Patents

Literature

120 results about "Impression trays" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impression tray, and method for capturing structures, arrangements or shapes, in particular in the mouth or human body

InactiveUS20120064477A1Easy, dependable and accurateImpression capsTeeth fillingSpatially resolvedHuman body

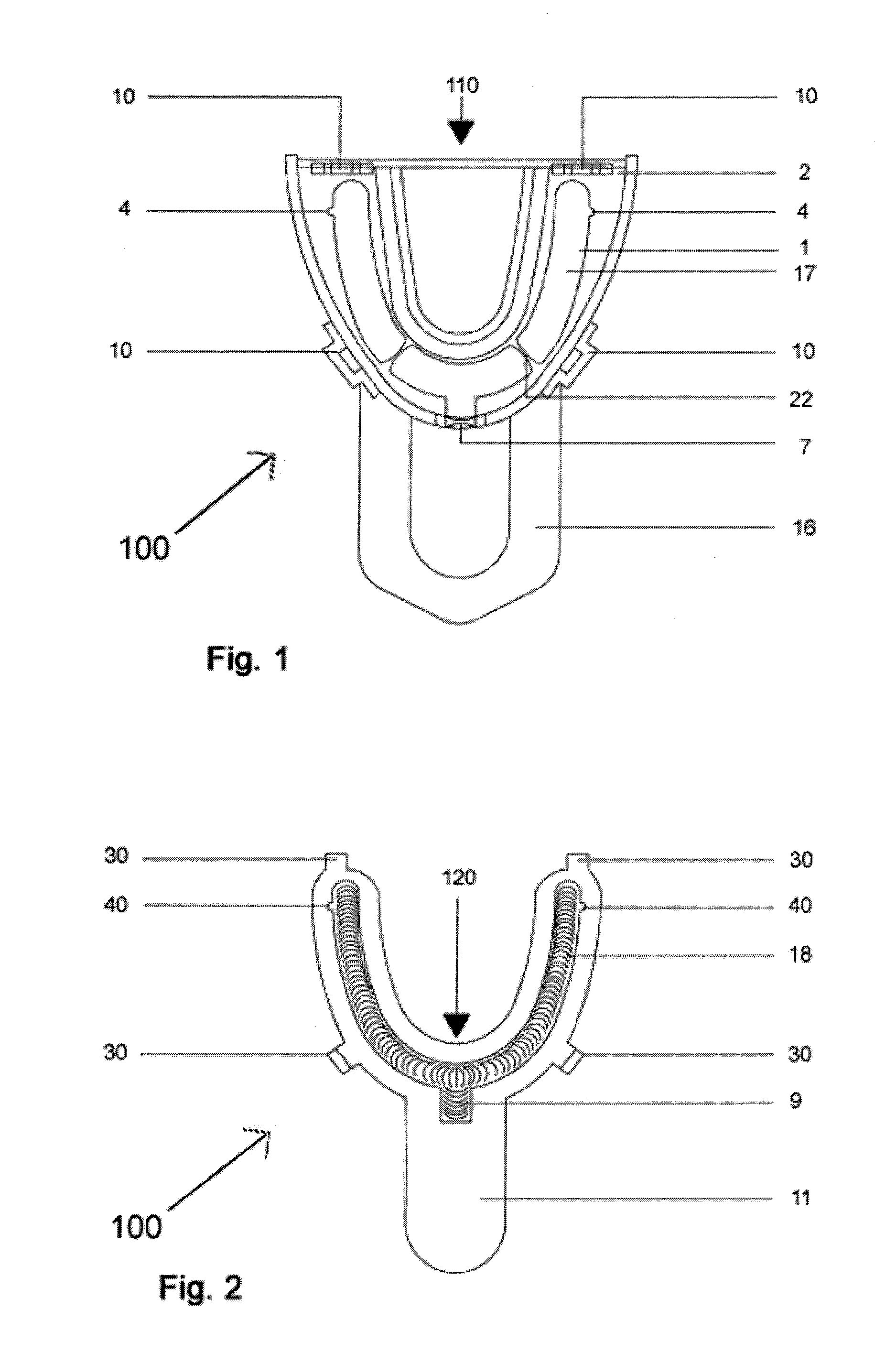

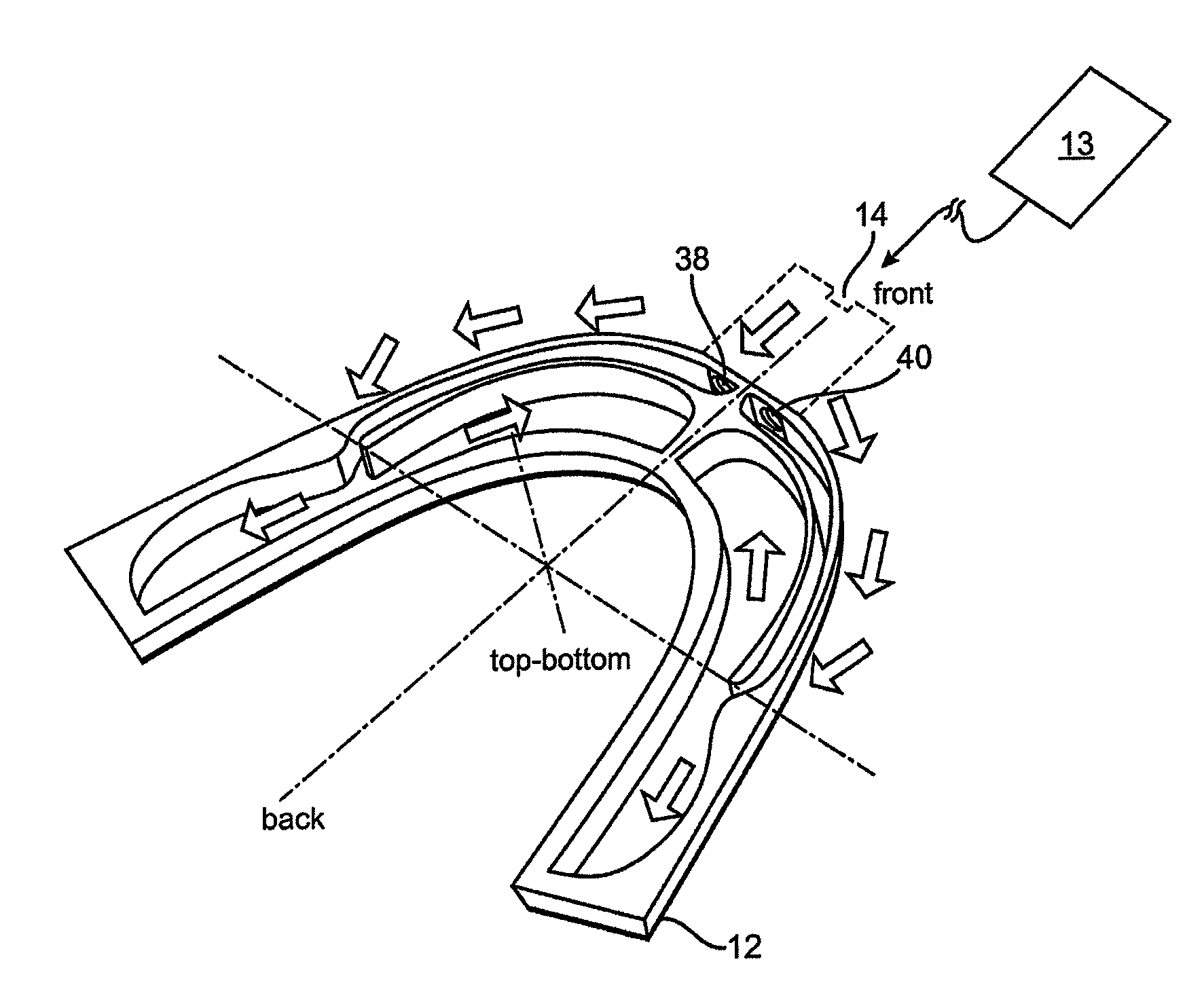

The invention relates to an impression tray, such as in particular a dental impression tray, which carries a deformable impression mass in order to prepare an impression of arrangements, shapes and / or dimensions, in particular in or on the human body, preferably in the mouth, and further preferred an impression of at least part of a tooth or of dental structures, wherein furthermore sensor devices are present, by means of which a change of at least one physical property and / or variable of the impression mass can be captured in a spatially resolved manner when preparing an impression and can be provided in a form that is suited for electronic data processing. The invention further relates to a method for capturing structures, arrangements or shapes, such as preferably for capturing dental structures, arrangements or shapes in the mouth or in the human body, whereby a deformable impression compound is brought onto or into the structures, arrangements or shapes in particular, is introduced, into the mouth or body and a change of at least one physical property and / or variable of the impression compound is transmitted there in a spatially resolved manner directly to sensor devices when preparing an impression and is captured by the sensor devices and, furthermore, provided in a form that is suitable for electronic data processing.

Owner:MEDENTIC

Apparatus for Producing Dental Impressions

Owner:NEUSCHAFER GERD

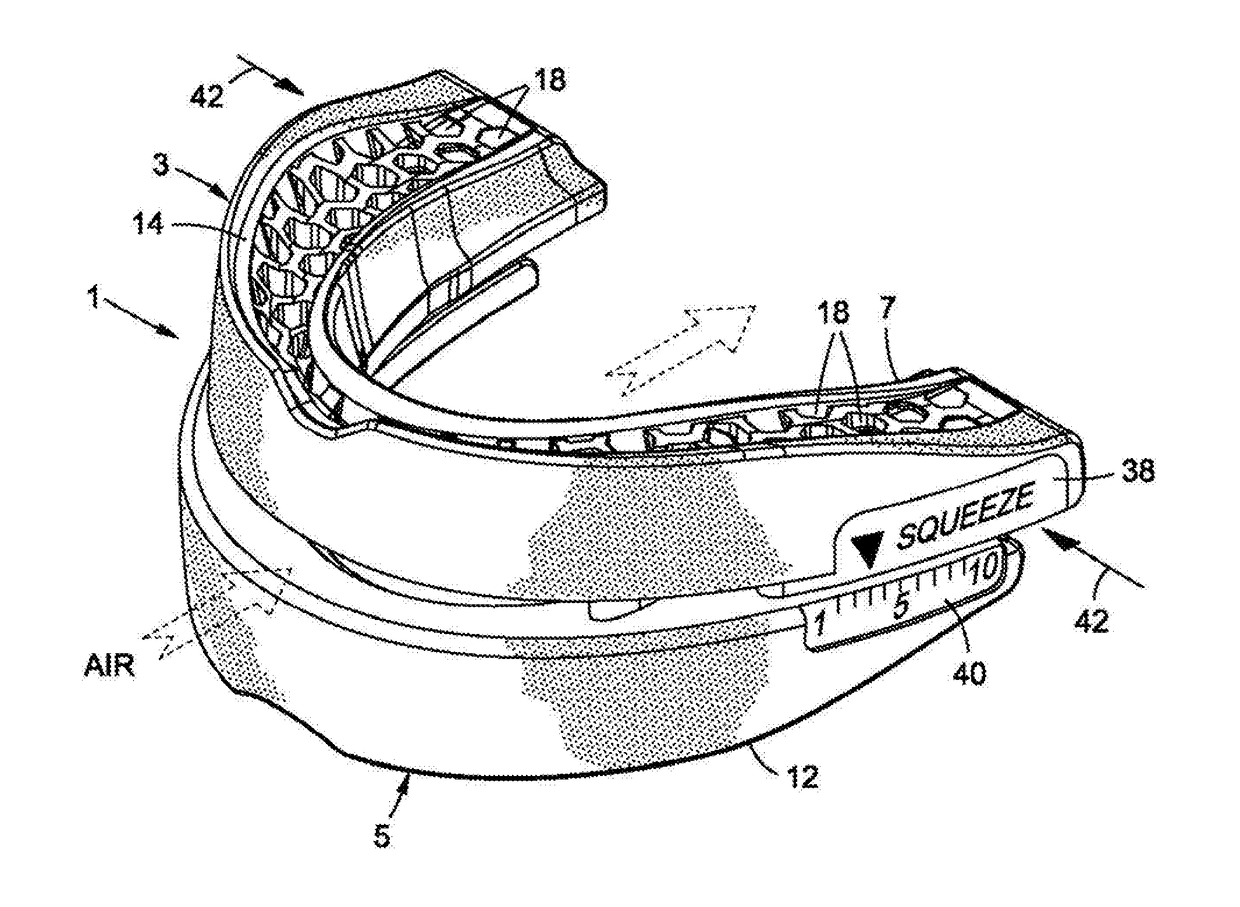

Apparatus and methods for accelerating dental treatments

InactiveUS6382979B2High activityIncrease ratingsImpression capsTeeth fillingElectrical resistance and conductancePotassium nitrate

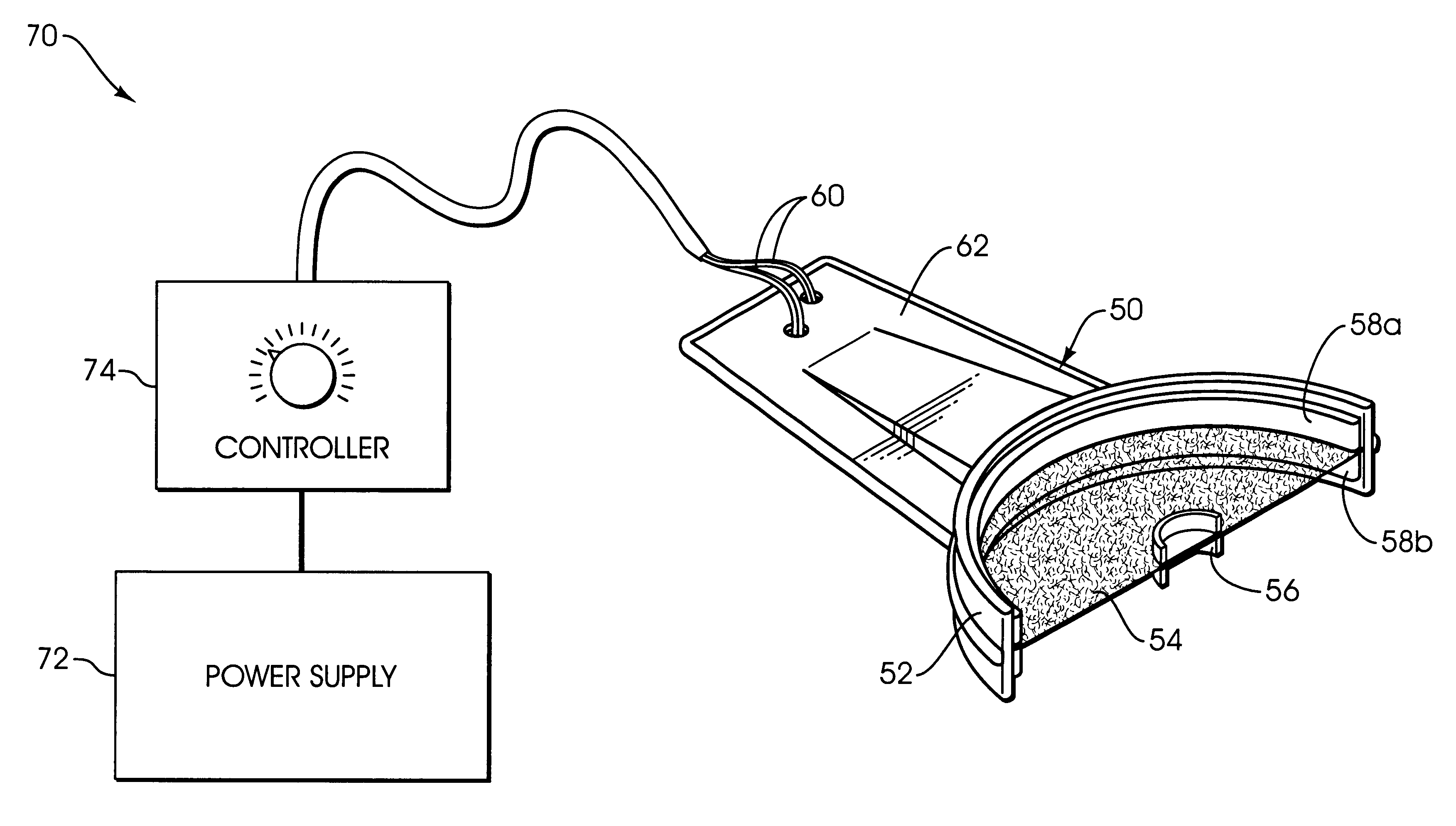

Apparatus, kits and methods for providing accelerated treatment of a patient's teeth. The apparatus, kits and methods involve the use of a dental impression tray that includes a patient dentition impression formed from a dental impression material such as an alginate. The impression tray advantageously includes heating means for heating and maintaining the formed patient dentition impression at a temperature greater than about 105° F. The heated dental trays may be used to accelerate the activity of dental bleaching agents (e.g., peroxides), desensitizing agents (e.g., potassium nitrate), remineralizing agents (e.g., fluoride salts), and the like. A dental office procedure for treating teeth involves the basic steps of: (1) coating a specially-prepared patient dentition impression with a dental composition such as a bleaching, desensitizing or remineralizing composition; (2) placing the coated patient dentition impression into the patient's mouth; (3) heating the patient dentition impression and dental composition to a temperature of at least about 105° F.; and (4) retaining the patient dentition impression in position for period of time in a range of about 1 minute to about 60 minutes. The procedure can be adapted to microwave heating, electrical resistance heating, or hot fluid heating of the patient dentition impression.

Owner:LINDQUIST SHERRILL F DDS +1

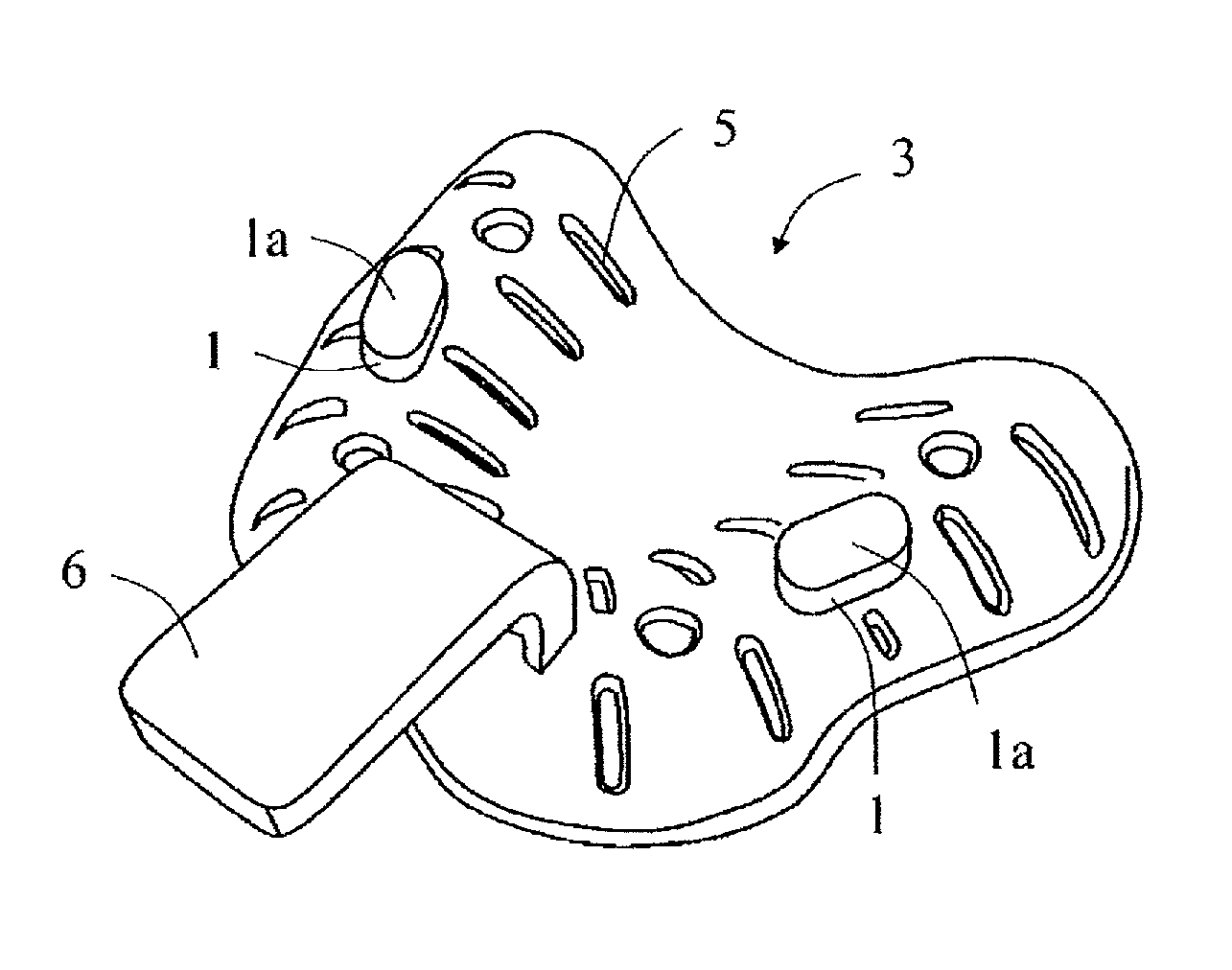

Removable handle scan body for impression trays and radiographic templates for integrated optical and ct scanning

InactiveUS20120230567A1Simple methodAvoid dependenceAdditive manufacturing apparatusImpression capsComputed tomographyImpression trays

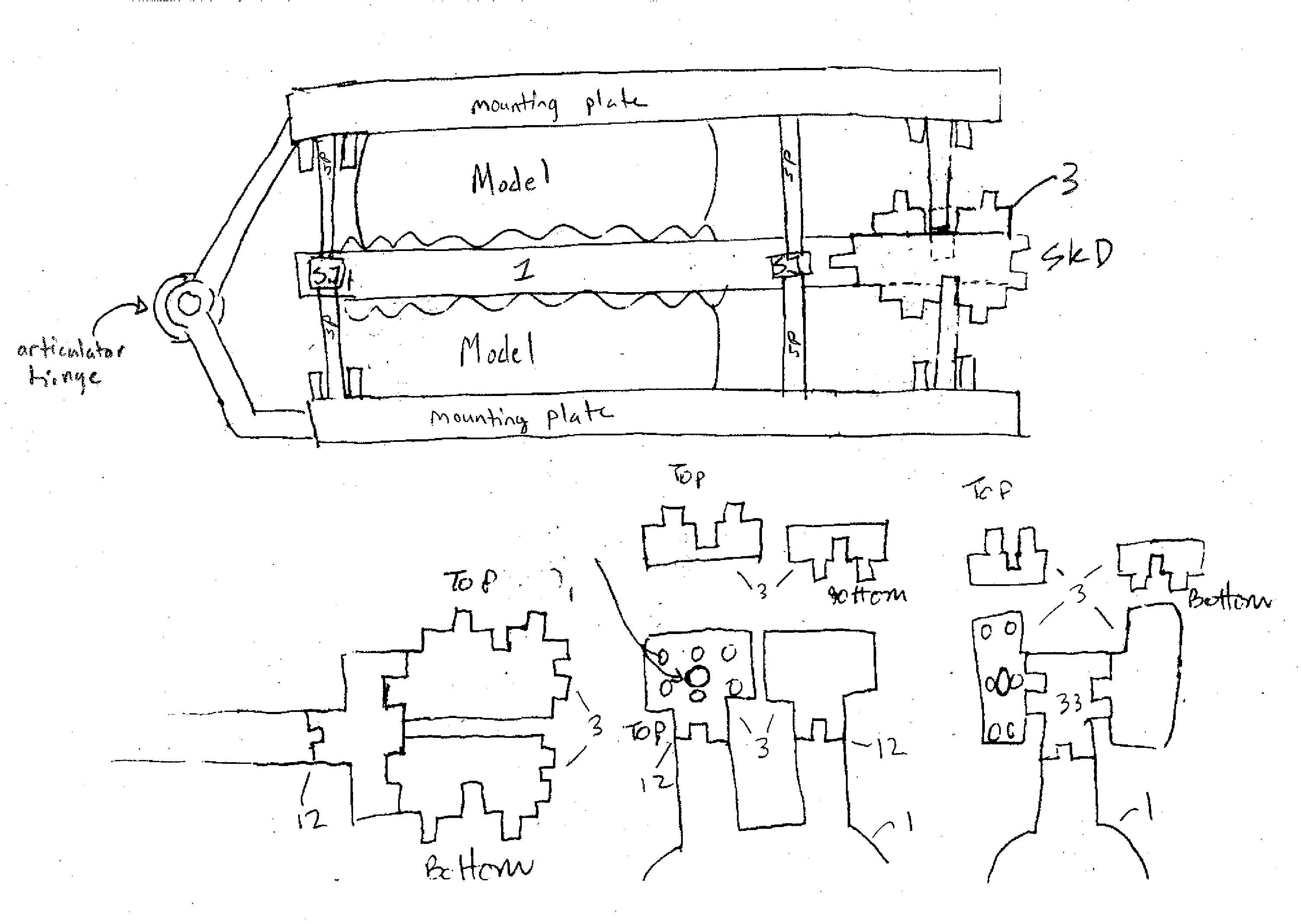

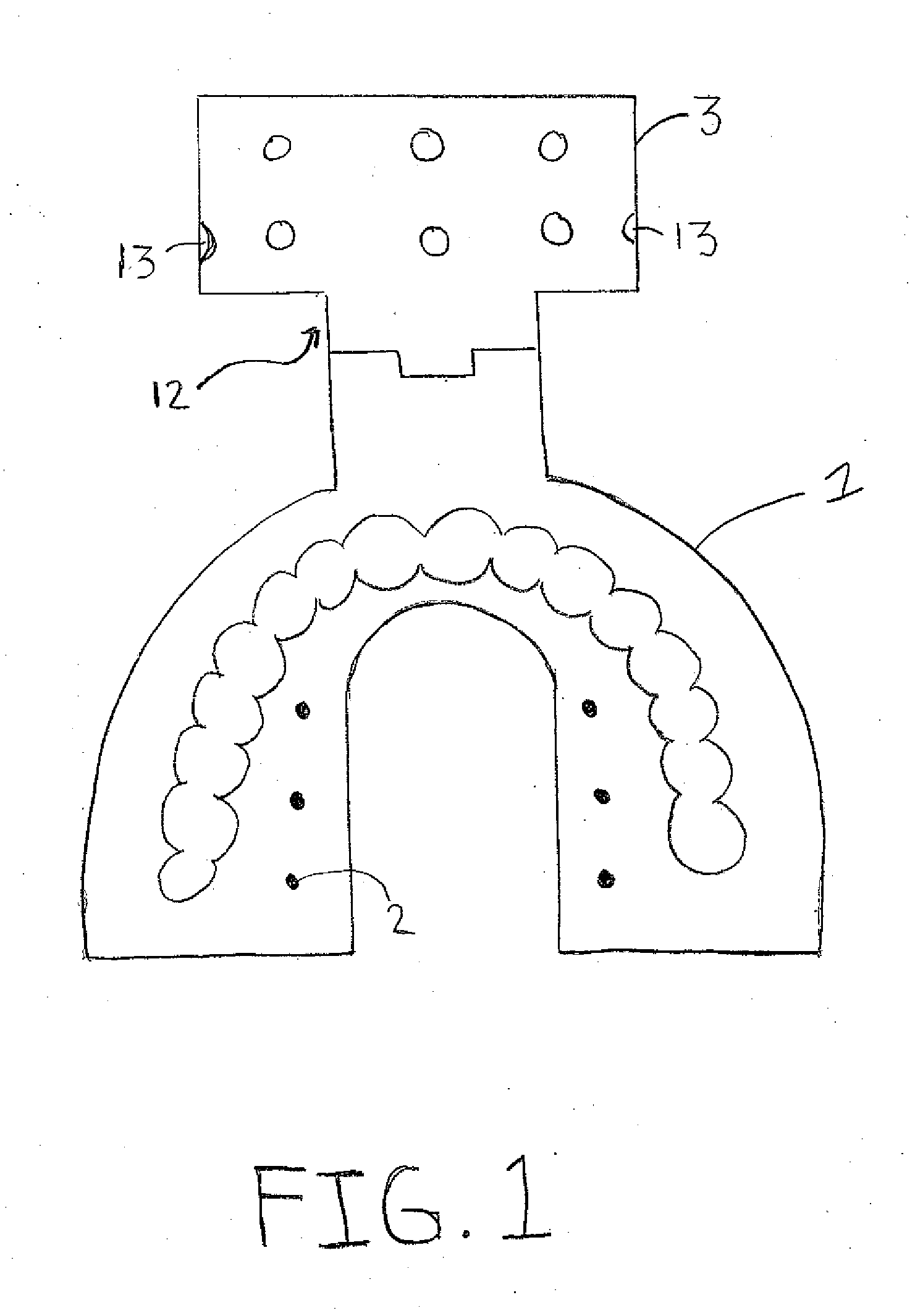

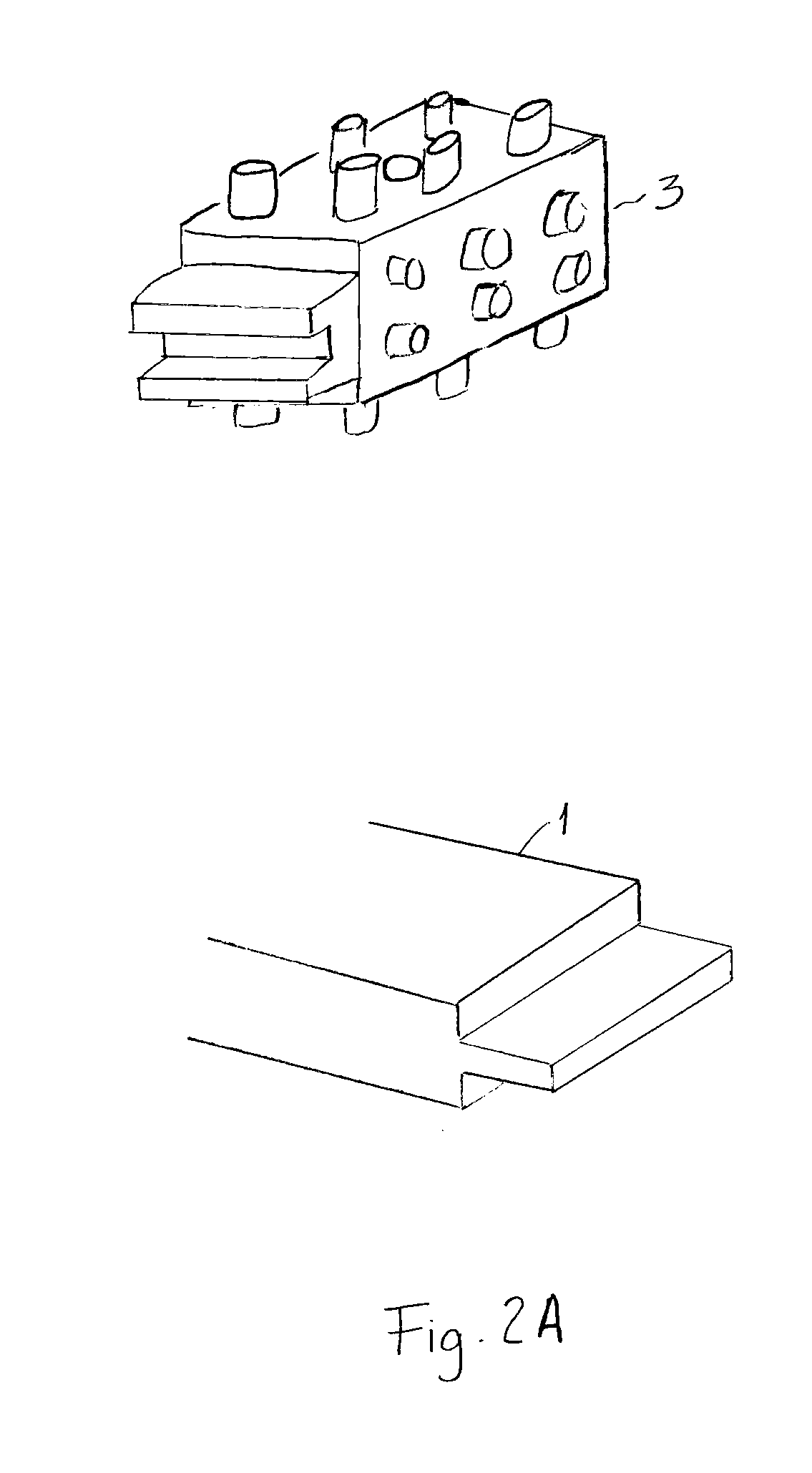

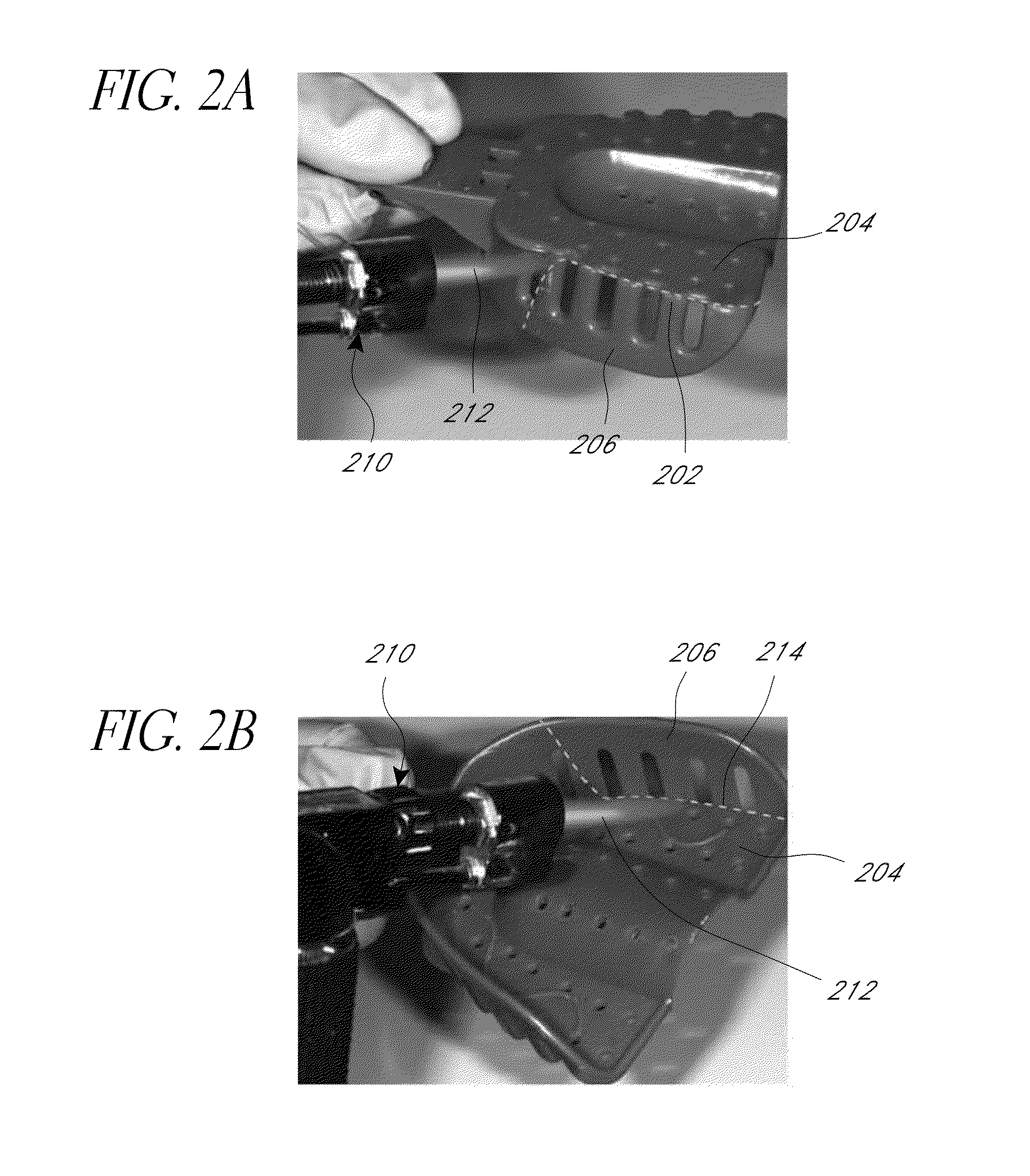

A device for use in optical scanning and CT scanning including a radiographic template and at least one shape of known dimension (SKD). The radiographic template includes a plurality of radio-opaque markers and is configured to take an impression of at least one surface of a patient. The SKD is removably attached to the radiographic template and serves as a basis for registration of data of a CT scan of the device with data of an optical scan of the device. The device may further comprise a mounting plate. The SKD is mounted on the mounting plate such that the at least one SKD is in an exact same position with respect to surfaces in a model formed from the impression as when the impression of the patient is formed in the radiographic template.

