Patents

Literature

423results about How to "Ensure electrical connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

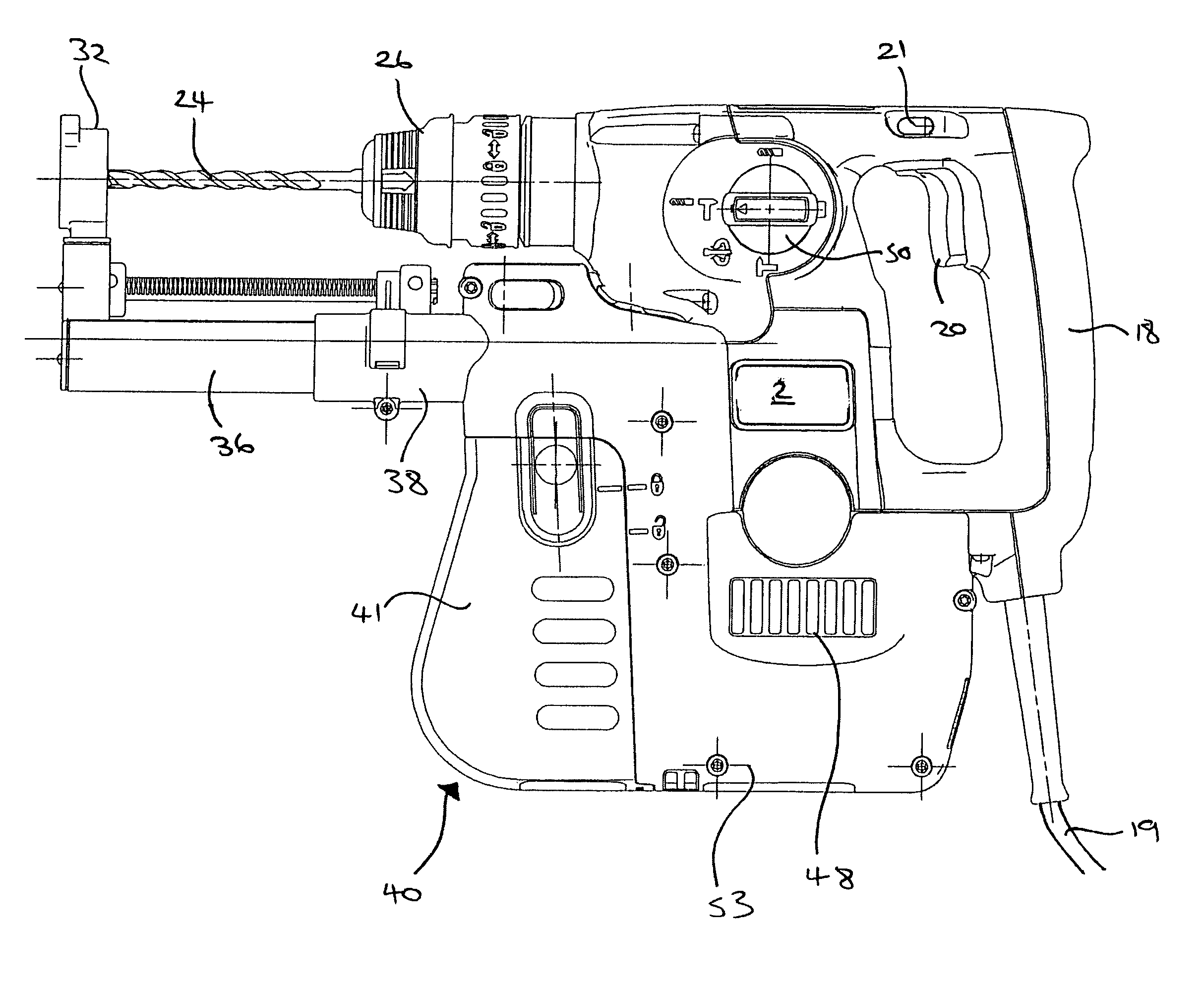

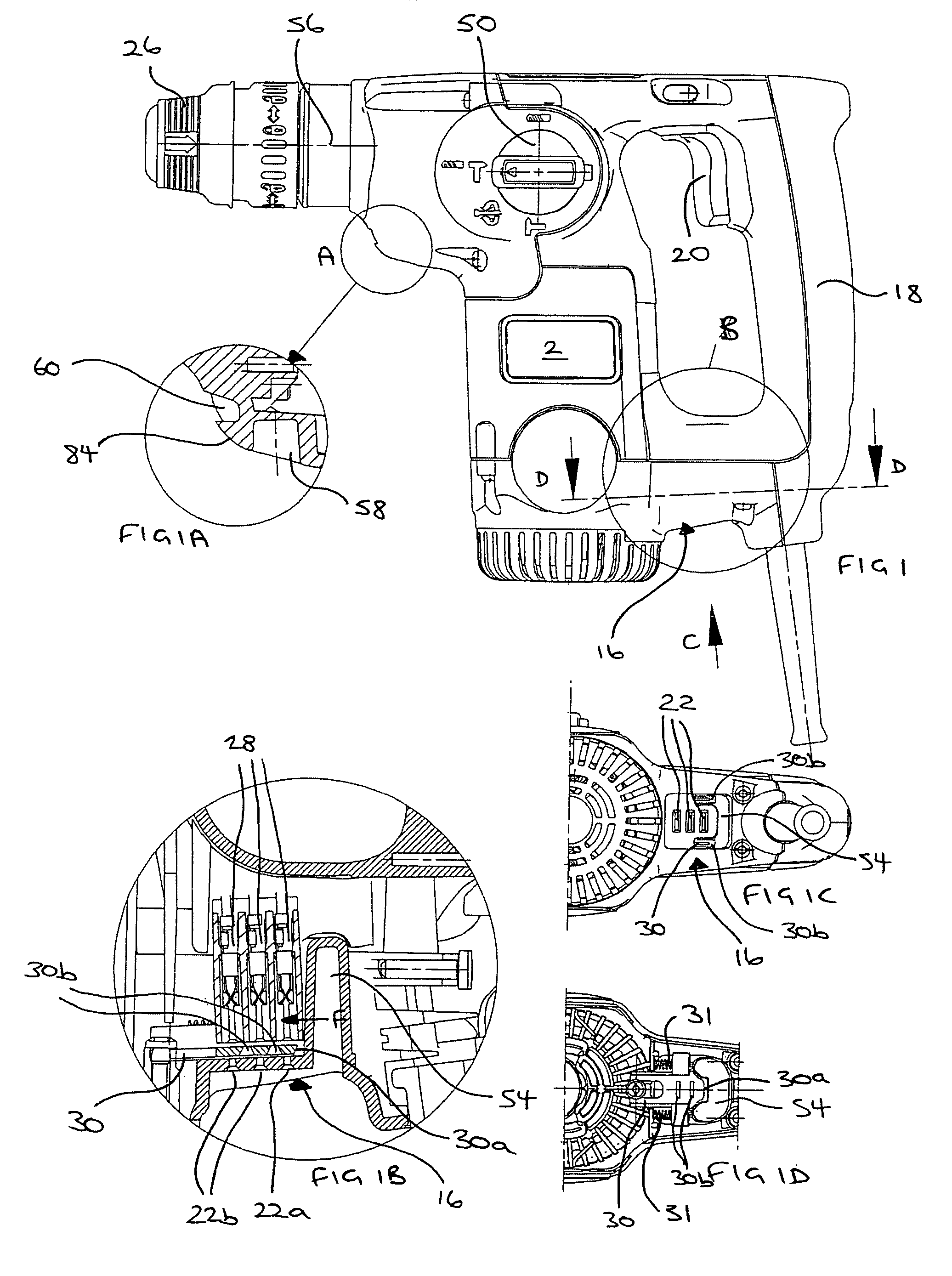

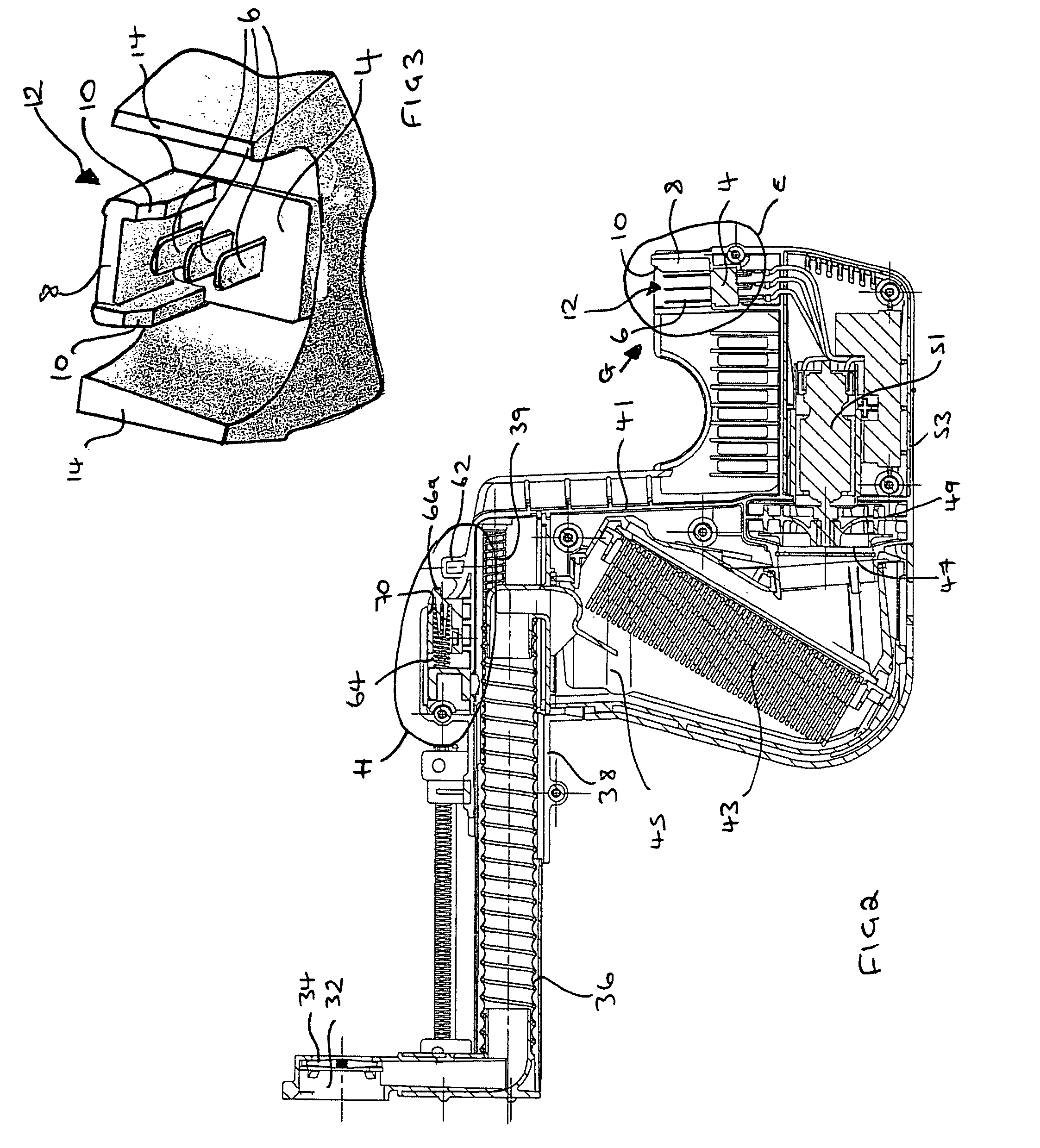

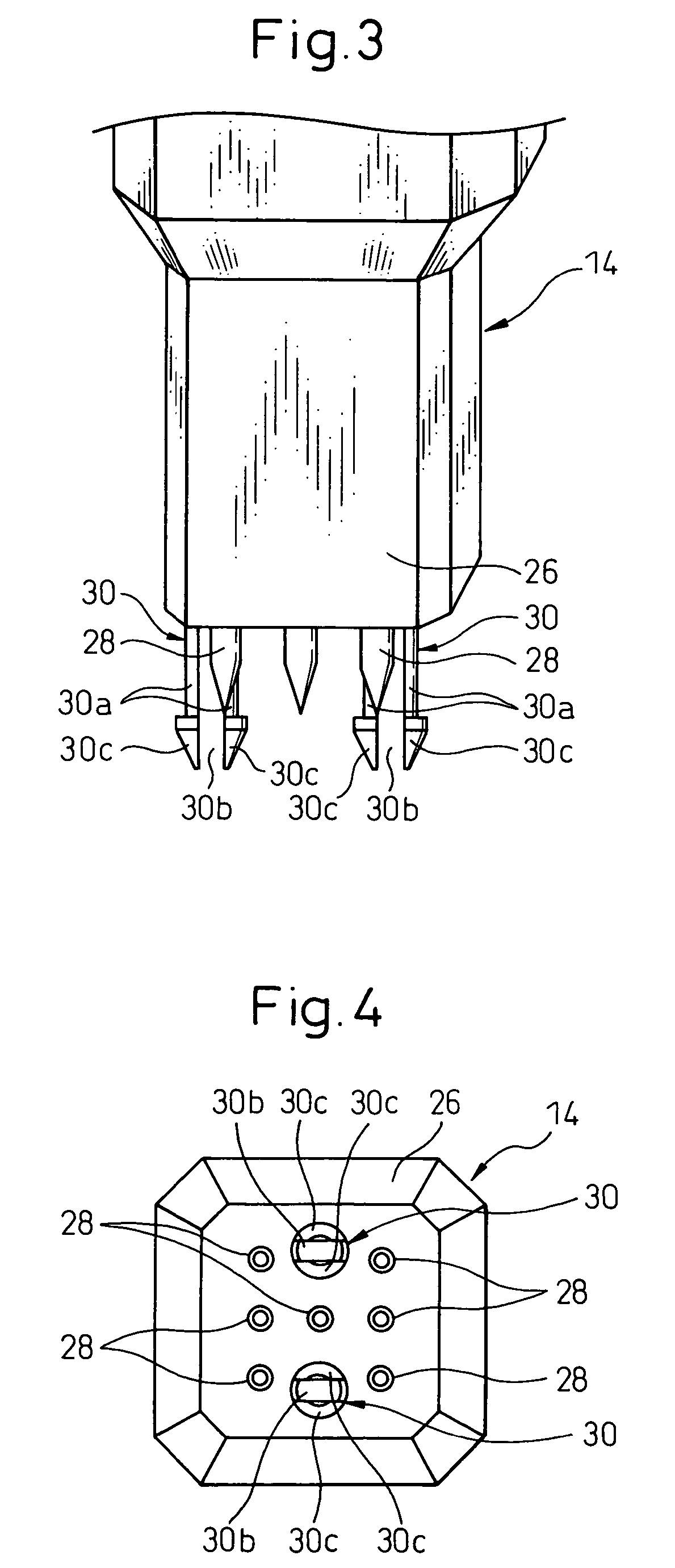

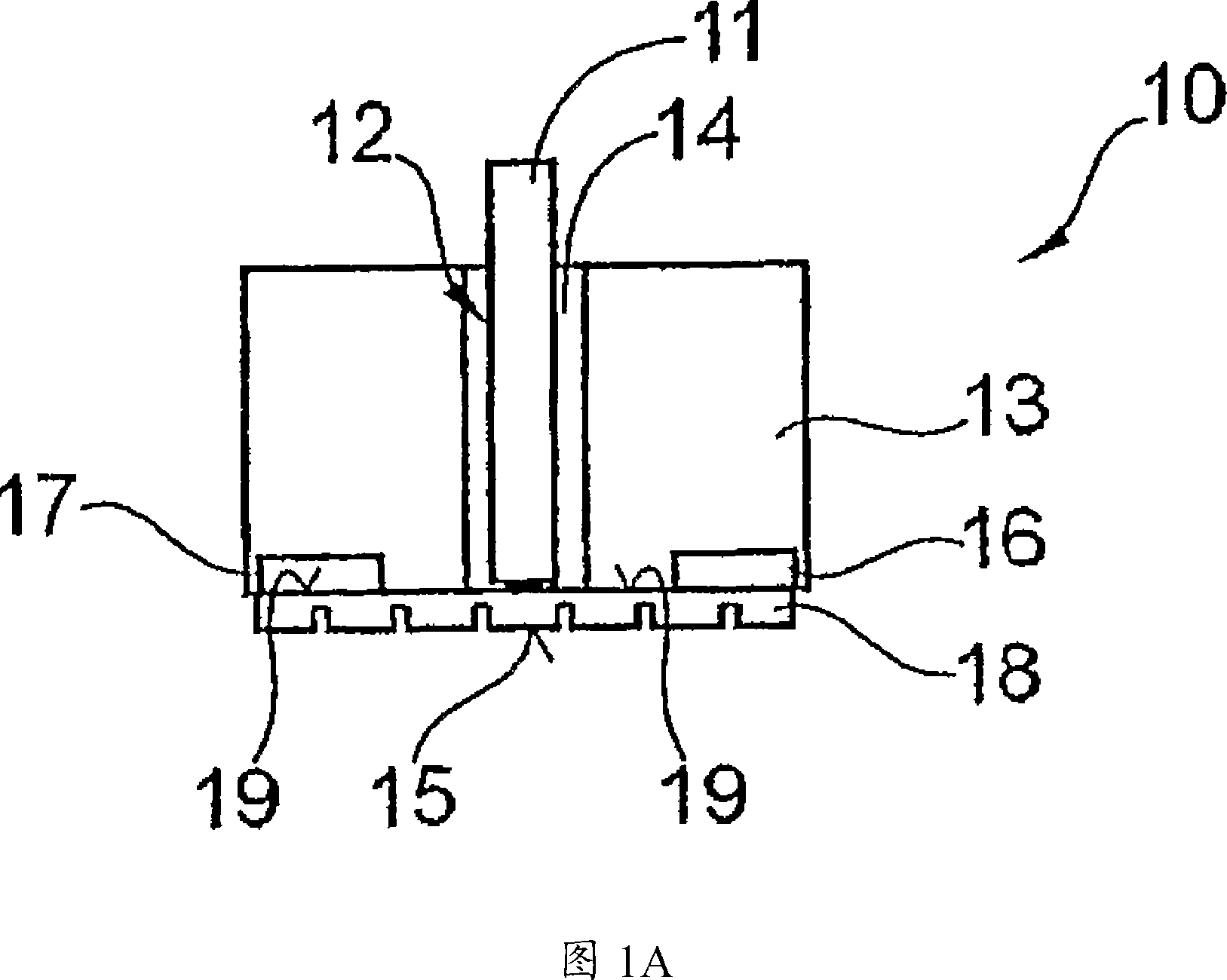

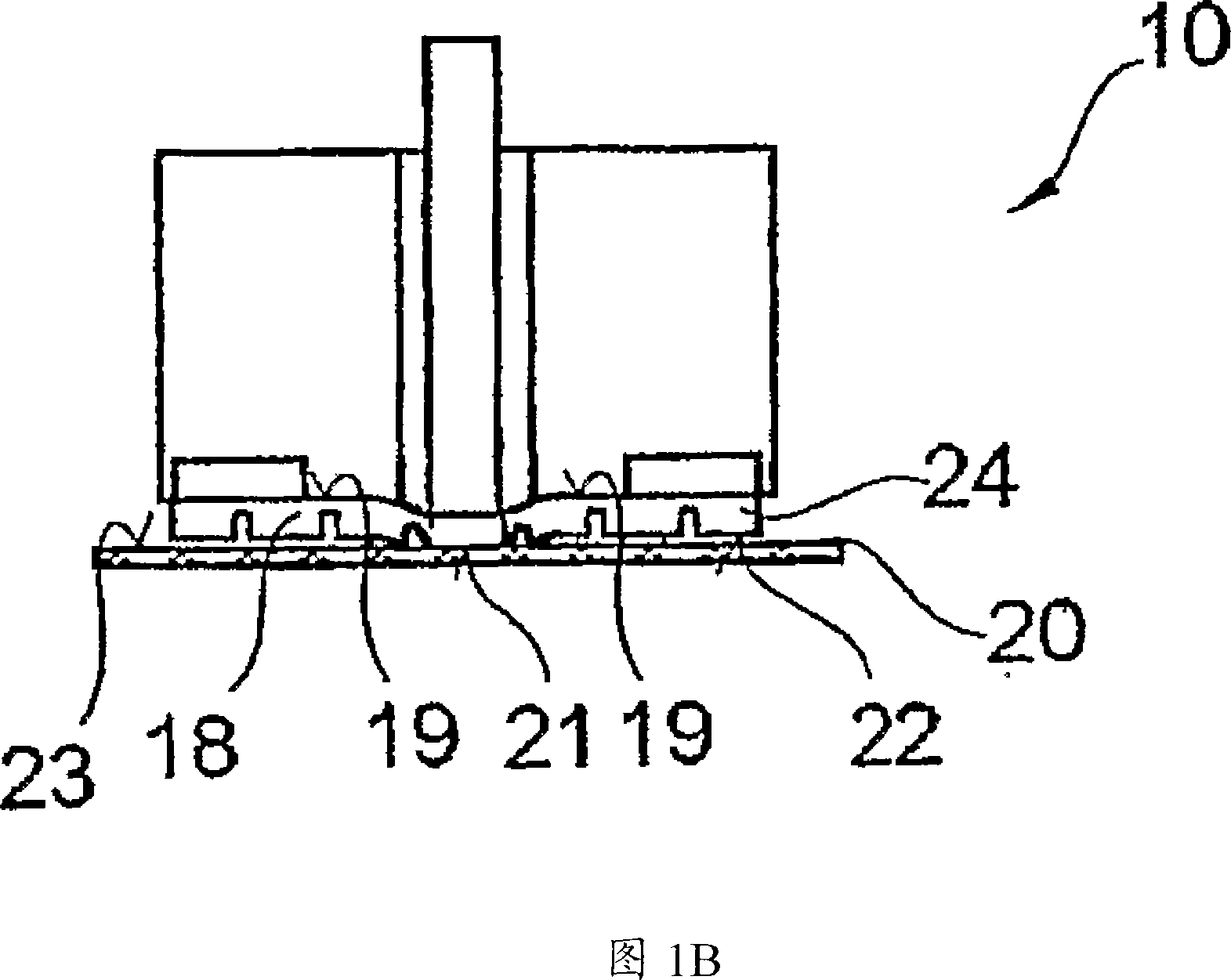

Hand held drilling and/or hammering tool with dust collection unit

InactiveUS7017680B2Efficient processEasy to installThread cutting feeding devicesDrilling rodsHand heldElectrical connection

Owner:BLACK & DECKER INC

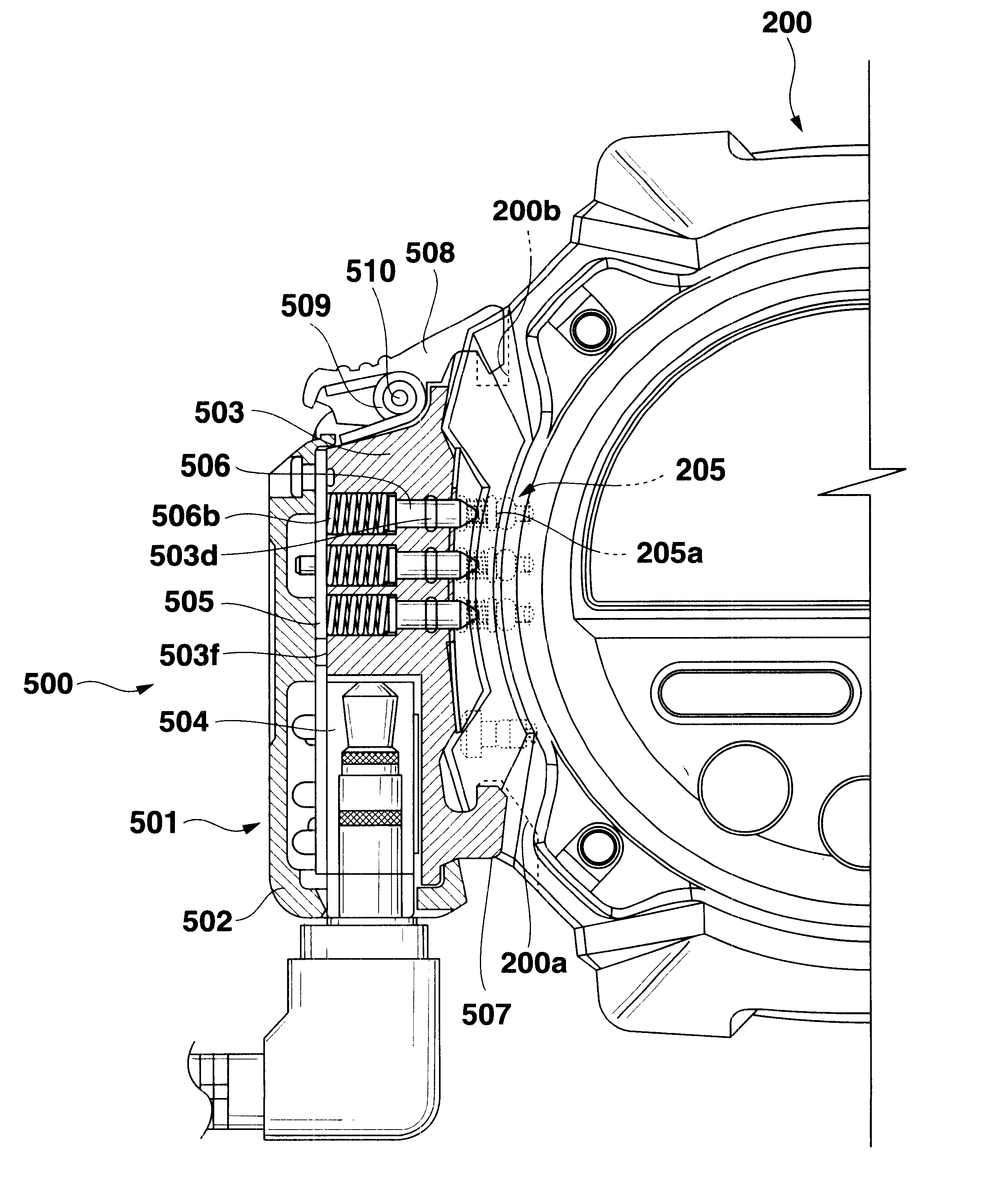

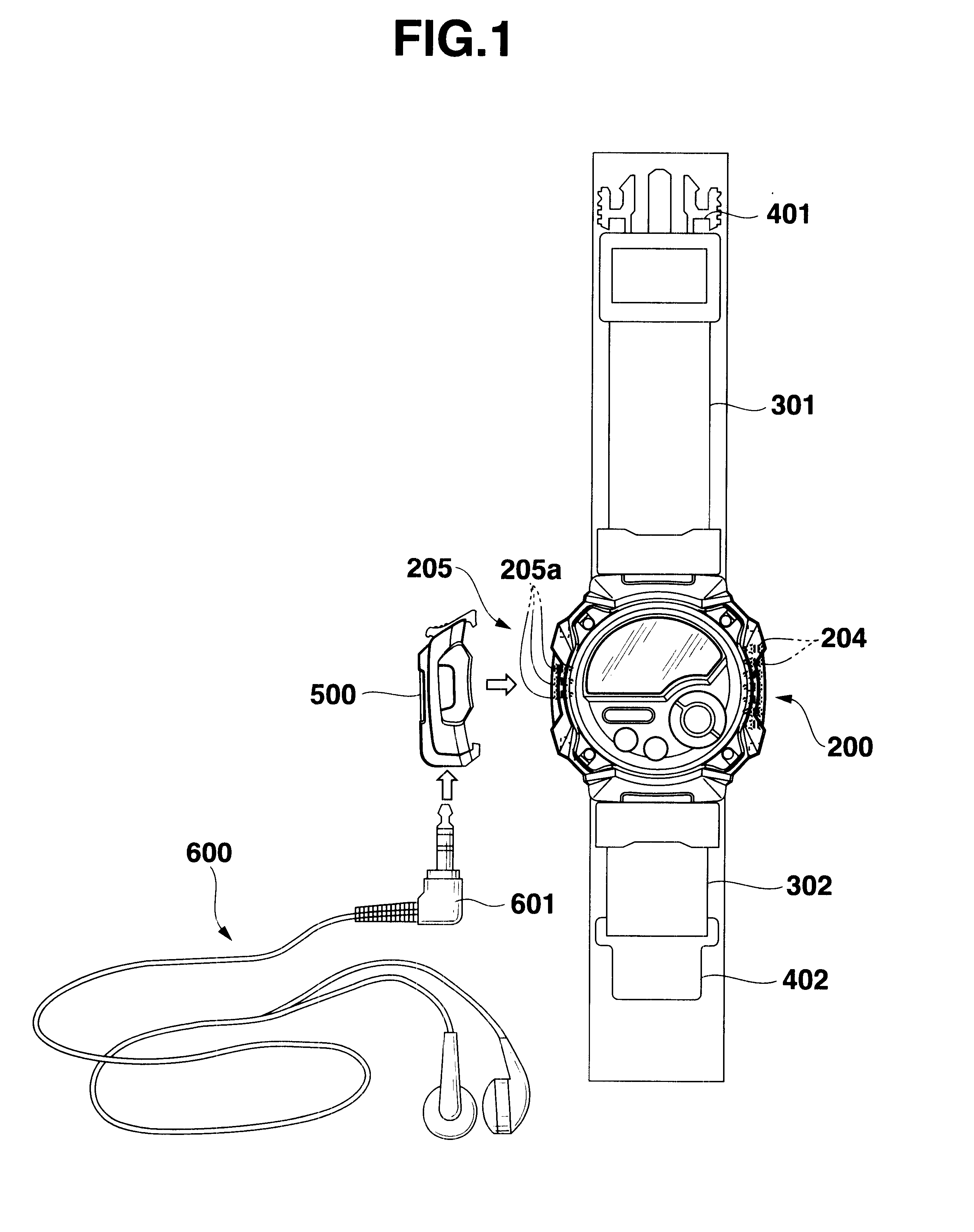

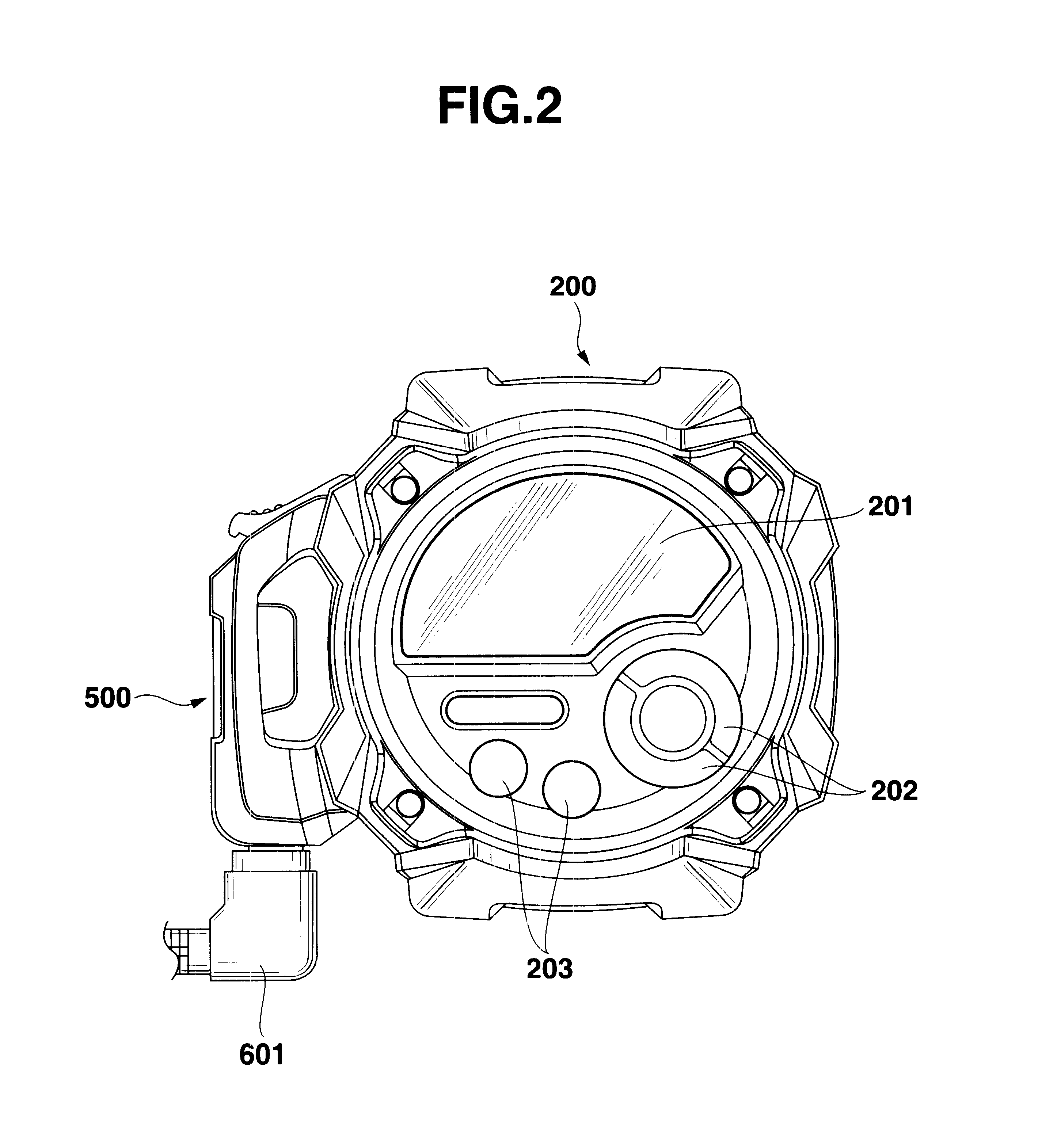

Adapter for external connection and electronic apparatus

InactiveUS6454608B1Good adhesionEasy detachmentEngagement/disengagement of coupling partsTwo pole connectionsEngineeringMusic player

The present invention relates to a connecting adapter 500 for connecting an earphone 600 with a body part 200 of a writs type of music player. In a casing 501, an earphone jack 504, and a circuit board 505 having a continuity with the earphone jack 504 are provided. A connection terminal 506 having a continuity with an earphone connector 205 of the body art 200 is provided so as to penetrate the inside and the outside of the casing 501 and have a continuity with the circuit board 505. On the outer surface of the casing 501, a fixed hook 507 for engaging with a concavity 200a of the body part 200 and a movable hook 508 for engaging with a concavity 200b of the body part 200, which is incorporated so as to be rotatable and to be biased toward the body part 200, are provided.

