Degradable anti-adhesion compound membrane and preparation method thereof

A composite film and anti-adhesion technology, used in medical science, surgery, etc., can solve the problems of polyester-polyether copolymer mechanical strength limitation, loss, and difficulty in meeting the needs of surgery, so as to shield wounds and avoid wear and tear. Transparent and thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

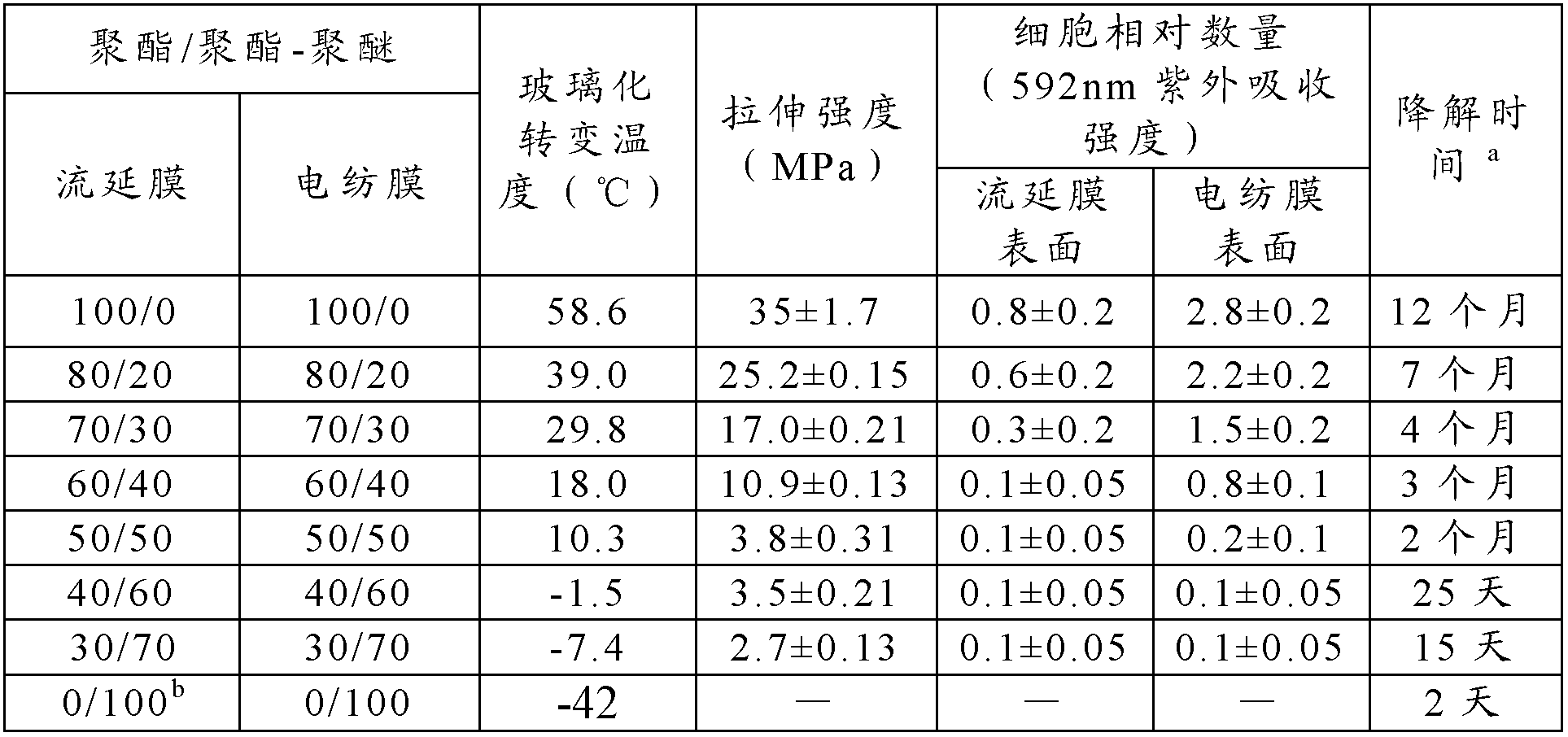

Embodiment 1

[0045] Synthesis of polyester: place 50 grams of dehydrated and purified L-lactide and glycolide in a weight ratio of 85 / 15 in a 500ml reaction bottle, and then add a stannous octoate catalyst with a total weight of 0.02% of the polymerized monomers , 150 ° C under vacuum conditions for 15 hours to obtain a random polymer polyester. The polymer was dissolved in chloroform, precipitated in ethanol, and the precipitate was dried in a vacuum desiccator for 48 hours. The viscosity-average molecular weight of the product is 480,000, and the weight ratio of L-lactide accounts for 85% in the polyester as determined by nuclear magnetic 1H spectrum. The glass transition temperature was determined to be 57°C.

