Patents

Literature

103results about How to "Reduce mechanical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

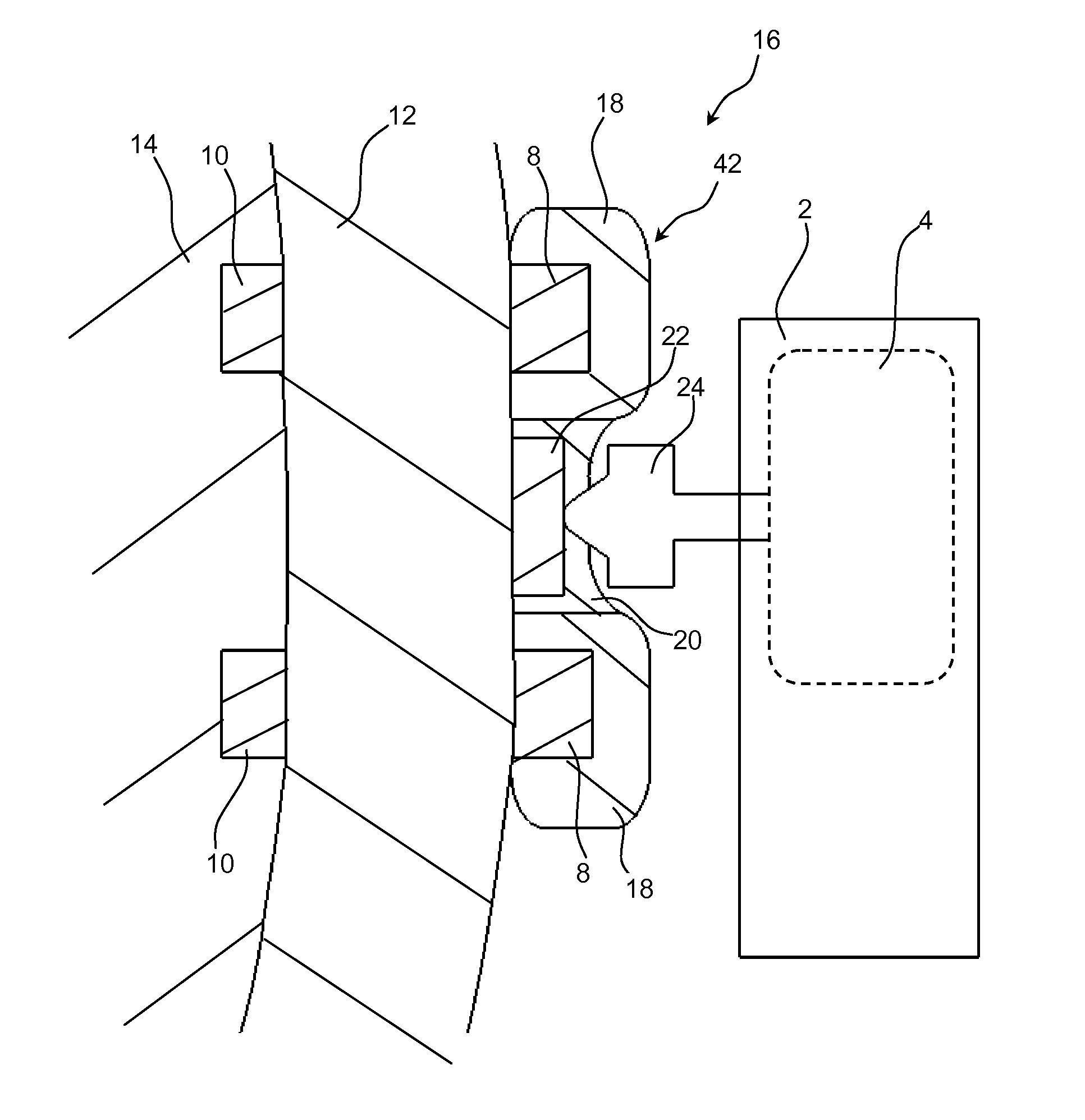

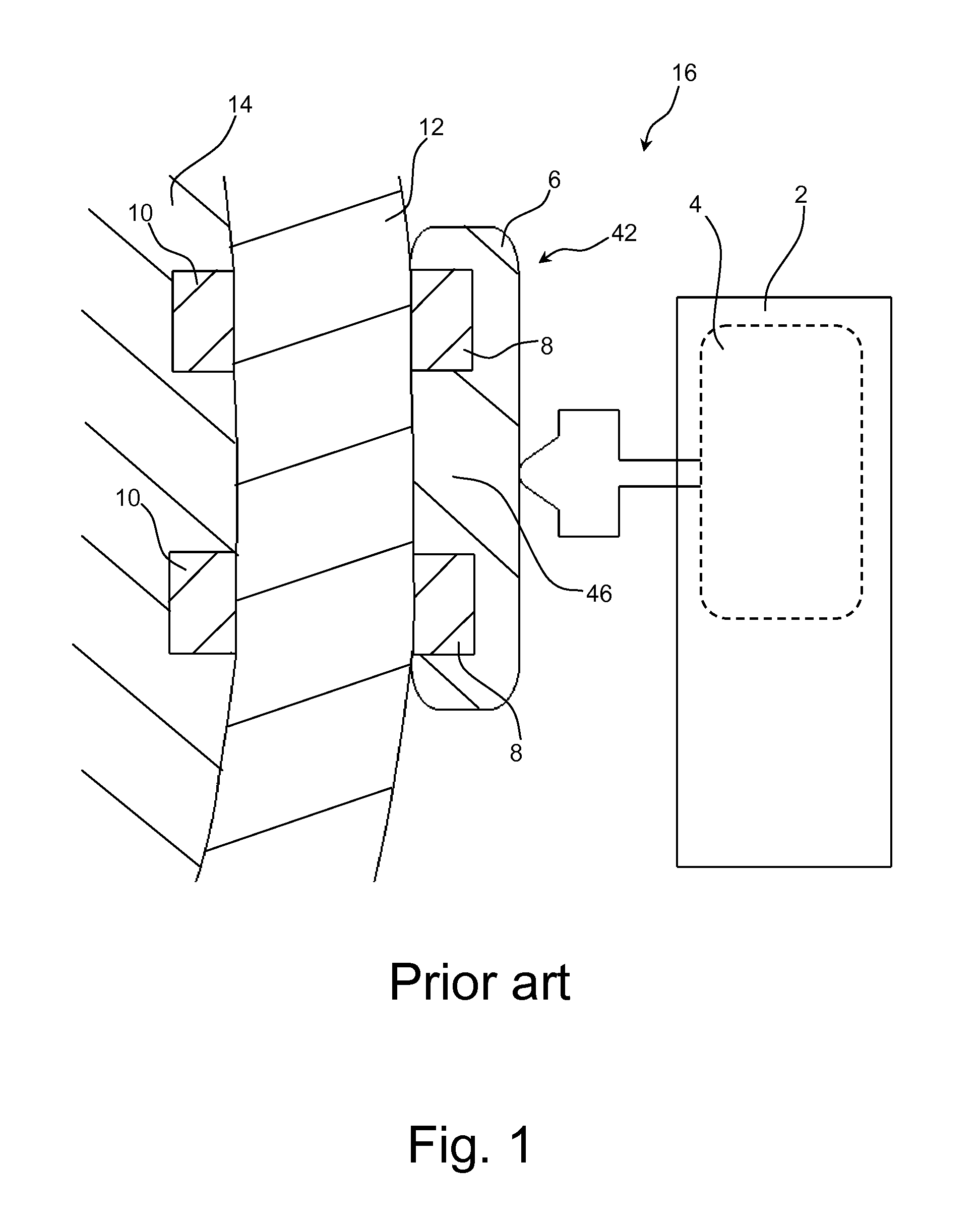

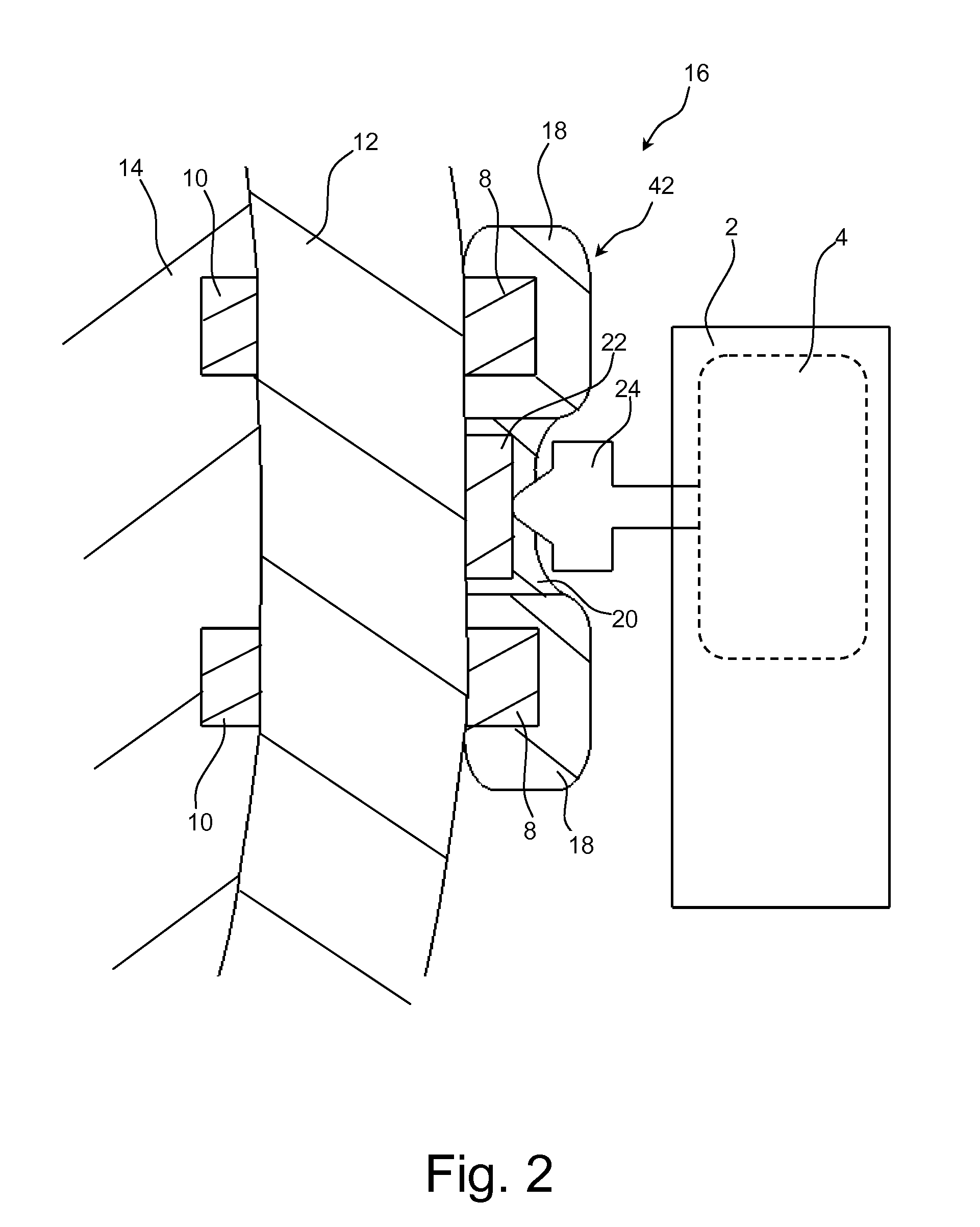

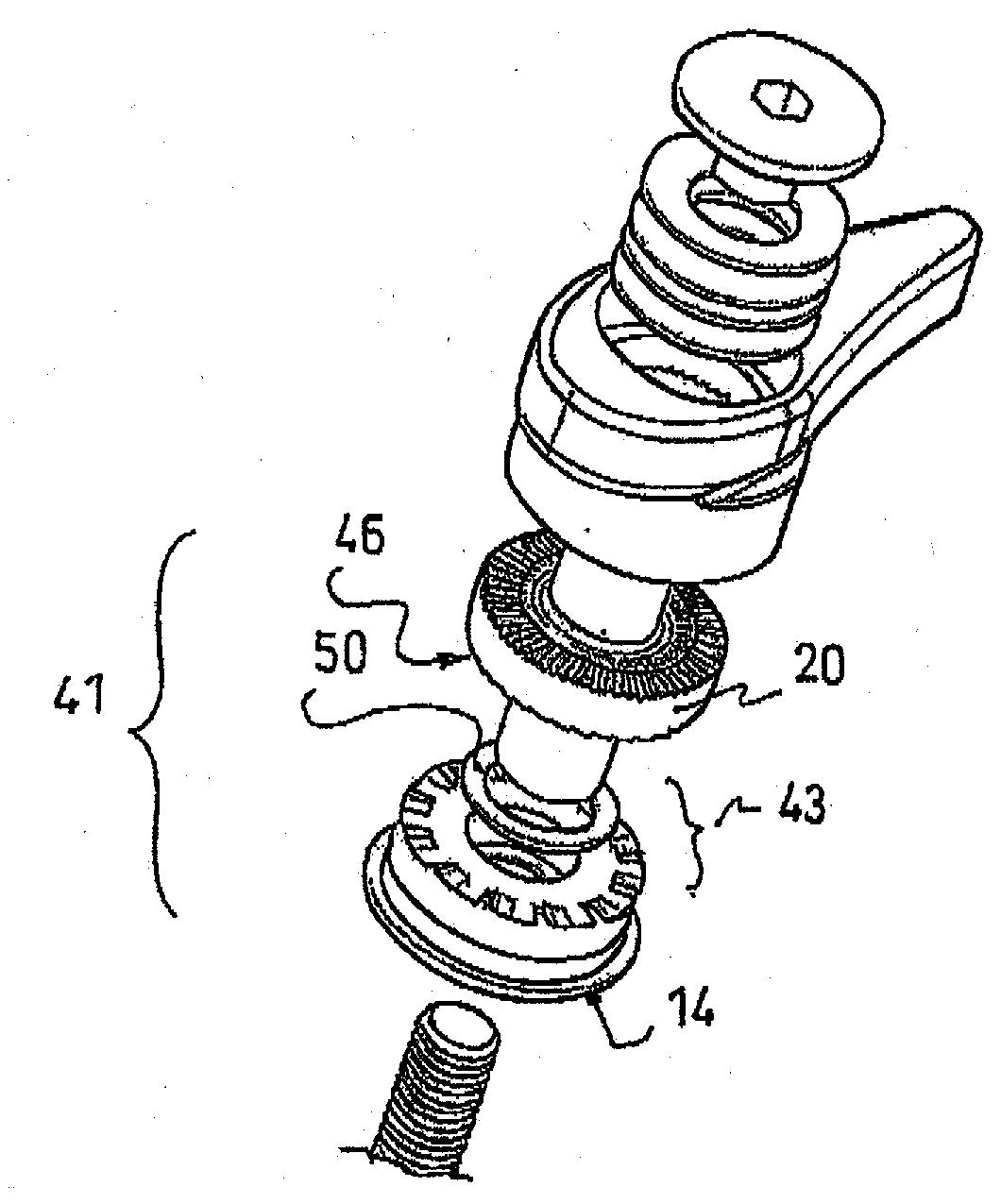

Holding unit for a vibration transmitter and a vibration transmission system using it

ActiveUS20150049889A1Improves feedback marginReduce mechanical resistanceBone conduction transducer hearing devicesImplantable hearing aidsCouplingPersons With Hearing Impairments

A holding unit and a vibration transmission system are disclosed. The holding unit comprising a holding plate is configured to be attached to the skin by means of magnetic attraction between a number of external magnets that are either:a) integrated within the holding plate;b) mechanically attached to the holding plate; orc) constituting the holding plateand a number of internal magnets implanted under the skin of a hearing impaired person. The holding unit comprises a transmission member or plate member configured to transfer mechanical vibrations from a vibrator through the skin to the bone of the person. The transmission member or plate member is interconnected by a mechanical flexible coupling to the magnet(s) of the holding plate.

Owner:OTICON MEDICAL

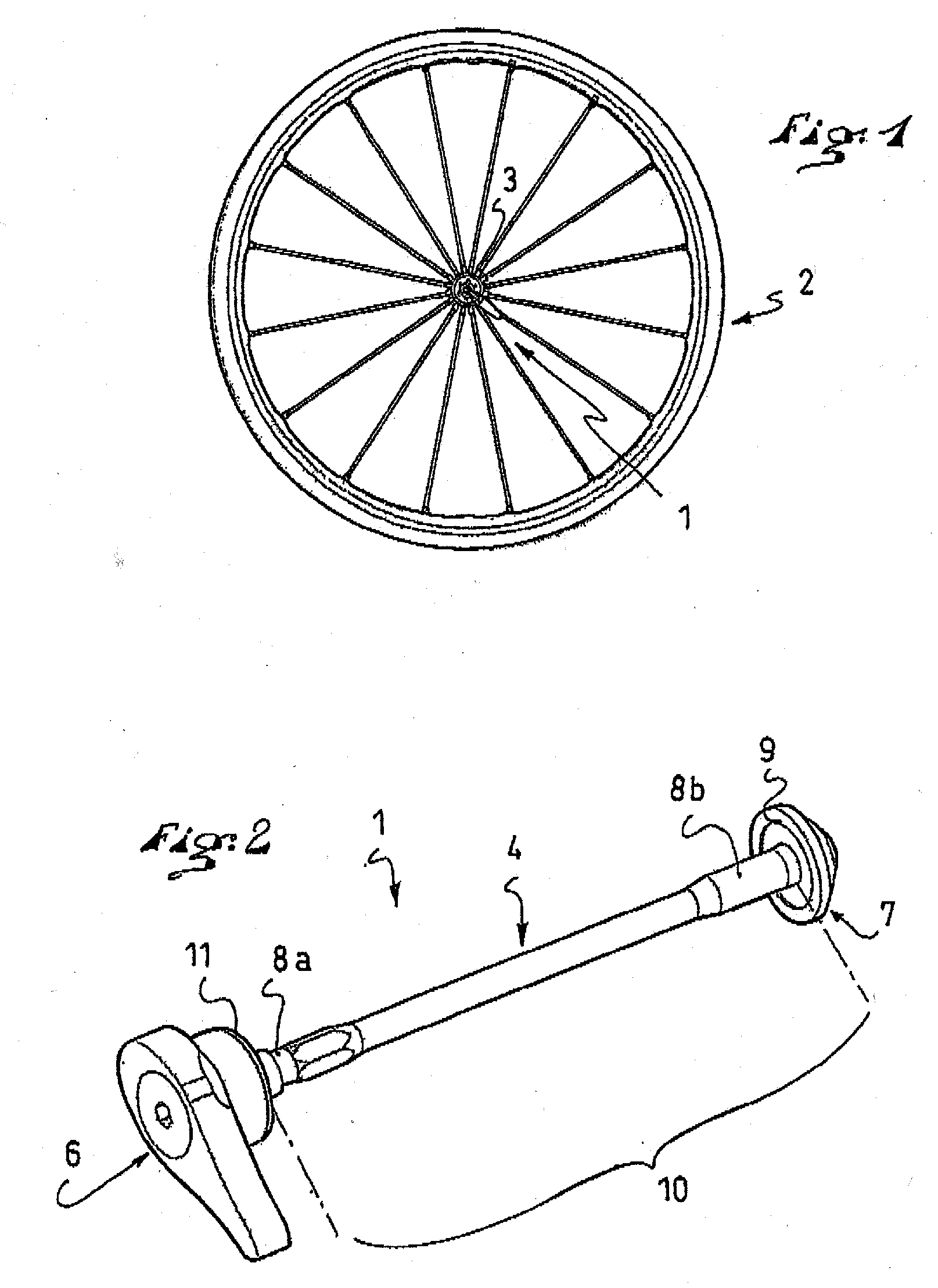

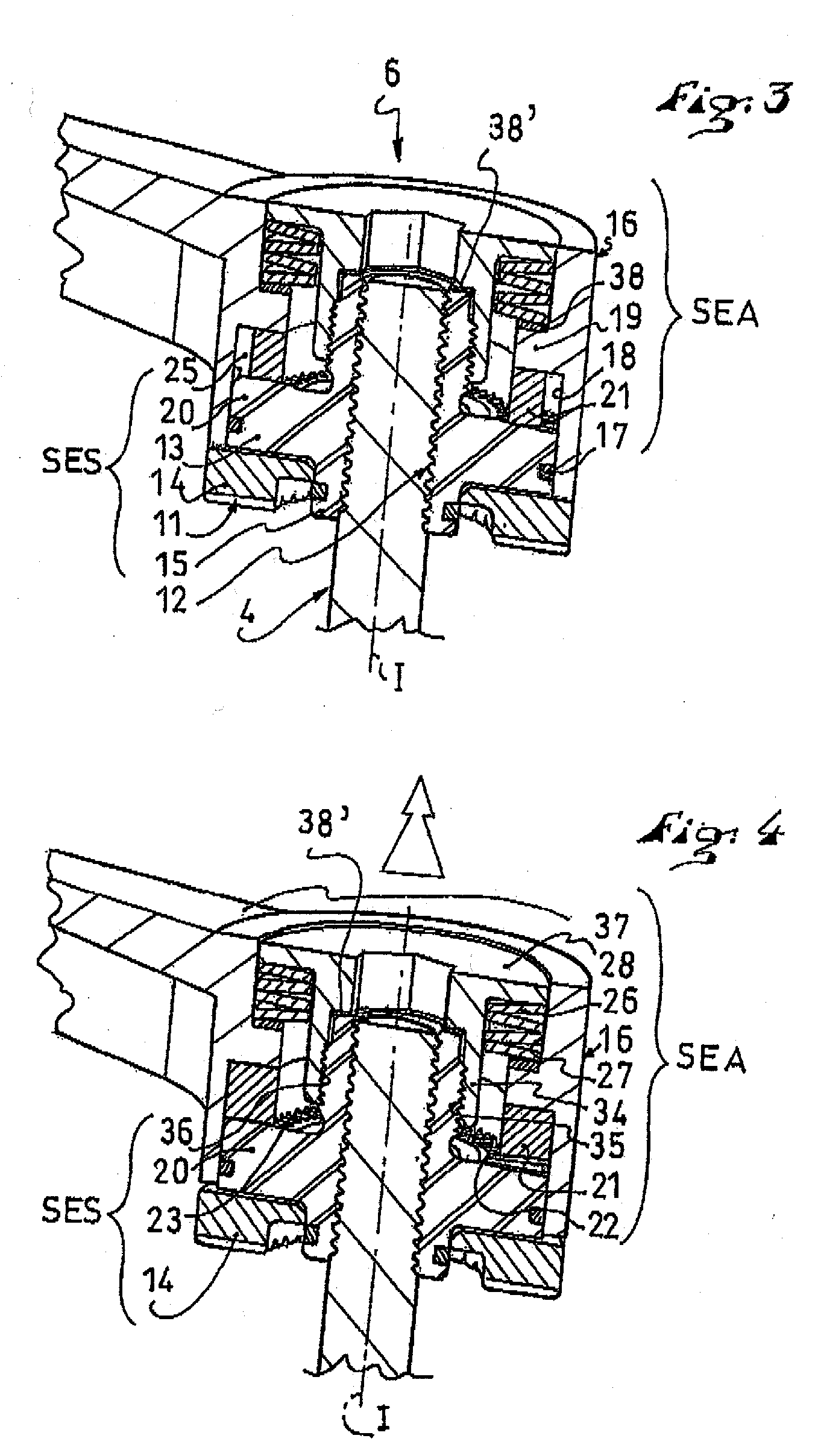

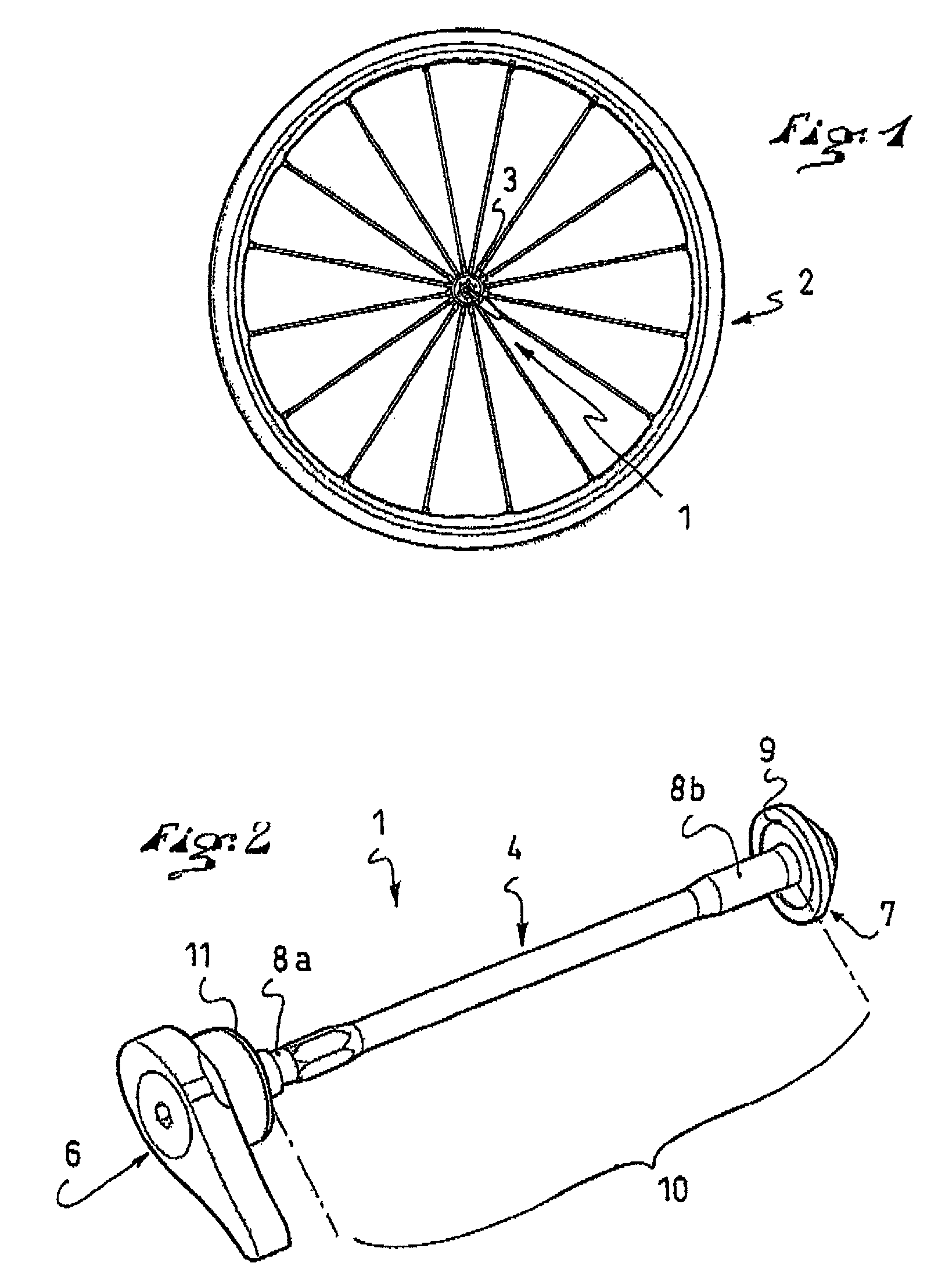

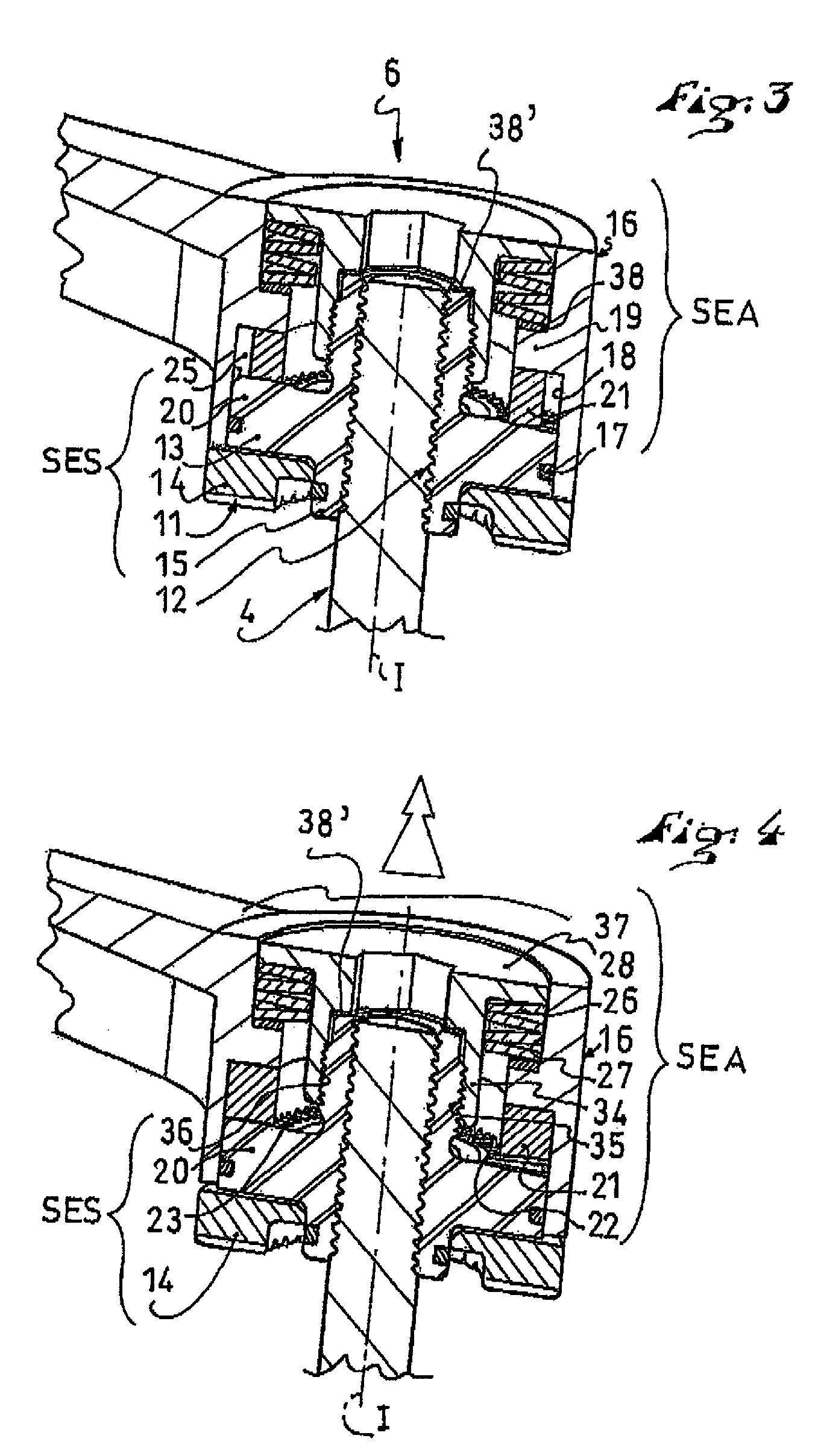

Quick-tightening system for cycle with tightening torque control

ActiveUS20090102276A1Reduce mechanical resistanceReduce weightHubsLoad modified fastenersDirect torque controlControl theory

A quick-release system for a quick-release device, in particular for a cycle, such as a bicycle, the device being of the type including an axially extending skewer and an end support element mounted on a first end of the skewer adapted to be supported on a first tightening surface of the cycle. The quick-release system includes a tightening sub-assembly including a support surface and an actuation sub-assembly including a movable actuating mechanism, capable of axial rotation around the skewer and configured to transmit a tightening torque to the tightening sub-assembly when the device is being tightened. The system includes tightening torque limiting mechanism making it possible to limit the torque transmitted by the actuation sub-assembly to the tightening sub-assembly.