Owner:CASIO COMPUTER CO LTD

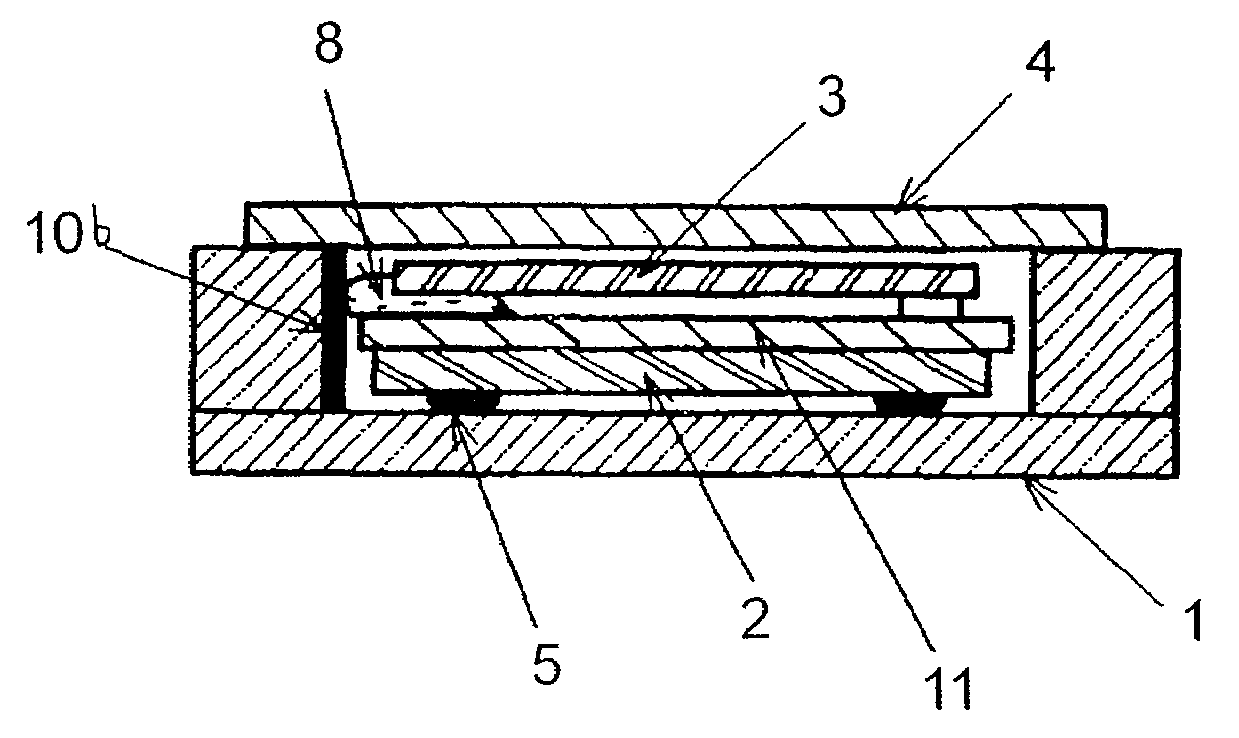

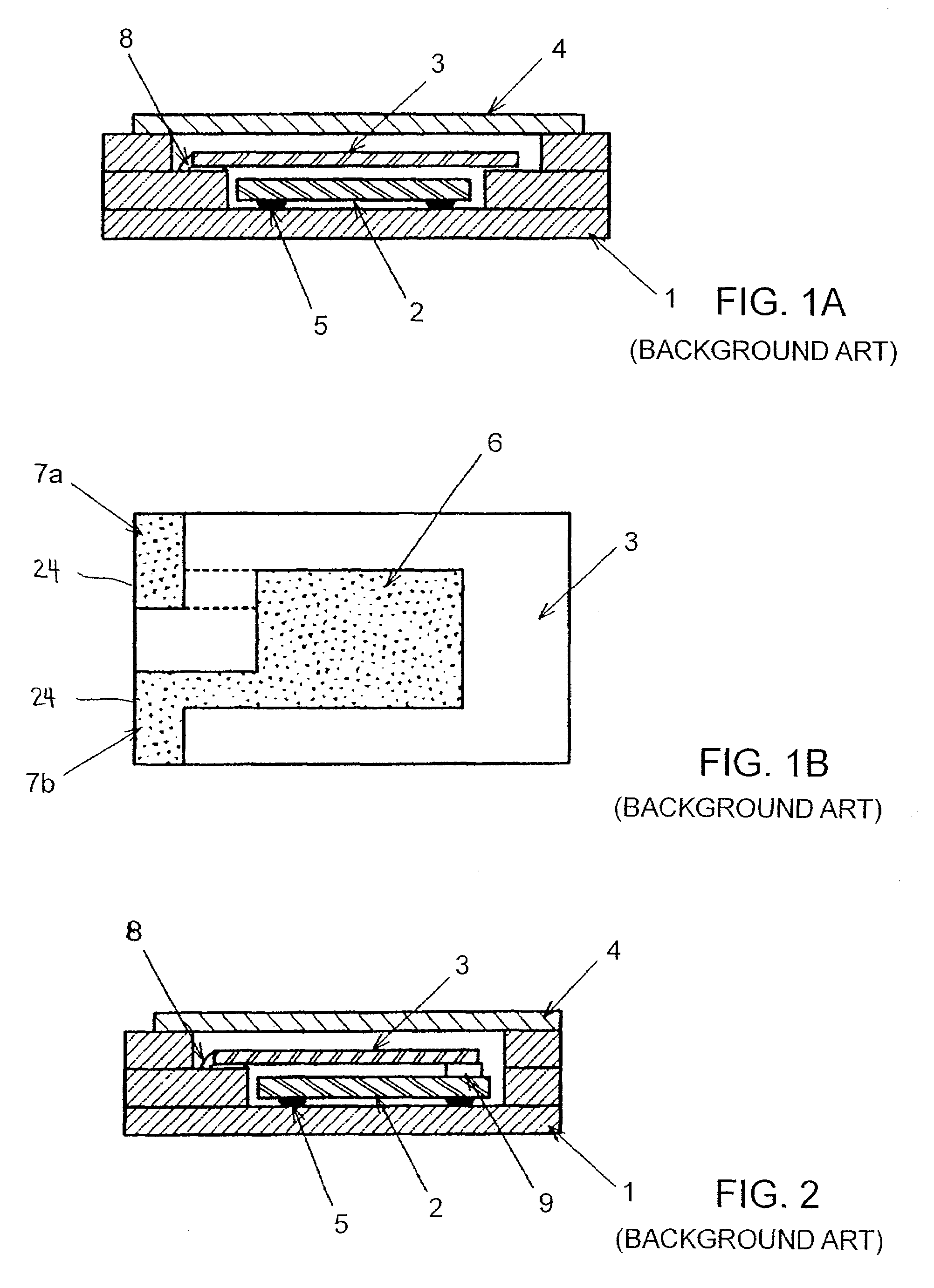

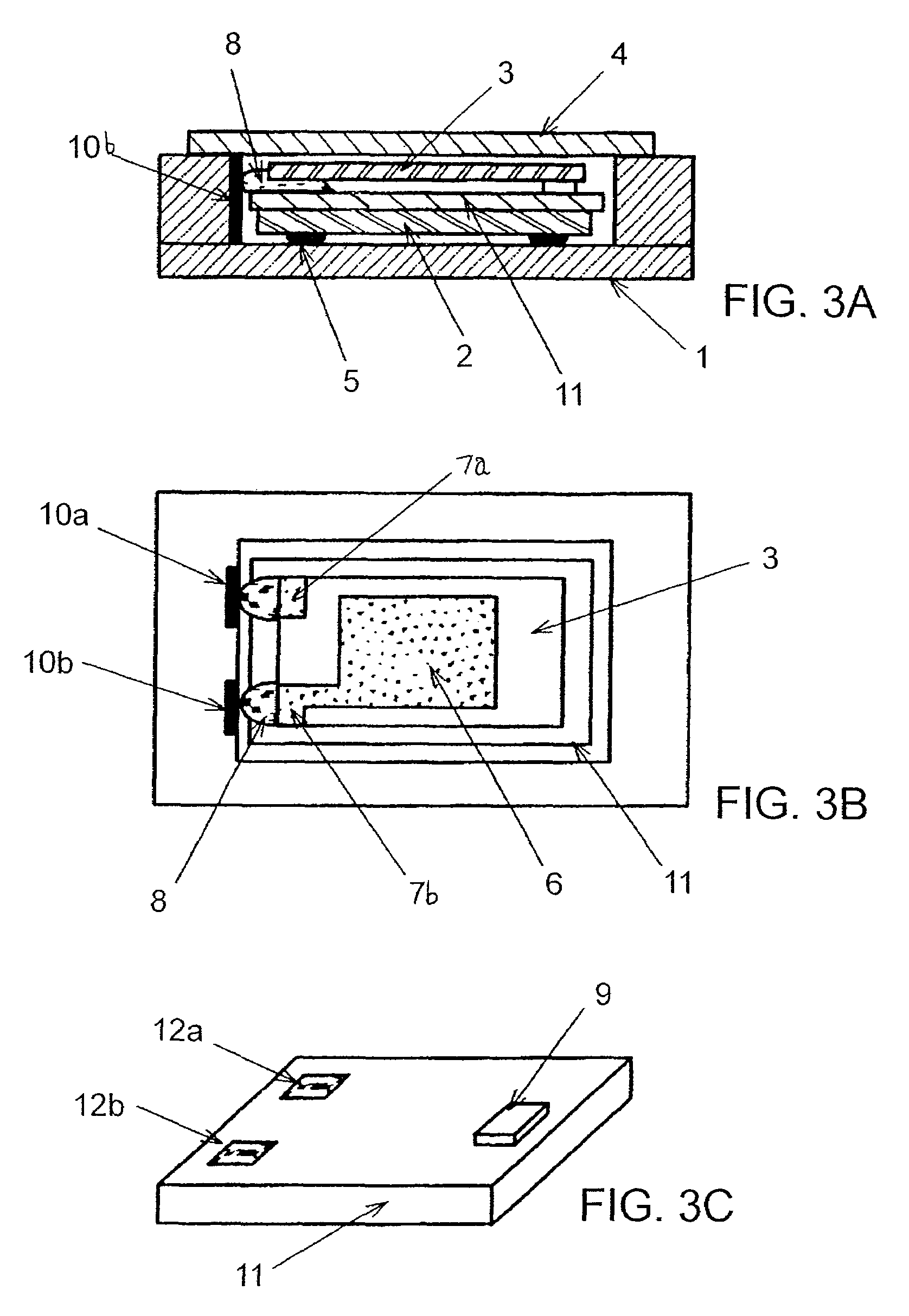

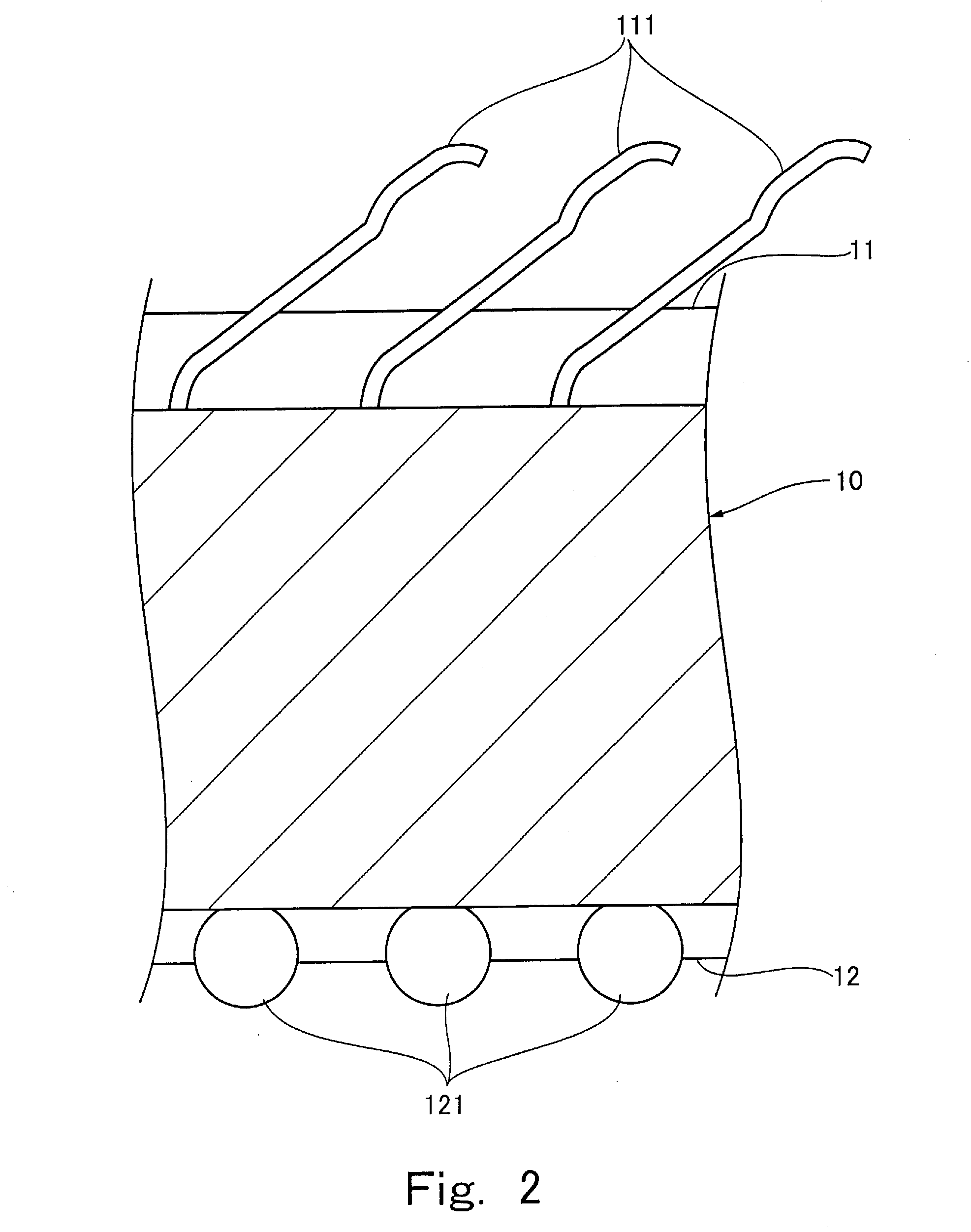

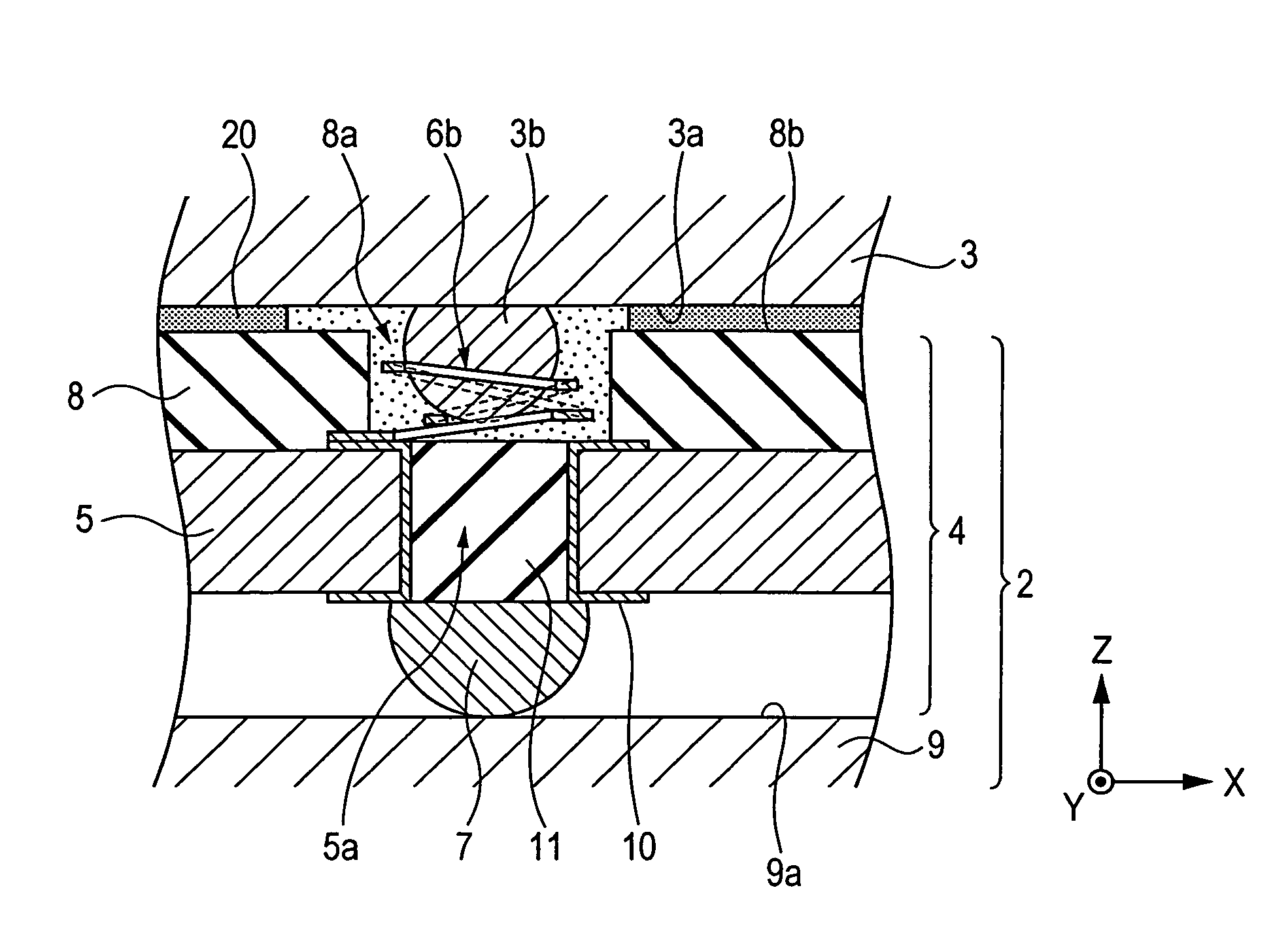

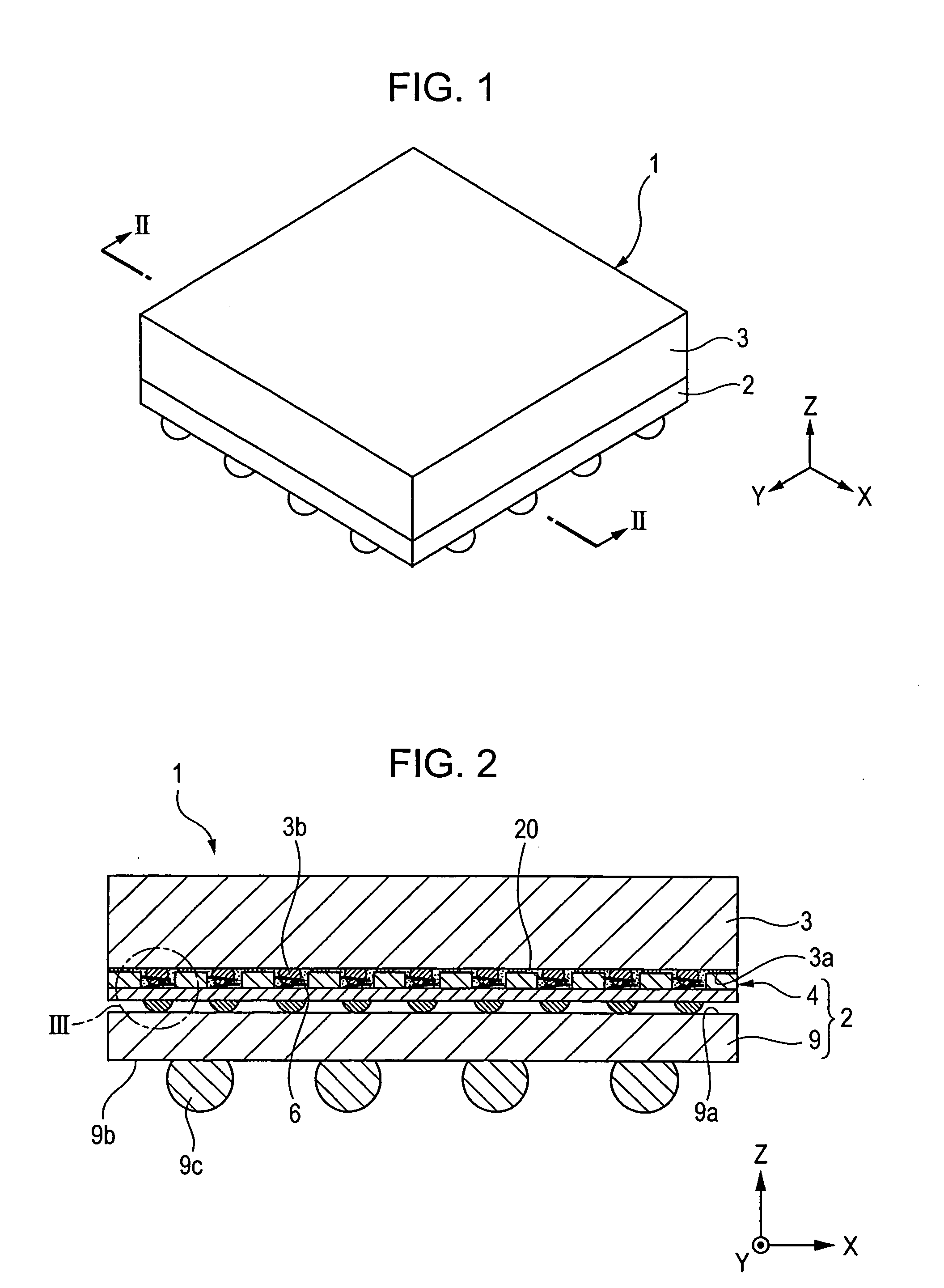

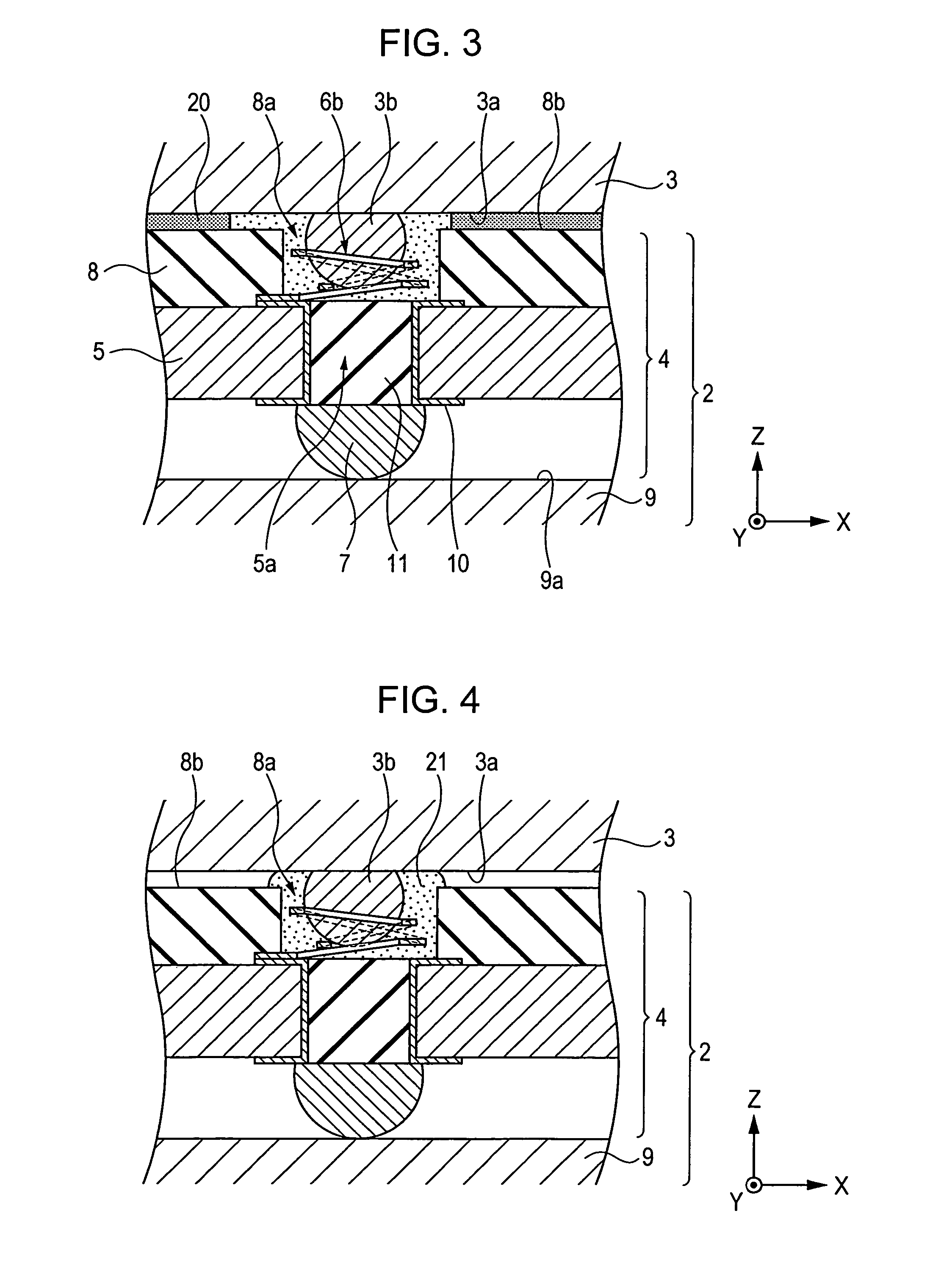

Surface mount crystal oscillator

InactiveUS7135810B2Small sizeSatisfactory vibration characteristicPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAdhesiveSurface mounting

