Patents

Literature

52results about How to "Quickly and easily adapted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

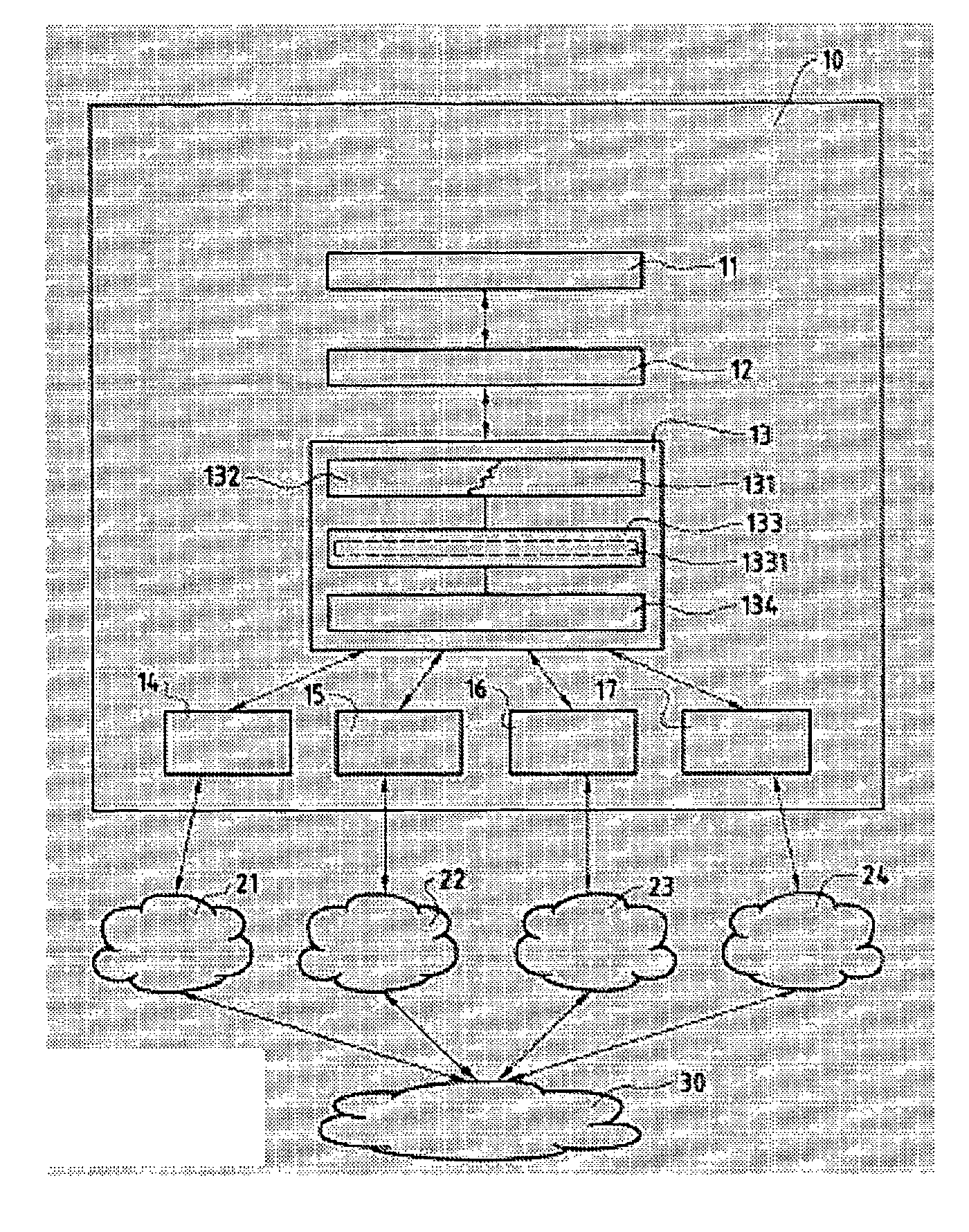

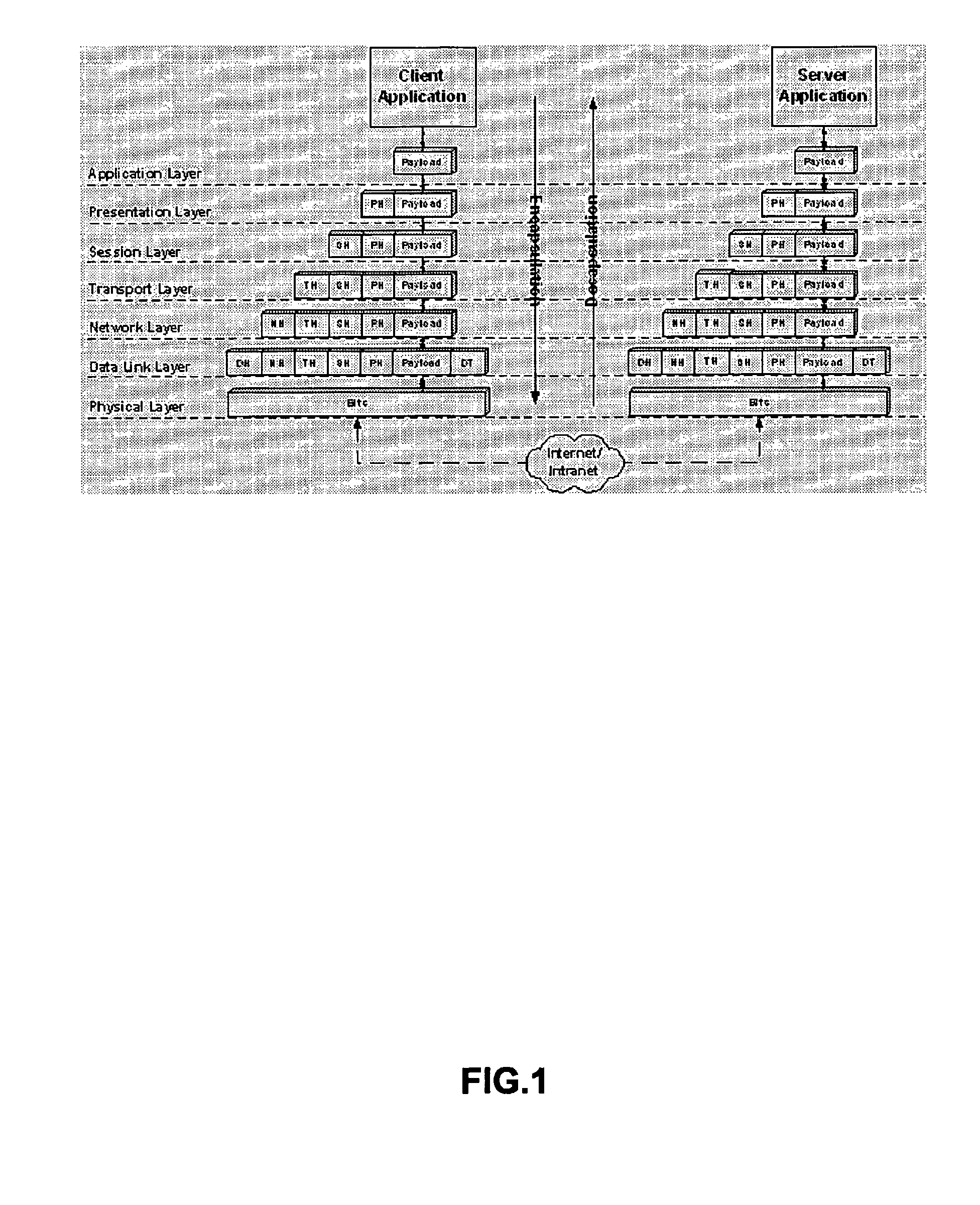

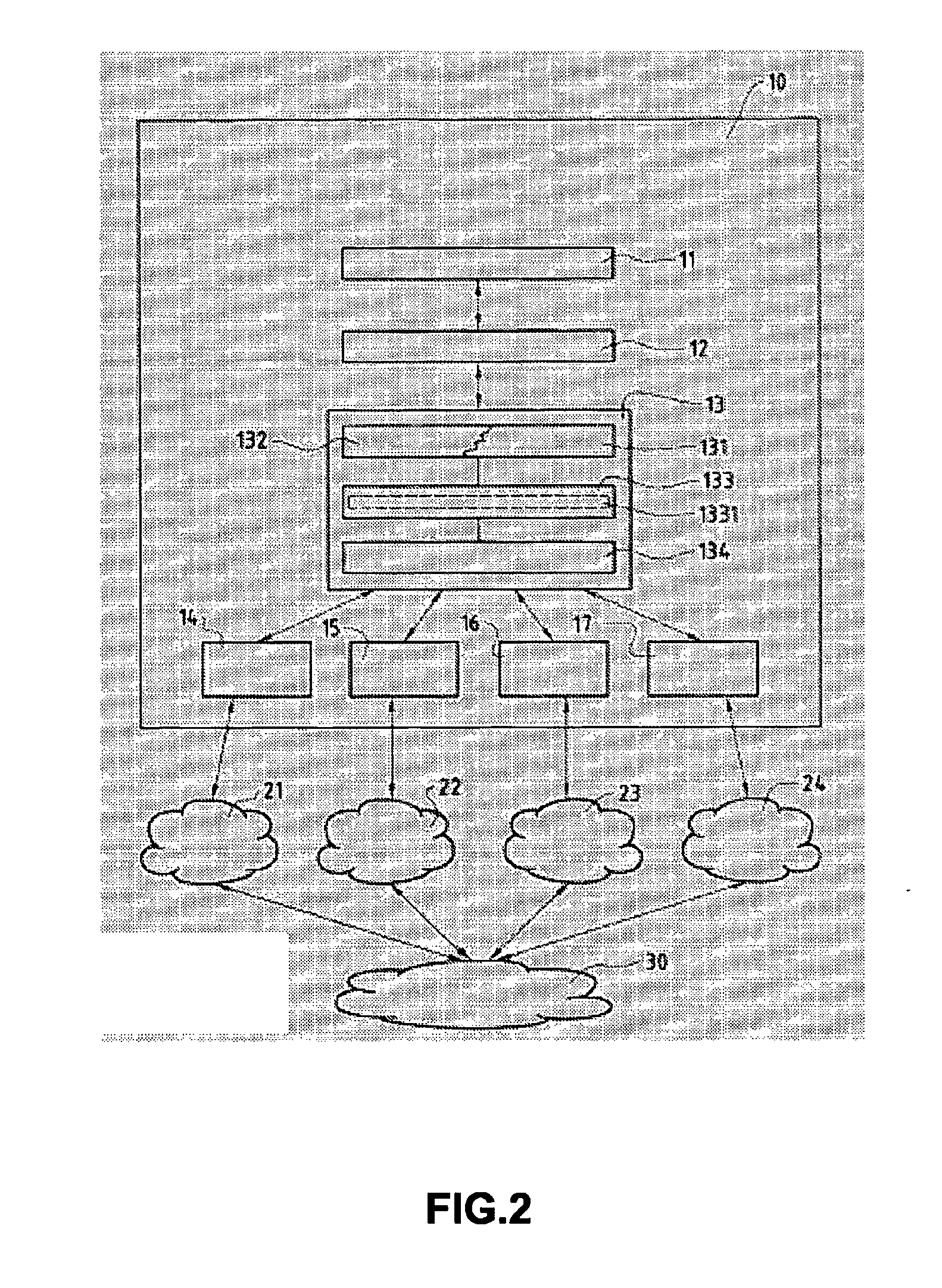

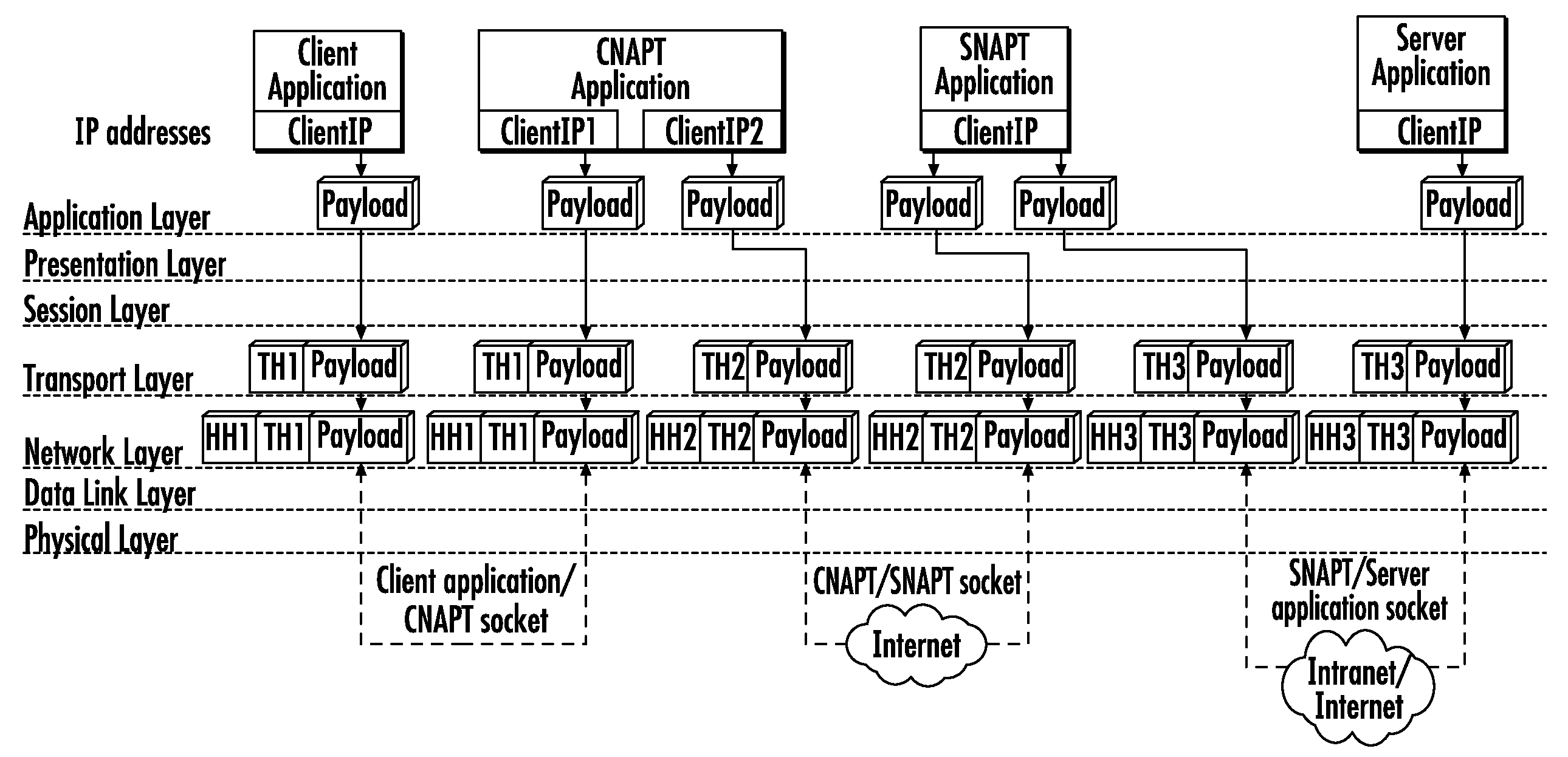

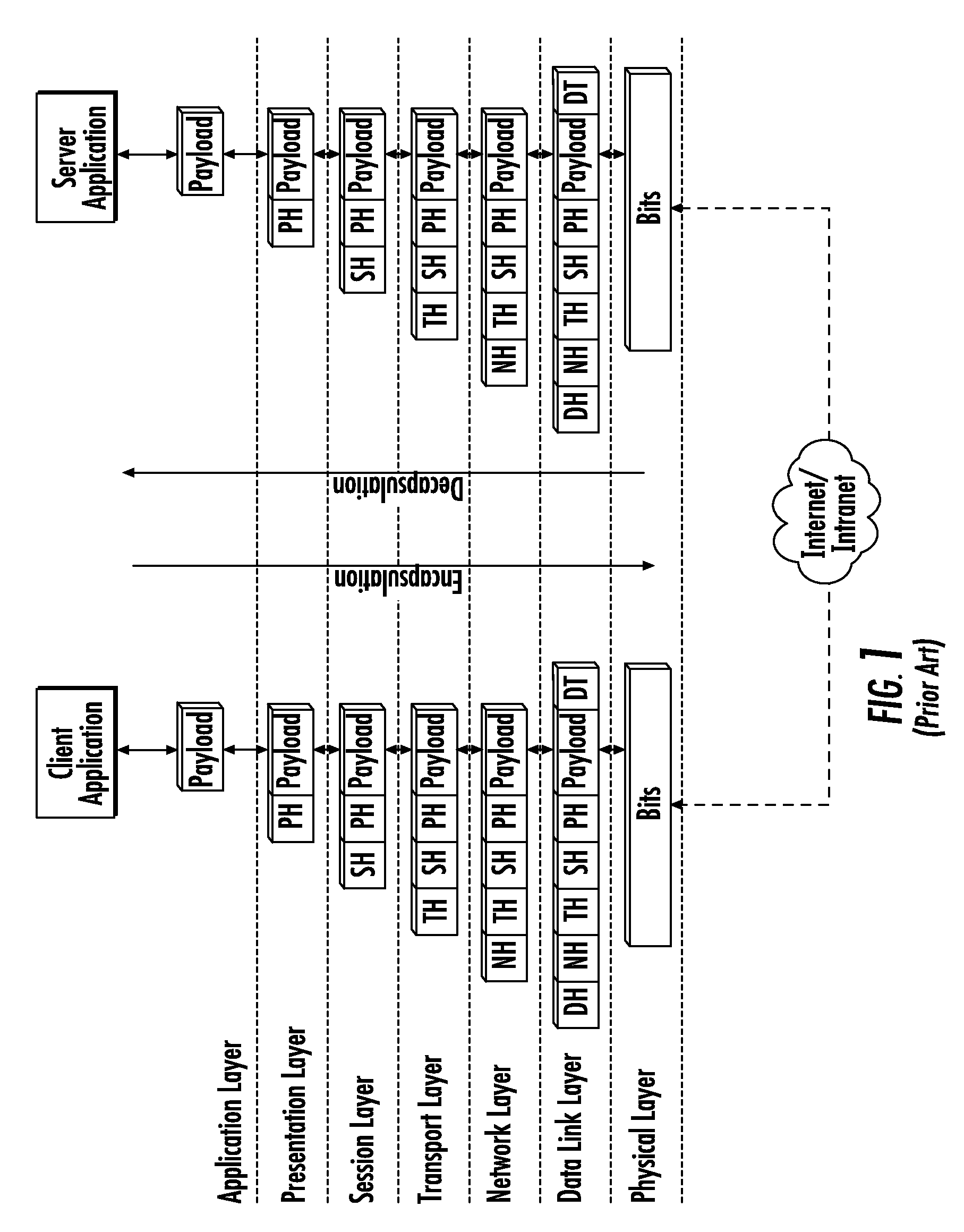

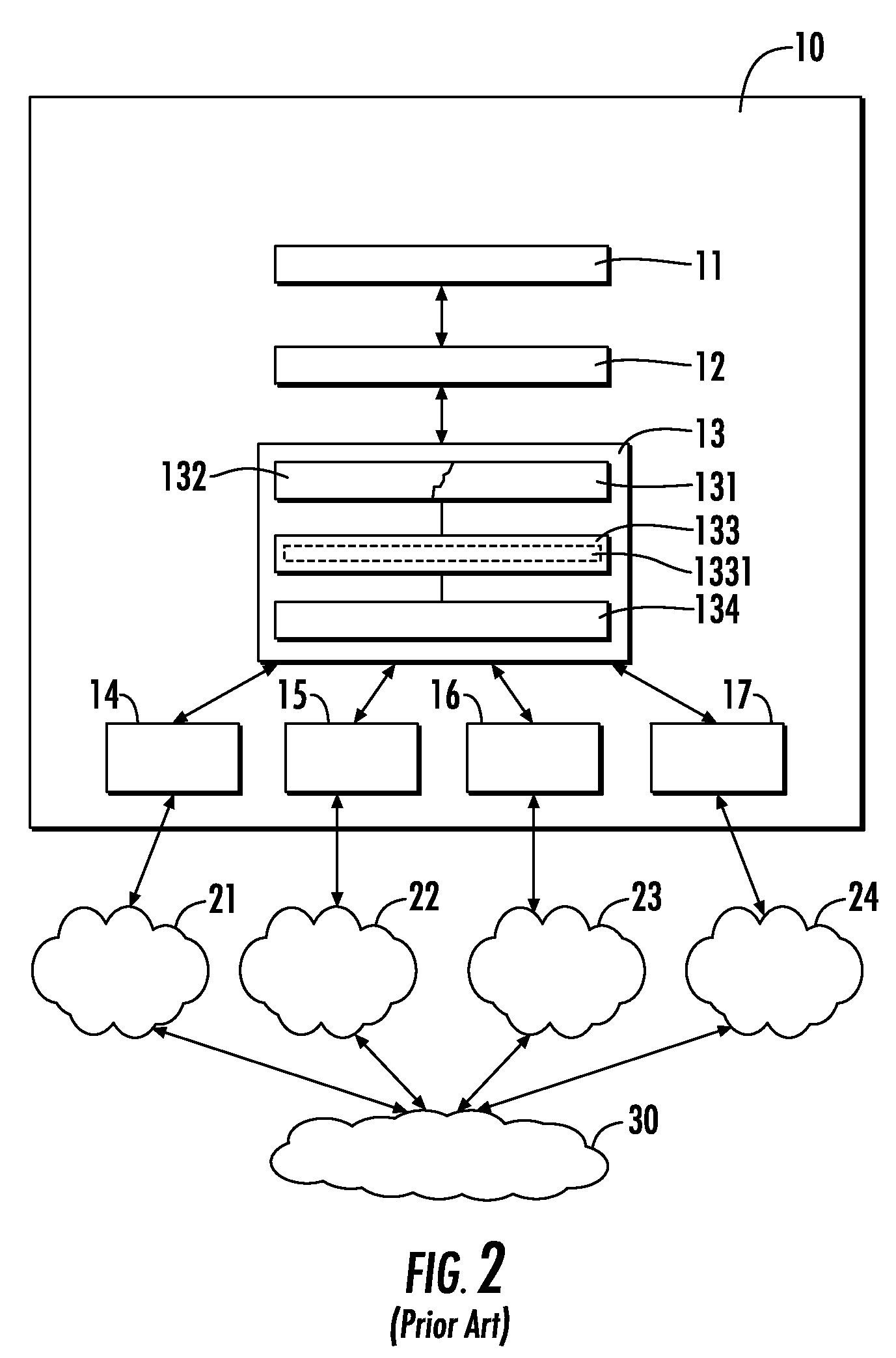

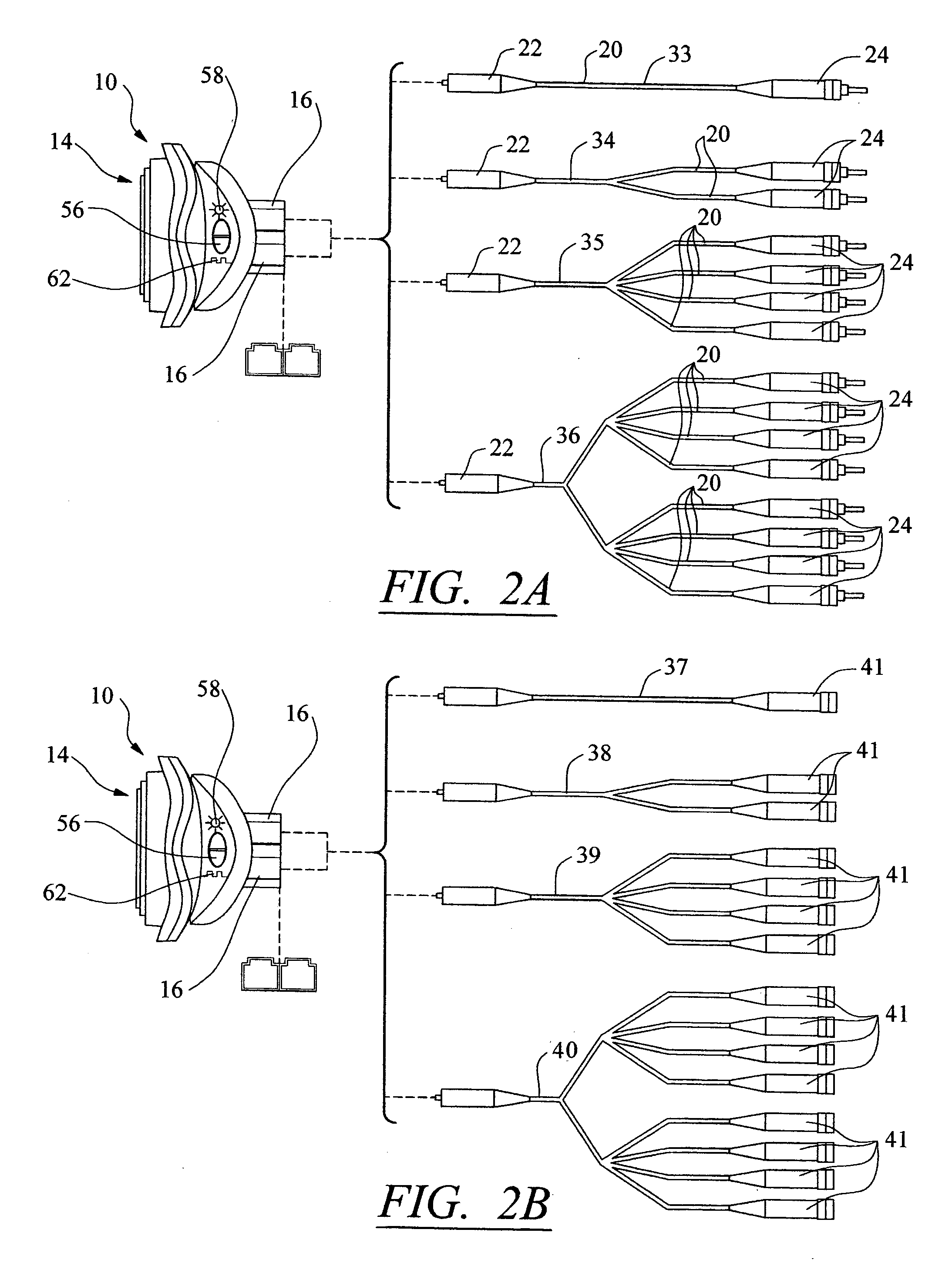

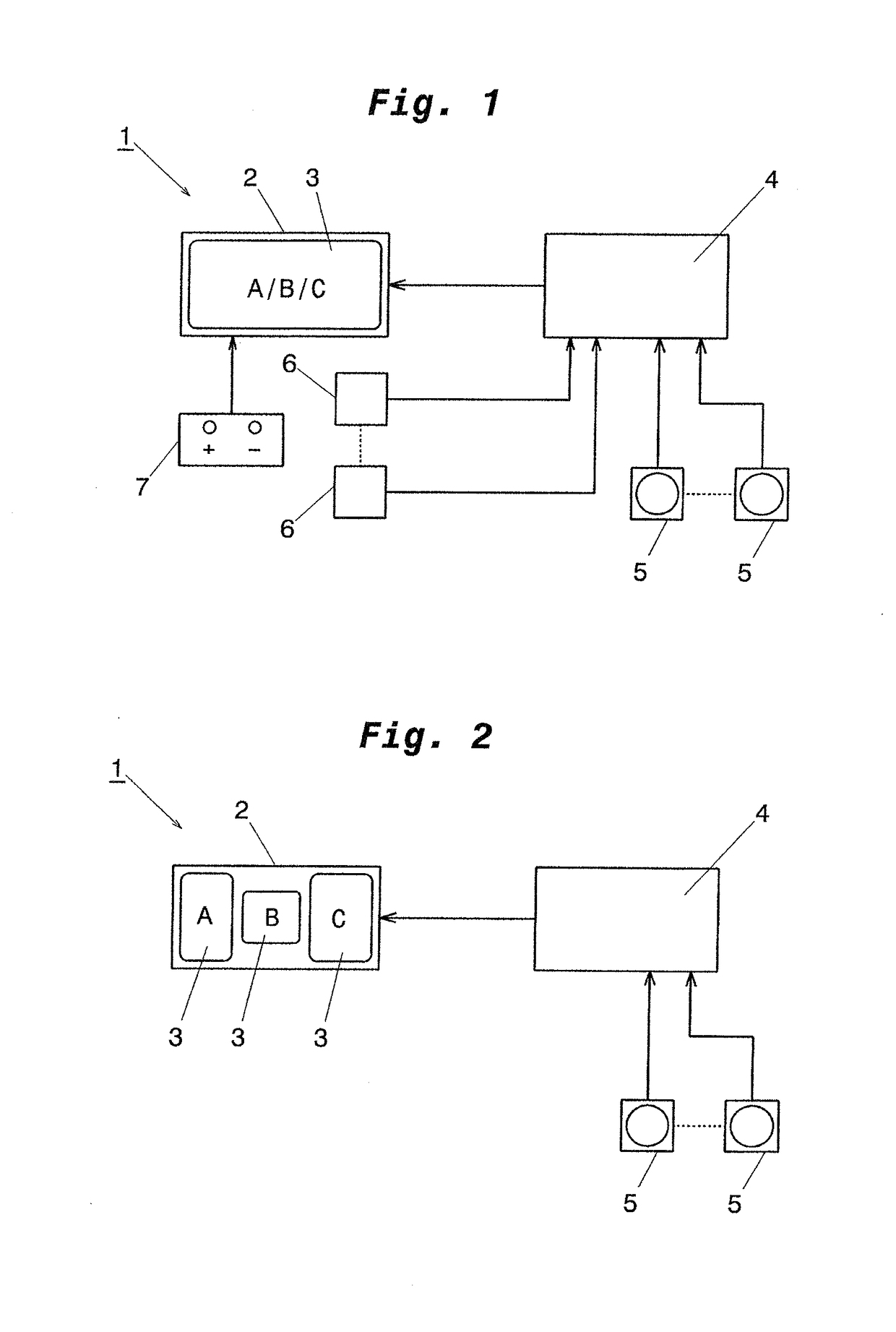

Method and system for seamless handover of mobile devices in heterogeneous networks

ActiveUS20070165572A1Avoid modificationQuickly and easily adaptedTime-division multiplexData switching by path configurationHeterogeneous networkAccess technology

The invention relates to a method for seamless handover of mobile devices in heterogeneous networks. A mobile device (10) is moved between different topological network locations (30 / 31 / 32 / 33) and transmits and / or receives data by means of different network access technologies without the data transfer between a Client IP application (11), running on the mobile device (10), and a Server IP application (21) being interrupted, wherein the Client IP application (11) of the mobile device (10) makes a request with first data units to a client-service module (12), wherein the client service module (12) creates second data units based on the received first data units and makes a request to a server-service module (22) with the second data units, wherein the server-service module (22) creates third data units based on the received second data units and makes a request to the Server IP application (21) with the third data units to handle the data exchange between the Client IP application (11) and the Server IP application (21).

Owner:ZAMA INNOVATIONS LLC

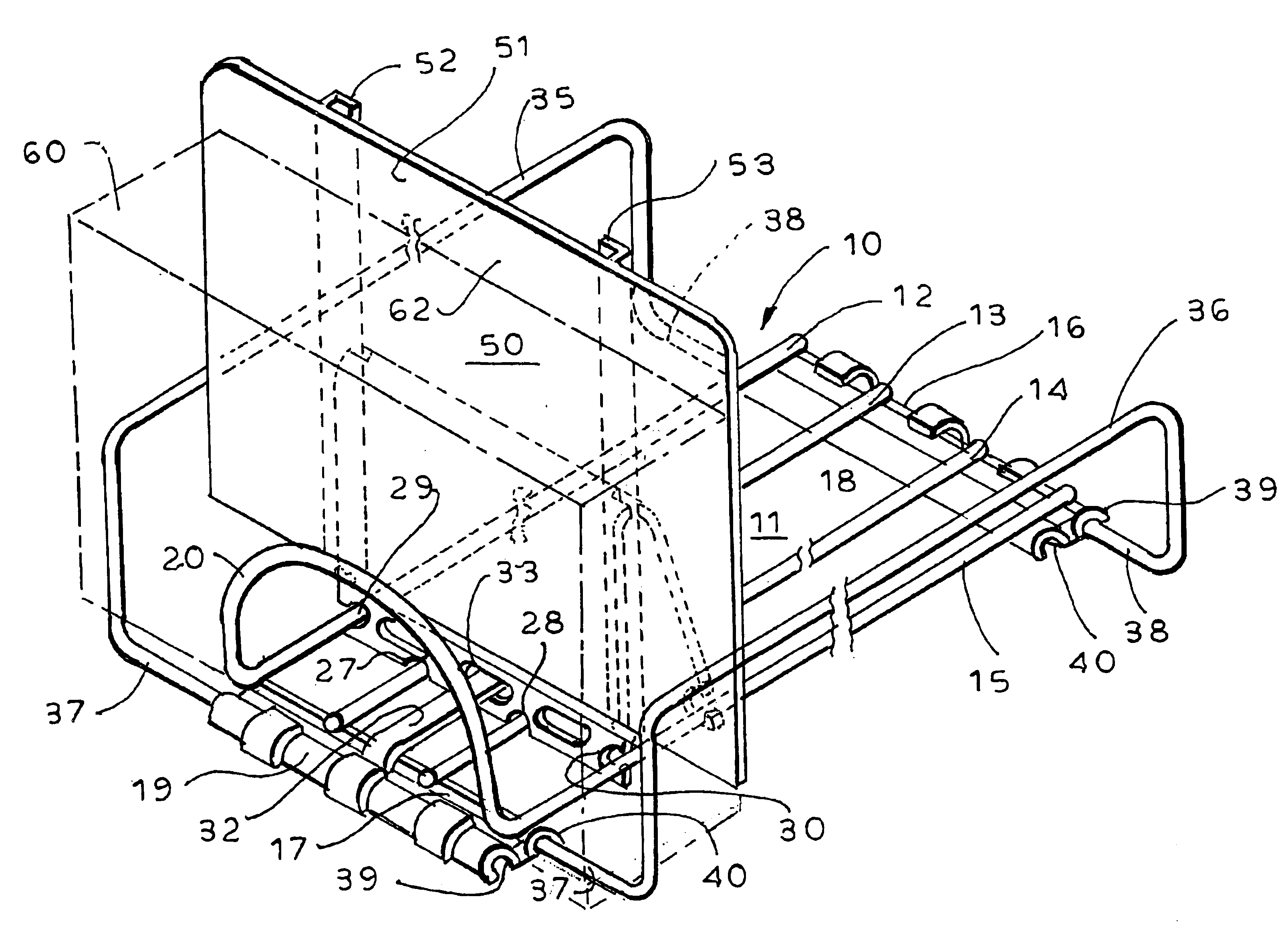

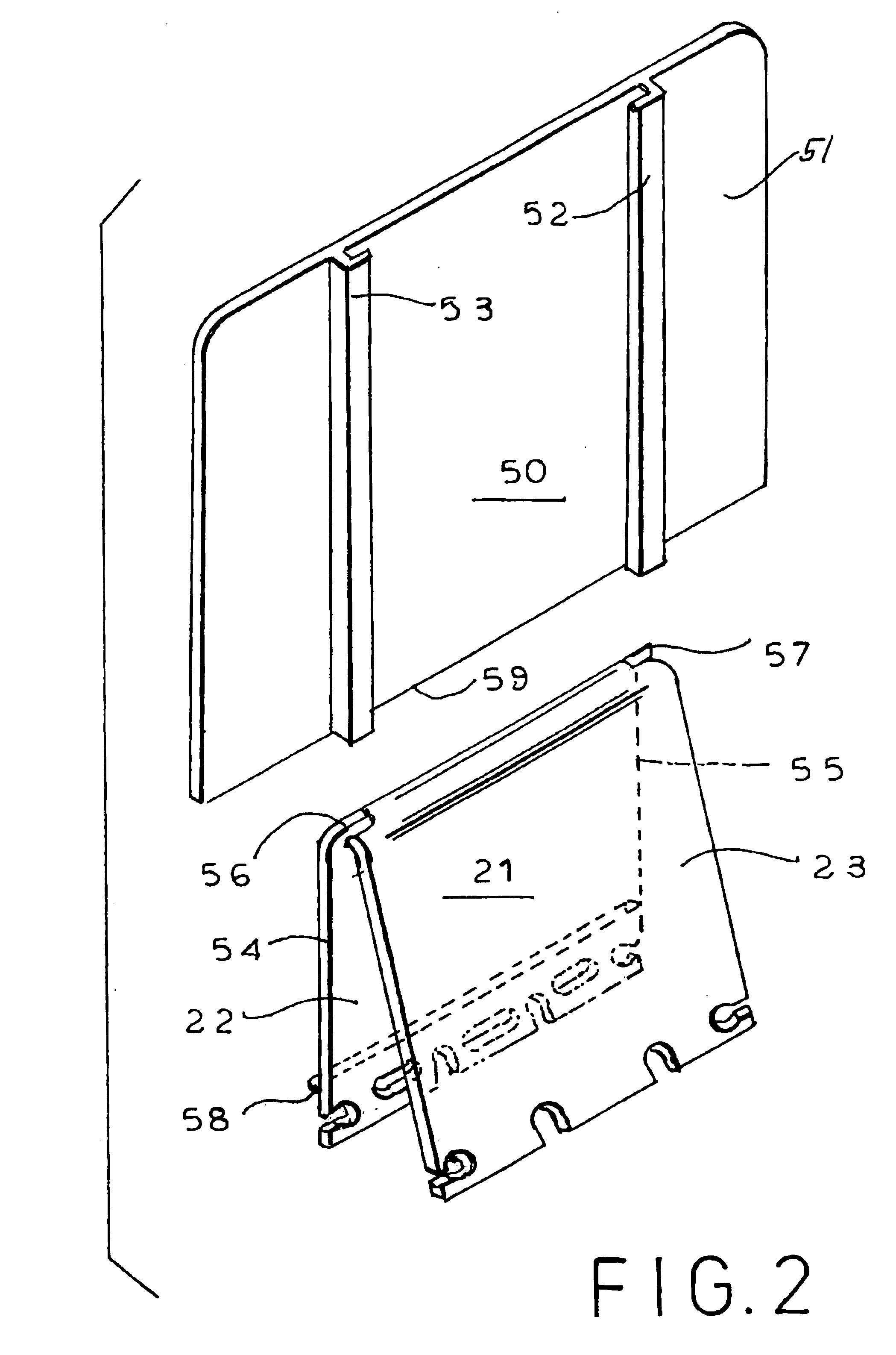

Adjustable product display rack with extension panel

InactiveUS6886700B2Simple and convenient storageQuick installationRacksShow shelvesDisplay deviceFront panel

A display rack assembly for the display of product packages, with provisions for pushing packages toward the front of the display as individual packages are removed. The assembly includes a support base for supporting the packages and slidably mounting a spring-urged pusher. The pusher has front and back panels, with the back panel being joined along its upper edge to the back of the front panel, and the respective bottom edges being spaced apart in the front to back direction. A generally flat, front extension panel is removably attached to the front pusher panel to extend its dimensions upwardly or laterally, or both. This enables a standardized display rack to be easily adapted for tall and / or wide packages, as well as packages of smaller sizes. Interchangeable extension panels also can be provided with product advertising, specific to the product being displayed, which can be replaced or interchanged when a new product is displayed.