Owner:GREENBERG SURGICAL TECH

Injection impression tray

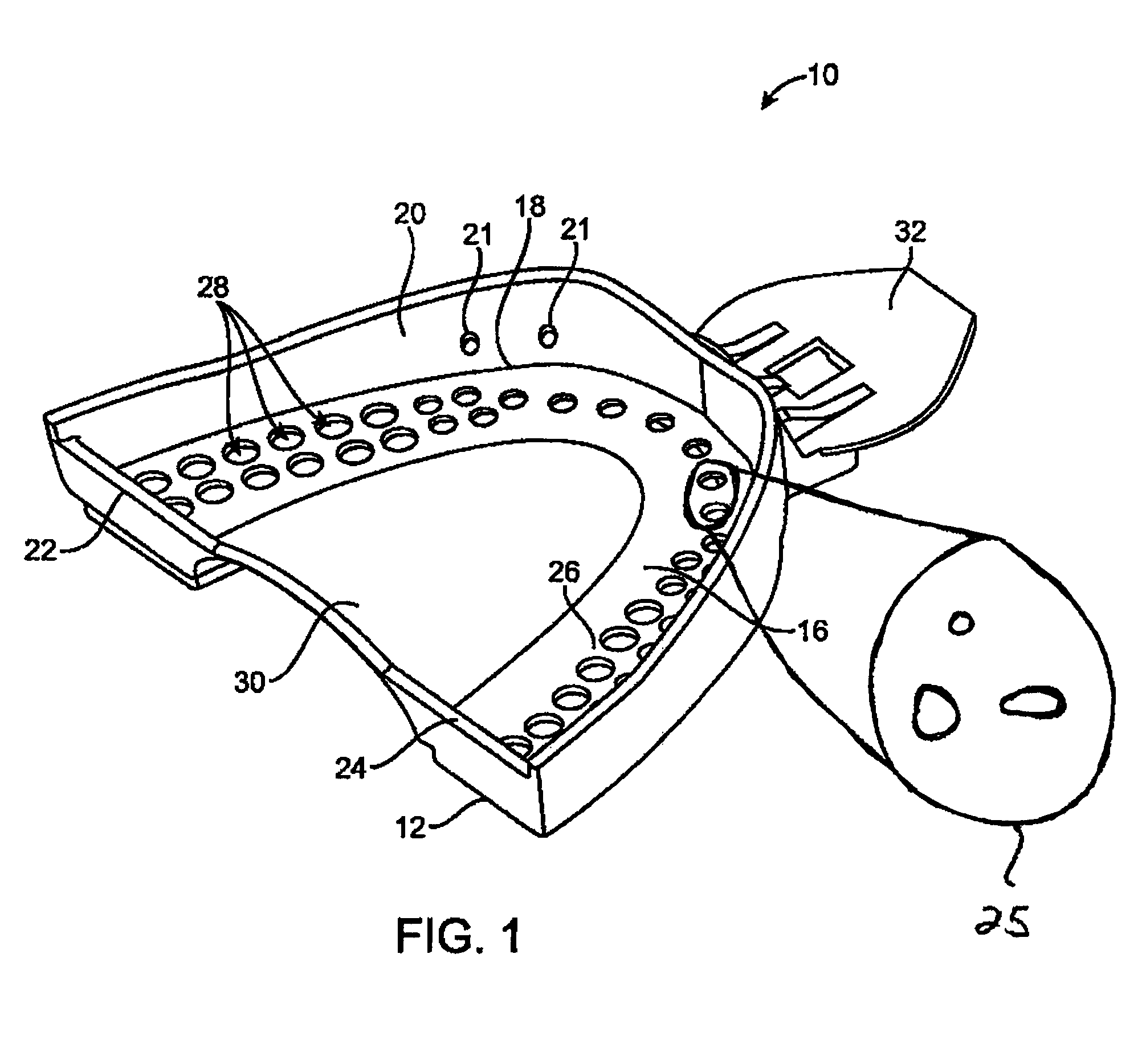

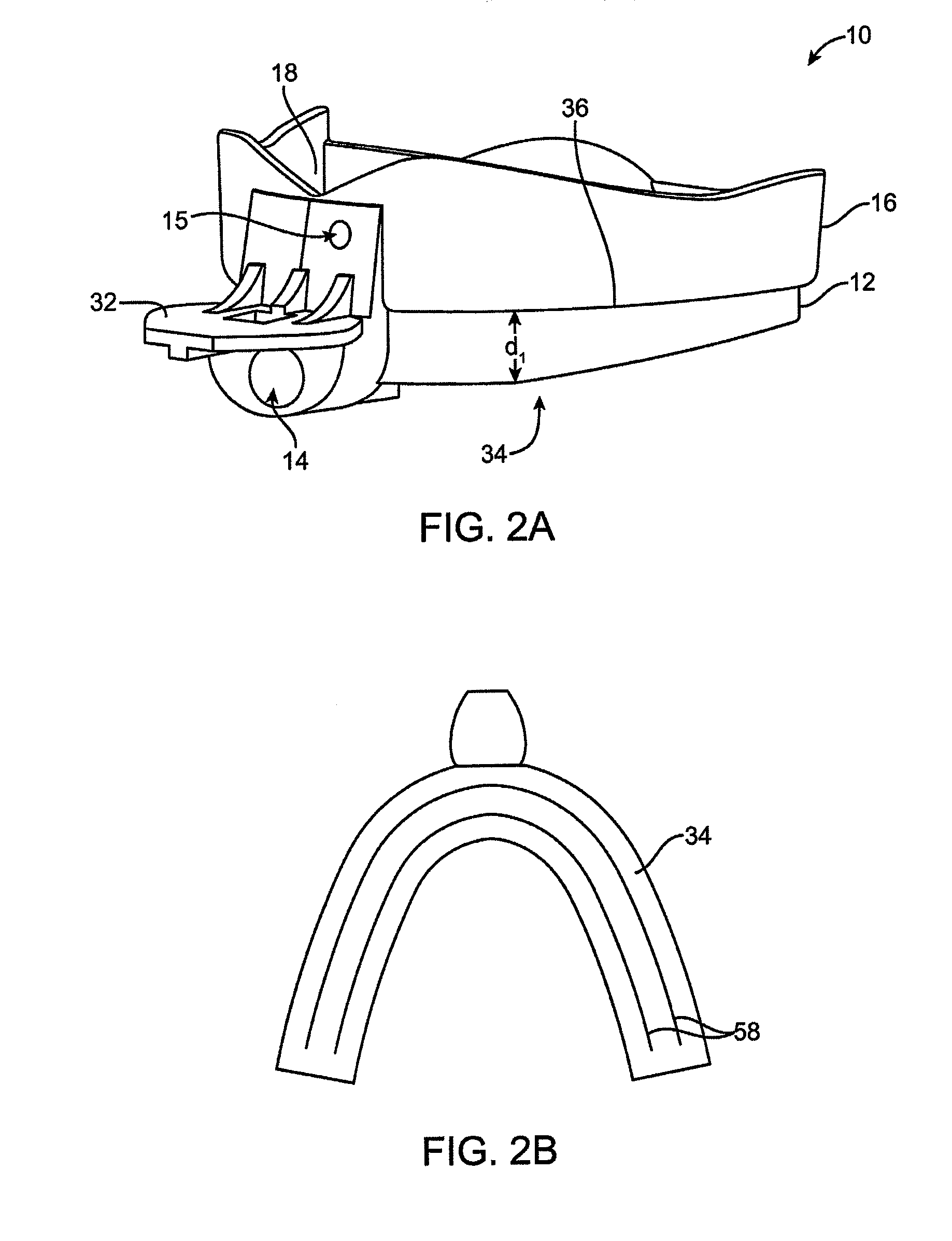

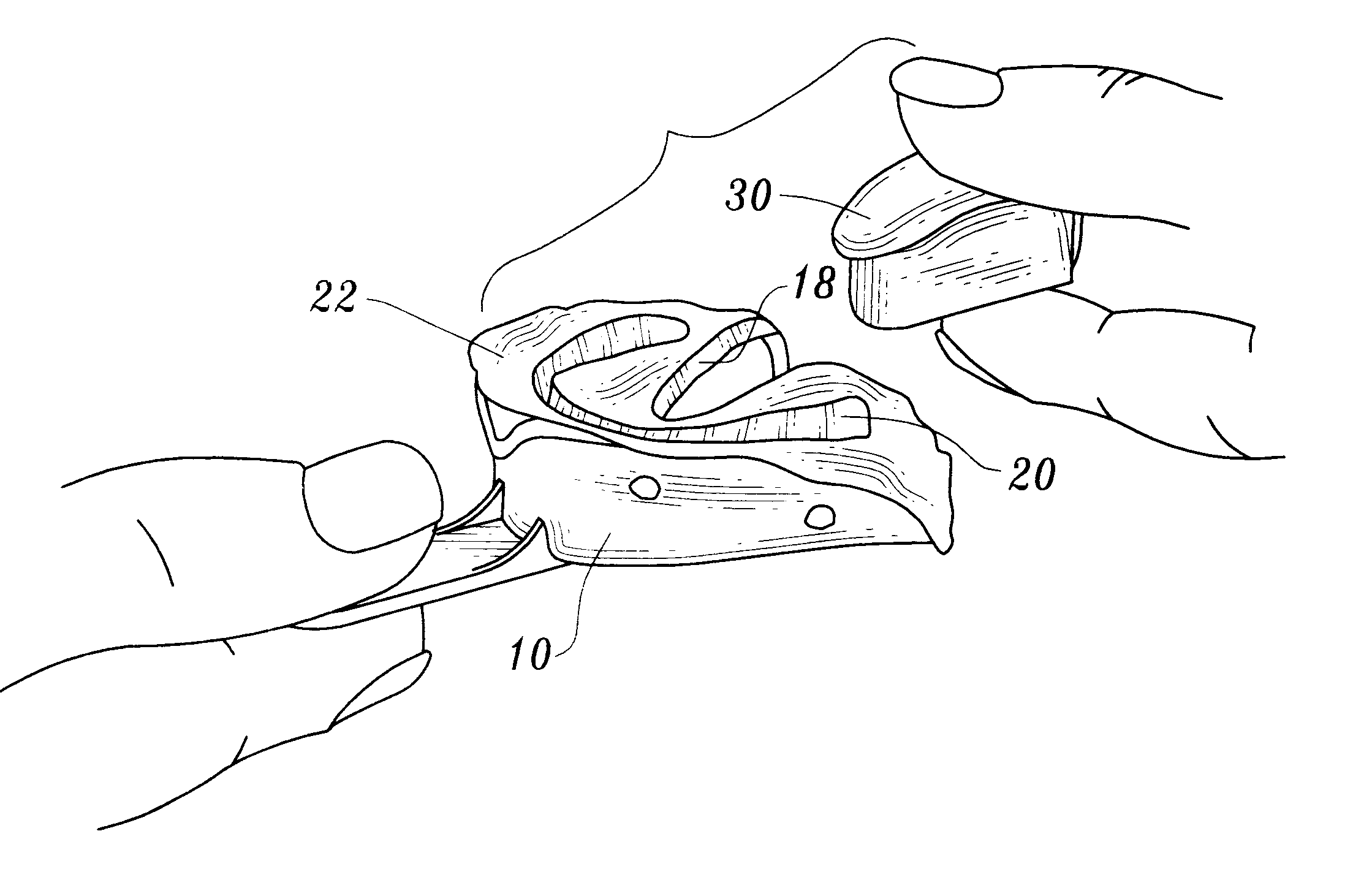

The present invention relates to an improved dental impression tray and related methods. In one embodiment, a dental impression tray includes a first portion for receiving impression material from a source and a second portion is configured for receiving a patient's upper or lower teeth and will at least partial define a cavity shaped to receive the teeth during use. In use, impression material introduced into the first portion can pass through openings and into the second portion and around a patient's teeth.

Owner:ALIGN TECH

System for forming dental impressions

A block member is selectively positioned on a dental impression tray with an outer engagement surface of the block member in engagement with the tray portion defining a lingual recess to block entry of plaster or other casting material into the lingual recess.

Owner:MAYWEATHER GEORGE S

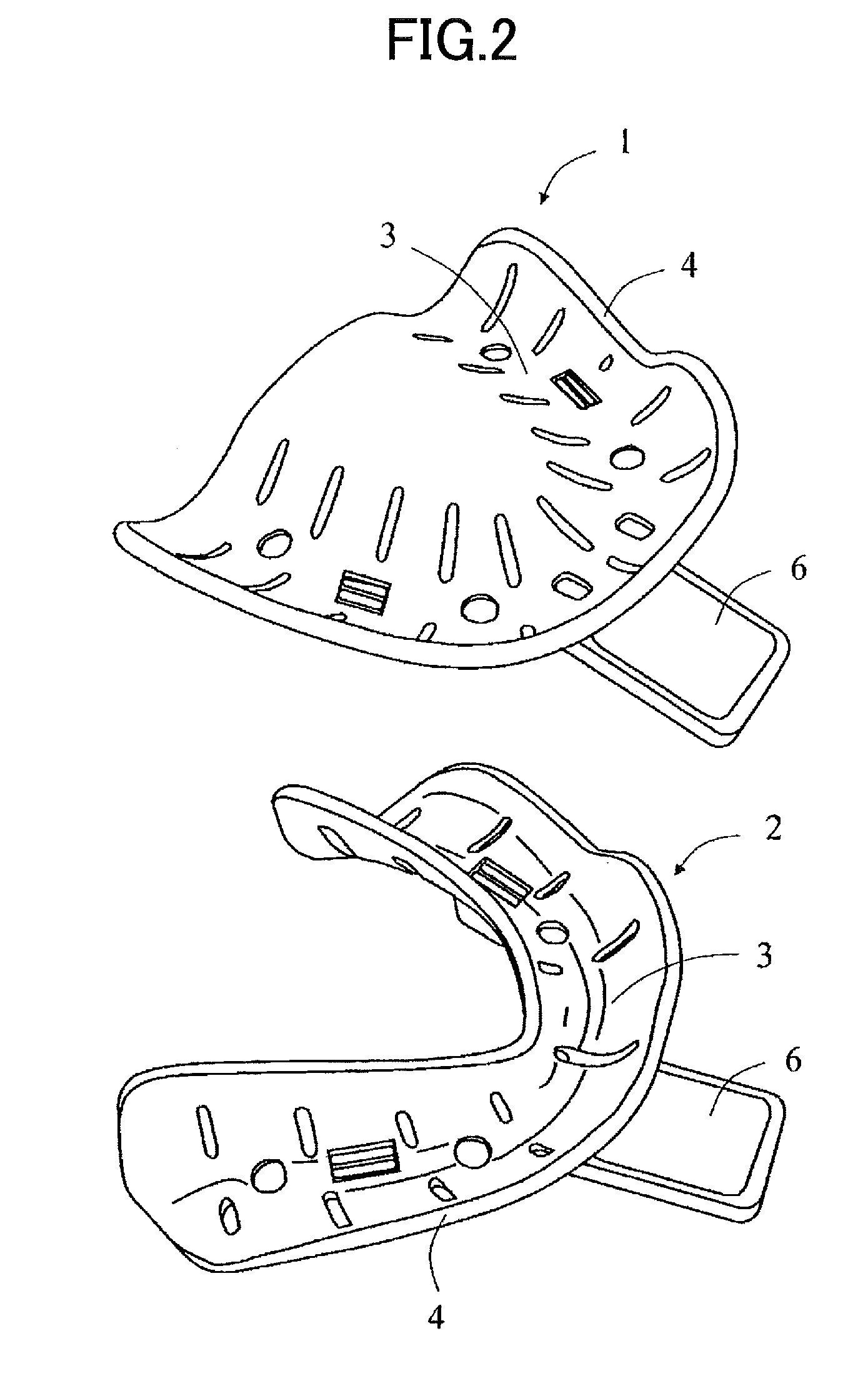

Adjustable impression tray with variable geometry

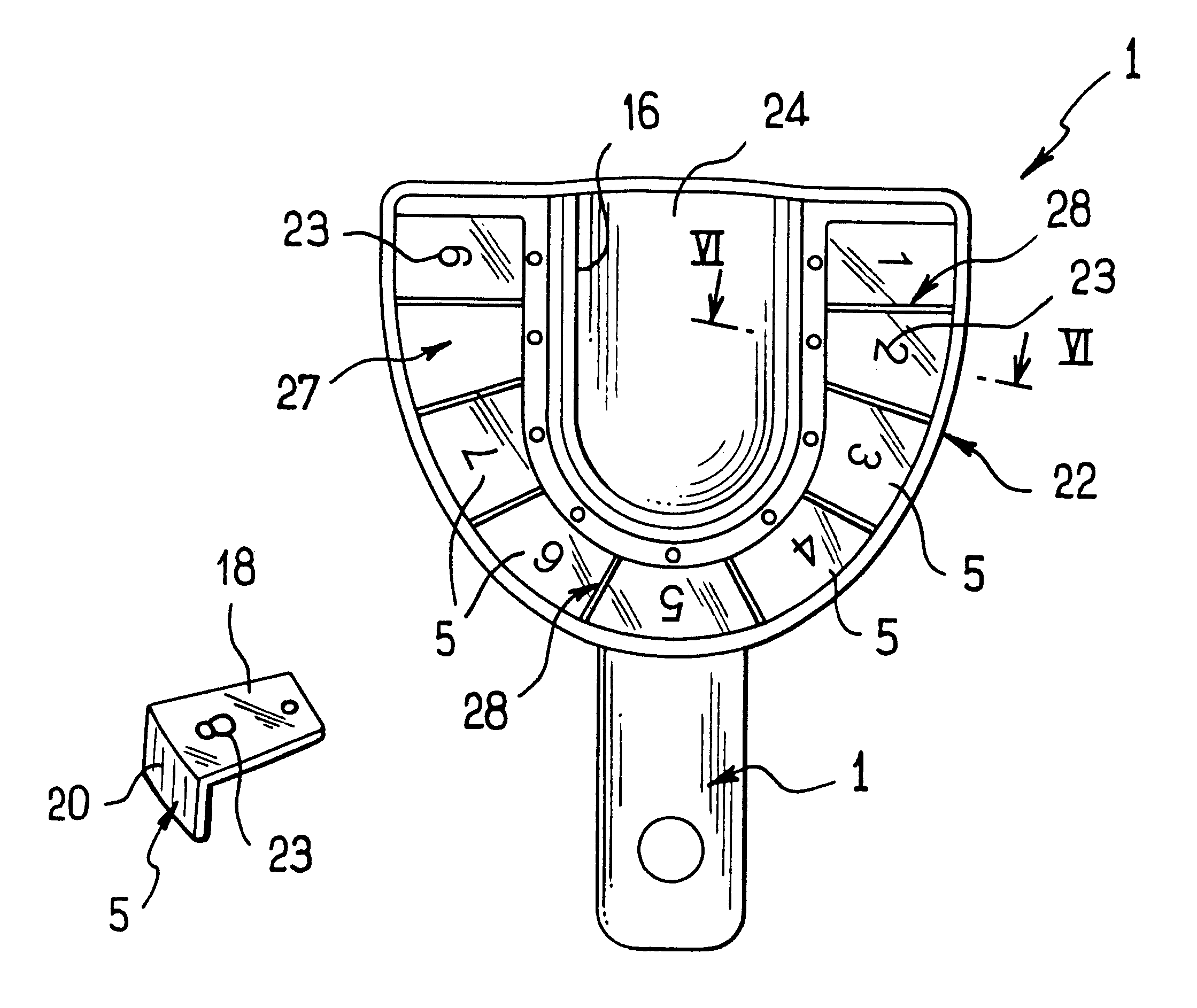

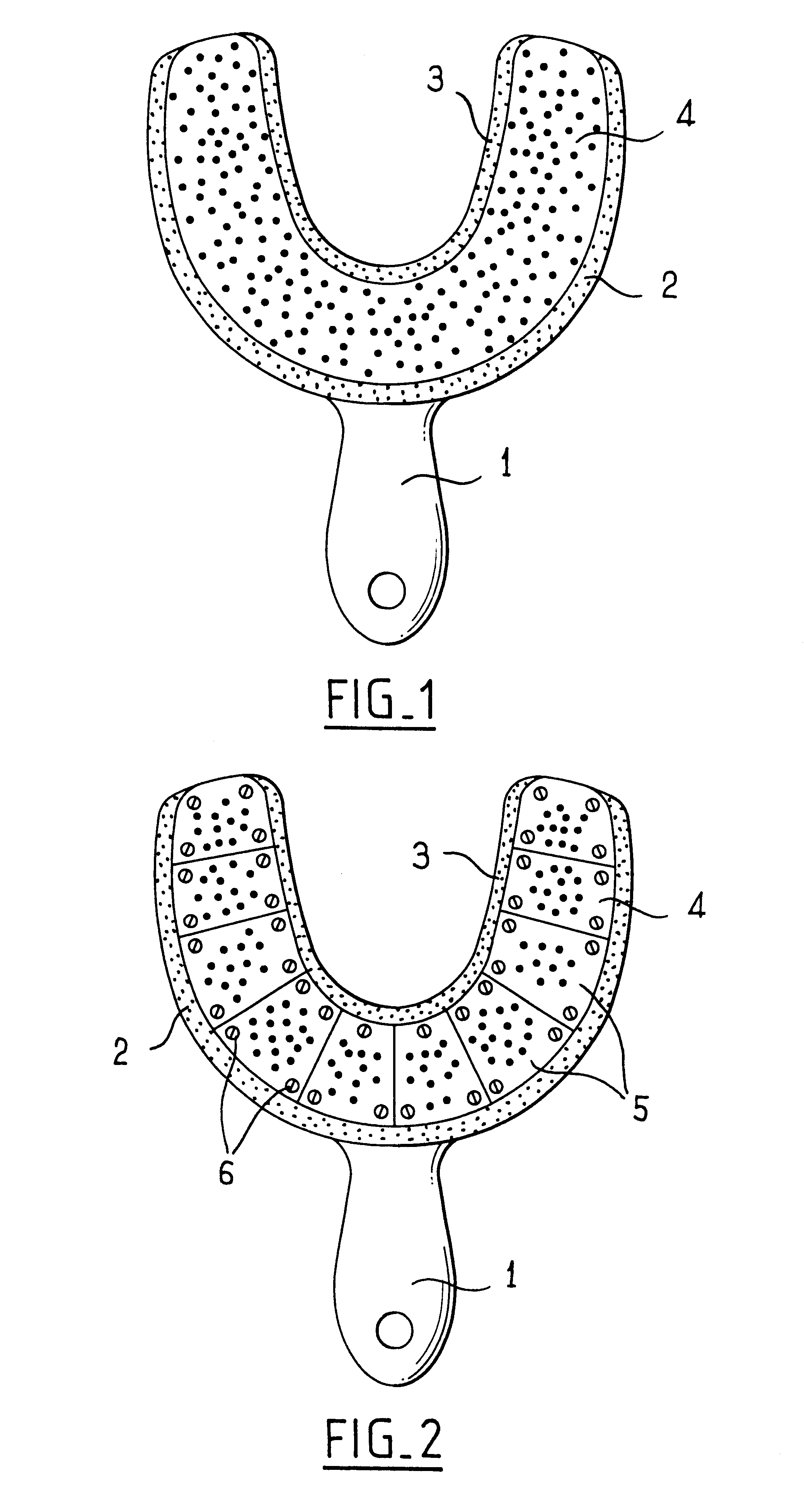

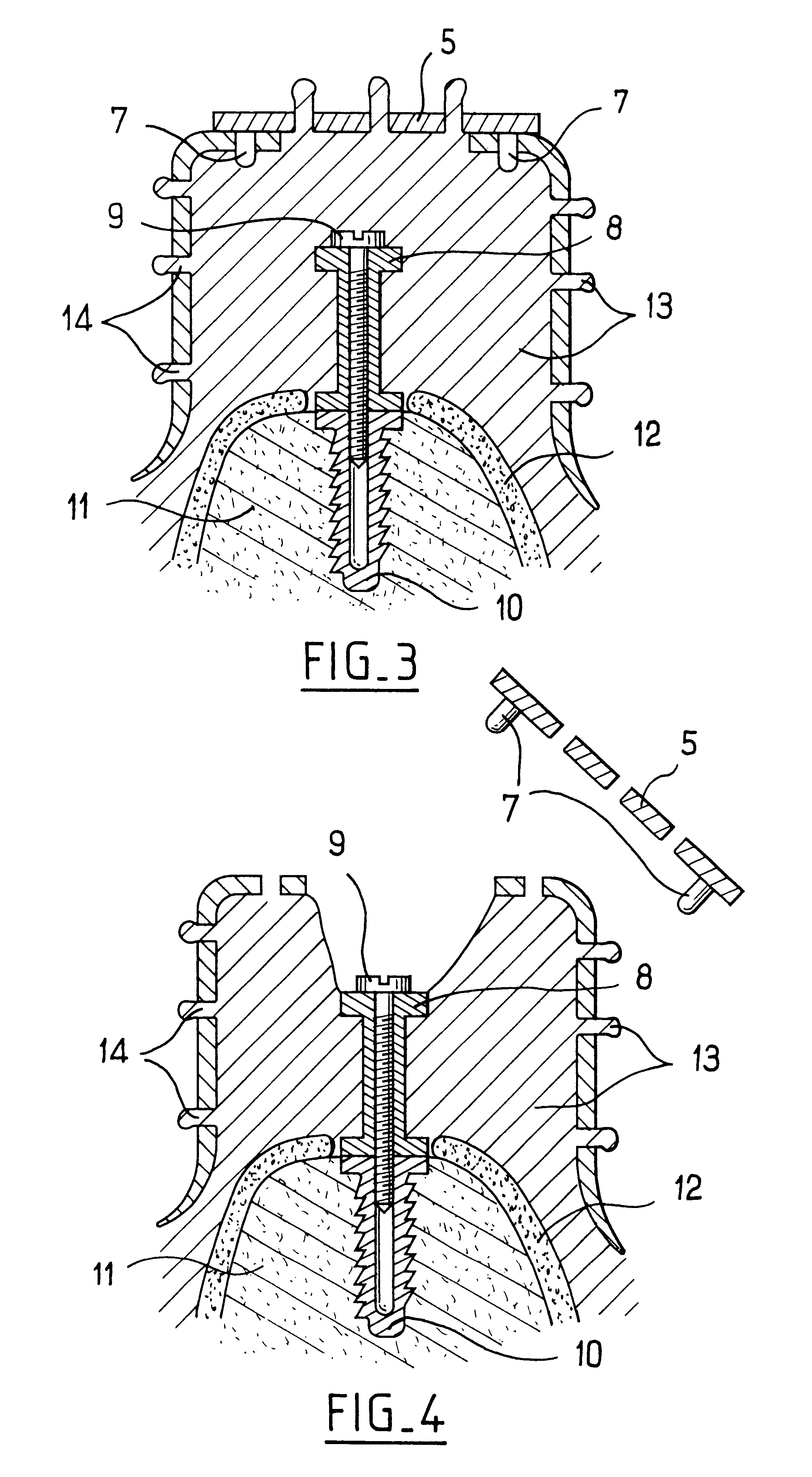

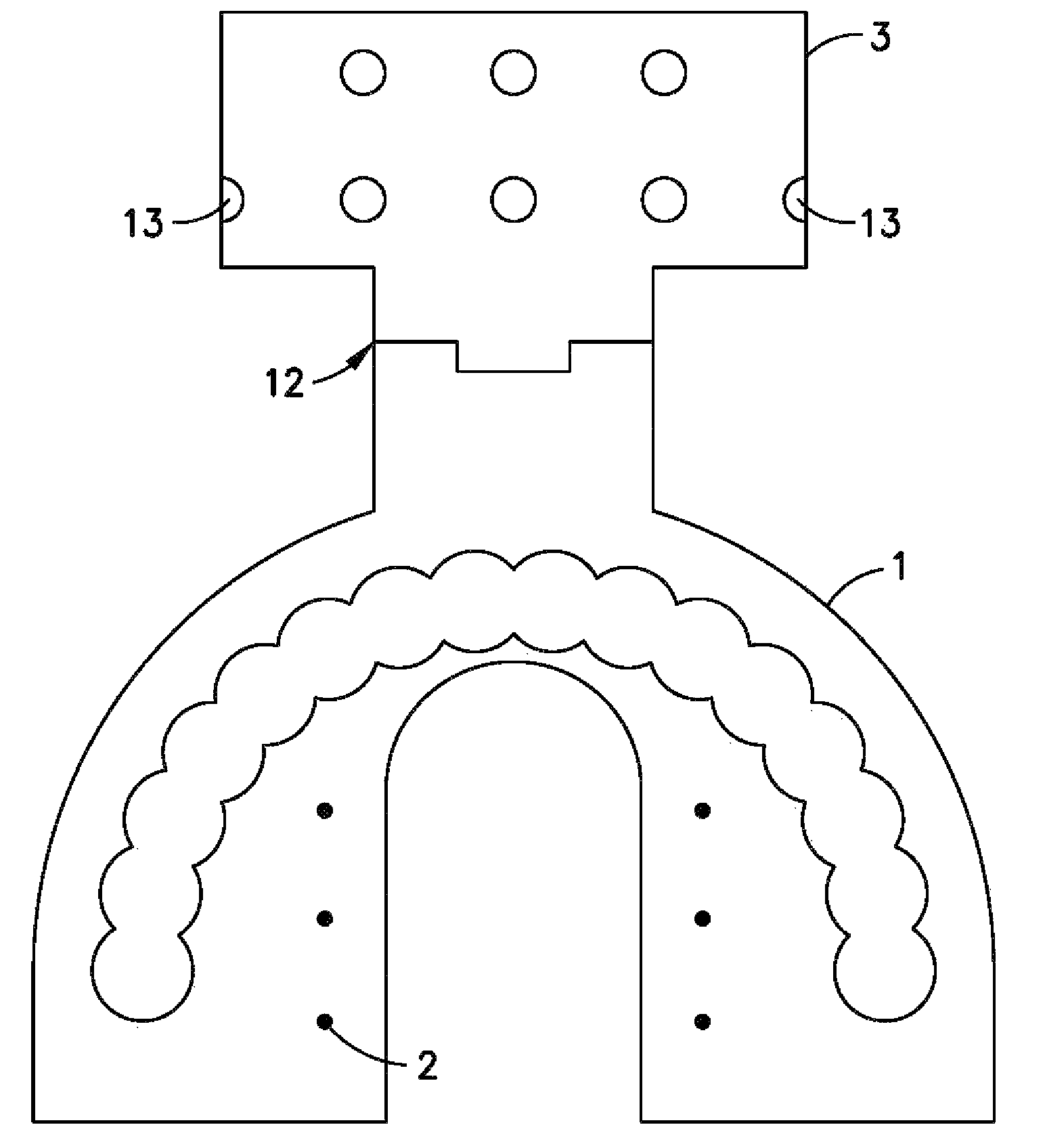

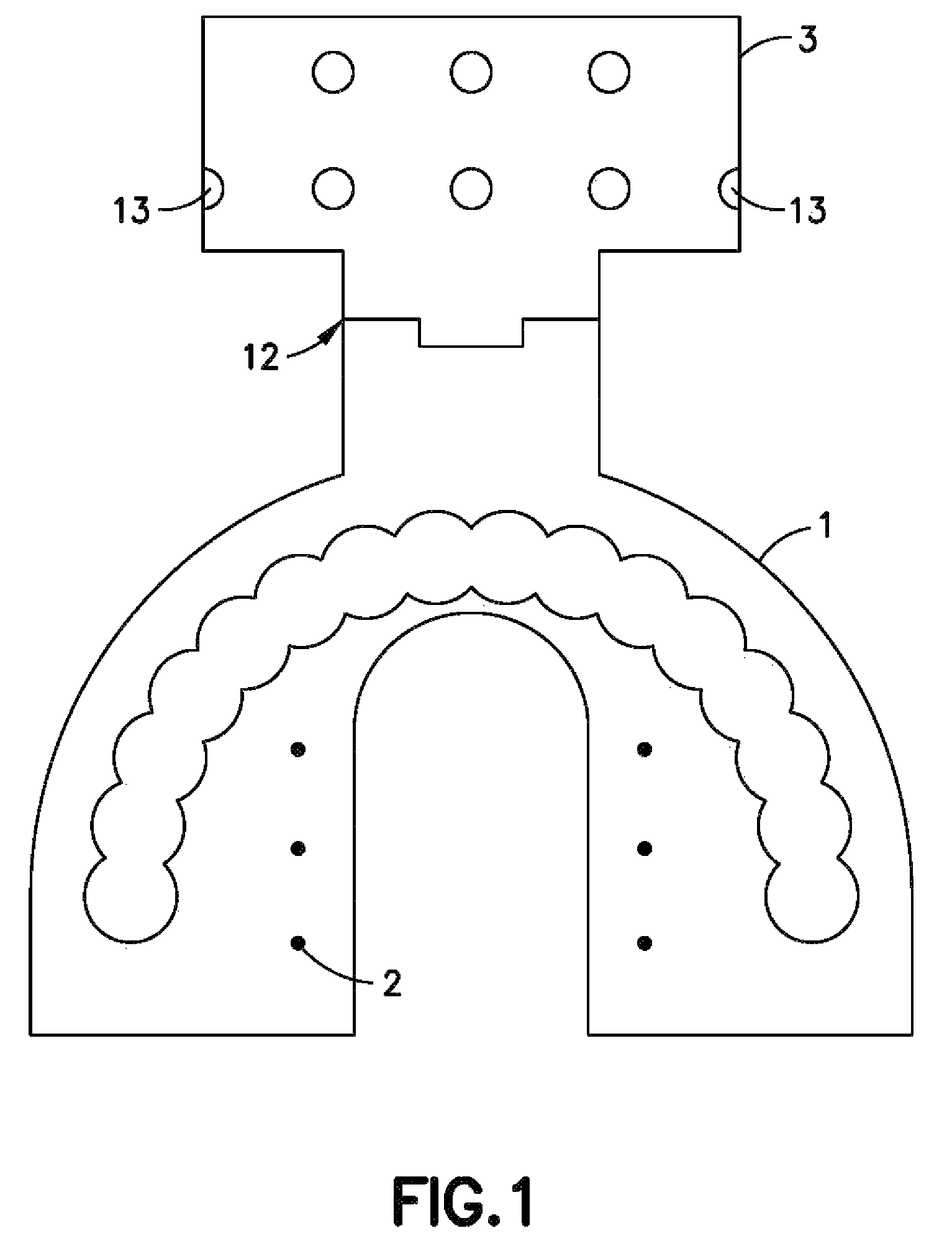

InactiveUS20050153256A1Reduce mechanical resistanceAdapt the impression tray easily and quicklyImpression capsImpression traysDental Equipment

