Patents

Literature

423 results about "Impressions materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

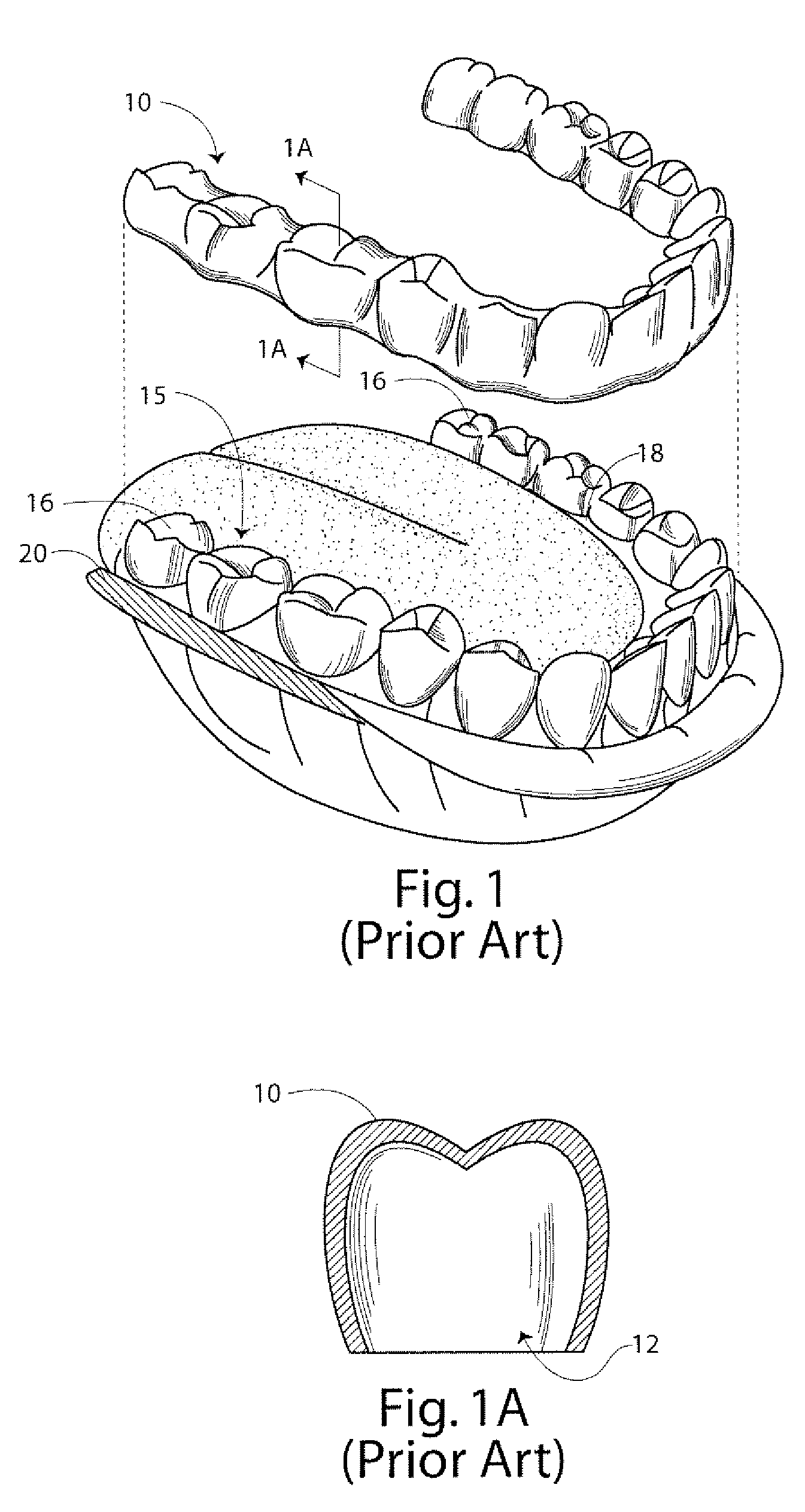

A custom dental model or cast. A dental impression is a negative imprint of hard (teeth) and soft tissues in the mouth from which a positive reproduction (cast or model) can be formed. It is made by placing an appropriate material in a stock or custom dental impression tray which is designed to roughly fit over the dental arches.

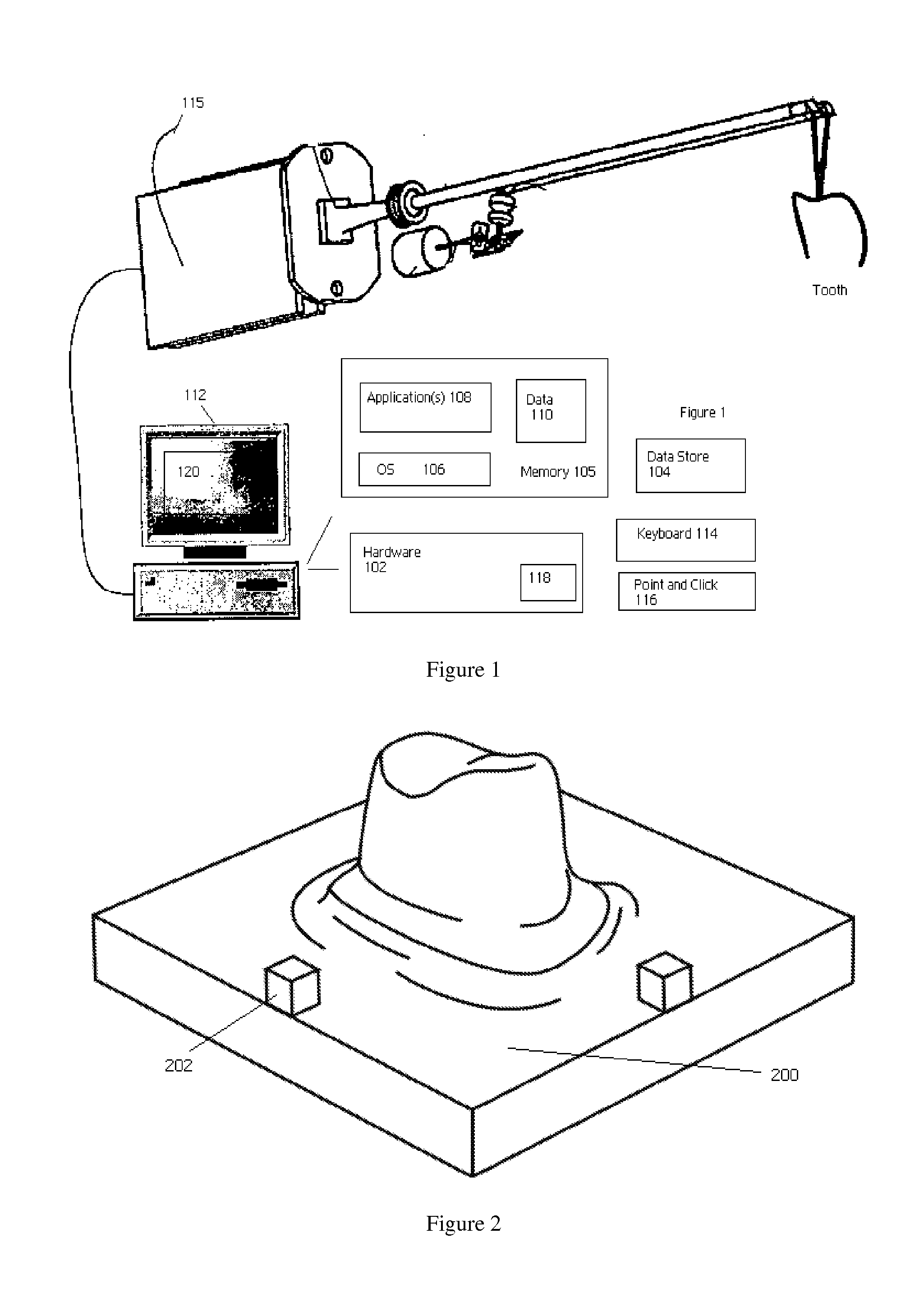

Dental imaging and treatment system

InactiveUS20050202363A1Good precisionShort curing timeImpression capsDental toolsTooth whiteningDental structure