Owner:NIHON DEMPA KOGYO CO LTD

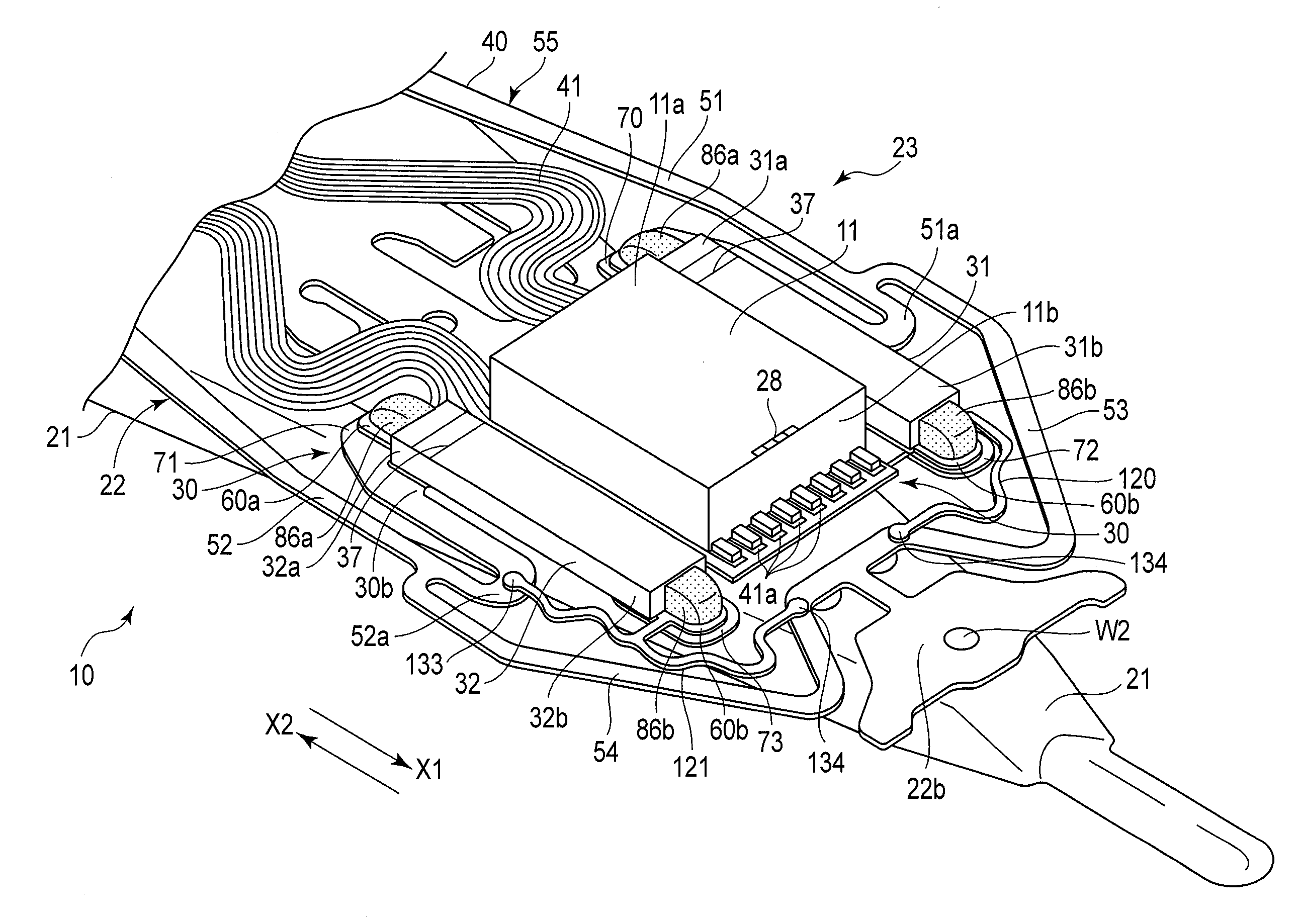

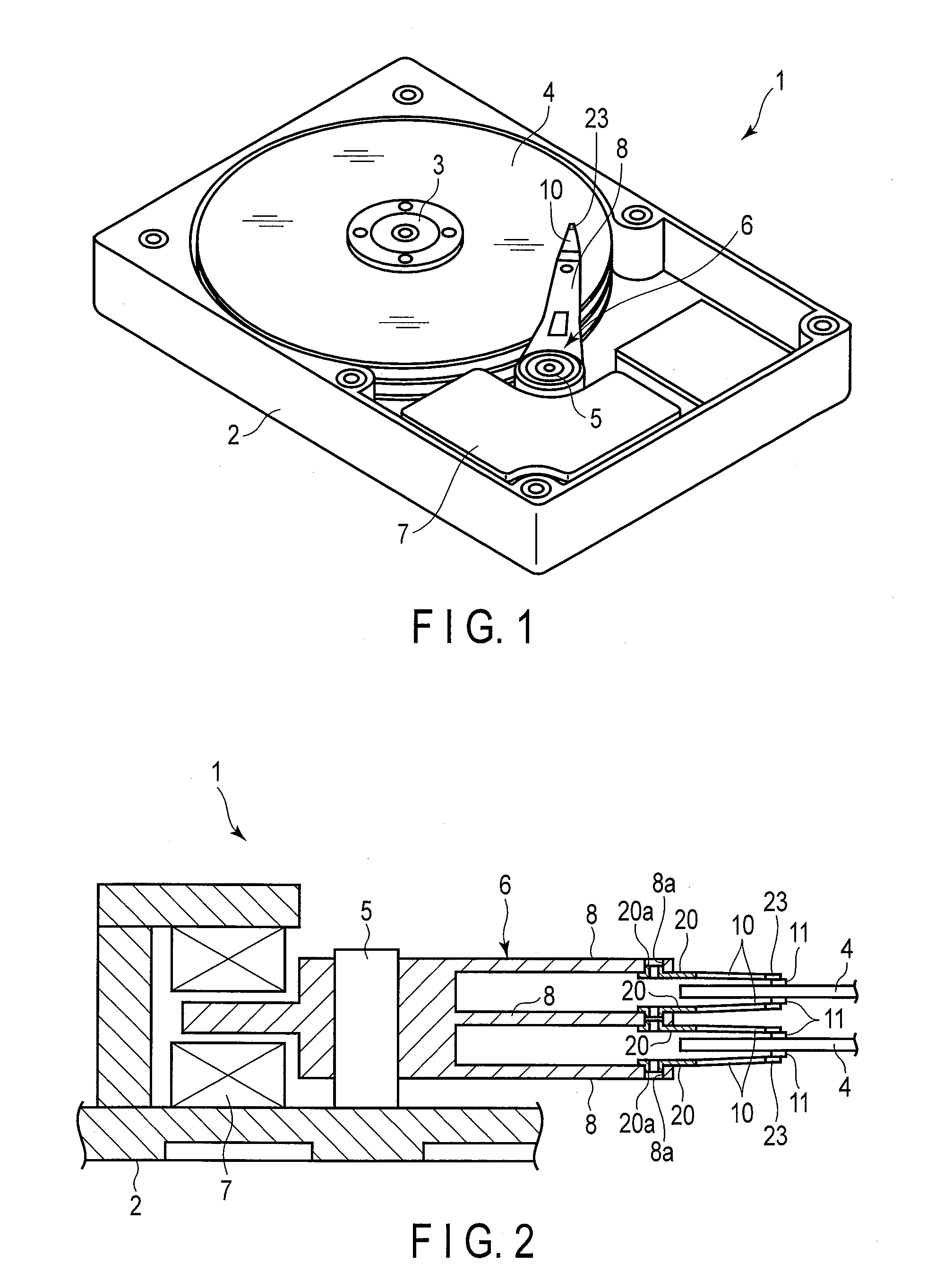

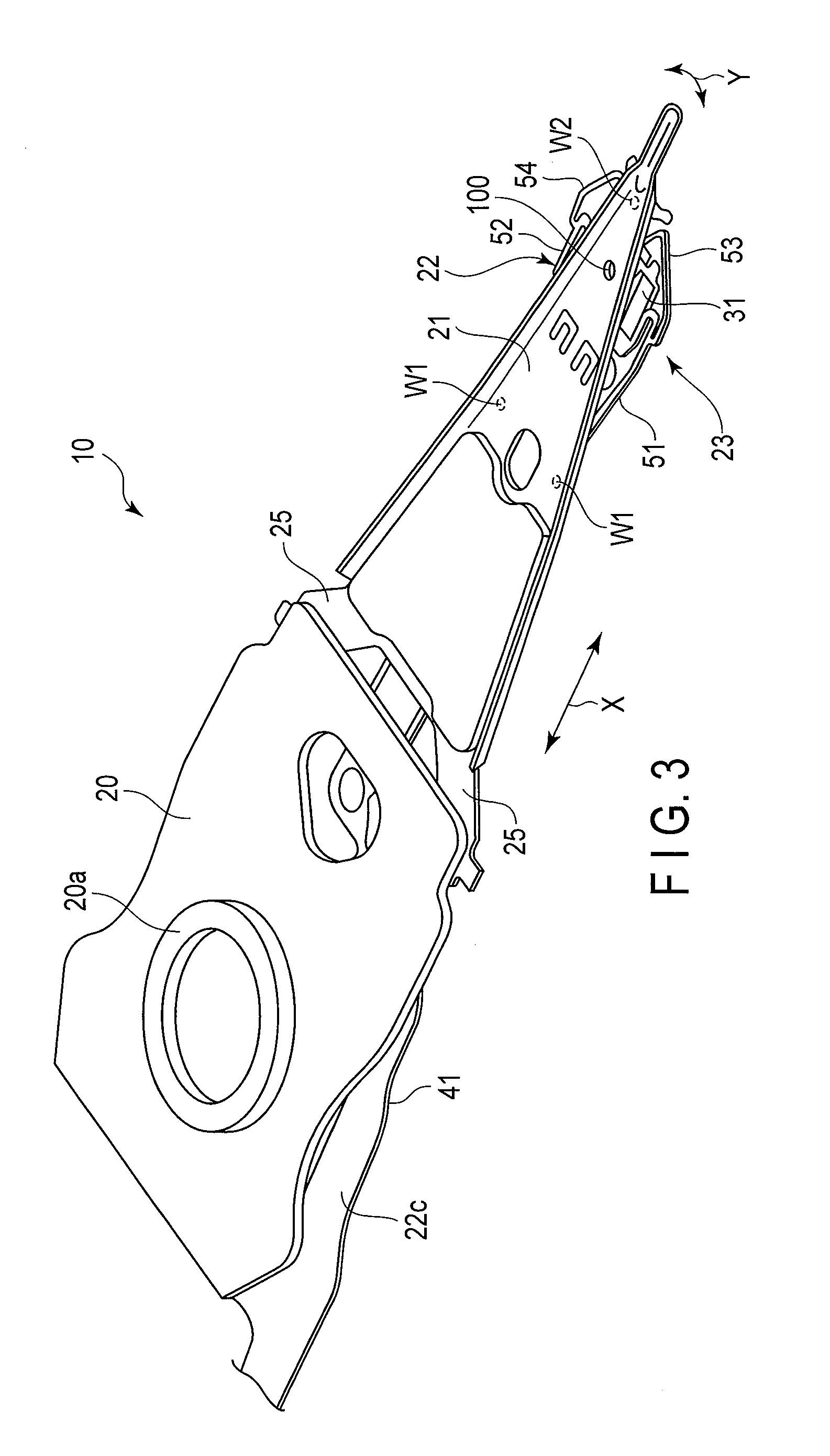

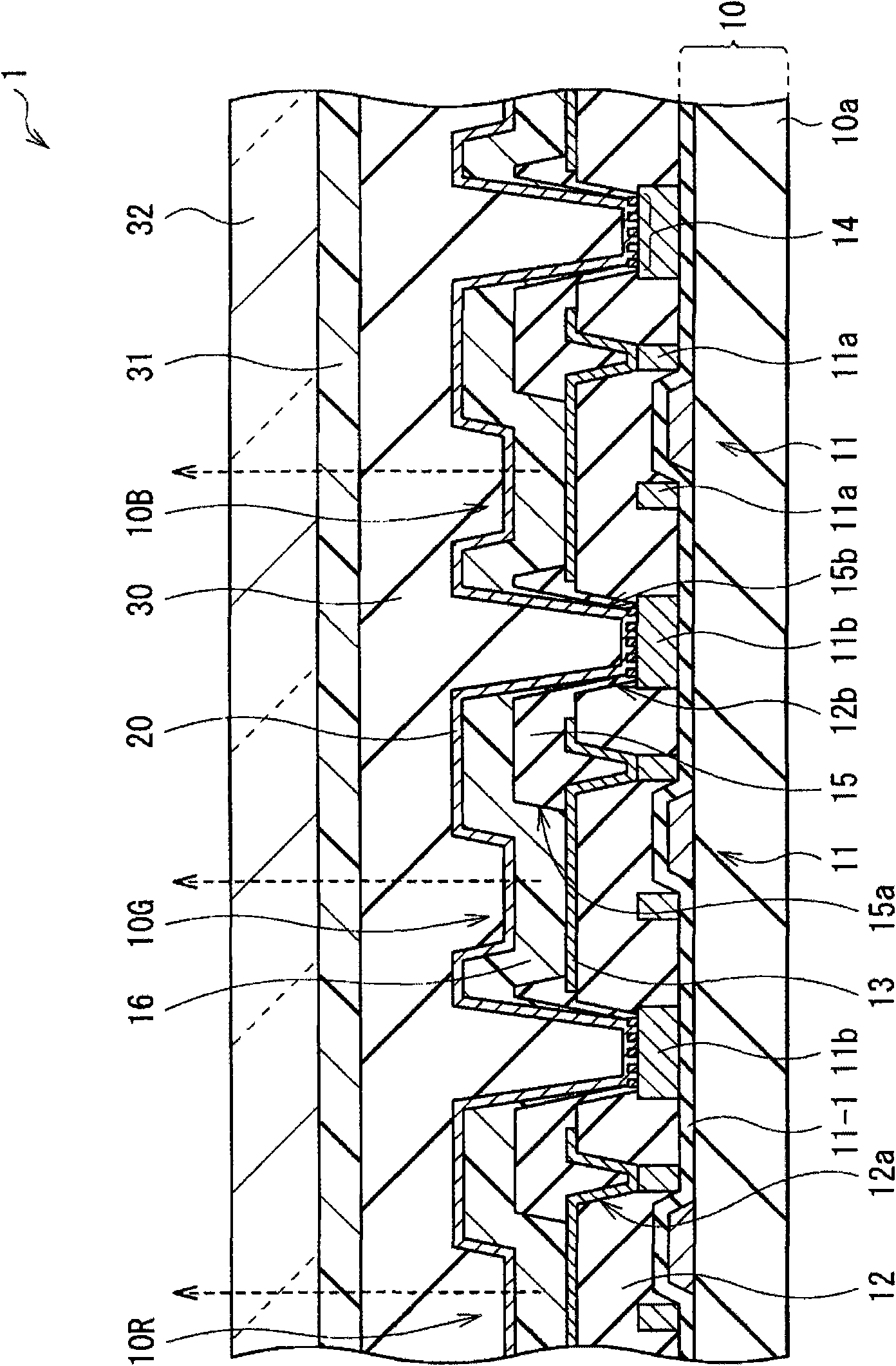

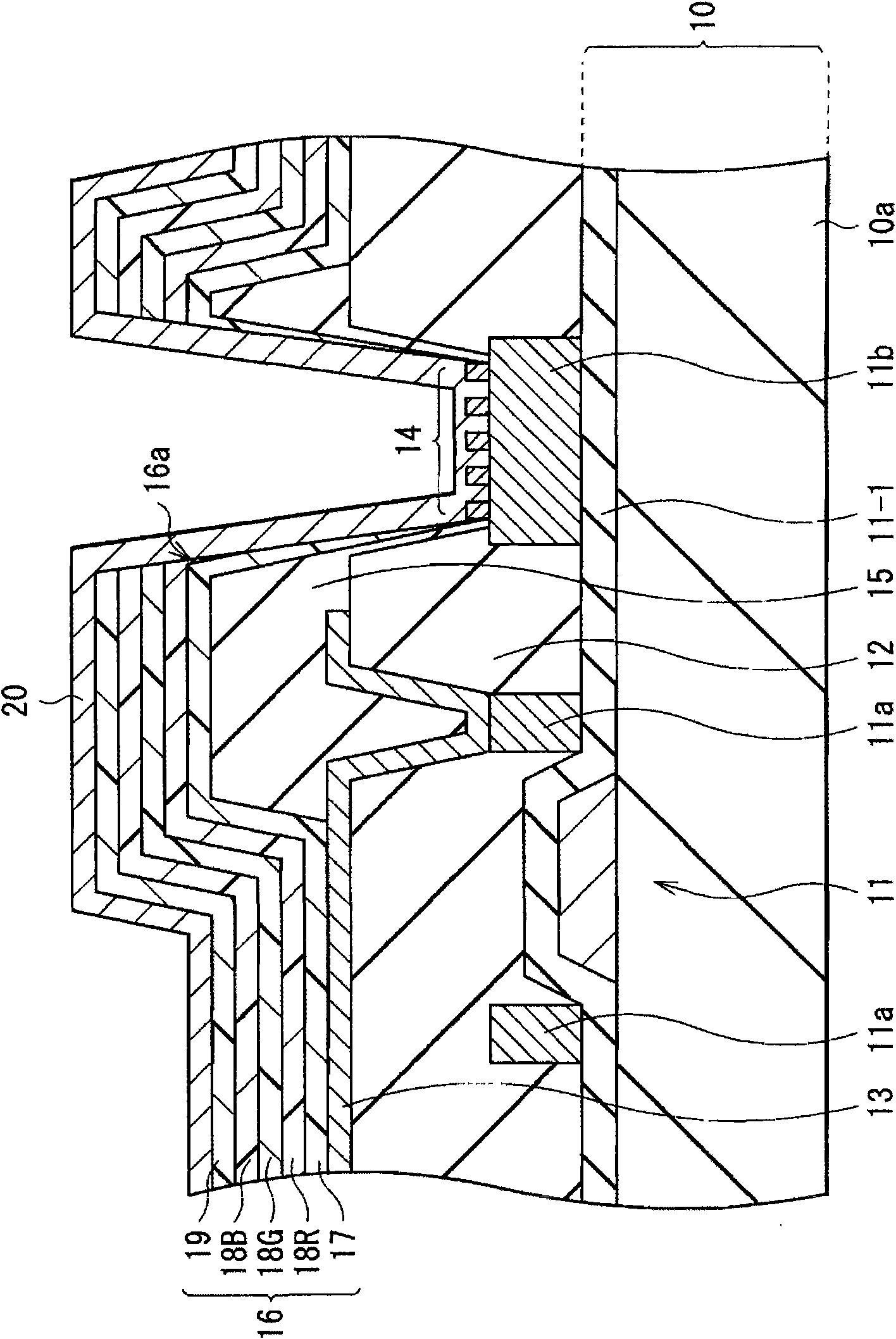

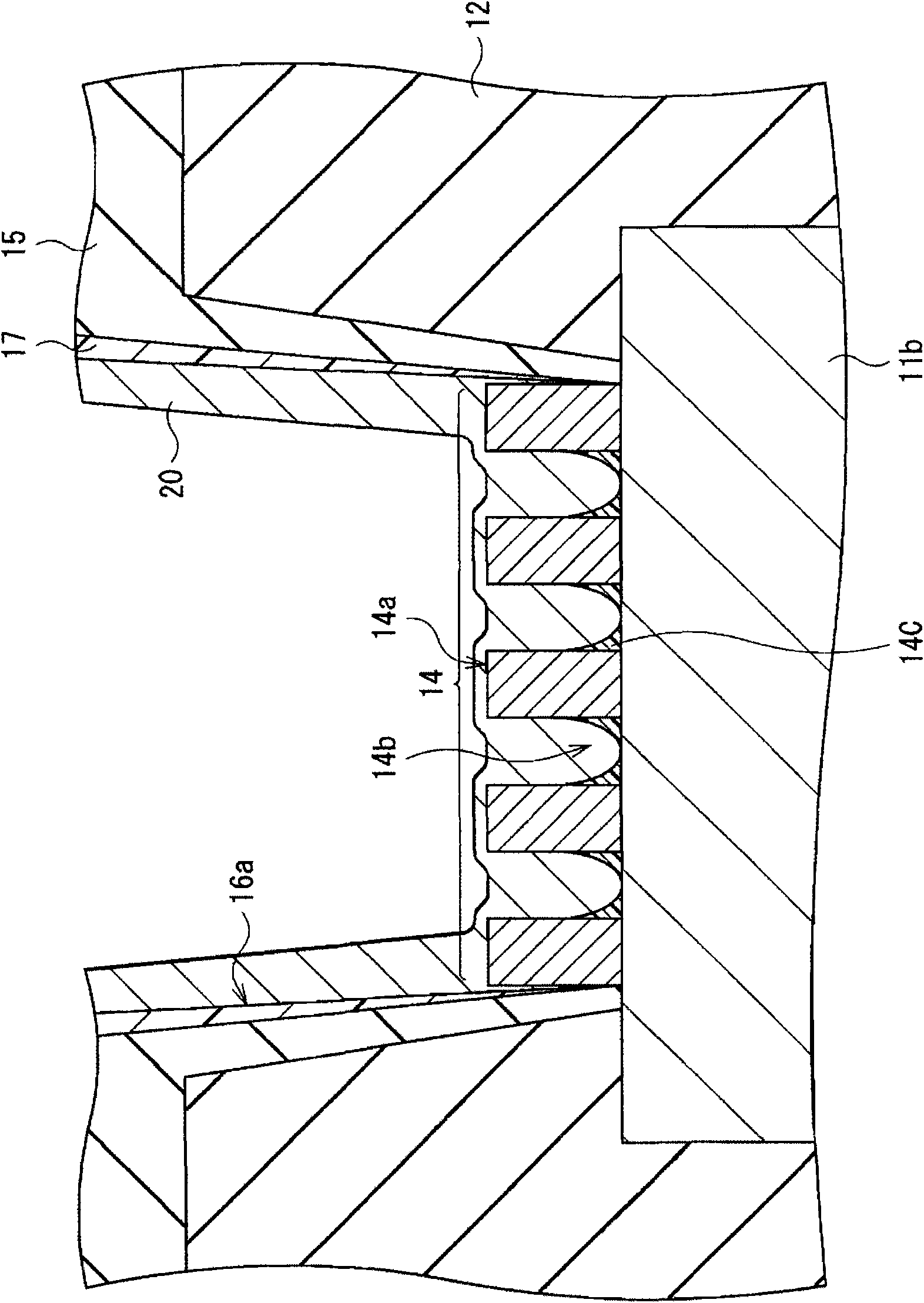

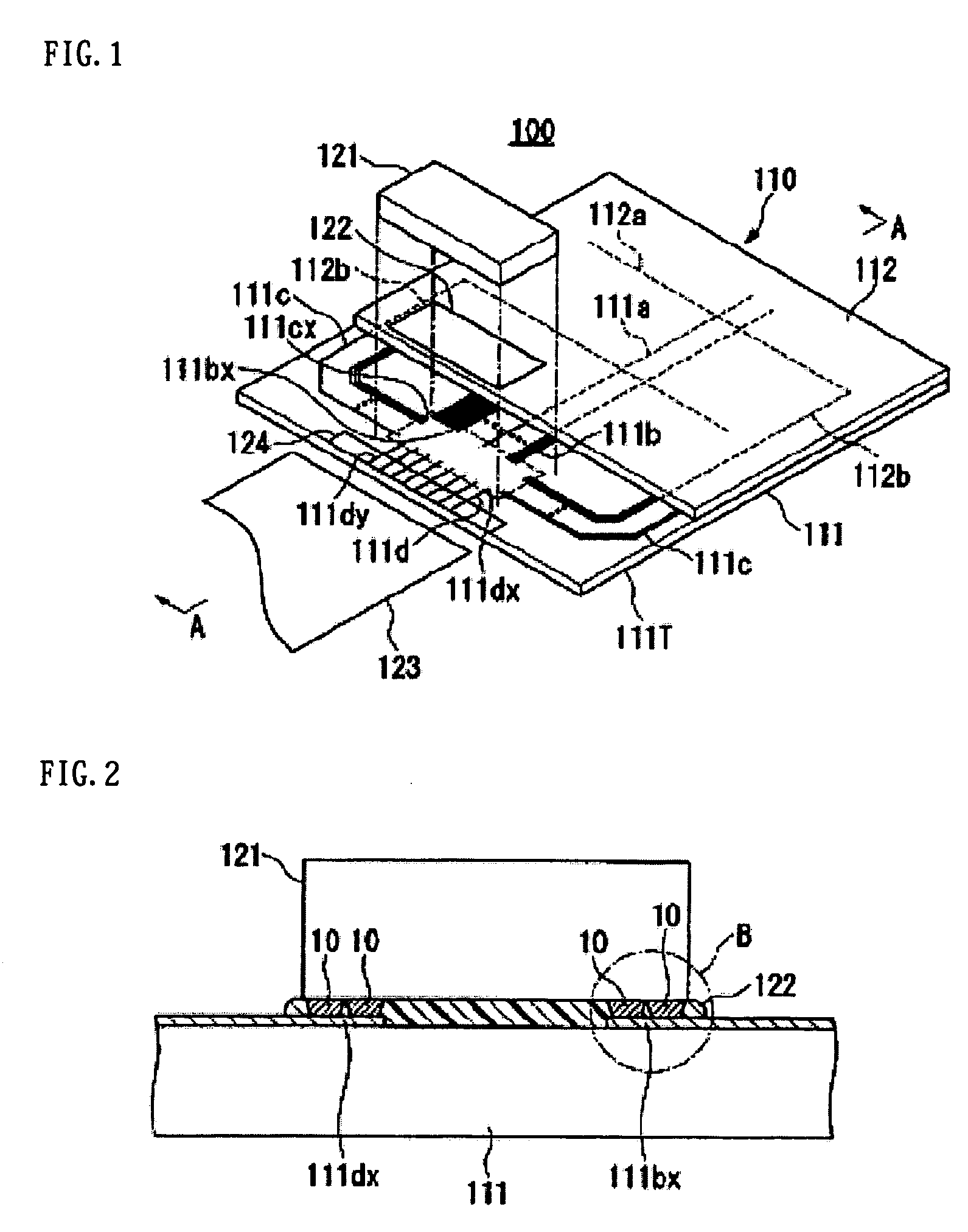

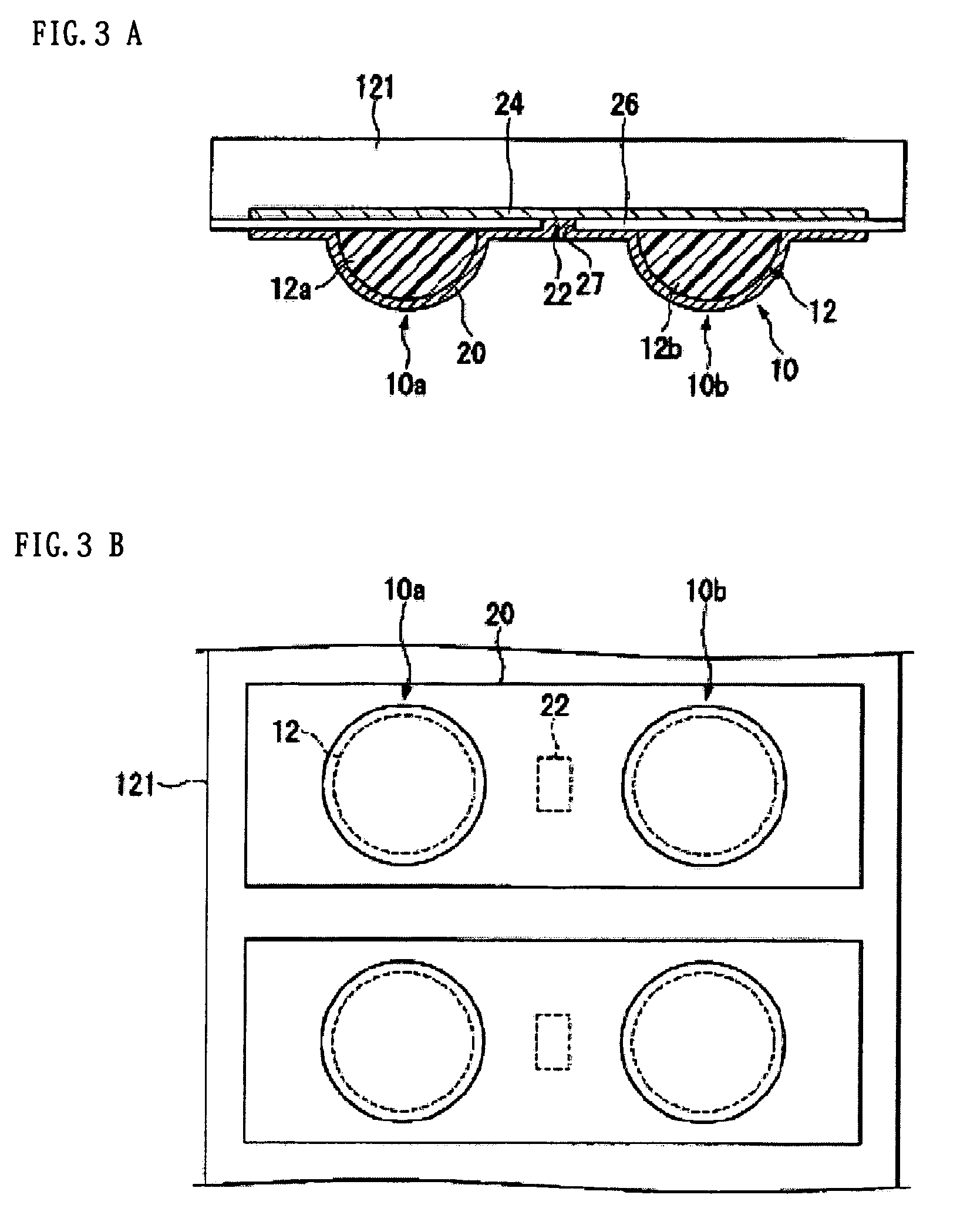

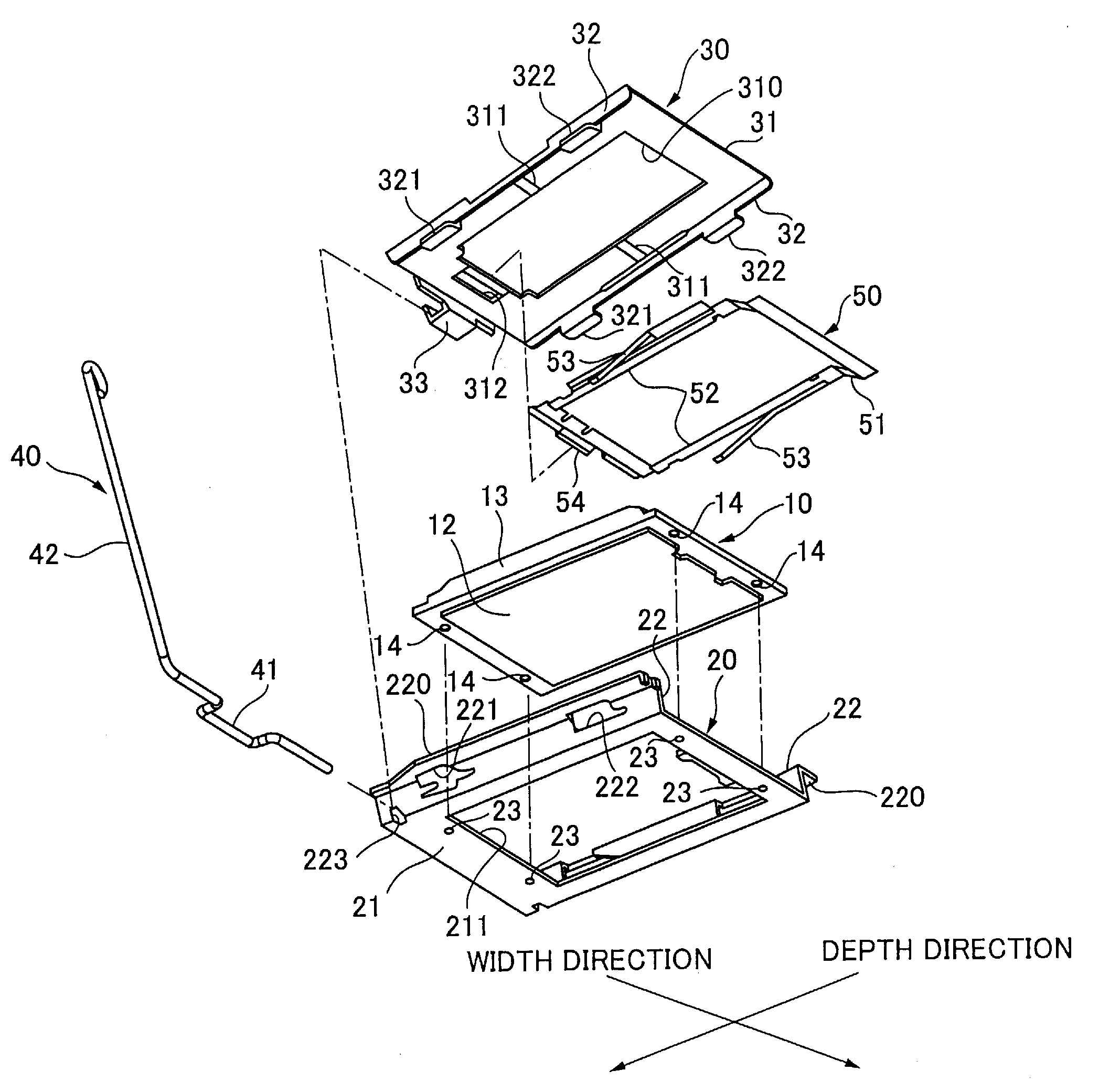

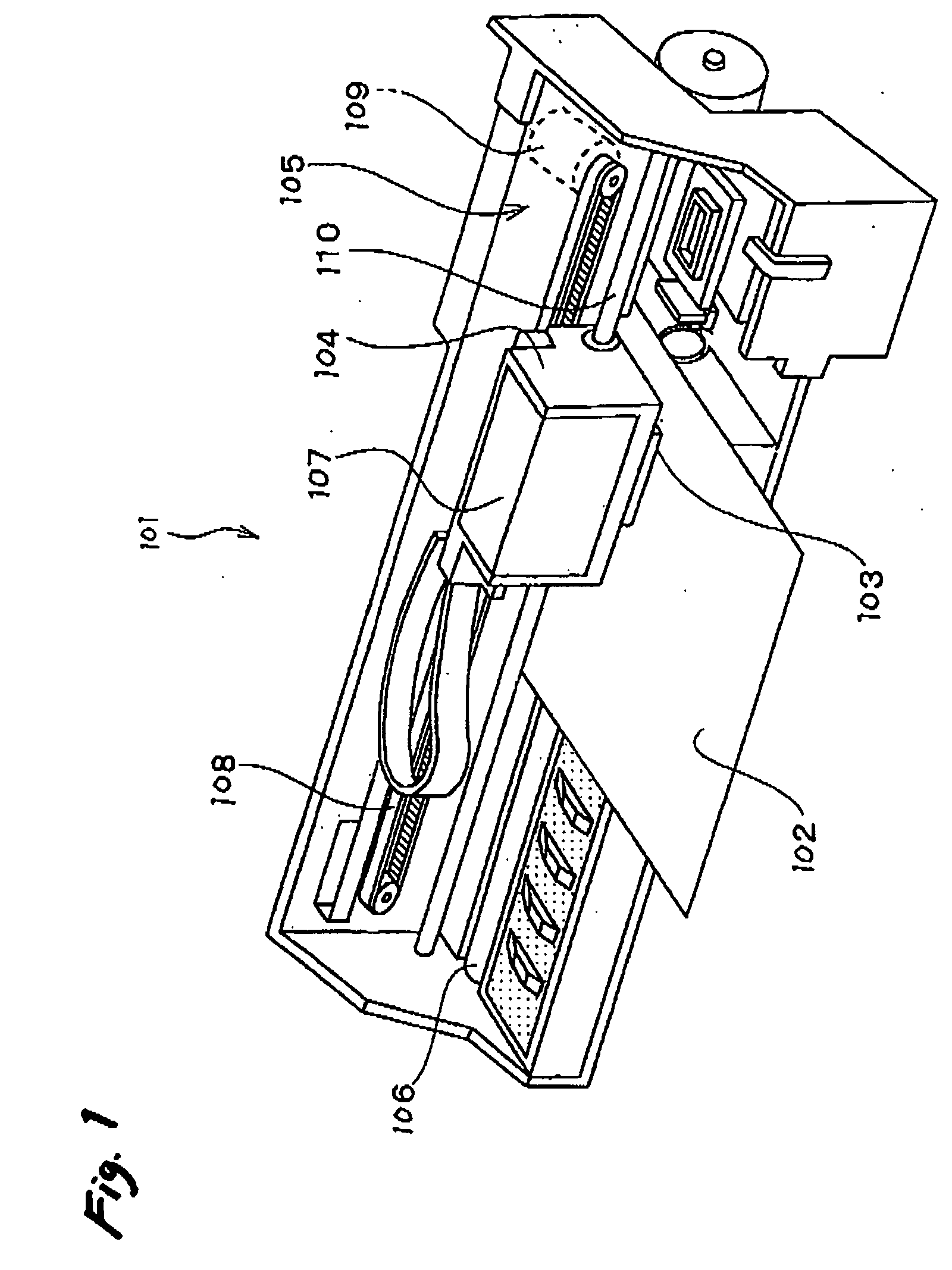

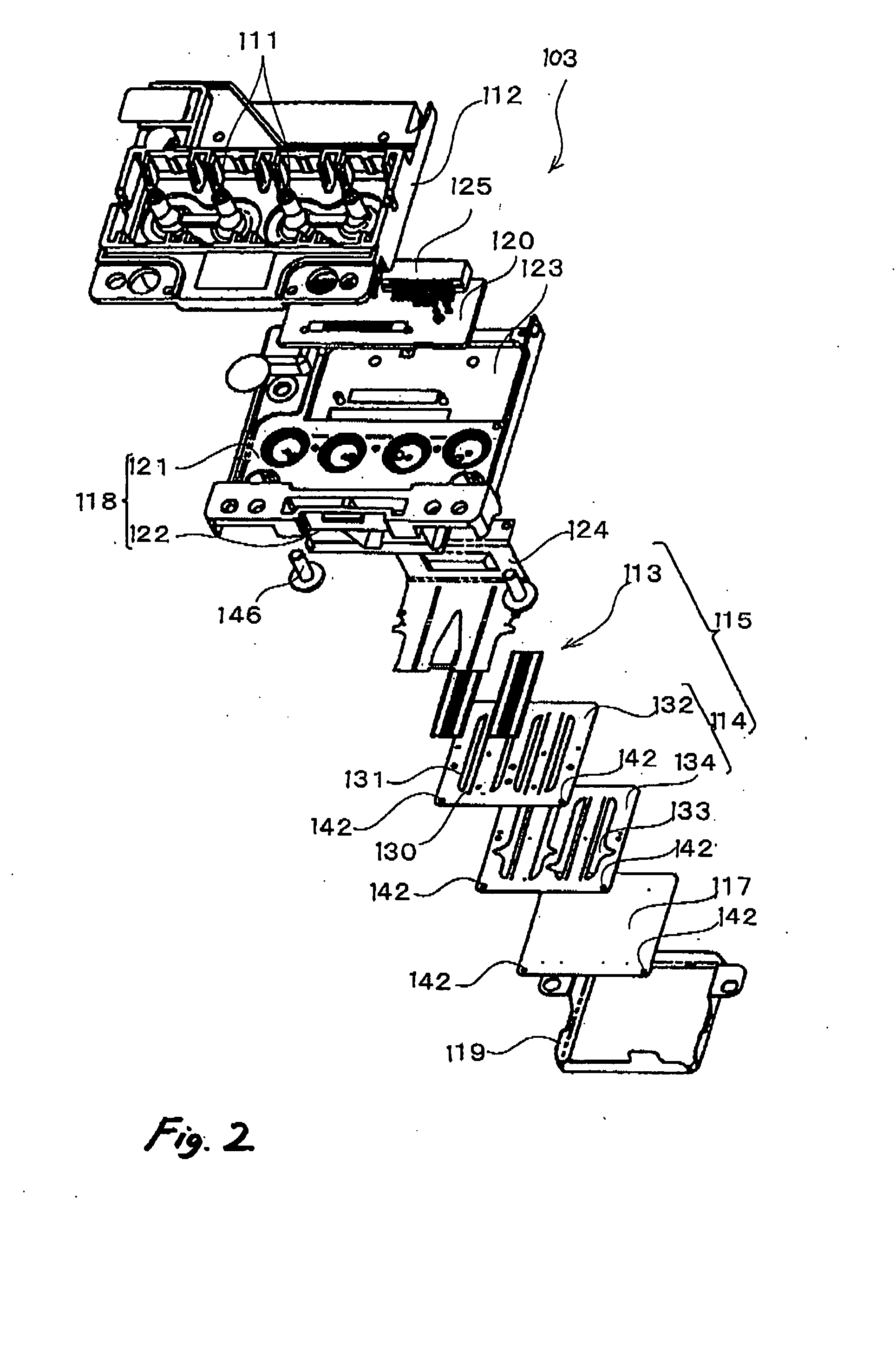

Disk drive suspension

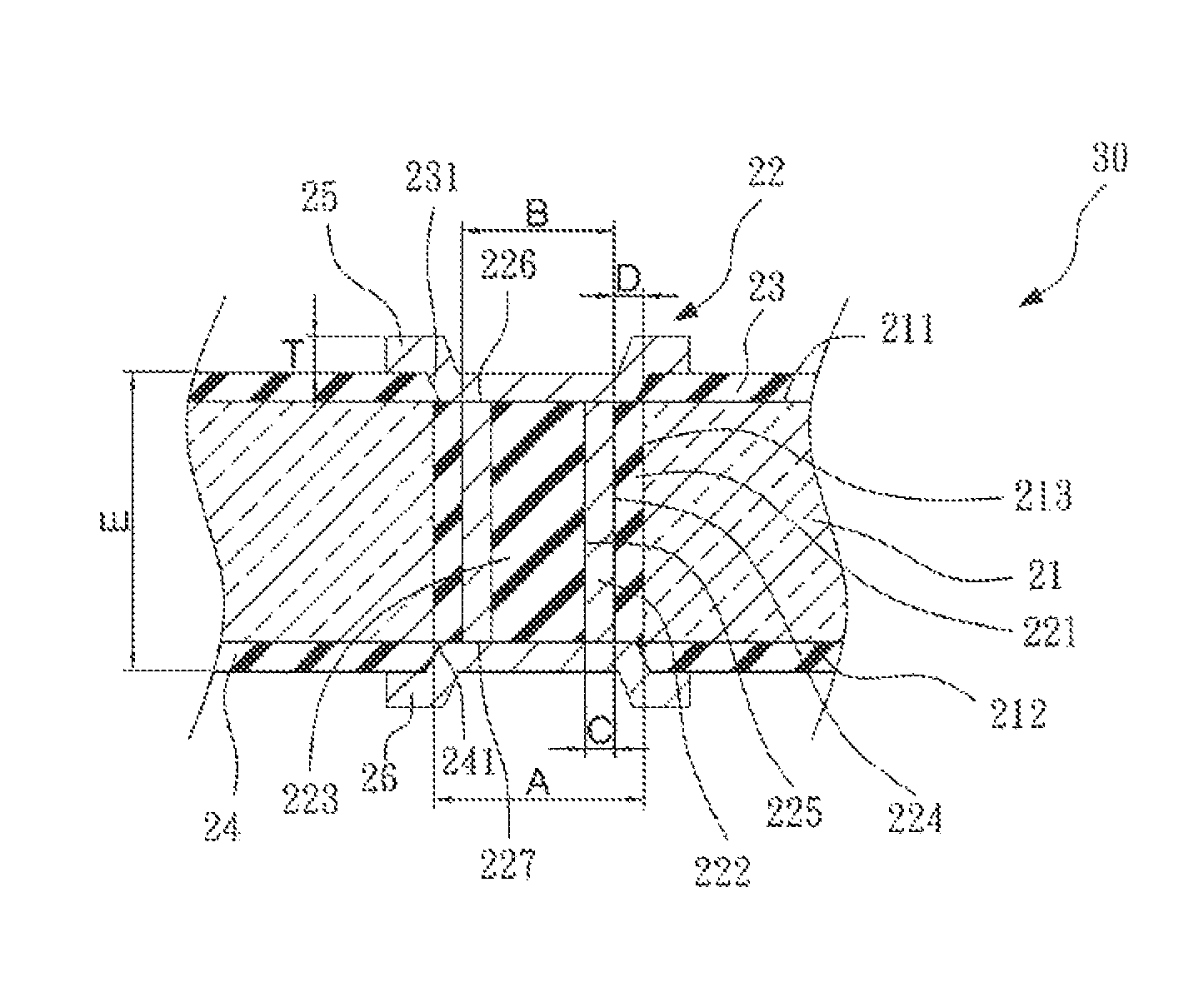

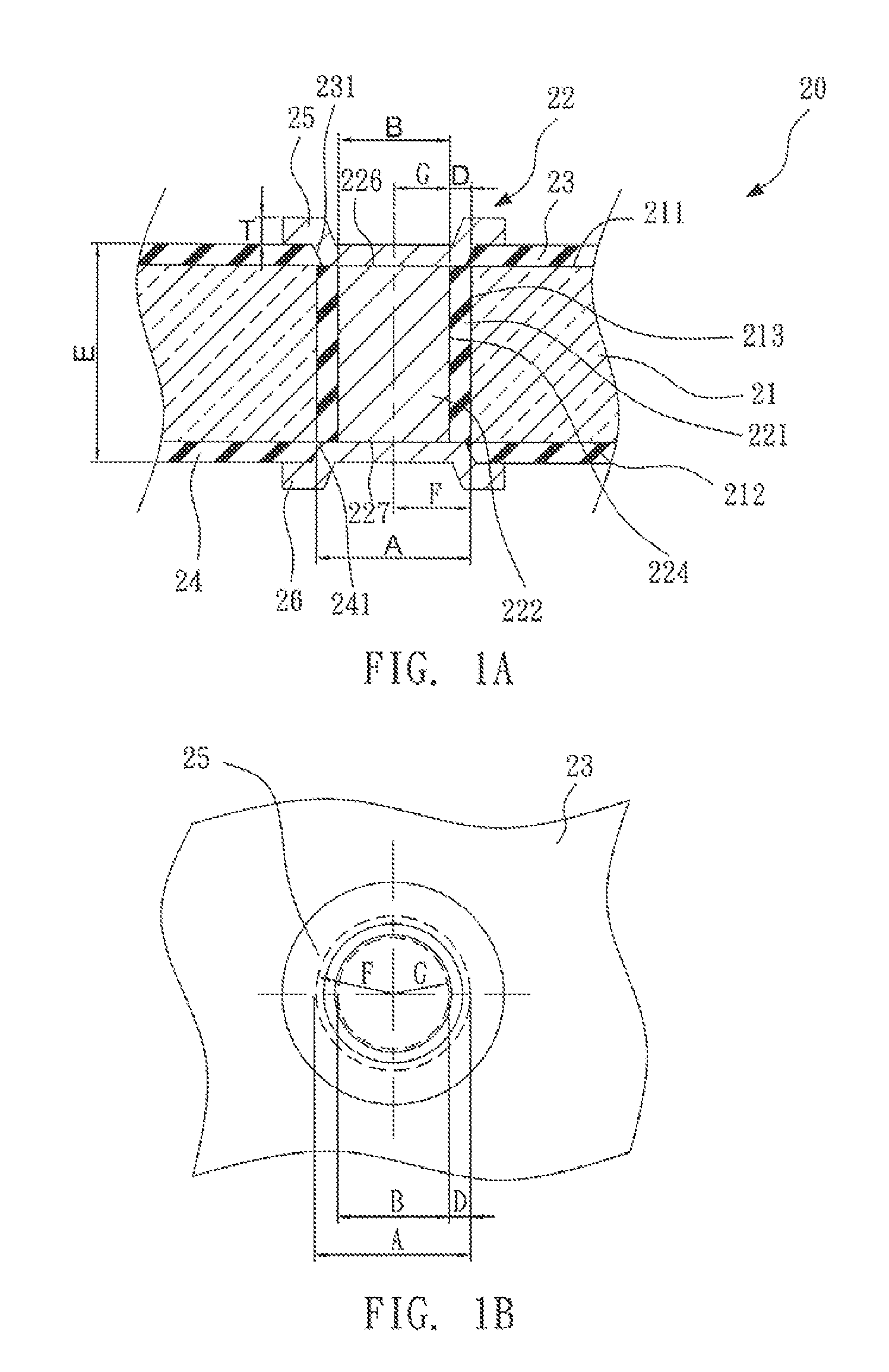

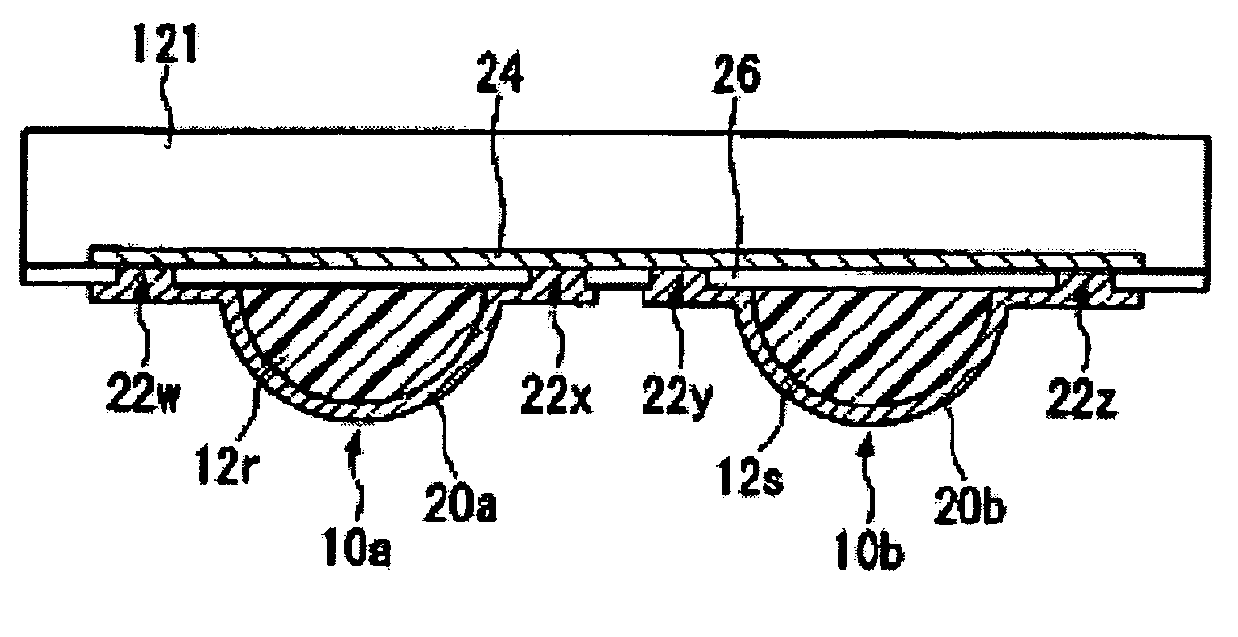

ActiveUS20140022675A1Ensure electrical connectionEasy to separateRecord information storageMounting of arm assembliesElectrically conductiveAdhesive

A microactuator element is disposed on a gimbal portion of a flexure. A first end of the element is secured to a first supporting portion by a first insulating adhesive. A second end is secured to a second supporting portion by a second insulating adhesive. A first conductor is disposed on the first supporting portion. A second conductor on the ground side is disposed on the second supporting portion. A first electrode is disposed on a first end of the element. A first electrically conductive paste is provided between the first electrode and the first conductor. A second electrode is disposed on a second end of the element. A second electrically conductive paste is provided between the second electrode and the second conductor.

