Liquid crystal device, liquid crystal display, and liquid crystal projector

A liquid crystal display and liquid crystal device technology, which is applied in the direction of projection devices, static indicators, instruments, etc., can solve the problems of increased steps for connecting flexible cables, restrictions on the shape of the package, and restrictions on connection accuracy, etc., to achieve enlarged manufacturing process margins, Effects of improving productivity and reducing compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

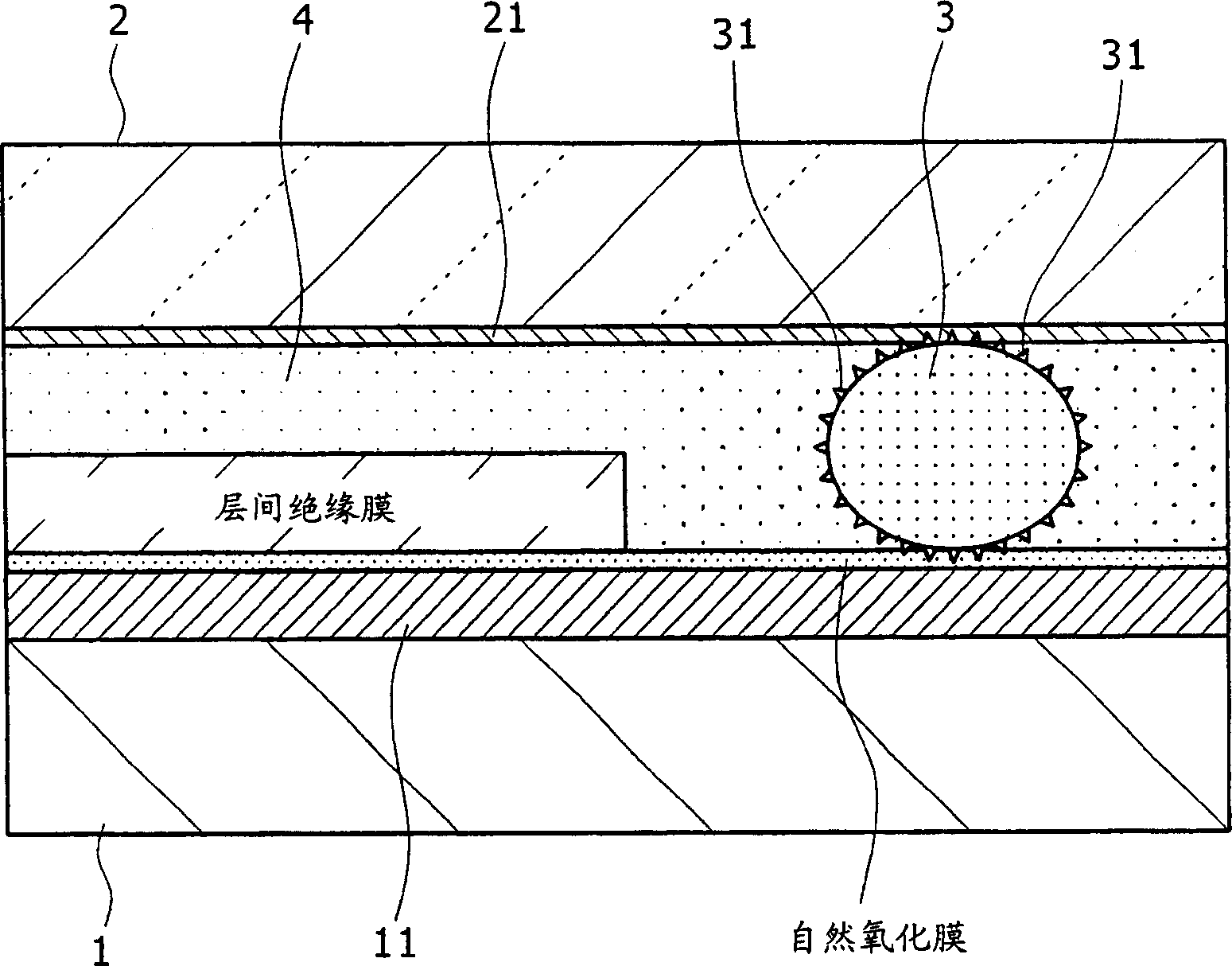

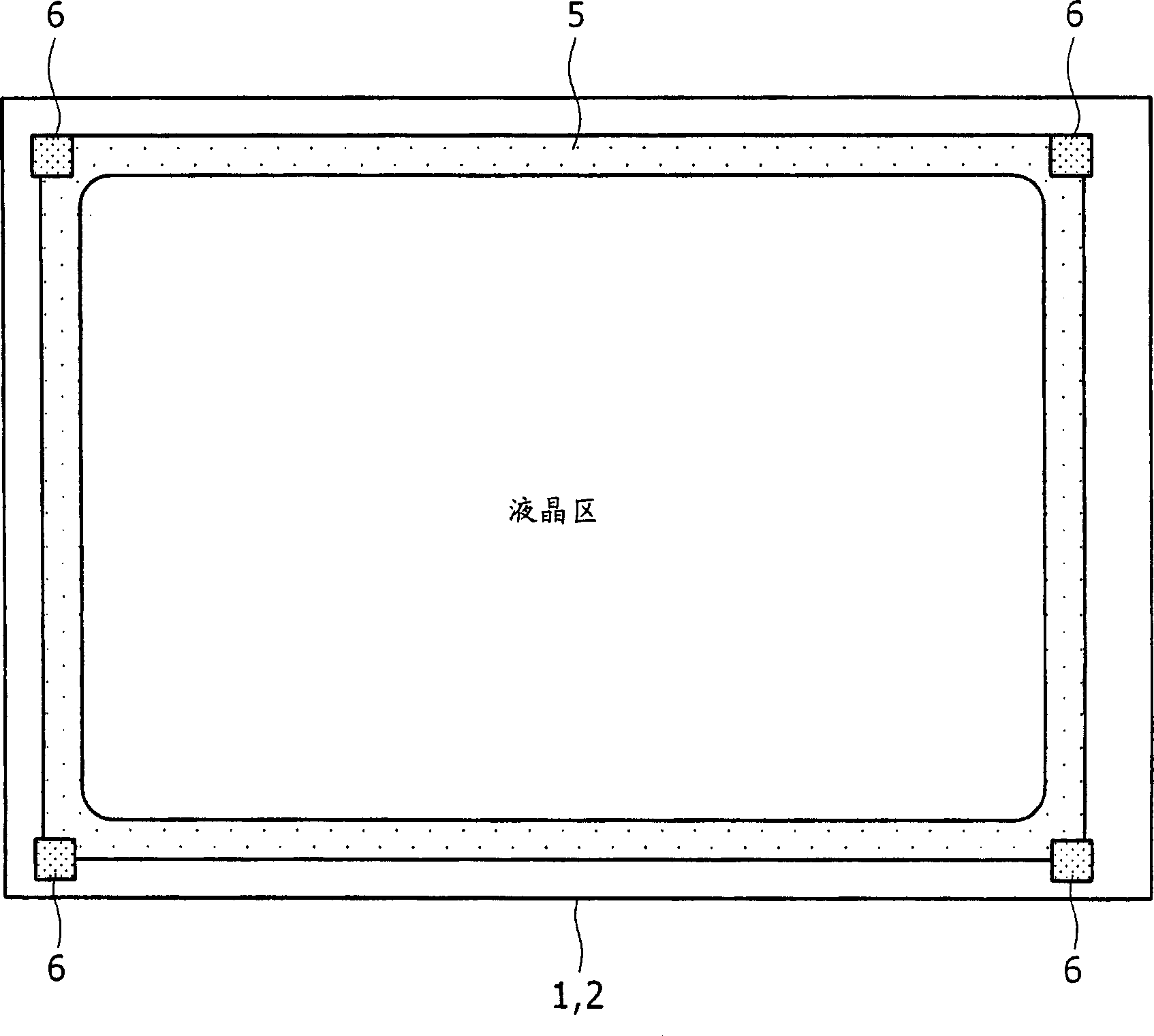

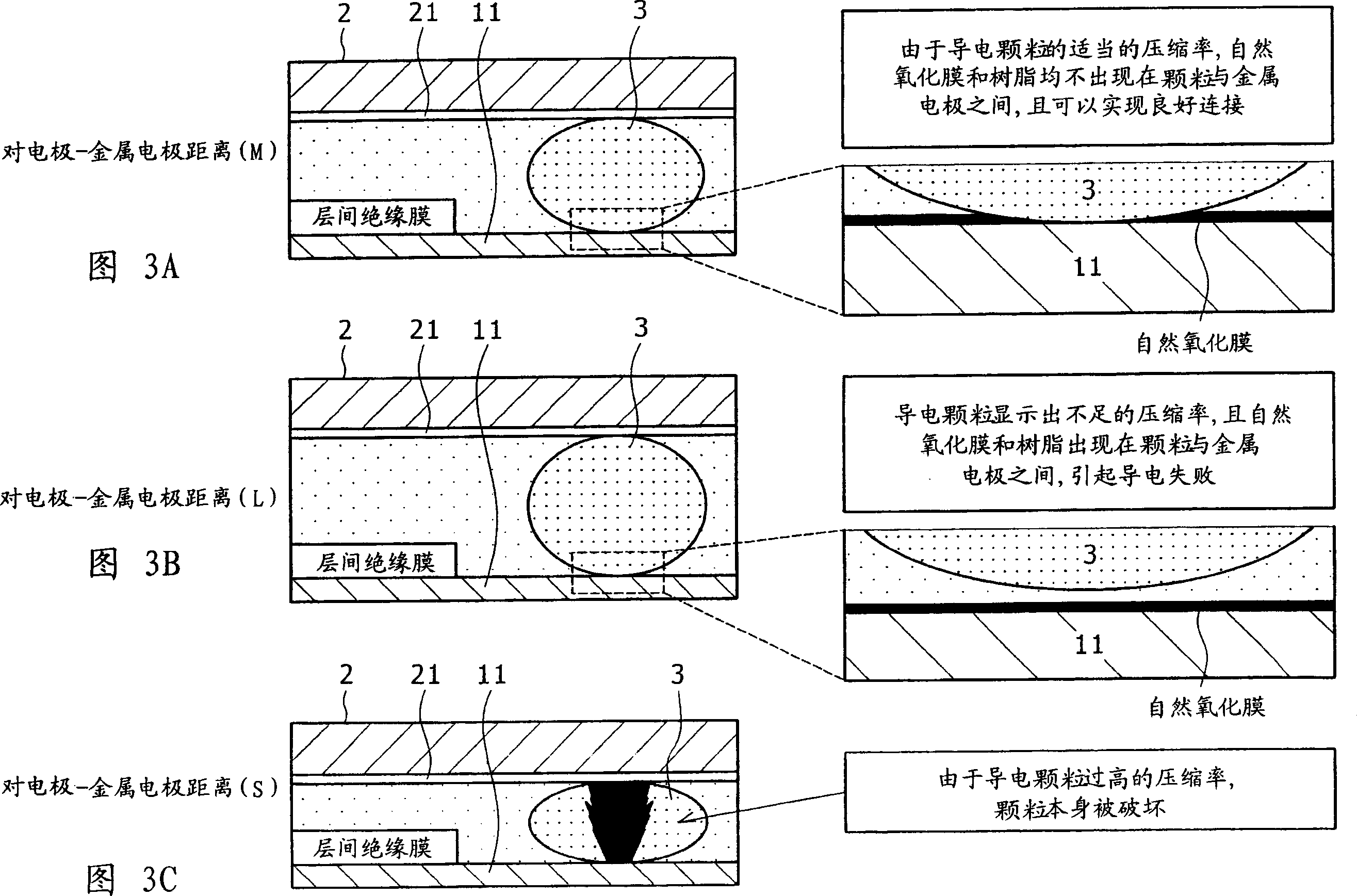

[0015] Now, an embodiment of the present invention will be described below based on the drawings. figure 1 is a schematic cross-sectional view for illustrating a liquid crystal display according to the present invention. Specifically, the liquid crystal display has a configuration in which a silicon drive substrate 1 and a glass substrate 2 are used as a pair of substrates disposed opposite to each other, the substrate 1 and the substrate 2 are bonded to each other with a predetermined distance therebetween, and the liquid crystal (not shown) out) inserted in between.

[0016] The silicon drive substrate is provided with a drive substrate side electrode (first electrode) 11 for supplying a voltage to a counter electrode (second electrode) 21 formed on the glass substrate 2 and for communication between the substrate side electrode 11 and the counter electrode 21. Conductivity, the conductive particles 3 are sandwiched between the silicon drive substrate 1 and the glass substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com