Uniform overflow type liquid distributor

A liquid distributor and overflow type technology, applied in the direction of separation method, evaporator accessories, horizontal tube evaporator, etc., can solve the problems of uneven spraying, poor anti-blocking ability, uneven liquid distribution point, etc., to avoid uneven Simultaneity and inhomogeneity, reducing the requirements for installation accuracy, and overcoming the effect of uneven liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

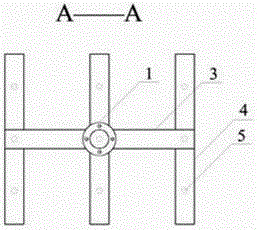

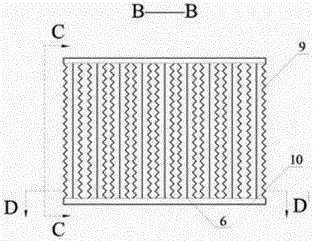

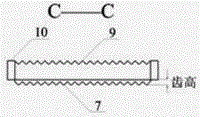

[0026] Such as figure 1 , the flange 1 is set at the entrance, the solution enters the horizontal branch pipe 3 through the feed pipe 2, the horizontal branch pipe 3 is connected with a plurality of spray pipes 4, the spray pipe 4 is arranged on the horizontal branch pipe 3 in parallel, and the center of the spray pipe 4 The line is perpendicular to the horizontal direction of the center line of the horizontal branch pipe 3, the number of the horizontal branch pipe 3 and the spray pipe 4 is determined according to the length of the heat exchange pipe 8 in the evaporator, and the distribution and number of the nozzles 5 are determined according to the number and length of the spray pipe 4 . When the solution is sprayed from the nozzle 5 onto the folded plate overflow tank 6, because the overflow channel 11 has a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com