Owner:NHK SPRING CO LTD

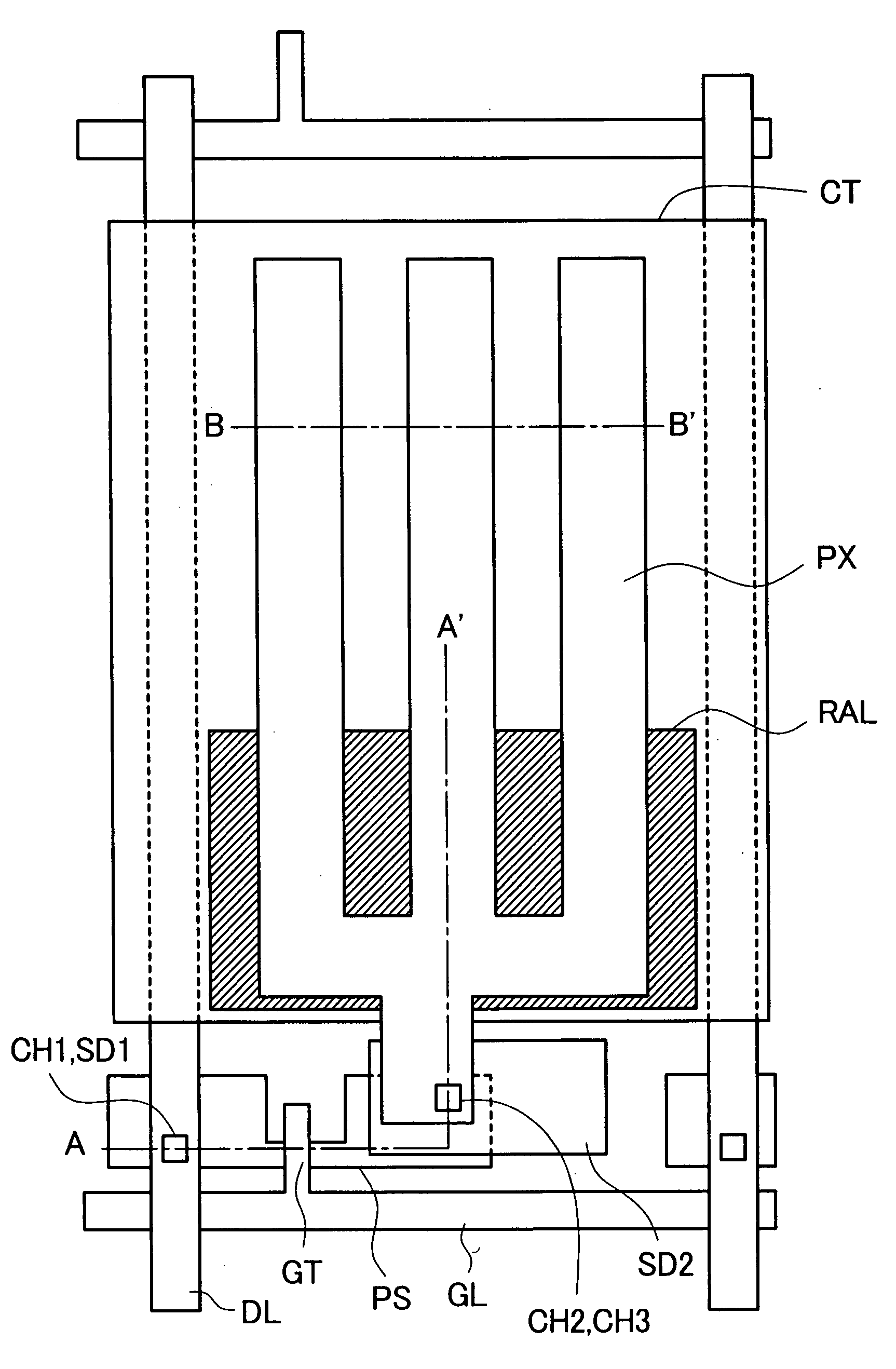

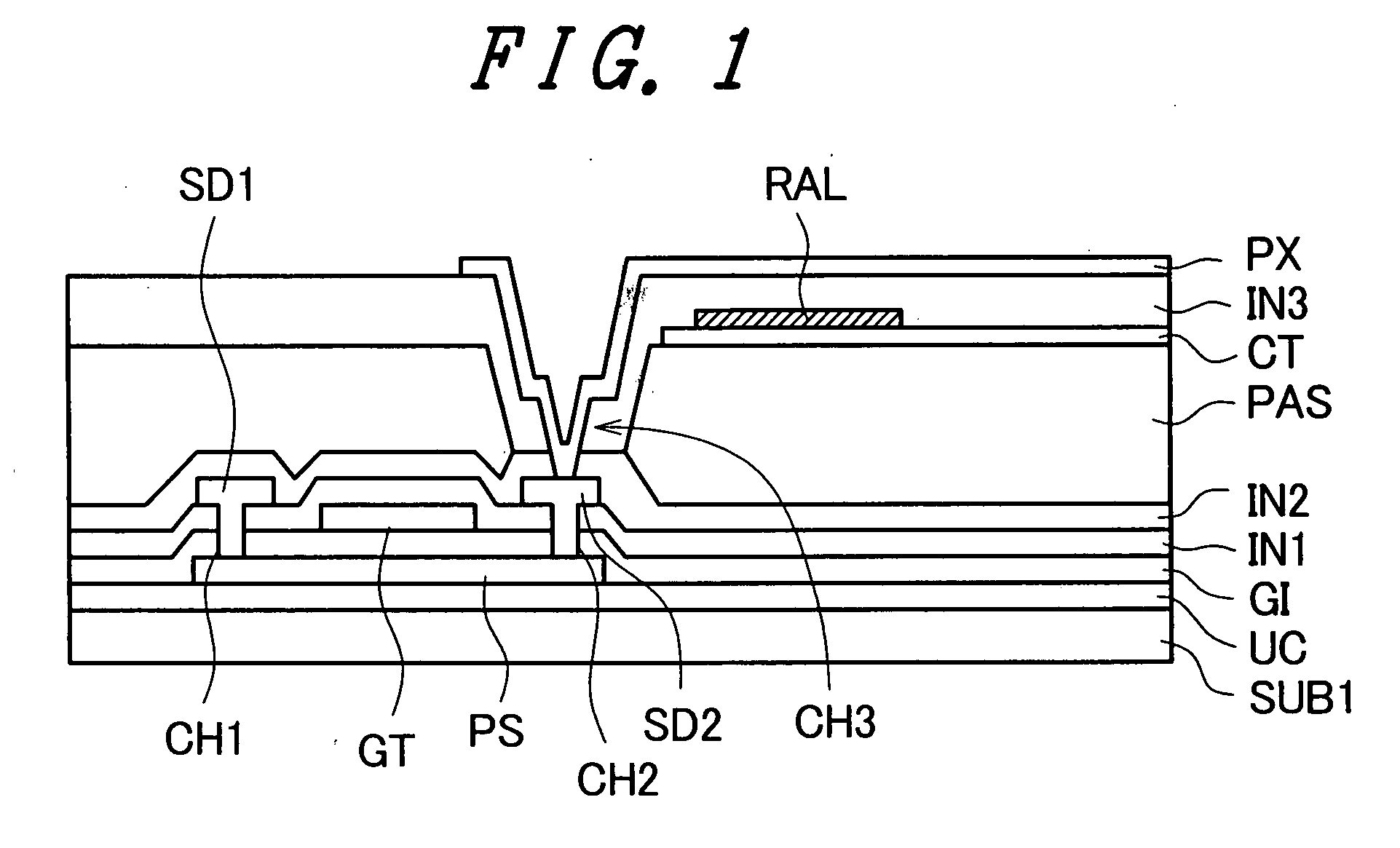

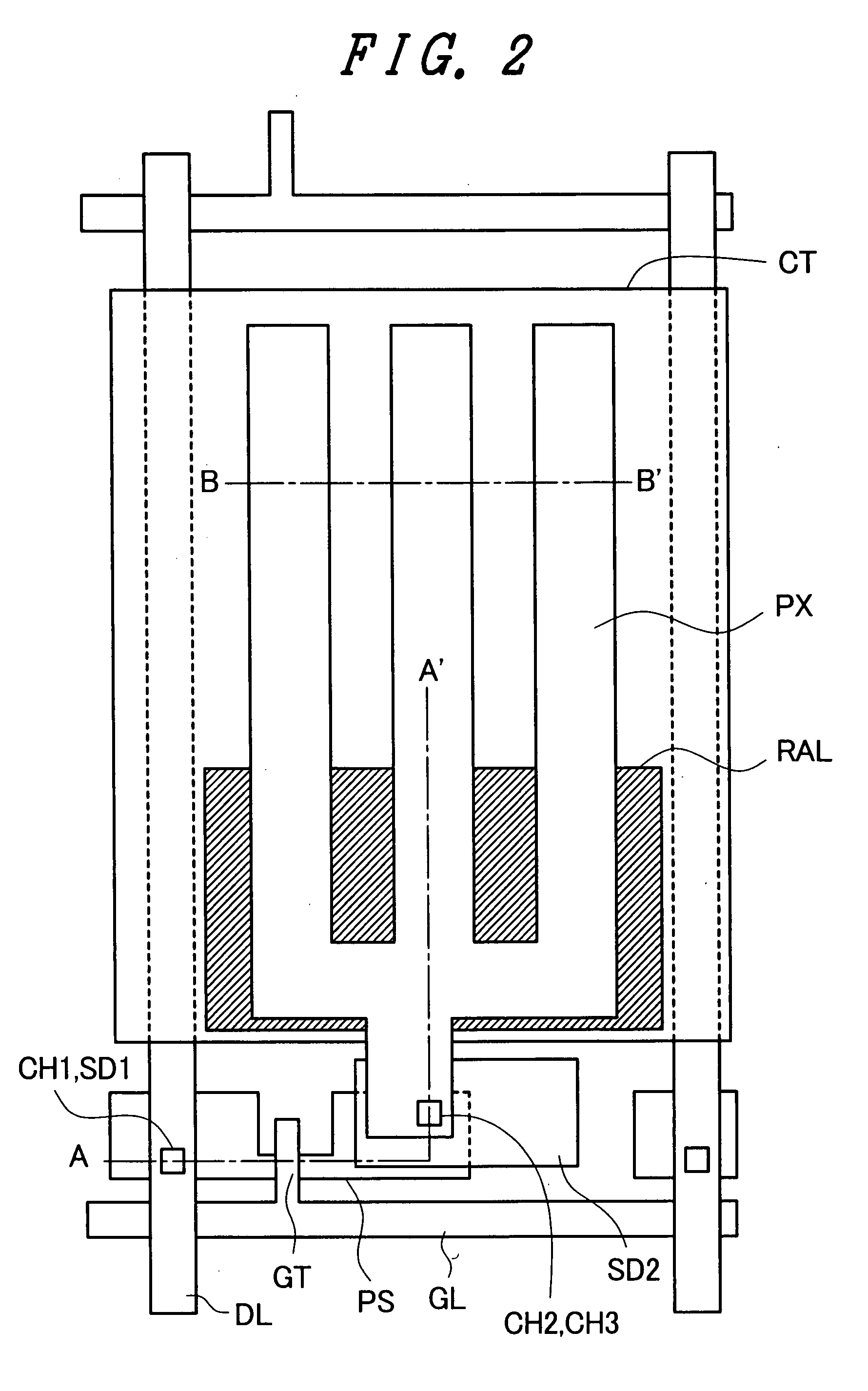

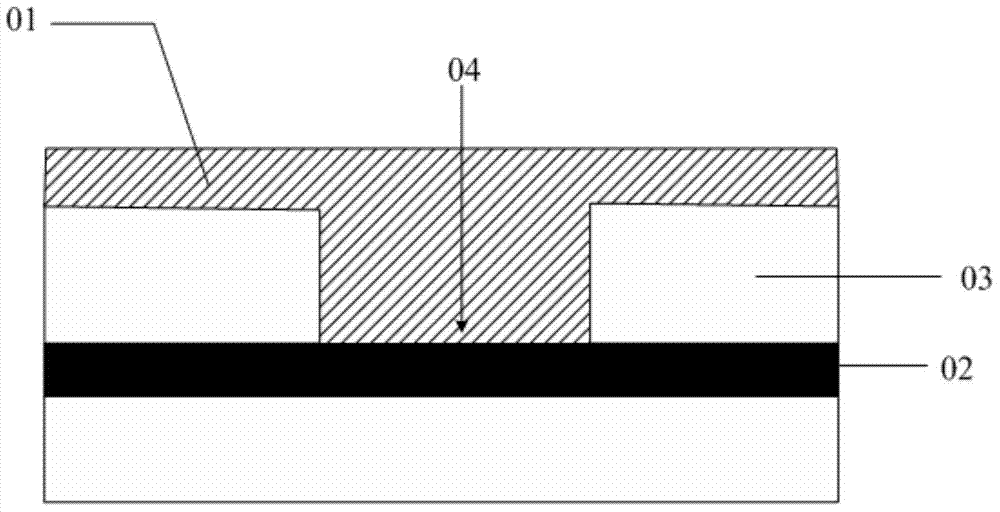

Liquid crystal display device

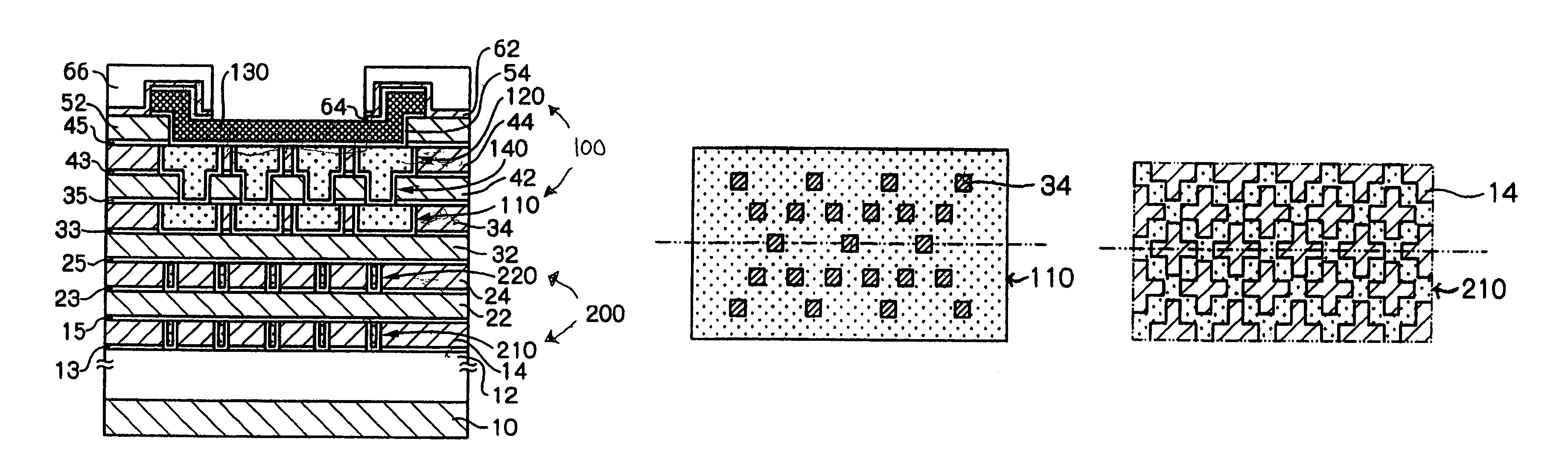

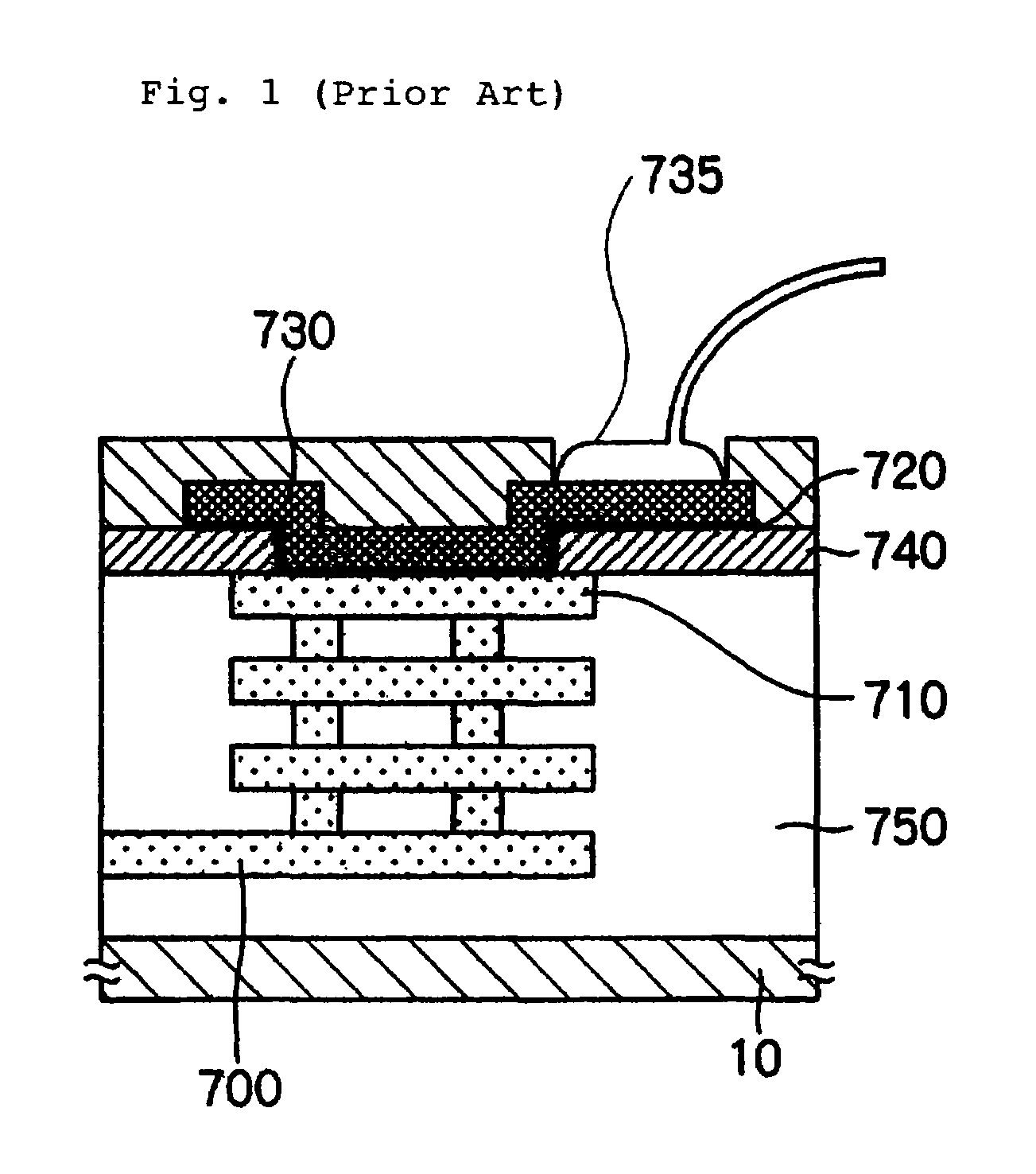

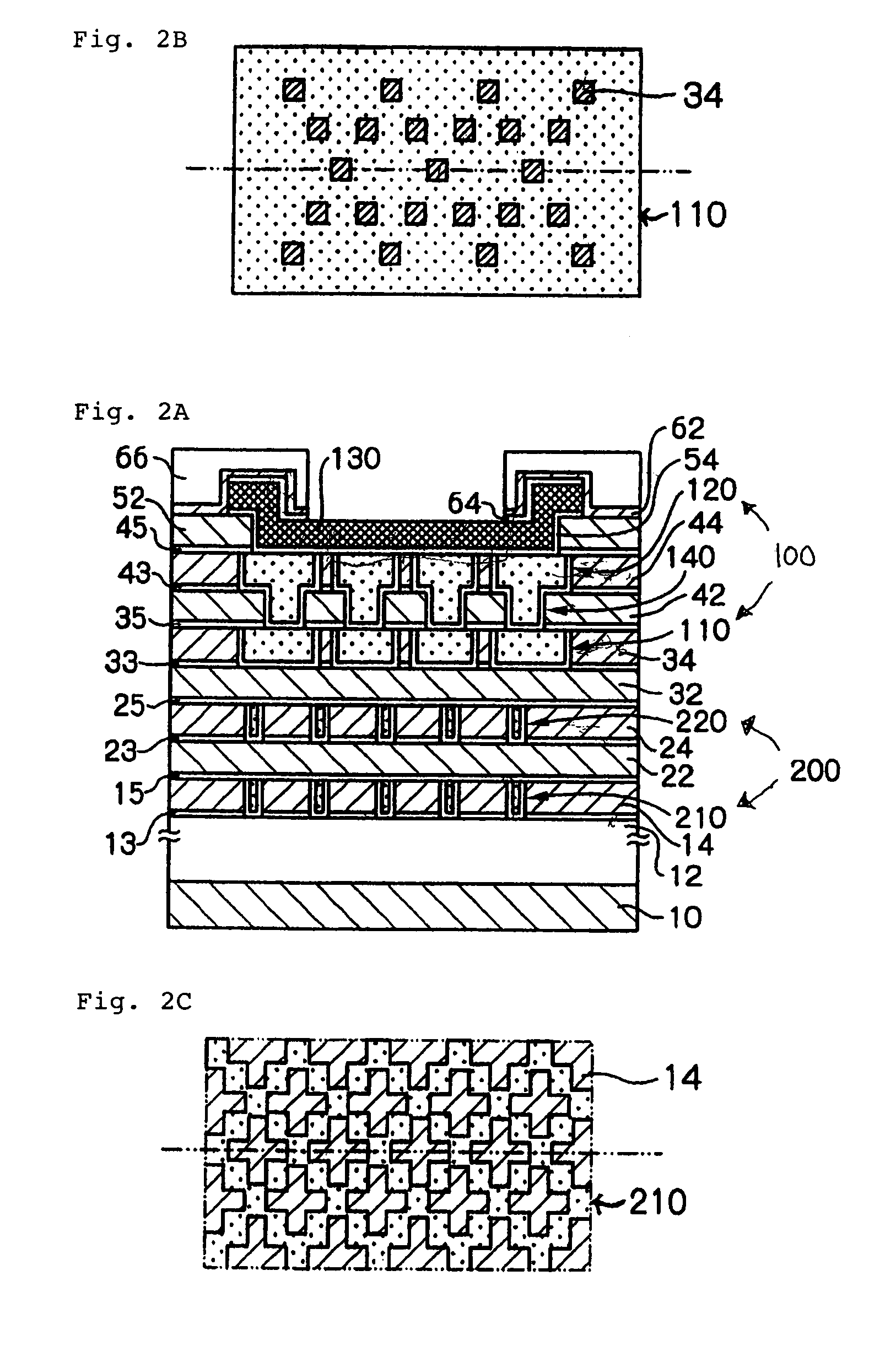

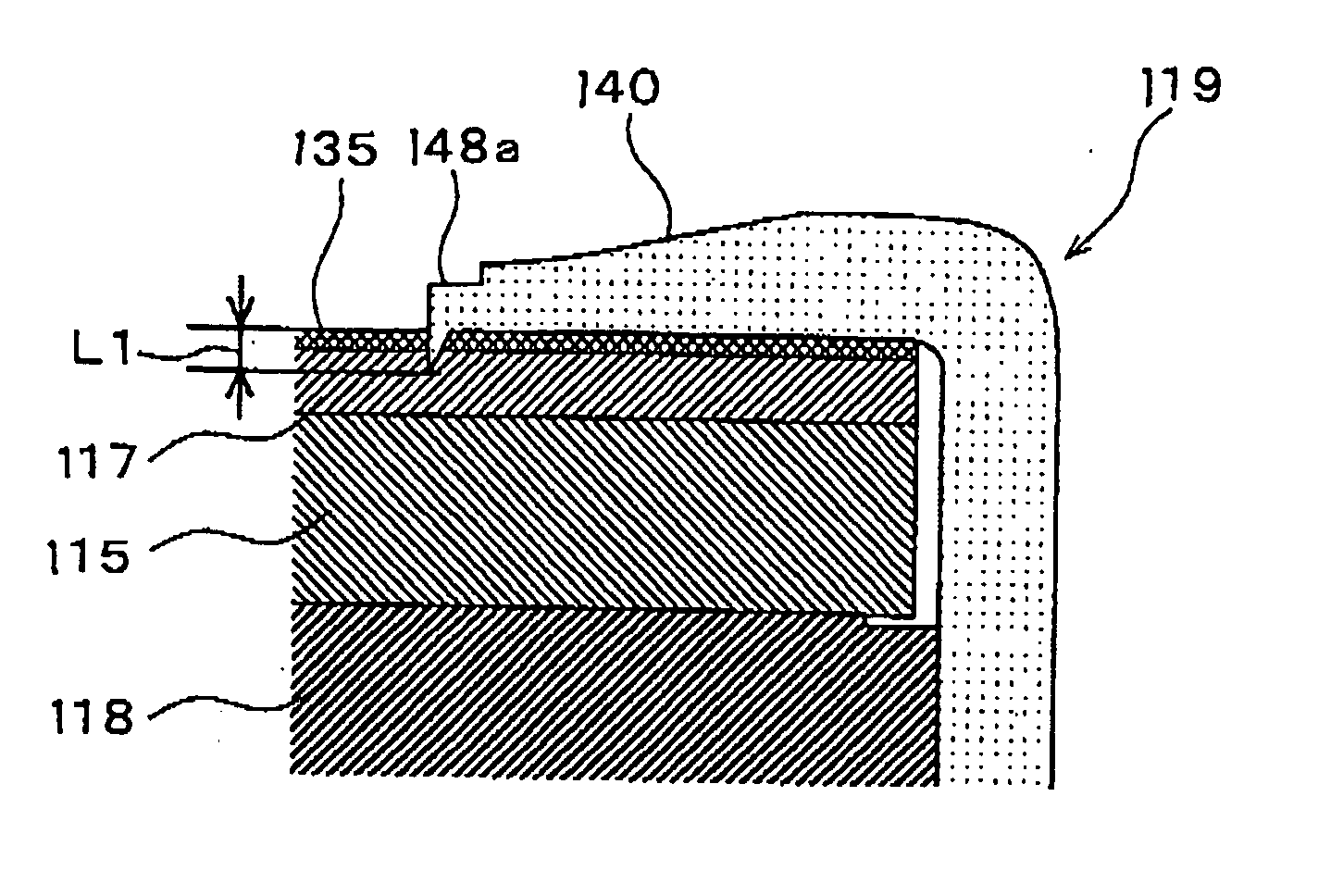

ActiveUS20070298538A1Large capacitanceAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLiquid-crystal display

The present invention provides a liquid crystal display device having a large holding capacitance in the inside of a pixel. A liquid crystal display device includes a first substrate, a second substrate arranged to face the first substrate in an opposed manner, and liquid crystal sandwiched between the first substrate and the second substrate. The first substrate includes a video signal line, a pixel electrode, a thin film transistor having a first electrode thereof connected to the video signal line and a second electrode thereof connected to the pixel electrode, a first silicon nitride film formed above the second electrode, an organic insulation film formed above the first silicon nitride film, a capacitance electrode formed above the organic insulation film, and a second silicon nitride film formed above the capacitance electrode and below the pixel electrode. The second silicon nitride film is a film which is formed at a temperature lower than a forming temperature of the first silicon nitride film. The first silicon nitride film and the second silicon nitride film form a contact hole therein by etching both of the first silicon nitride film and the second silicon nitride film collectively by dry etching. The second electrode and the pixel electrode are connected to each other via the contact hole. A potential different from a potential applied to the pixel electrode is applied to the capacitance electrode, and a holding capacitance is formed by the pixel electrode, the second silicon nitride film and the capacitance electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

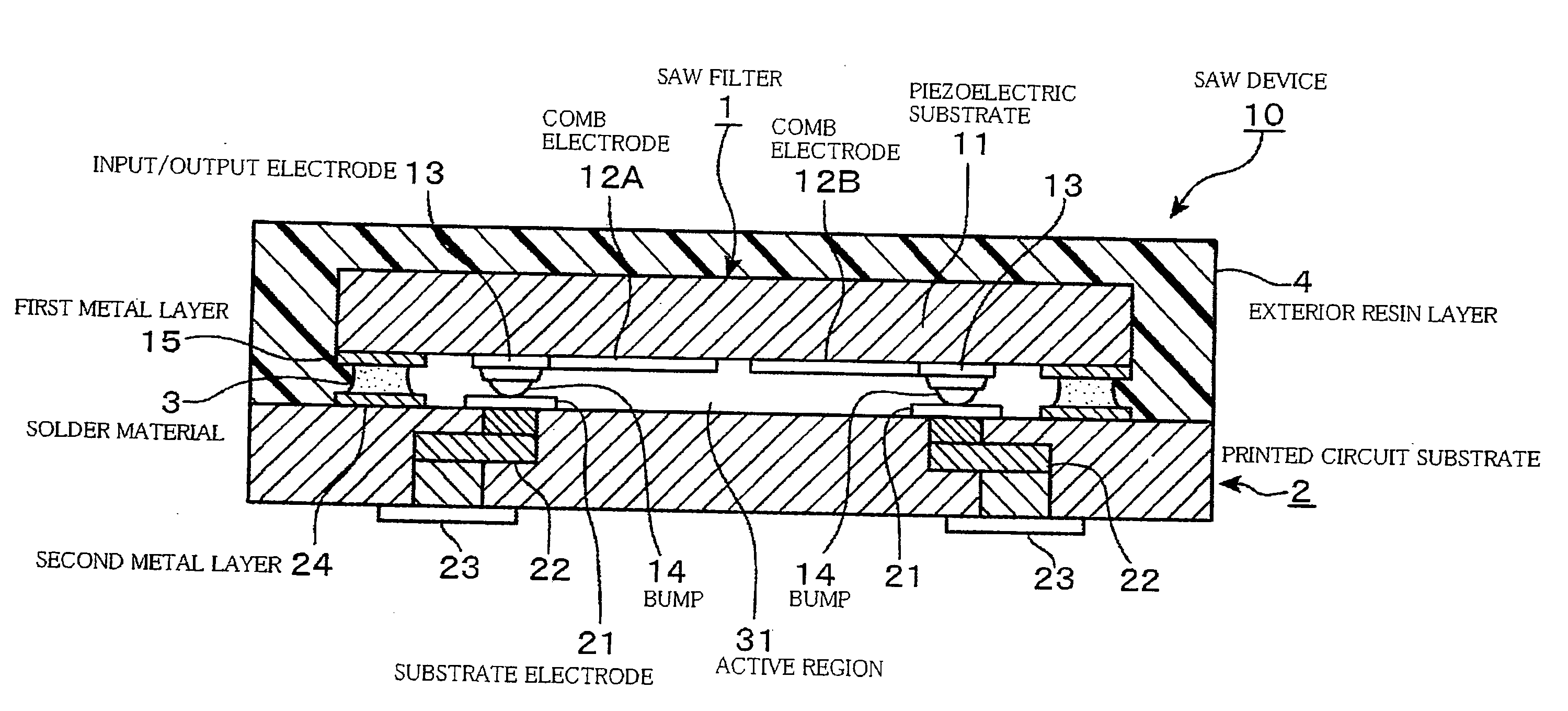

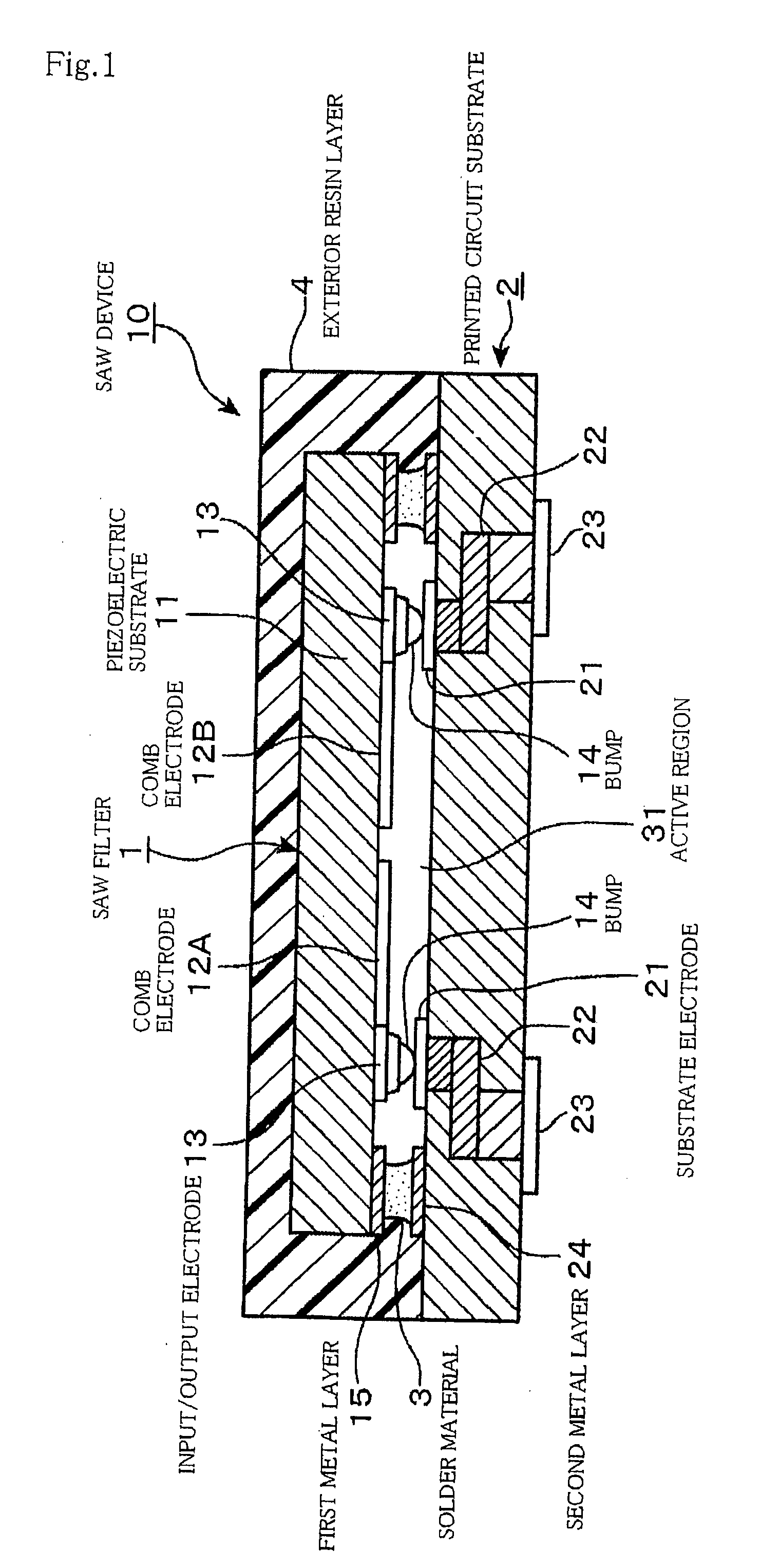

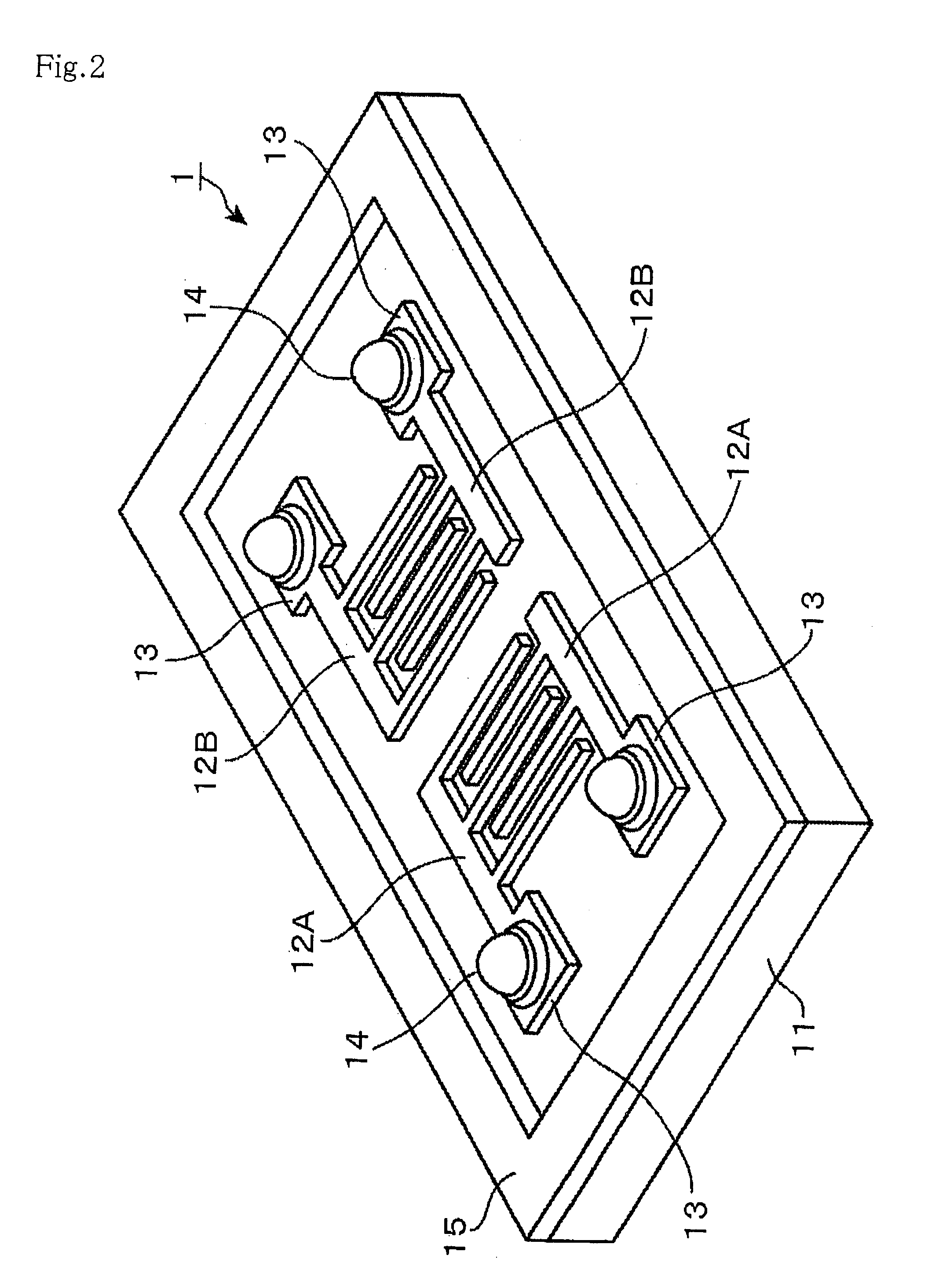

Electronic component and manufacturing method thereof

InactiveUS20070008051A1Improve moisture resistanceIncrease in sizeImpedence networksSolid-state devicesElectrical connectionMoisture resistance

There is provided an electronic component excellent in moisture resistance capable of ensuring electrical connection between electrodes and hermeticity of a sealed region including a vibrating part and suppressing an increase in size. An electronic component including a piezoelectric element provided with a vibrating part and a first electrode on one face of a piezoelectric substrate and a printed circuit substrate having a second electrode is constituted by including: a bump provided in advance on one of the first electrode and the second electrode and connected to the other of the first electrode and the second electrode; an annular first metal layer surrounding the vibrating part; and a solder material with a solidus temperature lower than the bump, sealing a space between the first metal layer and the printed circuit substrate to make a placement region of the vibrating part a hermetic space, whereby moisture permeation into the hermetic space and the outward spread of the solder material can be suppressed, and a space for the bump to spread by being melted can be omitted. Moreover, the electrical connection between the electrodes and the sealing of the placement region can be performed in separate processes, so that high hermeticity can be obtained.

