Hydraulically driven high counter force buffer

A buffer device and high-reflection technology, applied in ship cleaning devices, transportation and packaging, ships, etc., can solve the problems of not hindering the docking of rails, the large size of the buffer device, and rework, saving investment costs, simple structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

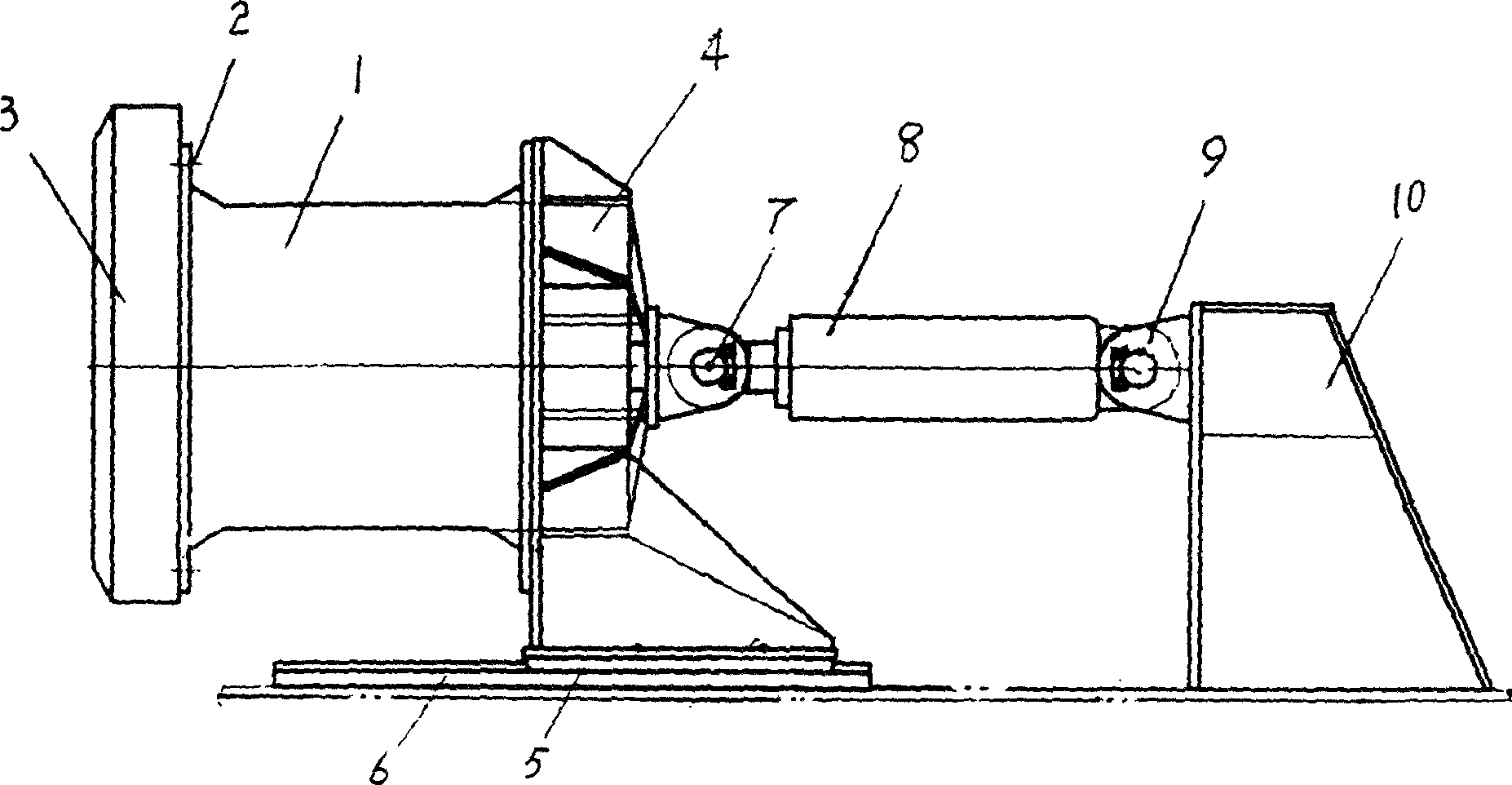

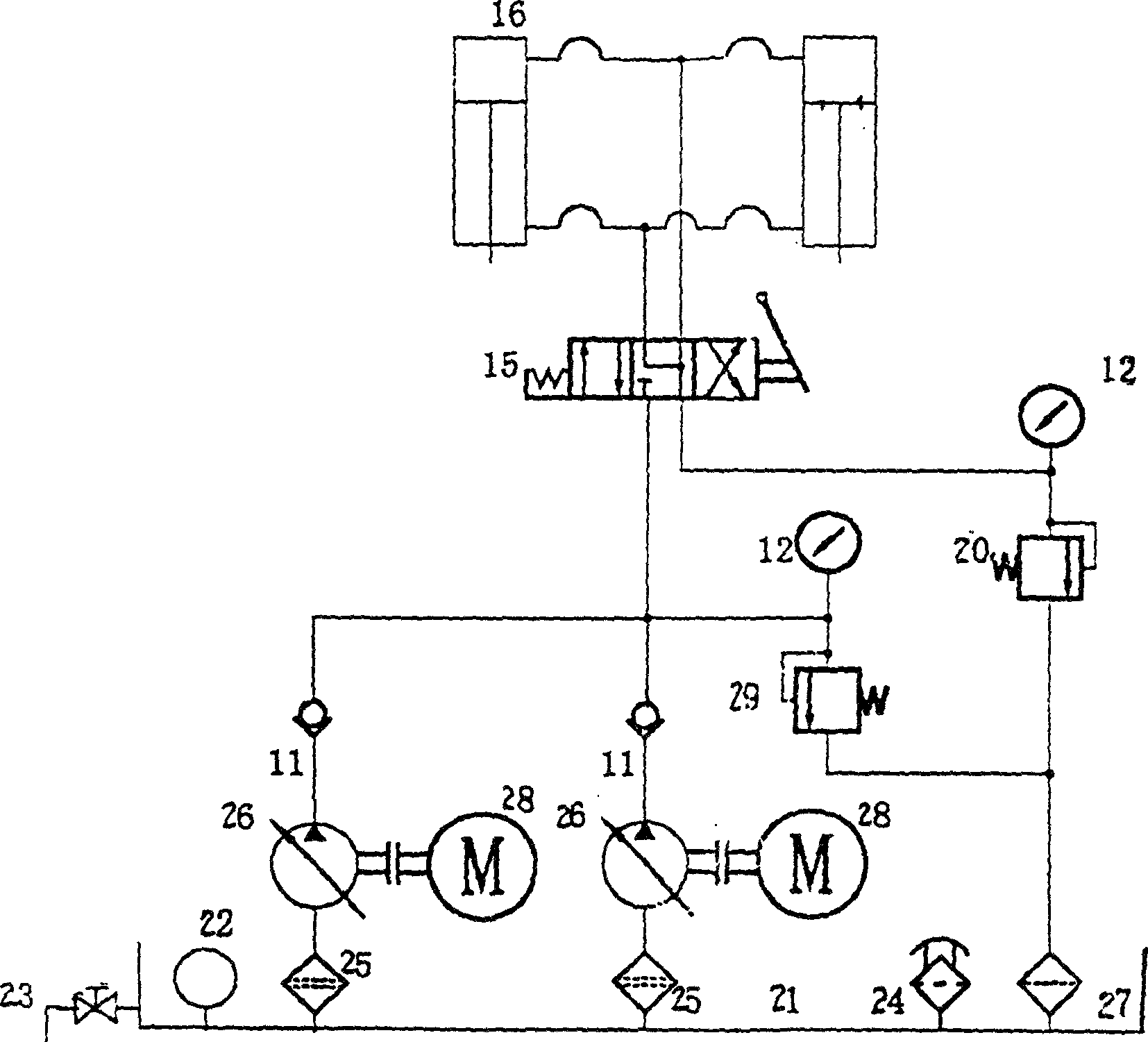

