Electrode for electrolysis and ion exchange membrane electrolytic cell

A technology of ion exchange membrane and electrolytic cell, which is applied in the field of electrodes, can solve the problems of uneven distance between electrodes, damage to ion exchange membrane, and inability to provide electrical connection, etc., and achieve the effects of easy handling, reliable current supply, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] A single-unit ion exchange membrane electrolysis cell was assembled as follows.

[0062] A dimensionally stable electrode obtained from Permelec Electrode, Ltd. was used as the anode, while an active electrode supported by a nickel microporous substrate was used as the cathode. The respective dimensions of the reaction surfaces of the anode and cathode are 110 mm wide and 1400 mm high. Flemion F-8934 obtained from Asahi Glass Co., Ltd. was used as the ion exchange membrane.

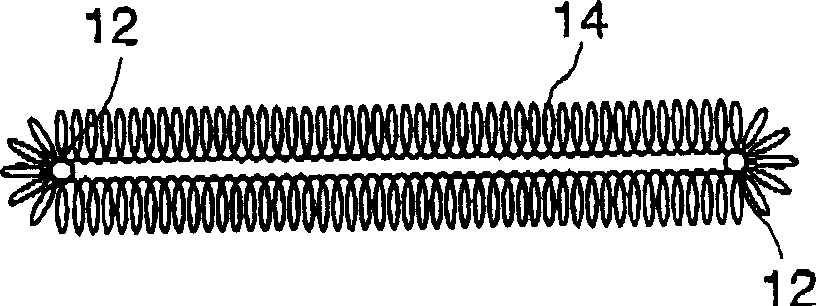

[0063] The winding diameter is 0.17mm, and the tensile strength is 620-680N / m 2 Nickel wire (JIS code: NW2201), giving a metal coil with a width of about 0.5 mm and a winding diameter (appearance diameter) of about 6 mm.

