Container door end assembling station

A container and assembly platform technology, applied in the direction of assembly machines, positioning devices, clamping, etc., can solve the problems of low assembly efficiency, complicated operation, and low efficiency, so as to improve the positioning accuracy of the plane, simplify the operation steps of workers, and ensure the flatness quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

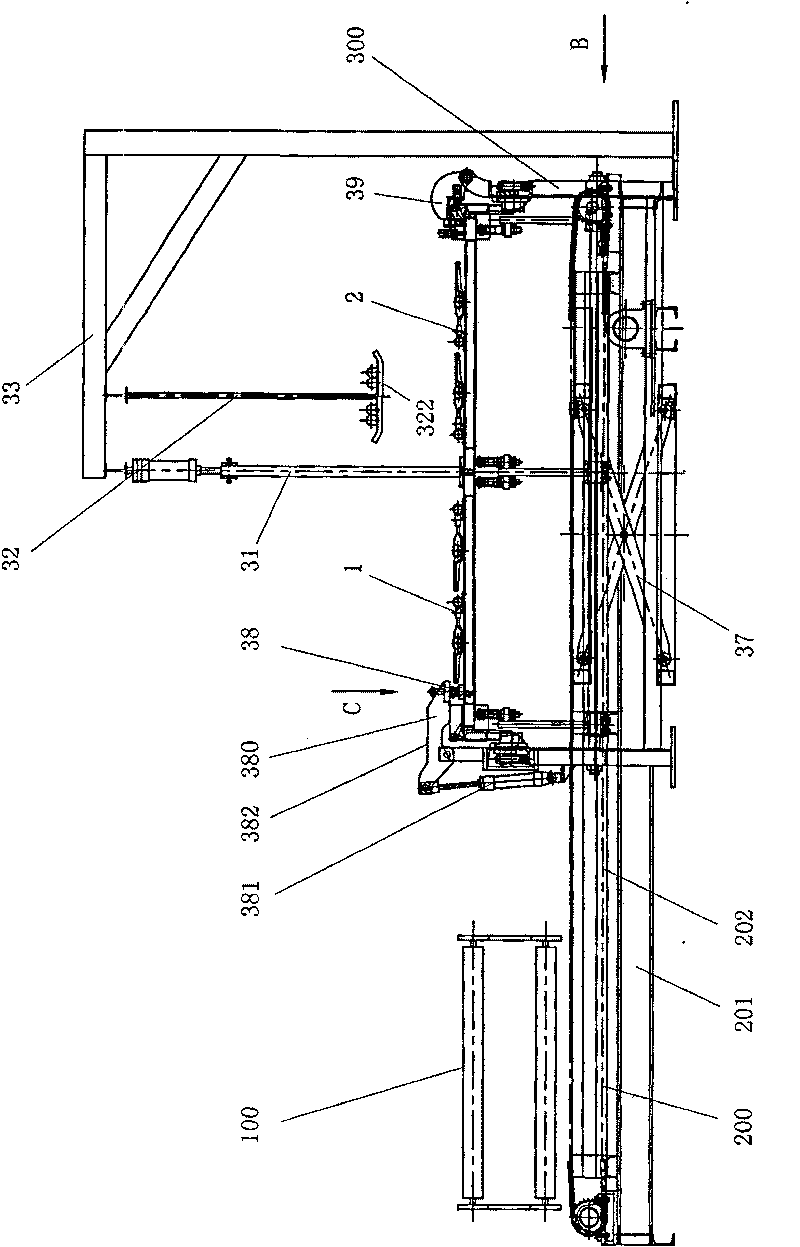

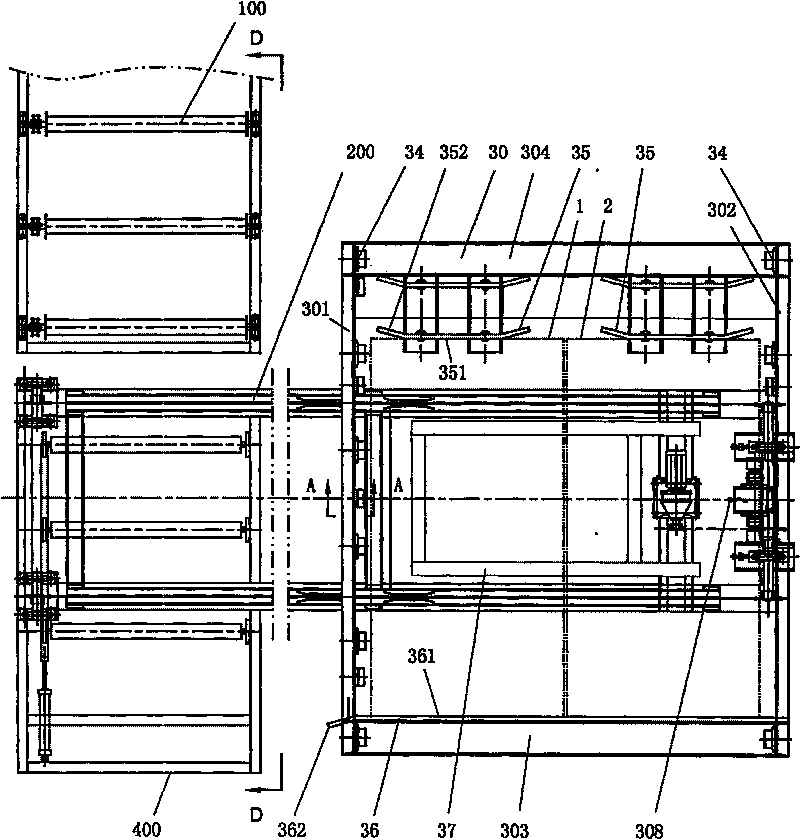

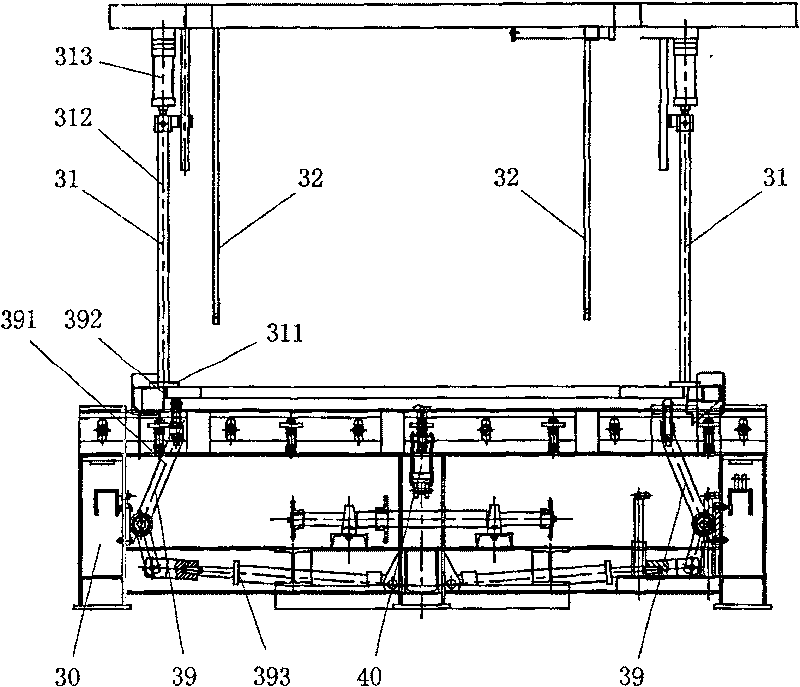

[0034] like figure 1 , figure 2 , image 3As shown, the container door end assembly platform of the present invention includes a rectangular base frame 30, a door frame presser foot device 380, a door frame conveying wheel set 34, a door panel lifting platform 37, door panel lower pressing devices 39 and 40, a door panel pressing device 31 and a cantilever bracket33. The door frame presser foot device 380 is installed on the base frame 30 adjacent to the assembled container door frame corner, and the door frame delivery wheel set 34 is respectively installed on the inner side upper end of the left side structure part 301 of the base frame 30 along the direction of the door end of the base frame 30. The inner upper end of the right structural member 302 is horizontally arranged at intervals, the door panel lifting platform 37 is installed at the bottom inside the base frame 30, and the door panel lower tightening devices 39 and 40 correspond to the four corners of the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com