Reinforcement butt welding machine for construction

A technology for building construction and butt welding machines. It is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc. It can solve the problems of low applicability, contact error, and inability to ensure the bonding of welding surfaces, etc., and achieve precise adjustment and avoid bending. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

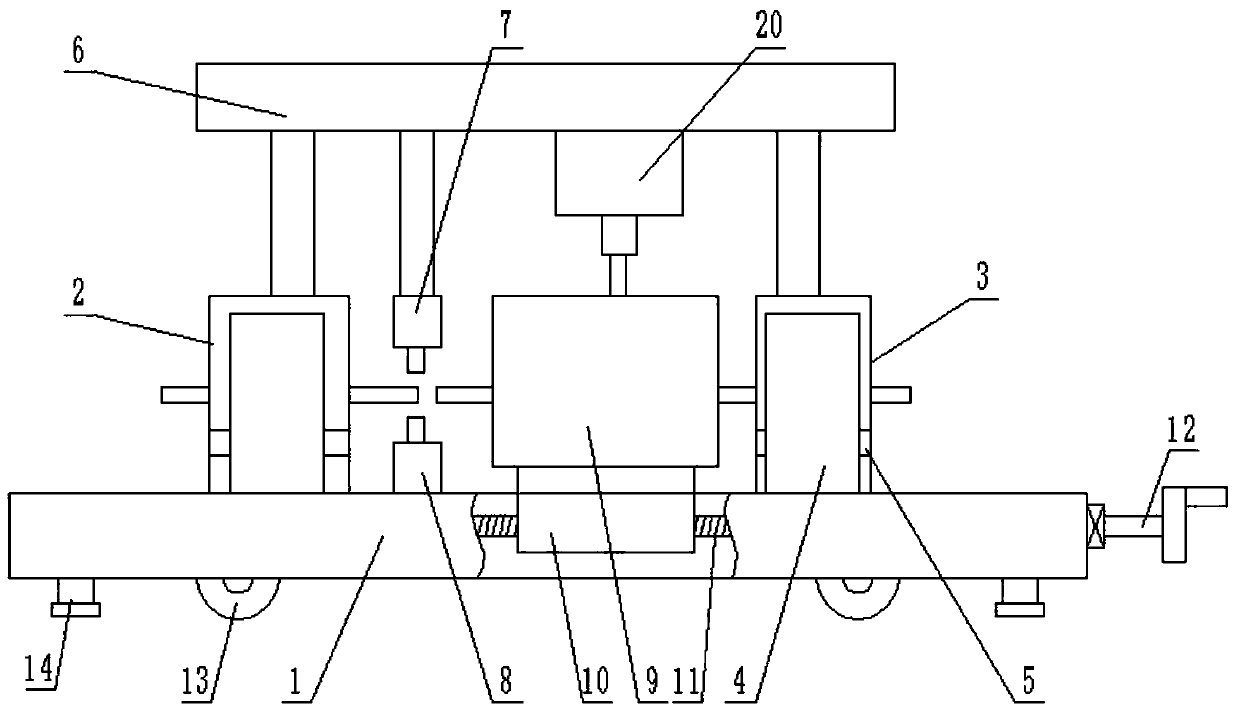

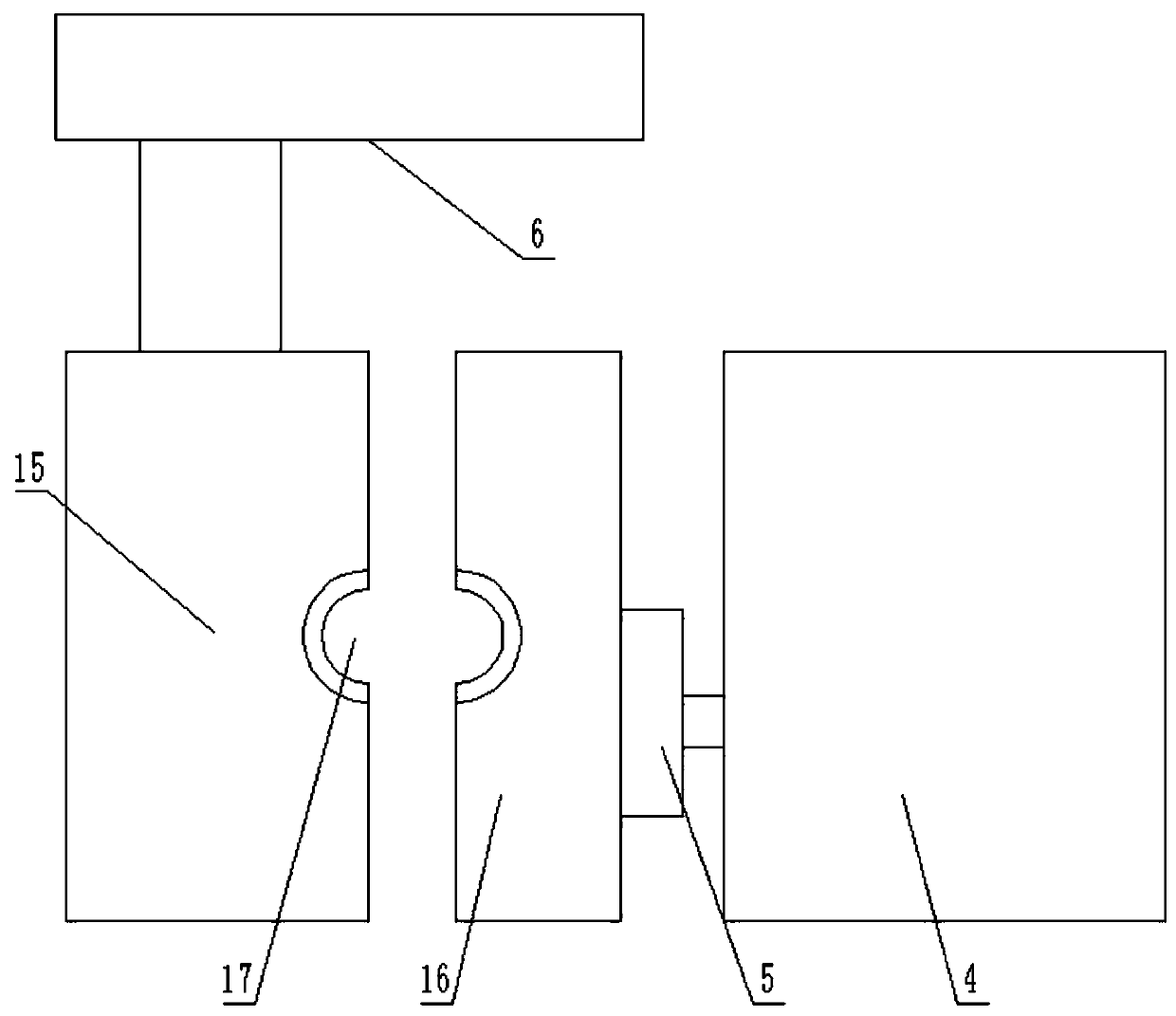

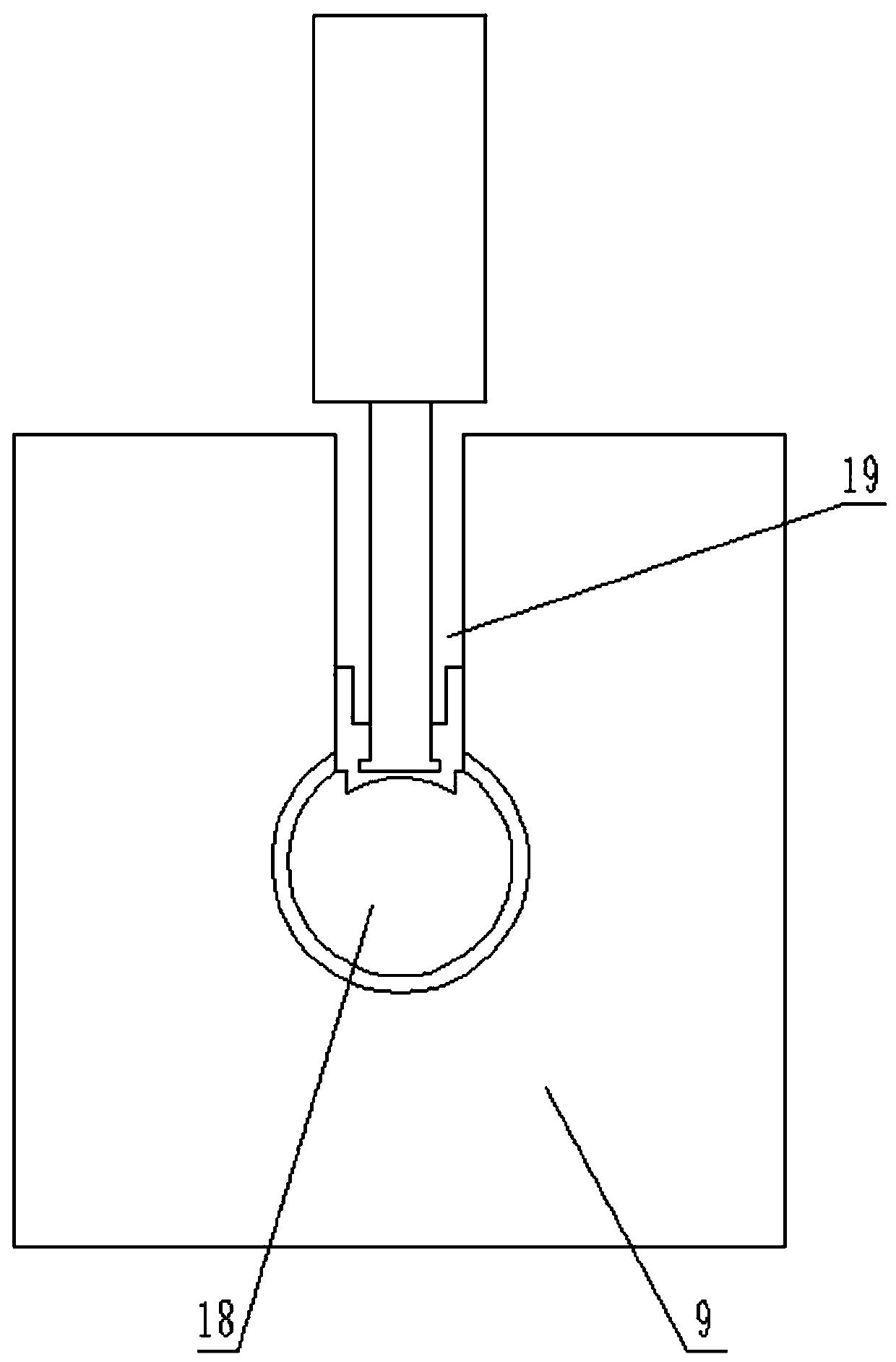

[0020] see Figure 1-4 , a steel bar butt welding machine for building construction, comprising an equipment frame 1, a wheel 13 is provided at the bottom of the equipment frame 1, a