Owner:TRION IND

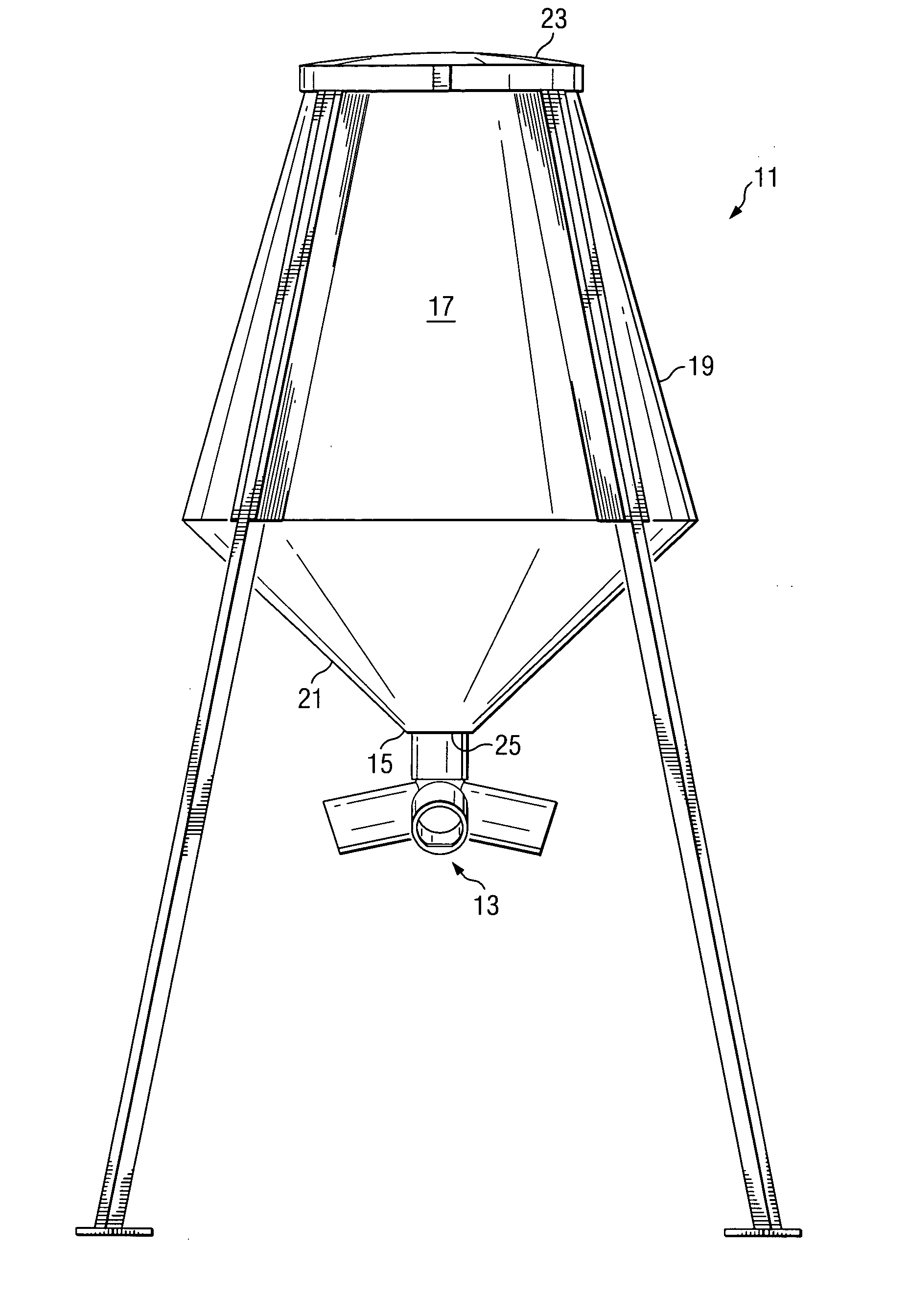

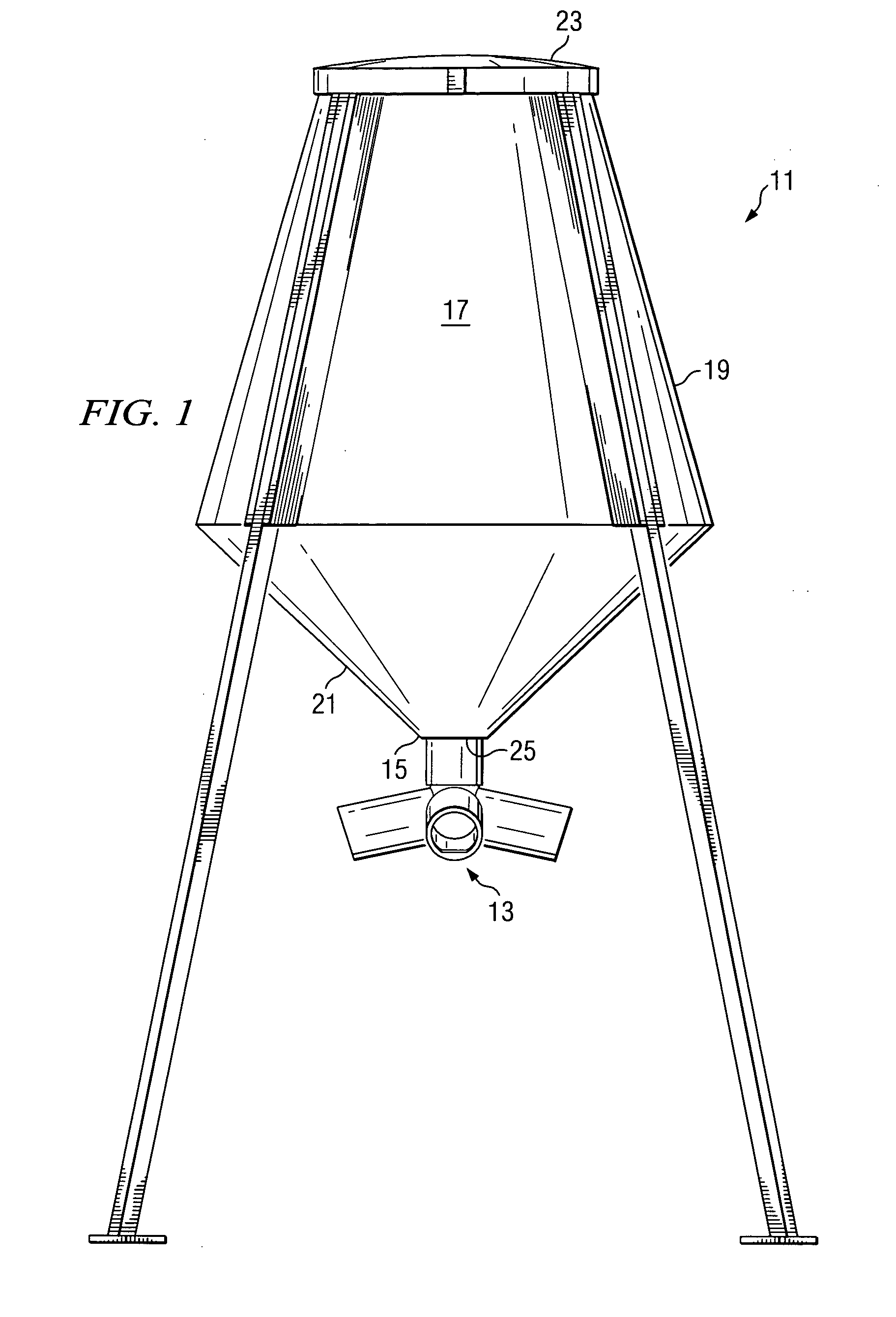

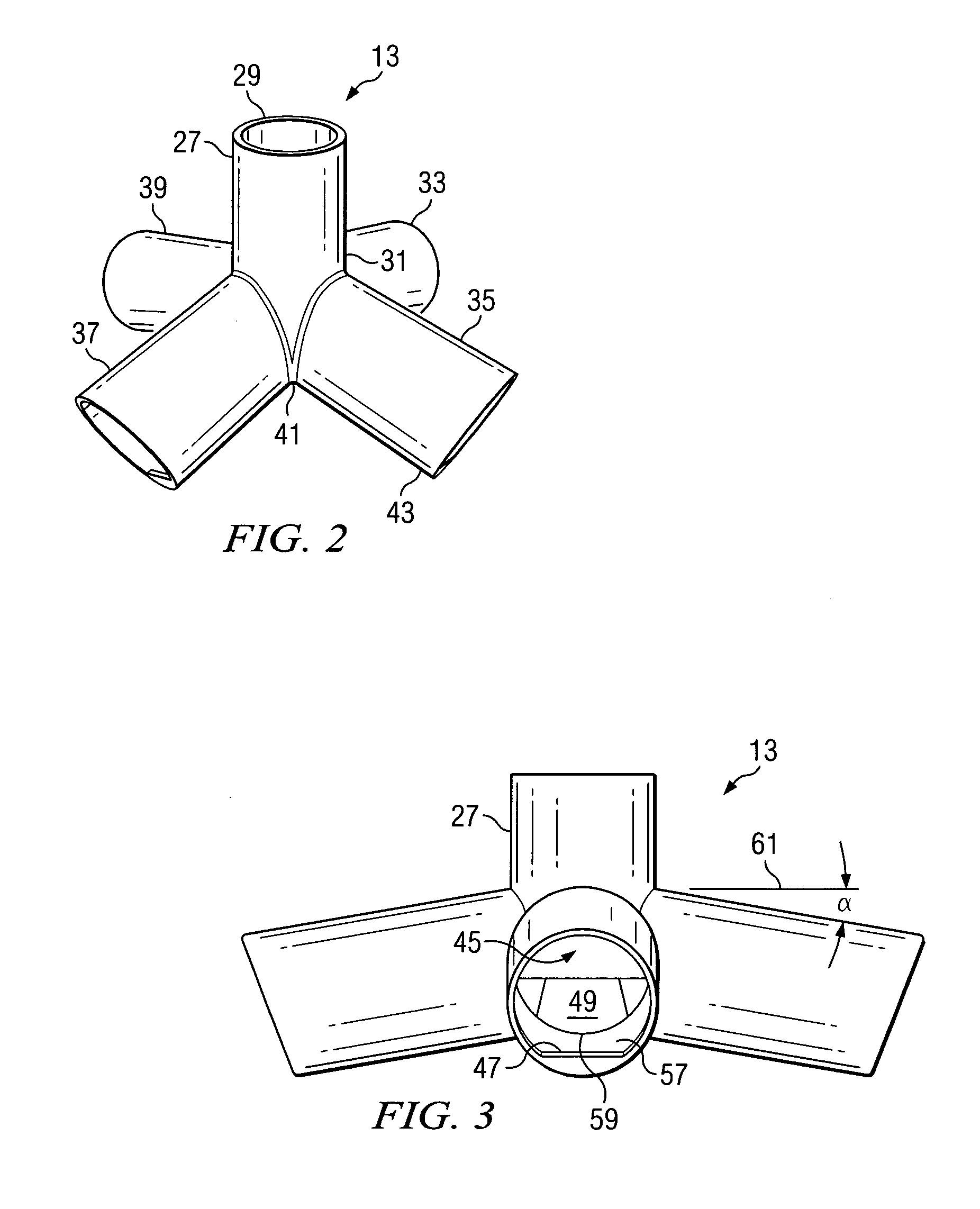

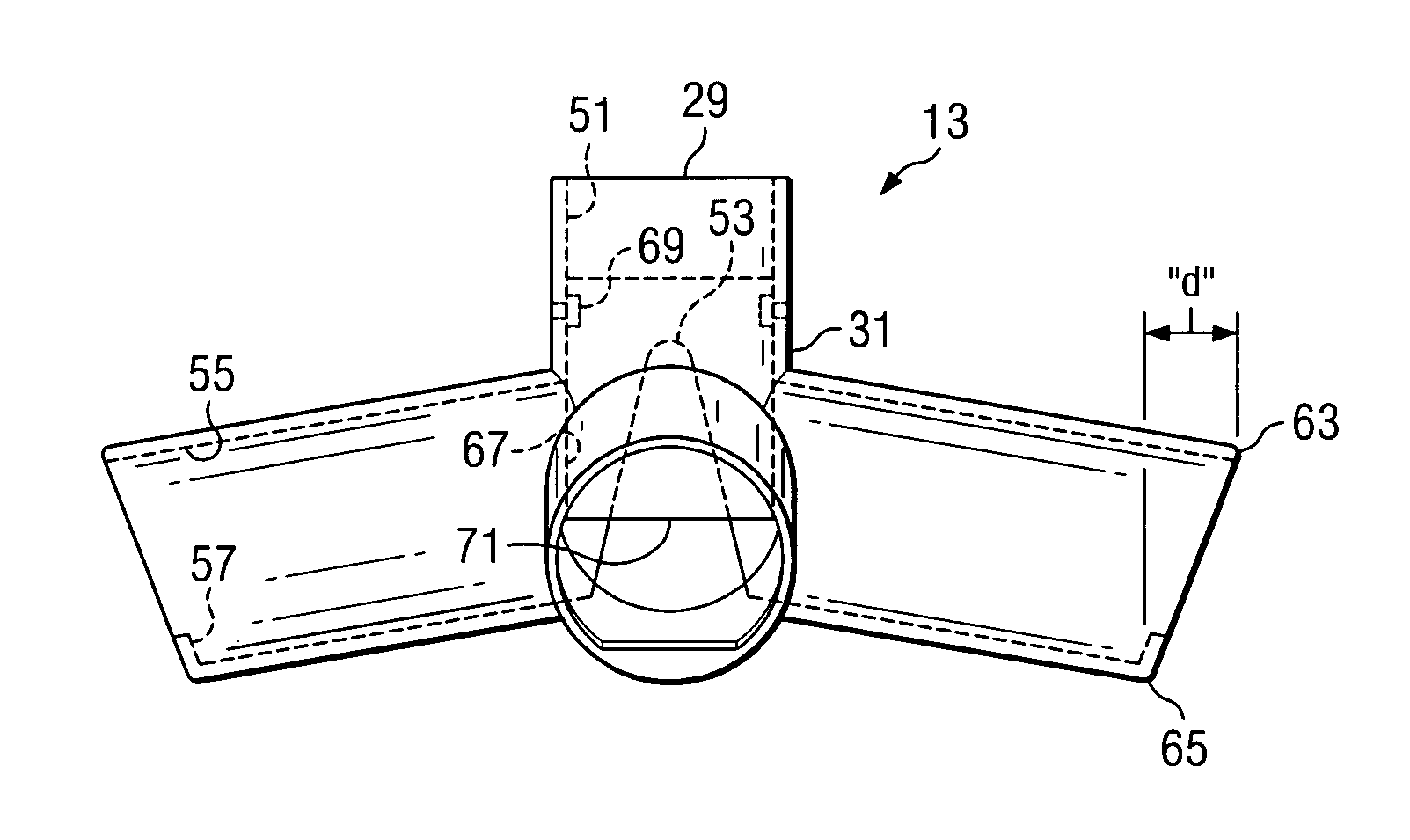

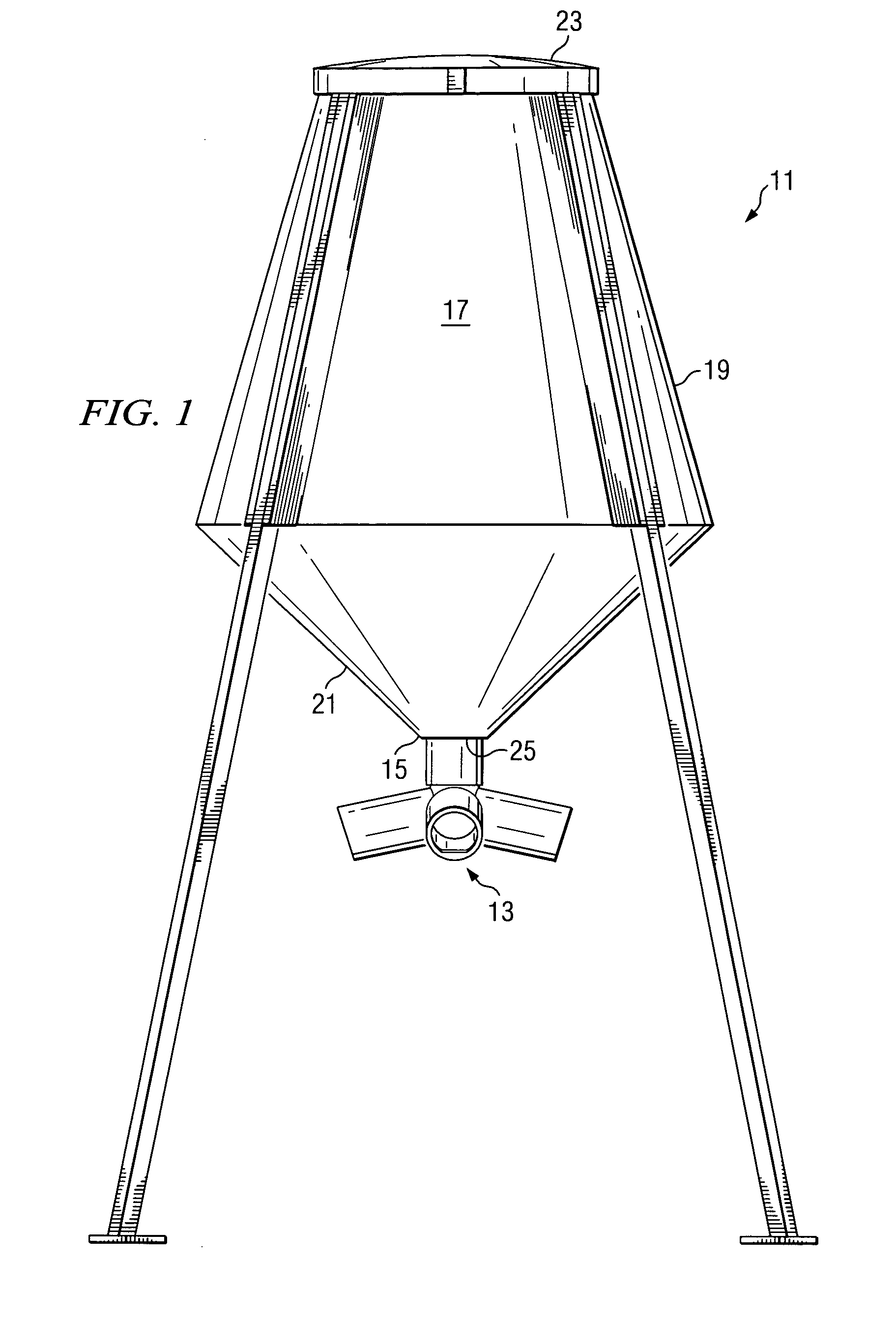

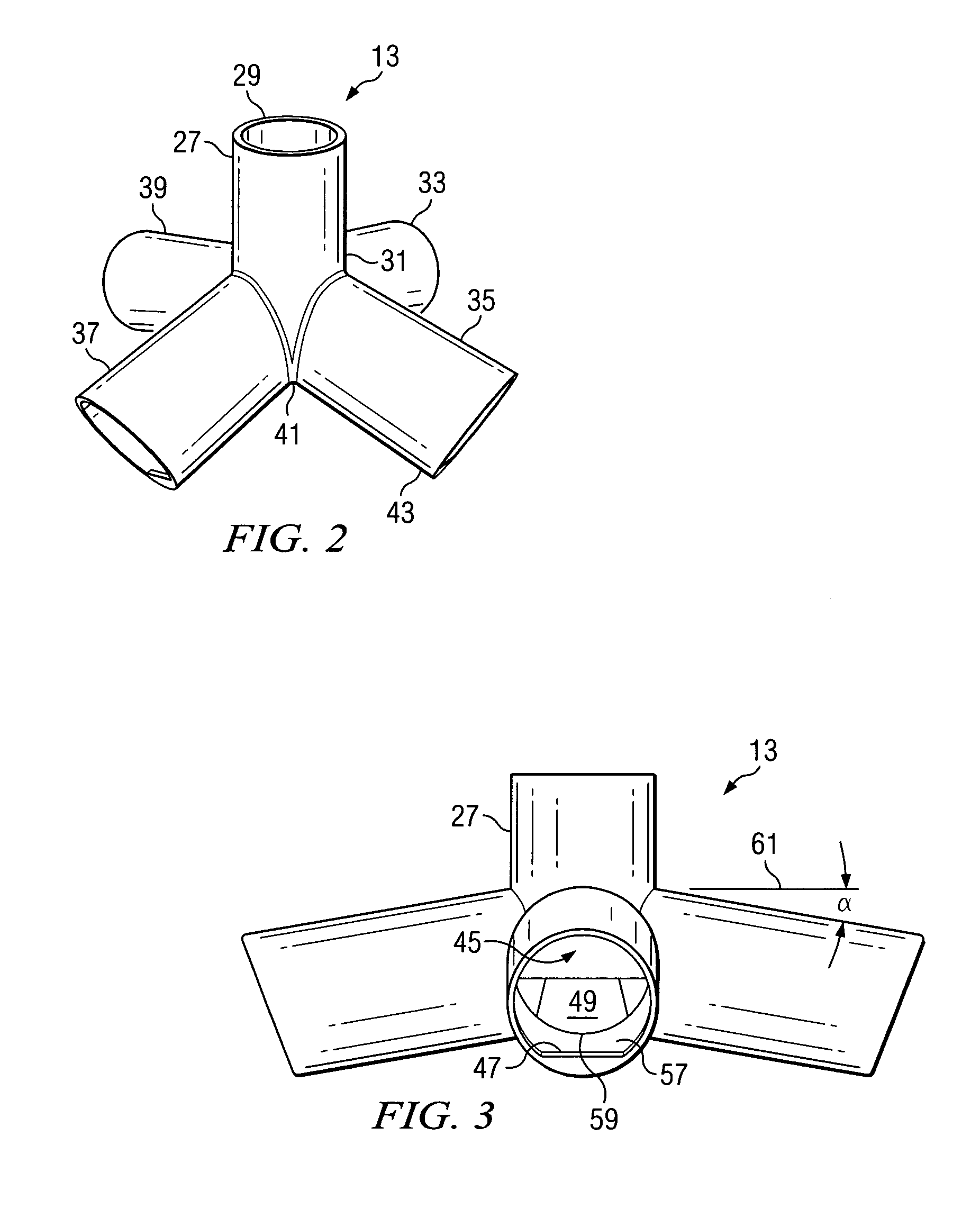

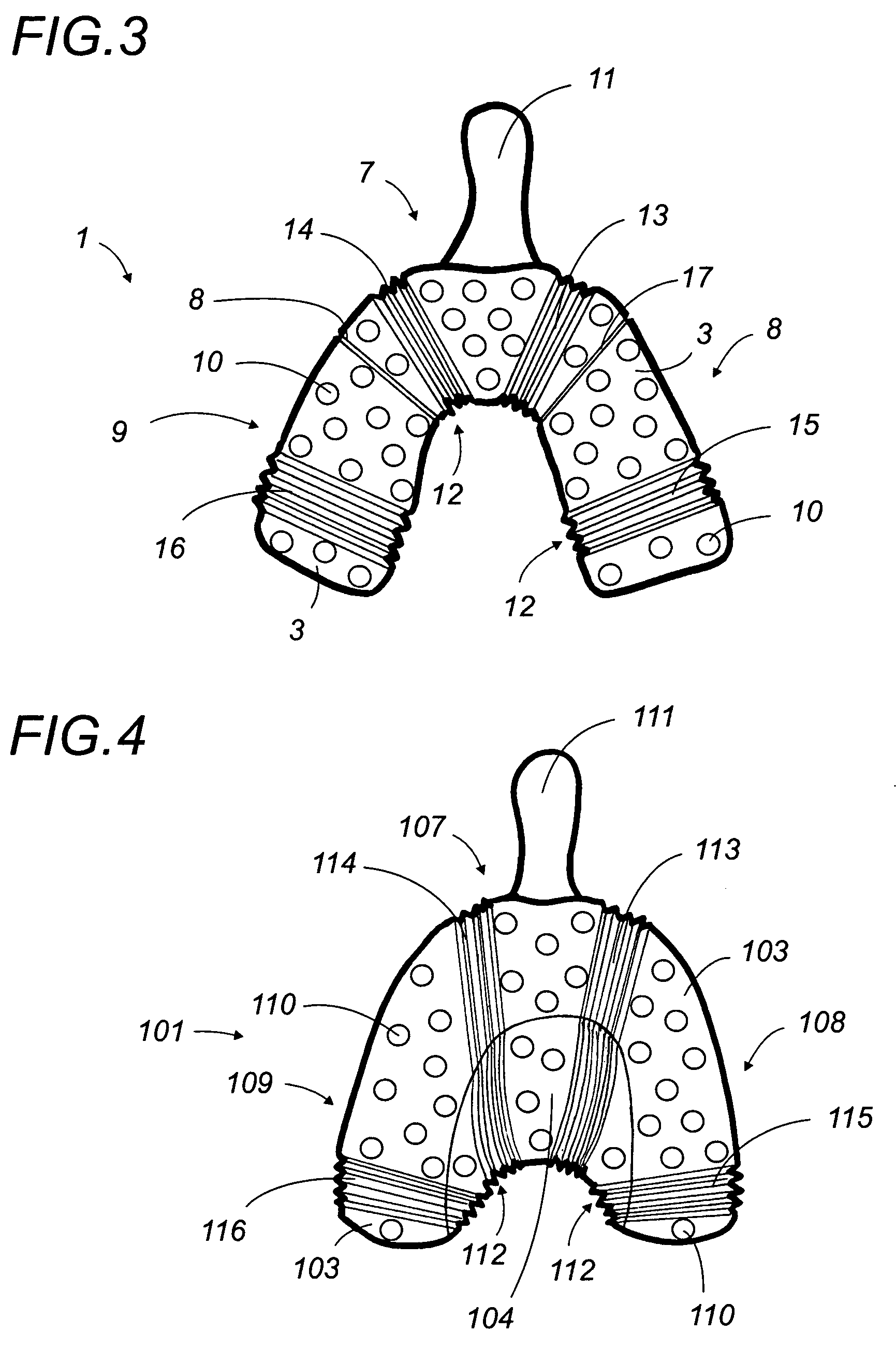

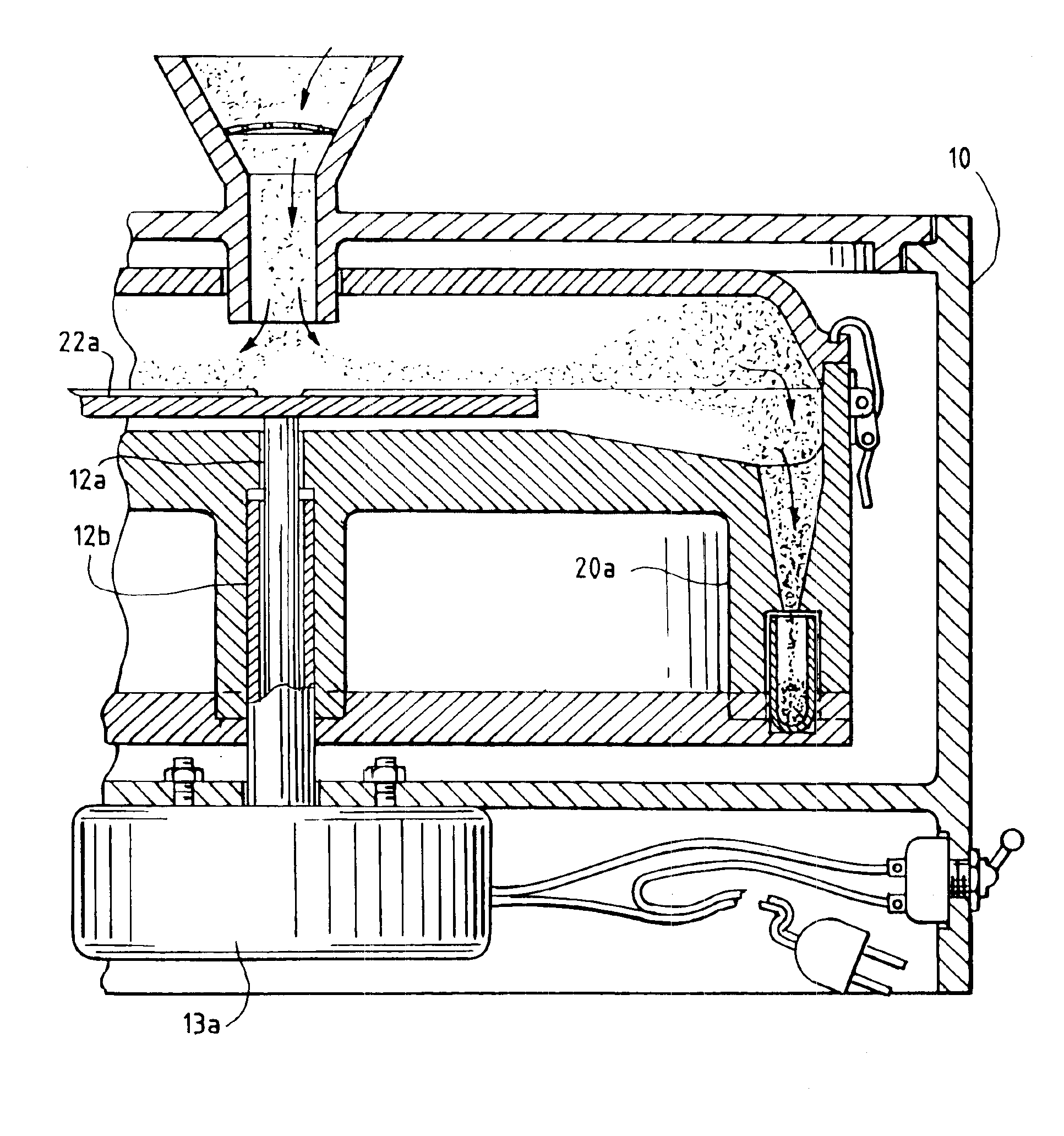

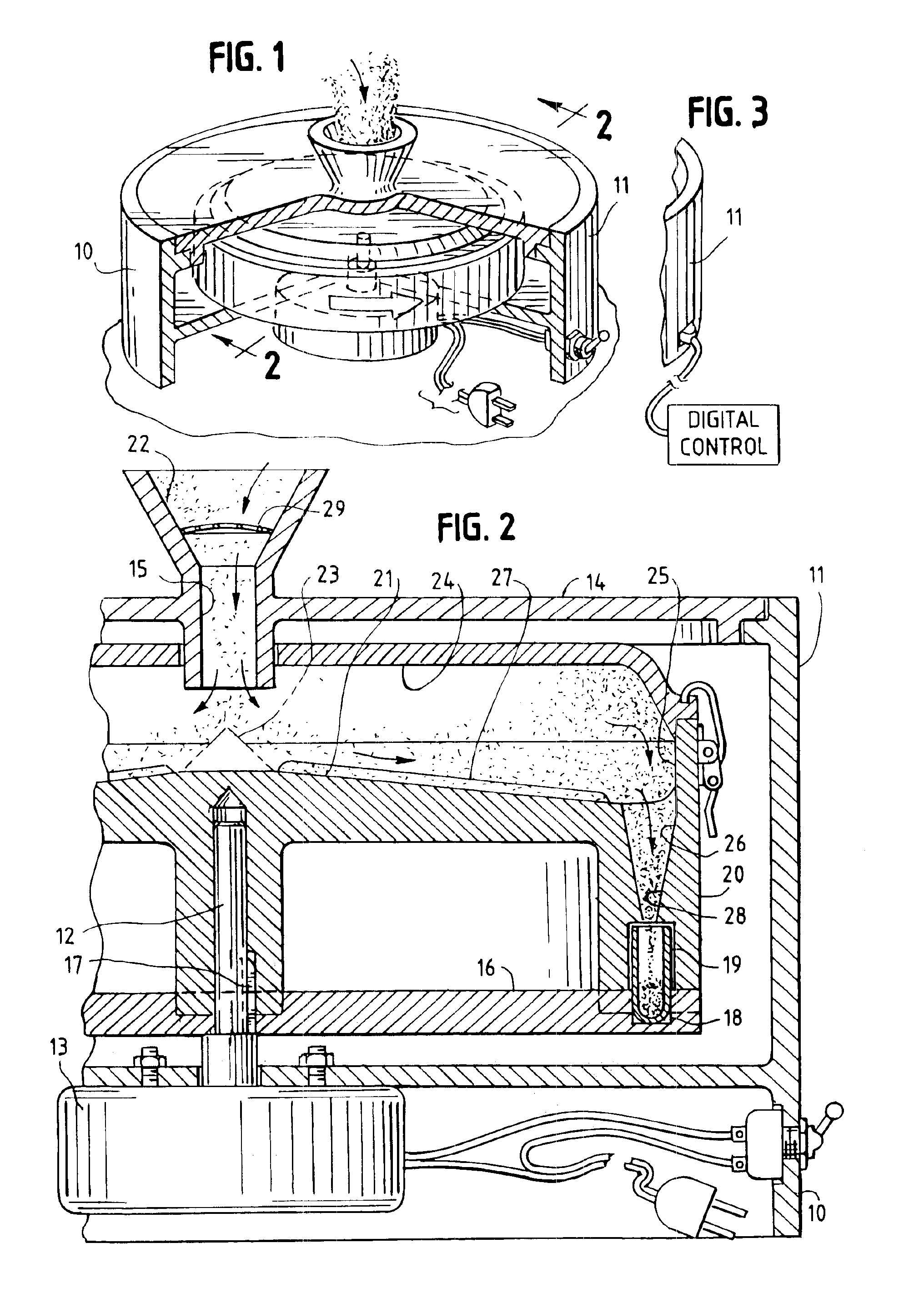

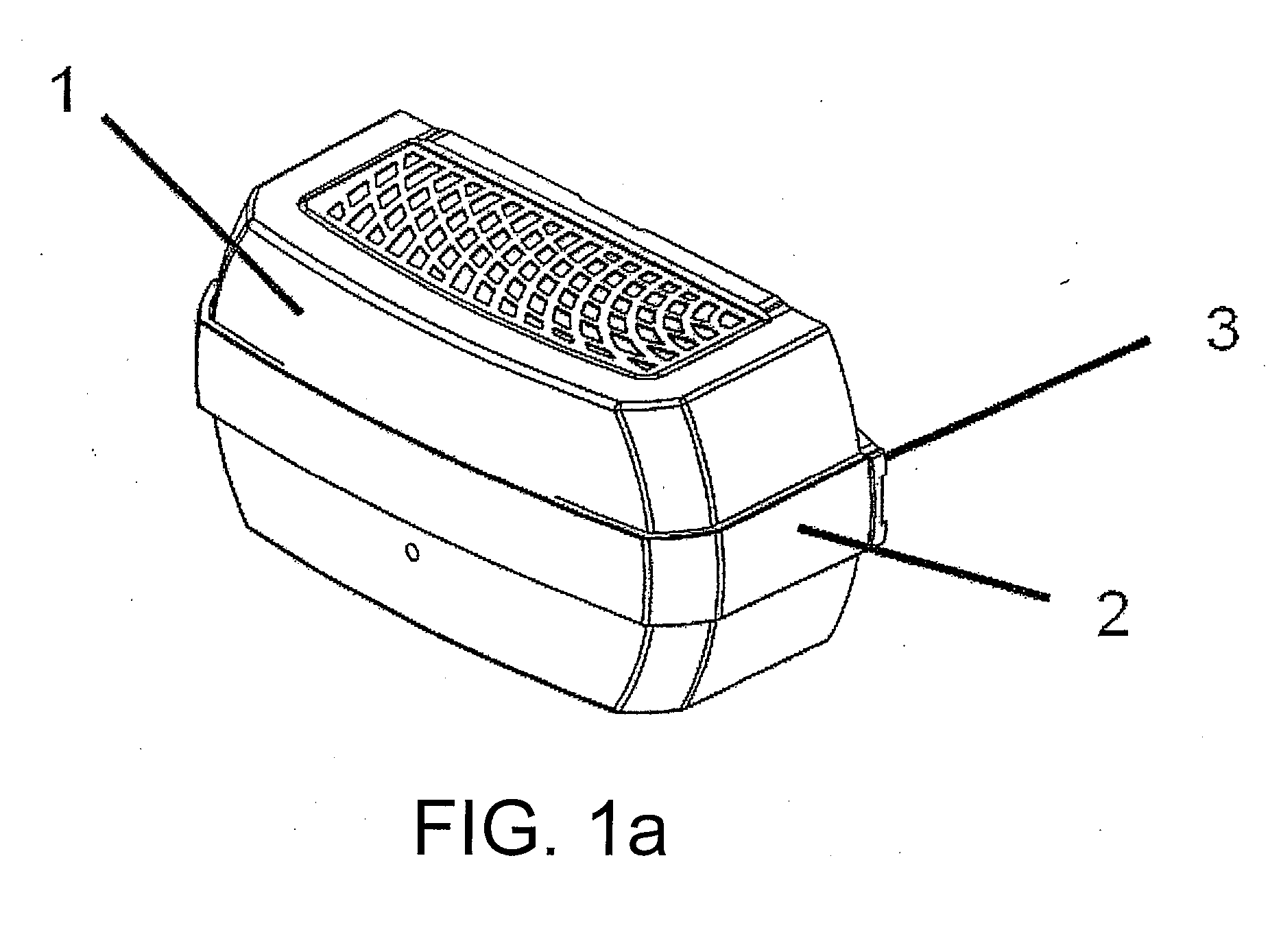

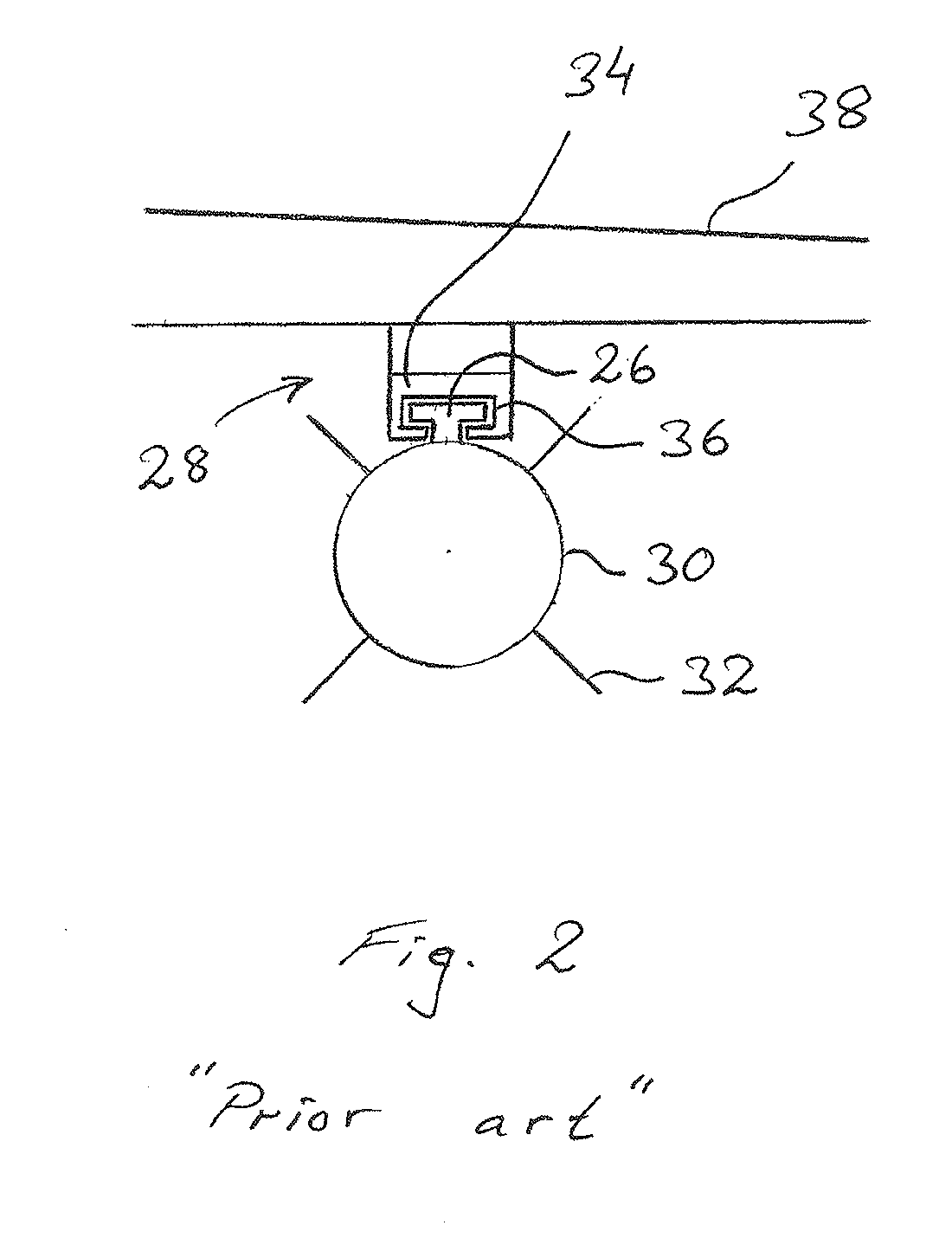

Discharge unit for a game feeder

ActiveUS20060048712A1Improve flow of feedHigh trafficAnimal feeding devicesAnimal housingCouplingEngineering

A discharge unit for an animal feeder attaches to the feed outlet of the feeder. The discharge unit has an upwardly extending coupling tube which engages the feeder outlet. Several feeder tubes extend outwardly from the lower end of the coupling tube and together with the lower end of the coupling tube define a central chamber of the discharge unit. A spreader cone is located within a floor region of the central chamber. Feed passing from the feed outlet of the feeder passes through the internal diameter of the coupling tube of the discharge unit and over the spreader cone before passing through the central chamber and through the feeder tubes to be discharged from the feeder.