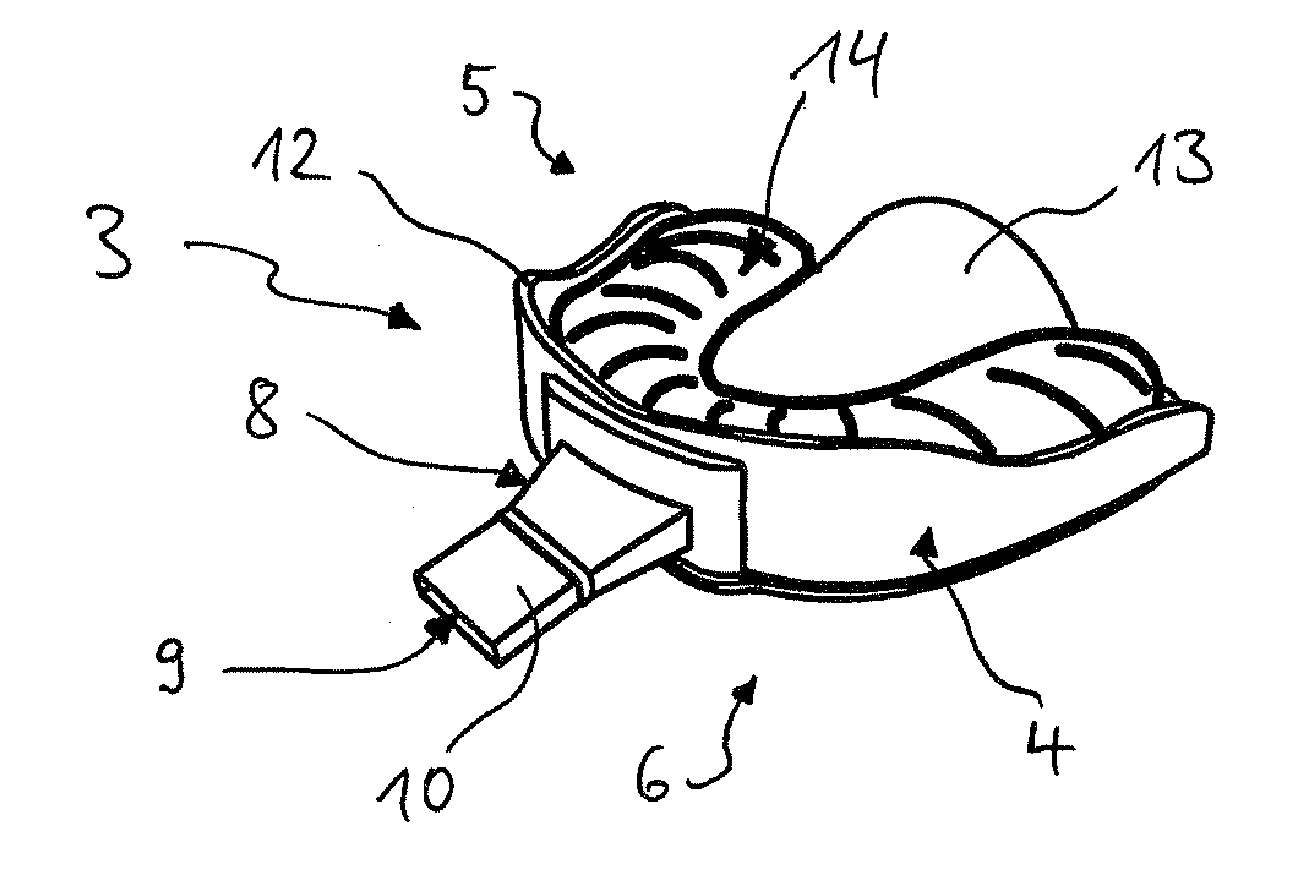

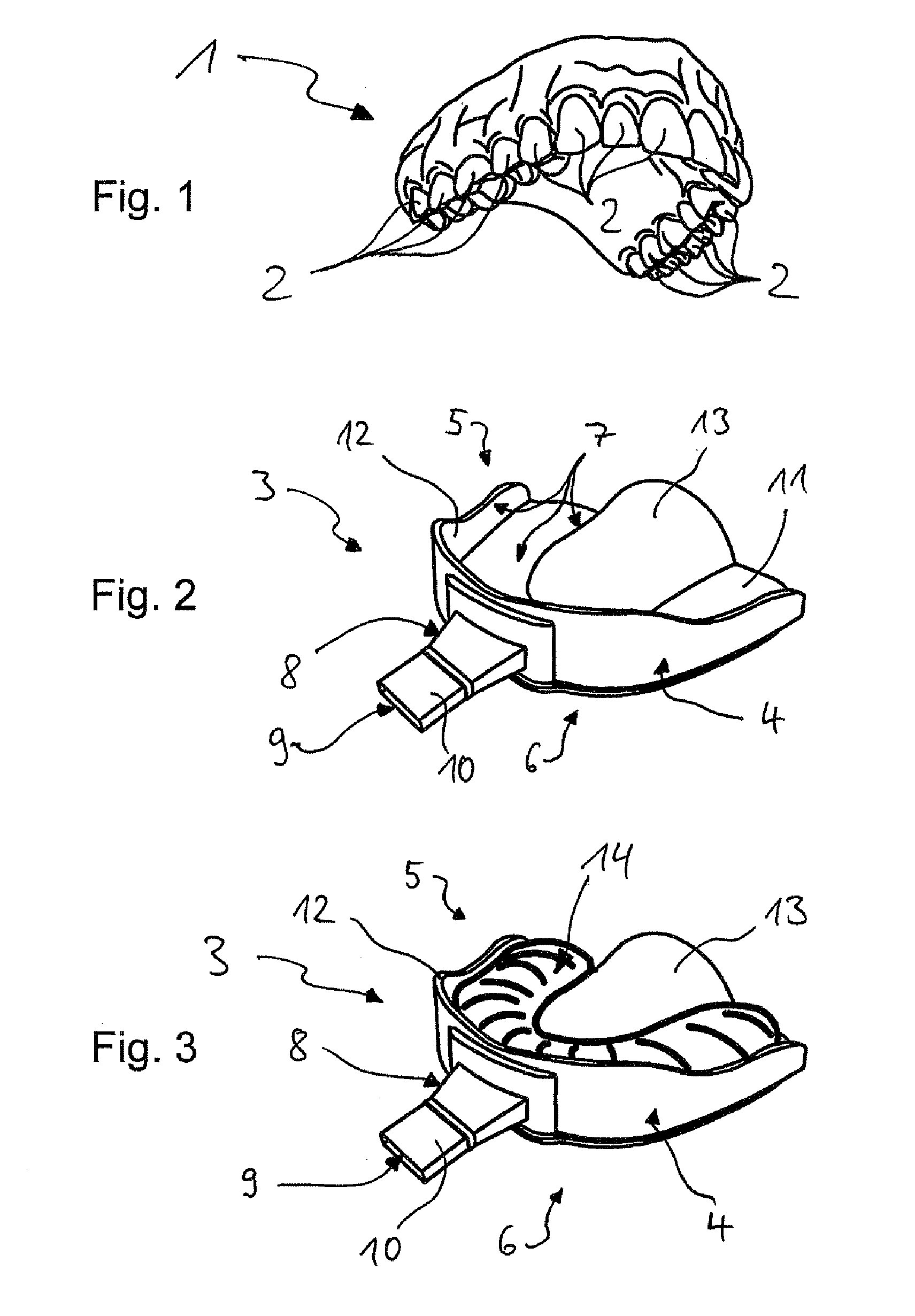

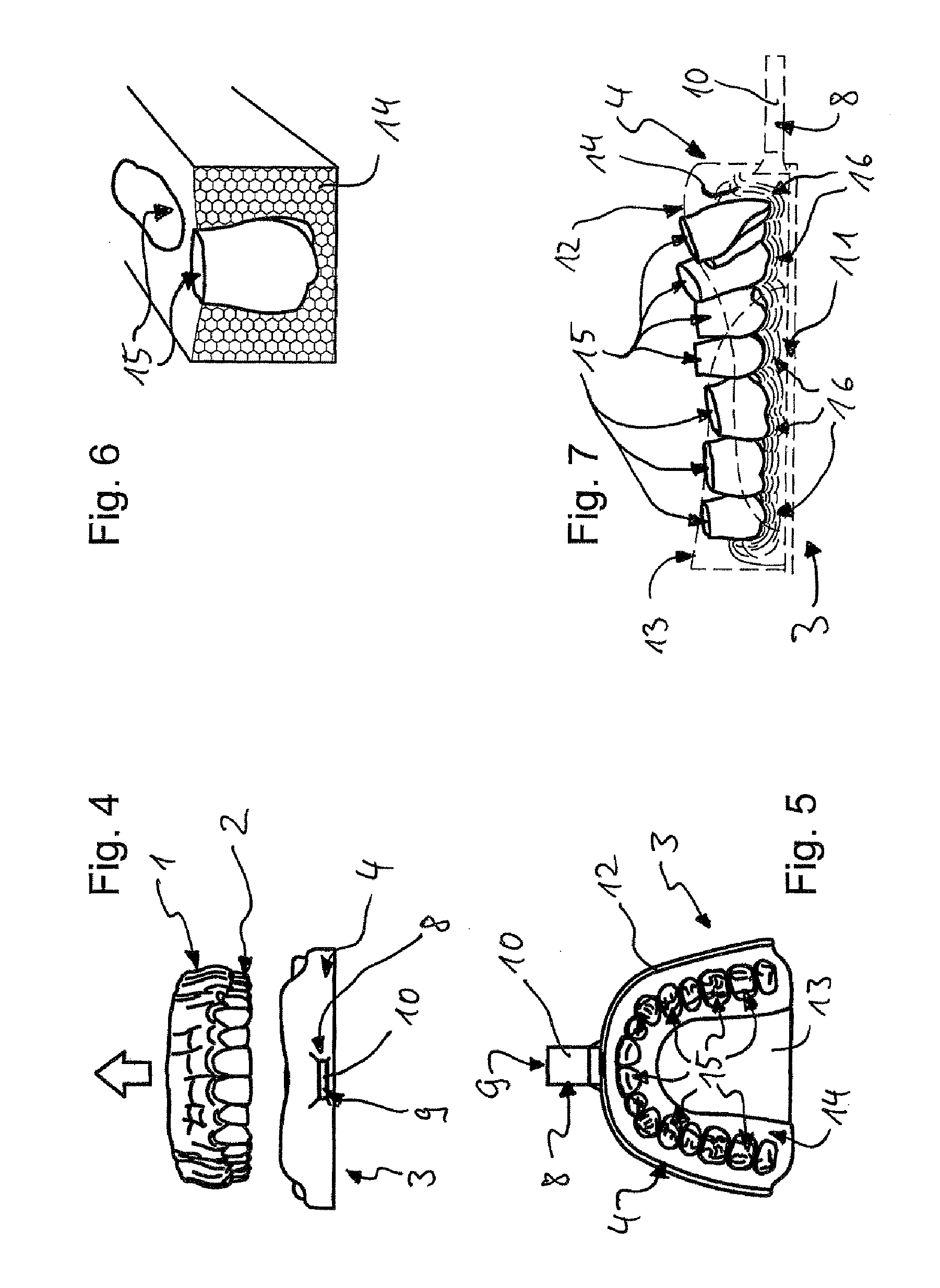

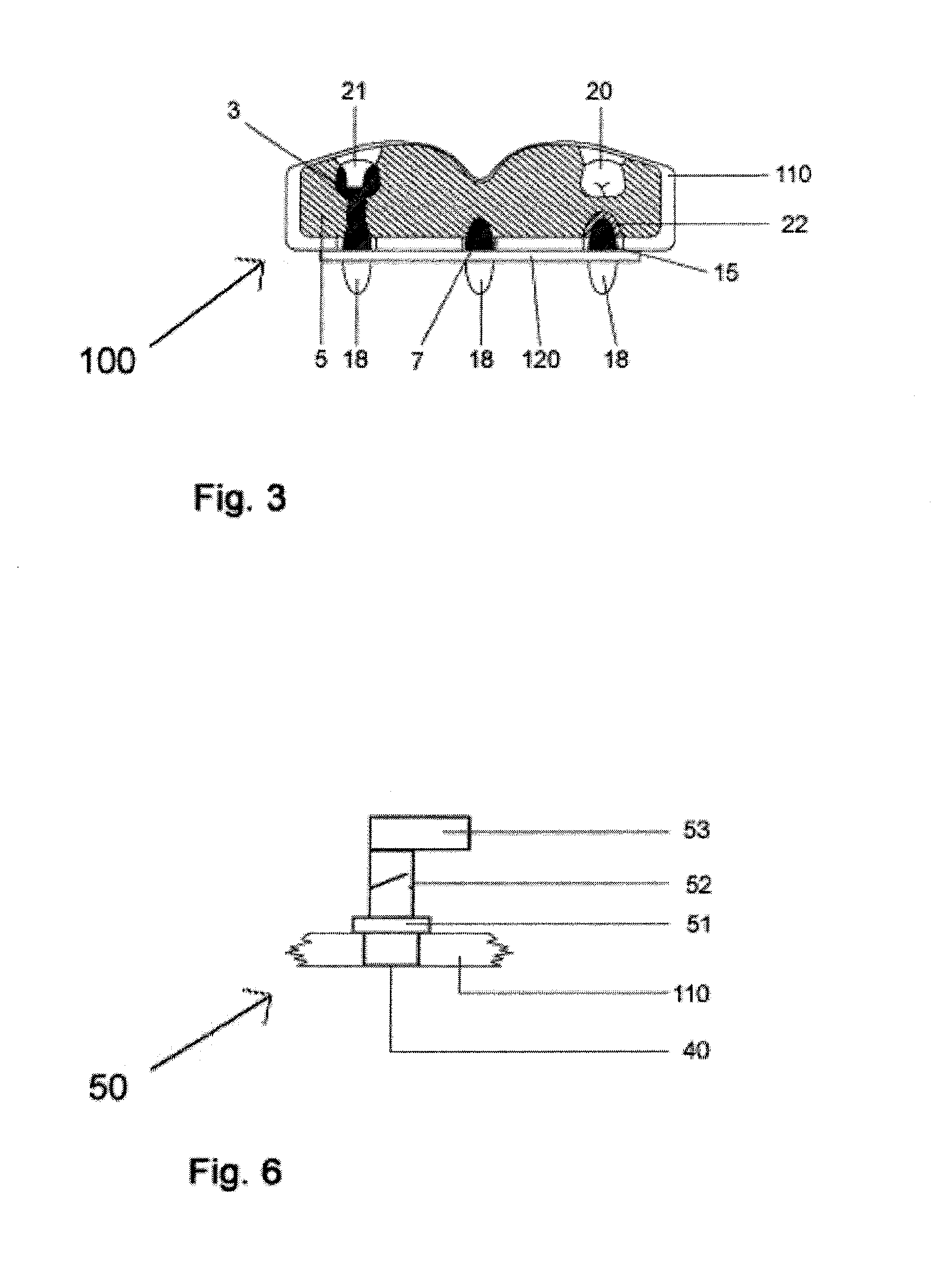

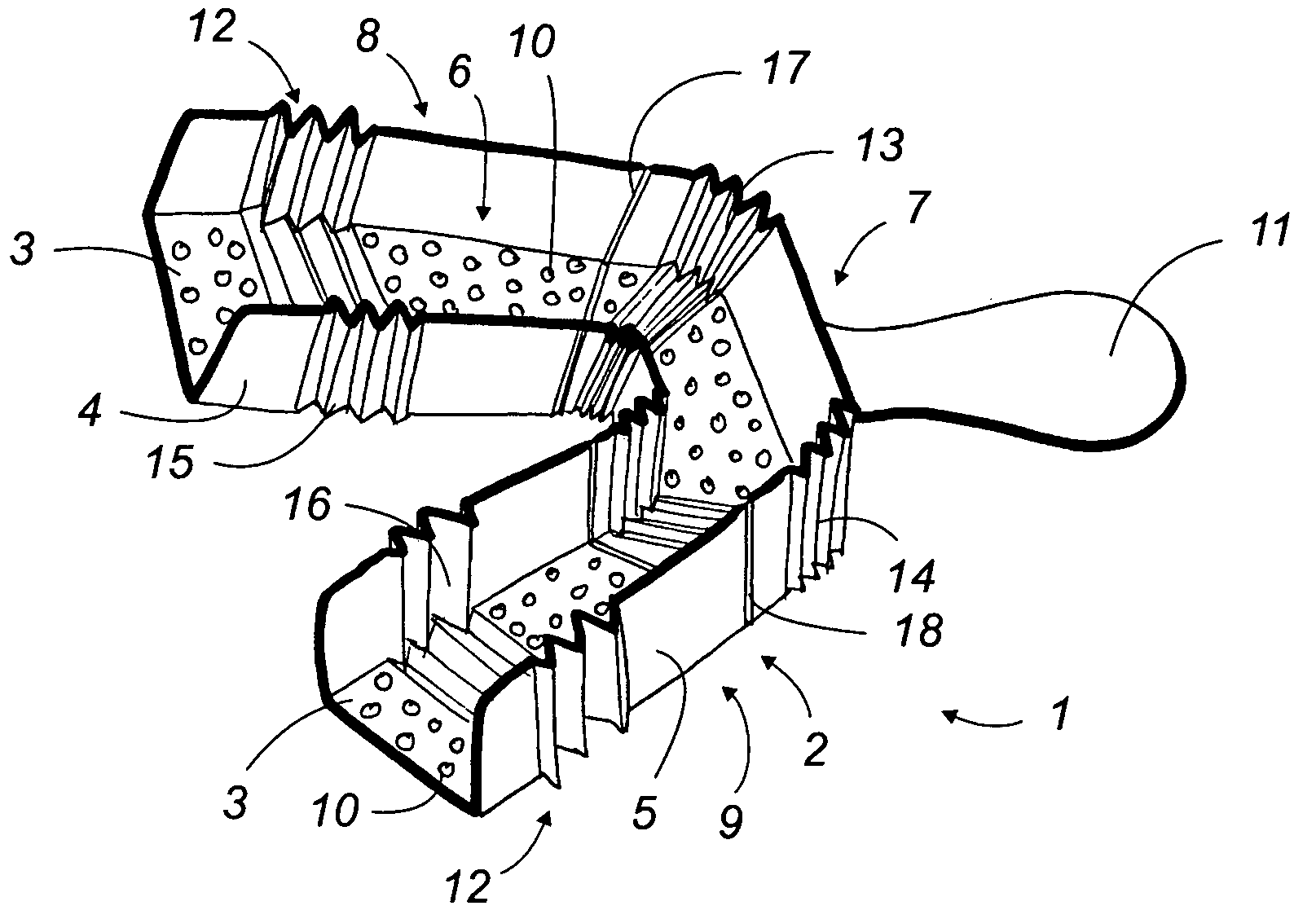

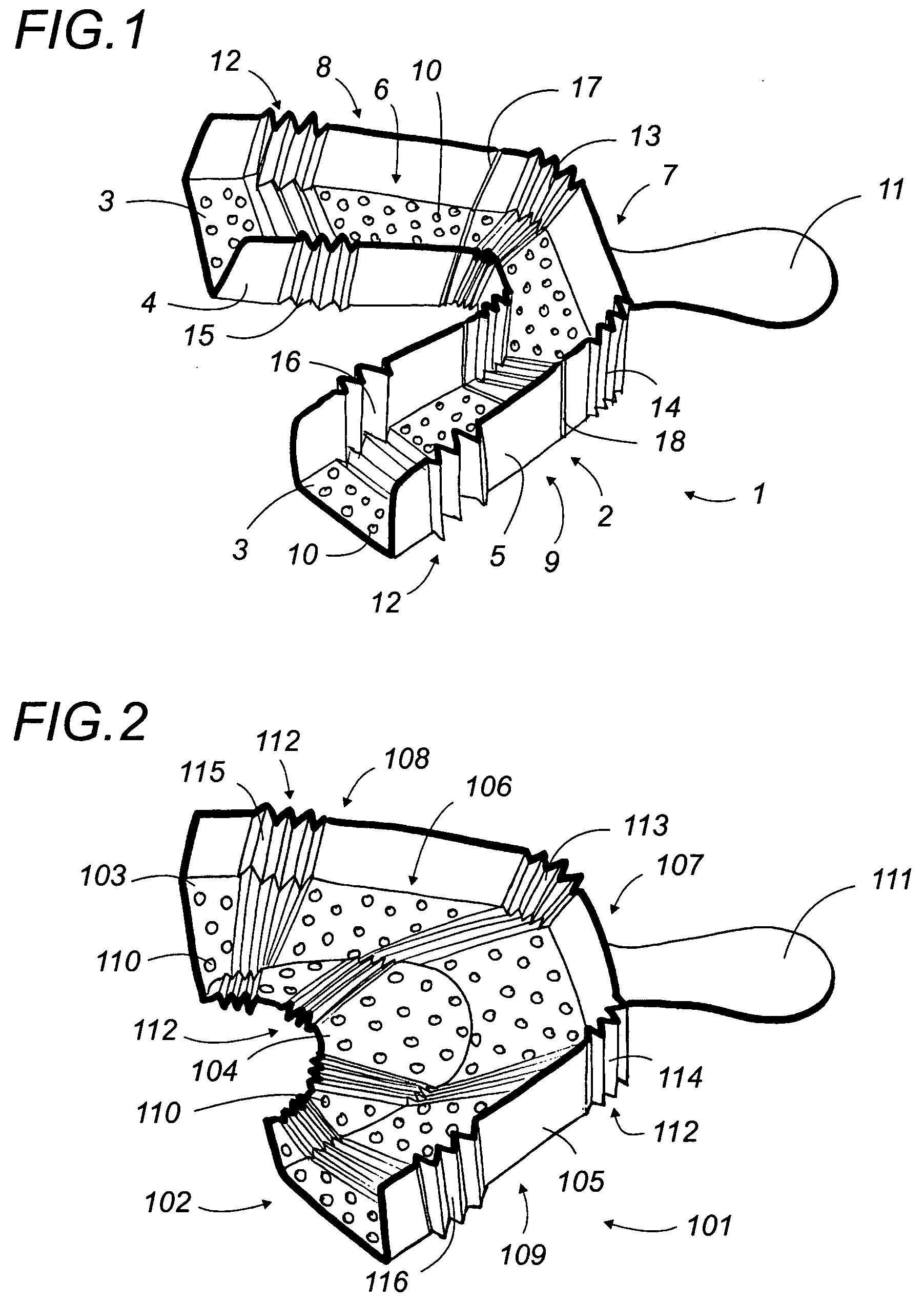

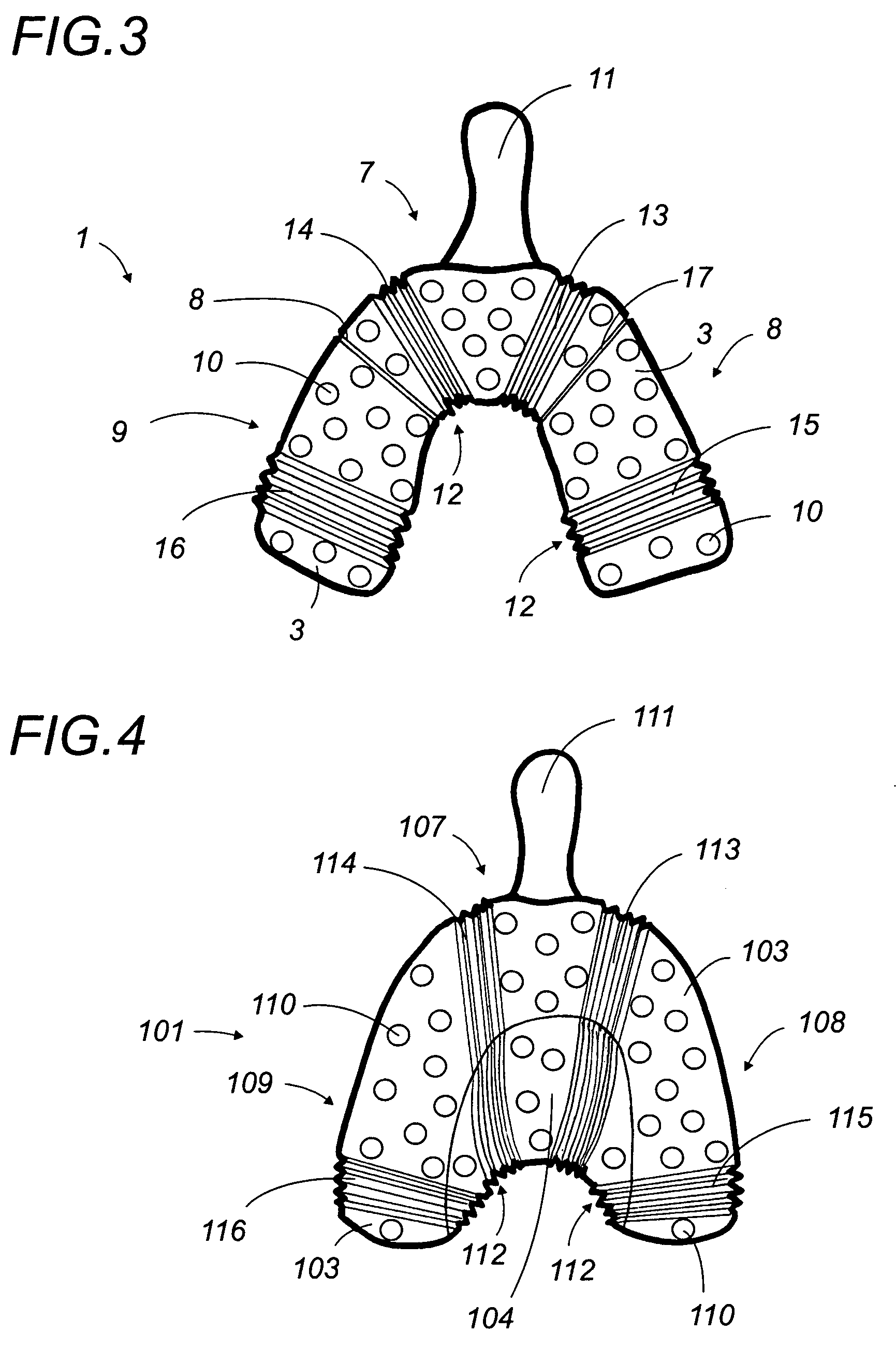

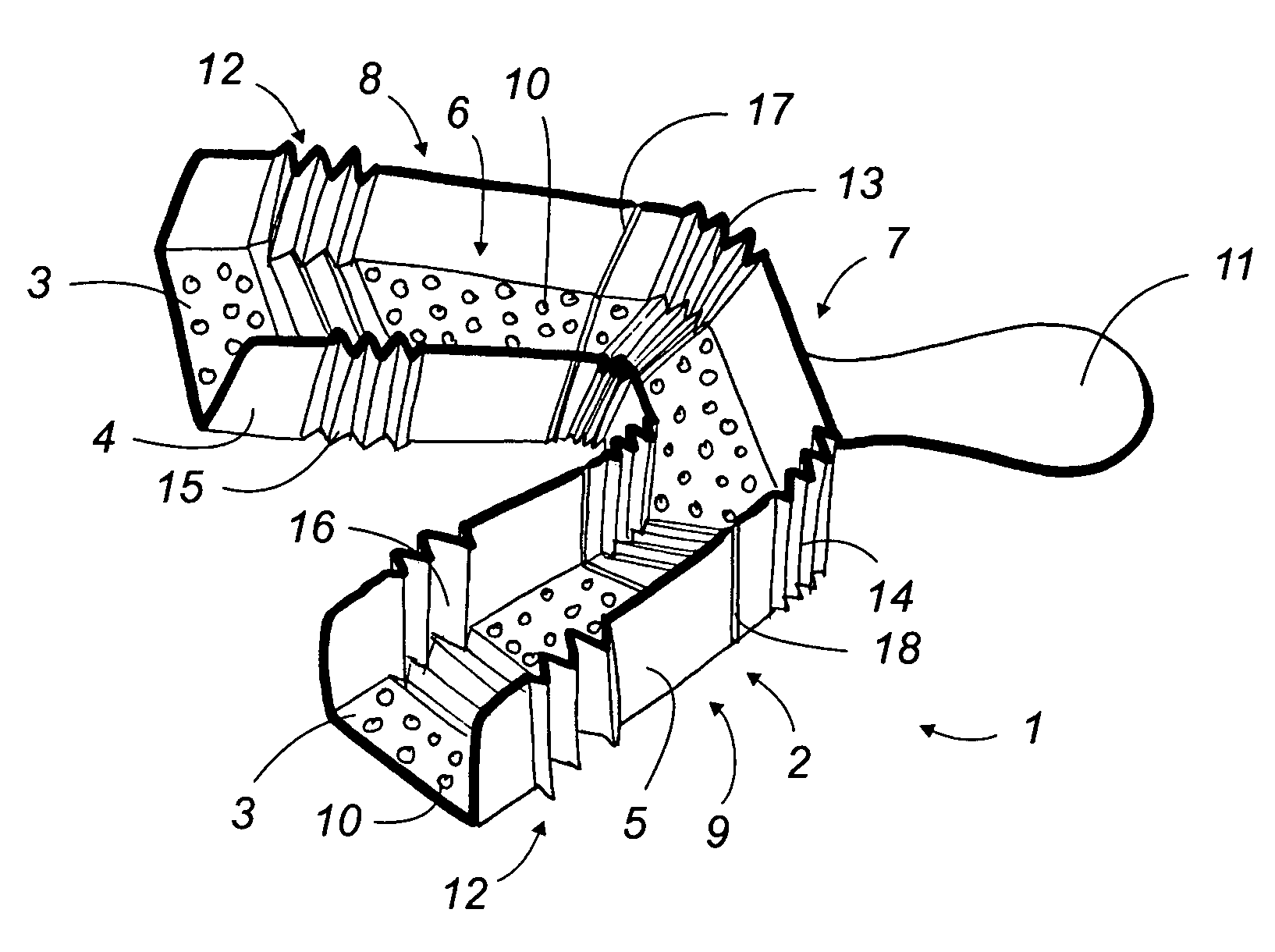

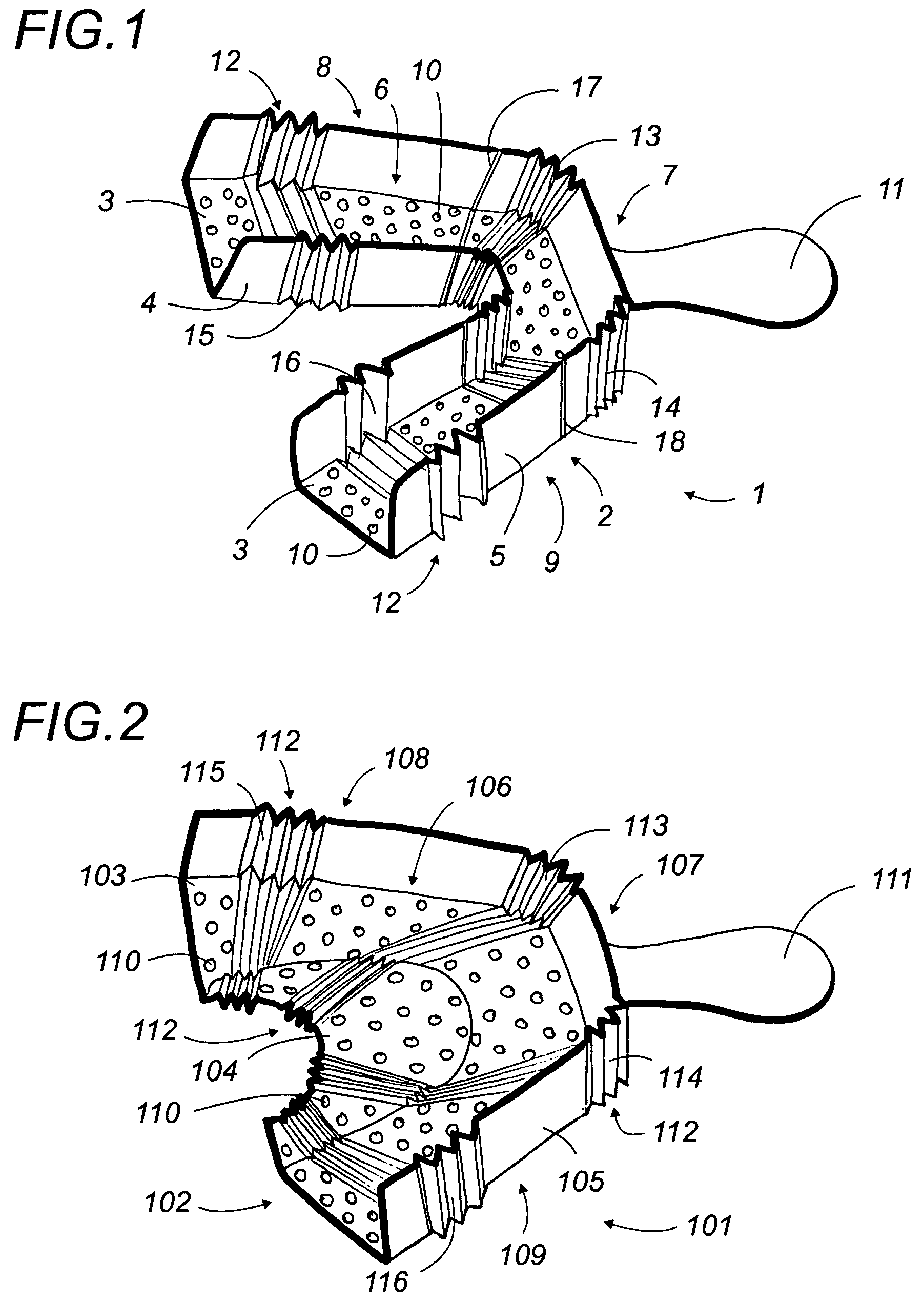

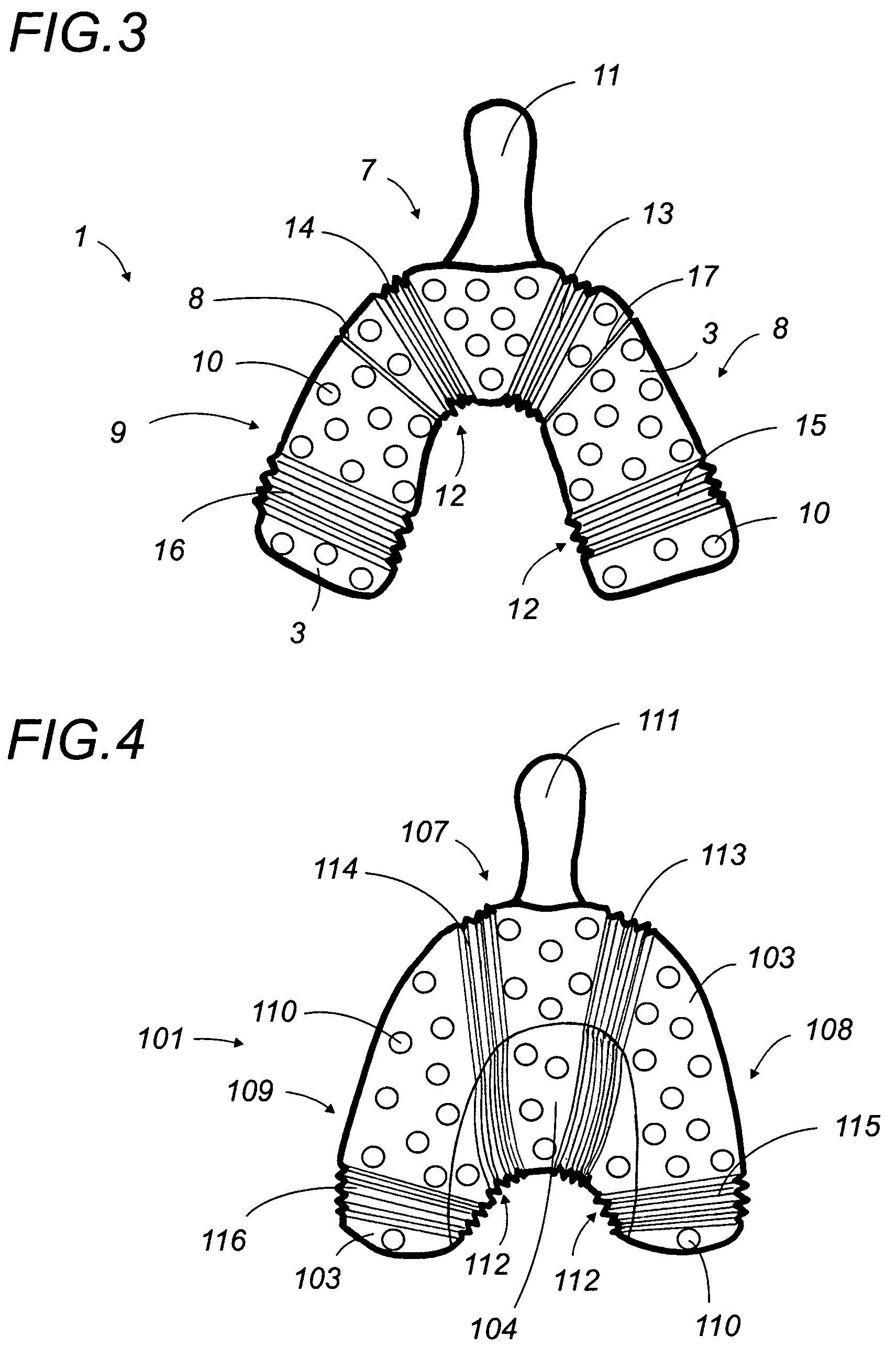

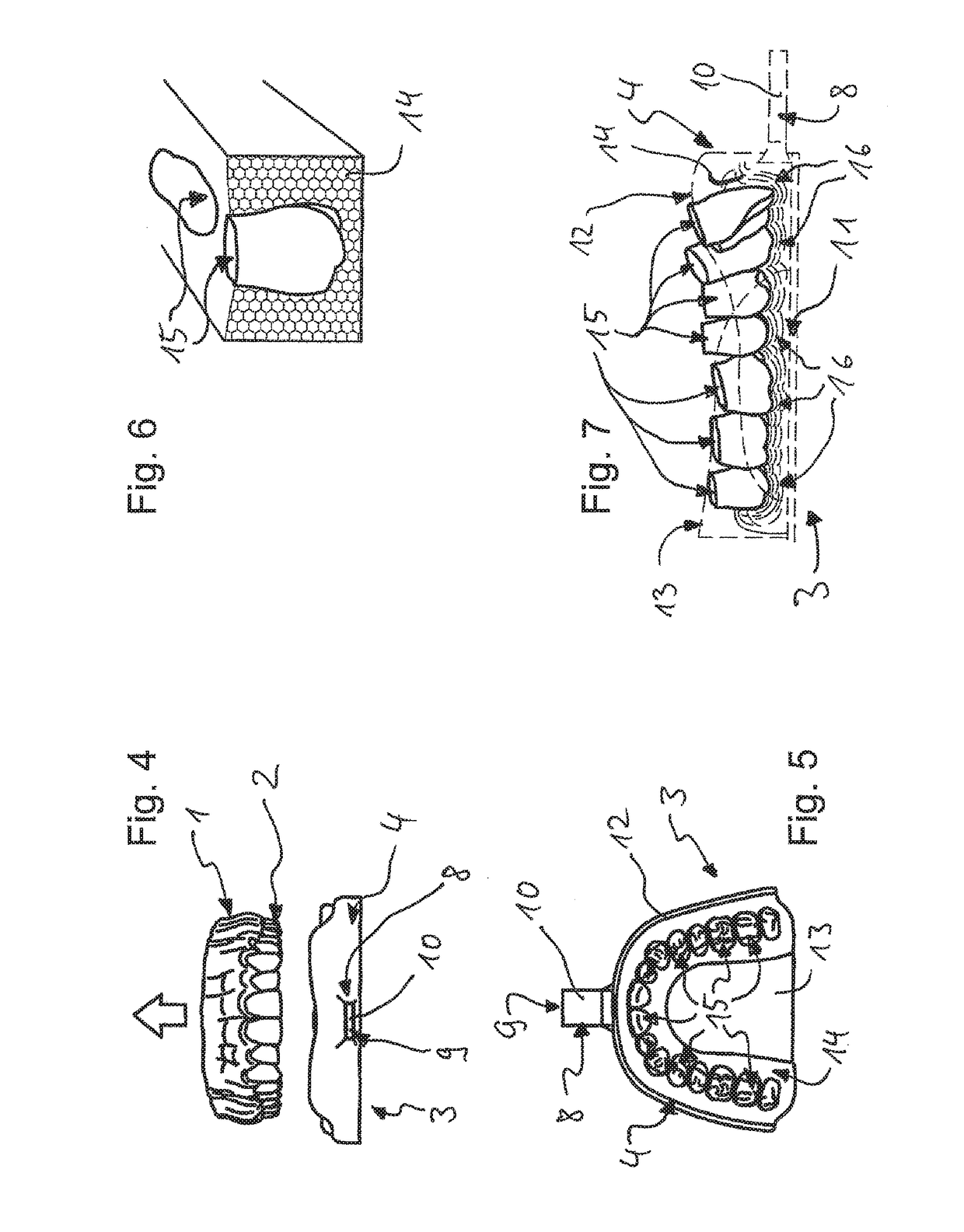

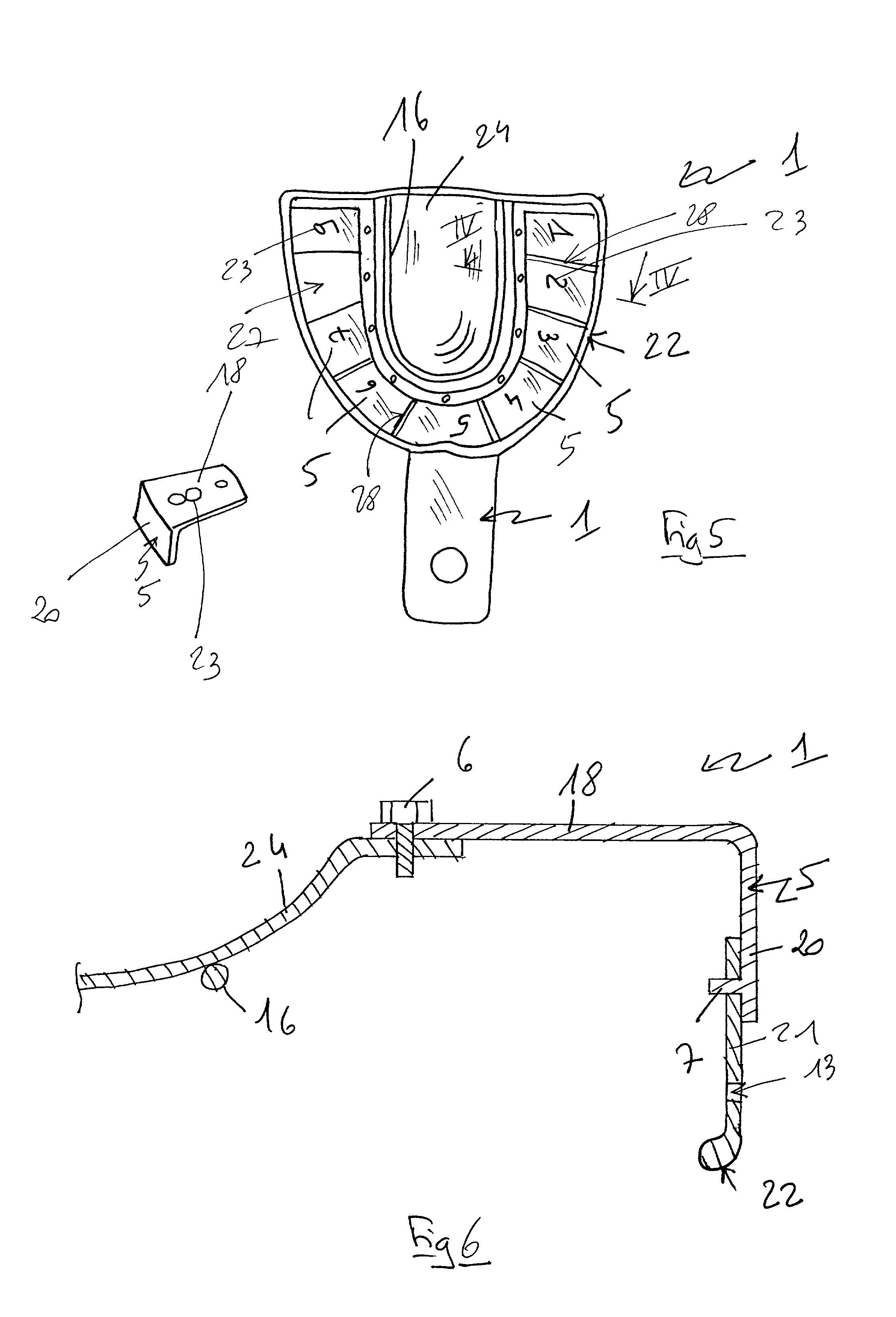

The invention relates to an adjustable impression tray (1) comprising a trough (2) in the form of an arch with a straight central portion (7) extended by two lateral branches (8,9), essentially matching the form of a dental arch and comprising several integral zones which may be deformed at the temperature of use in the form of a multi-directional extension means (12), for example an accordion-like bellows arrangement (13 to 16). The impression tray, preferably for single usage, advantageously comprises splitting zones (17, 18) which allow the production of impression trays of differing sectors, which by comprising one or several deformation zones are equally adjustable. The invention is of interest to dentists and prosthetic dentists and more generally to producers and users of dental equipment.

Owner:LIVOLSI LYDIE

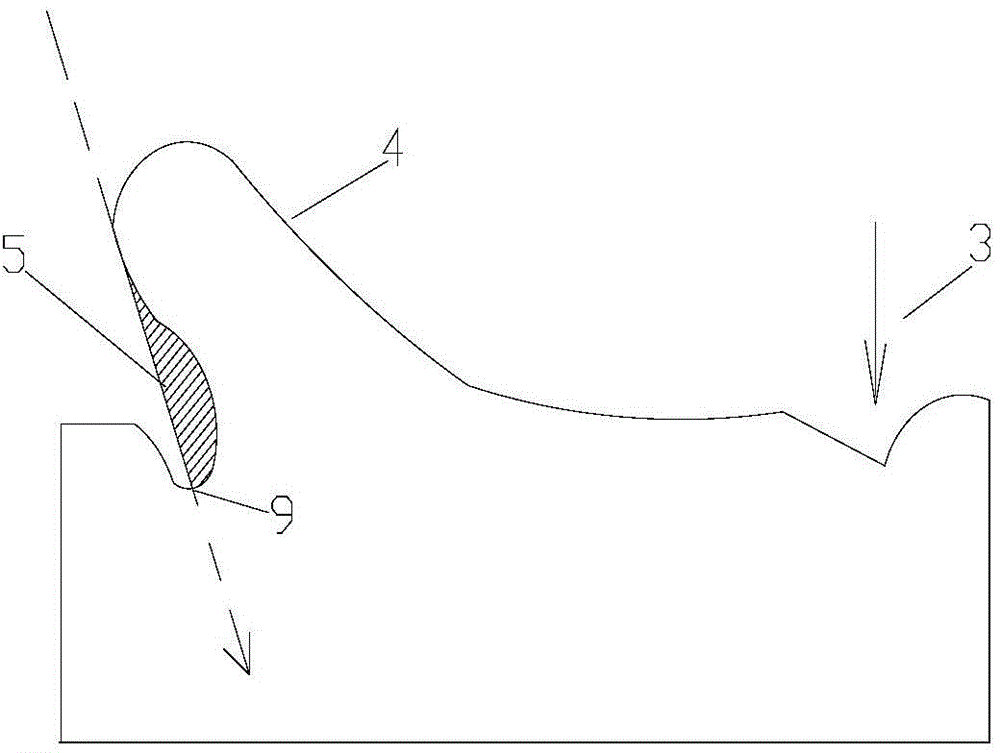

Hydraulic pressure bite-down dental impression

In an exemplary embodiment, a method of creating an impression of structures of the human oral cavity comprises: preparing impression trays: creating a first, or base, impression; grinding out portions of the base impression; and using the void(s) in the ground out base impression to take a second, or wash, impression. The base impression is taken with an excess of a high-density impression material which is positioned to extend beyond the structures of interest (of which the impression is being taken). The base impression is removed and all fine structure surrounding the structure(s) of interest is ground out. A wash impression is then taken using a low-density impression material. The base impression creates a seal around the structure(s) of interest (a closed system), thereby producing omnidirectional hydraulic pressure on the low-density material. Such omnidirectional hydraulic pressure produces a highly detailed final impression from which a high-quality model (e.g., cast) can be made.

Owner:EVOLVE DENTAL TECH

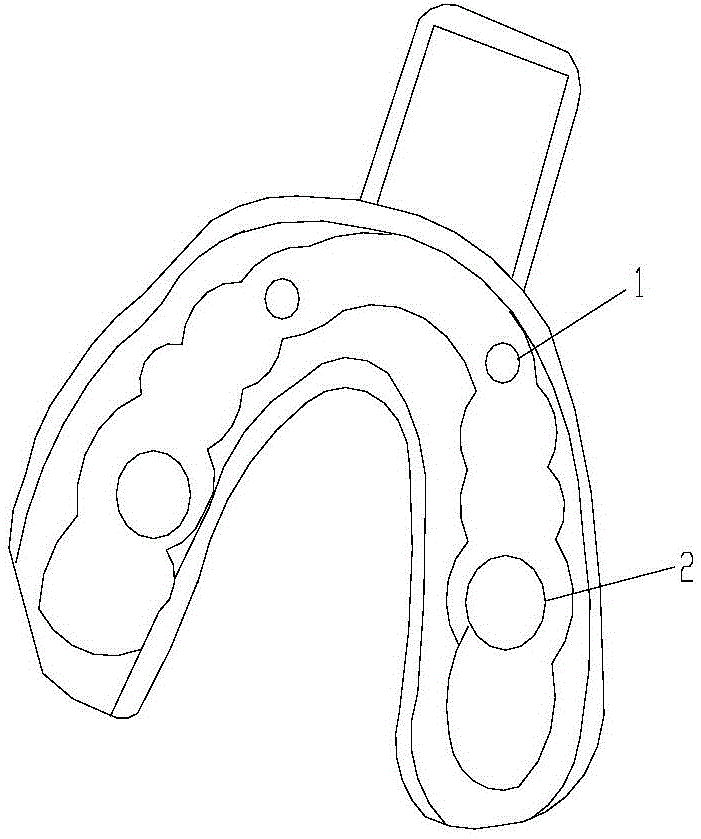

Digital preparation method of edentulous jaw individual impression tray

ActiveCN105078598AImproving the technical level of clinical treatment operationImprove the efficiency of diagnosis and treatmentImpression capsPoint cloudImpression trays

The invention relates to a digital preparation method of an edentulous jaw individual impression tray. The method comprises the following steps: preparing a preliminary impression, or forming a plaster model by pouring; scanning the preliminary impression or scanning the plaster model; introducing scanning data into reverse engineering software and intercepting tissue surface point cloud data of the edentulous jaw preliminary impression; acquiring point cloud data of undercut-free alveolar ridge surface; uniformly enlarging the alveolar ridge surface by 1-2mm in the normal direction of the alveolar ridge surface so as to obtain a virtual tray inner surface; uniformly thickening the virtual tray inner surface by 2mm in the normal direction thereof; designing an upper jaw virtual tray handle and a lower jaw virtual tray handle; and fusing data boundaries of the inner and outer surfaces of the virtual tray as well as the handle and saving the data in an STL format, importing the data into a computer system connected to 3D printing equipment, and making the edentulous jaw individual impression tray from a polymethyl methacrylate (PMMA) material by virtue of the 3D printing equipment. The digital designing and manufacturing method of the edentulous jaw individual impression tray can replace traditional hand-made manufacturing method.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Devices and methods for shipping and analyzing dental impressions

A shipping container that is configured to store, protect, and transport a dental impression is disclosed. The shipping container includes an exterior surface that encloses an interior area; a support located within the interior area that is configured to receive an impression tray that includes a patient's dental impression; and a means attached to or integrally formed with the support that is configured to hold the impression tray in place on the support and to position the impression tray in a standardized orientation. The shipping container, including its exterior surface and internal support(s), are made of a material that will not interfere with a selected non-invasive imaging scan. The shipping container is configured and used to obtain a digital scan of the dental impression, without the need to open the shipping container or directly handle the dental impression.

Owner:CLEARCORRECT OPERATING LLC

Adjustable impression tray with variable geometry

InactiveUS7125251B2Adapt the impression tray easily and quicklyLengthened and shortenedImpression capsImpression traysDental Equipment

The invention relates to an adjustable impression tray (1) comprising a trough (2) in the form of an arch with a straight central portion (7) extended by two lateral branches (8,9), essentially matching the form of a dental arch and comprising several integral zones which may be deformed at the temperature of use in the form of a multi-directional extension means (12), for example an accordion-like bellows arrangement (13 to 16). The impression tray, preferably for single usage, advantageously comprises splitting zones (17, 18) which allow the production of impression trays of differing sectors, which by comprising one or several deformation zones are equally adjustable. The invention is of interest to dentists and prosthetic dentists and more generally to producers and users of dental equipment.

Owner:LIVOLSI LYDIE

Method and components for producing edentulous dentures

A method and component devices for producing edentulous dentures. The method includes obtaining a cast impression of a jaw, any teeth and gingiva area with a first set of dental trays including selecting a properly sized upper dental tray and a properly sized lower dental tray, applying impression material in each said tray and placing each said dental impression tray with said impression material in said oral cavity in order to deform uncured impression material. A second set of dental trays is utilized including a lower dental tray having a contact plate with an upwardly extending shoulder surrounding a tapered opening, a ball nut retained in the tapered opening, and a post adjustably secured to the ball nut. A striking plate is attached to a second upper dental tray in order to accurately obtain an established occlusal vertical and centric relation positions. A third upper dental tray with a wax impression is inserted for esthetic blue printing to establish the shape of the patient's upper lip and mouth. A third lower dental tray with wax impression material is utilized to determine functional position including tongue, cheek and lip positioning.

