Method and device for transferring a chip to a contact substrate

A chip transfer and substrate technology, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

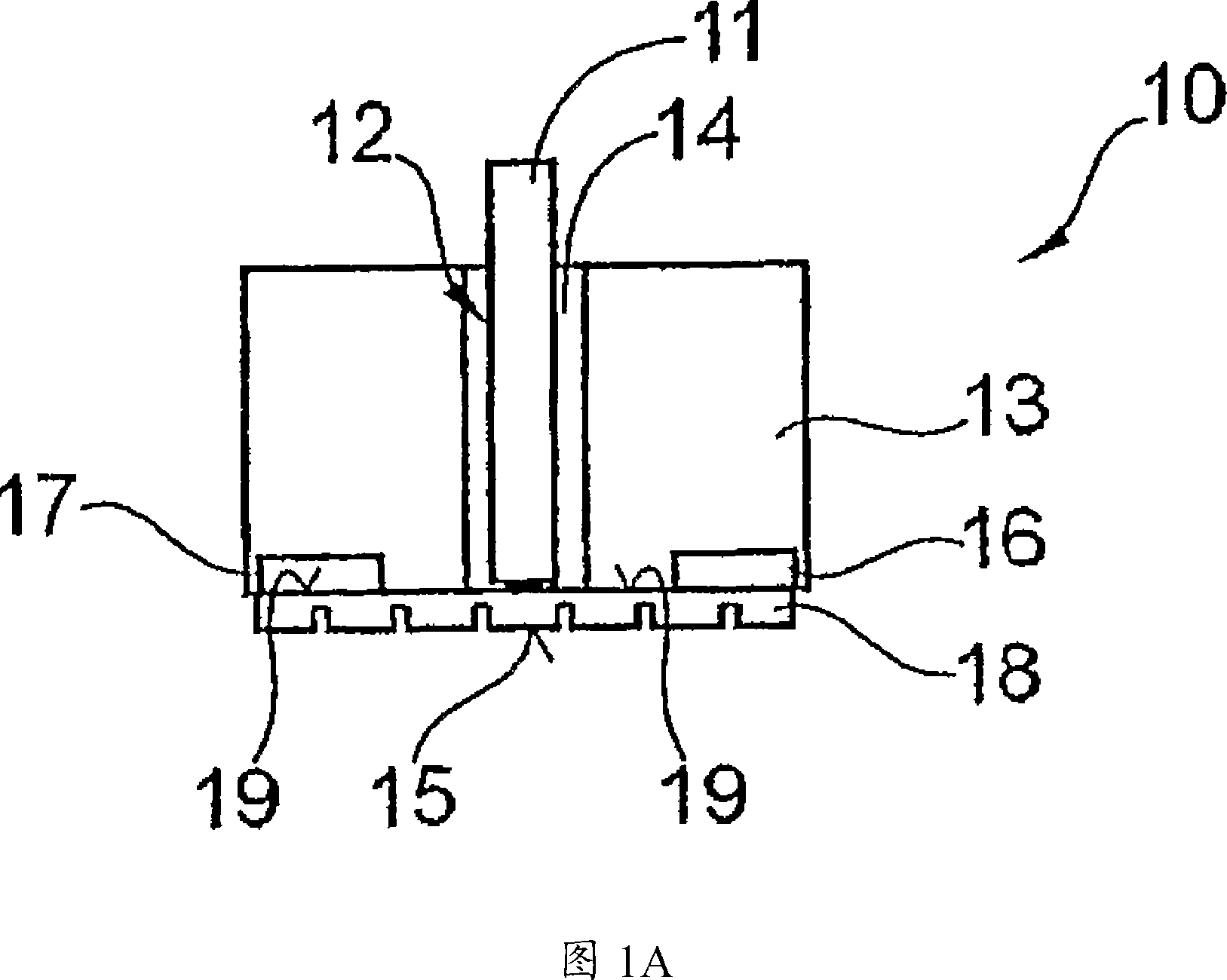

[0033] Referring to a simplified schematic diagram of an embodiment of the present invention, FIGS. 1A and 1B show a transfer tool 10 including a laser device in the form of an optical fiber 11 . The laser device can also serve as the pressing device 12 , and the optical fiber 11 can be guided in a channel 14 provided on the workpiece 13 . The lower front face of the workpiece 13 is arranged to contact a base positioning device 15 on which the foil 17 can be maintained through the vacuum opening 16 . A number of chips 18 are mounted on the foil 17 and the chips 18 are adhered to the foil 17 by means of an adhesive (not shown) between their back 19 and the foil 17 .