Owner:GOOD SPORTSMAN MARKETING LLC A DELAWARE LLC

Method and system for seamless handover of mobile devices in heterogeneous networks

ActiveUS7620015B2Quickly and easily adaptedHigh degreeDigital computer detailsTime-division multiplexHeterogeneous networkData transmission

Owner:ZAMA INNOVATIONS LLC

Discharge unit for a game feeder

ActiveUS7302912B2Speed up the flowHigh trafficAnimal feeding devicesAnimal housingCouplingEngineering

Owner:GOOD SPORTSMAN MARKETING LLC A DELAWARE LLC

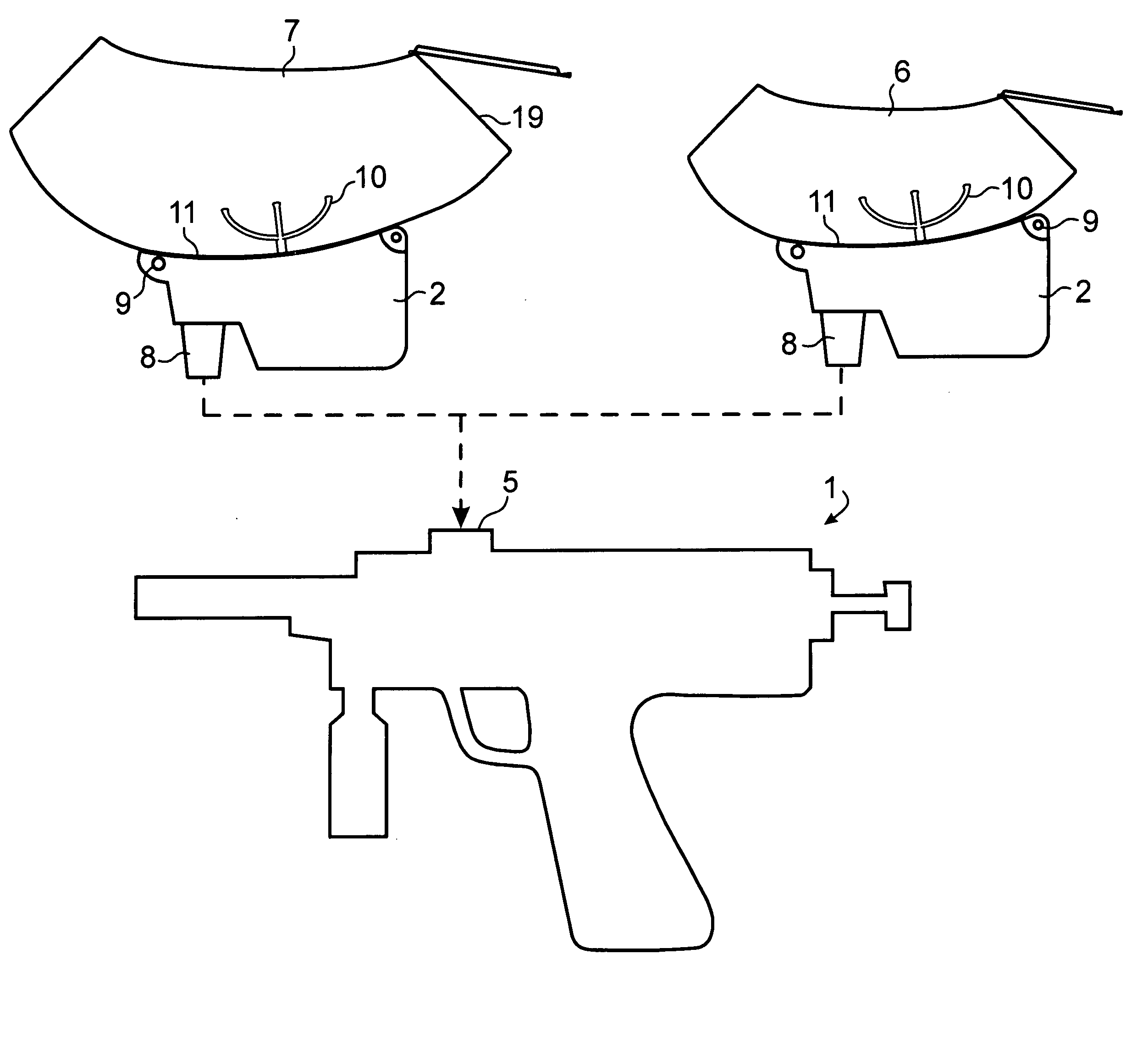

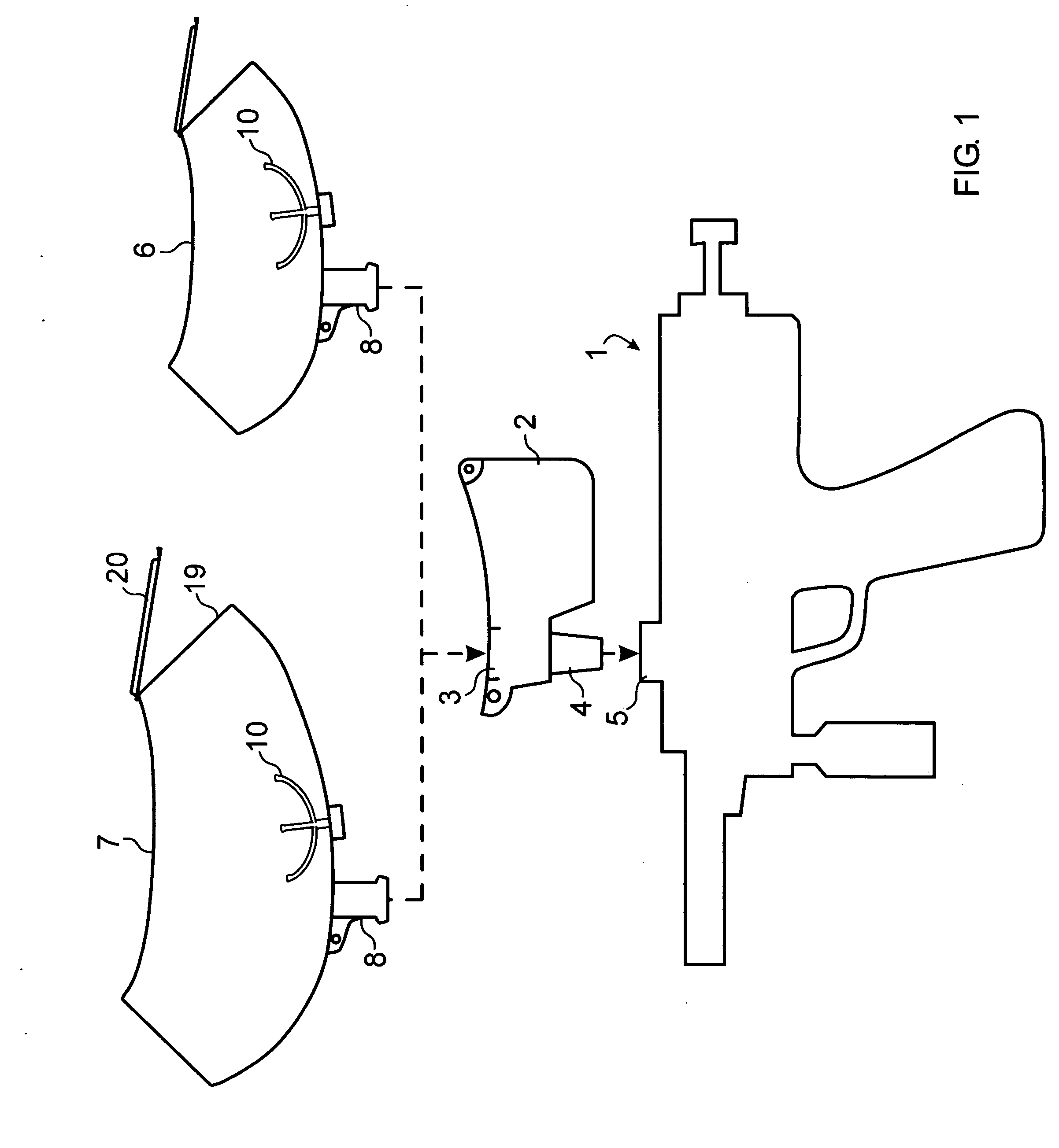

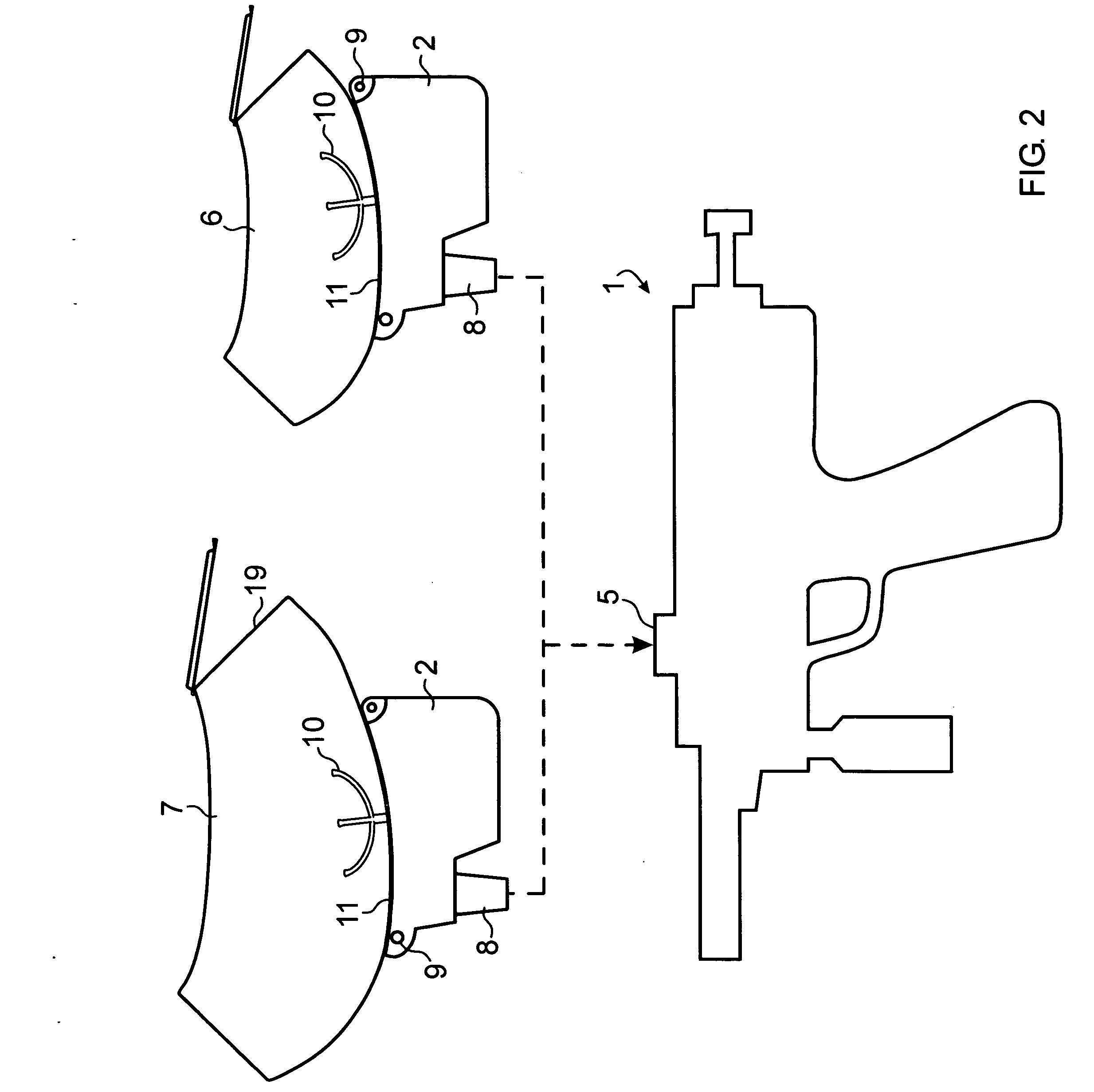

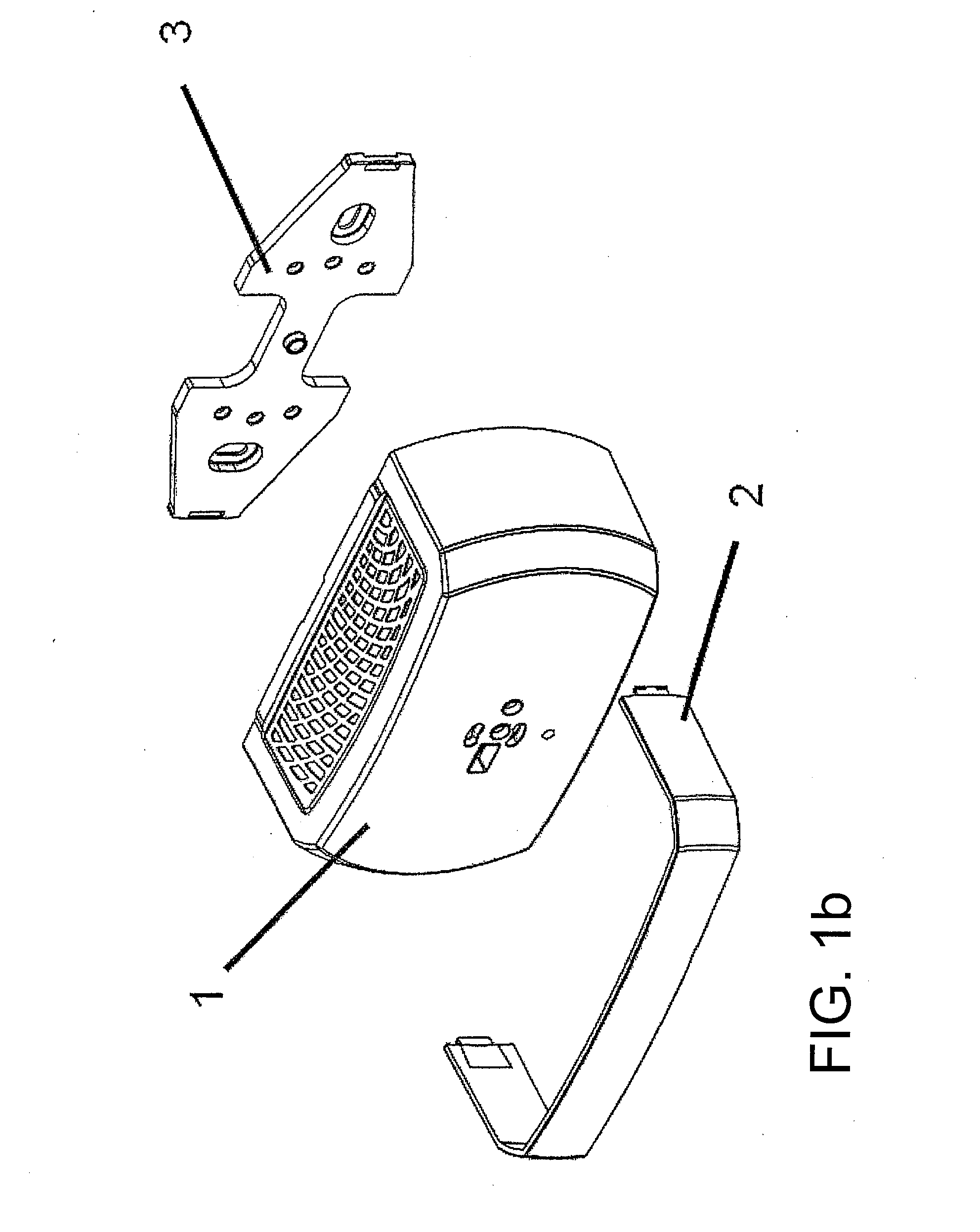

Adjustable capacity loader for paintball markers

InactiveUS7322347B2Quickly and easily adaptedLimiting fire powerAmmunition loadingCompressed gas gunsCouplingEngineering

Owner:KEE ACTION SPORTS I

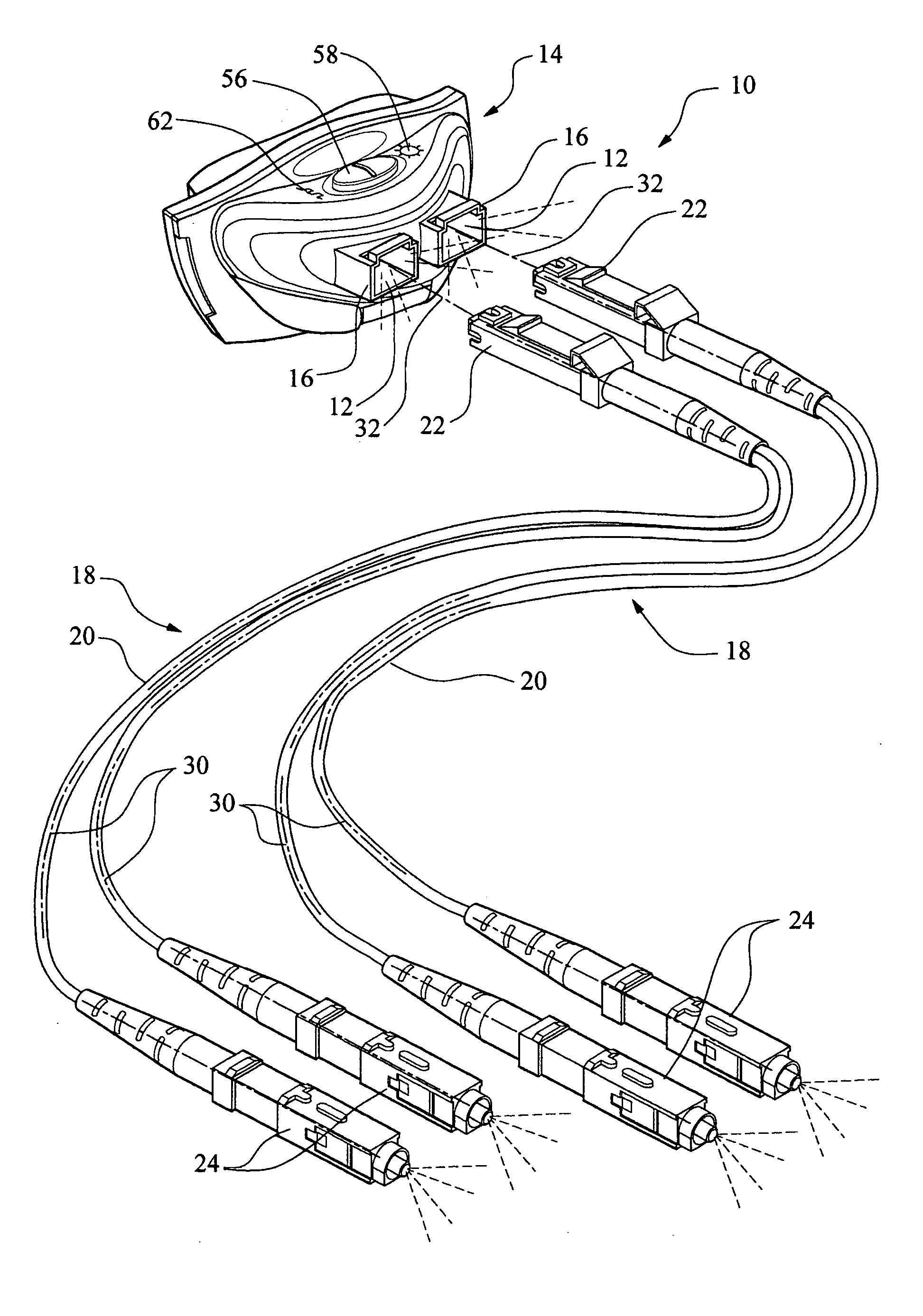

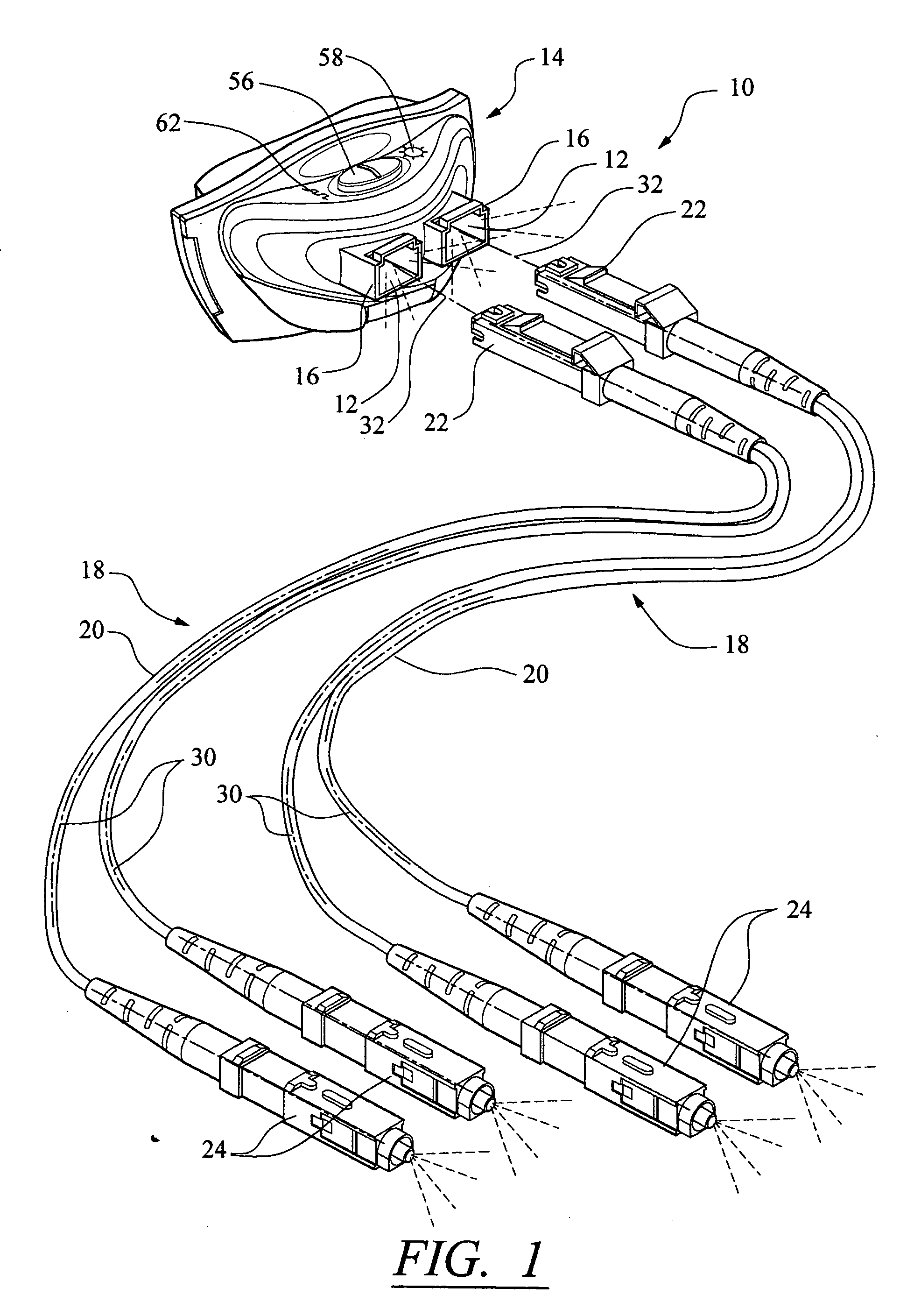

Fiber optic tester

InactiveUS20070014526A1Adaptable for useLight weightCoupling light guidesTesting fibre optics/optical waveguide devicesLight sourceEngineering

Owner:LAZO DANIEL OTONIEL

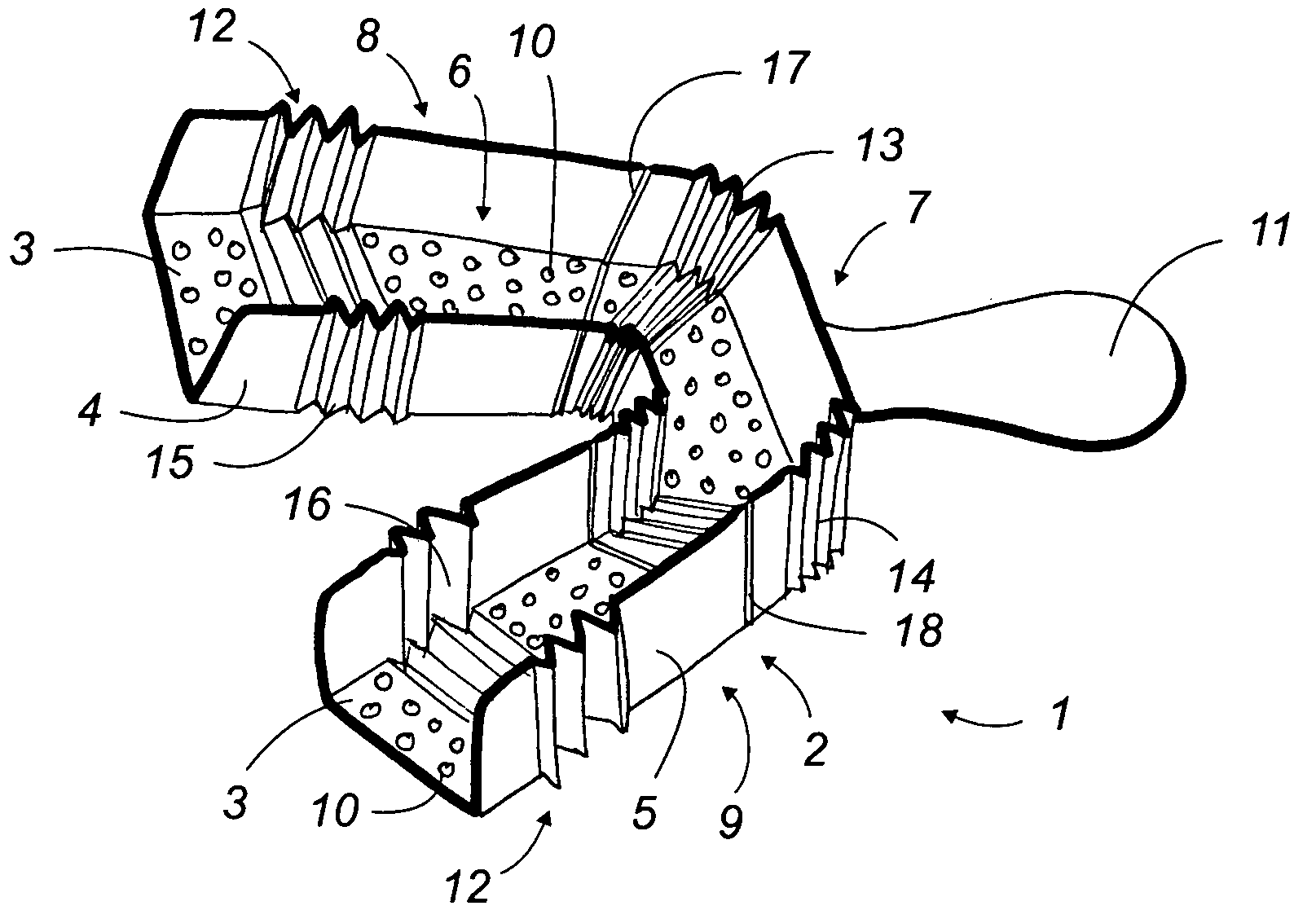

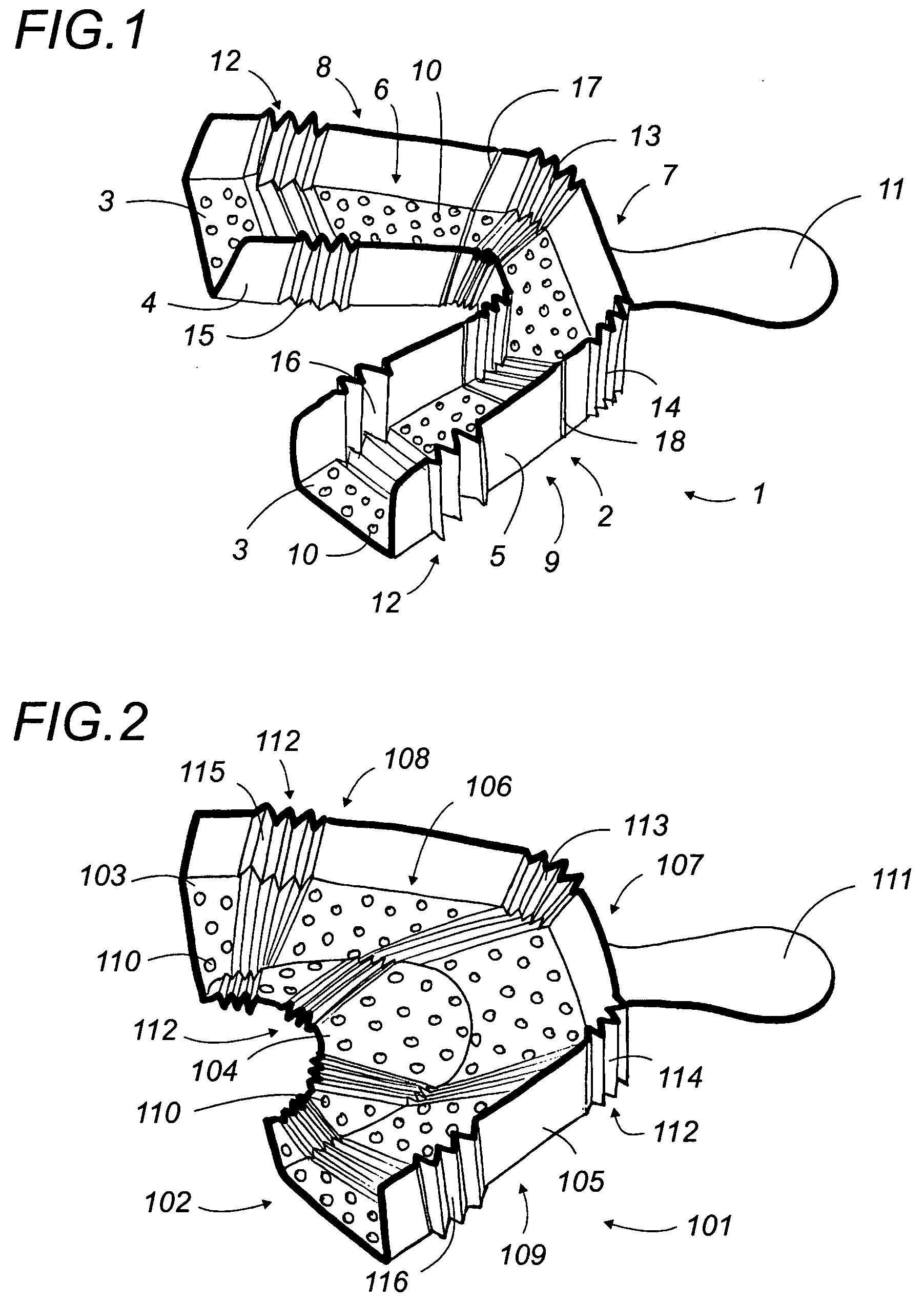

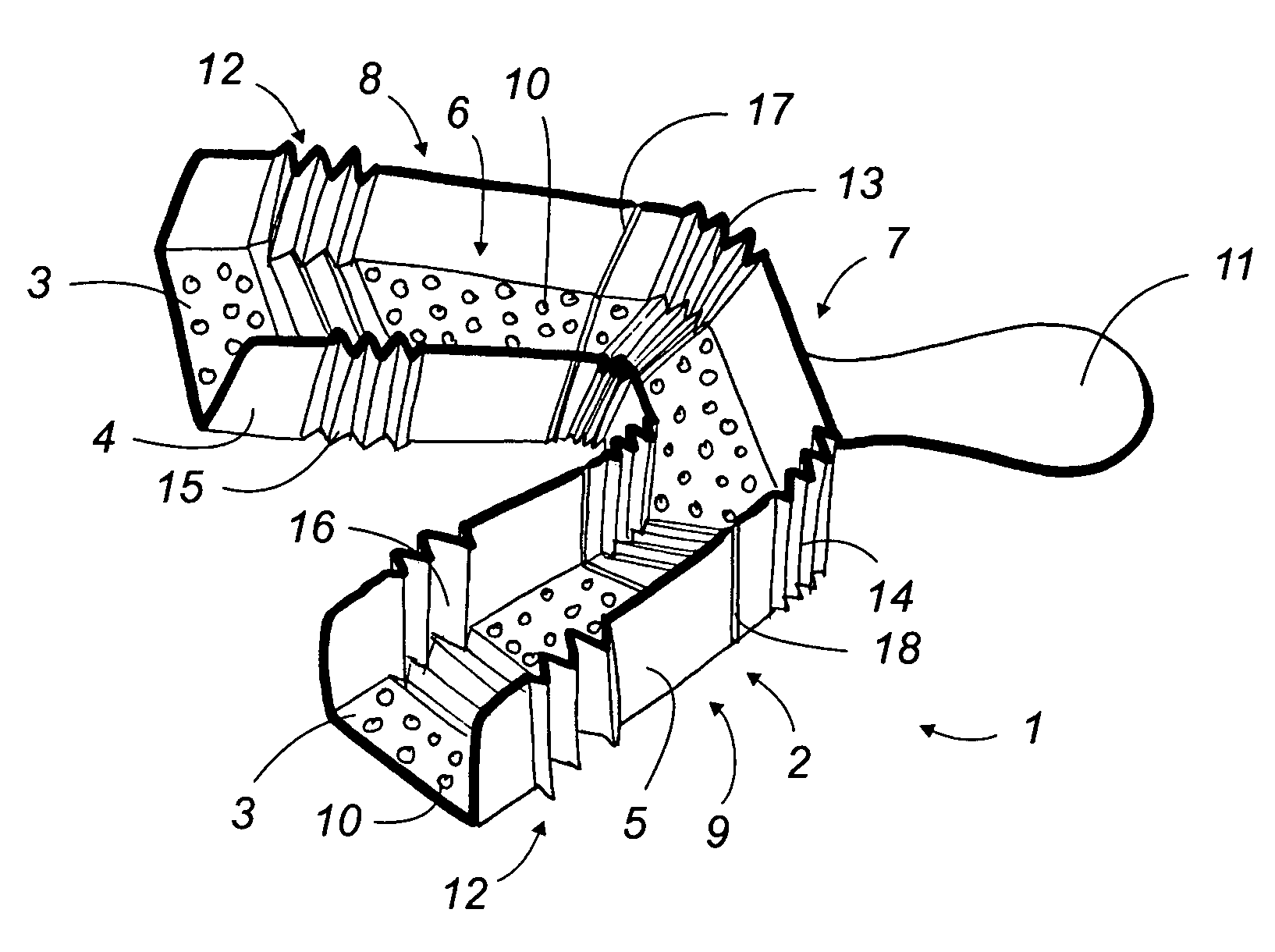

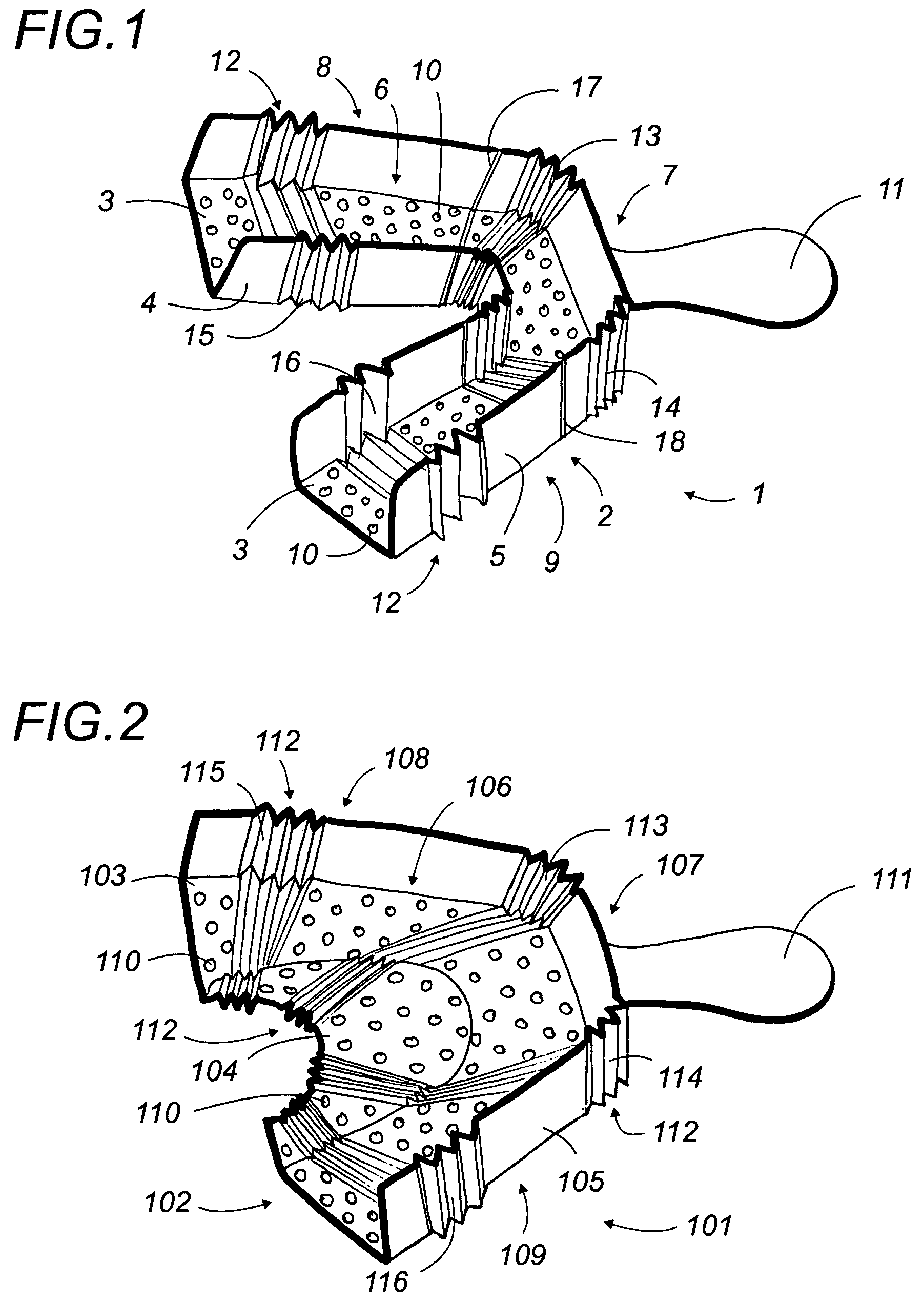

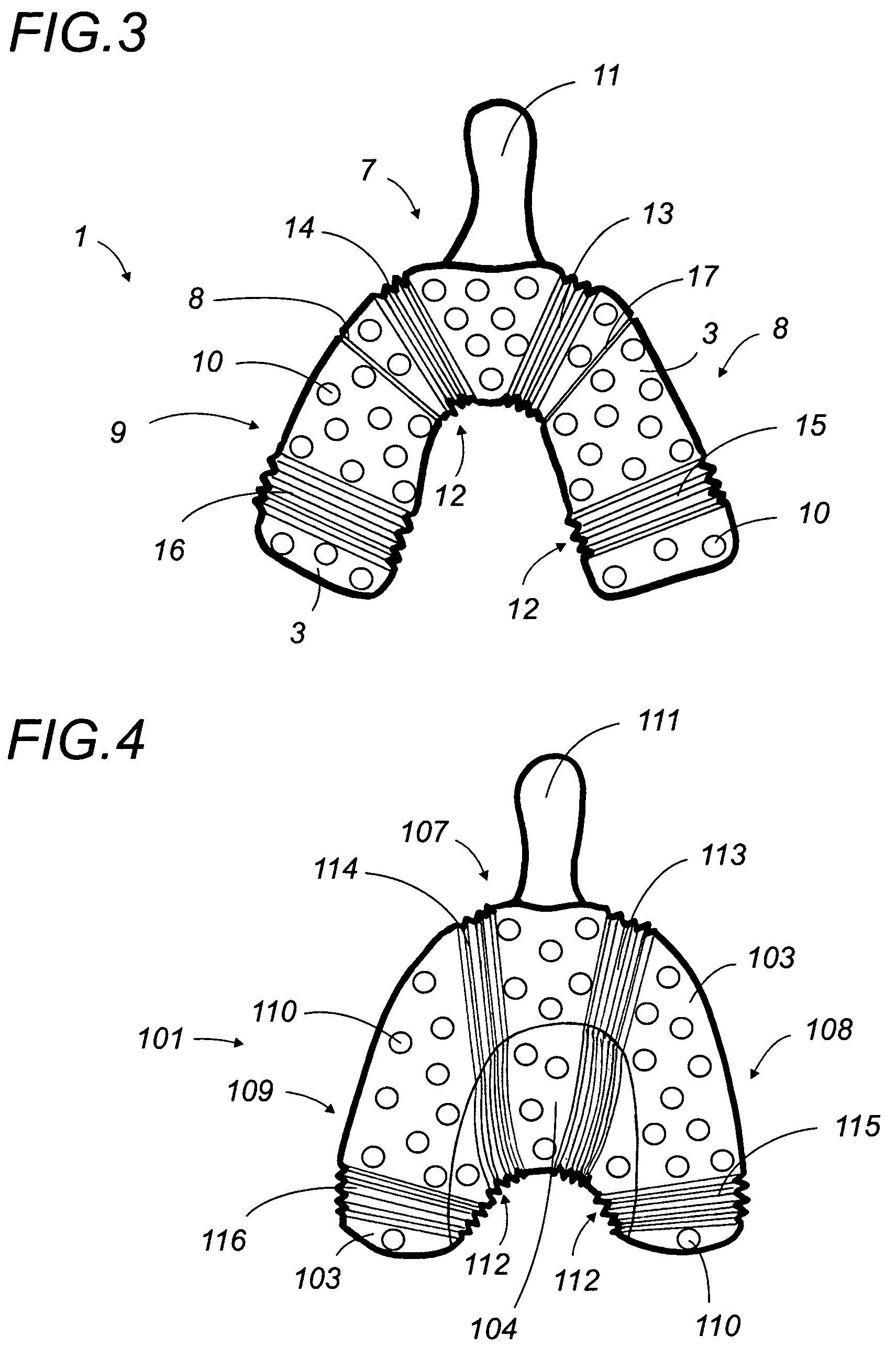

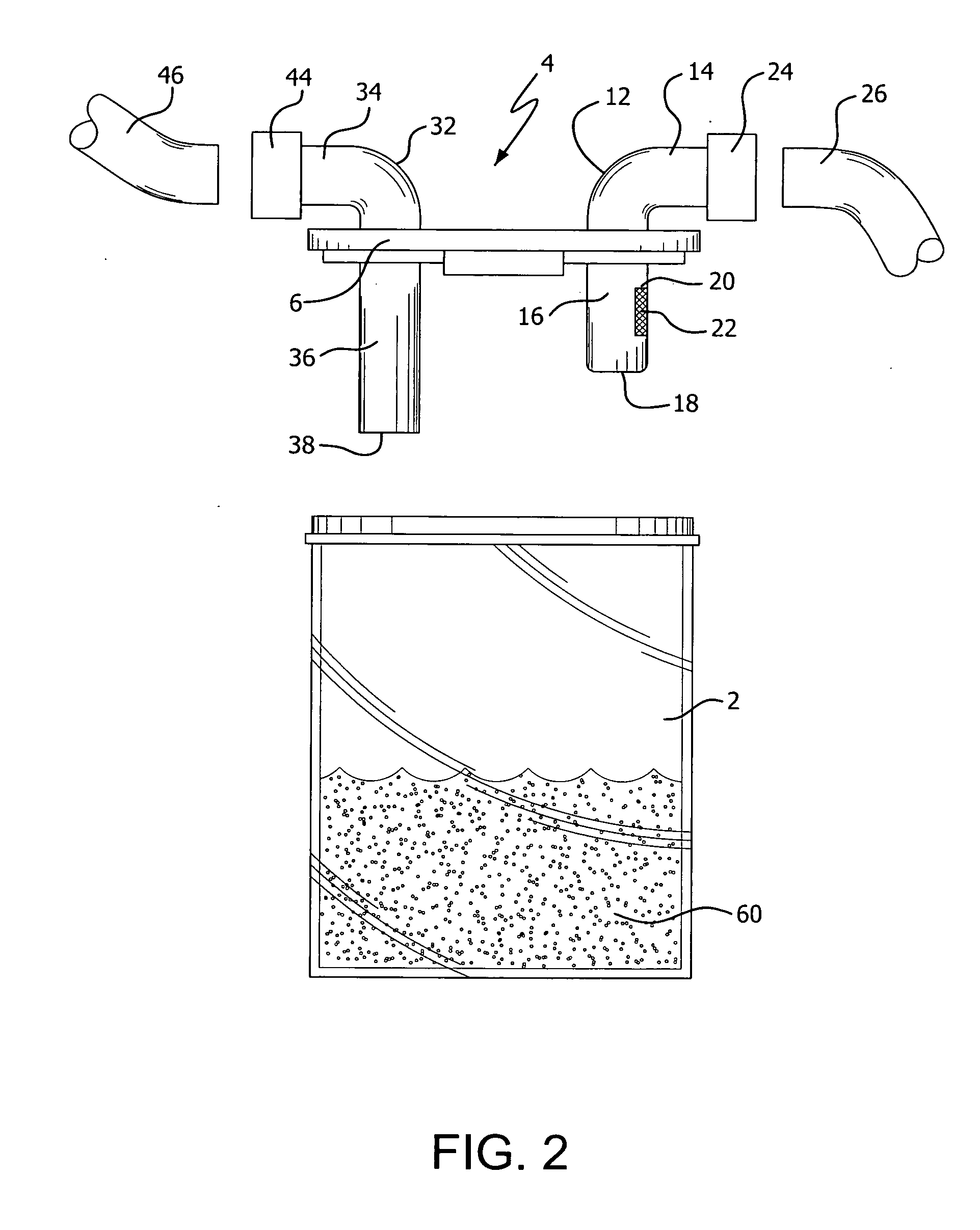

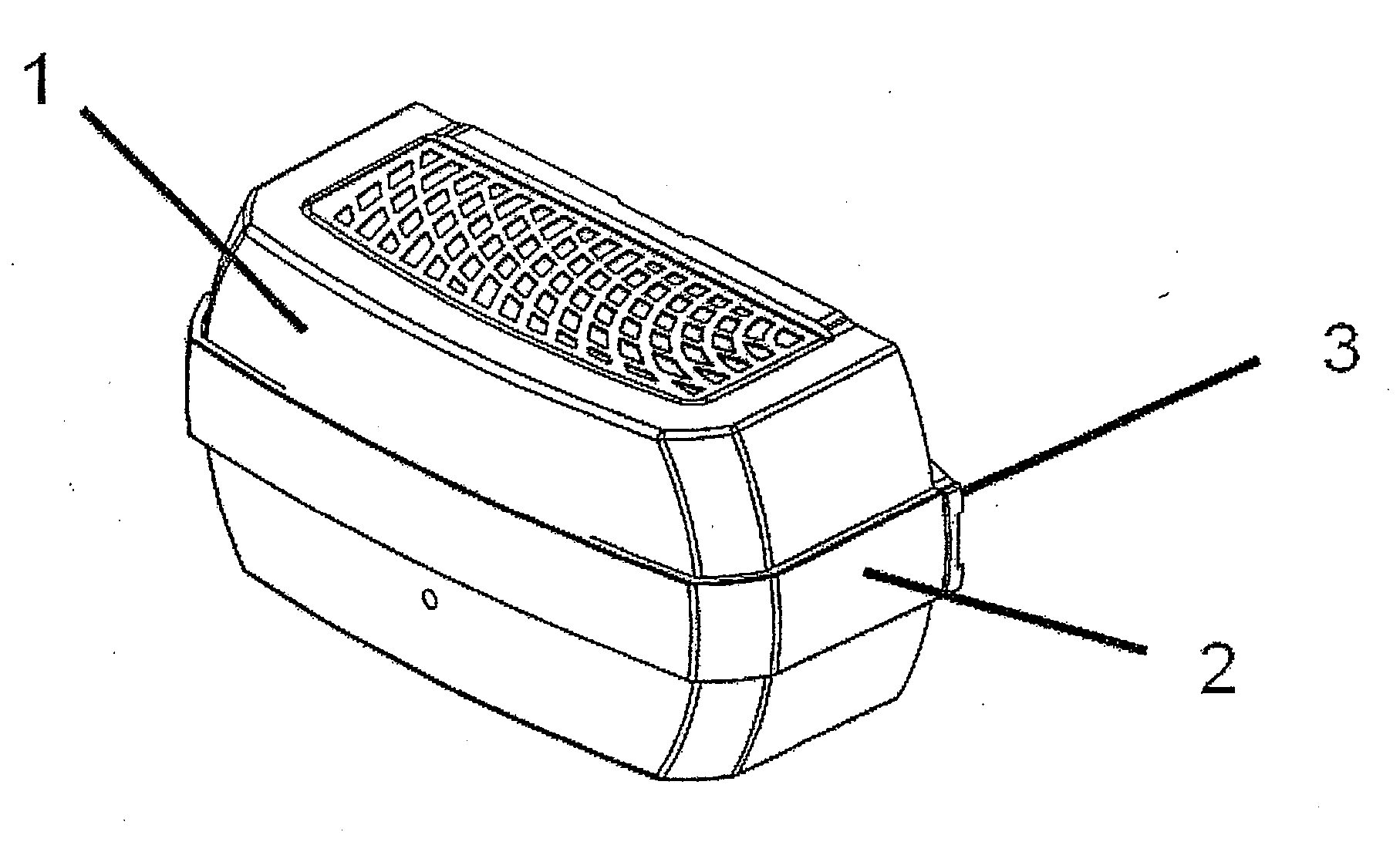

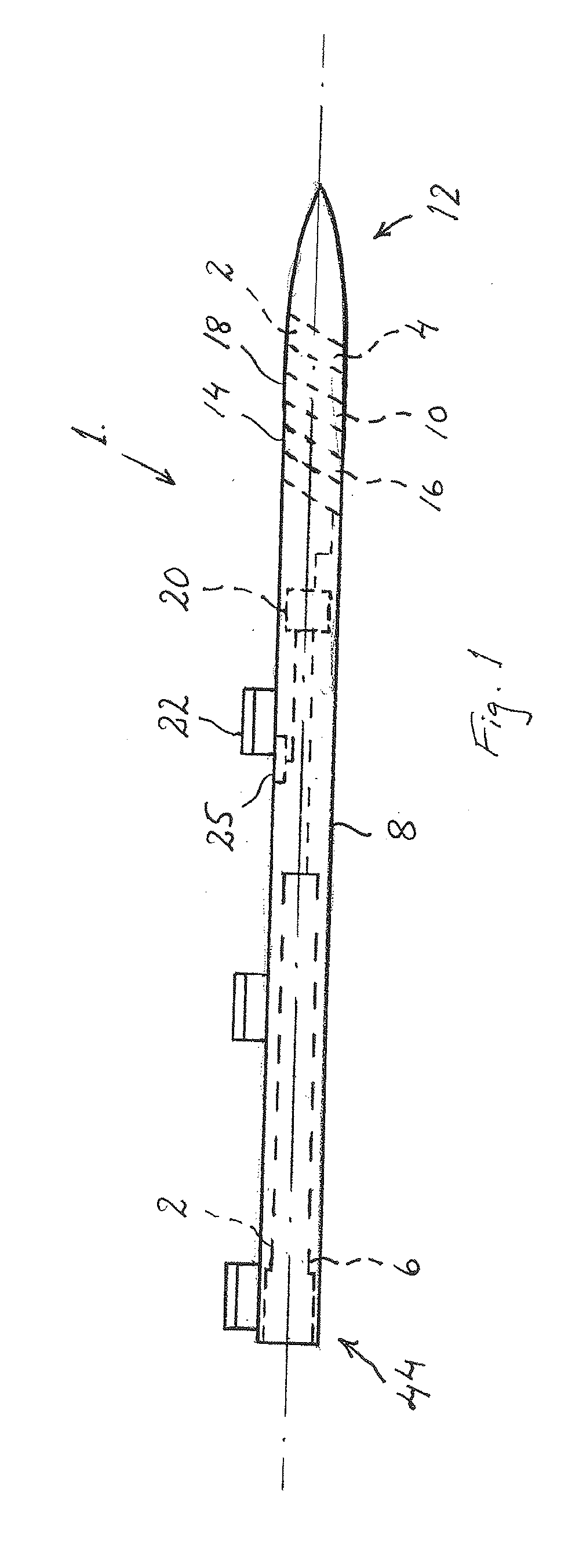

Adjustable impression tray with variable geometry

InactiveUS20050153256A1Reduce mechanical resistanceAdapt the impression tray easily and quicklyImpression capsImpression traysDental Equipment

The invention relates to an adjustable impression tray (1) comprising a trough (2) in the form of an arch with a straight central portion (7) extended by two lateral branches (8,9), essentially matching the form of a dental arch and comprising several integral zones which may be deformed at the temperature of use in the form of a multi-directional extension means (12), for example an accordion-like bellows arrangement (13 to 16). The impression tray, preferably for single usage, advantageously comprises splitting zones (17, 18) which allow the production of impression trays of differing sectors, which by comprising one or several deformation zones are equally adjustable. The invention is of interest to dentists and prosthetic dentists and more generally to producers and users of dental equipment.

