, 800W), centrifuge, take the supernatant, add 800 ml of 1% chlorine Salt out with sodium, centrifuge after 10 minutes, take the precipitate and dry it in hot air at 70°C, and the product is zein.

Embodiment 2

[0021] Mix 100 grams of corn yellow powder and 800 ml of 80% ethanol in a glass container with a volume of 2000 ml, heat in microwave for 6 minutes (microwave condition: 915MHz, 800W), centrifuge, take the supernatant, add 800 ml of 1% chloride Salt out with sodium, centrifuge after 10 minutes, take the precipitate and dry it in hot air at 70°C, and the product is zein.

Embodiment 3

[0023] Mix 100 grams of corn yellow powder and 800 ml of 90% ethanol in a glass container with a volume of 2000 ml, heat in microwave for 6 minutes (microwave condition: 915MHz, 800W), centrifuge, take the supernatant, add 800 ml of 1% chloride Salt out with sodium, centrifuge after 10 minutes, take the precipitate and dry it in hot air at 70°C, and the product is zein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com