An intra-oral dental irradiation device for use in dental procedures for whitening teeth, imaging teeth, and making impressions of tooth structures of a patient. The device features one or a plurality of LED devices mounted to an arched shaped structure which project light upon or through teeth. In the whitening mode the light of the proper spectrum to activate enamel whitening material is projected. In the imaging mode light projected by the LED devices is received by a charged coupled device which communicates the image of the light passing through the teeth from the LED devices, to a computer. In making dental impressions, the device projects light in a spectrum that provides the catalyst to material that hardens when exposed to that spectrum thereby hardening dental impression material when inserted over the teeth of a patient.

Owner:NOVA RANGER

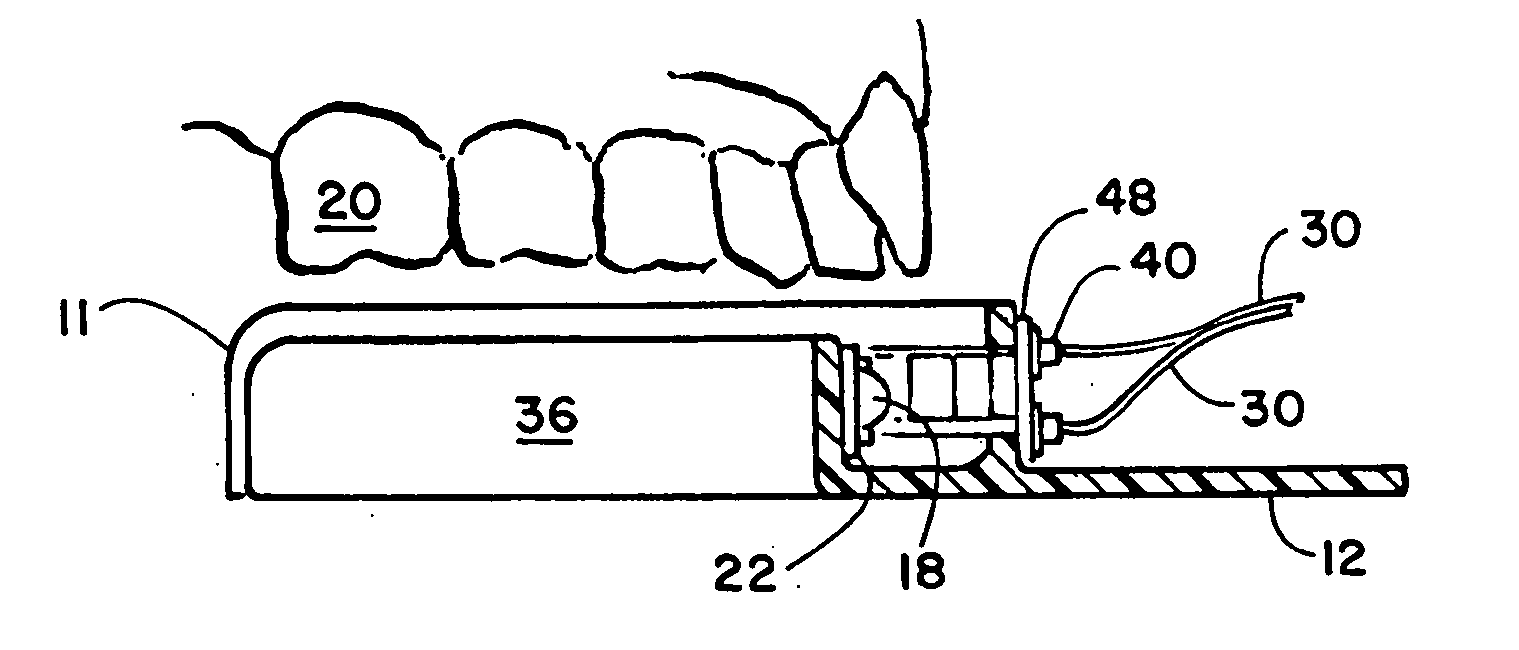

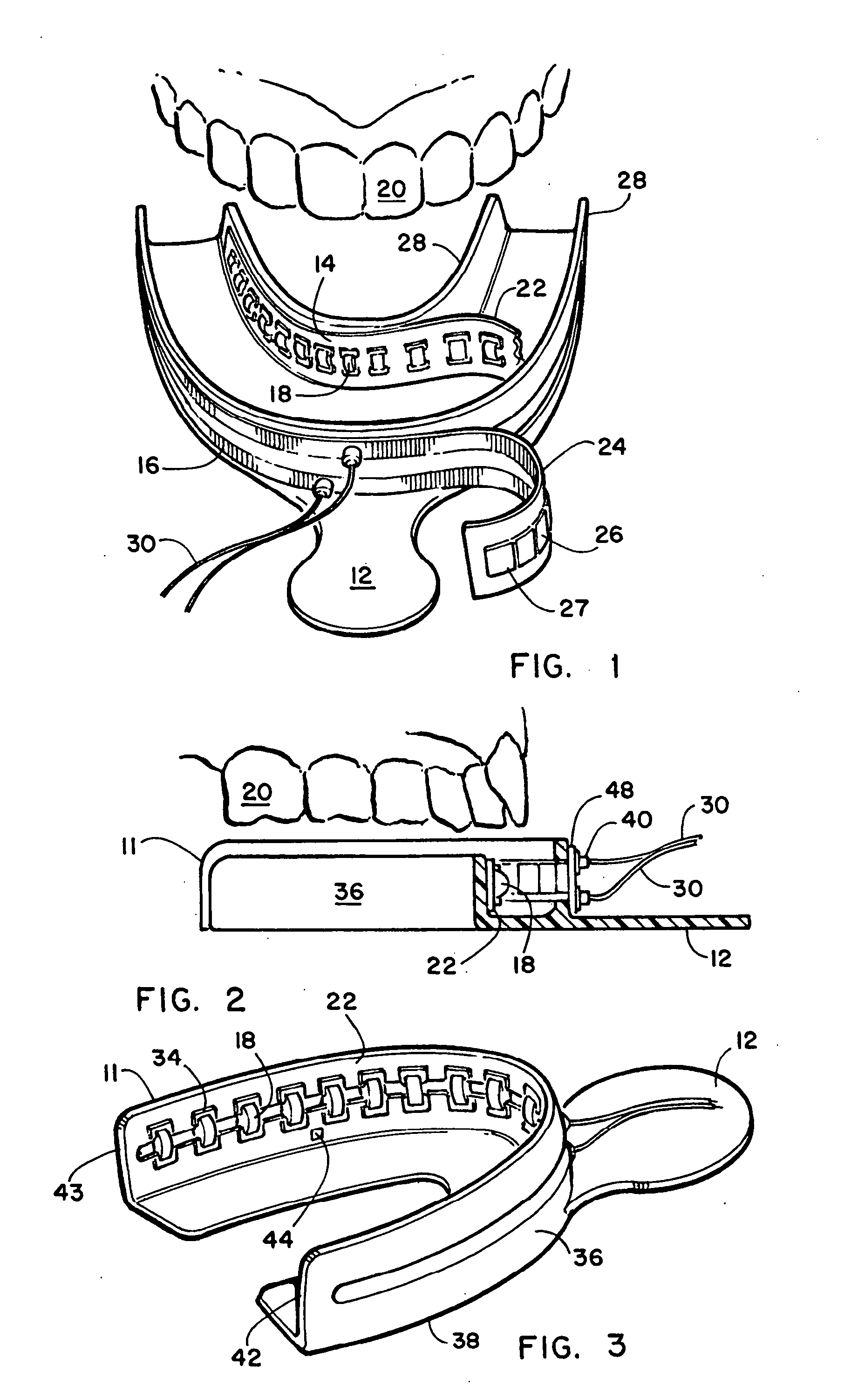

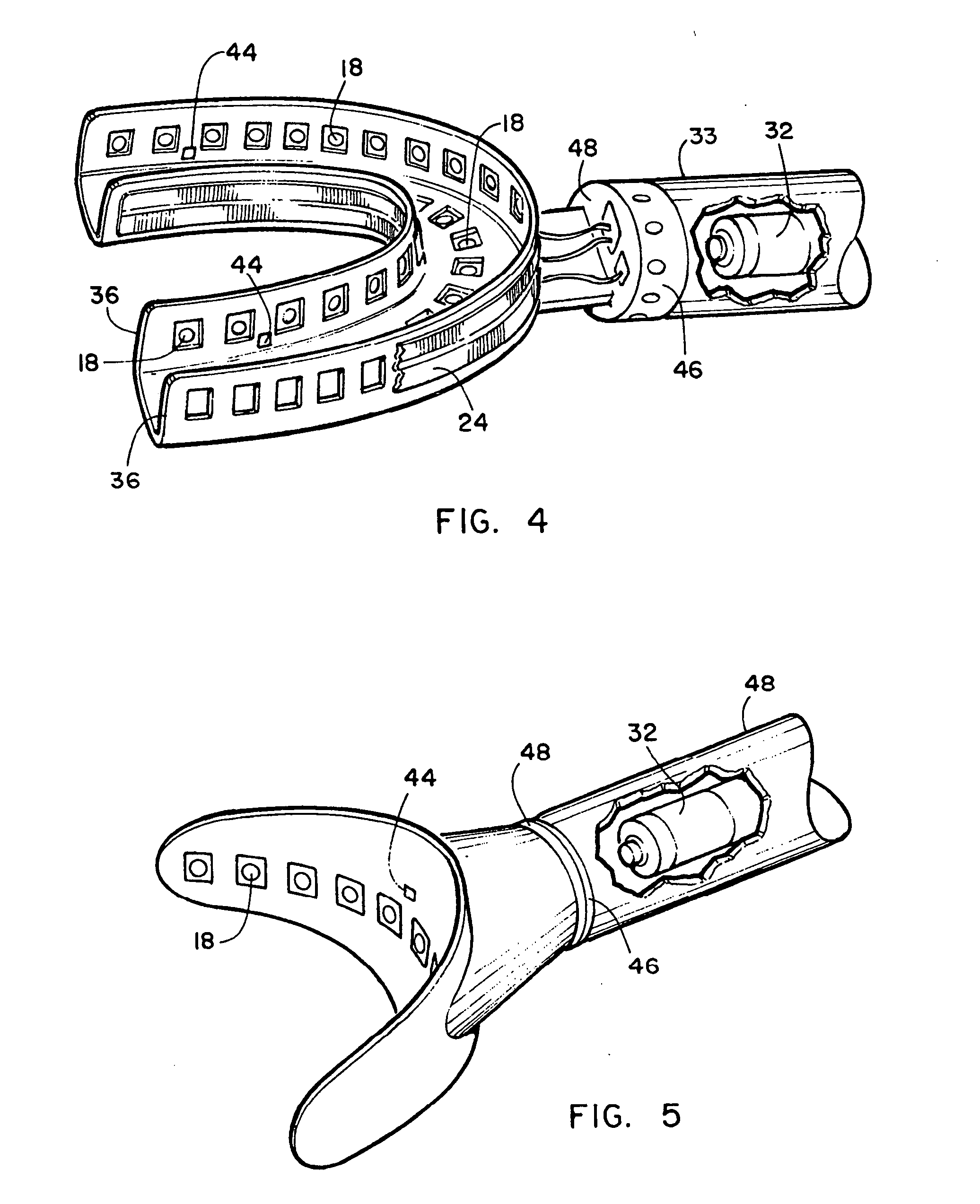

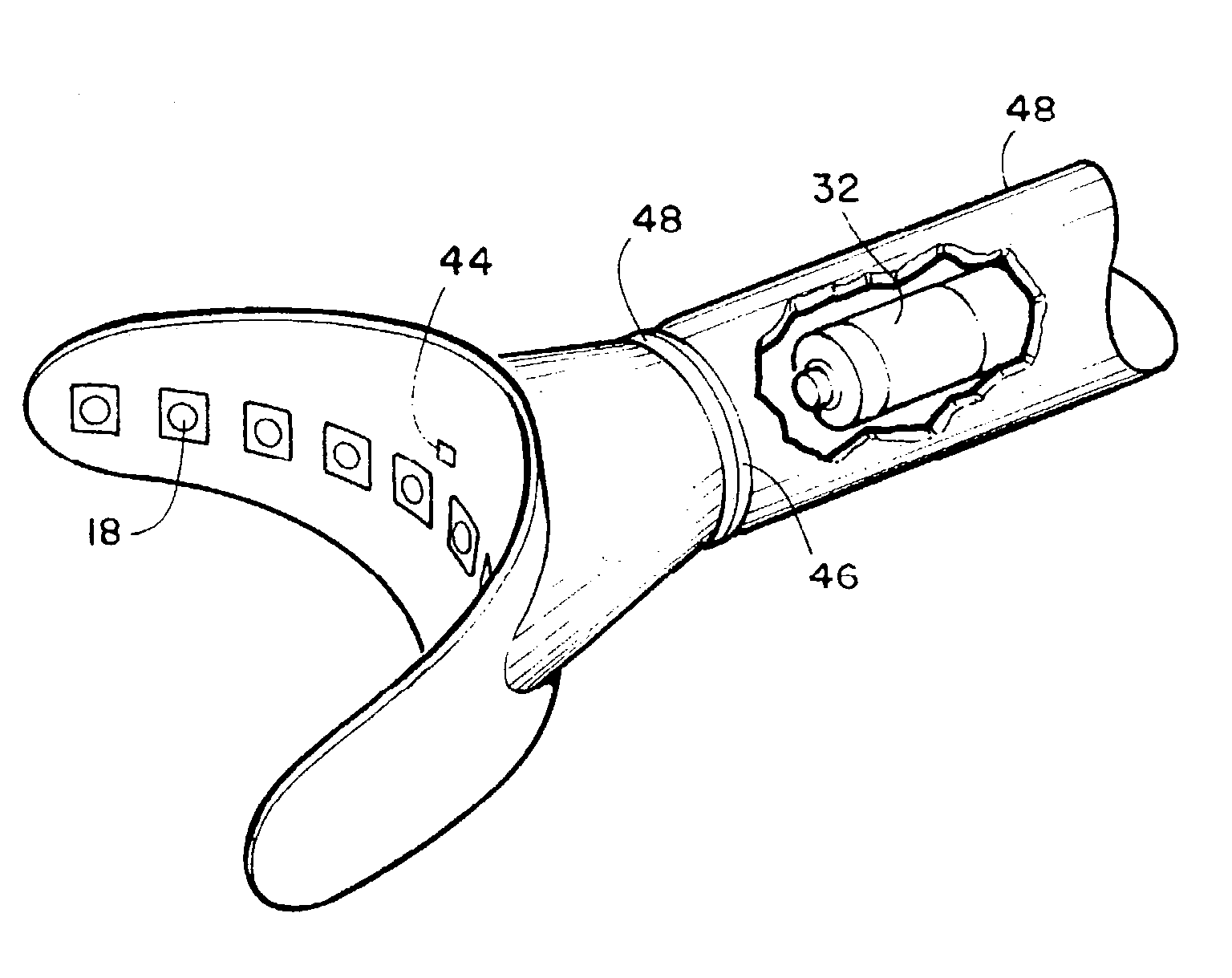

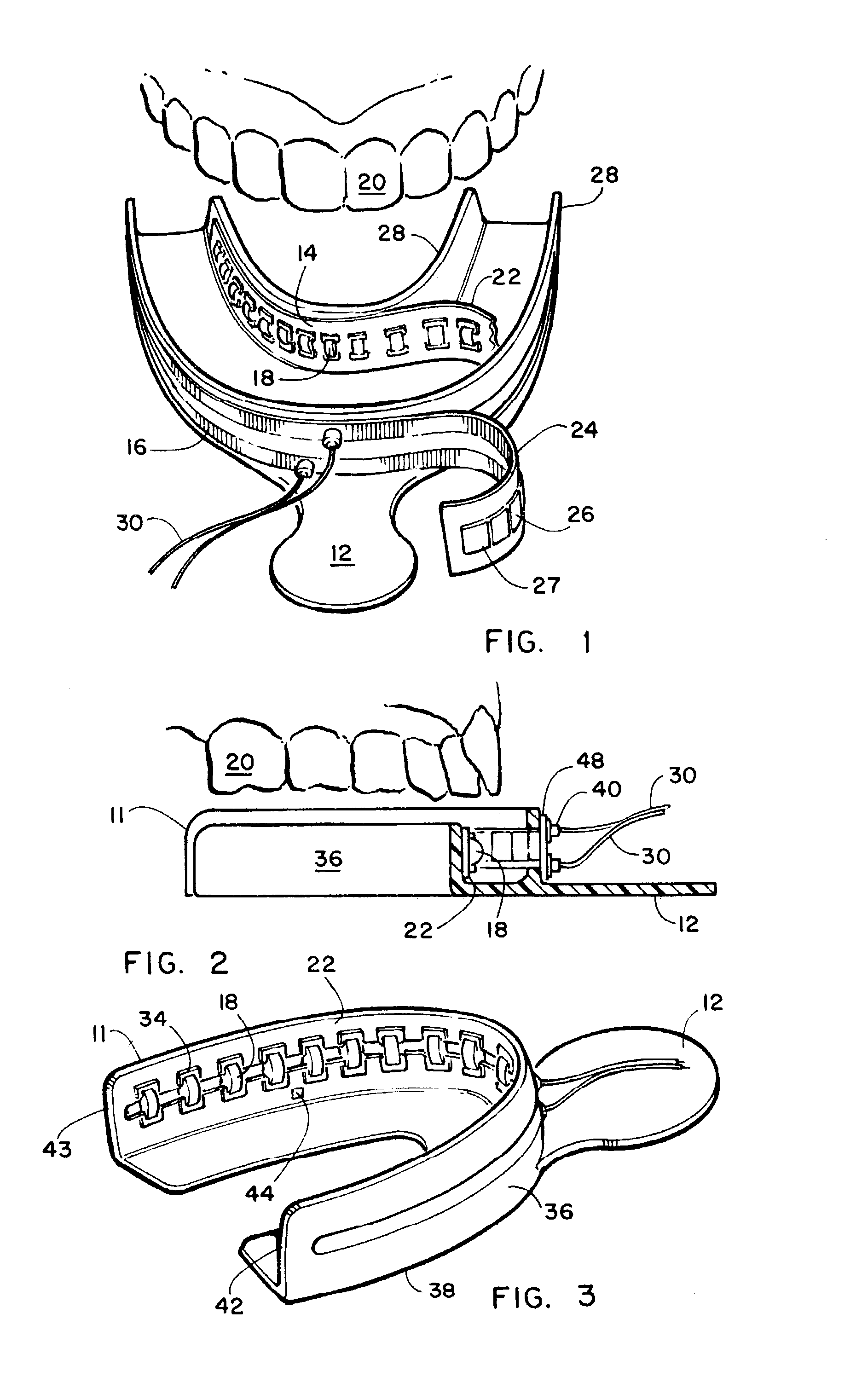

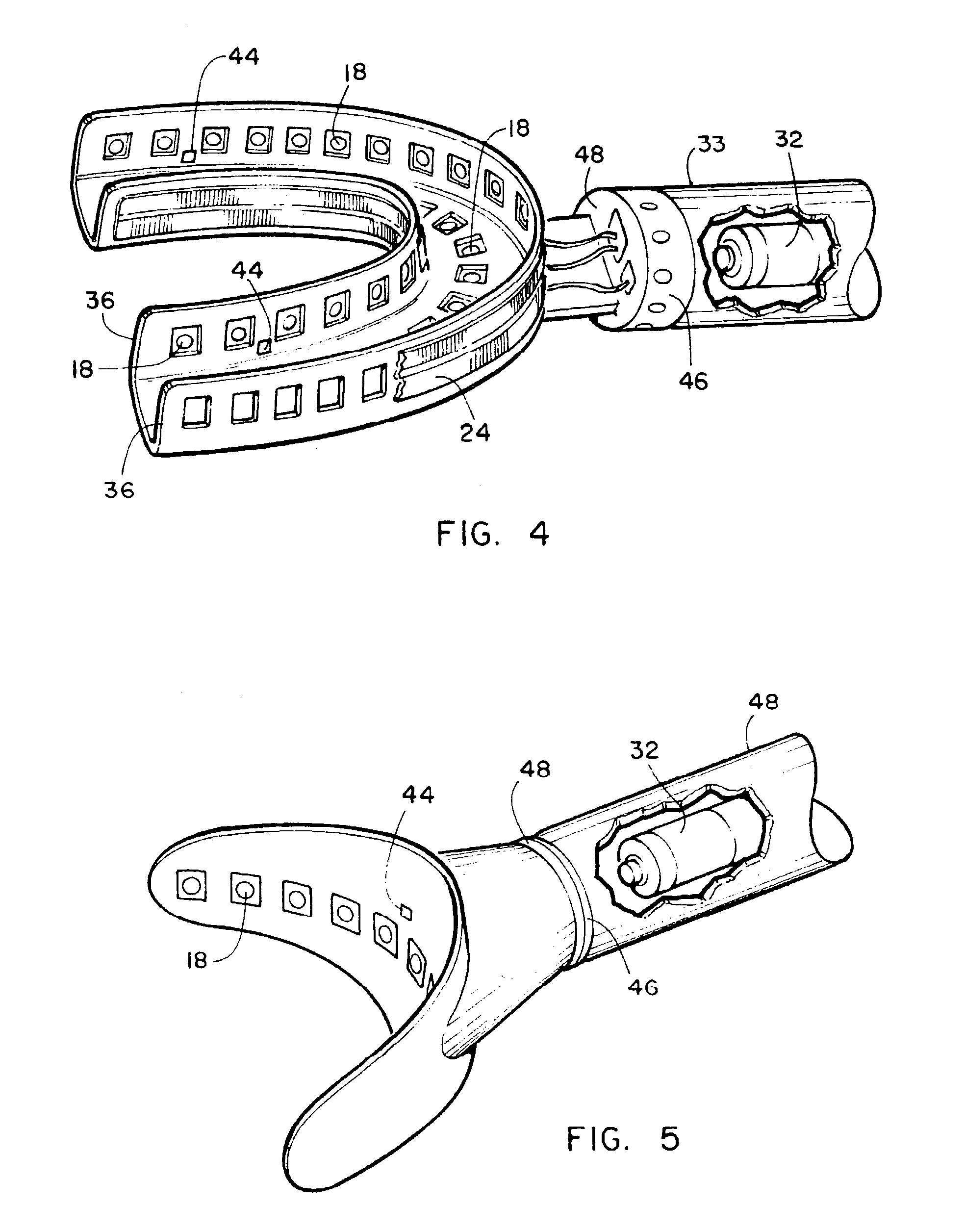

