Patents

Literature

101results about How to "Guaranteed docking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

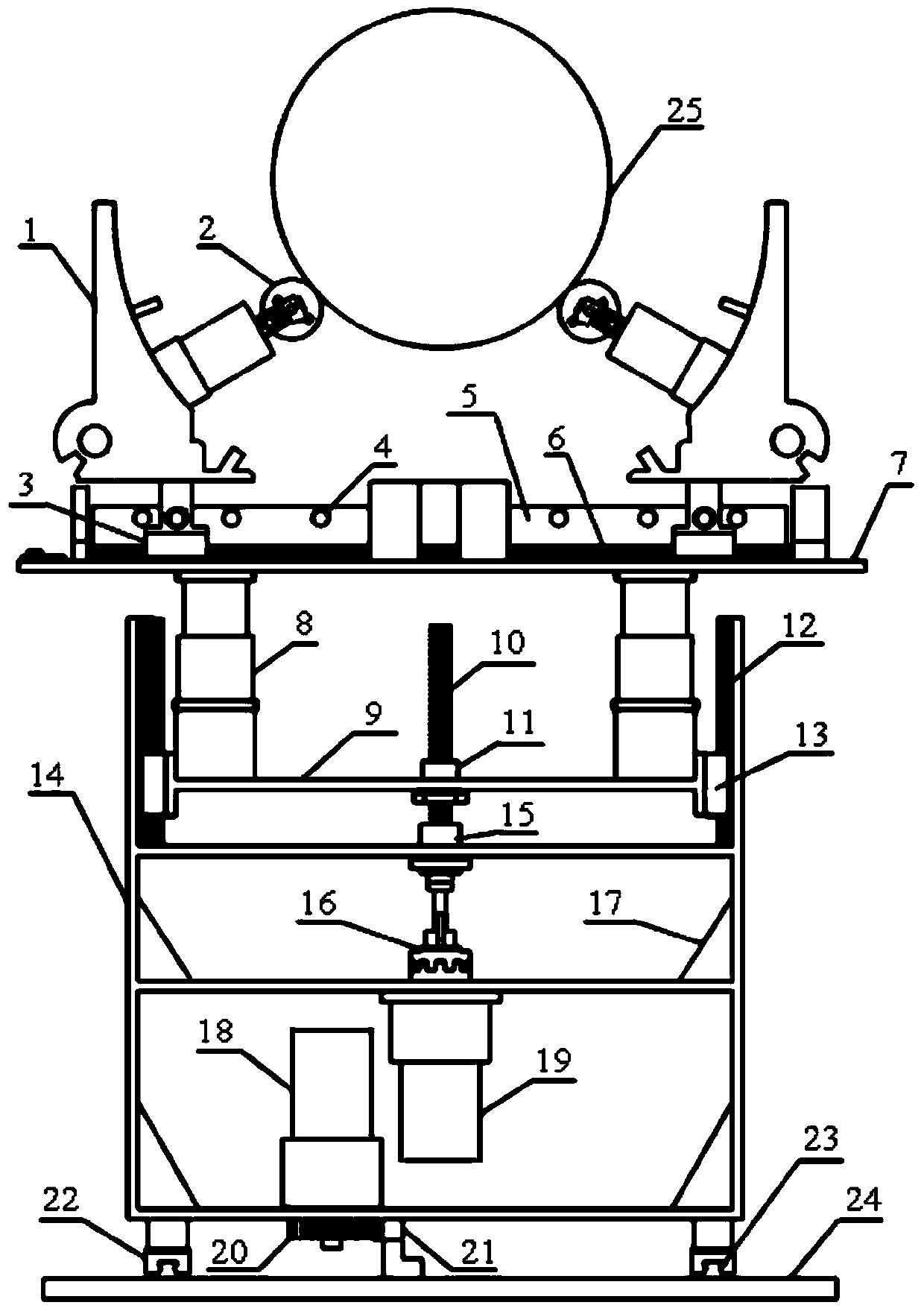

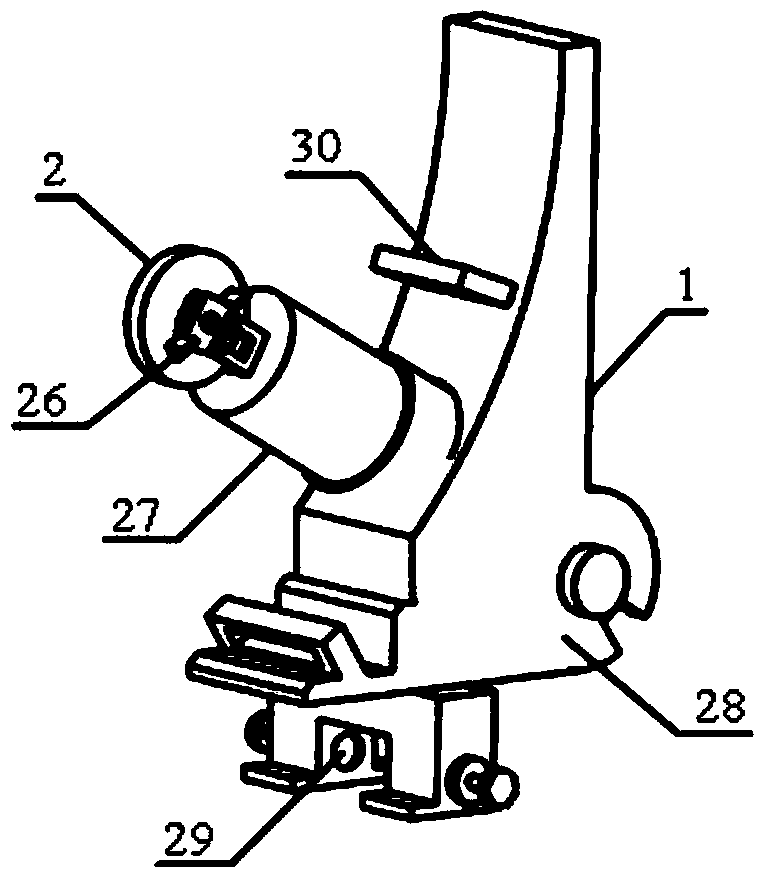

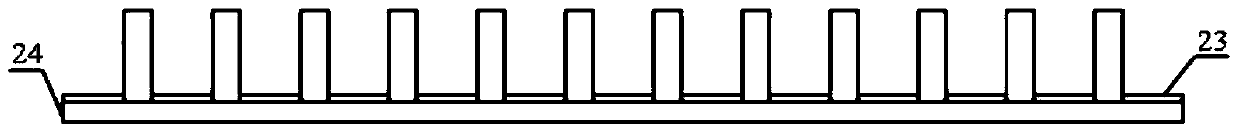

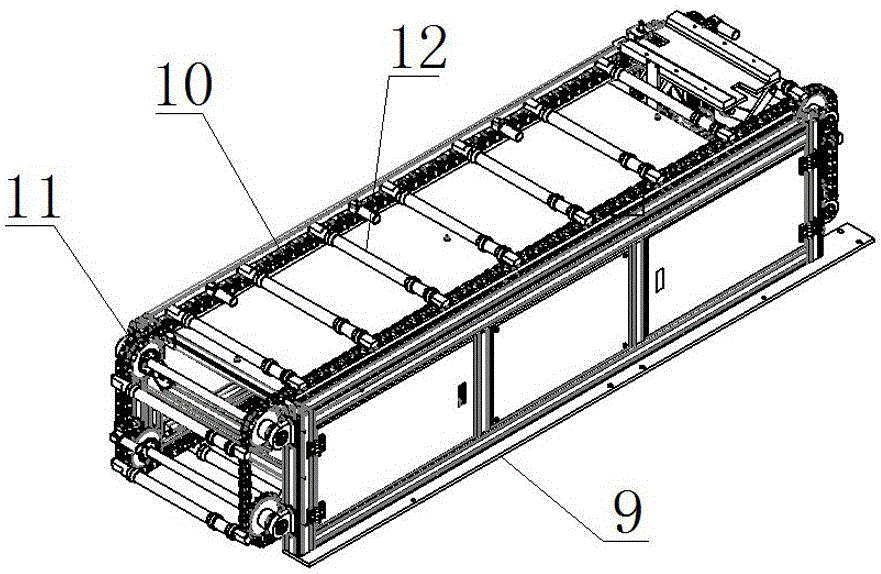

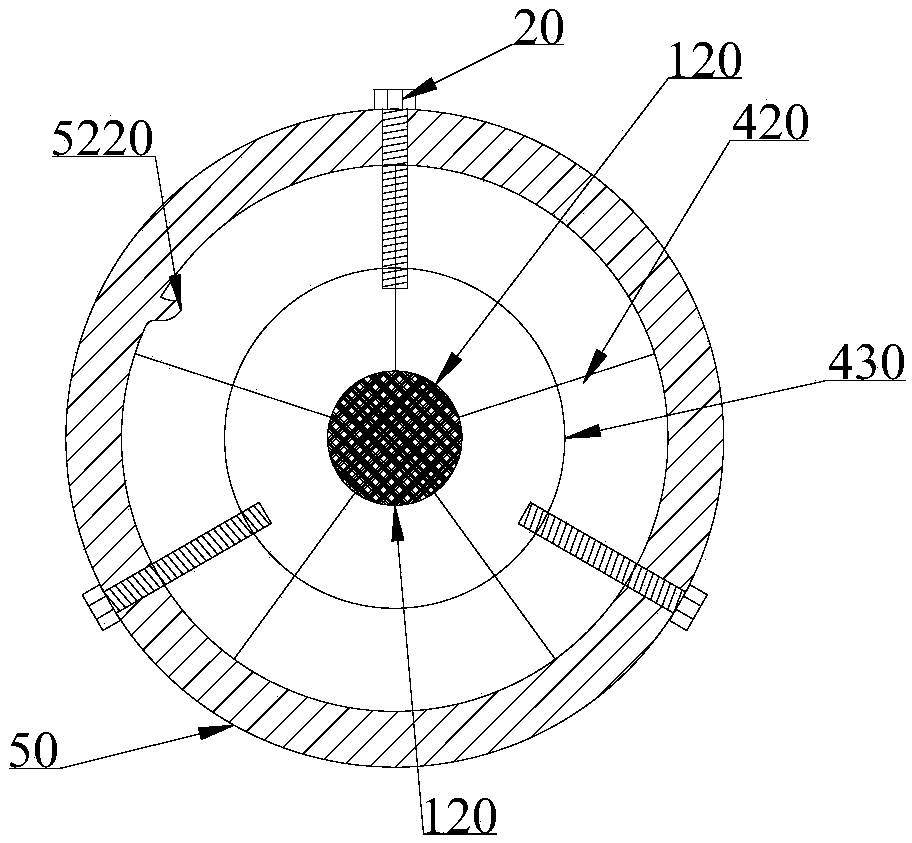

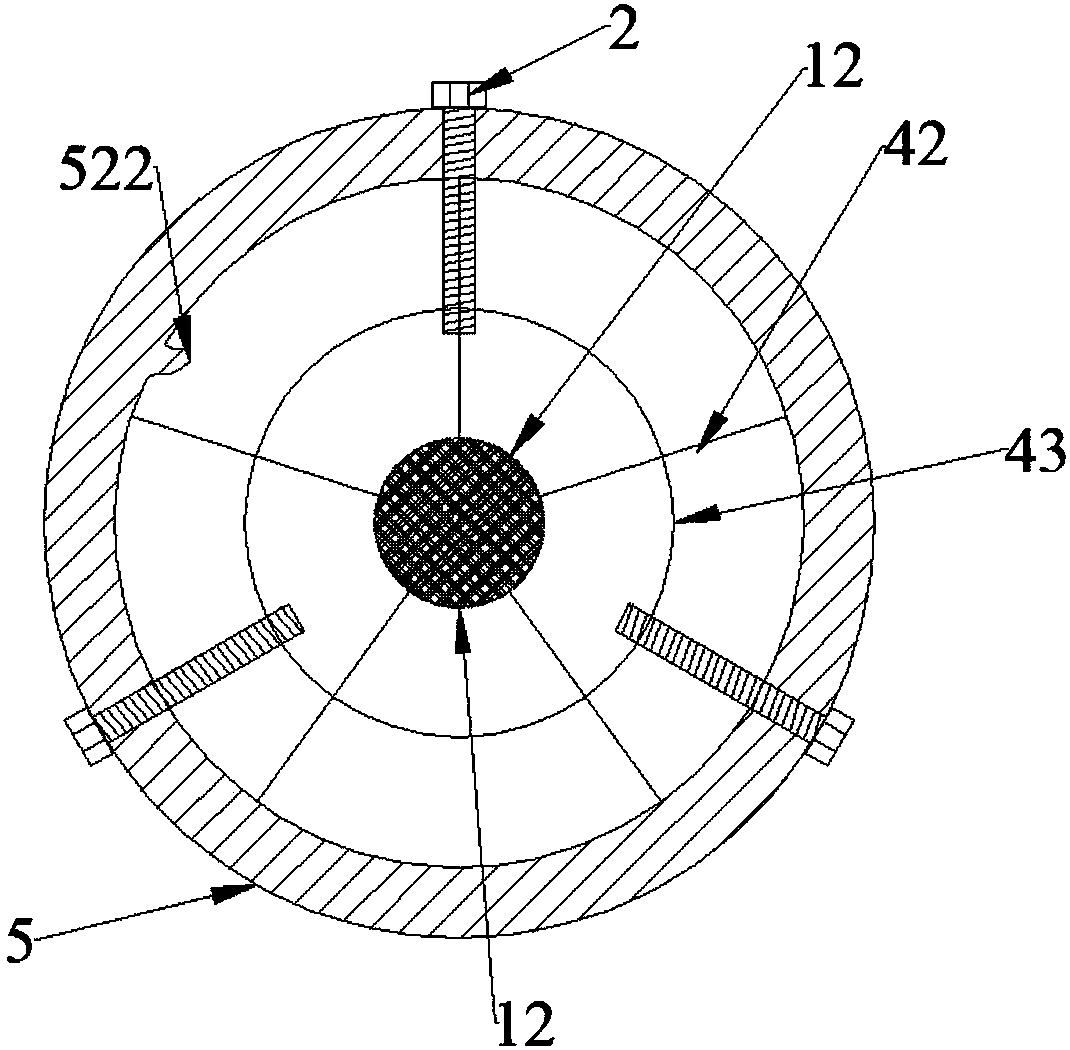

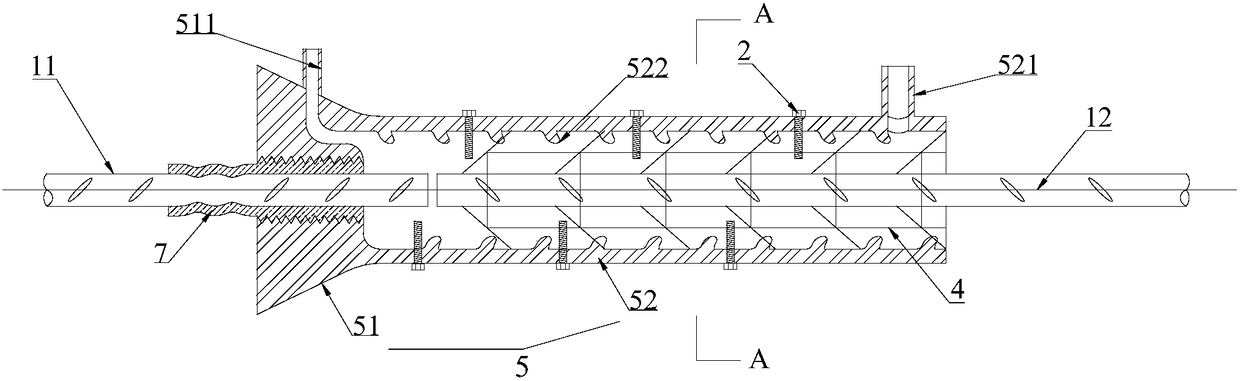

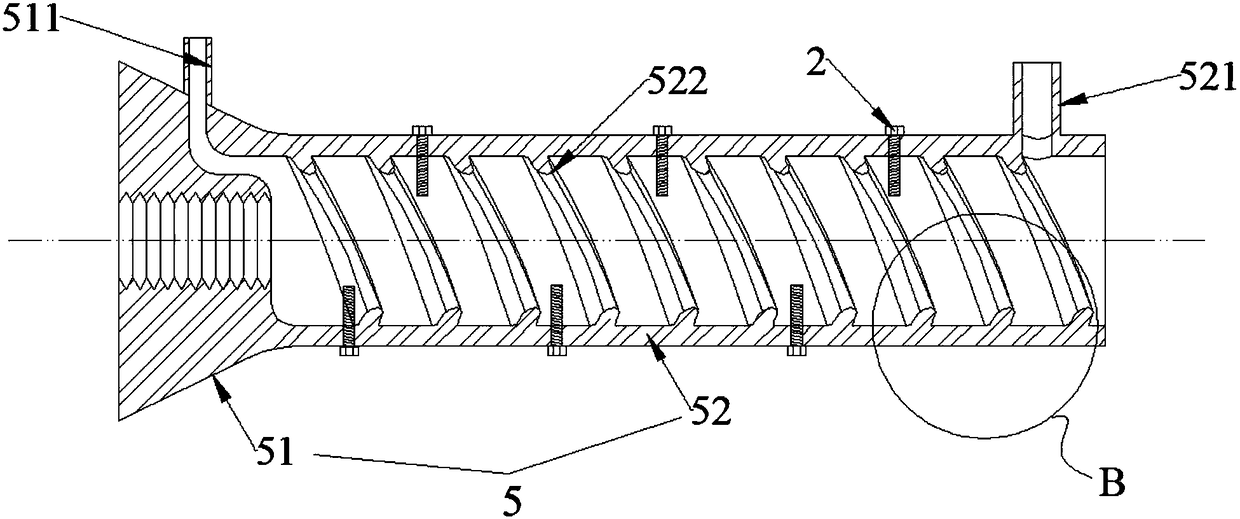

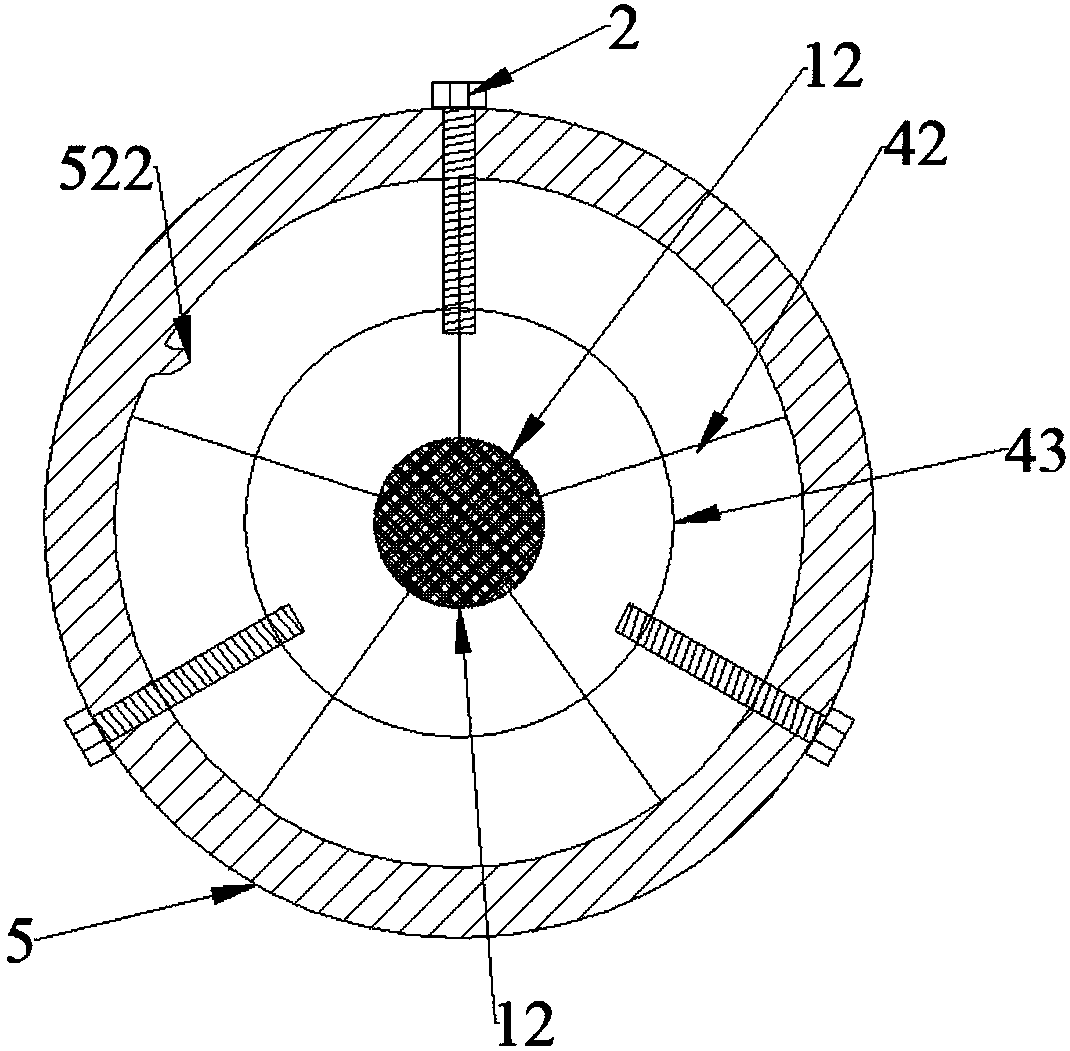

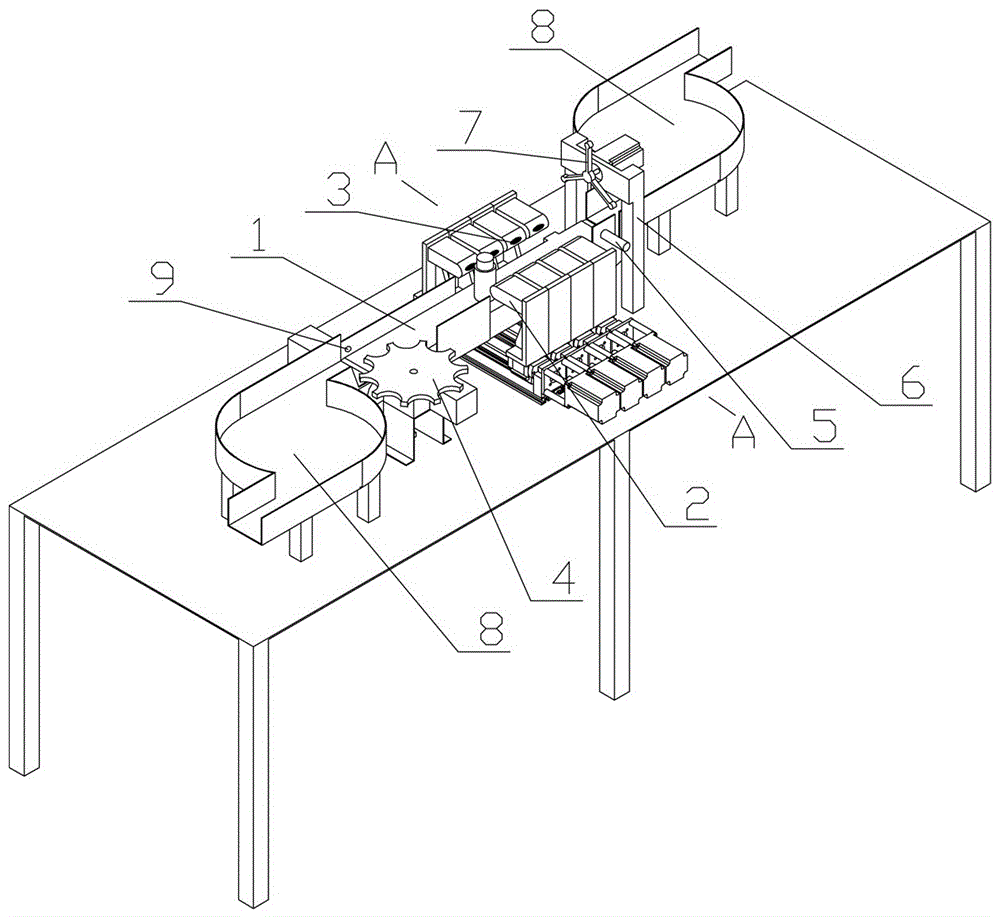

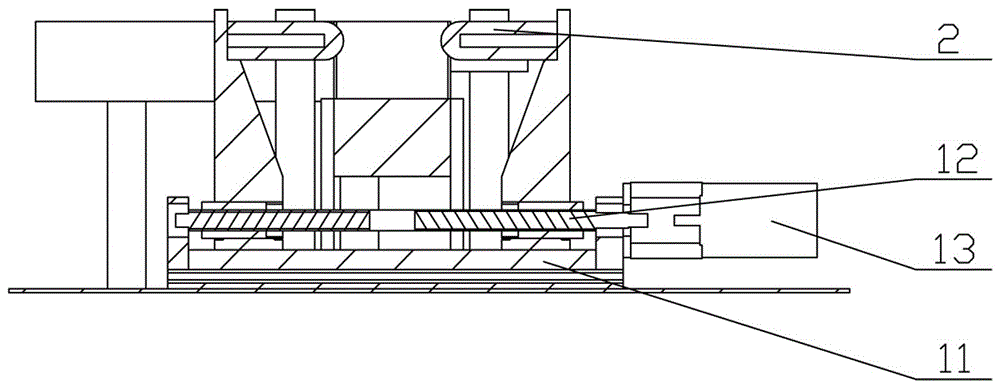

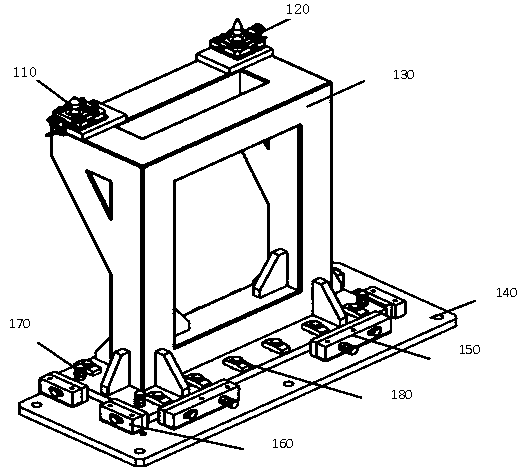

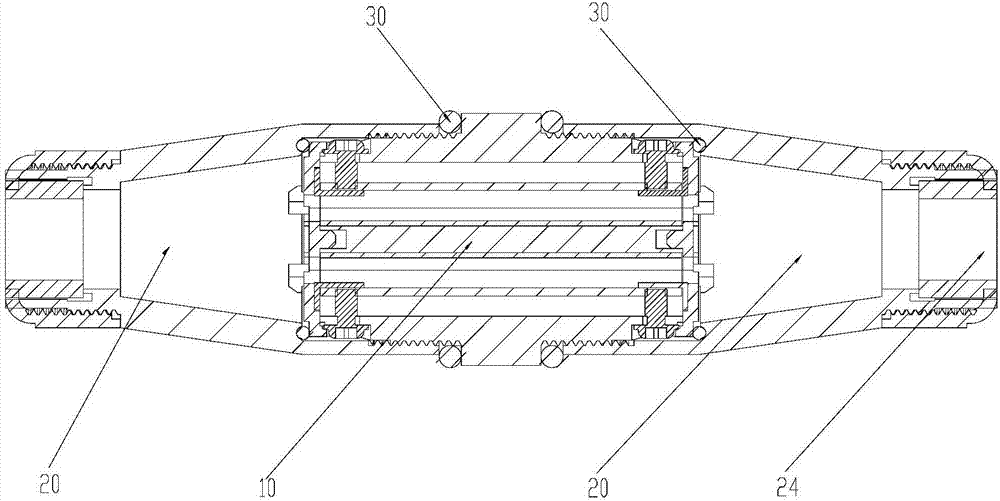

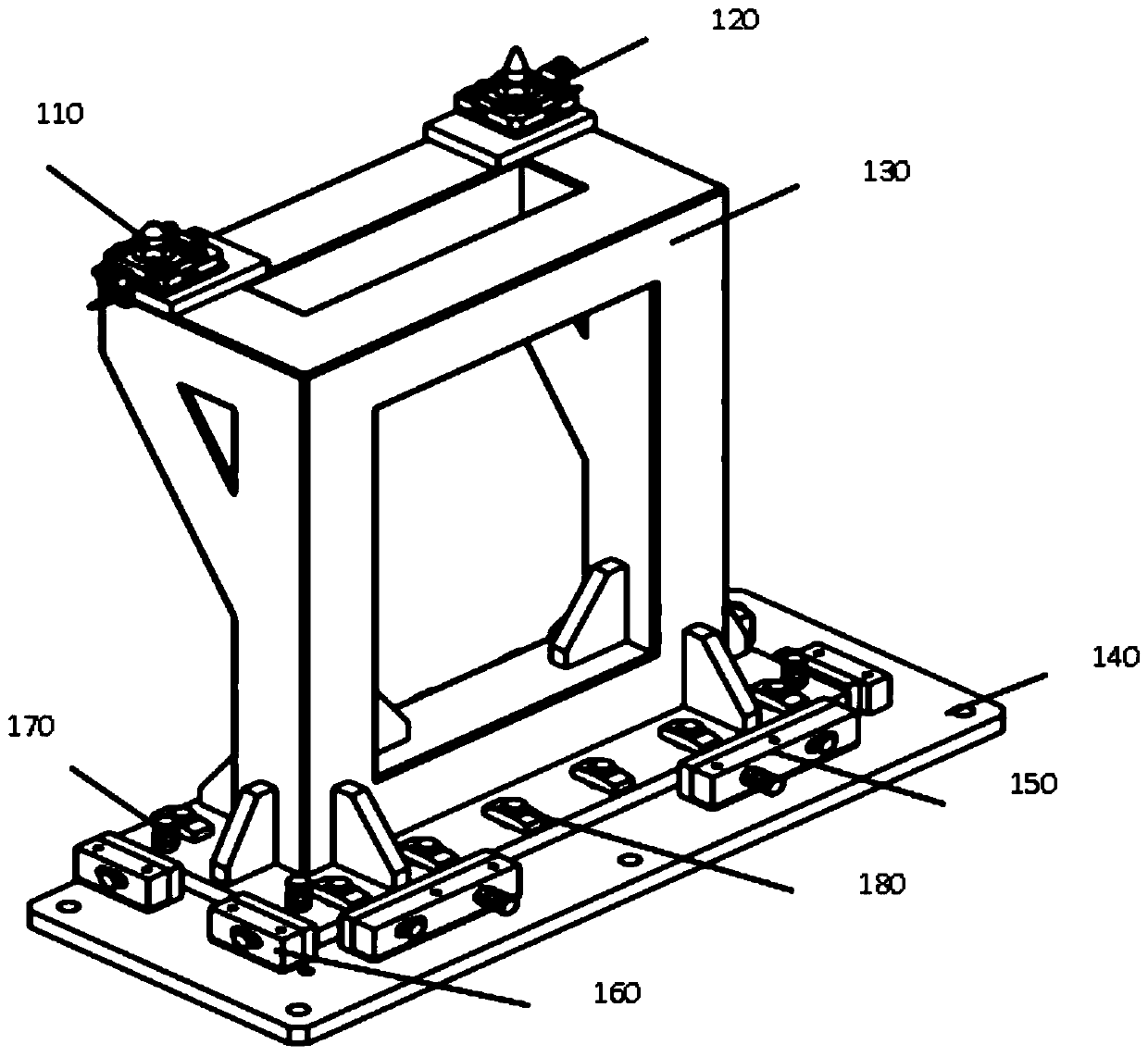

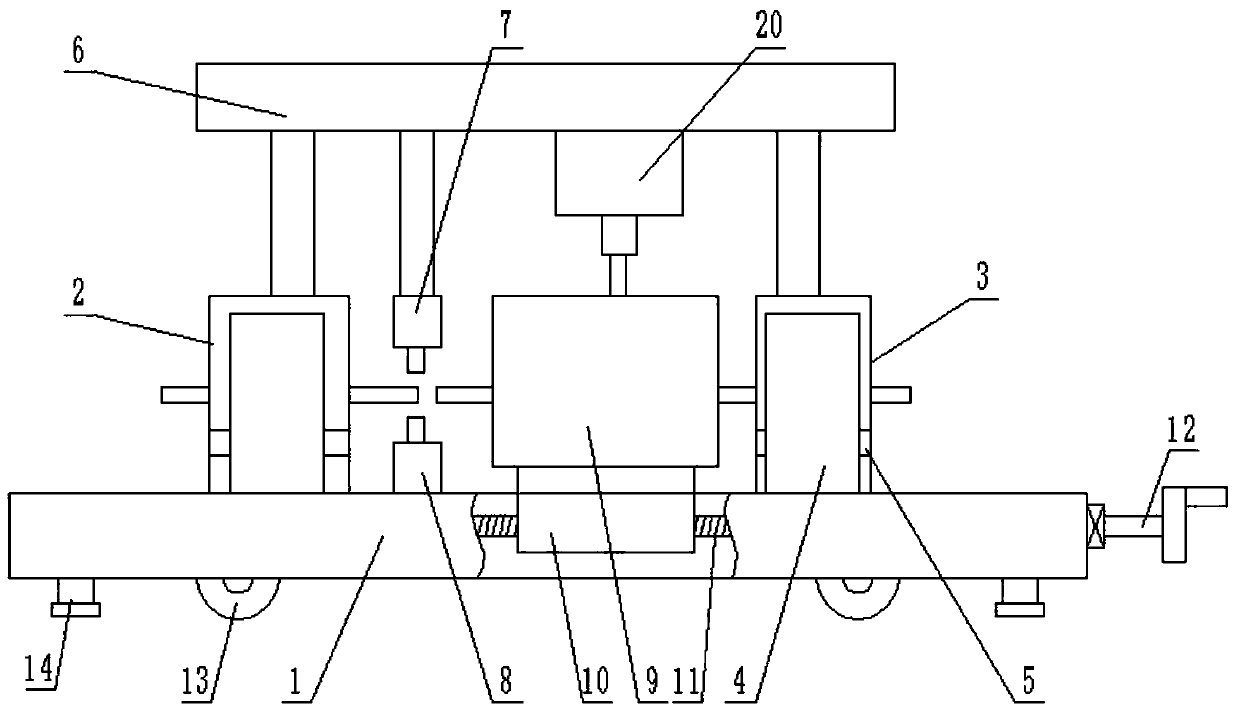

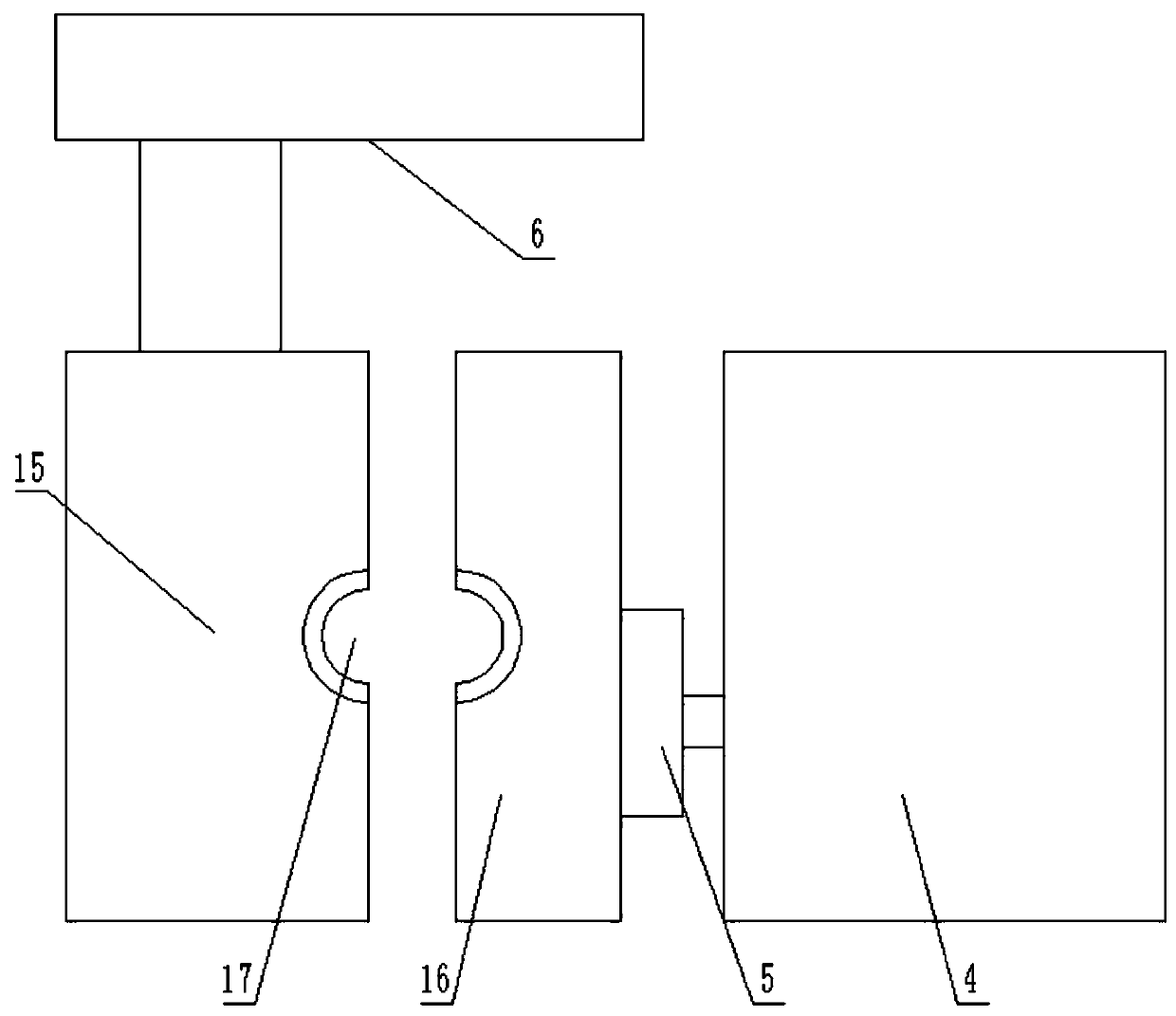

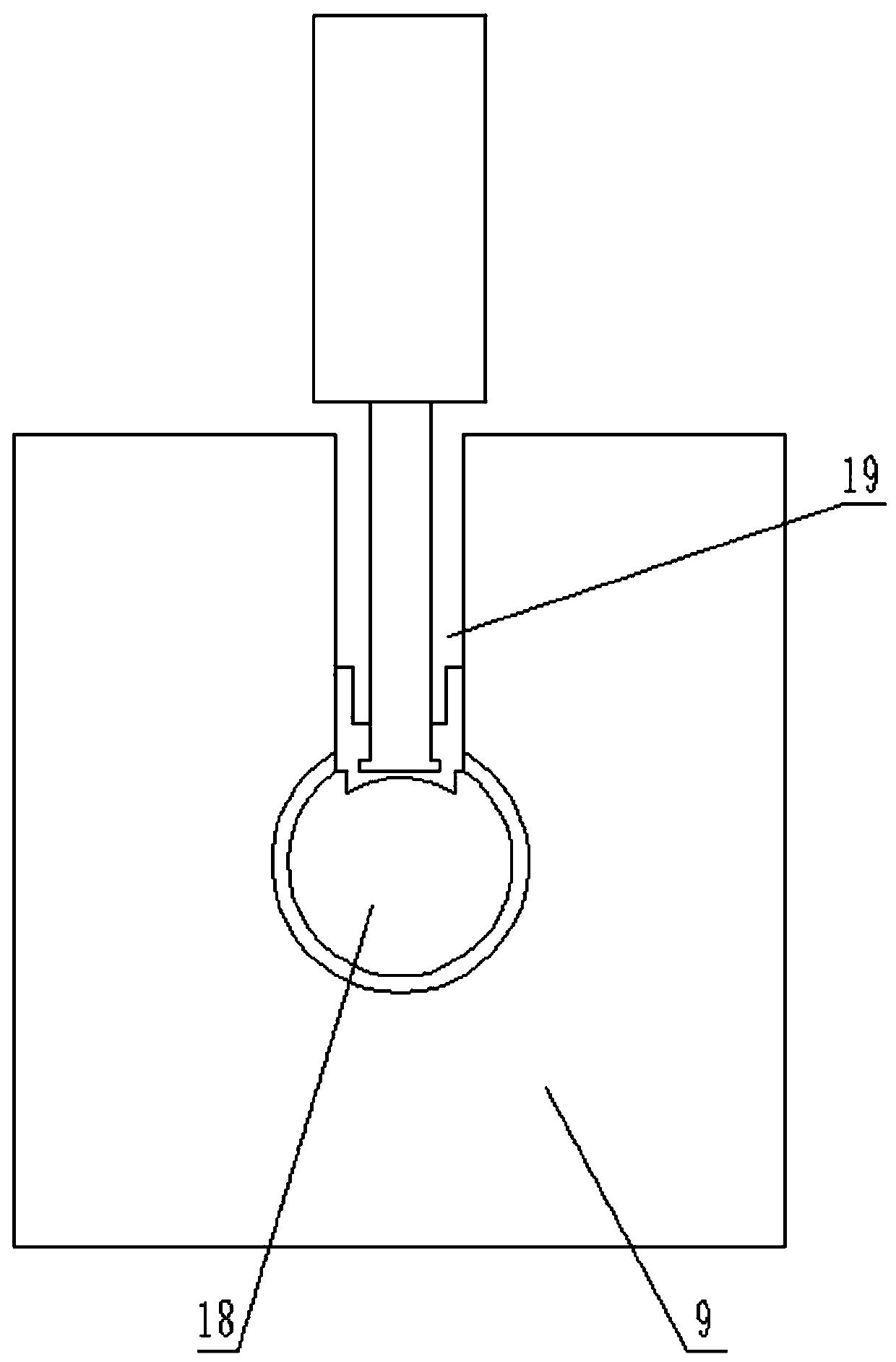

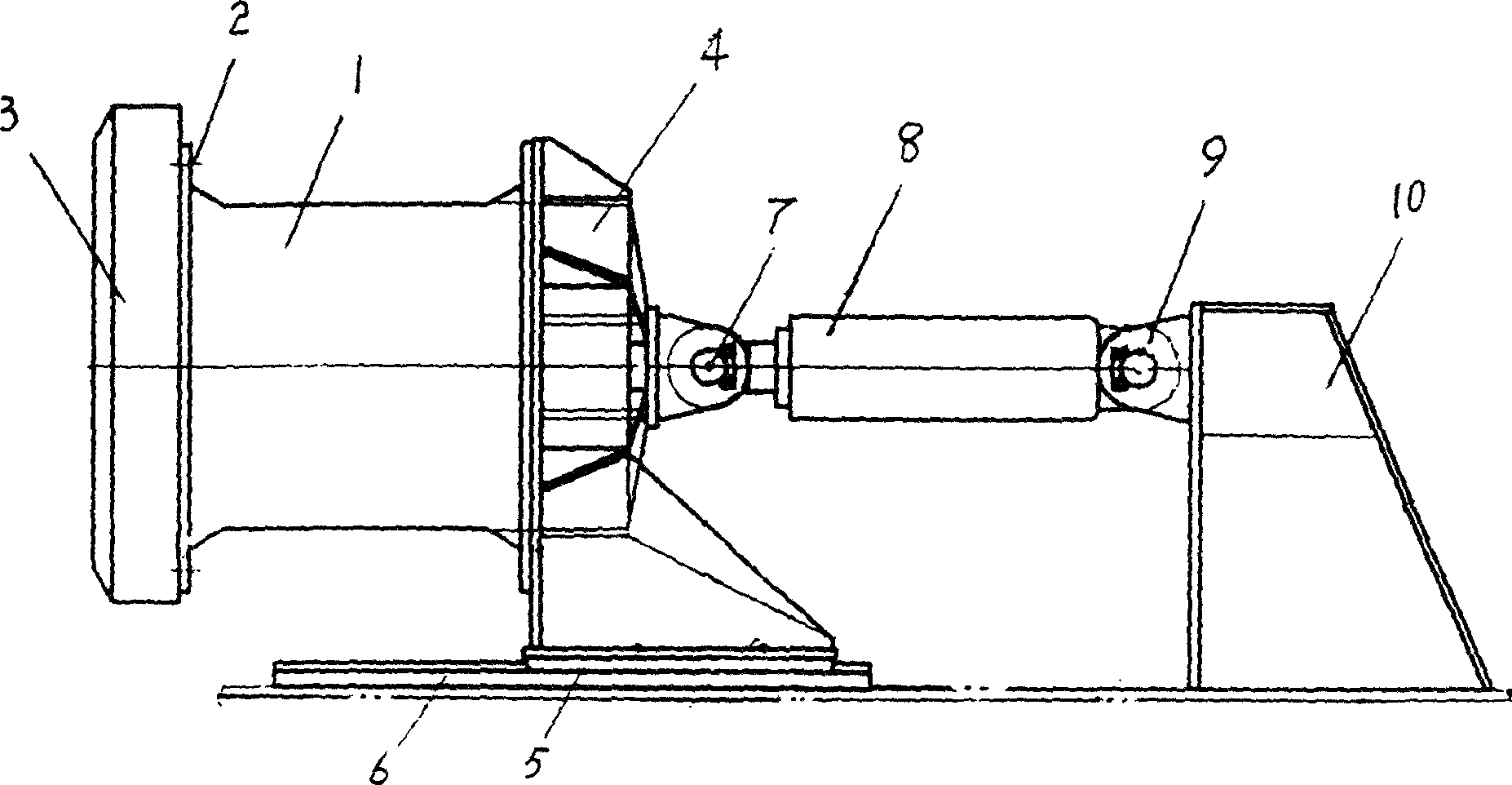

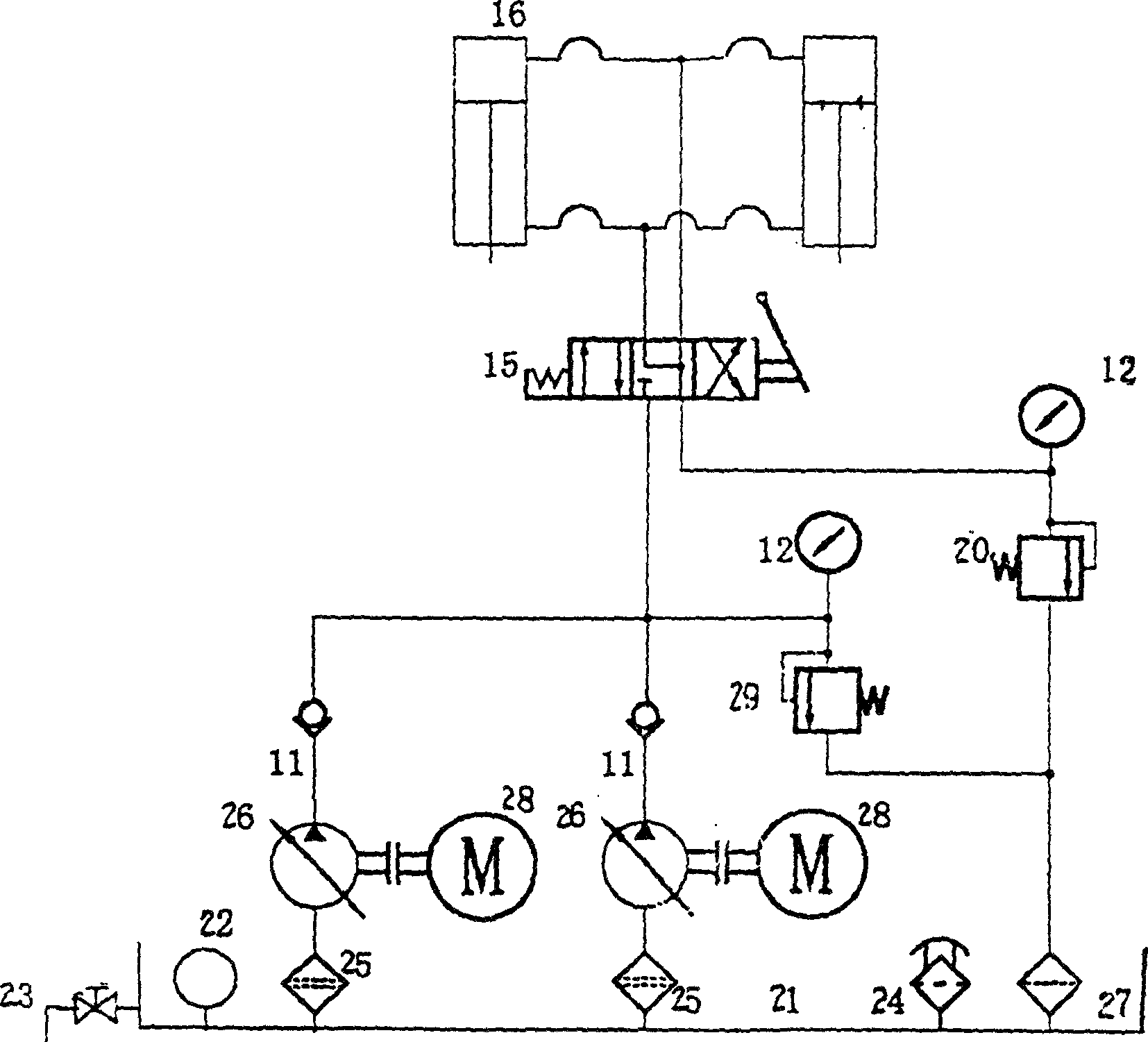

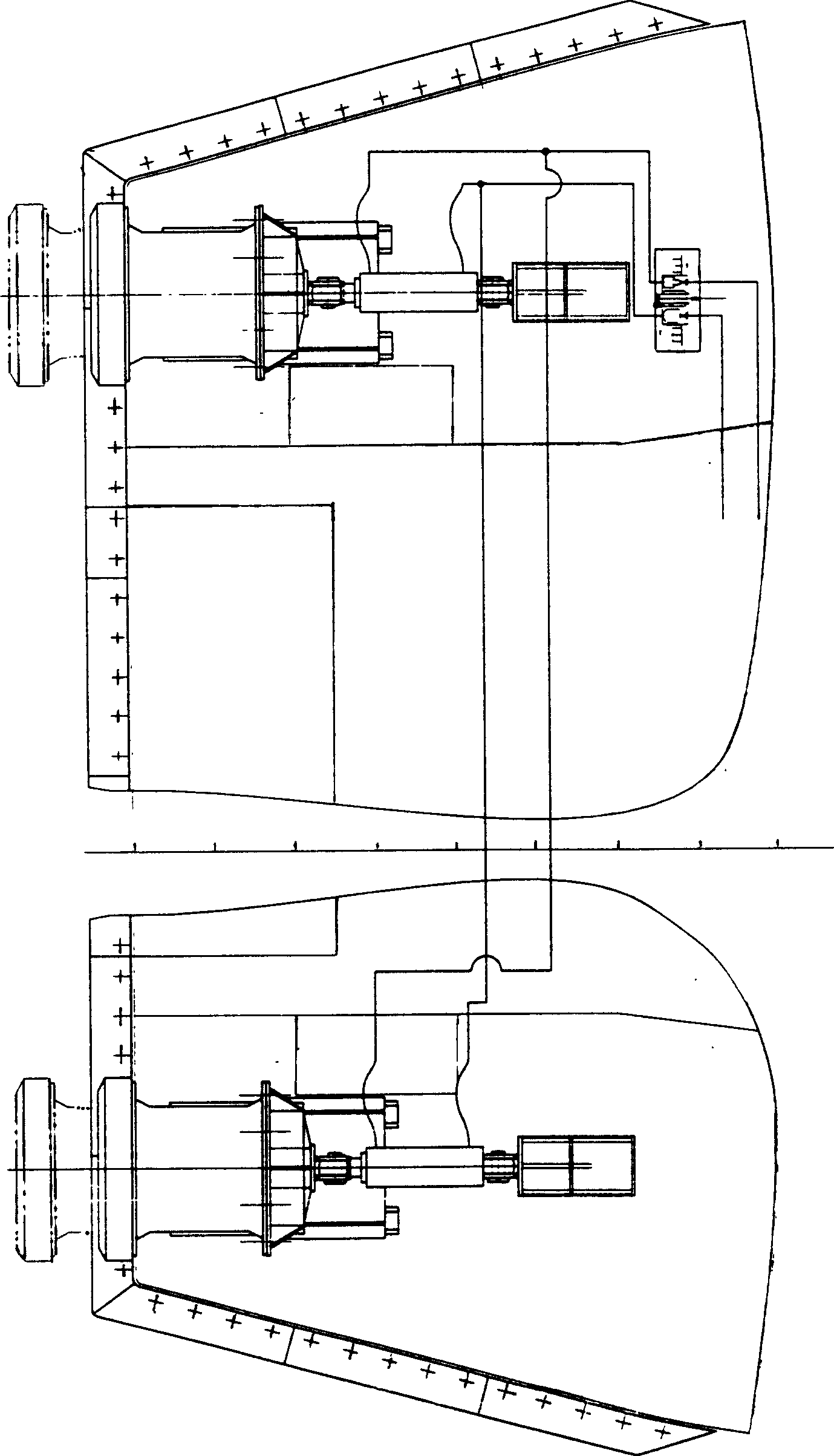

Cylindrical cabin docking assembly

InactiveCN103737310AGuaranteed dockingGuaranteed straightnessMetal working apparatusPositioning apparatusMotor driveGear wheel

The invention discloses a cylindrical cabin docking assembly comprising an open and close movement mechanism, a lifting mechanism, a horizontal movement mechanism, a frame and a computer. The lifting mechanism and the horizontal movement mechanism are arranged in the frame, and