Owner:THULE SWEDEN AB

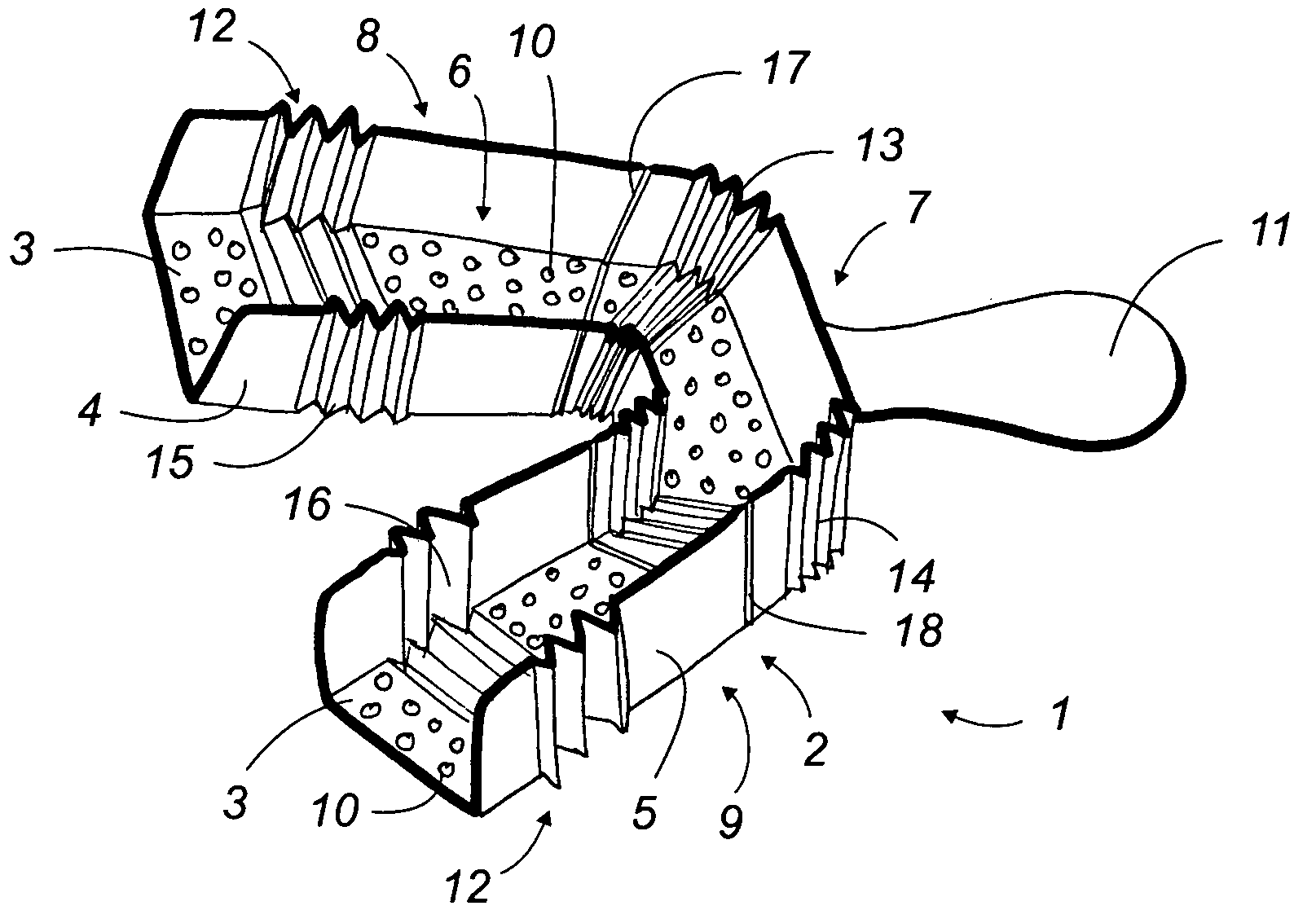

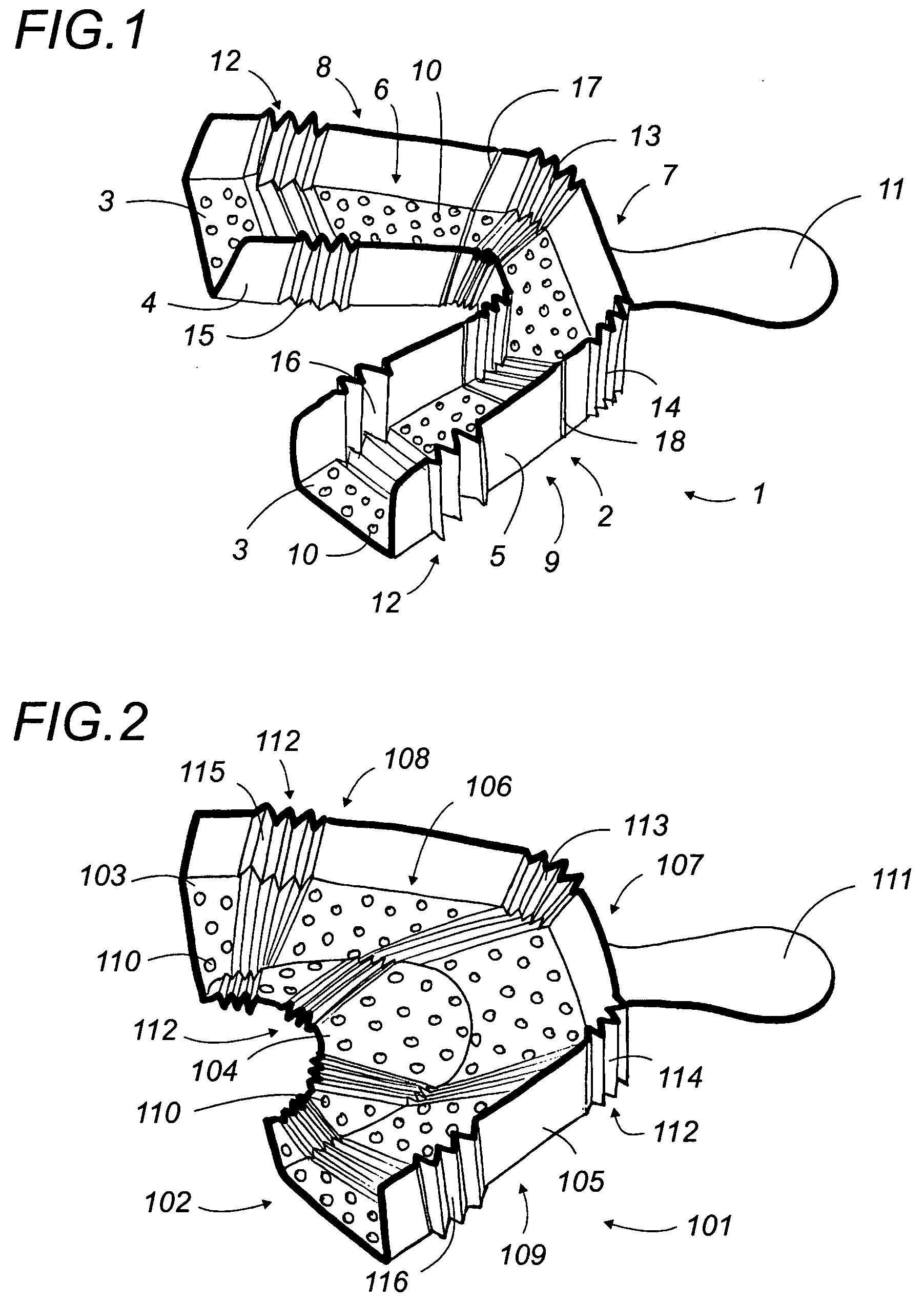

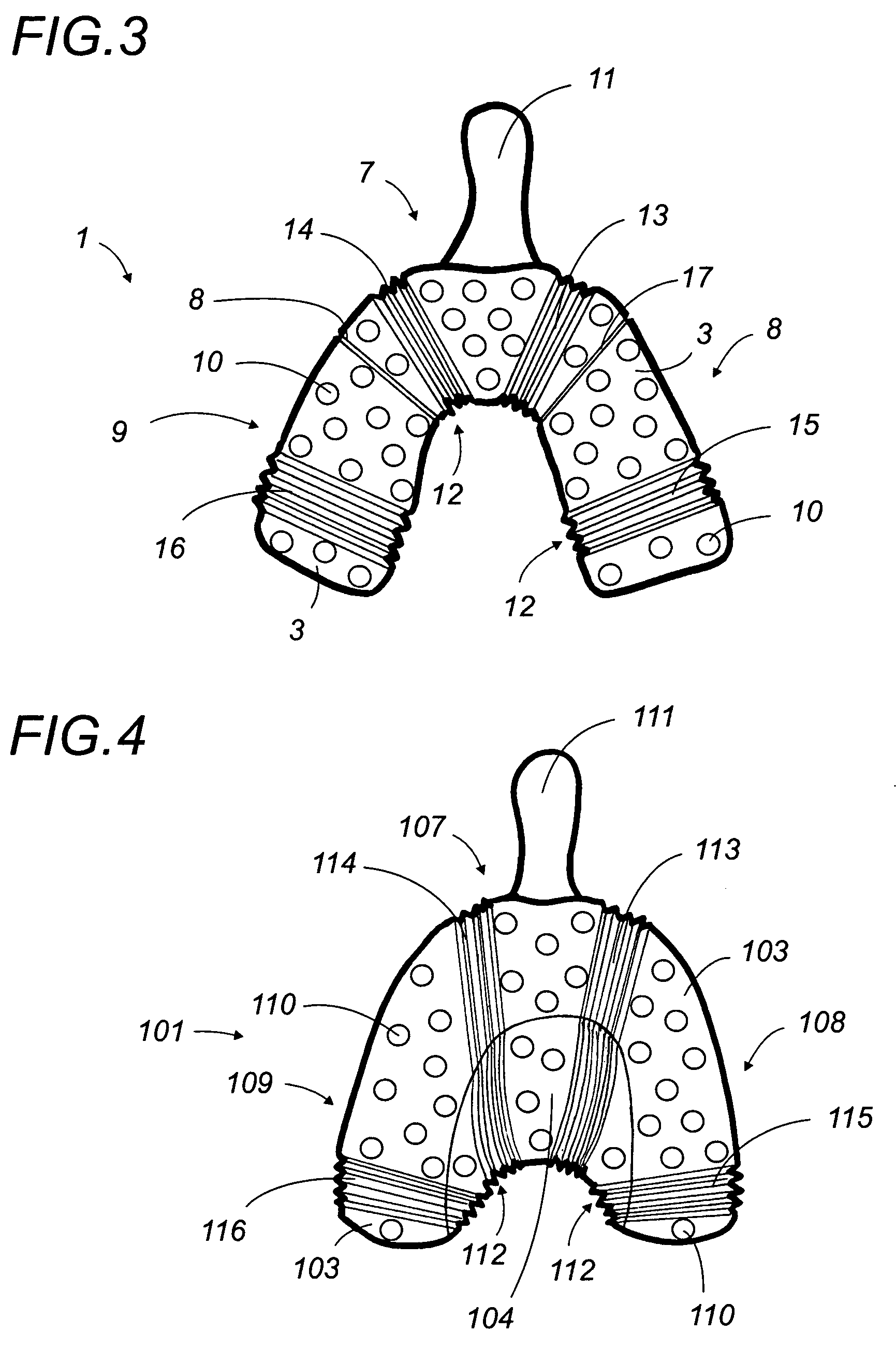

Adjustable impression tray with variable geometry

InactiveUS20050153256A1Reduce mechanical resistanceAdapt the impression tray easily and quicklyImpression capsImpression traysDental Equipment

The invention relates to an adjustable impression tray (1) comprising a trough (2) in the form of an arch with a straight central portion (7) extended by two lateral branches (8,9), essentially matching the form of a dental arch and comprising several integral zones which may be deformed at the temperature of use in the form of a multi-directional extension means (12), for example an accordion-like bellows arrangement (13 to 16). The impression tray, preferably for single usage, advantageously comprises splitting zones (17, 18) which allow the production of impression trays of differing sectors, which by comprising one or several deformation zones are equally adjustable. The invention is of interest to dentists and prosthetic dentists and more generally to producers and users of dental equipment.

Owner:LIVOLSI LYDIE

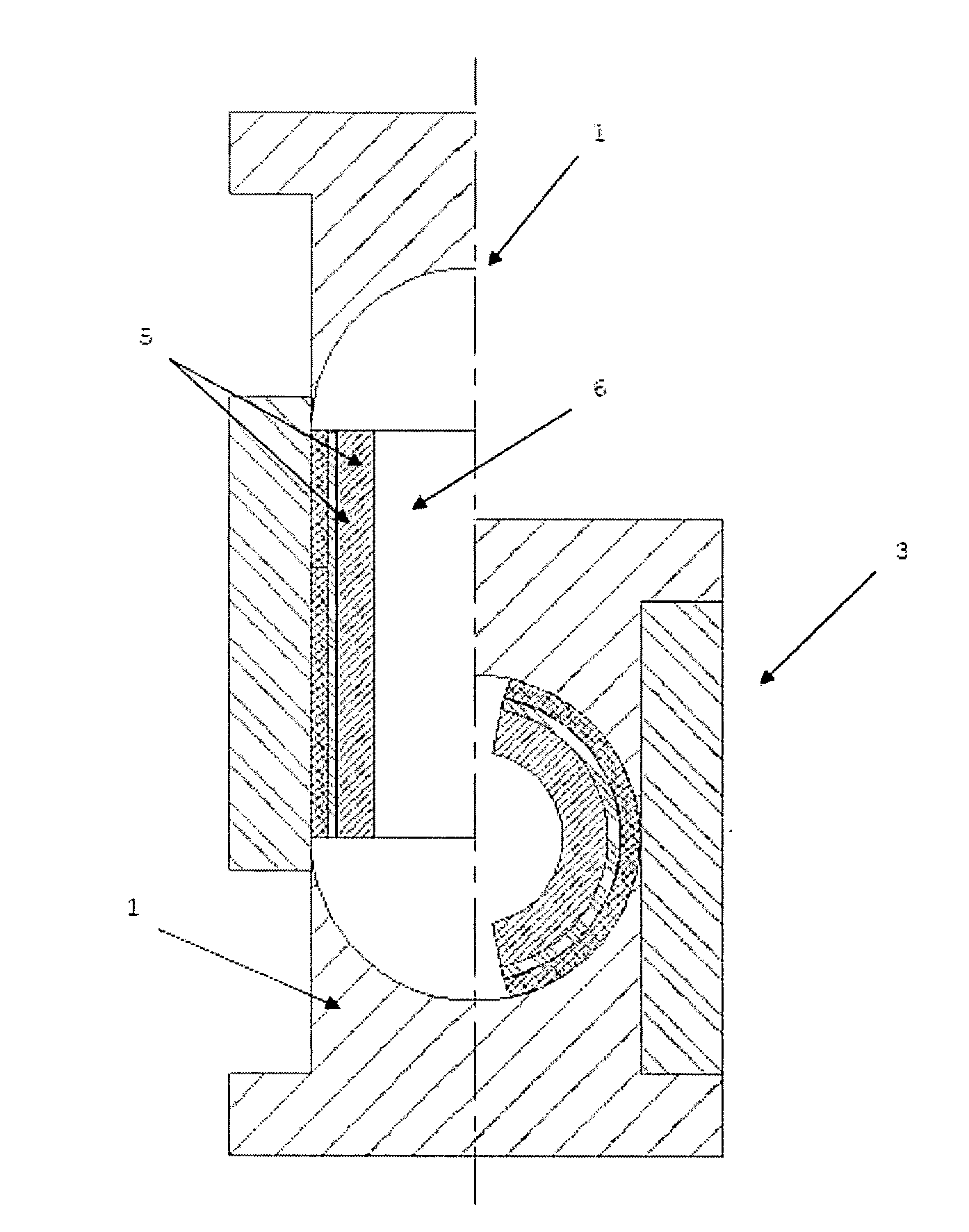

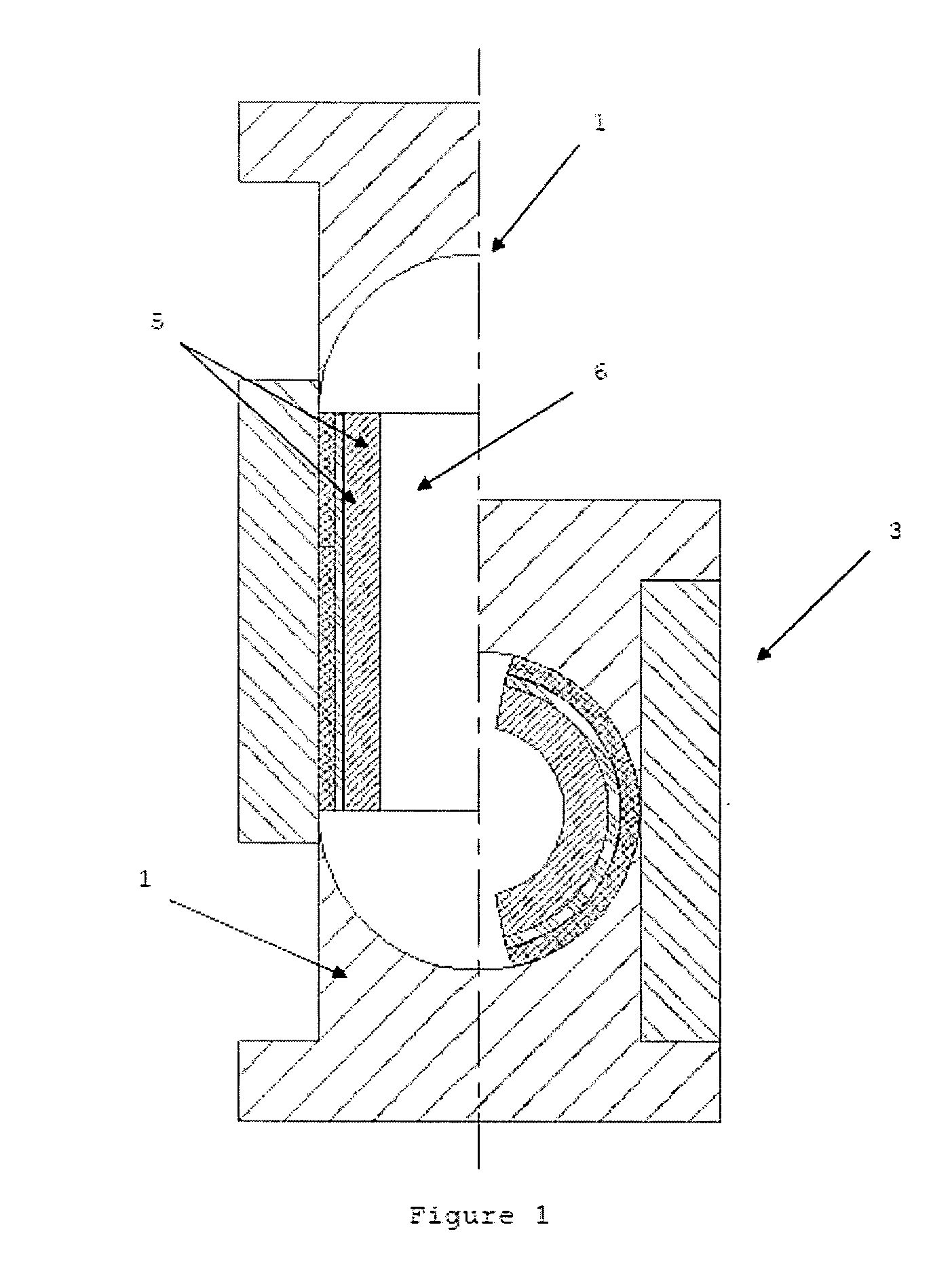

Plastic deformation technological process for production of thin wall revolution shells from tubular billets

InactiveUS20100310815A1Good molding effectReduce mechanical resistanceLayered productsThin material handlingMachine pressThin walled

This invention refers to a process of plastic deformation for production of thin wall revolution shells from tubular billets. The process consists in end-forming a hollow circular section billet, which can be composed of a multi- layered assembly, by using sharp edge internal domed shaped molds (1) that are guided externally by a constraining sleeve (3). This mold-sleeve tool can be assembled in a press in order to generate the pressure forces necessary for the forming process. The plastic deformation can result in thin walled spheres or cylinders with domed ends. The resultant revolution shells have two opposite (polar) circular openings. Both the shell's length as the polar hole diameter is mainly determined by the billet's initial dimensions and mold (1) domed geometry. An innovative flexible inner mandrel may be introduced to considerably improve overall shell characteristics, allowing reduction of shell polar opening diameter, giving control of along-meridian thickness, solving typical thin wall forming problems such as buckling, wrinkling and ruptures and improve both outer and inner surface quality. This mandrel can be discarded and / or recycled after forming. This invention enables a low-cost and high-rate process for production of structural revolution shells capable of being used as high-pressure vessels.

Owner:OMNIDEA

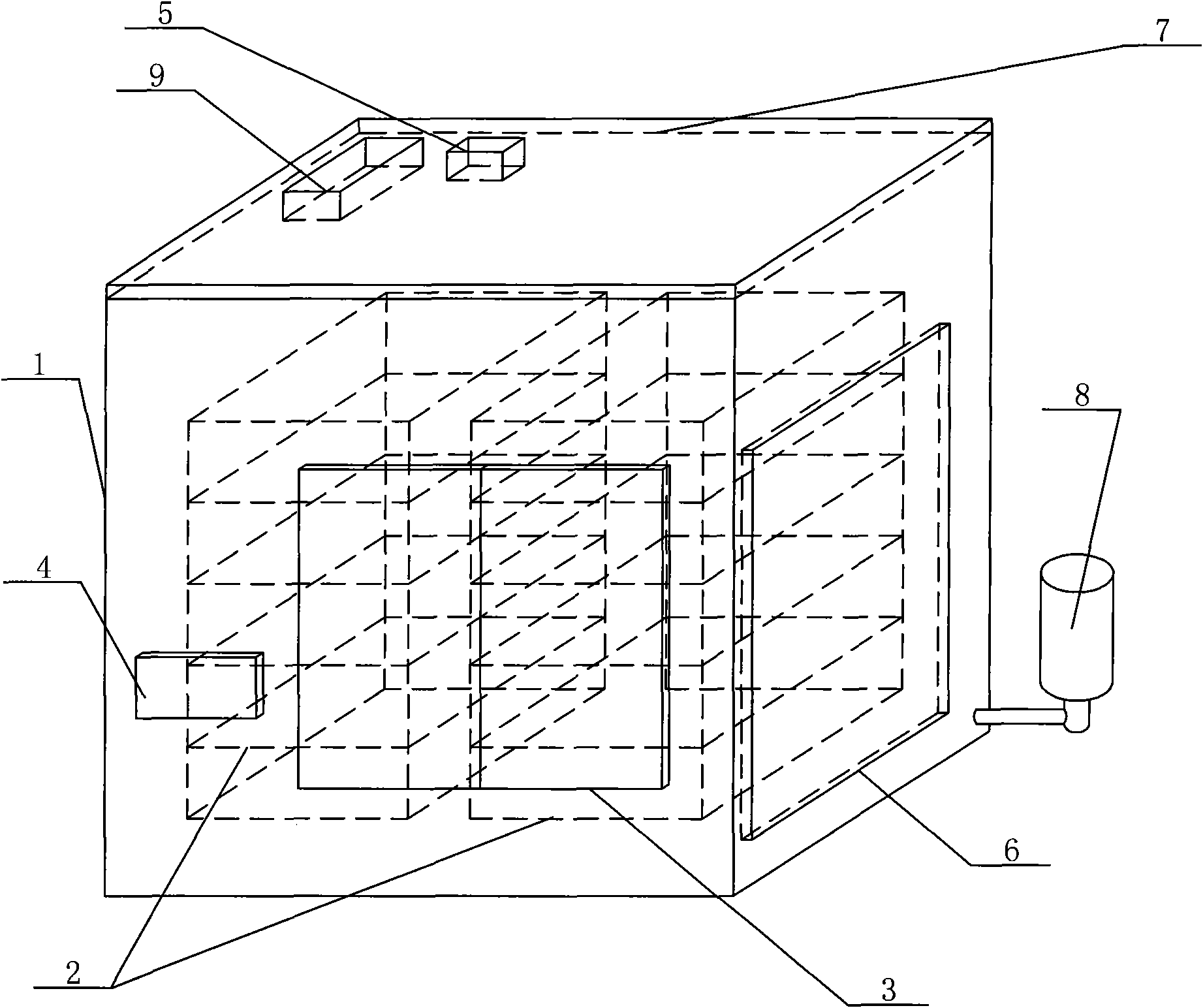

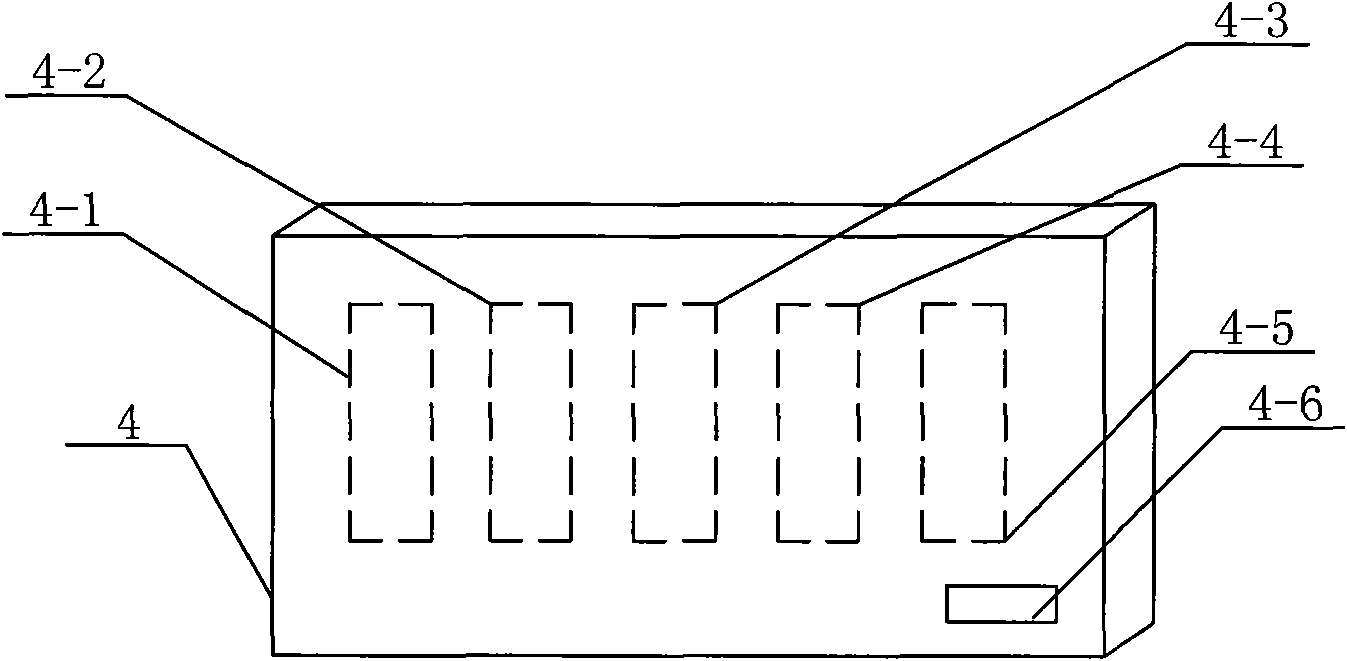

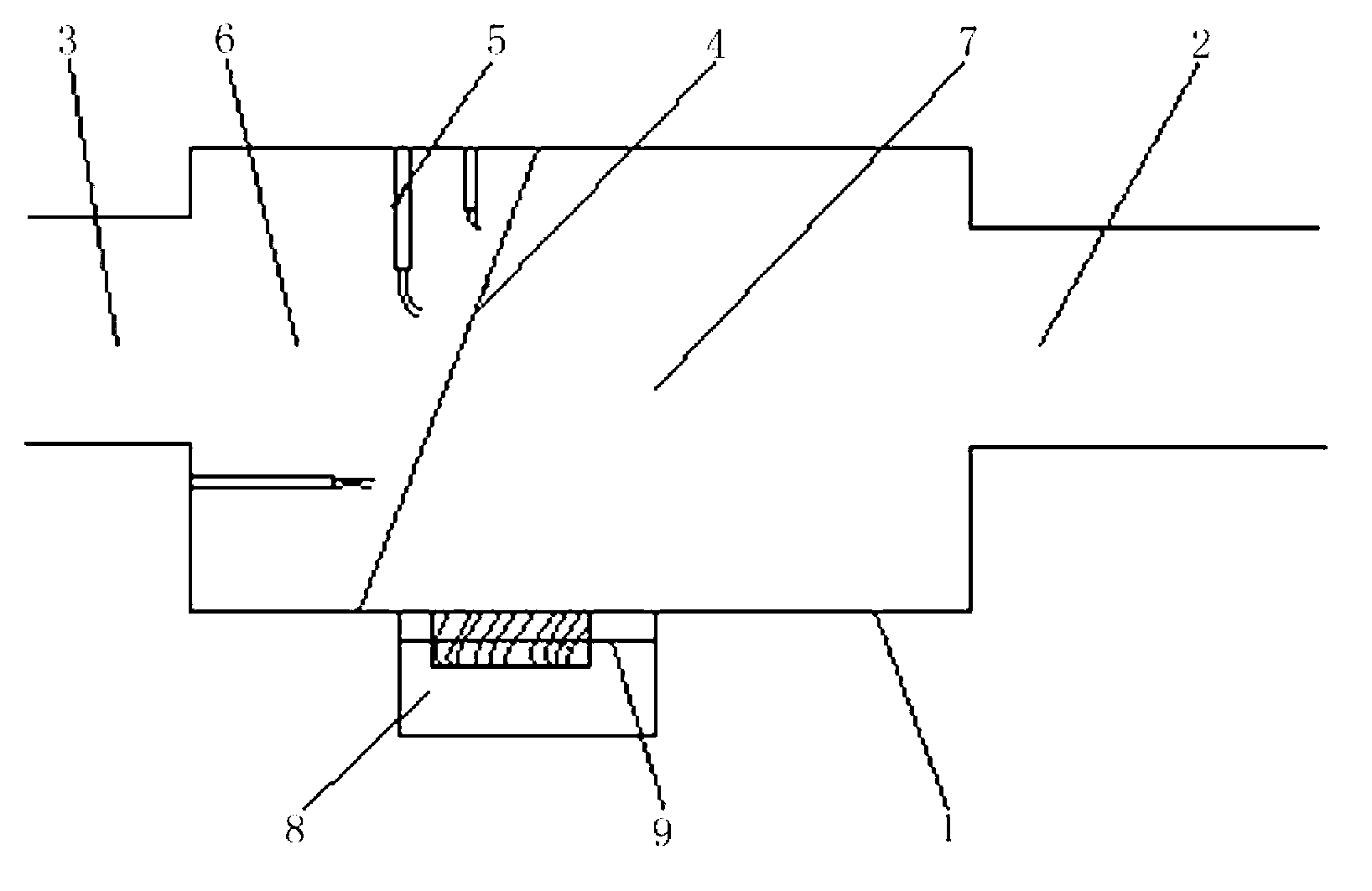

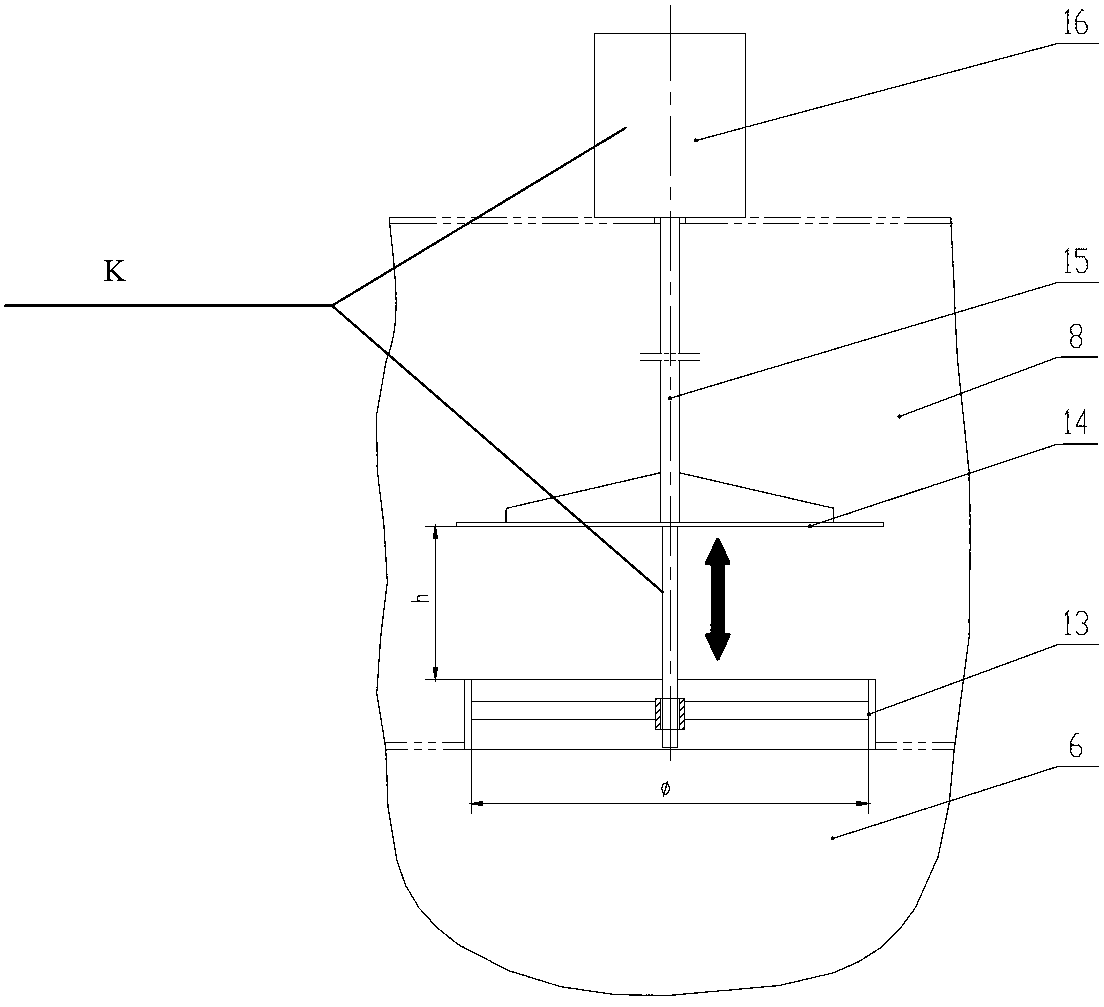

Ultrasound quick-breeding system

InactiveCN101578957AGood effectIncrease commodity rateCultivating equipmentsHorticulture methodsSeedlingBiology

The invention discloses an ultrasound quick-breeding system, and relates to a breeding device, in particular to an ultrasound biological breeding device. An air-tight door (2) is arranged on the front lateral surface of a breeding tank body (1), a stereo breeding tank rack (3) is arranged in the breeding tank body (1), a humidifier (5) is arranged on the front lateral surface of the breeding tank body (1), a thermal baffle (7) is arranged on the top surface of the breeding tank rack (3), a water osmosis treatment device (8) is arranged at one side of the breeding tank body (1), and an ultrasound generator (9) is arranged at one side of the top end of the breeding tank body (1). Seedlings bred by the system have shorter period, well-developed root and quick growing development. The ultrasound quick-breeding system has good effect and better growth vigour on the varieties which are quick to breed and difficult to root and the varieties which do not resist water and moisture, and is easy to implement intensification and factory production and breed the seedlings with high commodity rate.