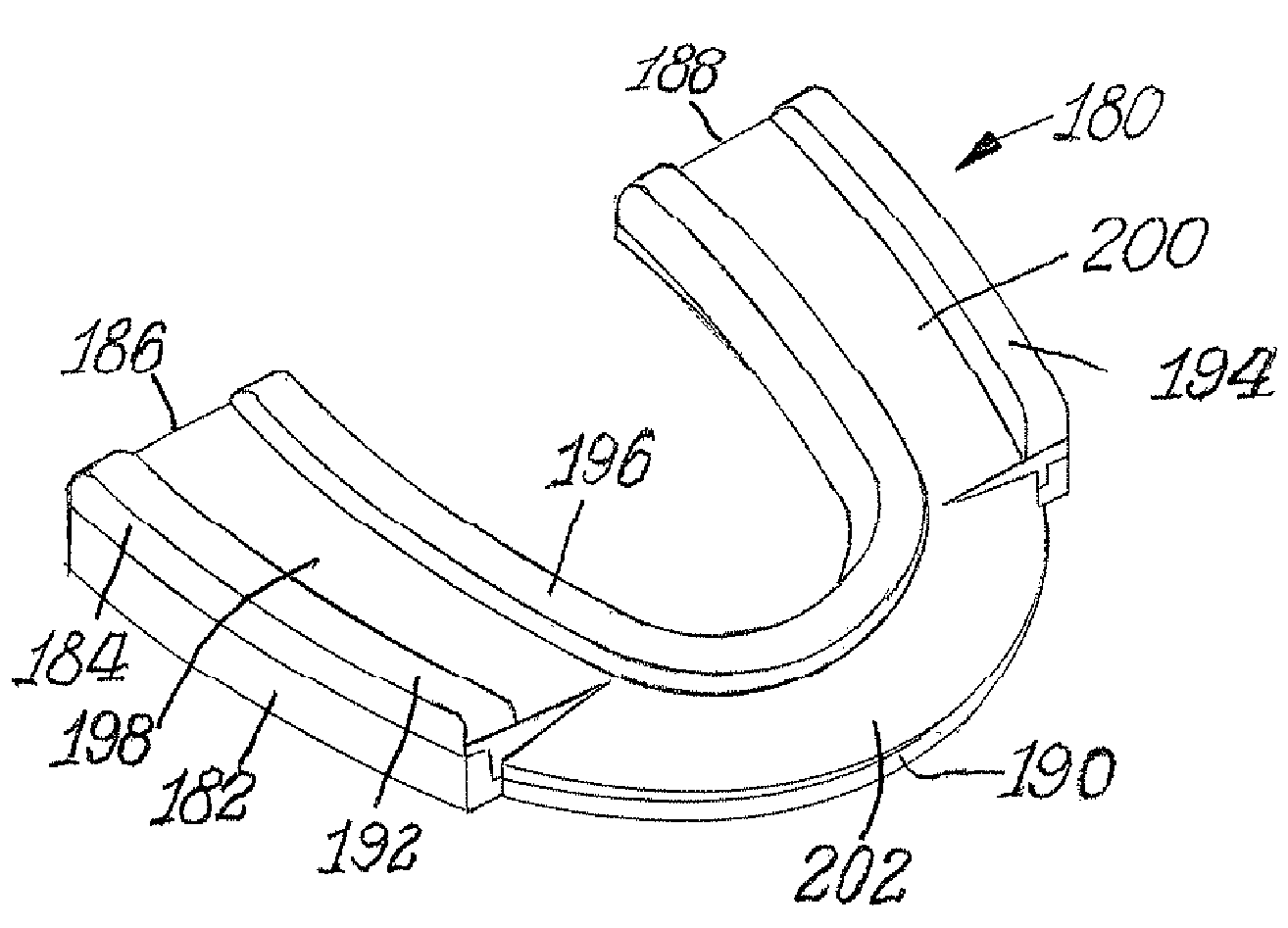

Intra oral dental irradiation device for material curing and dental imaging

InactiveUS6976841B1Eliminate health hazardsStrong specificityImpression capsDental toolsDental impression materialDental procedures

An intra-oral dental irradiation device for use in dental procedures for whitening teeth, imaging teeth, and making impressions of tooth structures of a patient. The device features one or a plurality of LED devices mounted to an arched shaped structure which project light upon or through teeth. In the whitening mode the light of the proper spectrum to activate enamel whitening material is projected. In the imaging mode light projected by the LED devices is received by a charged coupled device which communicates the image of the light passing through the teeth from the LED devices, to a computer. In making dental impressions, the device projects light in a spectrum that provides the catalyst to material that hardens when exposed to that spectrum thereby hardening dental impression material when inserted over the teeth of a patient.