the open and close movement mechanism is arranged above the frame. The lifting mechanism comprises a vertical support rod, a lifting support plane, a lifting sliding block, a lifting guide rail, a lead screw and a lifting motor. The lifting motor drives the lead screw to rotate to enable the lifting sliding block of the lifting support plane to move on the lifting guide rail. The open and close movement mechanism comprises two open and close support devices, a position control plate, an open and close sliding block, an open and close guide rail and a horizontal platform deck. The open and close support devices slide symmetrically on the guide rail via manual labor and are fixed by a locating pin. The horizontal movement mechanism comprises a horizontal motor, a rack, a gear, a rack, a horizontal sliding block and a horizontal guide rail. The horizontal motor drives the gear and the rack to mesh to drive the docking assembly to move on the horizontal guide rail; the horizontal motor and the lifting motor are controlled by the computer to realize automatic docking of the devices.

Owner:XIDIAN UNIV

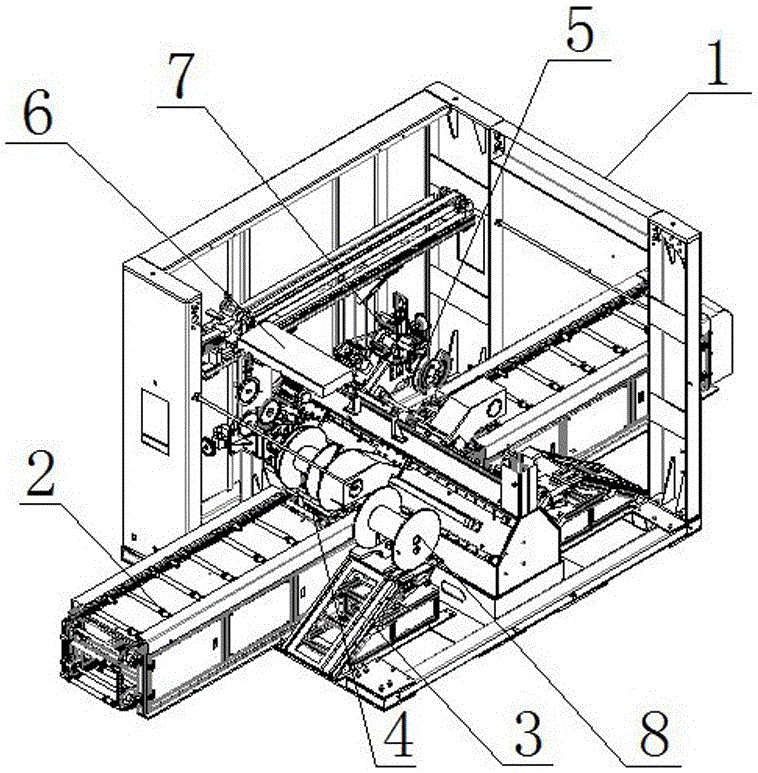

Automatic single and double-reel take-up device

ActiveCN106115368AGuaranteed alignmentGuaranteed centering; ensure the docking of the plate through the lifting system when the plate is releasedFilament handlingEngineeringAutomatic testing