Owner:GLOBAL DENTAL IMPRESSION TRAYS

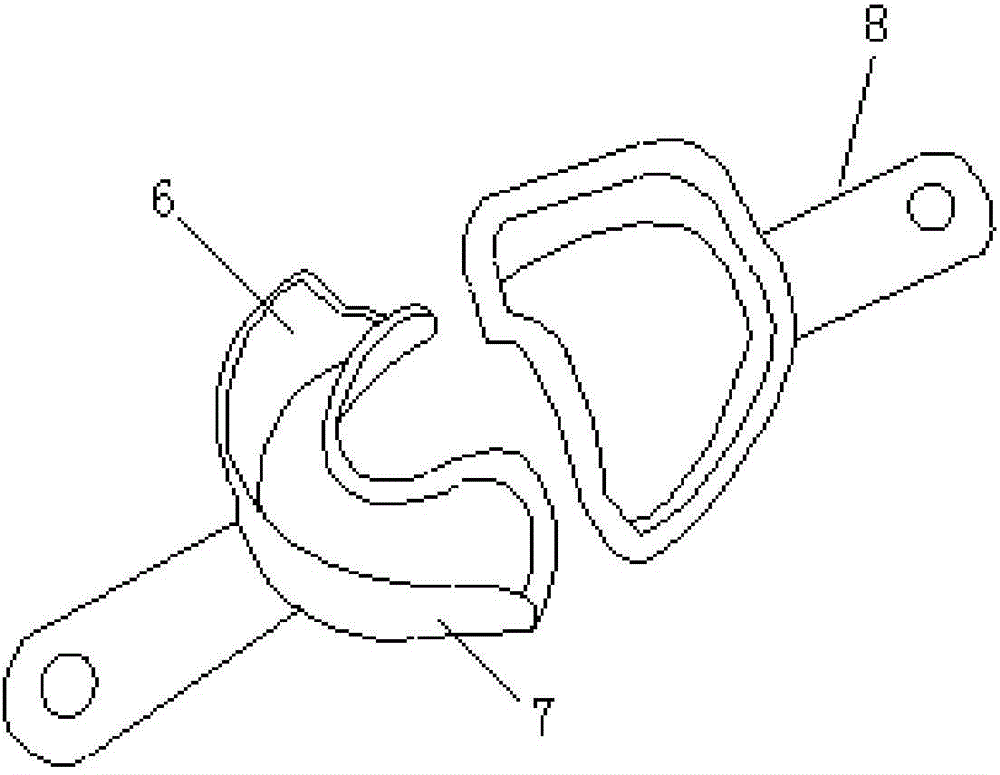

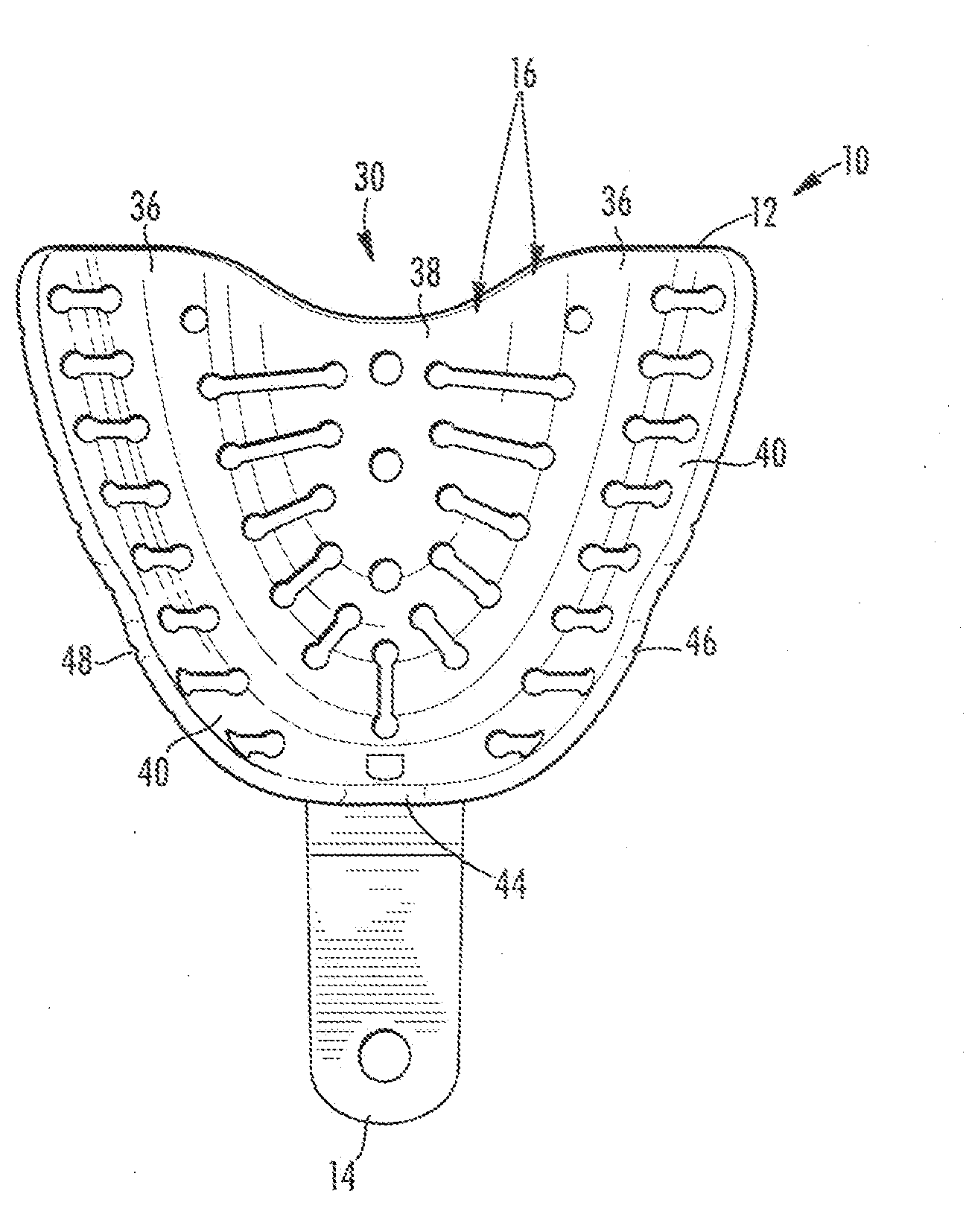

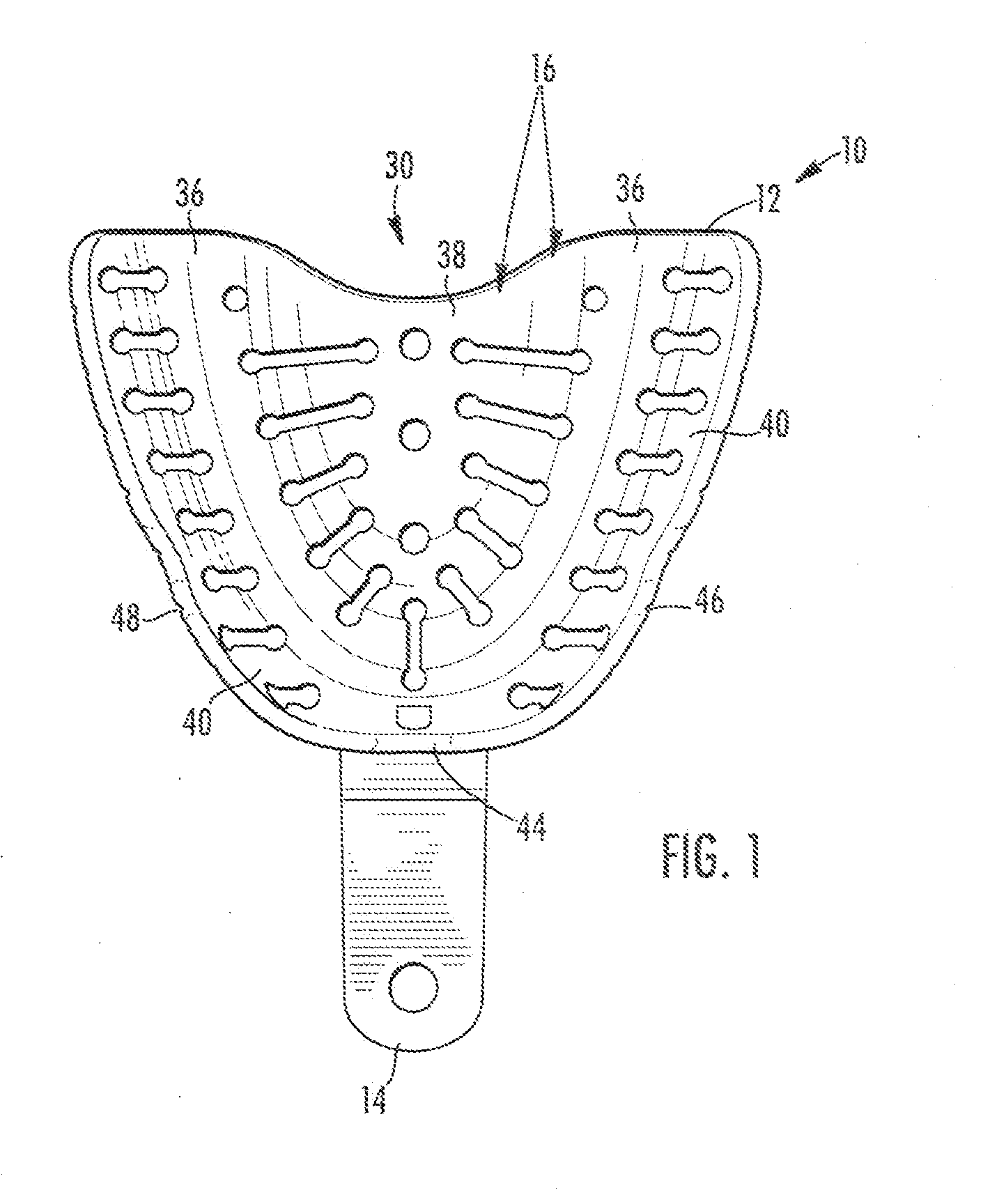

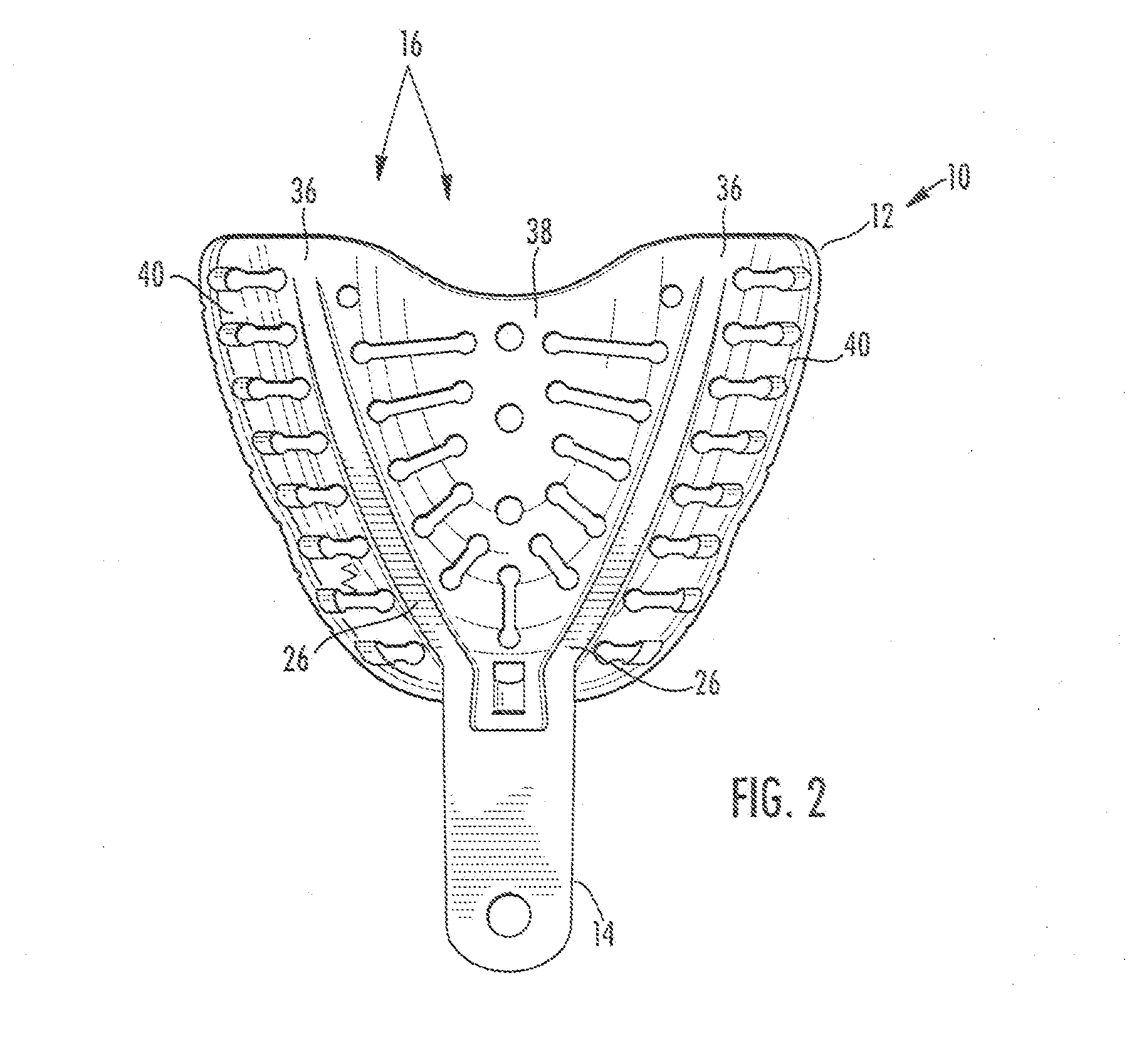

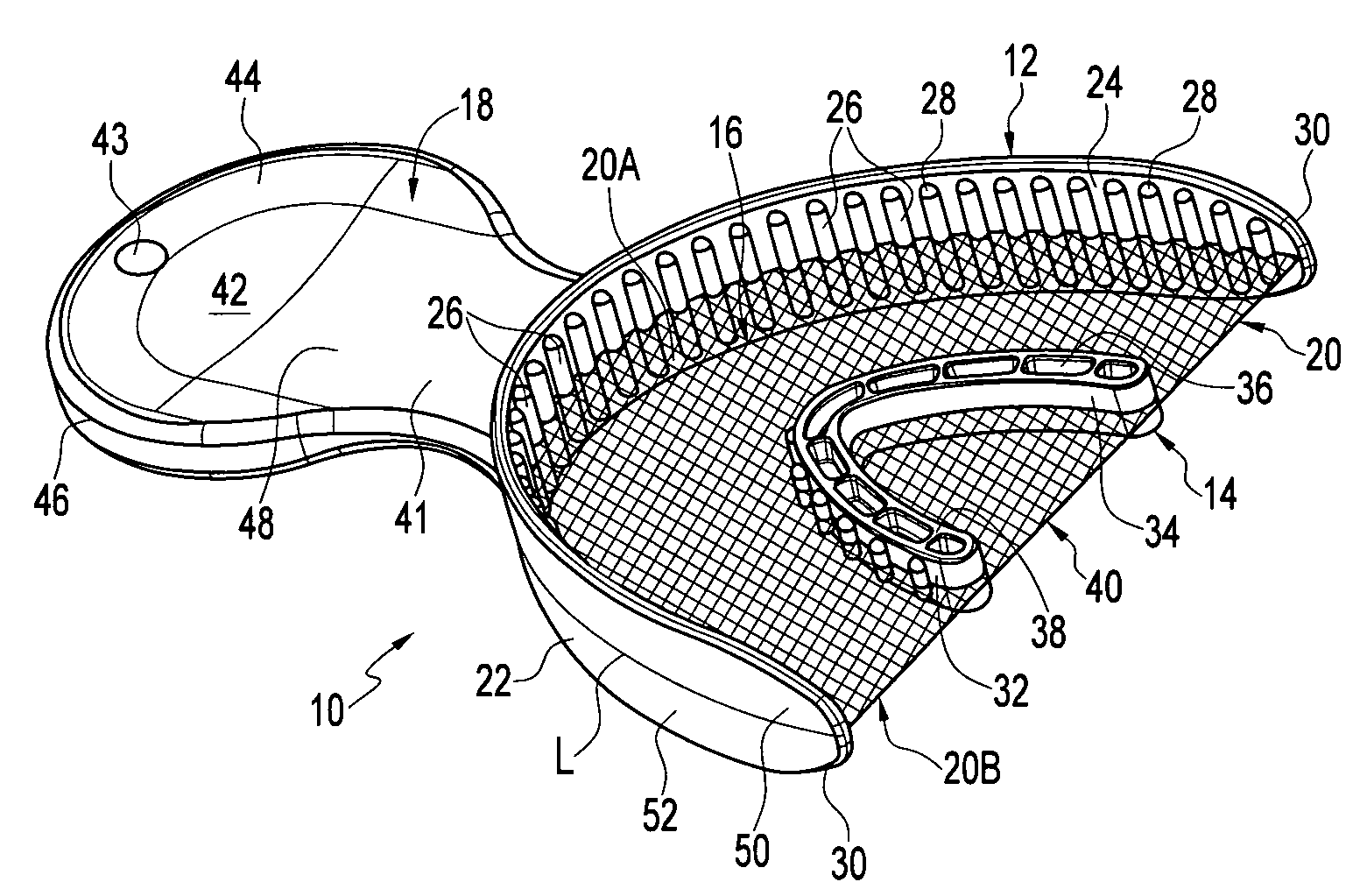

Dental impression trays

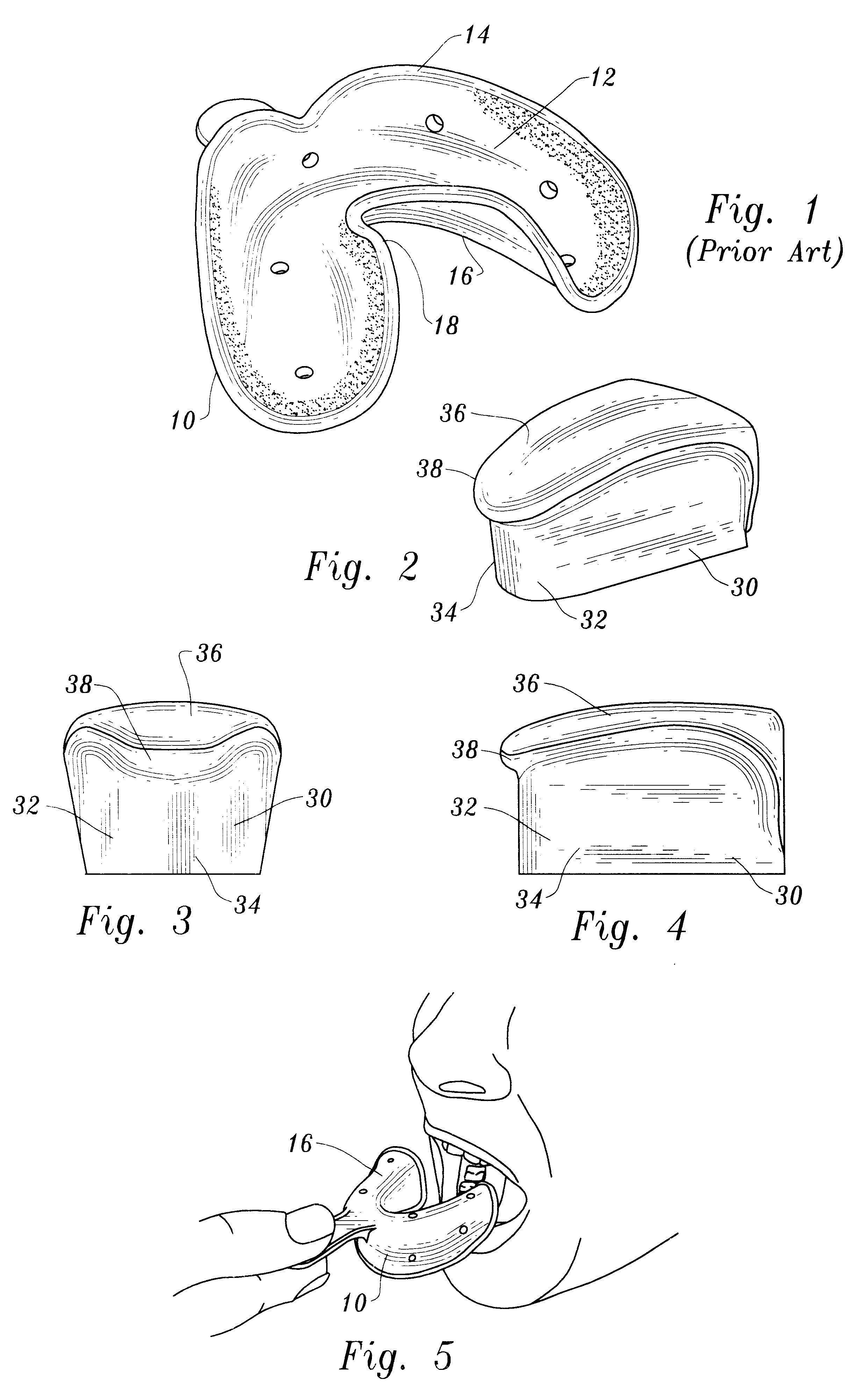

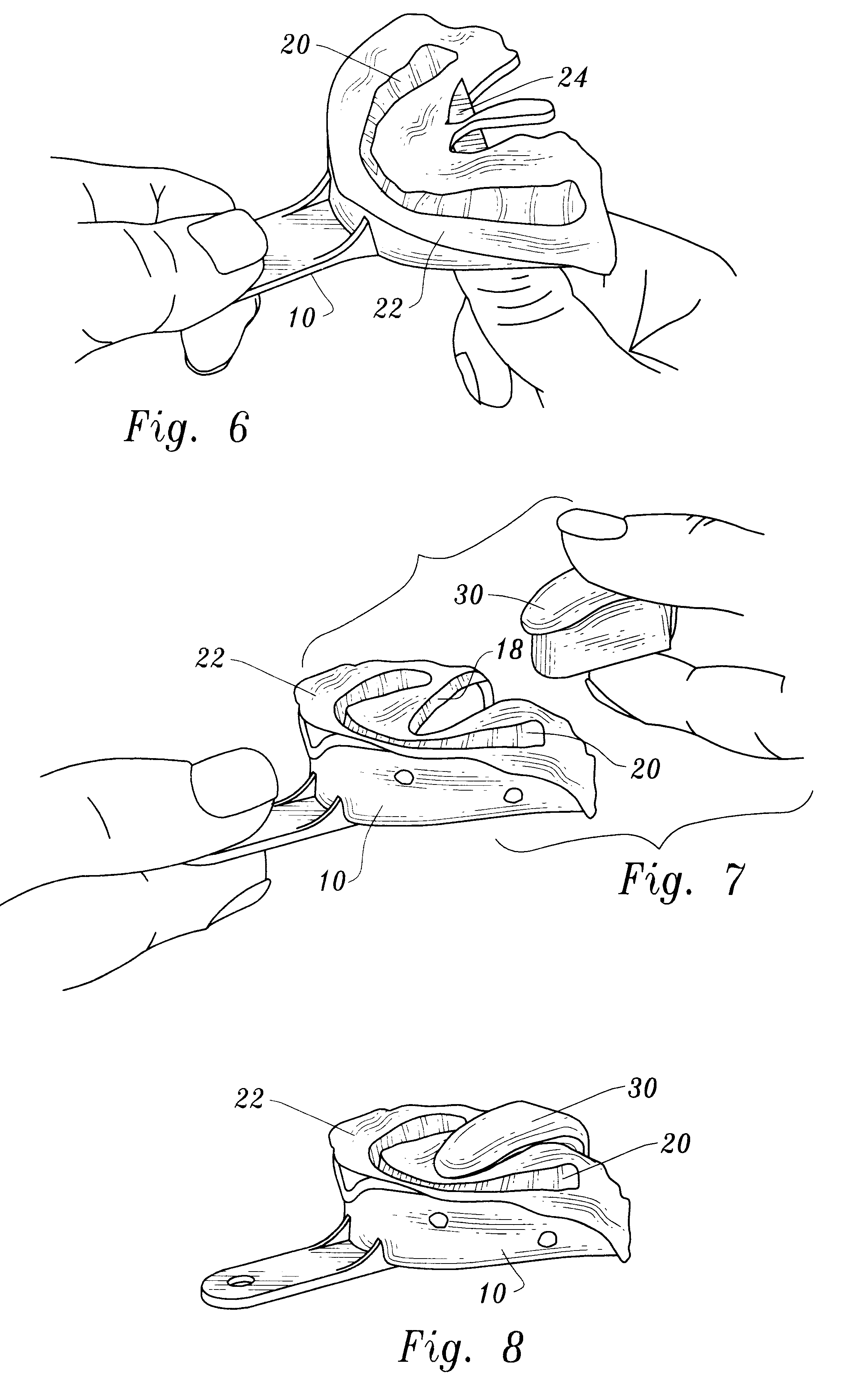

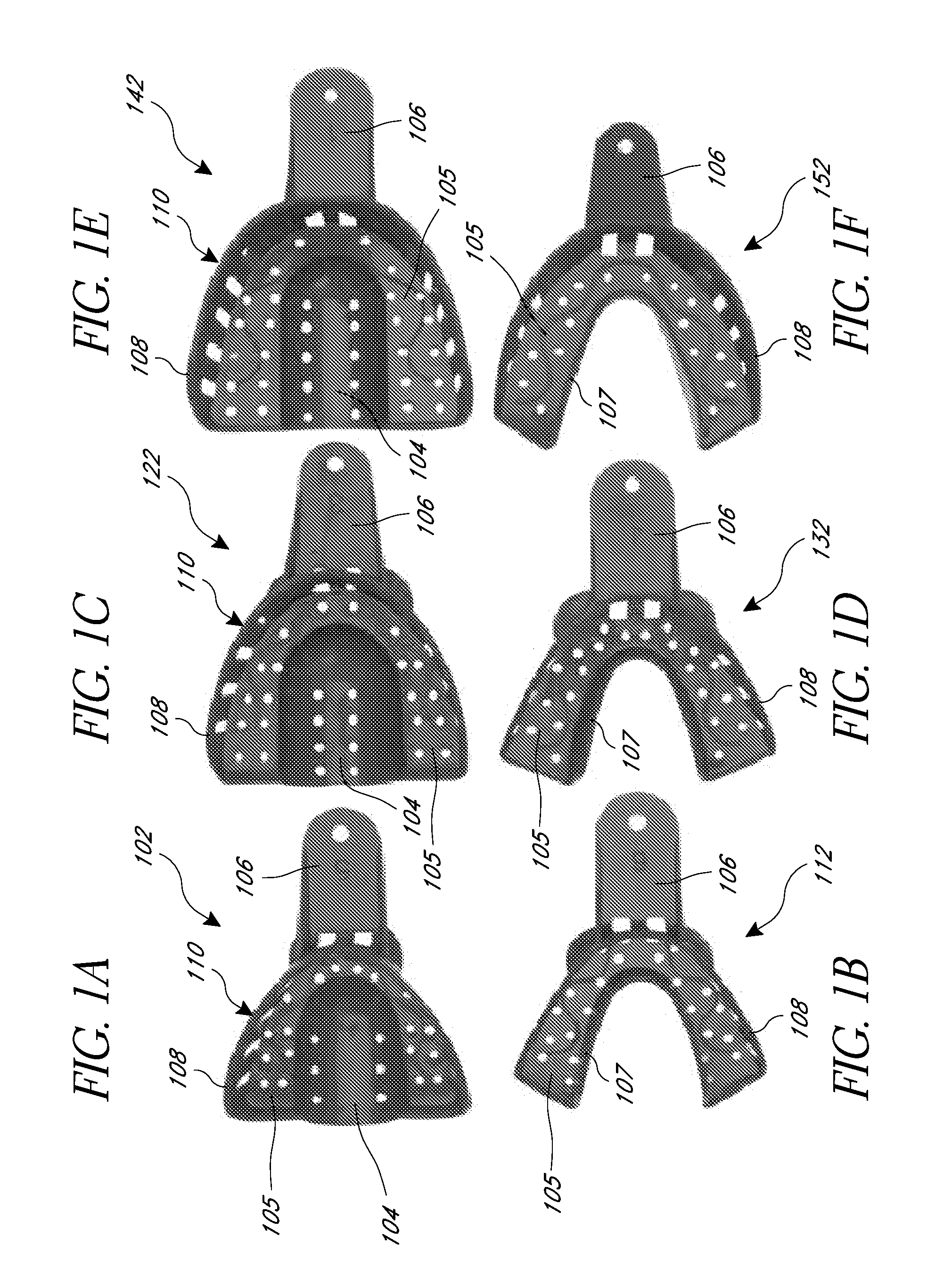

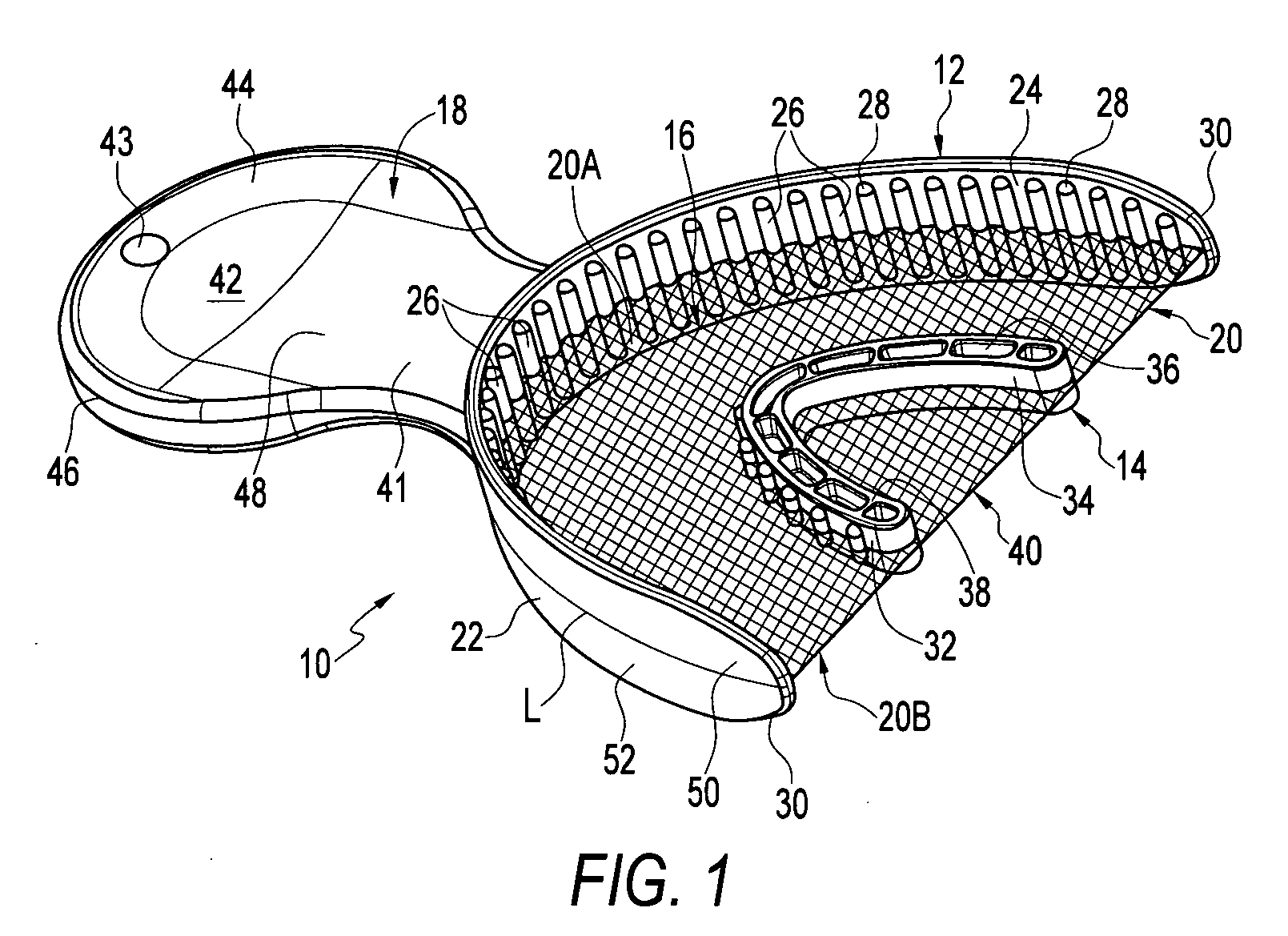

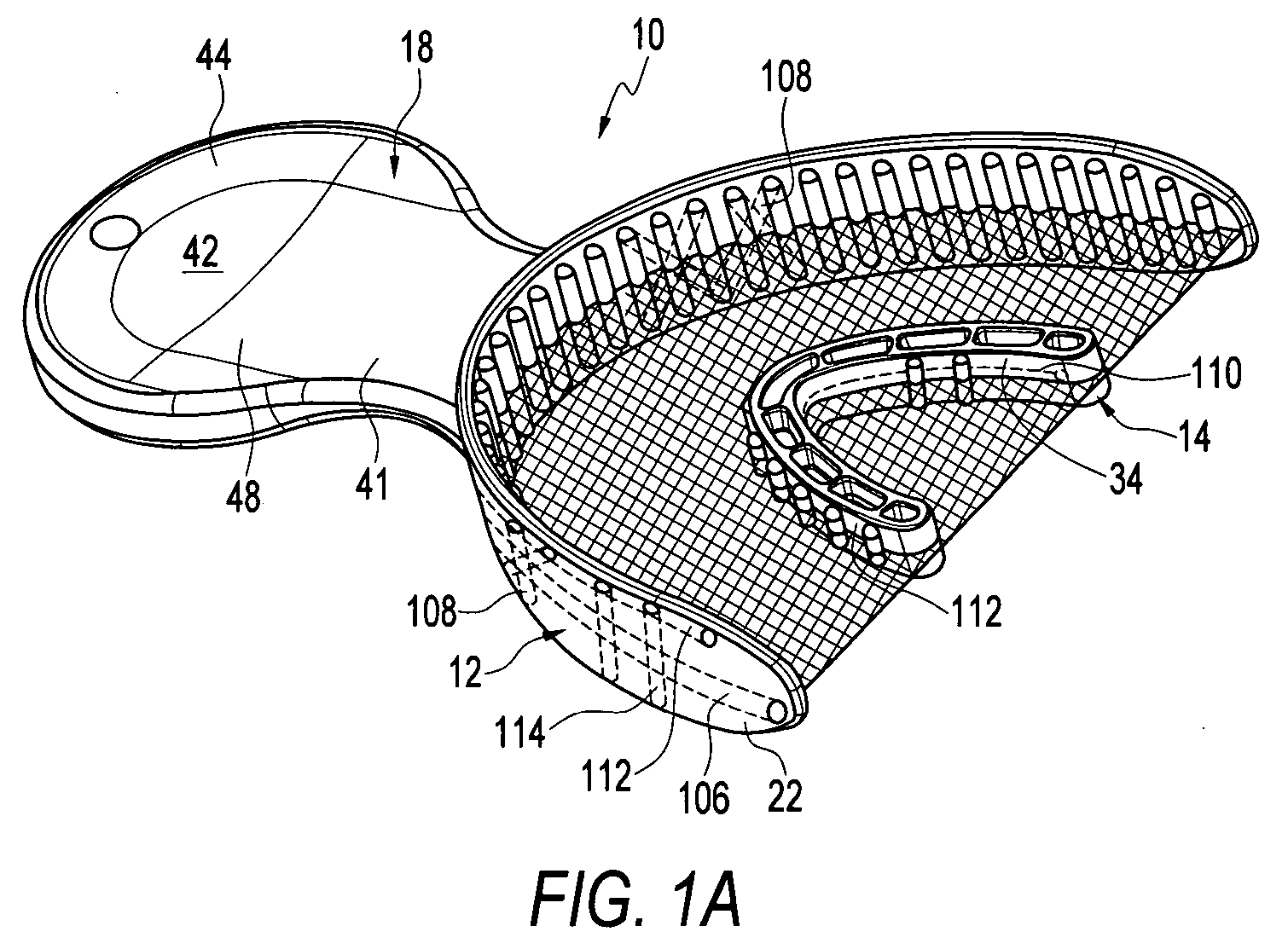

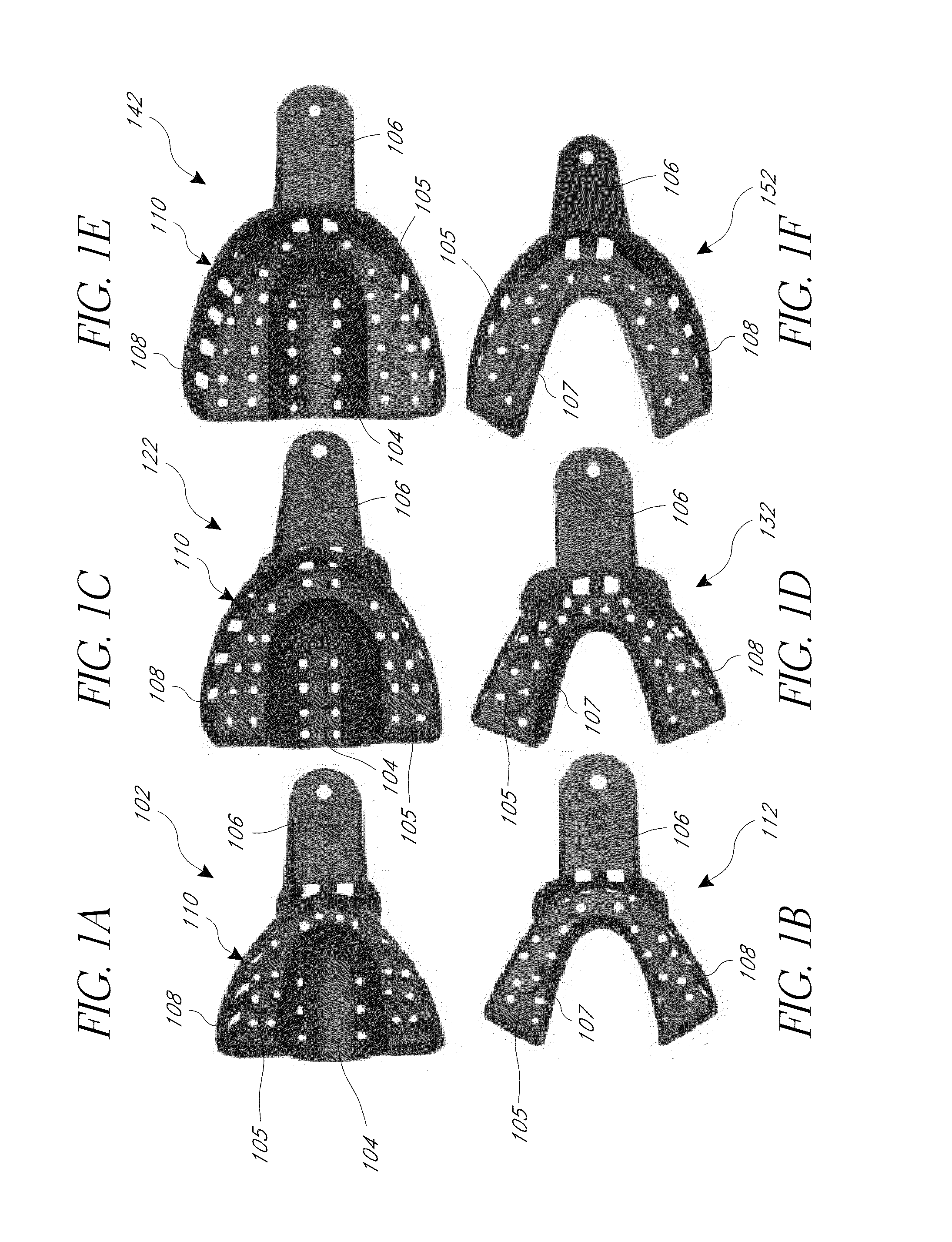

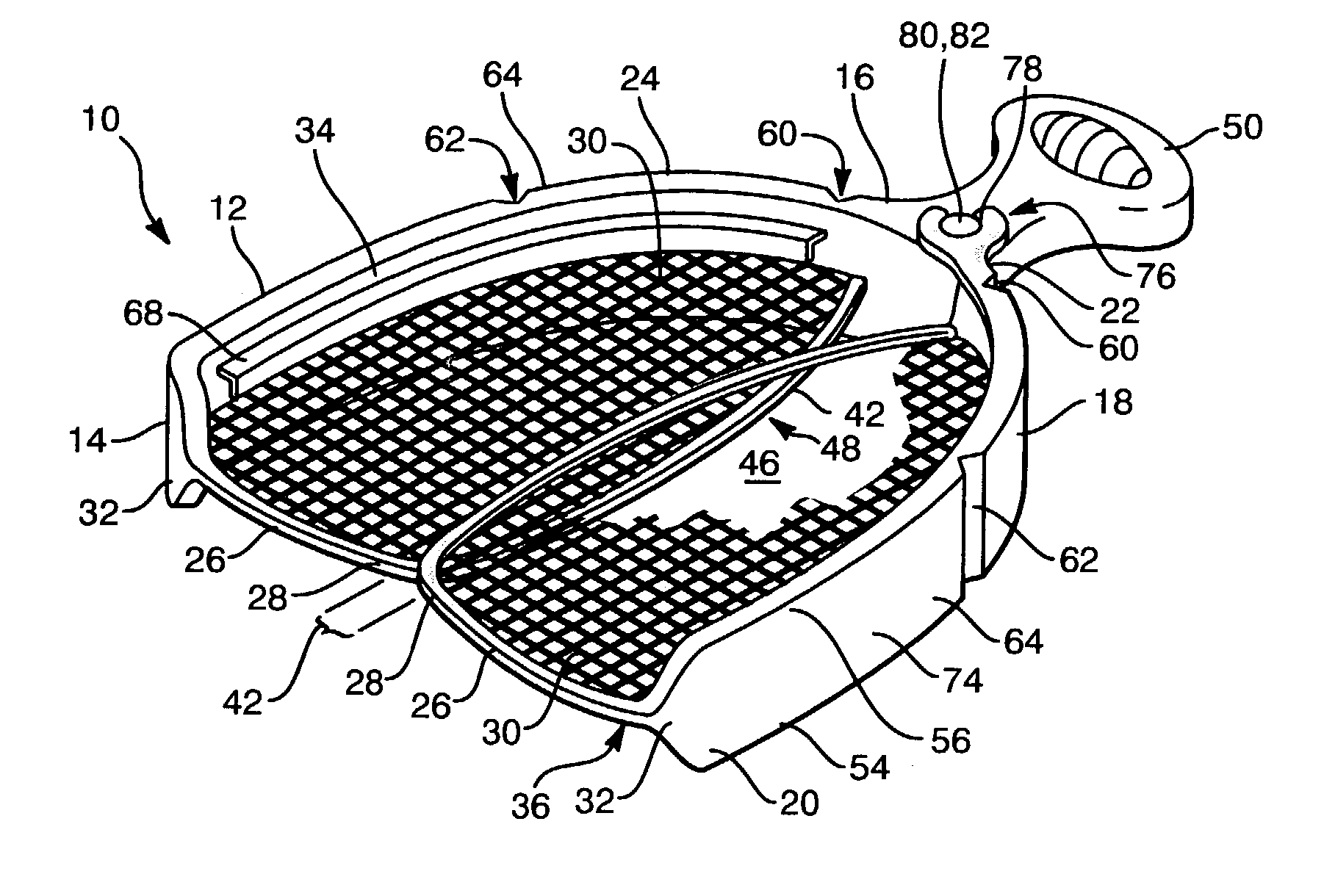

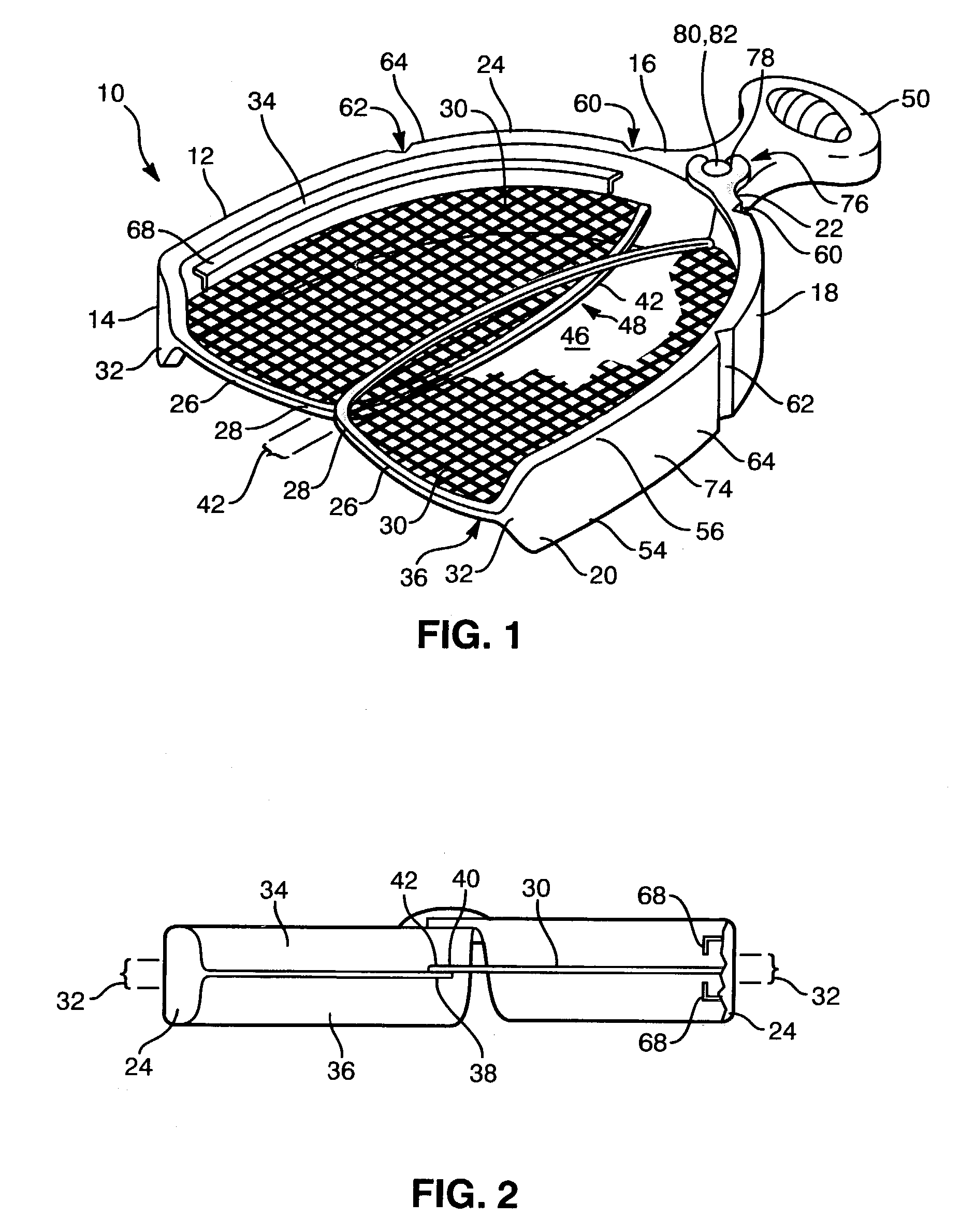

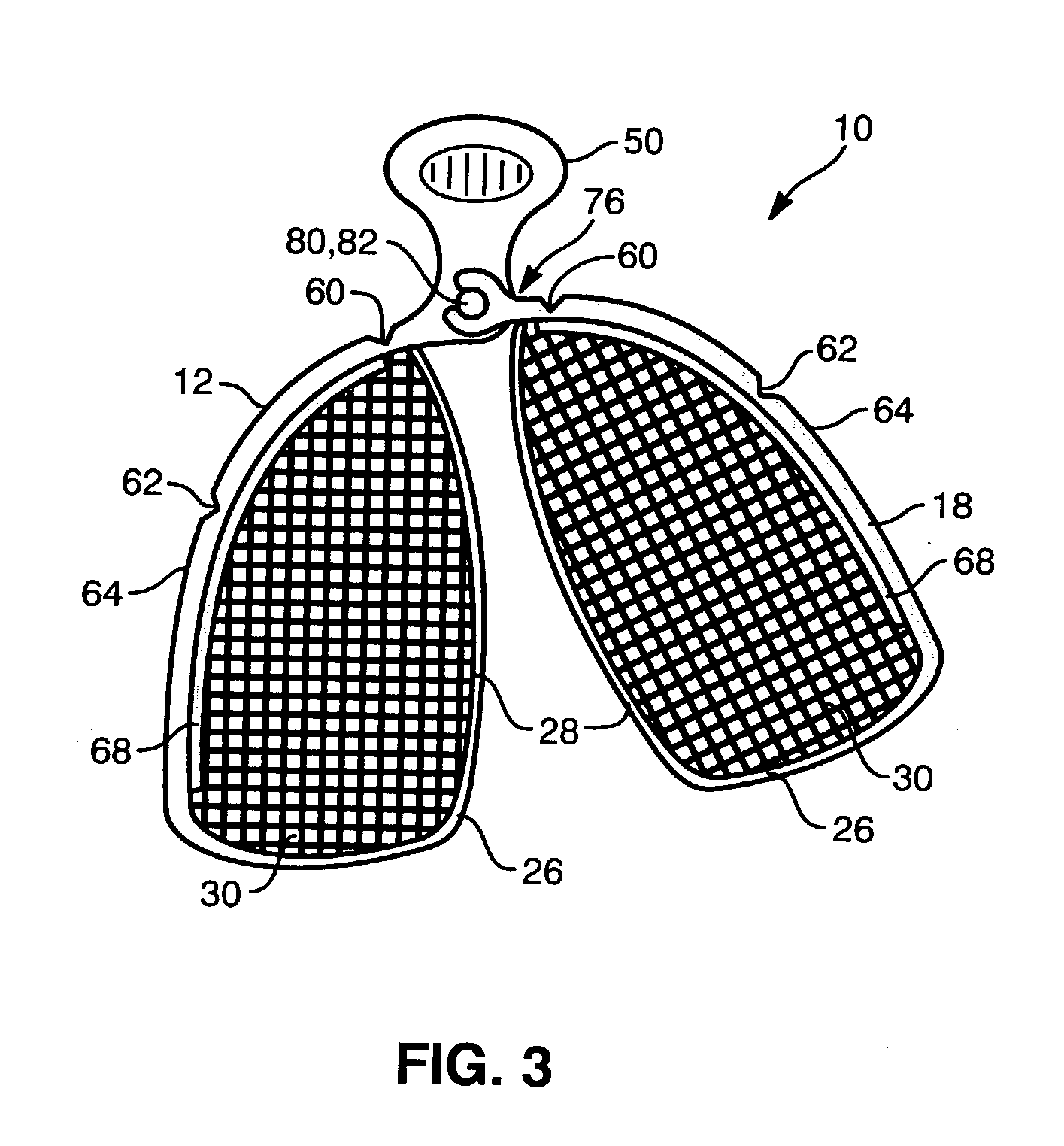

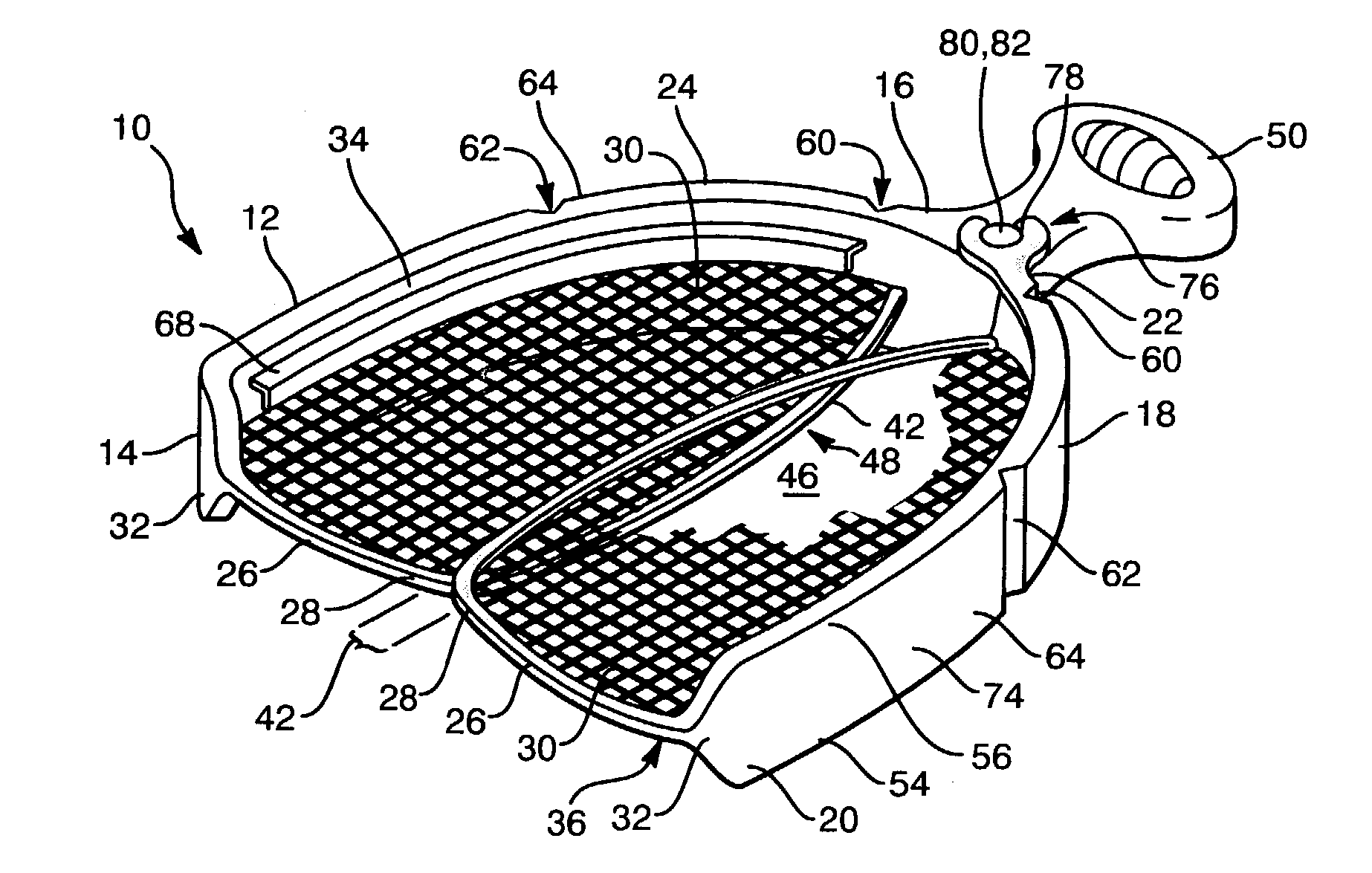

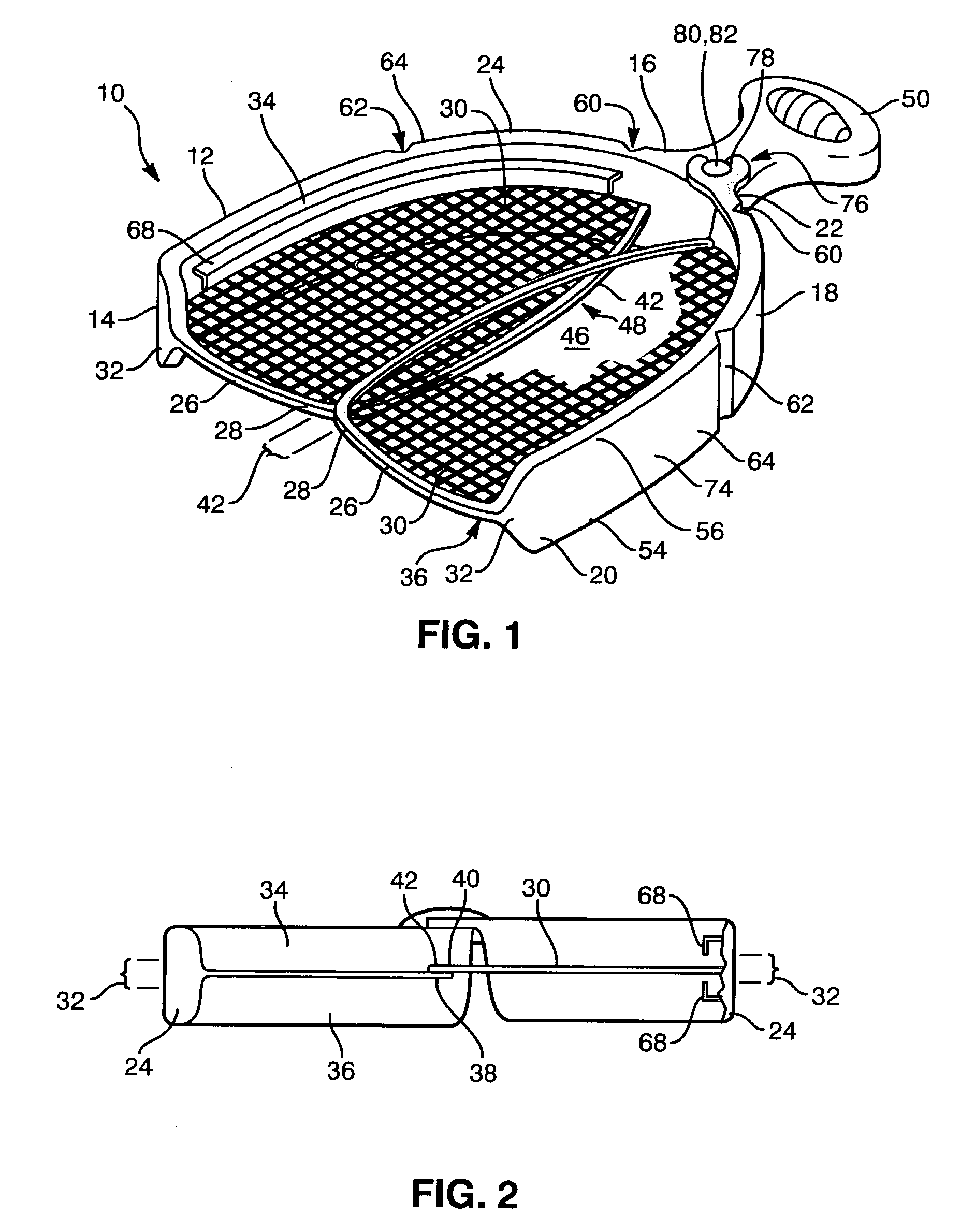

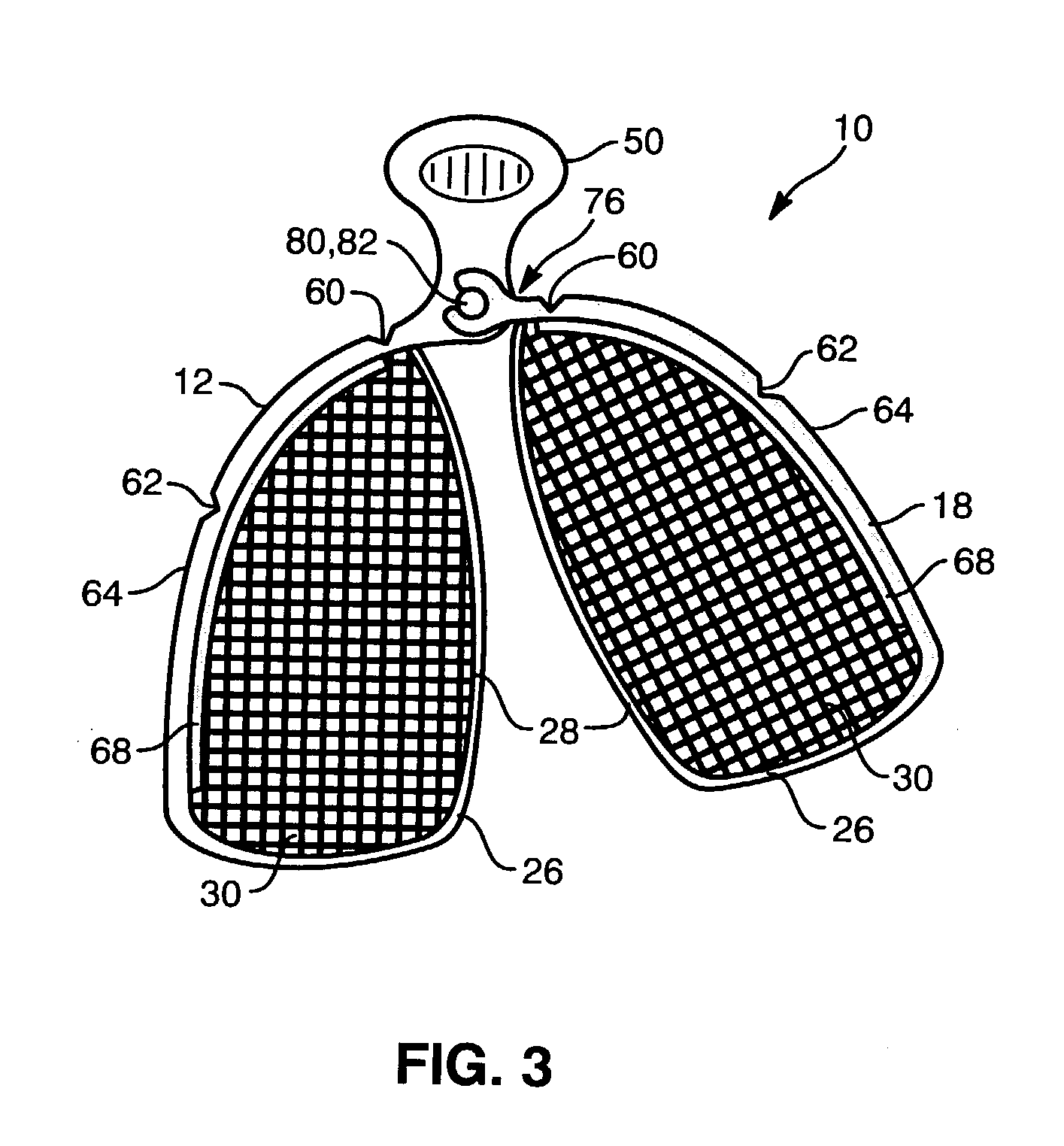

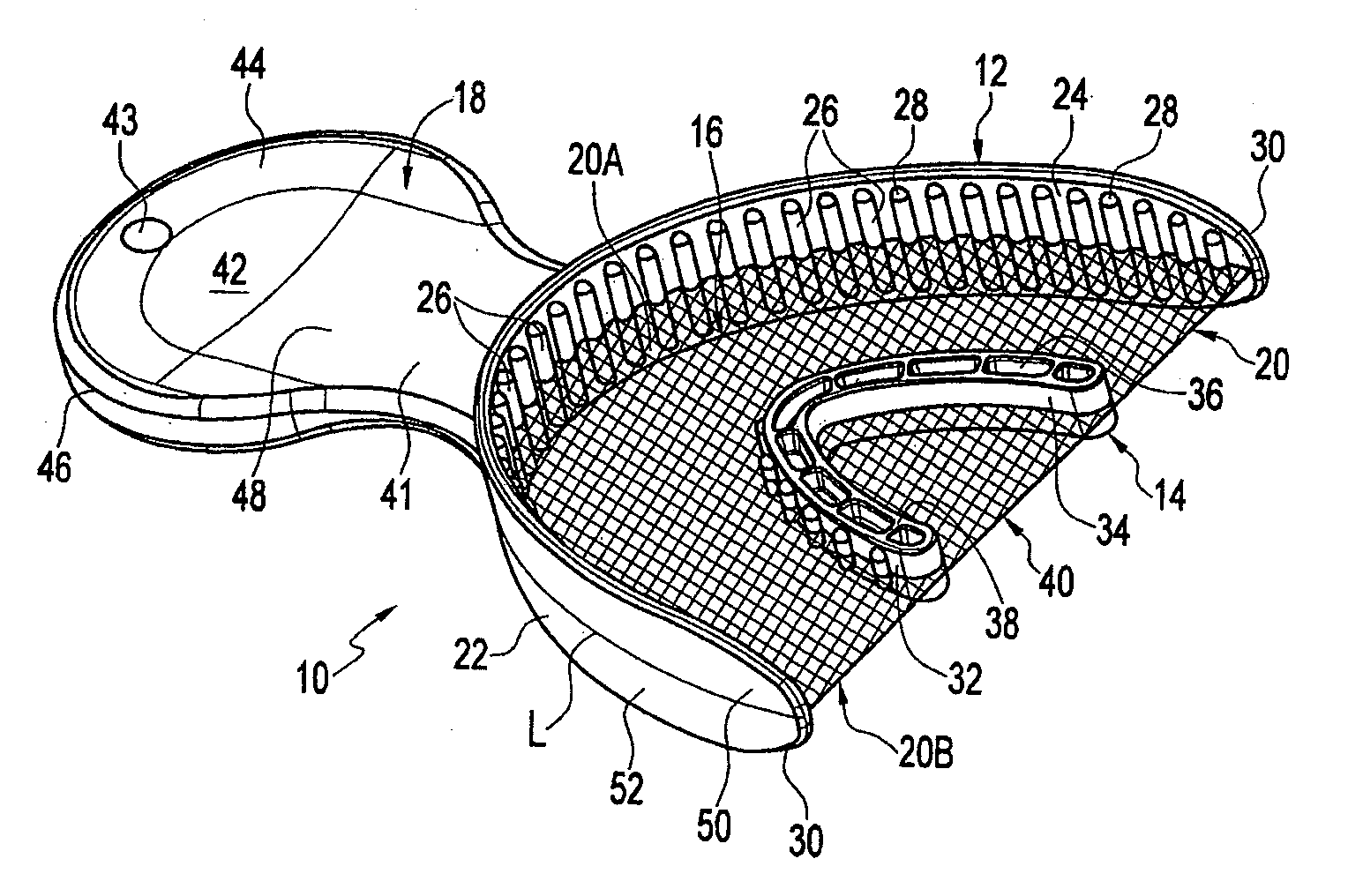

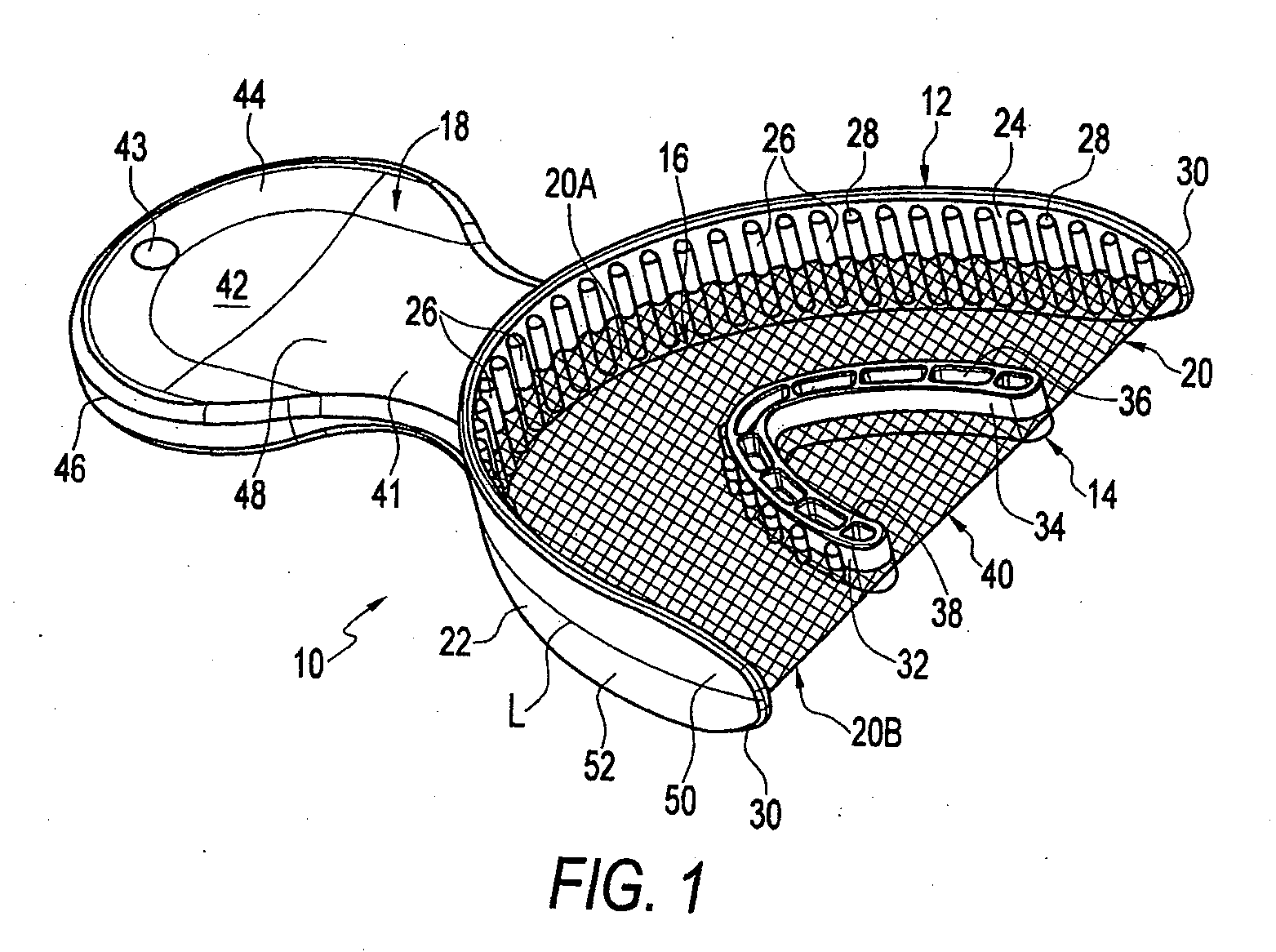

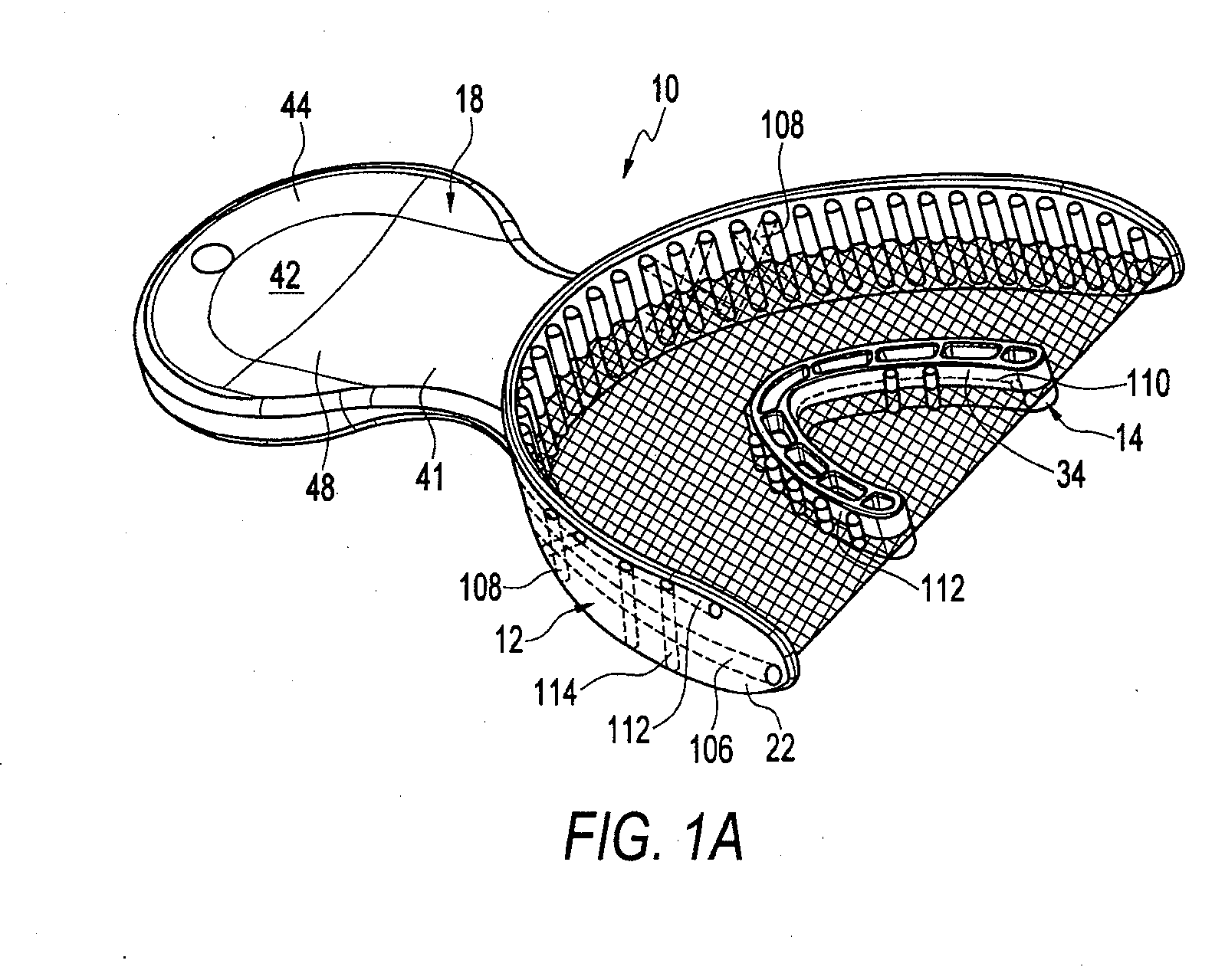

Impression trays for taking dental impression of a subject are discussed herein with particular discussion extended to impression trays know as triple trays. Triple trays are so coined for their ability to simultaneously capture the upper and lower impressions and the bite registration of a subject during a same dental procedure. The trays described elsewhere herein incorporate features that strengthen or increase the rigidity of the frame so that an impression taken of the dentition of the subject using one of the trays described elsewhere herein is not distorted and is therefore an accurate reflection of the true dentition.

Owner:DISCUS DENTAL LLC

Impression tray, and method for capturing structures, arrangements or shapes, in particular in the mouth or human body

InactiveUS20170100219A1Easy, dependable and accurateImpression capsDental impression compositionsSpatially resolvedHuman body

The invention relates to an impression tray, which carries a deformable impression mass in order to prepare an impression of arrangements, shapes or dimensions, in or on the human body, in the mouth, and an impression of at least part of a tooth or of dental structures, wherein sensor devices are present, with which a change of at least one physical property or variable of the impression mass can be captured in a spatially resolved manner. The invention further relates to a method for capturing structures, arrangements or shapes, whereby a deformable impression compound is brought onto or into the structures, arrangements or, is introduced, into the mouth or body and a change of at least one physical property or variable of the impression compound is transmitted to sensor devices when preparing an impression and provided in a form that is suitable for electronic data processing.

