Method for machining shock-resistant self-locking type half grouting sleeve and method for machining concrete member

A technology of semi-grouting sleeves and processing methods, which is applied in the direction of building components, building reinforcements, structural elements, etc., which can solve the problems of large area of reinforcement densification, difficult control of quality standards, sleeve wall thickness, etc., and achieve control of threaded connections quality, ease of threading quality, effect of increased shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

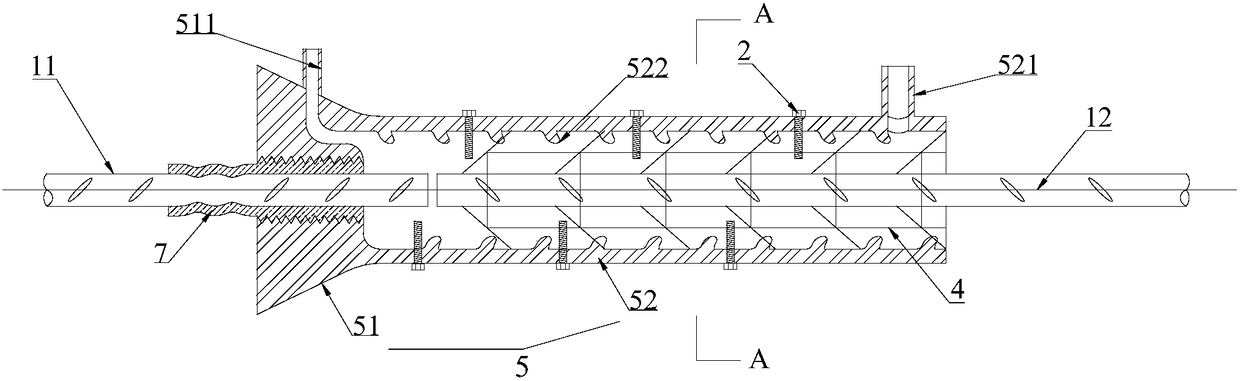

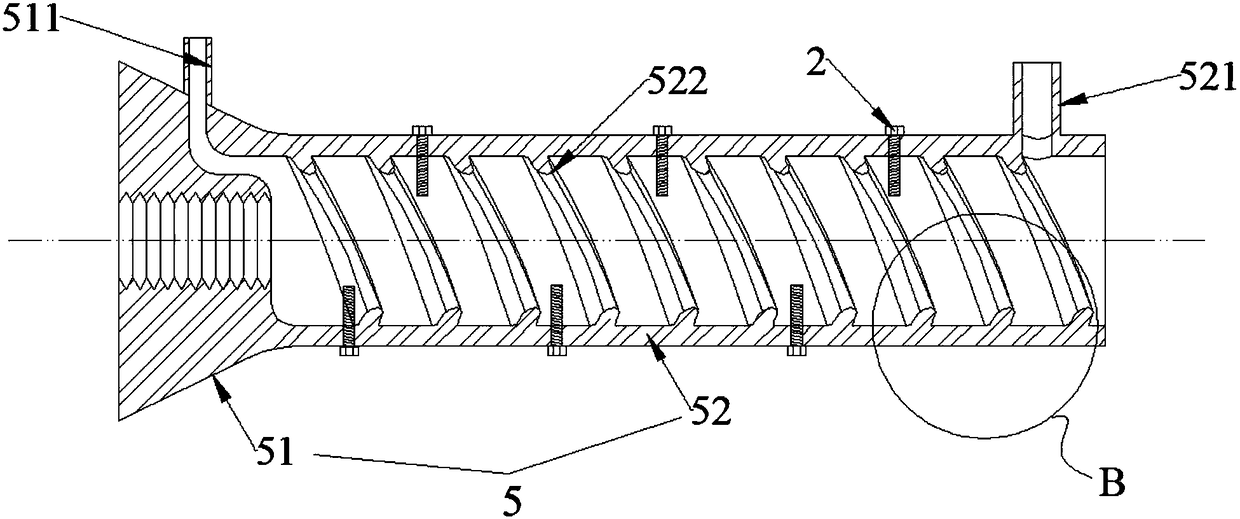

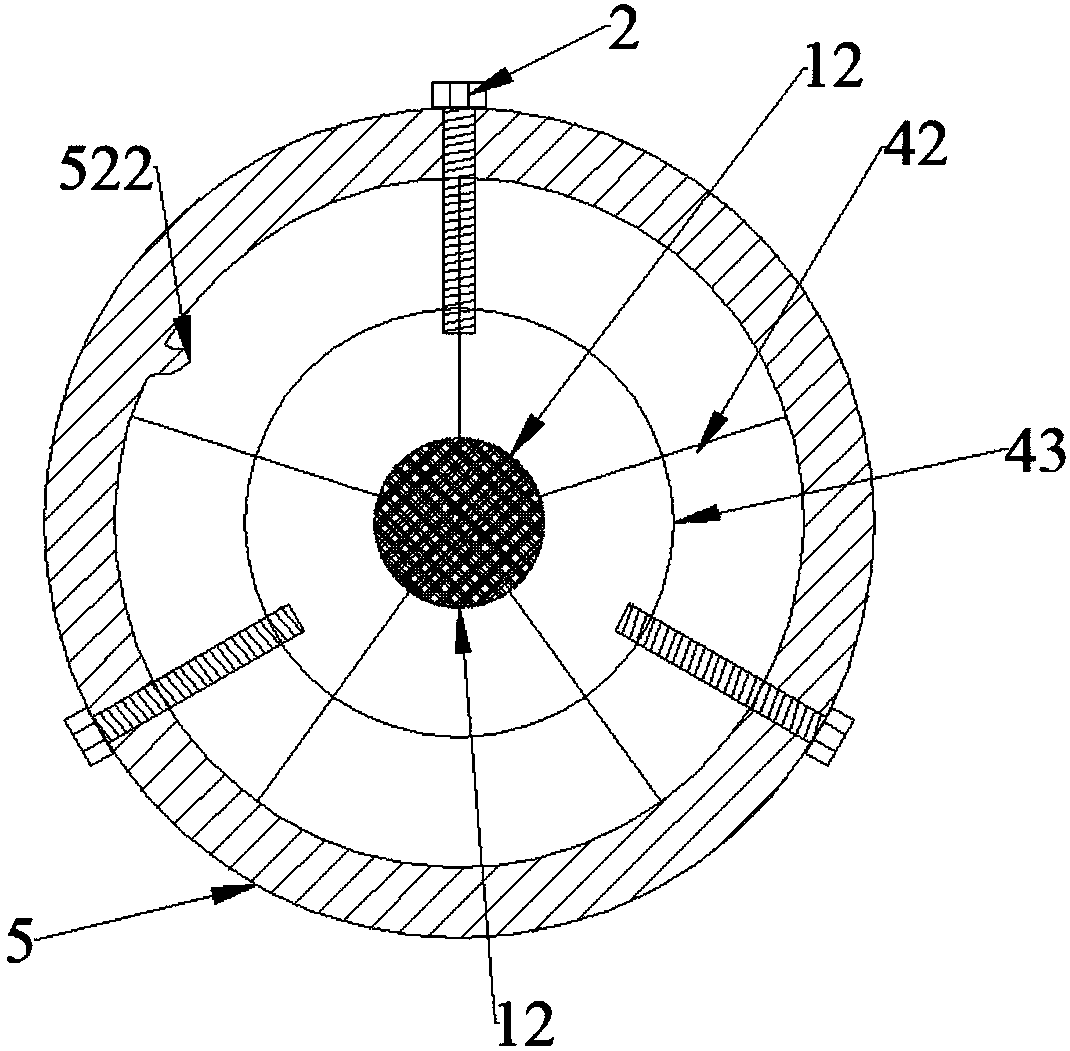

[0056] Such as figure 1 , figure 2 , image 3 As shown, an anti-seismic assembled self-locking semi-grouting sleeve, including a sleeve 5, a steel pipe transition section 7, and a self-locking steel skeleton 4;

[0057] The sleeve 5 includes a non-grouting connection section 51 and a grouting connection section 52; the non-grouting connection section 51 is a conical cylindrical structure, and the grouting connection section 52 is a cylindrical structure; the small diameter end of the non-grouting connection section 51 and the grouting connection section 52 One end of the connection is connected, and the connection is rounded. One end of the grouting connection section 52 away from the non-grouting connection section 51 is provided with a grouting hole 521, and the other end extends a vent hole 511 toward the non-grouting connection section 51. The vent hole 511 can specifically be: Offer an air hole that is first vertical and then horizontal on the cone, and this air hole ...

Embodiment 2

[0065] A method for processing an anti-seismic assembled self-locking semi-grouting sleeve: comprising the following steps:

[0066] Step 1. Grouting sleeve 5 processing