Owner:中天智能装备有限公司

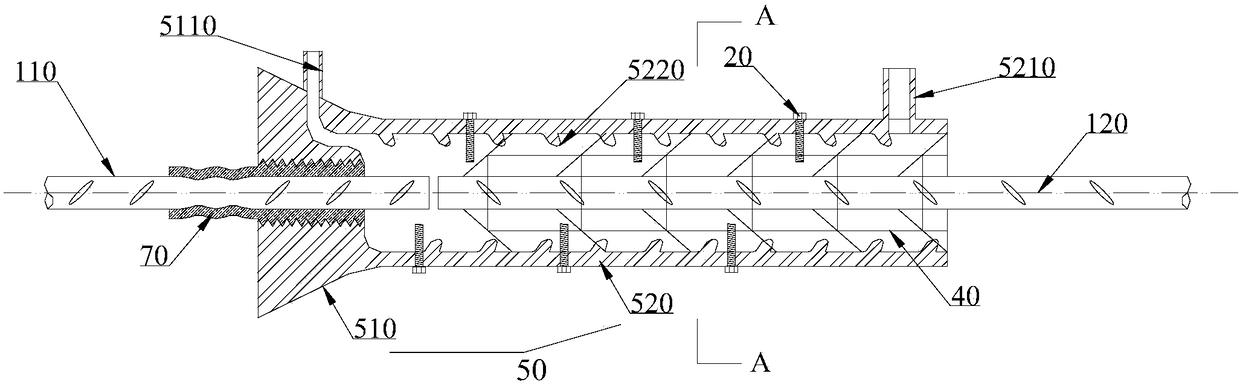

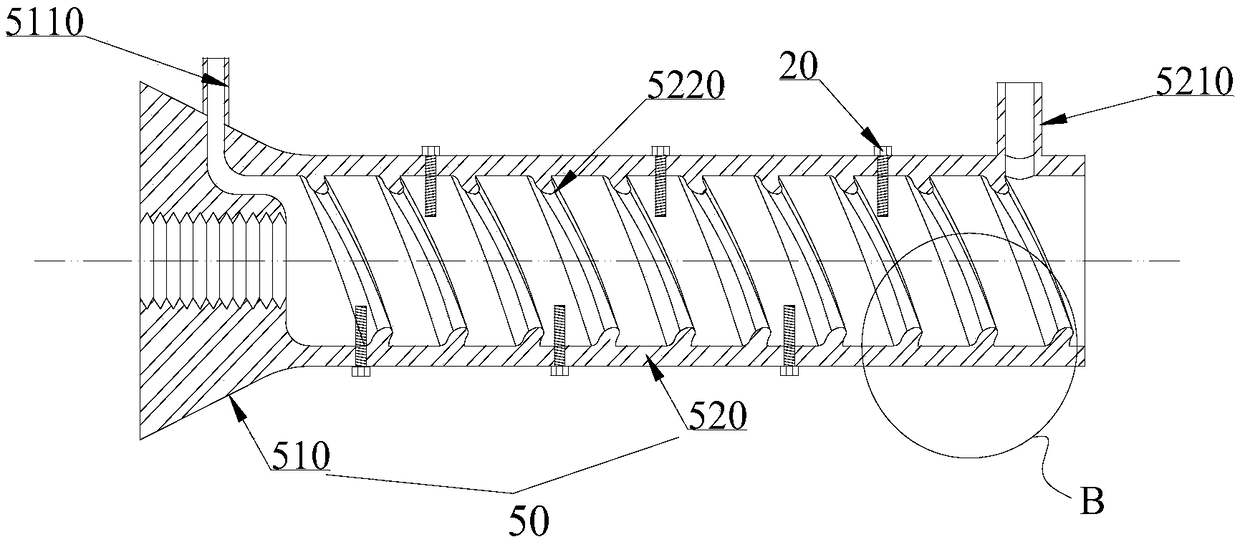

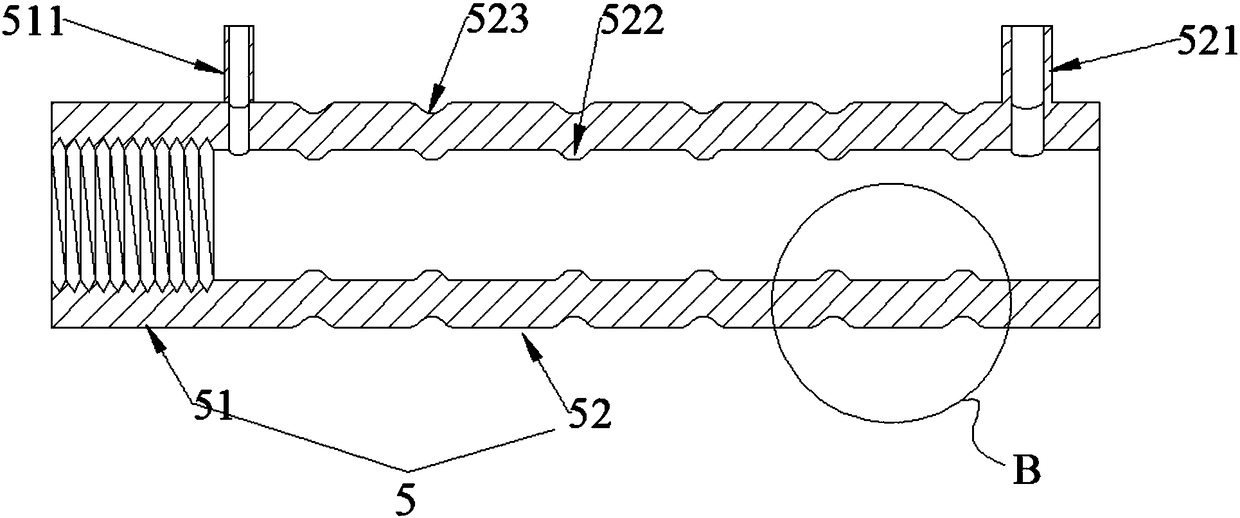

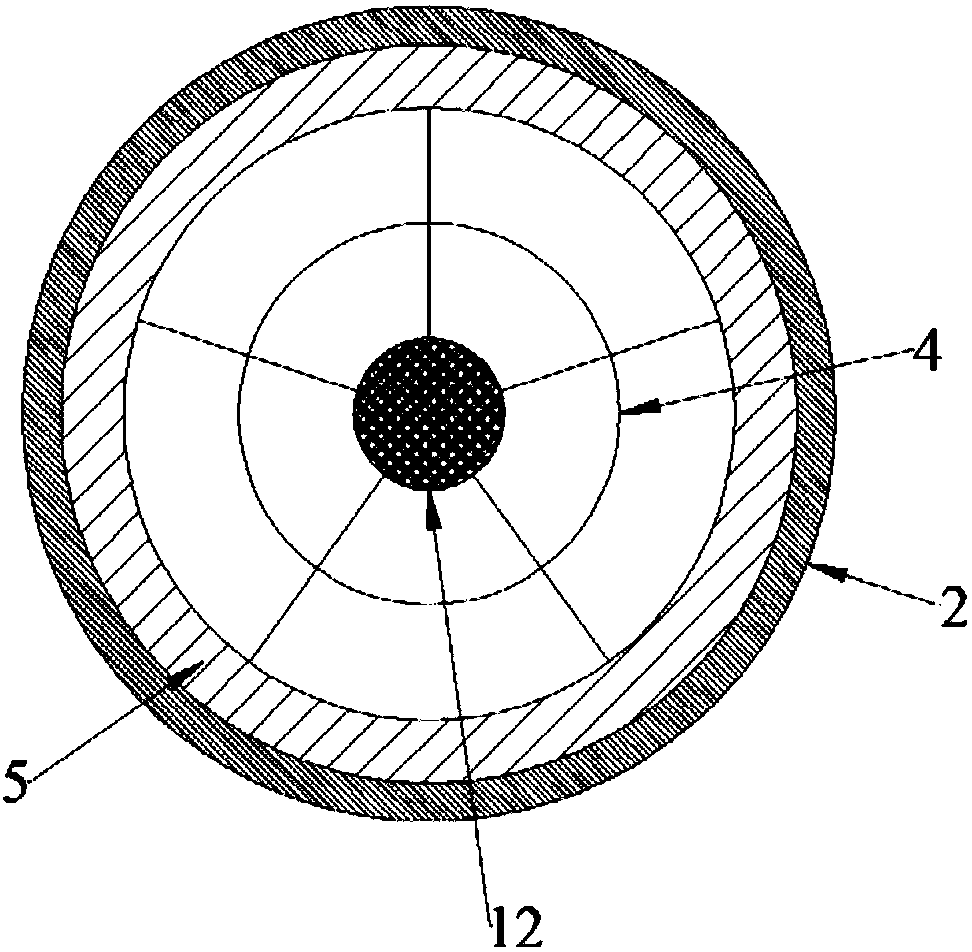

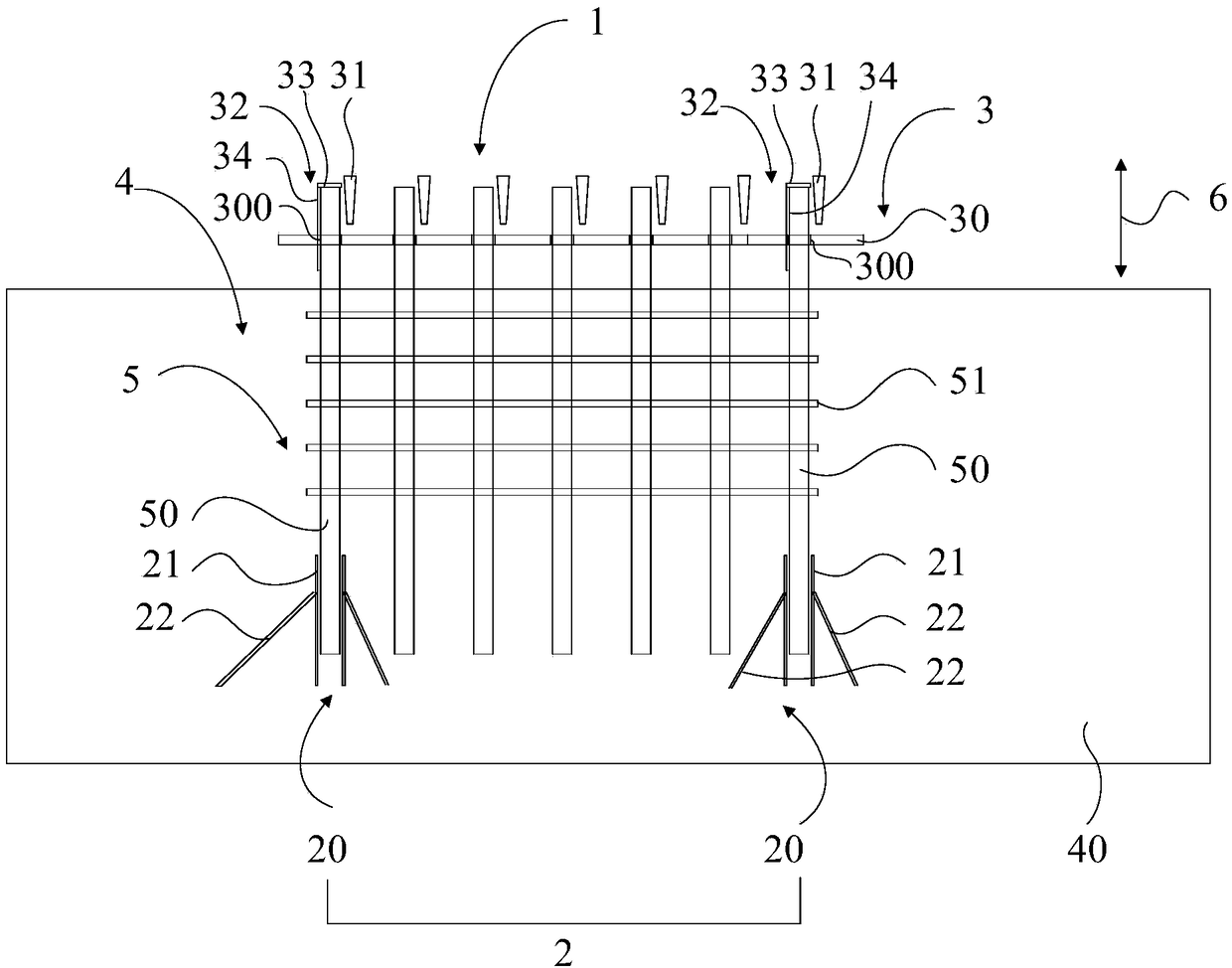

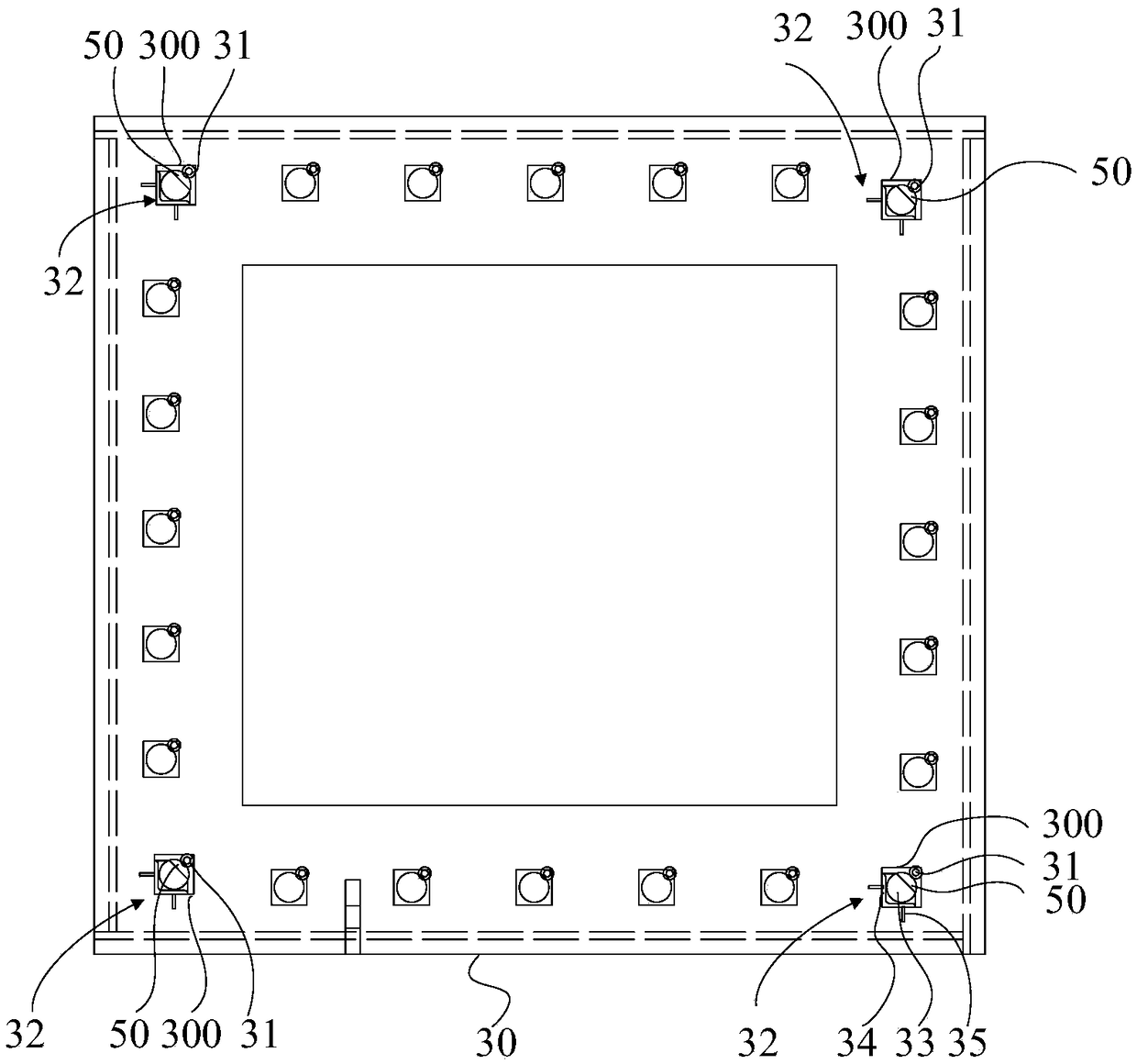

Assembly structure of assembly-type concrete member

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

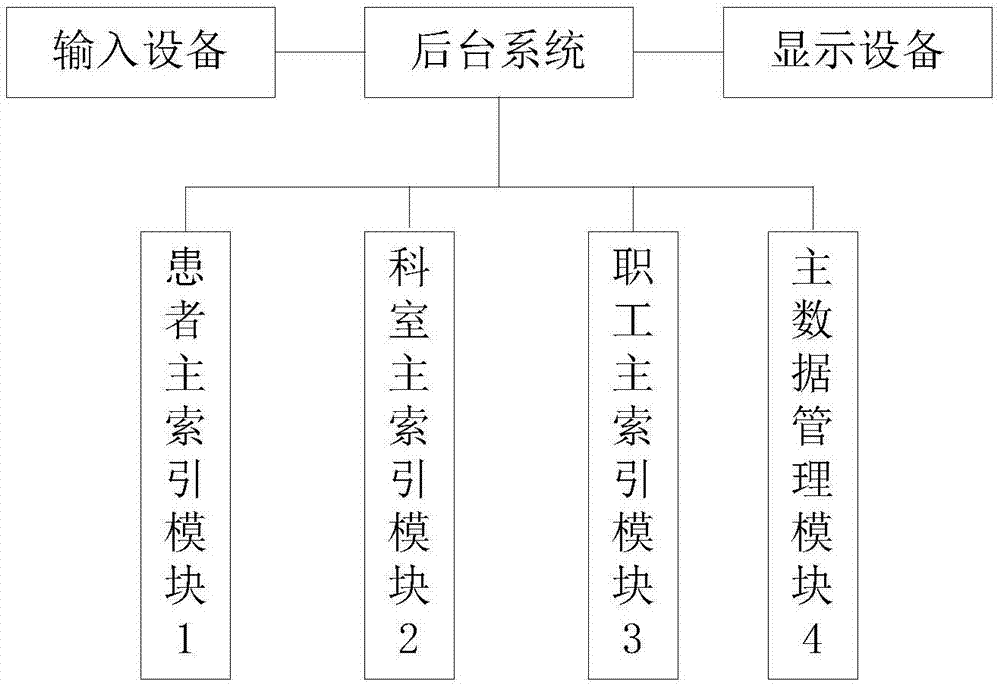

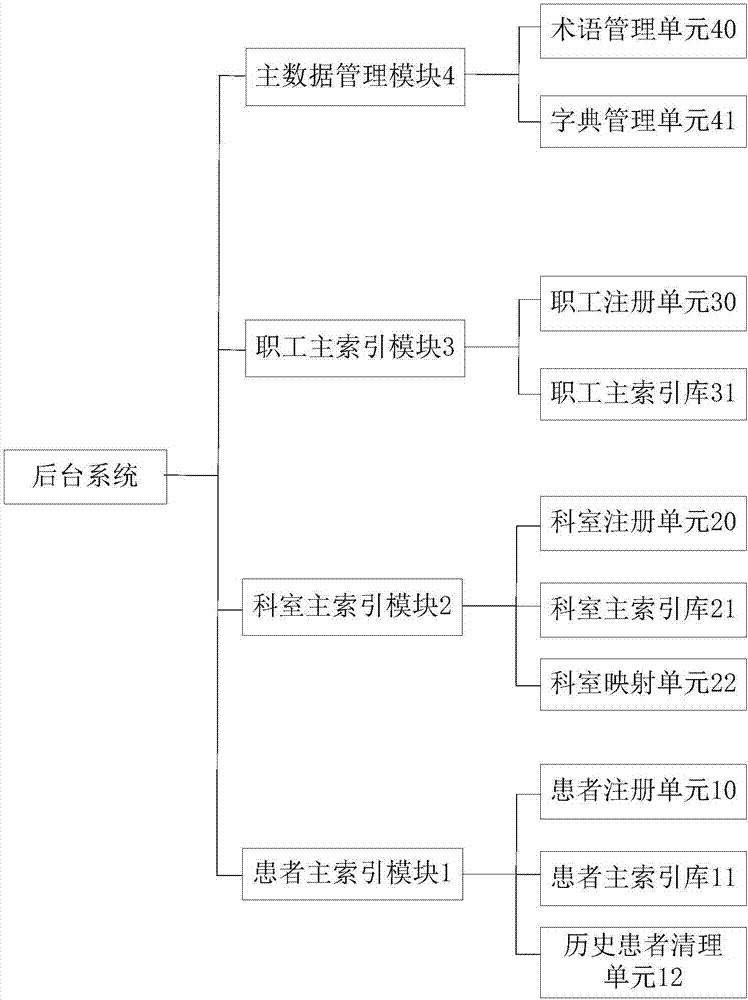

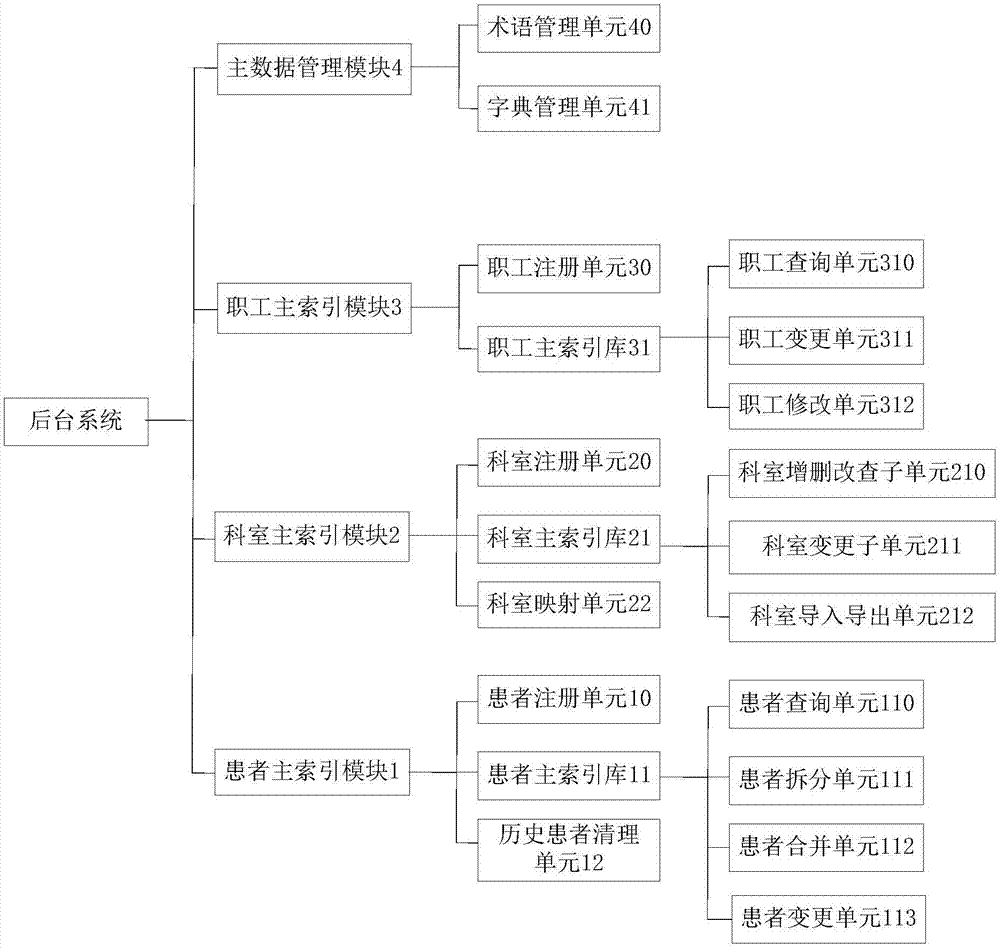

Doctor and patient data management system and method

InactiveCN107194167AAchieve uniqueThe only guaranteeSpecial data processing applicationsInformation sharingPatient data

The invention provides a doctor and patient data management system and method. The system comprises a patient main index module, a department main index module, a staff main index module and a main data management module, wherein the patient main index module generates patient main index information according to patient information and provides query and subscription services of the patient main index information; the department main index module generates department main index information according to department information and provides query and subscription services of the department main index information; the staff main index module generates staff main index information according to medical personnel information and provides query and subscription services of the staff main index information; and the main data management module obtains and stores standard business terms and standard business dictionaries, and provides query and subscription services of the standard business terms and the standard business dictionaries. According to the system and the method, unique patient main index, department main index and staff main index are realized among medical information systems, so that unique business terms and business dictionaries among the systems are ensured, and system connection and information sharing can be realized.

Owner:EWELL TEHCNOLOGY CO LTD

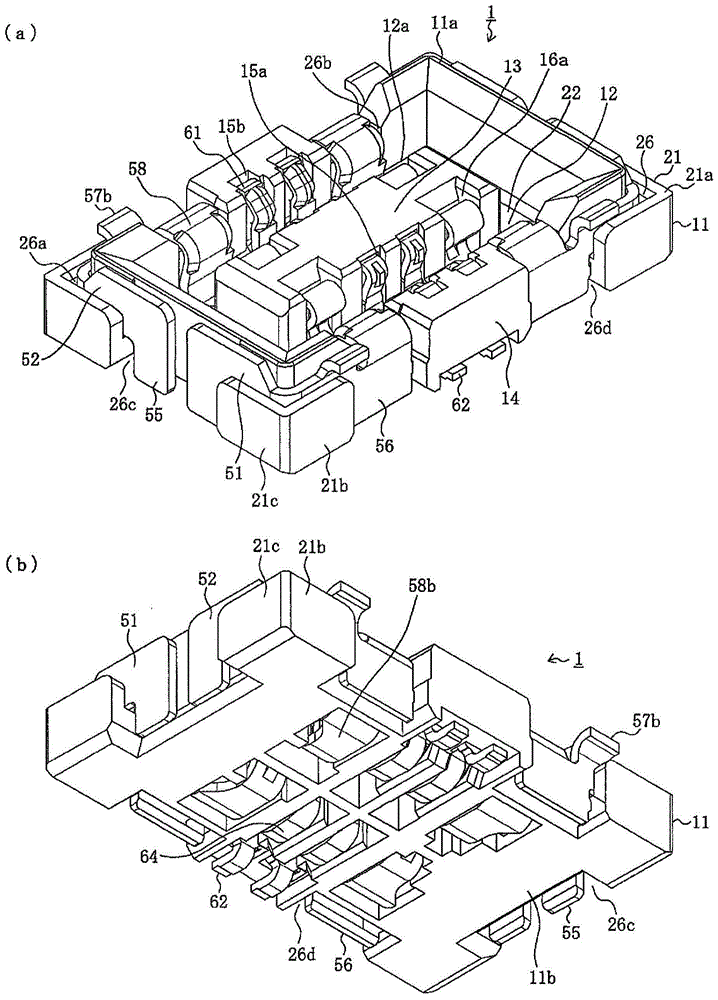

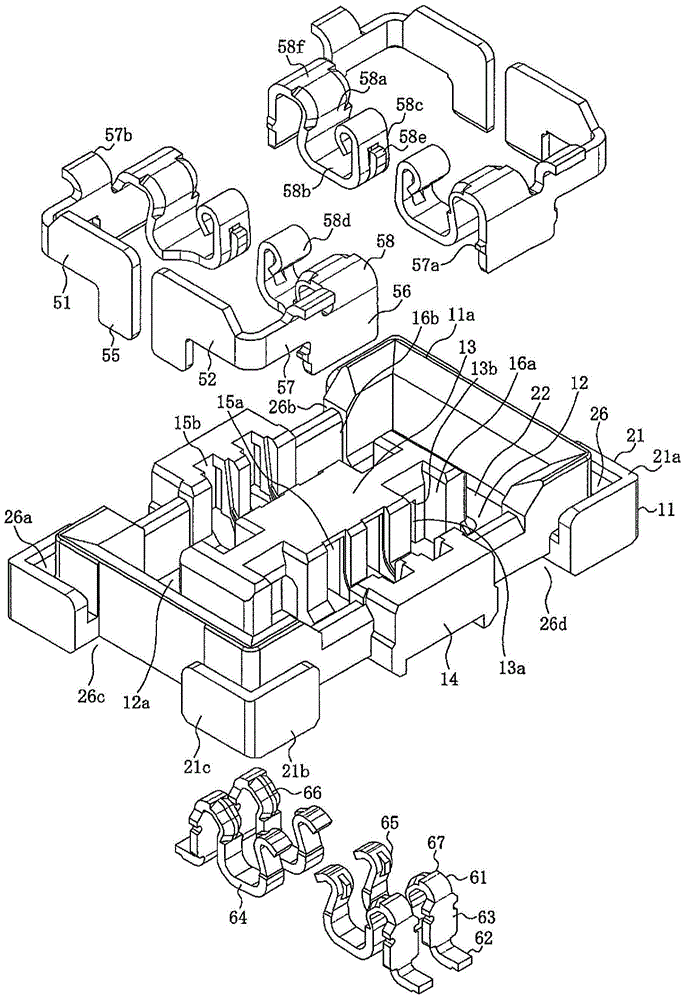

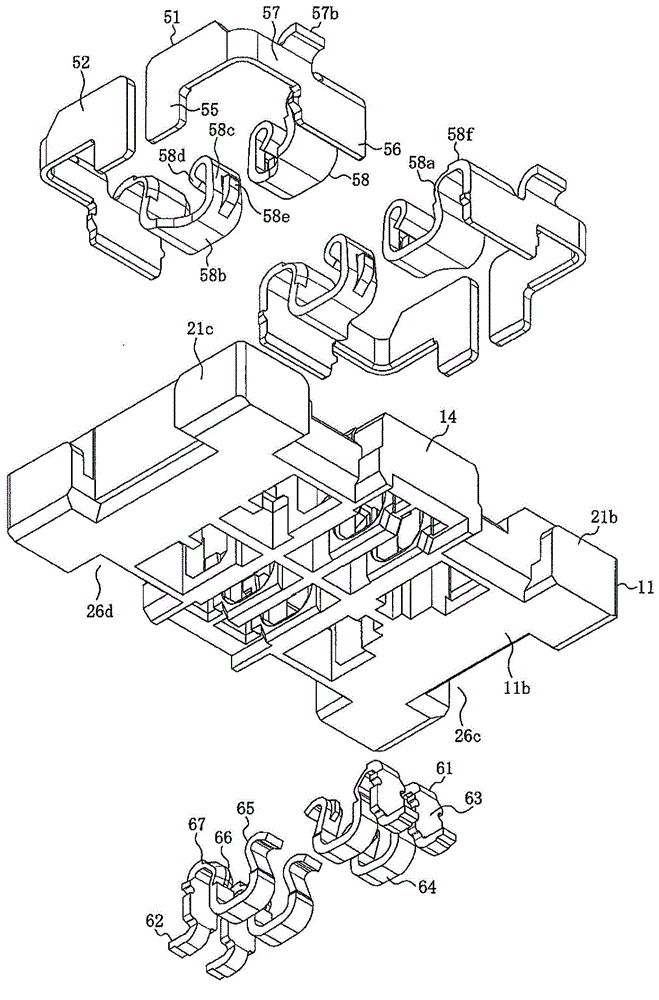

Connector

ActiveCN104682047AEnsure electrical connectionStay engagedCoupling contact membersButt jointElectrical connection

The invention provides a connector. Reinforced metal fittings of the connector can be reliably connected to reinforced metal fittings of another connector, electrical connections between the reinforced metal fittings are maintained, and the connector can be connected to another connector end to end. A connector body includes butt-joint guide portions and reinforced metal fittings. The butt-joint guide portions are formed on two vertical ends of the connector body so that the connector body is butt joint with a connector body of another connector. Each reinforced metal fitting includes a body portion, a side plate portion, and a contact arm portion, wherein the body portion extends transversely along the connector body, the side plate portion is connected to the body portion and extends vertically along the connector body, and the contact arm portion is connected to the side plate portion. The reinforced metal fittings are arranged to the left and to the right of the butt-joint guide portions. Each contact arm portion includes a first contact part and a second contact port that face each other. When the connector body is butt joint with the connector body of another connector, the reinforced metal fittings arranged on another connector body are inserted between the first and second contact parts, and the reinforced metal fittings are maintained by the first and second contact parts on two sides and contact the first and second contact parts.