[0046] Synthesis of polyether-polyester copolymer: put 50 grams of dehydrated and purified L-lactide, glycolide and methoxy single-capped polyethylene glycol 5000 in 500ml according to the weight ratio of 85 / 15 / 100 Add 0.05% stannous octoate catalyst to the reaction bottle, and r...

Embodiment 2

[0055] The following synthetic method is similar to that in Example 1, and is briefly described as follows:

[0056] Synthesis of polyester-polyether: 50 grams of dehydrated and purified DL-lactide and polyethylene glycol in a weight ratio of 1 / 2 are placed in a 500ml reaction bottle, and the viscosity-average molecular weight of the product after the reaction is 4.5 Wan, by NMR 1 According to H spectrum measurement, the polyether accounts for 68% of the polyester-polyether copolymer in the polyether-DL-lactide copolymer.

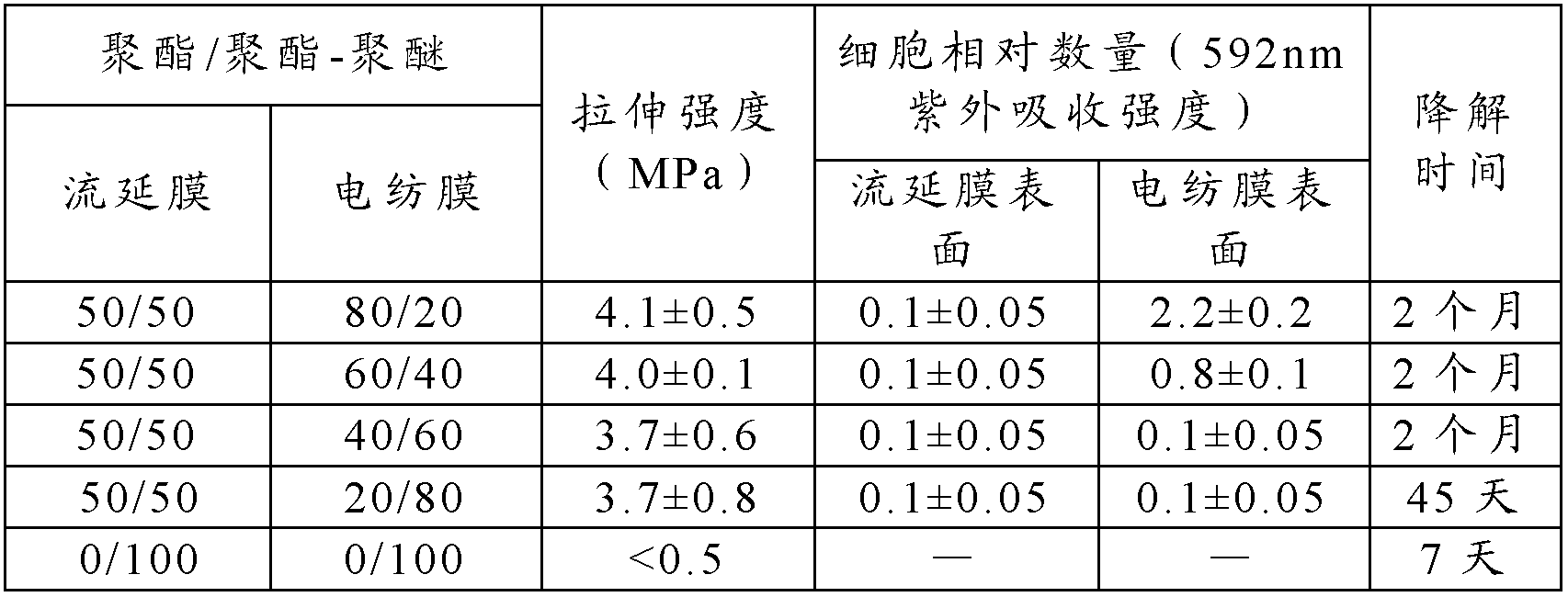

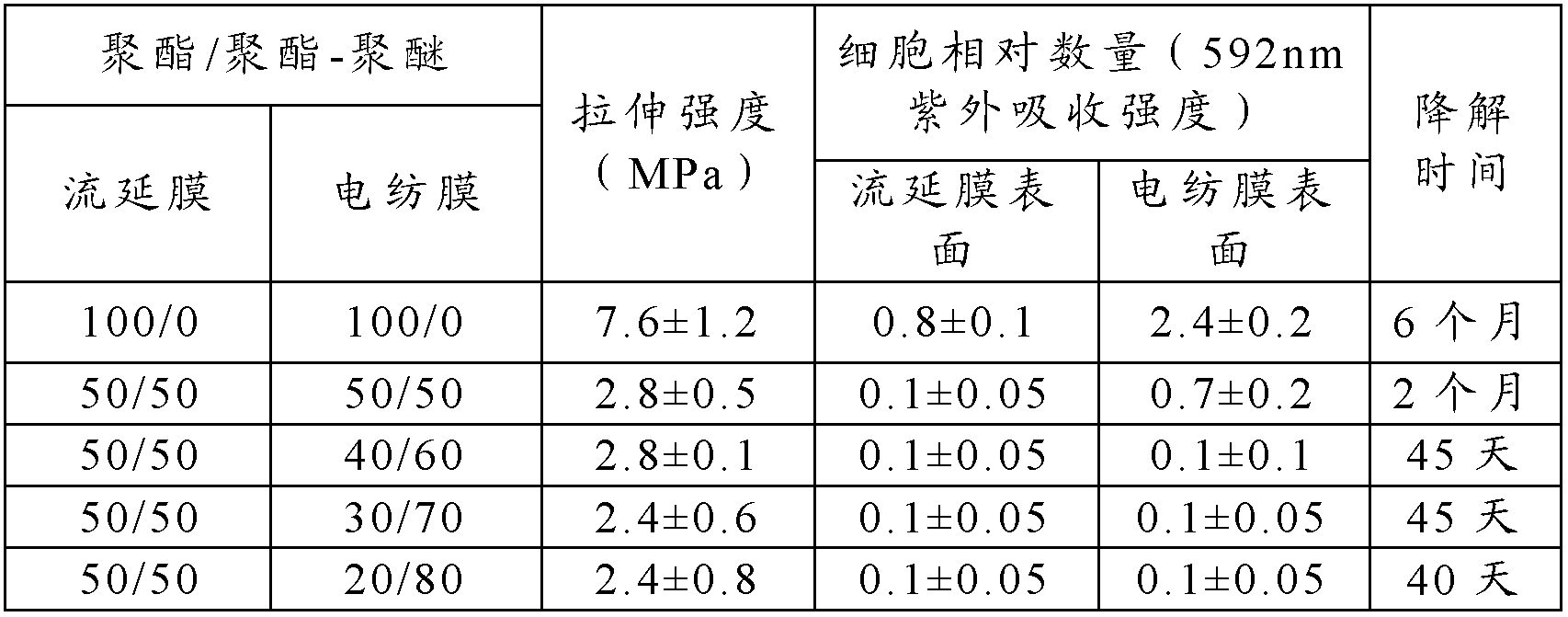

[0057] Preparation of composite film: blend the same polyester as in Example 1 with the polyester-polyether in Example 2 in a 50 / 50 ratio to form a chloroform solution with a concentration of 5%, pour 120ml of the solution into a 50*50cm in the flat mold. It was left still at 40° C. and a humidity of 50%. When it is not completely dry but has lost its fluidity, it is transferred to the electrospinning drum for the preparation of the electrospun layer. P...

Embodiment 3

[0063] The following synthetic method is similar to that in Example 1, and is briefly described as follows:

[0064] Synthesis of polyester: Put DL-lactide, glycolide, and caprolactone that have been dehydrated and purified in a weight ratio of 70 / 15 / 15, and put a total of 50 grams into a 500ml reaction bottle, and then add 0.02 % stannous octoate catalyst was reacted for 48 hours at 140° C. under vacuum conditions to obtain polyester random polymers. The polymer was dissolved in chloroform, precipitated in ethanol, and the precipitate was dried in a vacuum desiccator for 48 hours. The viscosity-average molecular weight of the product is 300,000, and the glass transition temperature is 28°C as measured by experiments.

[0065] Preparation of composite film: blend polyester with polyester-polyether in Example 2 at a ratio of 50 / 50 to form a chloroform solution with a concentration of 5%, and pour 120ml of the solution into a 50*50cm flat-bottomed mold. Naturally volatilize at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com