Air current flow distribution on-line adjusting device and method of electrostatic-fabric integrated dust collector

A technology of electric bag compounding and air flow, which is applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problem of uneven distribution of air flow and achieve the effect of reducing mechanical resistance, reducing filtration resistance and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

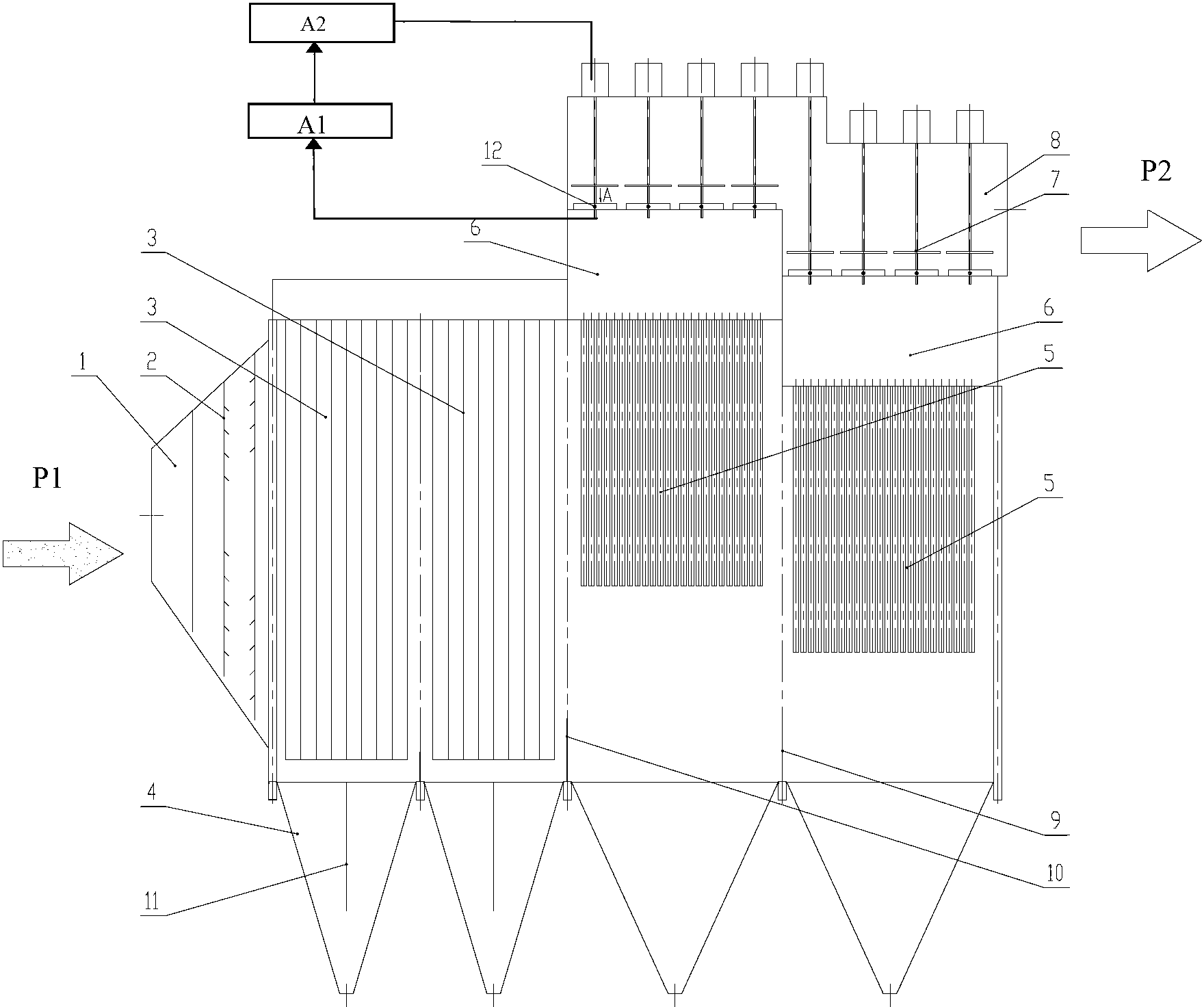

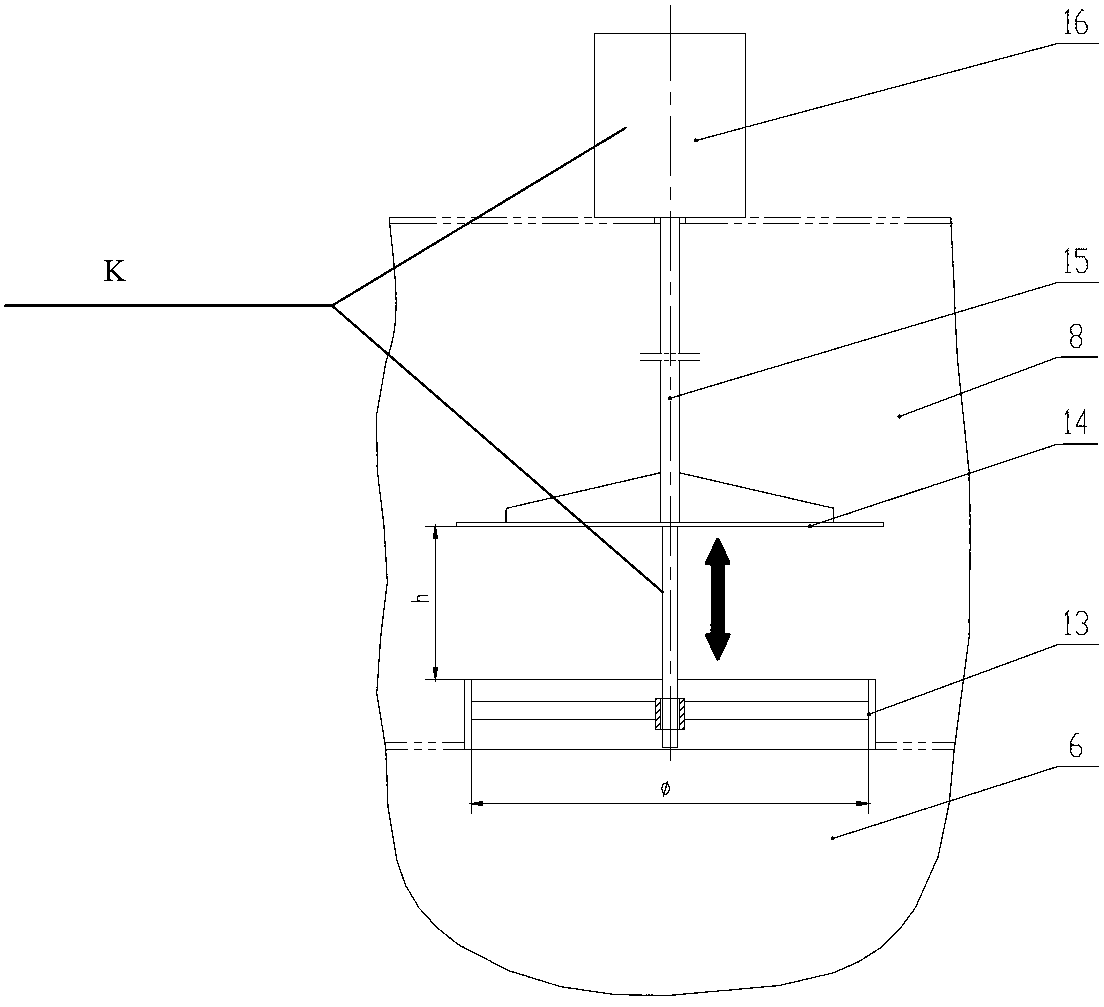

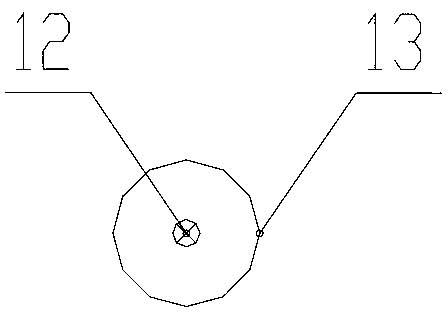

[0038] see Figure 1~3 , the embodiment of the present invention is equipped with an inlet horn 1, an air distribution plate 2, an electric field area 3, an ash hopper 4, a bag area 5, 2 clean air compartments (61, 62), a poppet valve 7, an outlet smoke box 8, a second Flow regulating plate 9, first flow regulating plate 10, ash hopper deflector 11;

[0039] The air flow distribution plate 2 is arranged between the outlet of the inlet horn 1 and the electric field area 3, the ash hopper 4 is arranged at the bottom of the electric field area 3, the ash hopper 4 is provided with an ash hopper deflector 11, and the first clean air A first flow regulating plate 10 is provided between the sub-chamber 61 and the electric field area 3, a second flow regulating plate 9 is provided between the second clean gas sub-chamber 62 and the first clean gas sub-chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com