Owner:NOVA RANGER

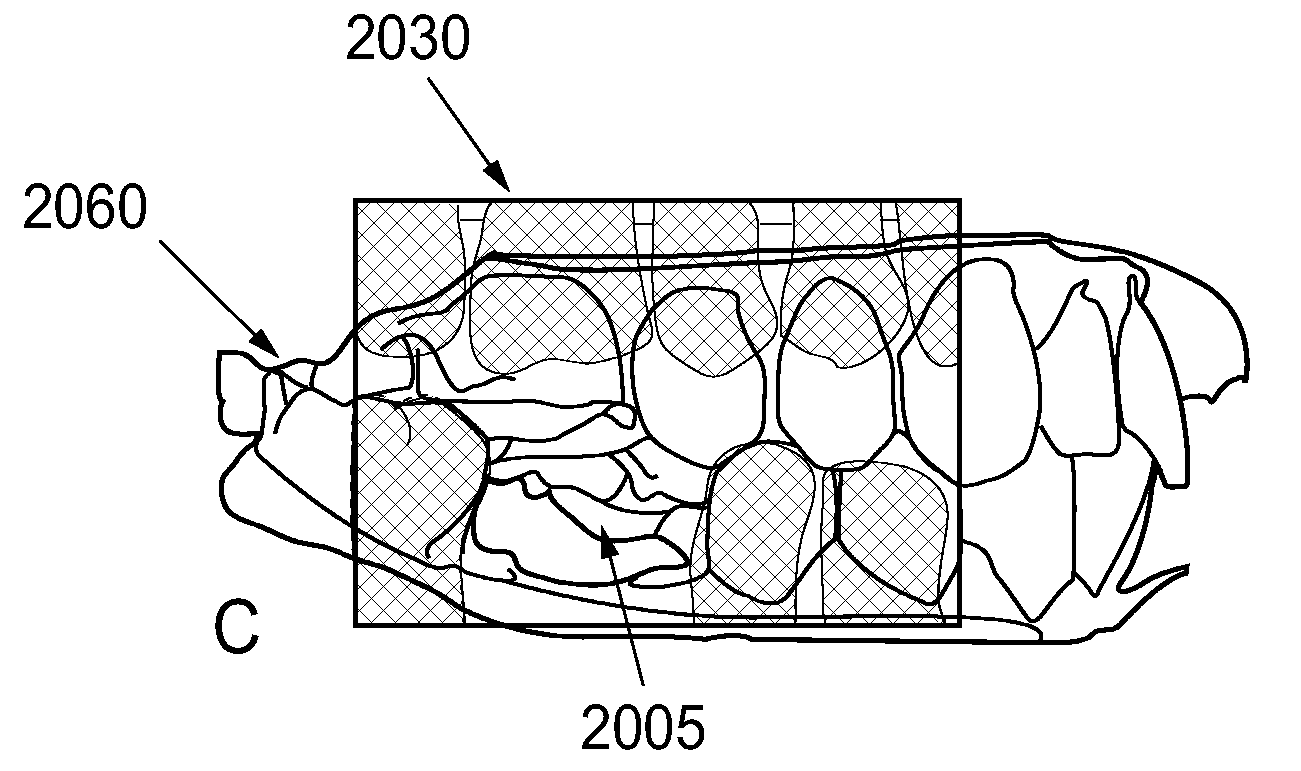

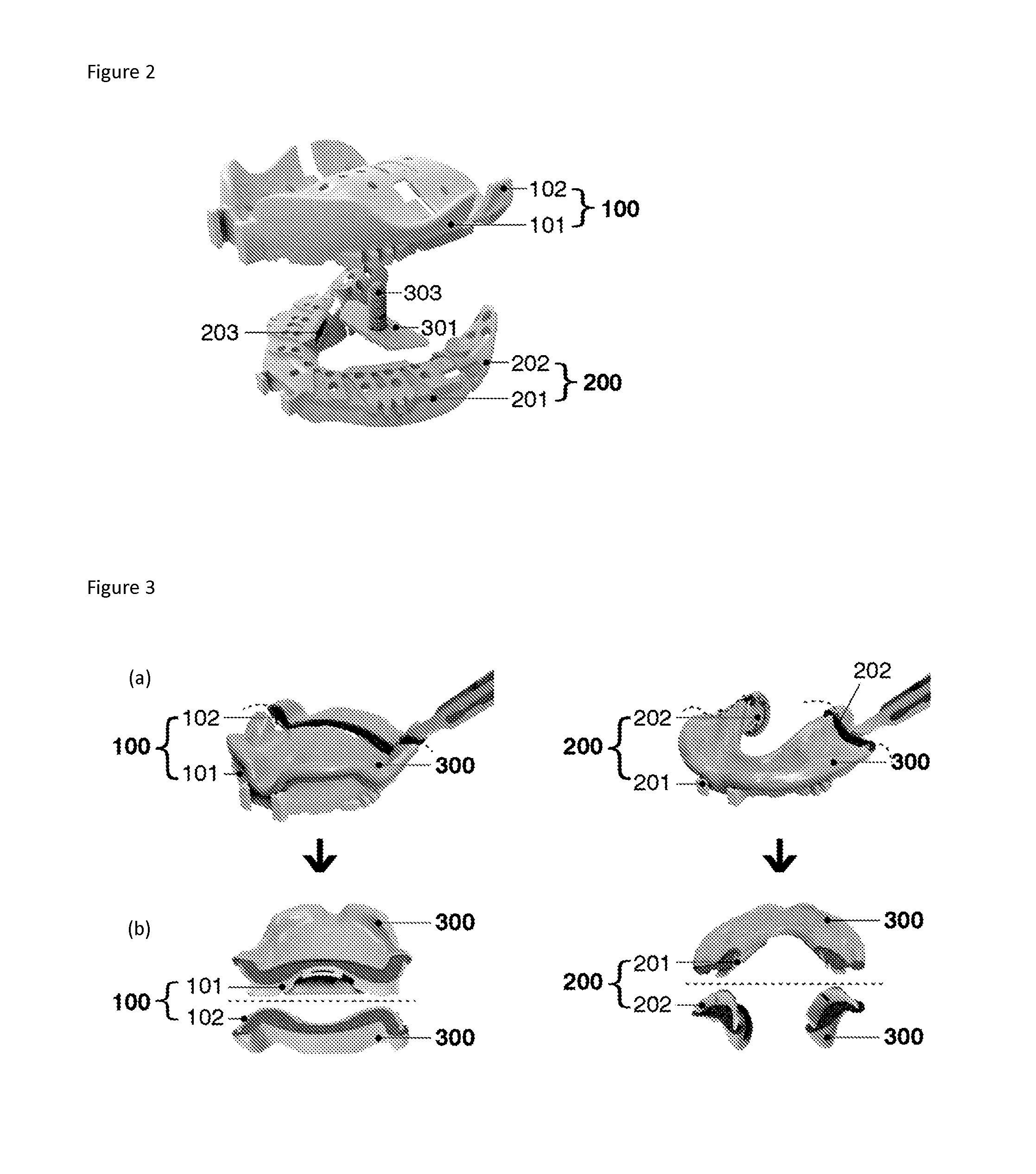

Method and system for dental planning and production

ActiveUS20110008751A1Reduce dosageEliminate needMechanical/radiation/invasive therapiesDental articulatorsComputed tomographyData set

A method and system useful for planning a dental restorative procedure of a patient and for producing at least one dental restoration or product related thereto to be used in said dental restorative procedure are disclosed. Input data from different sources, e.g. 3D data from a CT scan of a patient with a dental impression tray including a previously prepared dental impression of the patient in the patient's mouth, is matched with data from a high resolution 3D scan of the same dental impression. The resulting data is for instance matched by means of fiducial markers arranged at the dental impression tray. Thus reliable planning and production are enabled by means of the same, matched data set. In this manner the dosage to which the patient is exposed to may be reduced in comparison to previous methods.

Owner:NOBEL BIOCARE SERVICES AG

Impression scanning for manufacturing of dental restorations

ActiveUS20090220916A1Simplify the scanning processAvoiding time-consume and costlyDental implantsImpression capsImpressions materialsDental restoration

The present invention relates to a method for obtaining an accurate three-dimensional model of a dental impression, said method comprising the steps of, scanning at least a part of an upper jaw impression and / or a lower jaw impression, obtaining an impression scan, evaluating the quality of the impression scan, and use the impression scan to obtain a three-dimensional model, thereby obtaining an accurate three-dimensional model of the dental impression.