Owner:MEDENTIC

Hydraulic pressure dental impression

In an exemplary embodiment, a method of creating an impression of structures of the human oral cavity comprises: preparing impression trays; creating a first, or base, impression; grinding out portions of the base impression; and using the void(s) in the ground out base impression to take a second, or wash, impression. The base impression is taken with an excess of a high-density impression material which is positioned to extend beyond the structures of interest (of which the impression is being taken). The base impression is removed and all fine structure surrounding the structure(s) of interest is ground out. A wash impression is then taken using a low-density impression material. The base impression creates a seal around the structure(s) of interest (a closed system), thereby producing omnidirectional hydraulic pressure on the low-density material. Such omnidirectional hydraulic pressure produces a highly detailed final impression from which a high-quality model (e.g., cast) can be made.

Owner:EVOLVE DENTAL TECH

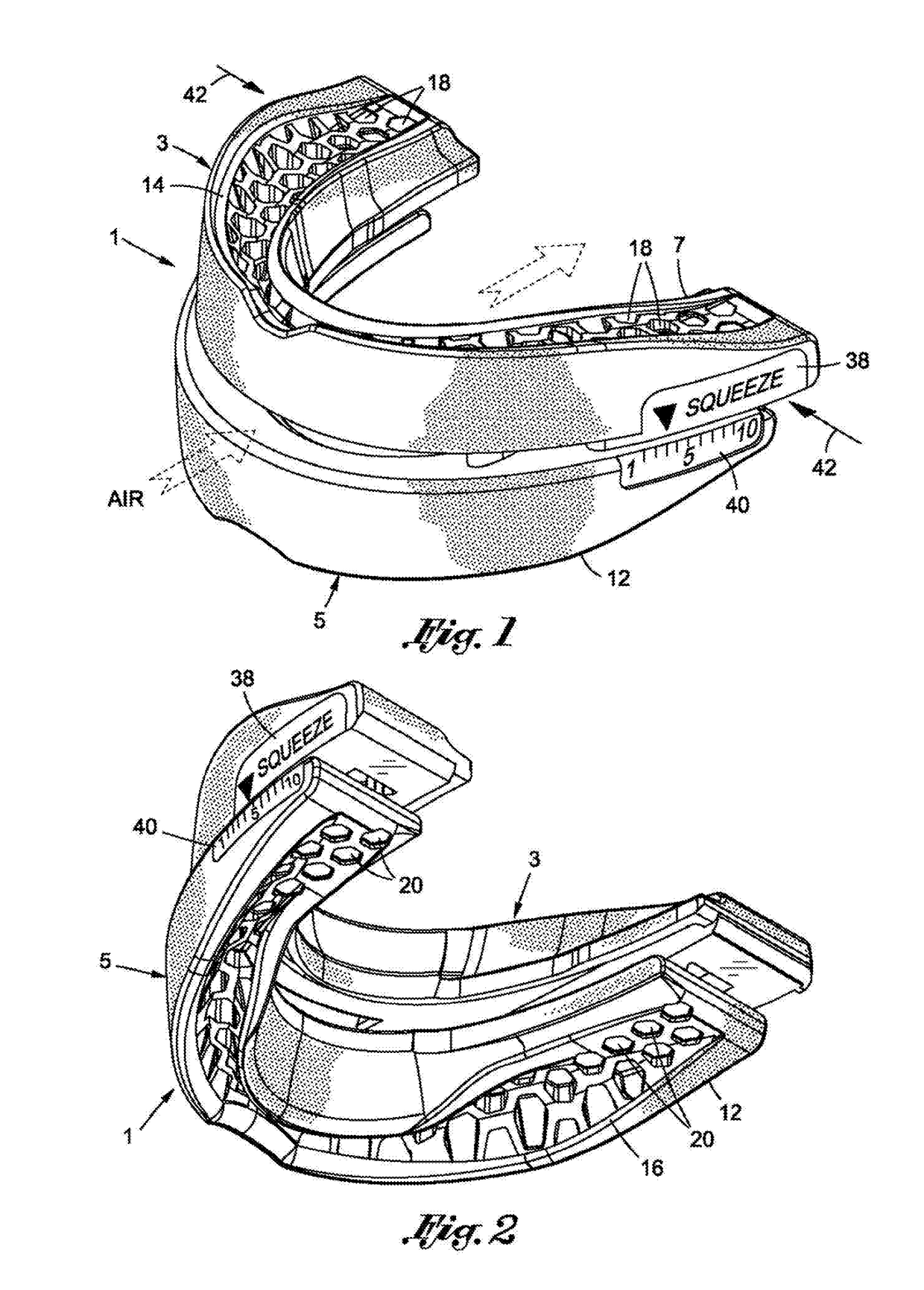

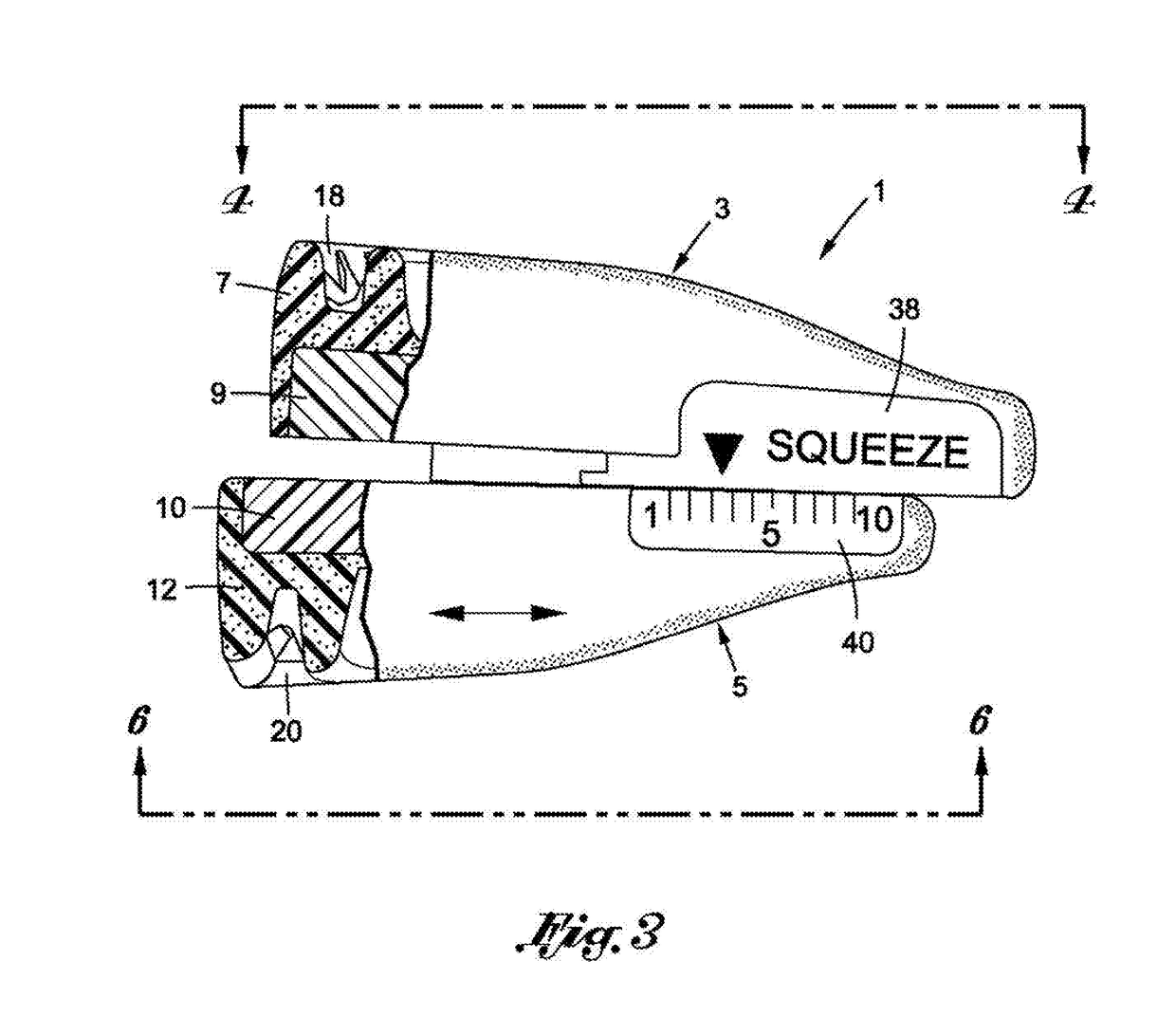

Adjustable dental impression tray and methods for using same

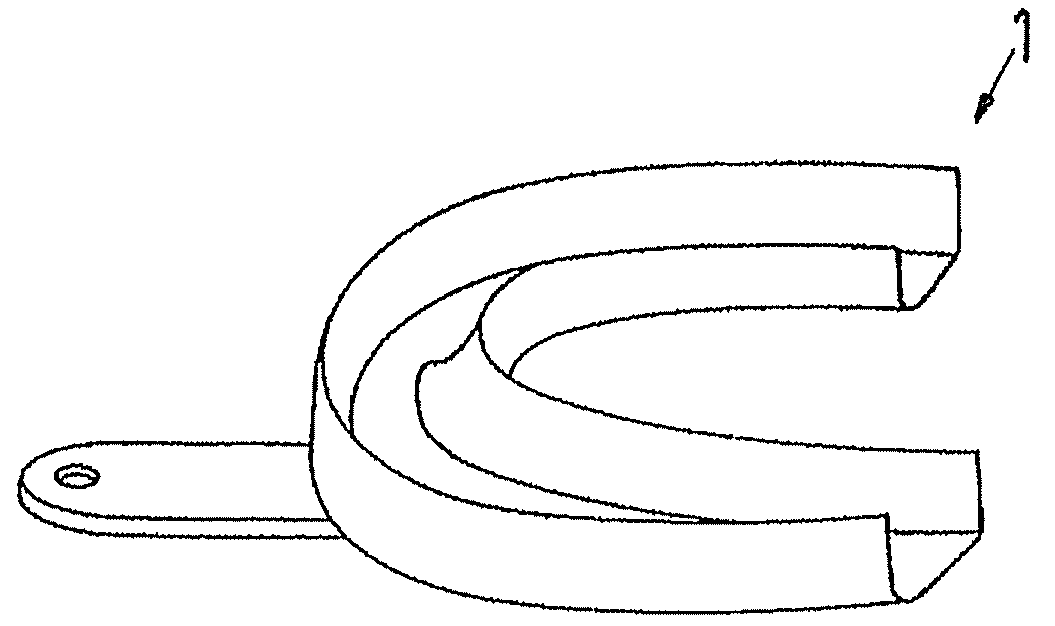

An adjustable dental impression tray including a first arcuate member and a second arcuate member configured to selectively engage the first arcuate member. The first and second arcuate members forming a channel adapted to receive a quantity of impression material. The adjustable dental impression tray having a handle formed at one end which facilitates the introduction and removal of the impression tray into and from the mouth of a patient. An adjustment mechanism engageably disposed in relation to the first and second arcuate members, wherein the adjustment mechanism provides for the selective adjustment of the first arcuate member in at least one fixed position relative to the second arcuate position, wherein defining one or more widths of the channel. Preferably, the channel is formed having a general U-shaped configuration which approximates the various sizes of the dentition of a patient. In preferred design, each of the arcuate members comprise an outer wall, an inner wall and a platform surface. A locking member is preferably formed in relation to the arcuate members to receive and retain the impression material in relation to the channel. In addition, one or more notches may be formed in the length of the arcuate members to provide means for removing at least a portion of the length of one or both of the arcuate members, thereby forming a "quadrant" or an "anterior" dental tray.