Owner:LIVOLSI LYDIE

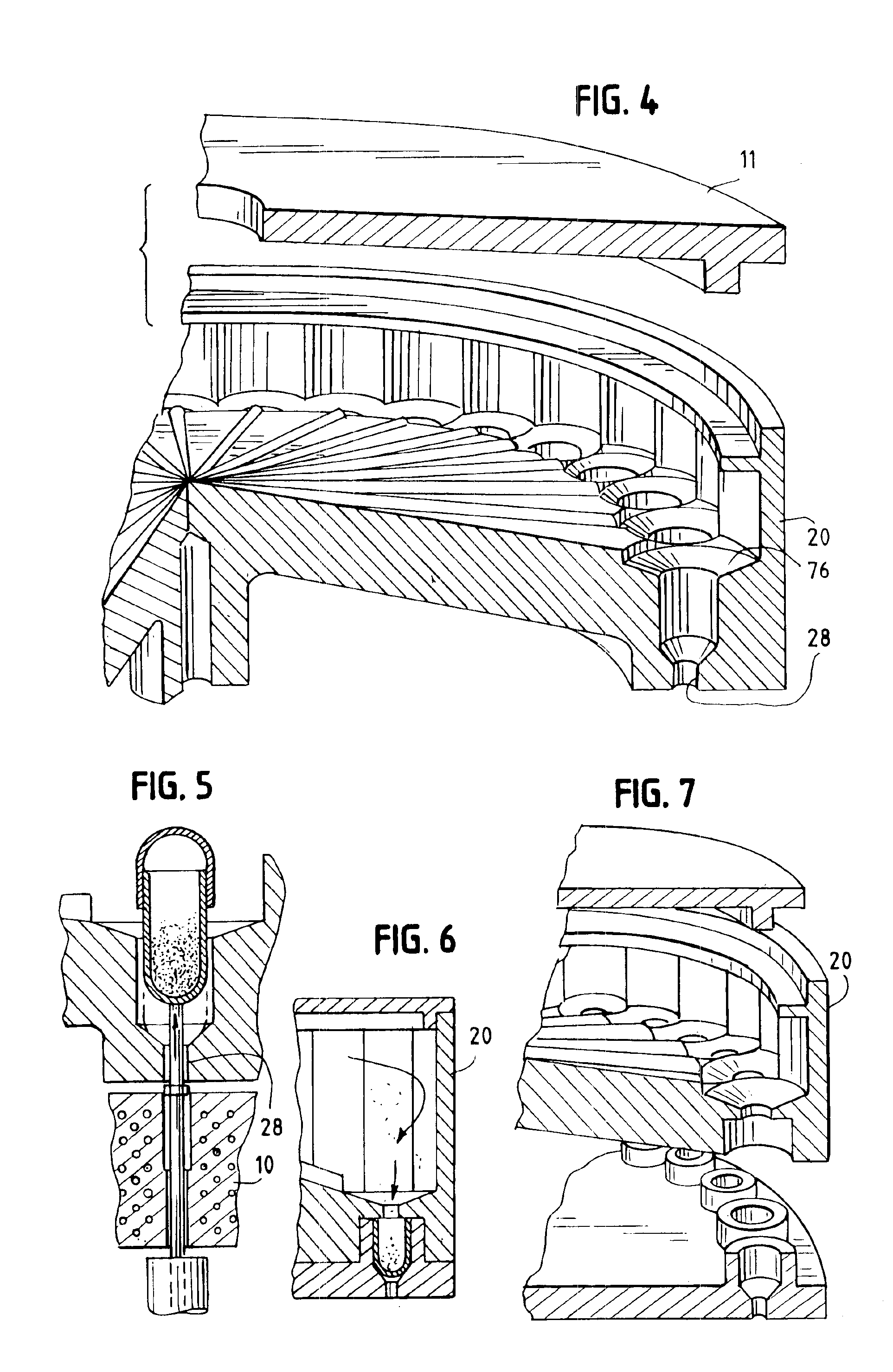

Capsule filling device and method of operation

ActiveUS6901972B1Quickly and easily adaptedSmall scaleLiquid fillingSolid materialFilling materialsEngineering

A device and method of operation for filling medicine capsules, in which a fixed quantity of open capsules to be filled are supported in a circular array by a holder plate beneath the periphery of a rotatable distribution drum. In use, a measured supply of filling medication, in dry granular form, is dispensed into the center of the rotating drum where it is distributed evenly by centrifugal force along the periphery of the drum. As the drum stops rotating, the medication flows by gravity into the capsules, which are then inspected, closed and packaged. The distribution of filler material is more even than if the capsules were filled by hand, and the average quantity (both by volume and by weight) of the filling material per capsule in the batch is variable to suit an individual patient's needs, and very accurately known. In addition, two or more compatible filler medications may be mixed in the same capsules to suit the specialized needs of a particular user. Because the provided quantity of medication is completely distributed into each batch of capsules, inadvertent double-filling is prevented.

Owner:NELSON JOHN

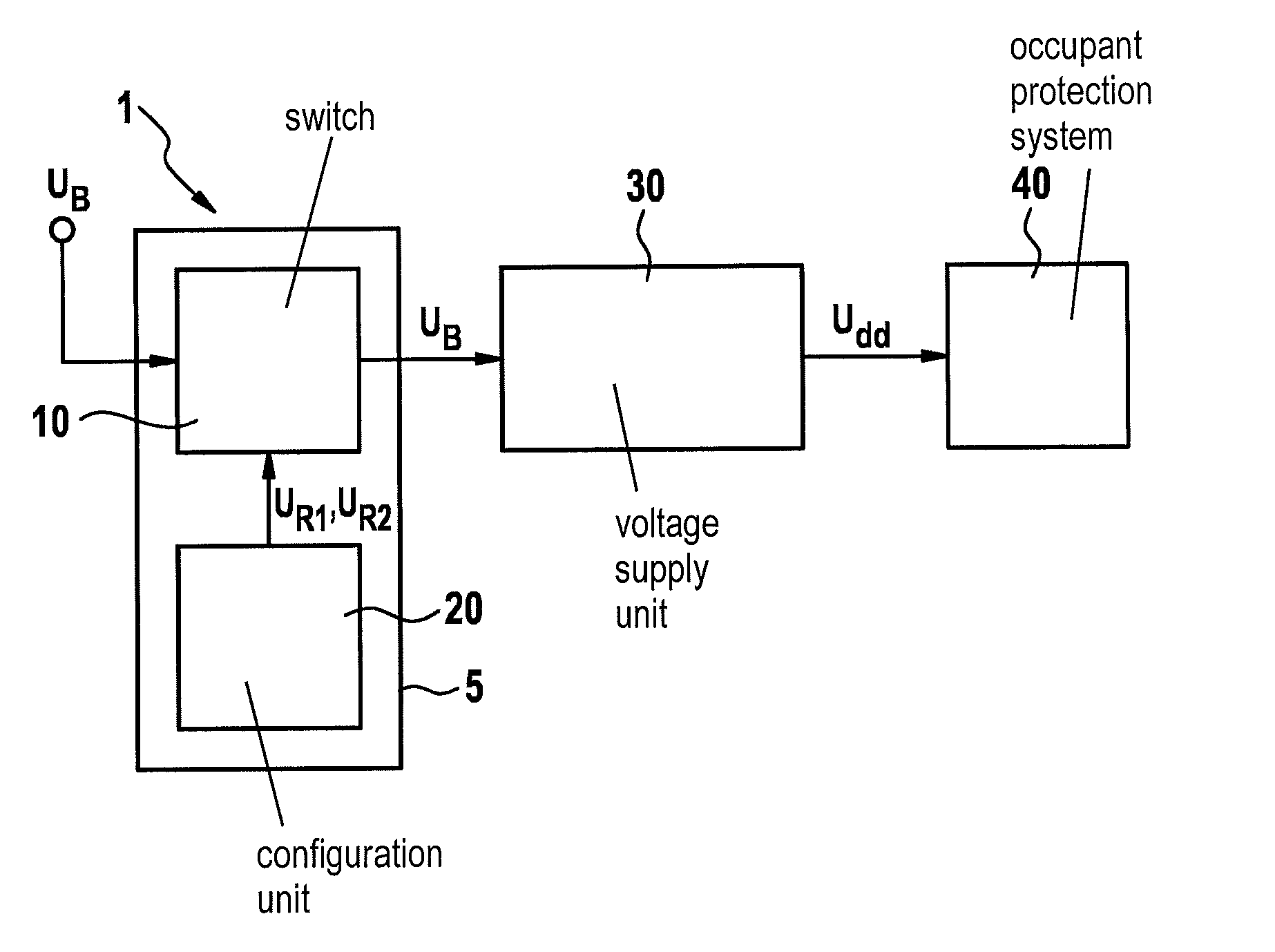

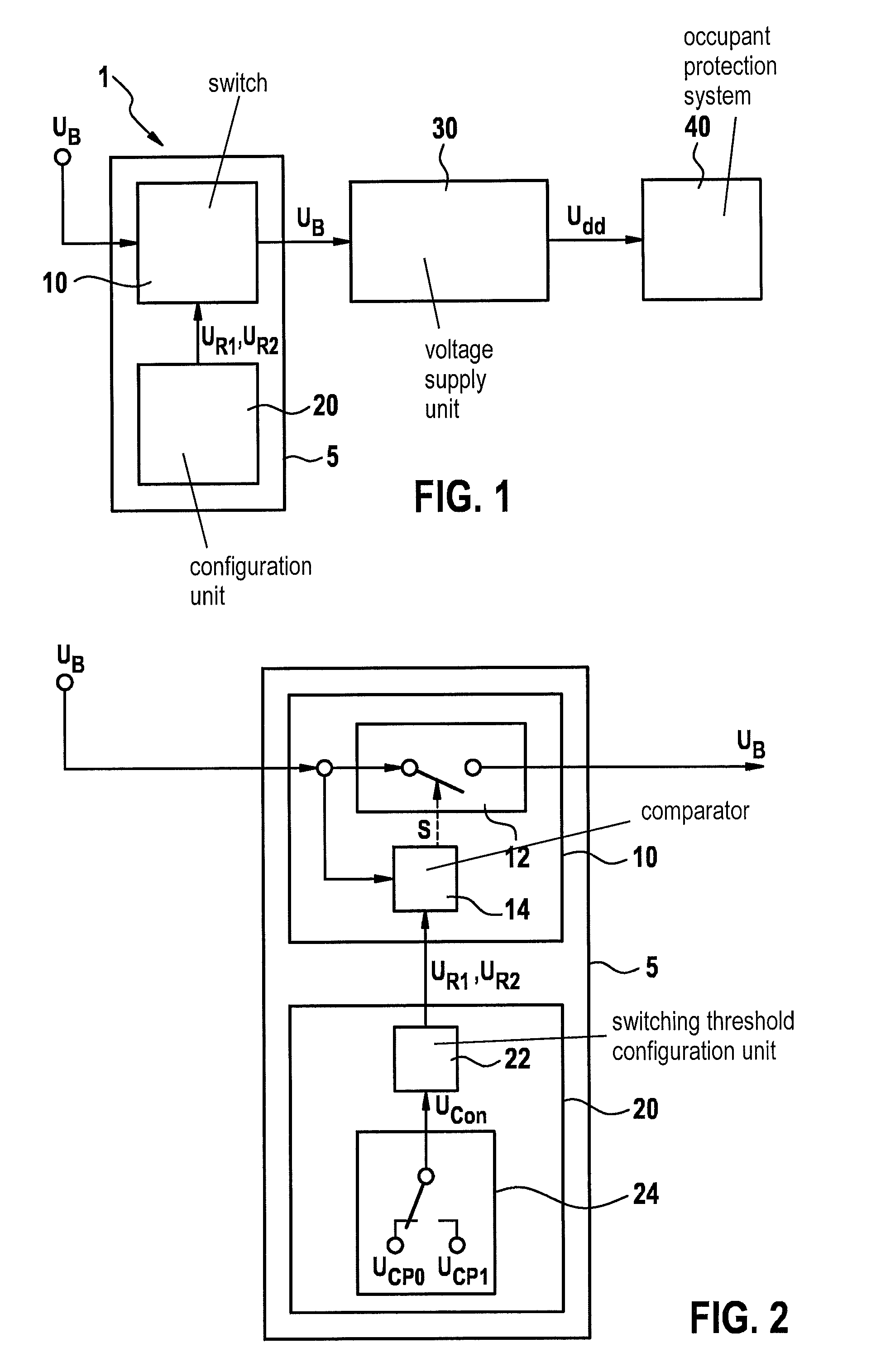

Device and method for the voltage supply of an occupant protection system

ActiveUS9561770B2Robust stateFully functionalPedestrian/occupant safety arrangementVoltage referenceEngineering

A device for the voltage supply of an occupant protection system in a motor vehicle having a switching unit and a voltage supply unit, which supplies an operating voltage to the occupant protection system, the switching unit providing a supply voltage to the voltage supply unit when the supply voltage exceeds a predefined threshold value voltage level. A configuration unit is also provided which provides various reference voltage levels for the switching unit as threshold value voltage levels.

Owner:ROBERT BOSCH GMBH

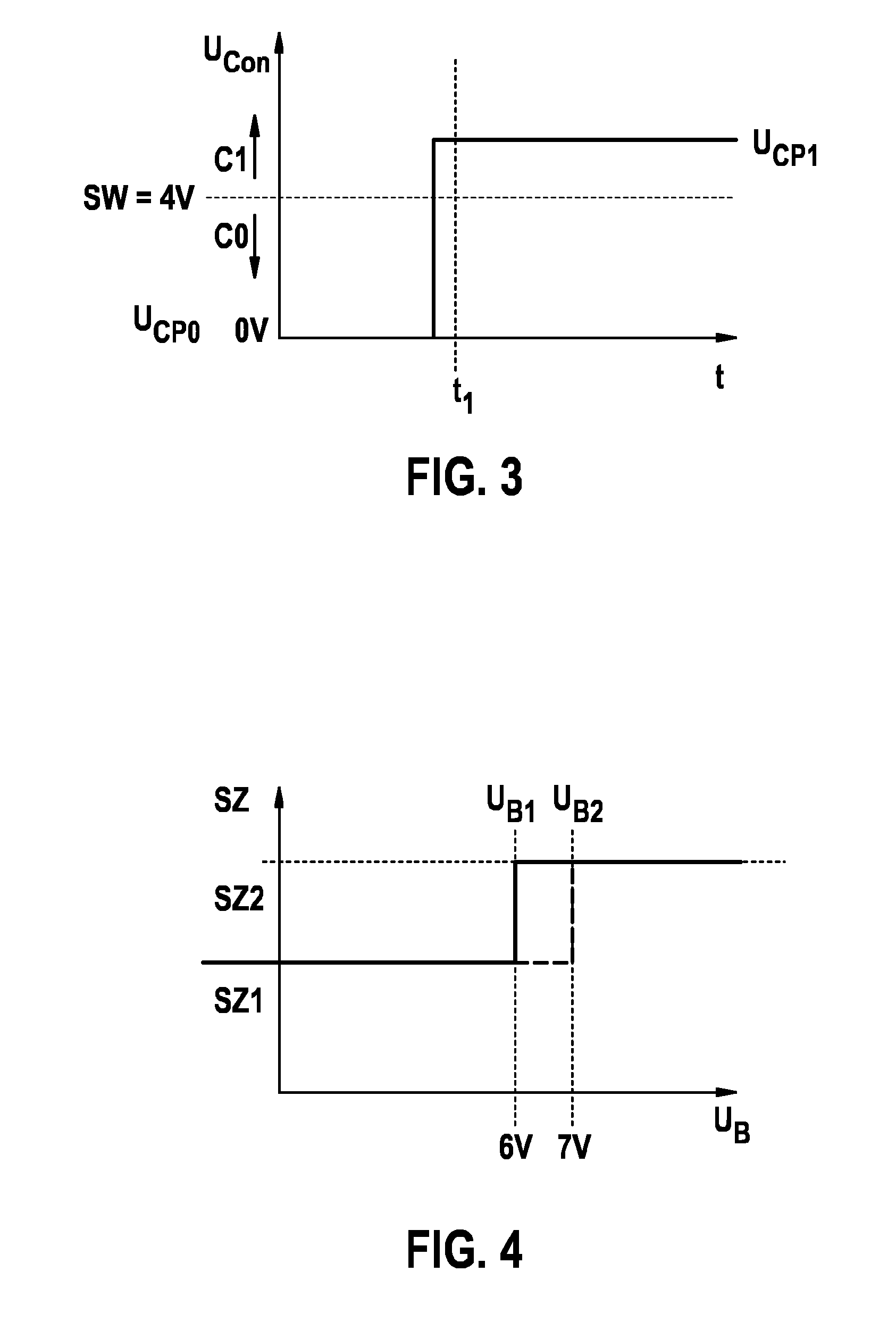

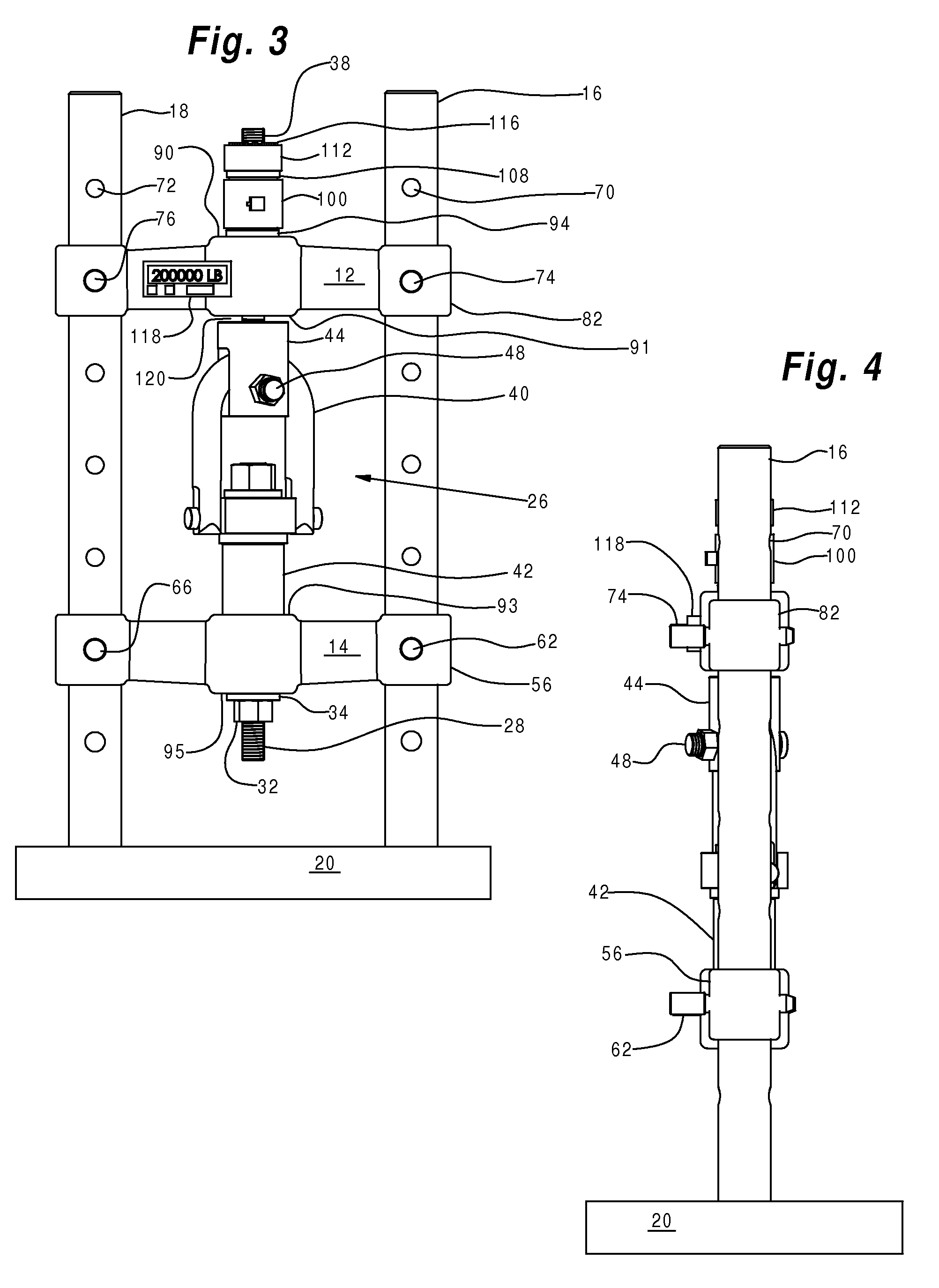

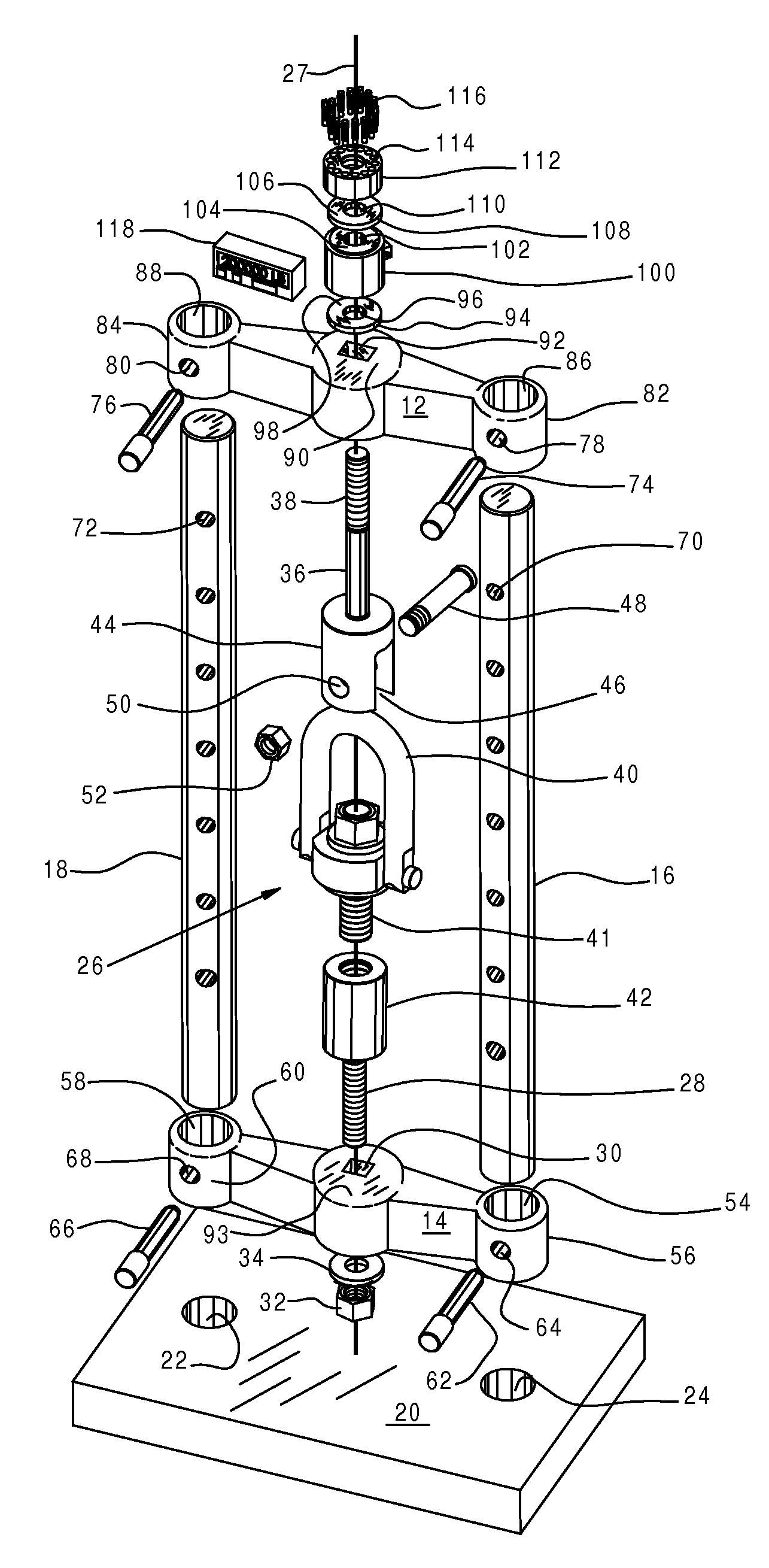

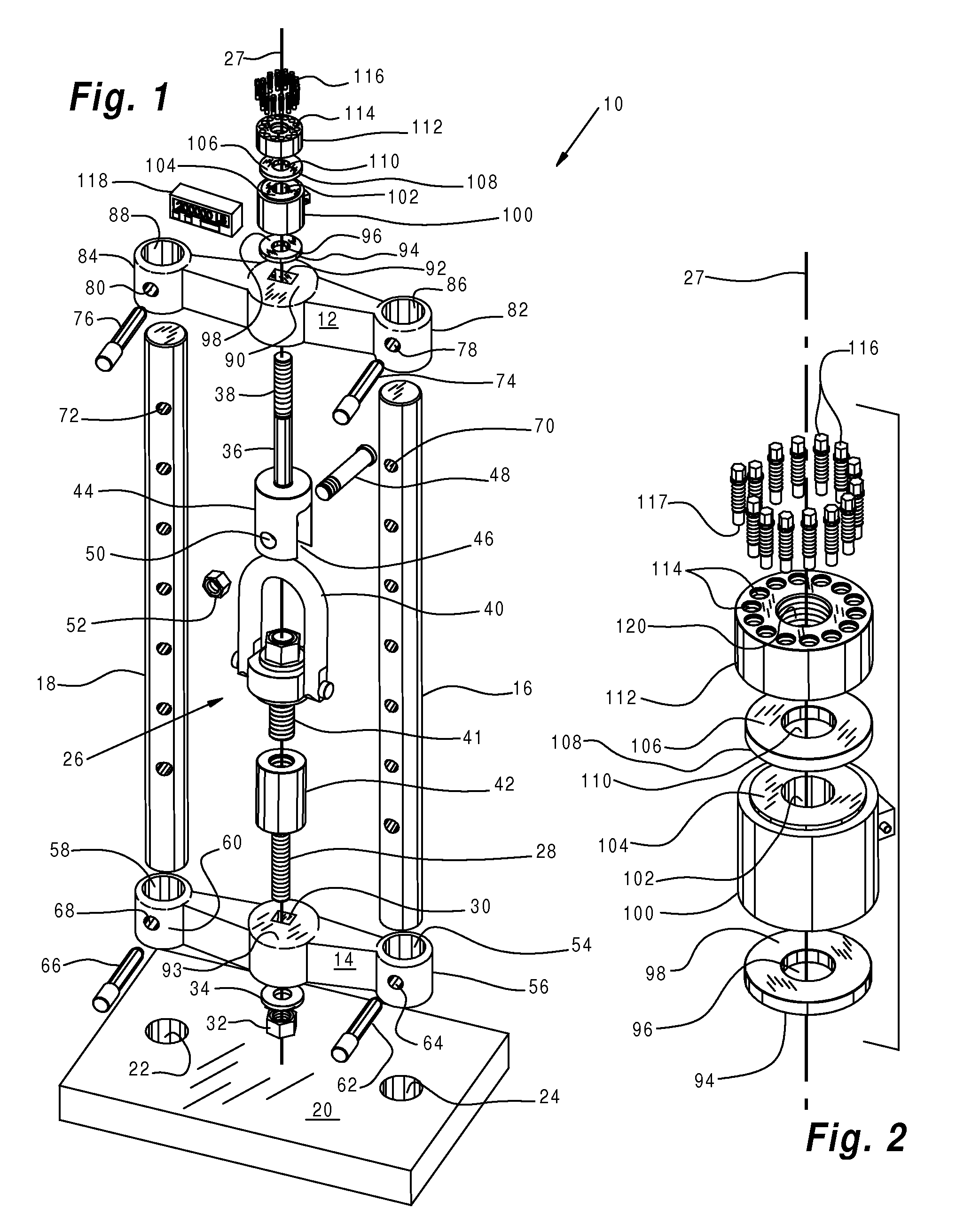

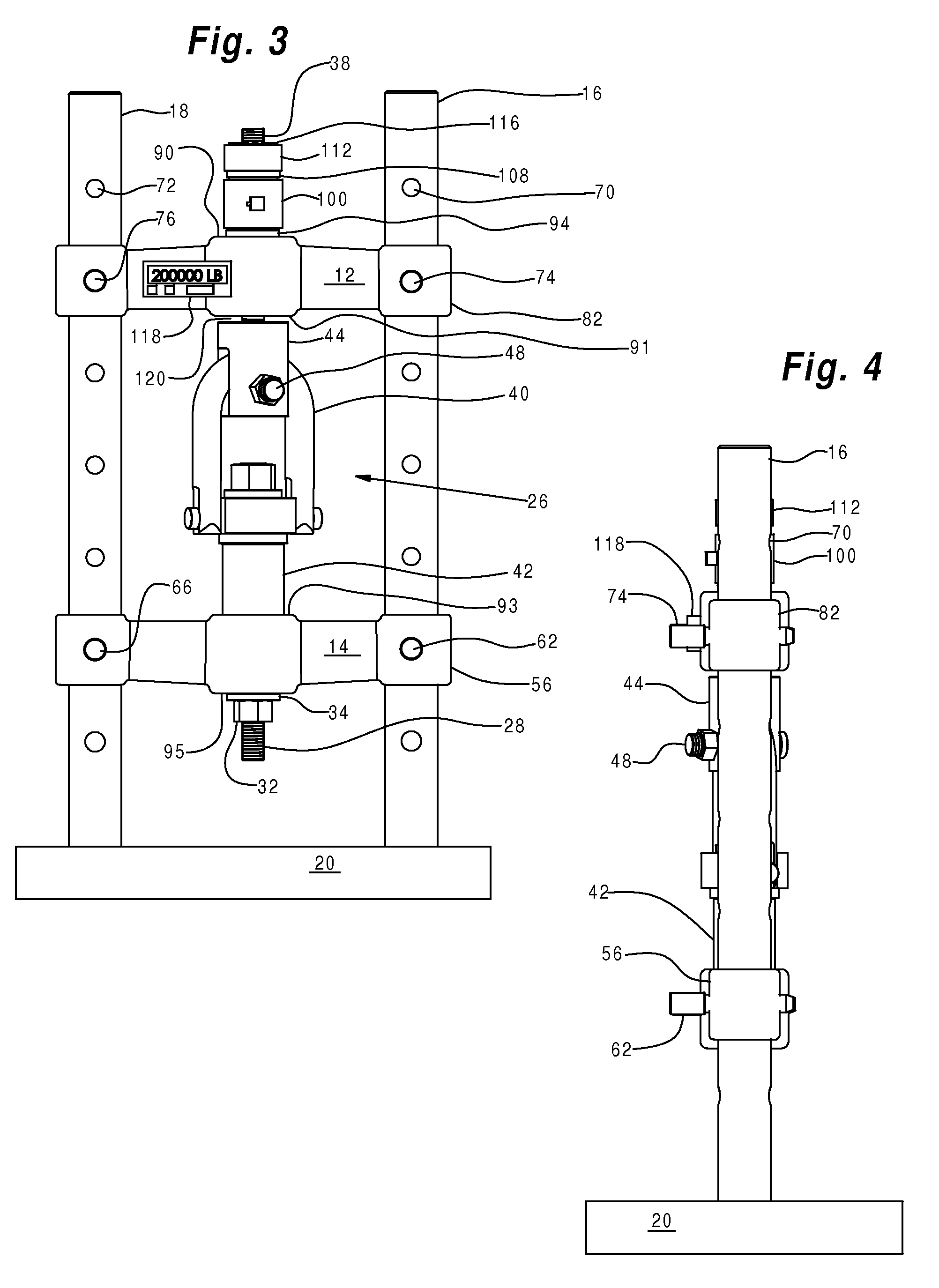

Jack bolt activated tensile strength test machine

InactiveUS20070227259A1Quickly and easily adaptedEfficient solutionMaterial strength using tensile/compressive forcesJackscrewEngineering

A tensile strength testing machine comprises a frame assembly that defines a test zone. The frame assembly includes a frame member that has first and second opposed ends. The ends have inner sides that generally face one another across the test zone, and outer sides that are generally opposed to one another and the test zone. An arbor element is mounted for generally axial movement relative to the first end. The arbor element is slidably mounted in the first end. The arbor element projects inwardly into the test zone and outwardly from the outer side of the first end. The arbor element is adapted to being attached to a test specimen, which mounted in the test zone. A portion of the arbor element that projects outwardly from the outer side of the first end is generally surrounded by an array of jack bolts. The jack bolts are threadably mounted in a collar member that is substantially axially fixed relative to the arbor element. The jack bolts are positioned to bear generally against the outer side of the first end. Typically, at least a thrust collar, and, preferably, a load determining assembly are interposed between this outer side and the bearing ends of the jack bolts. Torquing down the jack bolts against the outer side of the first end places the arbor element in tension. This tensile load is applied to a test specimen mounted in the test zone, and the magnitude of the load is determined.