[0067] The grouting sleeve 5 is processed by casting and integrally formed; one end is treated with internal thread, and multiple mounting holes are opened on the cylinder for standby;

[0068] Step 2. Steel pipe transition section 7 processing

[0069] Select a steel pipe of suitable length and thickness as the transition section 7 of the steel pipe; one end of the transition section 7 of the steel pipe is processed as an external thread for standby;

[0070] Step 3. Self-locking steel skeleton 4 processing

[0071] First, a plurality of longitudinal guiding steel bars 41 and a plurality of circumferential fixed steel rings 43 are welded into a cylindrical keel, and then a plurality of oblique steel branches 42 are radially and obliquely welded on multiple circular sections of the keel to form inner barbs...

Embodiment 3

[0075] A method for processing a prefabricated concrete member, comprising the following steps:

[0076] Step 1. Binding of reinforced skeleton of prefabricated concrete members

[0077] One end of the first steel bar 11 to be connected is bound and fixed with other steel bars to form a reinforced skeleton of the fabricated concrete member. The other end of the first steel bar to be connected is inserted into the rolling section 71 of the steel pipe transition section 7, and the steel pipe transition section 7 is realized by rolling machinery. The connection with the first steel bar 11 to be connected, so that the self-locking semi-grouting sleeve 5 is pre-installed in the reinforced skeleton of the prefabricated concrete member;

[0078] Step 2. Pouring of prefabricated concrete elements

[0079] Connect the plastic pipe 8 to the grouting hole 521 and the vent hole 511 on the side wall of the sleeve 5 and lead it out of the component formwork, then the concrete placing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com