Owner:SKINNER GREGORY C

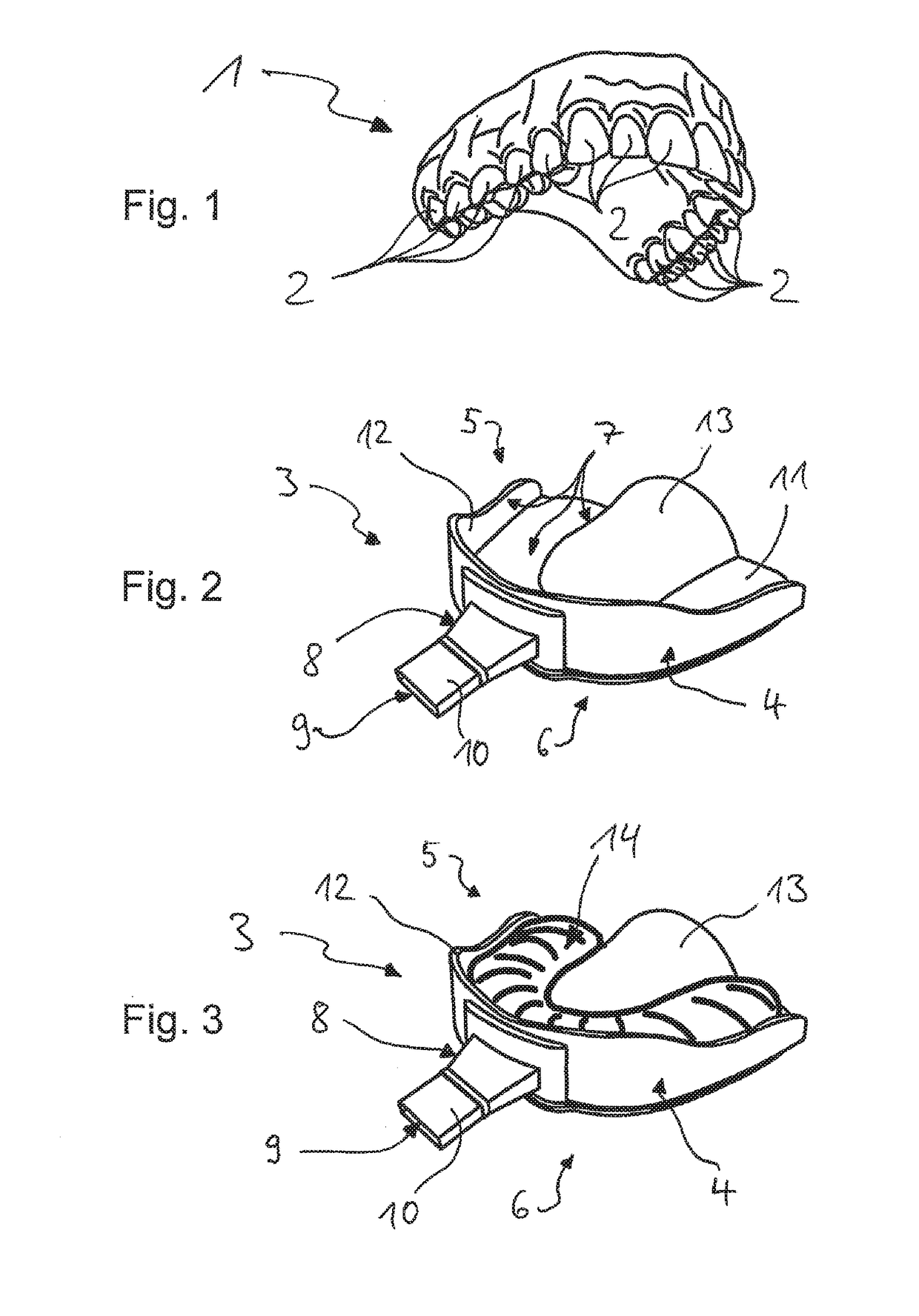

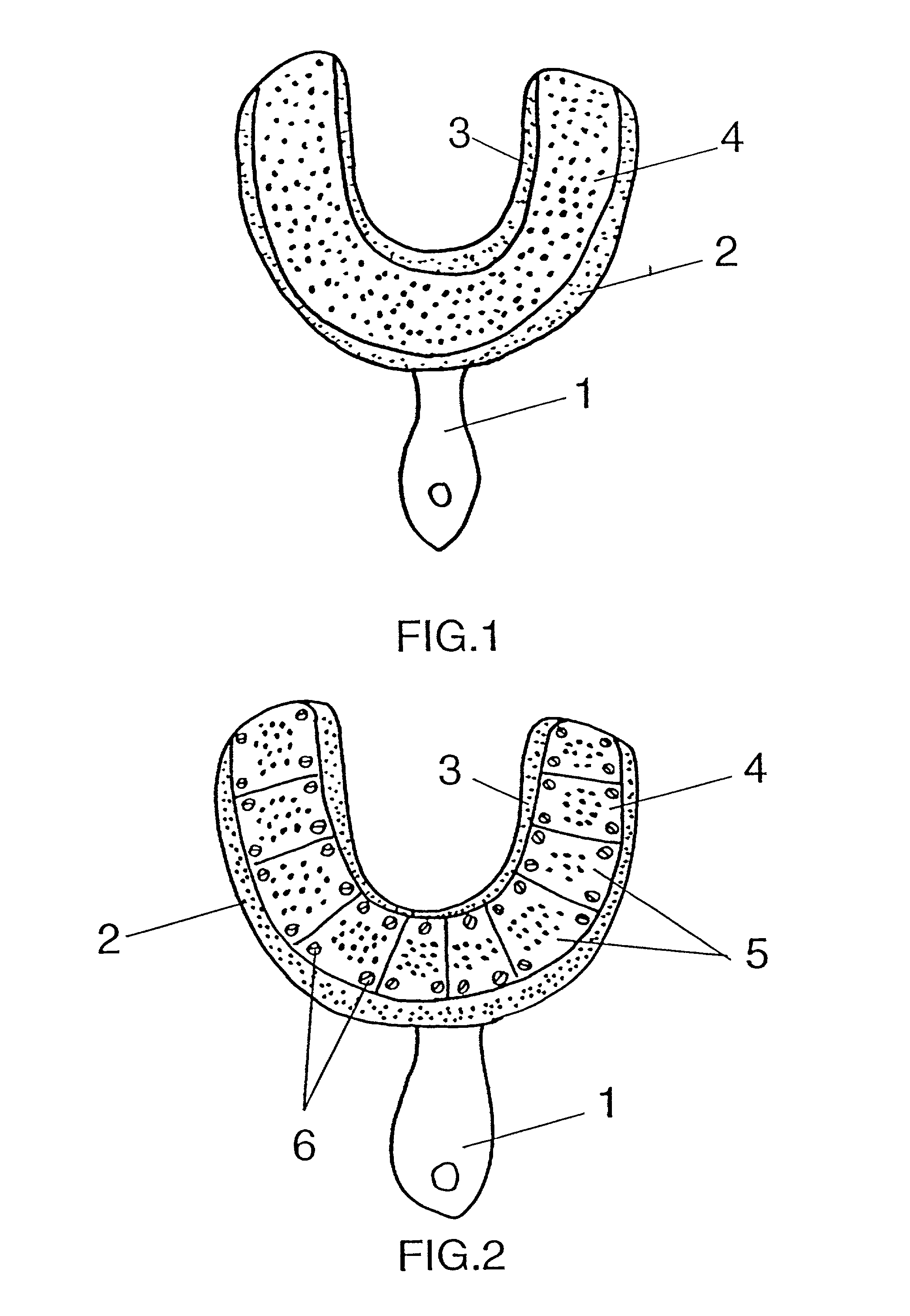

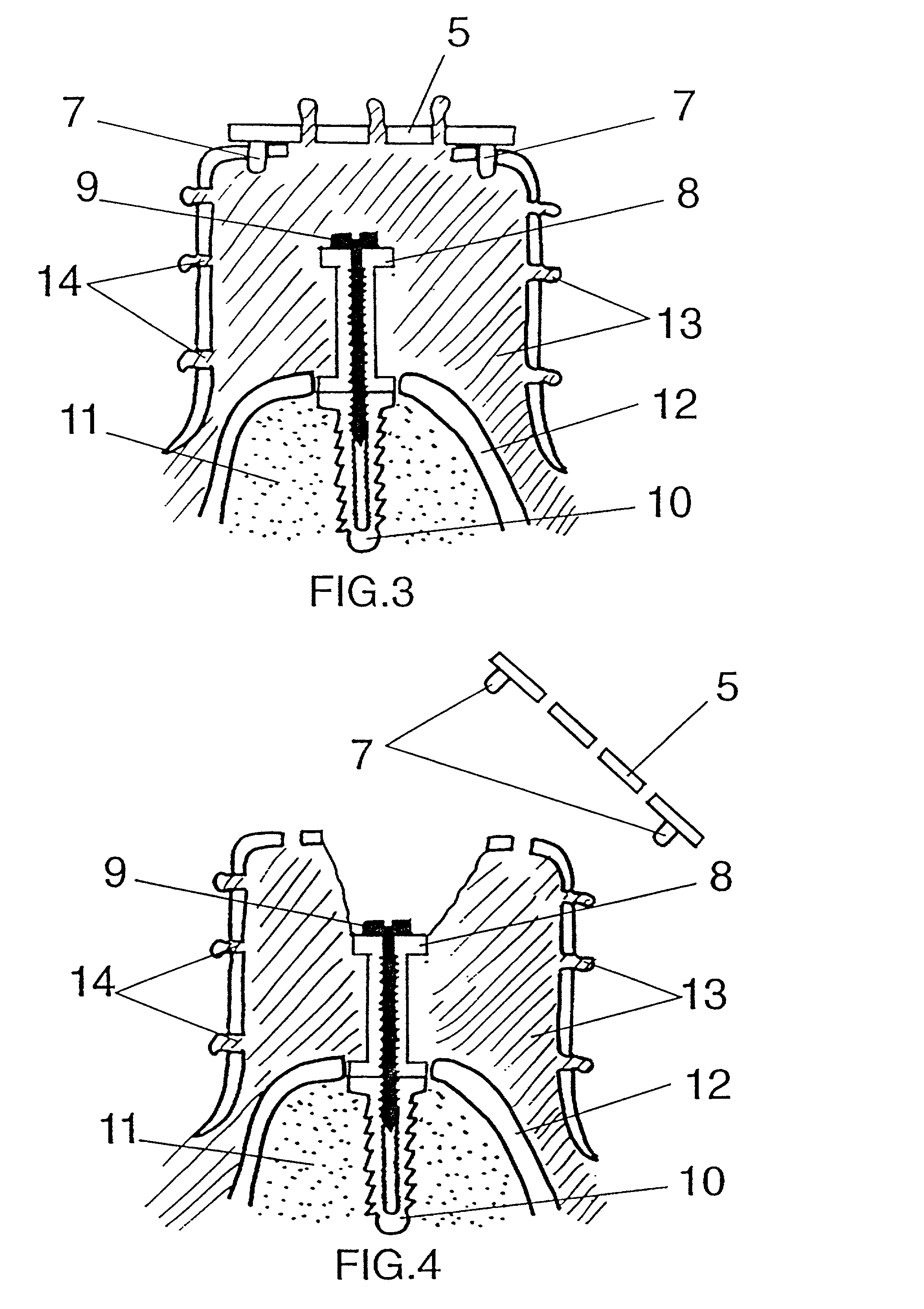

Method and Kit for Producing a Dental Product

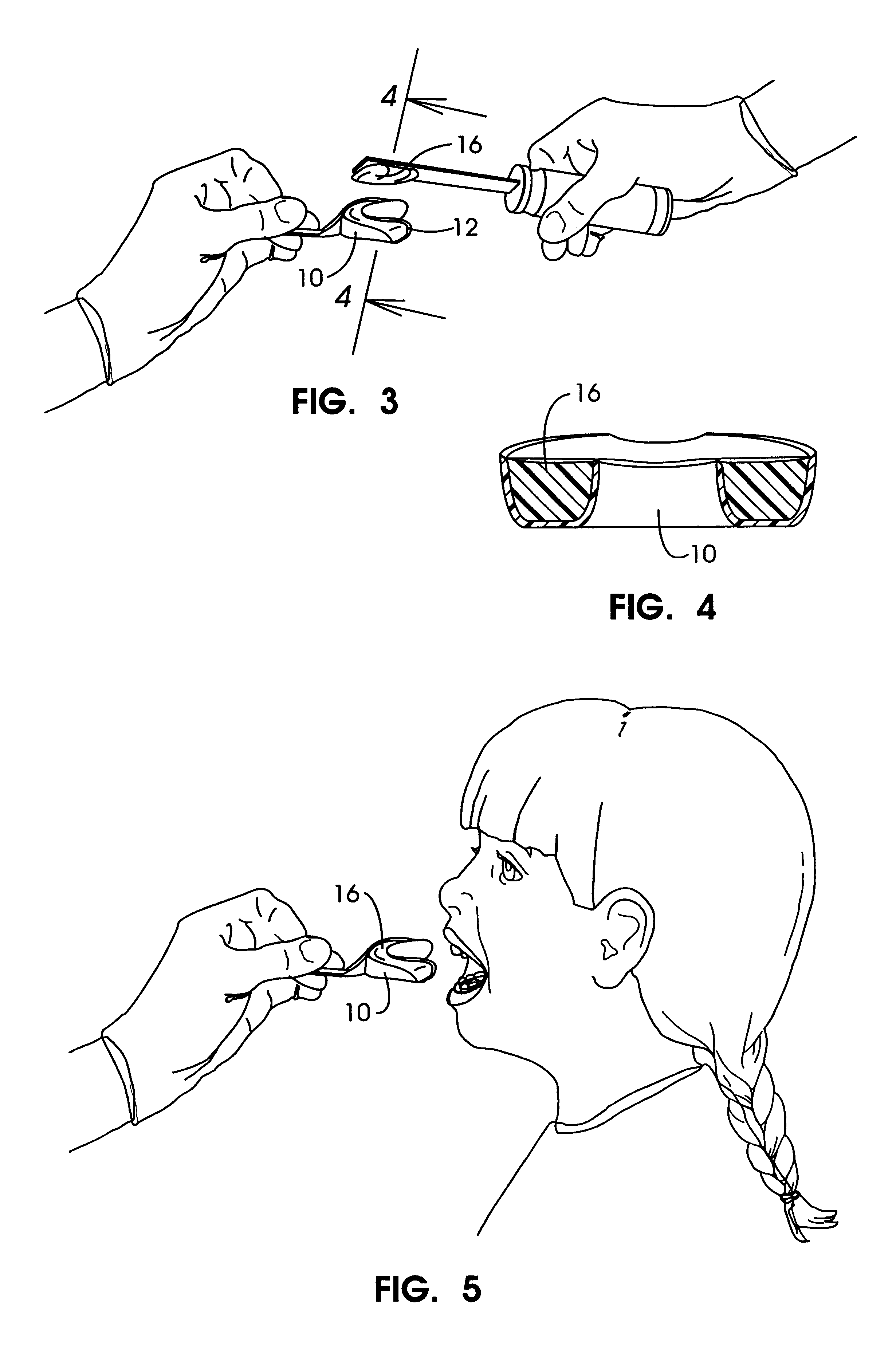

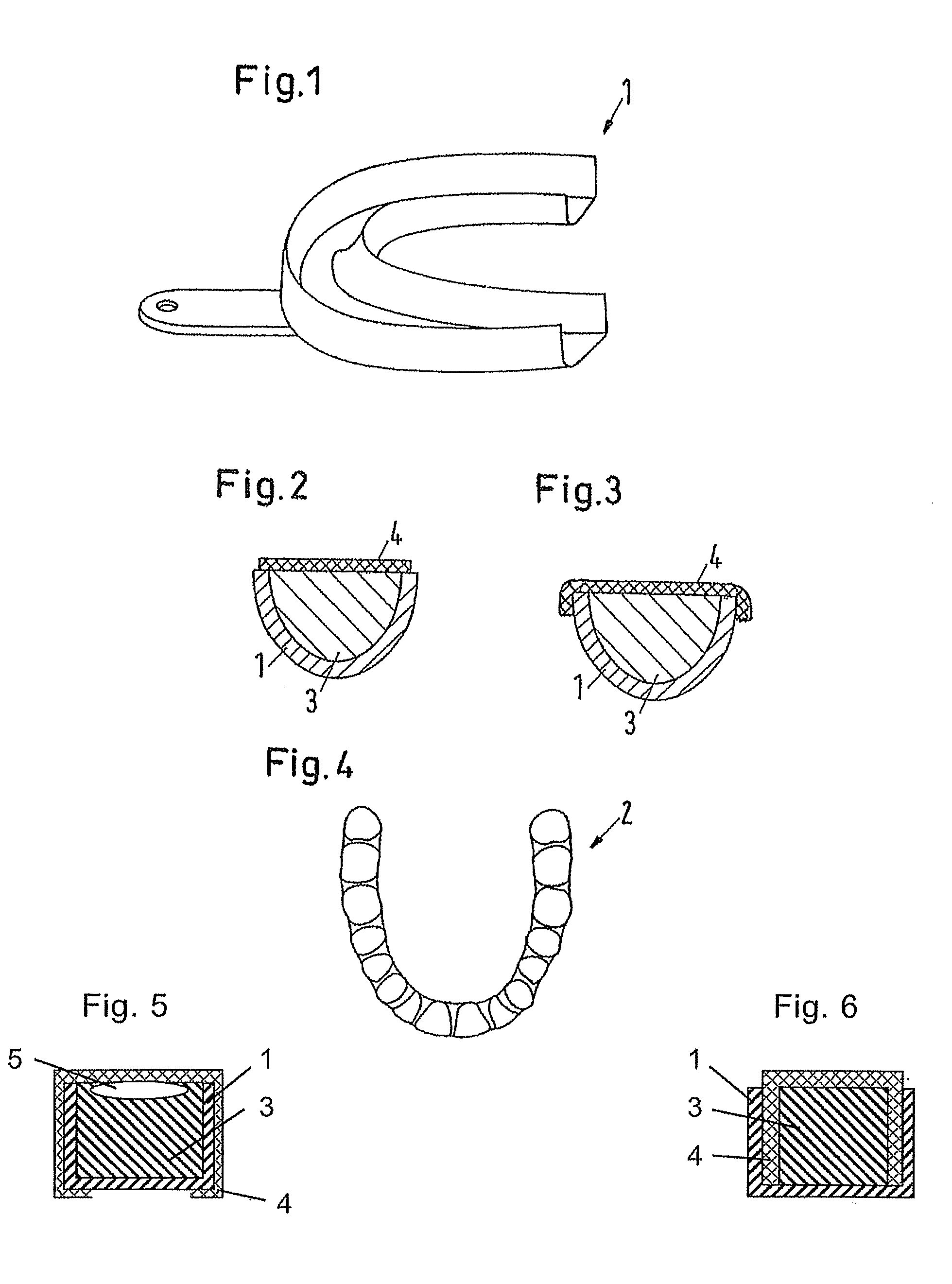

InactiveUS20090298018A1Easy to disassemblePlastically deformedImpression capsTeeth fillingImpression traysDental Product

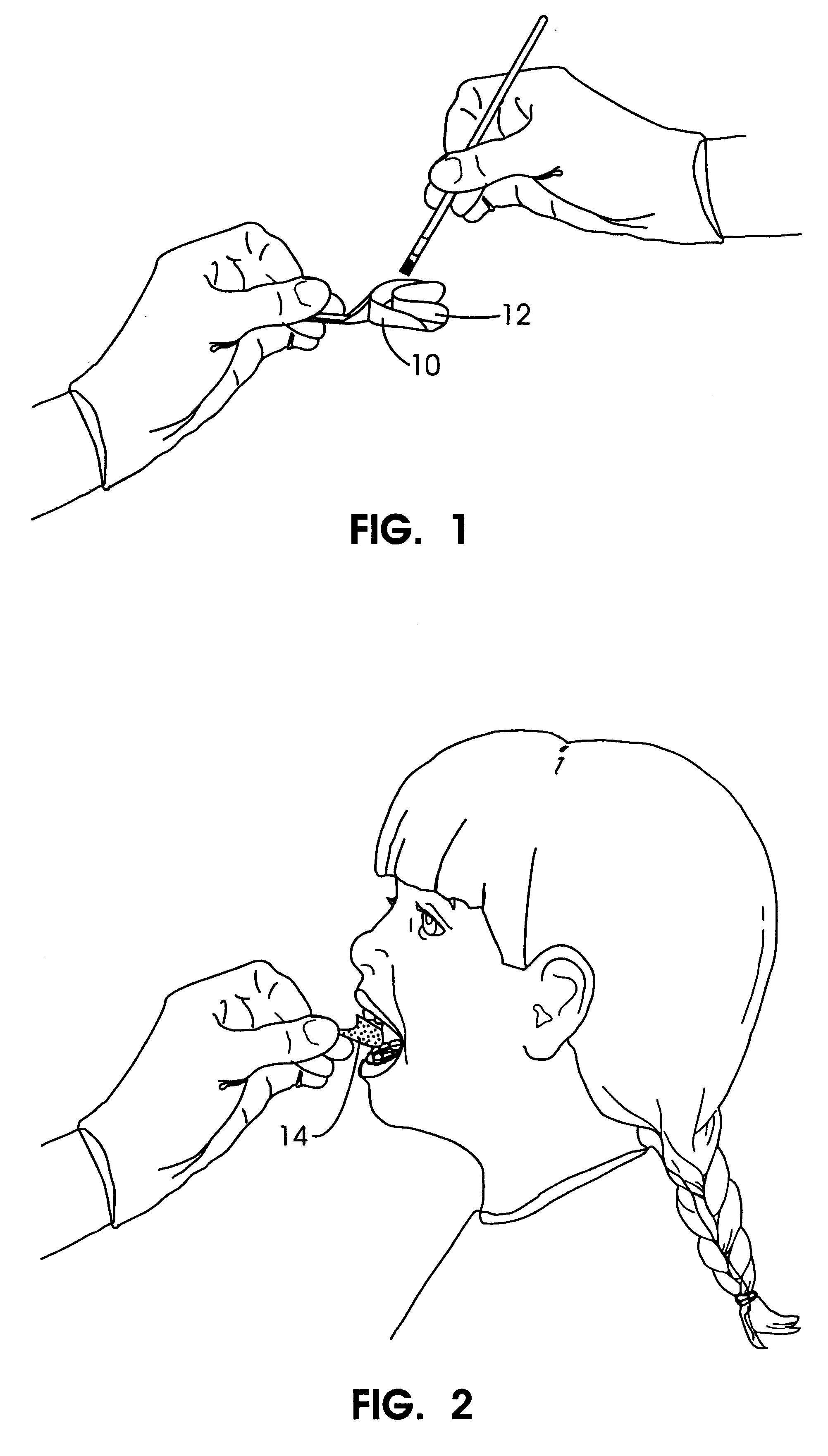

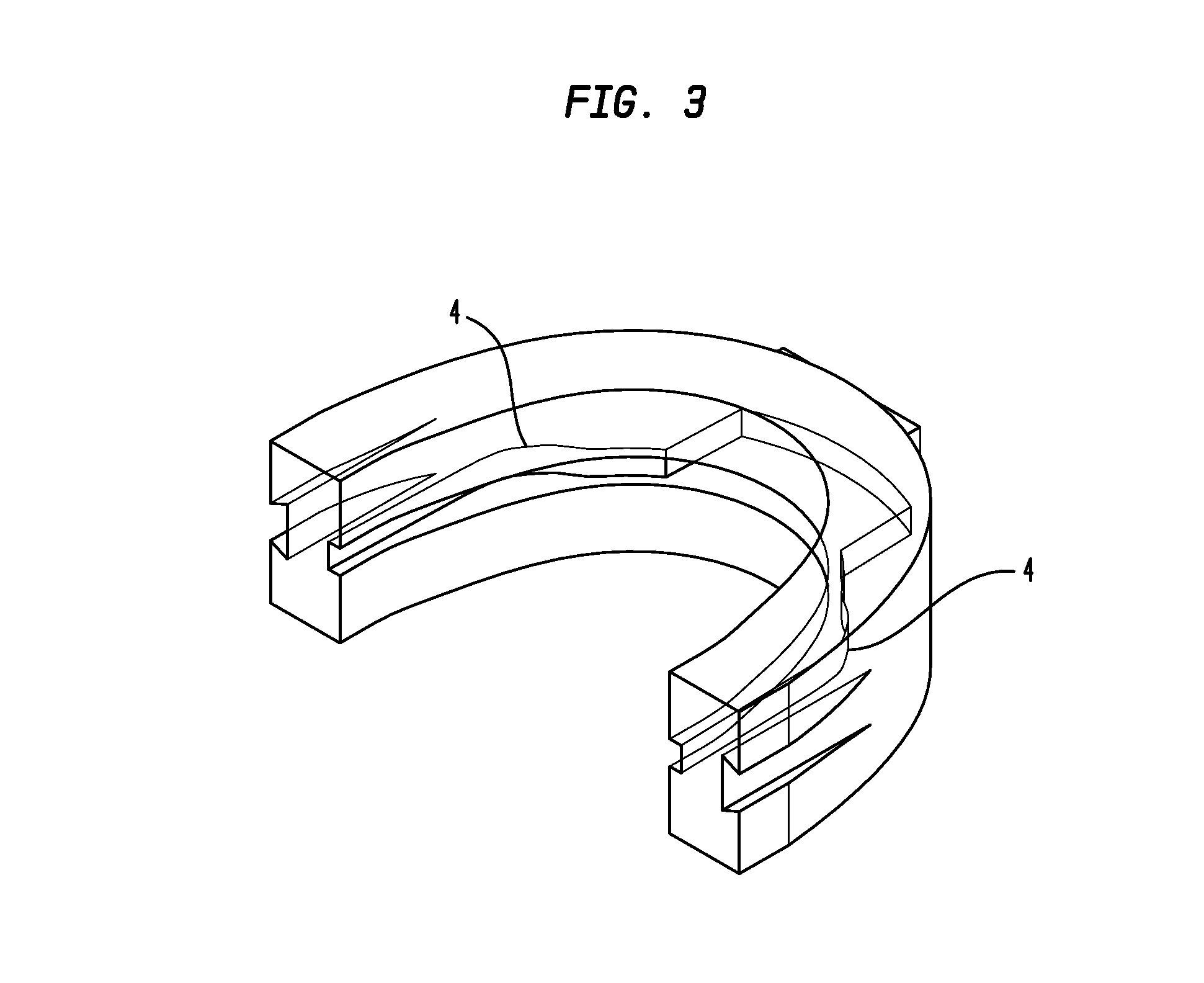

Method and kit for producing a dental product The invention relates to a method and a kit for producing a dental product. The invention also relates to a device that allows the method according to the invention to be implemented. According to the invention, a thermoplastic material (4) of said kit is selectively heated through the supply of targeted (directed) energy more strongly than an impression tray (1) and / or an impression material (3).

Owner:KETTENBACH GMBH & CO KG

Adjustable dental impression tray and methods for using same

An adjustable dental impression tray including a first arcuate member and a second arcuate member configured to selectively engage the first arcuate member. The first and second arcuate members forming a channel adapted to receive a quantity of impression material. The adjustable dental impression tray having a handle formed at one end which facilitates the introduction and removal of the impression tray into and from the mouth of a patient. An adjustment mechanism engageably disposed in relation to the first and second arcuate members, wherein the adjustment mechanism provides for the selective adjustment of the first arcuate member in at least one fixed position relative to the second arcuate position, wherein defining one or more widths of the channel. Preferably, the channel is formed having a general U-shaped configuration which approximates the various sizes of the dentition of a patient. In preferred design, each of the arcuate members comprise an outer wall, an inner wall and a platform surface. A locking member is preferably formed in relation to the arcuate members to receive and retain the impression material in relation to the channel. In addition, one or more notches may be formed in the length of the arcuate members to provide means for removing at least a portion of the length of one or both of the arcuate members, thereby forming a “quadrant” or an “anterior” dental tray.

Owner:SKINNER GREGORY C

Removable handle scan body for impression trays and radiographic templates for integrated optical and CT scanning

InactiveUS8750590B2Avoid dependenceDental implantsImpression capsComputed tomographyImpression trays

A device for use in optical scanning and CT scanning including a radiographic template and at least one shape of known dimension (SKD). The radiographic template includes a plurality of radio-opaque markers and is configured to take an impression of at least one surface of a patient. The SKD is removably attached to the radiographic template and serves as a basis for registration of data of a CT scan of the device with data of an optical scan of the device. The device may further comprise a mounting plate. The SKD is mounted on the mounting plate such that the at least one SKD is in an exact same position with respect to surfaces in a model formed from the impression as when the impression of the patient is formed in the radiographic template.

