Method for automatically calibrating measuring head polarization quantity of polar coordinates gear measuring center

A gear measurement and offset technology, which is applied in the direction of measuring devices, instruments, etc., can solve the problem of low accuracy of measuring workpieces, and achieve the effect of reducing installation accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in combination with specific embodiments.

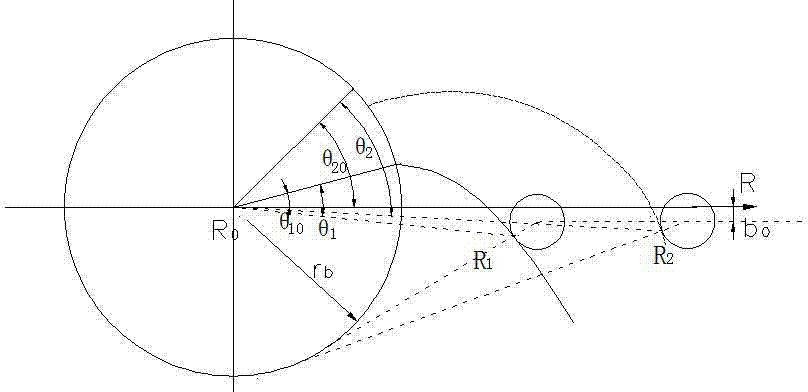

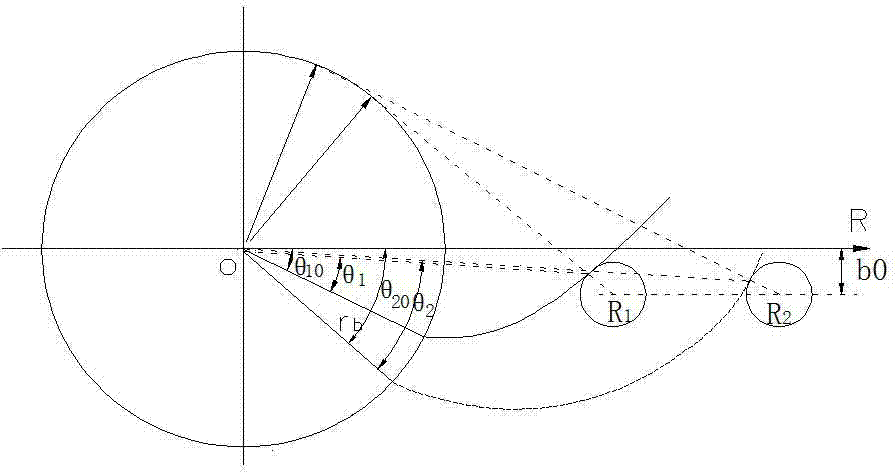

[0035] see figure 1 and figure 2 A method for automatically correcting the offset of a polar coordinate gear measuring center probe, comprising the following steps:

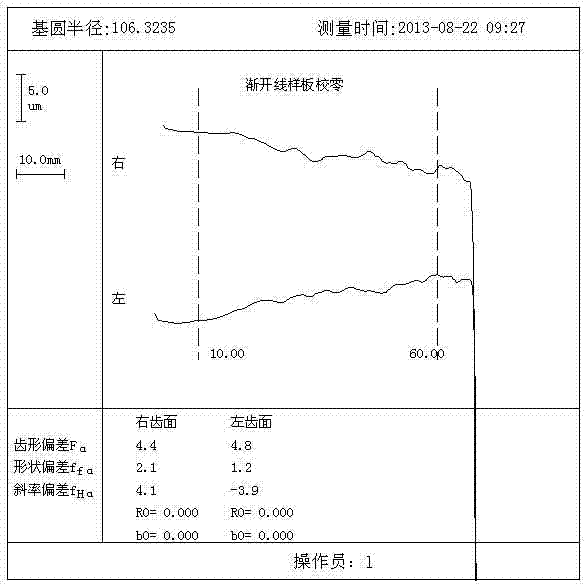

[0036] 1) Use the double-sided involute tooth profile to correct the offset of the probe, assuming that the radius of the base circle of the involute tooth profile is r b , using an involute template or a tooth surface of a standard involute gear, assuming that the offset in the vertical direction of the R axis caused by the installation error of the probe is b 0 Offset R with R axis direction 0 ;

[0037] 2) Clamp the involute tooth profile on the rotary shaft table, and set the measuring head at a measuring position accessible to one side of the involute tooth profile, and use the polar coordinate method to measure the involute tooth profile, which can Obtain a series of points on the involute (R 1j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com