Owner:NIHON DEMPA KOGYO CO LTD

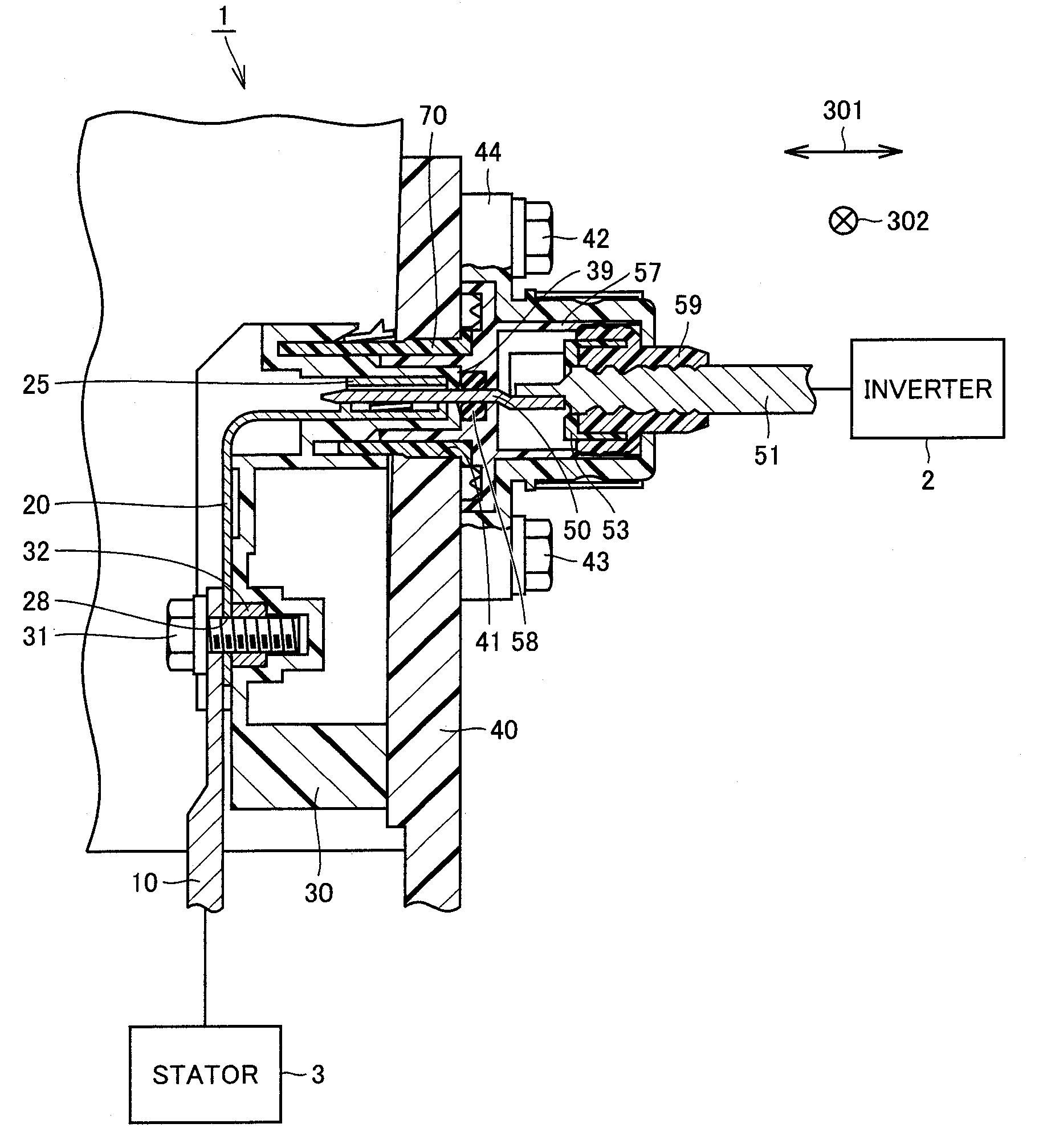

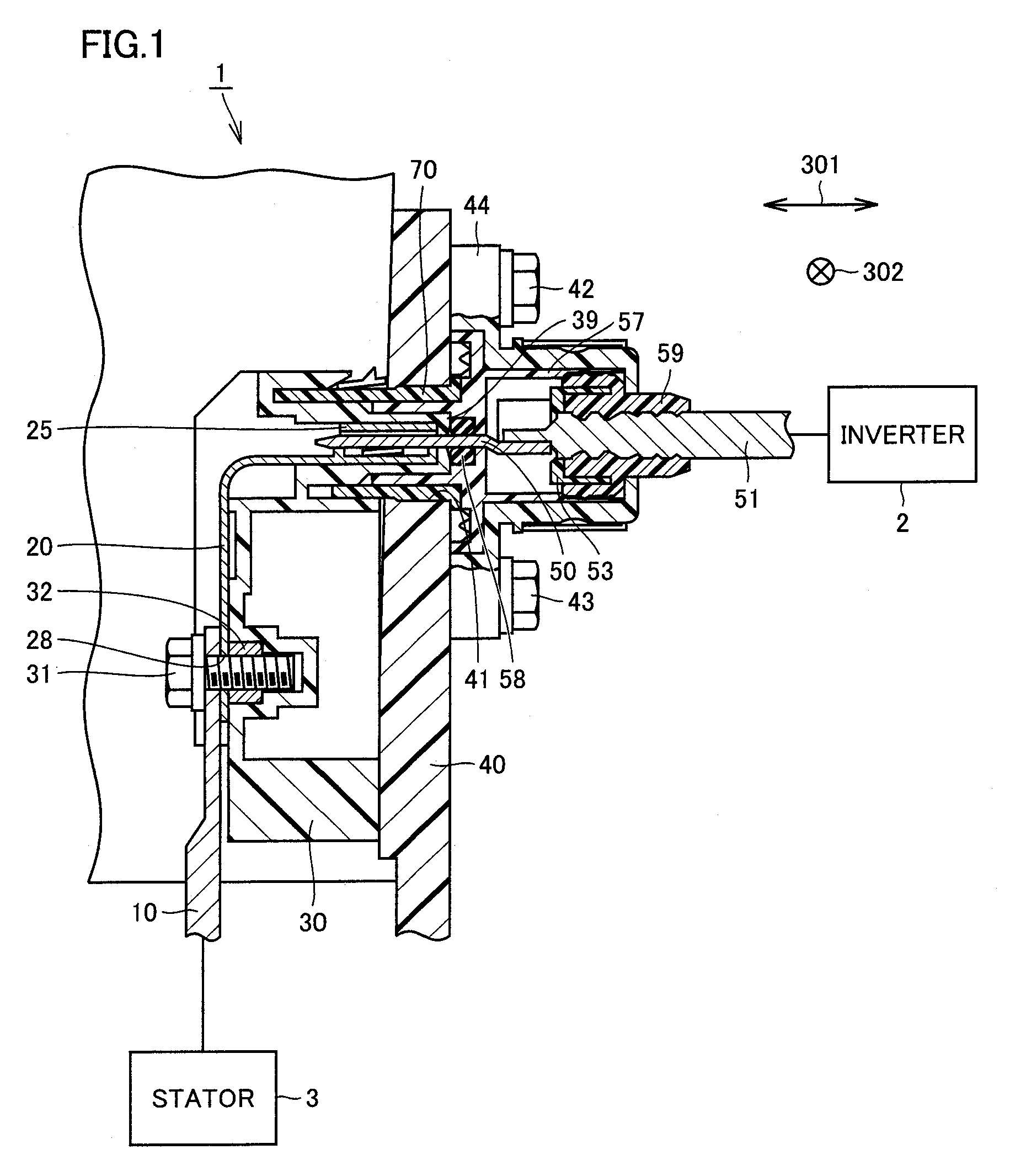

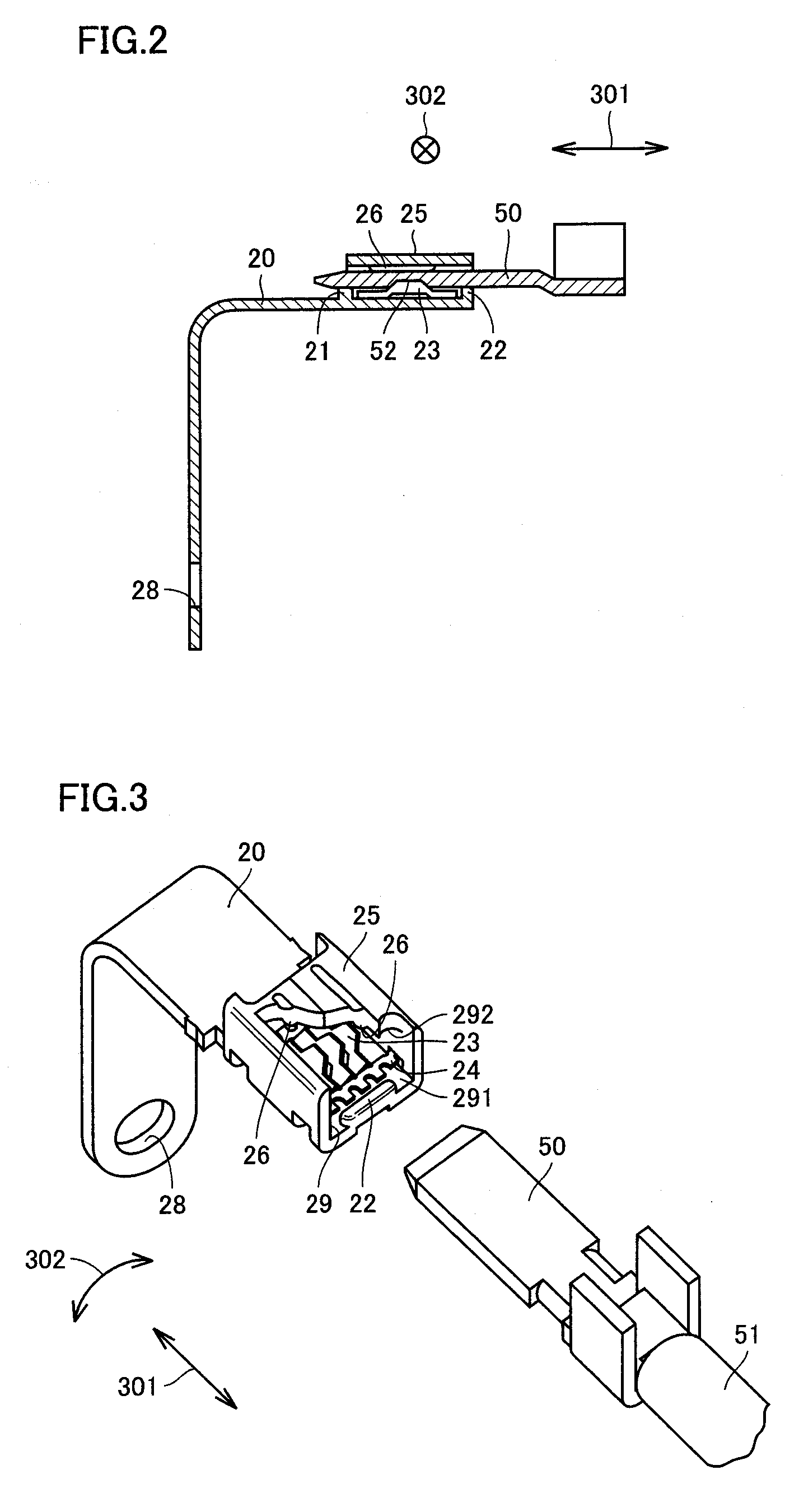

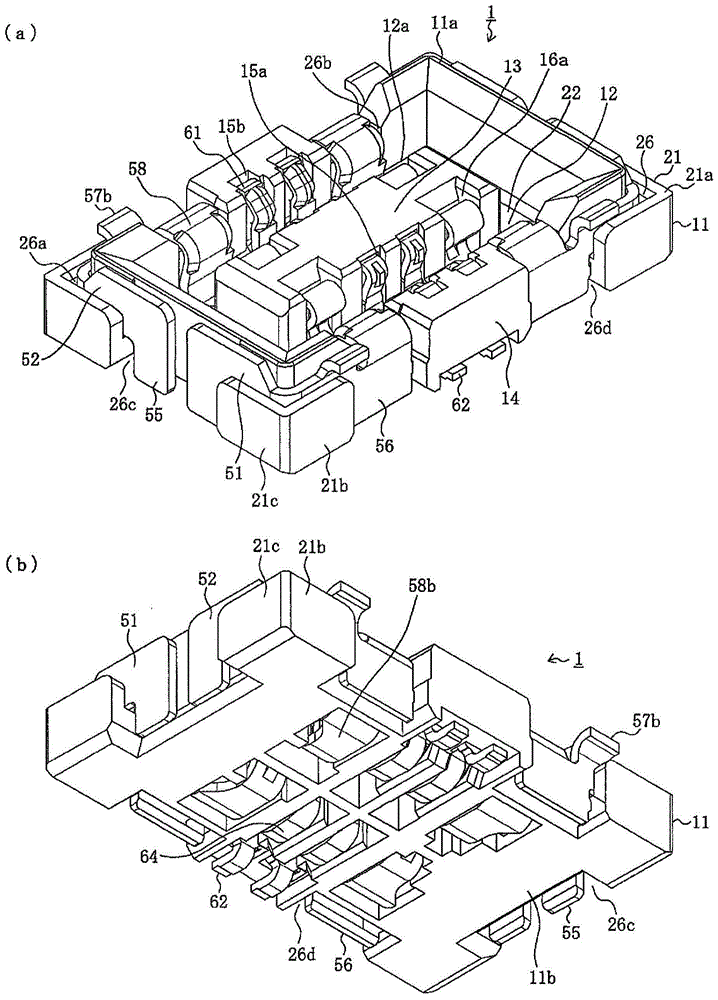

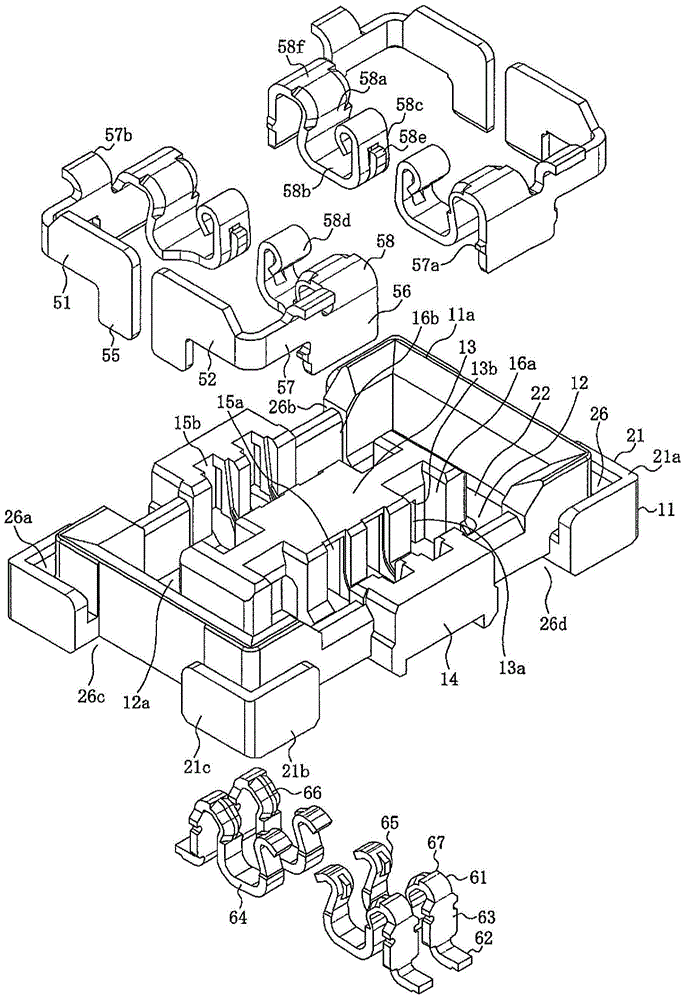

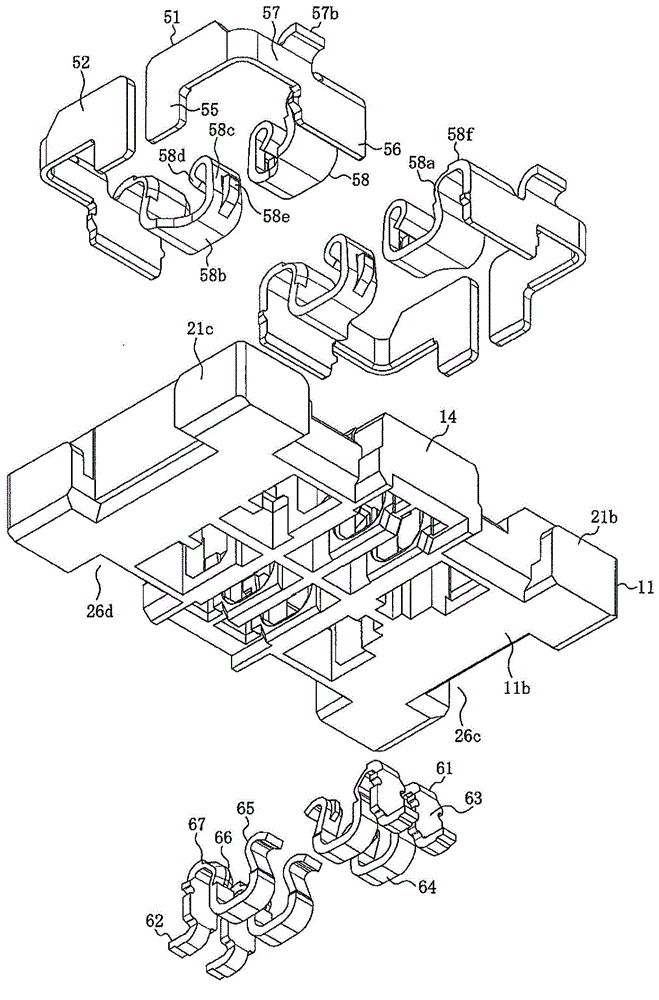

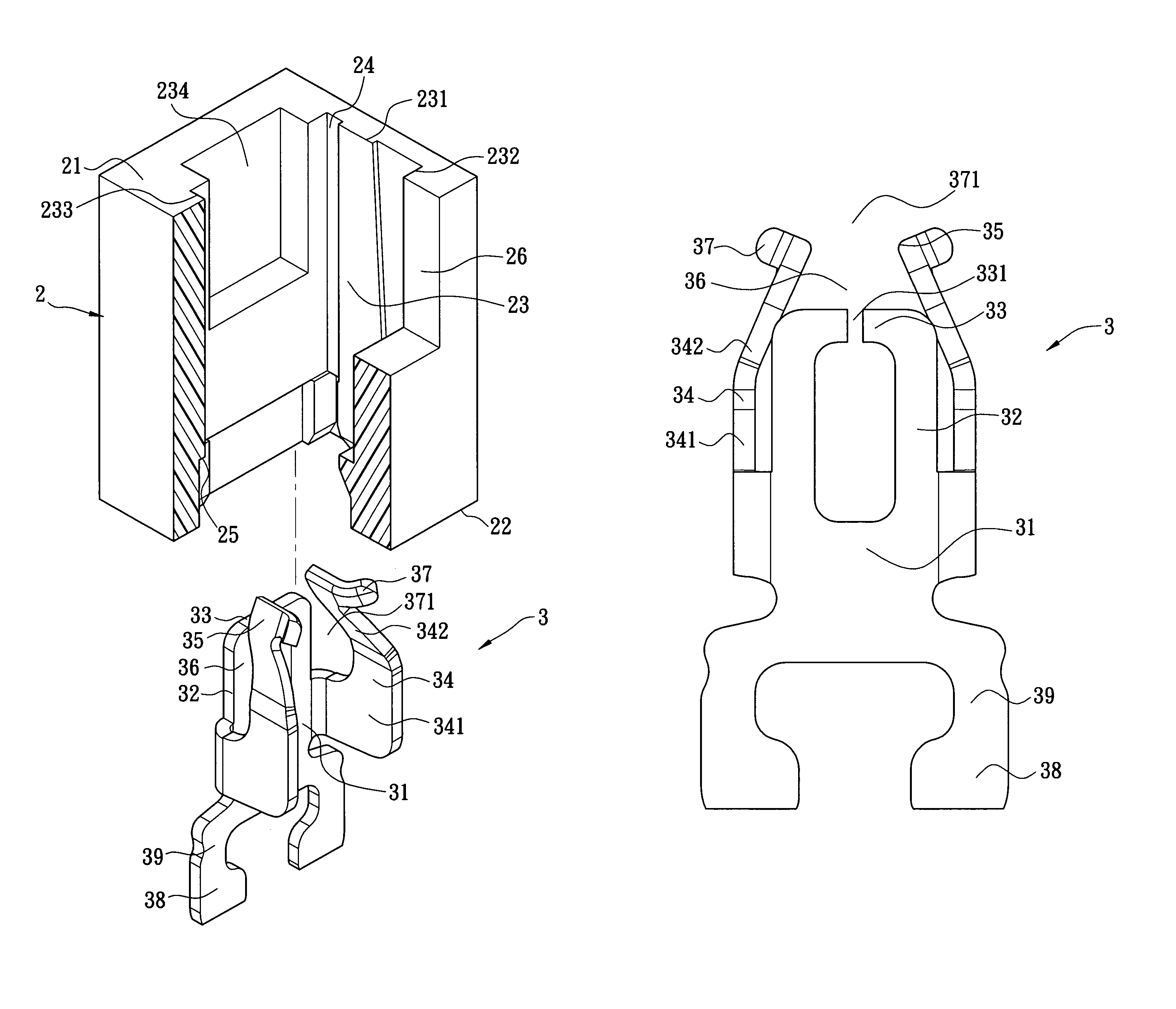

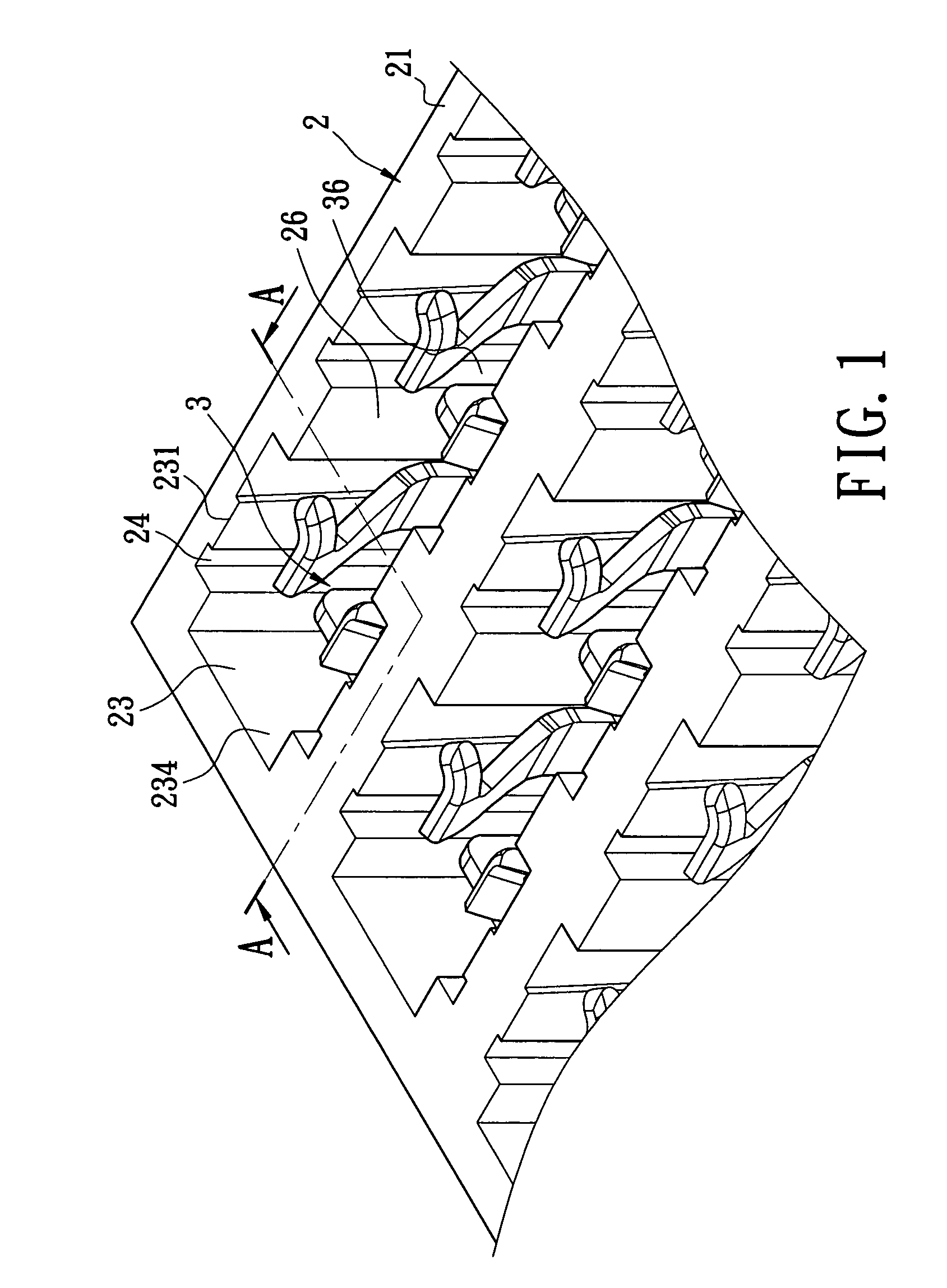

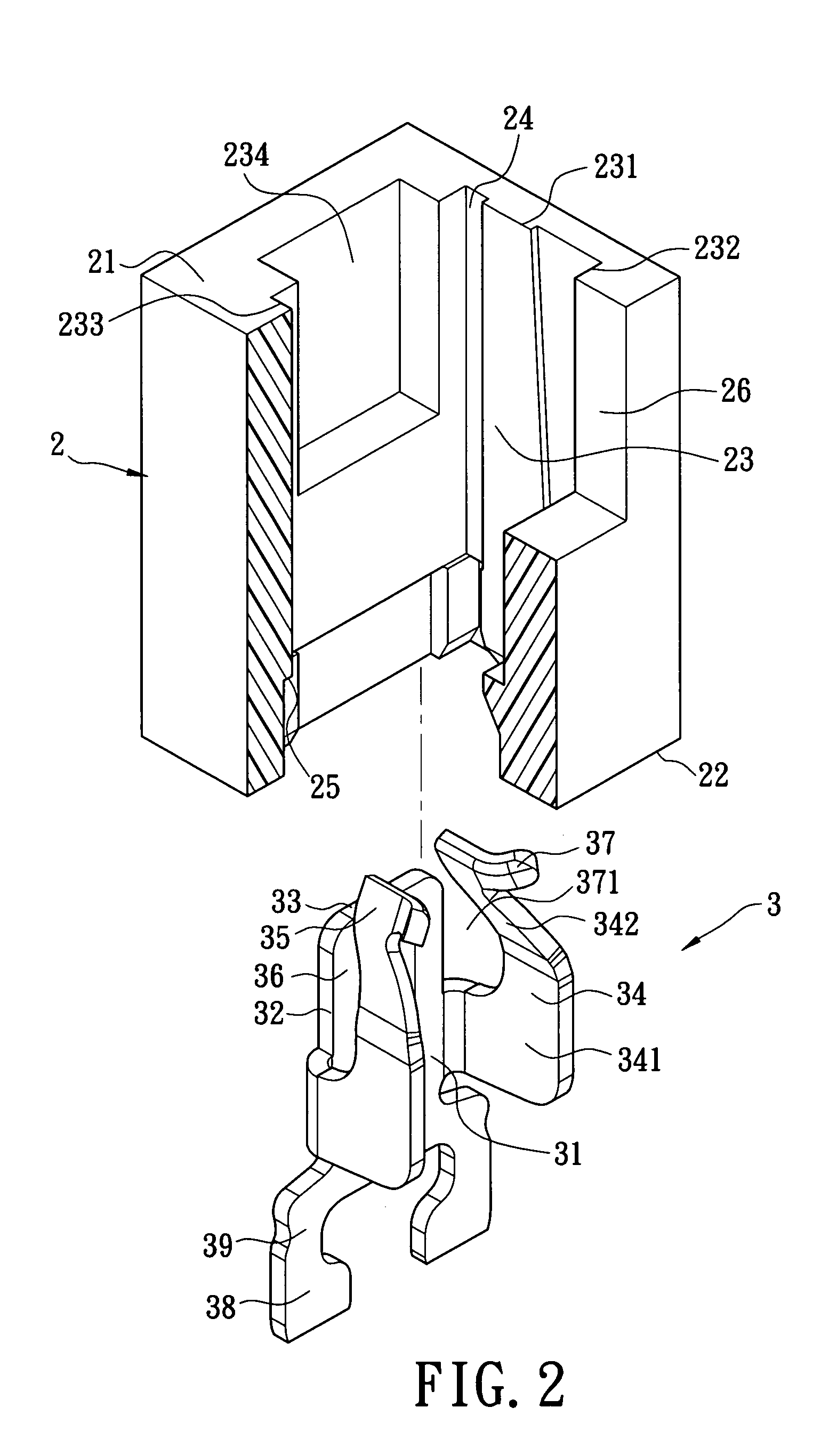

Connector structure and connector type terminal block structure

ActiveUS20070218736A1Ensure electrical connectionReduce manufacturing costOne pole connectionsVehicle connectorsBlock structureMechanical engineering

A connector structure that can ensure connection is provided. In the connector structure, a bus bar and a plate-like terminal mate with each other to establish an electric connection. A lower-side inner surface as a first inner surface defining the opening is provided with a plurality of conductive rotary members that rotate in a direction substantially perpendicular to a direction in which the plate-like terminal is inserted. It is also provided with a frame member that holds the rotary members and that is connected to the bus bar. The rotary members are twisted relative to the frame member and thereby biased relative to the plate-like terminal. By the plate-like terminal being inserted into and pulled out from the bus bar, the rotary members receive force from the plate-like terminal and rotate within a plane substantially perpendicular to a direction in which the plate-like terminal is inserted and pulled out.

Owner:TOYOTA JIDOSHA KK +1

Organic light emitting device, method of manufacturing the same, display unit, and electronic device

InactiveCN101599534AEasy to ensure electrical contact areaIncrease surface areaSemiconductor/solid-state device detailsSolid-state devicesOrganic light emitting deviceOrganic layer

An organic light emitting device capable of securing favorable electric connection between an auxiliary wiring layer and a second electrode without using a pixel separation mask, a method of manufacturing the same, a display unit, and an electronic device are provided. In the organic light emitting devices, for example, the auxiliary wiring layer, a first electrode as an anode, an insulating film between pixels, an organic layer including a light emitting layer, and the second electrode as a cathode are formed in this order over a substrate. In a region of the organic layer corresponding to the auxiliary wiring layer, an aperture is provided. On the auxiliary wiring layer, a connection section having a plurality of convex sections is formed. In the aperture of the organic layer, the auxiliary wiring layer and the second electrode are electrically connected by the connection section.

Owner:SONY GRP CORP

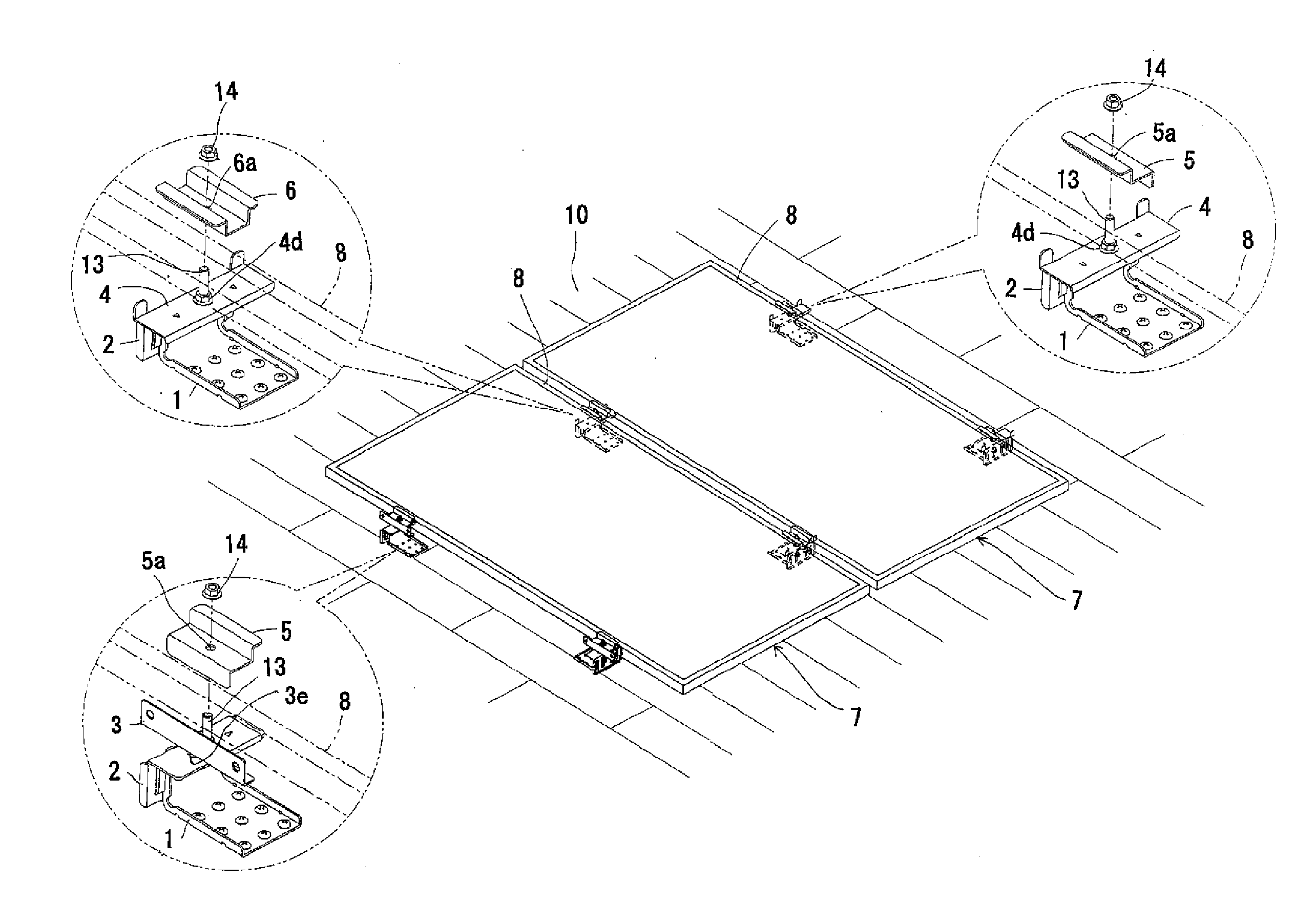

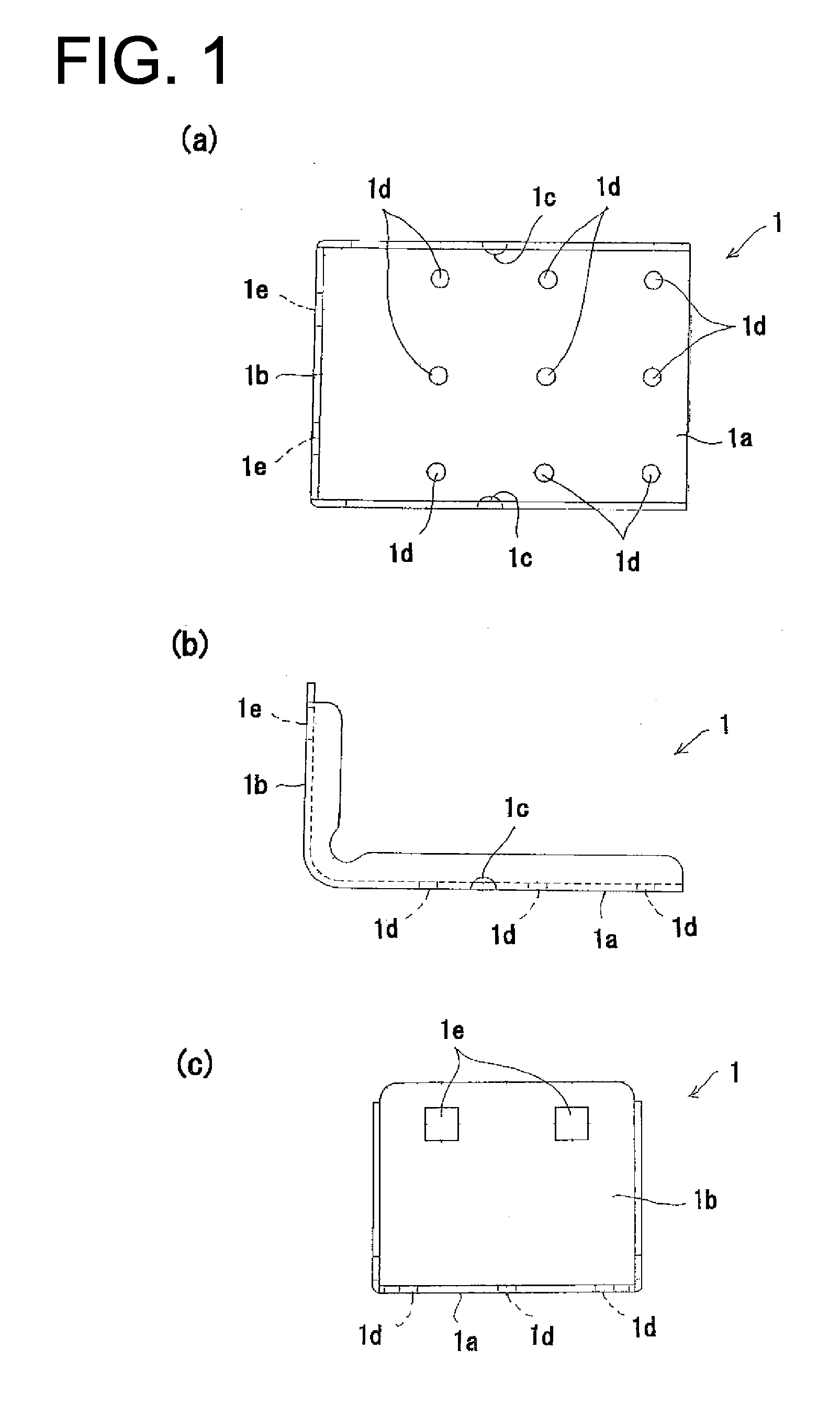

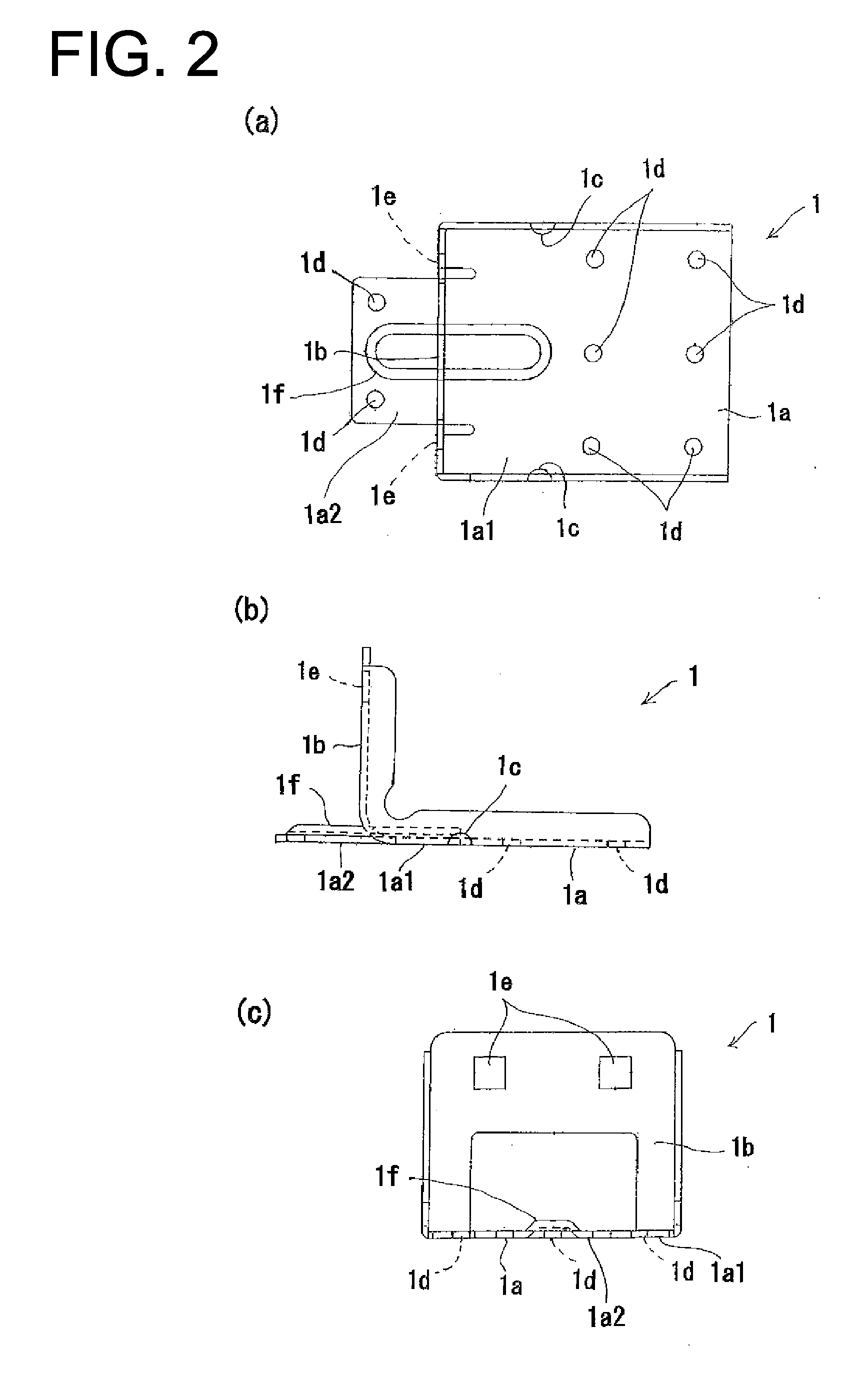

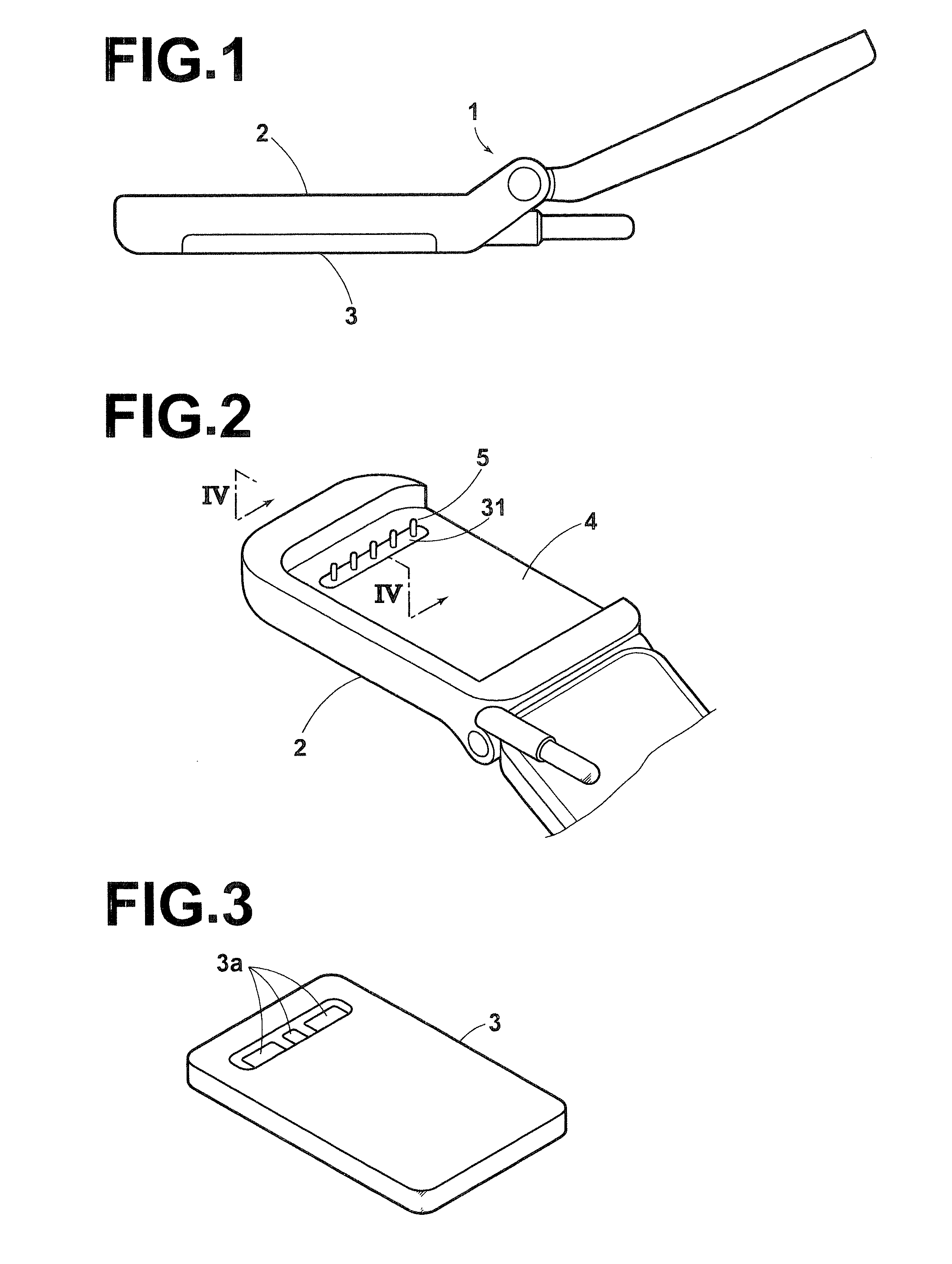

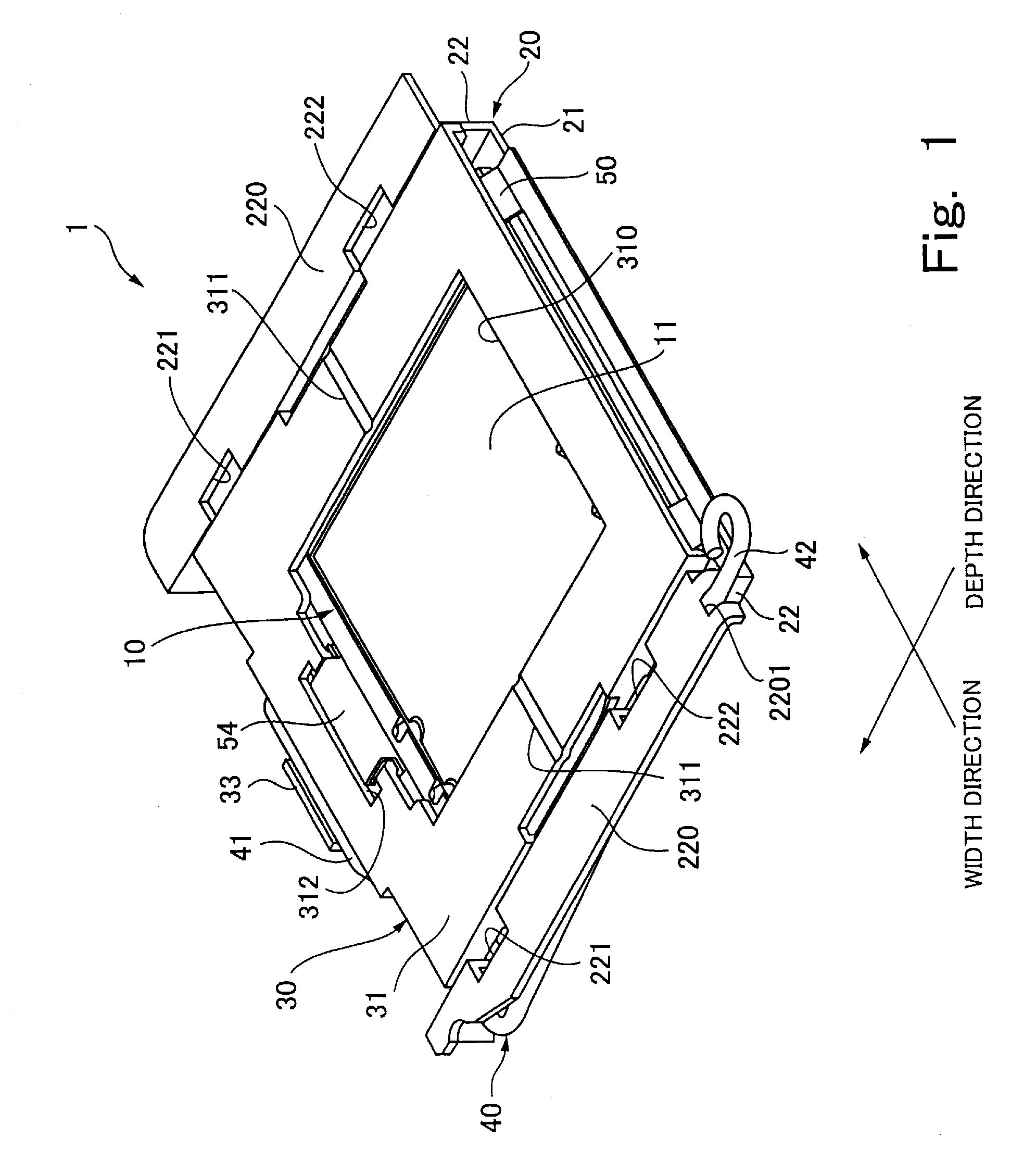

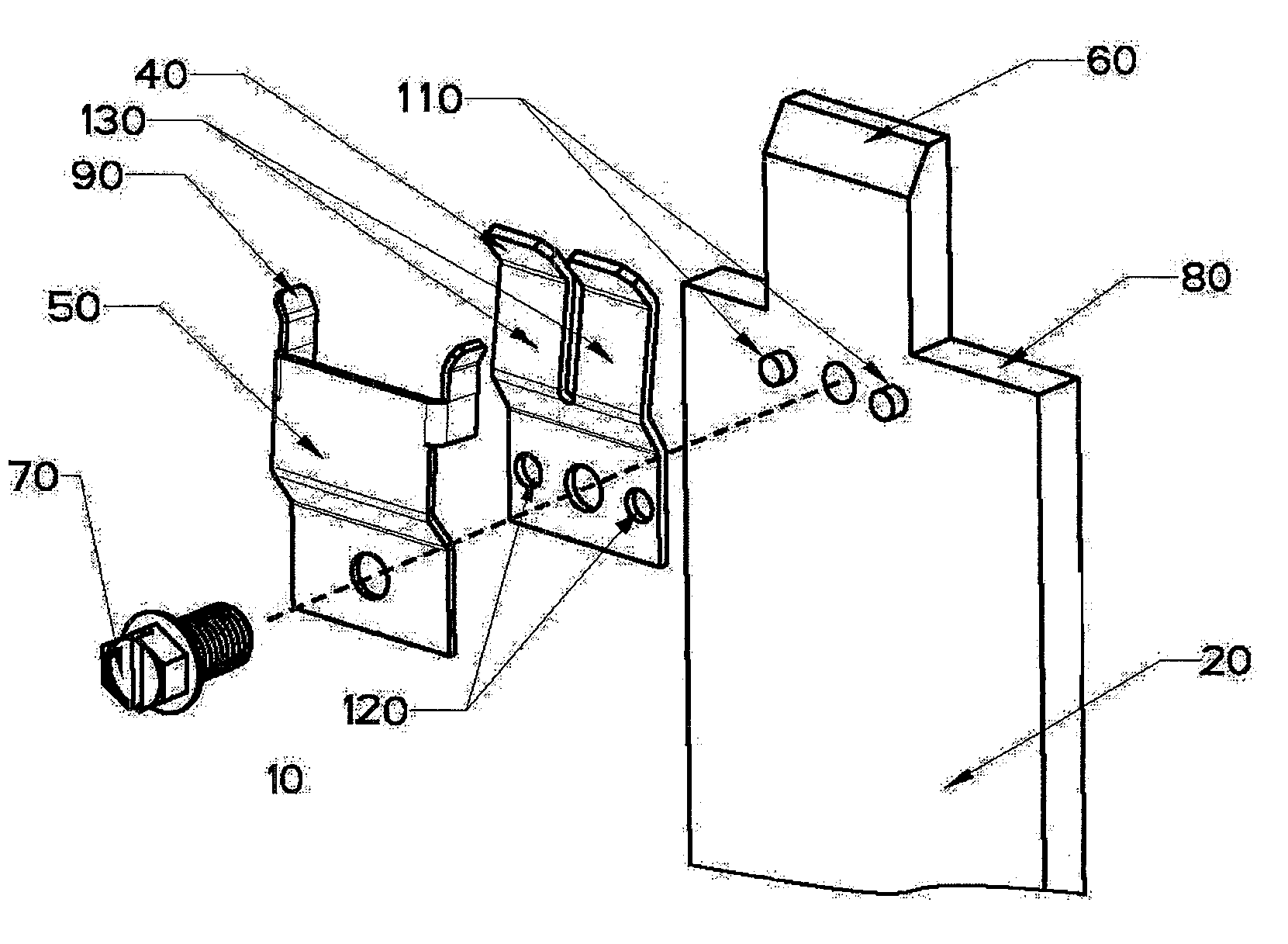

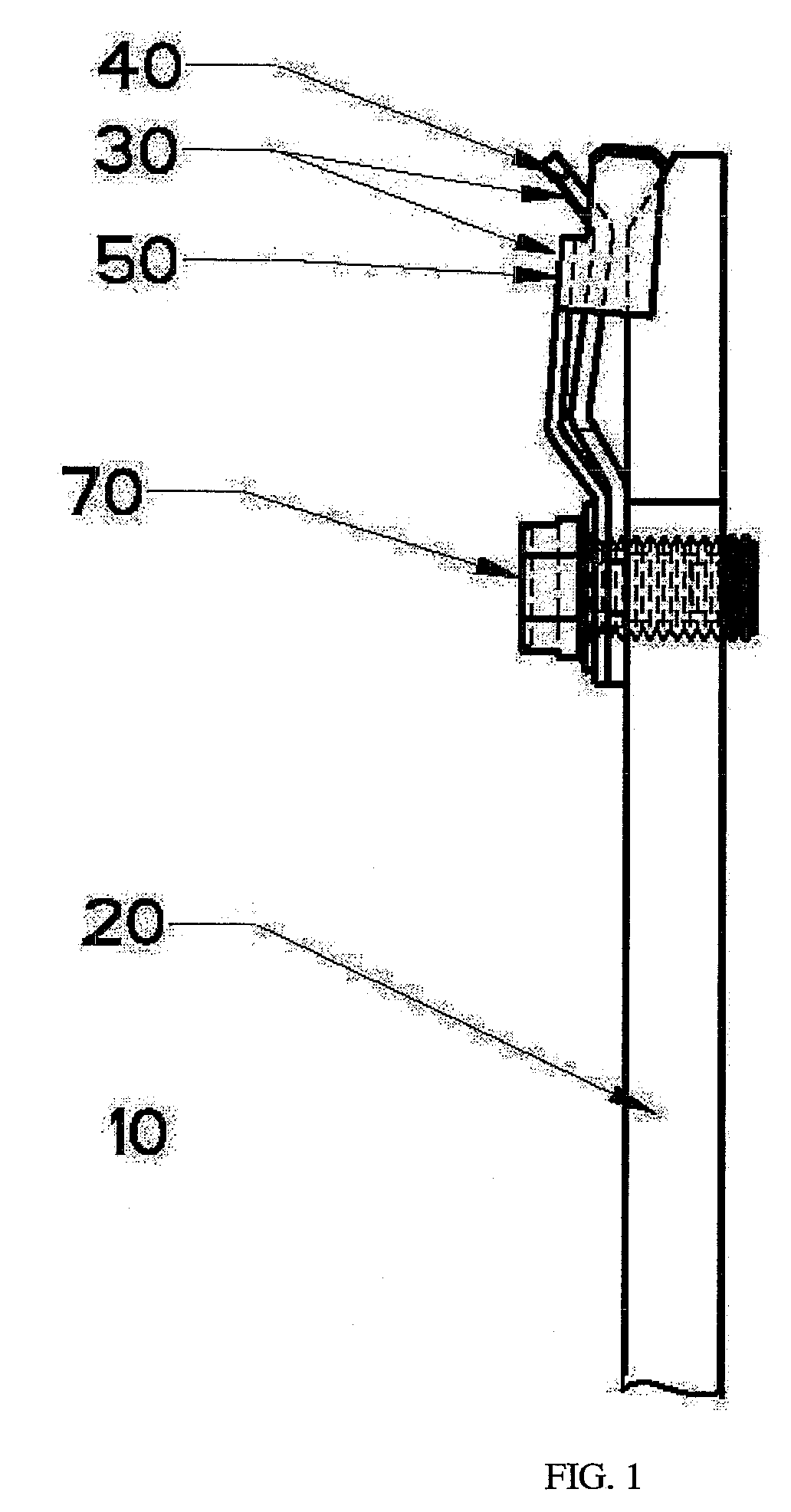

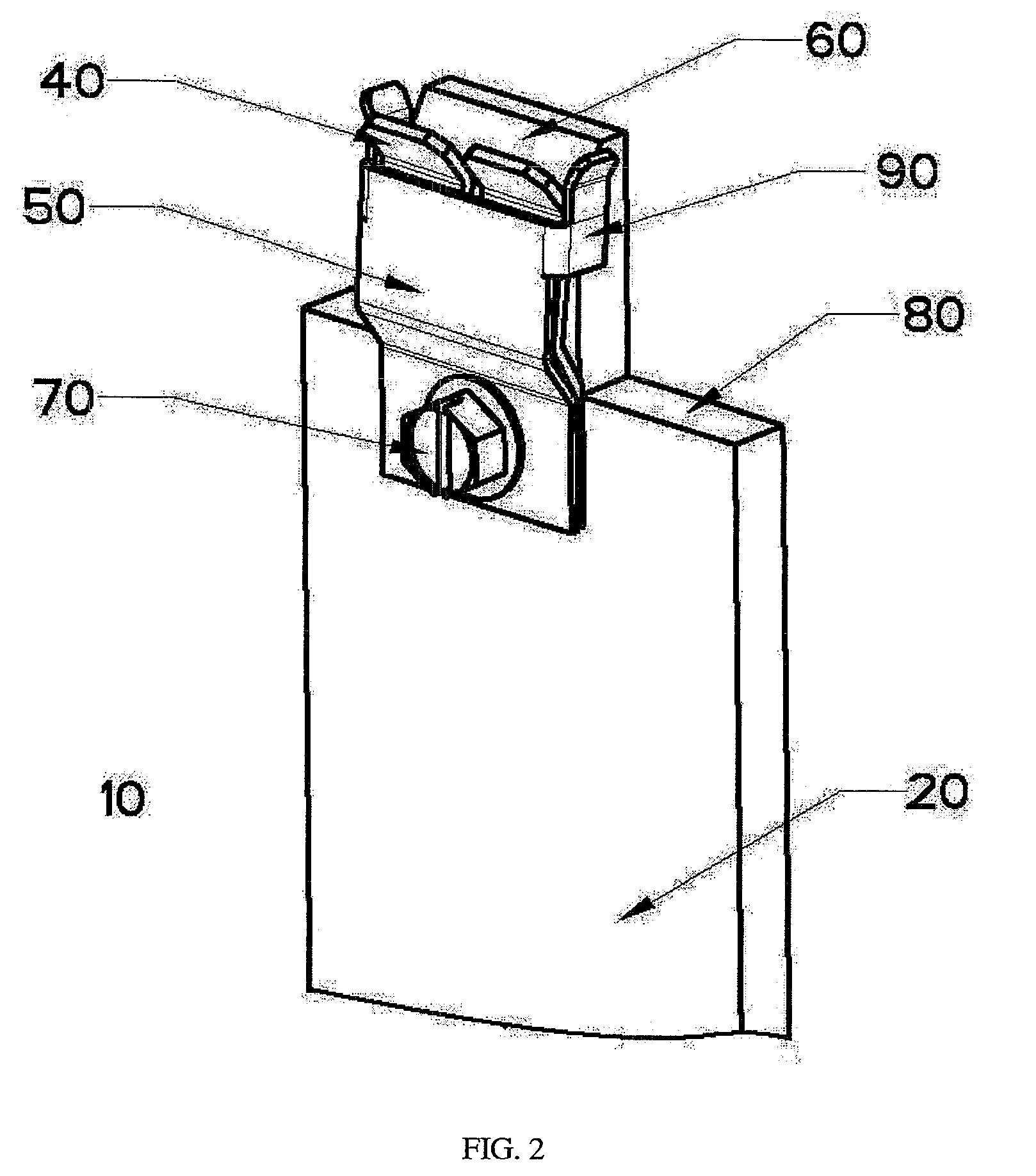

Solar Battery Module Fixture

InactiveUS20130263917A1Reduce weightAdjustable positionPhotovoltaic supportsSolar heating energyElectrical conductorEngineering