Owner:侯金波

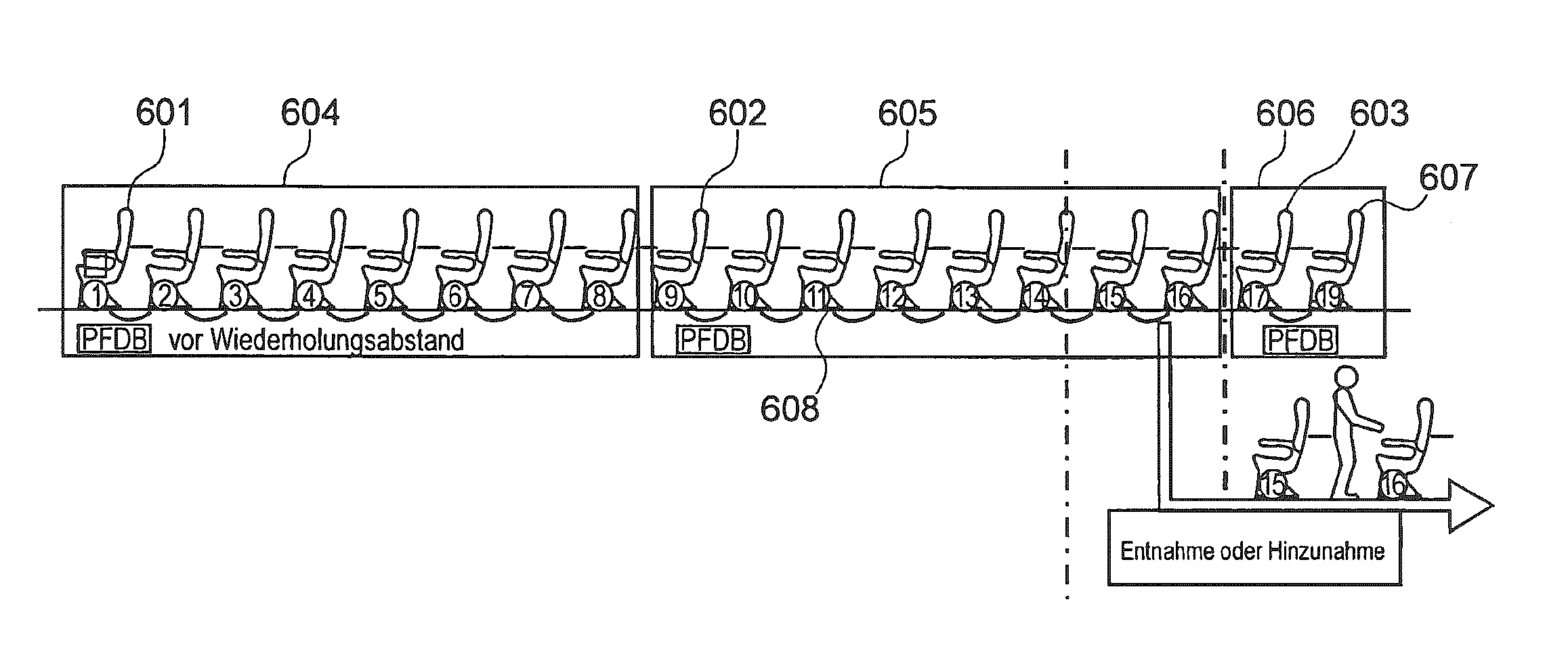

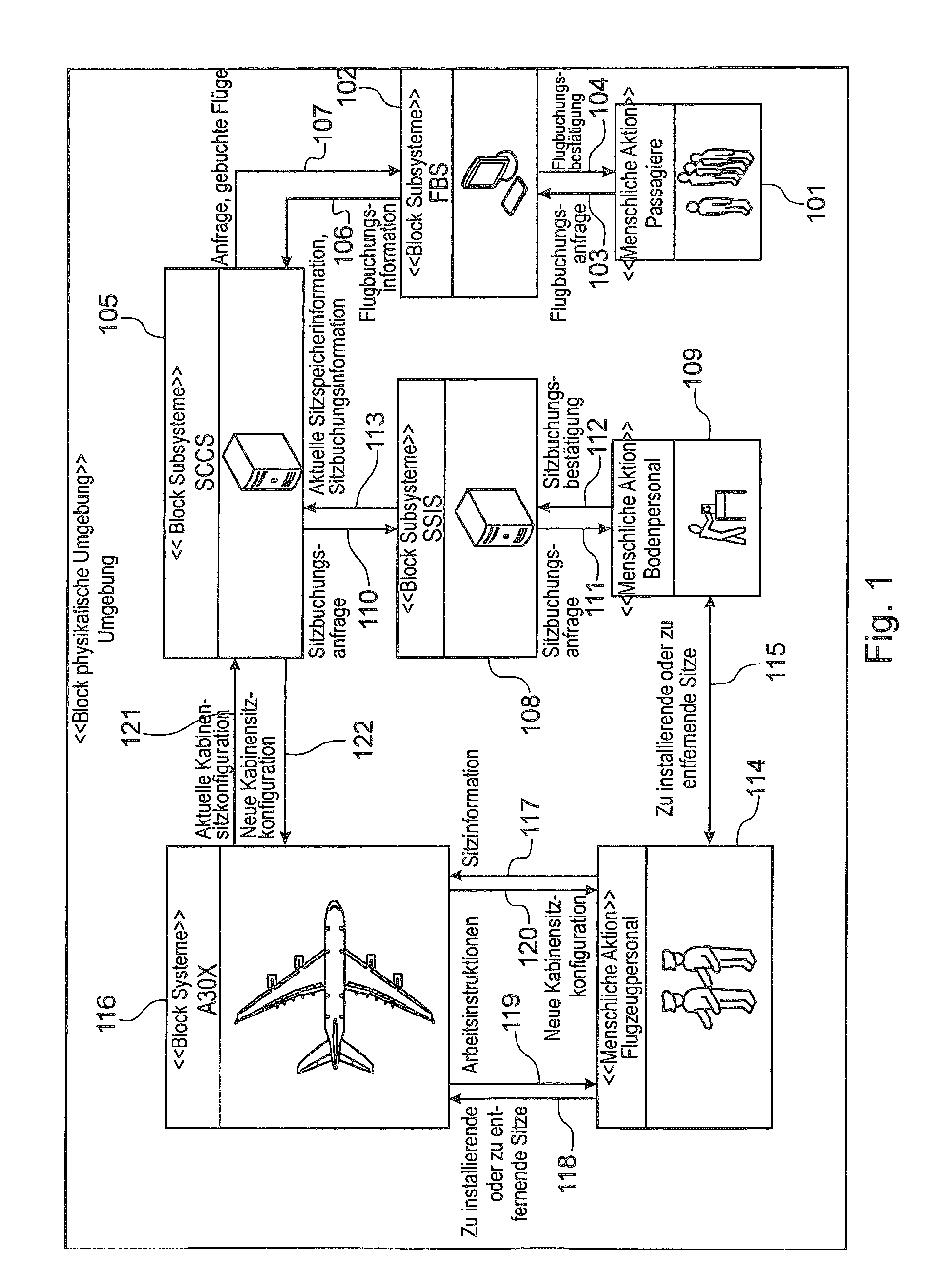

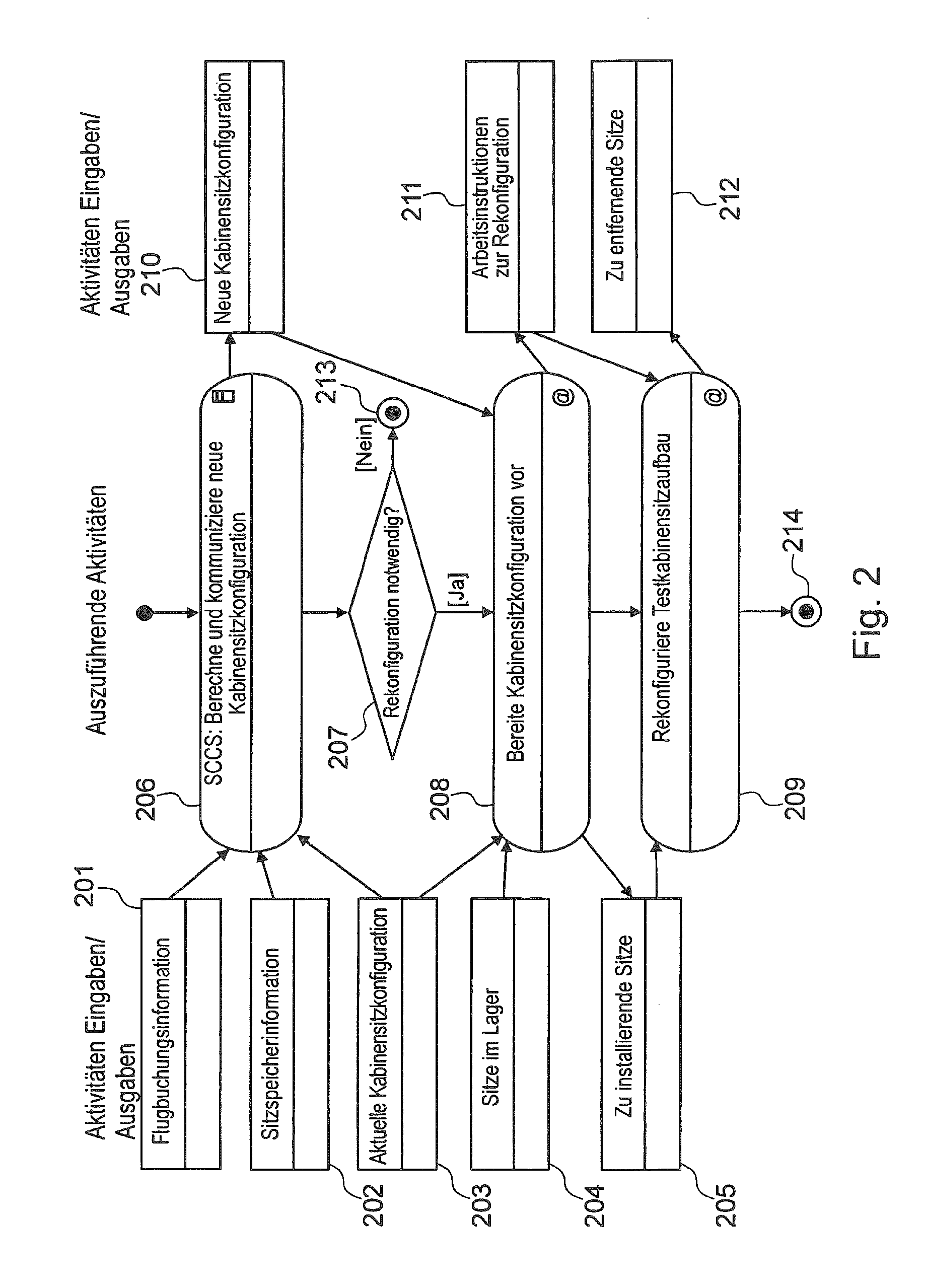

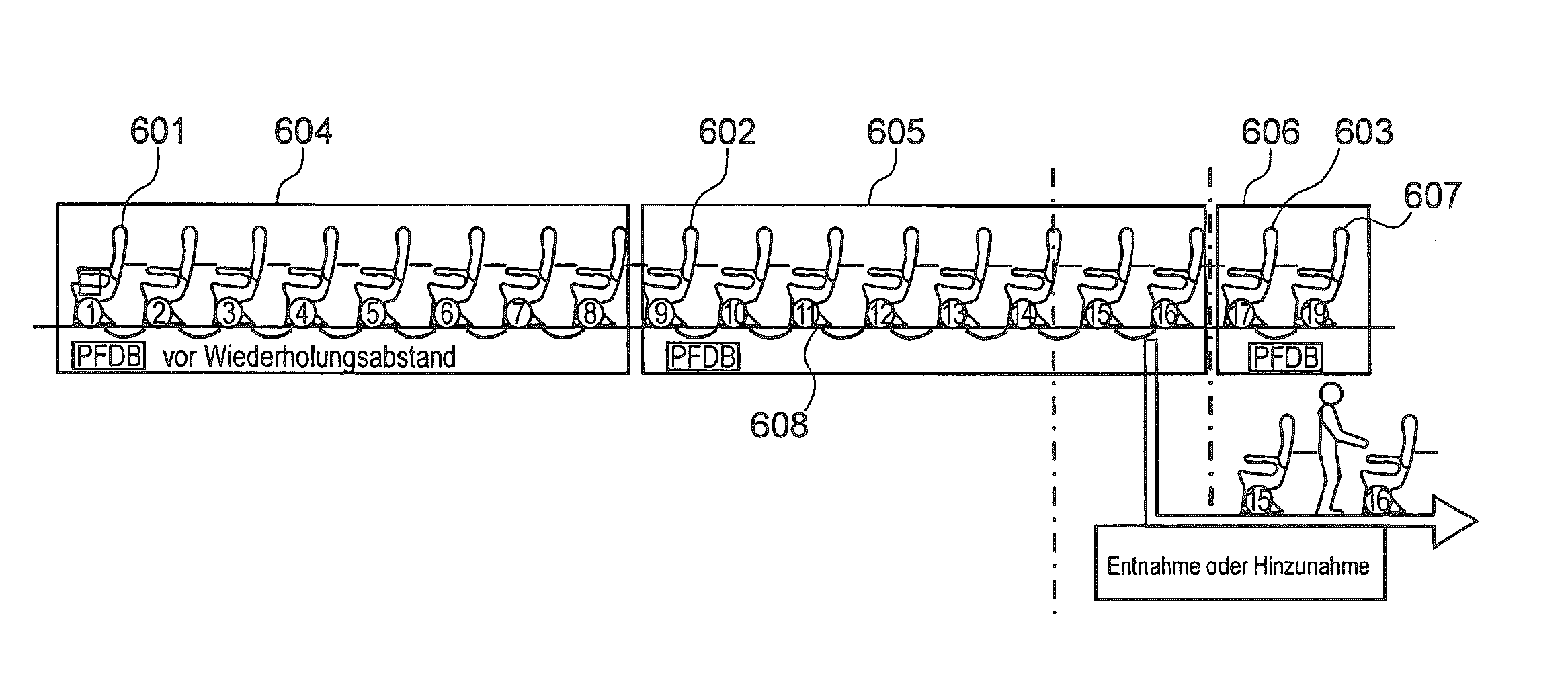

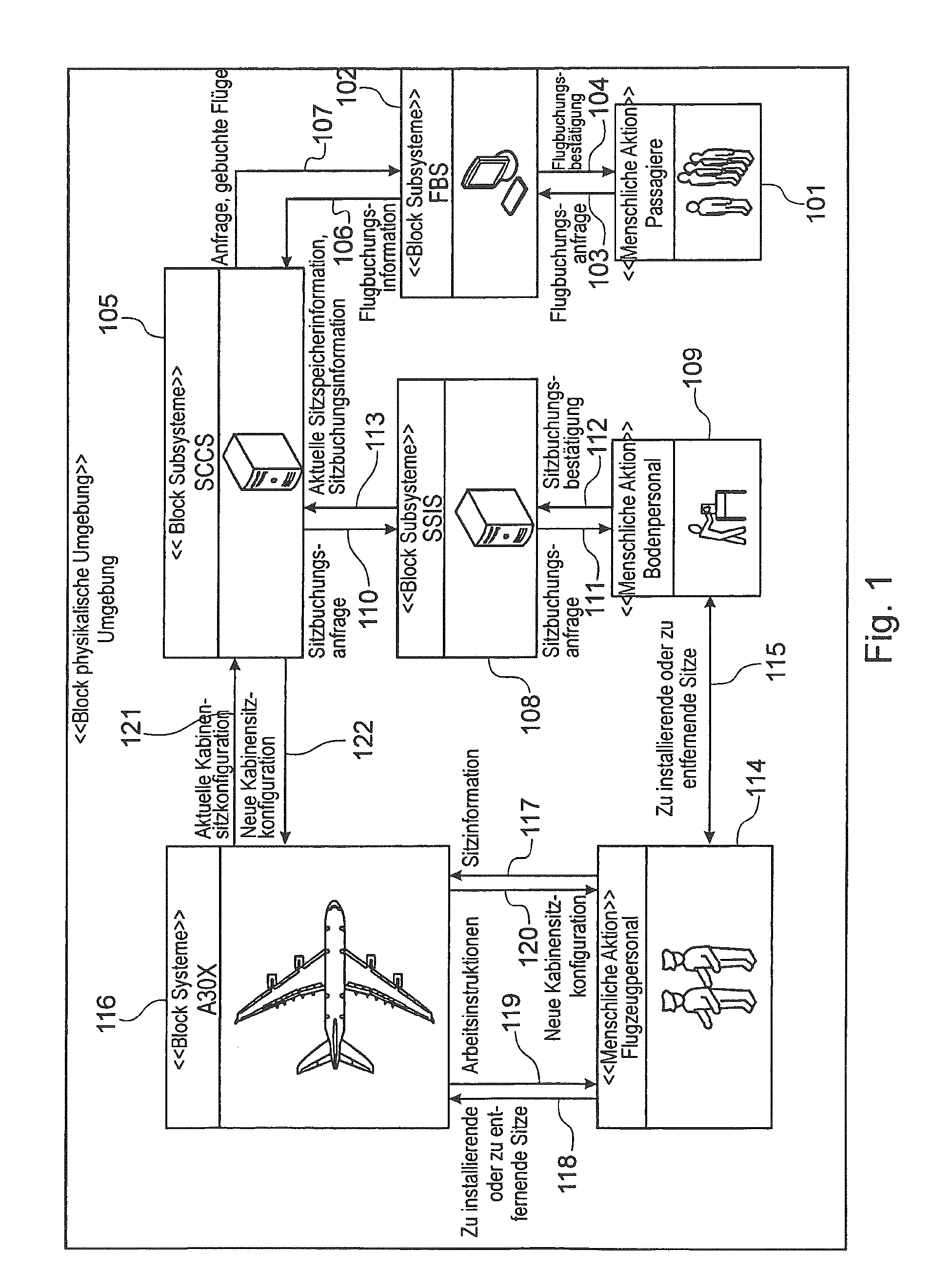

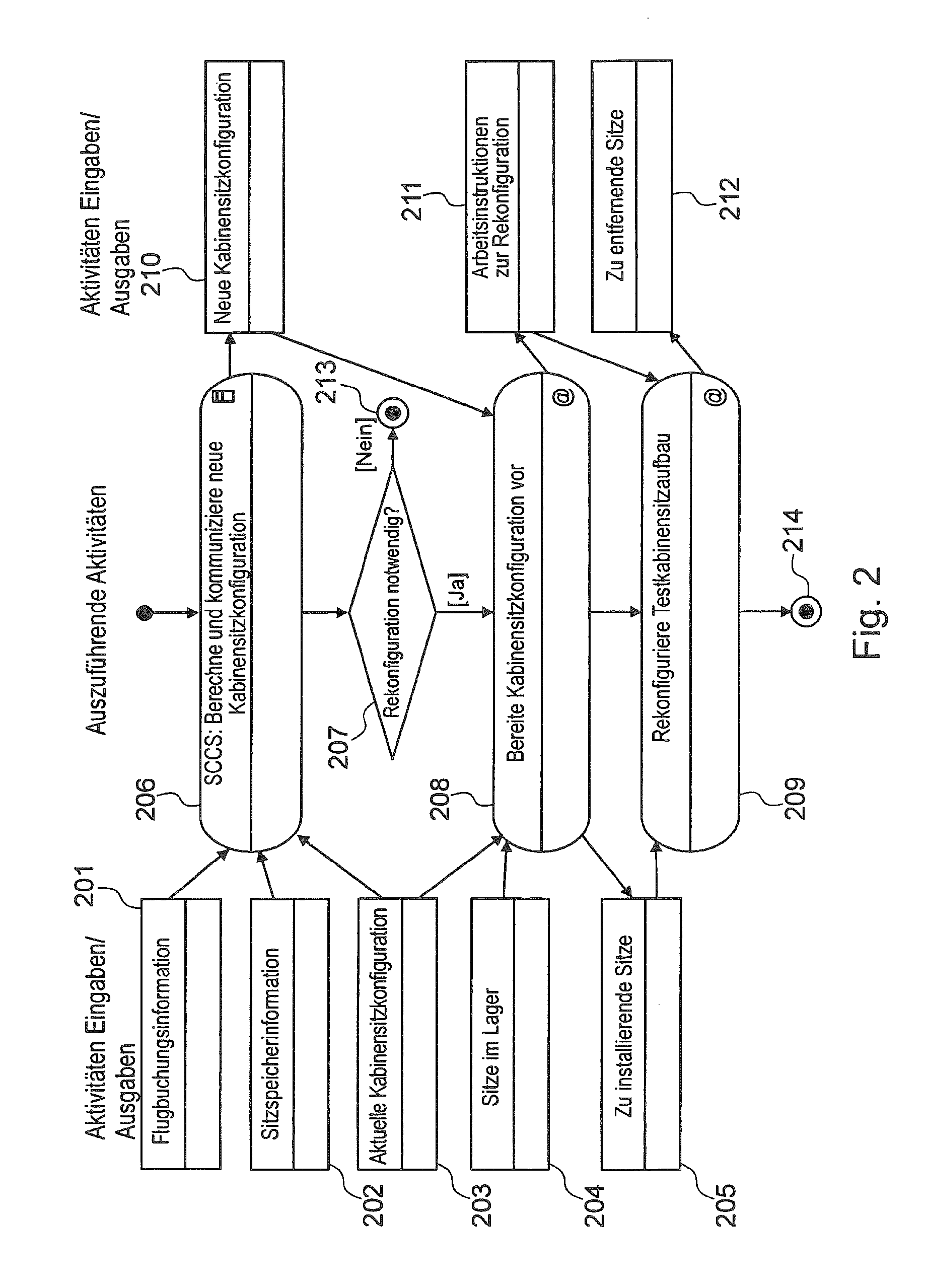

Variable Seat Separation Adjustment In An Airplane

InactiveUS20110017869A1Increase and decrease seat pitch of seatReduce mechanical resistanceSeating arrangementsAir-treatment apparatus arrangementsEngineeringAirplane

According to an exemplary embodiment of the invention, a system for simultaneous longitudinal shifting of several selected seats or seat rows in an aircraft is stated, in which system a drive device for shifting the seats is provided, wherein shifting the seats takes place according to a change in seat configuration planning.

Owner:AIRBUS OPERATIONS GMBH

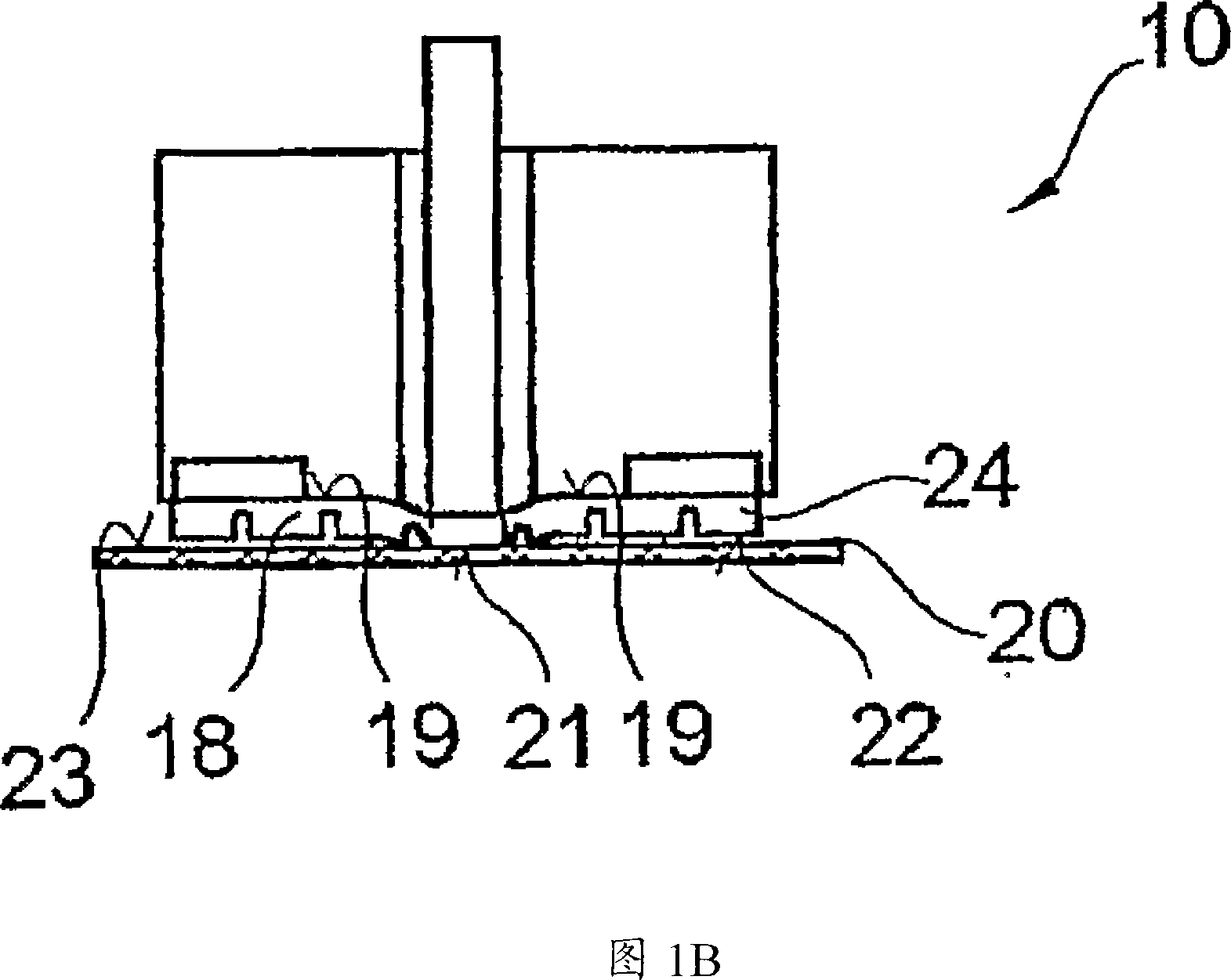

Method and device for transferring a chip to a contact substrate

ActiveCN101164150AReduce mechanical resistanceReduce thermal resistanceSolid-state devicesSemiconductor/solid-state device manufacturingMechanical engineeringMaterials science

A method and device for transferring a chip ( 18 ) situated on a transfer substrate ( 26 ) to a contact substrate ( 50 ), and for contacting the chip with the contact substrate, in which the chip, the back side ( 19 ) of which is attached adhesively to a support surface of the transfer substrate facing the contact substrate, is charged with laser energy from behind through the transfer substrate, and the chip contacts ( 59, 60 ) thereof that are arranged opposite a contact surface ( 58 ) of the contact substrate are brought into contact with substrate contacts ( 56, 57 ) arranged on the contact surface by means of a pressing device ( 45, 46 ) from behind through the transfer substrate, and a thermal bond is created between the chip contacts and the substrate contacts.

