Prefabricated toilet floor slab construction method

A construction method and toilet technology, applied in the direction of floors, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problems of inaccuracy, leakage, installation, pipe hole and pipeline positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

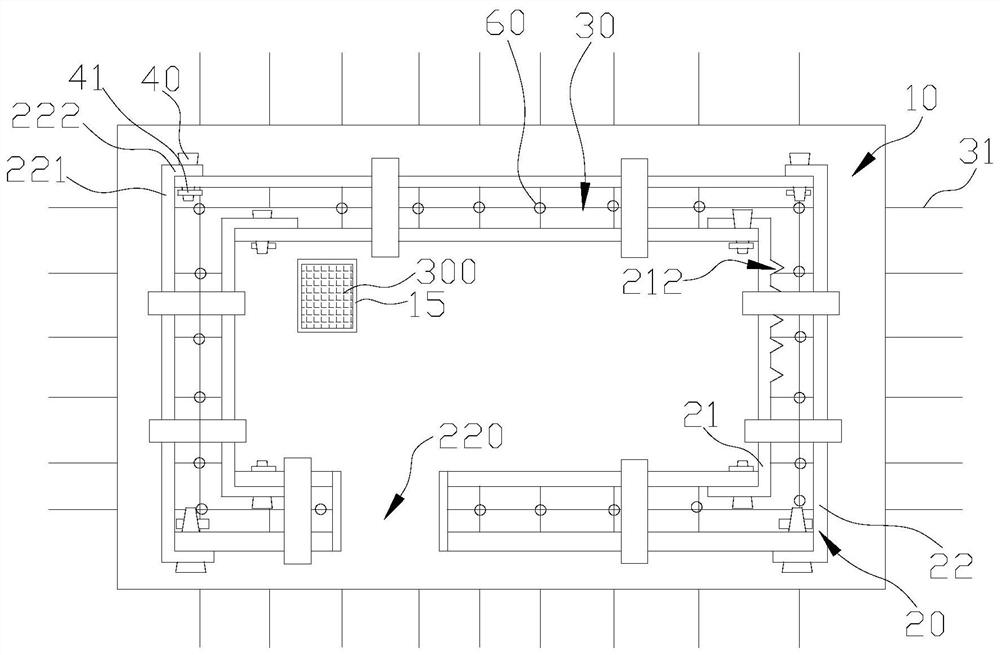

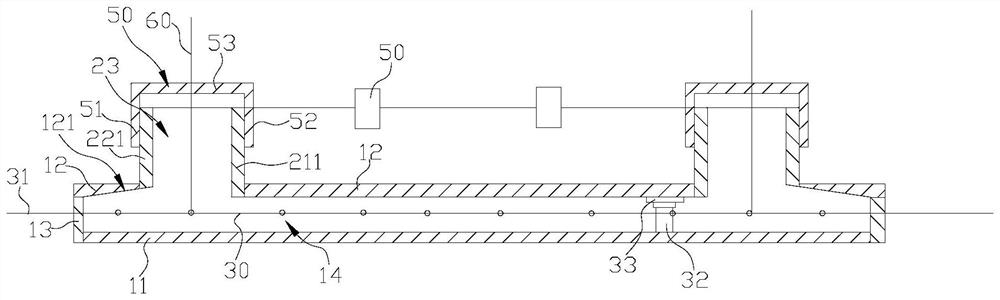

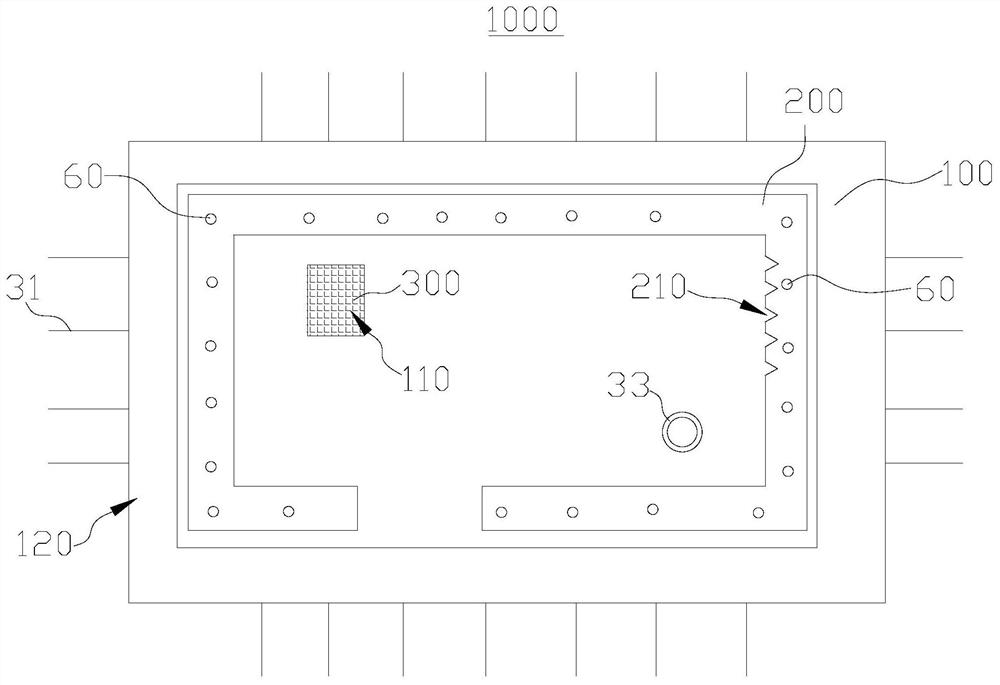

[0039]The embodiment of the present application provides a prefabricated toilet floor 1000 construction method, the prefabricated toilet floor 1000 construction method includes assembling and strengthening the bottom slab pouring formwork 10 and the reverse sill pouring formwork 20, laying the floor reinforcement 30 on the bottom slab pouring formwork 10, laying the floor reinforcement 30 on the floor reinforcement 30 Install the positioning post 32 on the positioning post 32, set the water stop section 33 on the positioning post 32, pour concrete to the bottom plate pouring formwork 10 to form the bottom plate 100, pour concrete to the anti-sill pouring formwork 20 to form the anti-sill 200 and remove Base plate pouring formwork 10 and reverse sill pouring formwork 20 . The reverse sill pouring formwork 20 includes a reverse sill outer formwork 22 and a reverse sill inner formwork 21 , and a plurality of water supply and drainage pipeline grooving molds 212 arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com