[Problem] To be able to reliably fix a solar battery module in an appropriate position on a roof, to have light weight and few components, and to be able to reliably prevent slipping and perform grounding during temporary placement when the fixing position of the solar battery module is adjusted. [Solution] The present invention comprises: a base metal fitting fixed to a rooftop surface; a height-adjusting metal fitting capable of sliding in a vertical direction relative to the base metal fitting; a position-adjusting metal fitting capable of sliding in a horizontal direction relative to the height-adjusting metal fitting; and a fixing metal fitting for sandwiching and fixing the solar battery module between the fixing metal fitting and the position-adjusting metal fitting from the top and bottom, the fixing metal fitting being attached relative to the position-adjusting metal fitting. The position-adjusting metal fitting has: a mounting board part for mounting the solar battery module; a stopper capable of making contact with the edge of a frame provided to the periphery of the solar battery module when the solar battery module is mounted on the mounting board part; and a protrusion for making contact with a conductor part of the frame when the solar battery module is fixed to ensure electrical conductance.

Owner:NISSEI KINZOKU

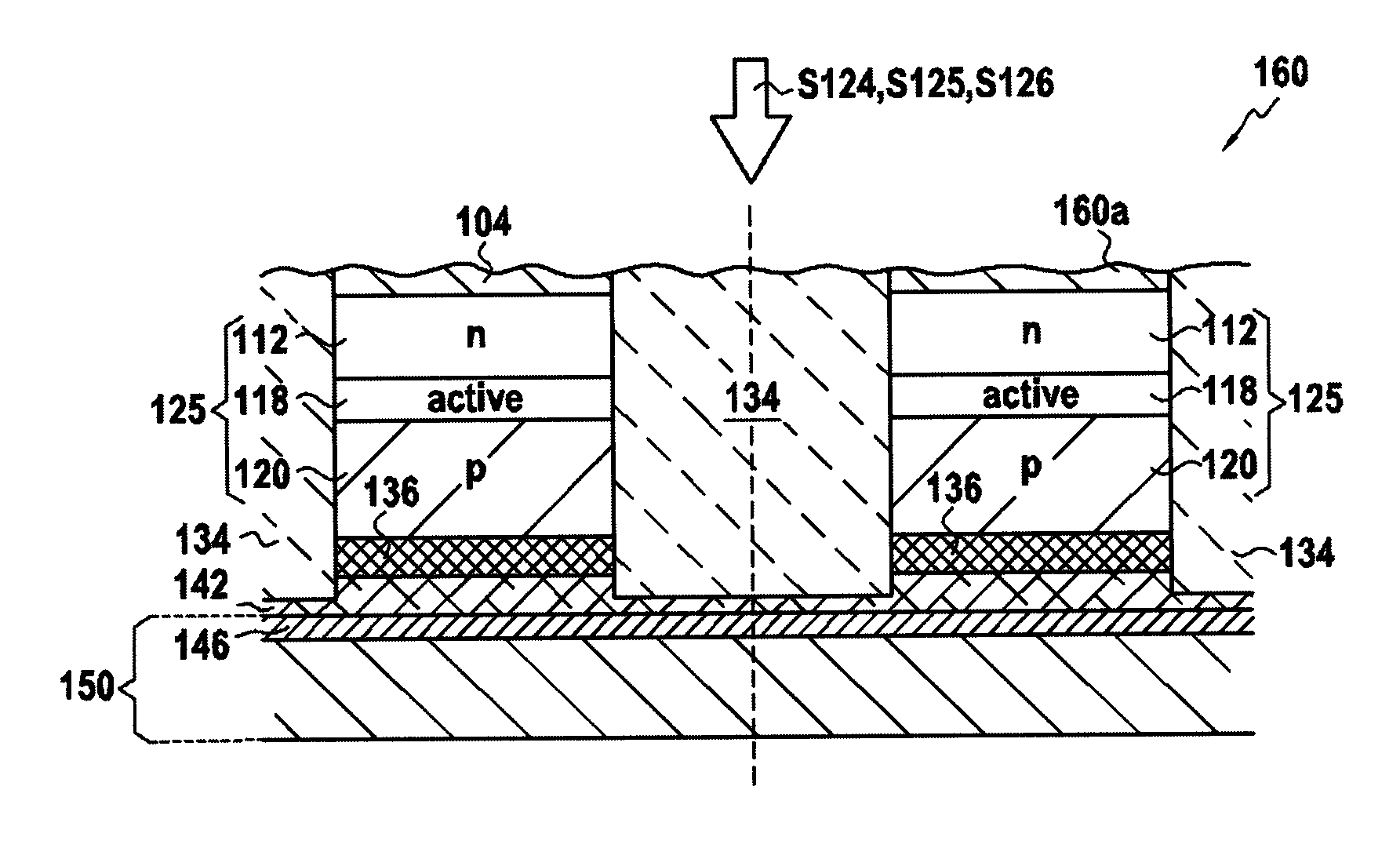

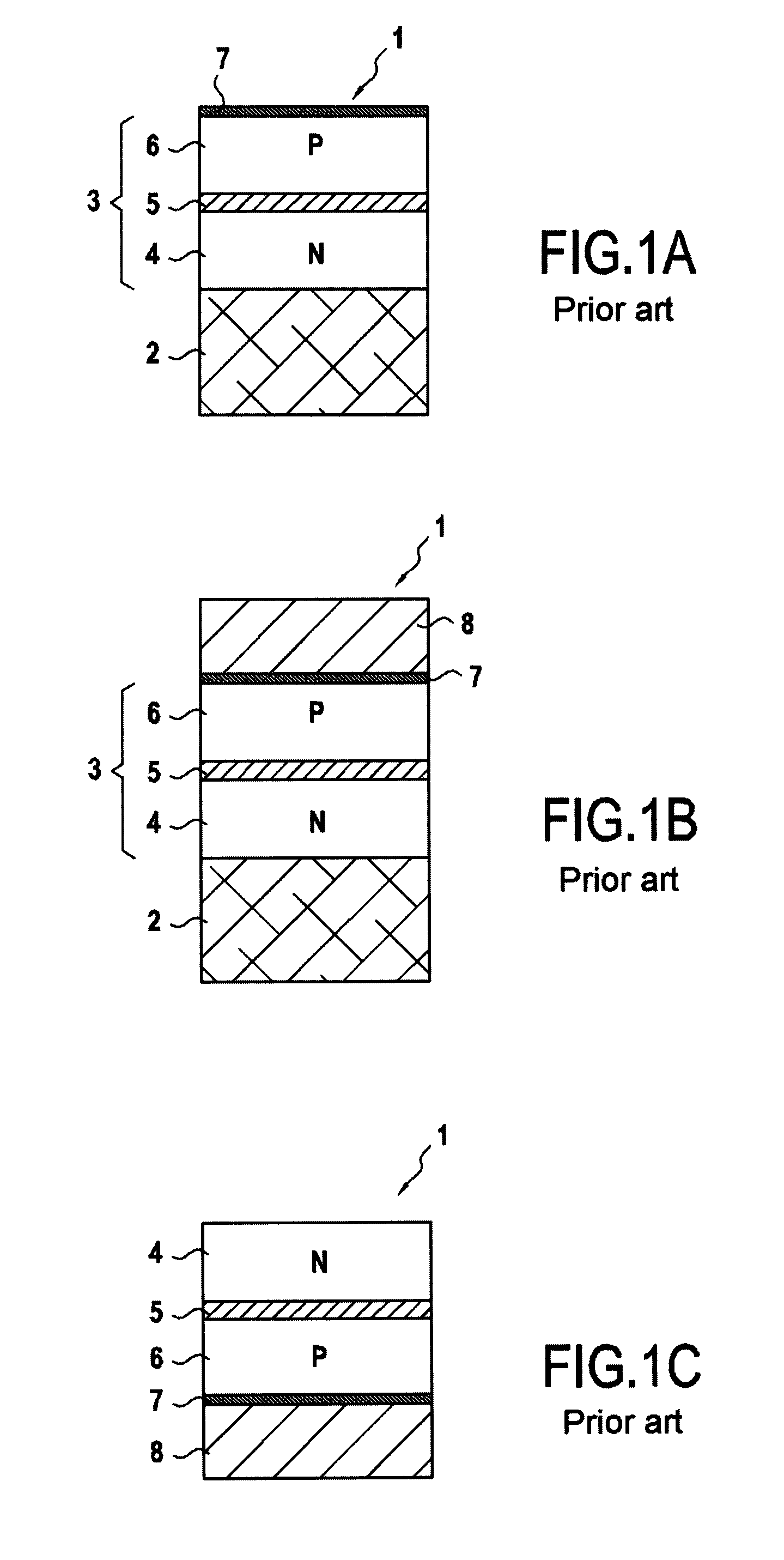

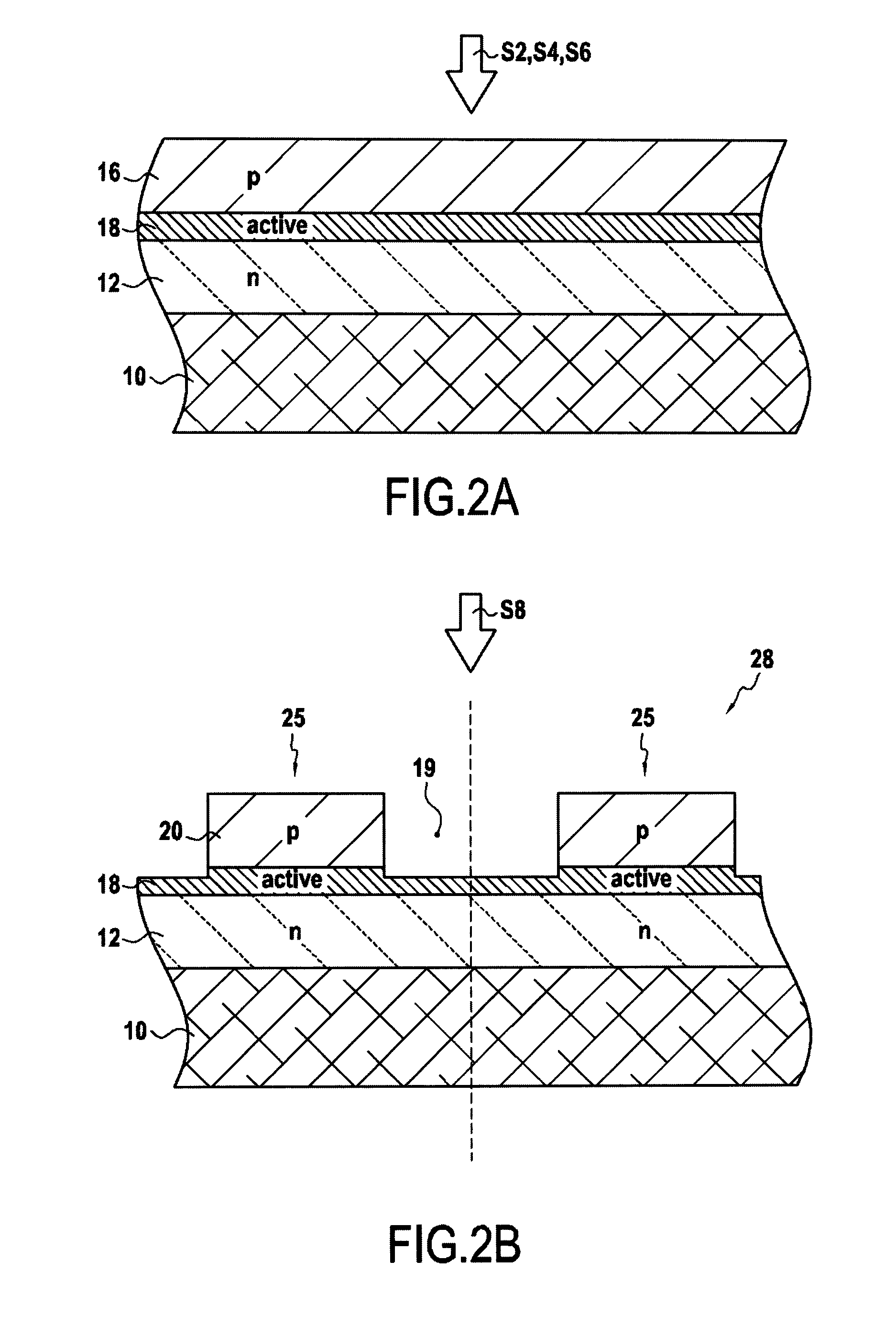

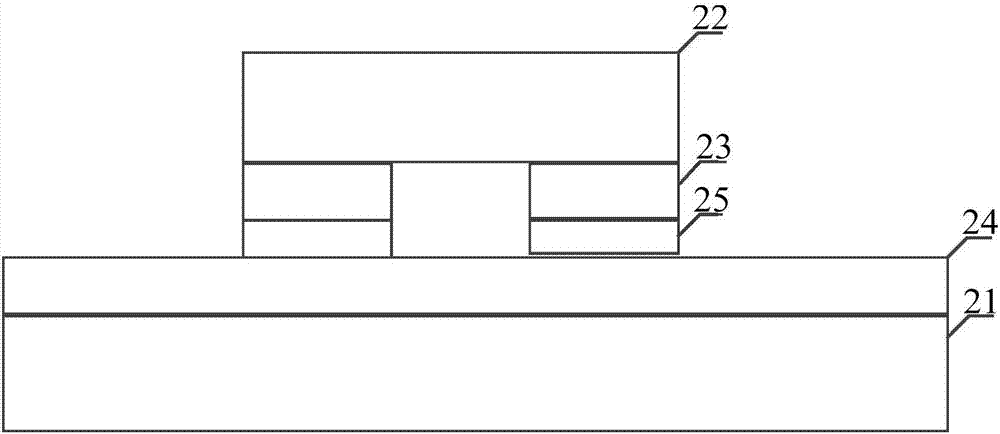

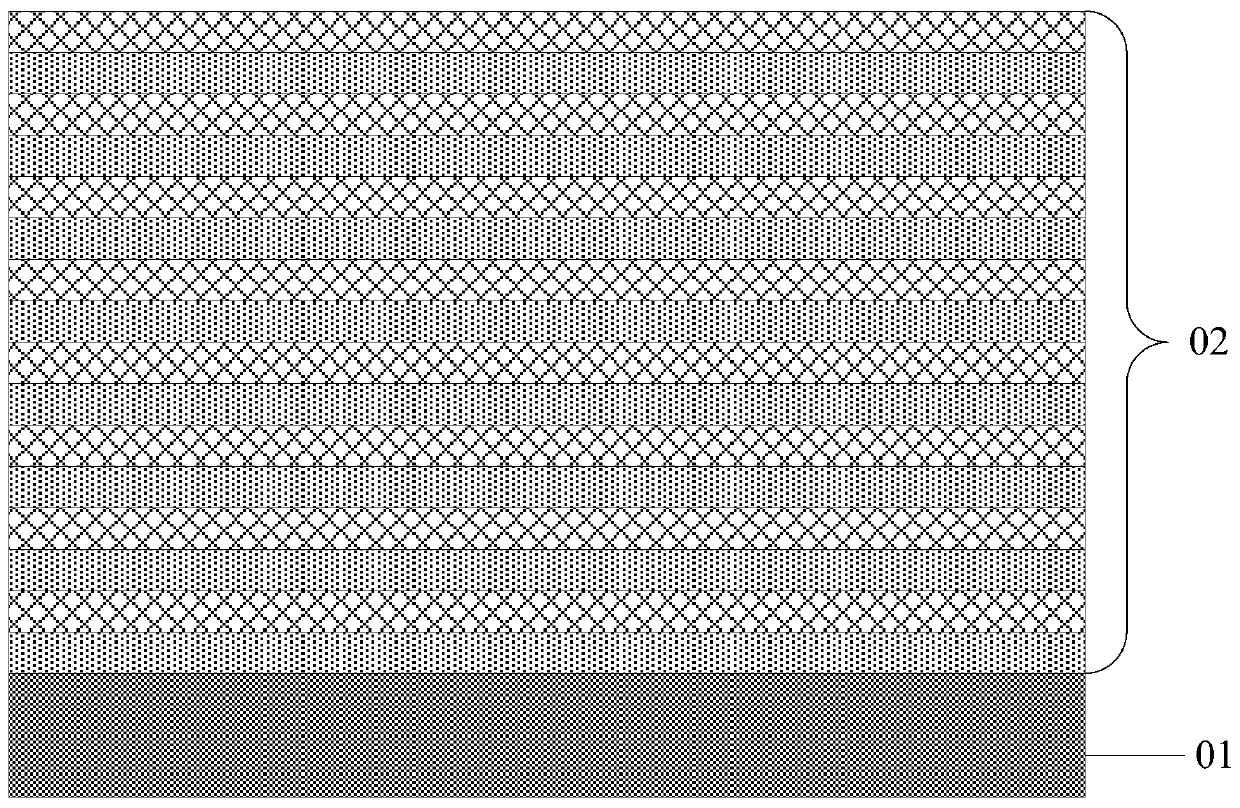

Method of manufacturing structures of leds or solar cells

ActiveUS20150115290A1OptimizationQuality improvementFinal product manufactureSolid-state devicesRoom temperatureSolar cell

The invention disclosure relates to a manufacturing method comprising the formation of elemental LED or photovoltaic structures on a first substrate, each comprising at least one p-type layer, an active zone and an n-type layer, formation of a first planar metal layer on the elemental structures, provision of a transfer substrate comprising a second planar metal layer, assembly of the elemental structures with the transfer substrate by bonding of the first and second metal layers by molecular adhesion at room temperature, and removal of the first substrate.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Semiconductor element having conductive vias and semiconductor package having a semiconductor element with conductive vias and method for making the same

ActiveUS8786098B2Improve yieldEnsure electrical connectionSemiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical connection

The present invention relates to a semiconductor element having conductive vias and a semiconductor package having a semiconductor element with conductive vias and a method for making the same. The semiconductor element having conductive vias includes a silicon substrate and at least one conductive via. The thickness of the silicon substrate is substantially in a range from 75 to 150 μm. The conductive via includes a first insulation layer and a conductive metal, and the thickness of the first insulation layer is substantially in a range from 5 to 19 μm. Using the semiconductor element and the semiconductor package of the present invention, the electrical connection between the conductive via and the other element can be ensured, and the electrical connection between the silicon substrate and the other semiconductor element can be ensured, so as to raise the yield rate of a product. Moreover, by employing the method of the present invention, warpage and shift of the silicon substrate can be avoided during the reflow process, so as to conduct the reflow process only a single time in the method of the present invention, thereby simplifying the subsequent process and reducing cost.

Owner:ADVANCED SEMICON ENG INC

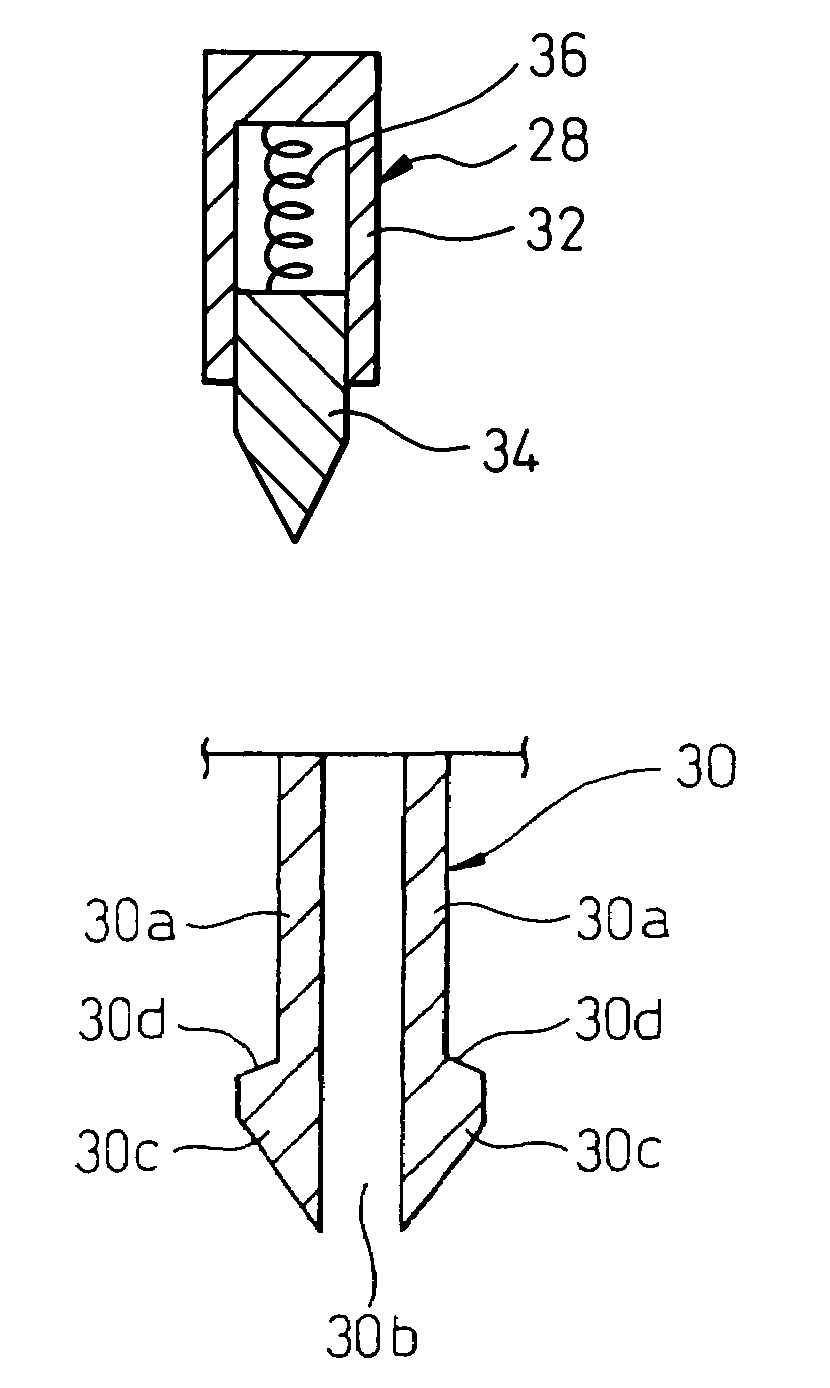

Conductor Pin

InactiveUS20070224889A1Reduction in minimum lengthEasy to produceCoupling contact membersCell component detailsElectrical conductorEngineering

Owner:WAKO SEIKI

Semiconductor device with bonding pad support structure

ActiveUS7397125B2Shock resistance during probing and bonding is more greatly improvedEnsure electrical connectionSemiconductor/solid-state device detailsSolid-state devicesCopperSemiconductor

A semiconductor device having bonding pads on a semiconductor substrate includes: an upper copper layer that is formed on the lower surface of the bonding pads with a barrier metal interposed and that has a copper area ratio that is greater than layers in which circuit interconnects are formed; and a lower copper layer that is electrically insulated from the upper copper layer and that is formed closer to the semiconductor substrate than the upper copper layer.

Owner:RENESAS ELECTRONICS CORP

Electronic component, mounted structure, electro-optical device, and electronic device

ActiveUS7166920B2Increase redundancyEnsure electrical connectionMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectronic component

An electronic component electrically connected to a counter substrate through a pad on an active surface, characterized in that a resin bump on the active surface and an electrically conductive film on the resin bump constitute a bump electrode, and that a plurality of bump electrodes are electrically connected to the one pad.

Owner:BOE TECH GRP CO LTD

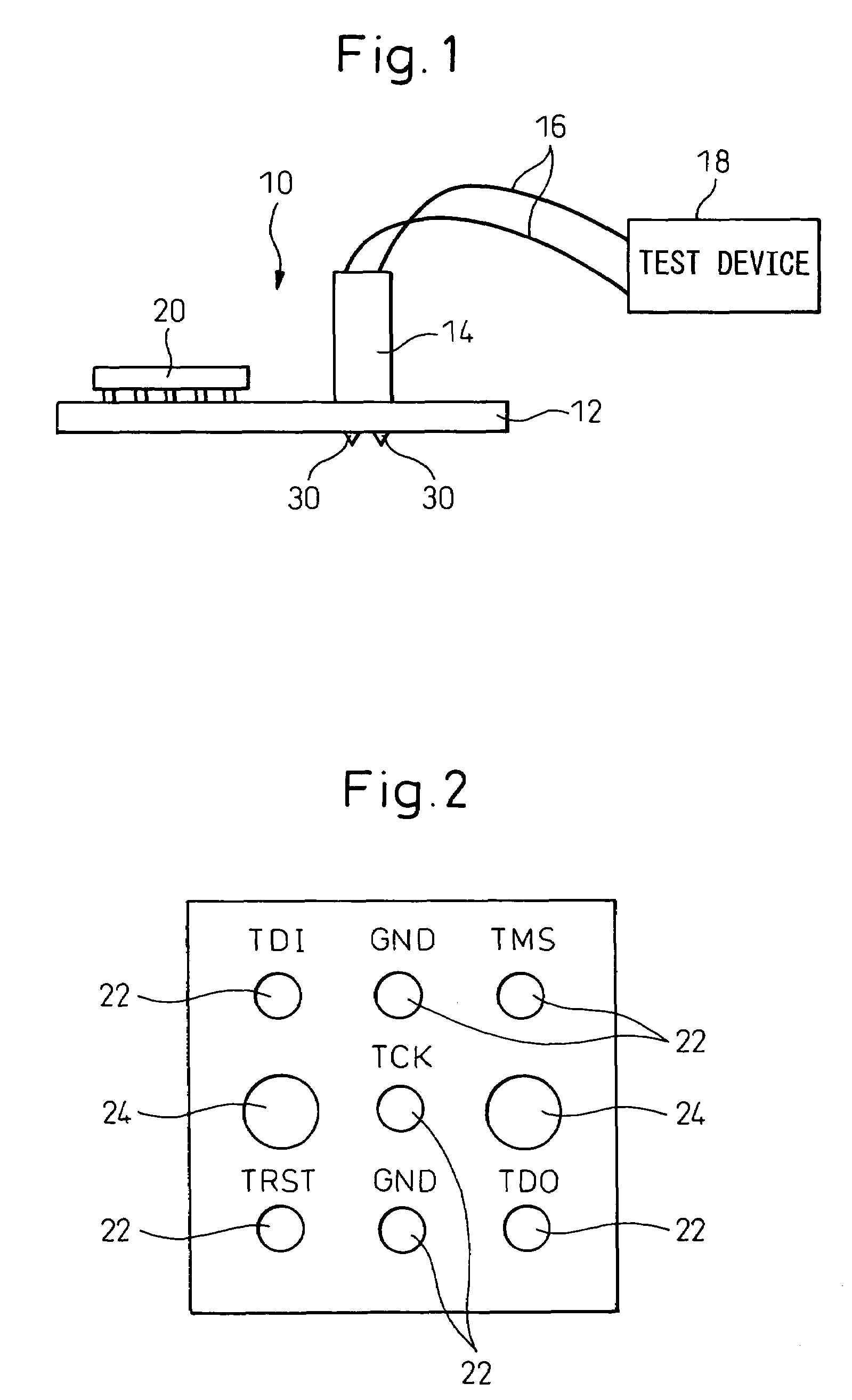

Connector circuit board

InactiveUS7134909B2Low costEasily and reliably electrically connectedSubstation/switching arrangement detailsCross-talk/noise/interference reductionElectrical connectionEngineering

A connector has conducting pins projecting from a connector body, and fixing pin extending substantially in parallel with the conducting pins. The fixing pins are longer than the conducting pins. The fixing pins are constructed such that they can be inserted in corresponding fixing holes of a printed circuit board when the connector is attached to the printed circuit board. The fixing pins are locked in the fixing holes to secure the electrical connection between the conducting pins and corresponding electrode pads and the mechanical connection between the connector and the printed circuit board.

Owner:FUJITSU LTD

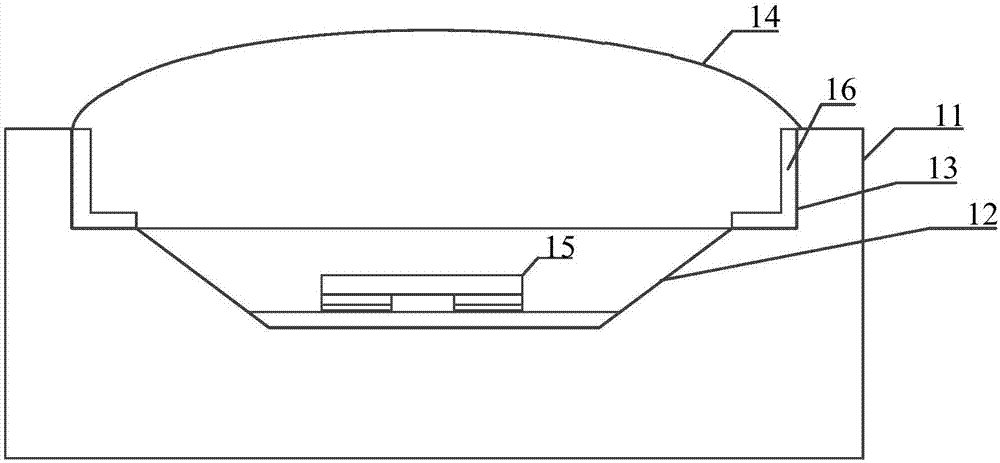

Ultraviolet LED device

The present invention discloses an ultraviolet LED device, which comprises a ceramic base, a groove arranged on the ceramic base, a table-shaped stepped structure arranged on the ceramic base and positioned on the groove, a quartz glass cover plate arranged at the table-shaped stepped structure, and an ultraviolet LED chip welded to the bottom surface of the groove in the eutectic flip-chip manner. At least two metal layers, good in heat conductivity and electrical conductivity, are arranged between the positive and negative electrodes of the ultraviolet LED chip and the bottom surface of the groove. In this way, the eutectic flip welding of the ultraviolet LED chip is realized. According to the invention, through the metal layers good in heat conductivity and electrical conductivity, the ultraviolet LED chip is welded inside the ultraviolet LED device in the eutectic flip-chip manner. Therefore, the application of the traditional solid crystal organic glue is avoided. Meanwhile, on the premise that the electrical connection of the ultraviolet LED chip is ensured, the heat is conducted to the ceramic base. The heat conductivity of the device is improved, so that the stability and the service life of the device are increased. As a result, according to the technical scheme of the invention, the heat dissipation performance of the ultraviolet LED device is improved.

Owner:GUANGDONG UNIV OF TECH

Connector

ActiveCN104682047AEnsure electrical connectionStay engagedCoupling contact membersButt jointElectrical connection

The invention provides a connector. Reinforced metal fittings of the connector can be reliably connected to reinforced metal fittings of another connector, electrical connections between the reinforced metal fittings are maintained, and the connector can be connected to another connector end to end. A connector body includes butt-joint guide portions and reinforced metal fittings. The butt-joint guide portions are formed on two vertical ends of the connector body so that the connector body is butt joint with a connector body of another connector. Each reinforced metal fitting includes a body portion, a side plate portion, and a contact arm portion, wherein the body portion extends transversely along the connector body, the side plate portion is connected to the body portion and extends vertically along the connector body, and the contact arm portion is connected to the side plate portion. The reinforced metal fittings are arranged to the left and to the right of the butt-joint guide portions. Each contact arm portion includes a first contact part and a second contact port that face each other. When the connector body is butt joint with the connector body of another connector, the reinforced metal fittings arranged on another connector body are inserted between the first and second contact parts, and the reinforced metal fittings are maintained by the first and second contact parts on two sides and contact the first and second contact parts.