Owner:3SHAPE AS

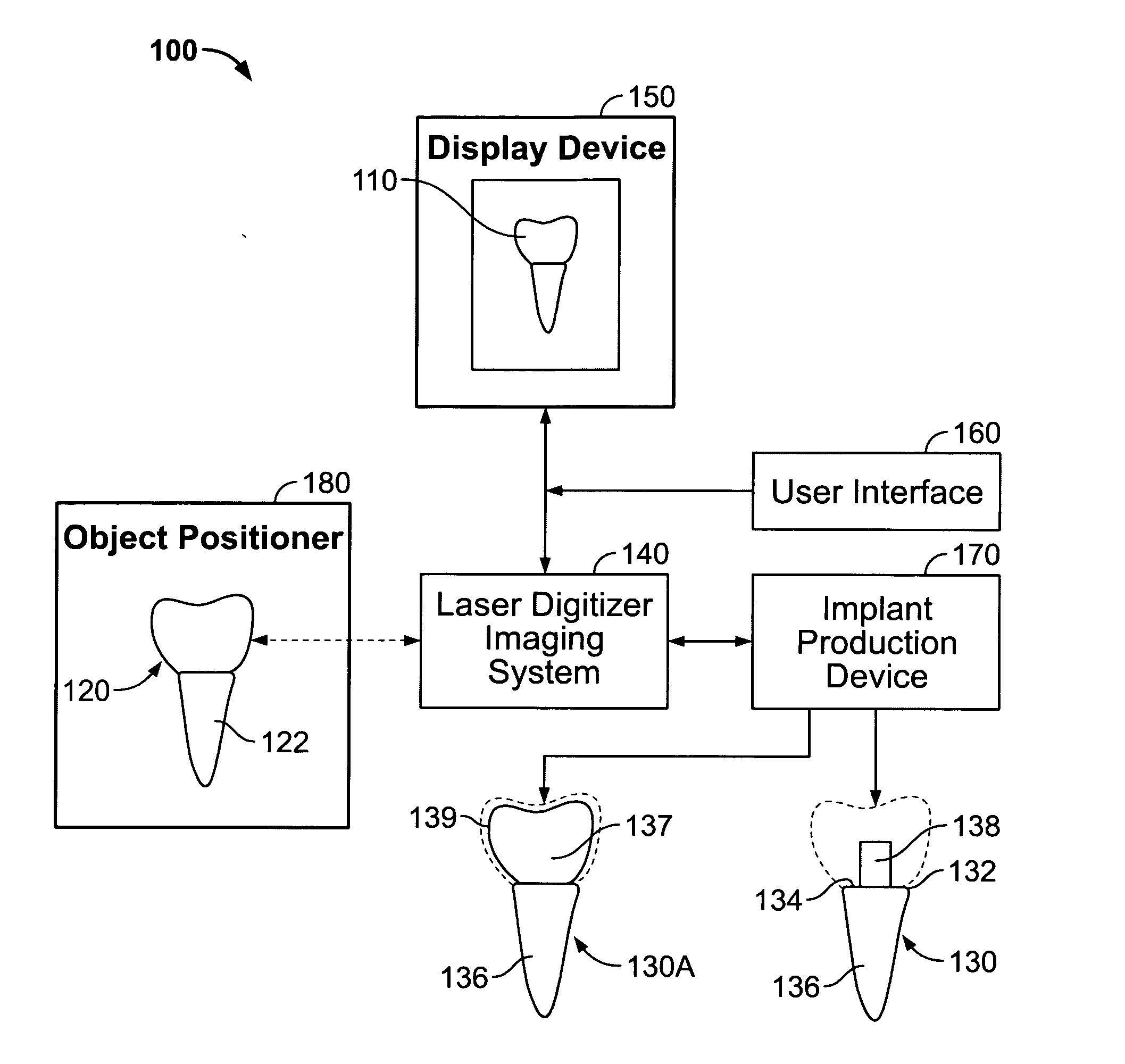

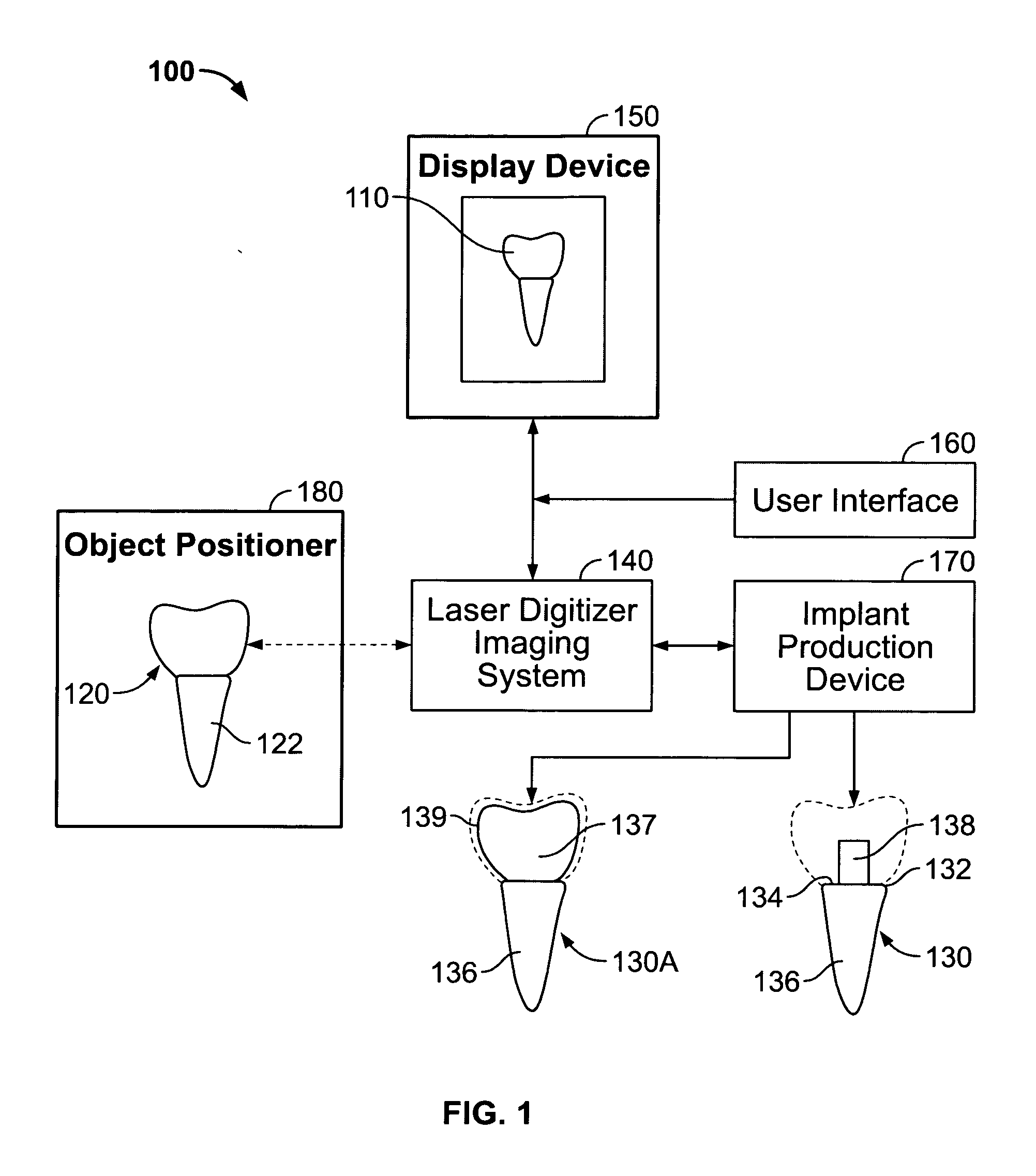