Owner:MJT HLDG

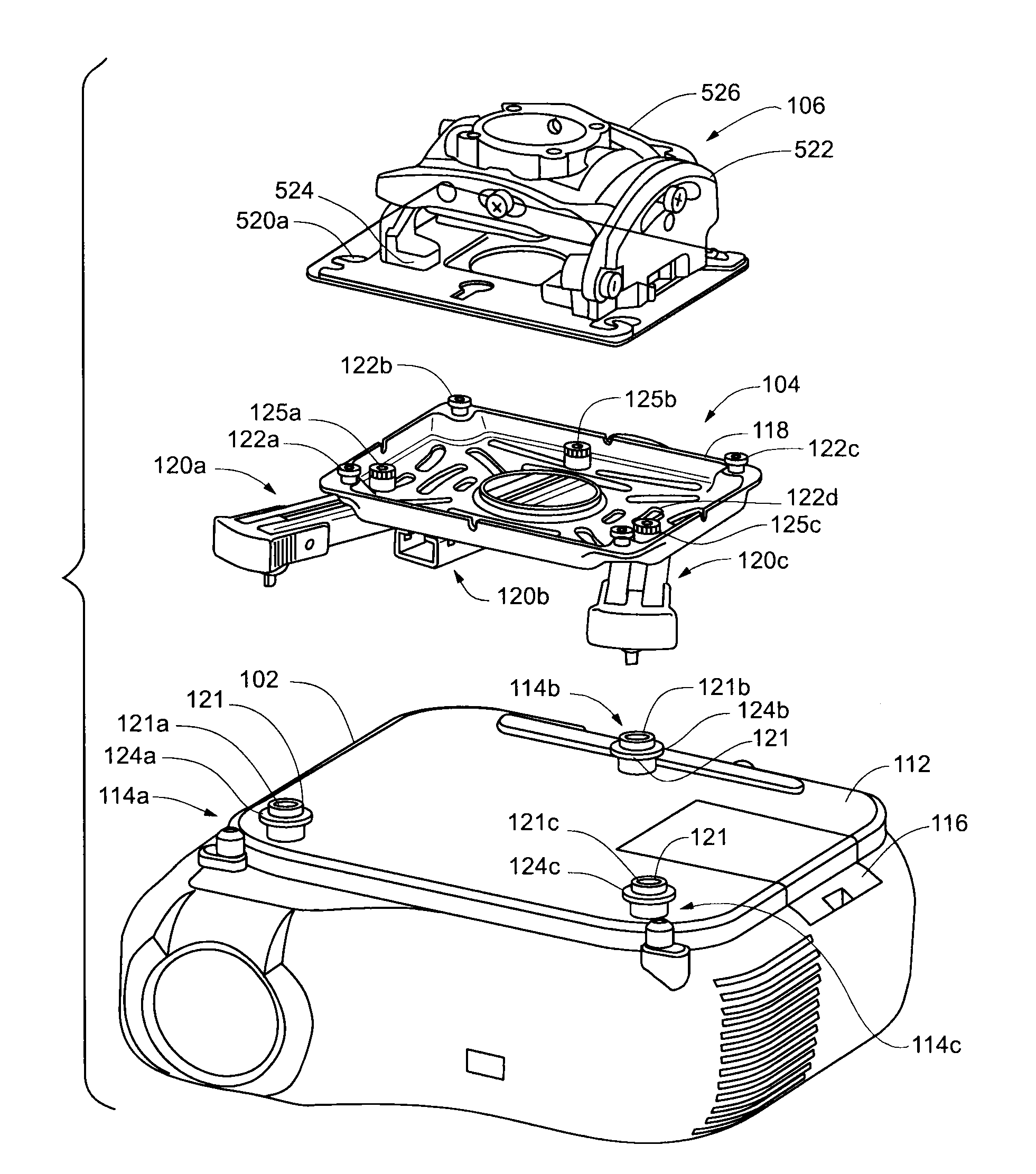

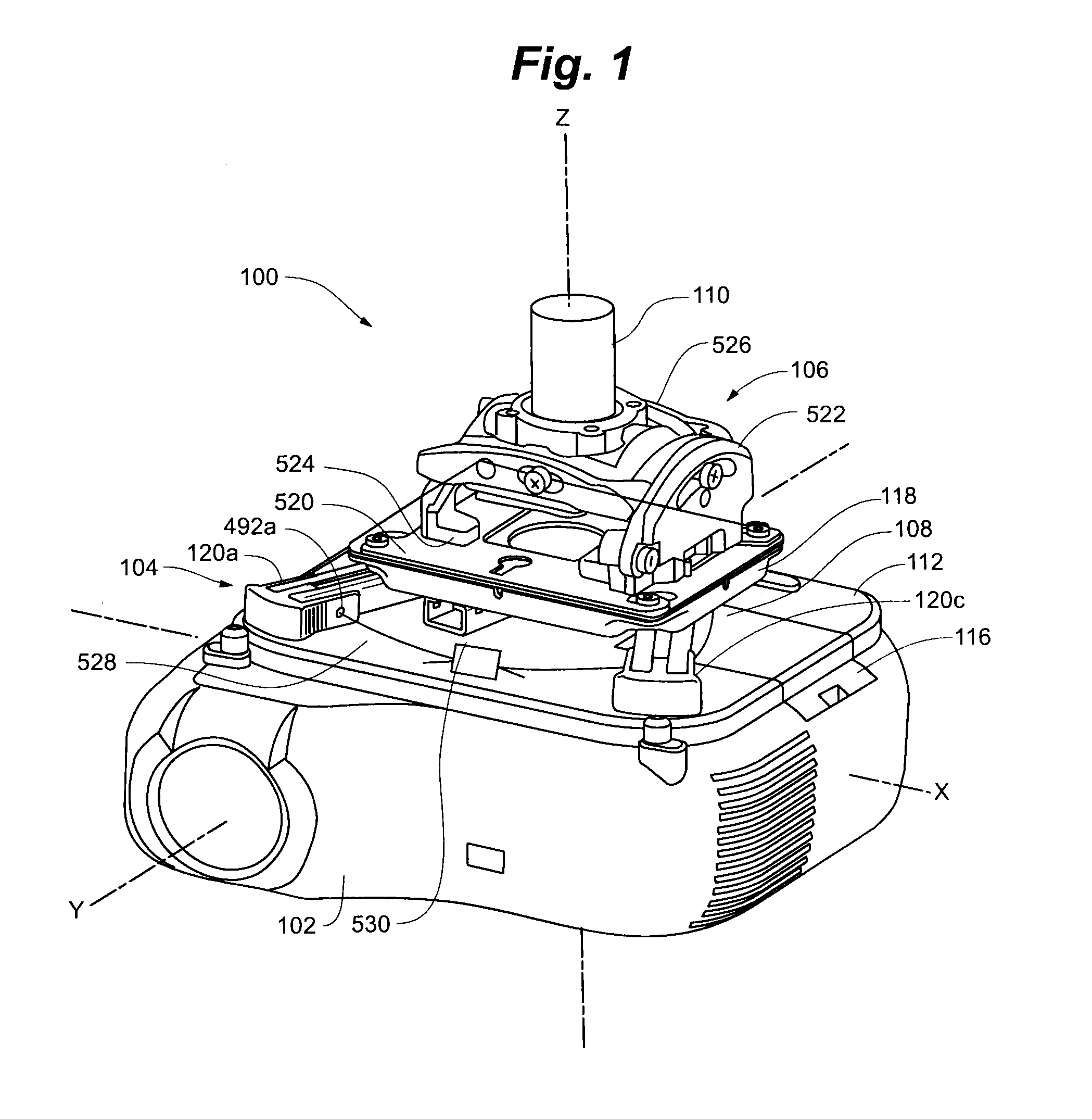

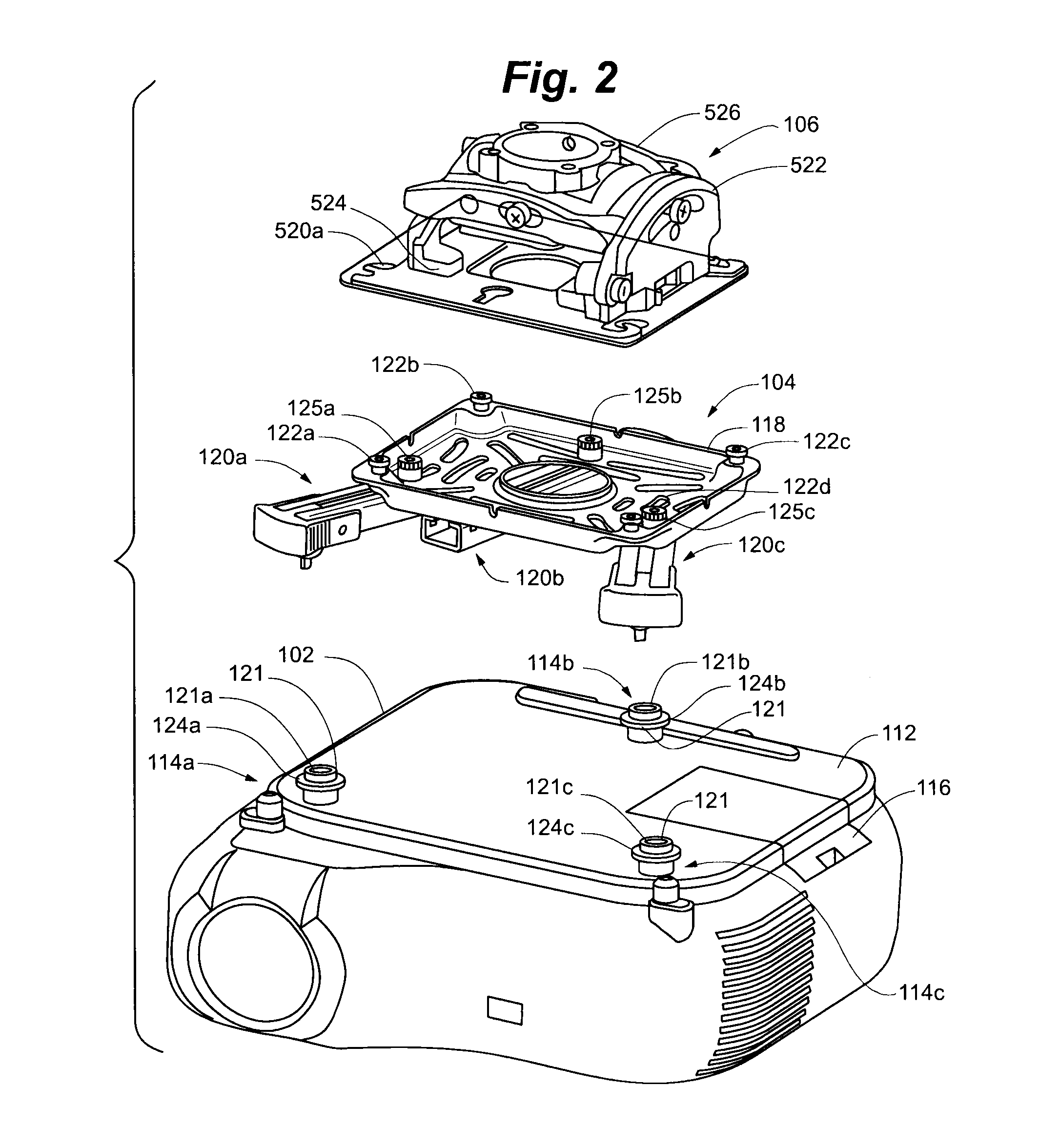

Universal projector interface with sustainable alignment

ActiveUS20090316118A1Quickly and easily adaptedEasy maintenanceProjectorsMaterial analysis by optical meansCouplingProjector

A universal projector interface including a mount interface portion with a plurality of elongate arm assemblies coupled thereto. Each arm assembly is selectively rotatable and translatable relative to the mount interface, and includes a coupling portion. The coupling portion of each arm assembly is selectively shiftable between a first position in which the coupling portion is securely engaged with a projector attachment member on the projector and a second position in which the coupling portion is freely disengageable from the projector attachment member.

Owner:MILESTONE AV TECH

Jack bolt activated tensile strength test machine

InactiveUS7513168B2Quickly and easily adaptedEfficient solutionMaterial strength using tensile/compressive forcesJackscrewEngineering

A tensile strength testing machine comprises a frame assembly that defines a test zone. The frame assembly includes a frame member that has first and second opposed ends. The ends have inner sides that generally face one another across the test zone, and outer sides that are generally opposed to one another and the test zone. An arbor element is mounted for generally axial movement relative to the first end. The arbor element is slidably mounted in the first end. The arbor element projects inwardly into the test zone and outwardly from the outer side of the first end. The arbor element is adapted to being attached to a test specimen, which mounted in the test zone. A portion of the arbor element that projects outwardly from the outer side of the first end is generally surrounded by an array of jack bolts. The jack bolts are threadably mounted in a collar member that is substantially axially fixed relative to the arbor element. The jack bolts are positioned to bear generally against the outer side of the first end. Typically, at least a thrust collar, and, preferably, a load determining assembly are interposed between this outer side and the bearing ends of the jack bolts. Torquing down the jack bolts against the outer side of the first end places the arbor element in tension. This tensile load is applied to a test specimen mounted in the test zone, and the magnitude of the load is determined.

Owner:MJT HLDG

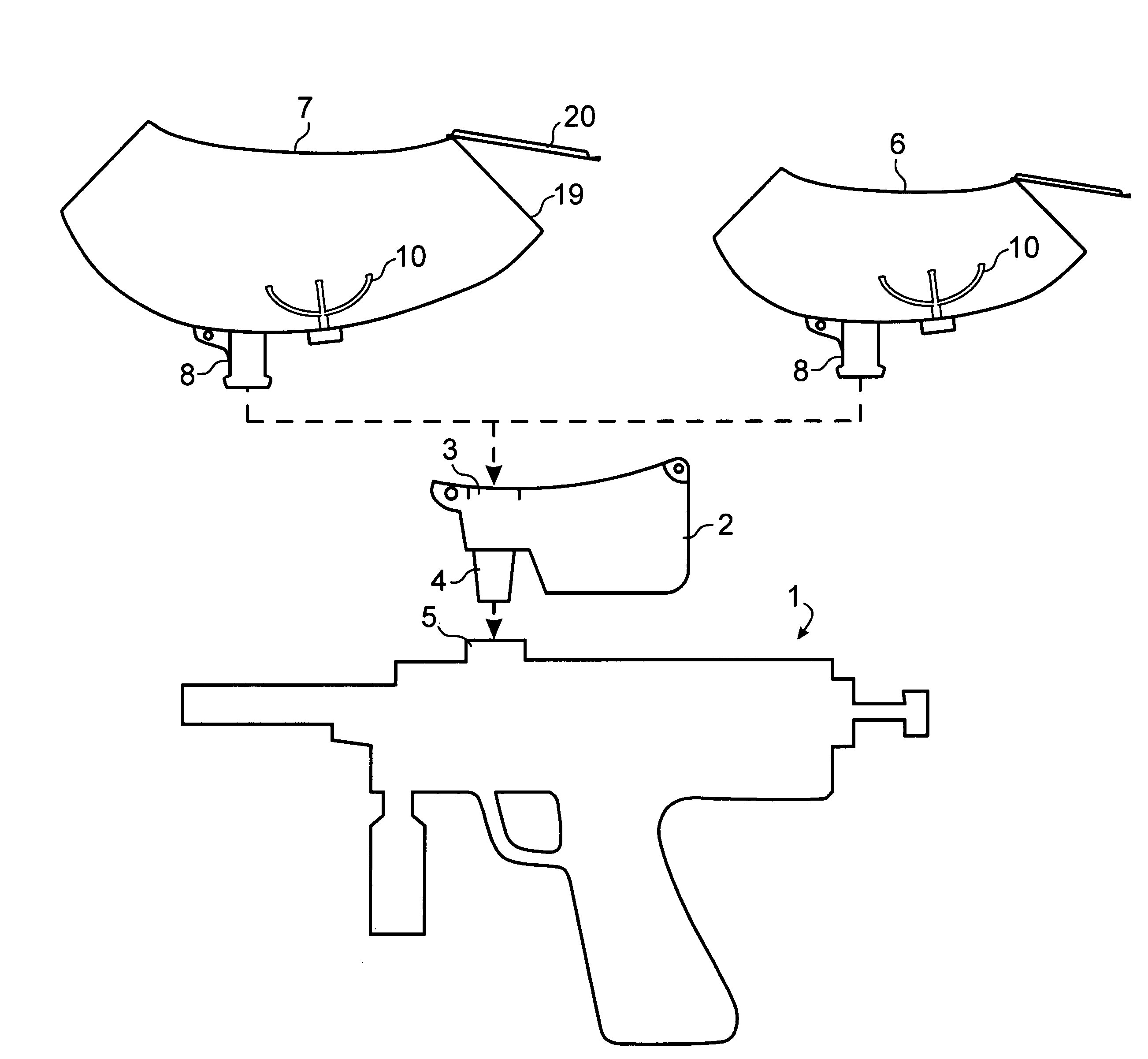

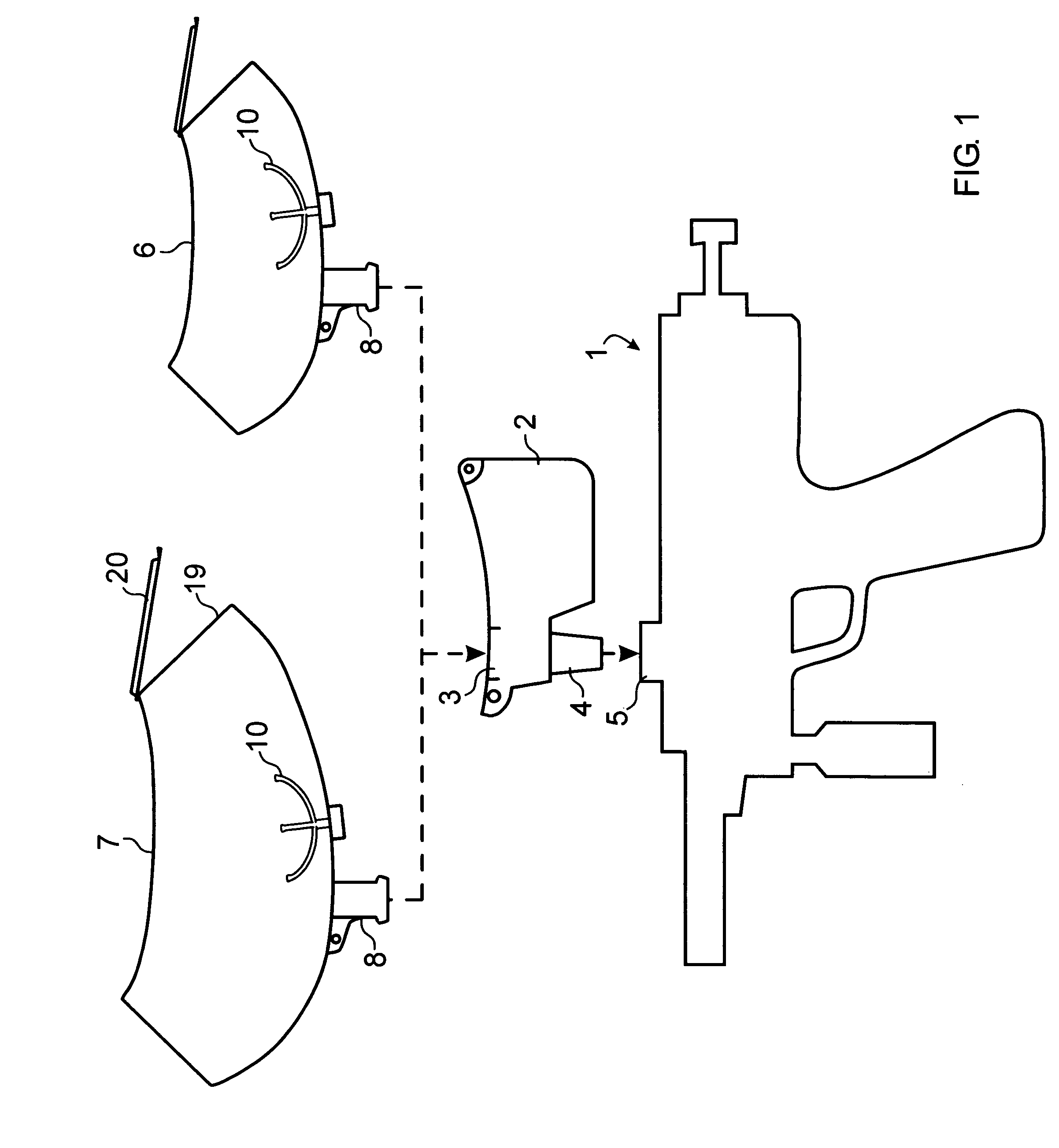

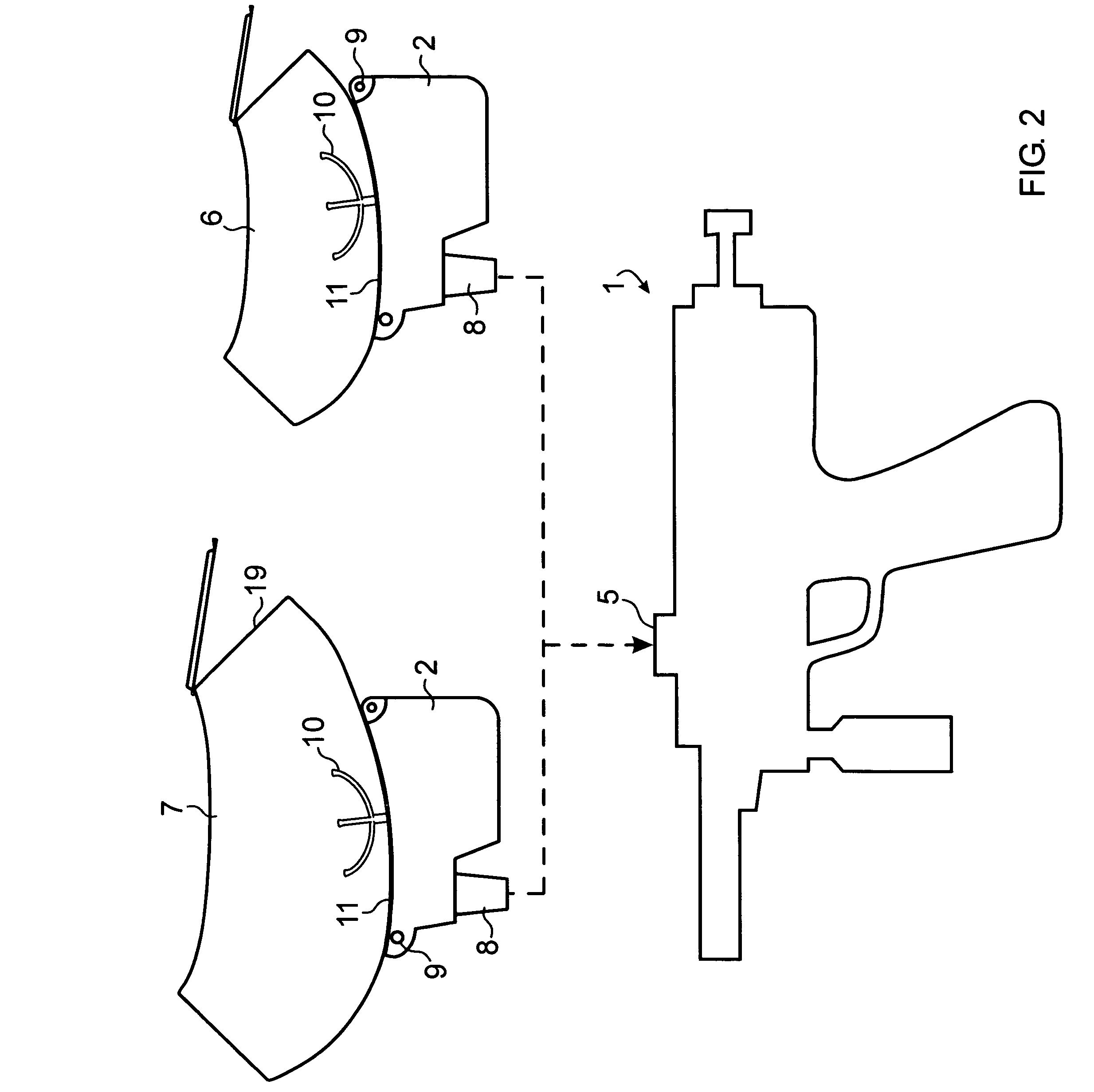

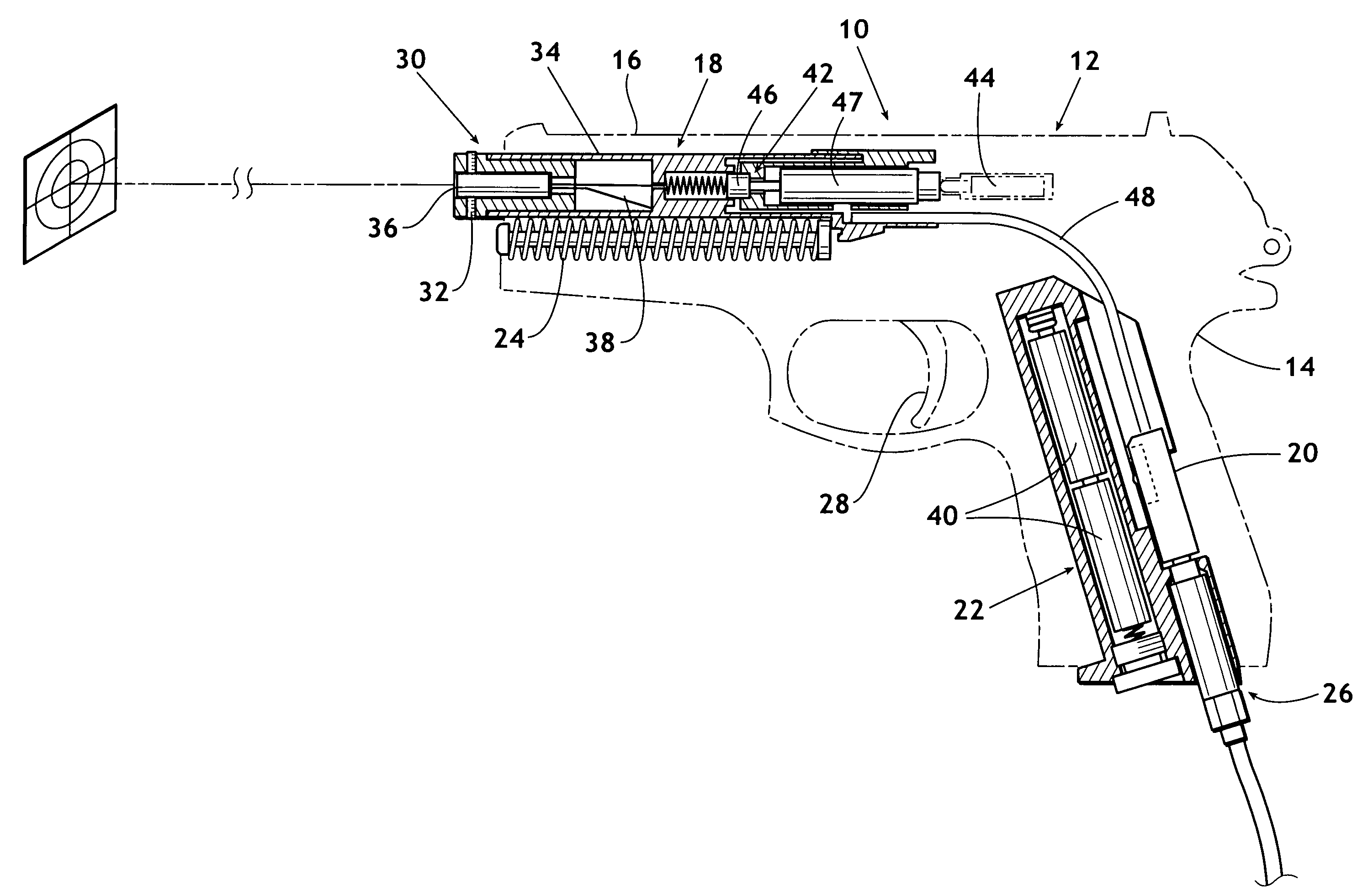

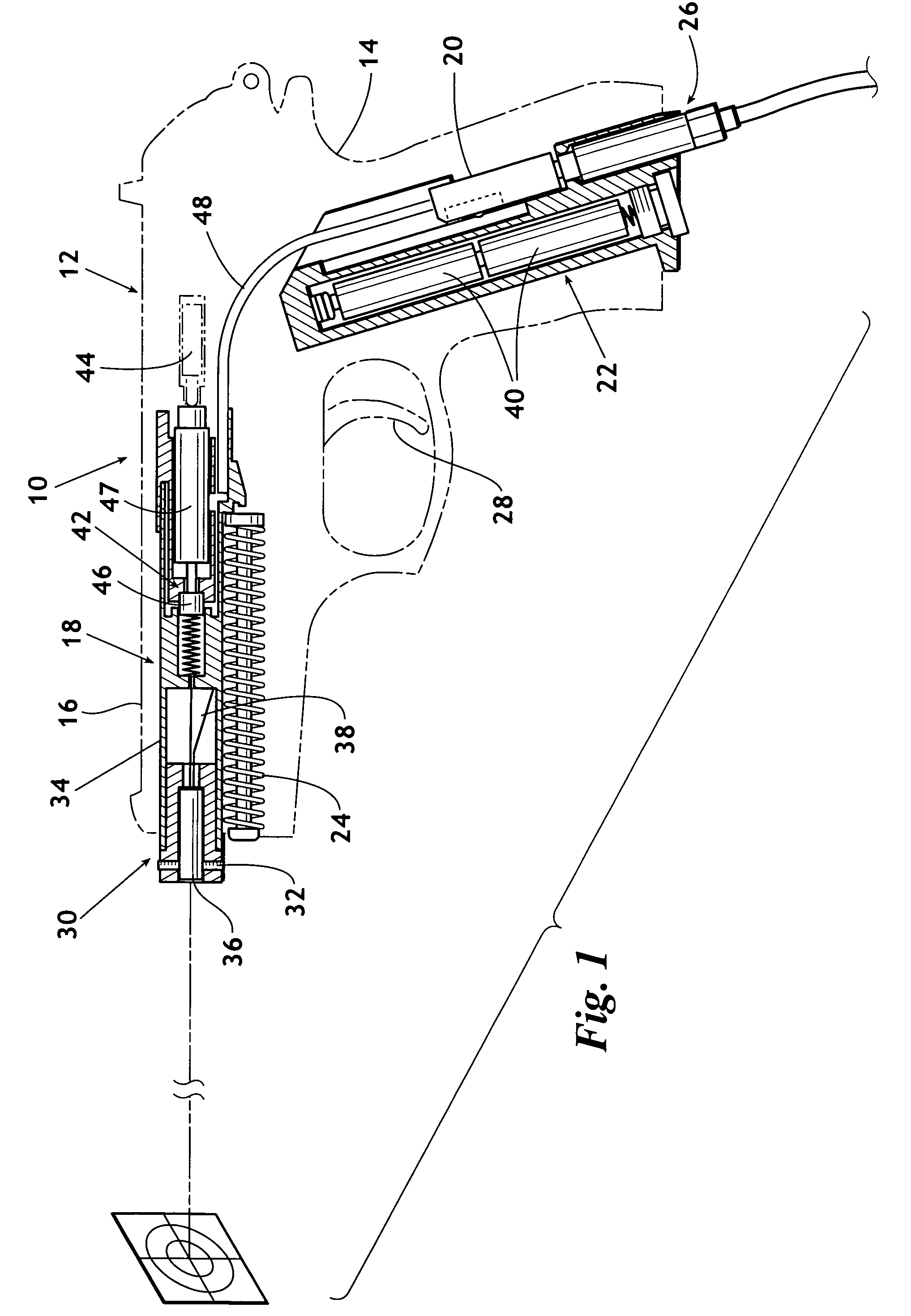

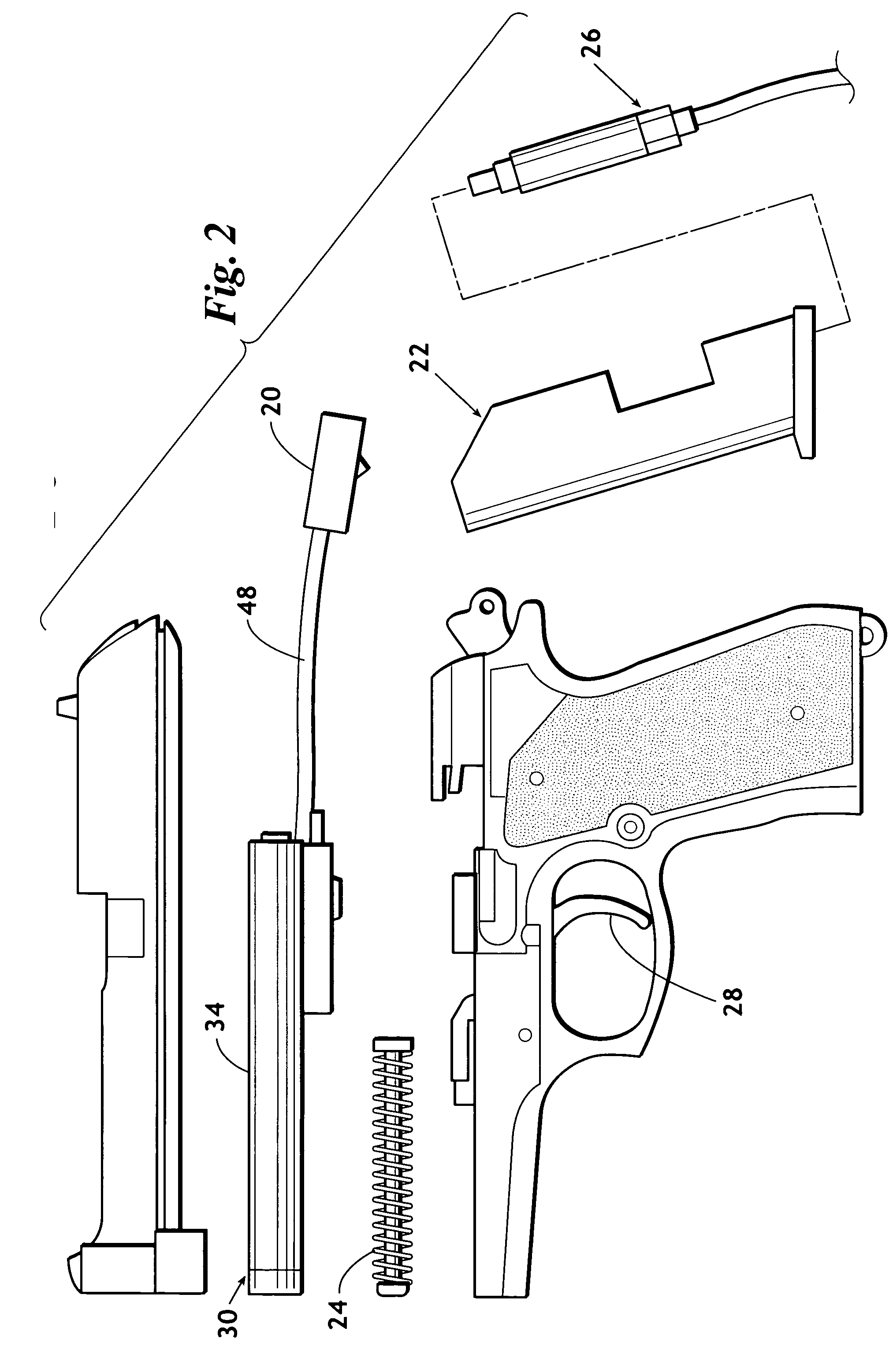

Training weapon

InactiveUS20050191601A1Efficient use ofQuickly and easily adaptedAiming meansTraining adaptationElectricityEngineering

A training weapon which is quickly and easilyassembled from a standard weapon without requiring any physical modification (alteration) of any component of the standard weapon. A few components of the standard weapon are removed and replaced by components of the invention. This replacement does not exceed skill level beyond a standard field-strip procedure of the particular weapon. Action of the training weapon is of the same character as the action of the standard weapon, while developing trainee's responses to the substitute firing action, and at the same time improving trainee's skill, all without the use of live ammunition. Installed components include means of cycling the the weapon's mechanism thus simulating recoil using compressed gas, optional laser pointer activating a target, and a replacement magazine including source of electricity and an electronic control circuit and operable with a gas passage unit. Weapon's original trigger mechanism remains unchanged and is utilized to initiate the substitute firing cycle.

