Vacuum cleaner conversion system

a vacuum cleaner and conversion system technology, applied in the field of vacuum cleaner conversion system, can solve the problems of clogging the vacuum filter, user to either rent a wet/vac unit or incur the cost of purchasing one, and the vacuum type unit is not designed to clean up water or water soaked debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

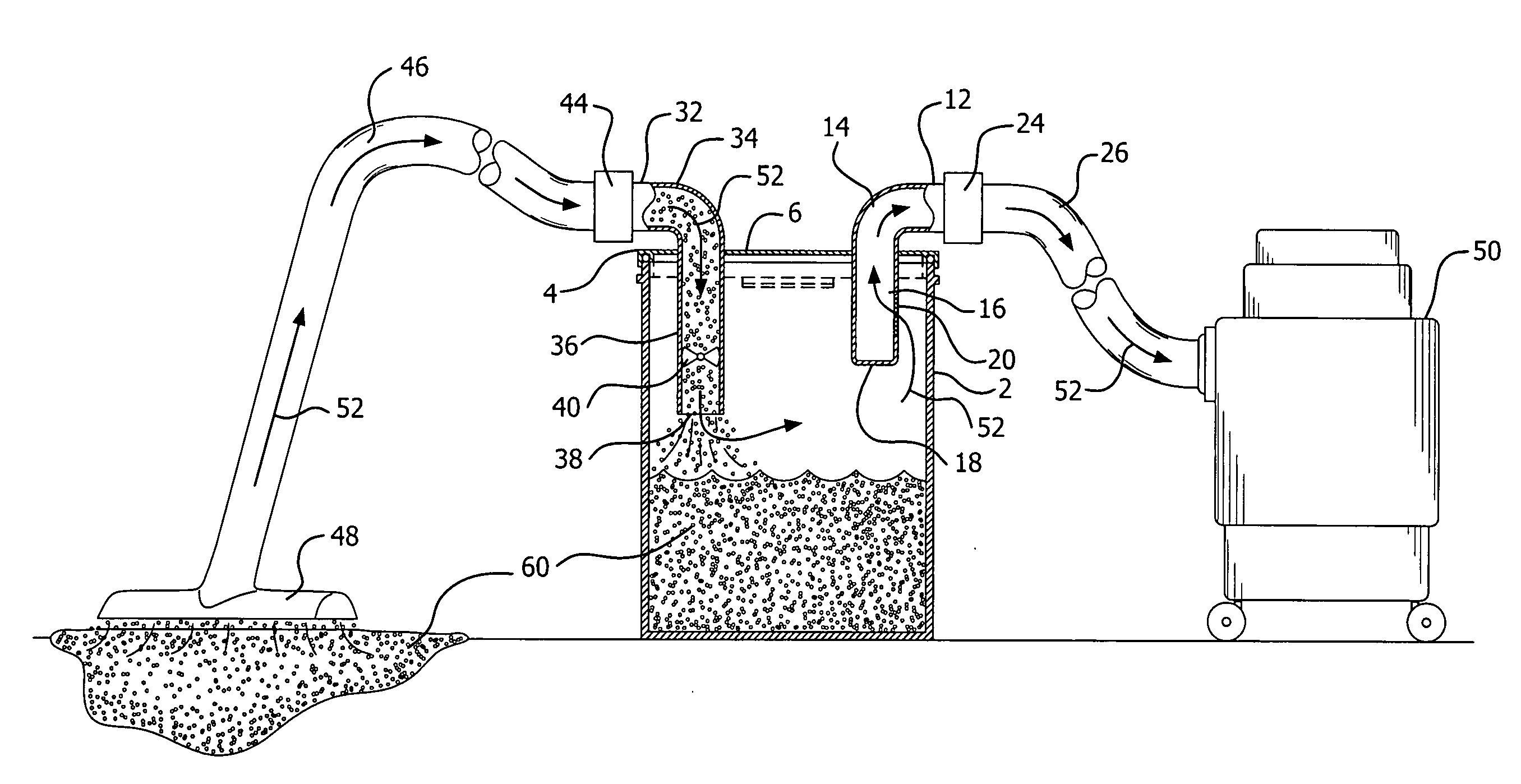

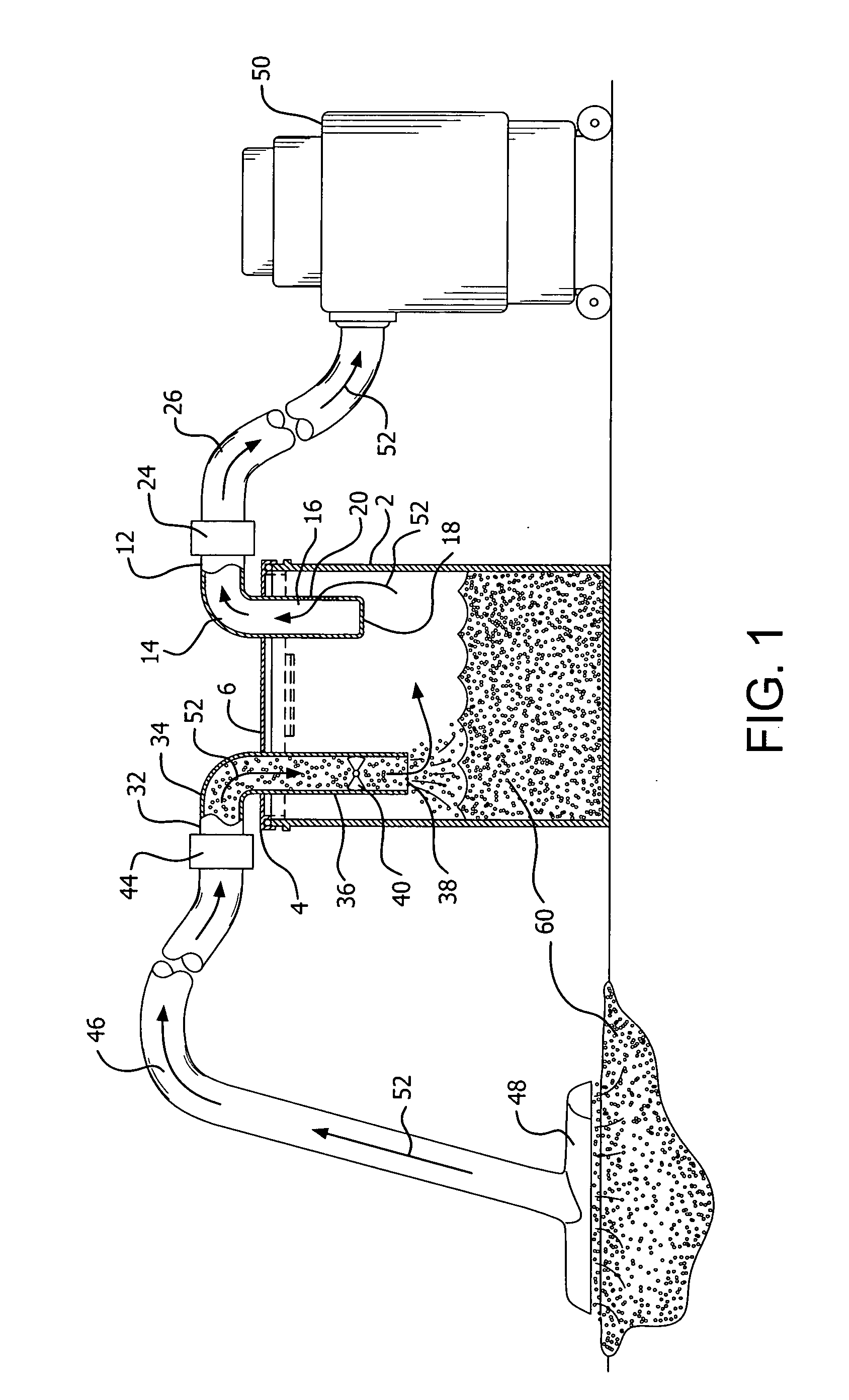

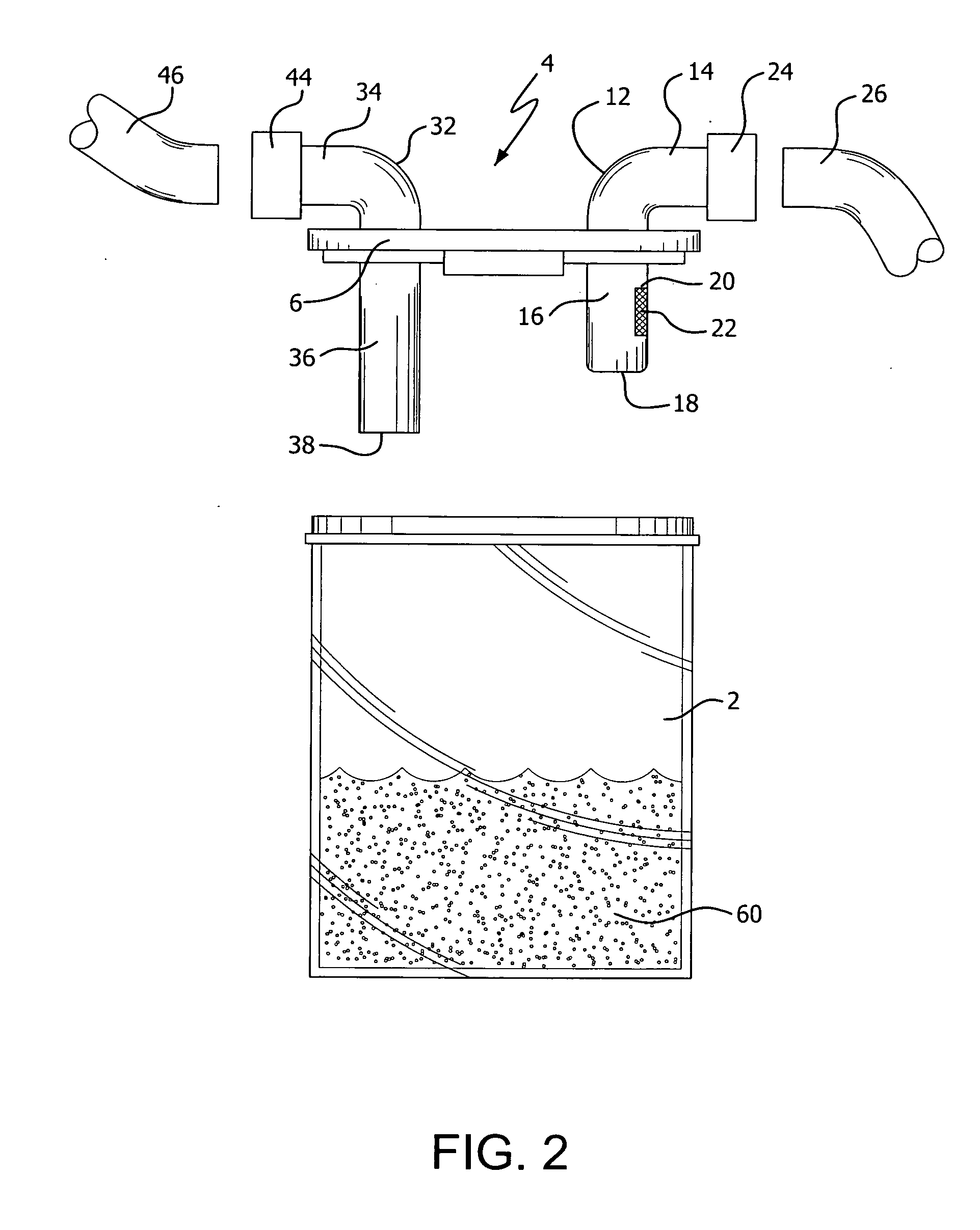

The vacuum cleaner conversion system of the present invention comprises container or receptacle 2 having an open top. Lid component 4 comprises cover section 6 configured to be positioned over the open top of receptacle 2. Lid clamps 8 and 9, with gasket 10, secure lid component 4 onto receptacle 2, providing a watertight seal between the lid component and the receptacle.

Lid component 4 further comprises conduit 12 which extends through cover 6 of the lid component. Conduit 12 comprises upper section 14 which extends above cover 6 at a right angle thereto and lower section 16 which extends into receptacle 2. Lowermost end 18 of lower section 16 is totally closed off. However, opening 20 extends through a side of lower section 16. Screen member 22 overlays opening 20 to prevent dirt and debris from entering conduit 12. Upper section 14 of conduit 12 comprises end connector 24 configured to provide an airtight seal between conduit 12 and dry hose or similar passage 26 extending betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com