Owner:MOLEX INC

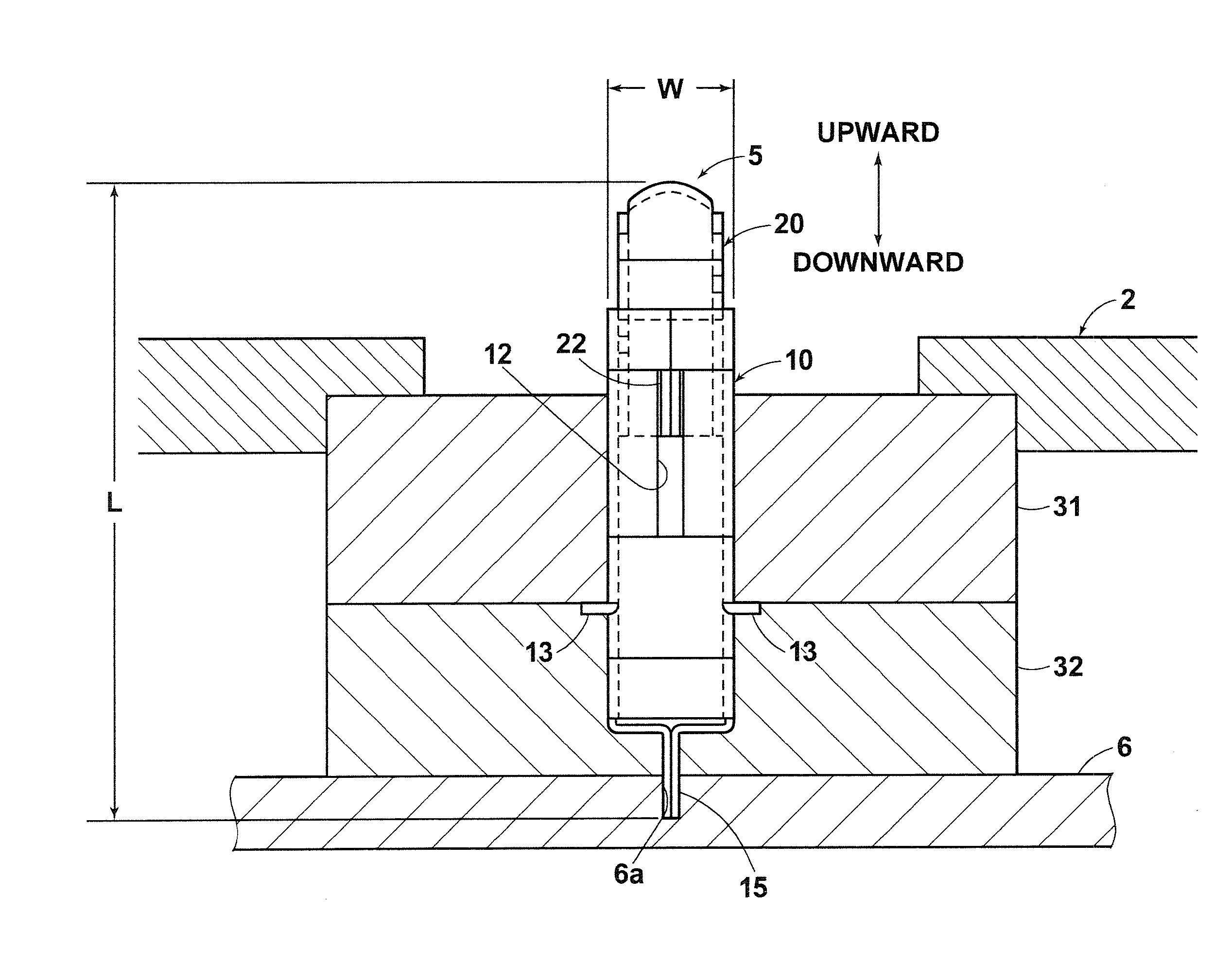

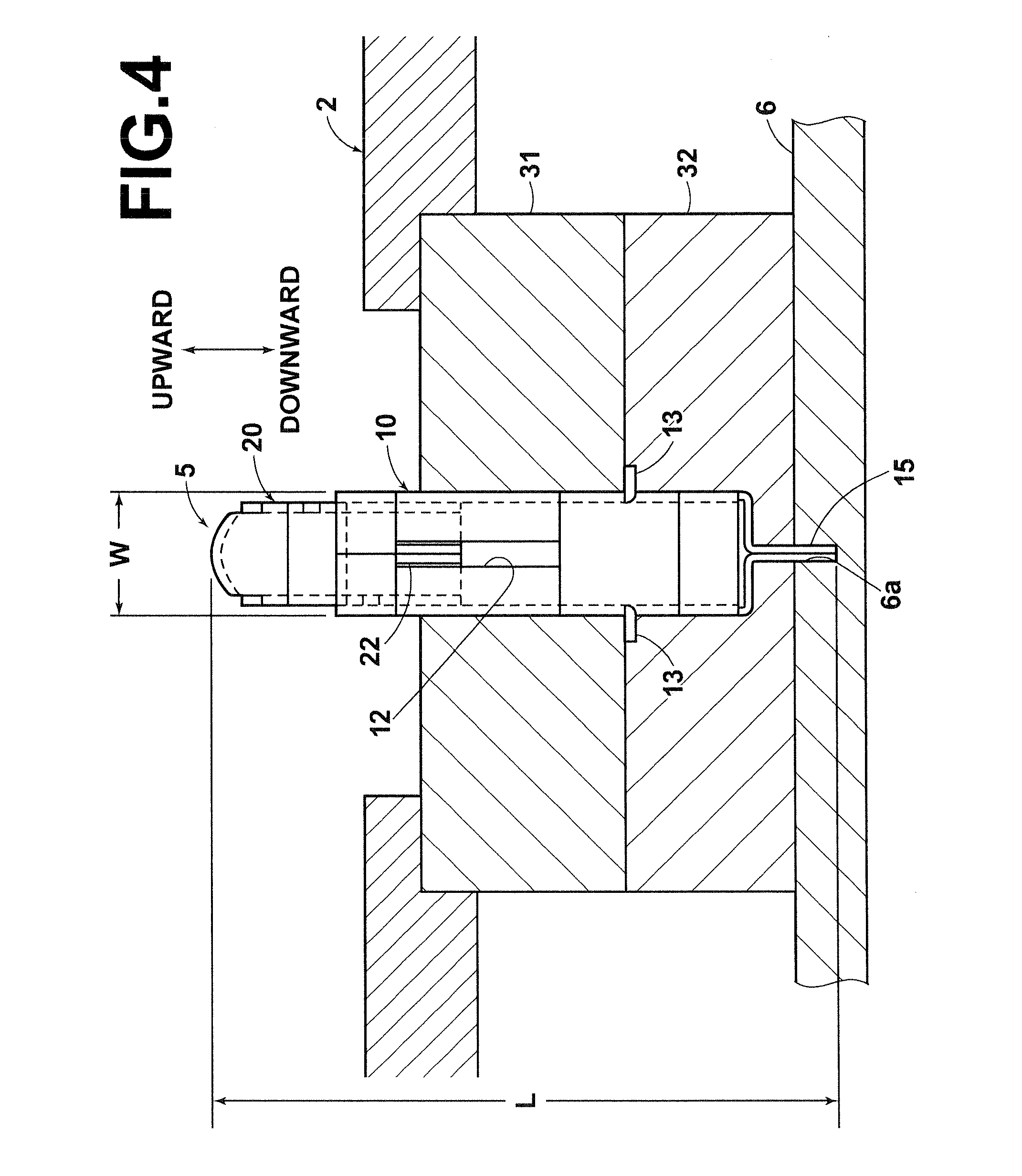

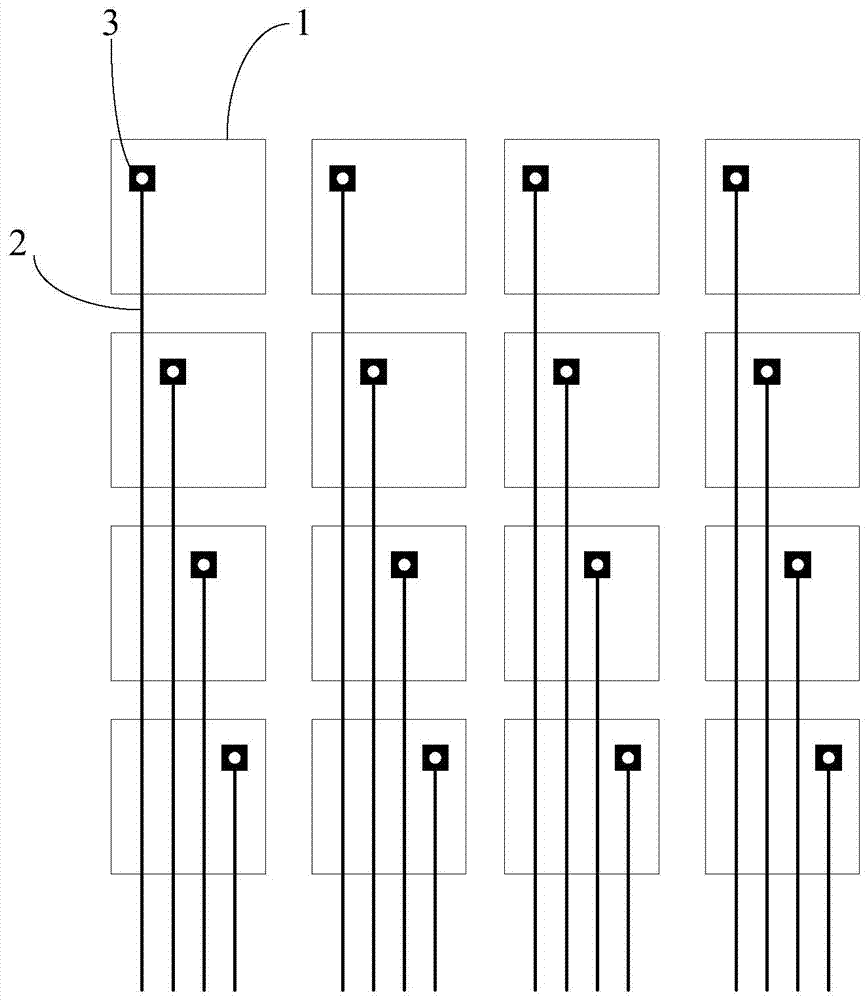

IC socket

ActiveUS7374446B2Ensure electrical connectionSufficient strokeEngagement/disengagement of coupling partsElectric connection basesElectrical connectionEngineering

There is provided an IC socket for an IC package having plural pads disposed in a matrix manner on the lower face thereof, on which the IC package can be loaded with a small number of operations, and after the loading, the electrical connection between the pads and contacts can be ensured. The IC socket includes: a load support member having both side walls each provided with guide grooves having cam surfaces; a pressure application cover changing position between a load position which applies load to an IC package thereby pressing the pads against elastic contacts and a no-load position, and having nail sections sliding along the cam surfaces in the guide grooves; a lever including a crankshaft section causing the nail sections to slide along the cam surfaces in the guide grooves thereby causing the pressure application cover to change position between the load position and the no-load position.

Owner:TYCO ELECTRONICS JAPAN GK

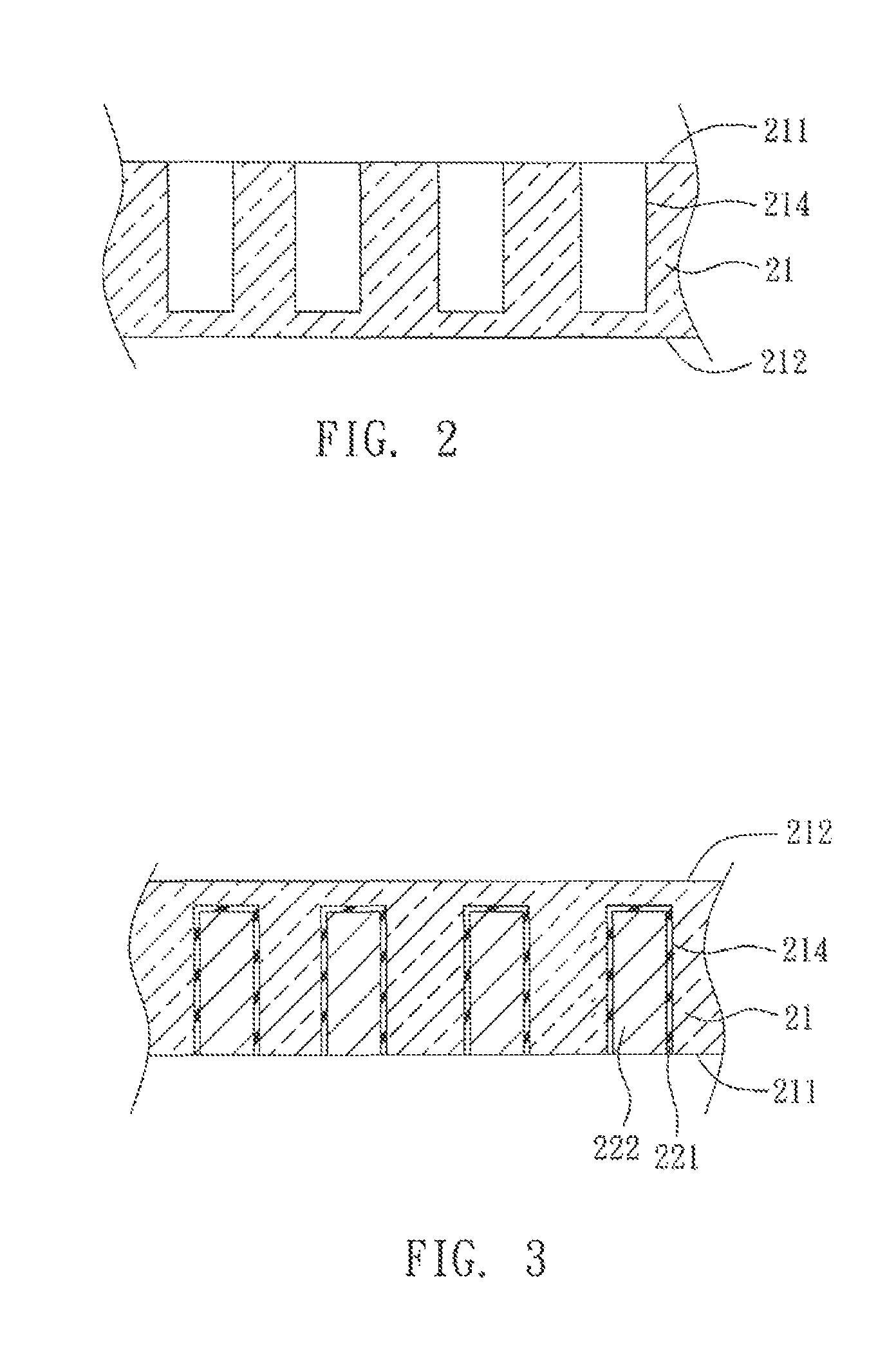

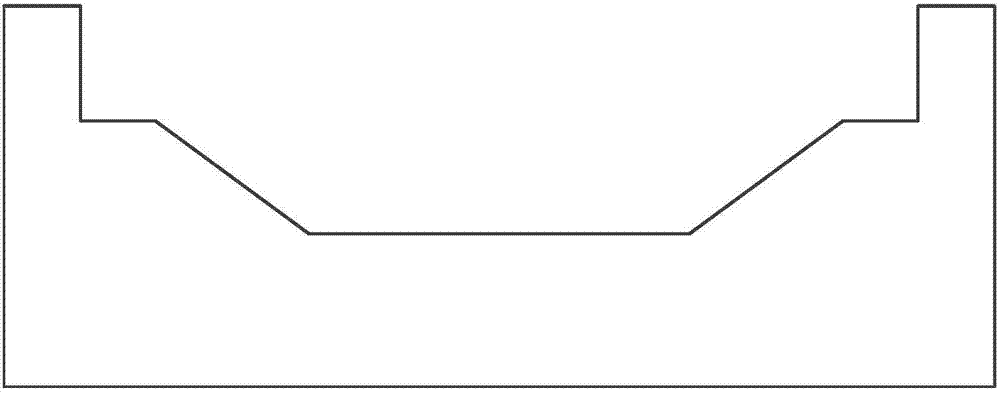

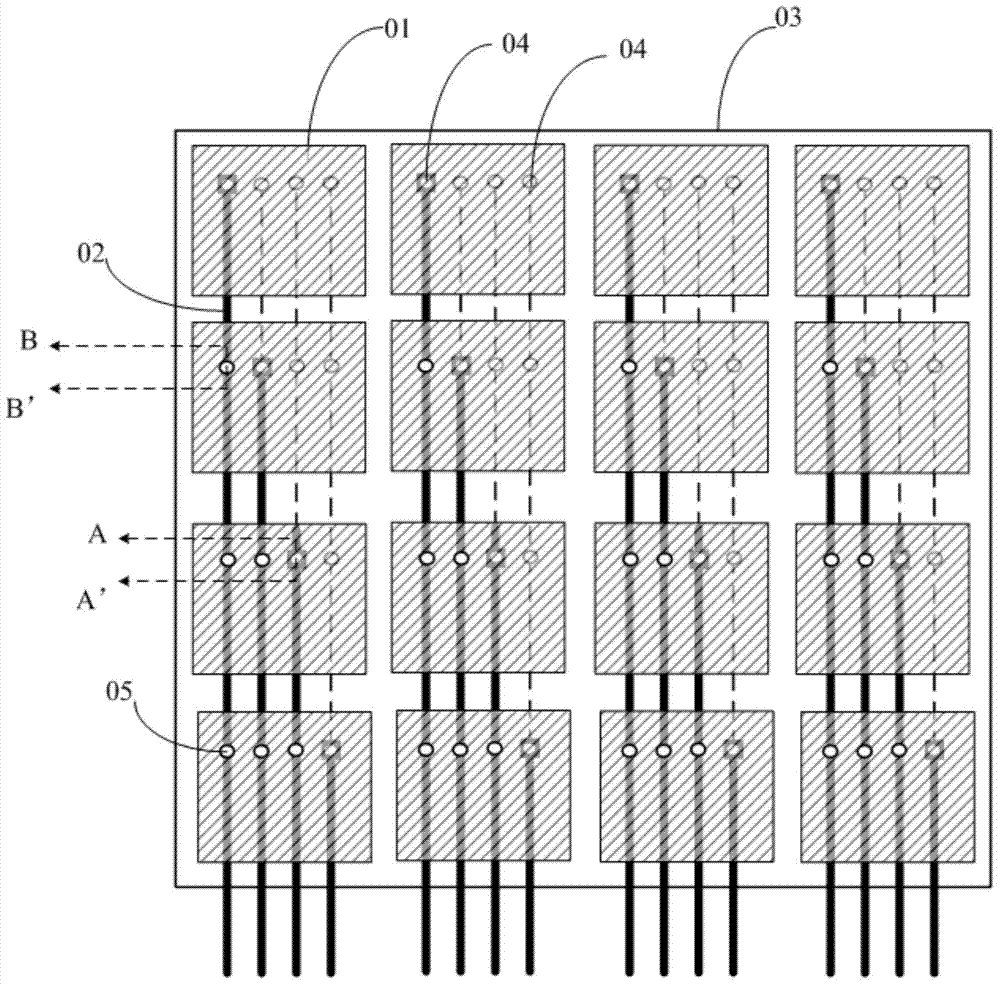

Embedded type touch screen and display device

ActiveCN104503648AEnsure electrical connectionUneven solutionInput/output processes for data processingElectricityCapacitance

The invention discloses an embedded type touch screen and a display device. An insulating layer is provided with at least a first via through the insulating layer in each area where respective capacity electrodes and wires are overlapped, the respective capacity electrodes are electrically connected with corresponding wires through the corresponding first vias, positions, corresponding to the first vias, of the respective capacity electrodes are provided with second vias in areas where the respective capacity electrodes and wires except the corresponding wires are overlapped, the second vias are through the respective capacity electrodes, and an orthographic projection of the second vias on a lower substrate covers an orthographic projection of the first vias on the lower substrate. According to the embedded type touch screen, on the basis that the first vias in the insulating layer are evenly distributed, correction connection of the respective capacity electrodes and the wires is guaranteed, so that the problem of uneven display images caused by uneven distribution of the vias in the insulating layer in the prior art is solved.

Owner:BOE TECH GRP CO LTD +1

Meter socket assembly

ActiveUS7347722B2Ensure electrical connectionMaximize contactElectric discharge tubesCoupling contact membersMechanical engineeringElectric energy

Owner:SIEMENS ENERGY & AUTOMATION INC

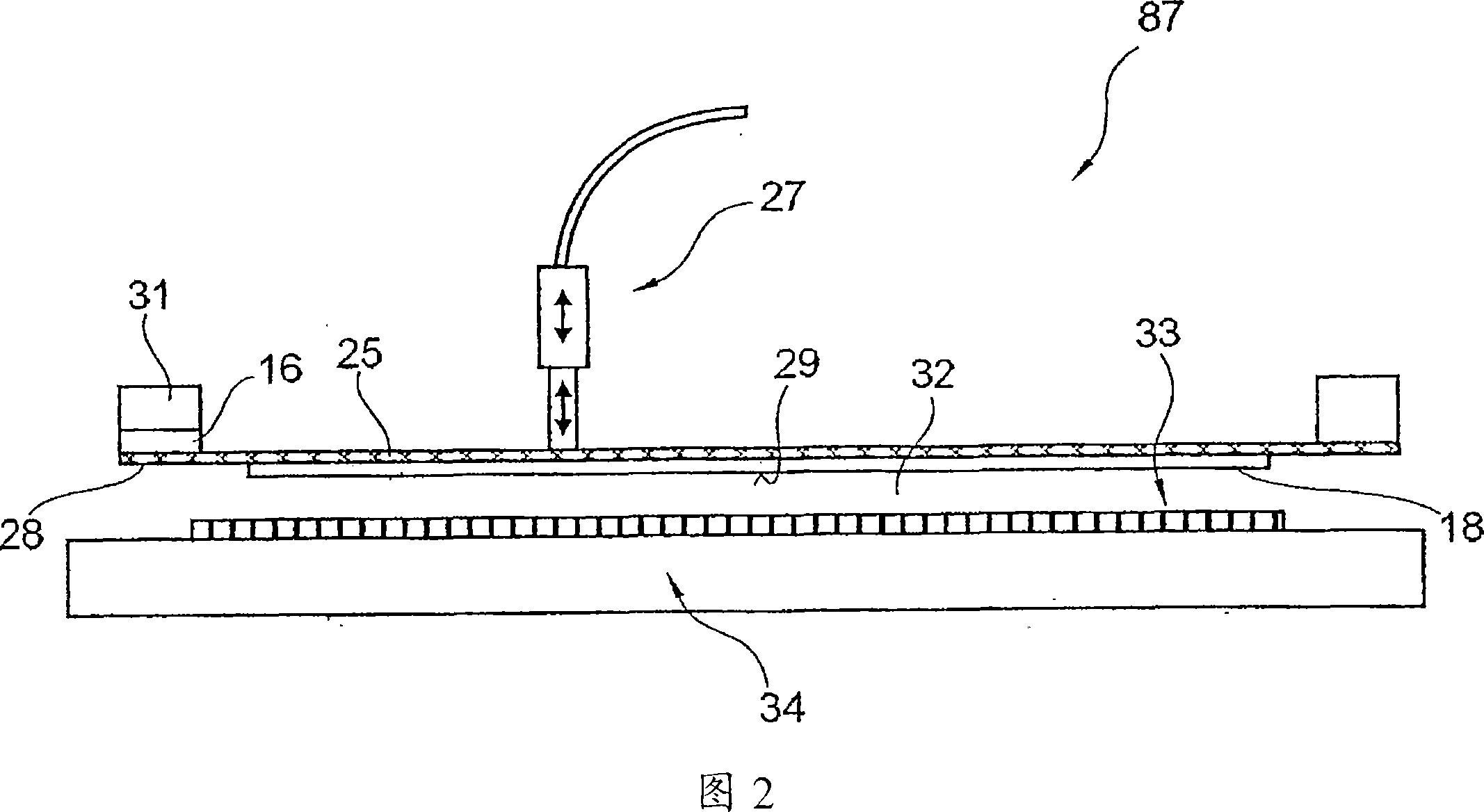

Method and device for transferring a chip to a contact substrate

ActiveCN101164150AReduce mechanical resistanceReduce thermal resistanceSolid-state devicesSemiconductor/solid-state device manufacturingMechanical engineeringMaterials science

A method and device for transferring a chip ( 18 ) situated on a transfer substrate ( 26 ) to a contact substrate ( 50 ), and for contacting the chip with the contact substrate, in which the chip, the back side ( 19 ) of which is attached adhesively to a support surface of the transfer substrate facing the contact substrate, is charged with laser energy from behind through the transfer substrate, and the chip contacts ( 59, 60 ) thereof that are arranged opposite a contact surface ( 58 ) of the contact substrate are brought into contact with substrate contacts ( 56, 57 ) arranged on the contact surface by means of a pressing device ( 45, 46 ) from behind through the transfer substrate, and a thermal bond is created between the chip contacts and the substrate contacts.

Owner:PAC TECH PACKAGING TECH

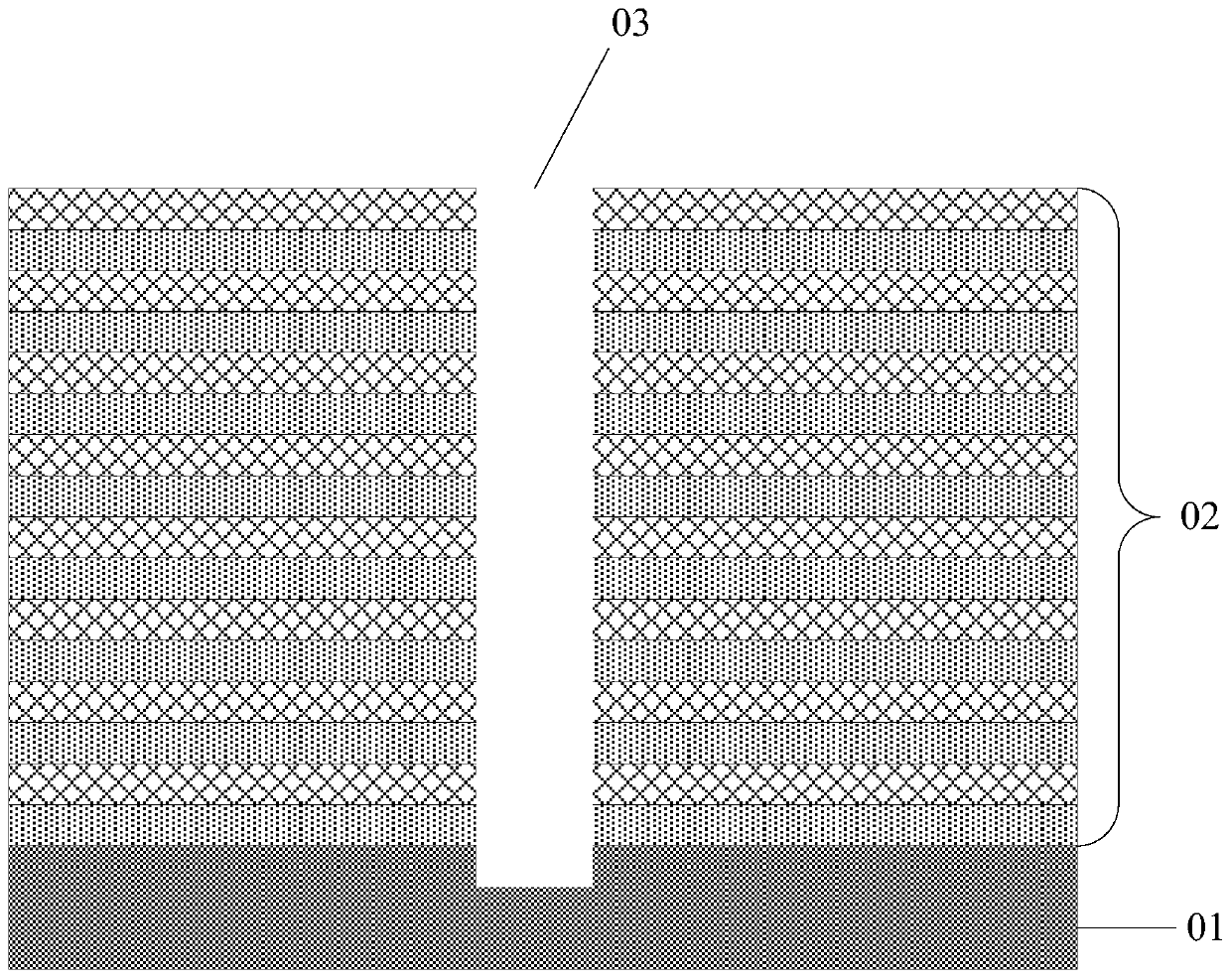

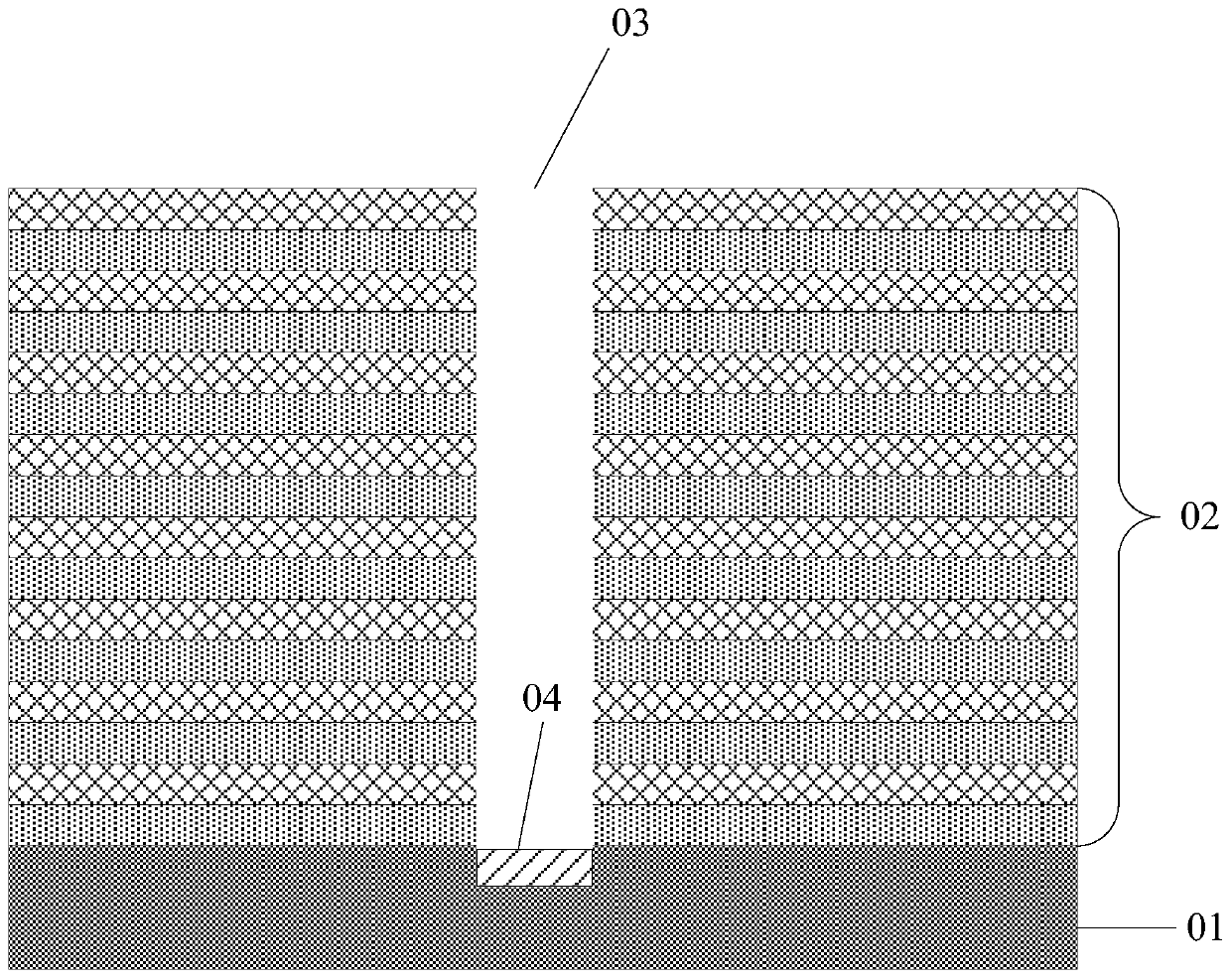

Three-dimensional memory and manufacturing method thereof

ActiveCN110752214AReduce processing difficultyImprove consistencySolid-state devicesSemiconductor devicesElectrical connectionCondensed matter physics

Owner:YANGTZE MEMORY TECH CO LTD

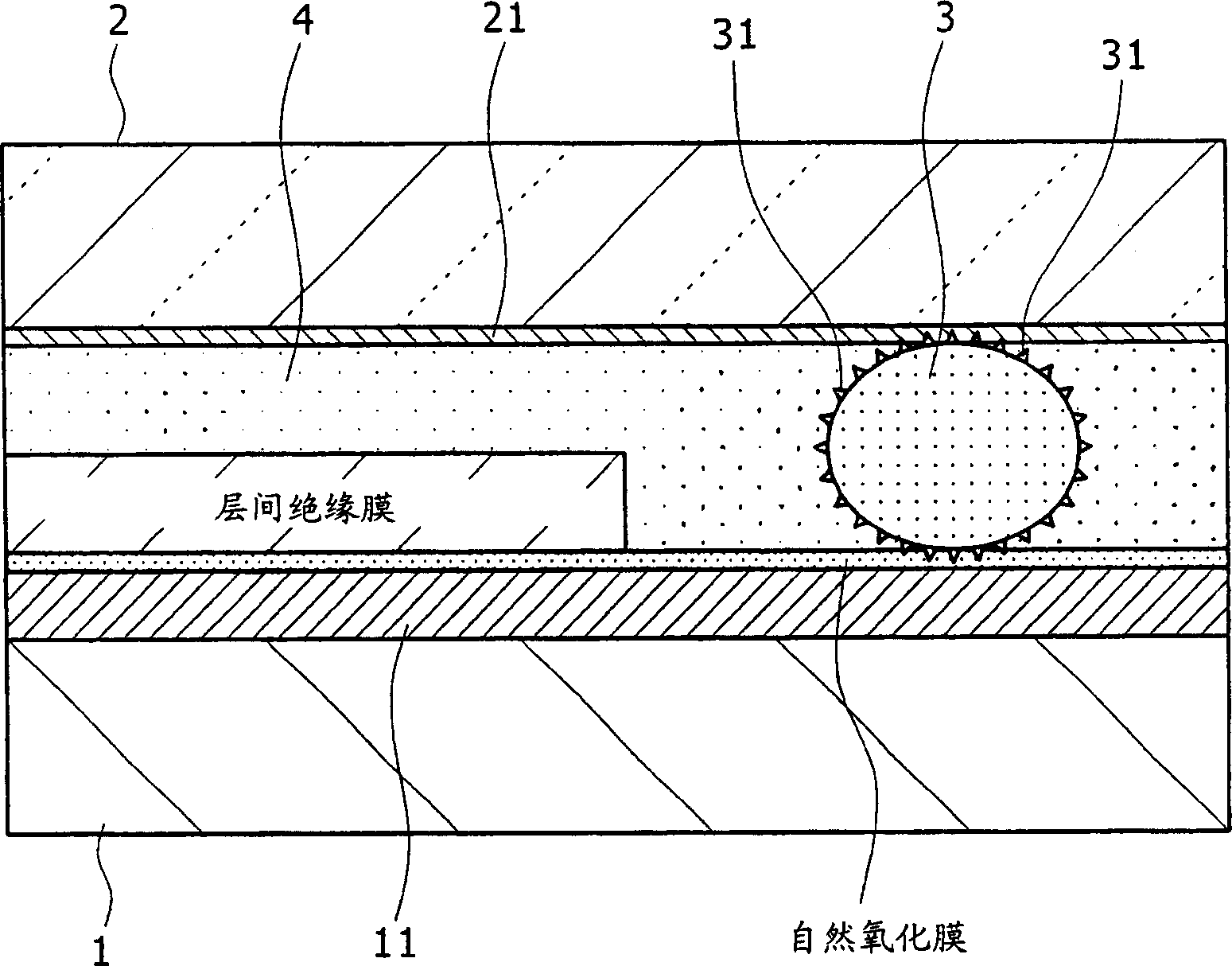

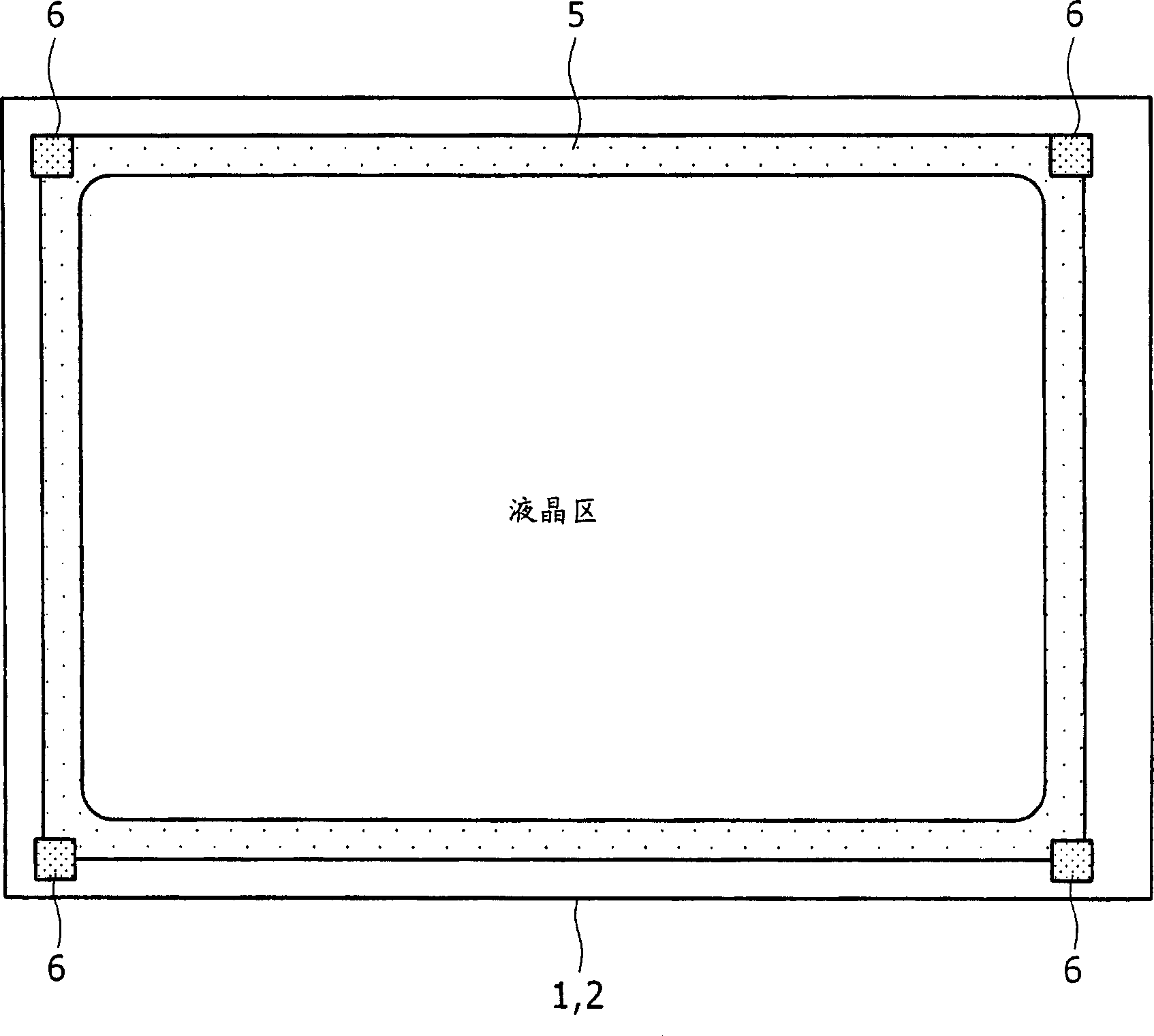

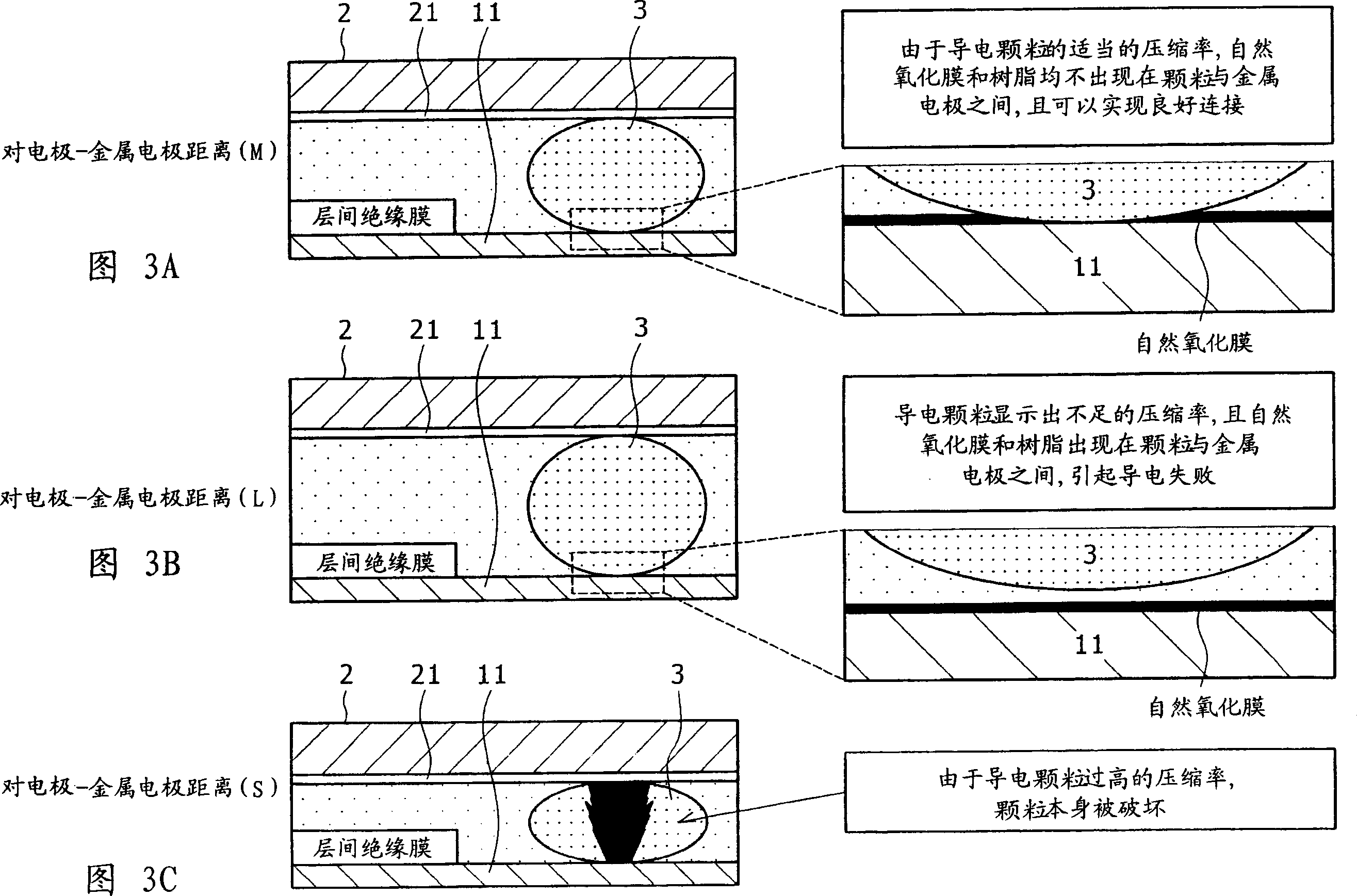

Liquid crystal device, liquid crystal display, and liquid crystal projector

InactiveCN1782795AReduce compressionImprove productivityStatic indicating devicesProjectorsElectrical connectionEngineering

A liquid crystal display, including: a liquid crystal inserted between a pair of substrates arranged opposite to each other; a driving substrate side electrode provided on the surface of a silicon driving substrate as one of the pair of substrates for driving the liquid crystal; a counter electrode , disposed on the surface of the glass substrate as the other of the pair of substrates, for driving the liquid crystal; and conductive particles, sandwiched between the pair of substrates, for obtaining between the driving substrate side electrode and the counter electrode Conductivity, wherein the conductive particles are provided with convex shapes on their surfaces.