Owner:PAC TECH PACKAGING TECH

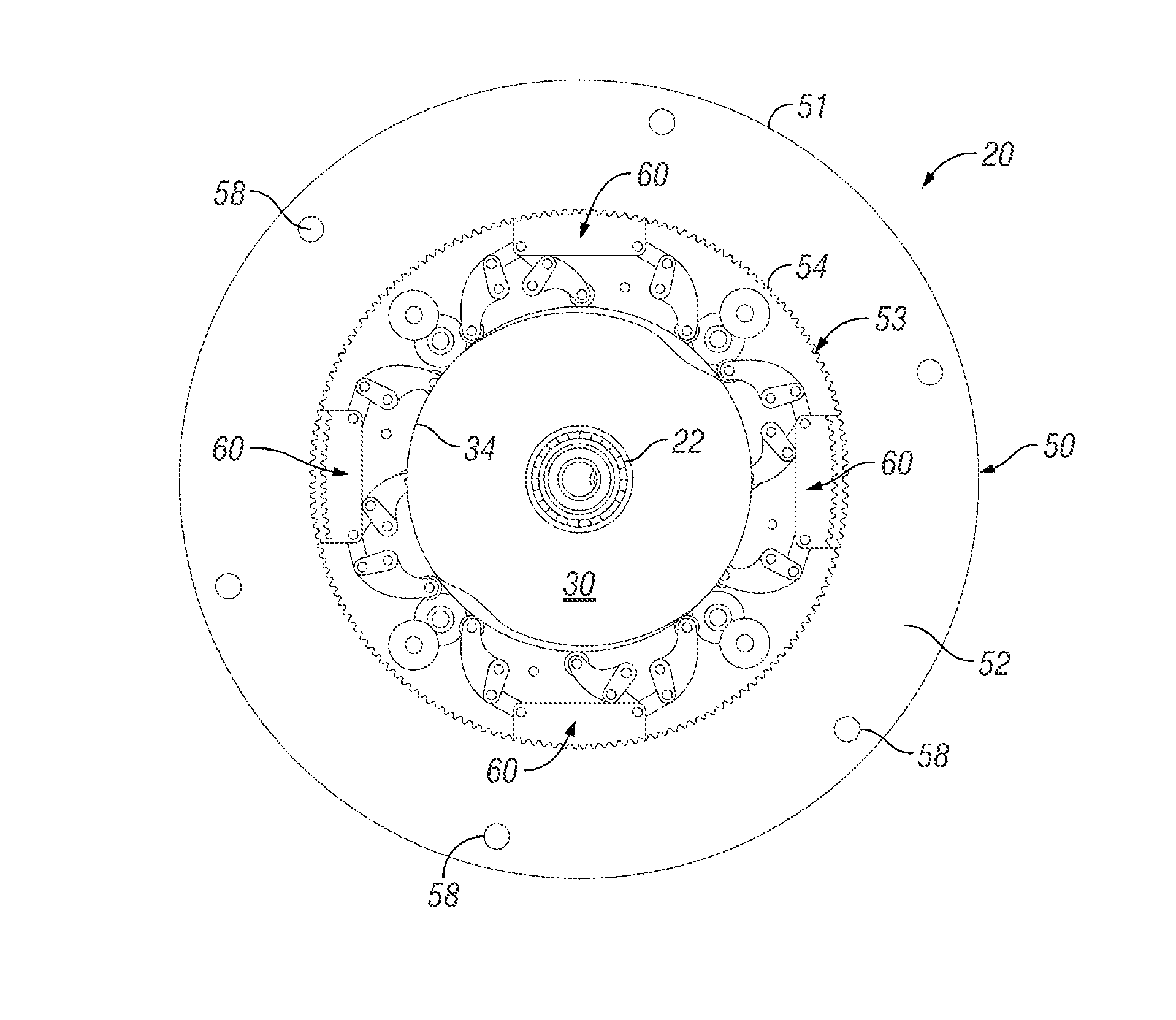

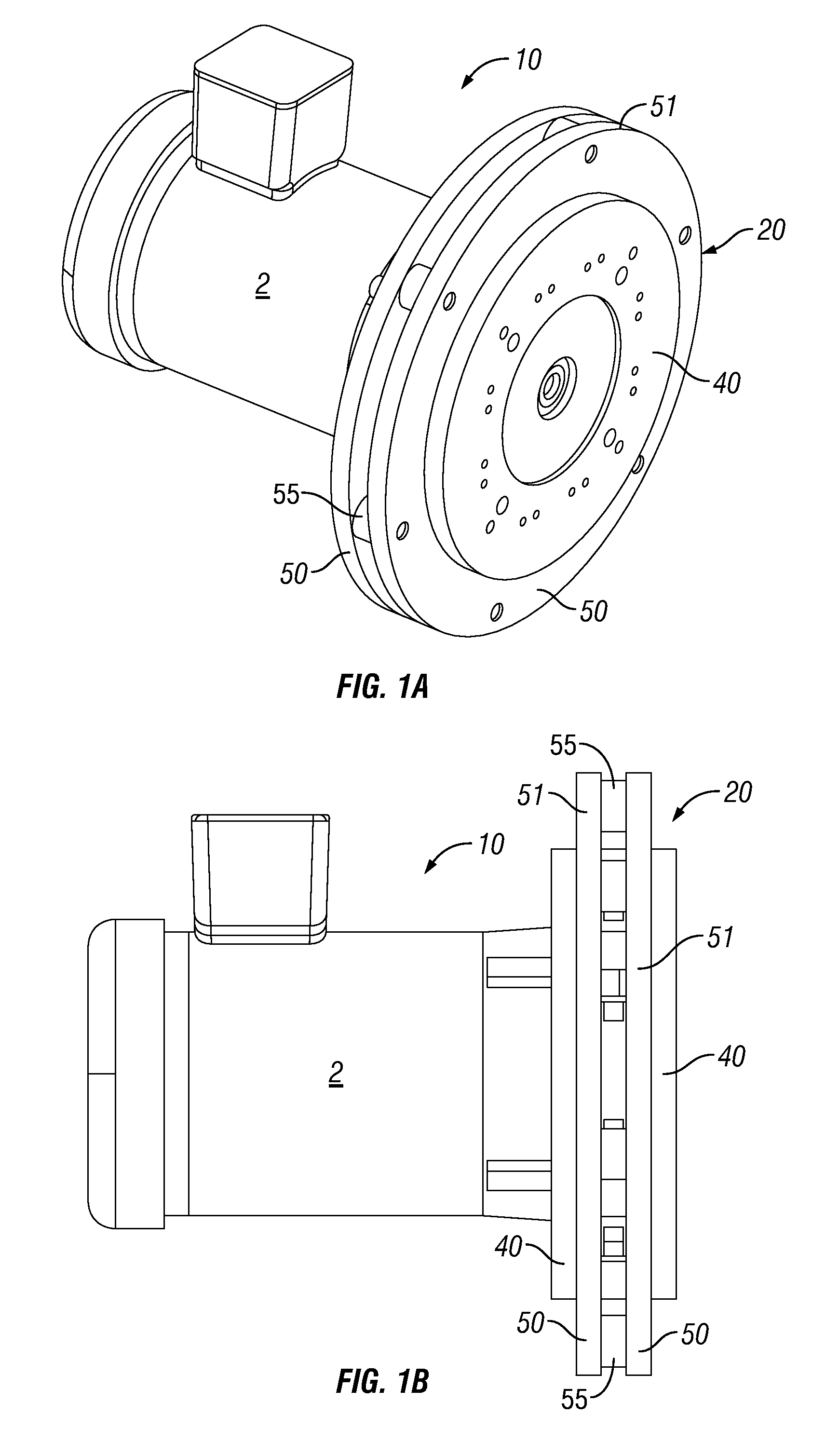

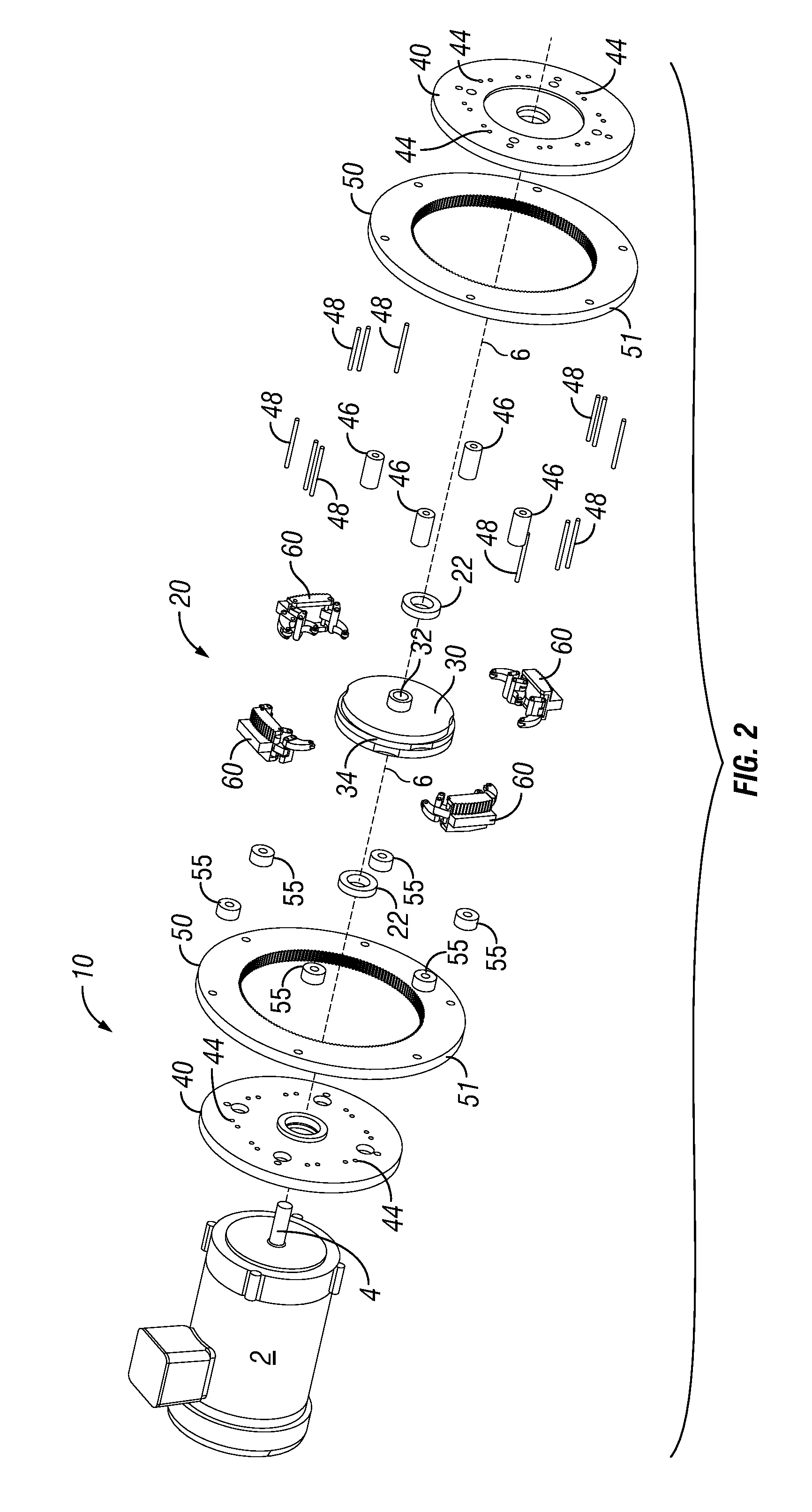

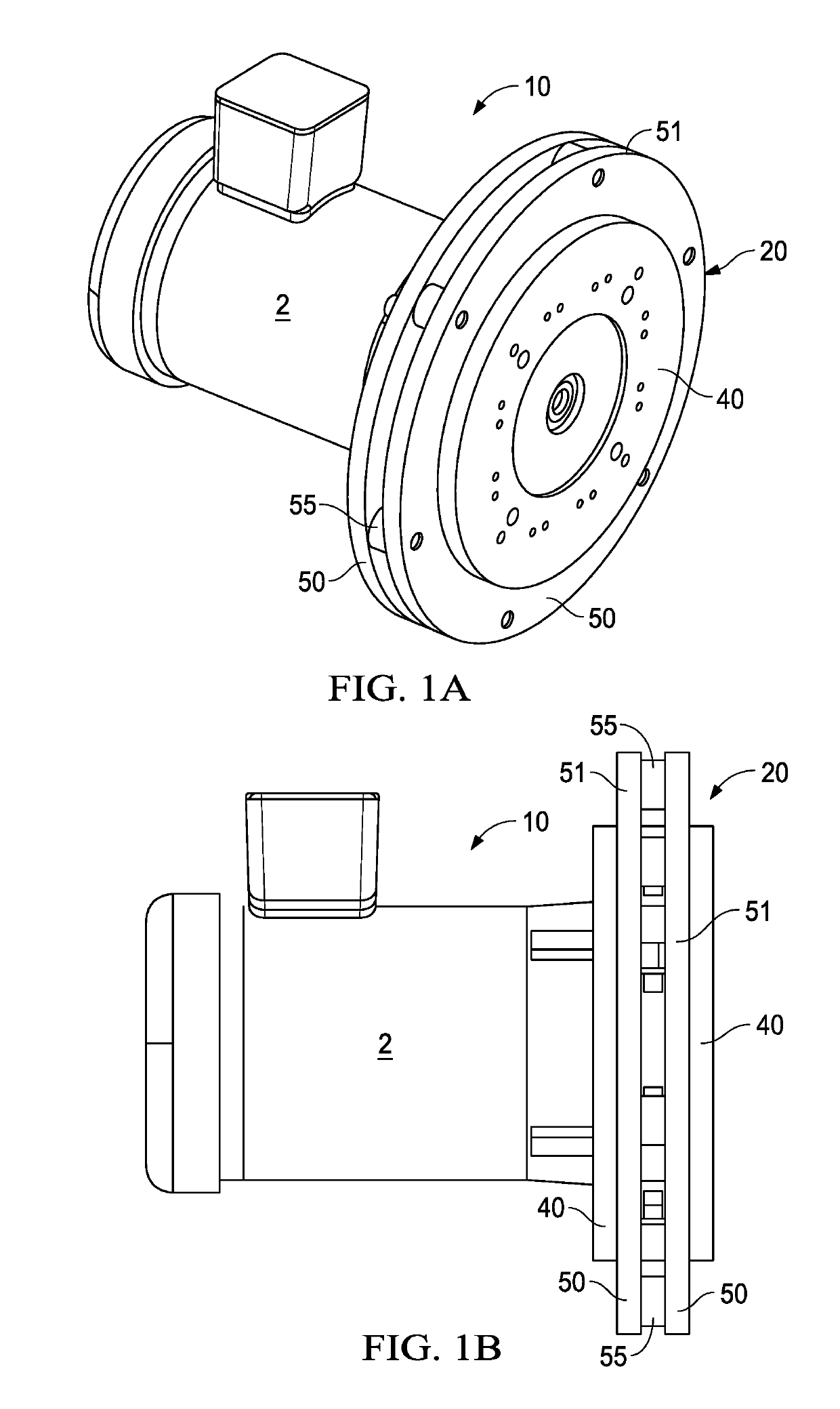

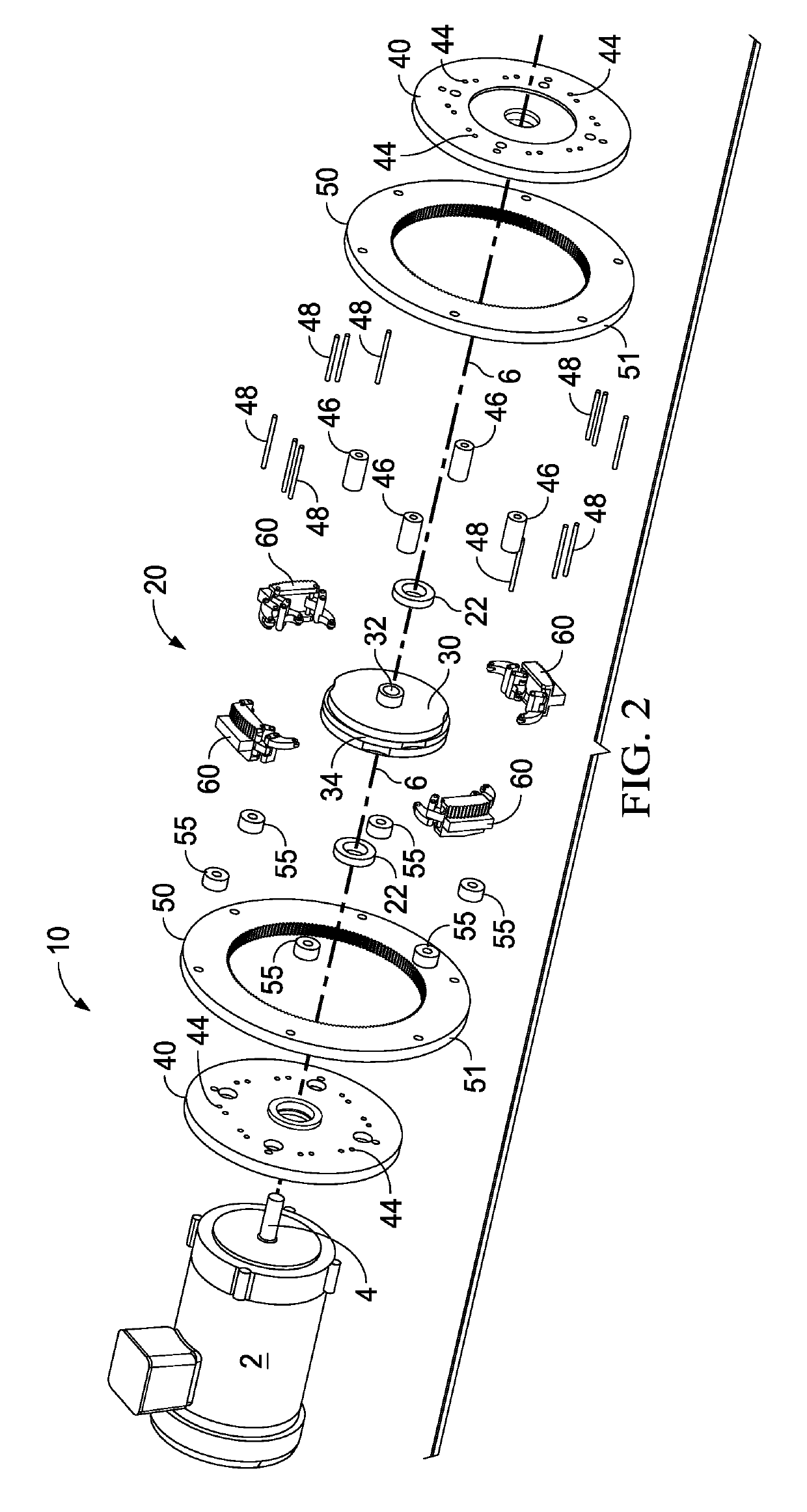

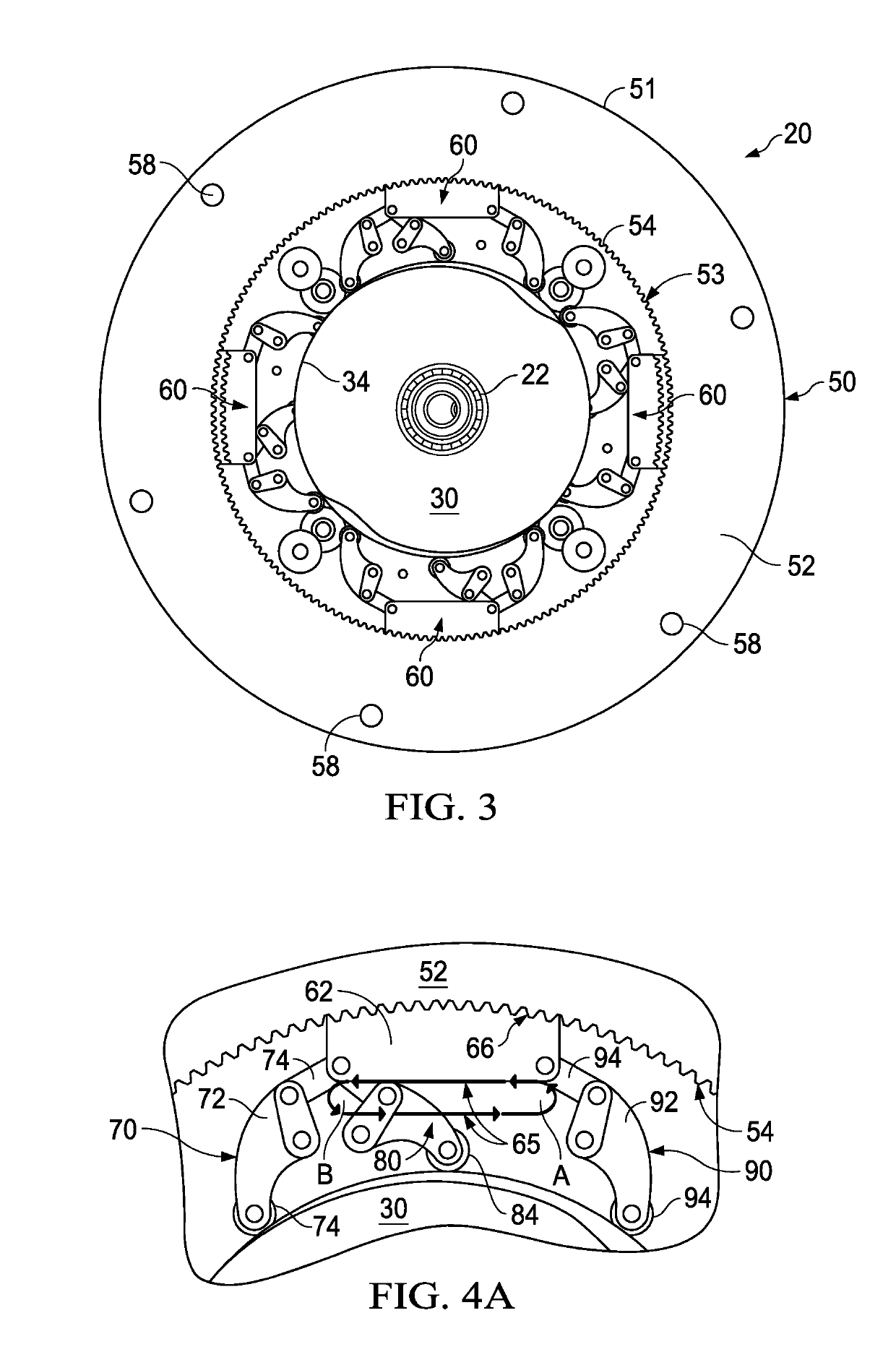

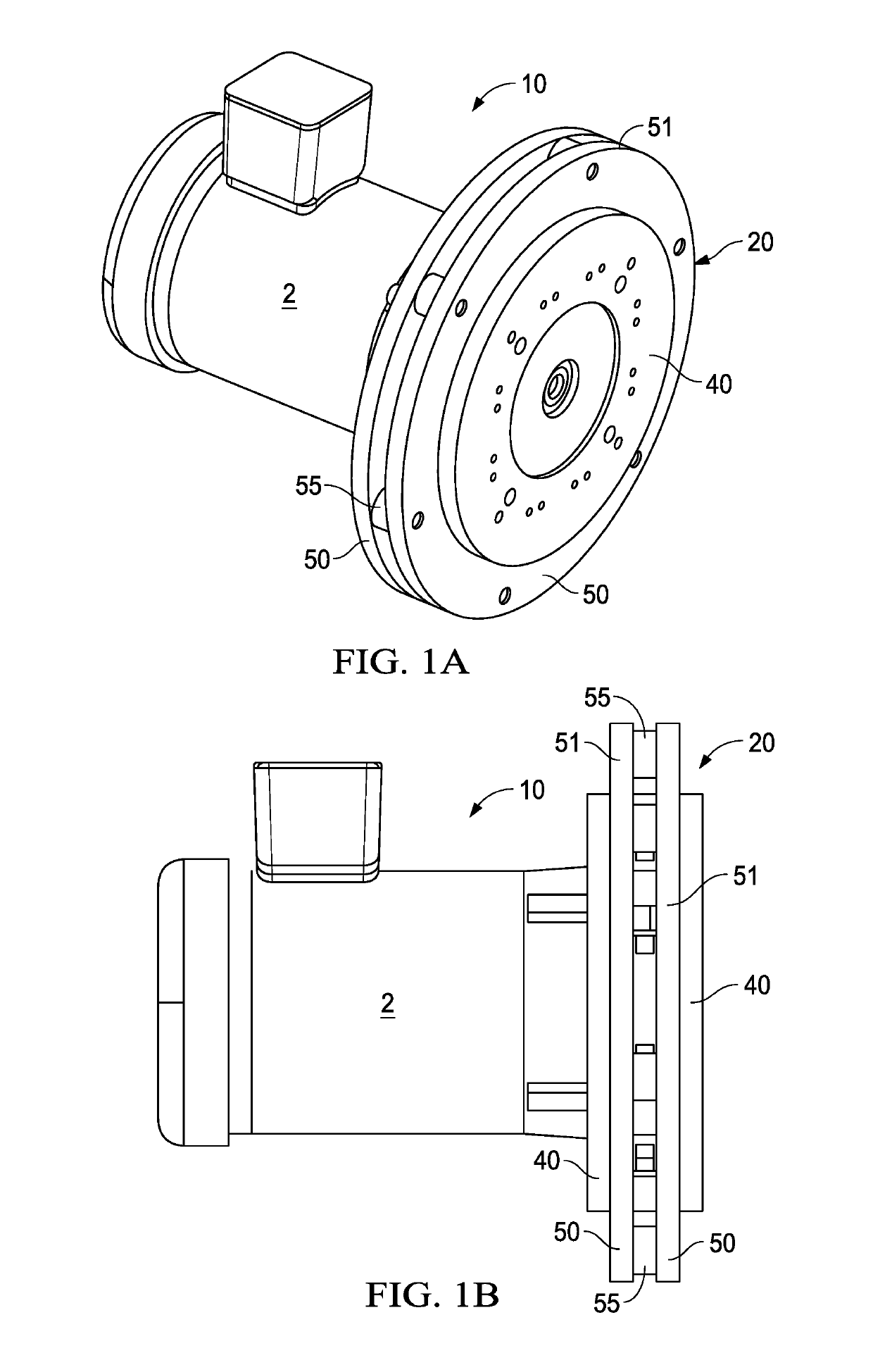

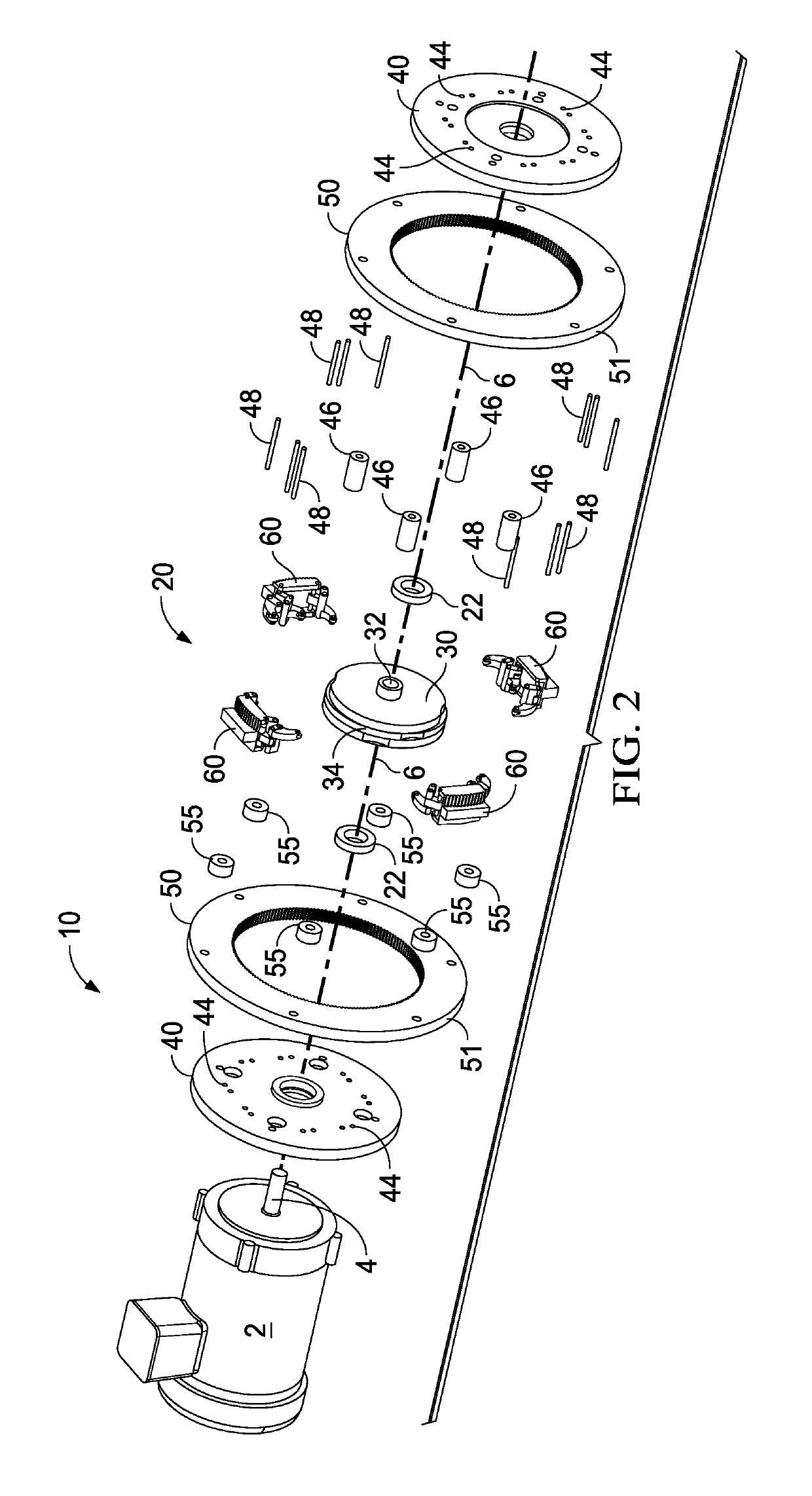

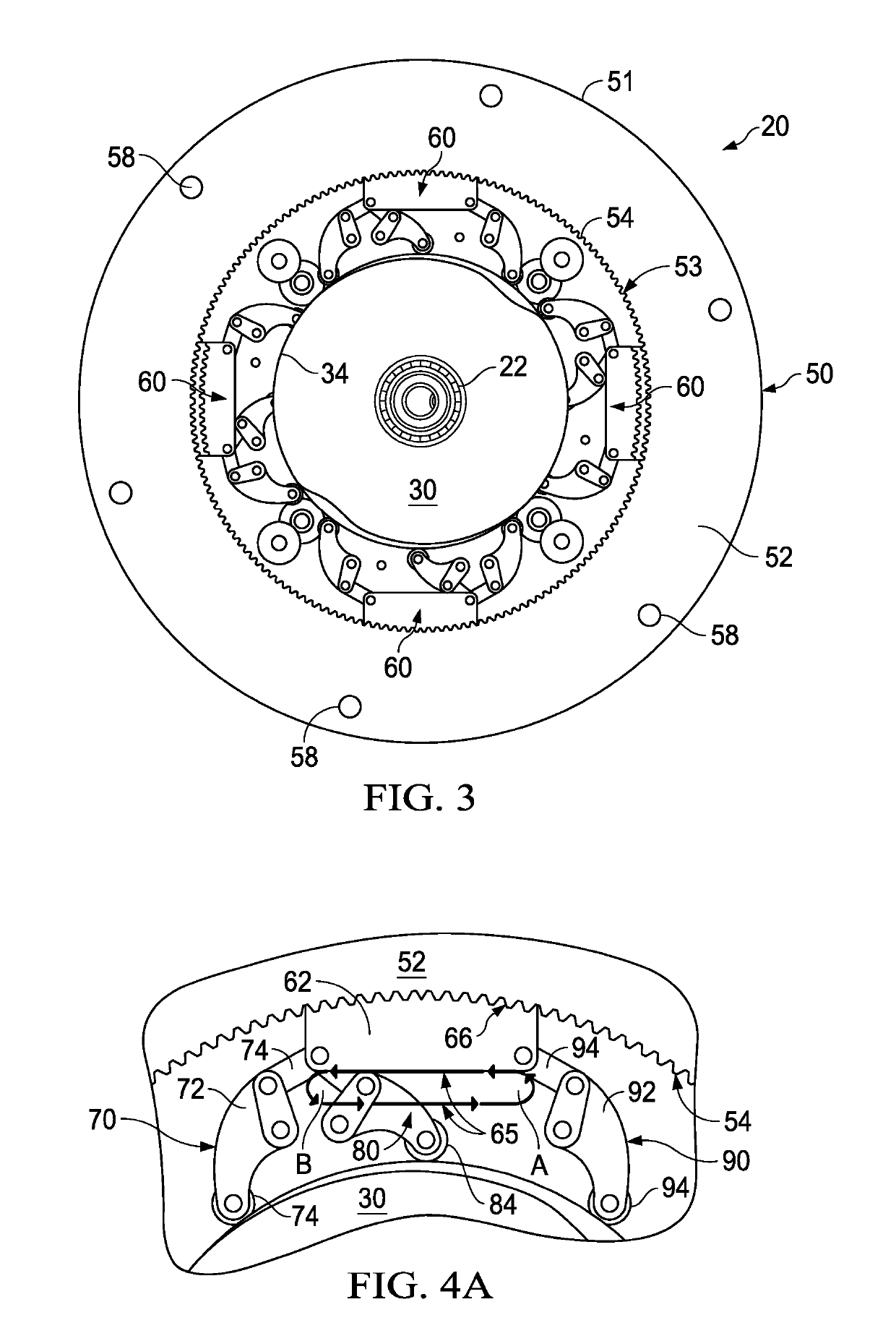

Gearbox mechanism

The improved gearbox mechanism of the present invention includes a plurality of cam-actuated gear block assemblies, which transfer power from a power shaft to a secondary or output gear element. Each gear block assembly includes a gear block having a surface that periodically interfaces with a secondary or output gear element. In a preferred embodiment the interface surface comprises a plurality of projections or teeth which correspond to complementary projections or gear teeth on the output gear element. Each gear block assembly further includes a plurality of linkage assemblies, which connect or link the gear block to a cam assembly, which in turn is connected to a power source. The cam assembly includes about its circumference a unique pathway or groove for each linkage assembly of a particular gear block assembly so that the movement of the gear block may be controlled in two dimensions in accordance with a certain design parameter.

Owner:MOTUS LABS LLC

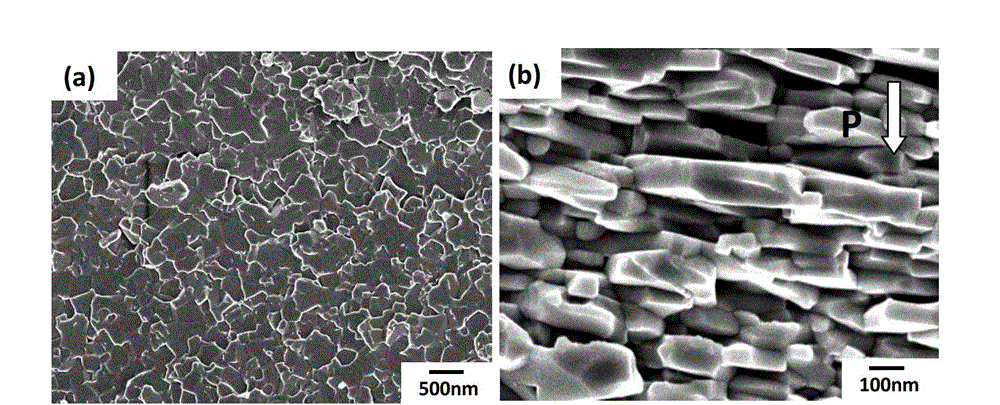

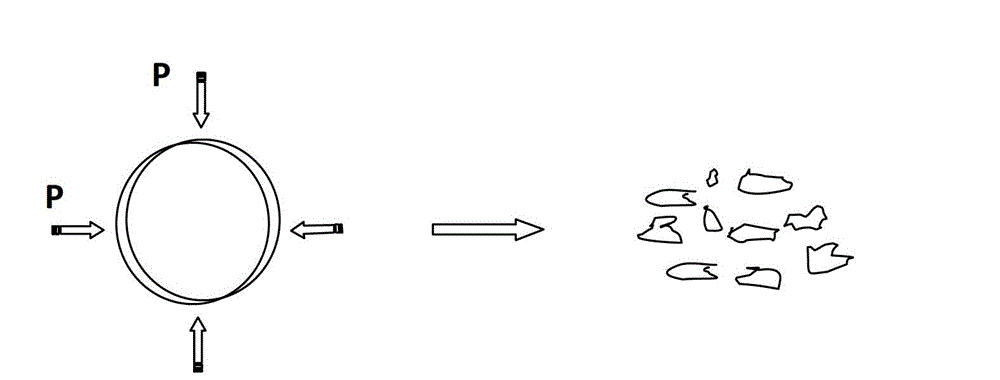

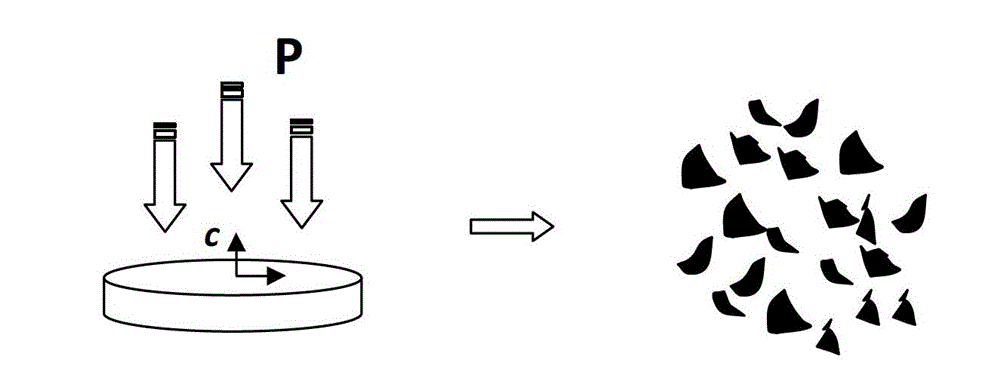

Method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking thermal deformed magnet

ActiveCN103151161AImprove coercive forceHigh energy productInductances/transformers/magnets manufactureMagnetic materialsThermal deformationRoom temperature

The invention discloses a method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking a thermal deformed magnet. The method comprises the following steps: (1) preparing a full-densification isotropic neodymium iron boron magnet; (2) preparing a thermal deformation anisotropic neodymium iron boron magnet; (3) directionally breaking the thermal deformation magnet: directionally breaking the round-cake-shaped anisotropic neodymium iron boron magnet, prepared in the step (2), by applying a symmetrical and circulating applied force along a radial direction at room temperature under the protection of argon, wherein the breaking force is 600-700MPa, so as to obtain a lamellar magnetic sheet; and (4) breaking the magnetic sheet in a regularized way: carrying out regularized breaking on the magnetic sheet prepared in the step (3) under the protection of the argon by adopting a rolling minding method, so as to obtain the anisotropic neodymium iron boron magnetic powder.

Owner:SICHUAN UNIV

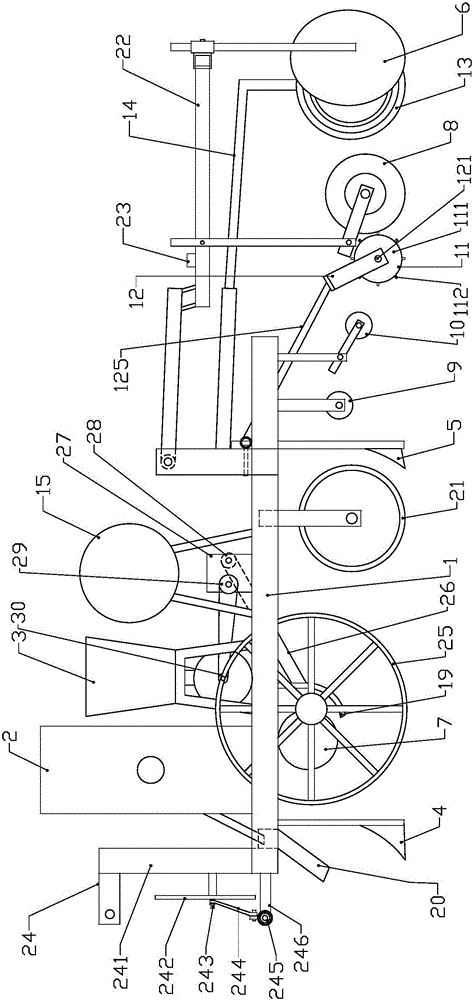

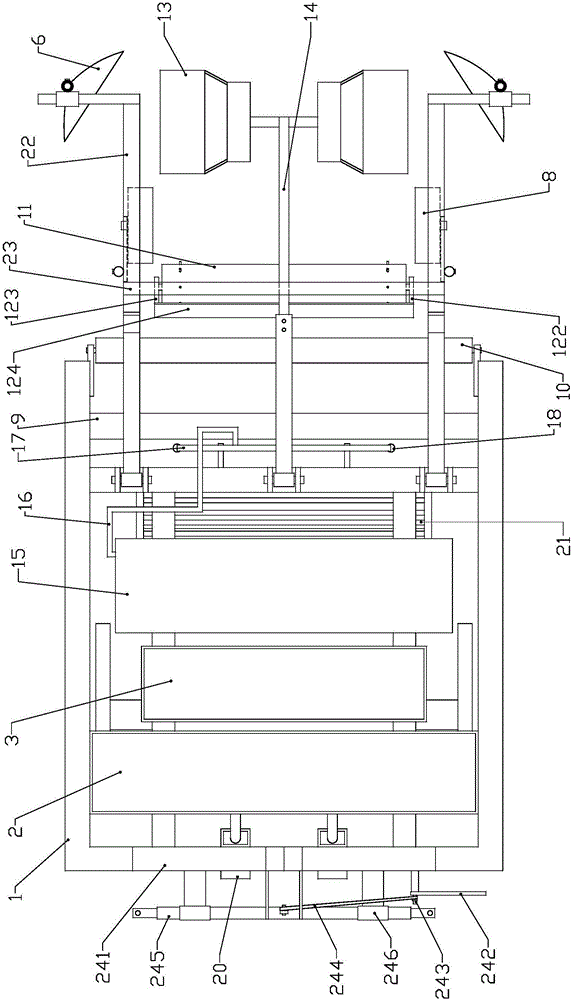

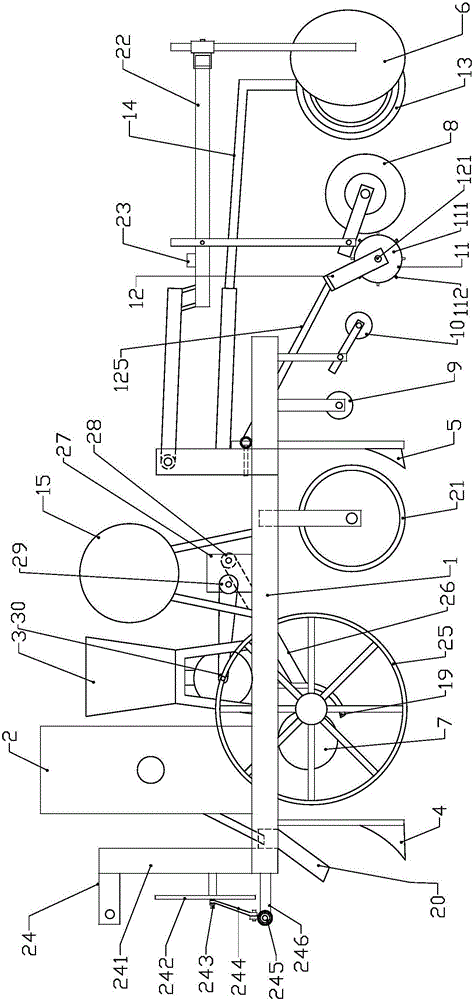

Peanut seeder

InactiveCN105684585AGuaranteed smoothReduce the temperatureSpadesPlantingSeederMechanical resistance

The invention discloses a peanut seeder, and belongs to agricultural machinery.The structure of the peanut seeder comprises a rack, a fertilizer box, a seed box, a ridging coulter, a ditching coulter and soil covering coulters; the lower portion of the seed box is provided with a seed feeding device, a compacting wheel is arranged between the ditching coulter and the soil covering coulters, the back portion of the rack is provided with a film covering frame, the two sides of the rack are provided with walking wheels, the back portion of the seed feeding device is provided with a coating agent spray head, and the coating agent spray head is connected with a coating agent pesticide drum through a pipeline; the lower portion of the front side of the rack is provided with a fertilizer falling tank which is connected with the fertilizer box; the back portion of the seed feeding device is provided with a roll cage type soil scraping device.The peanut seeder has the advantages that worker coating is changed into machine pesticide spraying, the effects of resisting diseases and increasing humidity are achieved, and meanwhile seed skinning is prevented; the fertilizer is applied to the ground in a sprinkling mode, fertilizing depth is reduced, and the ditching resistance is reduced; in addition, by arranging the mobile roll cage type soil scraping device, the ridge surface flatness is guaranteed, tidiness and uniformity of emerged seedlings are facilitated, the mechanical resistance generated in the ridging process is reduced, and farm operation is facilitated.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

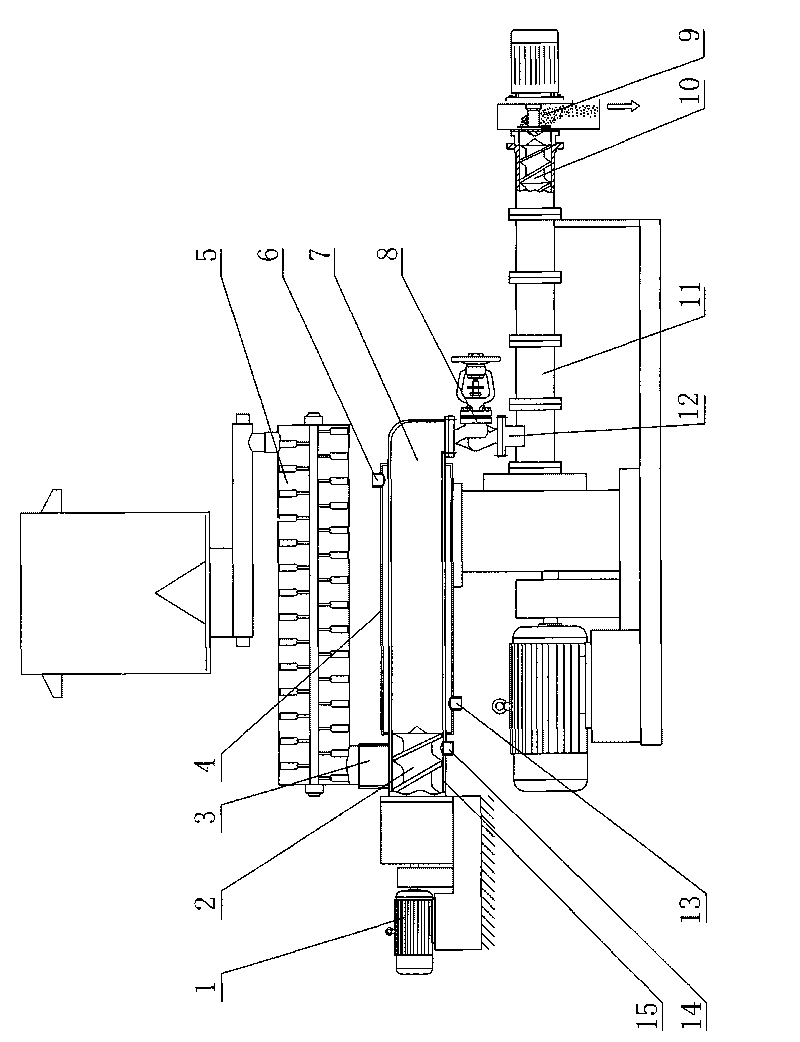

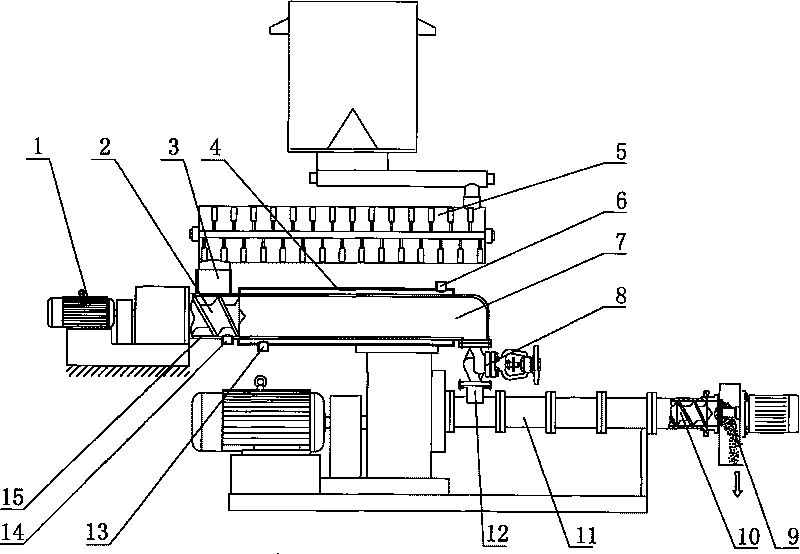

Processing device suitable for extrusion of foods and feeds

InactiveCN101692928AReduce consumptionReduce wearFeeding-stuffFood shapingFeed processingEngineering

The invention discloses a processing device suitable for extrusion of foods and feeds in food and feed processing field. The processing device comprises a conditioner and an extrusion cavity, wherein an extrusion screw is arranged inside the extrusion cavity, one end of the extrusion cavity is provided with a feeding hole, the other end of the extrusion cavity is provided with a discharging and cutting device, and pressure building device and an ager are arranged between the conditioner and the extrusion cavity in sequence; the pressure building device comprises a pressure building screw and a pressure building cavity, the pressure building screw is in driving connection with a driving device, and the inlet end of the pressure building cavity is connected with the outlet end of the conditioner; the ager comprises a pressure maintaining aging cavity and a heat-insulation shell arranged at the periphery, a steam inlet and a steam outlet are arranged on the heat-insulation shell, the outlet end of the pressure building cavity is connected with the inlet end of the pressure maintaining aging cavity, and the outlet end of the pressure maintaining aging cavity is connected with the feeding hole. In the device, most of energy resources for aging materials are from the energy of steam led to the heat-insulation shell, thereby the input of mechanical energy resources is effectively lowered, and the energy consumption for the extrusion of foods and feeds.

