Positioning tool and positioning method for reinforcing steel bar components in bearing platform

A technology for positioning tooling and internal steel bars, which is applied in building components, building reinforcements, infrastructure engineering and other directions, and can solve the problems of offset and inability to connect the steel bars of the columns and the corresponding reserved steel bars, so as to ensure the connection of steel bars and improve the Plane positioning accuracy, the effect of reducing the offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

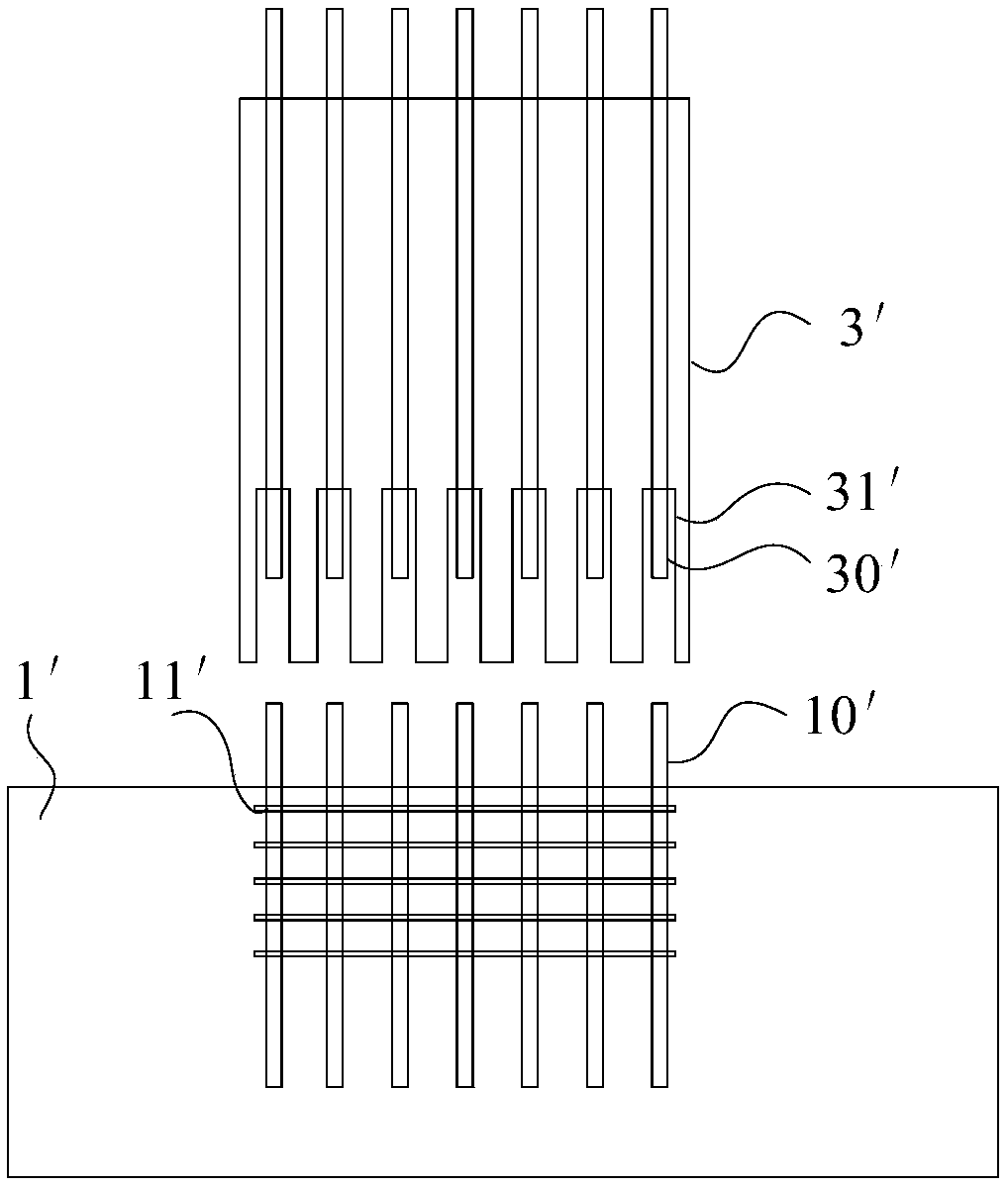

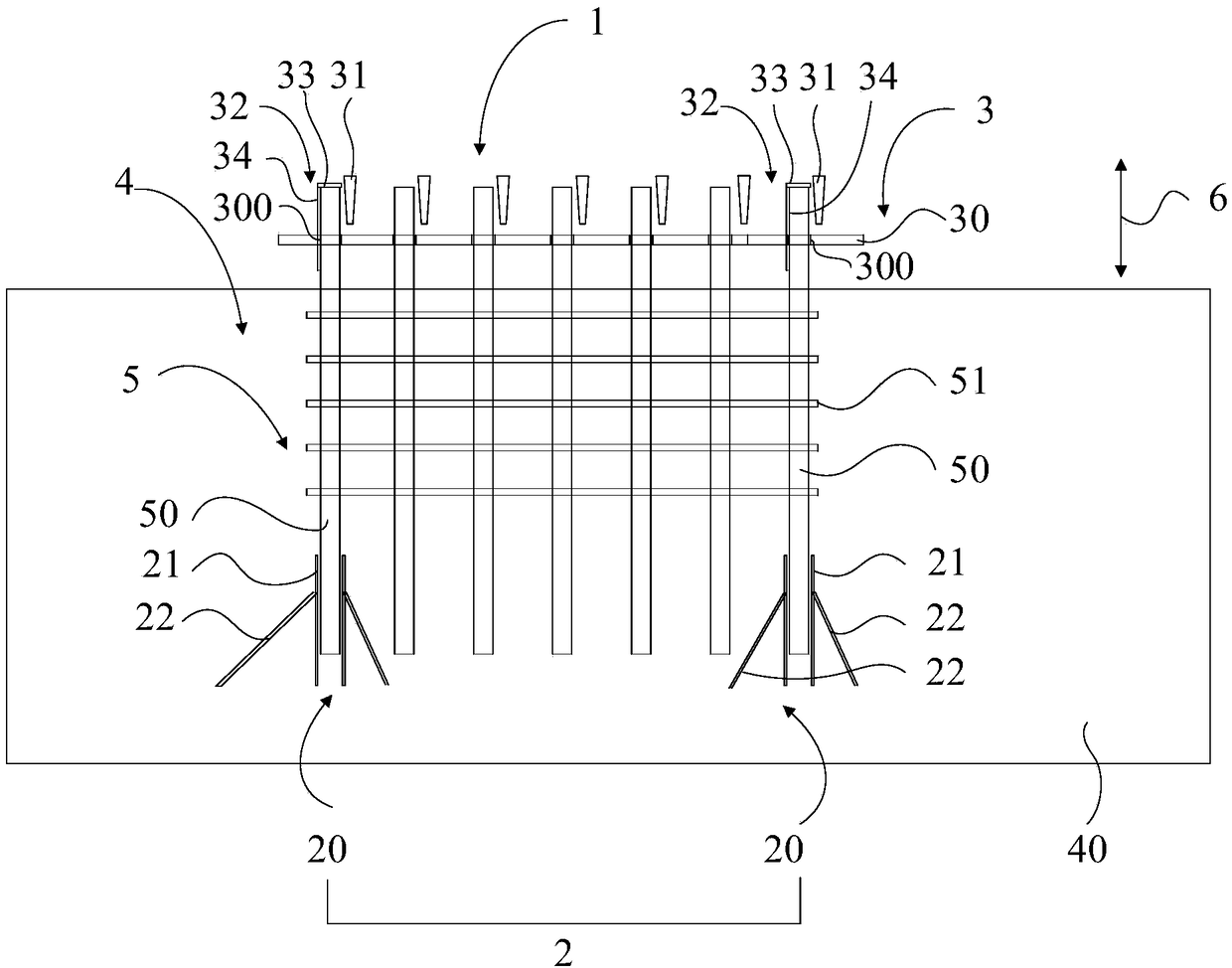

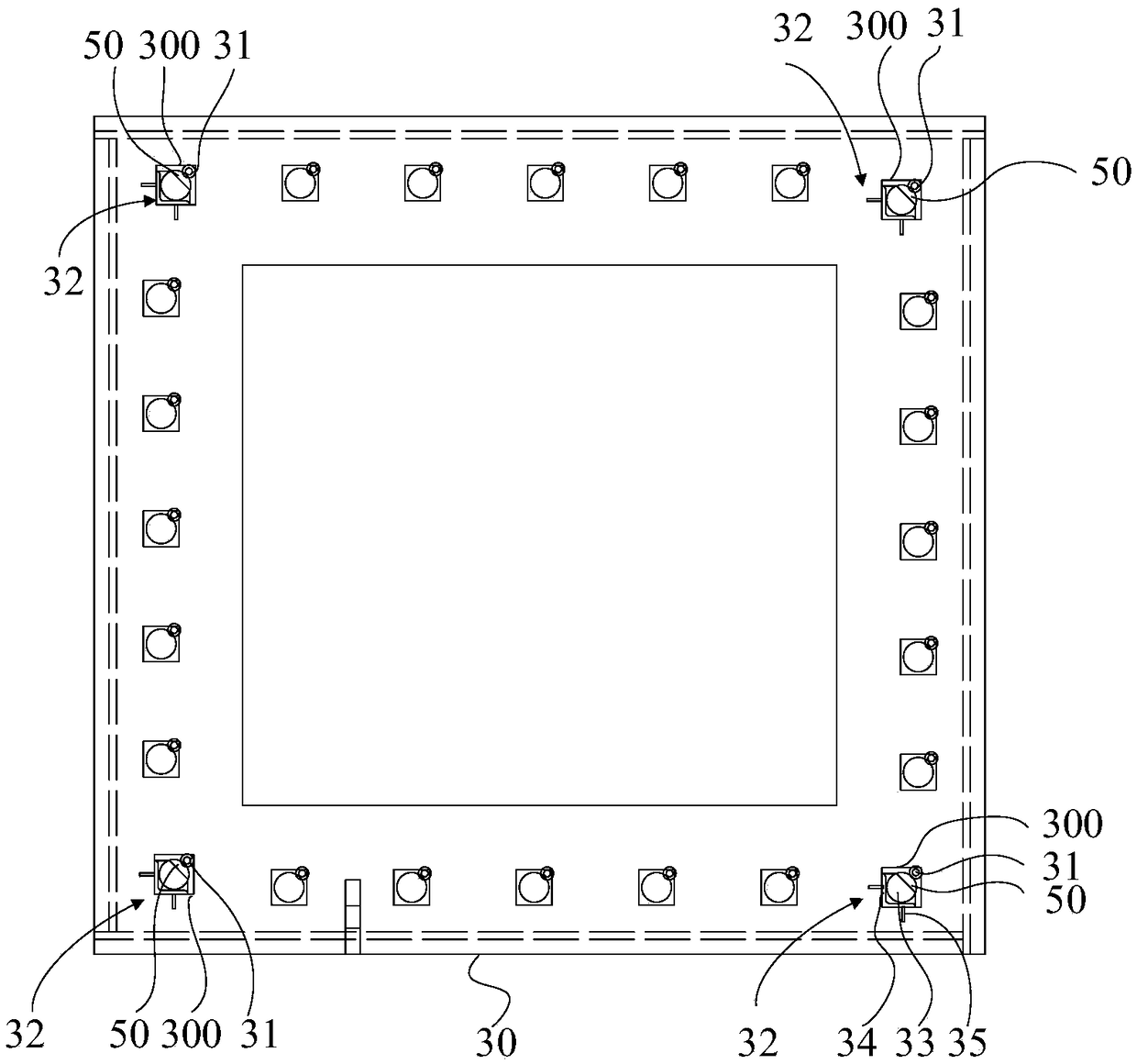

[0077] Figure 2-3 According to an embodiment of the present invention, a schematic diagram of a use state of a positioning tool for a steel bar assembly in a platform is shown. Such as Figure 2-3 As shown, the platform 4 has a cushion 40 . The steel bar assembly 5 includes a plurality of steel bars 50 and a bar support 51 . A plurality of steel bars 50 are connected to the steel bar bracket 51 to form an integral structure. Its rigidity is relatively large. A plurality of steel bars 50 are arranged at intervals and parallel to each other.

[0078] The positioning tool 1 includes a lower positioning device 2 and an upper positioning device 3 . The lower positioning device 2 is used to locate the bottoms of at least two steel bars 50 in the preset position of the cushion layer 40, so as to limit the height direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com