Owner:MOLEX INC

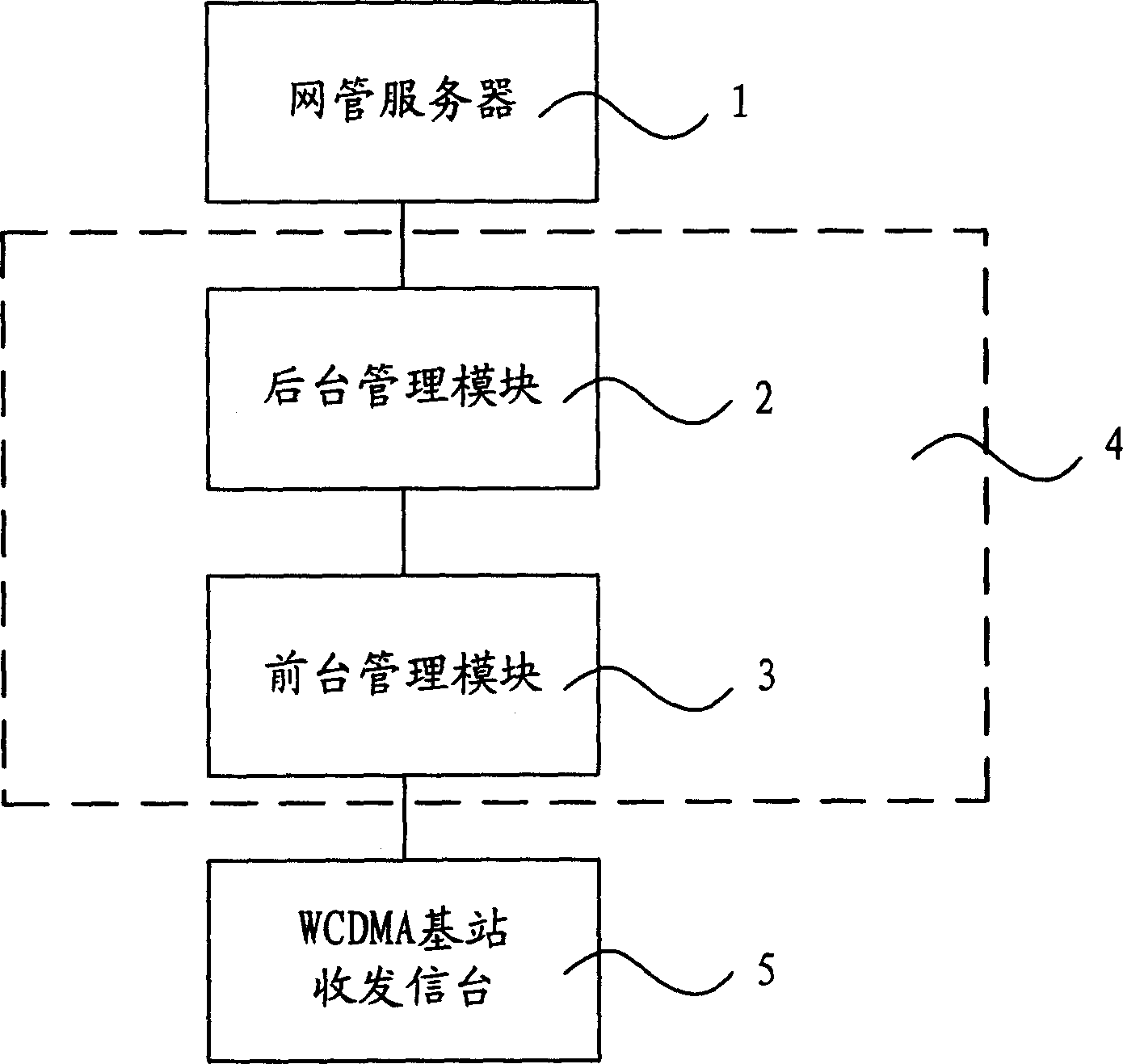

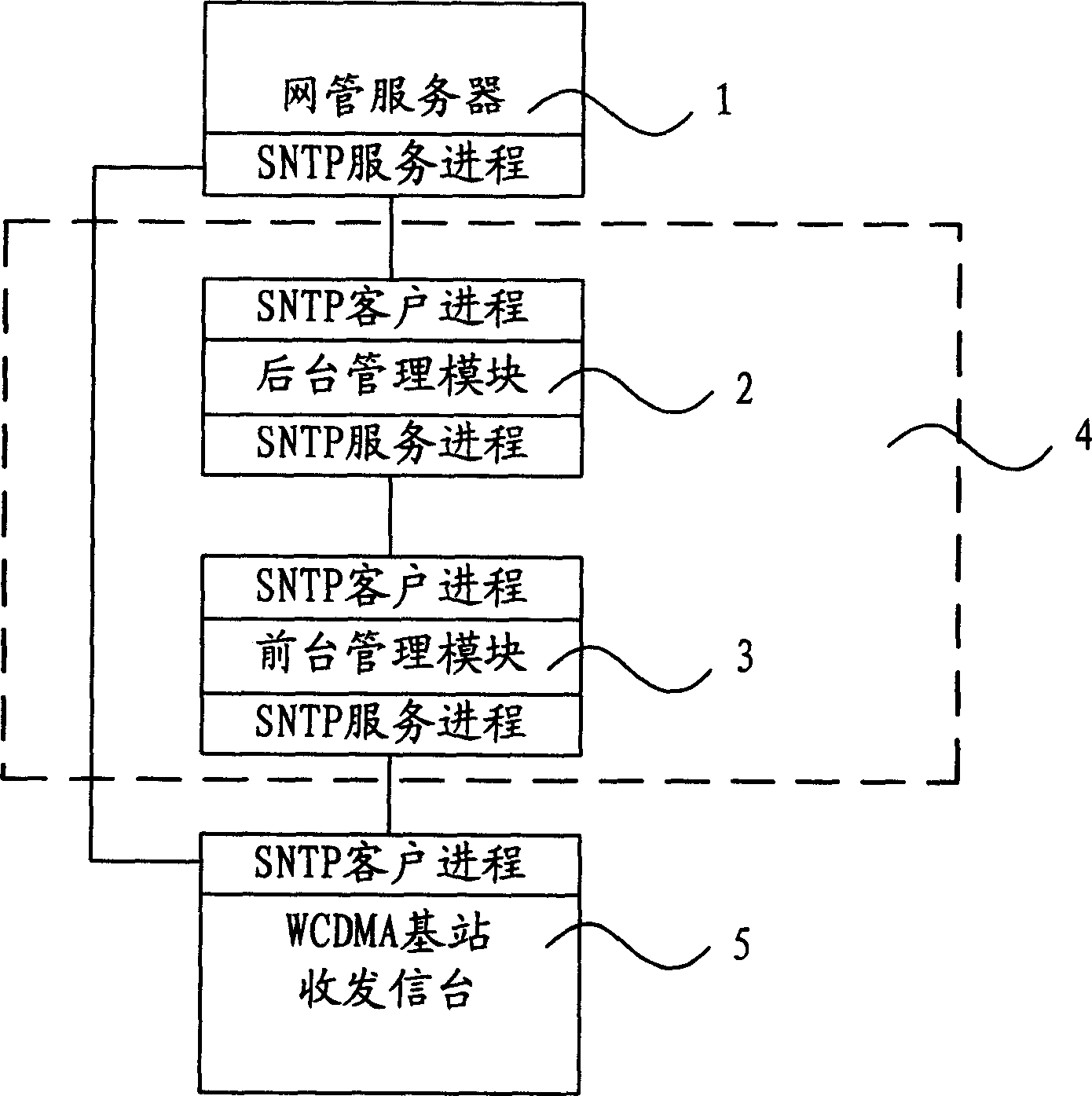

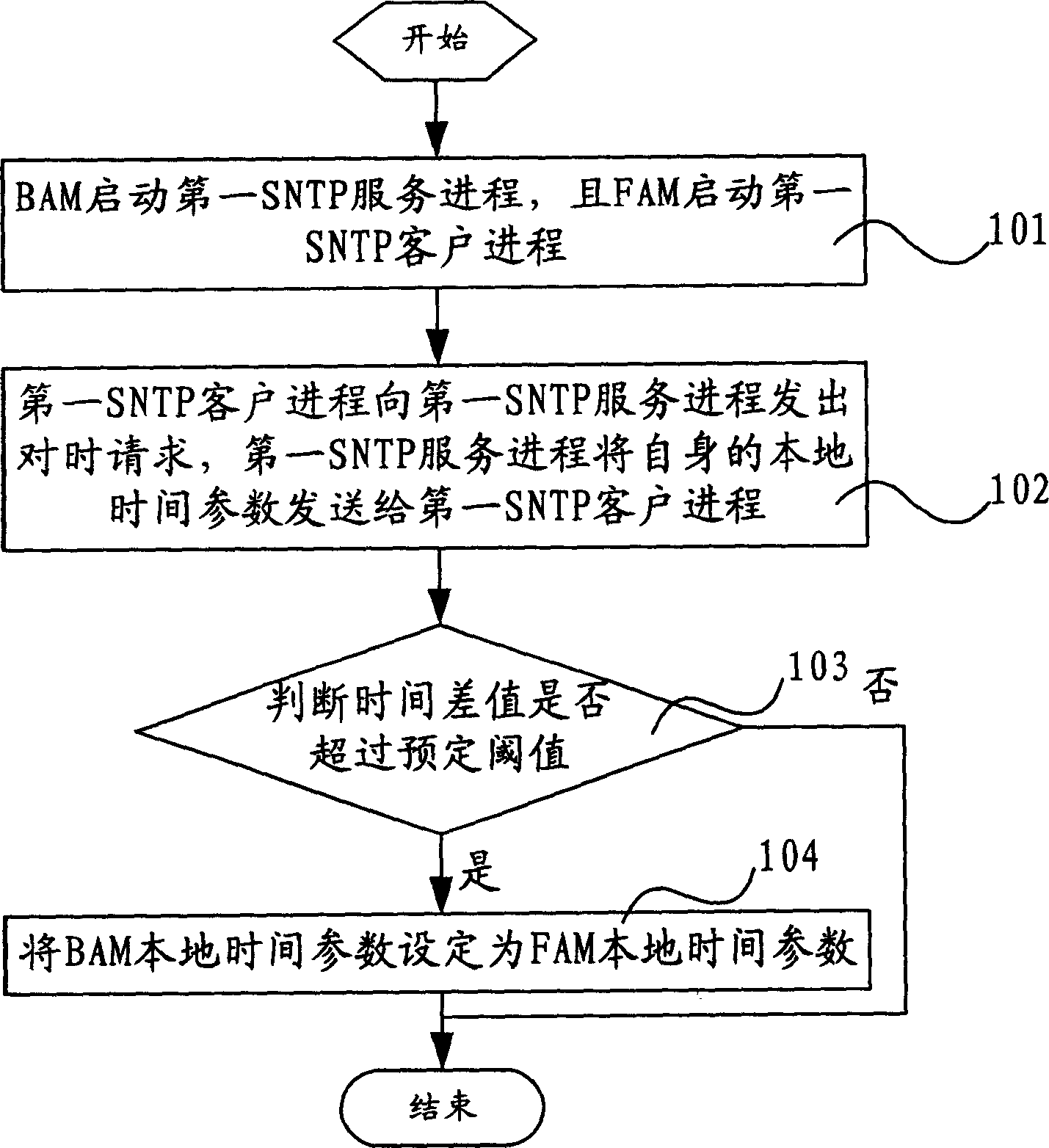

Network time synchronizing method based on simple network to time protocol

ActiveCN1889392AGood timing accuracyGuaranteed accuracyRadio transmission for post communicationData switching networksTime ProtocolNetwork management

This invention relates to a network time synchronous method based on SNTP including: the BAM of RNC starts up a first SNTP service process and the FAM of the RNC starts up a first SNTP customer process, which sends a request for checking the time to the first service process, which sends its own time parameters to the first customer process to judge if the difference of the received time parameter and the local time parameter surpasses a preset threshold, if so, it sets the received time parameter as the local parameter, which starts up the service and customer process of the SNTP and finishes the time synchronous operation based on the SNTP protocol and synchronous time parameters are kept among NE and NE and network management to secure the accuracy of the statistic to its performance.

Owner:XFUSION DIGITAL TECH CO LTD

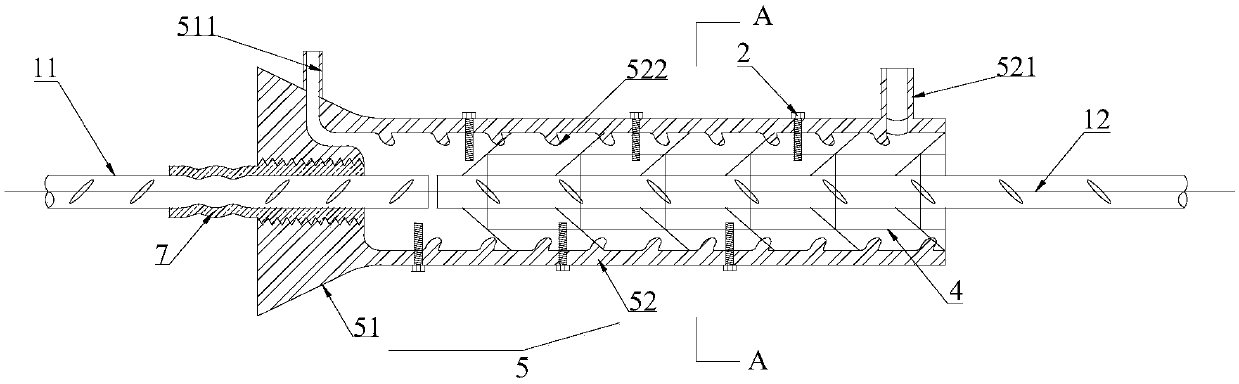

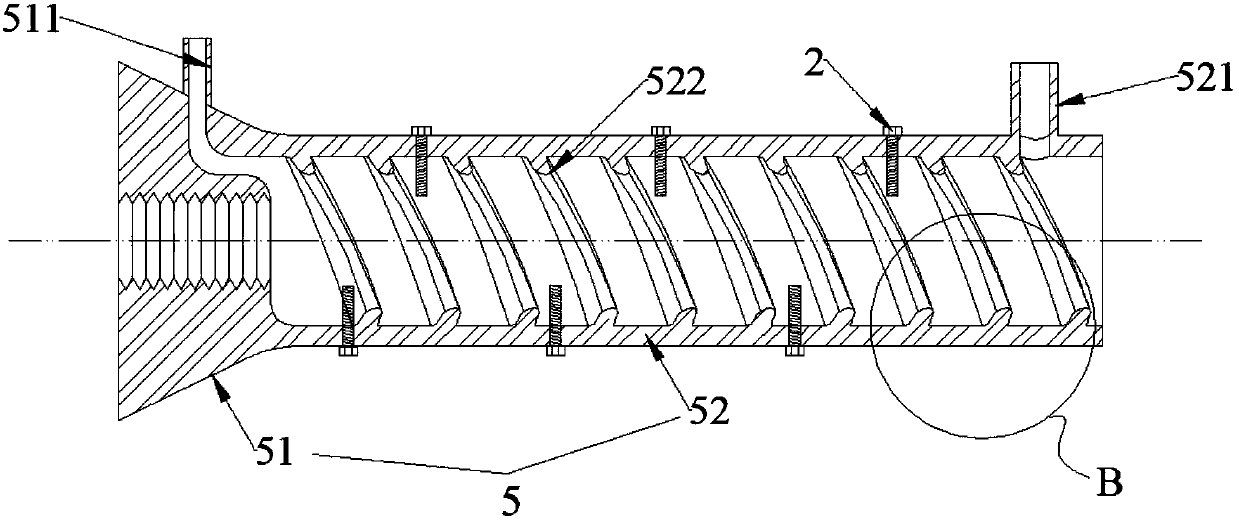

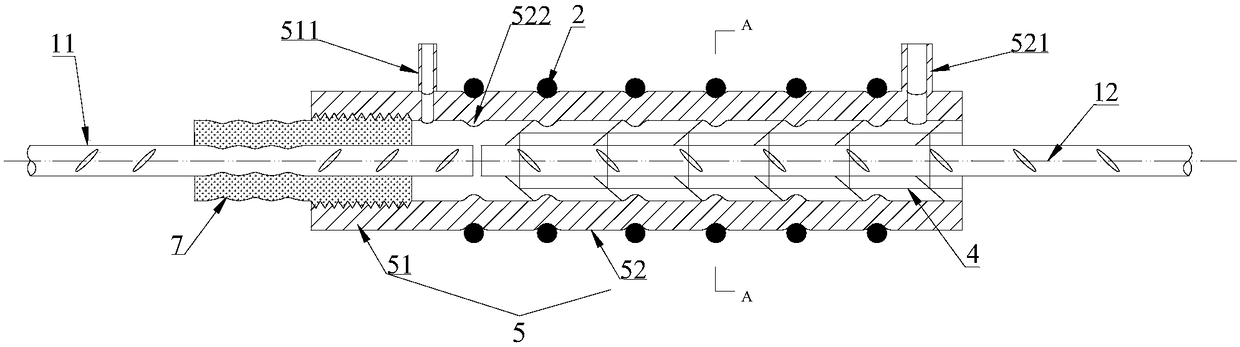

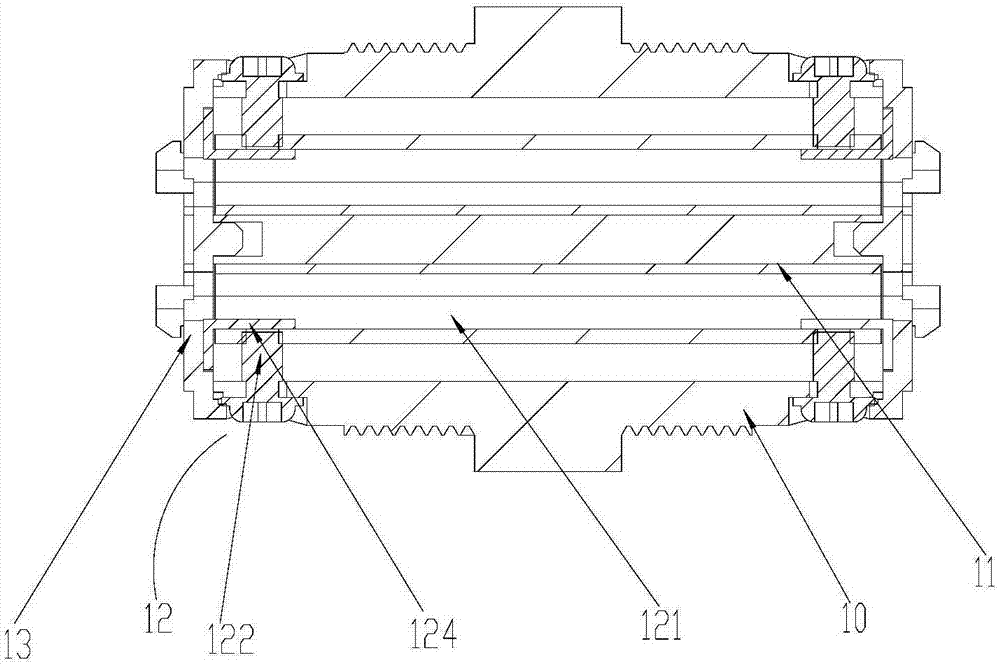

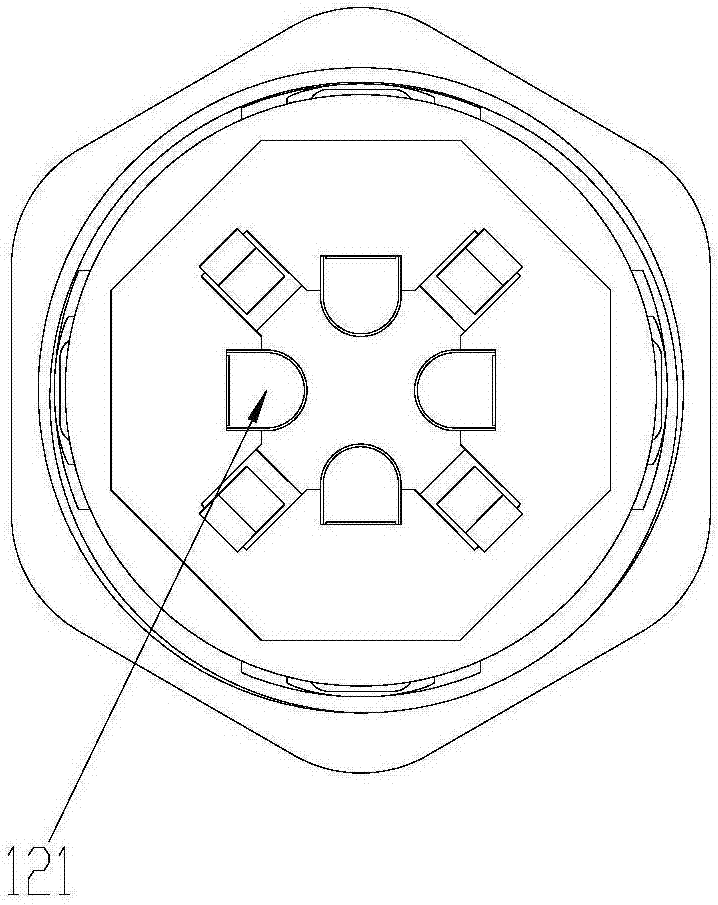

Anti-vibration assembly self-locking type semi-grouting sleeve

The invention provides an anti-vibration assembly self-locking type semi-grouting sleeve. The sleeve comprises a non-grouting connecting section and a grouting connecting section, wherein one tube body section of a steel tube transition section is fixedly arranged in the non-grouting connecting section; another tube body section extends to the outside of the non-grouting connecting section to forma rolling-pressing section which is in rolling-pressing connection with a first to-be-connected reinforcing steel bar; a steel framework comprises inner barbs and outer barbs; the inner barbs are enclosed to form a channel for allowing a second to-be-connected reinforcing steel bar to pass through, and the diameter of the channel is smaller than that of the second to-be-connected reinforcing steel bar; and the outline diameter enclosed by the outer bards is greater than the inner cavity diameter of the grouting connecting section. Each part of the grouting sleeve is separately processed and manufactured, re-assembled, and produced in batch, and easily controlled in quality; connection between the grouting sleeve and the steel tube transition section is operated in a plant through machinery, and threaded connecting quality is easily controlled; the first to-be-connected reinforcing steel bar and the steel tube transition section are directly connected in a rolling-pressing mode, so that processes are simple, and length, inserted into the sleeve, of reinforcing steel bars is easily controlled; and a self-locking type steel framework is adopted, so that the anti-pulling purpose is realized, and antiknock characteristic is improved.

Owner:HEFEI CONSTR ENG GRP

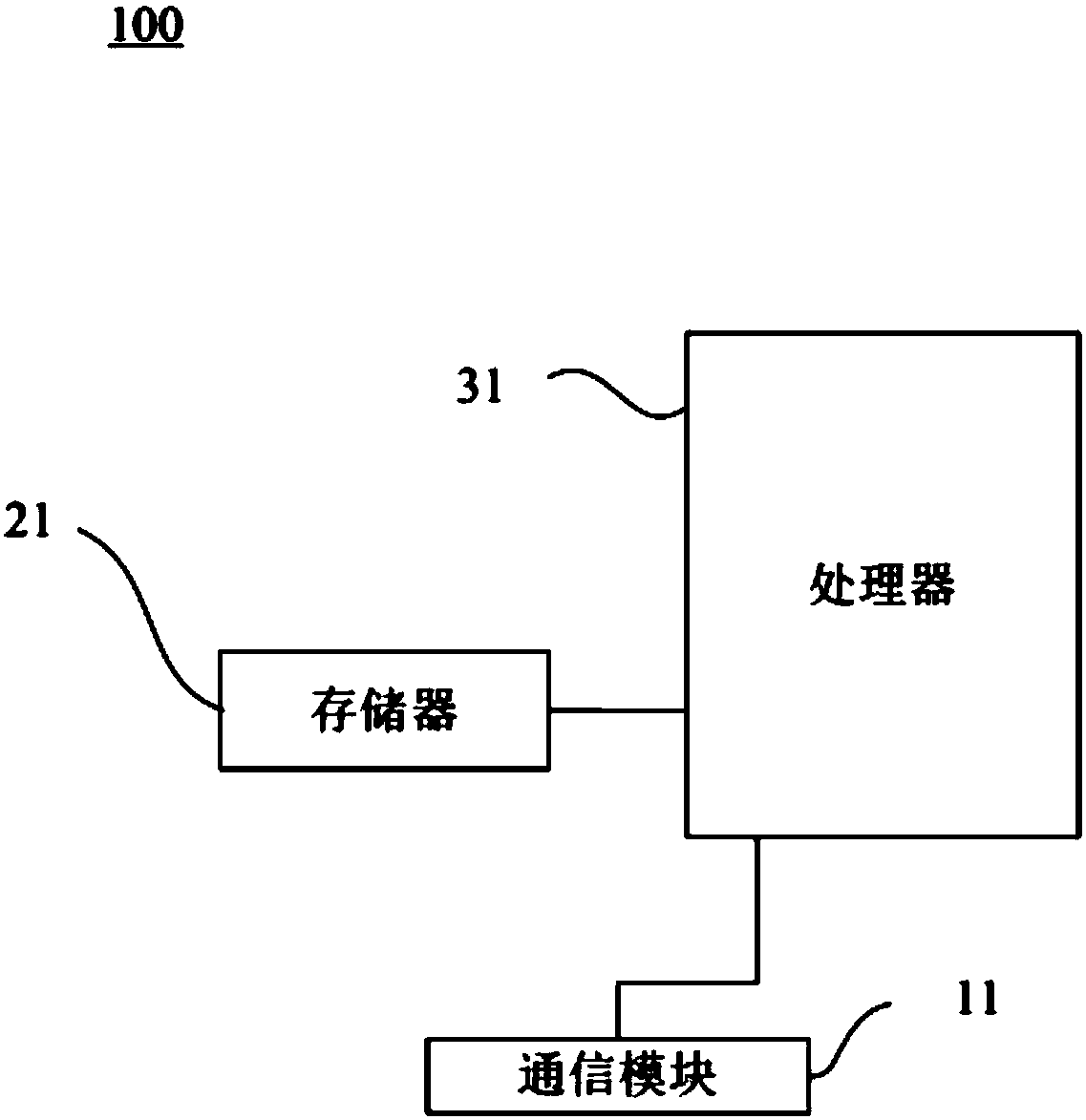

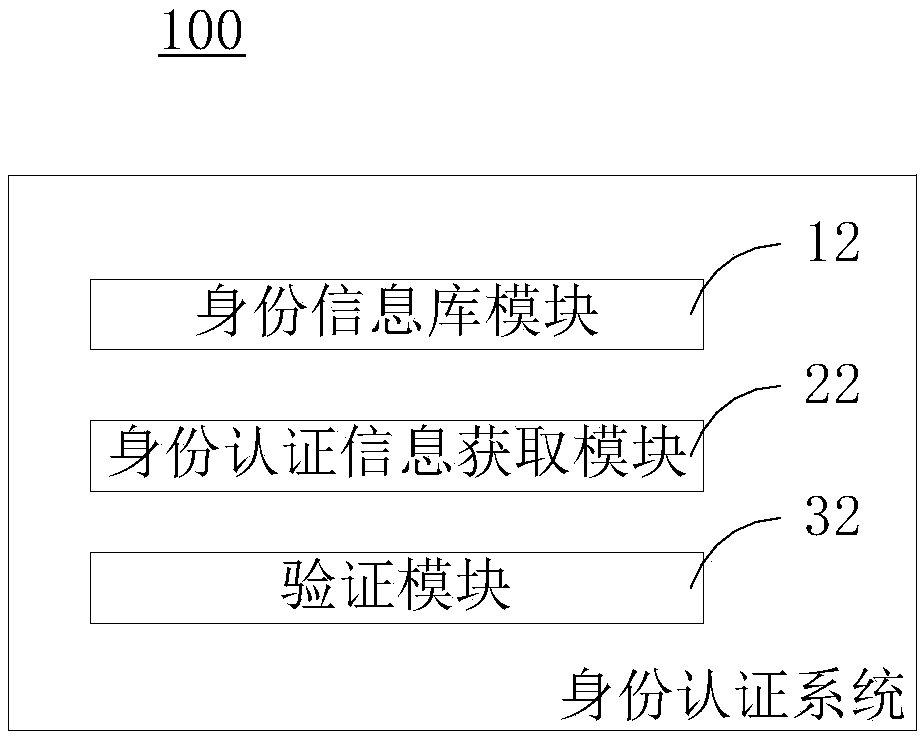

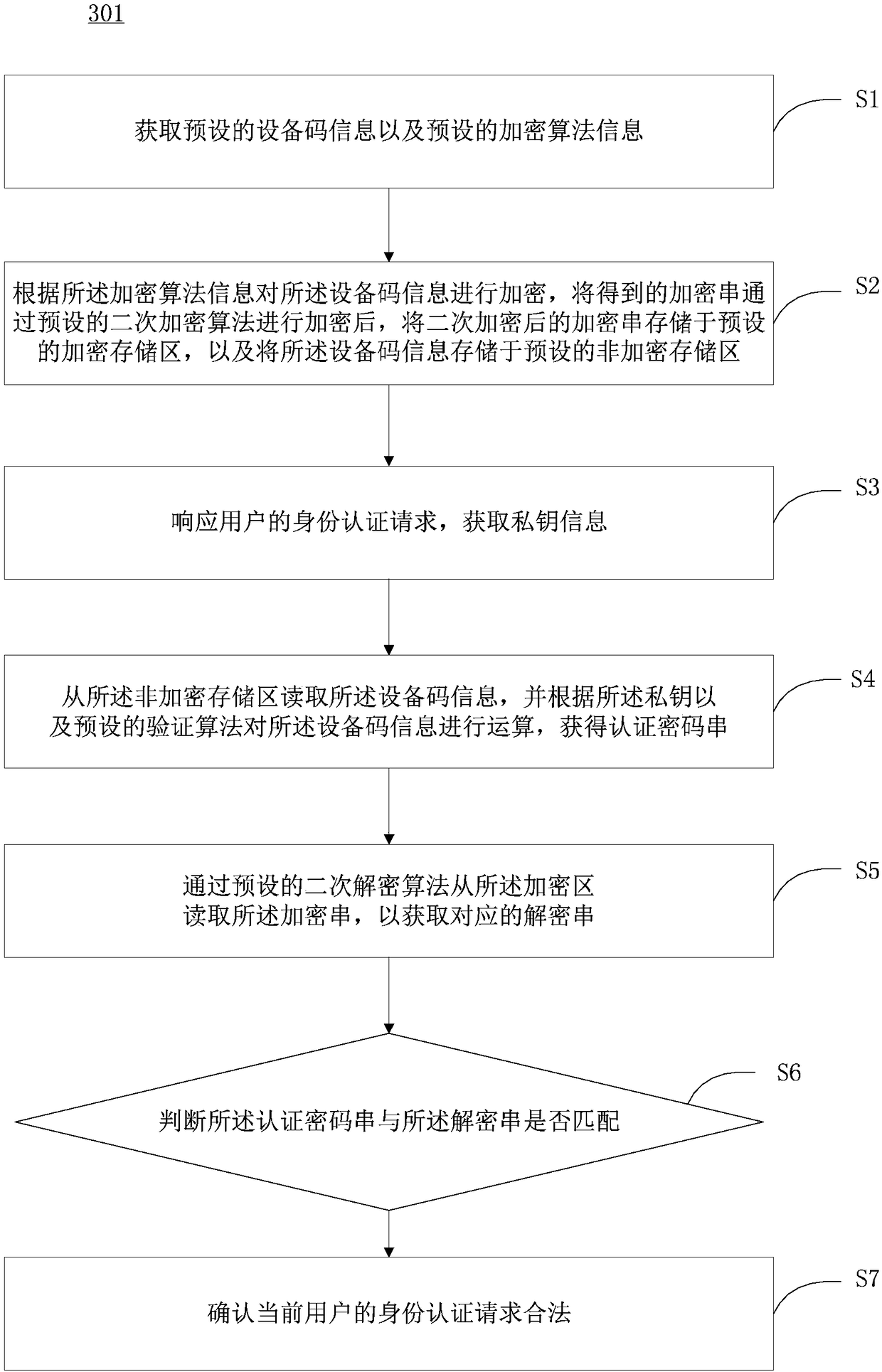

Identity authentication method and system and computer readable storage medium

ActiveCN108965222AEnsure safetyAvoid risk of crackingUser identity/authority verificationPasswordAuthentication system

The present invention discloses an identity authentication method. The method comprises the steps of: performing encryption of device code information according to encryption algorithm information, storing encryption strings after secondary encryption into a preset encryption storage area, and storing the device code information to a preset non-encryption storage area; when identity authenticationis performed, performing operation of the device code information according private keys to obtain authentication password strings; reading the encryption strings to obtain corresponding decryption stings; determining whether the authentication password strings are matched with the decryption strings or not; and performing verification of the validity of an identity authentication request of a current user. The identity authentication method does not depend on a server, and fully hides the identity information so as to effectively avoid the risk of crack based on the identity information files and achieve separation of three portions of hardware, encryption strings and the identity authentication program. The present invention further provides an identity authentication system and a computer readable storage medium.