Owner:JIANGSU MUYANG GRP CO LTD

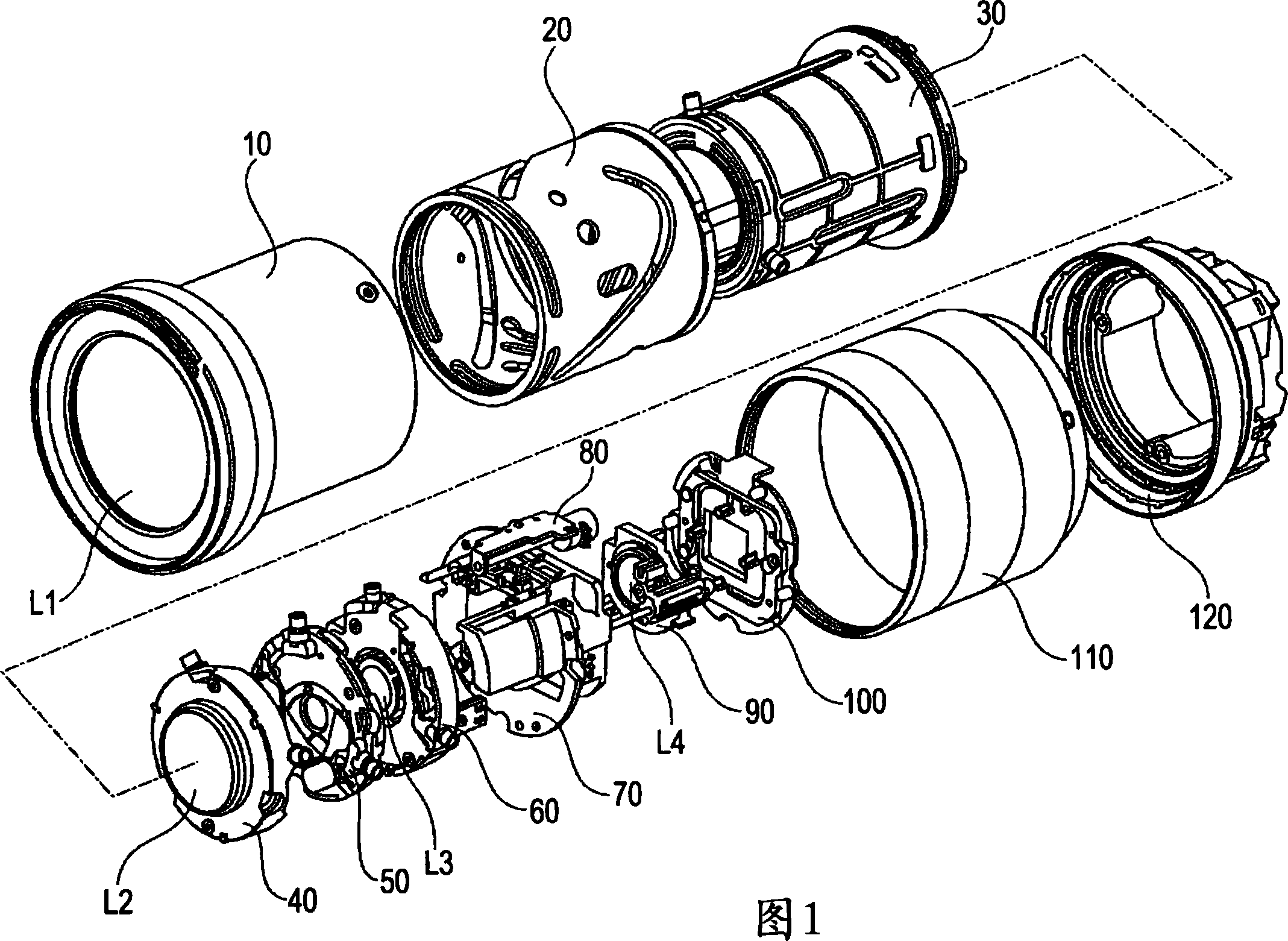

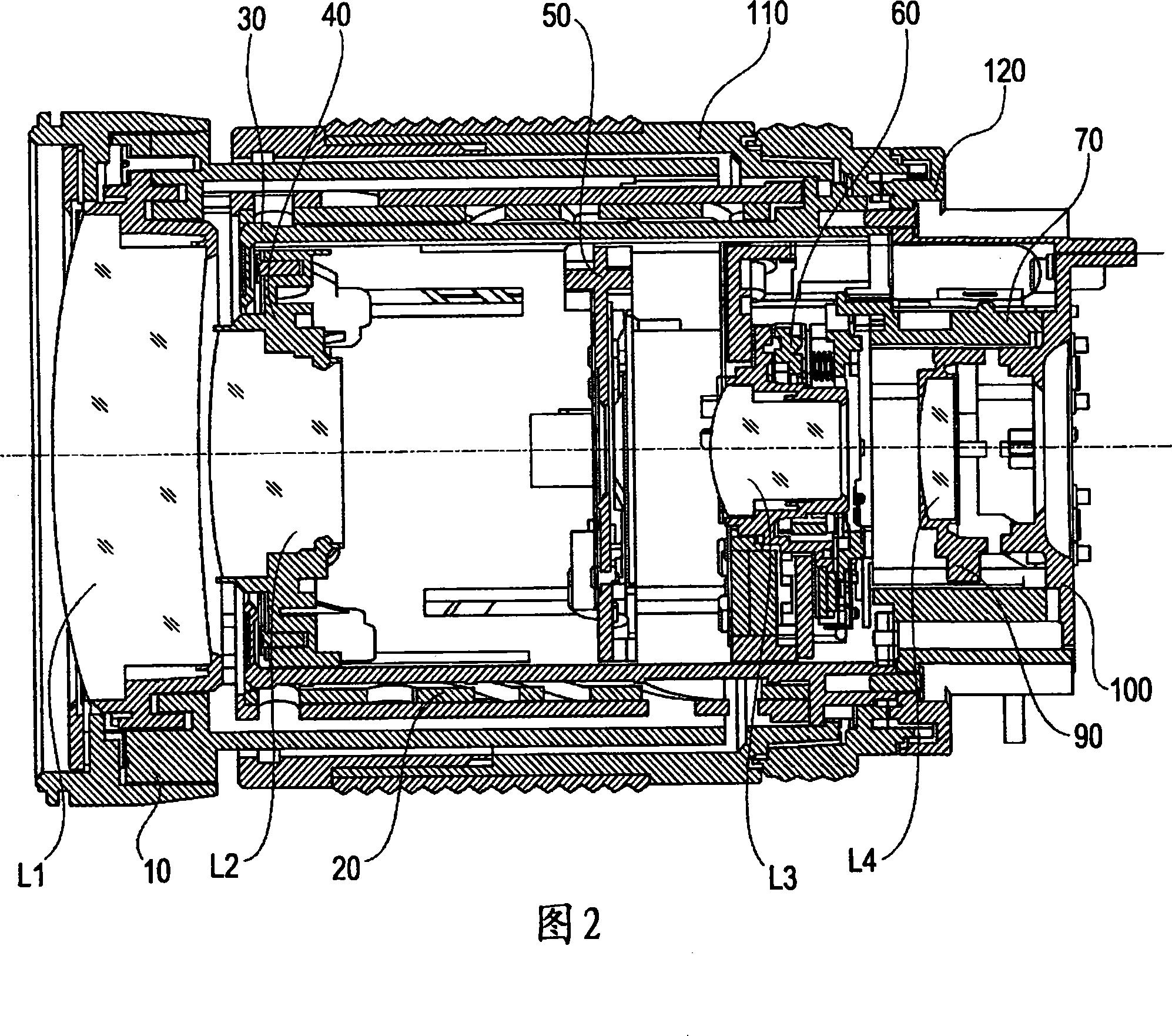

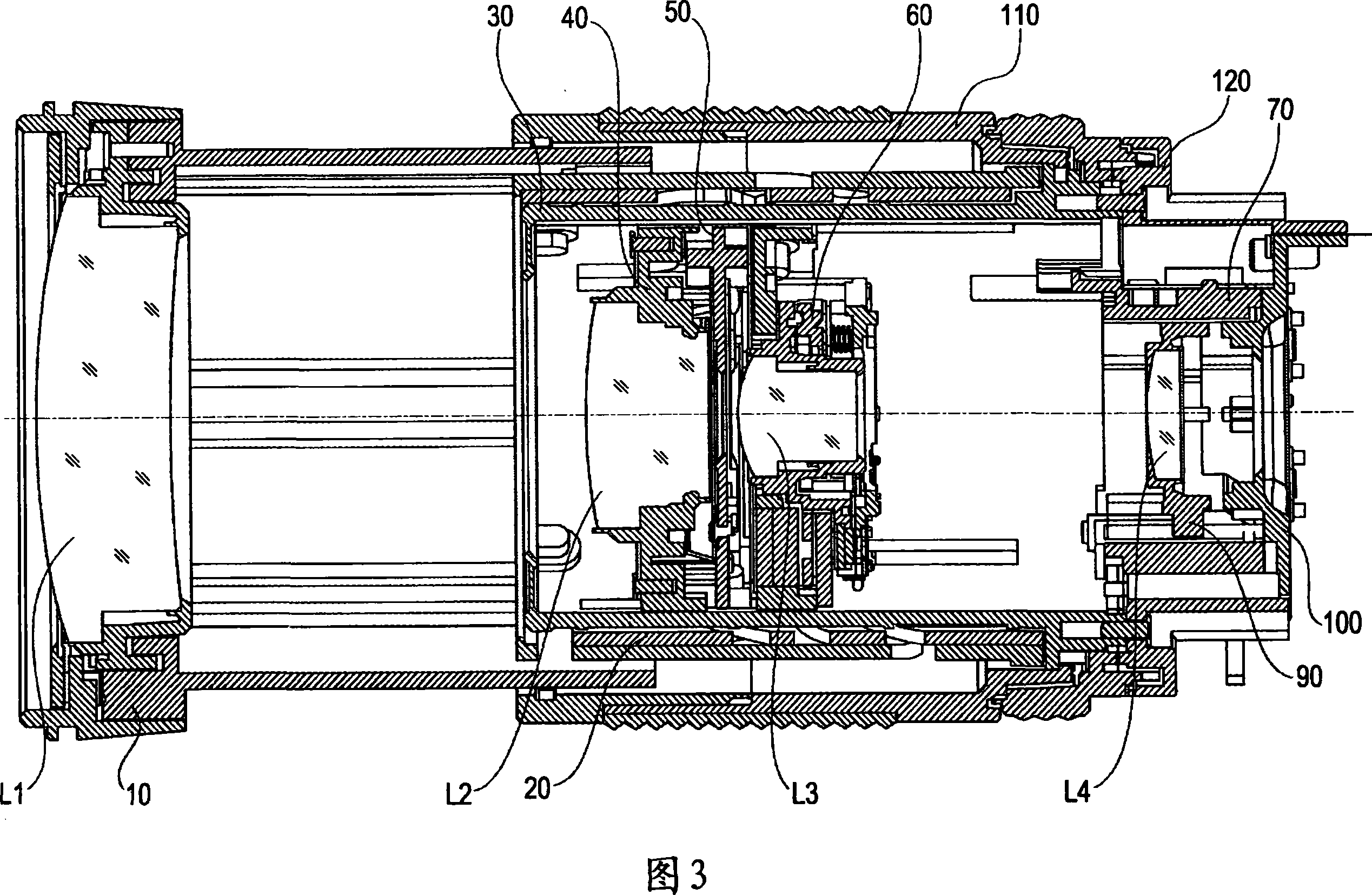

Lens barrel and imaging apparatus including the same

A lens barrel includes a first lens set configured to move manually along an optical axis, a second lens set configured to move electrically along the optical axis, a first holding member configured to hold the first lens set, a second holding member configured to hold the second lens set, a driving member configured to move the second holding member along the optical axis, a transmitting member configured to transmit a driving force of the driving member to the second holding member, and an urging member configured to relatively urge the transmitting member and the second holding member along the optical axis. The first lens set is movable within a range of motion of the second lens set. The urging member is displaced when the second holding member interferes with the first holding member.

Owner:CANON KK

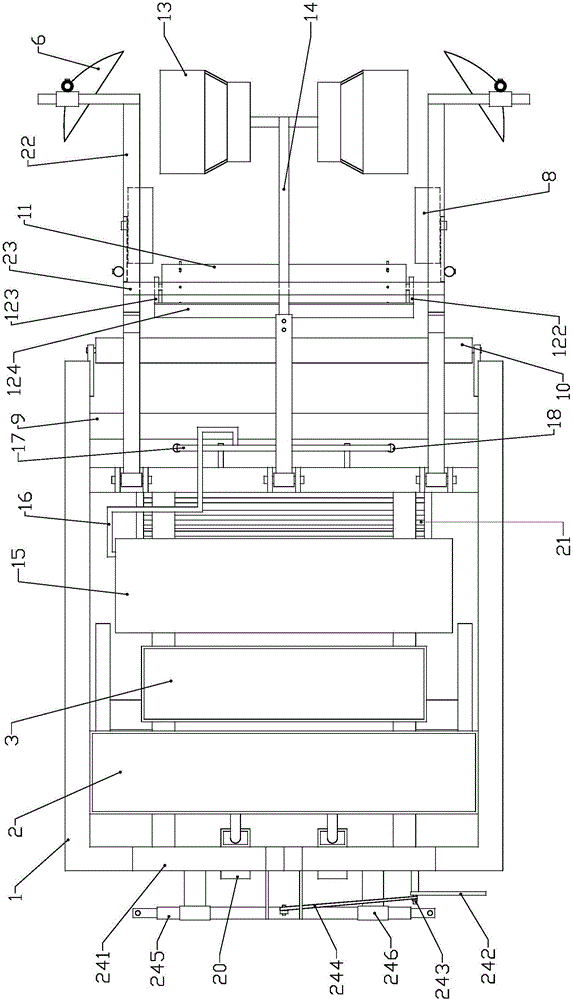

Automatic punching type peanut seeding machine

The invention discloses an automatic punching type peanut seeding machine, belonging to the agricultural machinery. The automatic punching type peanut seeding machine structurally comprises a stander, a fertilizer box, a seed box, a ridging coulter, a guttering coulter and an earthing coulter, wherein a seed sowing device is arranged at the lower part of the seed box; a compaction wheel is arranged between the guttering coulter and the earthing coulter; a film laminating frame is arranged at the rear part of the stander; a film pressing wheel is arranged at the lower part of the stander at the rear part of the film laminating frame; a punching press wheel is arranged behind the film pressing wheel, comprises a wheel body and a protruded upright post and is connected with the stander through a connecting device; and the connecting device comprises a rotating shaft, a left end plate, a right end plate, a connecting plate and a connecting rod, a wheel body of the punching press wheel is arranged on the rotating shaft, and the left end plate and the right end plate are respectively arranged at two ends of the rotating shaft. The automatic punching type peanut seeding machine has the characteristics that an automatic punching function is realized, the human input is reduced, the labor intensity is relieved, the ground surface temperature can be decreased, the burning of seedlings in summer is prevented, rainwater can be timely absorbed, hardened soil on films can be broken, and the like.

Owner:高唐县农业局 +1

Quick-tightening system for cycle with tightening torque control

ActiveUS8075065B2Reduce mechanical resistanceReduce weightHubsLoad modified fastenersControl theoryAxial rotation

A quick-release system for a quick-release device, in particular for a cycle, such as a bicycle, the device being of the type including an axially extending skewer and an end support element mounted on a first end of the skewer adapted to be supported on a first tightening surface of the cycle. The quick-release system includes a tightening sub-assembly including a support surface and an actuation sub-assembly including a movable actuating mechanism, capable of axial rotation around the skewer and configured to transmit a tightening torque to the tightening sub-assembly when the device is being tightened. The system includes tightening torque limiting mechanism making it possible to limit the torque transmitted by the actuation sub-assembly to the tightening sub-assembly.

Owner:THULE SWEDEN AB

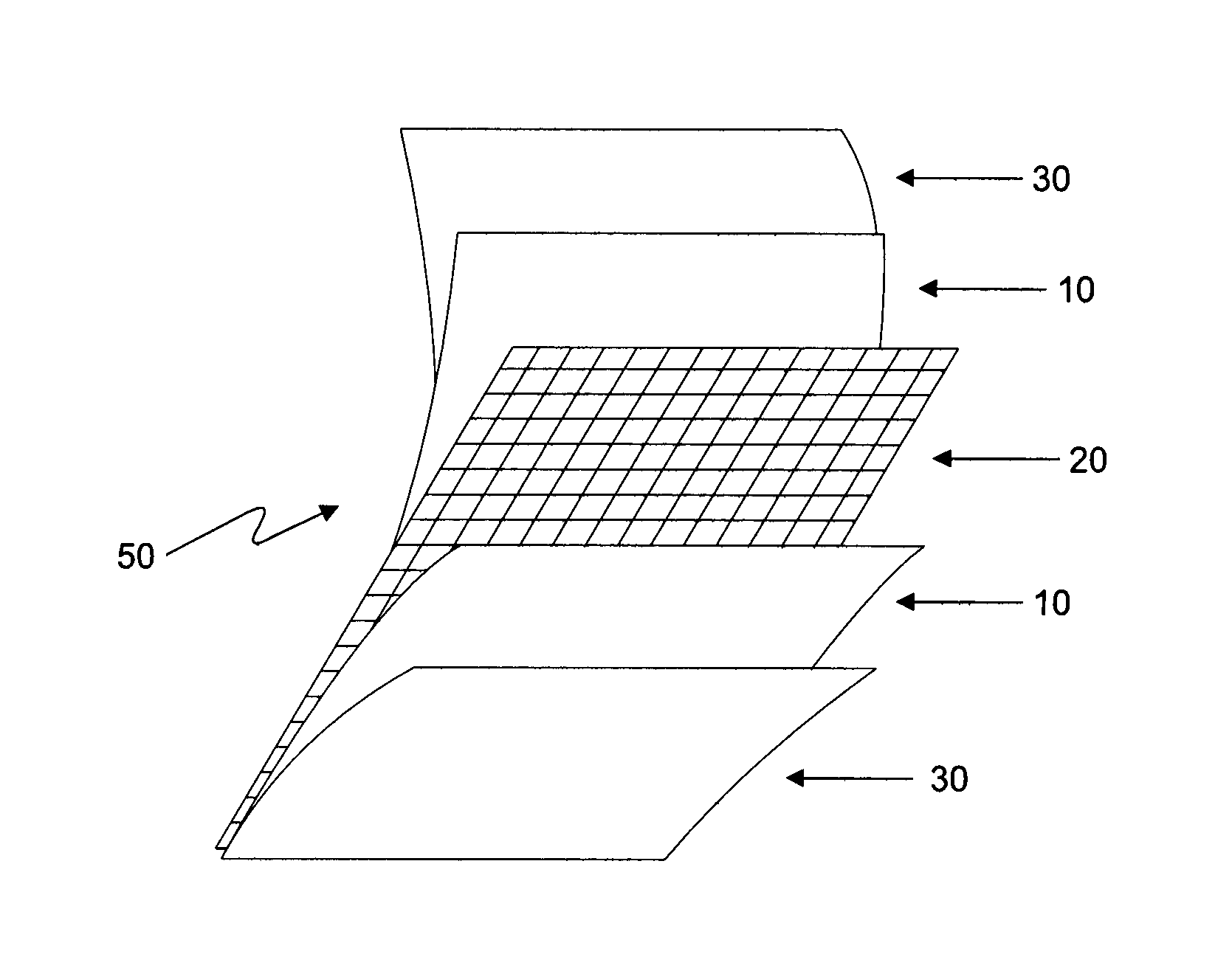

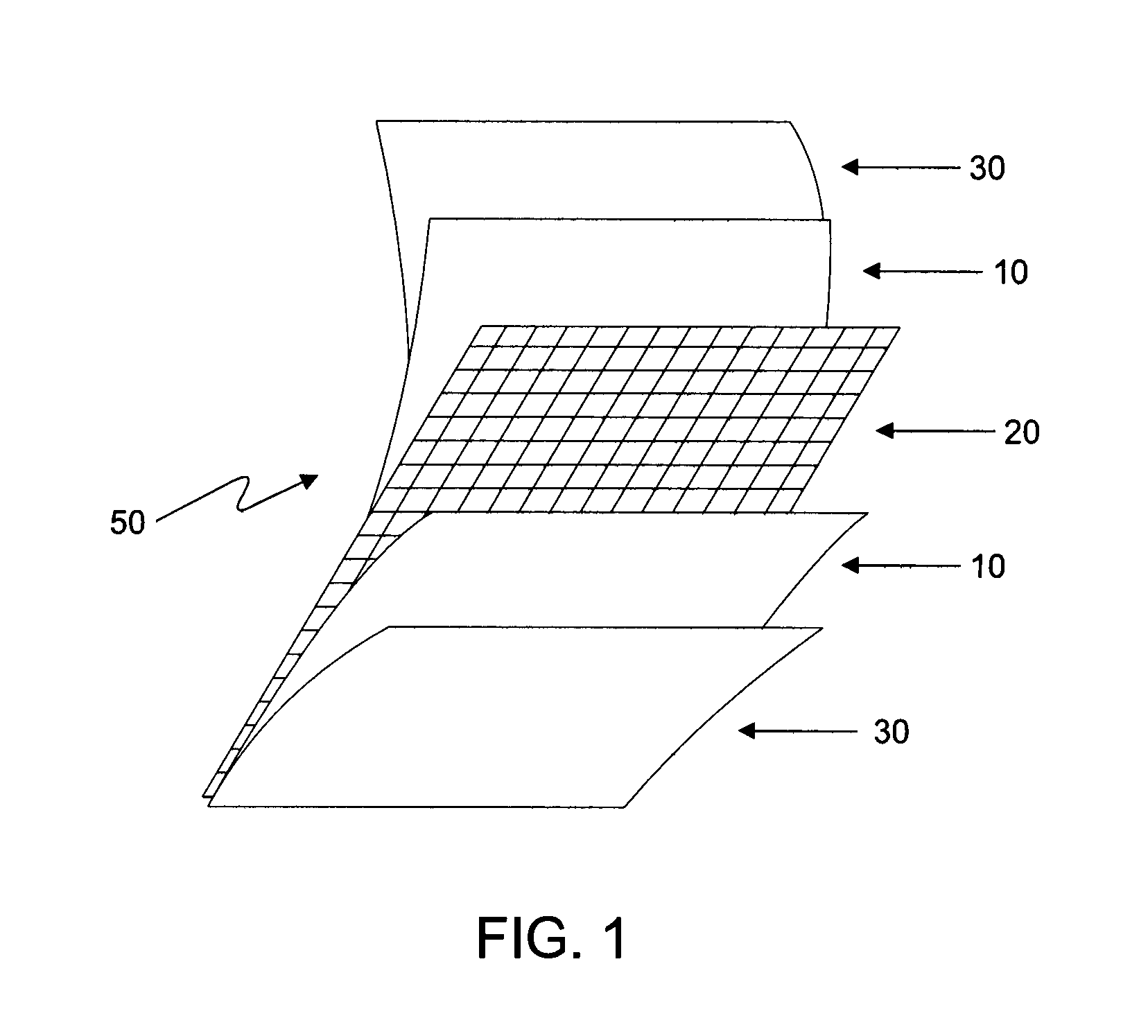

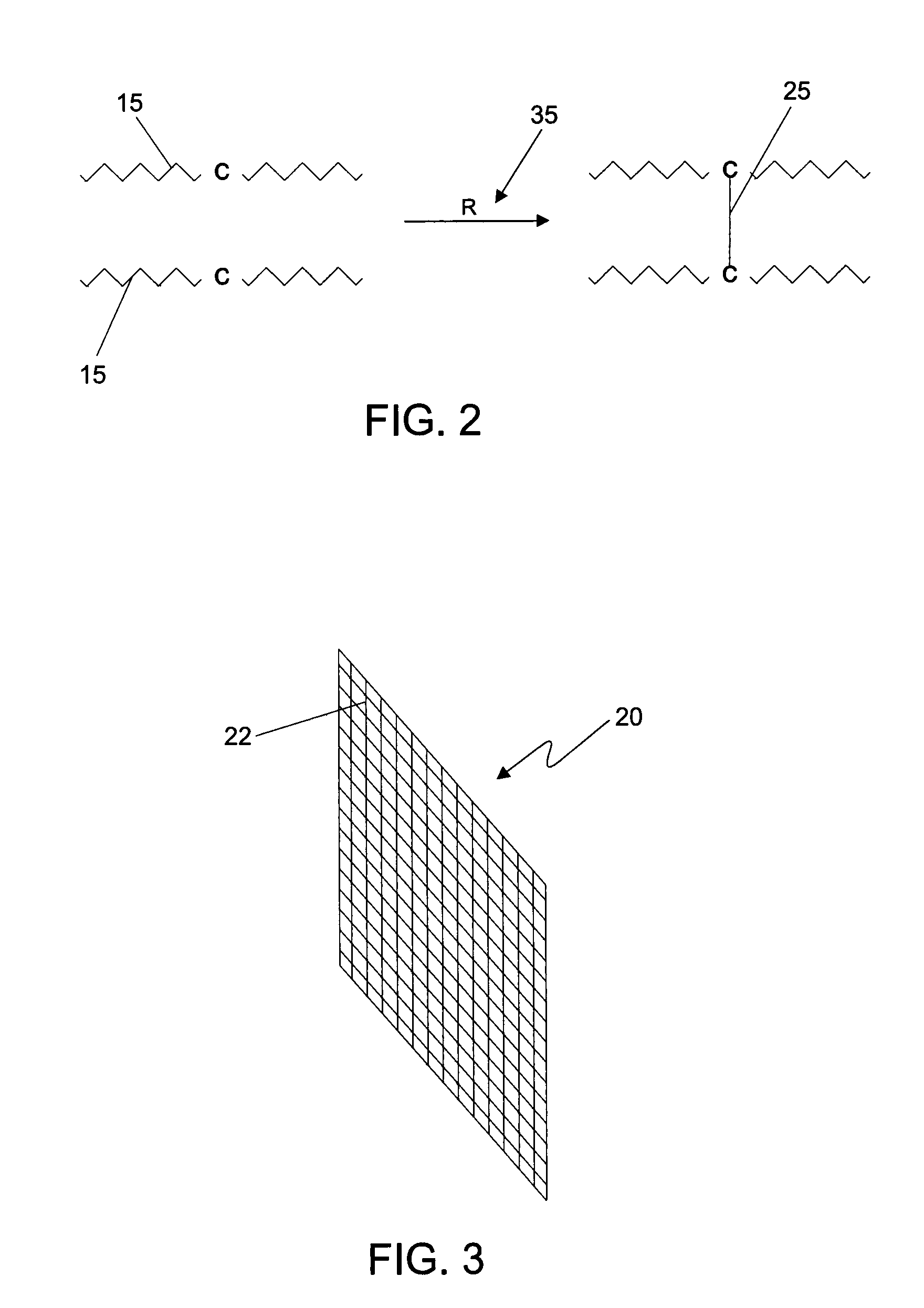

Radiopaque carbon-carbon linked elastomeric materials, preparation method and uses of same

InactiveUS20140106635A1Reduce mechanical resistanceHigh resistance and integrityWarp knittingAnimal housingElastomerAdhesive

An elastomeric matrix impregnated with at least 70% by weight of a high atomic number radiopaque substance, and cured with an organic peroxide, to form carbon-carbon links between elastomer molecular chains. The radiopaque elastomeric matrix may be used to create a flexible, lightweight, carbon-carbon linked, multilaminated protection material against ionizing radiation. The multilaminated protec tion material may include a mechanical reinforcement cloth layer to avoid material expansion or rupture; and additional external elastomeric layers for protection against aging, physical, biological and chemical hazards, as well as allowing mechanical memory of the material and easy cleaning, desinfection and sterilization. These layers are directly merged or incorporated into a single, fused sheet with the radiopaque elastomeric matrix, without the use of glues or adhesives, during a cure and pressure application wherein the elastomer molecules create reticulated carbon-carbon links between the internal and external elastomeric layers and through the pores of the reinforcement layer. The multilaminated material allows production of colored, flexible, lightweight, durable radiation protection articles for medical, dental, and industrial uses.

