Organic light emitting device, method of manufacturing the same, display unit, and electronic device

A technology for organic light-emitting devices and manufacturing methods, which are applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as insufficient electrical connection, and achieve the effects of suppressing brightness fluctuation, good display quality, and suppressing voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

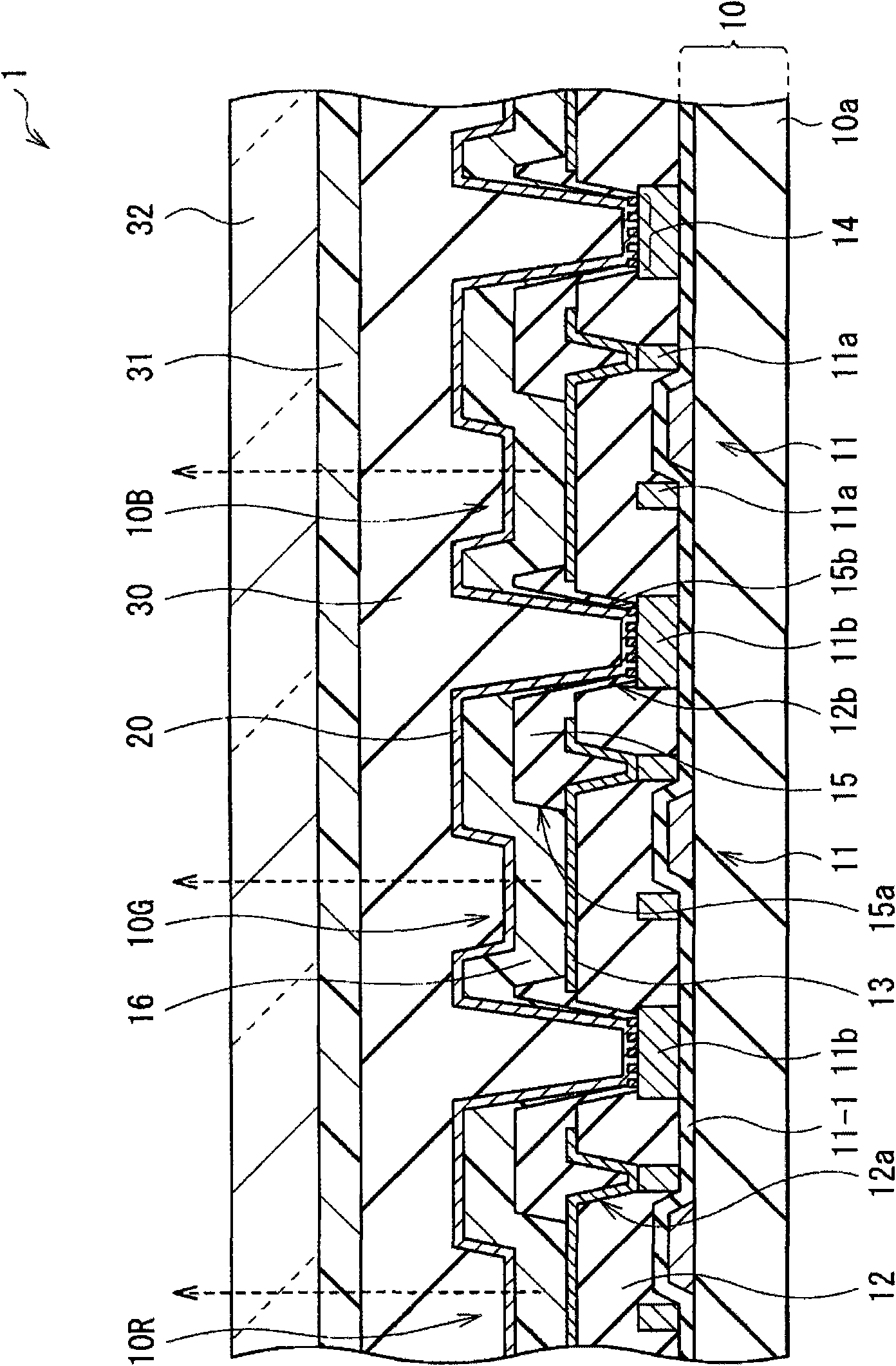

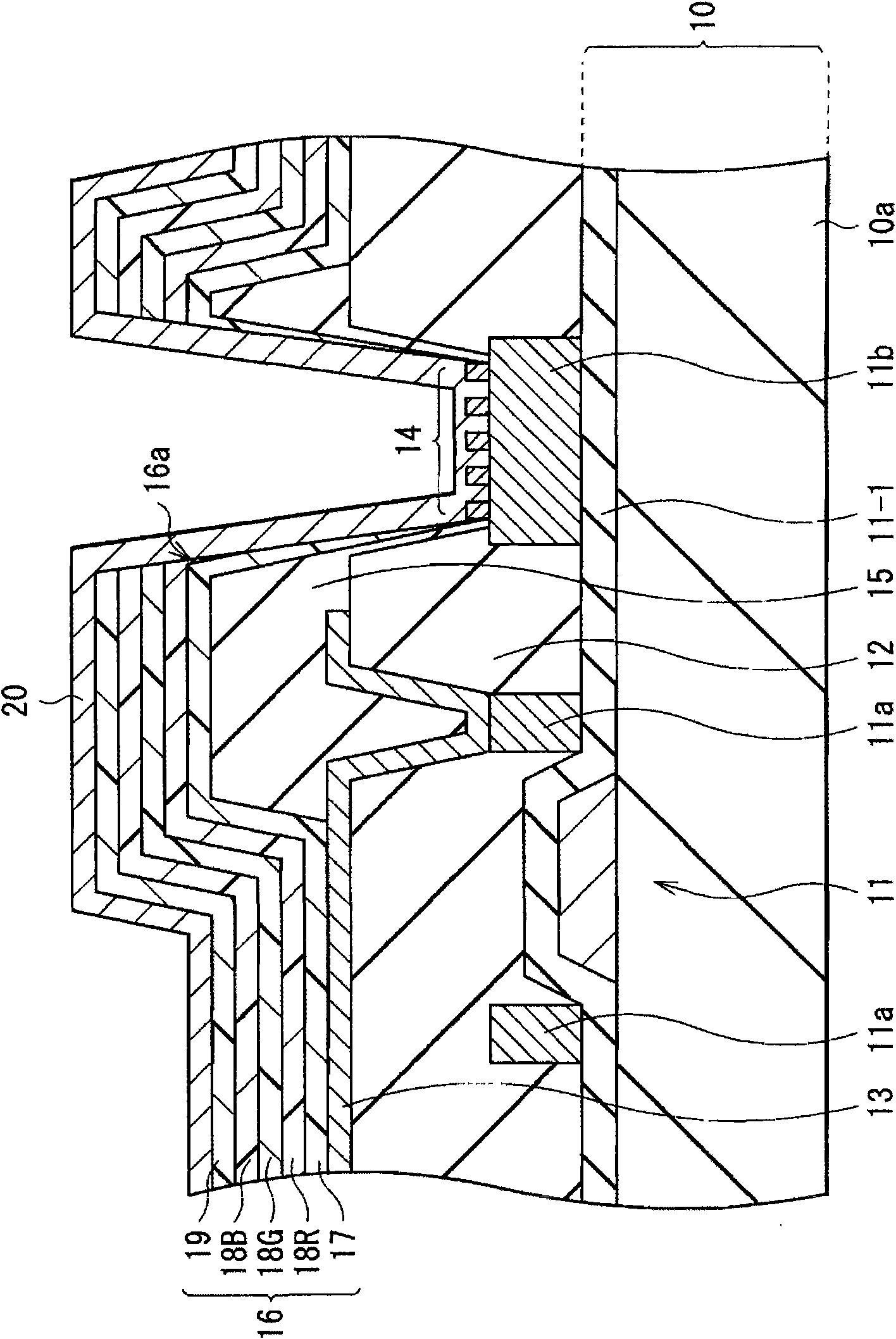

[0047] figure 1 A cross-sectional structure of the display unit 1 of the first embodiment of the present invention is shown. The display unit 1 is suitably used as a thin organic light emitting display in which the driving board 10 and the sealing board 32 are arranged oppositely, and the entire areas of the driving board 10 and the sealing board 32 are covered with a film made of, for example, a thermosetting resin. The adhesive layer 31 is bonded together. In the driving board 10, for example, an organic light-emitting device 10R generating red light, an organic light-emitting device 10R generating green light, and an organic light-emitting device 10R generating green light are arranged sequentially in a matrix state as a whole via a TFT 11 and a planarizing layer 12 over a substrate 10a of an insulating material such as glass. A light emitting device 10G and an organic light emitting device 10B generating blue light.