Owner:PUHUA YUNCHUANG TECH (BEIJING) CO LTD

Method for machining shock-resistant self-locking type half grouting sleeve and method for machining concrete member

The invention provides a method for machining a shock-resistant assembly self-locking type half grouting sleeve and a method for machining a concrete member. The method for machining the shock-resistant assembly self-locking type half grouting sleeve comprises the steps that (1) the grouting sleeve is machined in a casting mode and integrally formed, one end of the grouting sleeve is subjected toinner thread treatment, and a plurality of mounting holes are formed in a sleeve body for standby application; (2) one end of a steel pipe transition section is subjected to outer thread treatment forstandby application; (3) firstly, a plurality of longitudinal guiding steel bars and a plurality of circumferential fixing steel rings are welded to form cylindrical keels, then a plurality of inclined steel branches are welded on a plurality of annular sections of the keels in emissive and inclined modes to form inner barbs and outer barbs for standby application; and (4) assembly is conducted.All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and the steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, a first to-be-connected steel bar and the steel pipe transition section directly adopt the rolling mode, thus the connecting working procedure is simple, and the lengths of the steel bar parts inserted into the sleeve are easy to control; and a self-lockingtype steel skeleton is adopted, so that pulling preventing is achieved.

Owner:HEFEI CONSTR ENG GRP

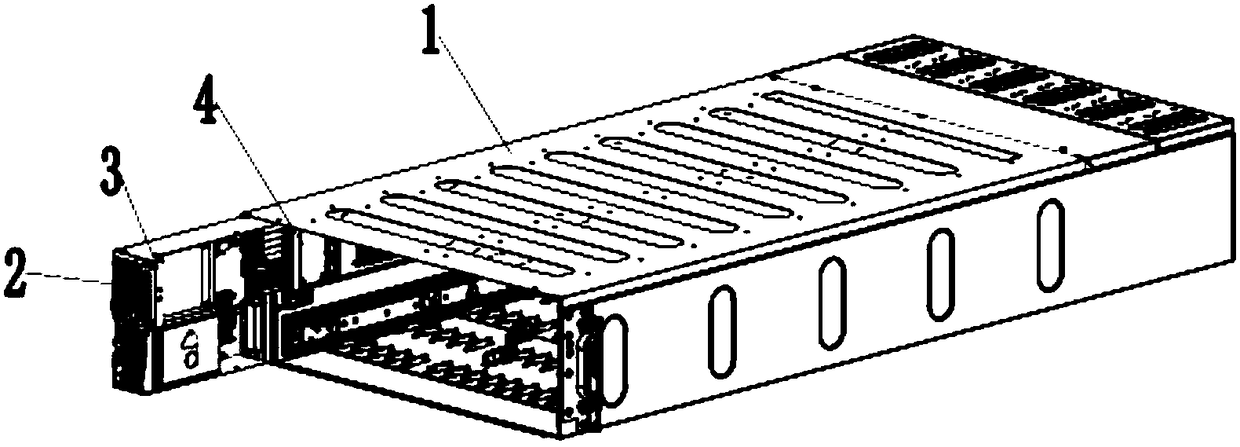

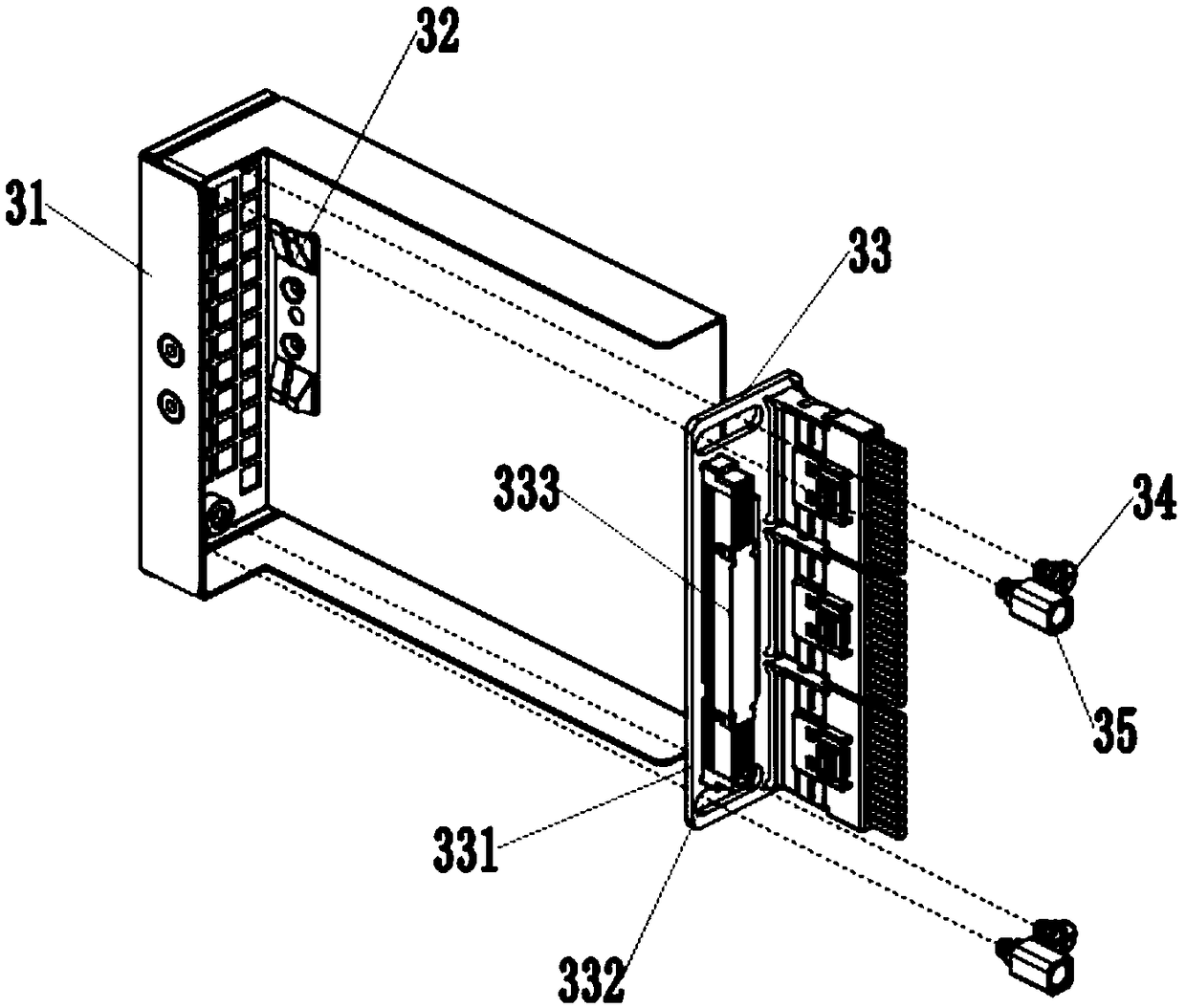

An adapter structure of a server node panel

ActiveCN109032270ASolve the lack of spaceEasy to operateDigital processing power distributionEngineering

An adapter structure of a server node panel is disclosed, including case. A computing node and a hard disk node are arranged in the case, a partition plate is arranged between the computing node and the hard disk node, a drag chain tray is arranged on the partition plate, a drag chain is arranged on the drag chain tray, the front end side of the computing node is provided with a floating plate module, the floating plate module comprises a floating plate tray, elastic pieces, and a floating plate, the floating plate tray is connected with a computing node, the floating plate is arranged insidethe floating plate tray, the floating plate is electrically connected to the computing node, the end of the floating plate is connected with the floating plate tray, both sides of the floating plate are provided with elastic pieces, the elastic pieces are connected with the floating plate tray, the end of the drag chain tray is provided with an adapter plate module, the adapter plate module is arranged close to the end of the drag chain chain, the adapter plate module comprises an adapter plate, one end of the adapter plate is matched with the floating plate, the other end of the adapter plateis connected with a line, and the line is electrically connected with the hard disk node through the drag chain.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

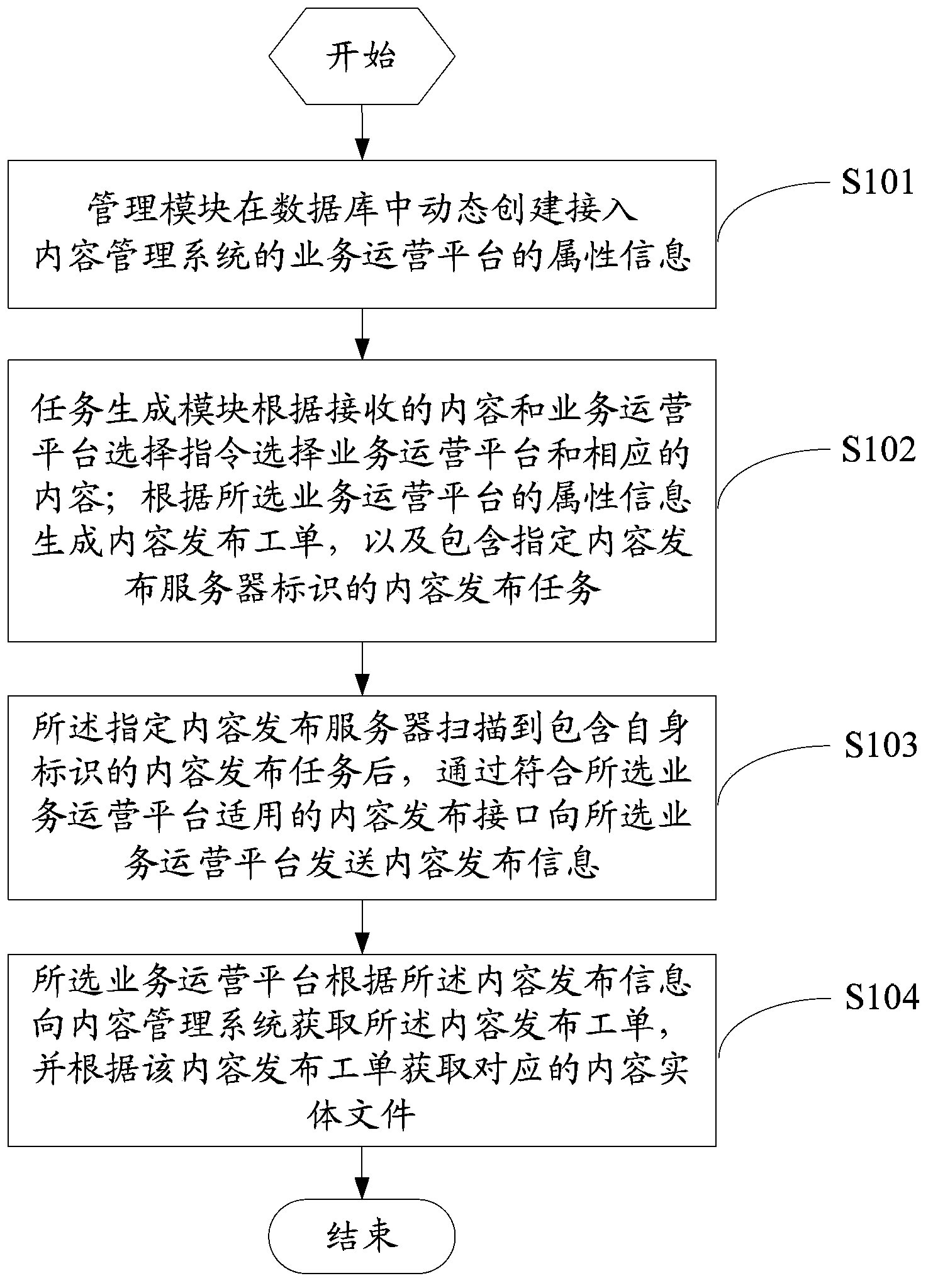

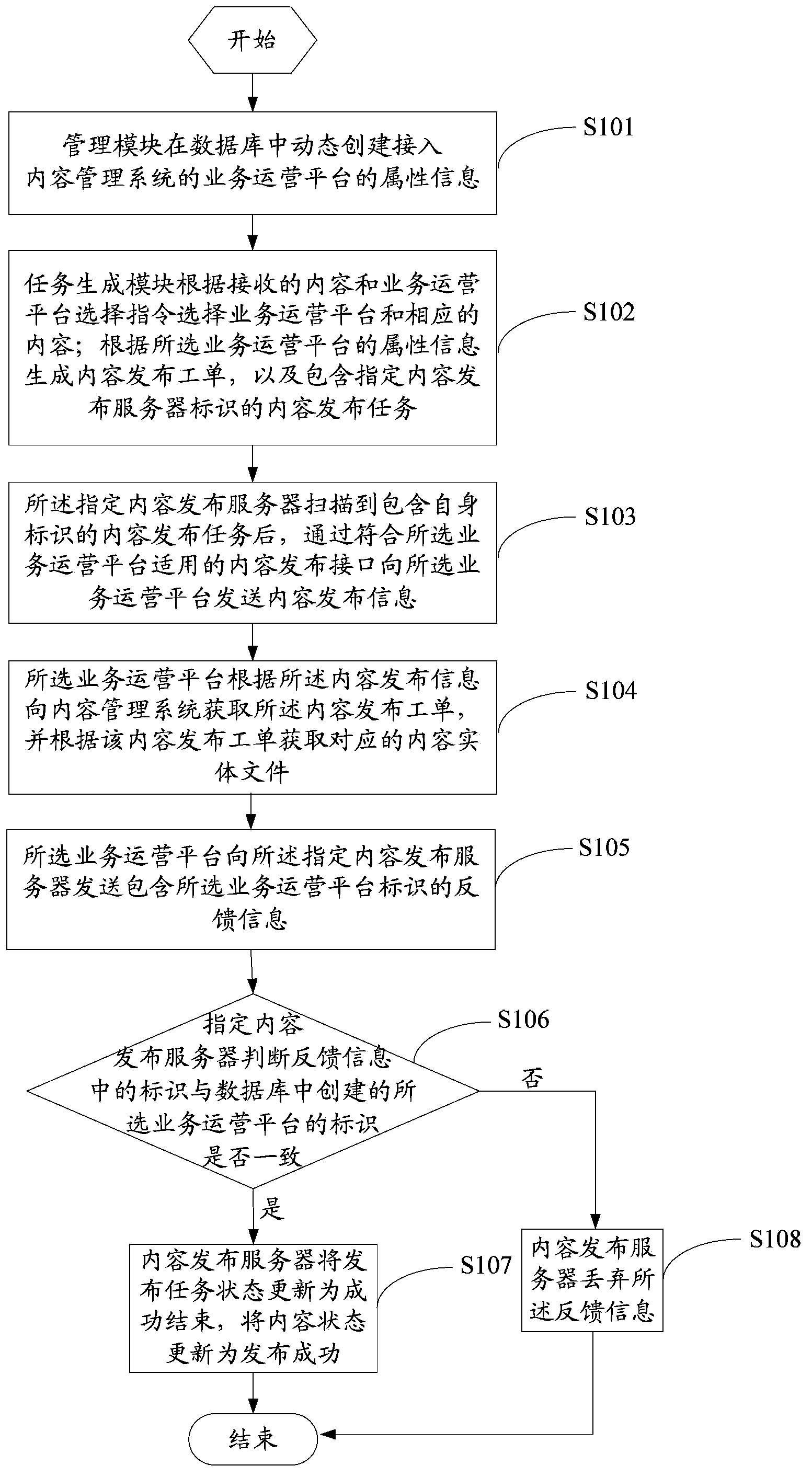

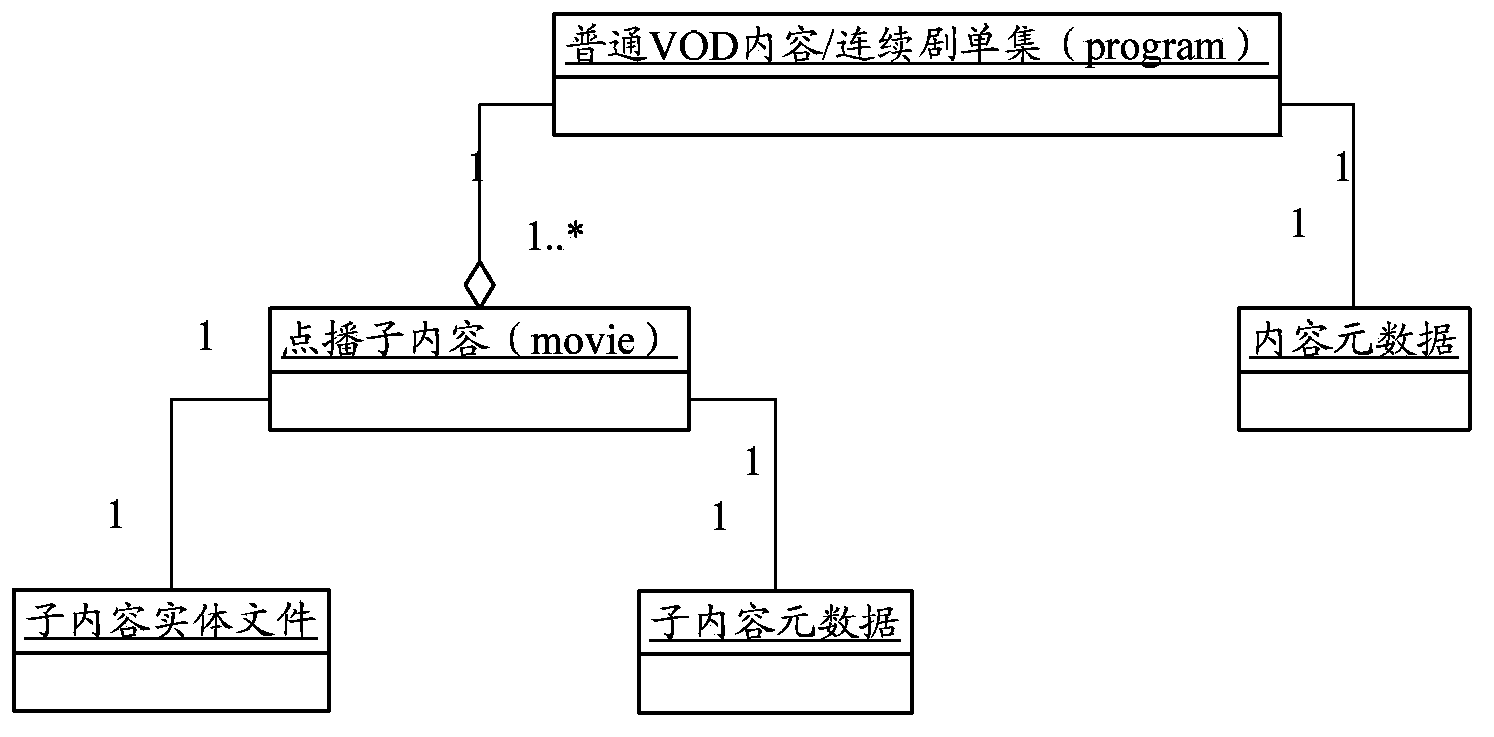

Content publishing system and content publishing method

InactiveCN103581141AGuaranteed dockingDigital data information retrievalProgram controlManagement systemContent management system

The invention discloses a content publishing system and a content publishing method. The content publishing method includes the steps that a management module dynamically establishes attribute information of service operation platforms which have access to a content management system; a task generation module selects the service operation platforms and corresponding content according to selection instructions; content publishing work orders and content publishing tasks are generated according to the attribute information; after a designated content publishing server scans the content publishing tasks containing self identification, content publishing information is sent to the selected service operation platforms through content publishing interfaces conforming to the service operation platforms; the service operation platforms obtain the content publishing orders to the content management system according to the content publishing information, and corresponding content entity files are obtained according to the content publishing work orders. According to the content publishing system and the content publishing method, under the condition that the content management system is docked with the service operation platforms, content needed by target service operation platforms is published to the target service operation platforms by the content publishing server according to actual requirements.

Owner:青岛黑花生文化创意有限公司

Prefabricated toilet floor slab construction method

InactiveCN111827665AGood leak-proof and seepage-proof performanceAvoid destructionFloorsForms/shuttering/falseworksFloor slabArchitectural engineering

The invention provides a prefabricated toilet floor slab construction method, and relates to the technical field of fabricated toilets. The prefabricated toilet floor slab construction method comprises the steps of assembling and reinforcing a bottom plate pouring formwork and a reverse sill pouring formwork, arranging floor slab reinforcing steel bars on the bottom plate pouring formwork, installing positioning convex columns on the floor slab reinforcing steel bars, sleeving the positioning convex columns with water stop joints, pouring concrete to the bottom plate pouring formwork to form abottom plate, pouring concrete to the reverse sill pouring formwork to form a reverse sill, and dismantling the bottom plate pouring formwork and the reverse sill pouring formwork. The reverse sill pouring formwork comprises a reverse sill outer form and a reverse sill inner form, and a plurality of water supply and drainage pipeline groove pressing molds are arranged on the inner side of the reverse sill inner form at intervals. The floor slab reinforcing steel bars are provided with steel bar extending parts extending towards the periphery. The bottom plate and the reverse sill of the toilet floor slab are integrally poured and formed, so that the leakage-proof and seepage-proof performance is better, and the situation that the leakage-proof and seepage-proof performance of the toilet floor slab is affected by cold joints due to the fact that the bottom plate is poured firstly and then the reverse sill is poured on the basis of the bottom plate is avoided.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Liquid plastic bottle leak detector for production line and detecting method thereof

InactiveCN106353037ARealize automatic eliminationLabor savingFluid-tightness measurementProduction lineEngineering

The invention relates to a liquid plastic bottle leak detector for production line, several mechanical hands are arranged on both end sides of moving directions of conveyor belt, the mechanical hands are connected with drive device, the clamping part of each mechanical hand is composed of a symmetrical clamping head, a pressure sensor is mounted on each clamping head, the pressure sensor is connected with external PLC control cabinet; a distributor is arranged at the entry end of the conveyor belt, the distributor arranges the distance of bottles entering the conveyor belt; a start detecting sensor is arranged at the entry end of conveyor belt. The bottle leak detector can detect the seal condition of plastic bottles by pressing lightly on the bottles, the device can realize effective identification so that products can be 100% detected, which avoids the problems caused by manual detecting, saves a lot of labor costs and improves the degree of automation of production enterprises.