Owner:PLANIDEIA CONFECCAO DE VESTUARIO DE PROTECAO LTDA - EPP

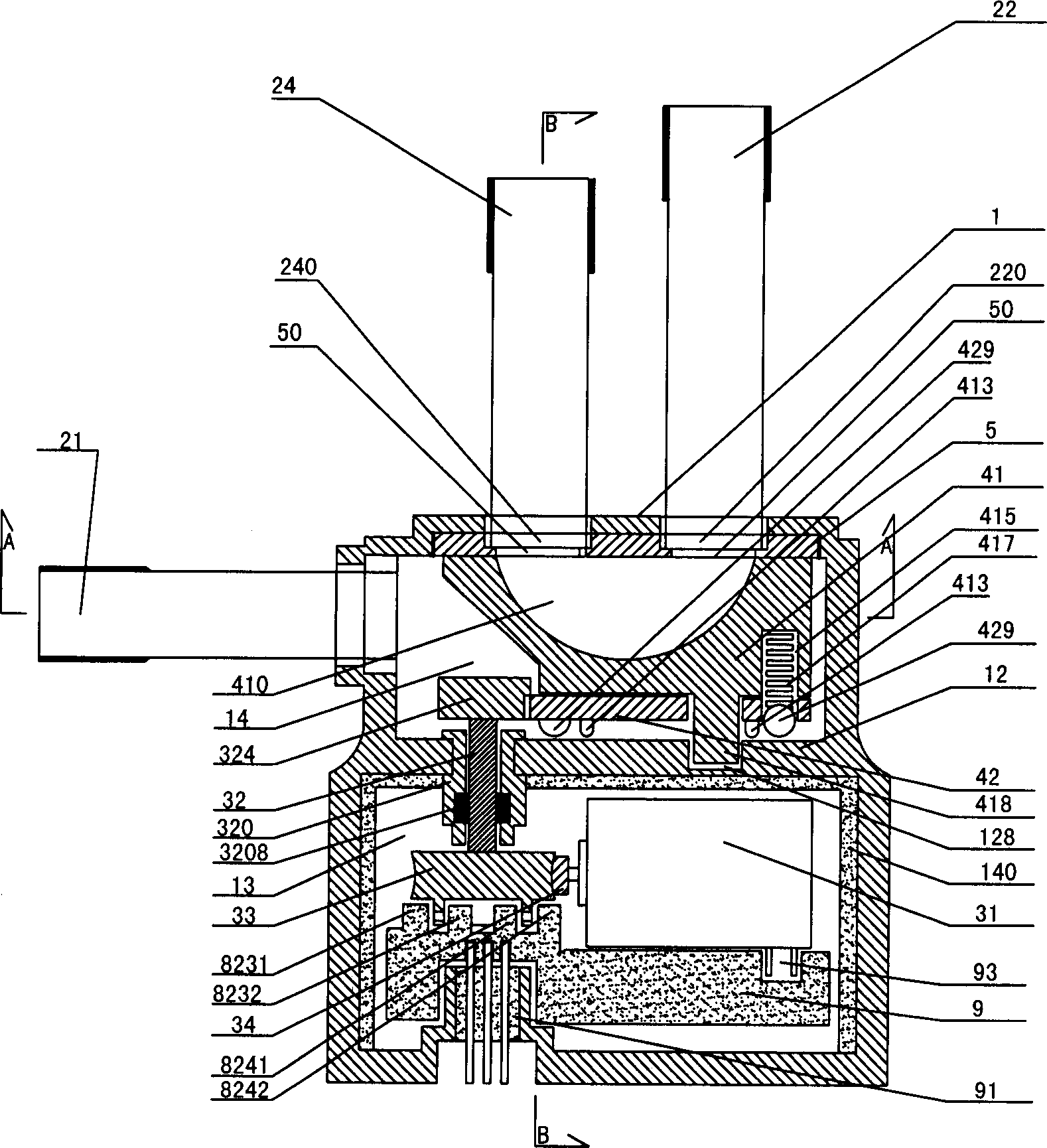

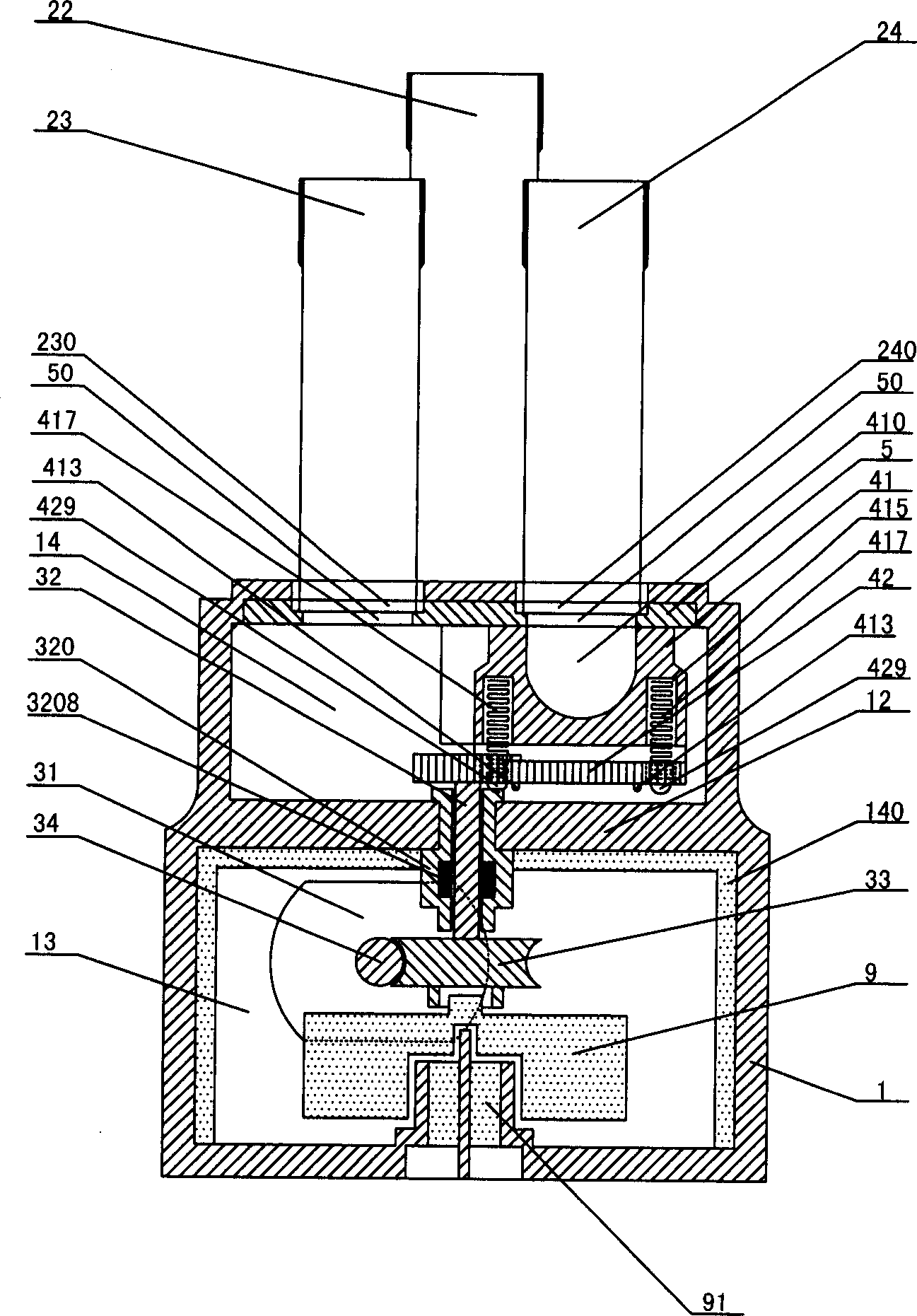

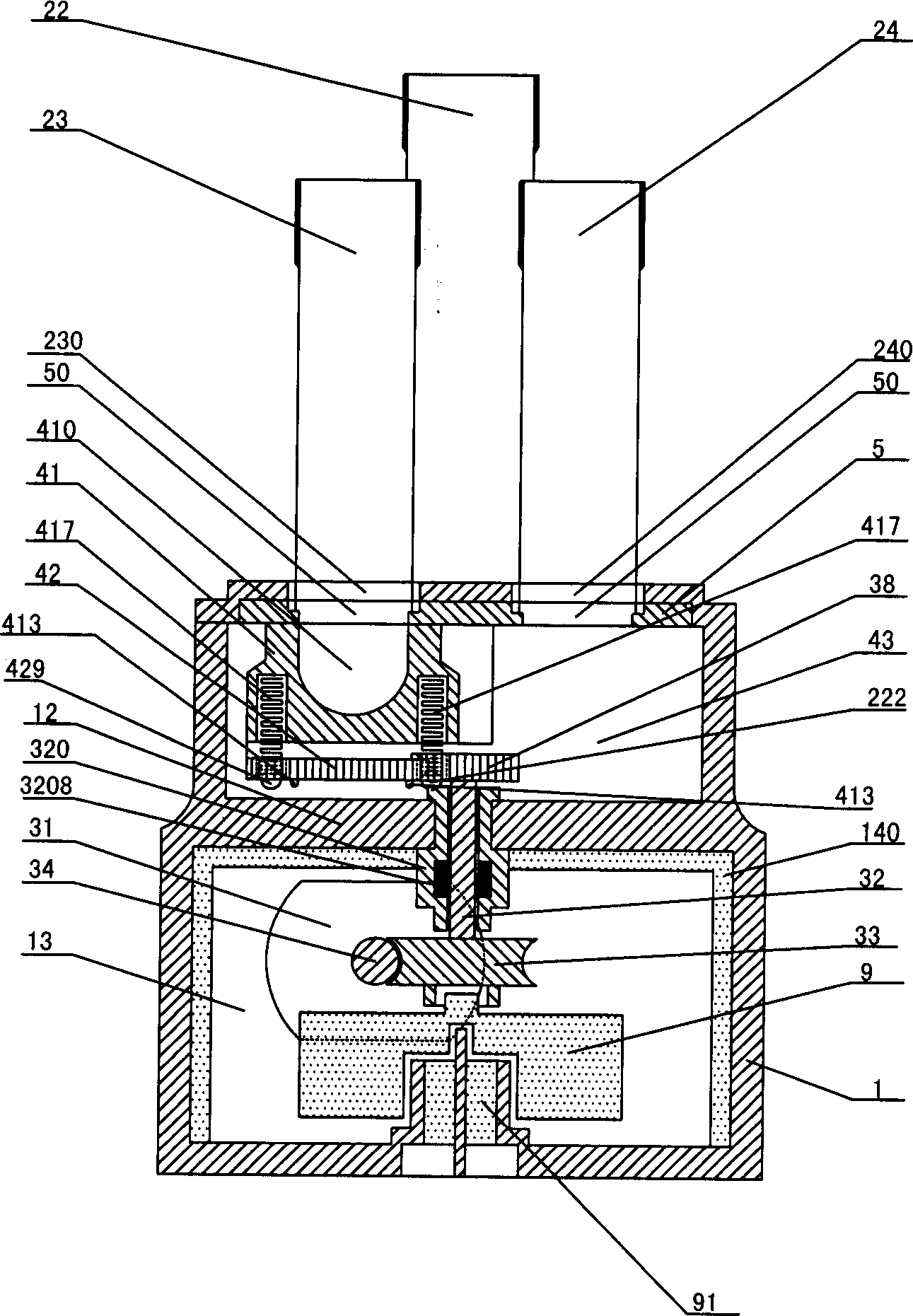

Photoelectrically controlled eccentric-positioning one-arm four-way reversing valve

InactiveCN1807945AReduce mechanical resistanceIncrease armOperating means/releasing devices for valvesElectronic switchingMechanical resistanceDrive shaft

The invention relates to a photo-electric control eccentric positioning single-arm four-way makeshift valve, which comprises a valve body which is divided into a high pressure chamber and a transmission valve via the baffle plate; a inlet tube connecting the valve body; a shared tube; the first exchange tube, the second exchange tube; and a transmission device and a makeshift device individually arranged at he transmission chamber and the high pressure chamber. Wherein, the transmission device comprises a motor and a transmission axle; the baffle plate has a axial hole; the shared tube, the first exchange tube and the second exchange tube are in triangle arranged in the high pressure chamber; the makeshift device comprises a single-arm swing block and a teeth plate which are contacted tightly; the single-arm swing block has a low pressure gas groove to cover the tube mouths between the shared tube and the first / second exchange tube; the bottom of single-arm swing block that relative to the mouth of shared tube is mounted on the baffle plate via the axle; the tope of transmission axle has a speed-reducing gear; the teeth plate has saw-tooth at its front; and the speed-reducing gear is meshed with the teeth plate. The invention uses the eccentric positioning to reduce the mechanical resistance in the transmission and improve the efficiency and accuracy.

Owner:文定国

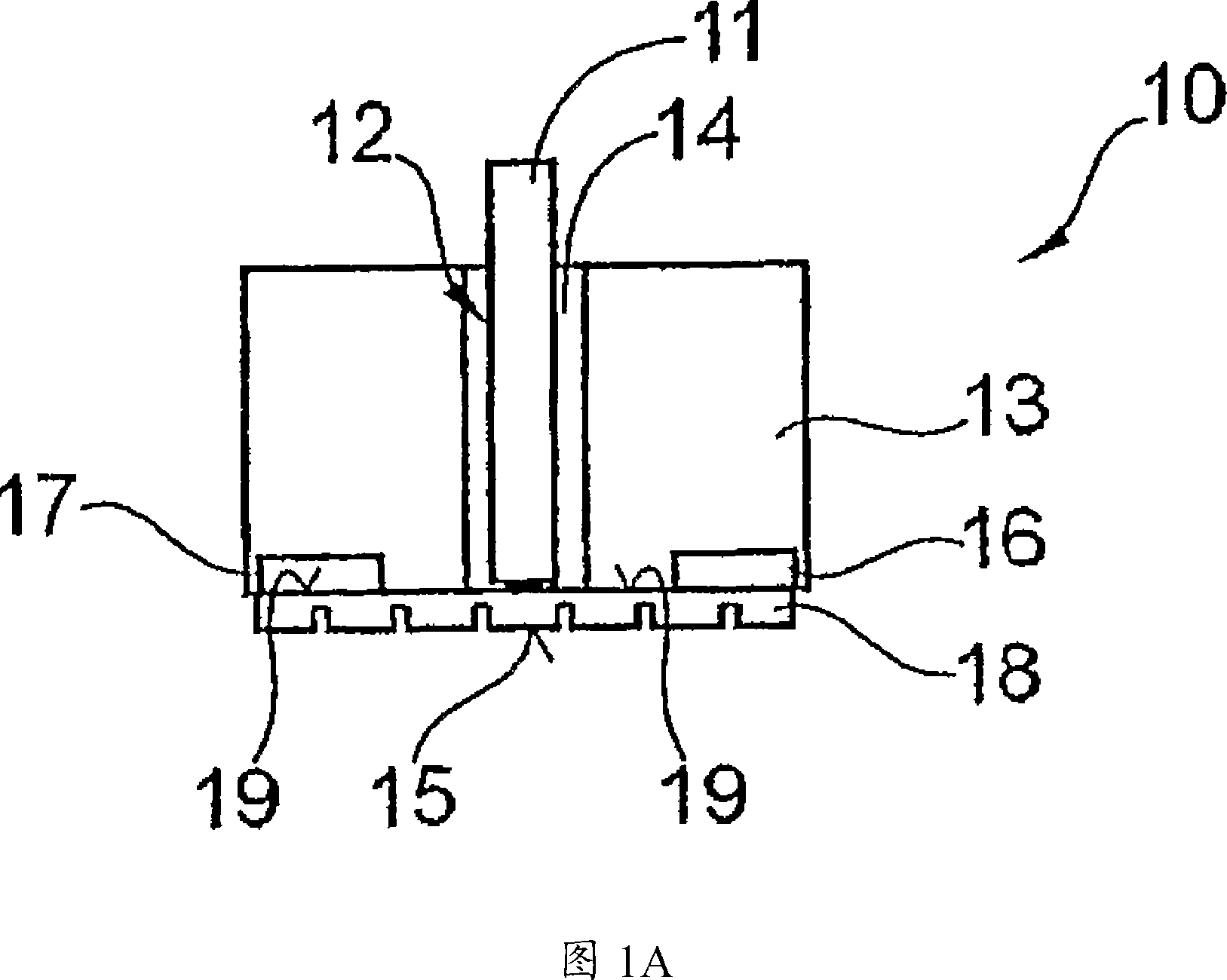

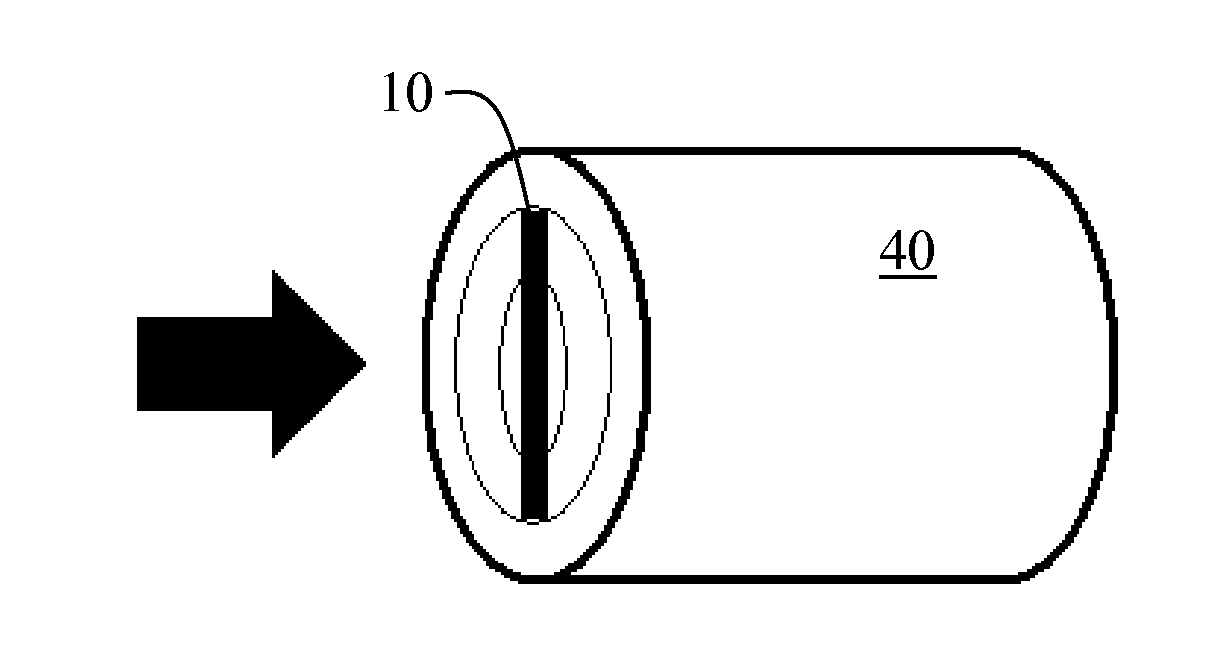

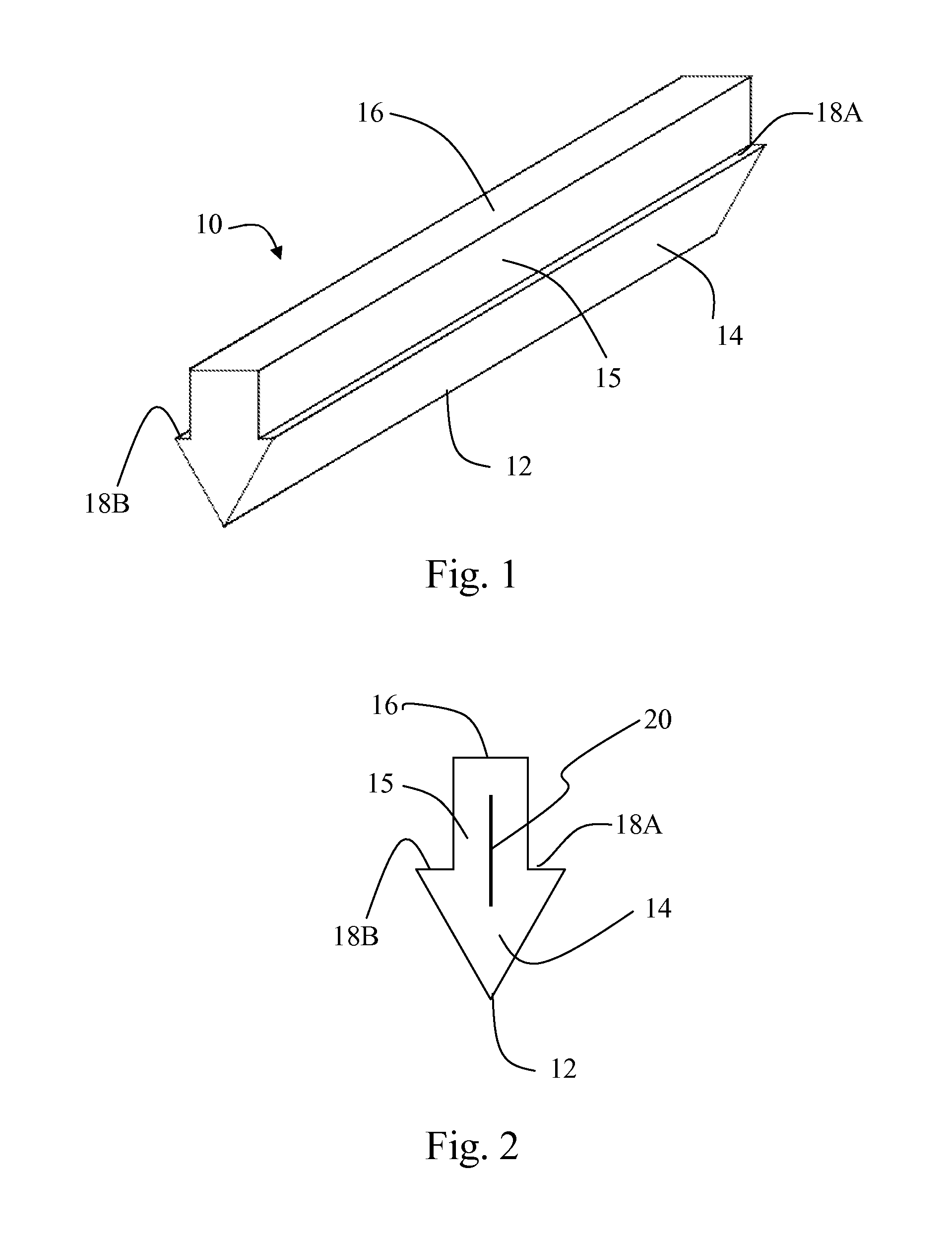

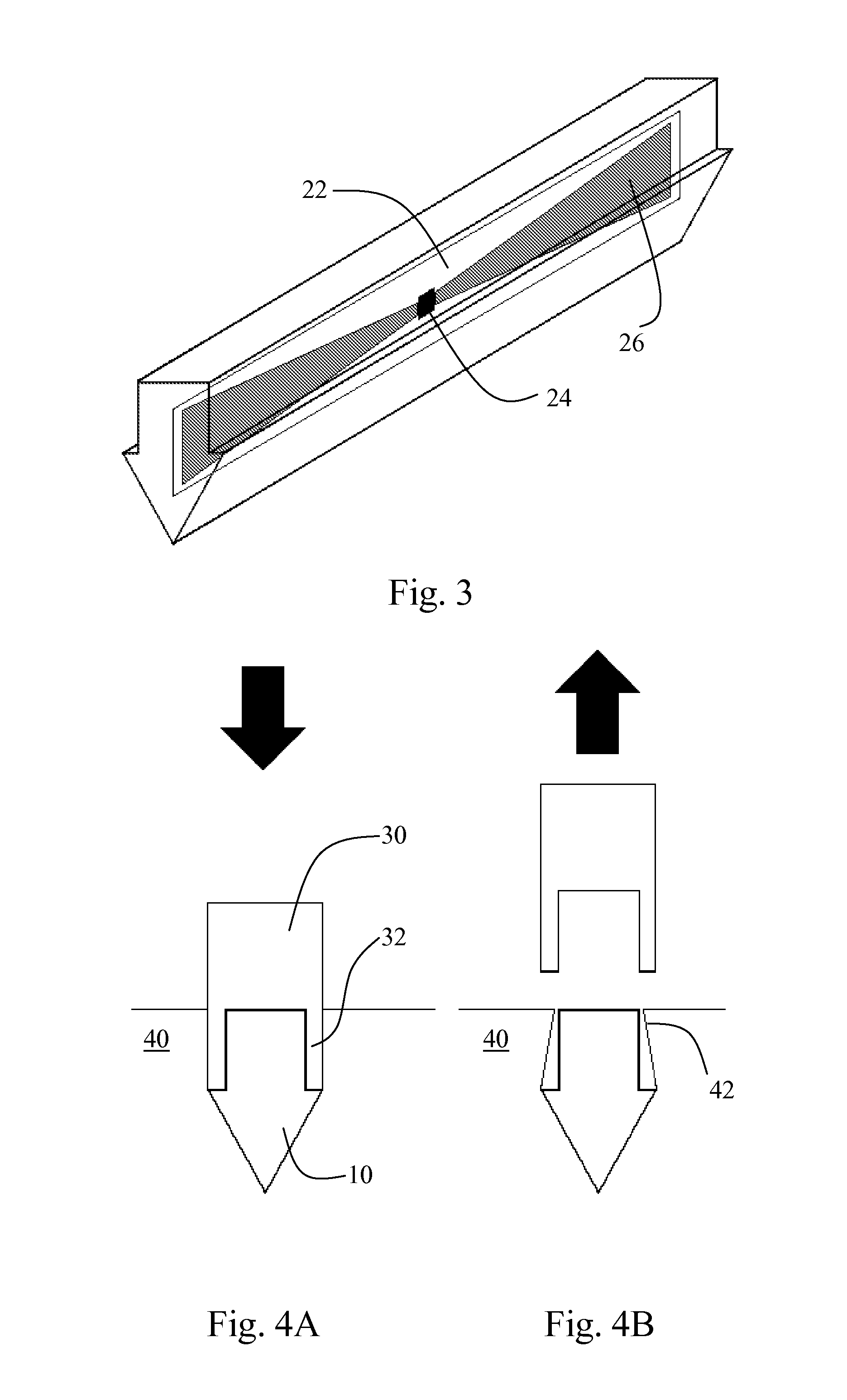

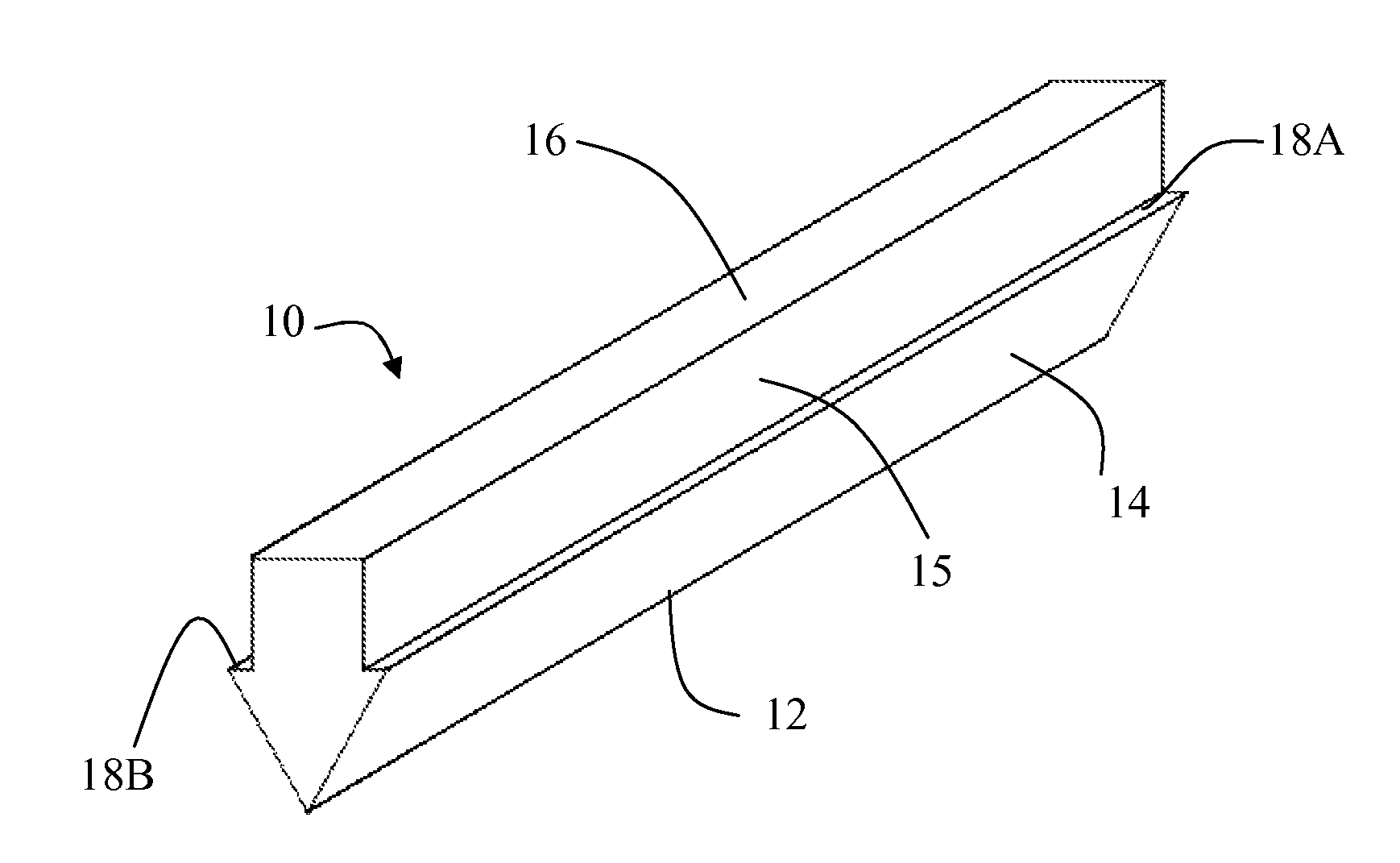

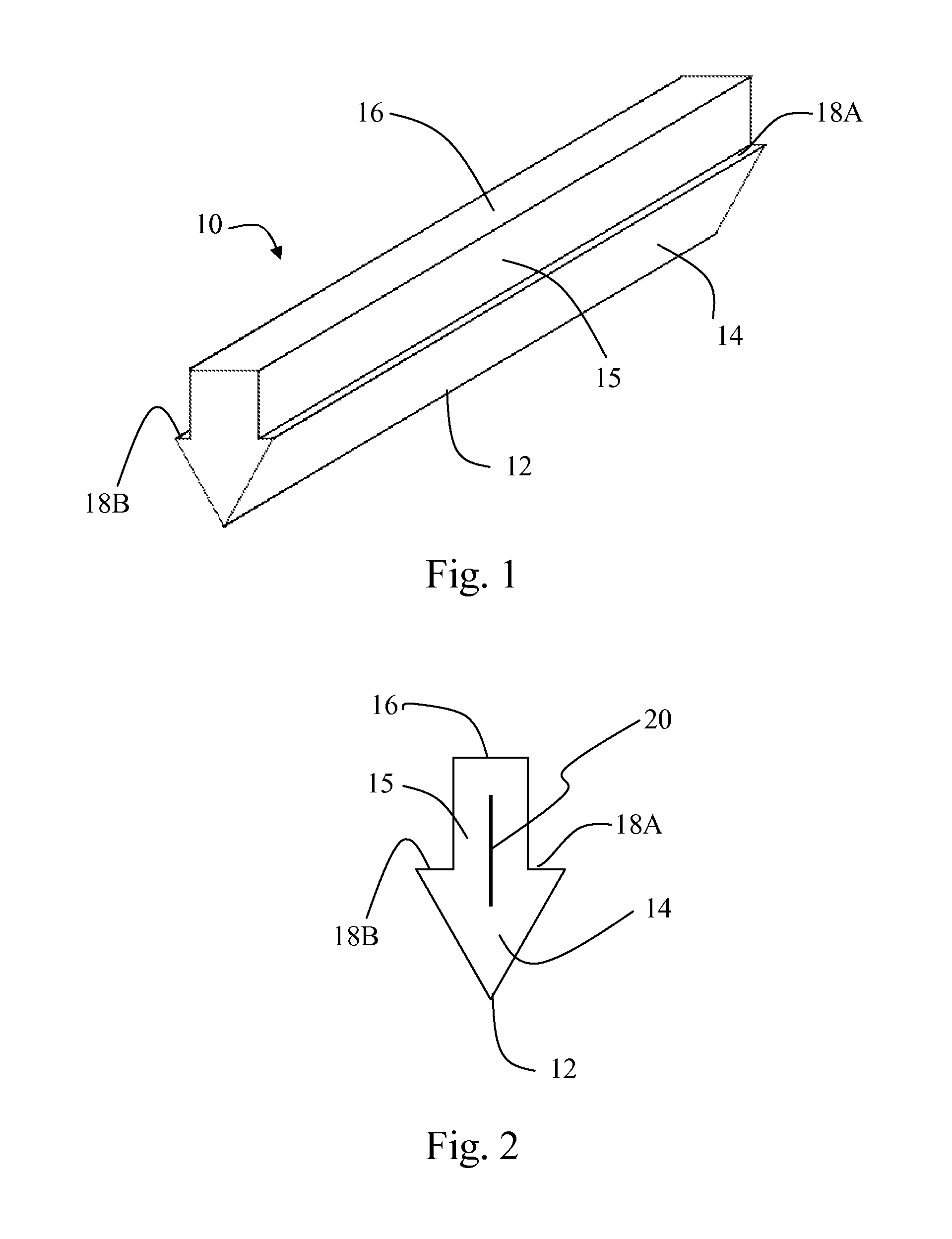

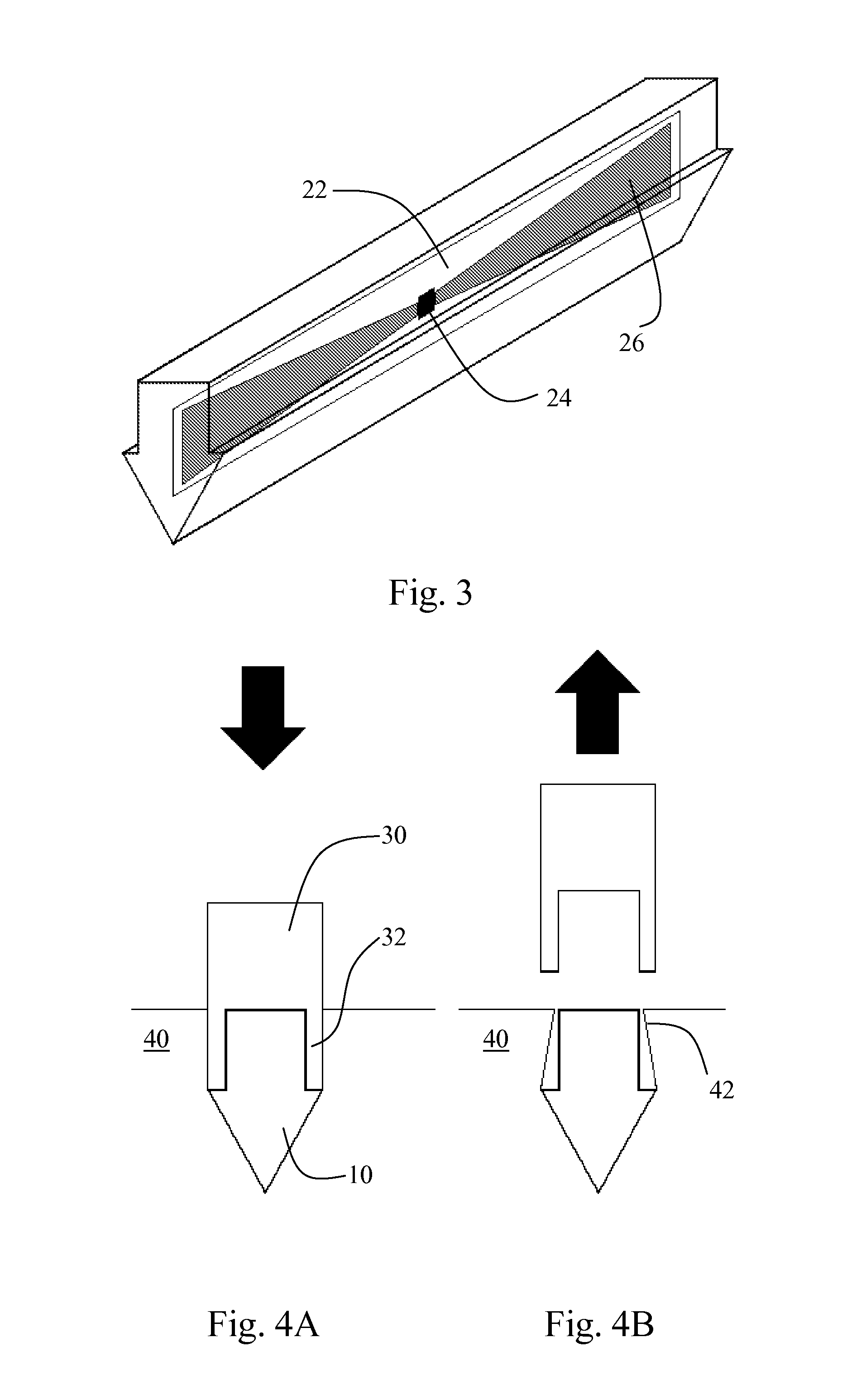

Transponder, transponder kit, method of applying the transponder and product comprising the transponder

InactiveUS20110315777A1Easy to insertSafely accommodatedSensing record carriersForestryPondingEngineering

The invention concerns a transponder (10), kit and method for marking wood material, such as logs. The transponder comprises a rigid casing adapted to be inserted into the wood material by means of impact, the casing comprising a wedge-shaped first edge (12) adapted to penetrate into the wood material due to said impact, and a second edge (16) opposite to the first edge, the first and second edges (12, 16) defining an insertion direction of the transponder, and radio-frequency trans-ponding means (20) covered by the casing. According to the invention, the casing is elongated in a direction perpendicular to the insertion direction. The transponder is easily applicable into a log and stays well within the log.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT +1

