Photoelectrically controlled eccentric-positioning one-arm four-way reversing valve

A four-way reversing valve, photoelectric control technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of no motor running time control, decreased positioning angle accuracy, and four-way reversing valve performance. , to achieve the effect of increasing the force arm, improving the accuracy, and increasing the life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing description and embodiment, the present invention will be further described:

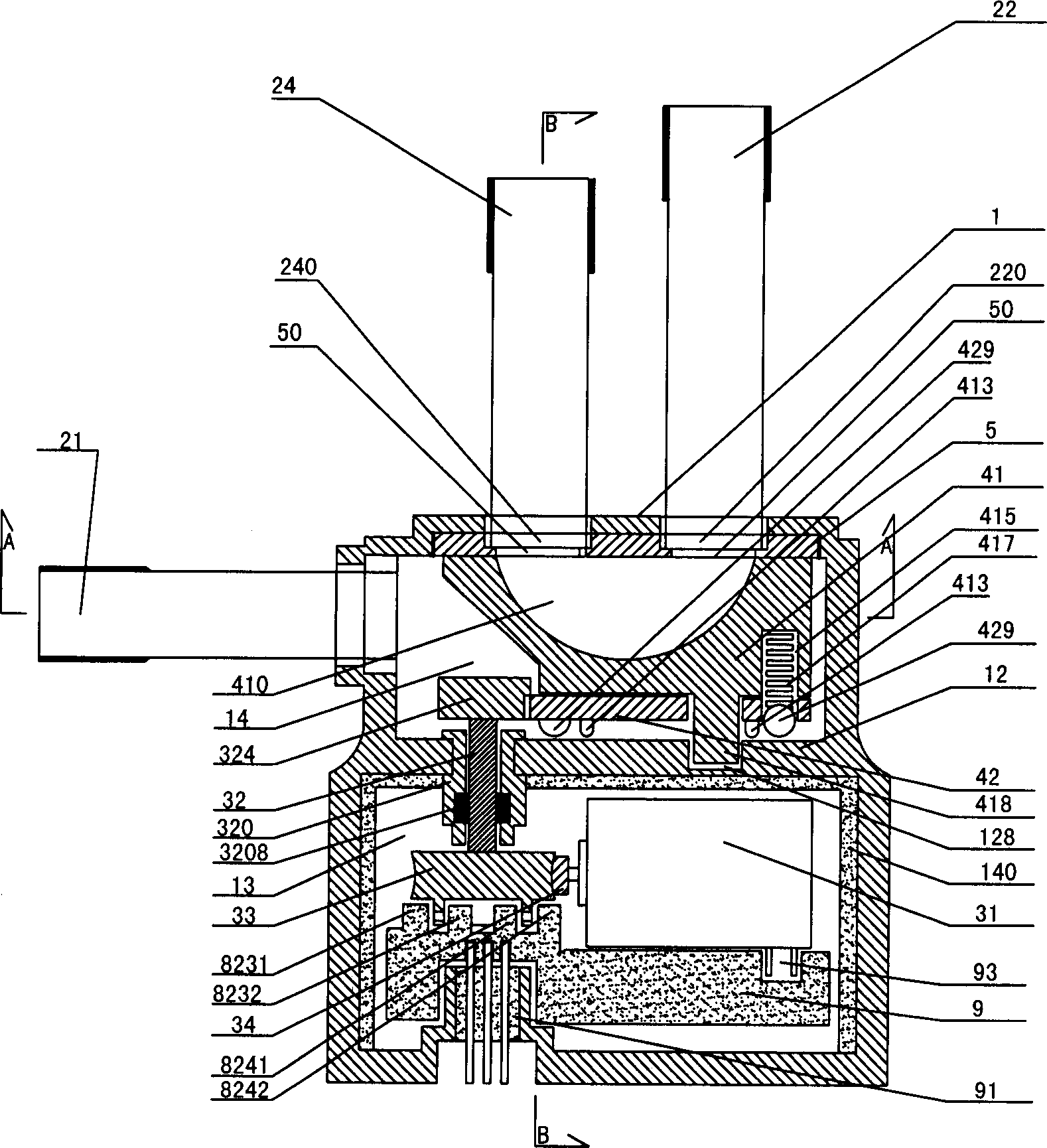

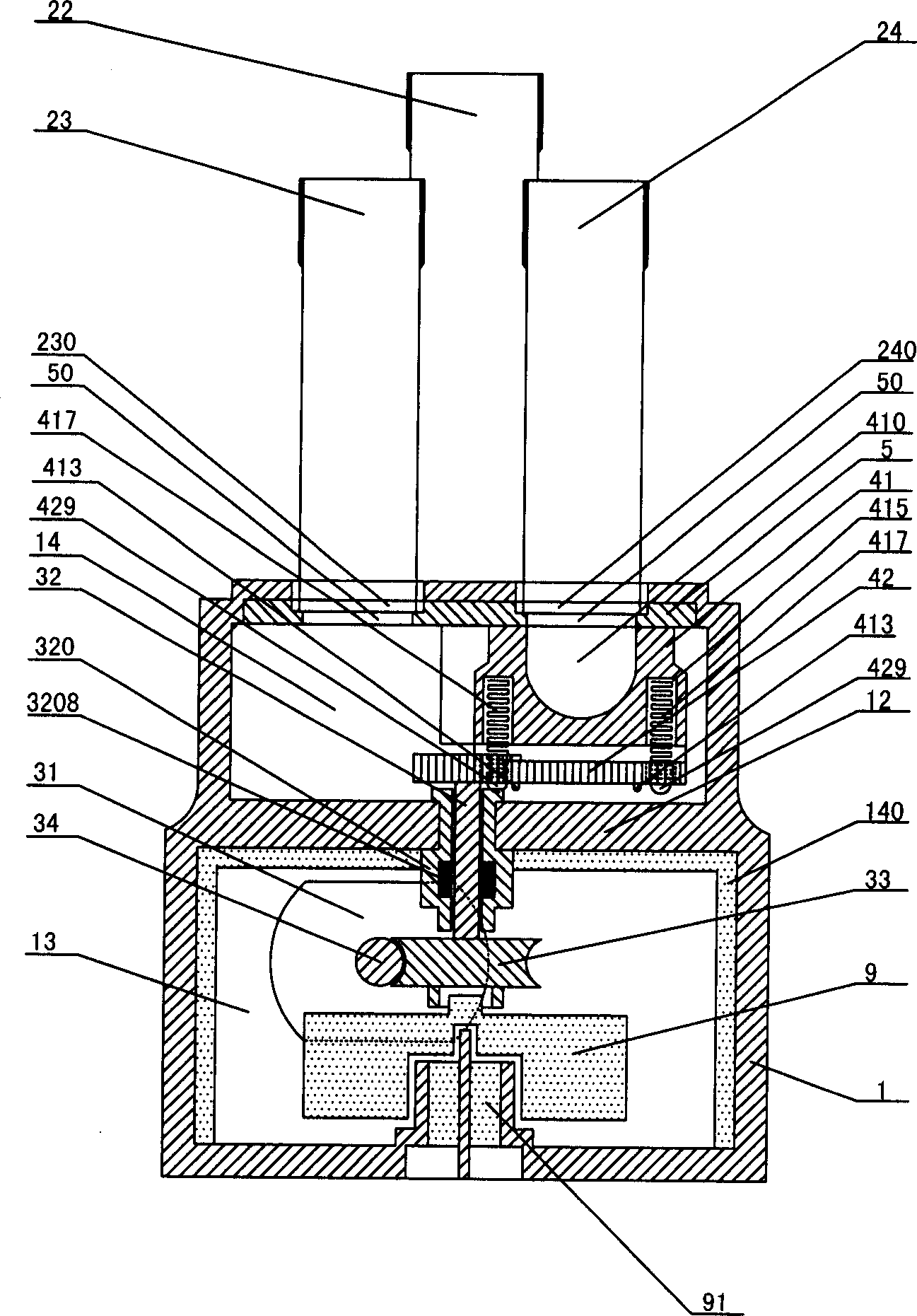

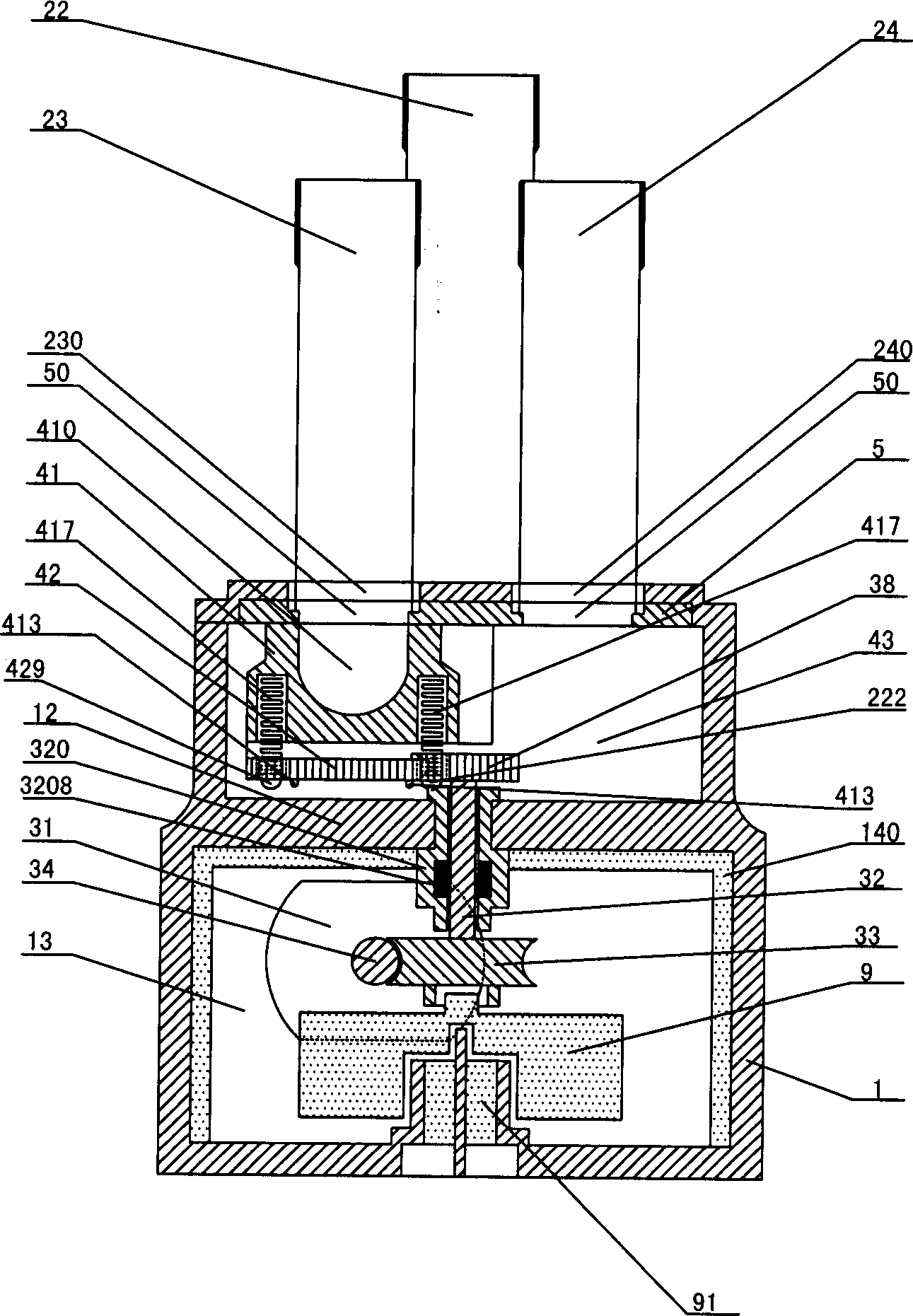

[0038] see Figure 1 to Figure 3 , The photoelectric control eccentric positioning single arm four-way reversing valve of the present invention includes a sealed valve body 1, an intake pipe 21, a common pipe 22, a first exchange pipe 23, a second exchange pipe 24, a transmission mechanism and a reversing device.

[0039] Wherein, the valve body 1 can be cylindrical and completely sealed, and is sintered by high-temperature glass. The middle part is divided into a high-pressure chamber 14 and a transmission and control chamber 13 by a partition 12 . Adopt one-piece molding or screw or other ways to connect. The air inlet pipe 21, the common pipe 22, the first exchange pipe 23 and the second exchange pipe 24 are all connected with the high pressure chamber 14, the air inlet pipe 21 is arranged on one side of the high pressure chamber 14, the comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com