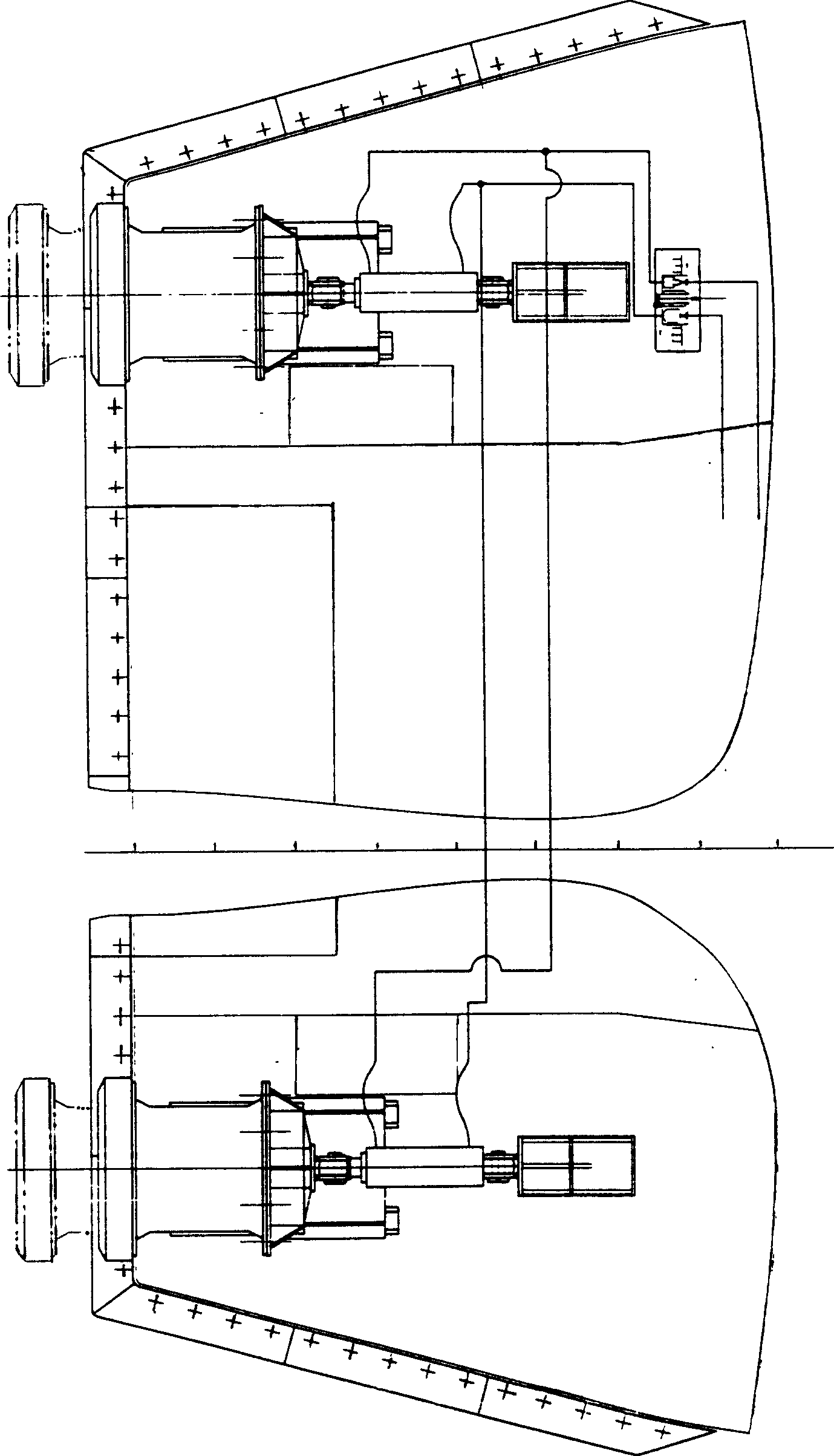

[0010] See figure 1 , the technical scheme of the present invention is composed of anti-collision plate, rubber fender, bracket, hydraulic cylinder, and oil cylinder support; rubber fender 1 adopts a high-reaction drum-shaped rubber fender with a maximum reaction force of 570KN~615KN, and the rubber fender The installation diameter of 1 is Φ1300mm and the length is 1000mm; the periphery of the front end of rubber fender 1 is connected with the anti-collision plate 3 by bolts 2, the thickness of anti-collision plate 3 is 250mm, and the periphery of the rear end of rubber fender 1 is fixed on the front surface of bracket 4 by bolts ;The rear side of the buffer device bracket 4 is provided with left and right brackets, and the left and right brackets are set at a distance of 826 mm. Two dovetail-shaped longitudinal parallel chute 5 is connected under the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com