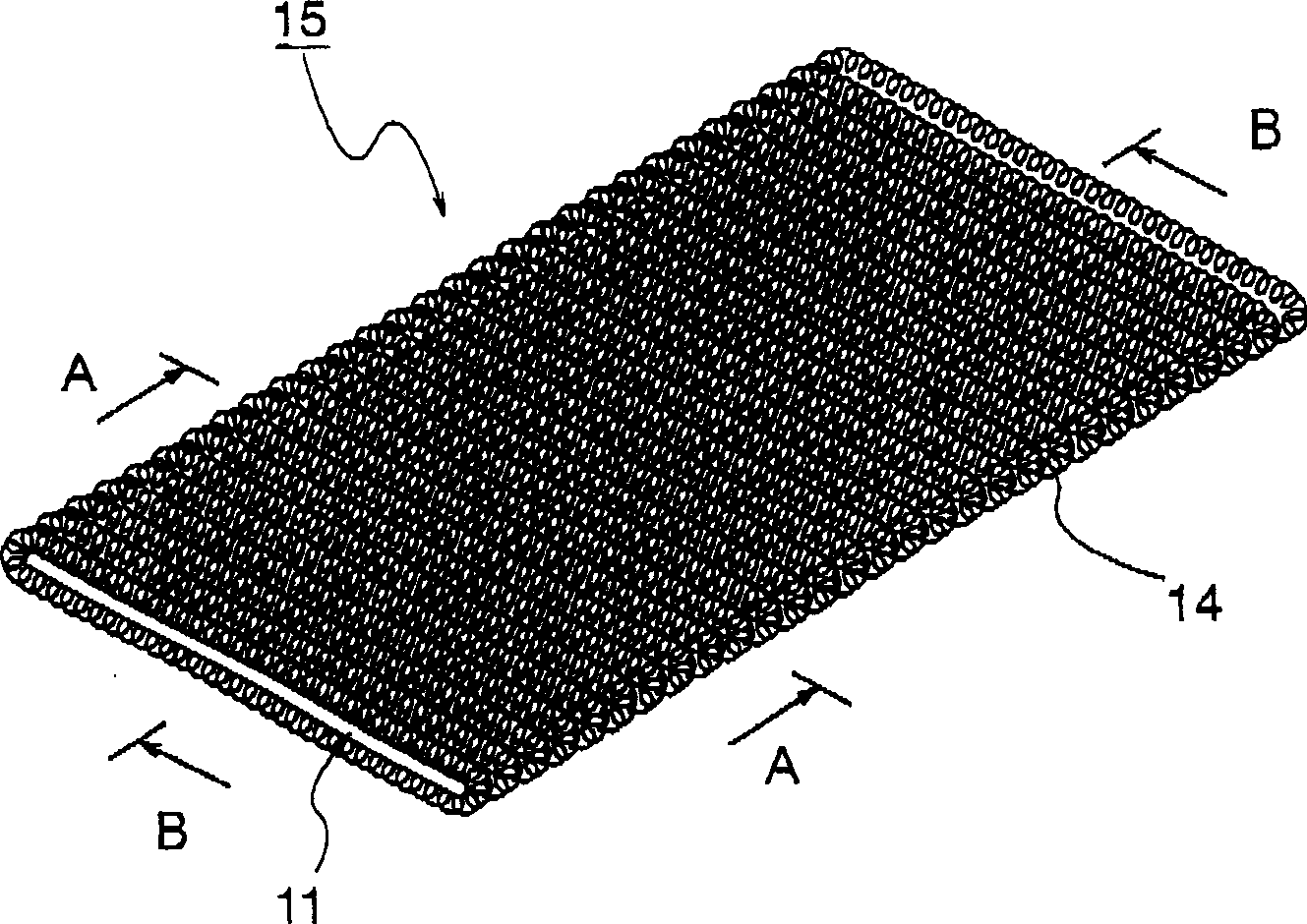

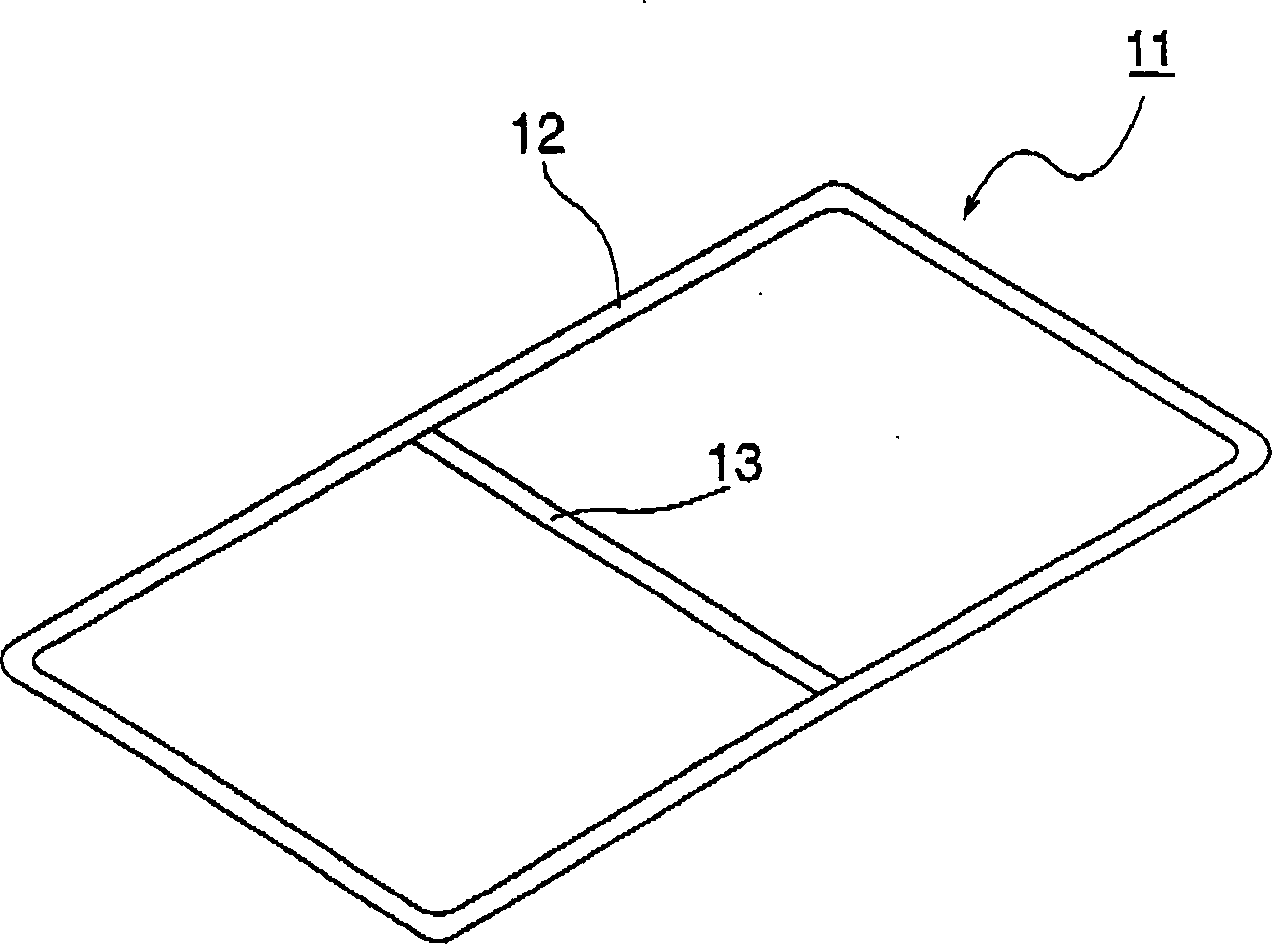

[0064] A metal wire was wound around a frame (anti-corrosion frame) formed of a round rod made of nickel with a diameter of 2 mm to adjust its shape to a rectangle, giving an elastic washer with a thickness of 10 mm, a width of 110 mm and a length of 350 mm. The metal coil mas...

example 2

[0068] A single-unit ion exchange membrane electrolysis cell was assembled as follows.

[0069] The effective area is 1540cm 2 An appropriately sized electrode (width 11 cm, height 140 cm) was used as an anode on which an electrode catalyst coating with a platinum group metal oxide was formed on a widened metal made of titanium obtained from Permelec Electrode, Ltd. And made. Using the anode flange, the anode is mounted on the anode chamber wall of the electrolytic cell.

[0070] A cathode current collector formed of widened nickel was mounted on the cathode chamber wall with a cathode flange formed of plate-like nickel.

[0071] The winding diameter is 0.17mm, and the tensile strength is 620-680N / m 2 Nickel wire (JIS code: NW2201), giving a metal coil with a width of about 0.5 mm and a winding diameter (appearance diameter) of about 6 mm.

[0072] A metal wire was wound around a frame (corrosion-resistant frame) formed of a nickel round rod with a diameter of 2 mm to adju...

example 3

[0079] A single-unit ion exchange membrane electrolysis cell was assembled as follows.

[0080] Set the effective area to 1540cm 2 An appropriately sized electrode (11 cm wide, 140 cm high) was used as the anode by forming an electrode catalyst coating with a platinum group metal oxide on a widened metal made of titanium obtained from Permelec Electrode, Ltd. layer made. With the anode flange, the anode is mounted on the anode chamber wall of the electrolytic cell.

[0081] A cathode current collector formed of widened nickel was mounted on the cathode chamber wall with a cathode flange formed of plate-like nickel.

[0082] Nickel fibers with a thickness of 5 mm, a width of 11 cm, and a length of 20 cm were woven by a fiber weaving machine to prepare a fabric in the form of uniform cotton threads. The fabric was soaked in a mixed solution containing an aqueous solution of hexahydrochloroplatinic acid (20 g / liter) and hydrochloric acid (10 g / liter) at room temperature for one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com