Owner:DVORAK VOJTECH

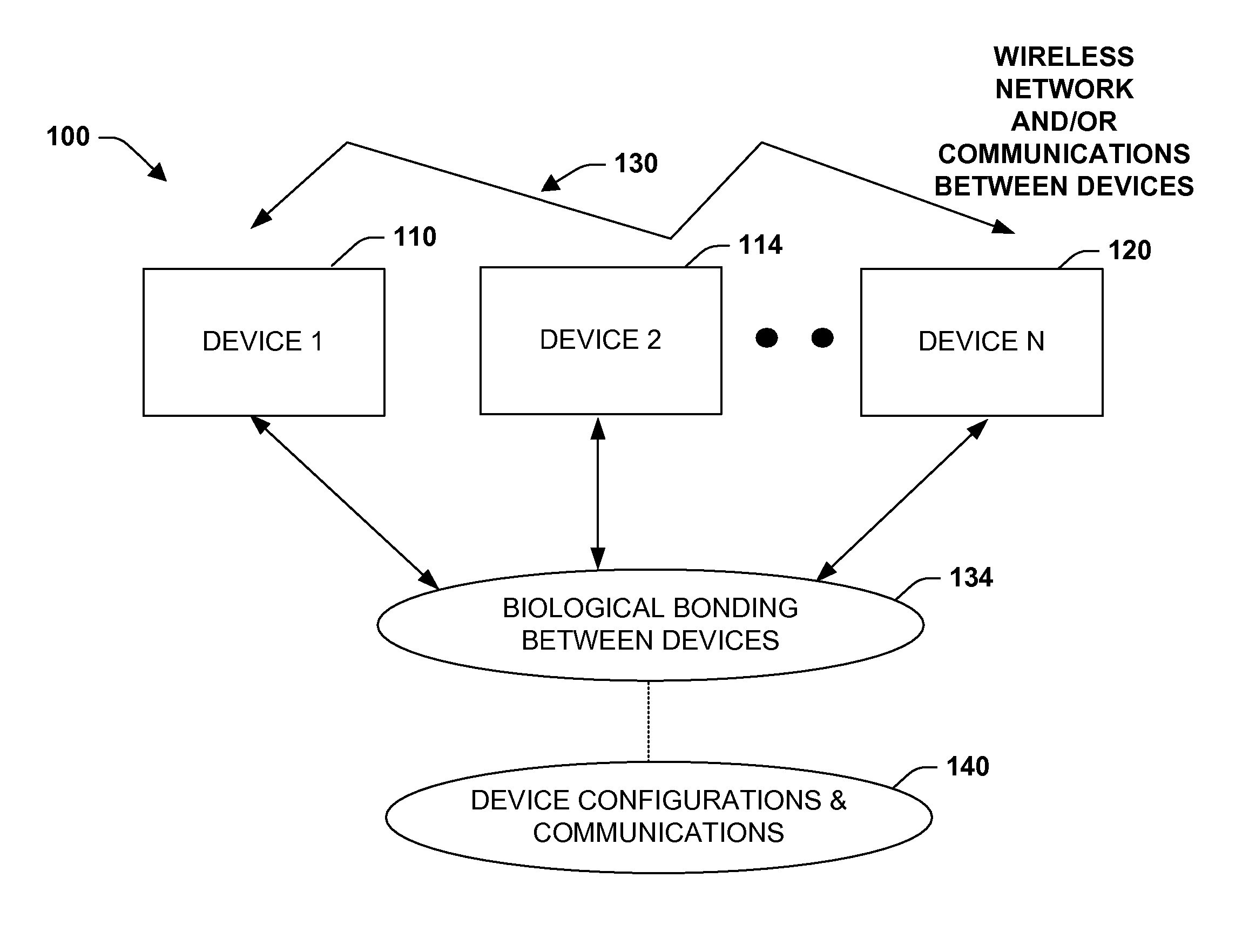

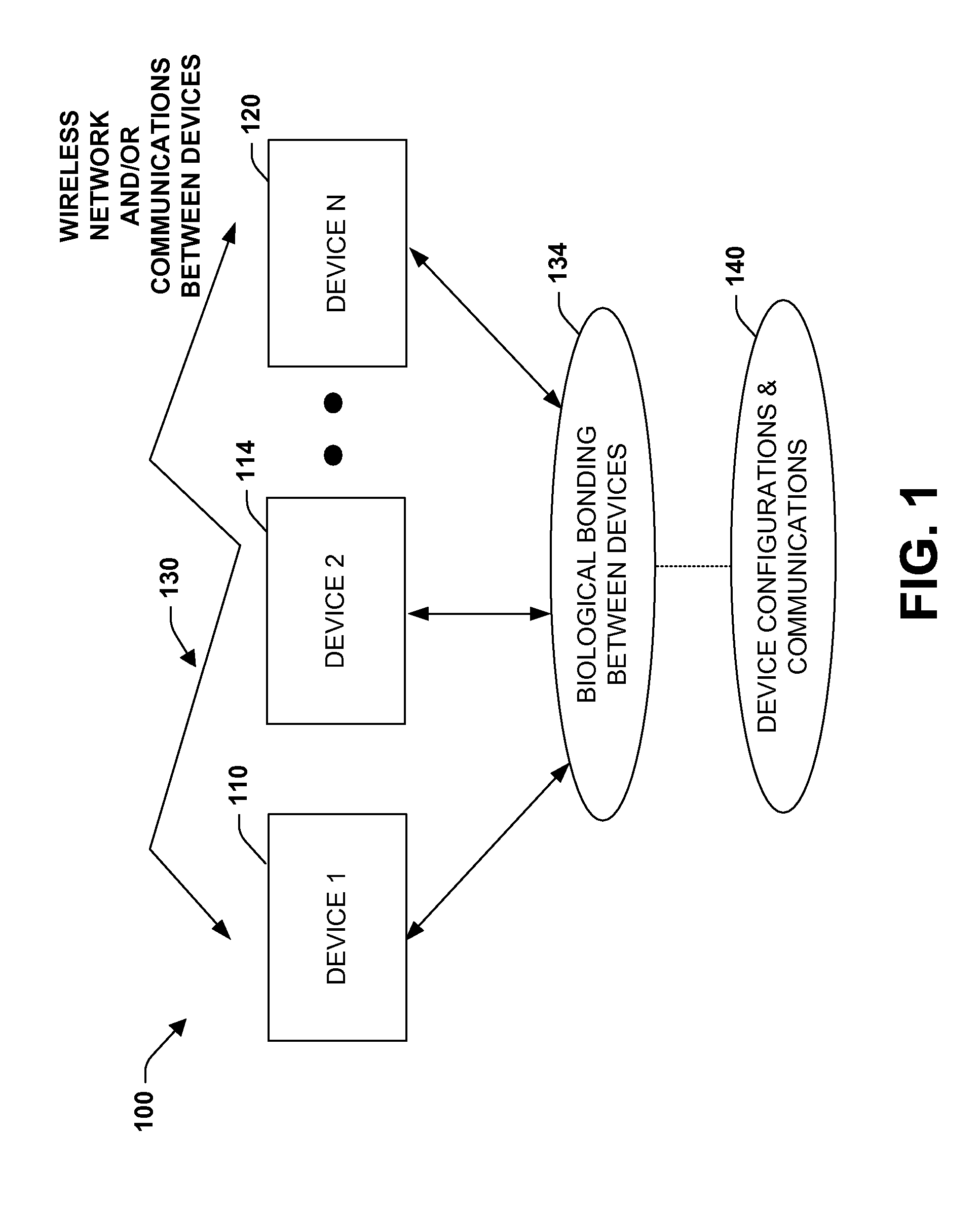

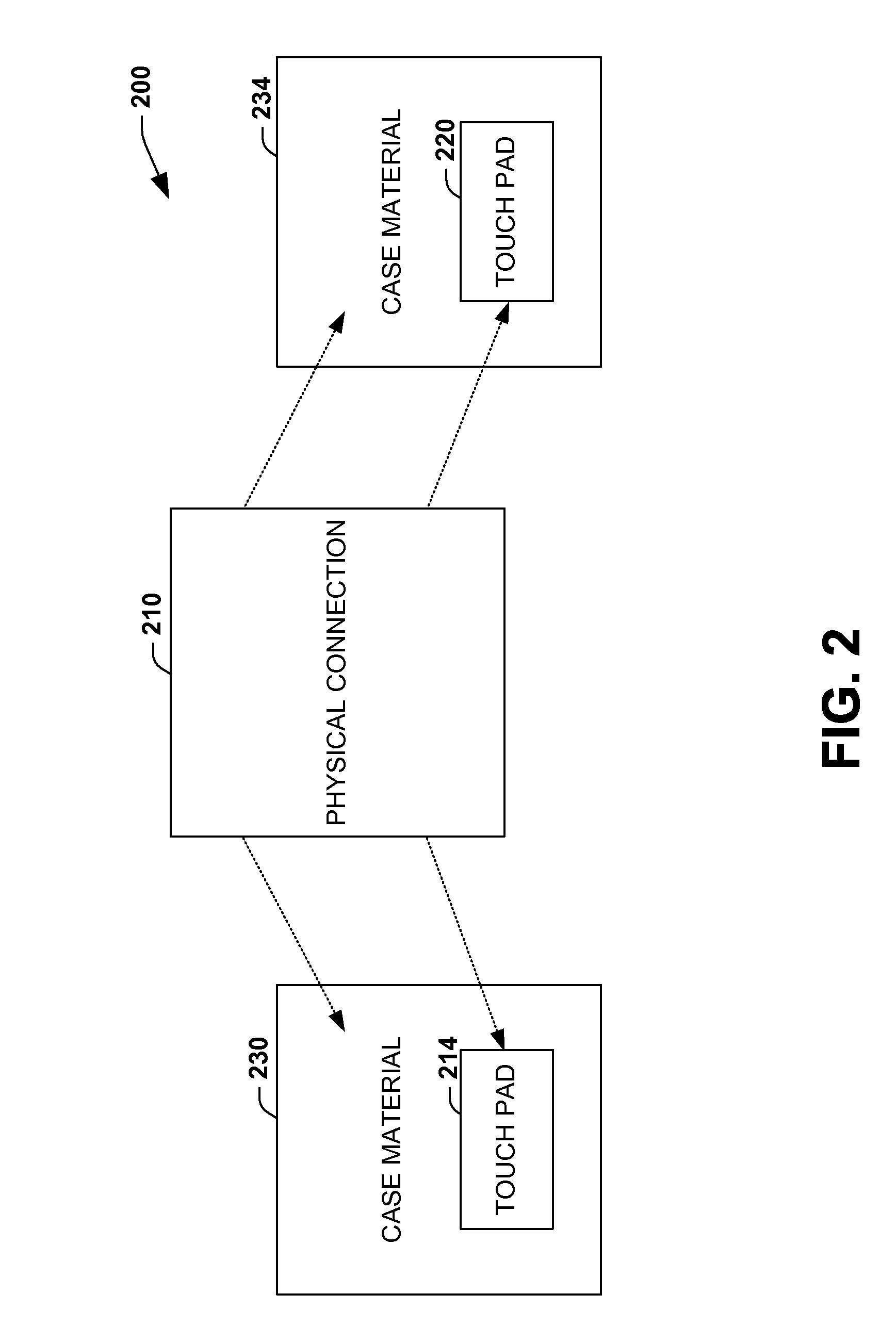

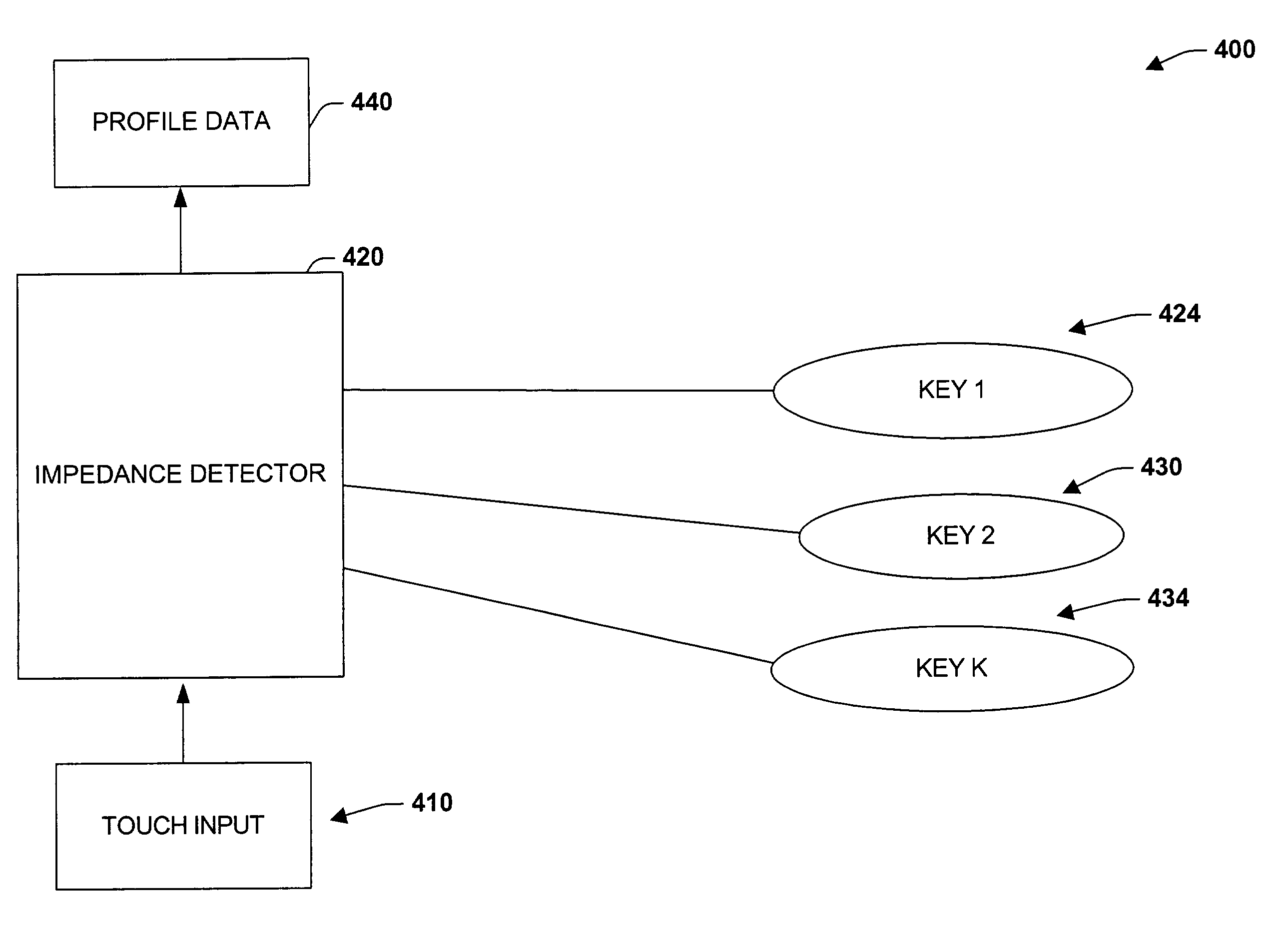

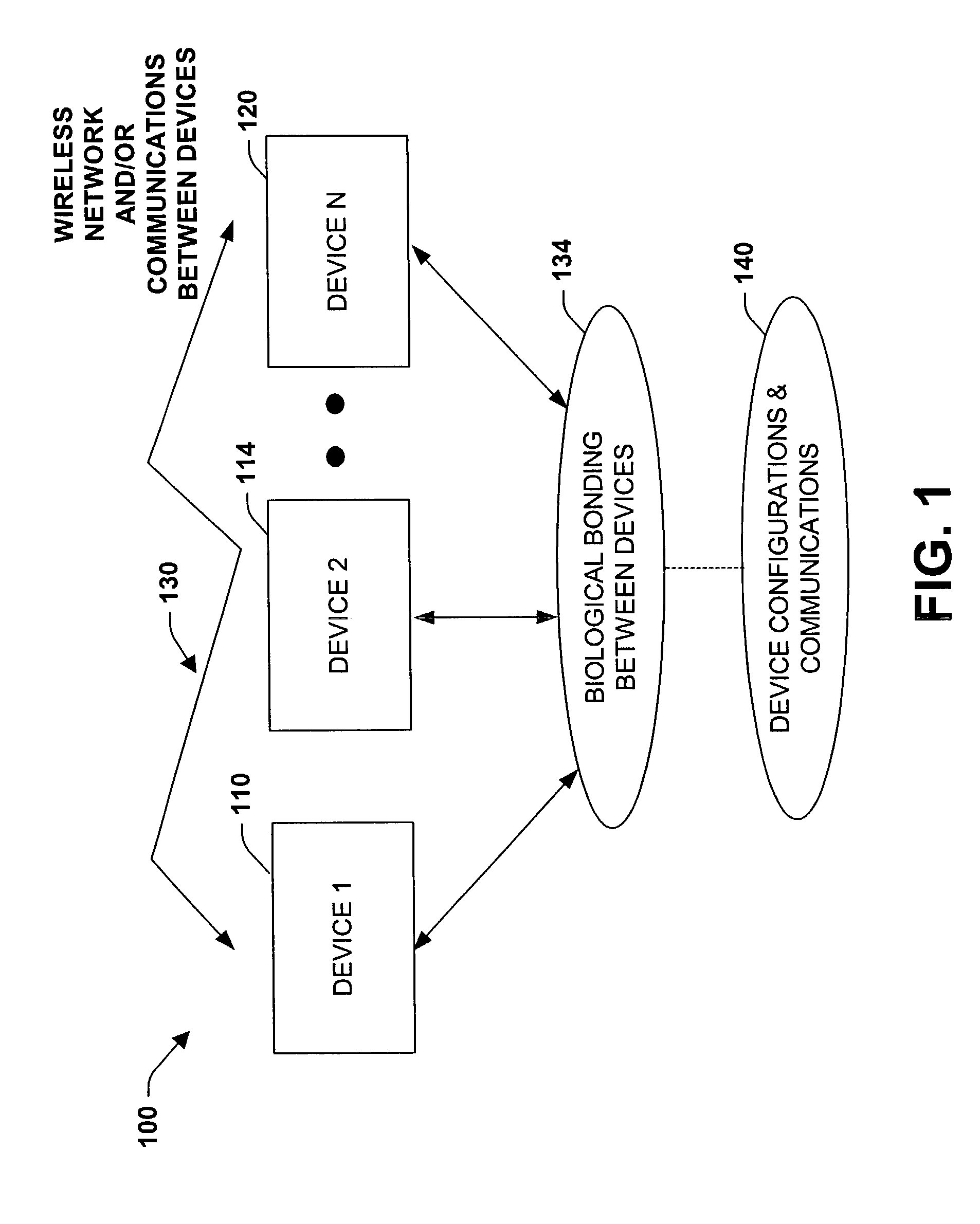

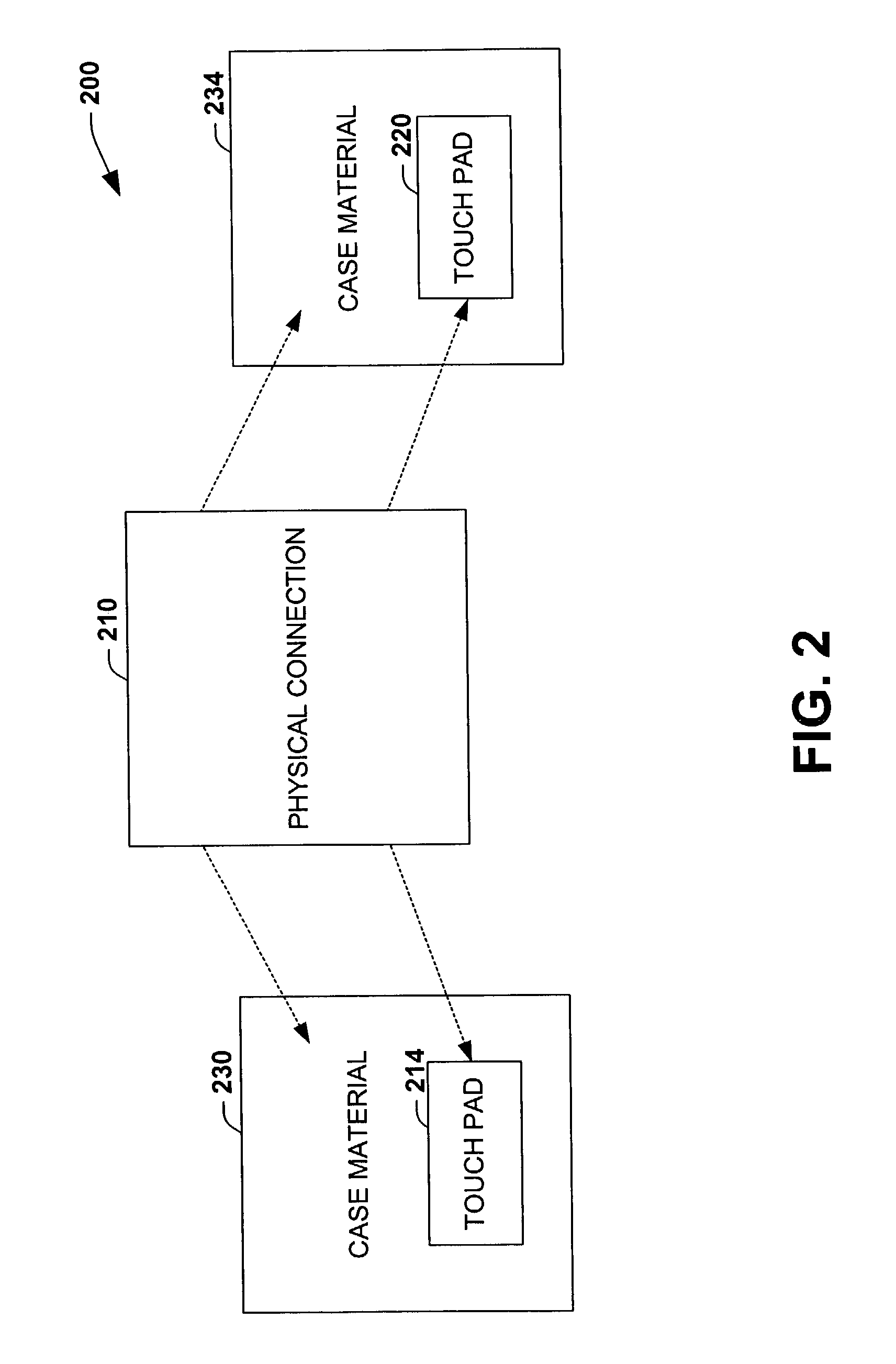

Capacitive bonding of devices

InactiveUS20060217064A1Easy to optimizeFacilitates flow of electricityNear-field transmissionElectric signal transmission systemsLocation detectionEngineering

The present invention relates to systems and methods that facilitate wireless device communications and configuration. A detection component identifies N devices that are coupled together via a biological medium, N being an integer, wherein the medium includes direct or indirect touching to a device or devices. After biological contact, a configuration component initiates a configuration between a subset of the devices. Although configurations and / or other communications can be conducted through a medium such as the human body, the present invention can employ an initial touch to identify respective devices whereby other electronic configuration sequences commence without further device contact. Other aspects include chain touching between users and / or devices to facilitate contact between the devices. Location detection components can also be provided to identify when users are present near a device, the detected presence to commence further automated procedures, and / or the location detection components can enable devices to identify other devices in a crowded wireless environment.

Owner:MICROSOFT TECH LICENSING LLC

Adjustable impression tray with variable geometry

InactiveUS7125251B2Adapt the impression tray easily and quicklyLengthened and shortenedImpression capsImpression traysDental Equipment

The invention relates to an adjustable impression tray (1) comprising a trough (2) in the form of an arch with a straight central portion (7) extended by two lateral branches (8,9), essentially matching the form of a dental arch and comprising several integral zones which may be deformed at the temperature of use in the form of a multi-directional extension means (12), for example an accordion-like bellows arrangement (13 to 16). The impression tray, preferably for single usage, advantageously comprises splitting zones (17, 18) which allow the production of impression trays of differing sectors, which by comprising one or several deformation zones are equally adjustable. The invention is of interest to dentists and prosthetic dentists and more generally to producers and users of dental equipment.

Owner:LIVOLSI LYDIE

Adjustable capacity loader for paintball markers

InactiveUS20060042614A1Quickly and easily adaptedSimple equipmentAmmunition loadingCompressed gas gunsCouplingEngineering

Each one of a set of substitutable paintball magazines of different capacities can be quickly mounted on a universal coupling base plugged into the projectile feeding port of a paintball marker. The coupling base incorporates a motor whose shaft connects to a paintball agitator within the magazine. The set of magazines offers a convenient selection of loading capacities to accommodate a variety of game circumstances and environments.

Owner:KEE ACTION SPORTS I

Capacitive bonding of devices

InactiveUS7684754B2Speed up the flowReduce distractionsElectric signal transmission systemsNear-field transmissionLocation detectionCapacitive sensing

The present invention relates to systems and methods that facilitate wireless device communications and configuration. A detection component identifies N devices that are coupled together via a biological medium, N being an integer, wherein the medium includes direct or indirect touching to a device or devices. After biological contact, a configuration component initiates a configuration between a subset of the devices. Although configurations and / or other communications can be conducted through a medium such as the human body, the present invention can employ an initial touch to identify respective devices whereby other electronic configuration sequences commence without further device contact. Other aspects include chain touching between users and / or devices to facilitate contact between the devices. Location detection components can also be provided to identify when users are present near a device, the detected presence to commence further automated procedures, and / or the location detection components can enable devices to identify other devices in a crowded wireless environment.

Owner:MICROSOFT TECH LICENSING LLC

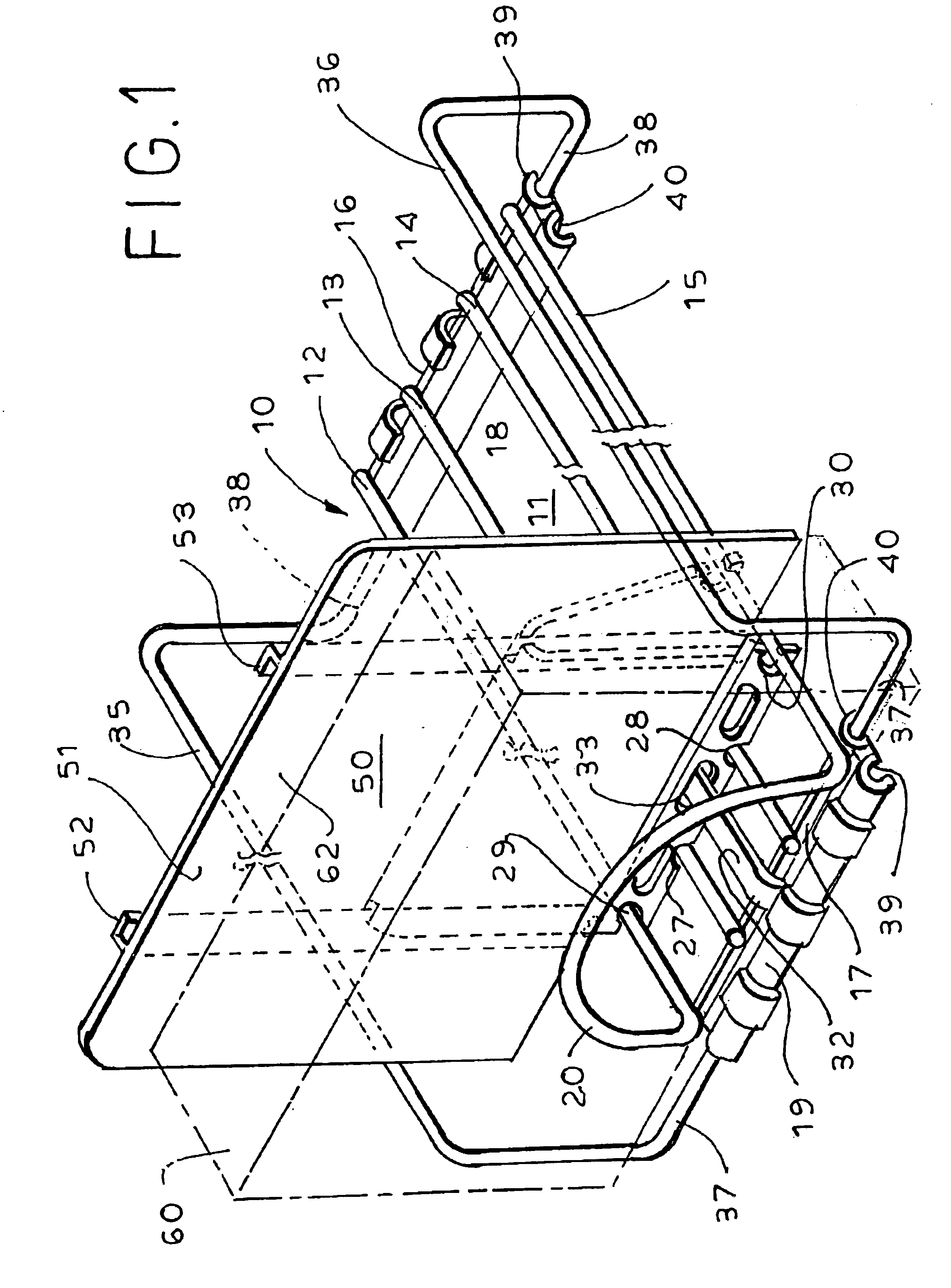

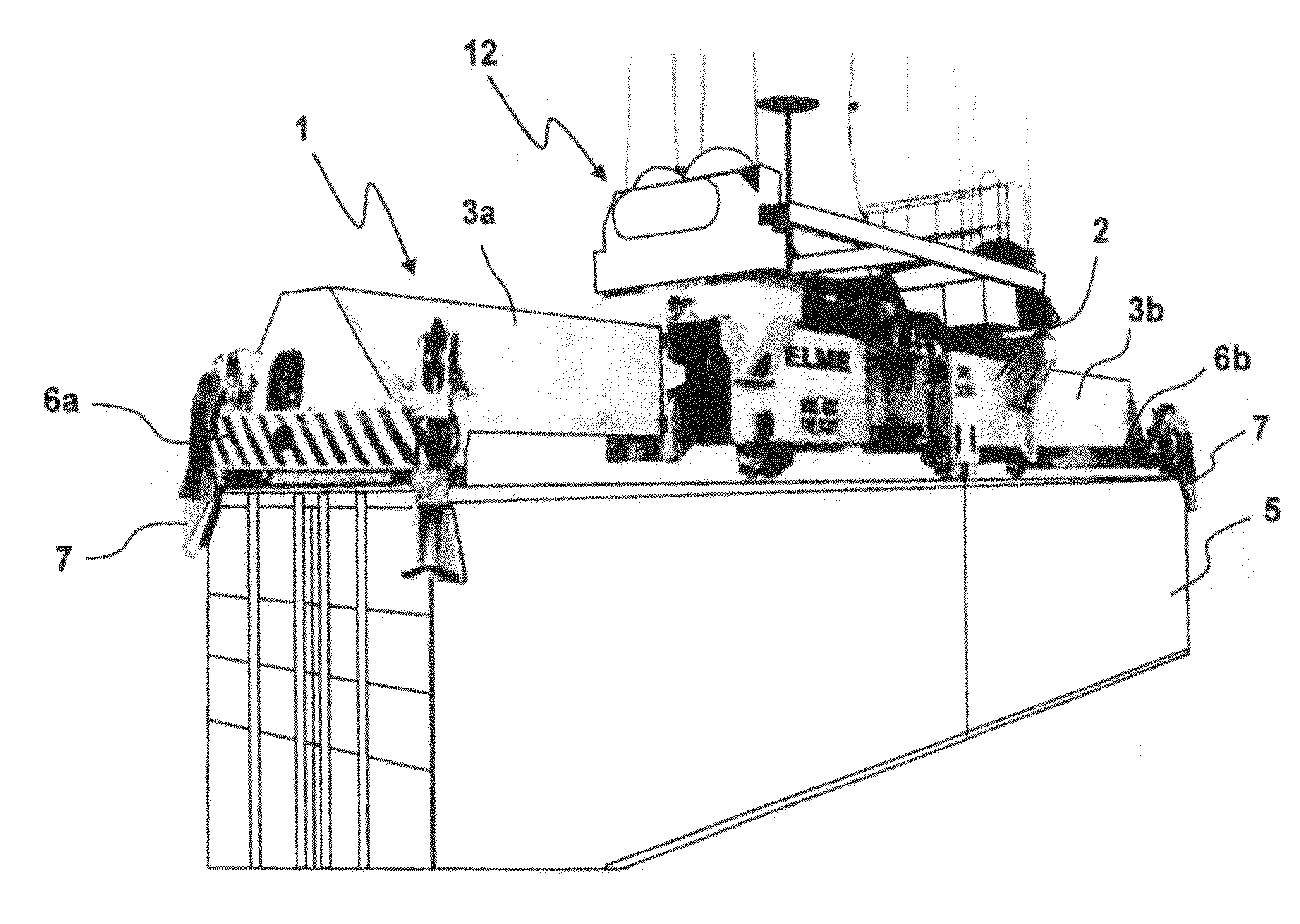

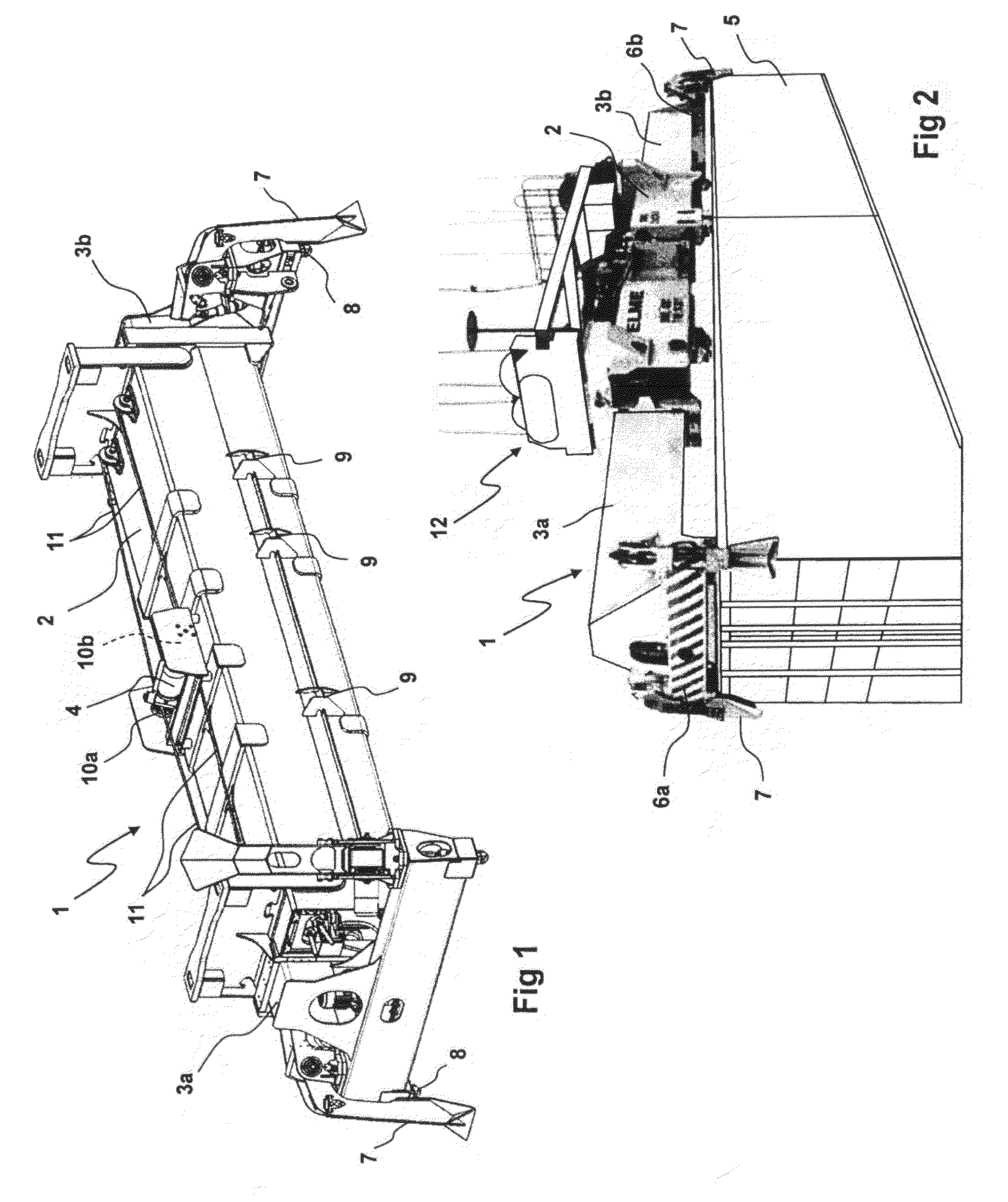

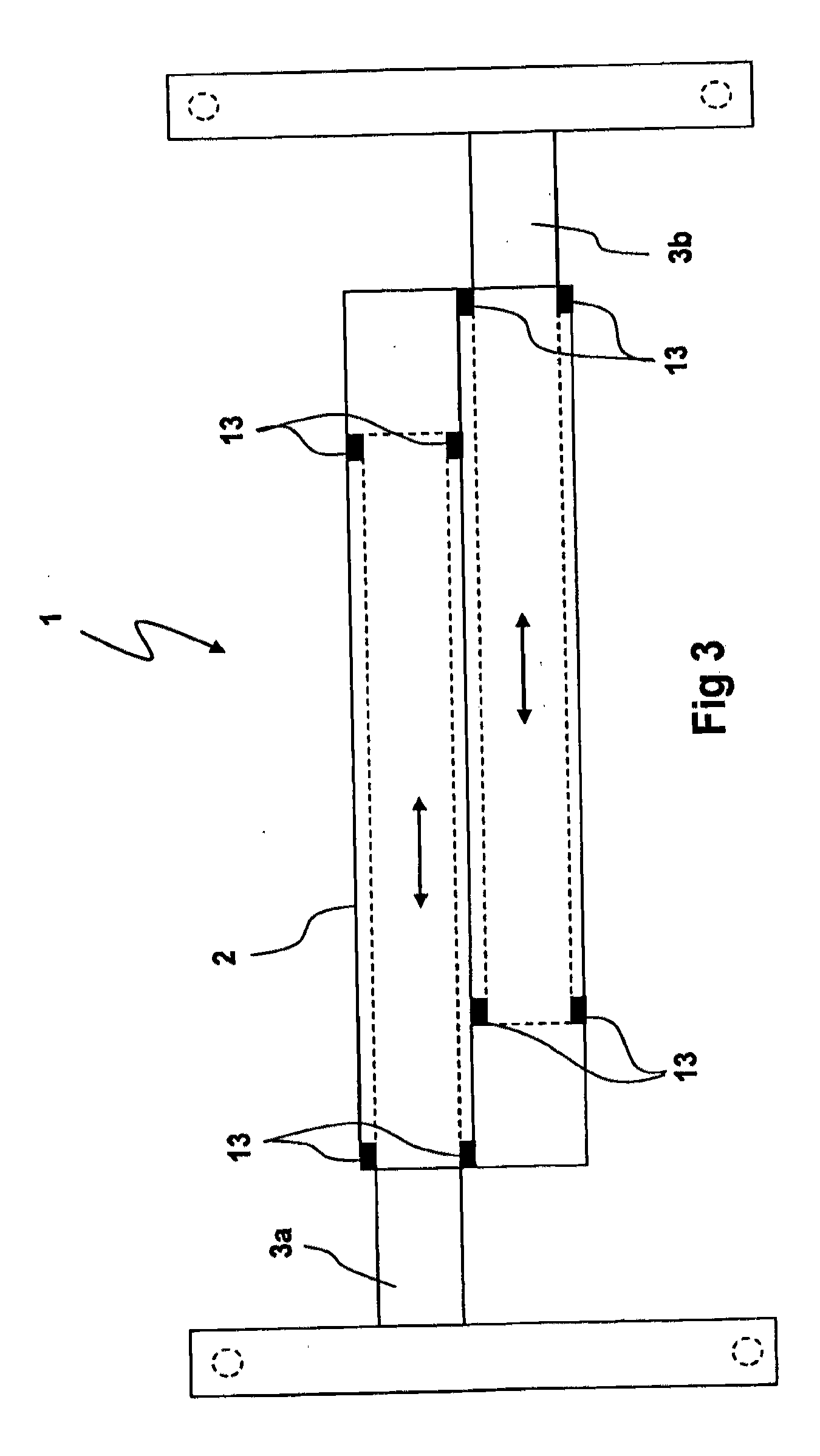

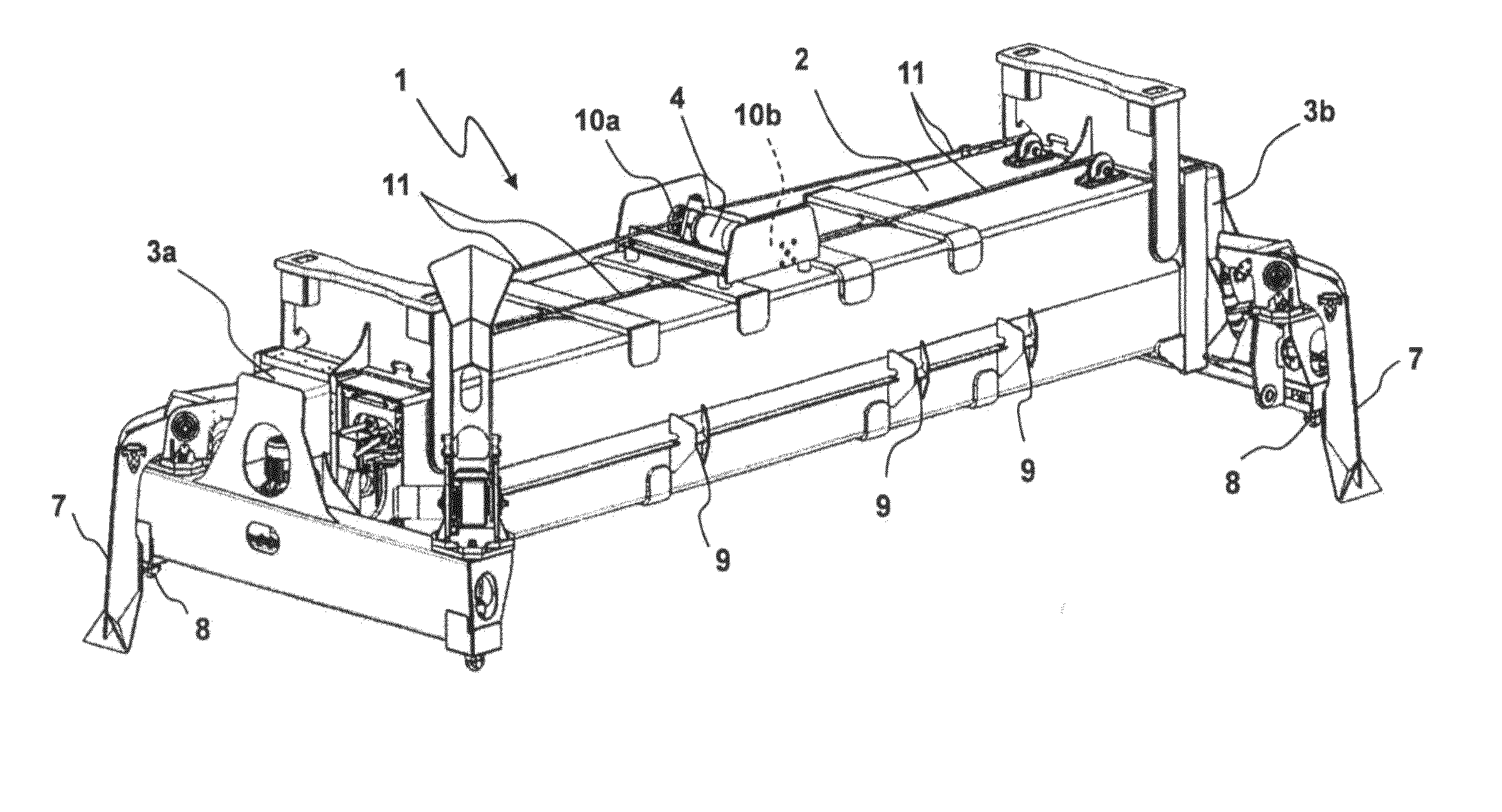

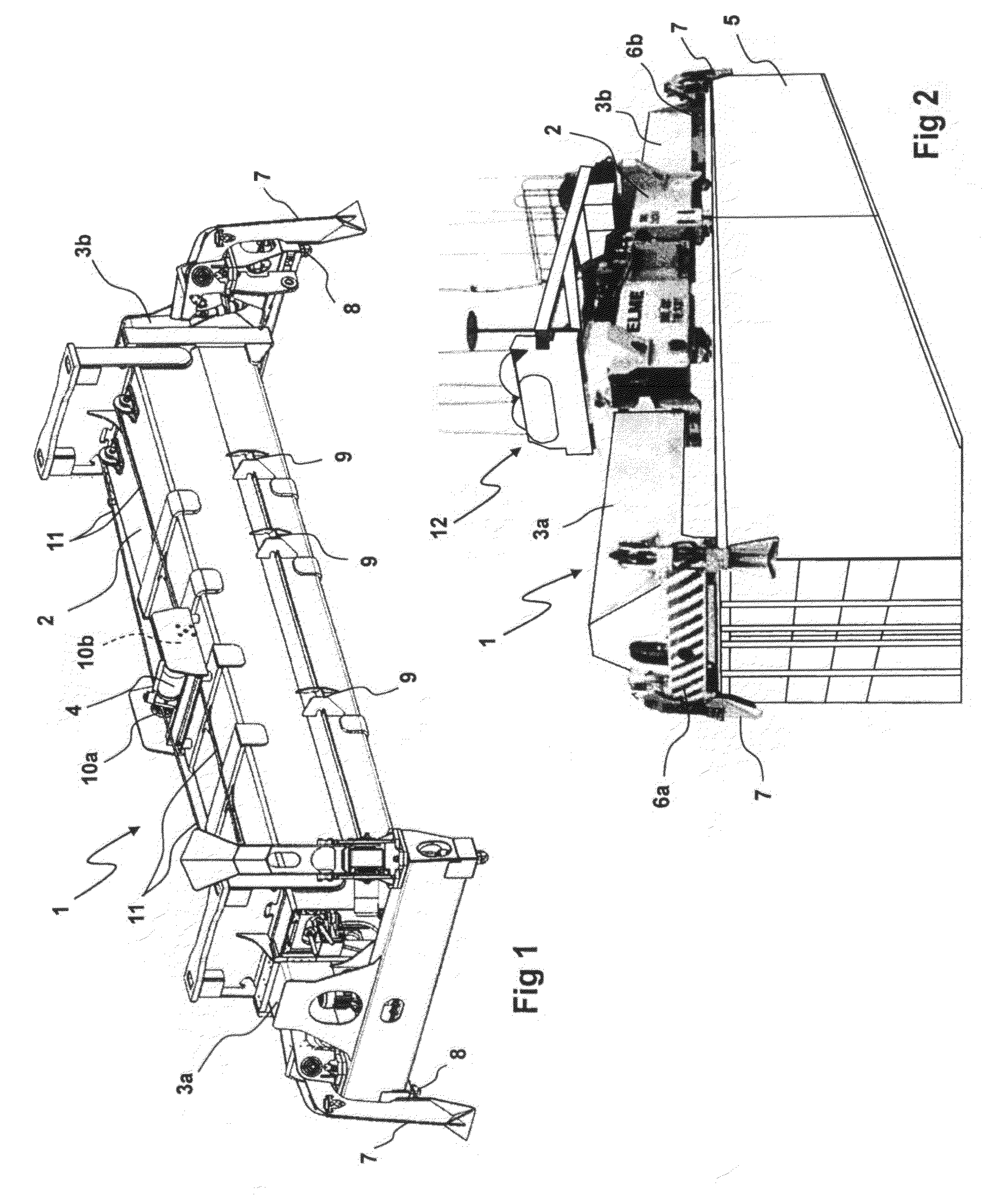

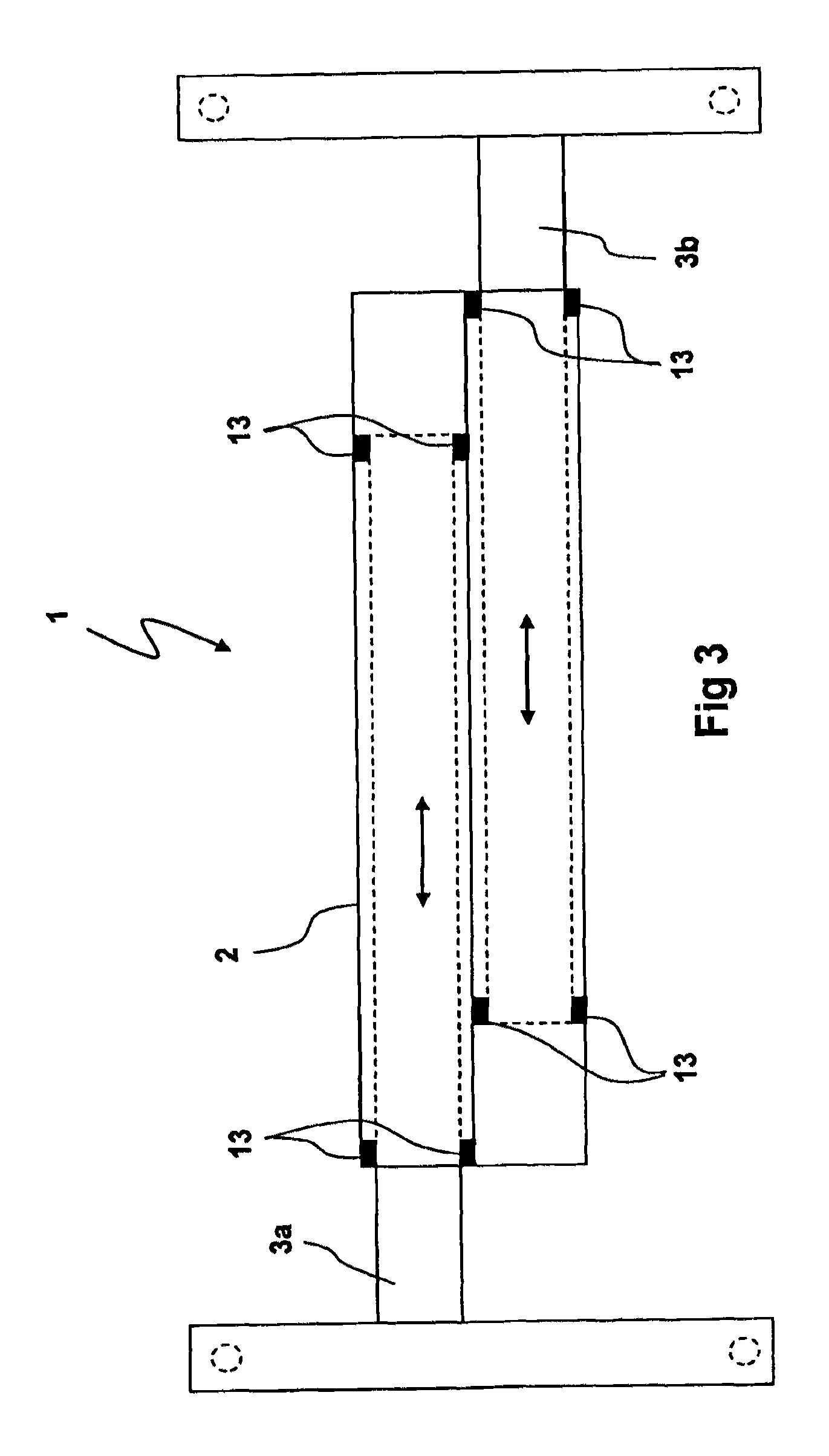

Cable-controlled container yoke

InactiveUS20120306223A1Quickly and easily adaptedFaster and simple and cheap mannerLifting devicesTrolley cranesEngineeringActuator

The invention relates to a container yoke (1) for lifting of at least one container (5), comprising a base frame (2), two travelling beams (3a,b), which are telescopically displaceable in the base frame (2) and on whose outer end portions are arranged transverse beams (6a,b) provided with locking members (8), so called twist locks, for engagement in, and locking to, the corner boxes of a container (5). The invention is realized by virtue of the fact that cables (11a,b) are arranged to displace a respective travelling beam (3a,b) into the desired position in the frame (2) of the container yoke, that the cables (11a,b), for displacement of a travelling beam (3a,b), are simultaneously reeled up and unreeled with the aid of one and the same cable drum (10b), that both cable drums (10a,b) of the container yoke (1) are driven by a common actuator (4), and that the cables (11a,b) are fastened in the end portion of a respective travelling beam (3a,b) via spring-loaded cable tensioners (15a,b).