Owner:阎文

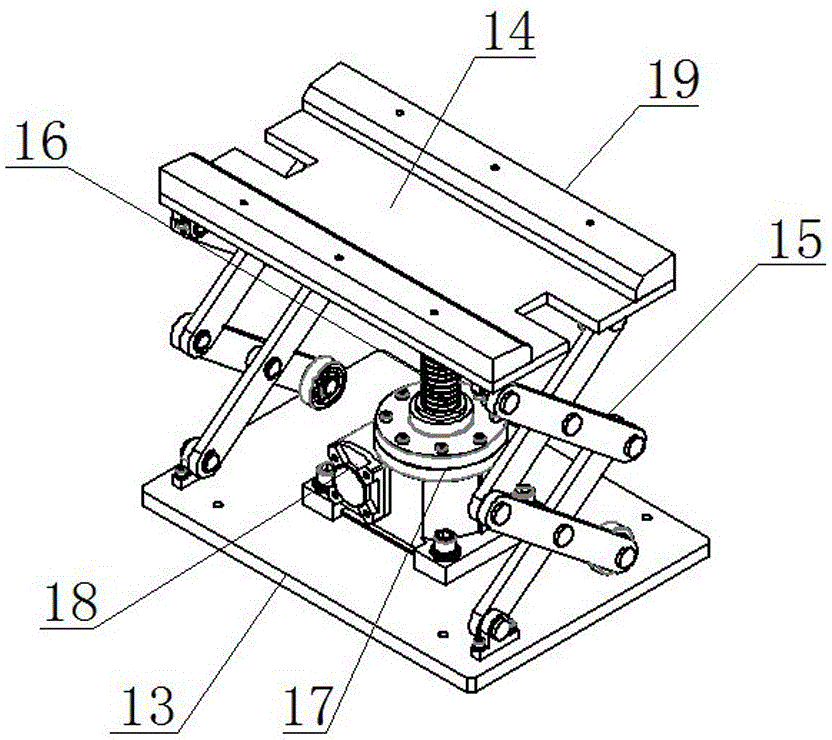

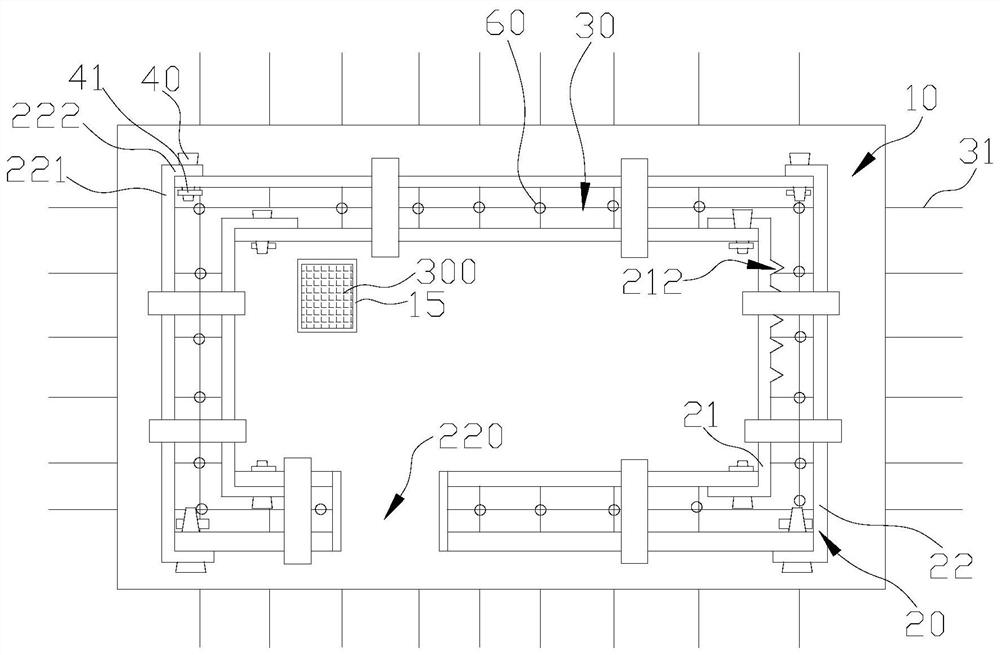

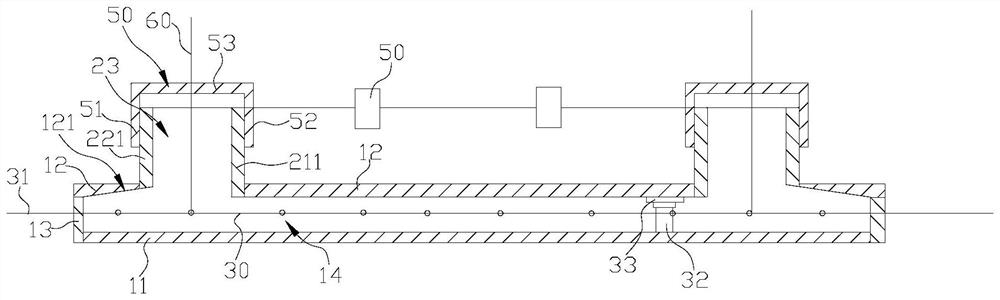

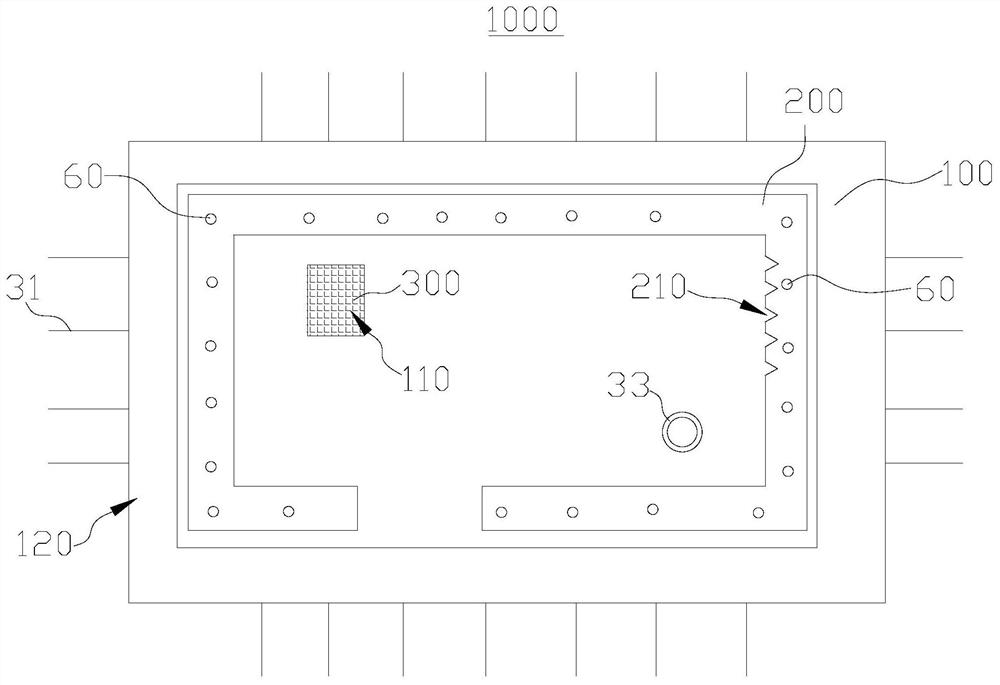

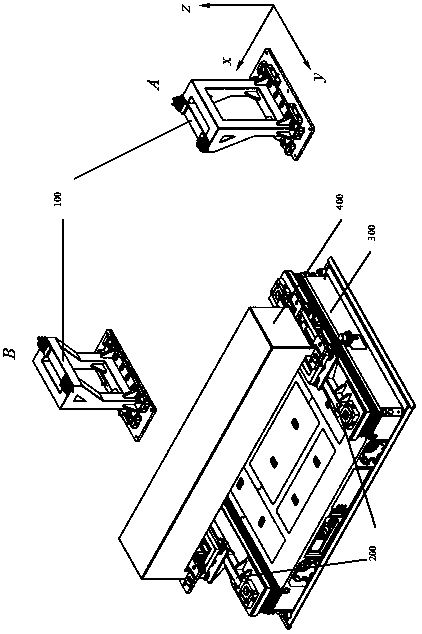

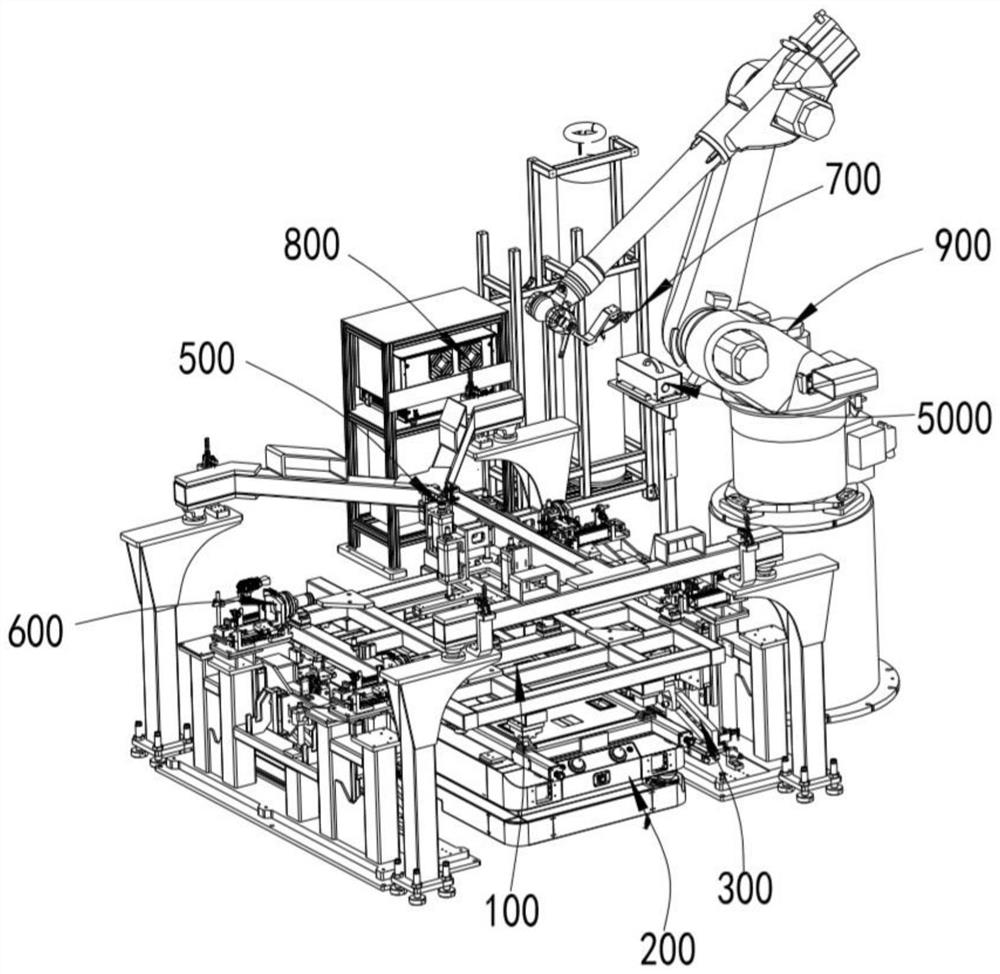

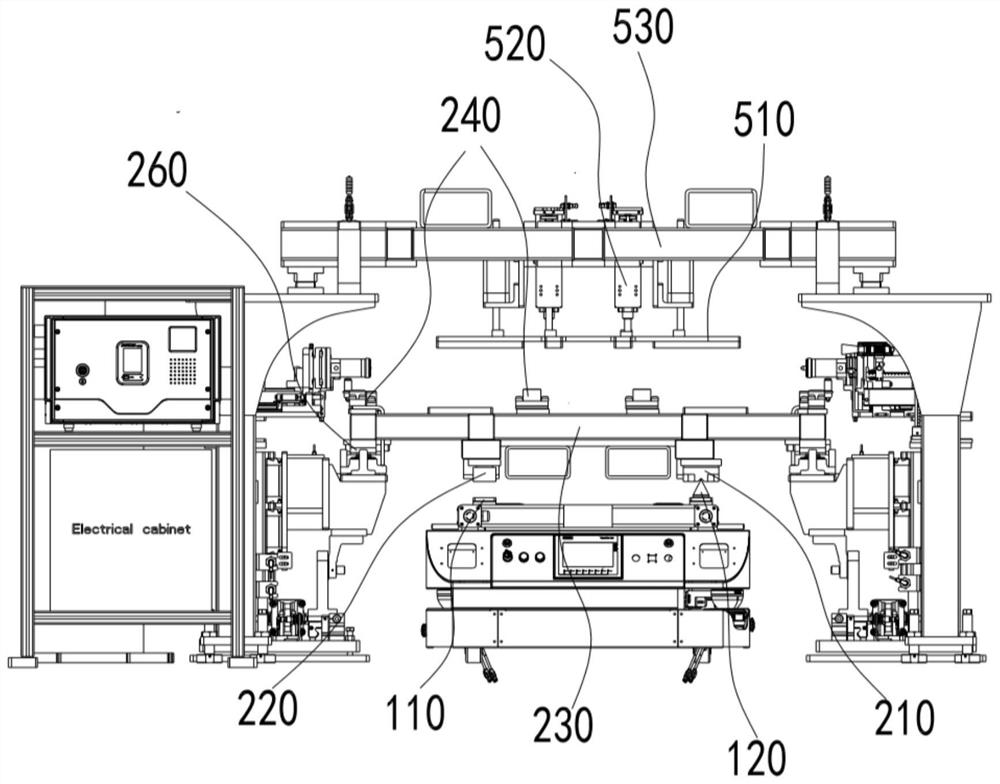

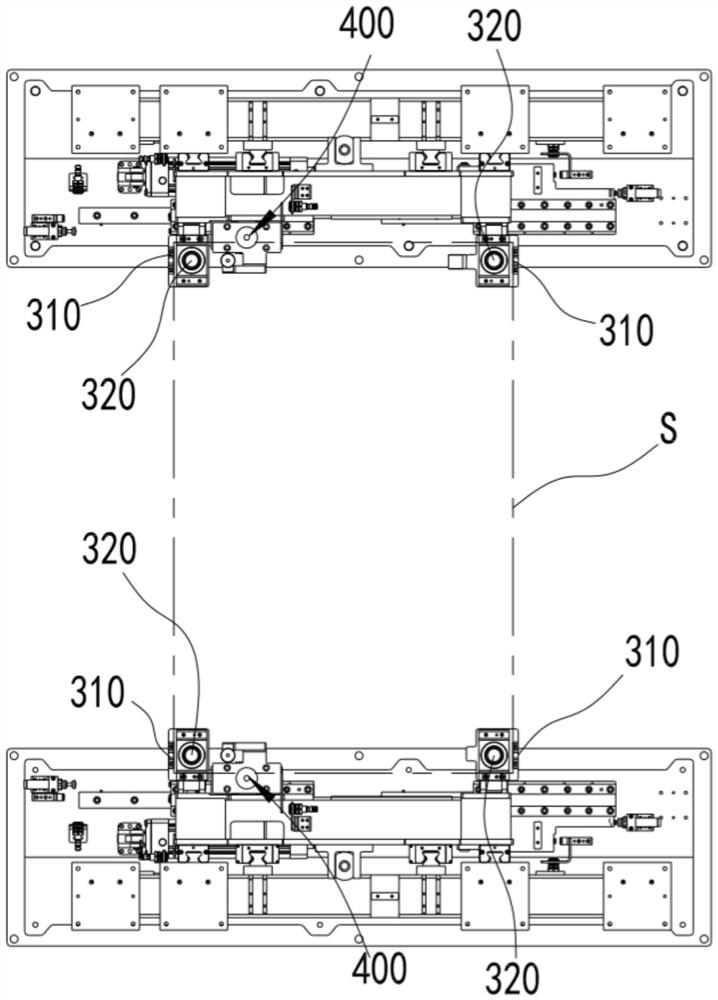

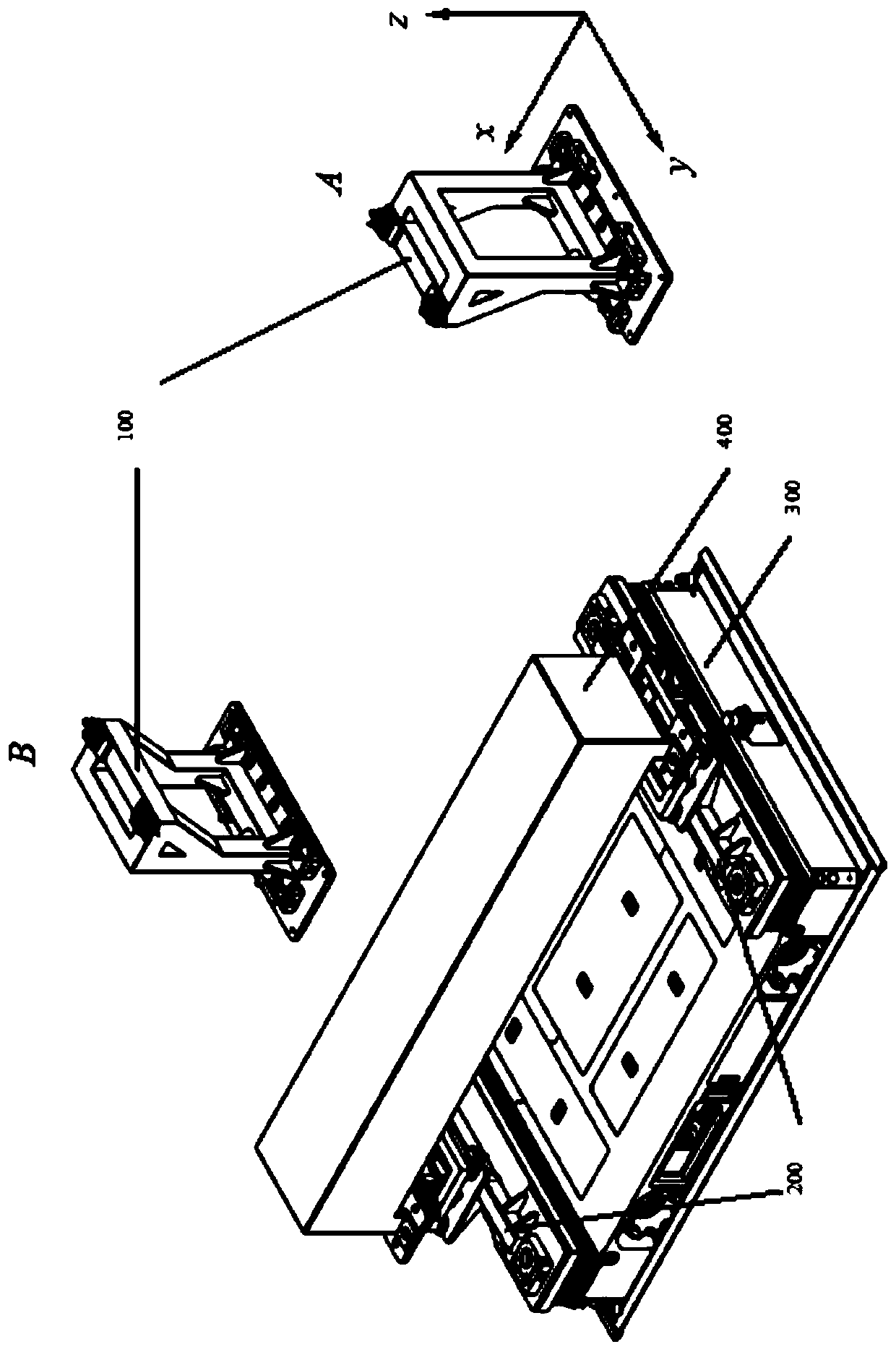

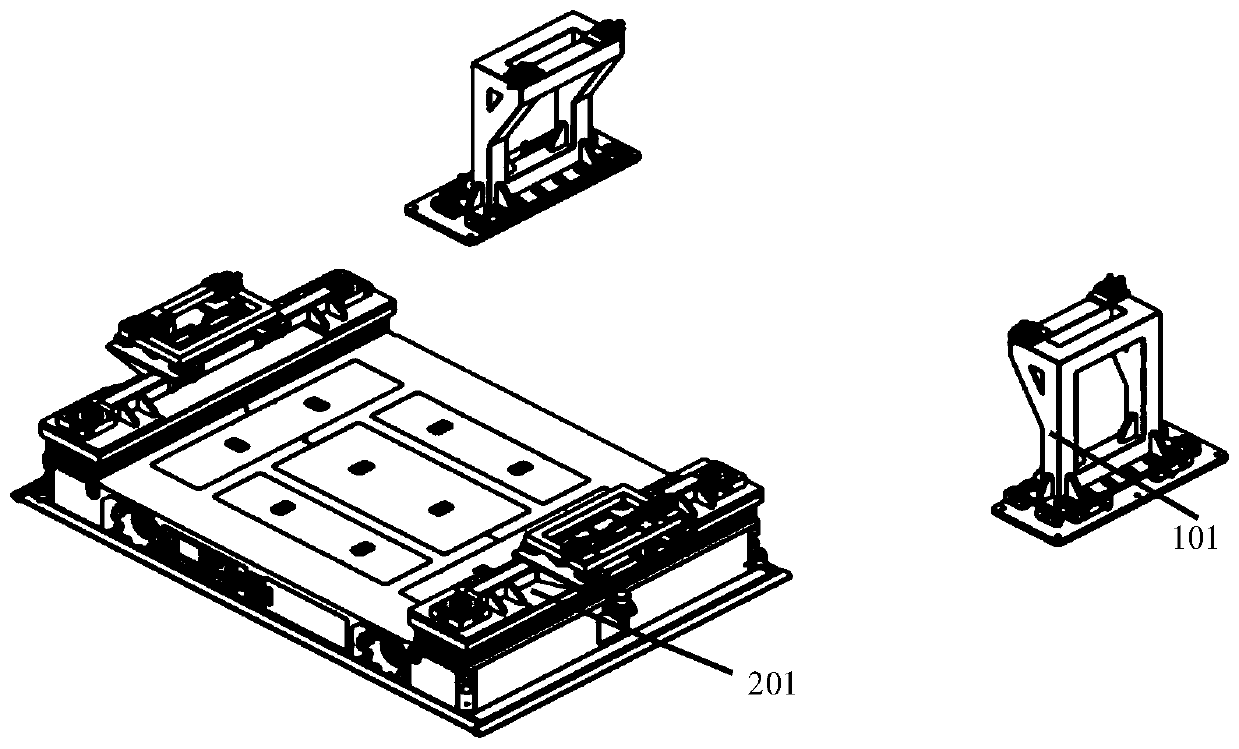

Flexible docking and rapid positioning system

ActiveCN110712020ALow positioning accuracy requirementsAchieve soft deliveryElectric/hybrid propulsionTotal factory controlControl engineeringProcess engineering

The invention provides a flexible docking and rapid positioning system, and belongs to the field of transport equipment of production lines or integrated production units. The flexible docking and rapid positioning system comprises a positioning frame system and an automatic guided vehicle (AGV); the AGV is provided with a flexible docking system; a cargo is transferred to the positioning frame system from the AGV under bearing of flexible docking structures; the positioning frame system includes positioning frames; the upper end of each positioning frame is provided with a positioning pin module and a guide pin module, wherein the positioning pin module is used for performing positioning on the cargo, and the guide pin module is used for guiding the cargo; the flexible docking system includes the flexible docking structures which are symmetric; each flexible docking structure includes a fixed frame and a floating frame; an X direction spring for limiting the X axis of the floating frame and Y direction springs for limiting the Y axis of the floating frame are arranged between each fixed frame and the corresponding floating frame; and the upper end of each floating frame is provided with the positioning pin module and the guide pin module, wherein the positioning pin module is used for performing positioning on the cargo, and the guide pin module is used for guiding the cargo.The flexible docking and rapid positioning system realizes flexible fetching and feeding of a product, and can realize accurate positioning of the product after the product reaches a station, so thatthe automatic docking need is met.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

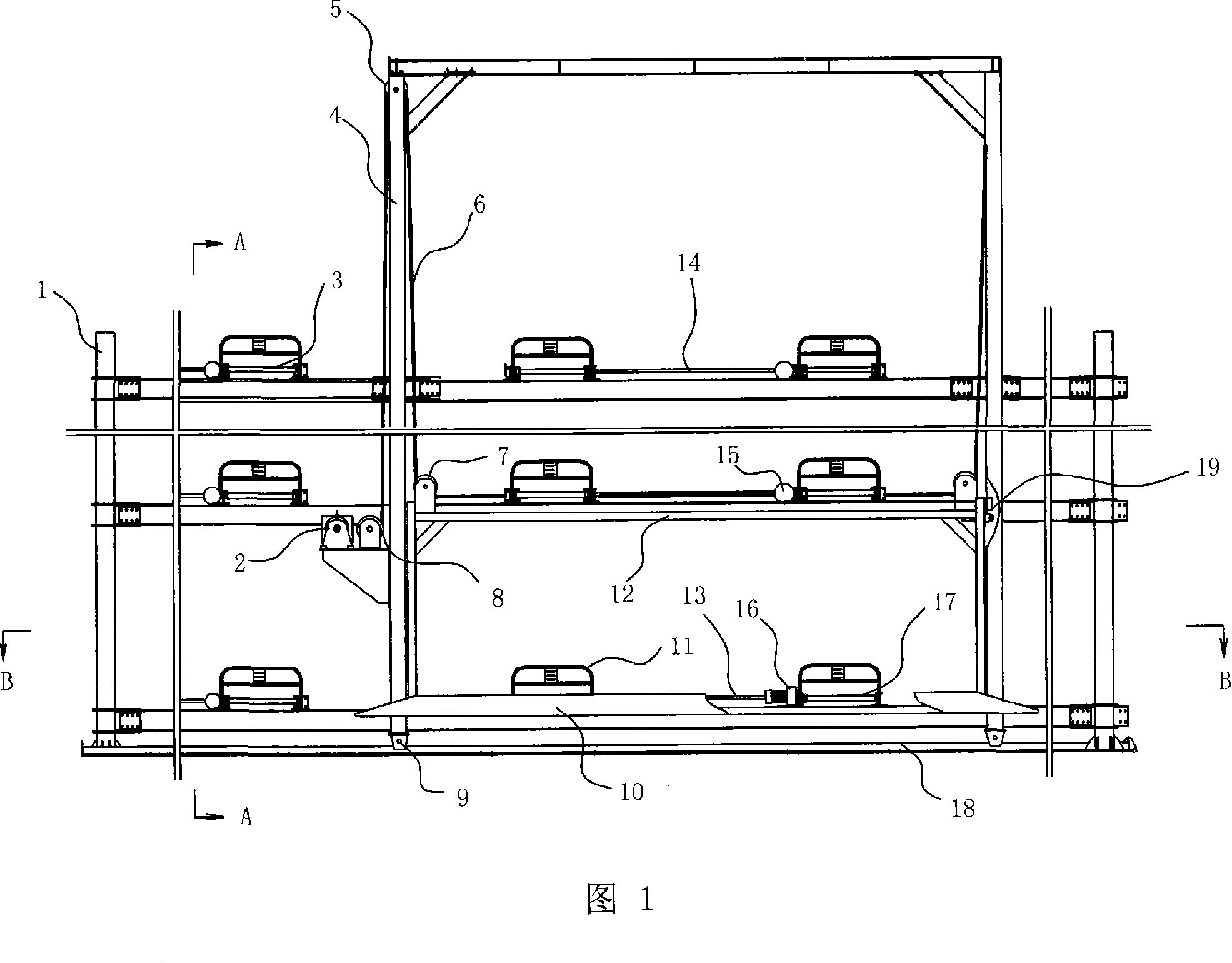

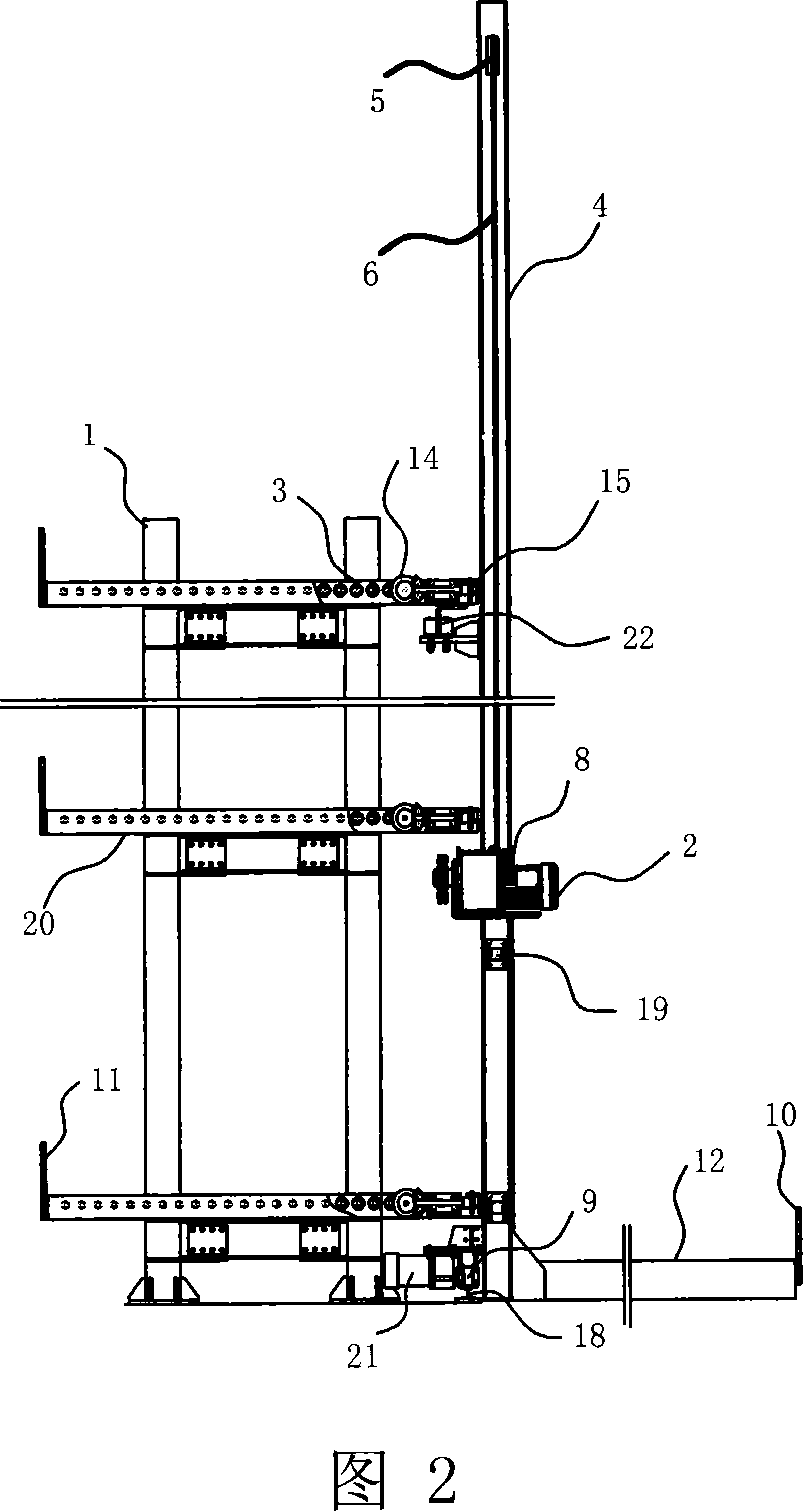

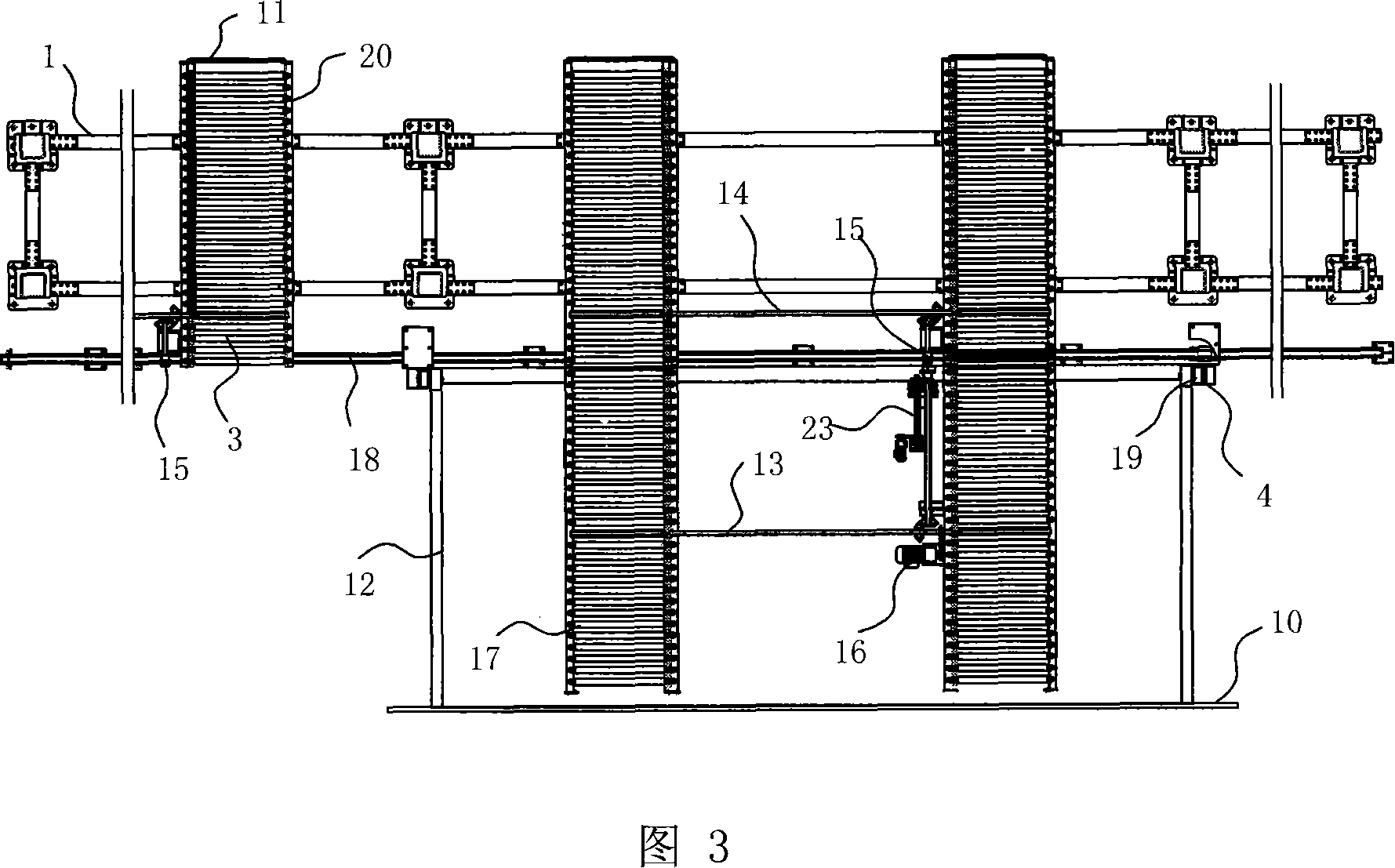

Stereo garage

The invention provides a technical process for a stereo garage, which comprises a frame with a plurality of vehicle-storing units. In each vehicle-storing unit, two vehicle-parking frames are provided; each vehicle-parking frame is provided with a vehicle-frame roller bed comprising cylindrical rolls; the two vehicle-frame roller beds are driven by a vehicle-frame-roller-bed drive; at one side of the vehicle-parking frame, a cross guideway is provided, on which a portal frame is provided; between the portal frame and the cross guideway, a cross drive is provided; in the portal frame, a lifting frame that can move up and down along the portal frame and is driven by an lifter on the portal frame is provided; at the bottom of the lifting frame, two frame roller beds comprising cylindrical rolls are provided, the two frame roller beds are driven by the frame-roller-bed drive, which is driven by the roller-bed drive; the vehicle-frame-roller-bed drive is driven by a roller drive through a roller drive clutch; between the portal frame and the parking frame, a column positioner is arranged; between the lifting frame and the parking frame, a row positioner is arranged.