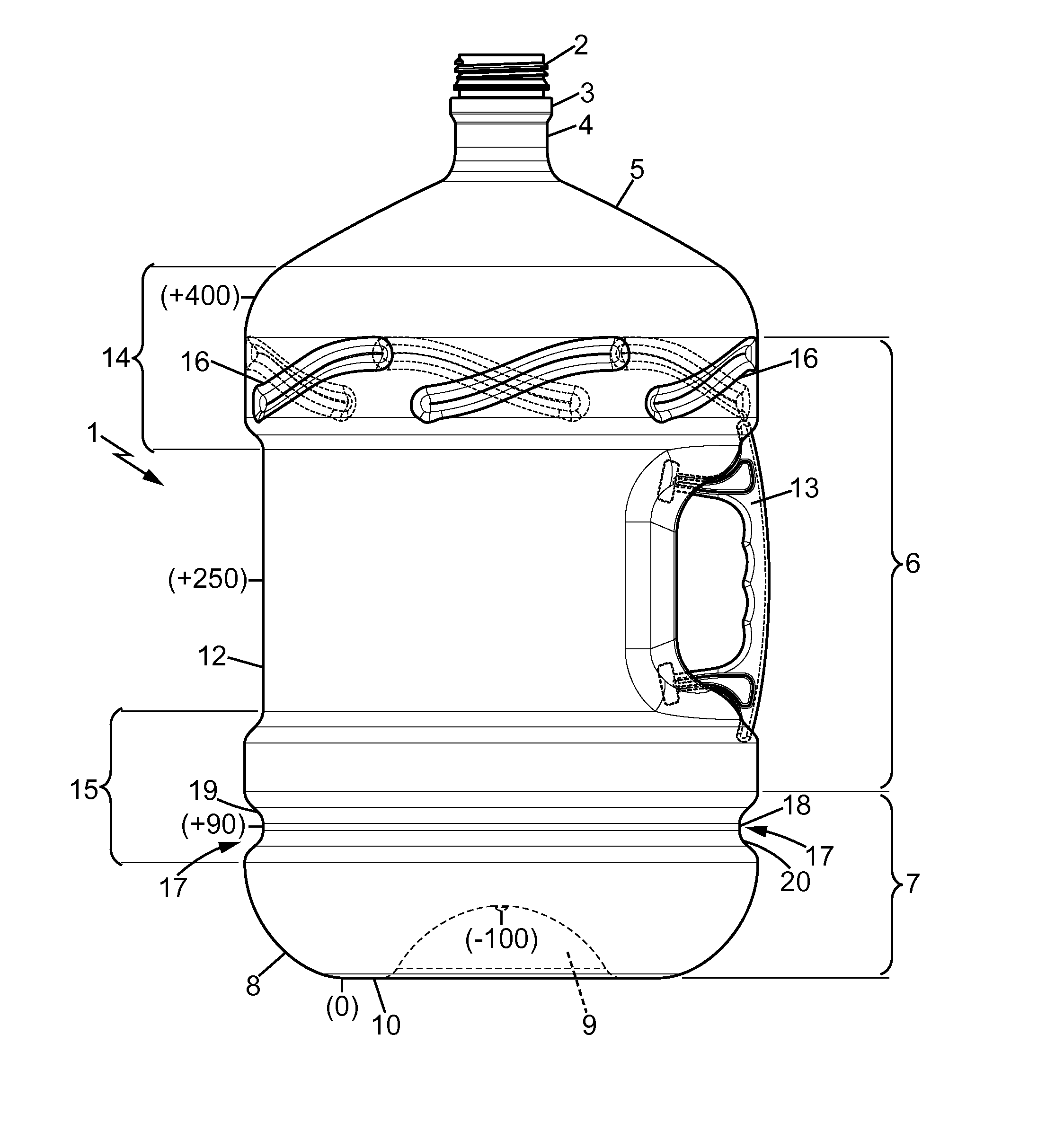

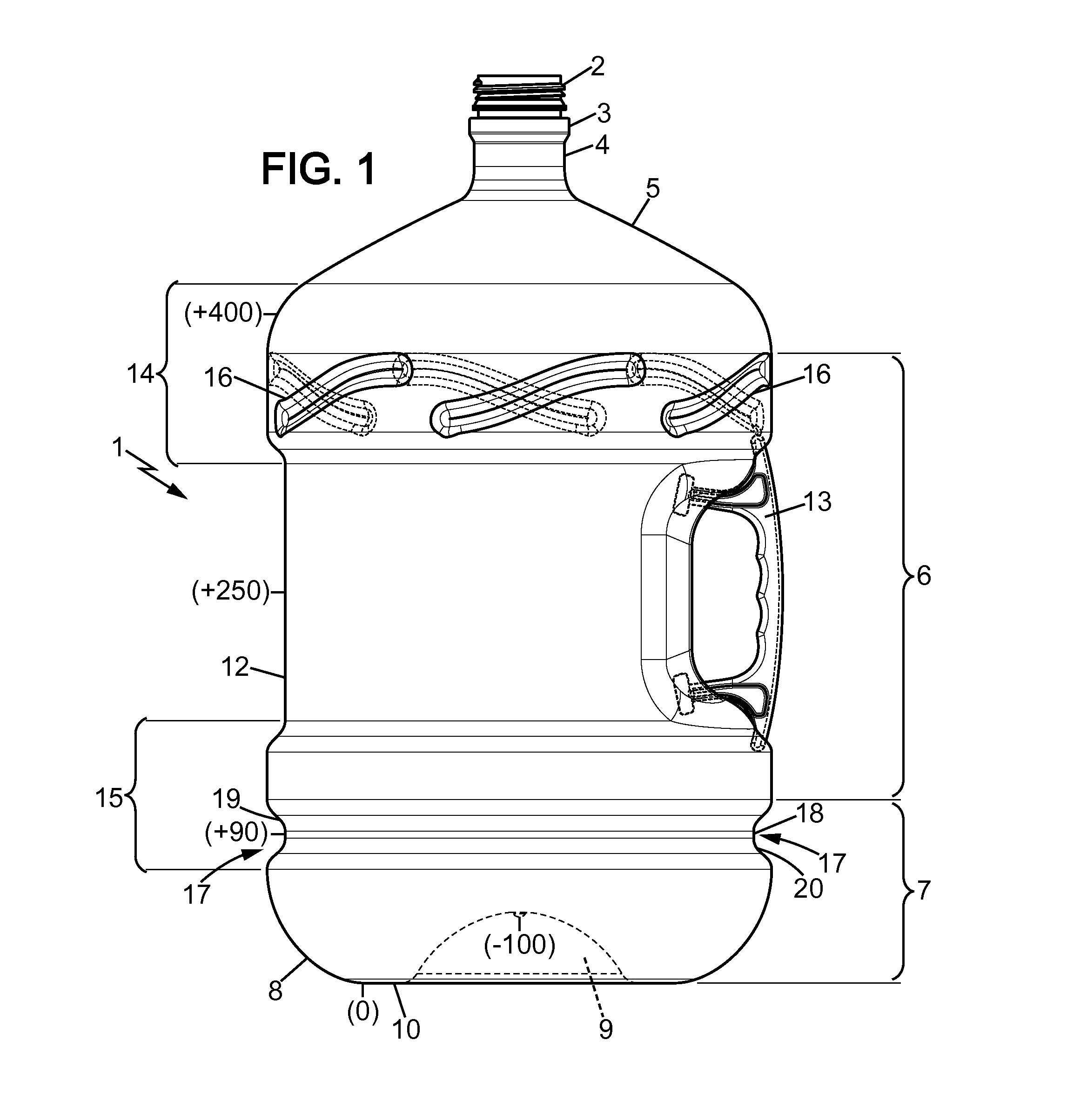

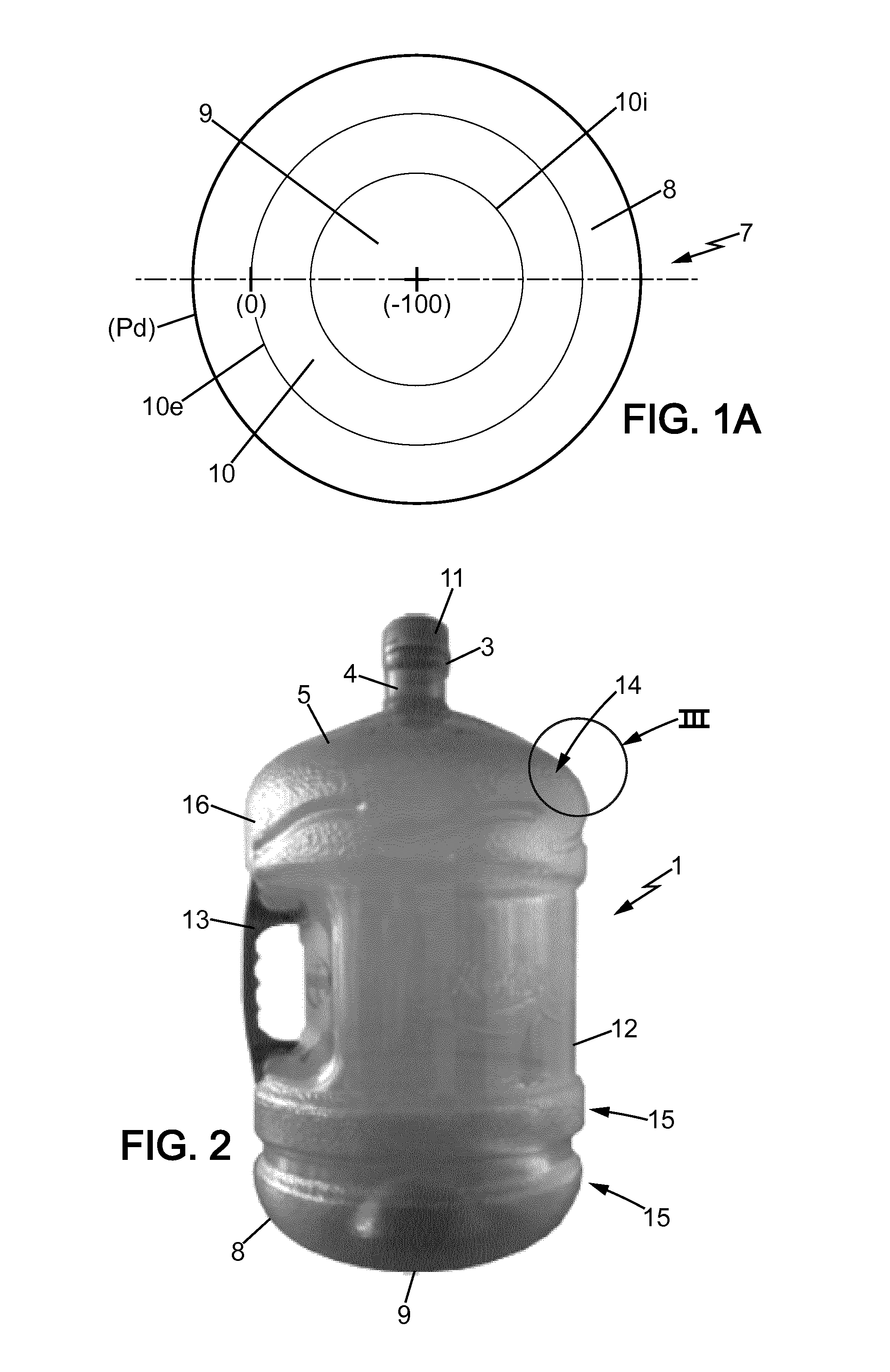

Blow Moulded Bottle, Method of Manufacturing and Mould

InactiveUS20150151869A1Increase crystallization rateGood mechanical resistanceBottlesContainer/bottle contructionEngineeringMedian plane

A blow moulded plastic bottle includes a neck, a shoulder, a tubular body portion, and an integral bottom structure including: a terminal curved portion, an internal axially inwardly directed dome, and an (annular) base joining the terminal curved portion to the dome; wherein: a spline comprises a flat part in the base plane (Pb) onto the bottle rests when it stands up; the height (h1) between (Pb) and the apex of the dome, the height (h2) between (Pb) and the spline diametral median plane (Pd) which is in the middle of the spline (17) and which is parallel to (Pb), and the maximum external diameter (Dm) of the tubular body portion, being so that [(h1) / (Dm)]*100 is comprised between 14.0 and 16.0% and (h1)<(h2)≦3.5(h1).

Owner:DES EAUX MINERALES DEVIAN

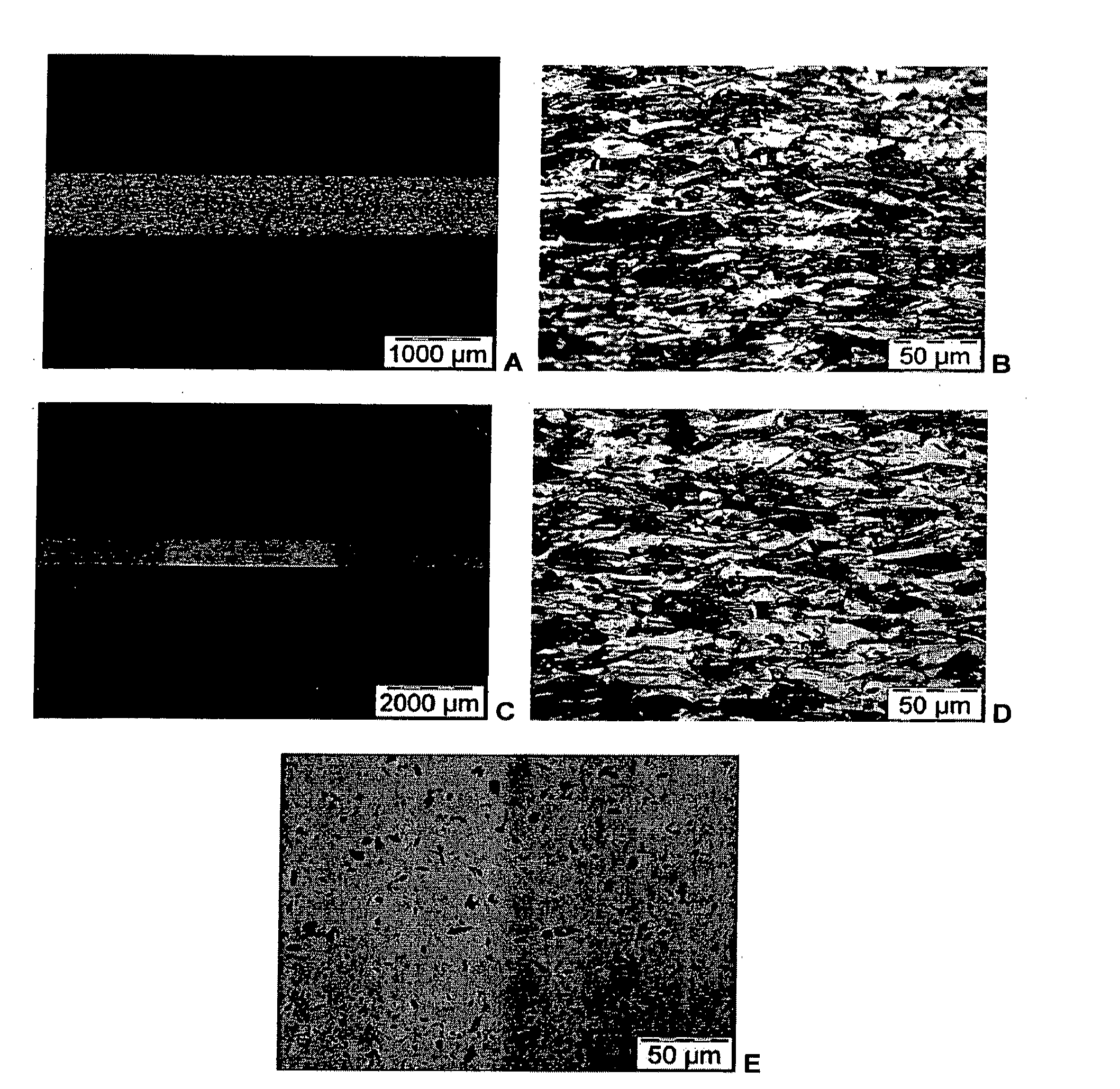

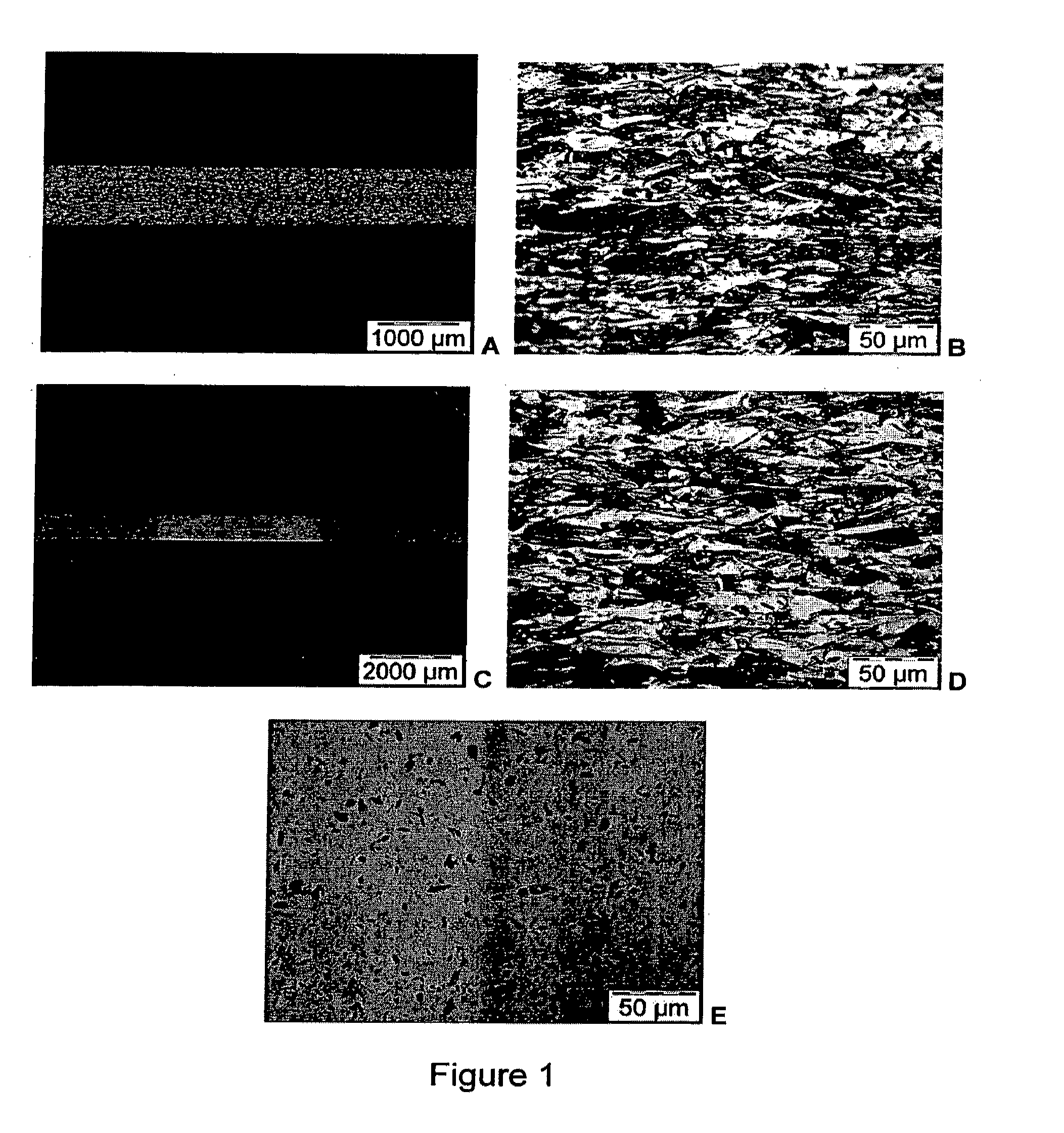

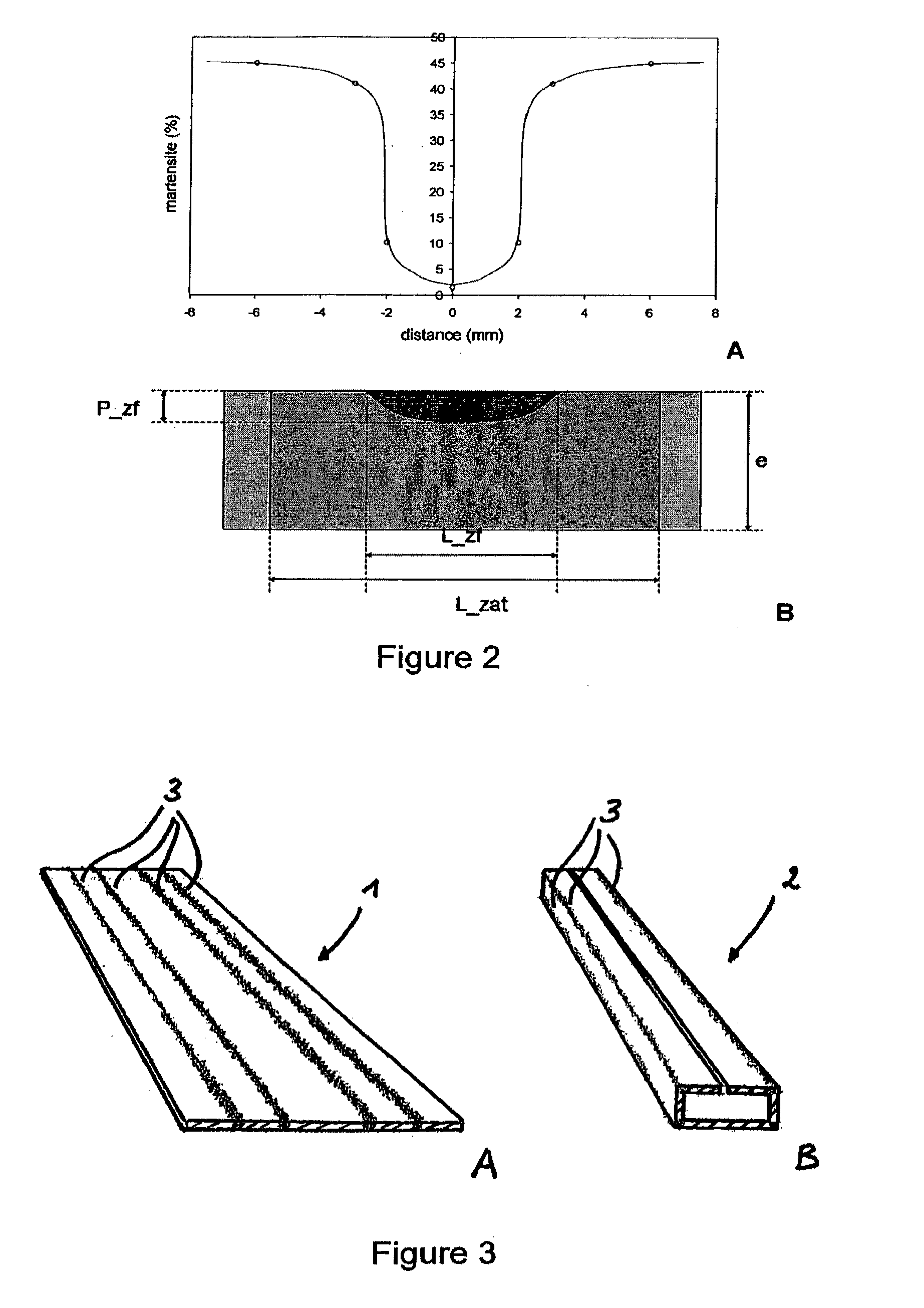

Stainless steel having local variations in mechanical resistance

InactiveUS20120237387A1Help shapeGood mechanical resistanceElectron beam welding apparatusLaser beam welding apparatusMechanical resistanceMartensite

The disclosure mainly relates to a stainless steel sheet containing a minimum of 10.5% by weight of Cr and a maximum of 1.2% by weight of C, the microstructure of which is martensitic or austeno-martensitic and comprises at least 2% by volume of martensite, essentially characterized in that it comprises at least one local portion of lesser mechanical resistance, having a martensitic content at least 10% lower than that of the remainder of said sheet; said local portion being at least partly with a thickness equal to that of said sheet. The disclosure also relates to a method for manufacturing this steel sheet and to a steel part which may be obtained by deformation of this sheet.

Owner:APERAM

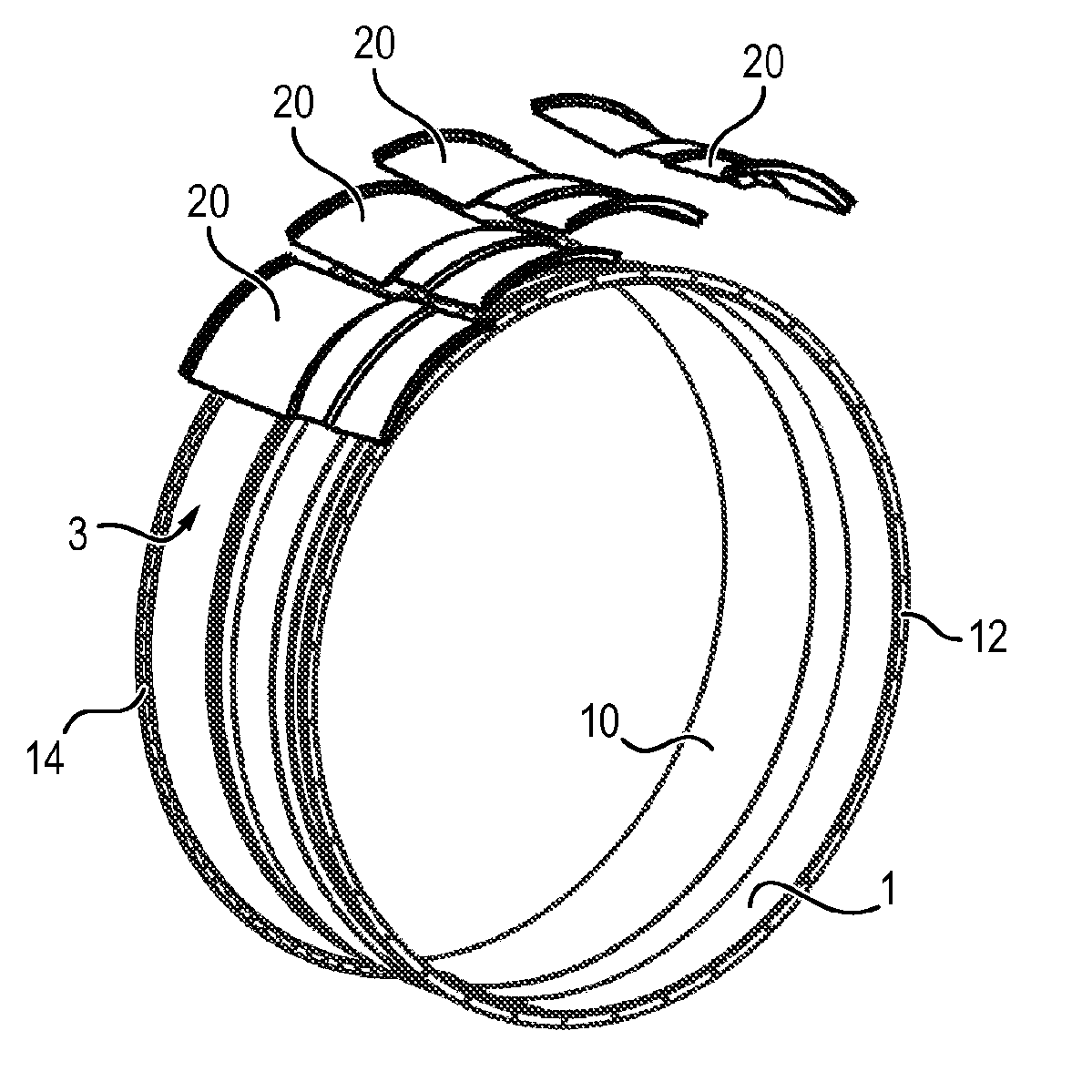

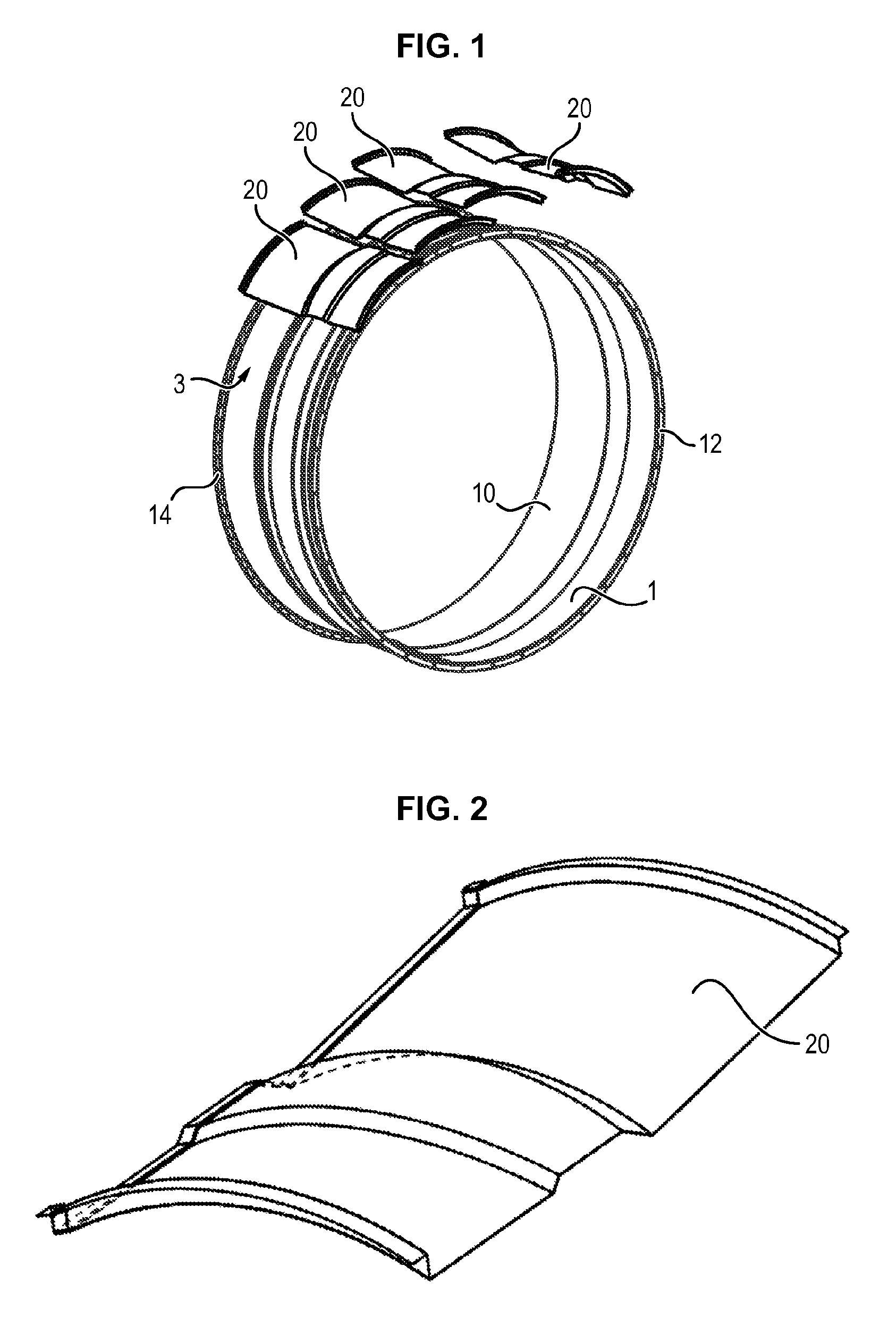

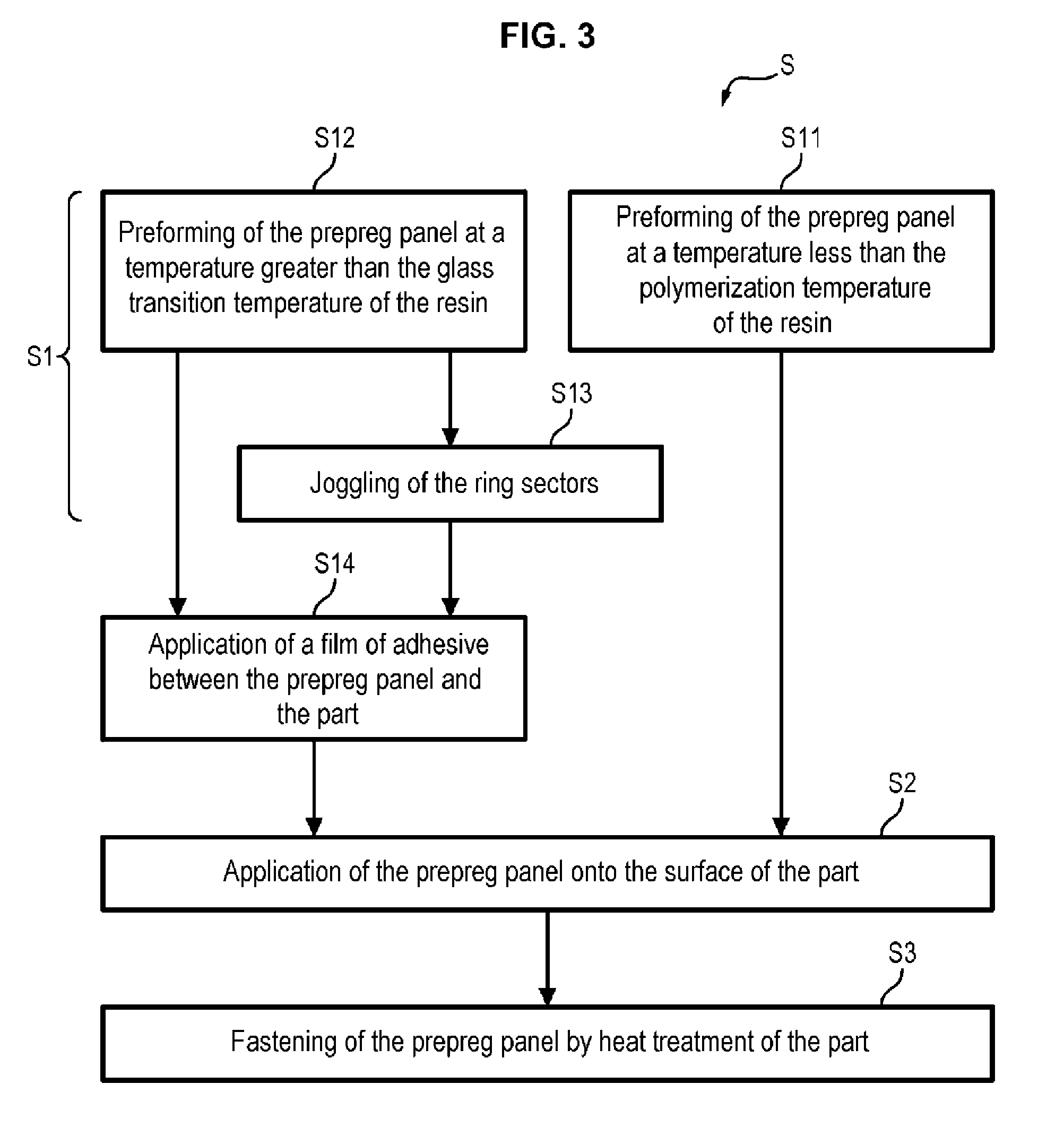

Fire protection of a part made of a three-dimensional woven composite material

ActiveUS20160327061A1Reduce mechanical resistanceReliable and efficaciousEngine manufacturePump componentsFire protectionEngineering

The invention relates to a method for fire protection (S) of a part (1) of a gas-turbine engine made of a composite material comprising a main fibrous reinforcement compregnated by a main matrix, the protection method (S) comprising the following steps: preforming (S1) a panel of pre-preg (20) such as to grant same a shape corresponding to the shape of a surface (3) of the part (1) to be protected against fire, said panel of prepreg (20) comprising a secondary fibrous reinforcement compregnated by a secondary matrix; applying (S2) the panel of prepreg (20) thus preformed to the part (1); and securing (S3) the panel of prepreg (20) to the surface (3) by thermal treatment of the part (1) provided with said panel of prepreg (20) in order to obtain a fire-protection layer (2).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

Simplified gearbox mechanism

The improved gearbox mechanism of the present invention includes a plurality of cam-actuated simplified gear block assemblies, which transfer power from a power shaft to a secondary or output gear element. Each gear block assembly includes a gear block having a surface that periodically interfaces with a secondary or output gear element. In a preferred embodiment the interface surface comprises a plurality of projections or teeth which correspond to complementary projections or gear teeth on the output gear element. Each gear block assembly further includes a gear block, a torque lever arm, cam followers and / or a socket, which connect or link the gear block to a cam assembly, which in turn is connected to a power source. The cam assembly includes about its circumference a unique pathway or groove for each linkage assembly of a particular gear block assembly so that the movement of the gear block may be controlled in two dimensions in accordance with a certain design parameter.