Owner:SONY CORP

Electrode for electrolysis and ion exchange membrane electrolytic cell

ActiveCN1537973AEnsure electrical connectionCellsElectrode shape/formsEngineeringIon-exchange membranes

Owner:CHLORINE ENGINEERS CORP LTD

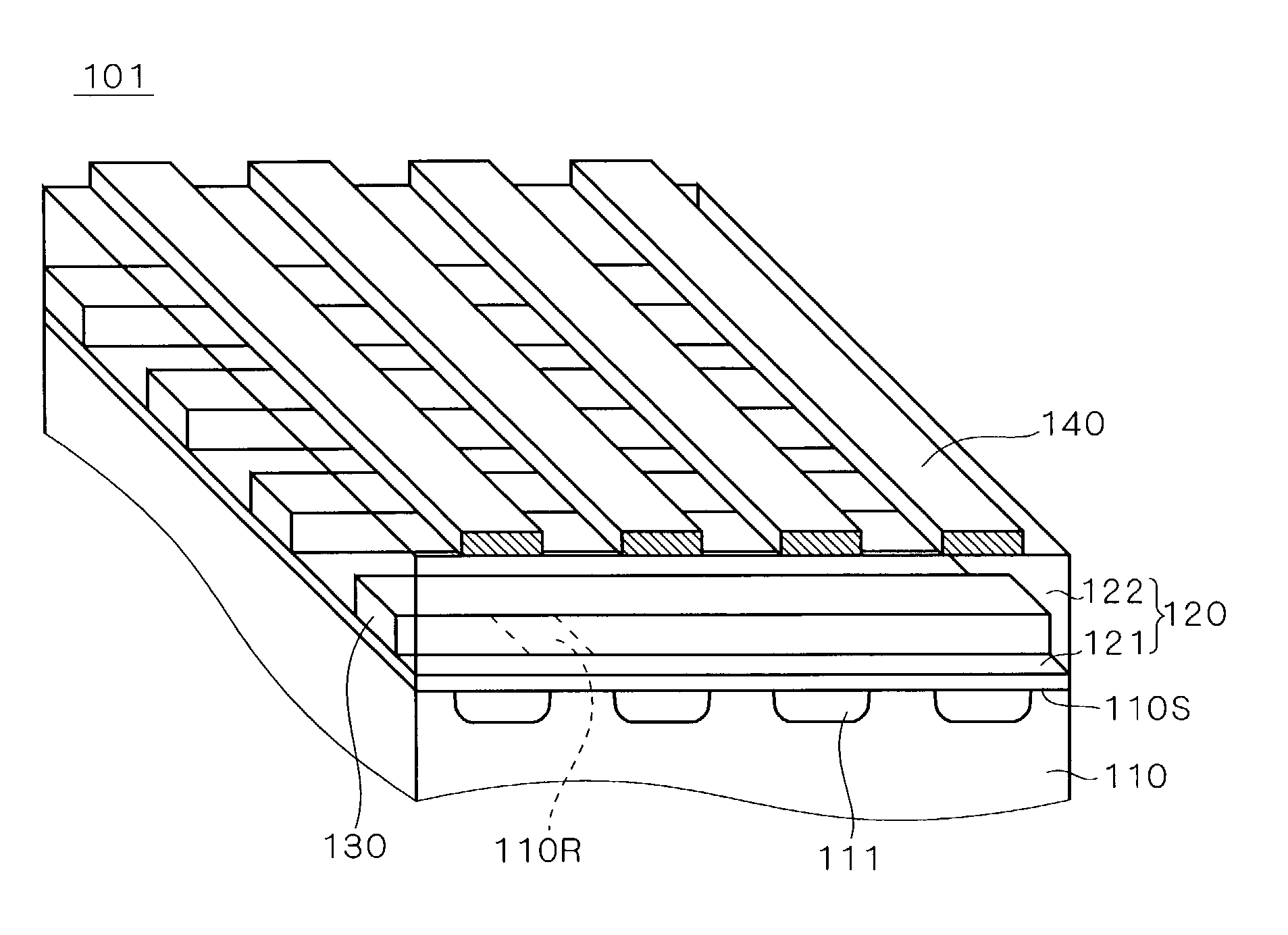

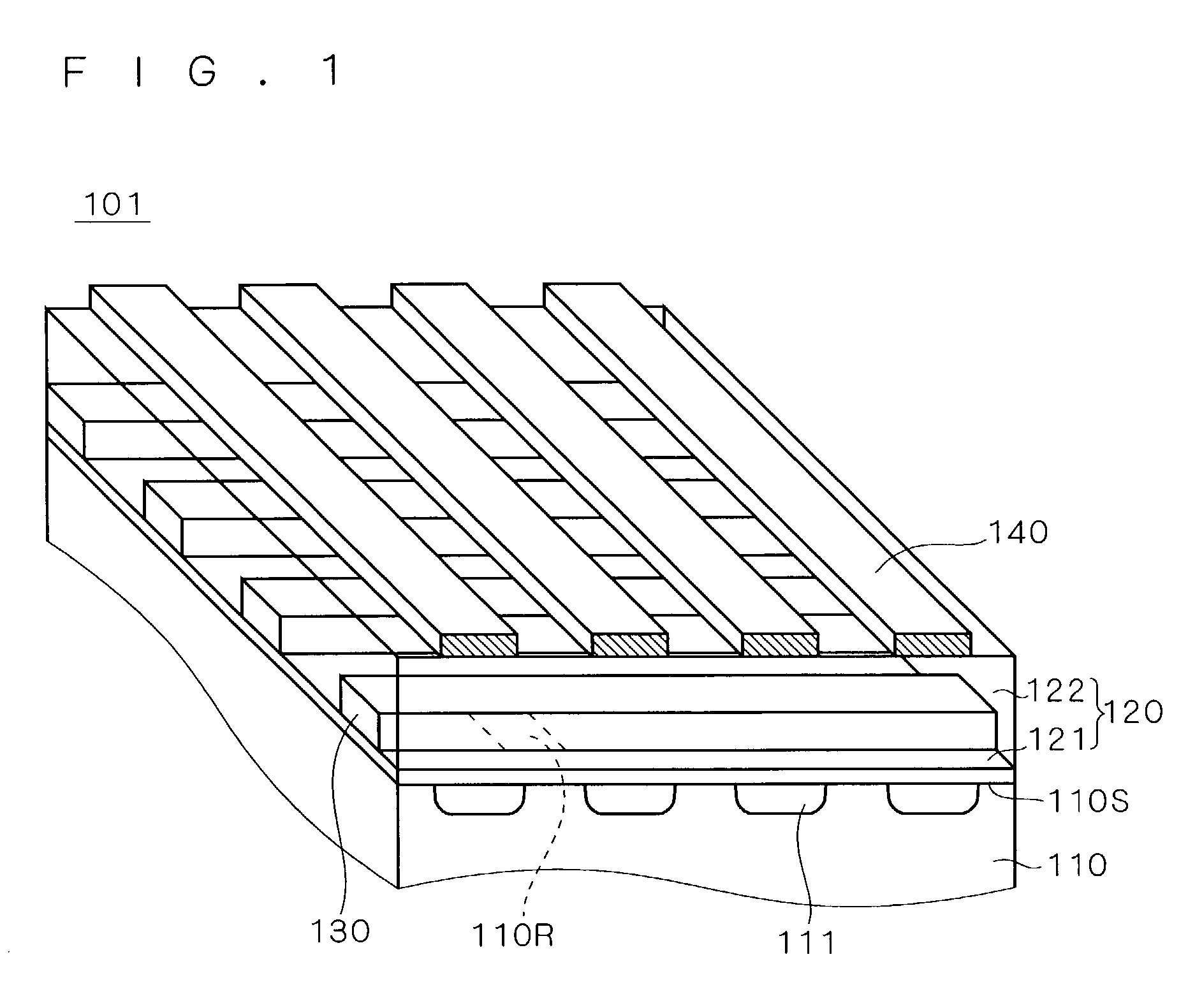

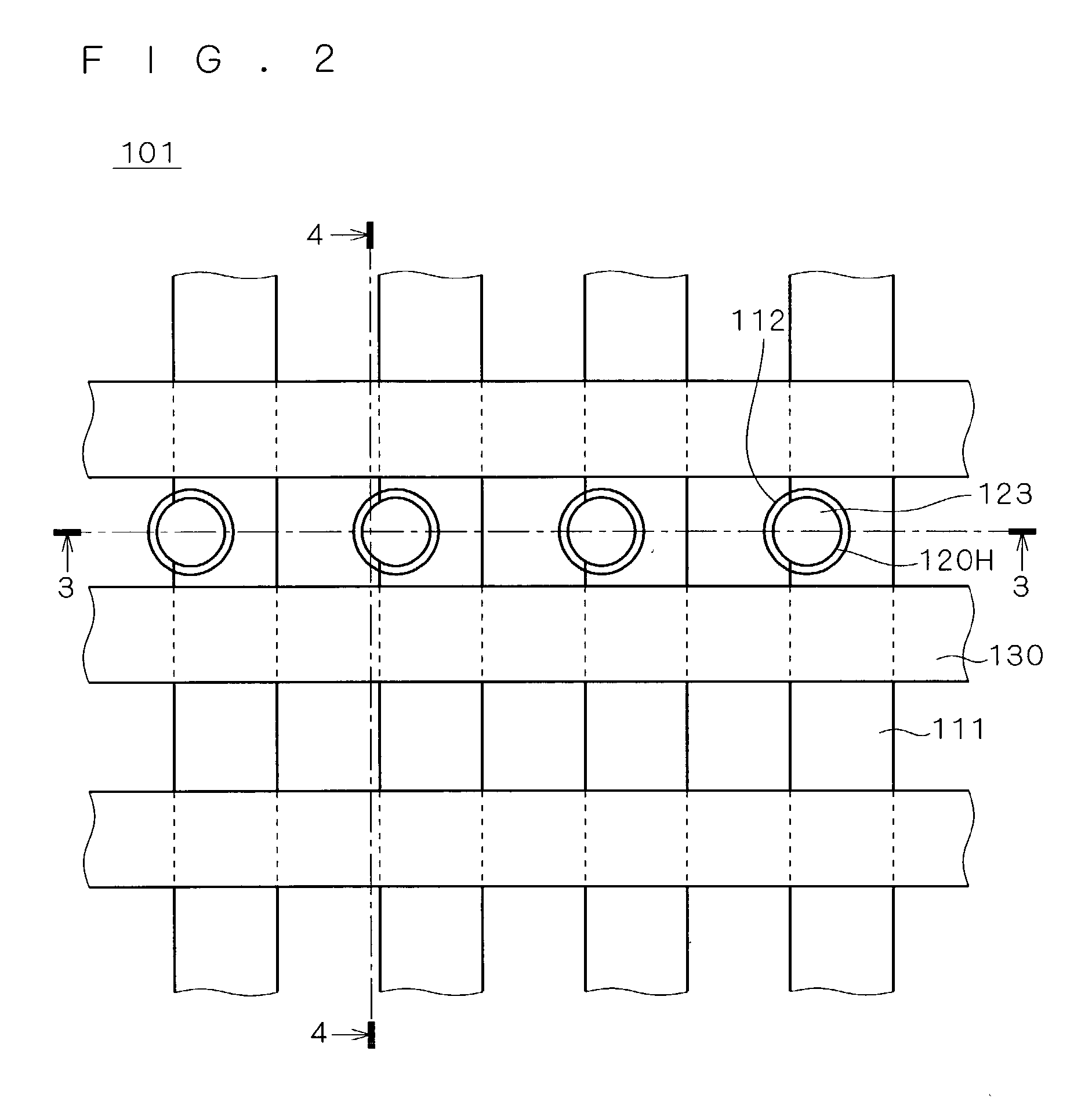

Semiconductor device including low-resistance wires electrically connected to impurity layers

InactiveUS20030189233A1Ensure electrical connectionTransistorSemiconductor/solid-state device detailsElectrical resistance and conductanceImpurity

A plurality of N-type first impurity layers (111) are provided that form stripes in a main surface (110S) of a P-type semiconductor substrate (110). At least one N-type second impurity layer (112) overlaps (or touches) one of the first impurity layers (111). A plurality of gate electrodes are provided on a gate insulating film (121). A plurality of gate electrodes form stripes crossing the first impurity layers (111). A plurality of low-resistance wires (140) are provided on an interlayer insulating film (122). The plurality of low-resistance wires (140) form stripes extending in the same direction as that of the first impurity layers (111). An end (123T2) of each contact plug (123) is entirely in contact with the second impurity layer 112, and does not touch a P-type region of the semiconductor substrate (110).

Owner:RENESAS TECH CORP

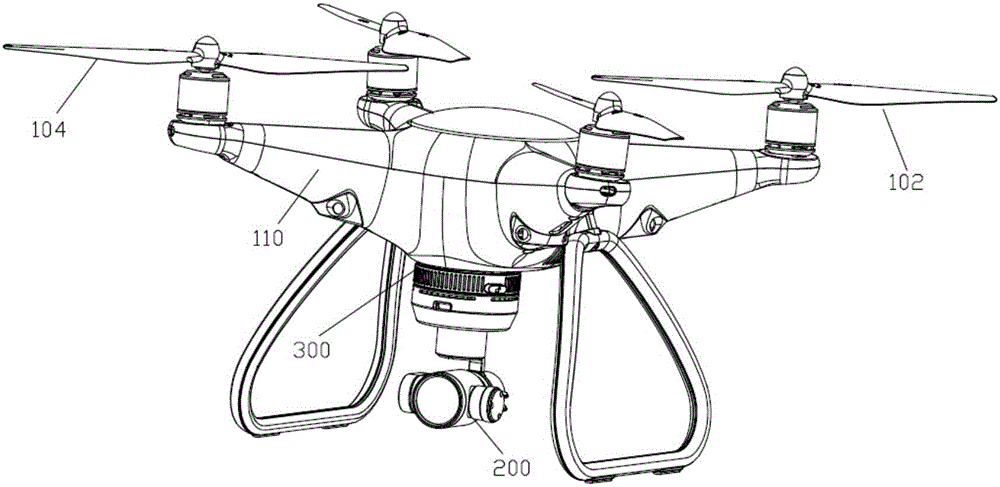

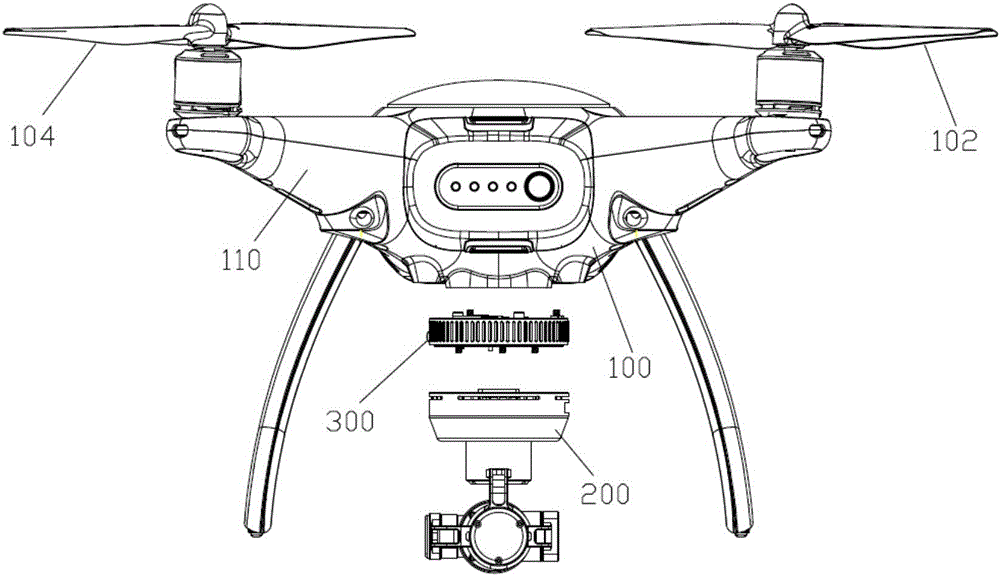

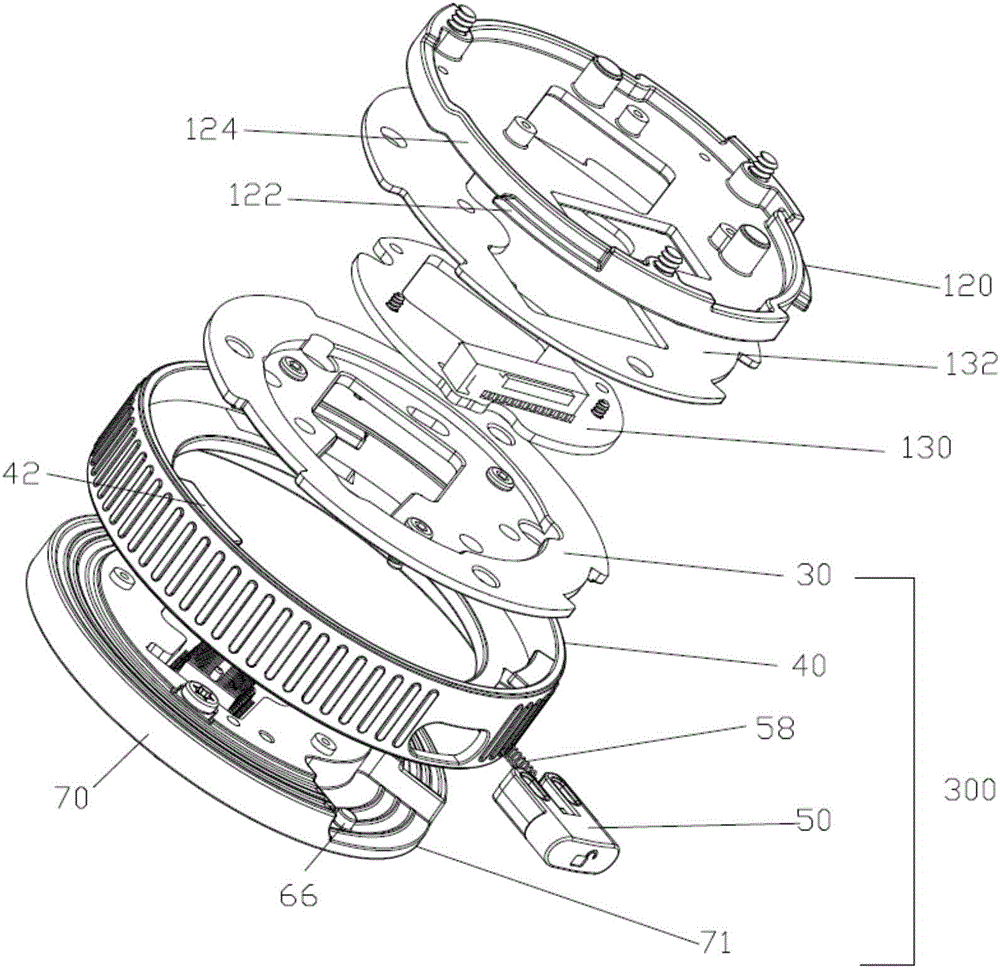

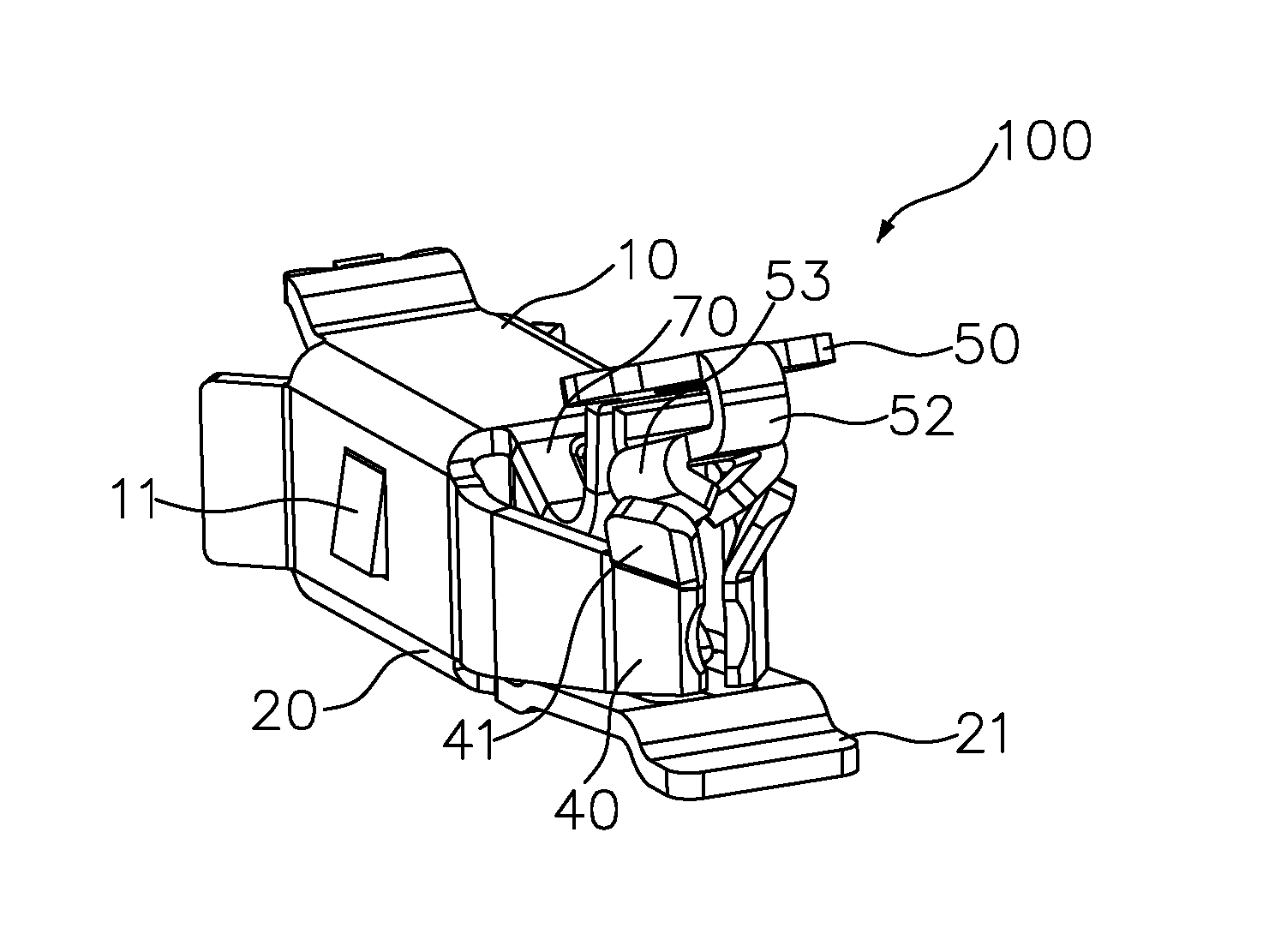

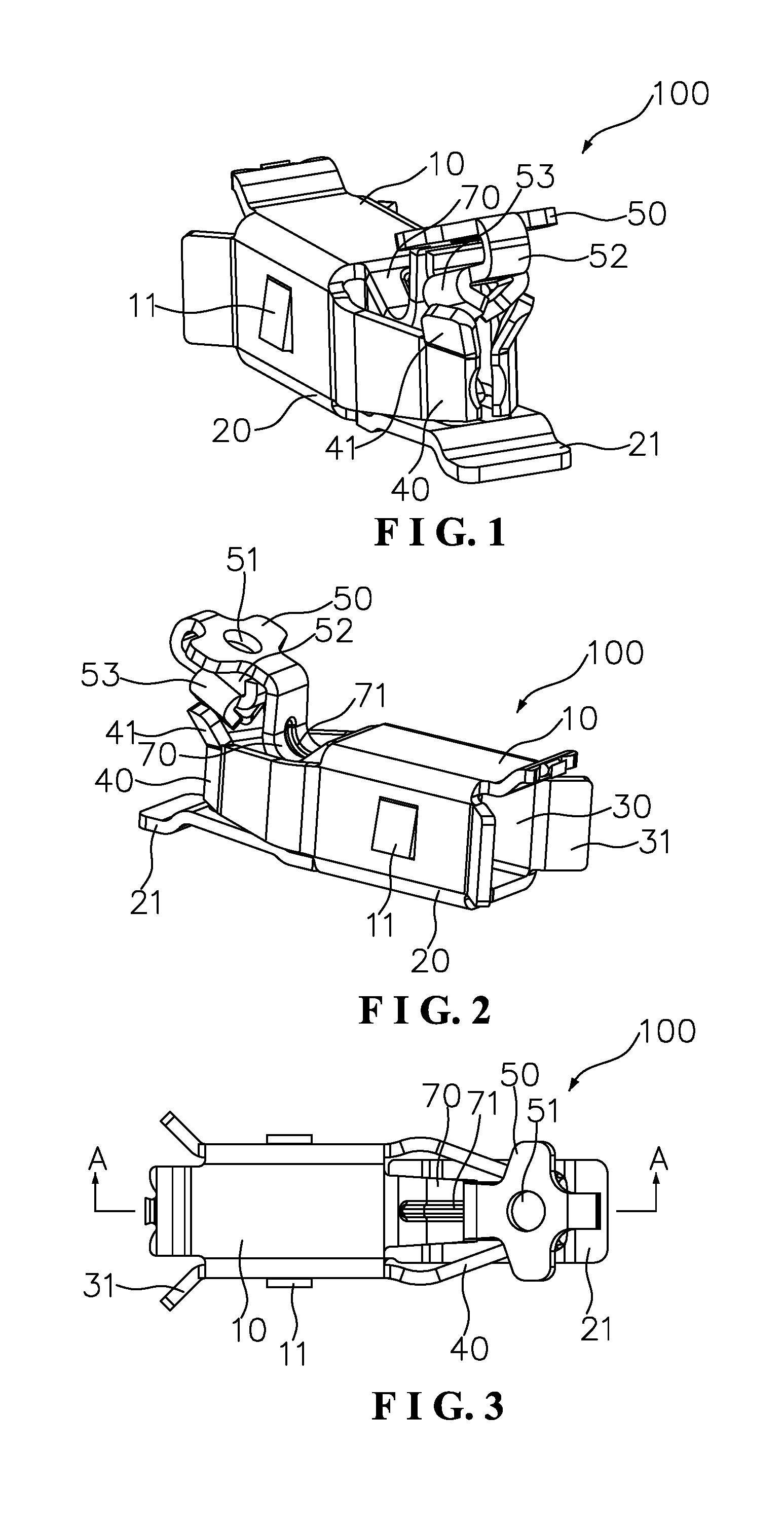

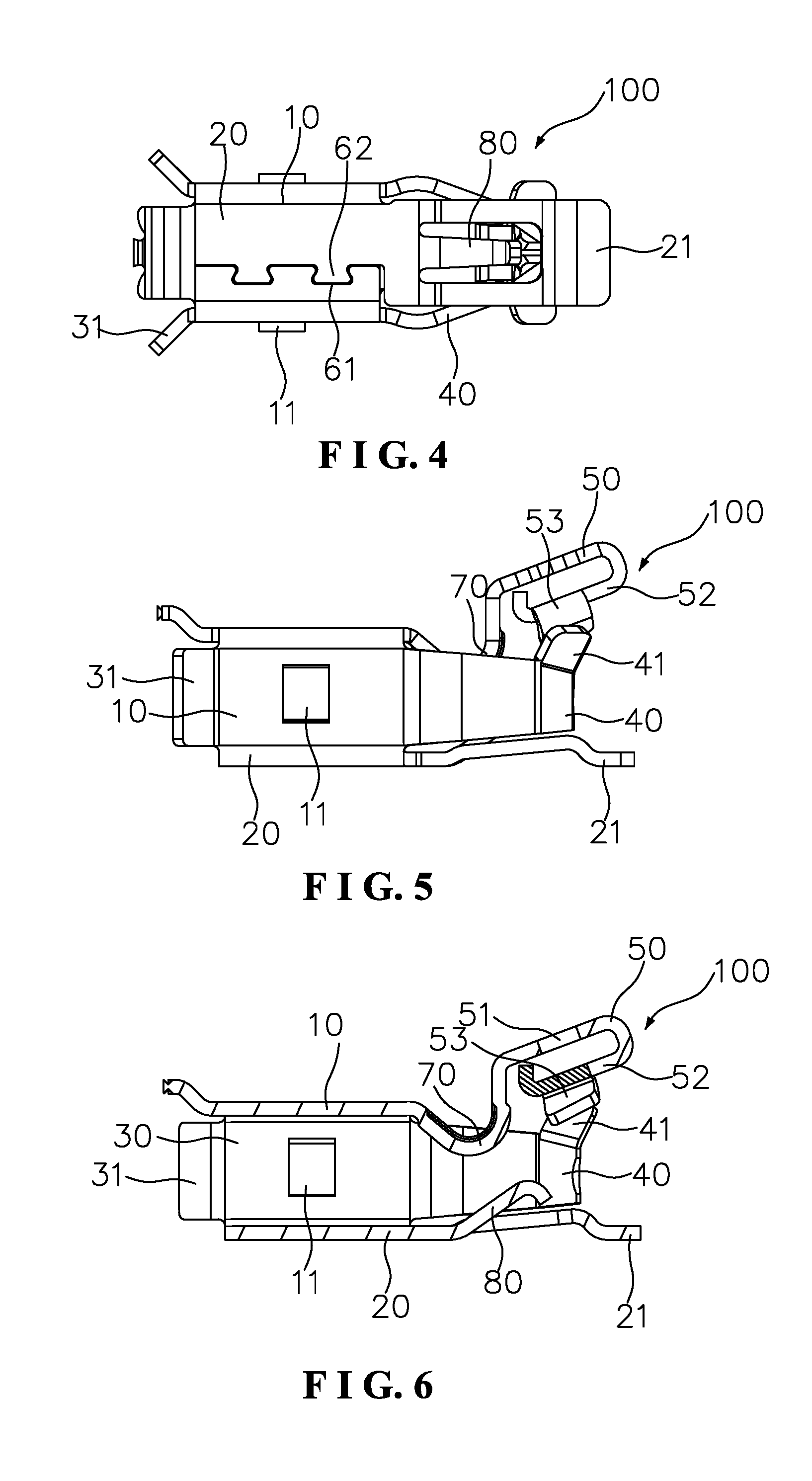

Detachable tripod head connection device and unmanned aerial vehicle

ActiveCN106628217AExtended service lifeEnsure electrical connectionAircraft componentsCoupling device detailsElectrical connectionEngineering

The invention discloses a detachable tripod head connection device and an unmanned aerial vehicle. The detachable tripod head connection device comprises an alignment assembly, a preinstallation assembly and a locking assembly. The alignment assembly is used for being aligned with an unmanned aerial vehicle circuit connection terminal and a tripod head circuit connection terminal. The preinstallation assembly is arranged on the alignment assembly and moves relative to the alignment assembly to fixedly connect a tripod head to a vehicle body of the unmanned aerial vehicle. The locking assembly is arranged on the preinstallation assembly. When the preinstallation assembly moves to the preset position relative to the alignment assembly, the locking assembly locks the preinstallation assembly. The tripod head using the tripod head connection device is detachably installed to the vehicle body, meanwhile, electrical connection of the unmanned aerial vehicle and the tripod head is ensured first, electrical contact only needs to be kept between the unmanned aerial vehicle circuit connection terminal and the tripod head circuit connection terminal, mechanical usage of the circuit connection terminals is reduced greatly, and the service life of the unmanned aerial vehicle is prolonged.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

Openable wire-mounting connector

ActiveUS9484639B1Simple structureConvenient insertionConnections effected by permanent deformationContact members penetrating/cutting insulation/cable strandsFunnel shapeEngineering

An openable wire-mounting connector includes a body. A bottom of the body forms a welding face. A front of the body forms a wire entrance. Two sides of a rear of the body bend oppositely to form elastic clips which allow an insertion of a conducting wire and hold the wire in place. A top edge of each elastic clip forms a funnel-shaped mouth which opens upwards. A top end of the rear of the base bends firstly to form a curved limiting part and then bends upwards to form an elastic button. The curved limiting part presses down on the conducting wire to prevent the wire from escaping. The elastic button is located above the funnel-shaped mouth. The elastic clips can be opened by pressing the elastic button which activates the funnel-shaped mouth.

Owner:XIAMEN GUANG WANG IND

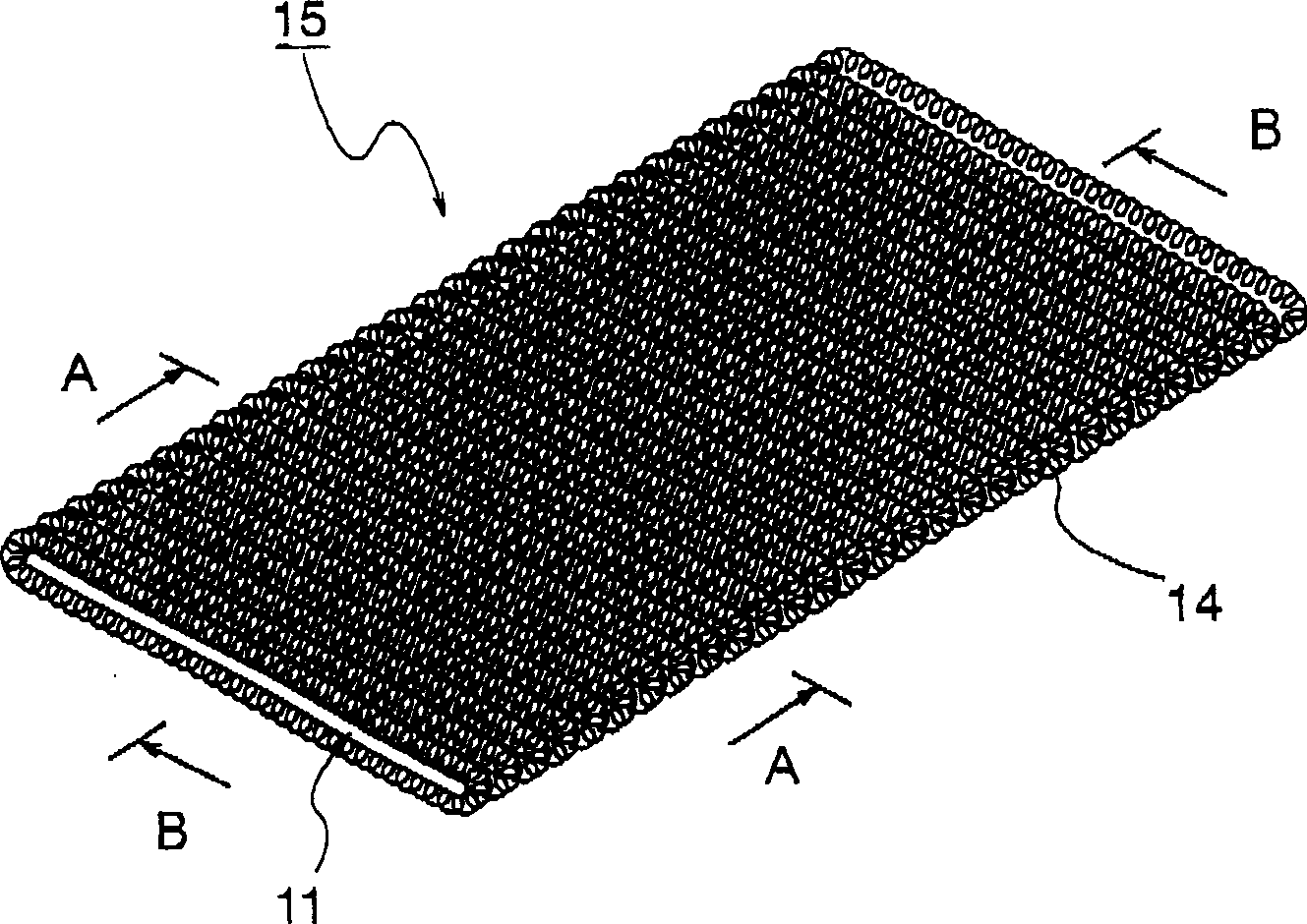

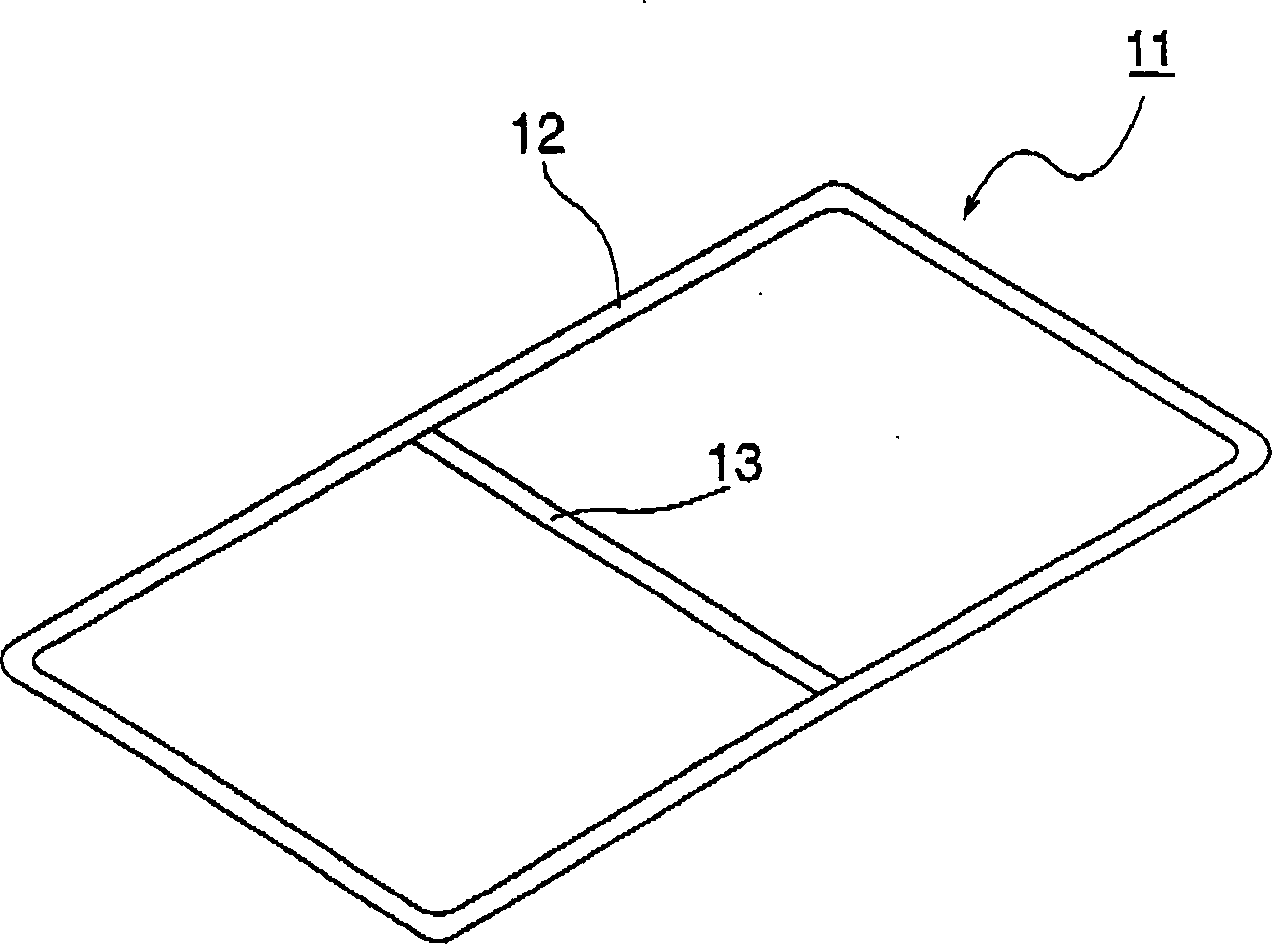

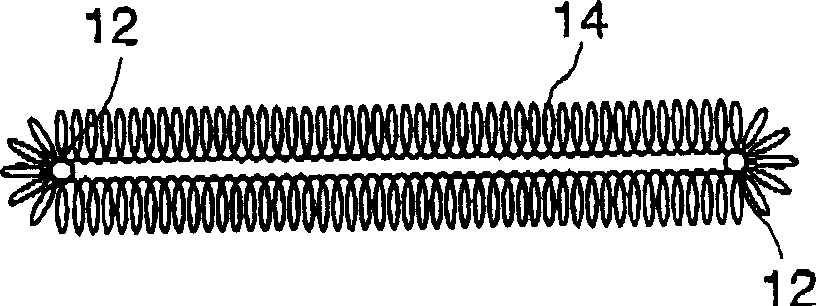

Electronic function part mounted body and method of manufacturing the electronic function part mounted body

InactiveUS20060210237A1Reduce wasteImprove productivitySemiconductor/solid-state device detailsPrinted circuit aspectsConductive pasteElectricity

A spiral contactor is provided on a substrate. An electronic function part and the substrate are adhered with an anisotropic conductive paste while an electrode portion of the electronic function part is being contacted with the spiral contactor. Thus, the electronic function part and the substrate can be securely fixed together while an adequate electrical connection between the electrode portion of the electronic function part and the spiral contactor is ensured.

Owner:ALPS ALPINE CO LTD

Liquid ejecting head

A conductive nozzle plate is formed with a nozzle orifice. An insulative layer is formed on a first face of the nozzle plate. A head body includes a pressure chamber adapted to contain liquid therein and a pressure generating element operable to cause pressure fluctuation in the liquid. The head body is attached to a second face of the nozzle plate so as to communicate the pressure chamber with the nozzle orifice. The second face of the nozzle plate and the head body are fixed to a head case. A conductive head cover covers a part of the first face of the nozzle plate while exposing the nozzle orifice. A part of the nozzle plate and the head cover directly come into contact with each other.

Owner:SEIKO EPSON CORP

Electrical connector terminal having two contact portions and two leaning portions extending from a base

InactiveUS7828578B1Increase flexibilityLarge movement distanceCoupling device detailsElectric connection basesEngineeringElectrical connector

An electrical connector and a terminal thereof are disclosed. The base portion of the terminal extends upwards to form two flexible arms. Each of the two flexible arms extends towards each other to form a leaning portion. There is a gap between the two leaning portions. Two arm portions extend from two sides of the base portions. The two arm portions respectively have a contact portion. The two contact portions and the two leaning portions are disposed at a front location and a rear location. The two leaning portions and the two contact portions surround to form a receiving space. The present invention can prevent the pins of the chip module from being deformed, improve the usage life of the terminals, and assure that the chip module is electrically connected with the electrical connector.

Owner:LOTES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com