Bundled round steel end face binocular vision system and spatial positioning and counting method

A binocular vision system and a technology for bundling round bars, which are applied in computing, image data processing, instruments, etc., can solve the problem of a systematic method for obtaining round bars without the end faces of bundles of round bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

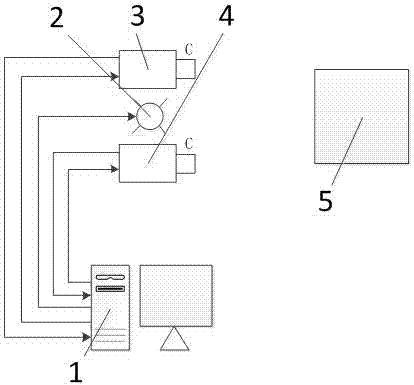

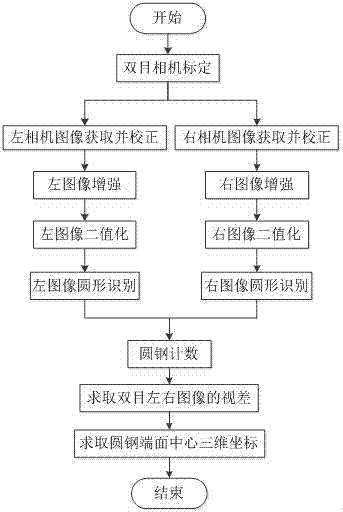

[0021] Taking the bundled round steel of Ø60mm as an example to introduce the present invention, in conjunction with the attached Figure 1-2 The present invention is described in detail.

[0022] First build as figure 1 The shown binocular vision system for the end face of bundled round steel includes: a computer 1 installed with an image storage and processing program, a light source 2 , a left camera 3 , a right camera 4 and a calibration plate 5 . The left camera 3 and the right camera 4 are placed side by side horizontally and perpendicular to the end face of the bundled round steel of the measured object. The light source 2 is at the middle position between the left camera 3 and the right camera 4. The camera 3 and the right camera 4 are connected together by a data cable, and placed in a position where the left camera 3 and the right camera 4 are not blocked, and the calibration plate 5 is placed within the depth of field range directly in front of the left camera 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com