A split ultra-precision aerostatic single-axis turntable

An air static pressure, single-axis turntable technology, applied in the field of ultra-precision transmission, can solve the problems of lower installation accuracy requirements and complex assembly and adjustment processes, and achieve the effects of lower installation accuracy requirements, guaranteed accuracy, and improved plane positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

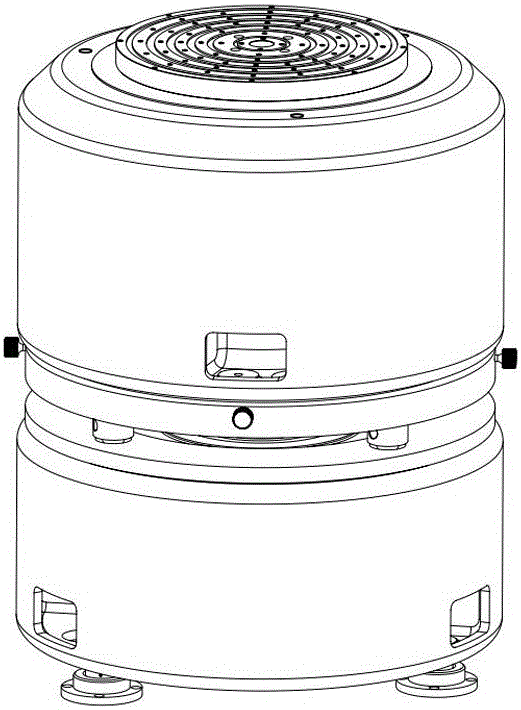

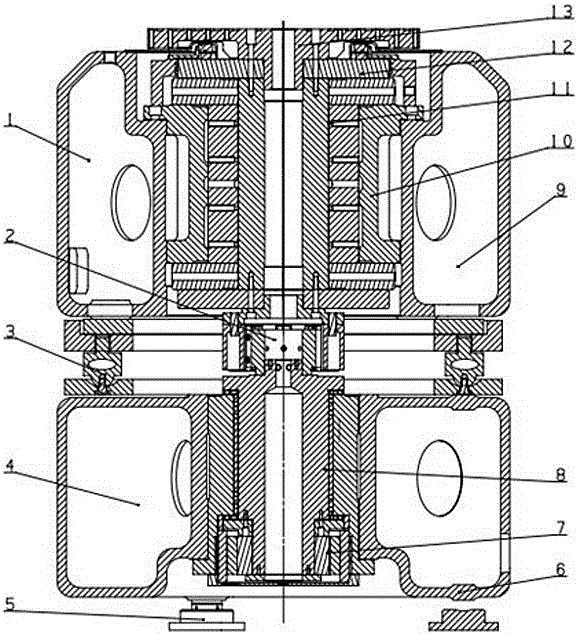

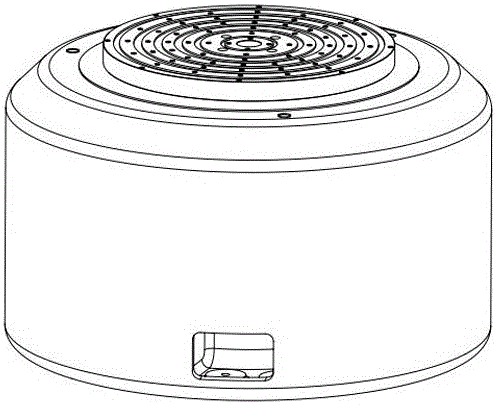

[0025] refer to Figure 1 to Figure 6 As shown, a split-type ultra-precision air static pressure single-axis turntable includes a turntable rotary shaft system 1, a drive shaft system 4 and a worktable surface 13, and also includes an air static pressure coupling 2, and the drive shaft system 4 passes through The aerostatic coupling 2 is connected to and drives the rotary shaft system 1 of the turntable. The working surface 13 is coaxially fixed on the rotary shaft system 1 of the turntable. The shaft hole of the ball bearing 8 is fixed coaxially with the driving motor 7, the aerostatic coupling 2 and the dense ball bearing 8 are coaxially ensured through the positioning slot, and are fastened with screws, and the rotary shaft system 1 of the turntable A radial air static pressure bearing 11 is provided, and the radial air static pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com