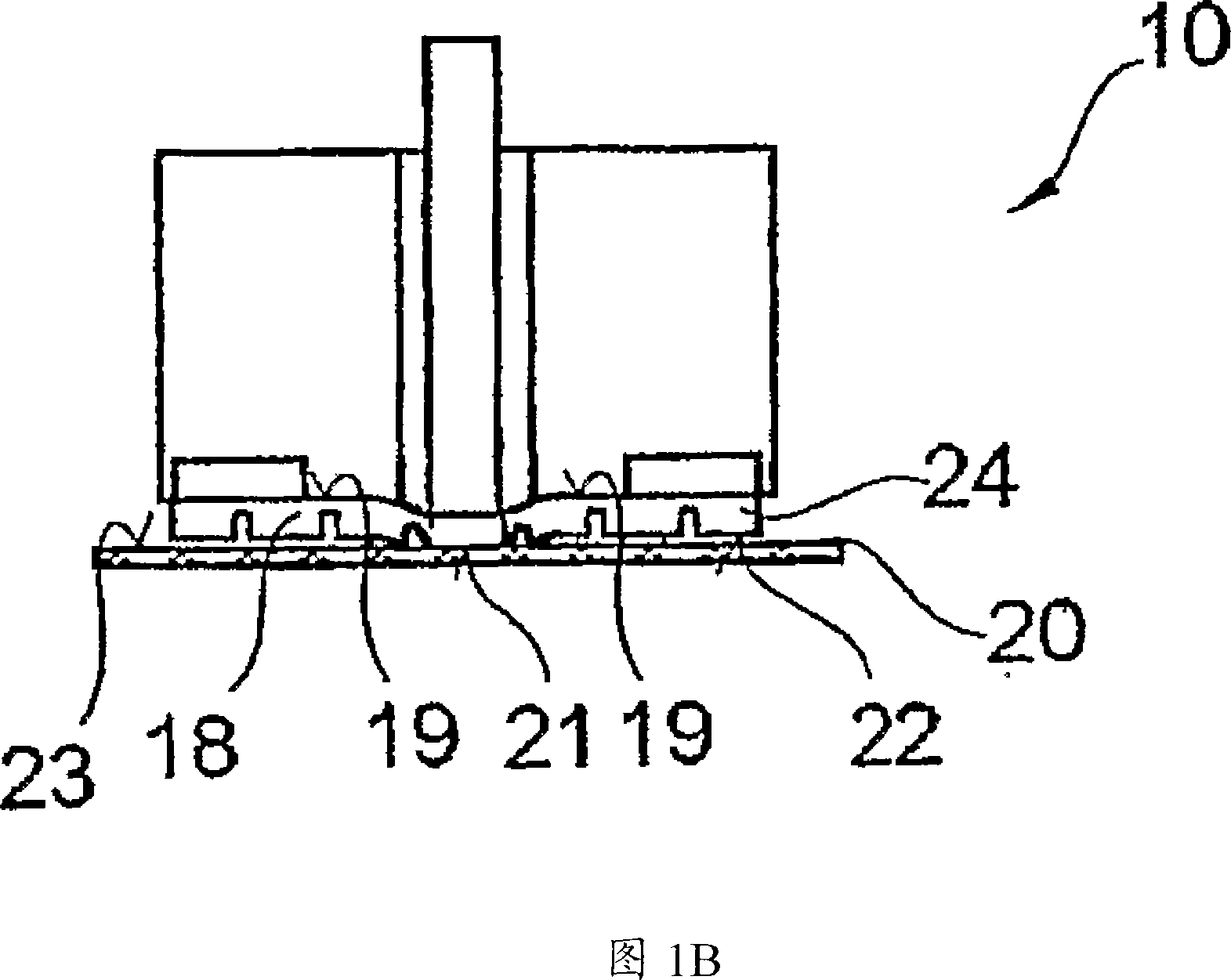

[0034] 1B shows a schematic diagram of the transfer process, the transfer tool 10 is located directly above a contact substrate 20, wherein the chip 18 opposite the free contact end 21 of the optical fiber 11 is pressed on the contact substrate 20 to conduct the chip 18 The contact gap 24 between the contact surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com