Preparation technology for superfine surface-modified nano calcium carbonate

A technology for surface modification of nanometer and nanometer calcium carbonate, applied in nanotechnology, calcium carbonate/strontium/barium, nanotechnology, etc. for materials and surface science, which can solve the problem of material performance decline, high cost, and easy particle agglomeration. and other problems, to achieve the effect of reducing mechanical resistance, high utilization rate of raw materials, and high reaction saponification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

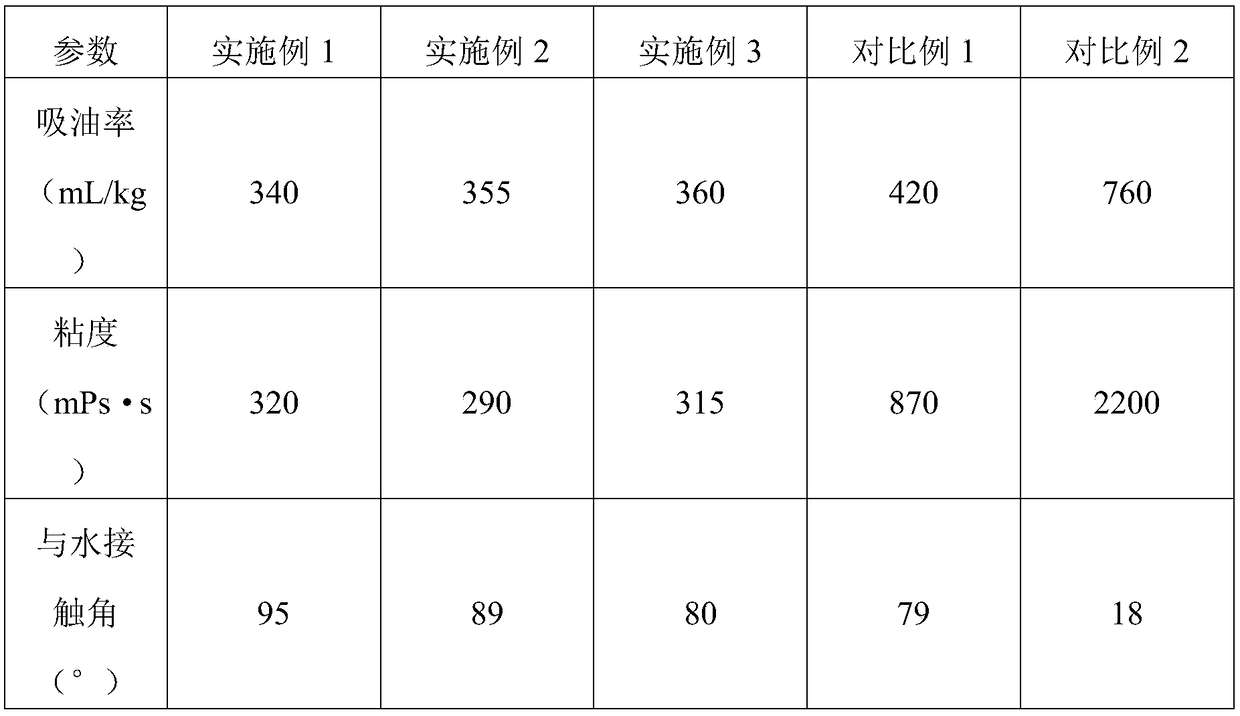

Examples

Embodiment 1

[0023] A kind of preparation technology of superfine surface modified nano-calcium carbonate, comprises the following steps:

[0024] (1) Pass 3m into 300kg calcium hydroxide suspension 3 / min carbon dioxide is carbonized, and simultaneously add 2kg sodium sulfate and sodium citrate mixed crystal form modifier, until slurry pH=7.0, obtain nano-calcium carbonate slurry;

[0025] (2) Add 2.5kg of vinyl bisstearamide to the nano-calcium carbonate slurry, stir at 100r / min and control the temperature at 40°C, and keep it warm for 20-30min;

[0026] (3) Add 4kg of surface modifier to the nano-calcium carbonate slurry in step (2), control the temperature at 50°C and ultrasonically vibrate at 200kHz for 30min;

[0027] (4) The nano-calcium carbonate slurry after the surface treatment is successively subjected to pressure filtration, centrifugal dehydration, drying, depolymerization and sieving to obtain a finished ultrafine surface-modified nano-calcium carbonate.

[0028] In this e...

Embodiment 2

[0030] A kind of preparation technology of superfine surface modified nano-calcium carbonate, comprises the following steps:

[0031] (1) Pass 3m into 300kg calcium hydroxide suspension 3 The carbon dioxide of / min carries out carbonization, and adds 2kg sodium sulfate and sodium citrate mixed crystal form regulator simultaneously, until slurry pH=7.0, obtains nano-calcium carbonate slurry;

[0032] (2) Add 2.5kg N-stearyl erucamide to the nano-calcium carbonate slurry, stir at 150r / min and control the temperature at 50°C, and keep it warm for 25min;

[0033] (3) Add 4kg of surface modifier to the nano-calcium carbonate slurry in step (2), control the temperature at 55°C and ultrasonically vibrate at 250kHz for 45min;

[0034] (4) The nano-calcium carbonate slurry after the surface treatment is successively subjected to pressure filtration, centrifugal dehydration, drying, depolymerization and sieving to obtain a finished ultrafine surface-modified nano-calcium carbonate.

...

Embodiment 3

[0037] A kind of preparation technology of superfine surface modified nano-calcium carbonate, comprises the following steps:

[0038] (1) Pass 3m into 300kg calcium hydroxide suspension 3 The carbon dioxide of / min carries out carbonization, and adds 2kg sodium sulfate and sodium citrate mixed crystal form regulator simultaneously, until slurry pH=7.0, obtains nano-calcium carbonate slurry;

[0039] (2) Add 2.5kg sulfobetaine to the nano-calcium carbonate slurry, stir with 200r / min and control the temperature at 60°C, and keep warm for 30min;

[0040] (3) Add 4kg of surface modifier to the nano-calcium carbonate slurry in step (2), control the temperature at 60°C and ultrasonically vibrate at 300kHz for 60min;

[0041] (4) The nano-calcium carbonate slurry after the surface treatment is successively subjected to pressure filtration, centrifugal dehydration, drying, depolymerization and sieving to obtain a finished ultrafine surface-modified nano-calcium carbonate.

[0042] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com