Connector

A technology for connectors and contact parts, which is applied in the direction of connections, parts of connecting devices, contact parts, etc., which can solve the problems of narrow contact area and increased contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following is a detailed description of embodiments of the present application with reference to the accompanying drawings.

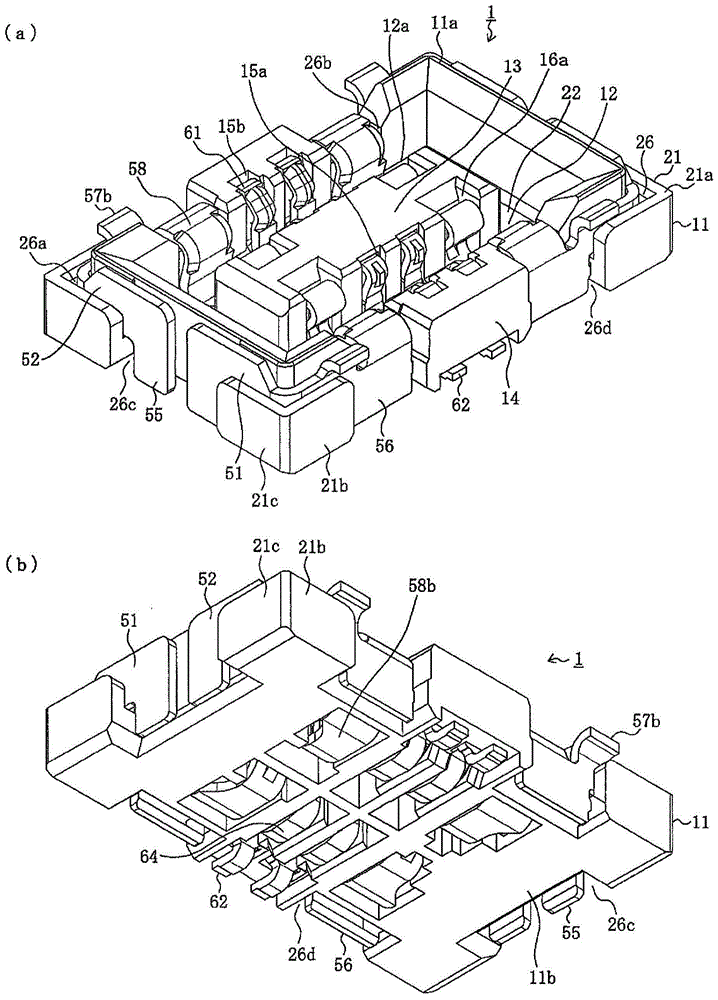

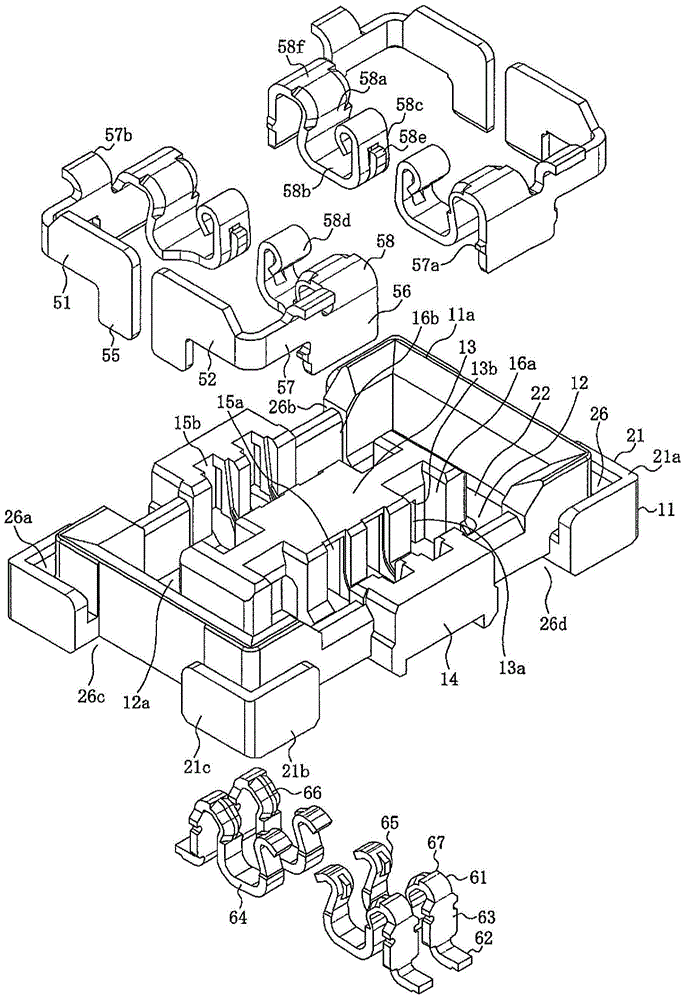

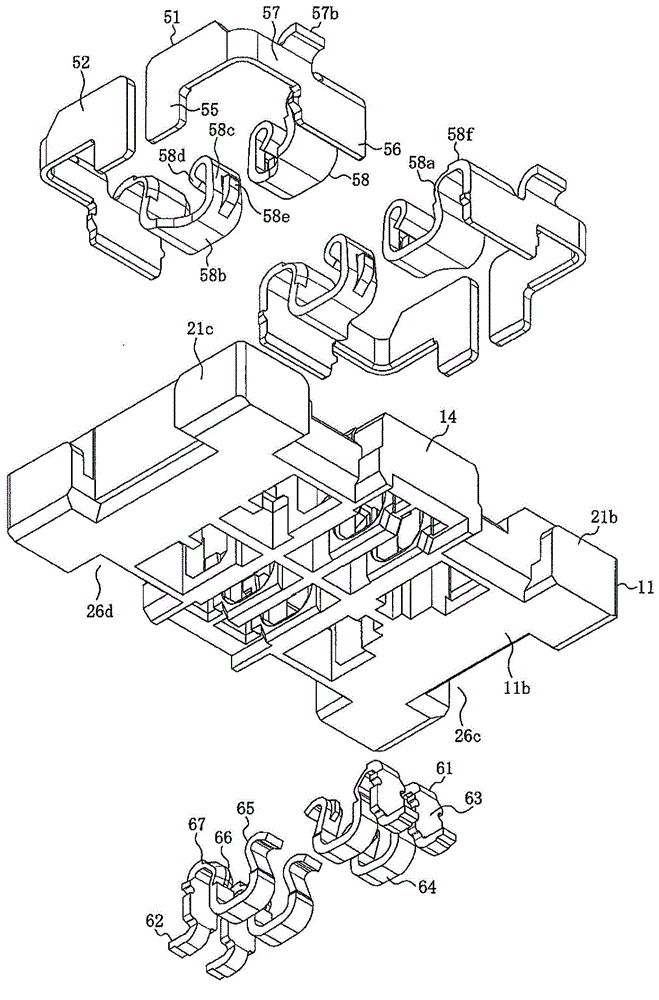

[0065] figure 1 A perspective view of the first connector in the first embodiment of the present application is shown. figure 2 is an exploded top view of the first connector in the first embodiment of the present application. image 3 It is a bottom exploded view of the first connector in the first embodiment of the present application. exist figure 1 Among them, (a) is a top view, and (b) is a bottom view.

[0066] In the figure, 1 is a first connector, which is one of a pair of board-to-board connectors of this embodiment. The first connector 1 is a surface mount connector, which is mounted on the surface of a first substrate (not shown) and mated with another connector or a second connector 101 (described later). In addition, 101 is a second connector, which is the other of the pair of board-to-board connectors in this embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com