[0048] The TFT 11 is a driving element corresponding ...

no. 2 example

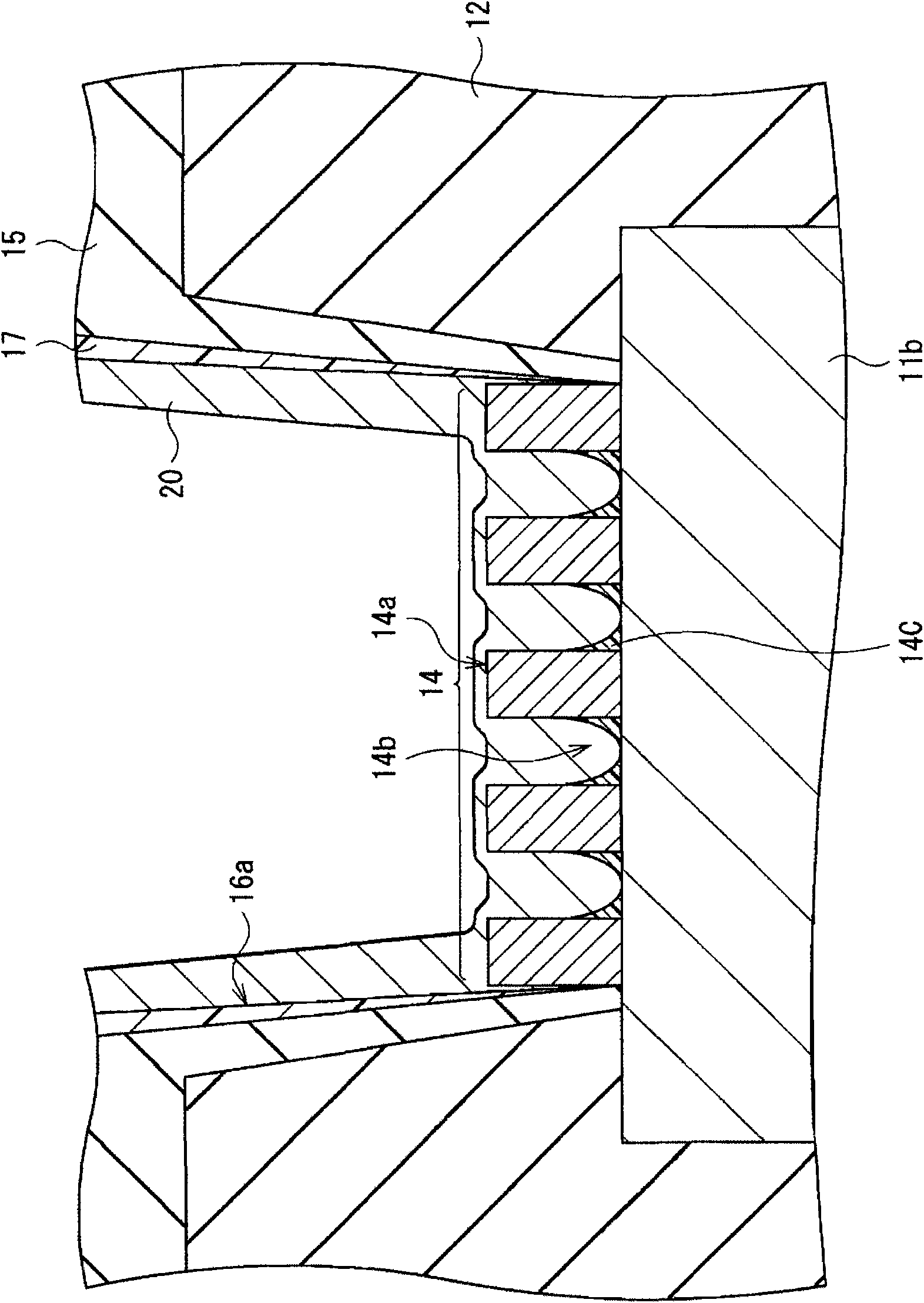

[0091] Figure 12 An enlarged view of a region where the connection portion 14 in the display unit of the second embodiment of the present invention is formed is shown. This embodiment has a structure similar to that of the first embodiment except that the structure of the organic layer 23c is different. Therefore, the same elements as those of the first embodiment are denoted by the same reference numerals, and descriptions thereof are appropriately omitted.

[0092] An organic layer 23 c is formed at the bottom surface of the concave portion 14 b of the connection portion 14 . The organic layer 23c contains, for example, conductive fine particles in addition to the constituent materials of the above-mentioned organic layer 16 . The second electrode 20 is formed so as to cover the organic layer 23c and the convex portion 14a. Examples of conductive fine particles include metal fine particles such as gold, silver, and aluminum, conductive fine particles such as ITO and ZnO,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com