High pure white carbon black produced by utilizing industrial silicon byproduct silica fume and production method of high pure white carbon black

A silicon by-product micro-production method technology, applied in chemical instruments and methods, silicates, silicon compounds, etc., can solve the problems of poor content controllability, a large amount of acidic wastewater, poor application reliability, etc., and achieves low cost and high. Economic value, effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

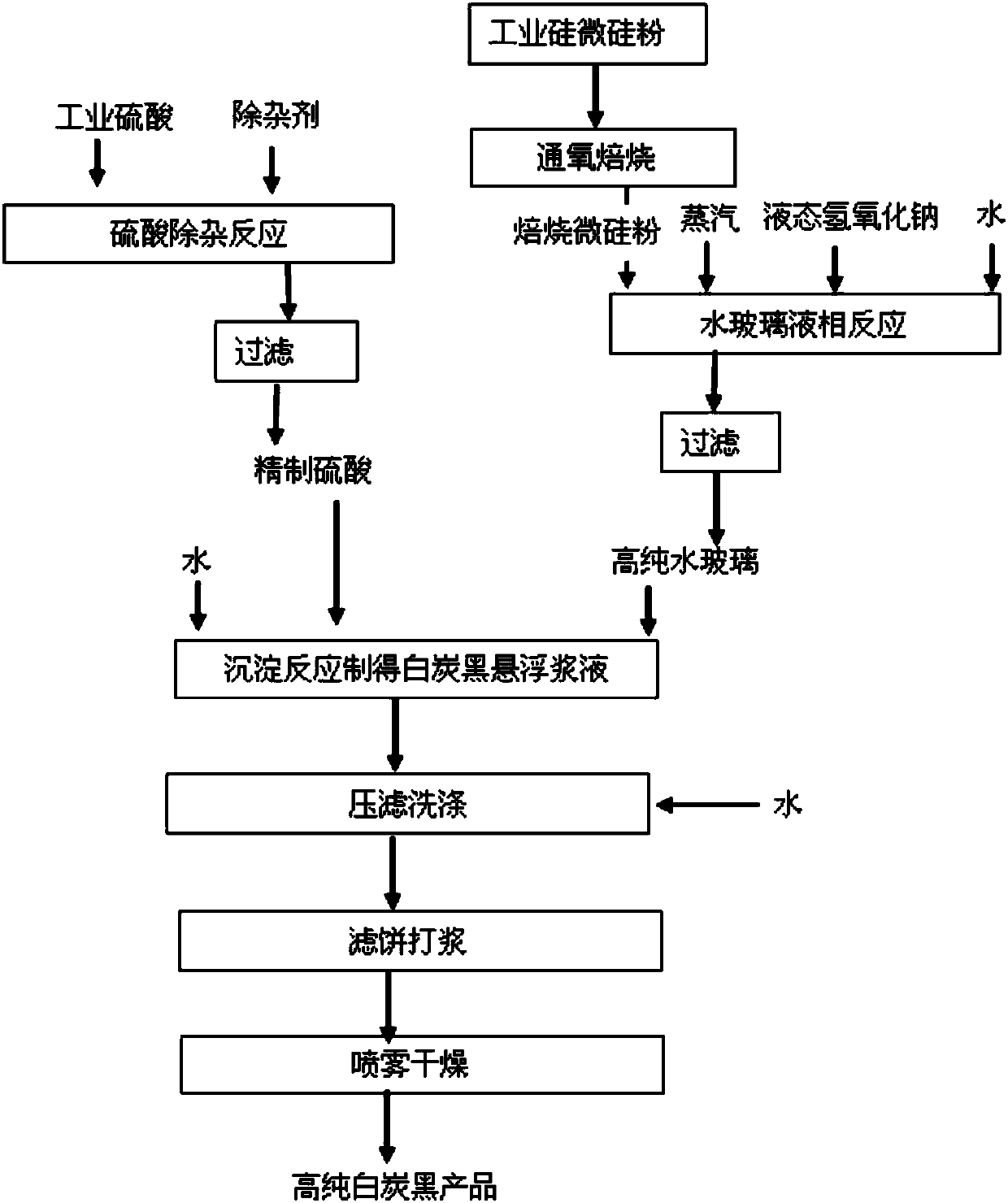

Method used

Image

Examples

Embodiment 1

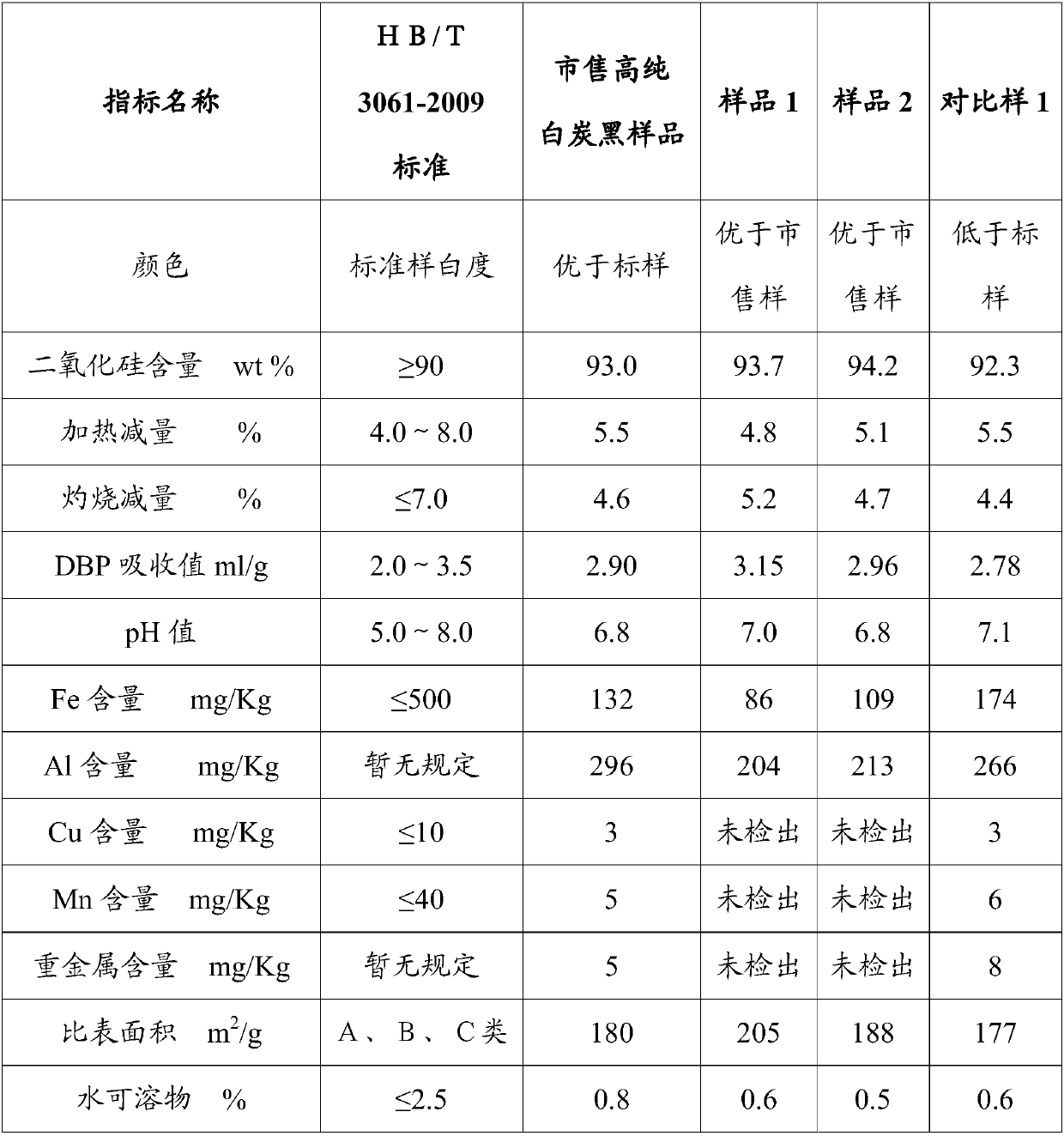

[0061] First, the micro-silica powder is continuously preheated to 600°C, and then continuously added to a roaster at 950°C for dynamic roasting for 20 minutes to remove organic volatiles such as coal tar and sintered to obtain porous spherical, gray-white particles of roasted micro-silica powder; the roasted micro-silica powder Add 24.75Kg of silicon powder, 33.5Kg of liquid sodium hydroxide with a mass fraction of 30wt%, and 65Kg of water into a 200L reactor, mix and stir evenly, and directly feed superheated steam with a pressure of 3.0MPa and a temperature of 450°C to heat the mixture to 175°C And hold the pressure for 180 minutes to react to generate water glass mother liquor. When the temperature is lowered to 70°C by heat exchange, it is filtered by a filter press to obtain colorless, odorless, transparent high-purity water glass. After analysis and detection, SiO in high-purity water glass 2 The content is 17.10wt%, Na 2 The O content is 5.69wt%, and the modulus is 3....

Embodiment 2

[0065] First, the micro-silicon powder is continuously preheated to 650°C, and then continuously added to a roaster at 880°C for dynamic roasting for 28 minutes to remove organic volatiles such as coal tar and sintered to obtain porous spherical, gray-white particles of roasted micro-silicon powder; the roasted micro-silicon powder Add 41.3Kg of silicon powder, 48Kg of liquid sodium hydroxide with a mass fraction of 30%, and 110Kg of water into a 300L reactor, mix and stir evenly, and directly feed superheated steam with a pressure of 3.0MPa and a temperature of 450°C to heat the mixture to 190°C and React for 240 minutes to generate water glass mother liquor. After the mother liquor is cooled to 75°C by heat exchange, filter it with a filter press to obtain colorless, odorless and transparent high-purity water glass. After analysis and detection, SiO in high-purity water glass 2 The content is 19.15%wt, Na 2 The O content is 5.82wt%, and the modulus is 3.4; after analysis by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com