Owner:青岛齐星车库有限公司

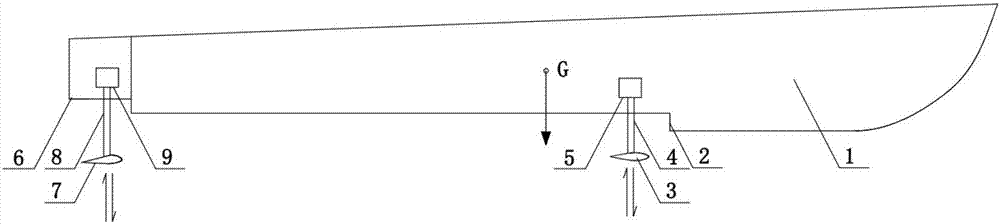

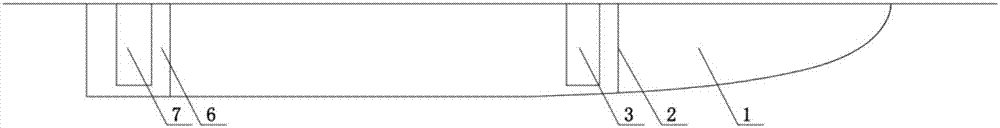

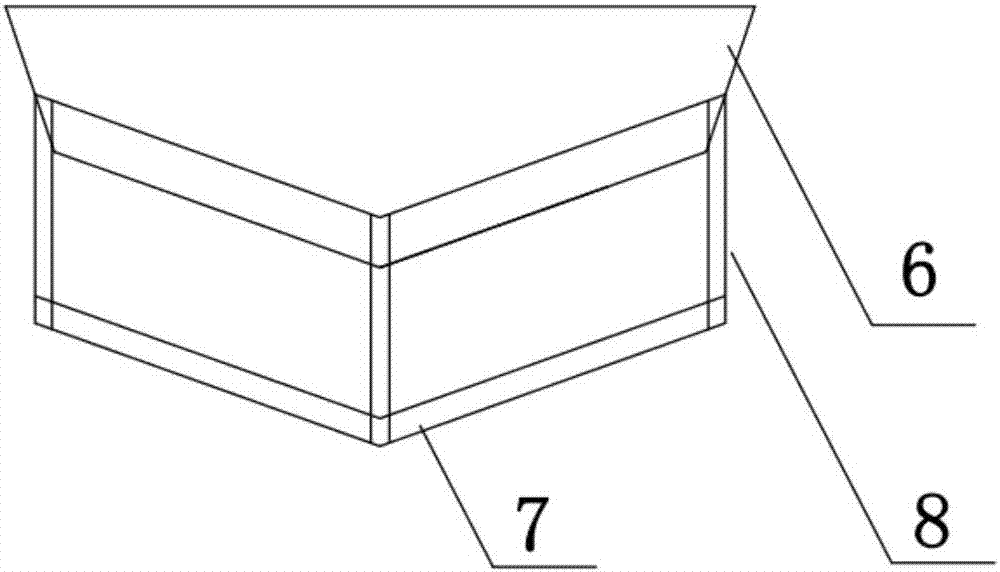

Step composite ship form with retractable type hydrofoils

InactiveCN107226169ASolving Recycling ProblemsIncrease hydropowerHydrodynamic/hydrostatic featuresMarine engineeringSelf stability

The invention provides a step composite ship form with retractable type hydrofoils. The step composite ship comprises a hull with a step and a fake tail, a front hydrofoil, a rear hydrofoil, supporting columns of the hydrofoils and devices for separately controlling the corresponding hydrofoil to extend / retract, wherein the front hydrofoil is located behind the step; the rear hydrofoil is located under the fake tail; the hydrofoil extending and retracting devices are arranged in the hull, and are used for extending / retracting the front hydrofoil and the rear hydrofoil; and when being unfolded, the hydrofoils are located under a baseline of the hull; and when the hydrofoils are retracted, the front hydrofoil is located behind the step, and the rear hydrofoil is located under the fake tail, and the front hydrofoil and the rear hydrofoil are close to the bottom of the hull. According to the step composite ship form with the hydrofoils which are additionally arranged disclosed by the invention, in an abyssal region, excellent hydrodynamic characteristics of the hydrofoils can be utilized to achieve the purposes of reducing resistance, increasing speed and saving energy, and the vertical damp of the hydrofoils and the longitudinal self-stability characteristic of a hydrofoil system can also be utilized to notably improve the movement performance of a ship and light boat; and in a shallow water region, after the front hydrofoil is retracted to the step, the rear hydrofoil can be retracted under the fake tail, so that the situation that the normal exerting of the functions of the ship and the light boat is influenced because the hydrofoils touch the ground is avoided.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

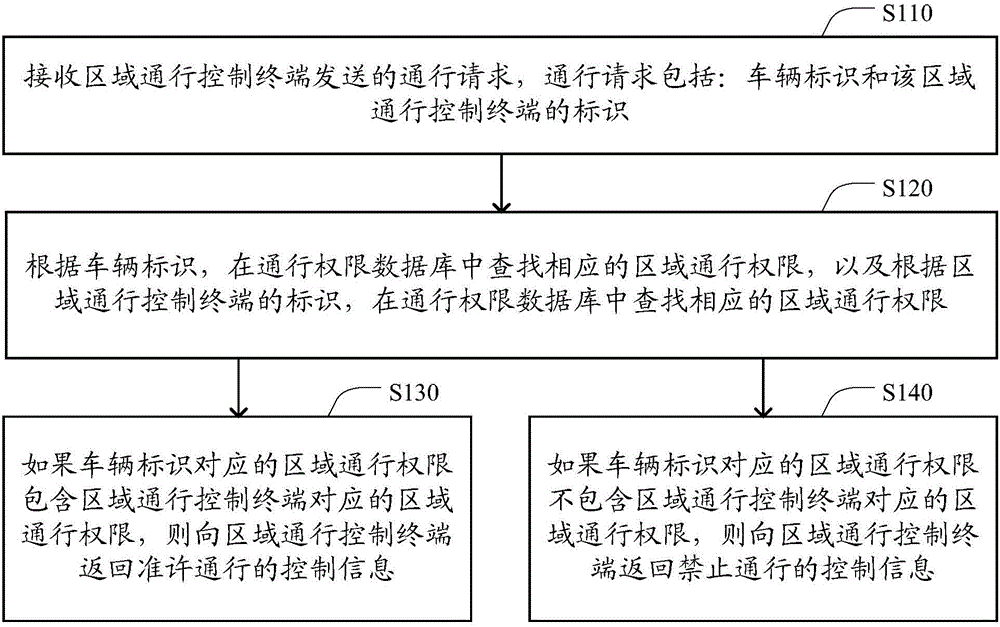

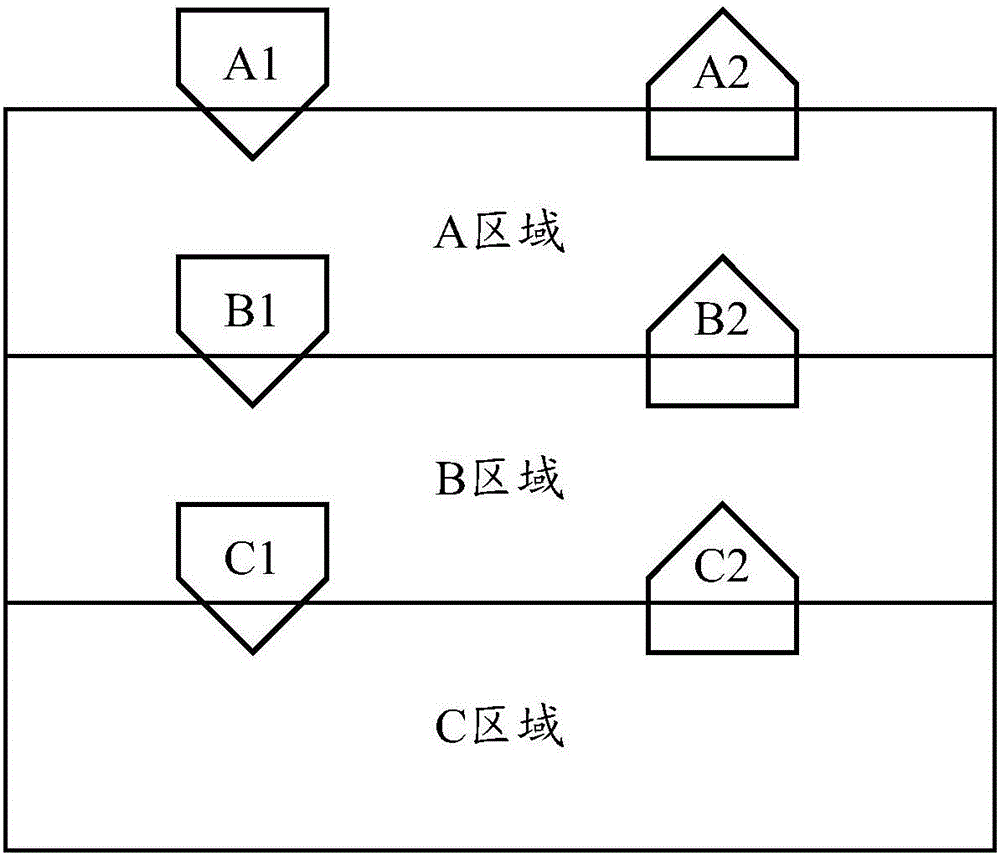

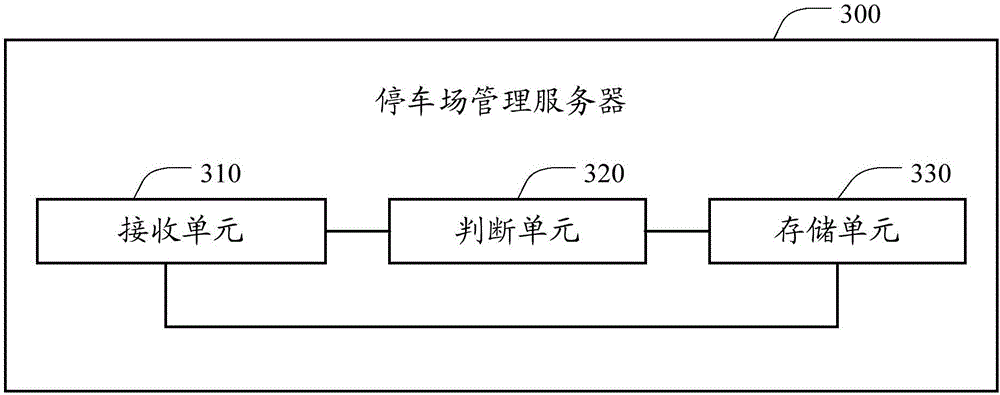

Parking lot management method, server and system

InactiveCN106448249ARealize intelligent controlGuaranteed dockingData processing applicationsIndication of parksing free spacesComputer terminalIntelligent control

The invention discloses a parking lot management method, server and system. The method comprises the steps of receiving a passing request sent by a regional passing control terminal, searching for a corresponding regional passing permission according to a vehicle identifier in the passing request, searching a passing permission database for a corresponding regional passing permission according to an identifier of the regional passing control terminal in the passing request; if the regional passing permission corresponding to the vehicle identifier includes the regional passing permission corresponding to the regional passing control terminal, returning passing allowance control information back to the regional passing control terminal; if the regional passing permission corresponding to the vehicle identifier does not include the regional passing permission corresponding to the regional passing control terminal, returning passing forbidding control information back to the regional passing control terminal. According to the technical scheme, intelligent control over the vehicle passing inside a parking lot is achieved, and the personnel cost is saved while it is ensured that vehicles are parked at the corresponding region normally.

Owner:北京悦畅科技有限公司

Processing method of anti-seismic self-locking-type rolling semi-grouting sleeve and processing method of concrete component

The invention provides a processing method of an anti-seismic self-locking-type rolling semi-grouting sleeve and a processing method of a concrete component. The processing method of the anti-seismicself-locking-type rolling semi-grouting sleeve comprises the following steps that 1) a seamless steel pipe with proper wall thickness is selected, an appropriate length of the seamless steel pipe is cut to prepare the sleeve, and the sleeve comprises a non-grouting connecting section and a grouting connecting section; and internal threads are formed in the inner wall of the non-grouting connectingsection, a plurality of grooves are formed in the grouting connecting section, and a plurality of convex ribs are rolled on the inner surface of the grouting connecting section; 2) annular reinforcing ribs are installed in the grooves of the side walls of the sleeve; 3) a seamless steel pipe with proper wall thickness is selected, a proper length of the seamless steel pipe is cut to prepare a steel pipe transition section, wherein external threads are formed on one section of the pipe body of the steel pipe transition section, and the other section of the pipe body of the steel pipe transition section is a rolling depression section; and 4) a plurality of longitudinal guiding rebars, a plurality of annular fixing steel rings and inclined steel branches are welded into a self-locking steelskeleton. Each part of the grouting sleeve is processed and manufactured separately, and the quality of each part is easy to control. The connection between the grouting sleeve and the steel pipe transition section is operated by machineries, the quality of threaded connection is easy to control, and the self-locking steel skeleton is adopted to realize pulling-resistance and improve anti- seismic performance.

Owner:HEFEI CONSTR ENG GRP

Wiring device and air conditioner

ActiveCN107240784AGuaranteed dockingNot easy to looseClamped/spring connectionsEngineeringStructural engineering

The invention provides a wiring device and an air conditioner. The wiring device includes a wire connector, a wiring hole extending along a length direction of the wire connector is arranged in the wire connector, and two ends of the wiring hole are provided with locking assemblies for locking leads. When the wiring device provided by the invention is adopted to connect the leads, through locking functions of the locking assemblies, the leads can be guaranteed to be in complete butt joint and not easy to be loose, the occurrence of a phenomenon that due to poor butt joint of the lead, and light striking discharging is prevented, thereby avoiding causing fire, and reducing potential safety hazards.

Owner:GREE ELECTRIC APPLIANCES INC

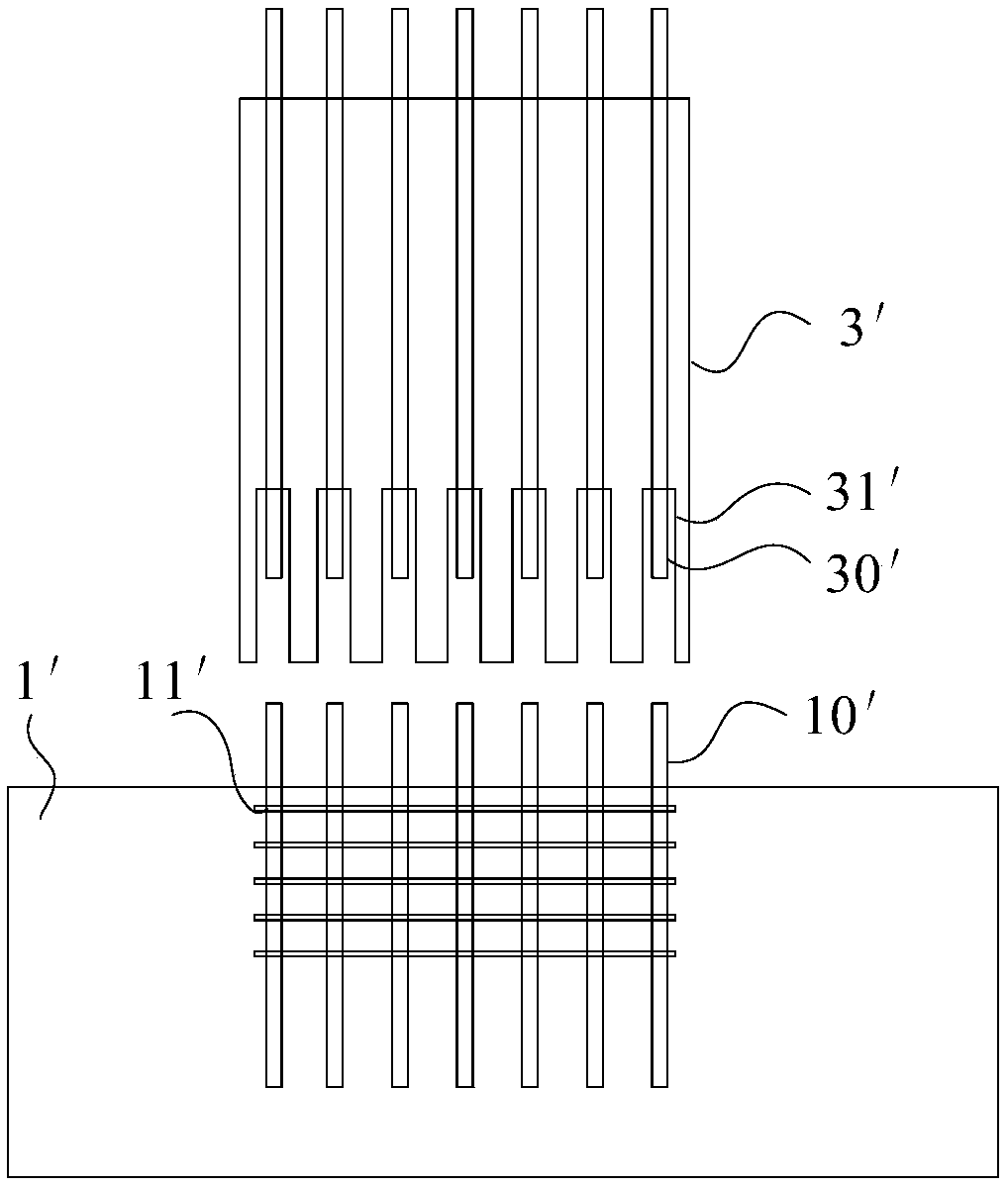

Positioning tool and positioning method for reinforcing steel bar components in bearing platform

PendingCN108867680AGuarantee plane positioning accuracyImprove plane positioning accuracyFoundation engineeringBuilding reinforcementsButt jointEngineering

The invention discloses a positioning tool and a positioning method for reinforcing steel bar components in a bearing platform. The positioning tool comprises a lower positioning device and an upper positioning device, wherein the lower positioning device is used for positioning the bottom parts of at least two reinforcing steel bars to the preset positions of a cushion layer; the upper positioning device comprises a positioning plate and multiple positioning parts; the positioning plate is provided with multiple positioning holes; the top part of each reinforcing steel bar penetrates throughthe corresponding positioning hole; support parts suspended on the top parts of the corresponding reinforcing steel bars are arranged in the areas, on which the at least three reinforcing steel bars are correspondingly arranged, on the positioning plate; each positioning part is inserted between each positioning hole and the corresponding reinforcing steel bar, so that the top part of each reinforcing steel bar is fixed to the corresponding positioning hole. The positioning method utilizes the positioning tool. According to the positioning tool and the positioning method for the reinforcing steel bar components in the bearing platform provided by the invention, the plane positioning accuracy among the multiple reinforcing steel bars in the bearing platform is improved, and the offset produced between a stand column reinforcing steel bar and the corresponding reinforcing steel bar in the bearing platform when the bearing platform and a stand column are in butt joint is greatly reduced or almost avoided, so that the stand column reinforcing steel bar and the corresponding reinforcing steel bar in the bearing platform are ensured to be in butt joint.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

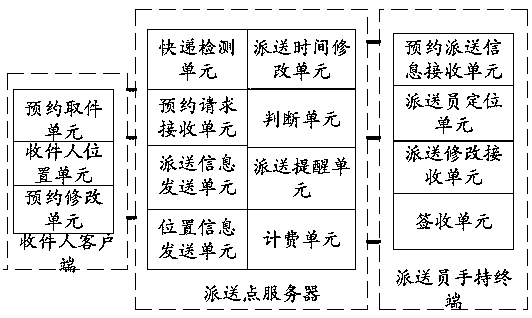

Express delivery pick-up reserving system and express delivery pick-up method

InactiveCN107748922AResolution timeGuaranteed dockingReservationsTransmissionAppointment timeHand held

An express delivery pick-up reserving system disclosed by the present invention is characterized by comprising an addressee client, a delivery station server and a deliverer hand-held terminal, wherein the addressee client is used to send the pick-up reservation time to the delivery station server, at the same time, send the positions of the addressees and check the positions of the deliverers, and submit the reservation time modification requests; the delivery station server is used to communicate with the addressee client and the deliverer hand-held terminal separately; and the deliverer hand-held terminal is used to check the delivery information, send the positions of the deliverers and receive the delivery instructions. According to the present invention, the problem that the addressees cannot sign face to face is solved, the delivery success rate can be improved effectively, at the same time, the addressees can select the proper time to pick up the express deliveries conveniently, and the express delivery safety is guaranteed.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

Satellite docking structure, docking satellites and docking method

ActiveCN108100312AMeet the requirements of small loadGuaranteed dockingCosmonautic vehiclesCosmonautic component separationFlangeMagnet

Owner:星际漫步(北京)航天科技有限公司

Leak hunting device and leak hunting method

PendingCN112284642AEvenly distributedGuaranteed accuracyMeasurement of fluid loss/gain rateVacuum pumpingEngineering

The invention discloses a leak hunting device and a leak hunting method, wherein the leak hunting device comprises a suction head, a leak hunting instrument connected with the suction head and a leaktest gas inflation mechanism, the leak test gas inflation mechanism comprises gas inflation heads, a gas source and a gas supply pipeline connected with the gas inflation heads and the gas source, andthe gas supply pipeline comprises gas inflation branches and a mixing branch which are connected in parallel. The mixing branch comprises a circulating pump, and valve bodies are arranged at the connecting points of the inflation branches and the mixing branch respectively. According to the leak hunting device, the first inflation branch, the second inflation branch and the mixing branch are arranged to be connected with the inflation heads and the gas source, inflation can be stopped after inflation is conducted for a period of time, gas mixing in a cavity is achieved through the mixing branch with a circulating pump, and thus inflated helium can be evenly distributed, and the helium leak hunting precision can be ensured favourably on the basis of no vacuum pumping.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

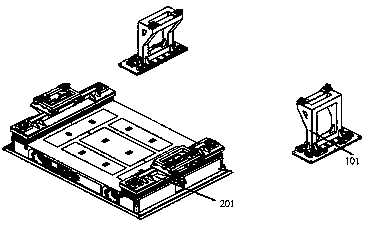

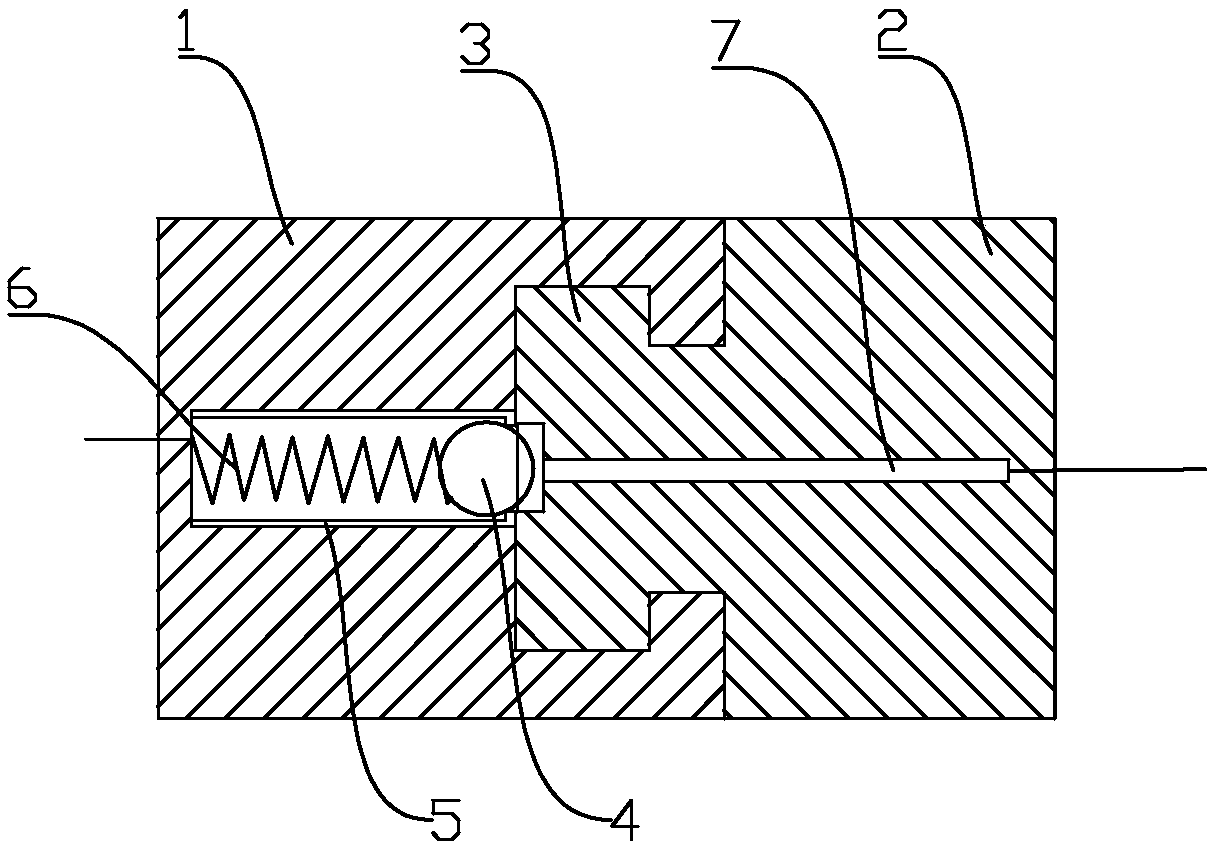

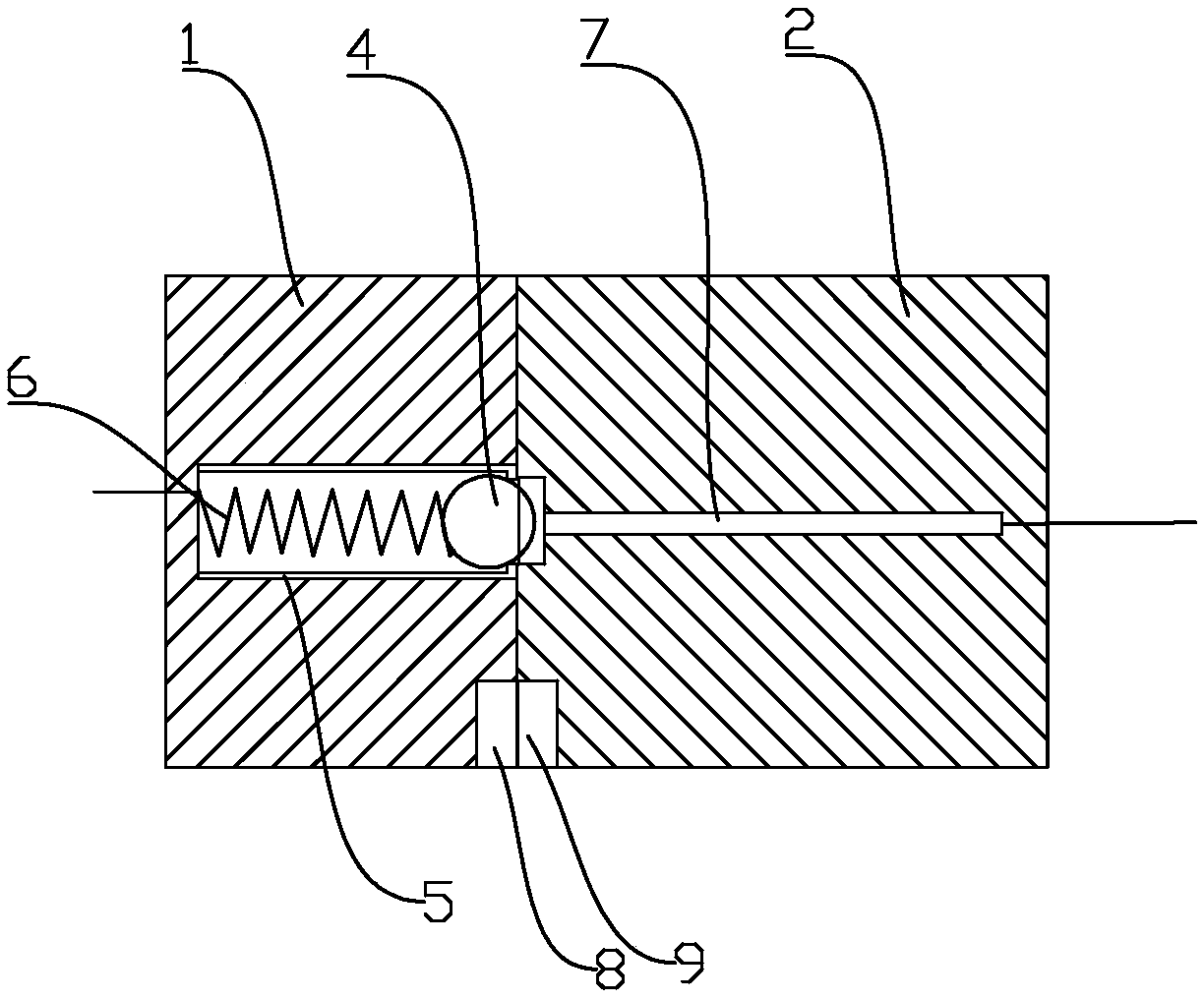

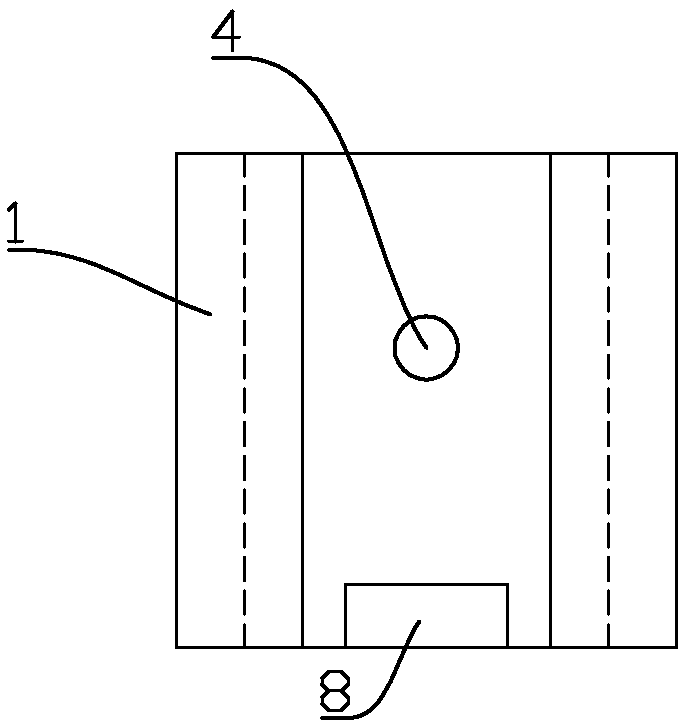

Float type butting structure

PendingCN110834914ALow positioning accuracy requirementsAchieve soft deliveryVehiclesMechanical conveyorsButt jointProduction unit

The present invention provides a float type butting structure, and belongs to the field of transportation equipment of production lines or integrated production units. The float type butting structurecomprises a symmetrical flexible butting structure, wherein the flexible butting structure comprises a fixed frame and a floating frame, the fixing frame is fixedly connected with an AGV, the floating frame is arranged on the upper end face of the fixing frame and is arranged relative to the fixing frame in a floating mode, an X-direction spring for limiting the X-axis of the floating frame is arranged between the fixing frame and the floating frame, an Y-direction spring for limiting the Y-axis of the floating frame is arranged, and the upper end of the floating frame is provided with a positioning pin module for positioning goods and a guiding pin module for guiding the goods. According to the float type butting structure, flexible taking and conveying of products can be realized, and meanwhile accurate positioning of the products after the products reach stations can be realized, and automatic butt joint requirements are met.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Reinforcement butt welding machine for construction

ActiveCN110576285AGuaranteed dockingAvoid bendingWelding/cutting auxillary devicesAuxillary welding devicesButt weldingButt joint

The invention discloses a reinforcement butt welding machine for construction. The machine comprises an equipment frame; wheels are arranged at the bottom of the equipment frame; a front fixator and aback fixator are arranged on the top surface of the equipment frame; an upper welding gun and a lower welding gun are arranged between the front fixator and the back fixator, and are symmetrically arranged; the lower welding gun is fixed on the top surface of the equipment frame; the upper welding gun is fixed at the bottom of a top frame; the two sides of the top frame are fixed on the top surfaces of the front fixator and the back fixator through vertical rods; and a movable fixator is arranged between the front fixator and the back fixator. When the machine performs the positioning work, one reinforcement is firstly fixed through the front fixator, then, the other reinforcement is inserted in a ring groove in the movable fixator; a lifting rod is descended; after the reinforcements arefixed through a lifting slide block, the movable fixator moves to guarantee butt joint of the two reinforcements; and then, the reinforcements are fixed through the back fixator for welding, so thatthe adjustment is precise, and the reinforcements in butt joint are prevented from bending.