Owner:ELME SPREADER

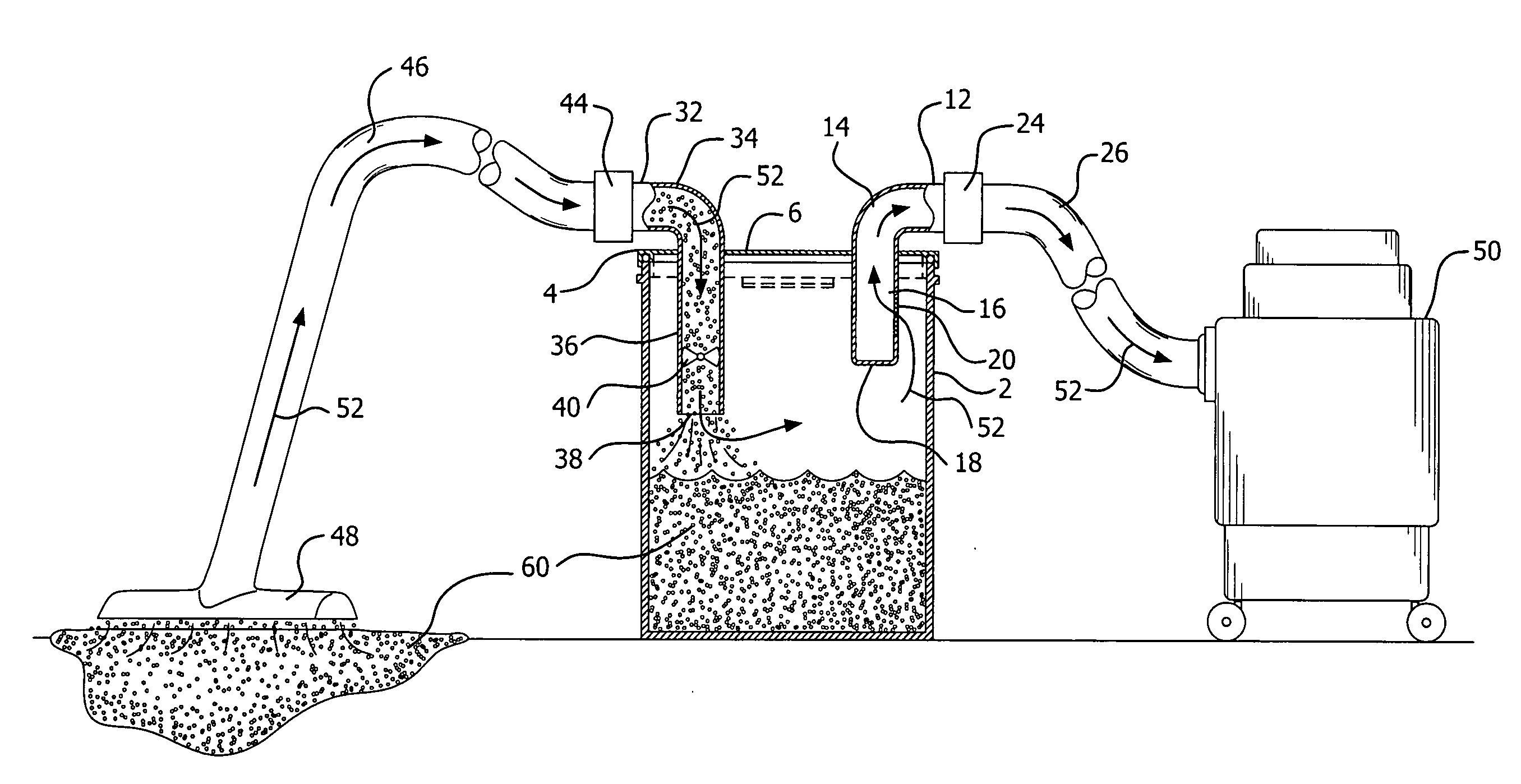

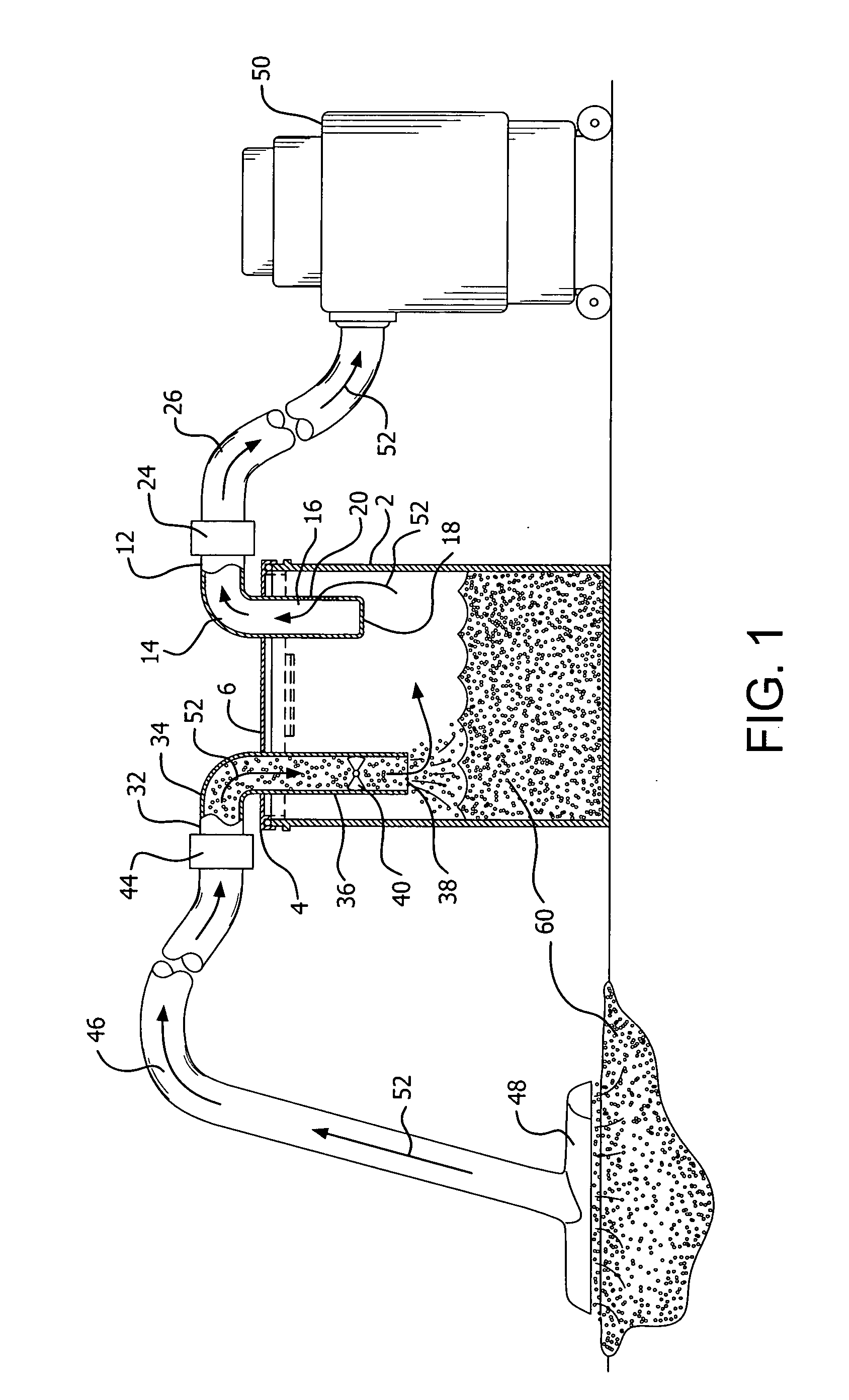

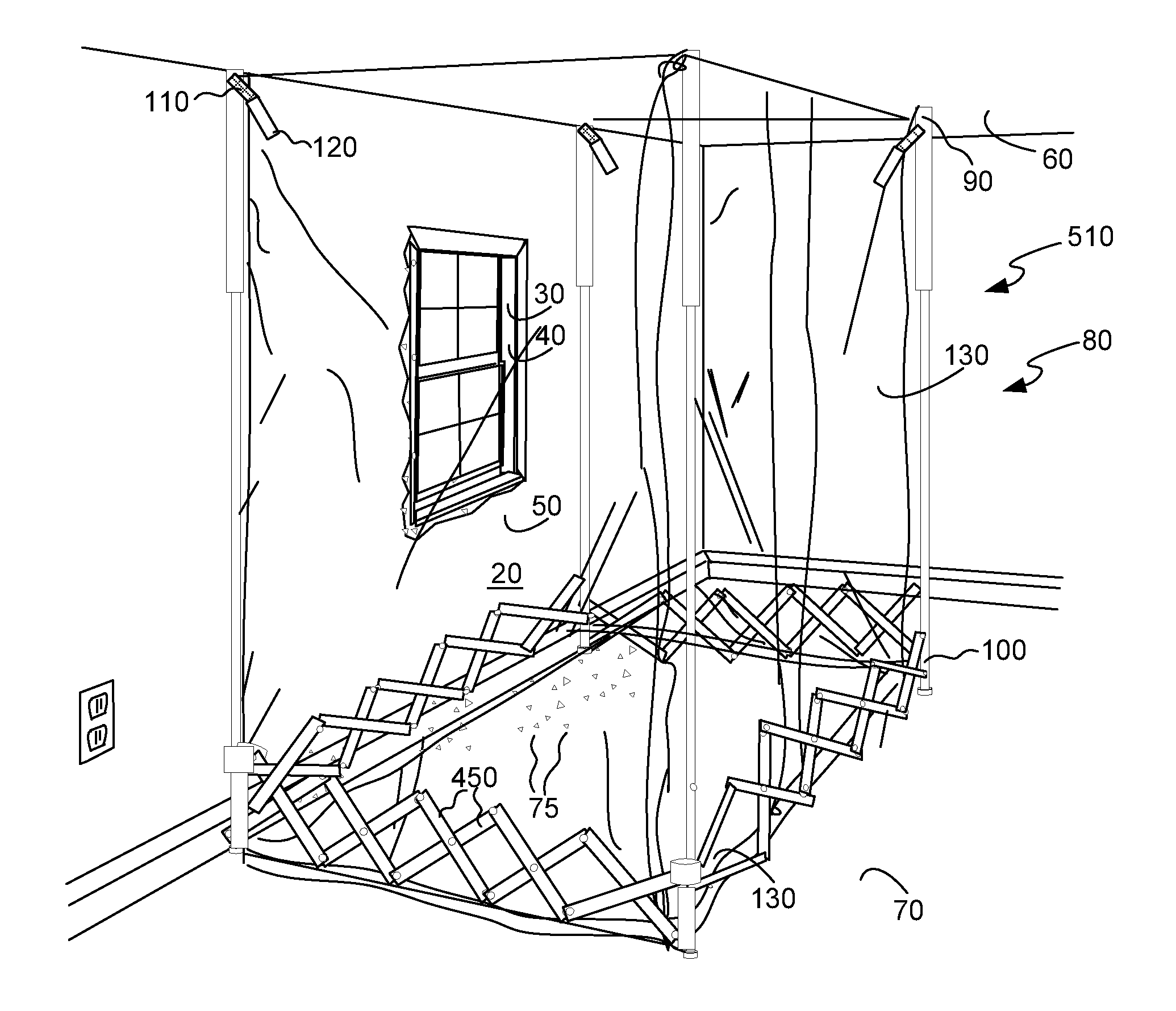

Vacuum cleaner conversion system

InactiveUS20110283475A1Quickly and easily adaptedEasy to operateSuction cleanersEngineeringVacuum cleaner

A vacuum cleaner conversion system utilizes a container or receptacle with an open top. A cover unit is configured to be positioned over the top of the receptacle and to be clamped to the receptacle to form a watertight connection. A first conduit extends through the cover unit. The conduit has an upper section extending above the cover and a lower section extending below the cover and into the receptacle. The lower section is totally enclosed at its lowermost end, but has an opening extending through its side surface. A second conduit extends through the cover. The second conduit has an upper section extending above the cover and a lower section extending below the cover and into the receptacle. The second conduit is open at its lowermost end. The first conduit has a connector providing an airtight connection between the conduit and a hose connected to a stand-up vacuum. The second conduit has a connector which establishes a watertight connection between the conduit and a hose extending to a dirt and debris collector nozzle unit. Once all elements of the conversion systems are in place, the vacuum cleaner is turned on. The suction provided by the vacuum cleaner extends through the first conduit and its opening, into the receptacle, and through the second conduit, its hose, and the nozzle unit, which allows the nozzle to suck up wet dirt and debris back through the wet hose, into the second conduit and then into the receptacle.

Owner:CAPPUCCIO LOUIS W +1

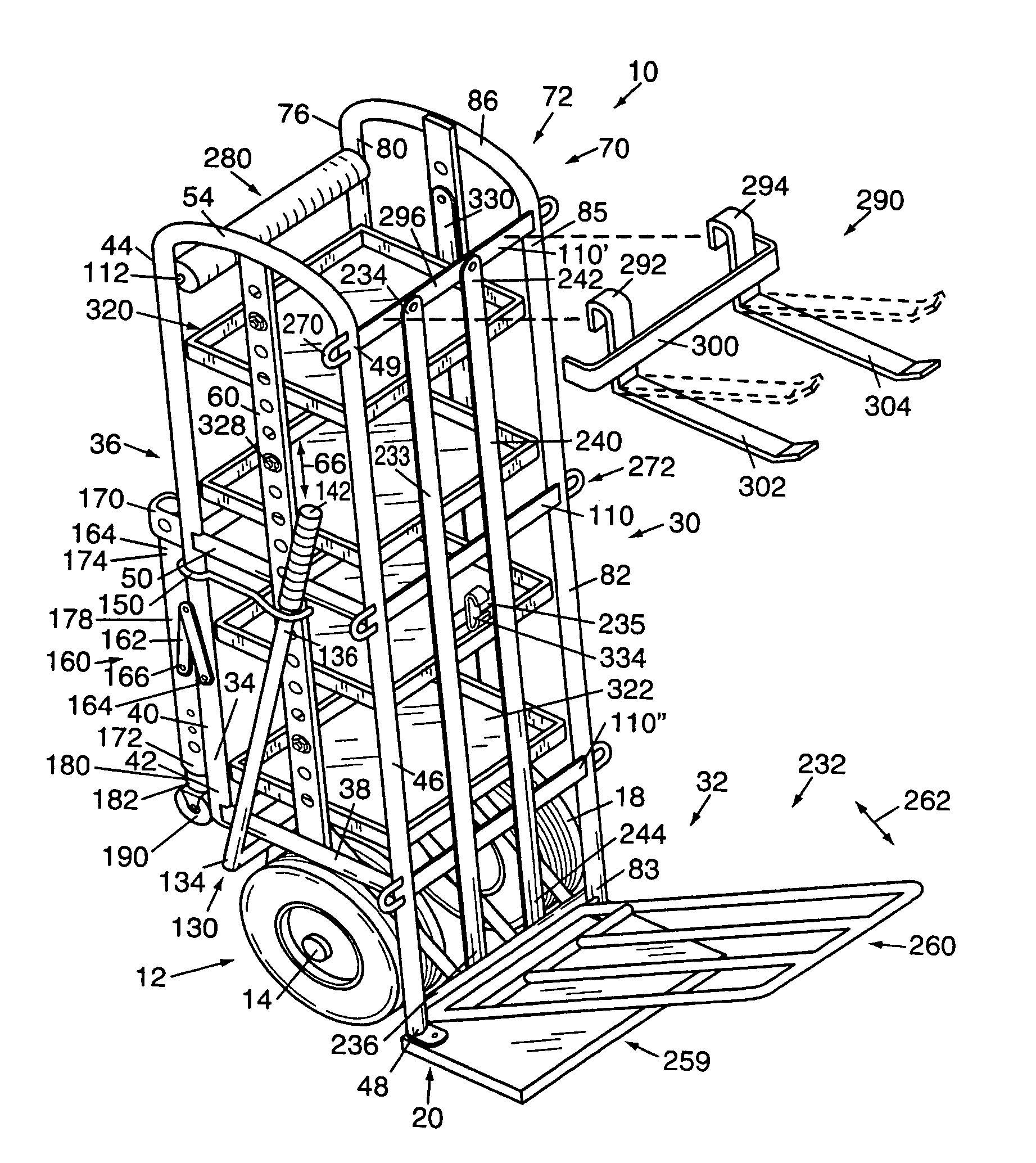

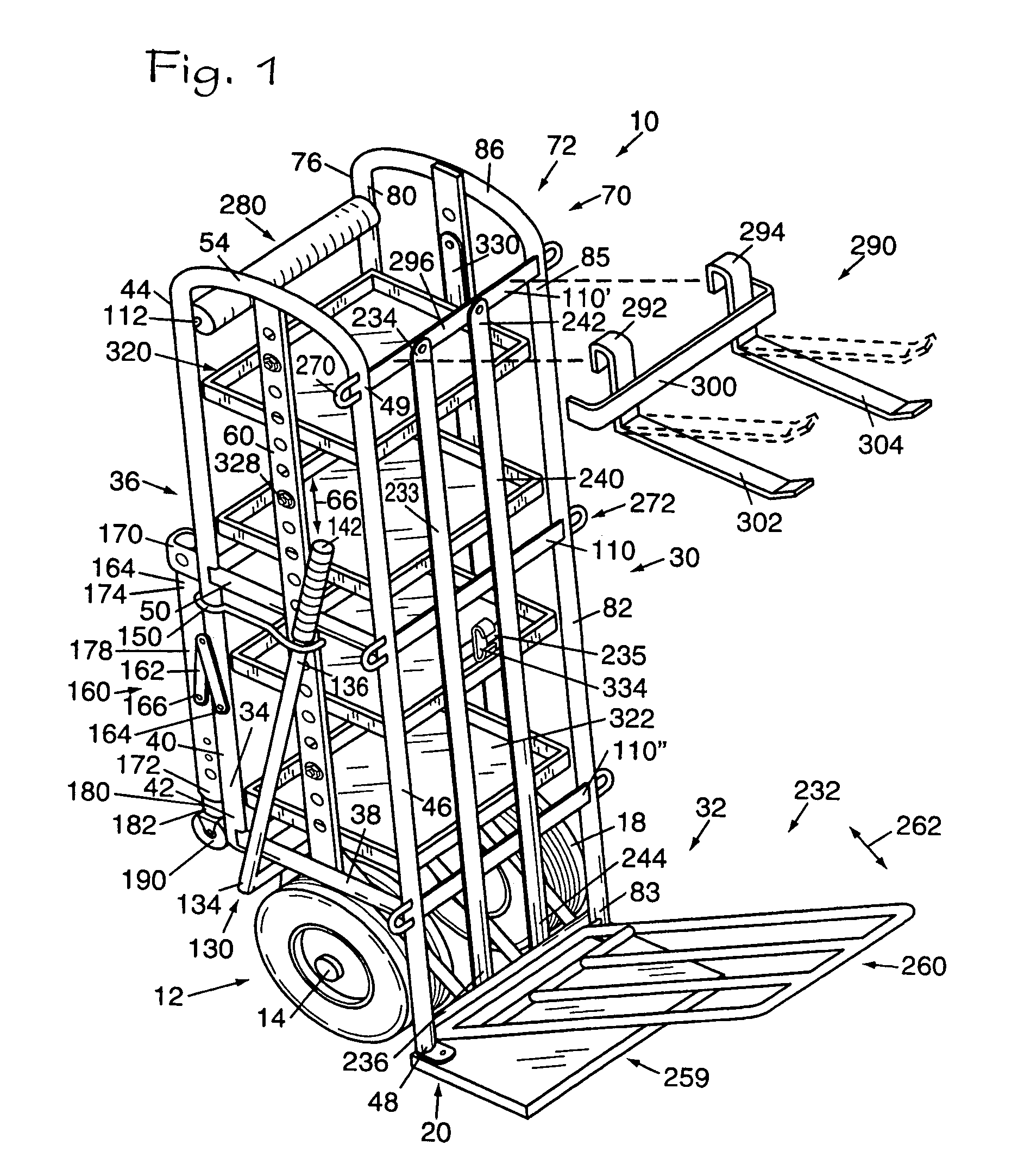

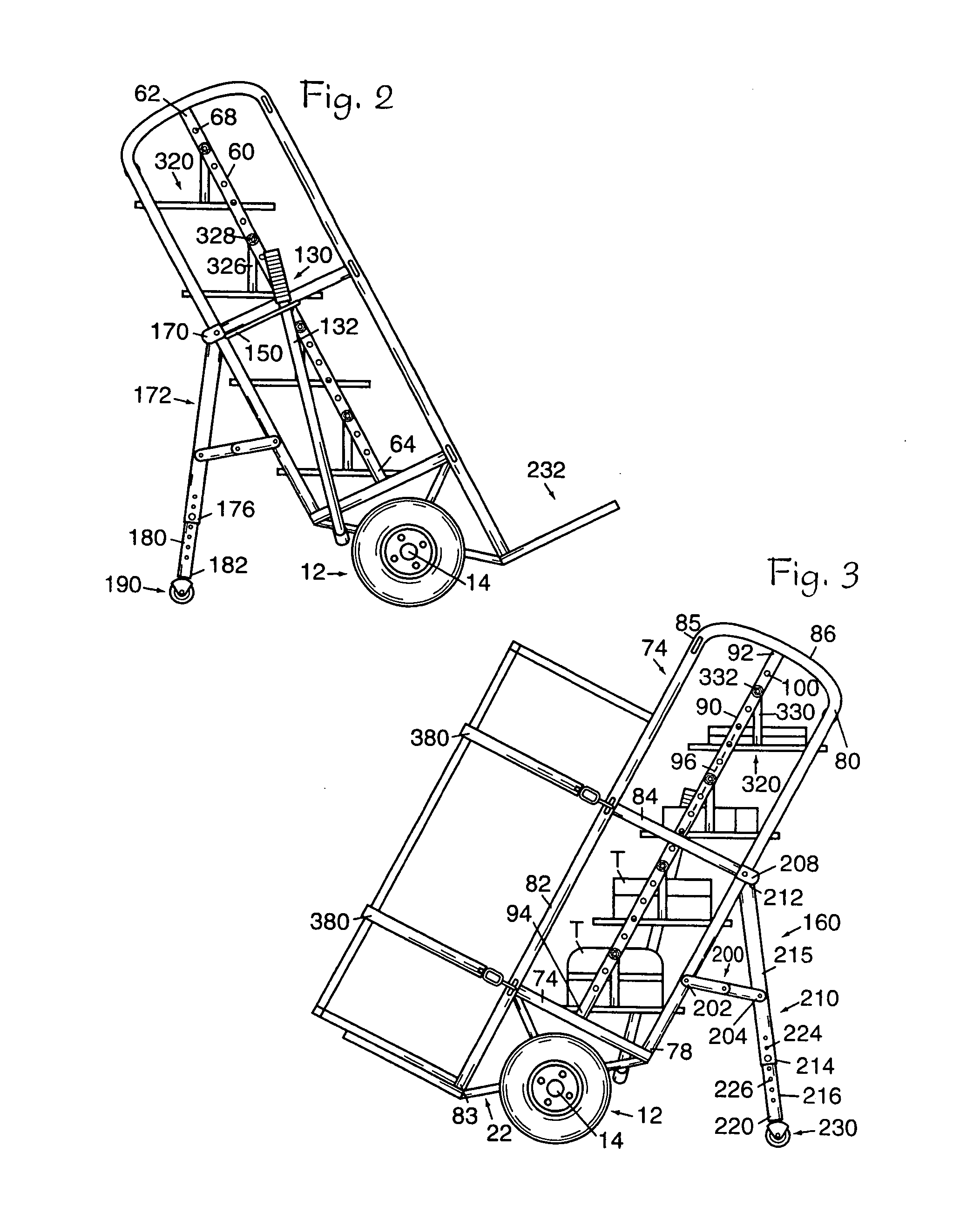

Versatile carrier

InactiveUS7278645B1Increase the number ofEasy to deployCarriage/perambulator with single axisSupporting partsEngineeringBiomedical engineering

A carrier includes a supporting unit that is amenable to supporting a wide variety of items. The carrier includes shelves and / or baskets as well as a unit that can be used to support large and / or bulky items. The carrier further includes a stabilizer unit as well as a brake unit. Various attachments can also be mounted on the carrier.

Owner:DAVIS SAM B

Apparatus for monitoring a door with a 3D sensor

ActiveUS20120150487A1Improves mountingImprove installation convenienceOptical rangefindersDigital computer details3d sensorControl unit

An apparatus for monitoring a door with a 3D sensor which is able to detect distances to an object in the monitoring area as the third dimension, the 3D sensor being arranged in a housing, and immovably arranged transmission means for transmitting a measurement beam and receiver means for receiving a reflected measurement beam being provided in the housing, characterized in that provision is made of a control unit which is designed to obtain an item of information relating to the position of the apparatus, and in that the control unit evaluates the measurement beam on the basis of an item of position information.

Owner:CEDES AG

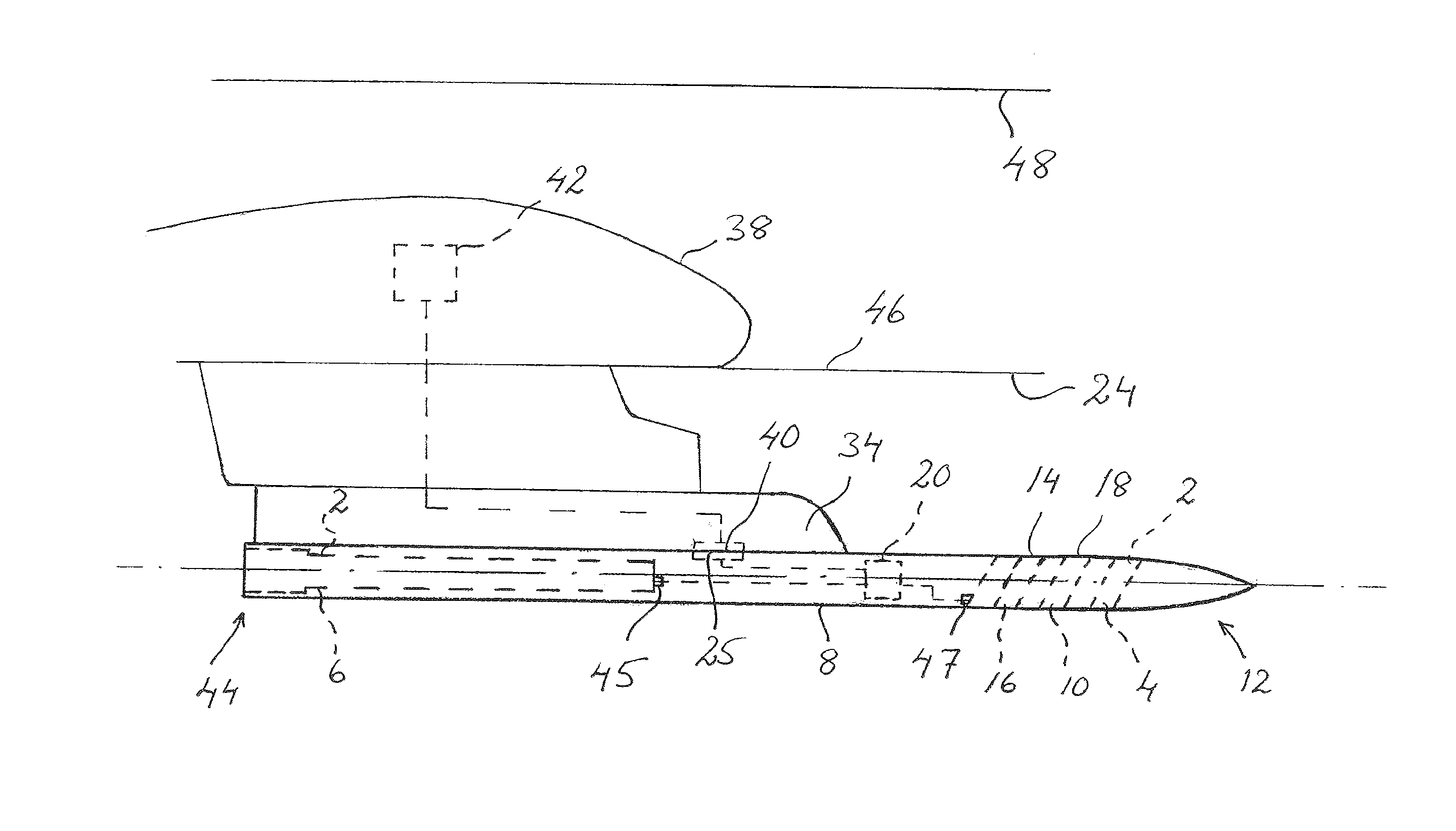

Countermeasure arrangement

ActiveUS20120097795A1Low costEffective countermeasure arrangementAmmunition projectilesDefence devicesCountermeasureEngineering

A countermeasure arrangement including a countermeasure dispenser. An envelope at least partly encloses the countermeasure dispenser. A first control module is configured to control the countermeasure dispenser. A suspension module is arranged on the envelope for suspending the envelope on an aircraft. The suspension module has a form and a design that substantially correspond to the form and design of a suspension rail of a missile, so that the suspension module mates to a hard point on the aircraft, which is adapted to the missile.

Owner:SAAB AB

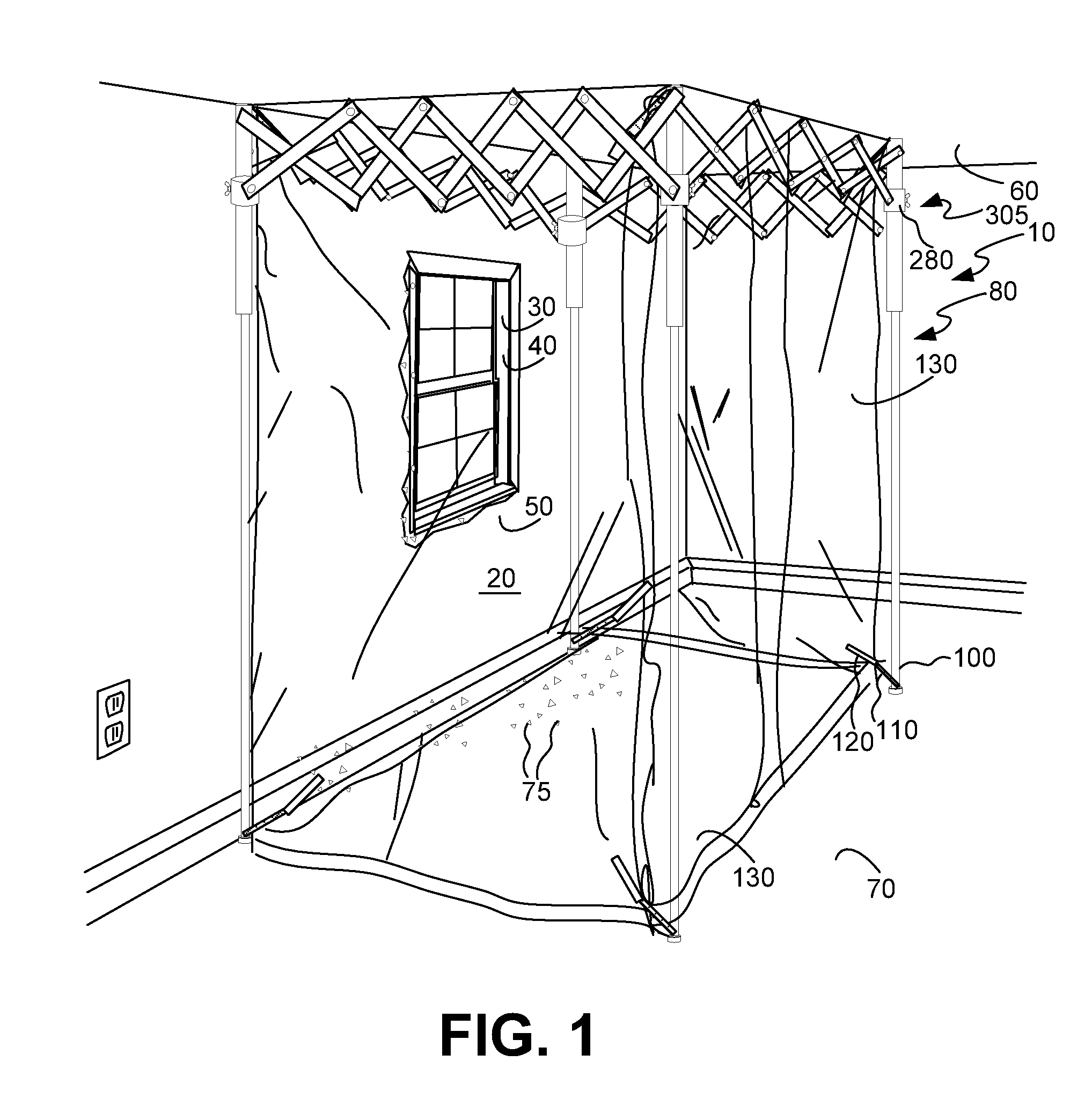

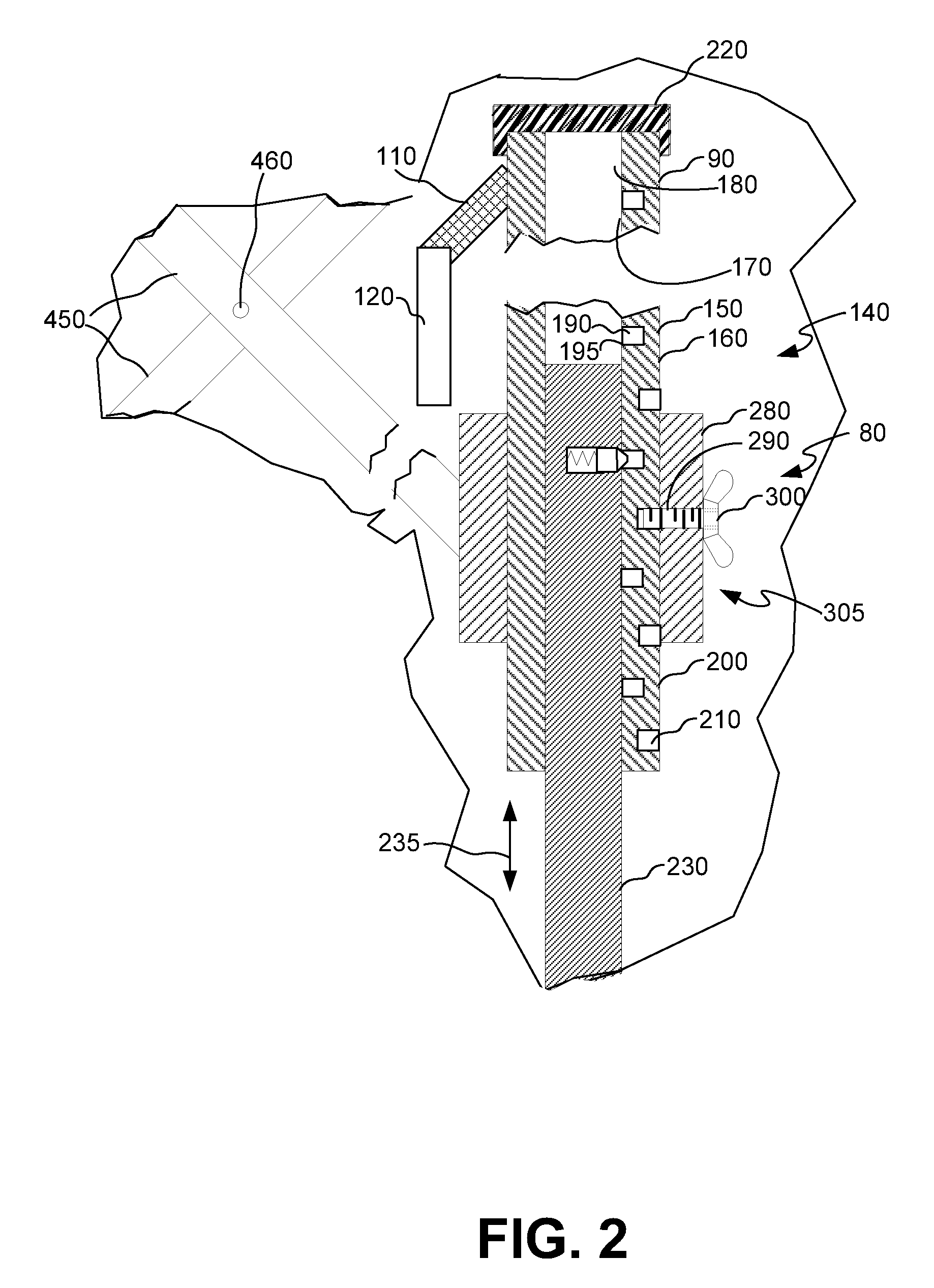

Adjustable enclosure and method for enclosing a work space having a surface therein to be worked upon, the surface bearing a lead-based paint

InactiveUS20130008620A1Quickly and easily adaptedQuickly adjusting distanceScreensLight protection screensEngineeringWork space

Adjustable enclosure and method for enclosing a work space having a surface therein to be worked upon, the surface bearing a lead based paint. According to an exemplary embodiment, the adjustable enclosure comprises a plurality of height-adjustable uprights capable of accommodating ceilings of various heights and also capable of being disposed in spaced-apart relationship about various sizes of the work space. Each height-adjustable upright includes a clasp for reliably securing a portion of a plastic containment sheet adapted to contain lead-based paint dust and chips within the work space. Extent-adjustable horizontal connectors are capable of arranging the adjustable enclosure in a desired configuration about the work space. The adjustable enclosure is quickly and easily adaptable to building structures and work spaces of various sizes in order to contain lead-based paint dust and chips generated during renovation, repair and painting operations.

Owner:CUSICK MICHAEL

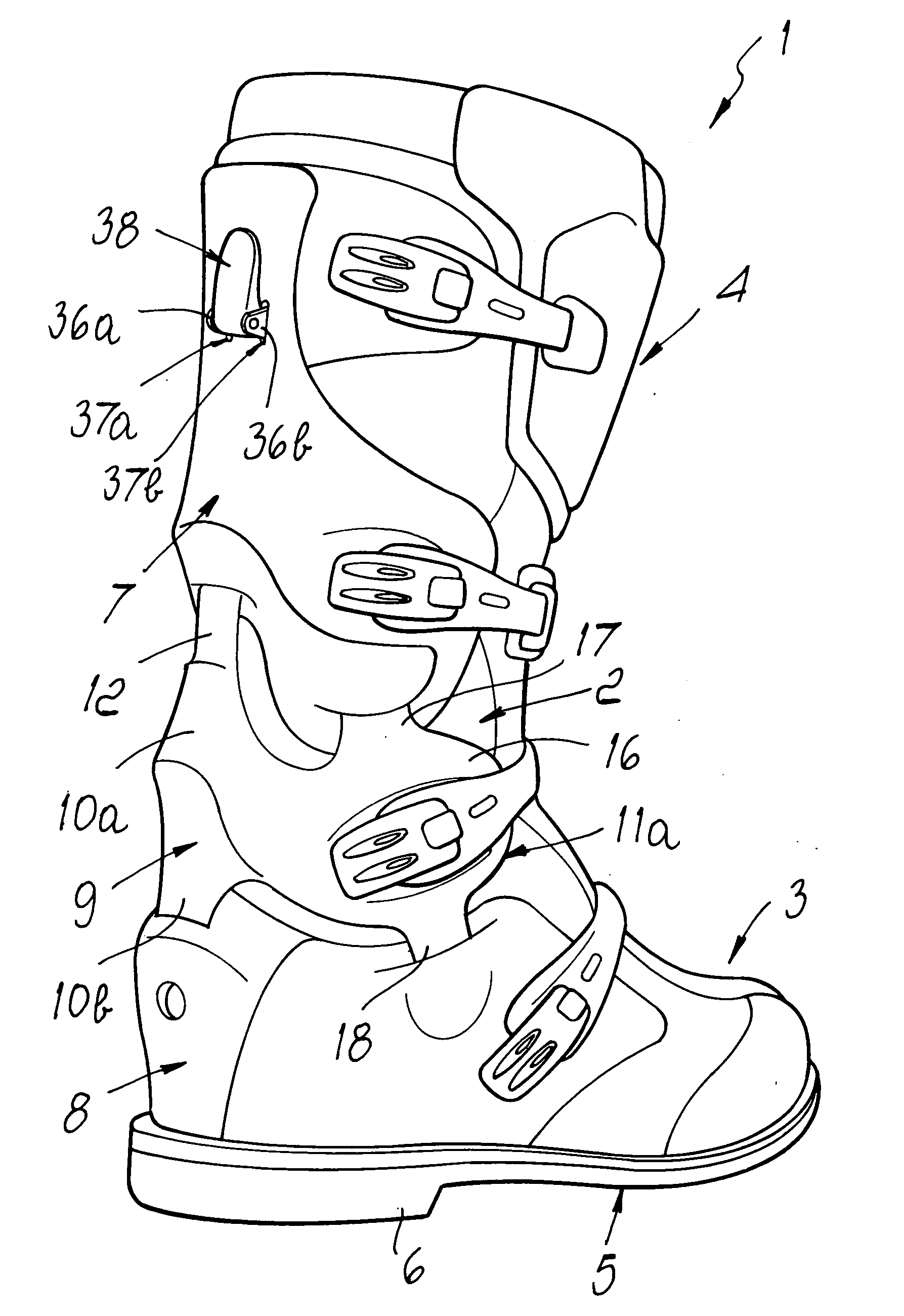

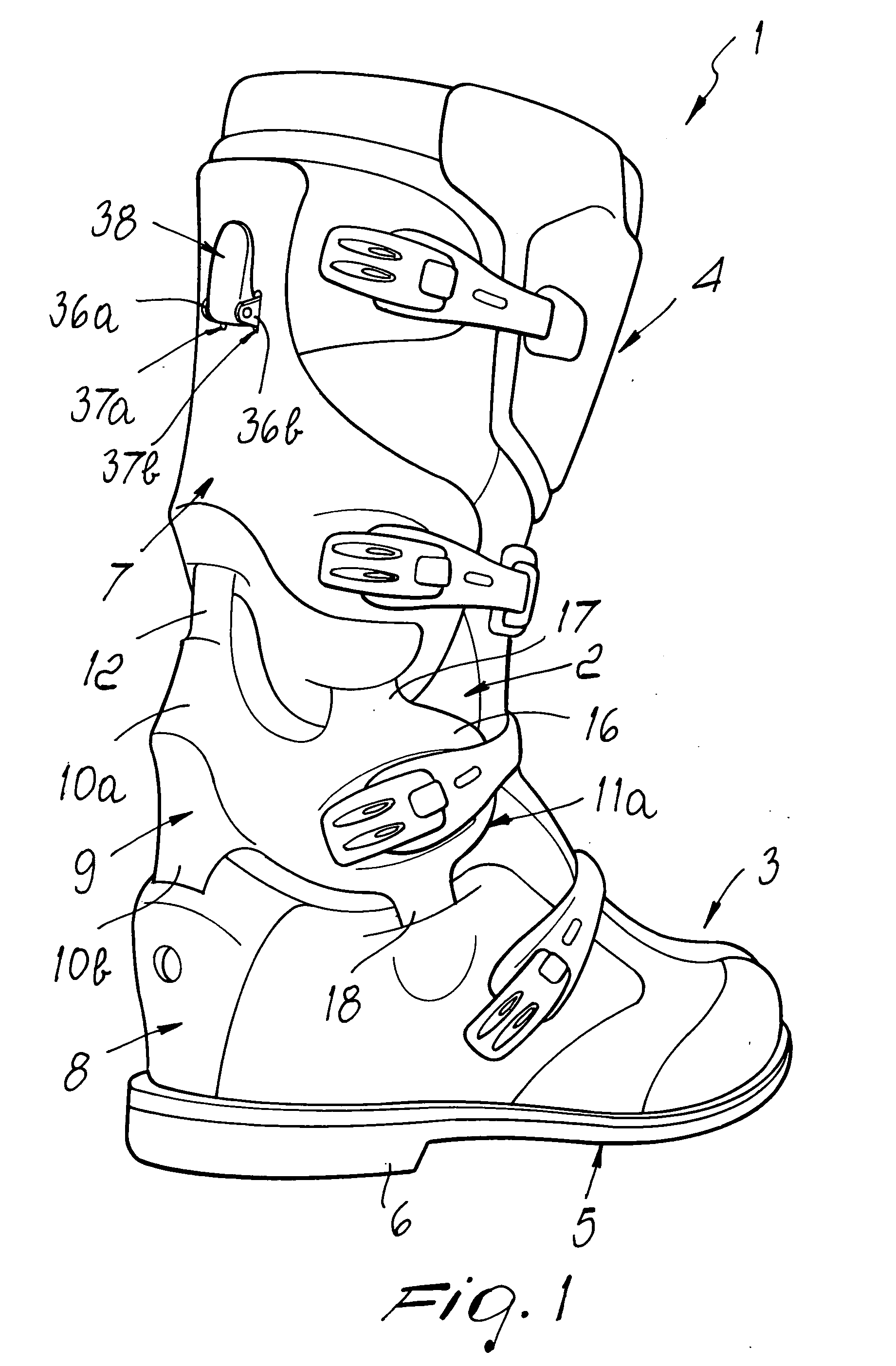

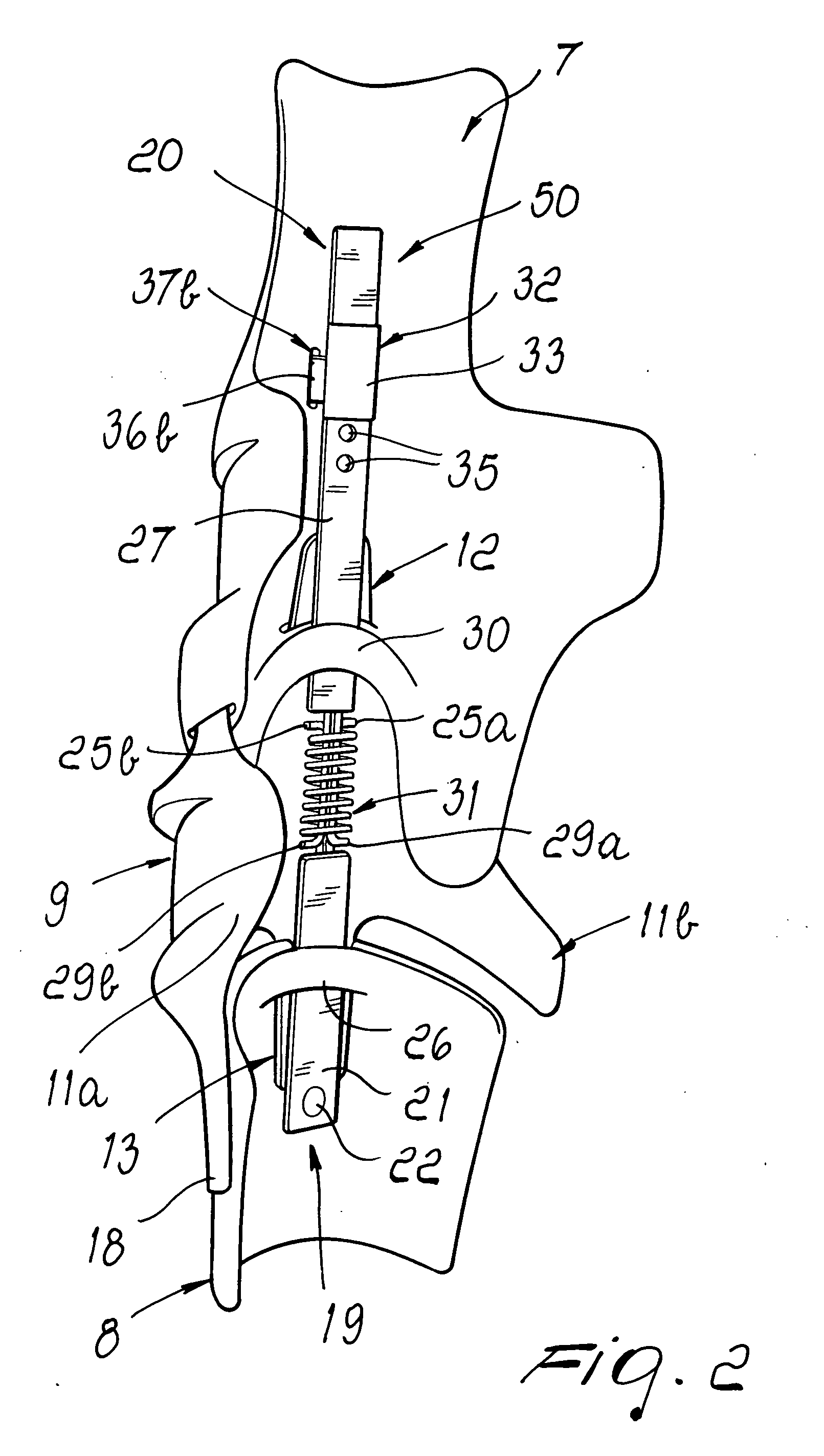

Flex control device particularly for a motocross boot

InactiveUS20070175069A1Sufficient protectionQuickly and easily adaptedFootwearEngineeringMechanical engineering

A flex control device, for the quarter of a motocross boot, which comprises a soft upper provided at the rear with a semirigid cuff and a semirigid counter, which are connected respectively to the upper and to the upper and / or sole. The device is constituted by a first rod shaped element and a second rod shaped element, the first rod shaped element being rigidly coupled to the counter, the second one being selectively associable with the quarter, the first and second rod shaped elements being slidingly associated in contrast with at least one elastically deformable element.