front fixer 2 and a rear fixer 3 are arranged on the top surface of the equipment frame 1, and the front fixer 2 and the rear fixer Device 3 is respectively used for fixing two steel bars to be welded, and is convenient to carry out welding work, is provided with upper welding gun 7 and lower welding gun 8 between front fixer 2 and rear fixer 3, upper welding gun 7 and lower welding gun 8 are arranged symmetrically, the lower welding gun 8 is fixed on the top surface of the equipment frame 1, the upper welding gun 7 is fixed on the bottom of the top frame 6, and the two sides of the top frame 6 are fixed on the top surfaces of the front holder 2 and the rear holder 3 through vertical rods Above, a movable fixer 9 is provided between the front fixer 2 and the rear fixer 3, and the movable fixer 9 i...

Embodiment 2

[0024] On the basis of Embodiment 1, in order to facilitate the mobile operation, the bottom of the equipment rack 1 is provided with a plurality of jacking screws 14, and the jacking screw rods 14 are threadedly connected with the equipment rack 1. When the equipment rack 1 is moved as a whole, The jacking screw 14 is rotated up, and after positioning, the jacking screw 14 is rotated down so that the bottom of the jacking screw 14 is grounded and the wheels 13 are separated from the ground, which is convenient for welding work at the construction site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com