Owner:湖北富华建筑安装有限公司

Hydraulically driven high counter force buffer

InactiveCN1673032AAvoid frictionSimple structureVessel cleaningHullsKinetic energyMarine engineering

The hydraulically driven high counter force buffer as one buffer for reducing the collision between ship and trestle bridge is used for buffering the collision between train ferry and dock. The technological scheme is that the hydraulically driven high counter force buffer consists of collision preventing boards, rubber ship fender, rack, hydraulic cylinder, and cylinder support. The present invention features the drum-shaped rubber ship fender with maximum counter force of 570-615 KN and connected to the collision preventing board and the rack, the rack with sliding track fixed to the deck and forked hinged seat hinged to the piston rod in hydraulic cylinder, the hydraulic cylinder hinged to the cylinder support, and the cylinder support connected to the deck. The present invention is suitable for train ferry.

Owner:中国船舶工业第七〇八研究所

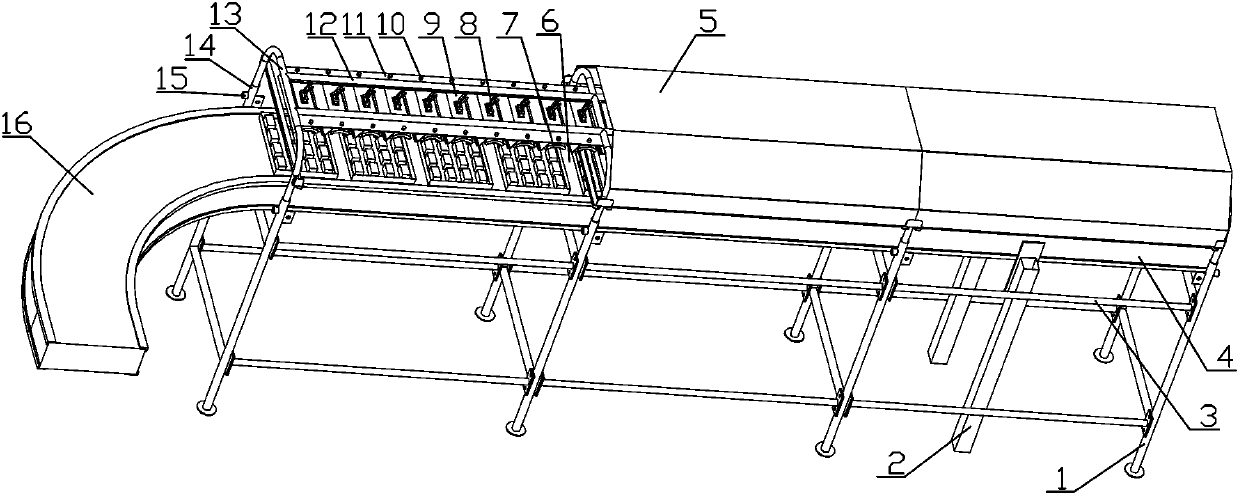

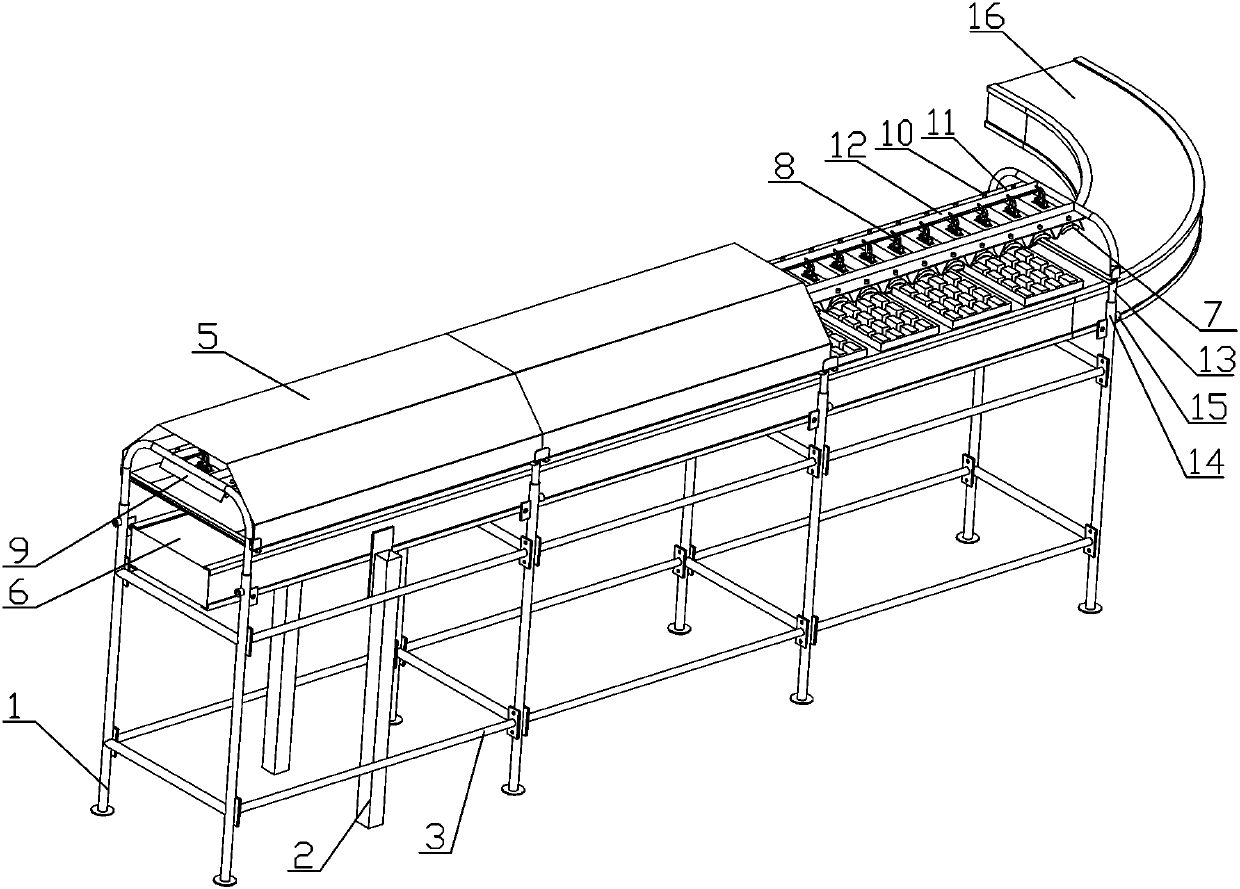

Bio-fertilizer drying transmission production line

InactiveCN109851406ANormal fermentation processReduce investmentClimate change adaptationOrganic fertiliser preparationProduction lineHorizontal transmission

The invention provides a bio-fertilizer drying transmission production line. The bio-fertilizer drying transmission production line comprises a plurality of groups of supporting vertical columns; a plurality of horizontal reinforcing rods of different heights are fixedly arranged among the supporting vertical columns; the tops of the supporting vertical columns are provided with a horizontal transmission rack; the horizontal transmission rack is provided with a horizontal conveyer belt; the top end of each group supporting vertical column is provided with a U-shaped rod through a height adjusting mechanism; the plurality of groups of U-shaped rods are fixedly connected through a top transverse rod; the bottom of the top transverse rod is fixedly provided with connecting plates through screws; a plurality of groups of heating devices are arranged among the connecting plates at equal intervals; the tops of the U-shaped rods are provided with a thermal insulation hood. The bio-fertilizerdrying transmission production line is capable of realizing bio-fertilizer transmission, drying and sterilizing bio-fertilizer in transmission process, reducing equipment investment cost, improving function structure, and increasing production efficiency.

Owner:湖北庄康生物科技股份有限公司

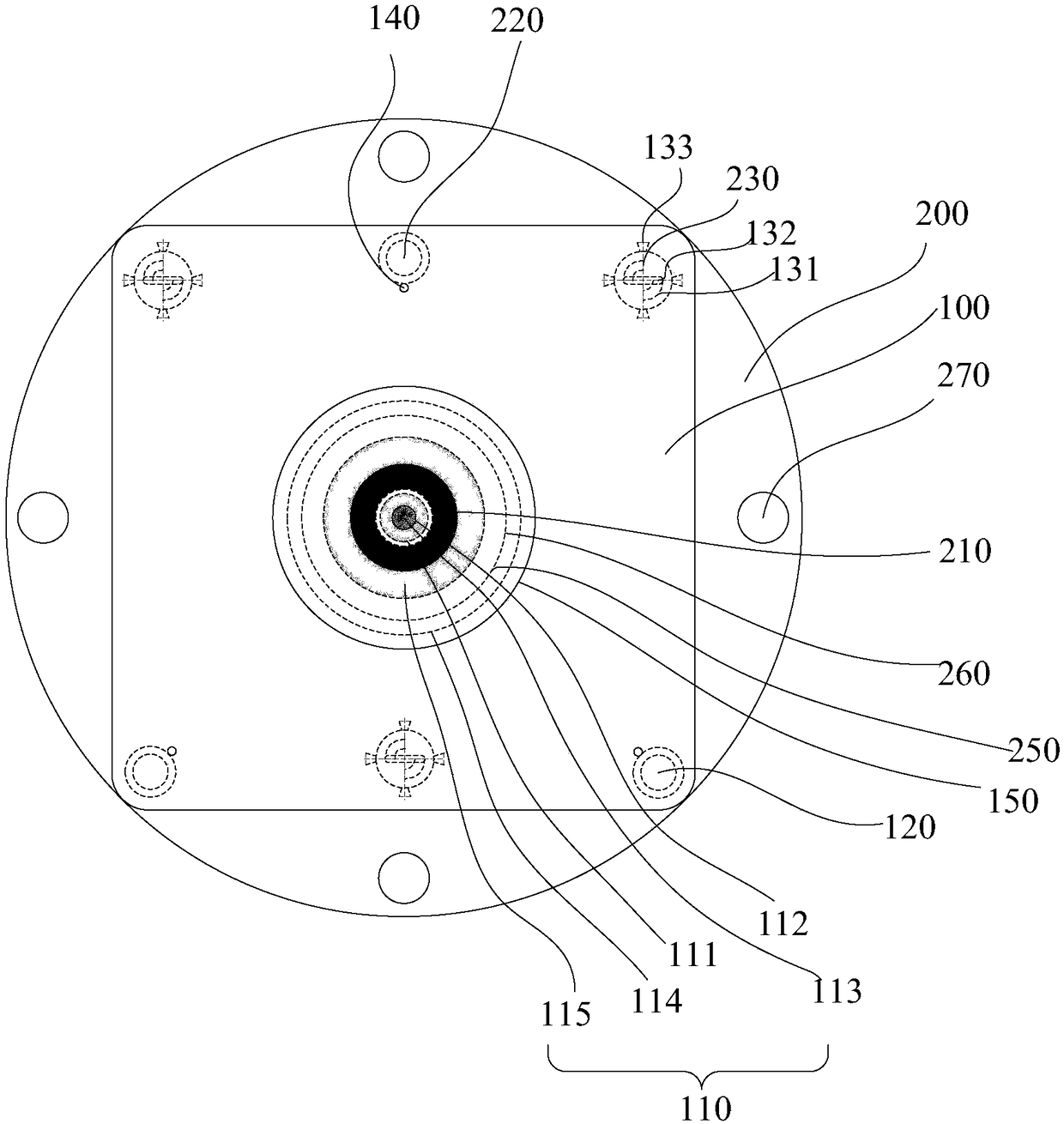

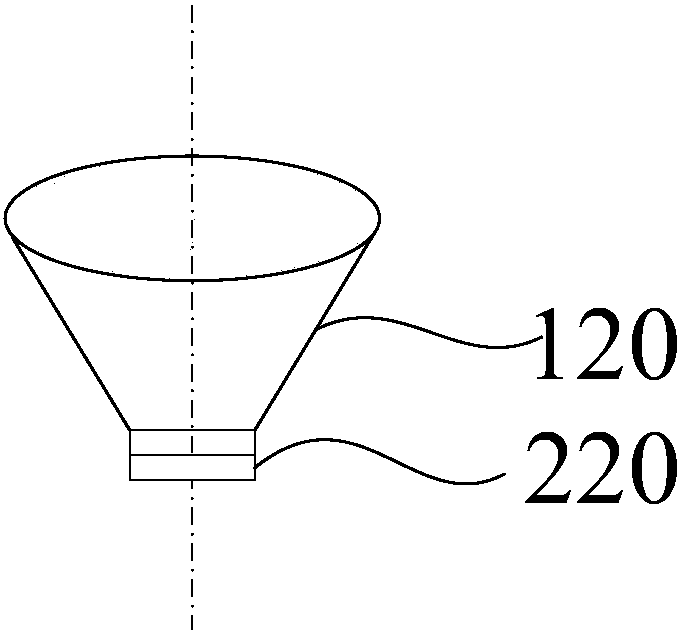

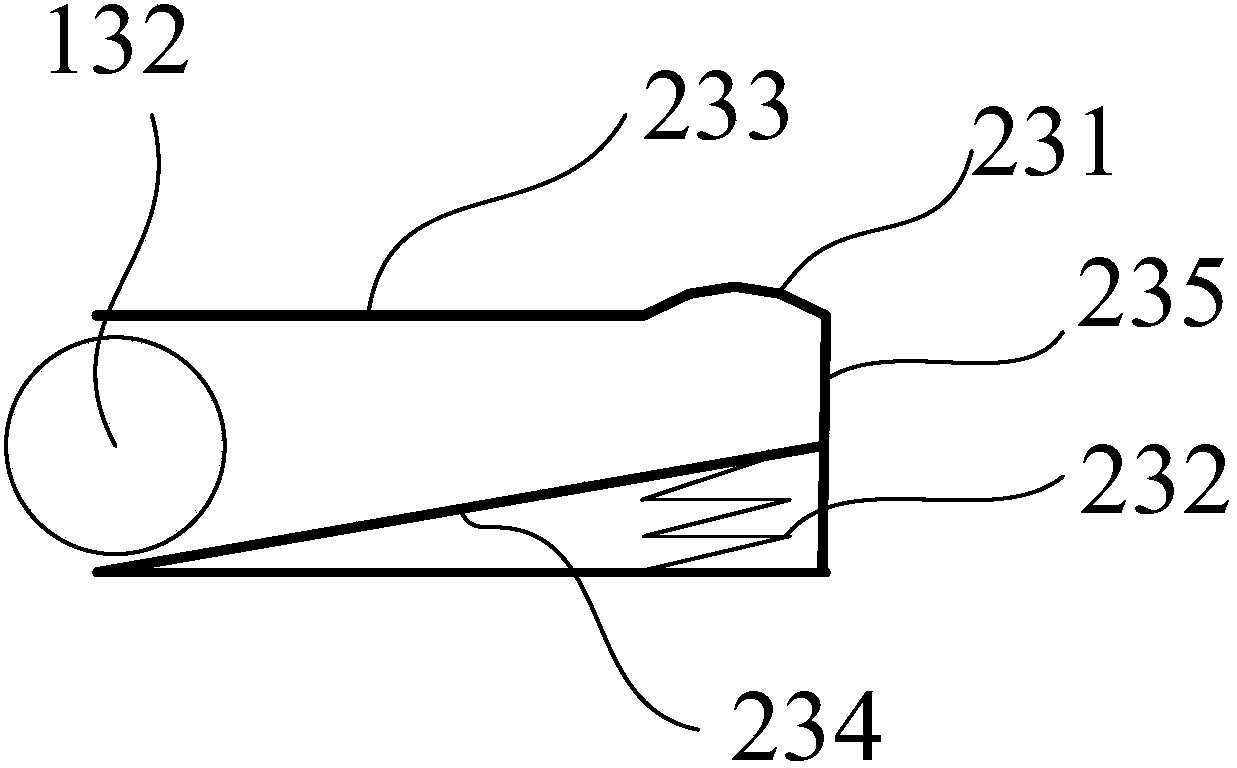

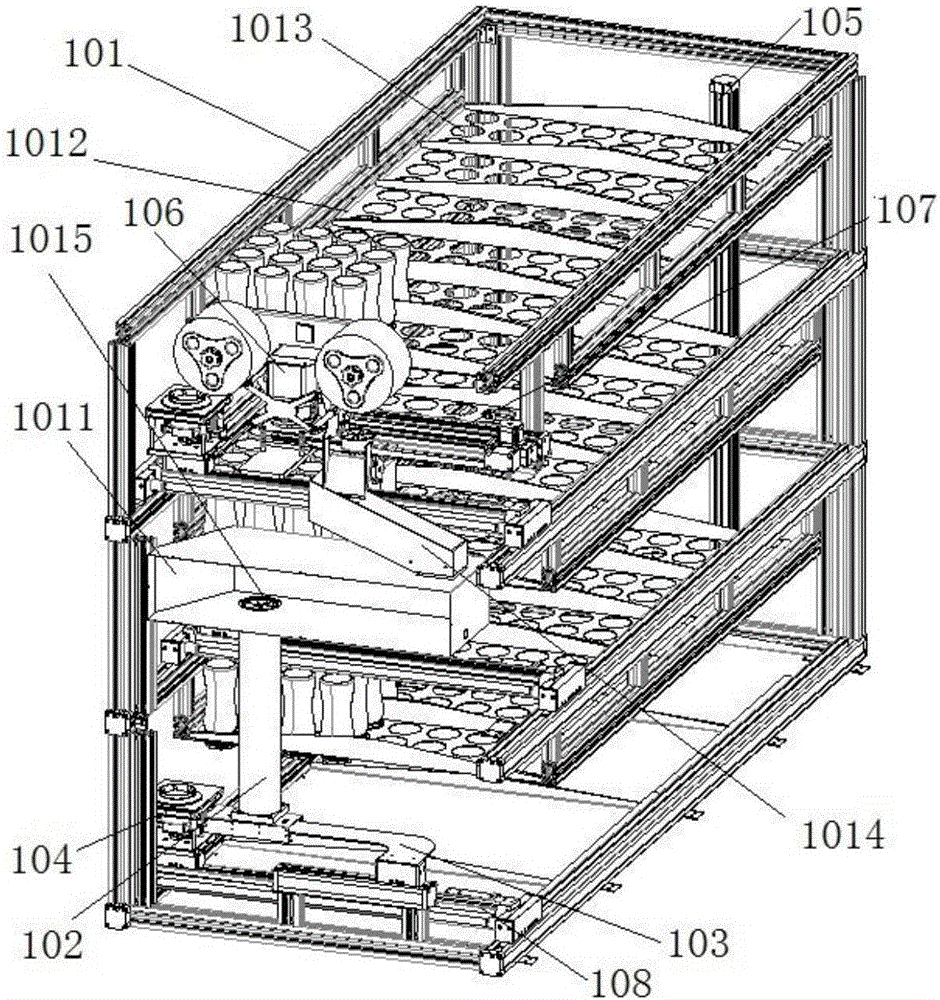

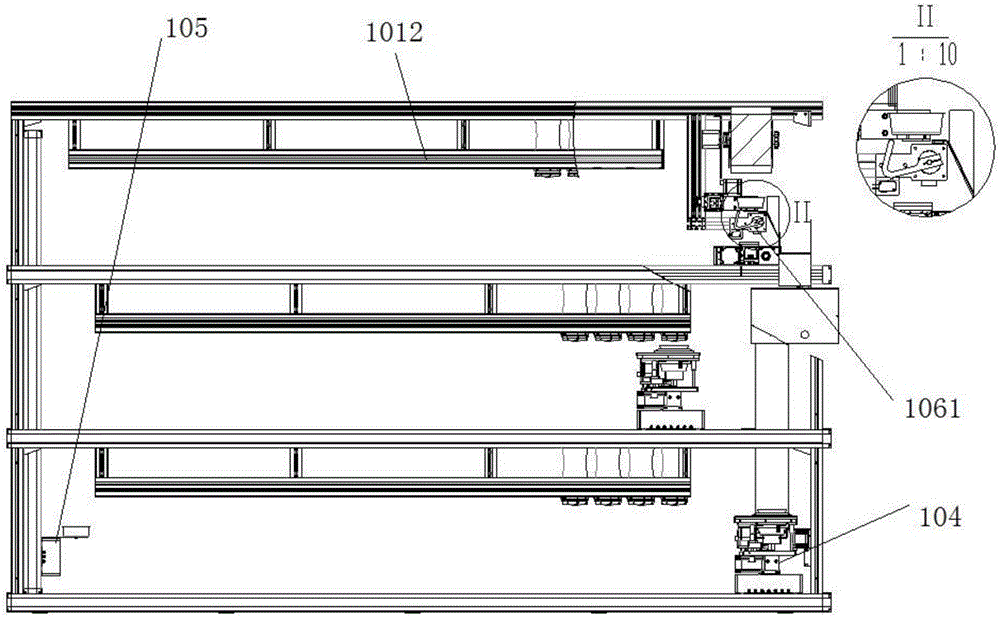

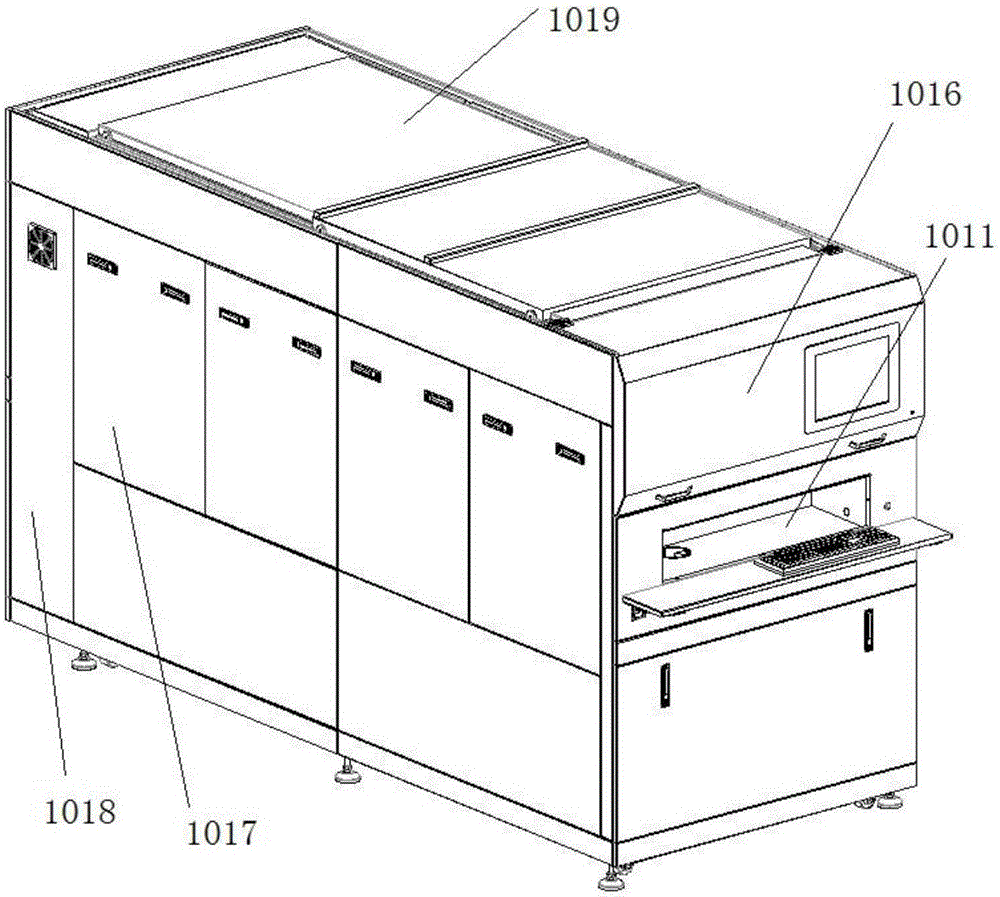

Multi-layer medicine dispensing machine

ActiveCN106697342AGuaranteed dockingGuaranteed disengagementSolid materialOperation roomBiomedical engineering

The invention discloses a multi-layer medicine dispensing machine. The multi-layer medicine dispensing machine comprises a machine frame body; a plurality of medicine bottle placing shelves are arranged in the machine frame body; a plurality of medicine bottle placing openings are formed in each medicine bottle placing shelf; a medicine dispensing mechanism is arranged below each medicine bottle placing shelf and is arranged on a left-right movement module, and the left-right movement module can do reciprocating rectilinear motion on installed machine frame guide rails; a front-back movement module is arranged between the medicine dispensing mechanism and the left-right movement module; the medicine dispensing mechanisms can run to any position of the plane where the medicine dispensing mechanism is located through the front-back movement module and the left-and-right movement module so as to carry out medicine dispensing; a picking and placing operation room is arranged on one side of the machine frame body; a medicine box placing inlet is formed in the position of the picking and placing operation room and is connected to a medicine box storage device; and a medicine box pushing mechanism is arranged at the bottom of the medicine box storage device. The multi-layer medicine dispensing machine has the advantages that the structure is ingenious, and multi-layer independent and synchronous medicine dispensing can be realized.

Owner:CHENGDU YH INTELLIGENT EQUIP TECH CO LTD

A splicing assembly and a lamp

PendingCN109193208ASimplified Arrangement SetupGuaranteed dockingEngagement/disengagement of coupling partsLighting support devicesElectric wire

The invention discloses a splicing assembly and a lamp. The lamp is applied with the splicing assembly. The splicing assembly specifically comprises a male connector, one end of which is provided witha slot, and one side wall of the slot is provided with an opening to form a T-shaped channel. The female connector has a fastening portion adapted to the slot and can be mounted on the male connectorby pushing the fastening portion into the slot from the end of the slot. Thus, two adjacent lamps which need to be stitched together can be securely stitched together through a male connector and a female connector; When the lamps are spliced together, the electric circuit is serially connected by the press-in type electric connector and the electric connector, and the power supply wires are onlyarranged at two ends of the spliced lamps, and the lamps located in the middle do not need to be separately arranged with the power supply wires, thus simplifying the arrangement of the electric wires, reducing the production cost, and having strong practicability.

Owner:范丰源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com