Owner:MOTUS LABS LLC

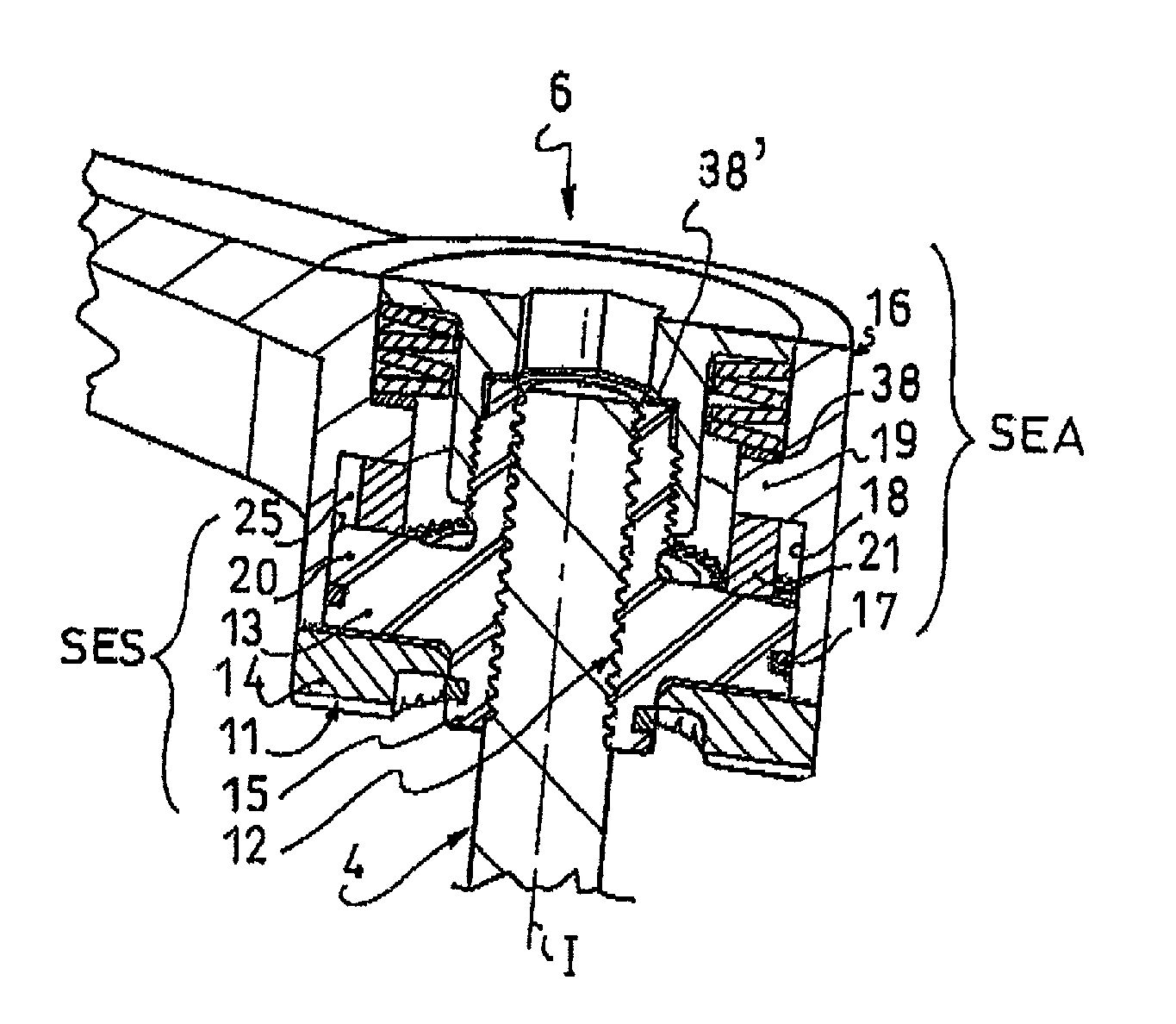

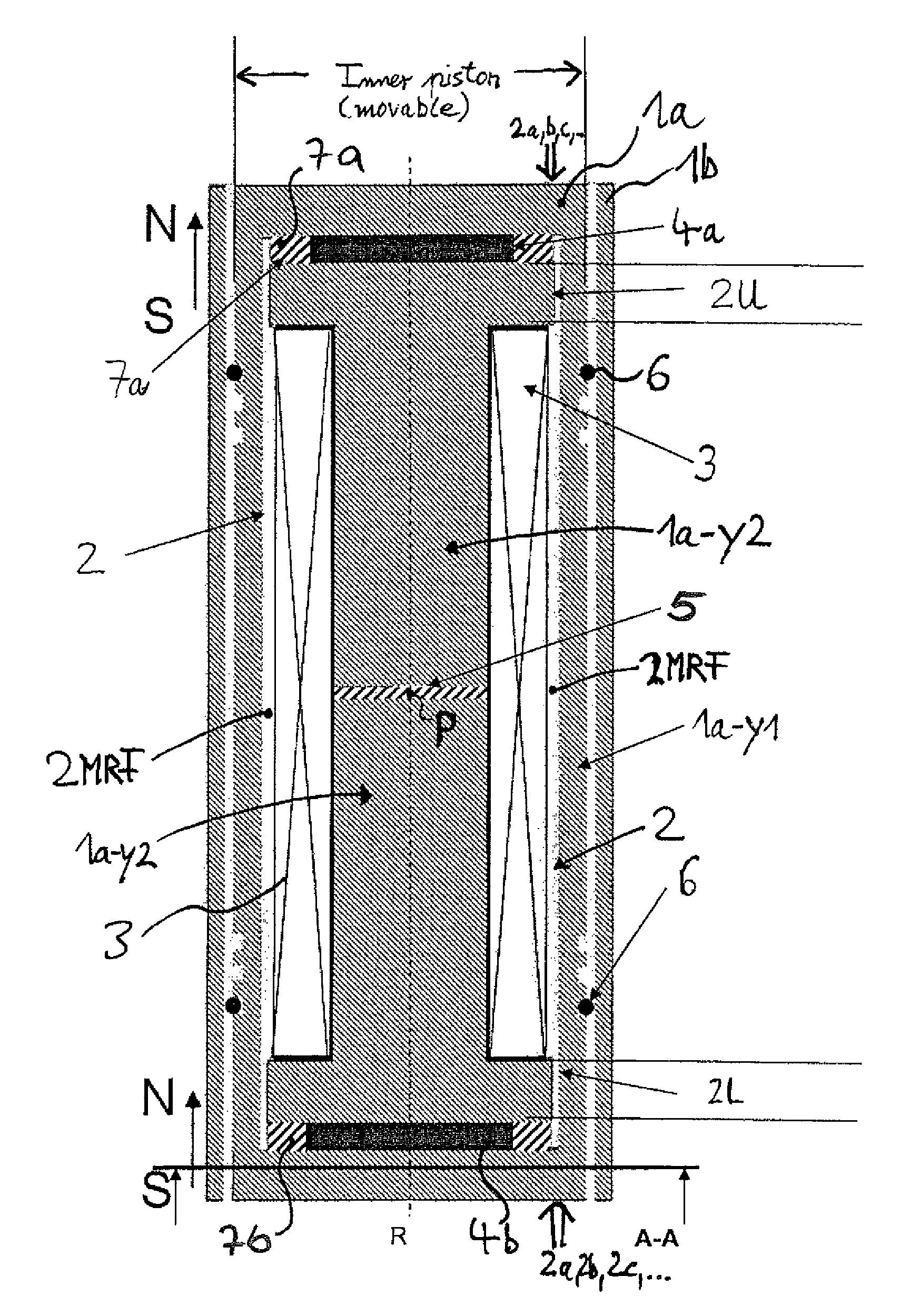

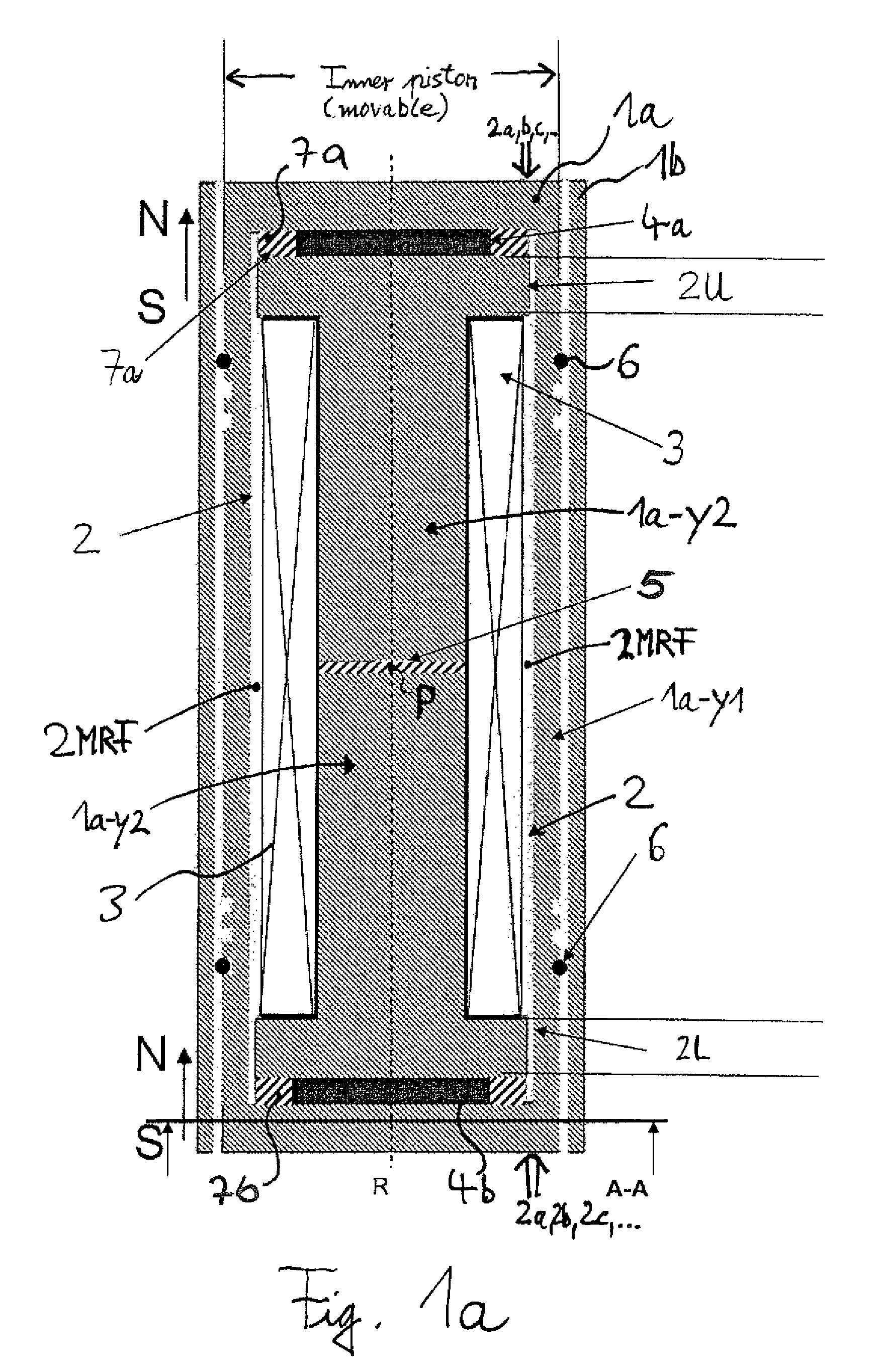

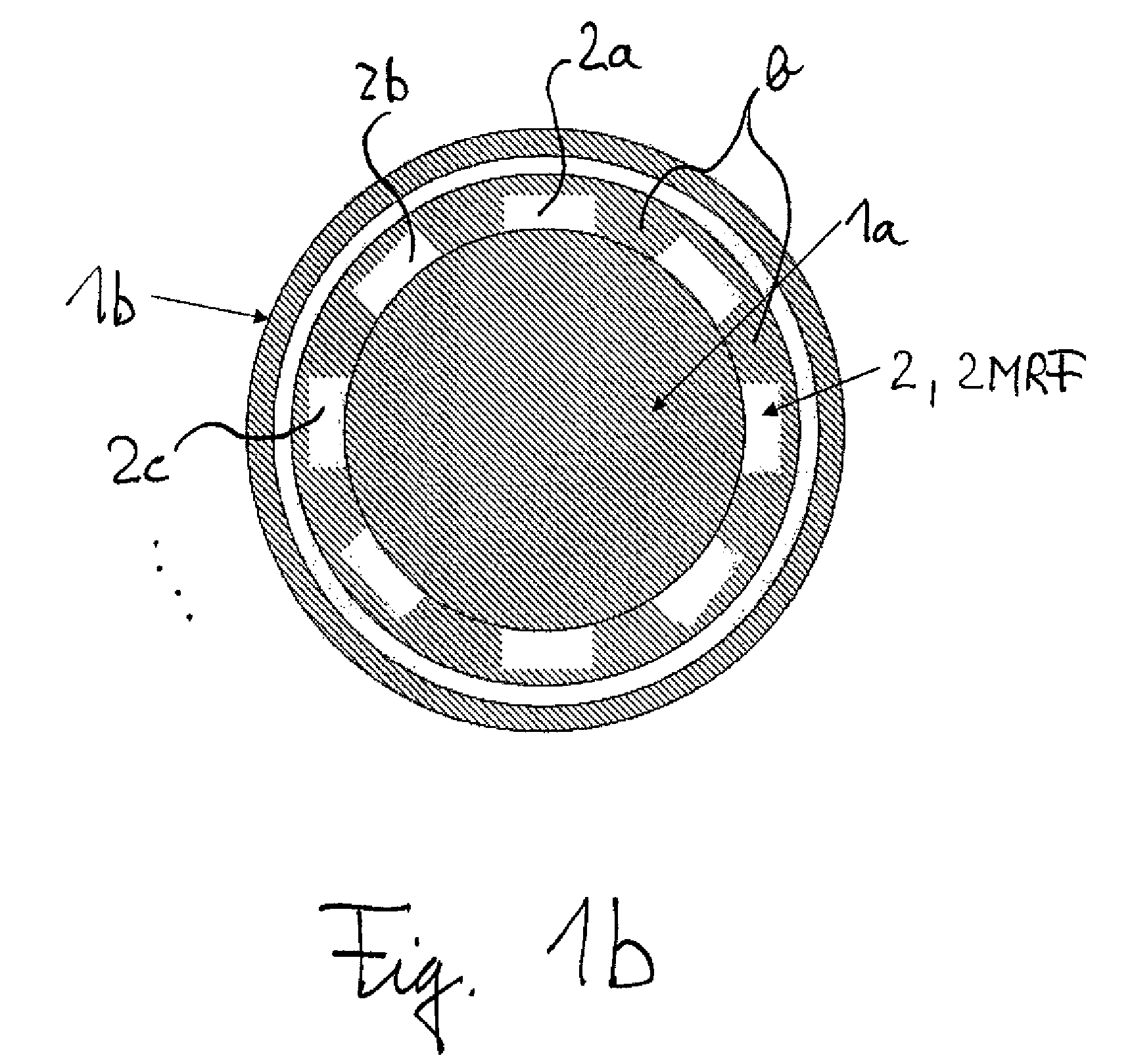

Magnetorheological force transmission device

InactiveUS8205728B2The degree of freedom becomes largerBehaviorSpringsNon-rotating vibration suppressionEngineeringMagnetic flux

The present invention discloses a magnetorheological force transmission device which comprises at least two solid body parts adapted to be moved in a substantially translational manner against each other, and an MRF gap, which is at least partially fillable and / or filled with a magnetorheological material 2MRF, the MRF gap being arranged at least partially inside one of or both of the two parts and / or being arranged at least partially in-between the two parts, and which is characterized in that the magnetic circuit system of the magnetorheological force transmission device being designed and / or disposed to generate a magnetic flux within at least part of the MRF gap comprises at least one electromagnet, at least one permanent magnet and at least one magnetic-field-balancing insert and / or magnetic isolator.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

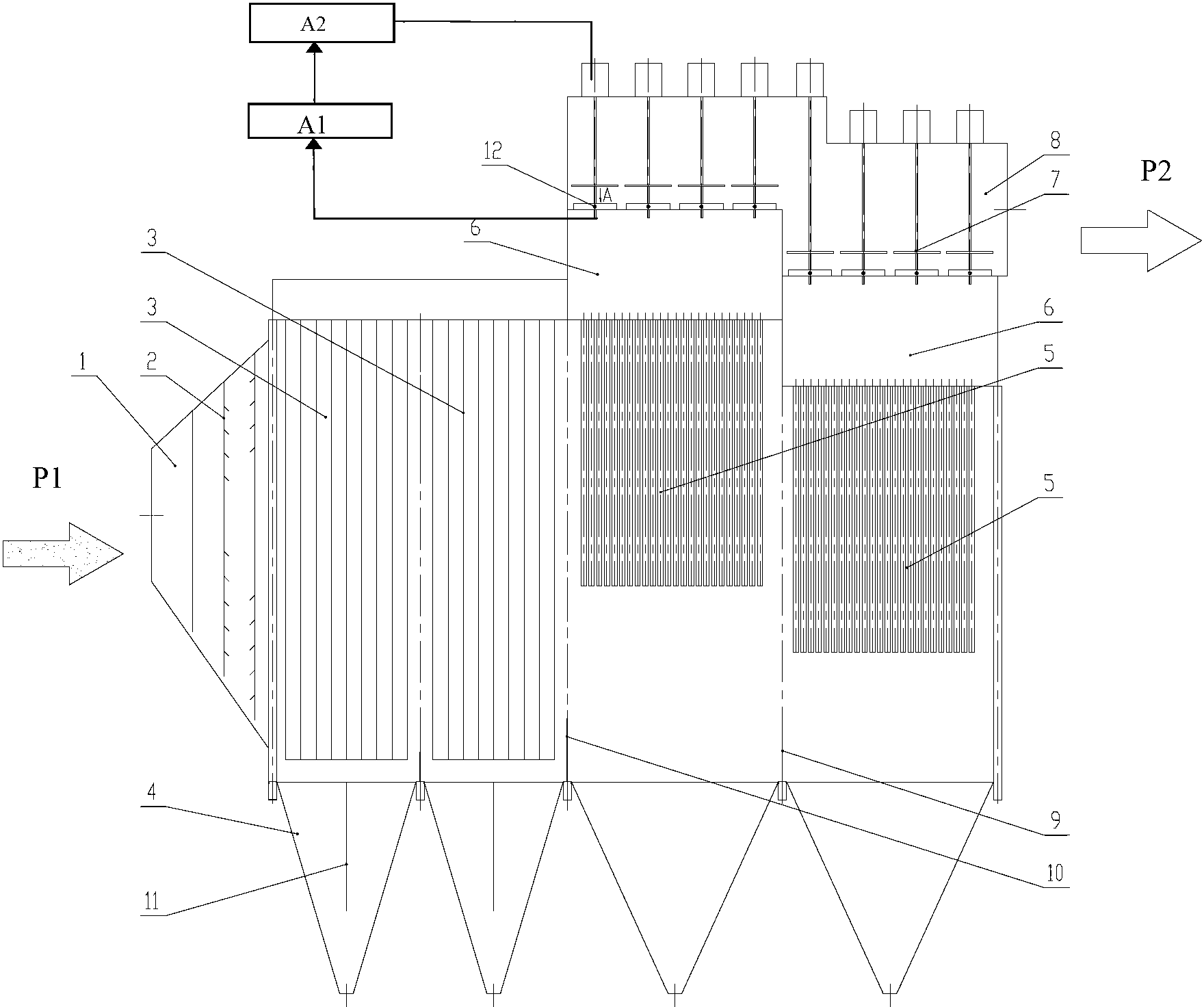

Smoke dust remover

The invention discloses a smoke dust remover. The remover comprises a dust removing box body, wherein a smoke inlet and a smoke outlet are formed at two ends of the dust removing box body respectively; the dust removing box body is further internally provided with a filtering plate and a spray head; the filtering plate divides the dust removing box body into an outer room and an inner room; the outer room is near to the smoke outlet; the inner room is near to the smoke inlet; the spray head is arranged in the outer room; a spray nozzle of the spray head is towards the filtering plate; and a water pool is arranged under the inner room and near to the filtering plate. The smoke dust remover comprises the following advantages: 1, a flushable filtering plate is adopted to remove dust, so that the effects of easiness in cleaning, and high strength are achieved, the service life of the dust remover is long, and the problem of short service life of a filtering bag is solved; 2, the filtering plate is automatically cleaned regularly, so that the mechanical resistance, the material filtering resistance and the dust resistance of the filtering plate are low, and the filtering plate can be cleaned thoroughly; 3, compared with the filtering bag, the dust remover has high reliability and low fault and repairing rates; and 4, water for cleaning the filtering plate can be recycled, so that the environmental friendliness and the resource conservation are achieved.

Owner:ANDESON SUPERCONDUCTING RF ACCELERATOR TECHCO +3

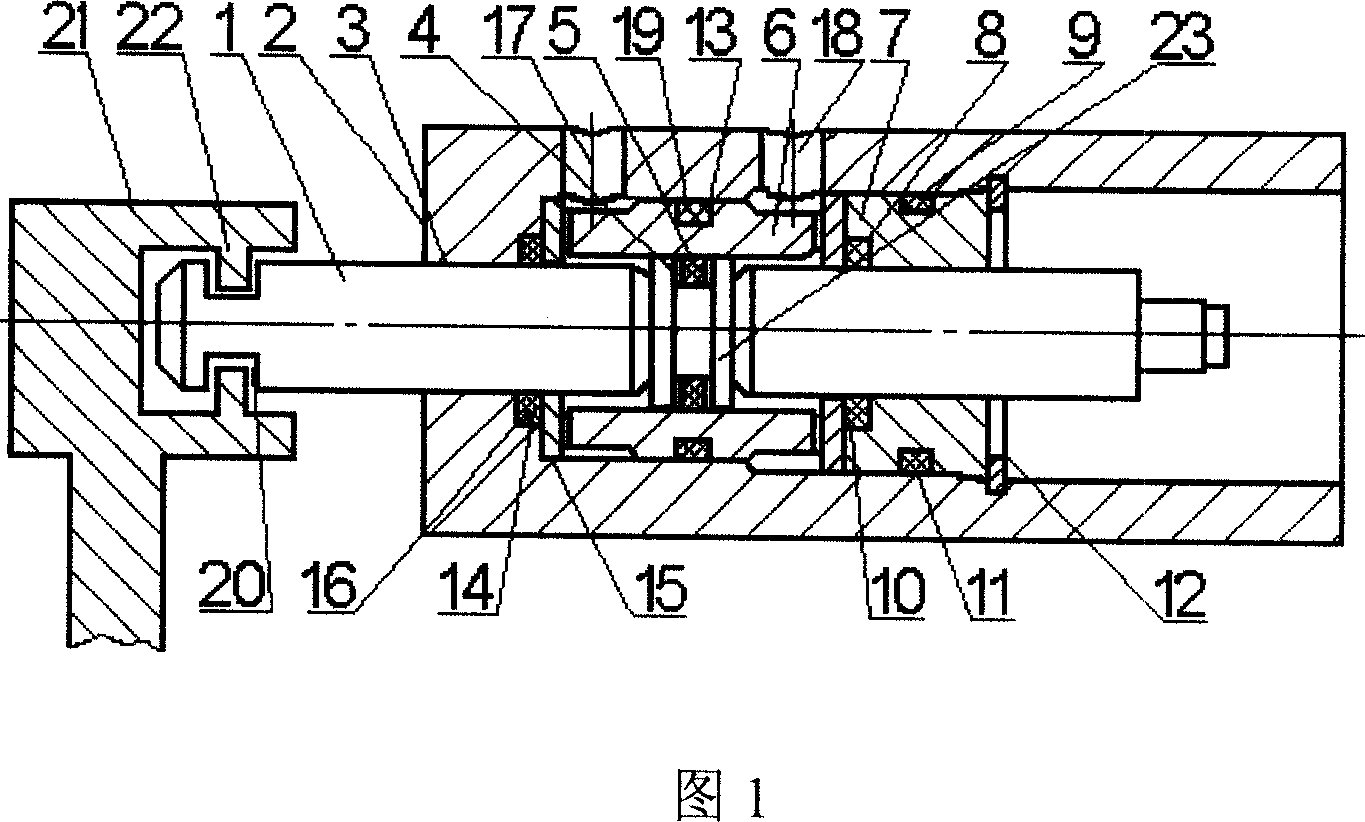

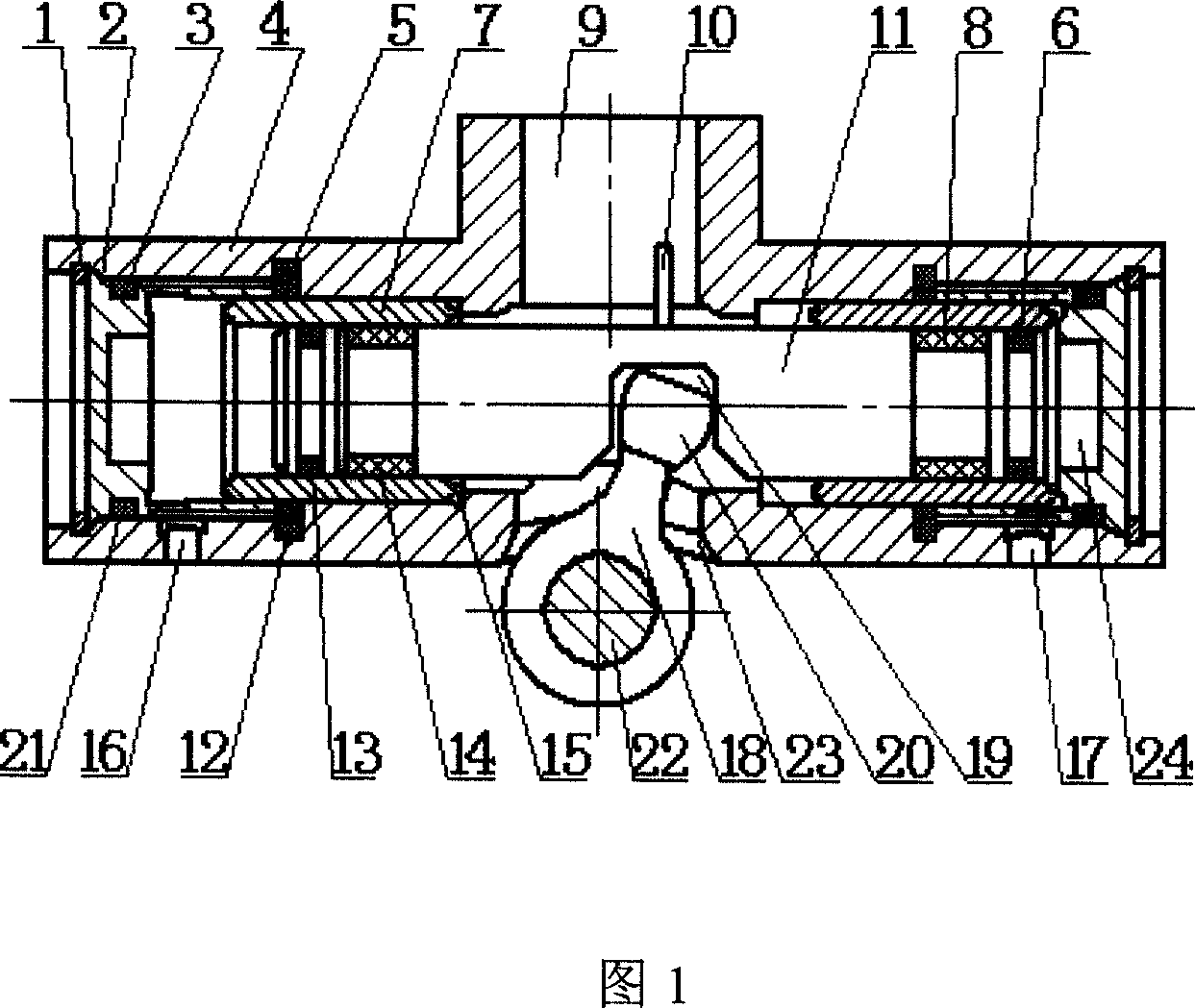

Electric control mechanical automatic gearbox gear selecting oil cylinder for automobile

ActiveCN1987156AOvercoming rigid connection defectsIncreased sensitivityGearing controlFluid-pressure actuatorsAutomatic transmissionEngineering

A gearshift cylinder for the electrically controlled mechanical automatic speed variator of car features that its cylinder body has a closed end with a through hole for piston rod, the extended head of piston rod is linked with the gearshift finger in plug-in mode, and its hydraulic unit is sealed by piston, cylinder body, intermediate bushing, sealing ring and sealing pad.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

Transponder, transponder kit, method of applying the transponder and product comprising the transponder

InactiveUS8511570B2Easy to insertSafely accommodatedSensing record carriersForestryPondingEngineering

The invention concerns a transponder (10), kit and method for marking wood material, such as logs. The transponder comprises a rigid casing adapted to be inserted into the wood material by means of impact, the casing comprising a wedge-shaped first edge (12) adapted to penetrate into the wood material due to said impact, and a second edge (16) opposite to the first edge, the first and second edges (12, 16) defining an insertion direction of the transponder, and radio-frequency trans-ponding means (20) covered by the casing. According to the invention, the casing is elongated in a direction perpendicular to the insertion direction. The transponder is easily applicable into a log and stays well within the log.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT +1

Variable seat separation adjustment in an airplane

InactiveUS8910907B2Increase and decrease seat pitch of seatReduce mechanical resistanceSeating arrangementsAir-treatment apparatus arrangementsEngineeringAirplane

According to an exemplary embodiment of the invention, a system for simultaneous longitudinal shifting of several selected seats or seat rows in an aircraft is stated, in which system a drive device for shifting the seats is provided, wherein shifting the seats takes place according to a change in seat configuration planning.

Owner:AIRBUS OPERATIONS GMBH

Air current flow distribution on-line adjusting device and method of electrostatic-fabric integrated dust collector

The invention relates to an air current flow distribution on-line adjusting device and a method of an electrostatic-fabric integrated dust collector and relates to an electrostatic-fabric integrated dust collector. The adjusting device comprises an inlet loudspeaker, an air current distribution board, an electric field area, an ash hopper, bag areas, net air branch chambers, lift valves, outlet smoke boxes, flow adjusting boards and an ash hopper guide plate; and the air current distribution board is arranged between an outlet of the inlet loudspeaker and the electric field area, the ash hopper is arranged at the bottom of the electric field area, the ash hopper guide plate is arranged in the ash hopper, the flow adjusting boards are arranged between the net air branch chambers and the electric field area, the bag areas are arranged in the net air branch chambers, and the lift valves are arranged above the net air branch chambers and arranged in the outlet smoke boxes. The on-line adjusting method includes performing on-line monitoring of flow of the net air branch chambers in the operating process of the electrostatic-fabric integrated dust collector; calculating relative flow deviation of the net air branch chambers; judging whether the relative flow deviation of the net air branch chambers meets requirements; and performing on-line adjusting of valve opening of the lift valve according to feedback signals of an on-line flow monitor, and balancing the flow of the net air branch chambers until the relative flow deviation of the net air branch chambers meets requirements.

Owner:FUJIAN LONGKING

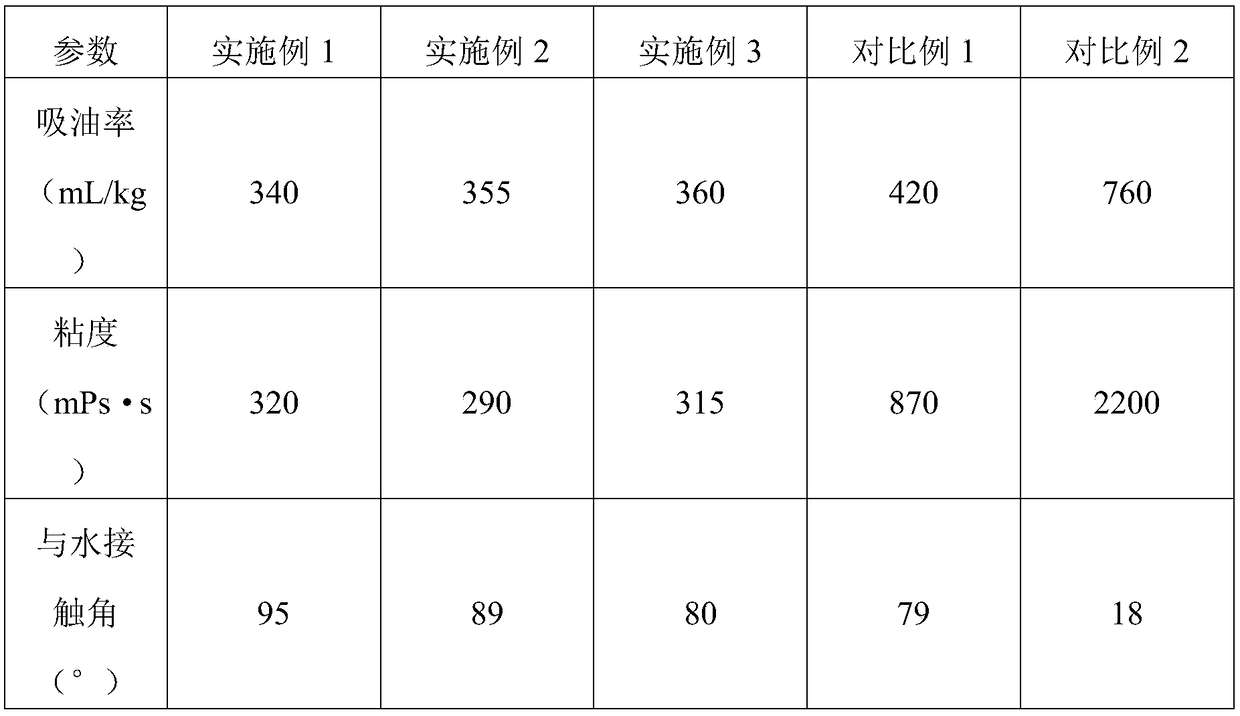

Preparation technology for superfine surface-modified nano calcium carbonate

InactiveCN108912741AAvoid reunionReduce reunionCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideSlurry

The invention discloses a preparation technology for superfine surface-modified nano calcium carbonate. The preparation technology comprises the following steps: (1) carbonizing calcium hydroxide suspension, and adding a sodium sulfate and sodium citrate mixed crystalline form modifier until a pH value of slurry is equal to 7.0 to obtain nano calcium carbonate slurry; (2) adding a dispersing agentto the nano calcium carbonate slurry, stirring and controlling a temperature, and heat-preserving; (3) adding a surface modifier to the nano calcium carbonate slurry in step (2), controlling the temperature and ultrasonic-oscillating; (4) filter-pressing, centrifugal-dewatering, drying, depolymerizing and sieving the nano calcium carbonate slurry after surface treatment to obtain a finished product of the superfine surface-modified nano calcium carbonate. The preparation technology is capable of preventing agglomeration of the nano calcium carbonate, reinforcing hydrophobicity and compatibility on the surface of the nano calcium carbonate, and enabling the nano calcium carbonate to be easily dispersed in a polymer. In a preparation process, hard sodium hyalurongot soup liquid is used as an emulgator and used as a saponifier, a reaction saponification rate is high, and a raw material utilization rate is high.

Owner:XUANCHENG YANGLIUQING CHEM CO LTD

Electric control mechanical automatic gearbox gear shifting oil cylinder for automobile

ActiveCN1987157AOvercoming rigid connection defectsIncreased sensitivityGearing controlFluid-pressure actuatorsAutomatic transmissionEngineering

A gearshift cylinder for the electrically controlled mechanical automatic speed variator of car is composed of a cylinder body and a piston in cylinder body. Said cylinder body has two end covers to form two oil cavities and an opening for connecting piston with a gearshift arm. Its hydraulic unit is sealed by piston, cylinder body, intermediate bushing, and sealing ring. A gearshift position sensor is used for detecting the gearshift stroke.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

Spiral cam gearbox mechanism

The improved gearbox mechanism of the present invention includes a plurality of cam-actuated gear block assemblies, which transfer power from a power shaft to a secondary or output gear element. Each gear block assembly includes a gear block having a surface that periodically interfaces with a secondary or output gear element. In a preferred embodiment the interface surface comprises a plurality of projections or teeth which correspond to complementary holes, projections or gear teeth on the output gear element. Each gear or torque block assembly further includes pivot assemblies, which connect or link the torque block to a cam assembly, which in turn is connected to a power source. The cam assembly comprises a set of corresponding cam elements arranged in a tandem configuration and having a unique circuitous pathway or groove formed therein so that the movement of the torque block may be controlled in three dimensions in accordance with a certain design parameter. In a preferred embodiment, a portion of the pathway is generally spiral in shape.

Owner:MOTUS LABS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com