Owner:GREENBERG SURGICAL TECH

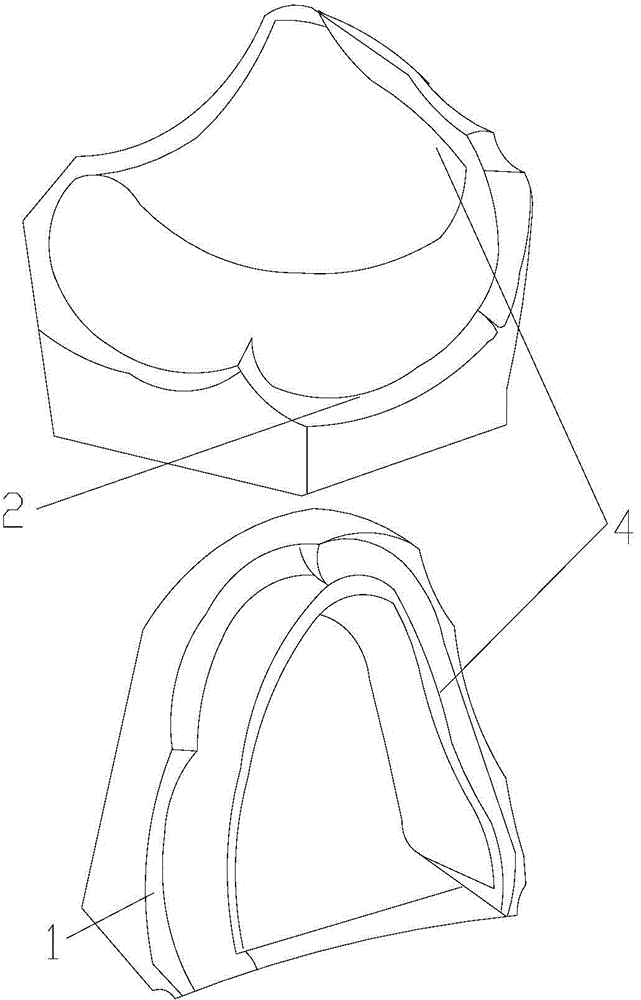

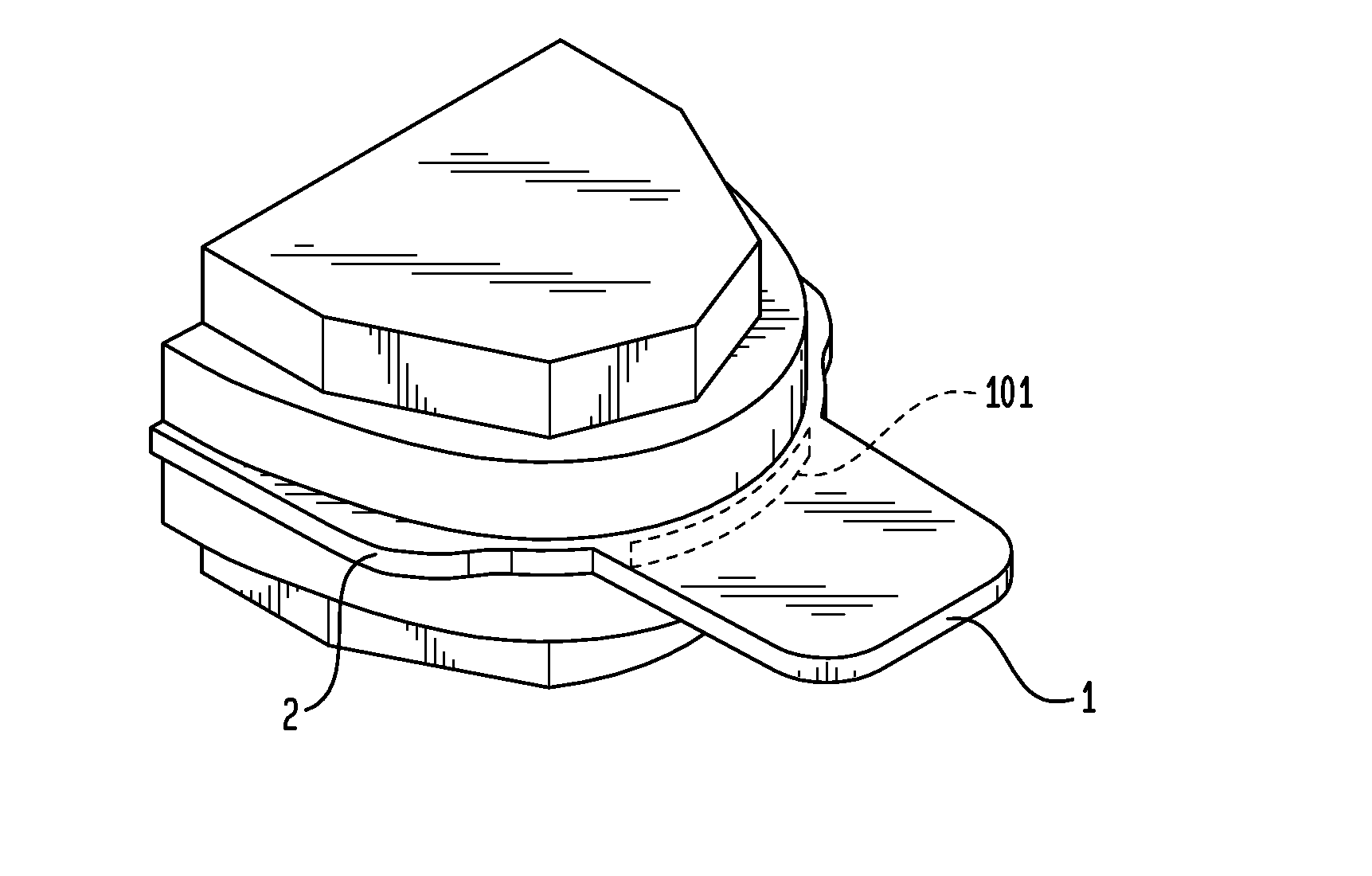

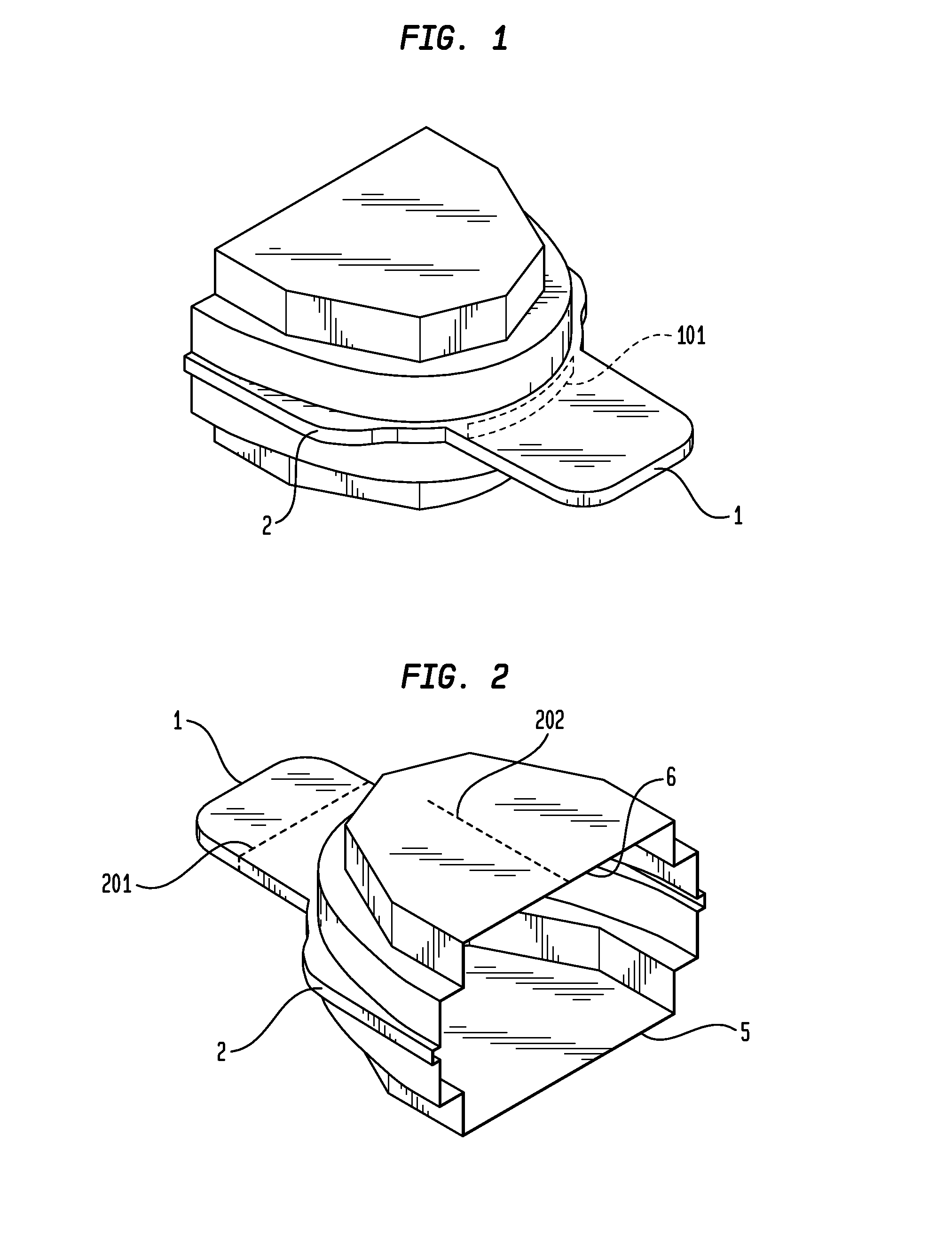

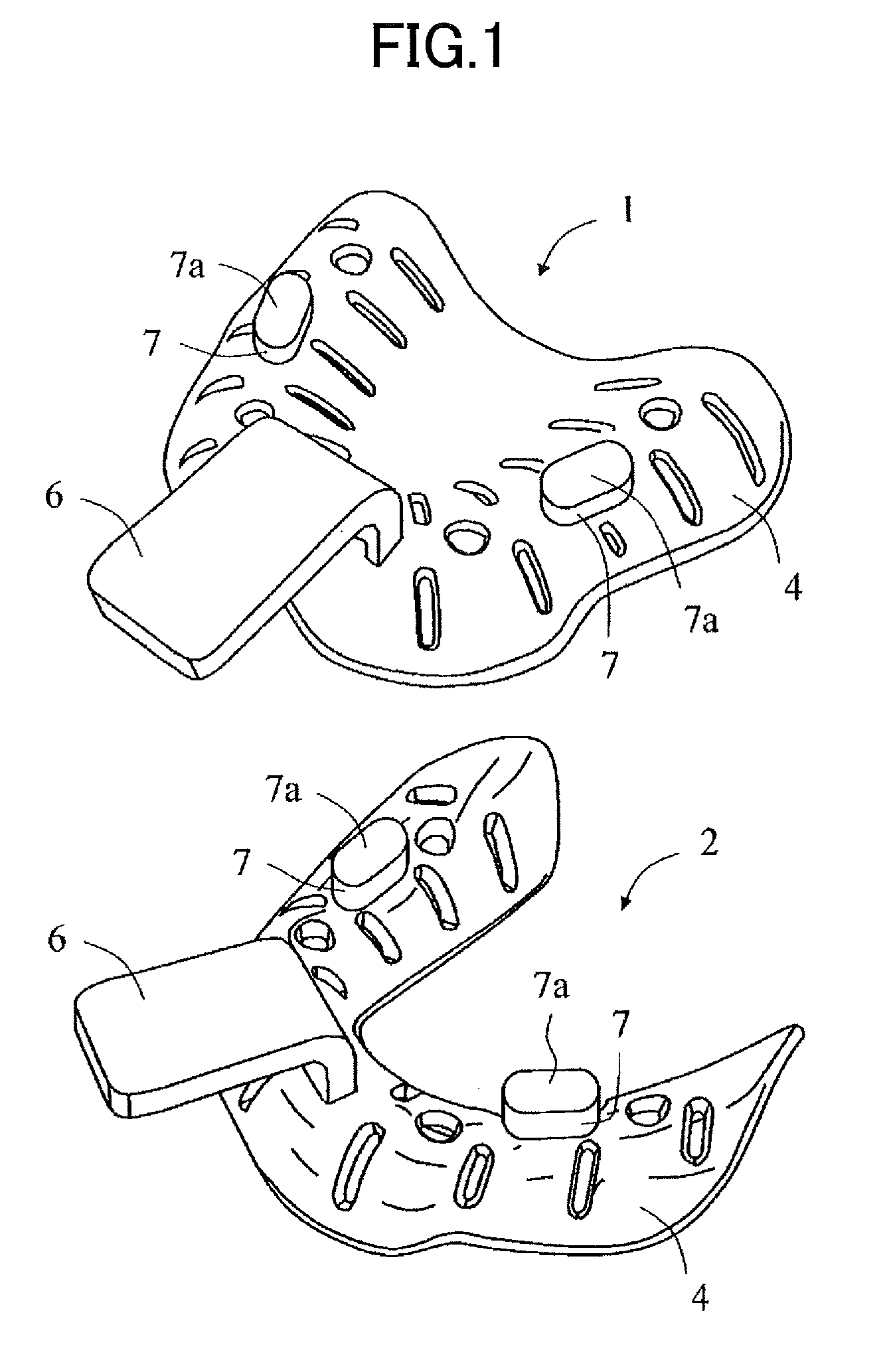

Full denture base manufacturing method

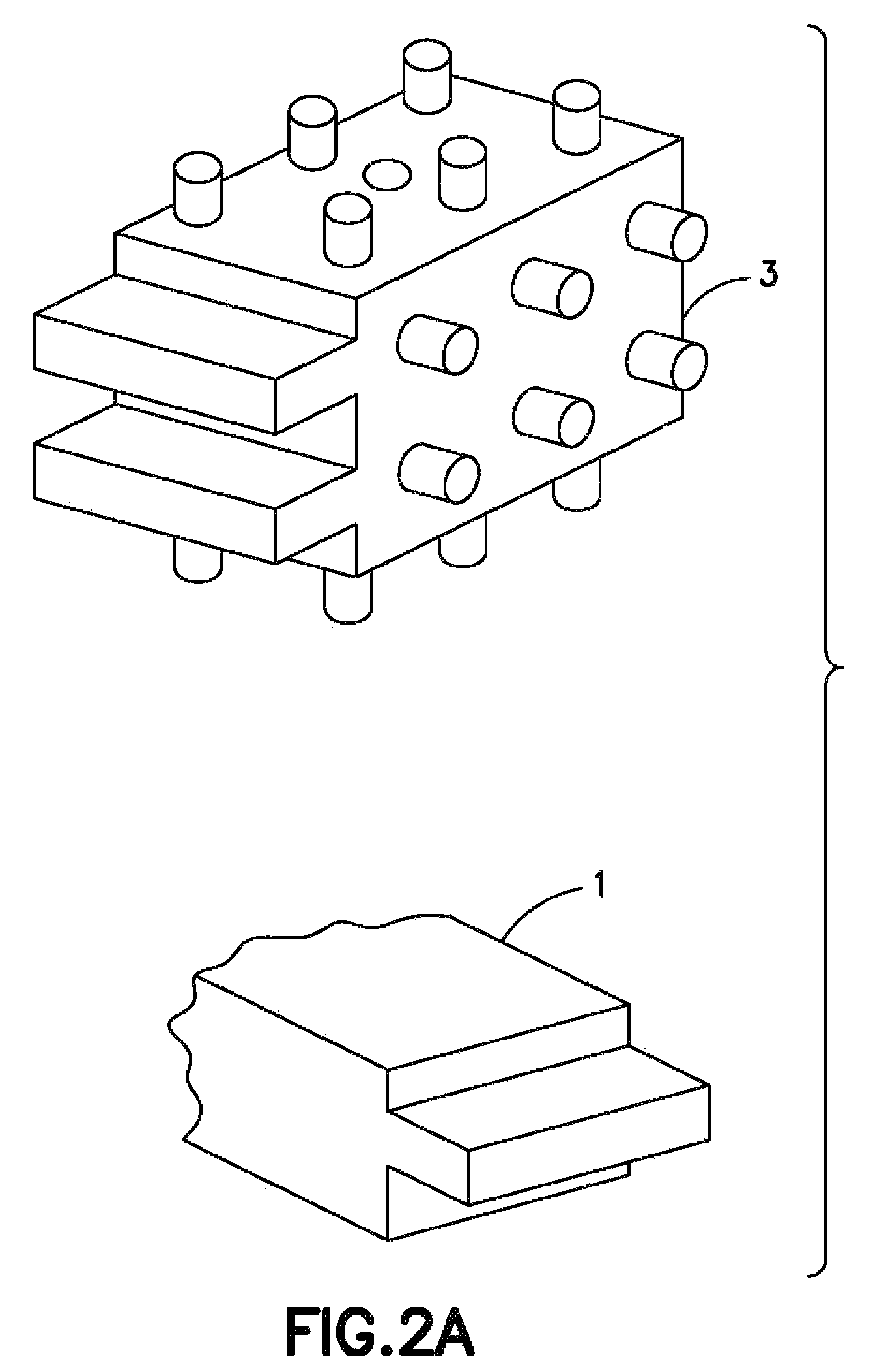

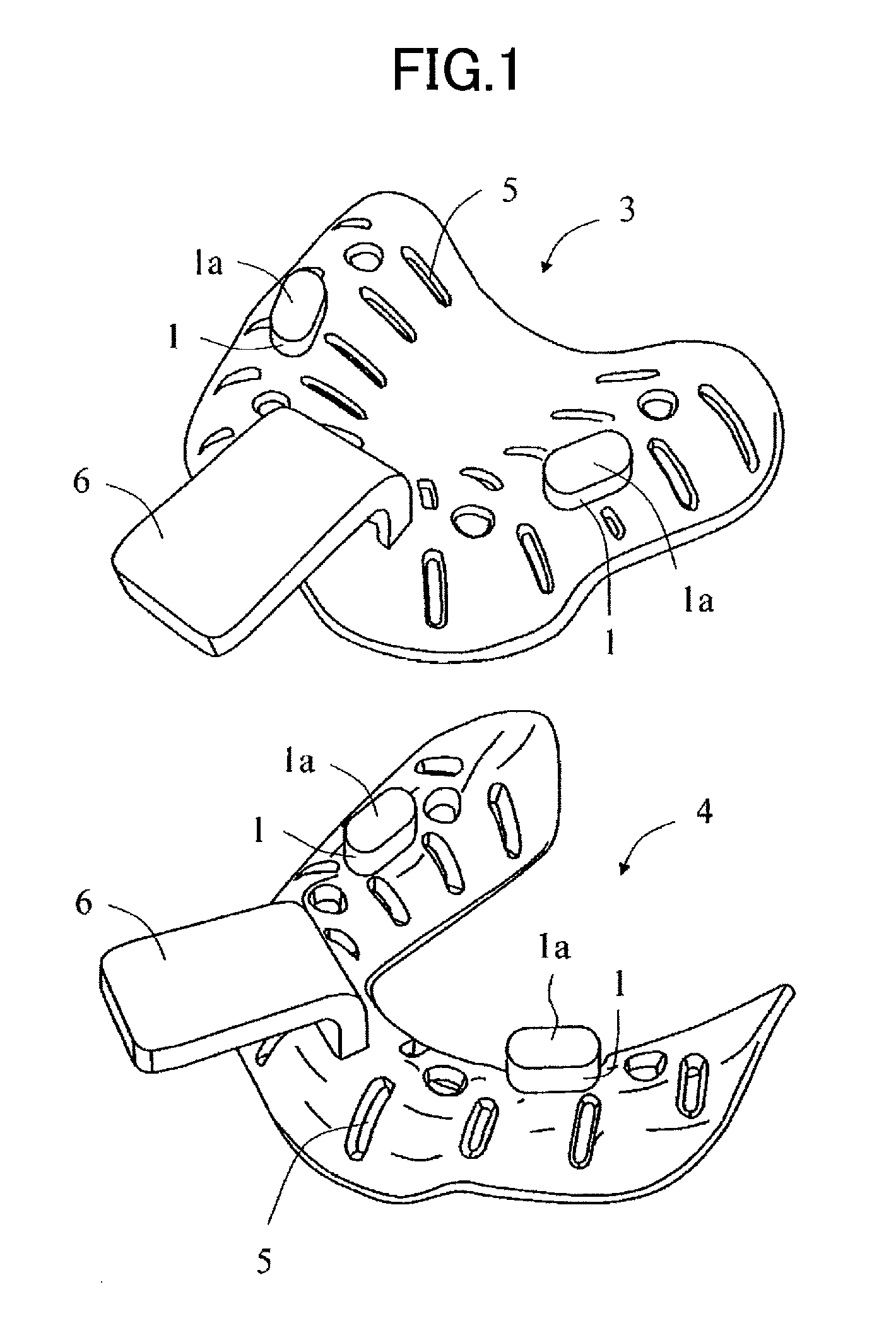

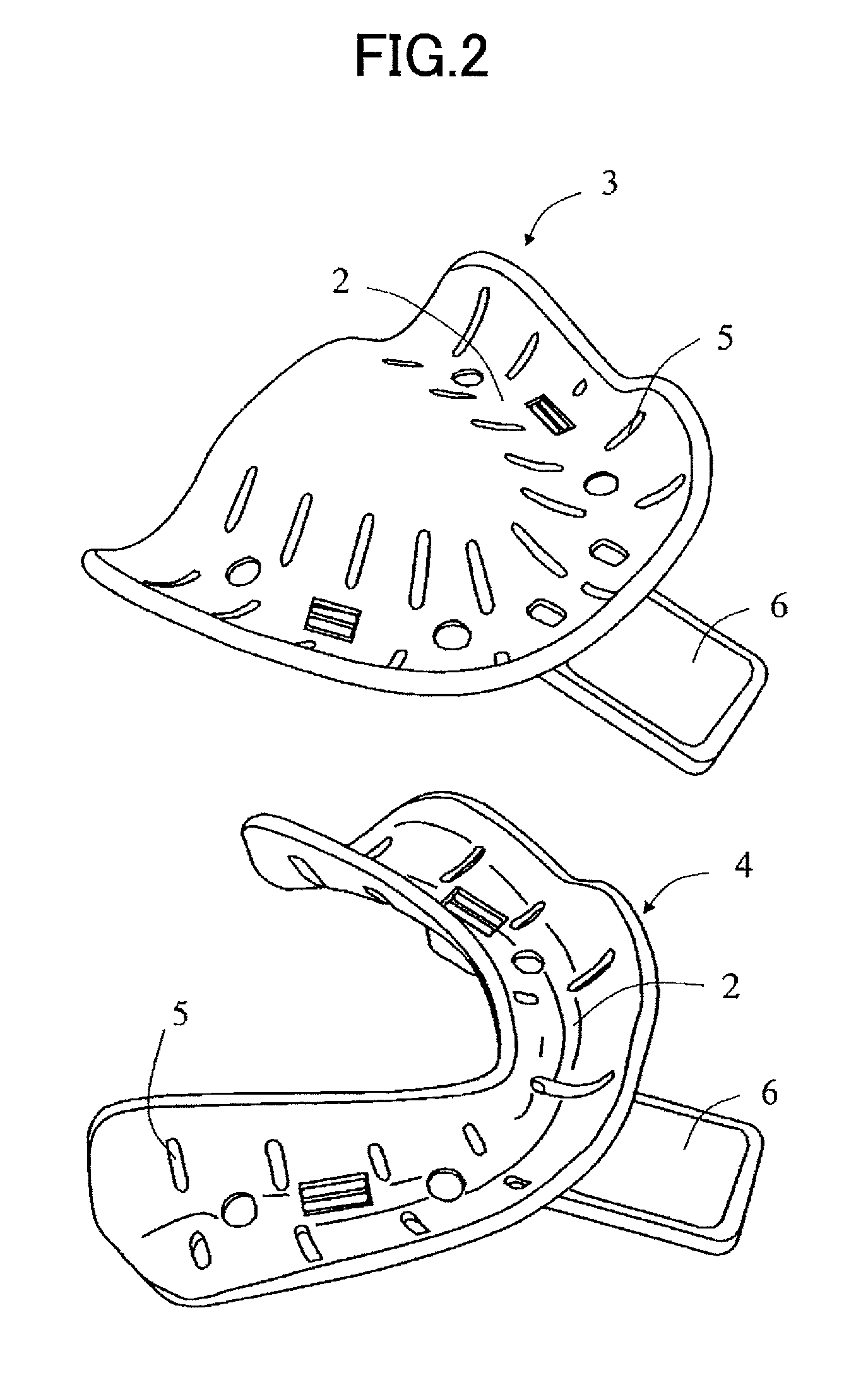

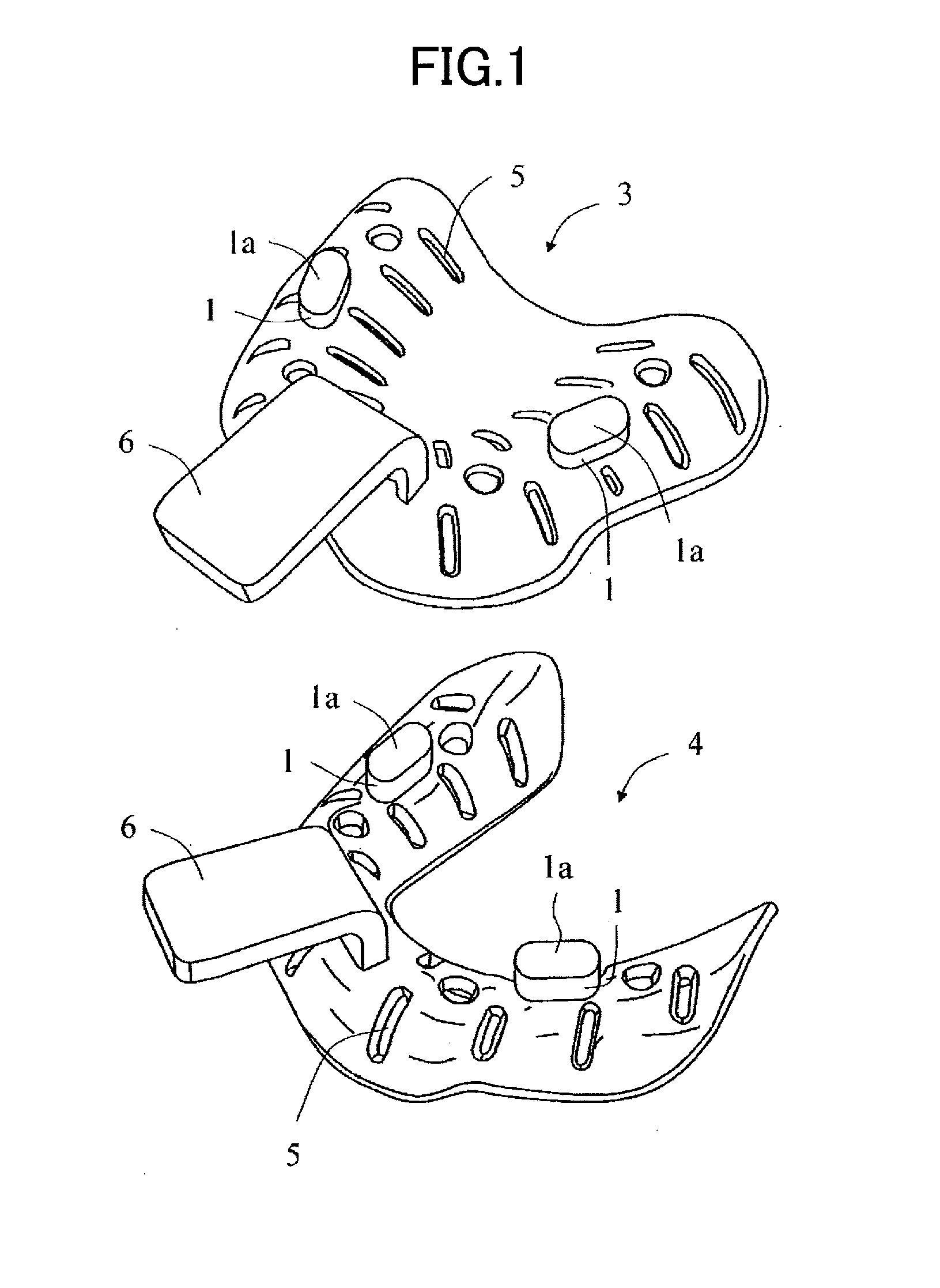

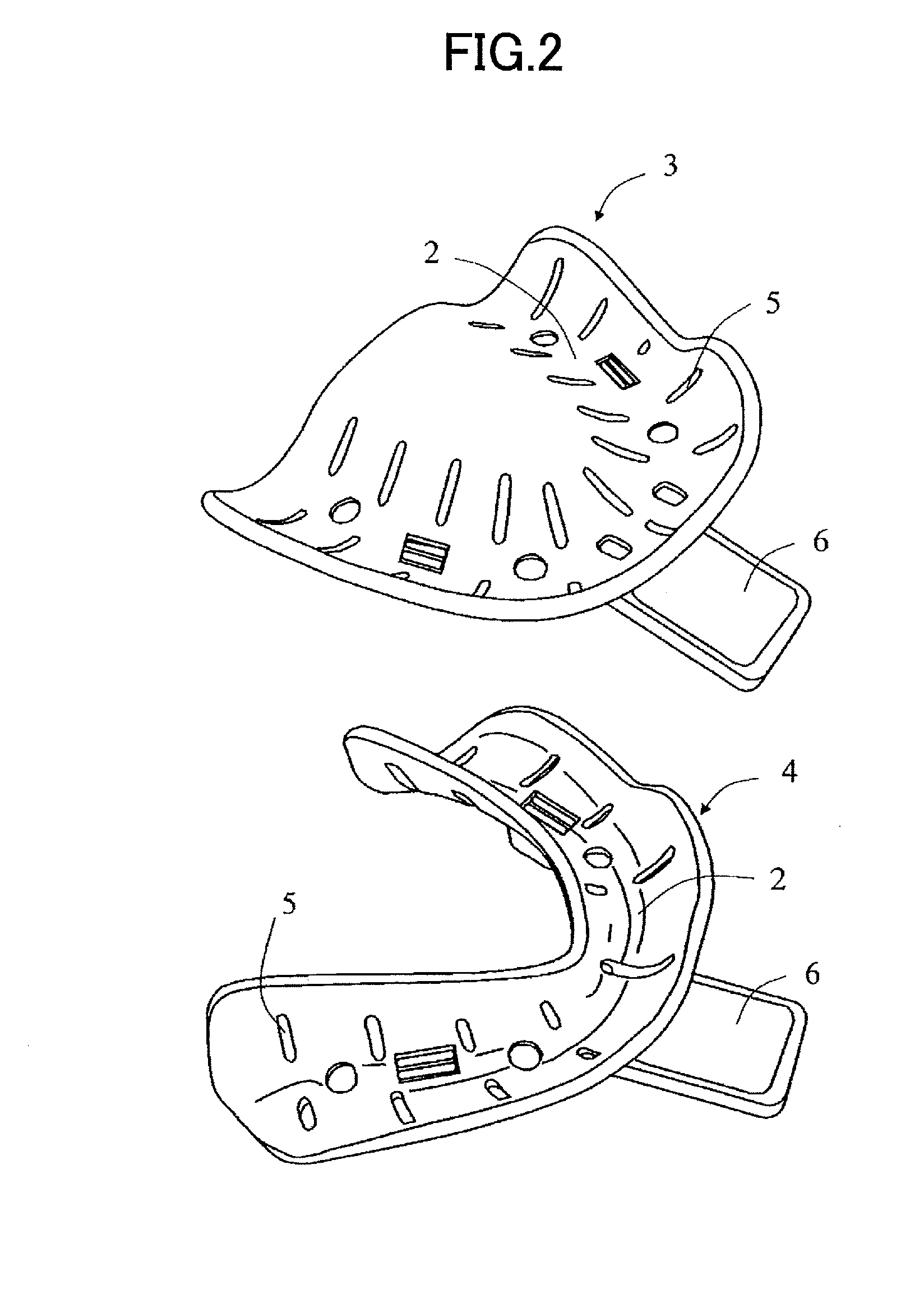

ActiveUS9498310B2Easy to copyEasy transferImpression capsMachines/enginesDental ArticulatorsImpression trays

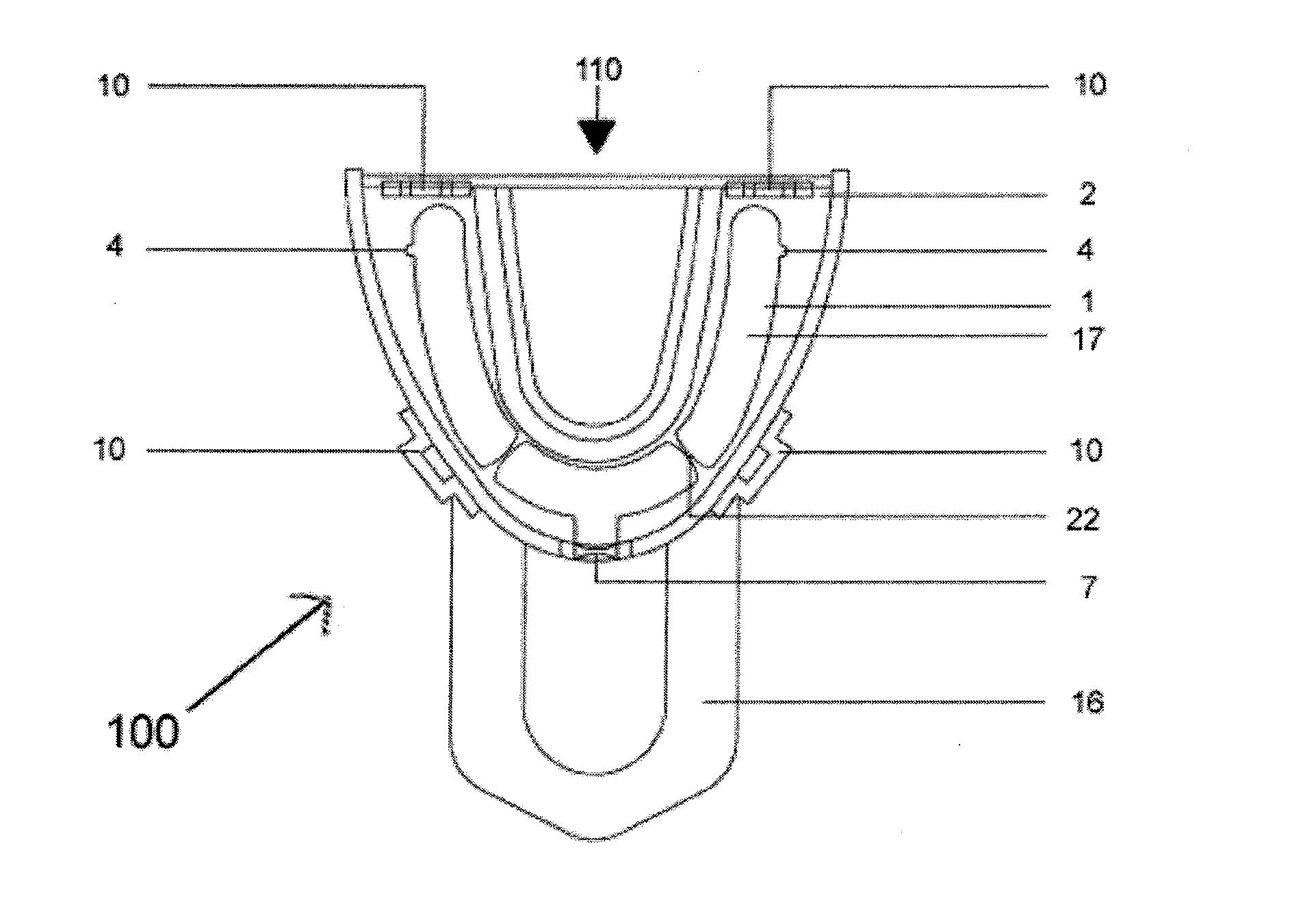

A full denture base manufacturing method is provided that can easily manufacture a full denture base, using a set of maxillary impression tray and a mandibular impression tray for taking an impression from a patient including an edentulous patient.An impression material is applied on each of a maxillary impression tray 3 and a mandibular impression tray 4 configuring a set of impression trays, and respectively having a U-shaped groove, the U-shaped groove having a front surface side on which the impression material is to be applied and being provided with projecting parts 1 on a back surface side thereof, and the applied impression material is pressed against an alveolar ridge within an oral cavity and set, to determine bite position and height in a state in which at least a part of flat top surfaces of the projecting parts 1 contact each other, the second impression material is applied between back surfaces of the impression trays 3, 4 and set in a state in which at least a part of the flat top surfaces contact each other, each of the impression trays 3, 4 and the impression material are removed from within the oral cavity in one piece of the maxillary and mandibular impression trays, or separately in two pieces of the maxillary and mandibular impression trays, and a model material is thereafter injected to each impression material on the removed maxillary and mandibular impression trays and set, in order to manufacture an edentulous jaw model, and the edentulous jaw model is set on an articulator in a state in which the bite position and height that are determined in advance are reflected, in order to manufacture a full denture base.

Owner:GC CORP

Imperssion tray device with removable segments for dental implant transfers

Owner:GUILLAUME BERNARD +1

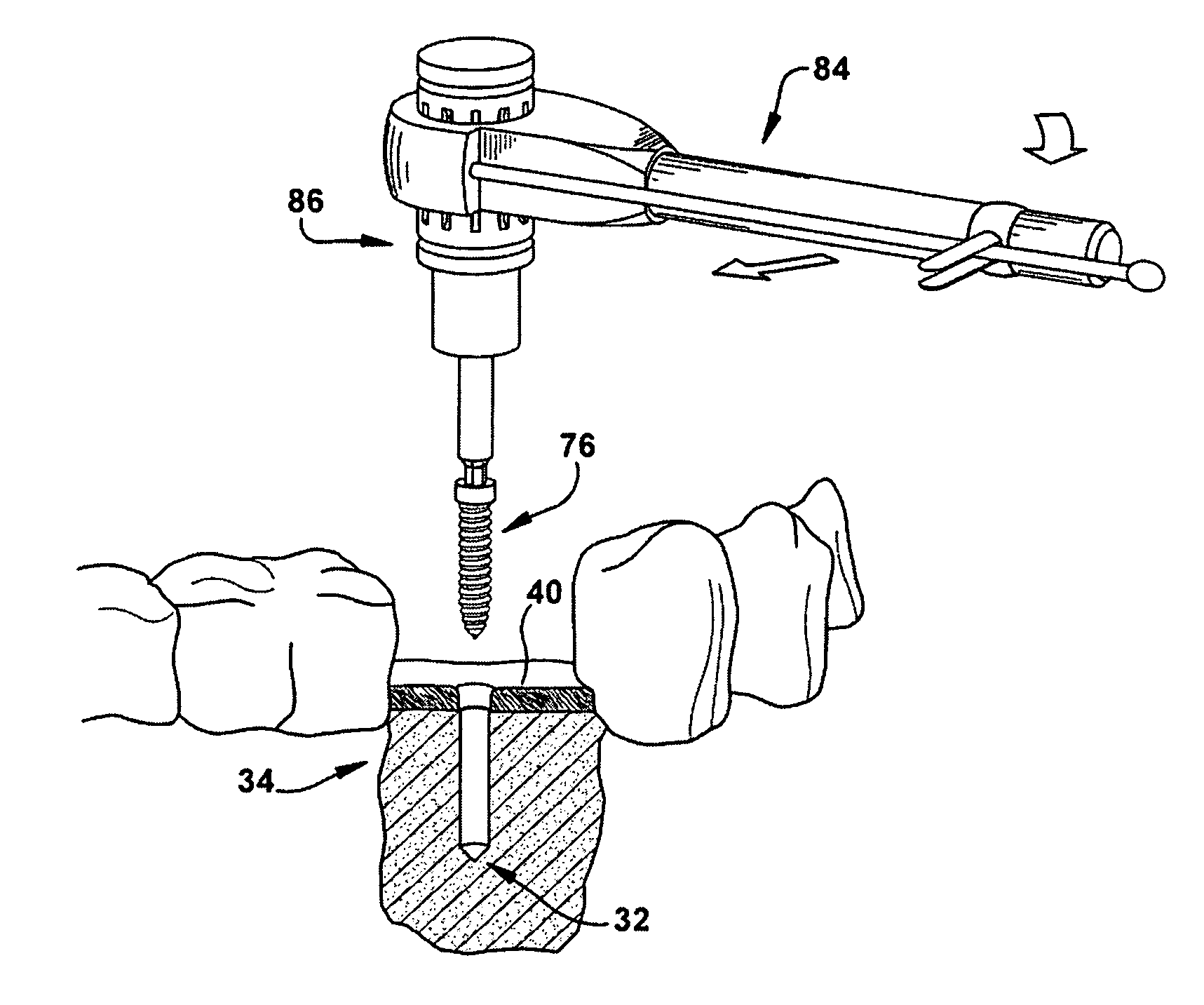

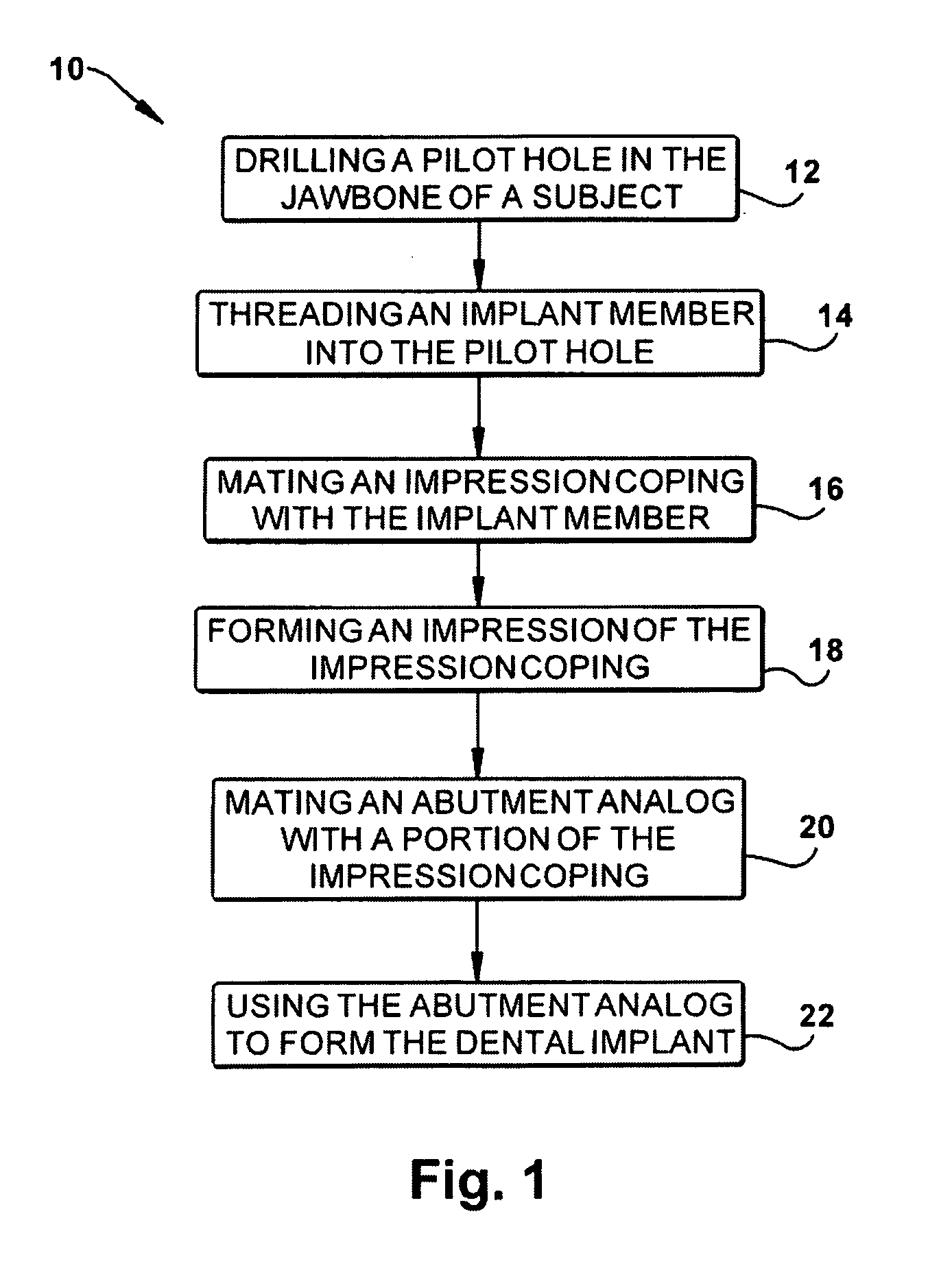

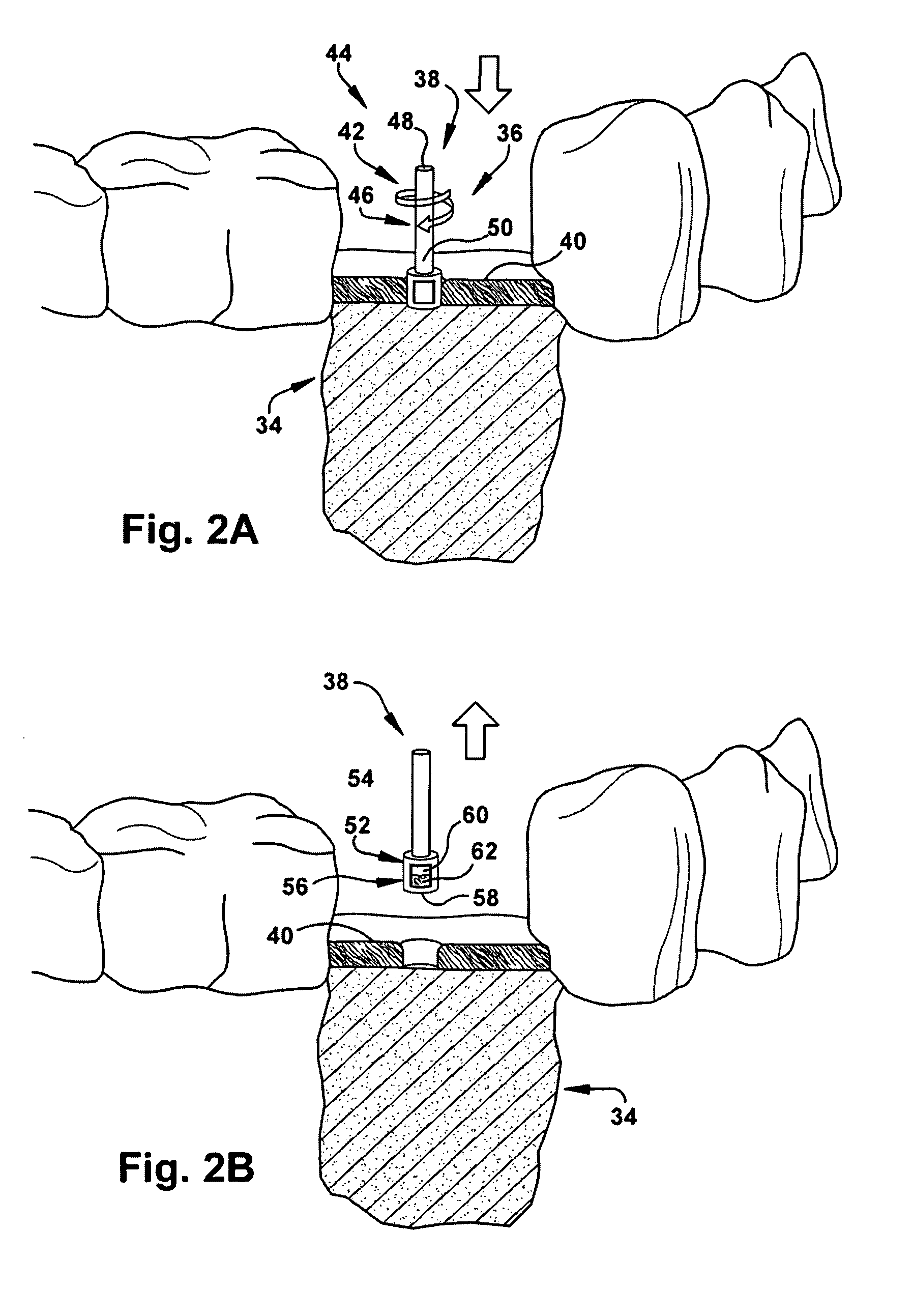

Method for forming a dental implant

A method for forming a dental implant includes drilling a pilot hole in the jaw bone of a subject and then threading an implant body into the pilot hole. The implant body includes a threaded portion integrally formed with a head portion having a polygonal recess. The implant body is threaded until the threaded portion reaches a predetermined seating depth. Next, an impression coping is mated with the polygonal recess of the implant body so that a portion of the impression coping is friction fit within the polygonal recess. After mating the impression coping with the implant body, an impression of the impression coping is formed. An implant analog is then mated with a portion of the impression coping without dissecting a portion of the impression tray. The implant analog is then used to form the dental implant.

Owner:ZUGA MEDICAL

Full denture base manufacturing method

ActiveUS20150190216A1Easy to copyEasy transferImpression capsDental articulatorsDental ArticulatorsFull dentures

A full denture base manufacturing method is provided that can easily manufacture a full denture base, using a set of maxillary impression tray and a mandibular impression tray for taking an impression from a patient including an edentulous patient.An impression material is applied on each of a maxillary impression tray 3 and a mandibular impression tray 4 configuring a set of impression trays, and respectively having a U-shaped groove, the U-shaped groove having a front surface side on which the impression material is to be applied and being provided with projecting parts 1 on a back surface side thereof, and the applied impression material is pressed against an alveolar ridge within an oral cavity and set, to determine bite position and height in a state in which at least a part of flat top surfaces of the projecting parts 1 contact each other, the second impression material is applied between back surfaces of the impression trays 3, 4 and set in a state in which at least a part of the flat top surfaces contact each other, each of the impression trays 3, 4 and the impression material are removed from within the oral cavity in one piece of the maxillary and mandibular impression trays, or separately in two pieces of the maxillary and mandibular impression trays, and a model material is thereafter injected to each impression material on the removed maxillary and mandibular impression trays and set, in order to manufacture an edentulous jaw model, and the edentulous jaw model is set on an articulator in a state in which the bite position and height that are determined in advance are reflected, in order to manufacture a full denture base.

