Cylindrical cabin docking assembly

A docking device, cylindrical technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of low degree of automation, large manual labor force, and inability to control multi-cabin docking at the same time, achieving high degree of automation and short adjustment time , The effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

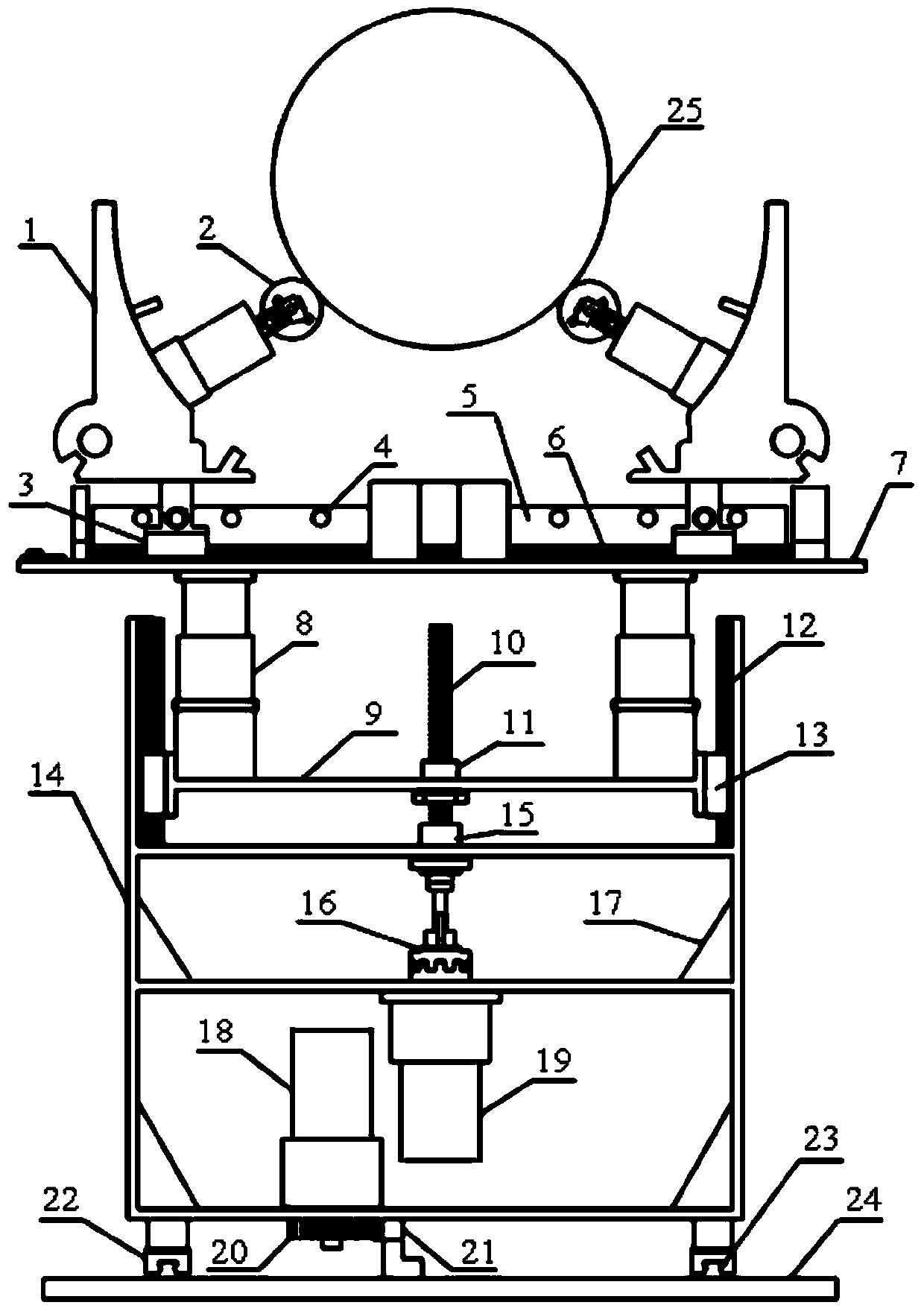

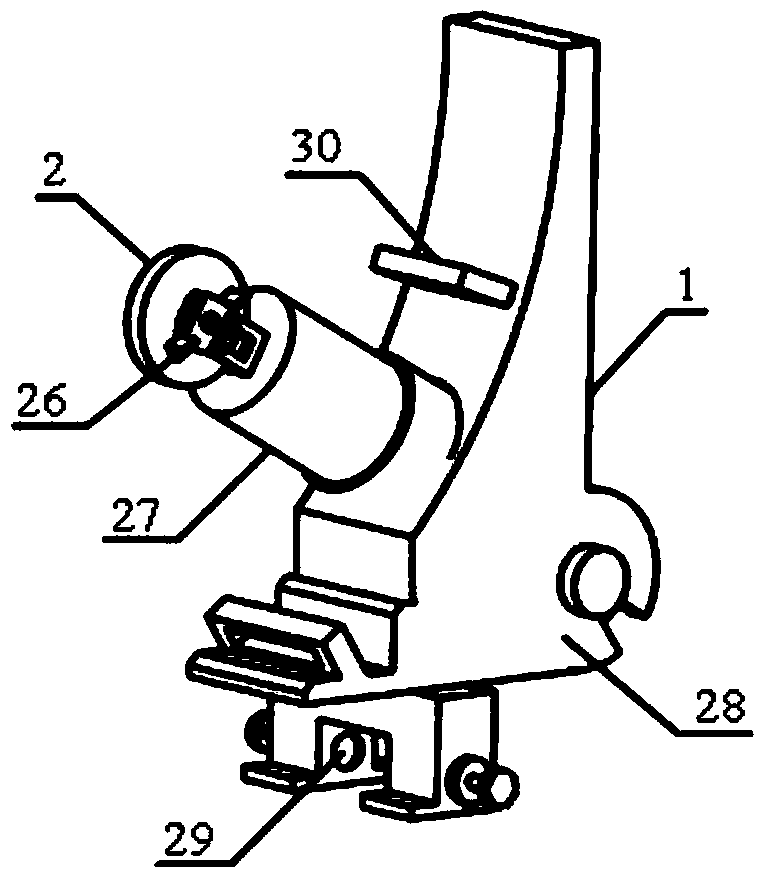

[0016] see figure 1 , The docking device of the cylindrical cabin section of the present invention is composed of an opening and closing movement mechanism, a lifting mechanism, a horizontal movement mechanism, a frame and a computer. The frame has a U-shaped structure, and two horizontal plates are arranged in the frame to divide the U-shaped space of the frame into three spaces: the bottom, the middle and the upper part. The horizontal movement motor 18 is installed on the bottom plate of the bottom space, and the lifting motor is installed vertically on the upper plate. 19. Thrust bearing 15 and shaft coupling 16 are equipped with on the upper plate of middle space, and shaft coupling 16 is installed on the shaft of lifting motor 19 and links to each other with thrust bearing 15, and described lifting mechanism is arranged in the upper space, is controlled by lifting mechanism. It consists of a vertical support column 8, a lifting support plane 9, a lifting slider 13, a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com