Owner:NOVATION MOTORBIKE

Cable-controlled container yoke

InactiveUS8840159B2Quickly and easily adaptedFaster and simple and cheap mannerLifting devicesTrolley cranesEngineeringActuator

A container yoke for lifting of at least one container, including a base frame, two travelling beams, which are telescopically displaceable in the base frame and on whose outer end portions are arranged transverse beams provided with locking members, so called twist locks, for engagement in, and locking to, the corner boxes of a container. The container yoke includes cables arranged to displace a respective travelling beam into the desired position in the frame of the container yoke. The cables, for displacement of a travelling beam, are simultaneously reeled up and unreeled with the aid of one and the same cable drum. Two cable drums of the container yoke are driven by a common actuator, and the cables are fastened in the end portion of a respective travelling beam via spring-loaded cable tensioners.

Owner:ELME SPREADER

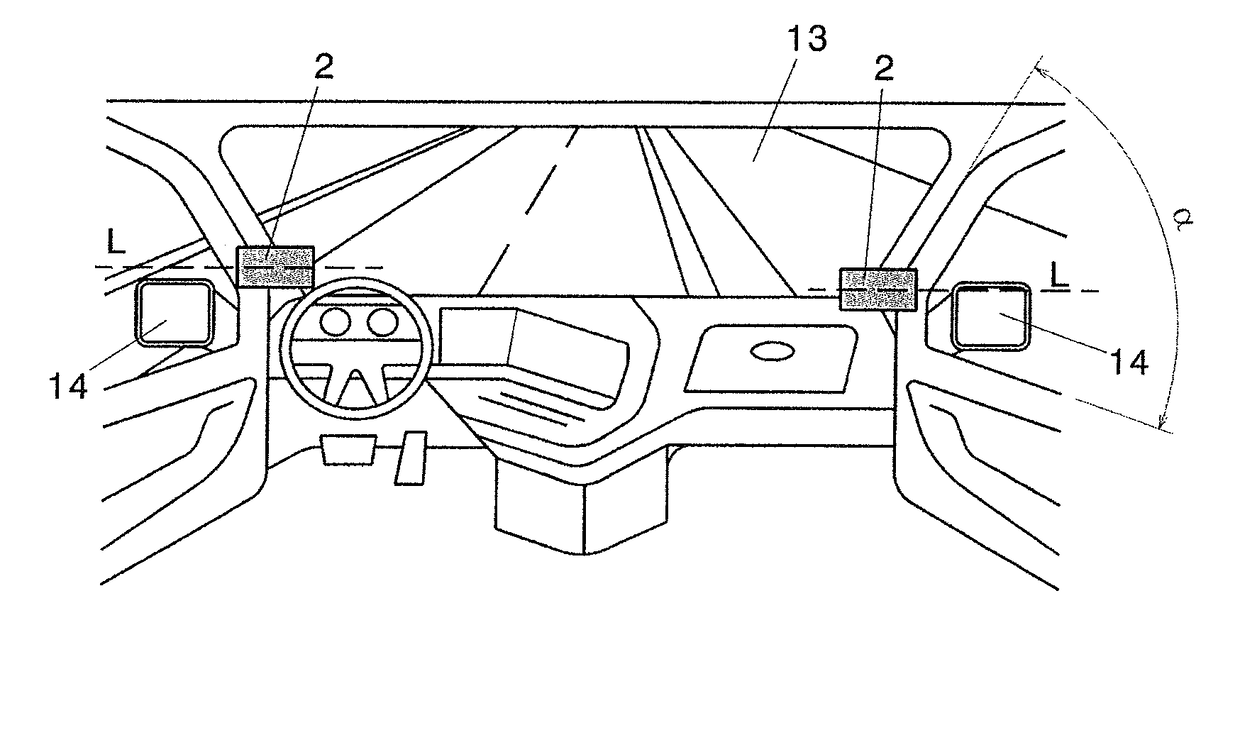

System for Visually Depicting Fields of View of a Commercial Vehicle

InactiveUS20170374287A1Improve driving safetyEasy to monitorTelevision system detailsCharacter and pattern recognitionDisplay deviceEngineering

System for visually depicting fields of view for a commercial vehicle within a driver's cab of the commercial vehicle, the system having at least one display device disposed within the driver's cab and having at least one display unit being configured to display at least one field of view, wherein the at least one display device is configured to be arranged within the driver's cab of the commercial vehicle such that the longitudinal axis thereof is substantially horizontally aligned.

Owner:MEKRA LANG GMBH & CO KG

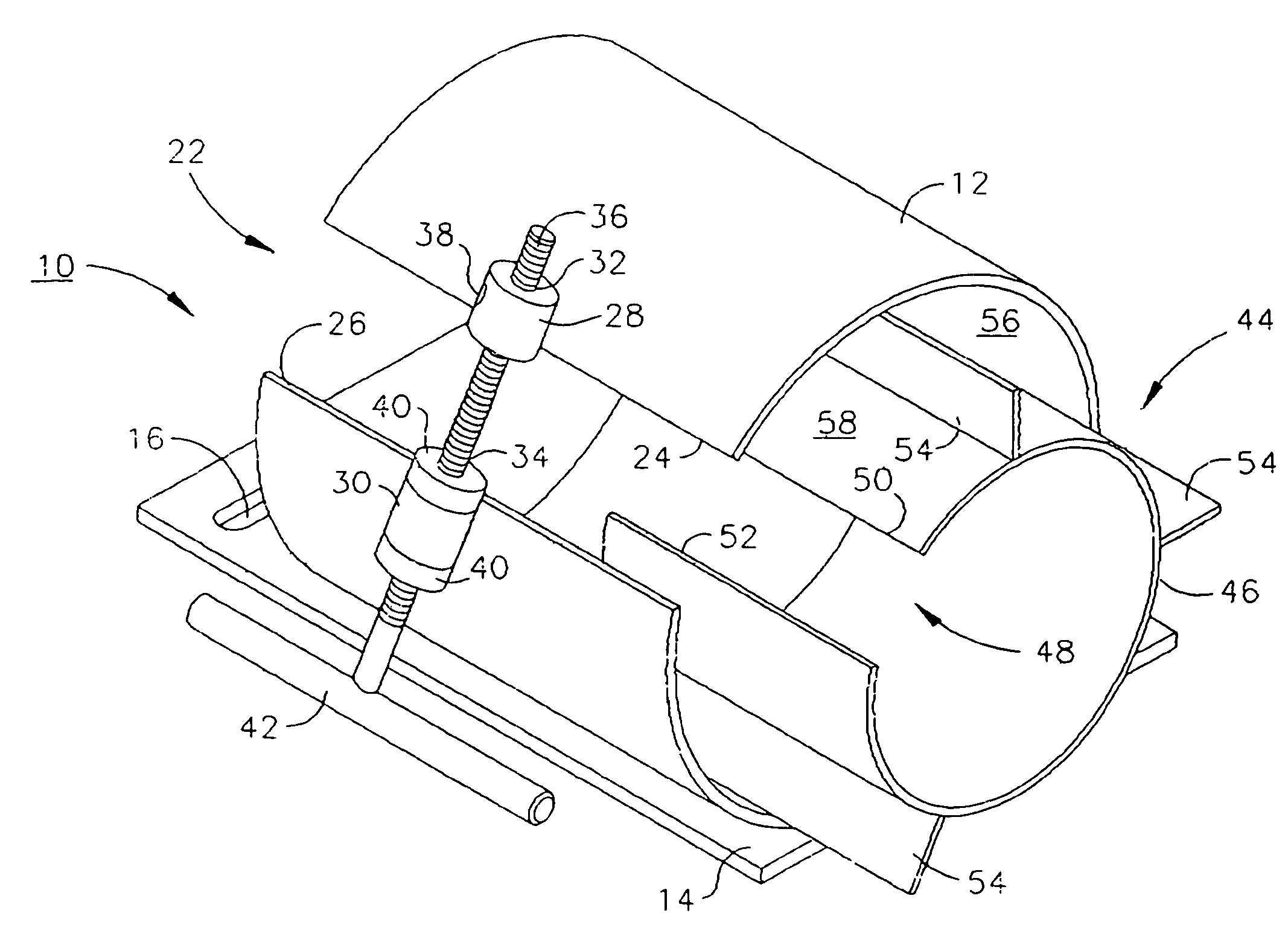

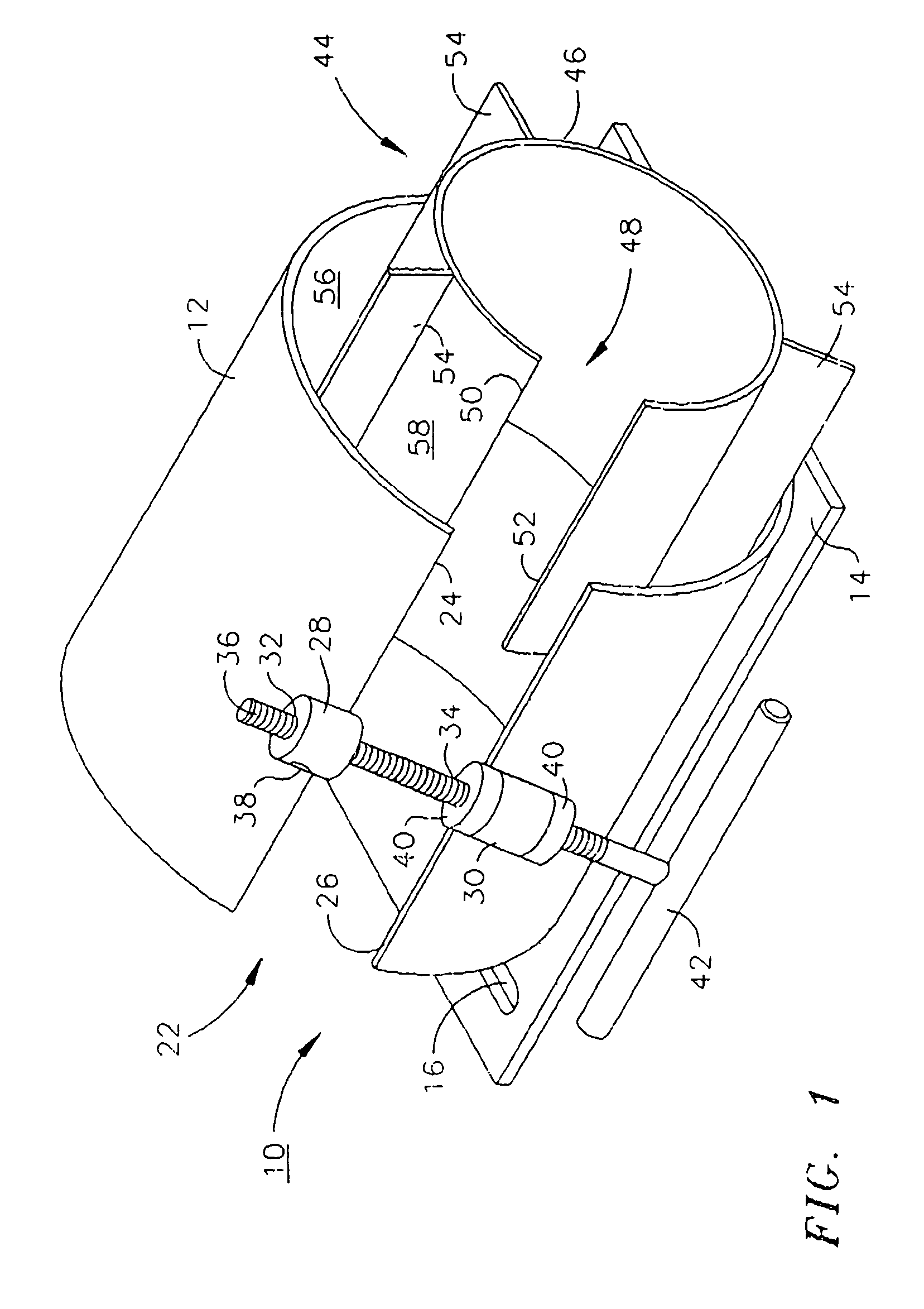

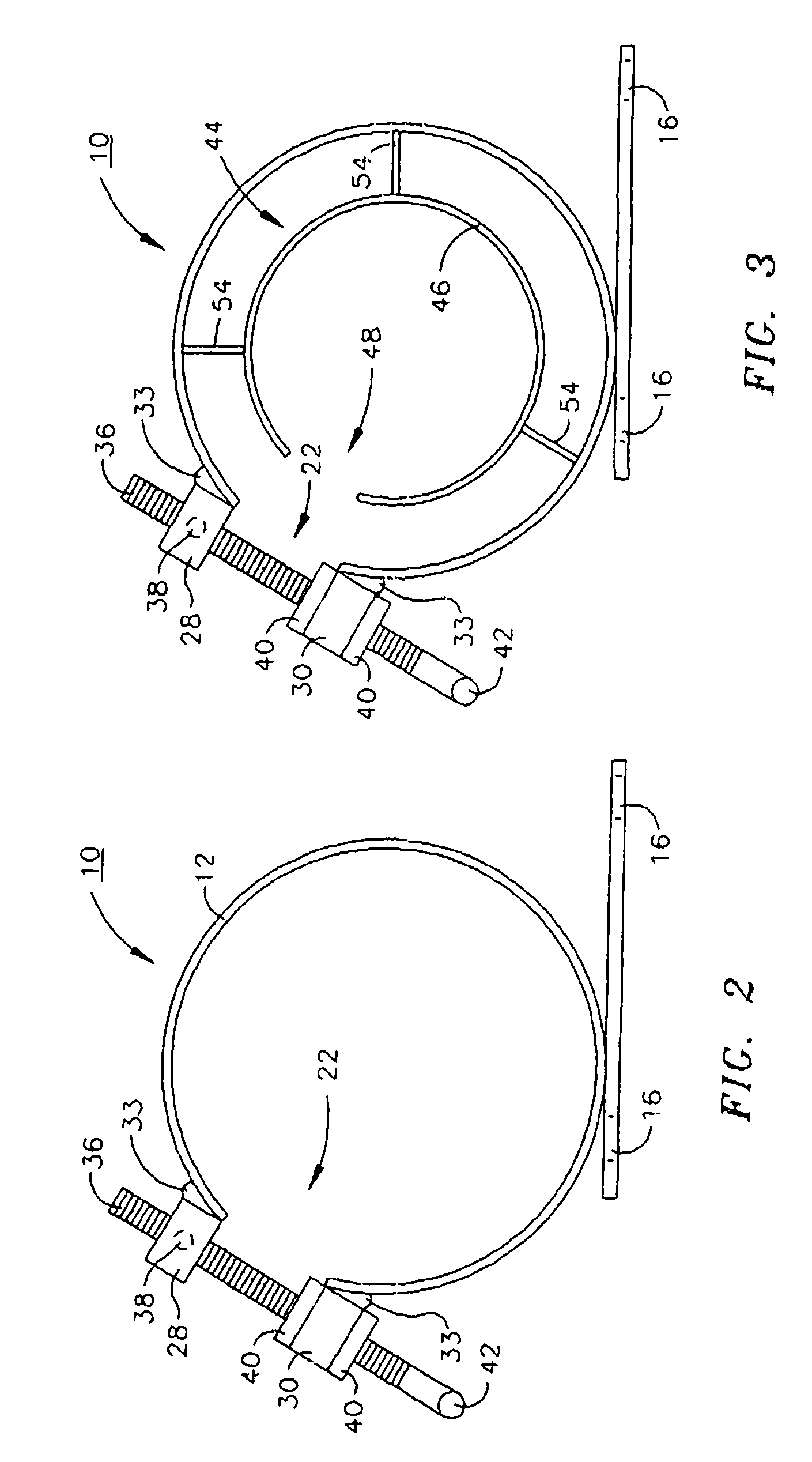

Test core clamp

Owner:GLYNN TIMOTHY DALE

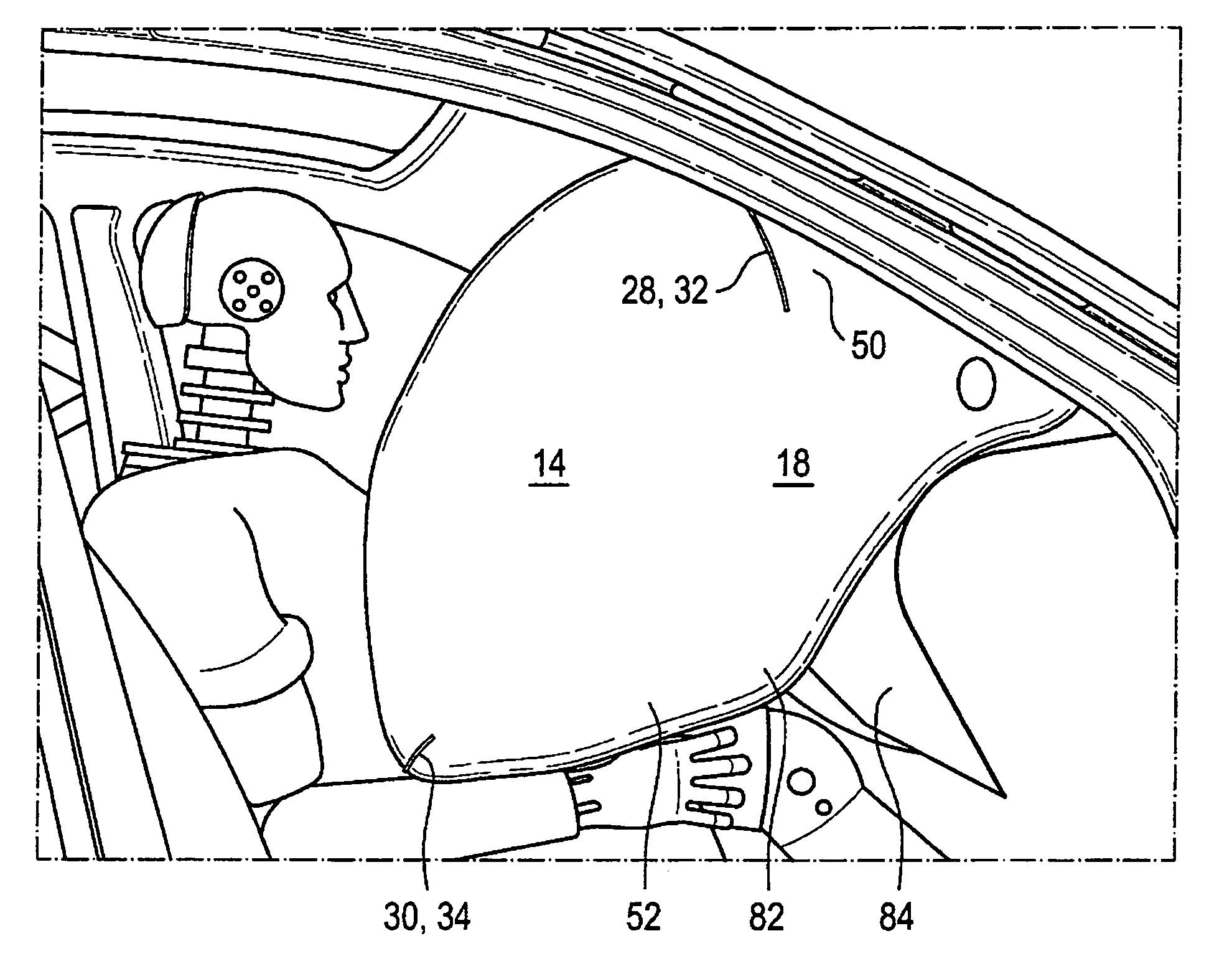

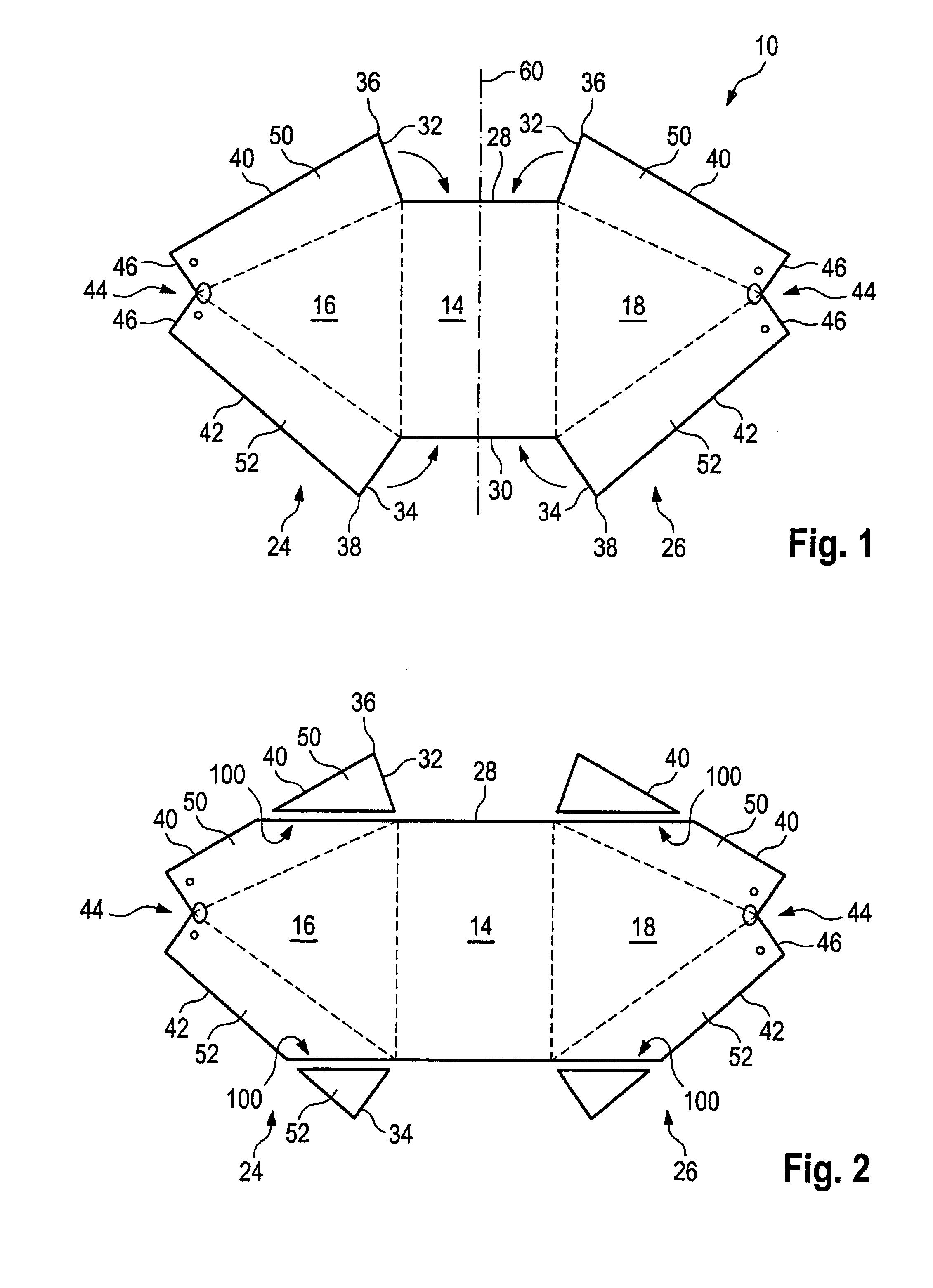

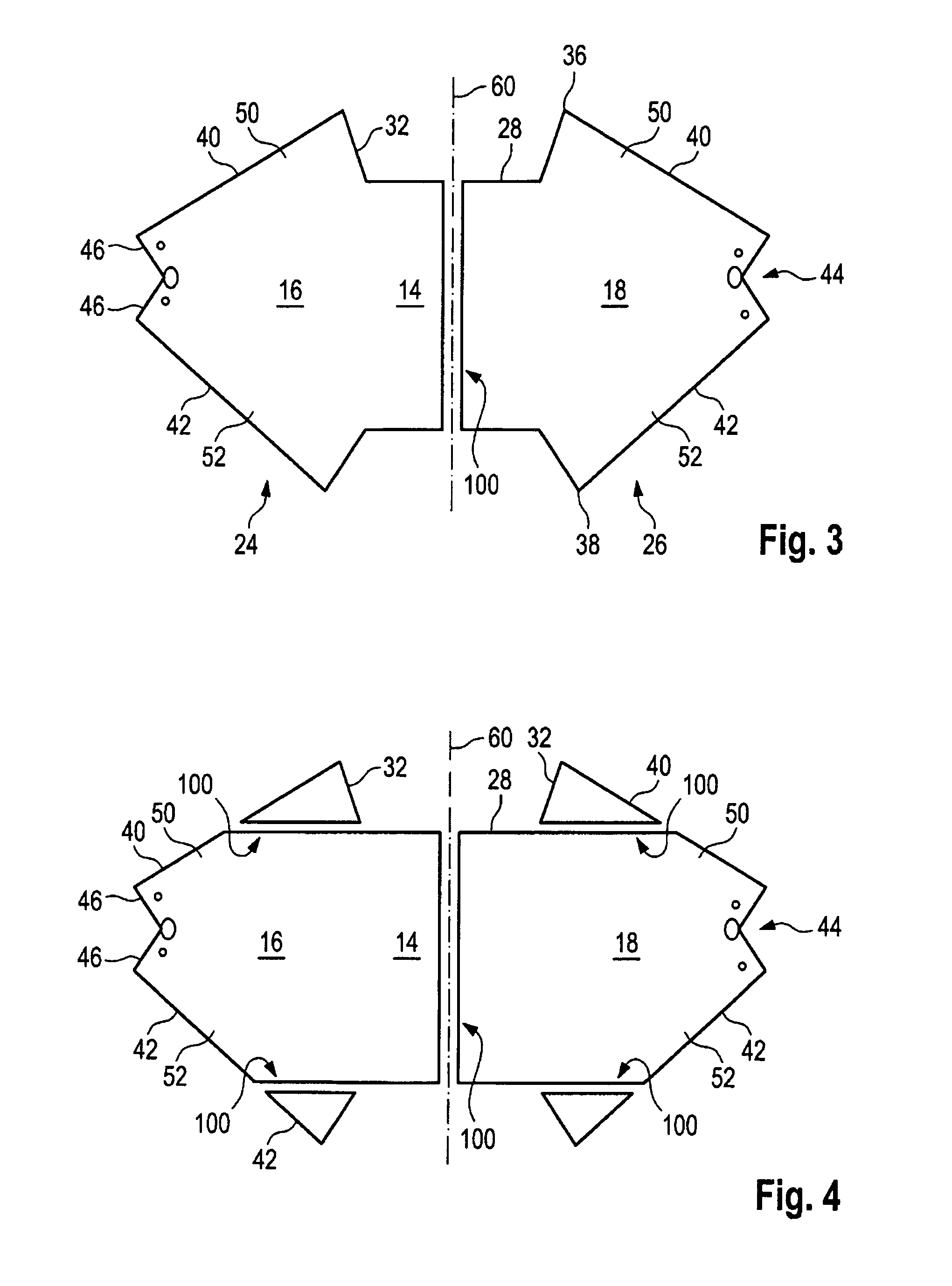

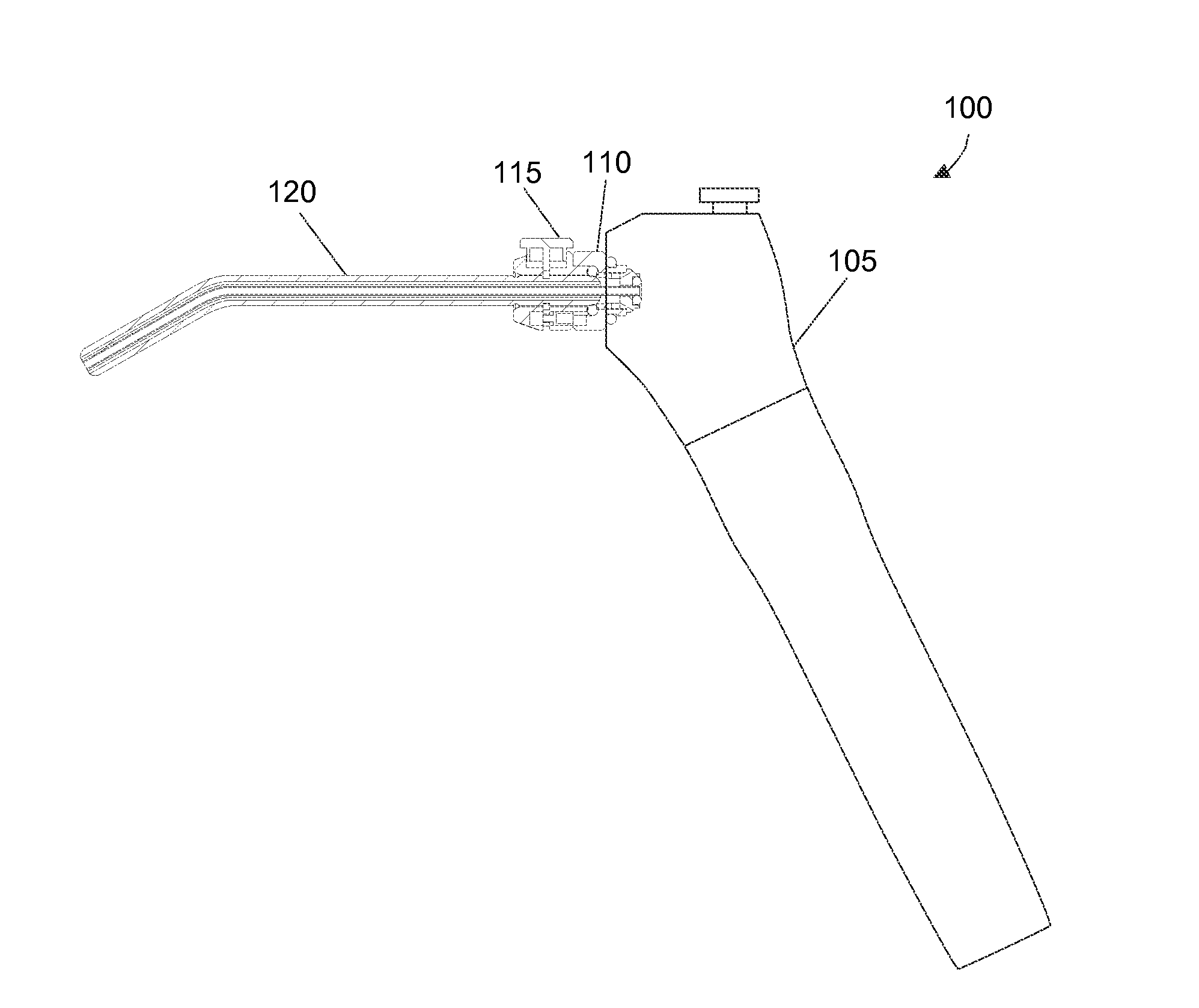

Airbag

ActiveUS20120098242A1Adapt quicklyIncrease expenditure timePedestrian/occupant safety arrangementEngineeringAirbag

An airbag, especially a passenger airbag, comprises a rear injection orifice, a front wall (14) for the impact of the occupant as well as two opposed sidewalls (16,18) and an upper wall and a lower wall. Each of the upper and lower walls is split and consists of side portions (50, 52) which are juxtaposed and are connected to each other along opposite margins (40, 42).

Owner:TRW AUTOMOTIVE GMBH

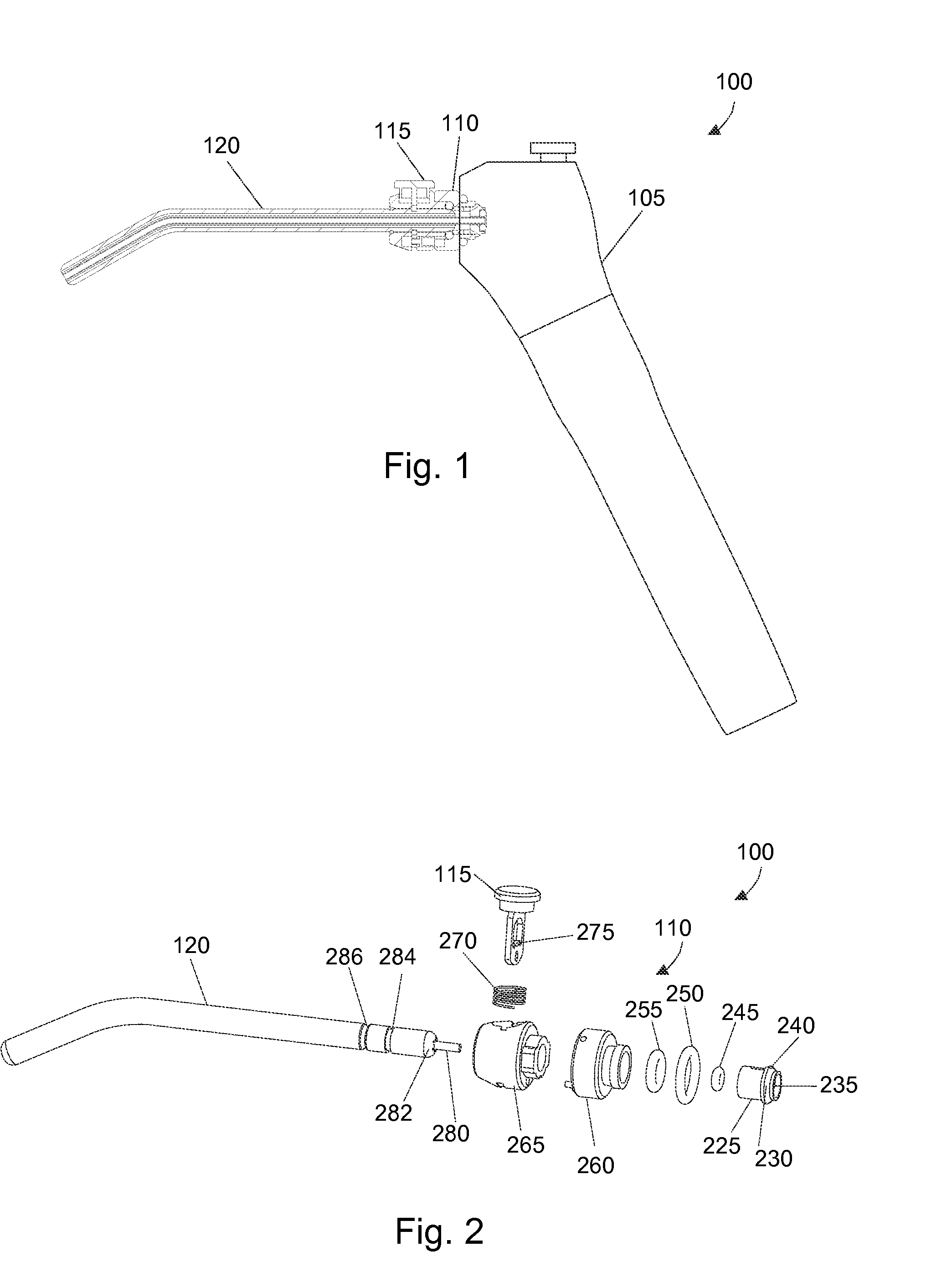

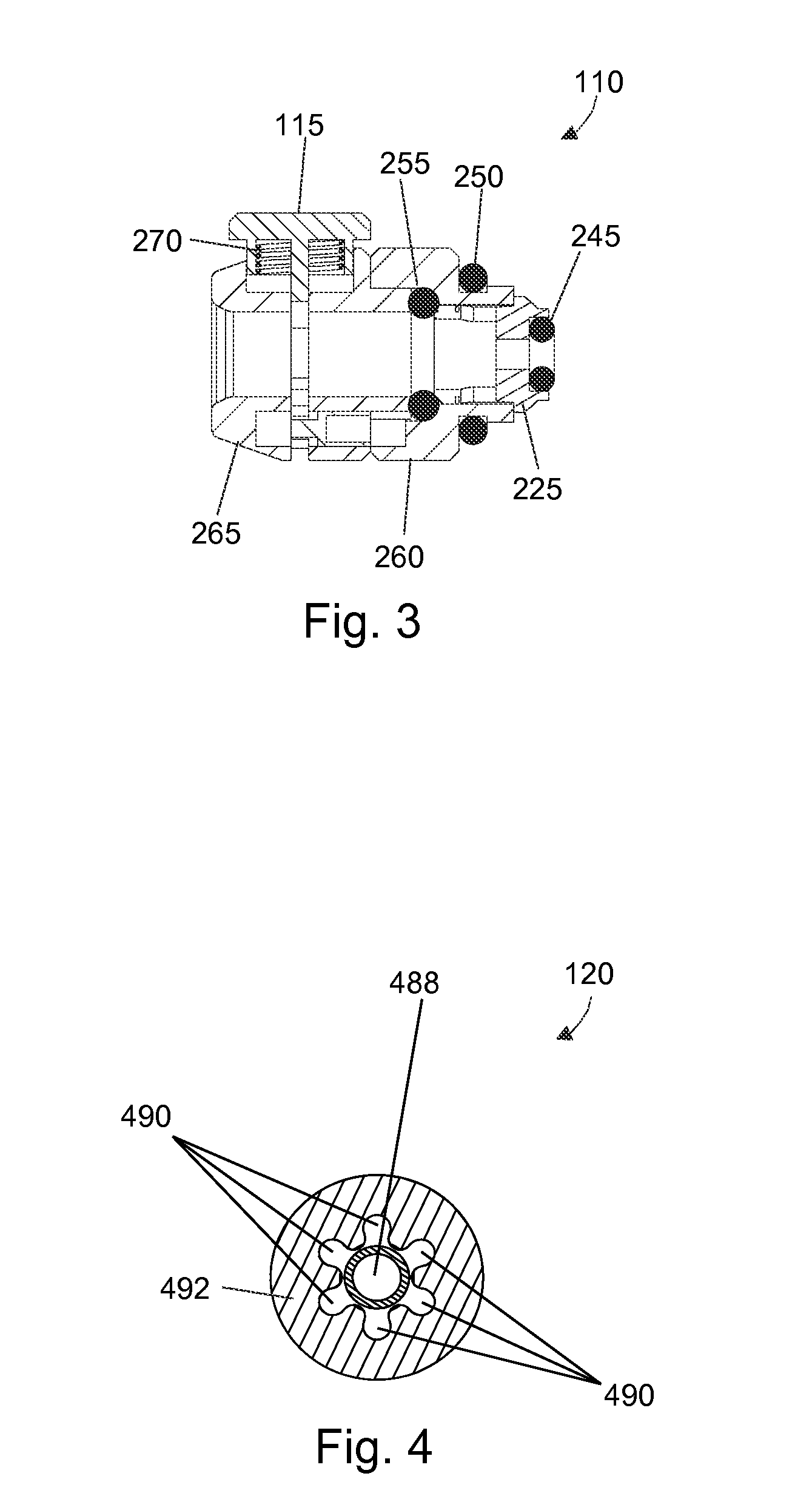

Adapter and tip for an air and water dental syringe device

A dental syringe device that provides air and water to a dental patient. The device includes an adapter that connects a dental tip to a dental syringe body. The dental syringe body provides a conventional syringe body with a handle for a dentist to hold onto and a source of air and water. The tip delivers the air and water to the dental patient. The adapter is an improved adapter having a unique release and attachment component allowing for a quick connect and disconnect between the dental syringe body and the tip. The tip advantageously includes an inner portion with large and uniform air channels for smooth transfer of air and an outer portion made from a rigid plastic that provides an improved cheek retraction feature.

Owner:PAC DENT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com