Owner:GC CORP

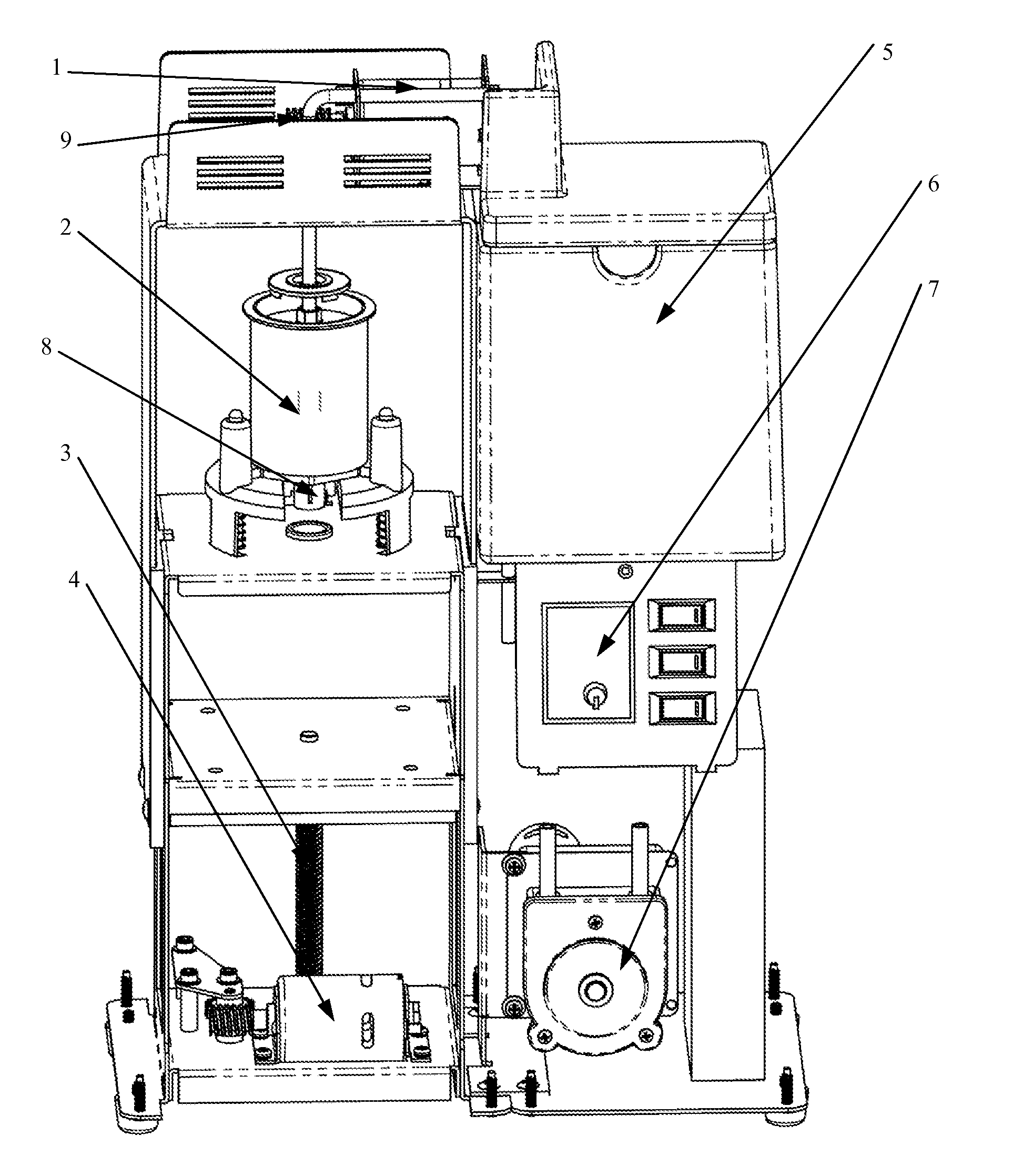

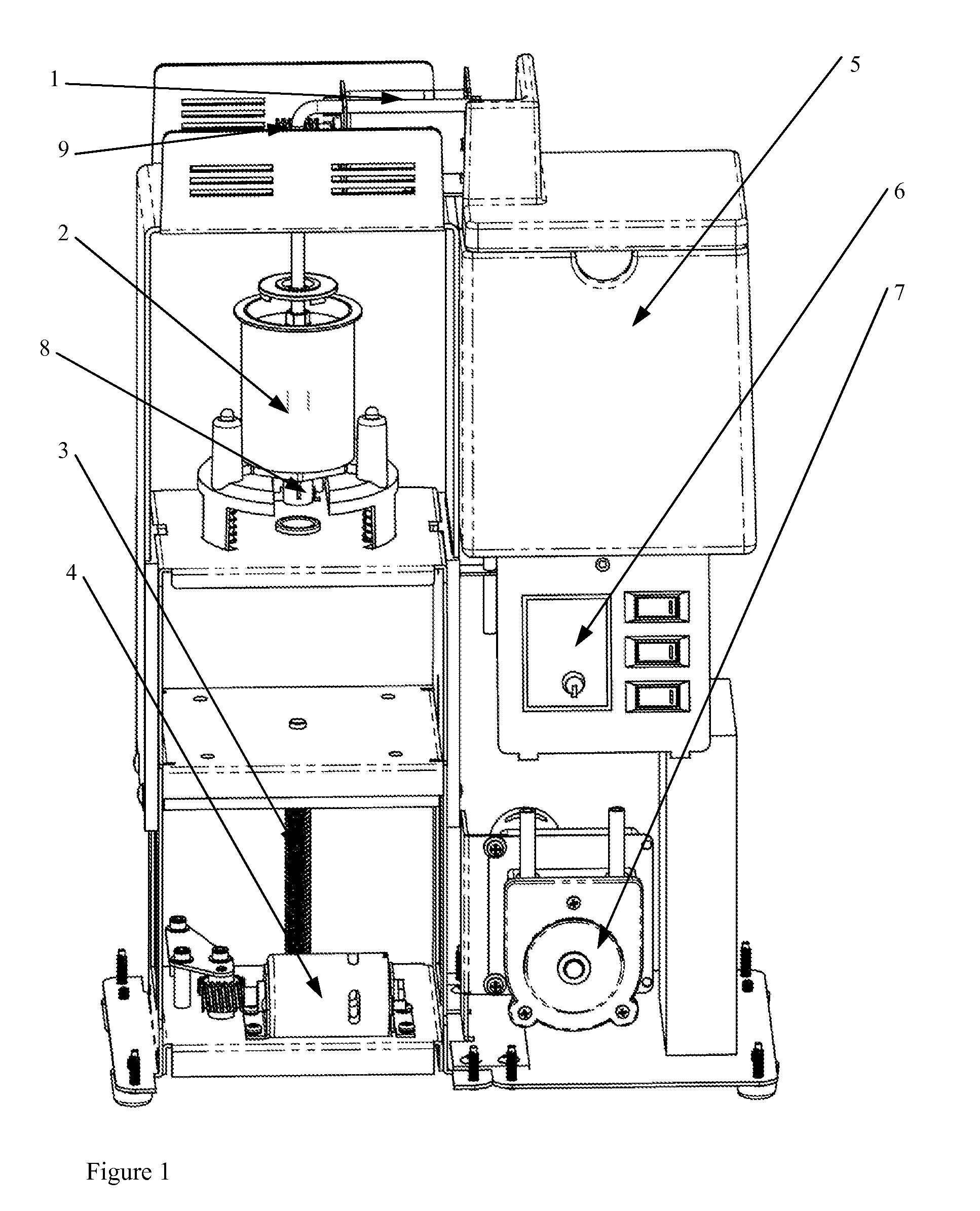

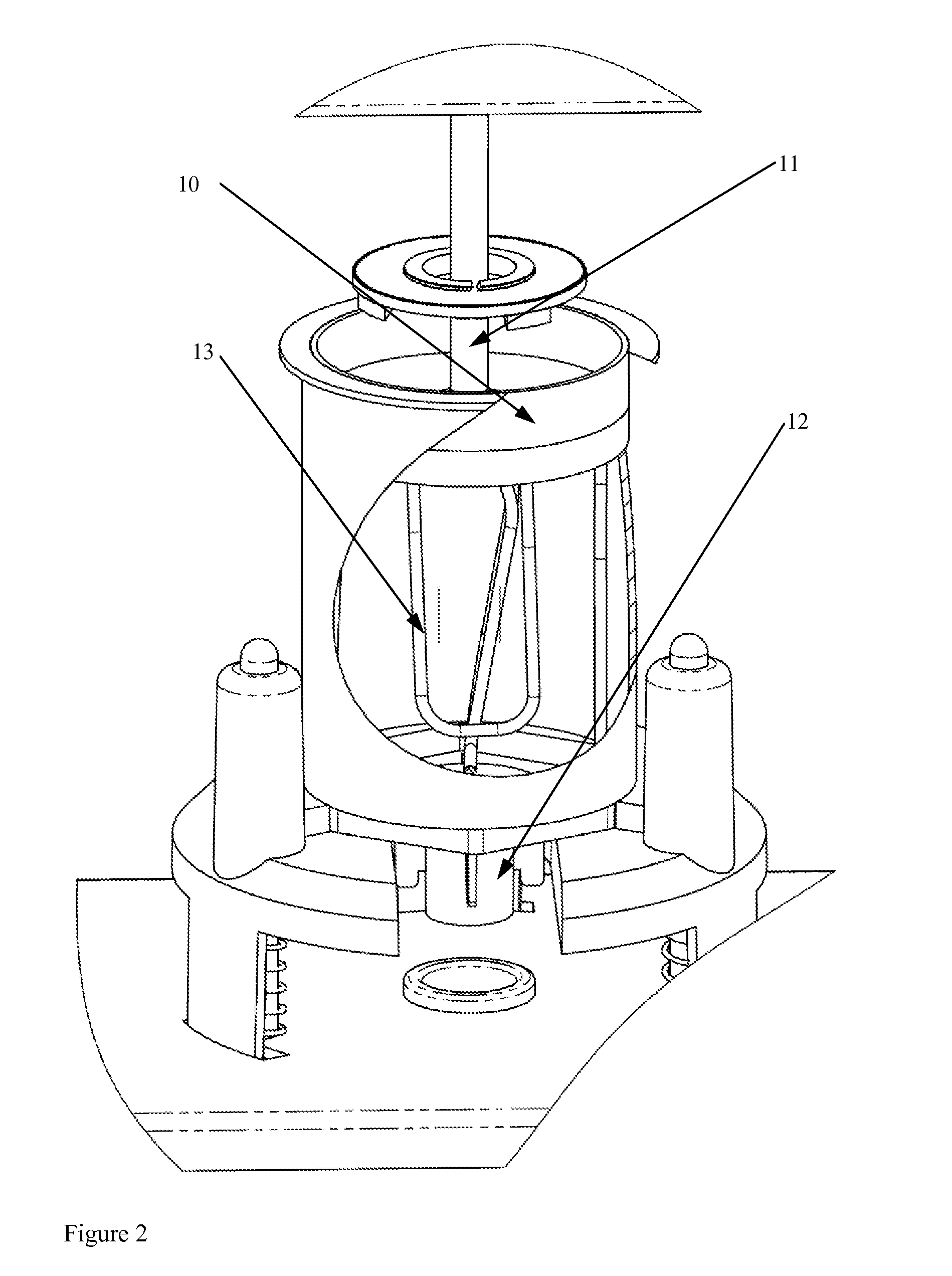

Method and apparatus for preparing and dispensing dental alginate compound

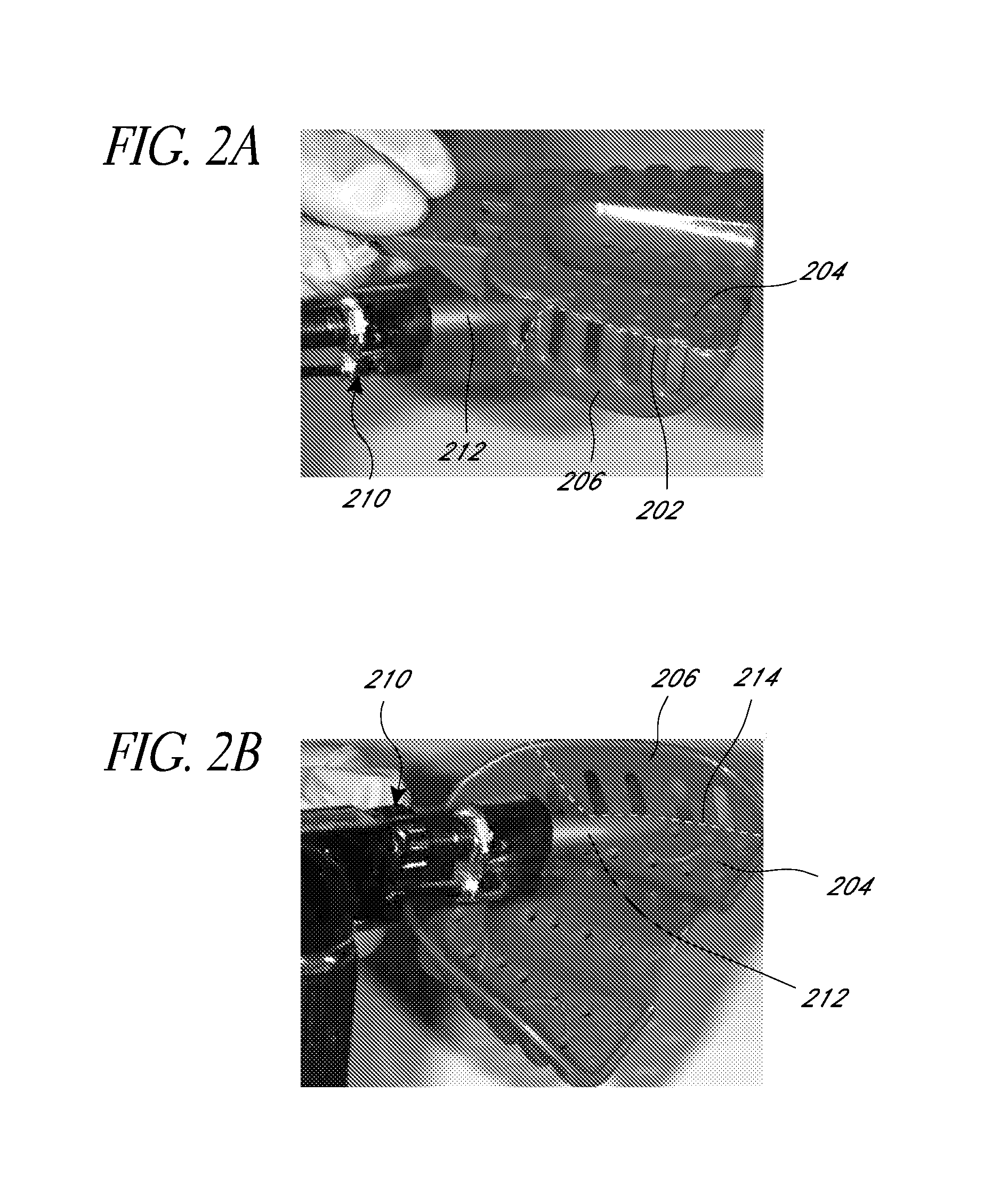

InactiveUS20110317512A1Controlling ratio of multiple fluid flowsRotary stirring mixersLinear motionCompound a

A method and apparatus for preparing and dispensing dental alginate compound comprising a disposable alginate mixing container containing a pre-measured amount of alginate compound powder, a water storage and dispensing means, and an alginate dispensing means. The alginate mixing container is comprised of an agitator utilizing mixing cords that are oriented at an angle to the plane of the arms of the agitator receiving the cords, and a plunger that is slidably engaged with the walls of the cylindrical mixing container. The angular relationship of the cords to the agitator arm pre-stresses the cords against the reactive forces generated by the impingement of the mixing cords and the alginate compound during mixing, and also provides a means to initiate the folding of the cords during the linear movement of the plunger as the alginate compound is dispensed from the mixing container into an impression tray.The water dispensing means is comprised of a constant volume pump driven by a motor under controls for speed and position.

Owner:OVERTON BRADFORD D +1

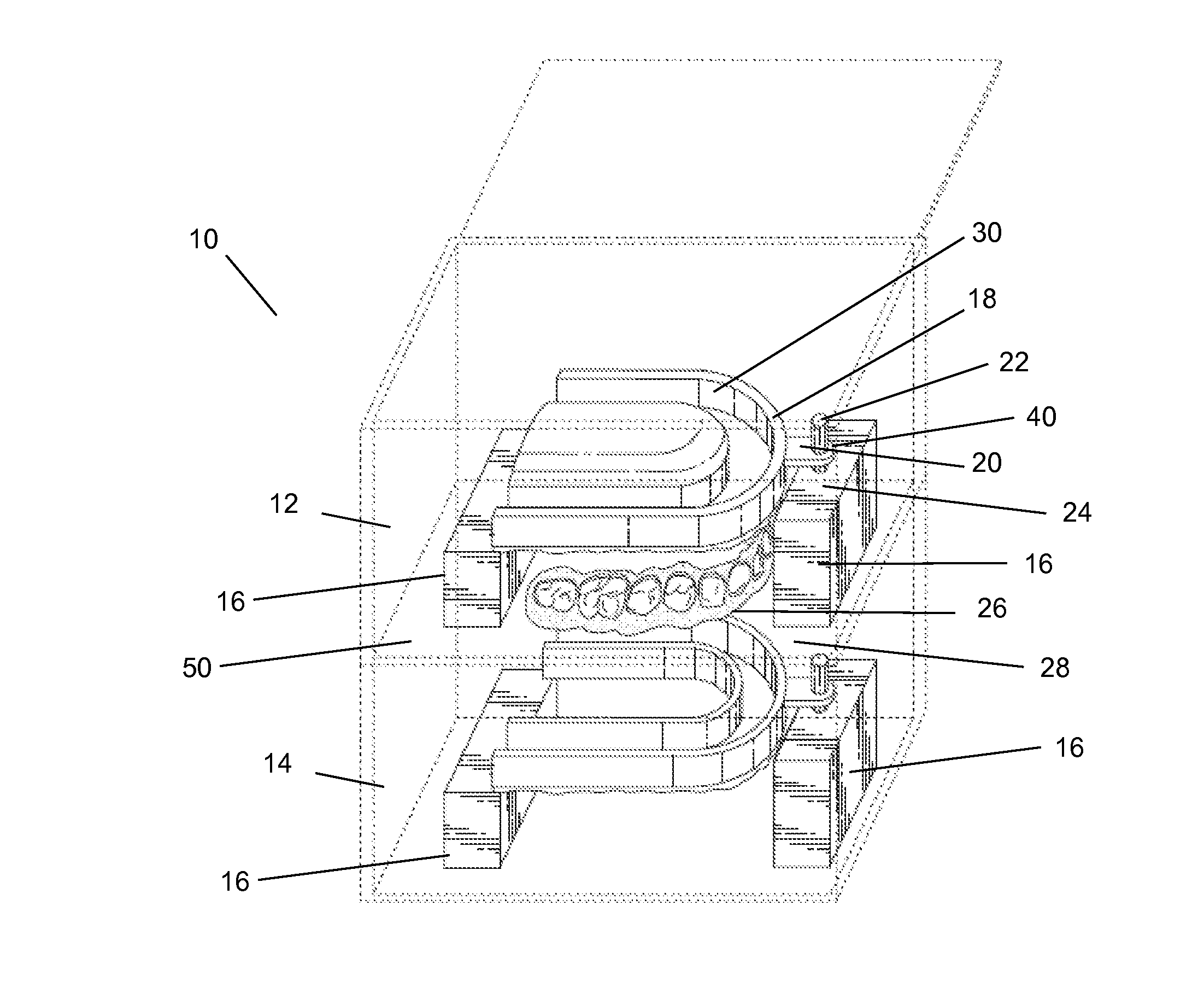

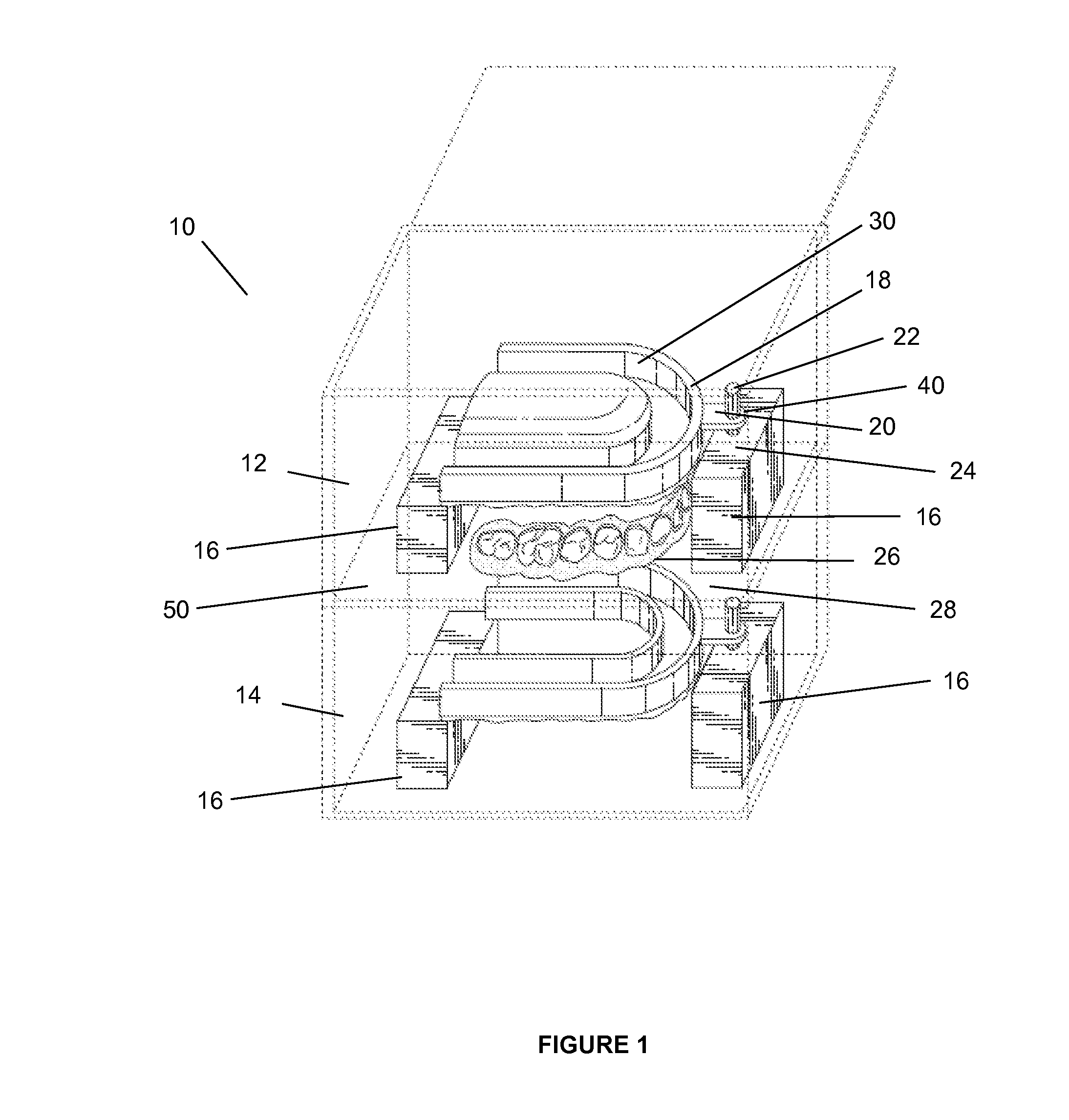

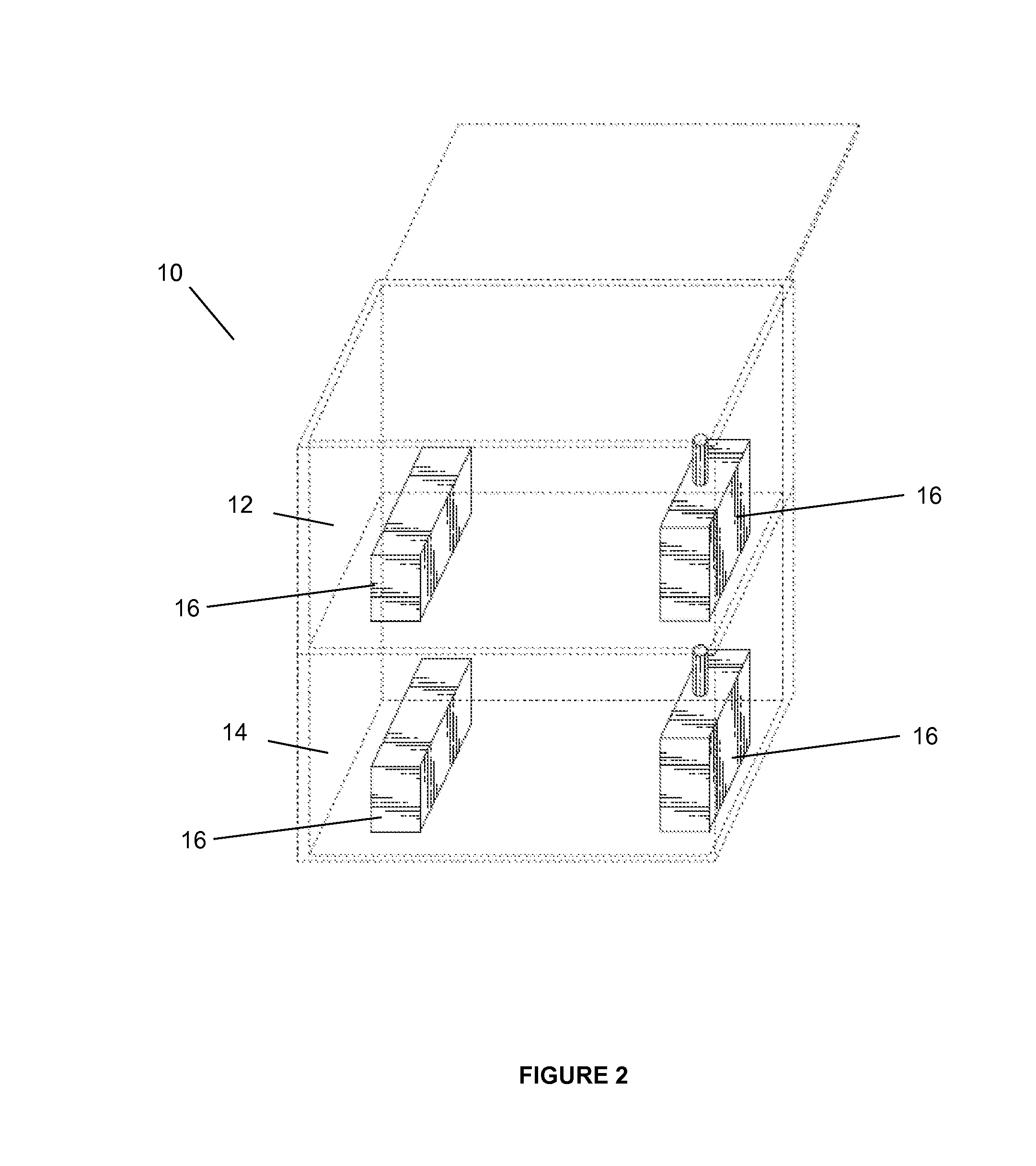

Dental Impression Model System, Apparatus, and Method

ActiveUS20160250004A1Reduces chance distortionReduce operating errorsImpression capsImpression traysModel system

Embodiments of this invention provide predictability and standardization in the field creating dental models. Embodiments of the invention are capable of accommodating multiple variations and goals of dental impressions, including but not limited to creating dental models for study models, mouth guards, night guards, whitening trays, sleep apnea / snoring devices, etc. Embodiments may incorporate single arch and dual arch impression trays, as well as base model formers and articulators, among other devices of varying shapes, dimensions, sizes and manufacturers. Embodiments of the invention use standard dimensions for accommodating various components. To adapt embodiments of the invention for multiple purposes, and to standardize the process, embodiments of the invention include a shell that allows for standardized dental models to be suspended in the shell during the process of creating dental molds, creating a reservoir for the dental mold. Embodiments allow for a trimming process where impressions are standardized by cutting away lateral excess impression material by running a knife along the lateral portion of upper and lower impression tray walls, and then by trimming away vertical excess by placing the tray into the vertical excess trimming device.In these embodiments, dental impressions and embodiments of a predetermined shell allow dental models to be created, including articulated models, in a simplified process.The present invention thus allows dental professionals to easily pour up single and double arch dental impressions, create base models, and, optionally, articulate models in fewer steps than currently available, allowing less waste, material, and use of time than traditional and current methods.

Owner:DIMARINO JAMES C

Dental impression trays

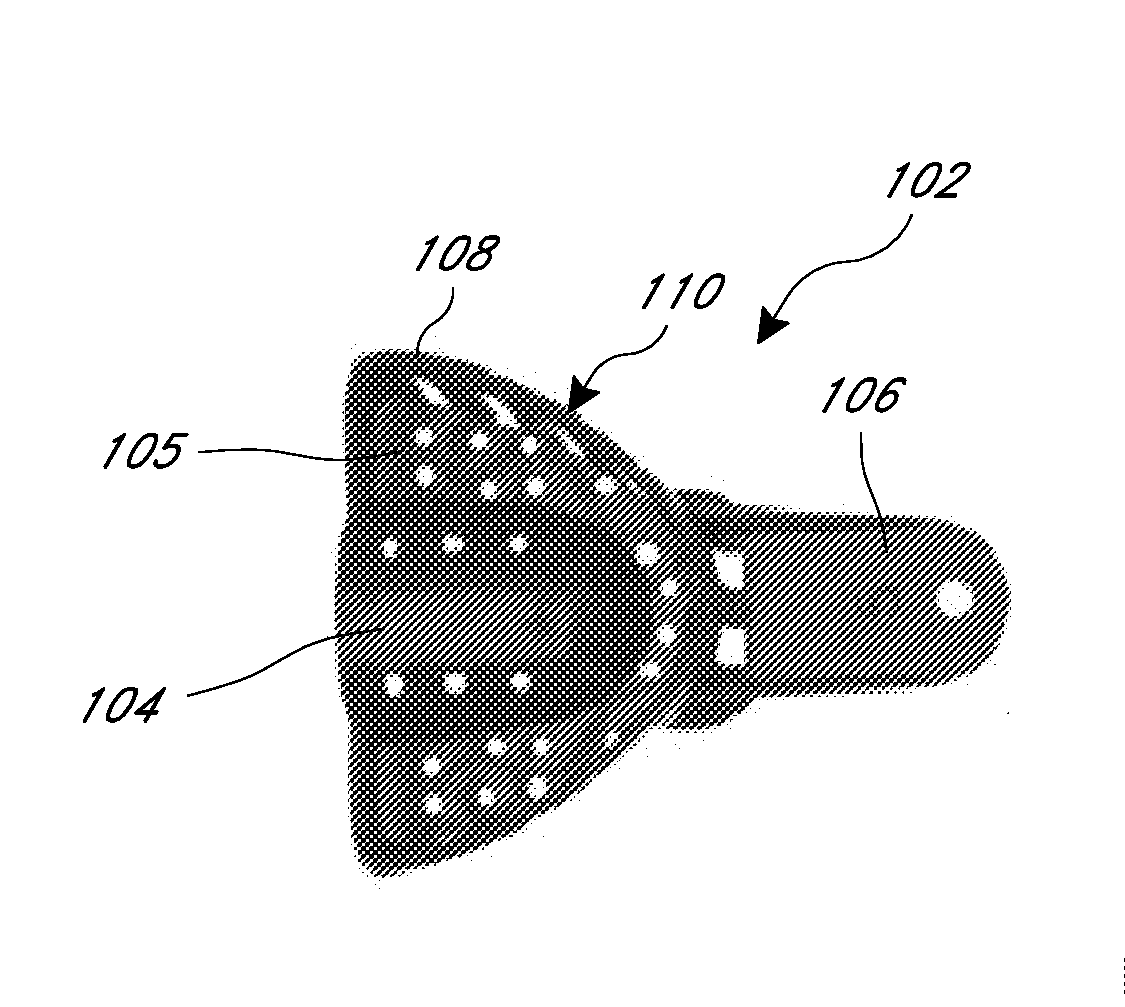

Impression trays for taking dental impression of a subject are discussed herein with particular discussion extended to impression trays know as triple trays. Triple trays are so coined for their ability to simultaneously capture the upper and lower impressions and the bite registration of a subject during a same dental procedure. The trays described elsewhere herein incorporate features that strengthen or increase the rigidity of the frame so that an impression taken of the dentition of the subject using one of the trays described elsewhere herein is not distorted and is therefore an accurate reflection of the true dentition.

Owner:DISCUS DENTAL LLC

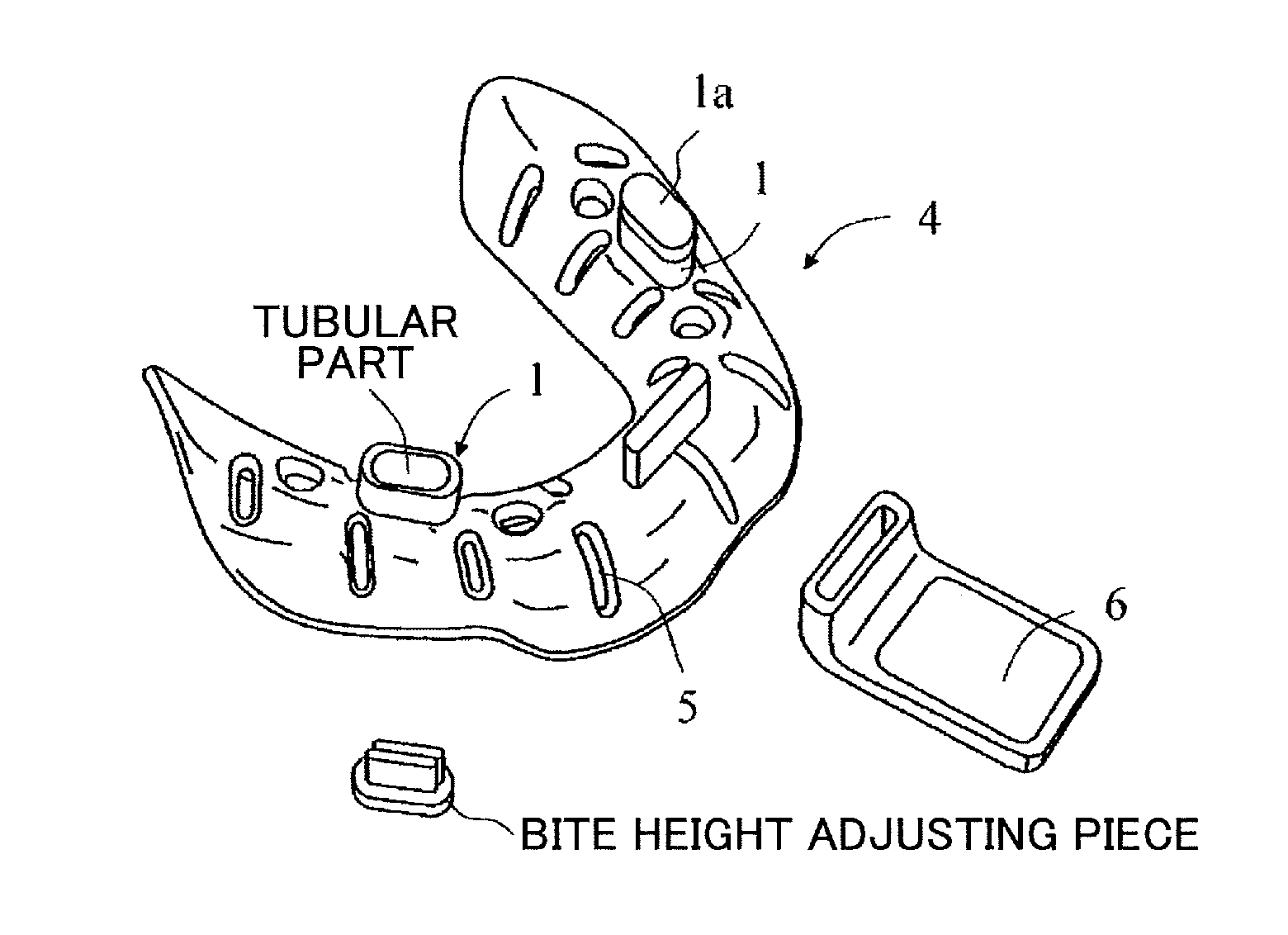

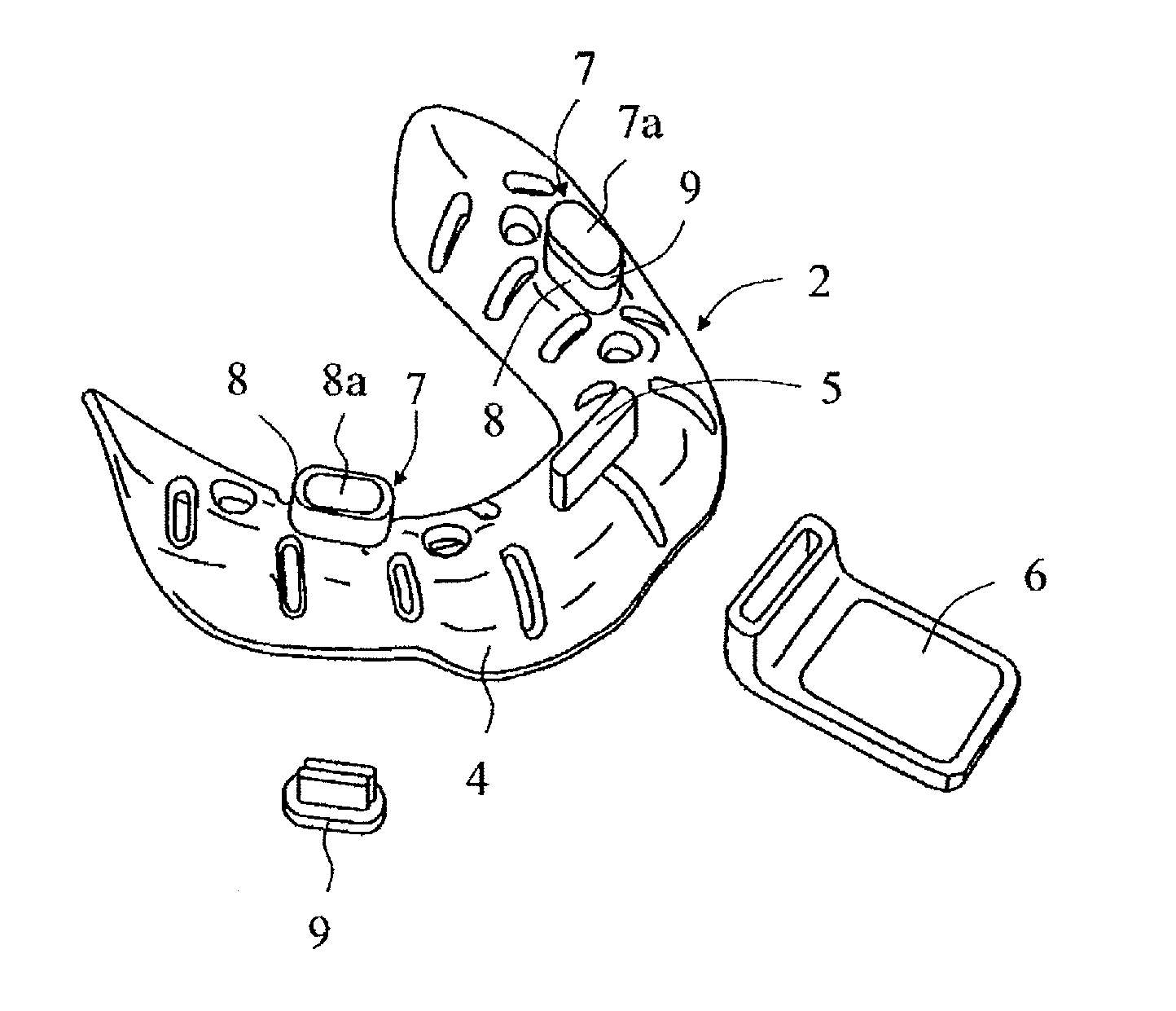

Impression tray set for edentulous jaw

ActiveUS9433483B2Prevent inaccurate impressionEasily be pressed against alveolar ridgeDental implantsImpression capsImpression traysEngineering

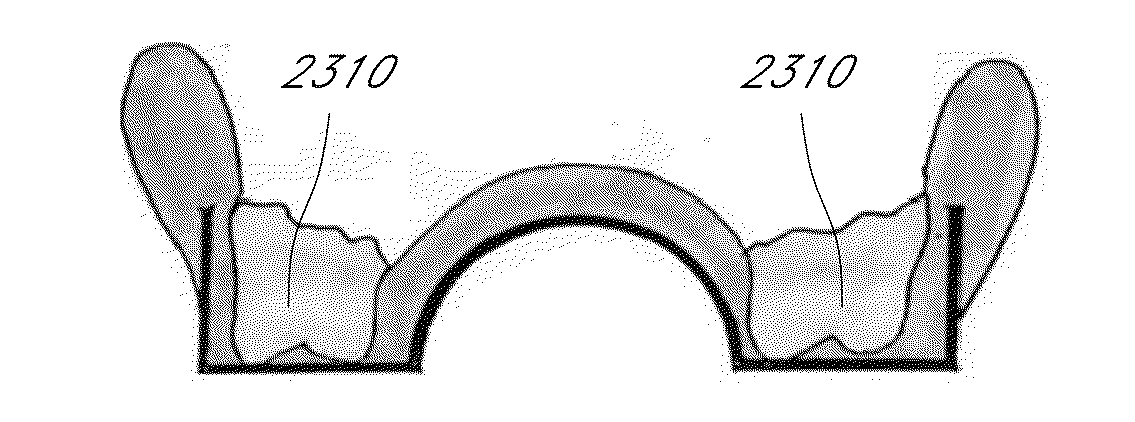

An impression tray set for edentulous jaw is formed by a maxillary impression tray and a mandibular impression tray respectively including a tray main body having a U-shaped groove on which an impression material is to be applied on a front surface thereof, an engaging part formed on a back surface of the U-shaped groove in a position corresponding to an alveolar ridge of front teeth, and a handle part detachably connected to the engaging part. Each of the maxillary and mandibular impression trays includes projecting parts provided on the back surface at portions corresponding to an alveolar ridge from a first molar part to a premolar part. The projecting parts determine bite position and height in a state in which at least a part of flat top surfaces of the projecting parts contact each other when taking an impression.

Owner:GC CORP

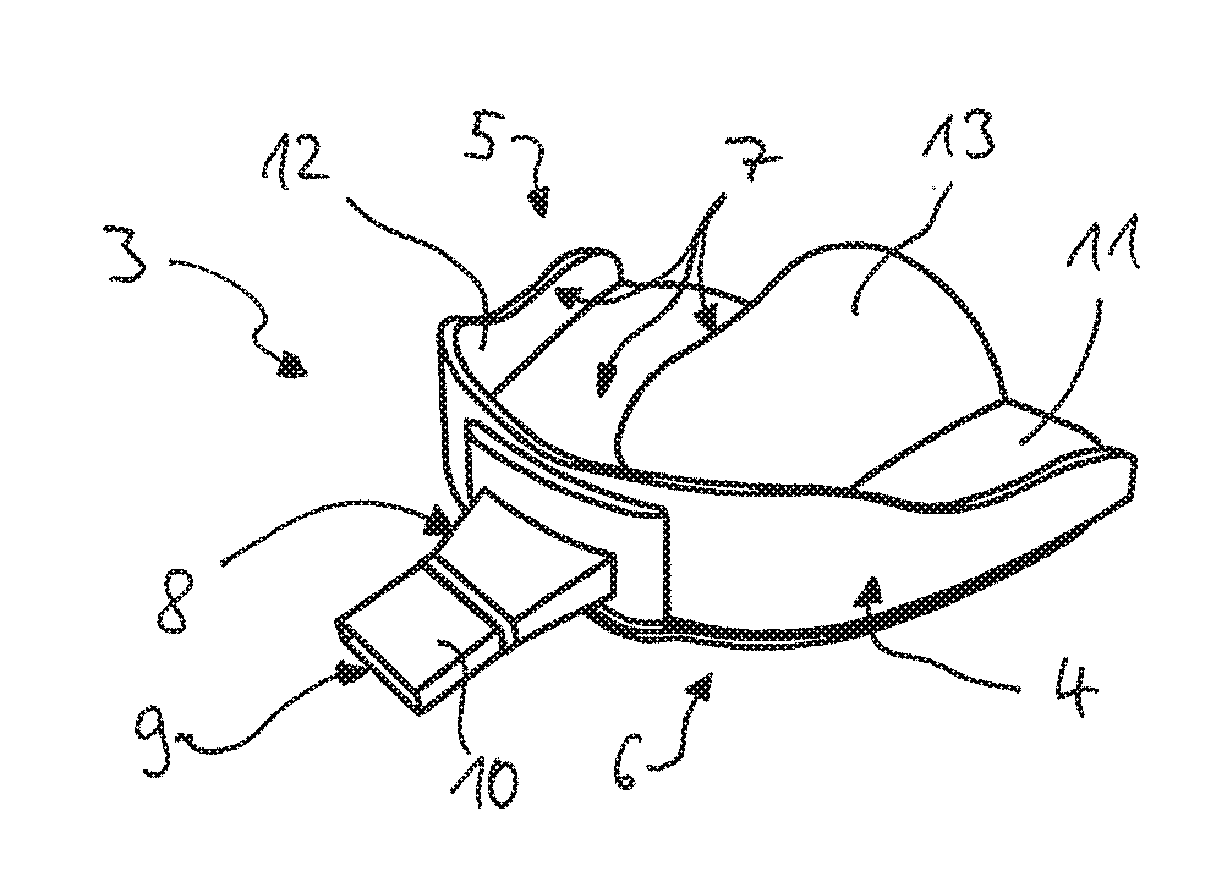

Jaw advancement oral appliance to reduce the effects of snoring and/or sleep apnea

A jaw advancement oral appliance is disclosed to be inserted in the mouth of a user to maintain an airway to the user's throat during sleep. The appliance includes an upper tray assembly against which the user's teeth carried by his upper jaw are seated and a lower tray assembly against which the user's teeth carried by his lower jaw are seated. Each tray assembly includes a bite impression tray having a plurality of holes formed therein and arranged in a honeycomb pattern. The bite impression trays are manufactured from a soft material so that a custom impression of the user's teeth is created when the appliance is heated and the user bites into the bite impression trays.

Owner:FALLON JAMES S

Design production method of dental implantation repair individual tray

ActiveCN106031665ARealize a high degree of automationImprove the level of design and manufacturingImpression capsAdditive manufacturing apparatusImpression traysCloud data

The invention relates to a design production method of a dental implantation repair individual tray. The design production method comprises: preparing an initial impression, and filling a plaster model; scanning the initial impression or plaster model; transferring the scanning data into a reverse engineering software, and extracting the cloud data of the tissue surface points inside the initial impression mucous membrane folding line; filling the inverted concave region; uniformly amplifying 2-3 mm along the data surface normal direction to obtain a virtual tray inner surface; uniformly thickening 2 mm along the virtual tray inner surface normal direction; reserving an impression rod penetrating hole on the surface of the tray in the implant corresponding region; designing a maxillary virtual tray handle and a mandibular virtual tray handle; and carrying out boundary fusion on the virtual tray inner surface data, the outer surface data and the handle data, storing in the STL format, and producing the edentulous personalized impression tray having the resin material through 3D printing equipment. According to the present invention, the produced dental implantation repair individual tray using the digital designing can replace the traditional hand-made production, and the precision of the opening implantation impression is easily improved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com