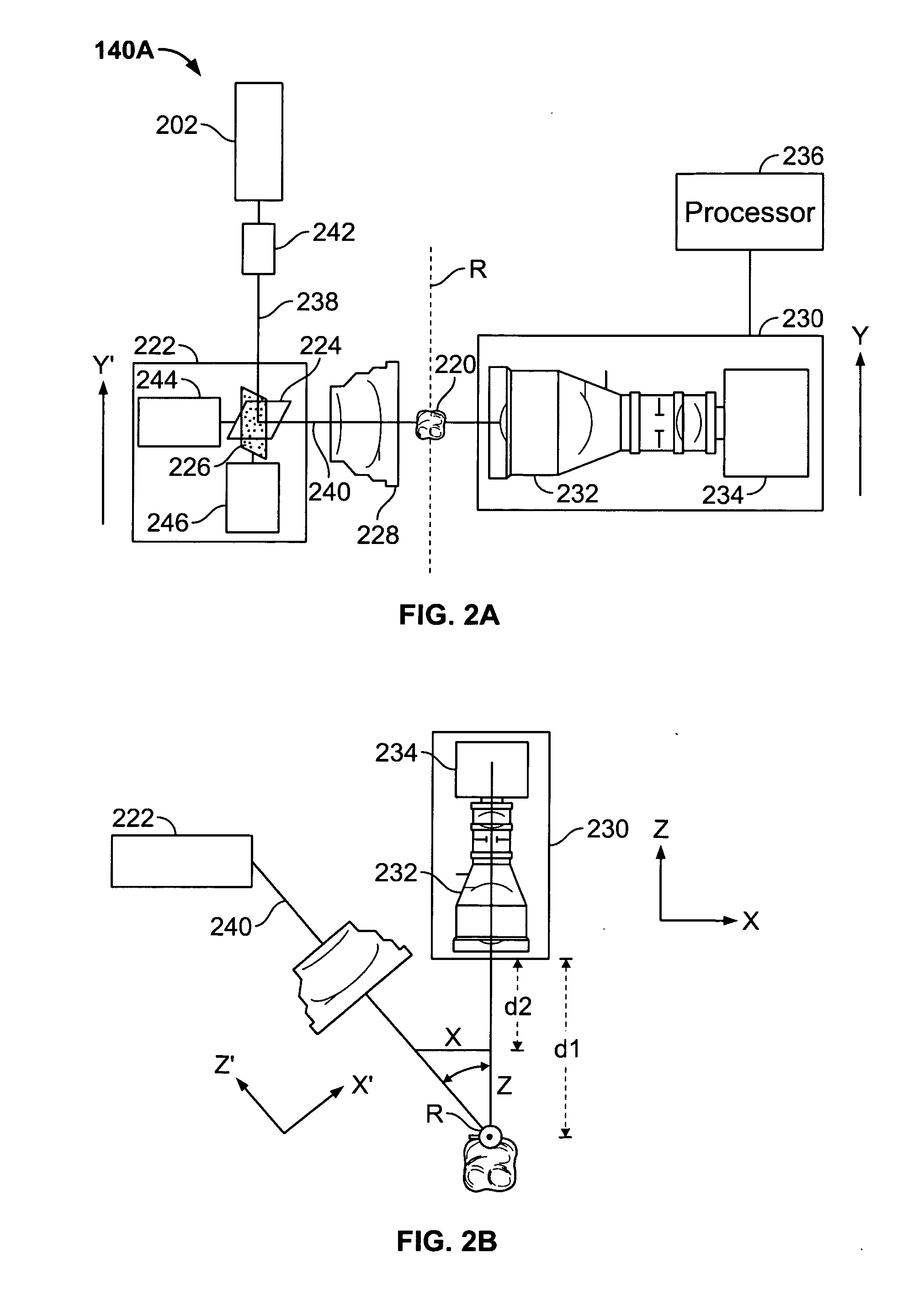

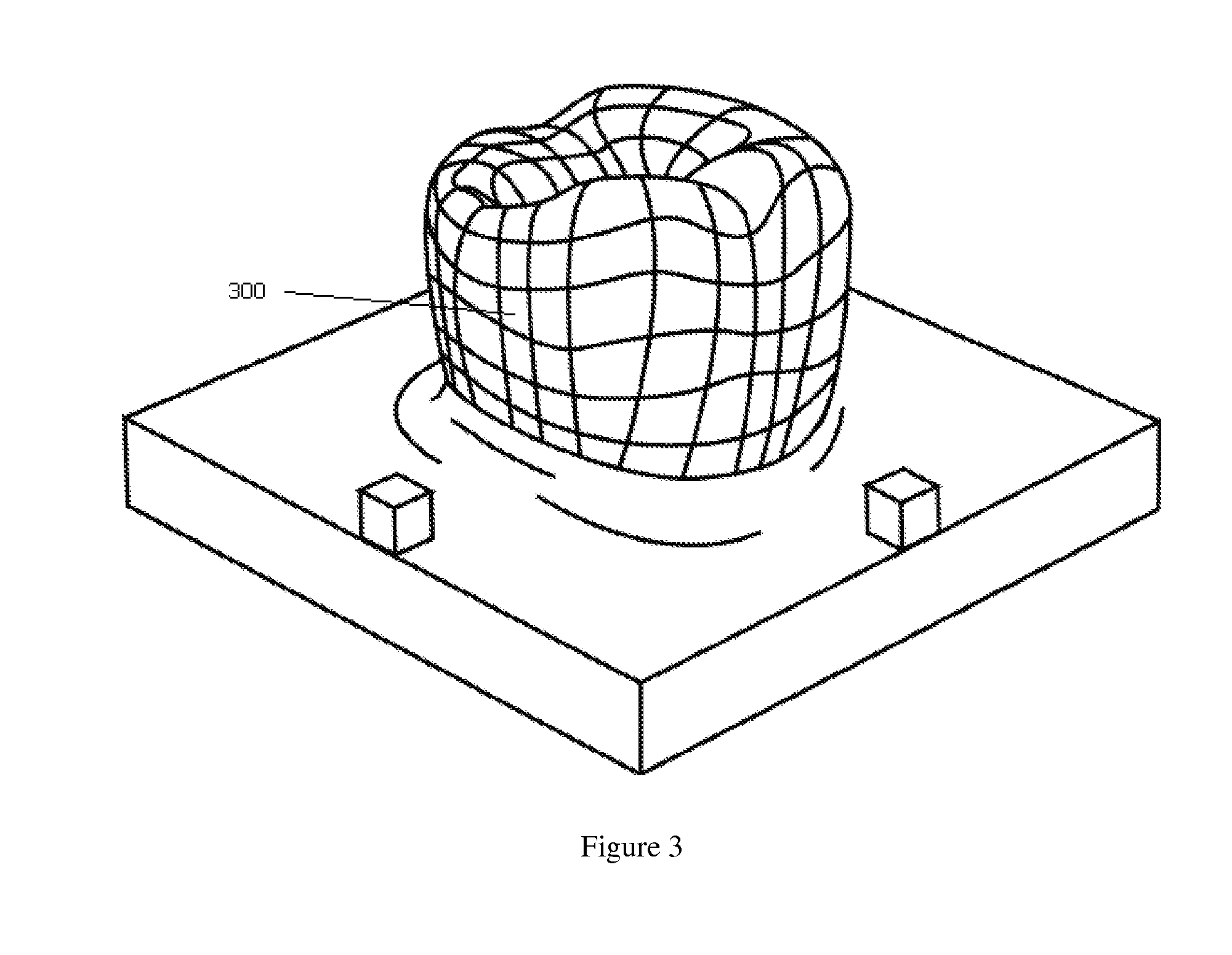

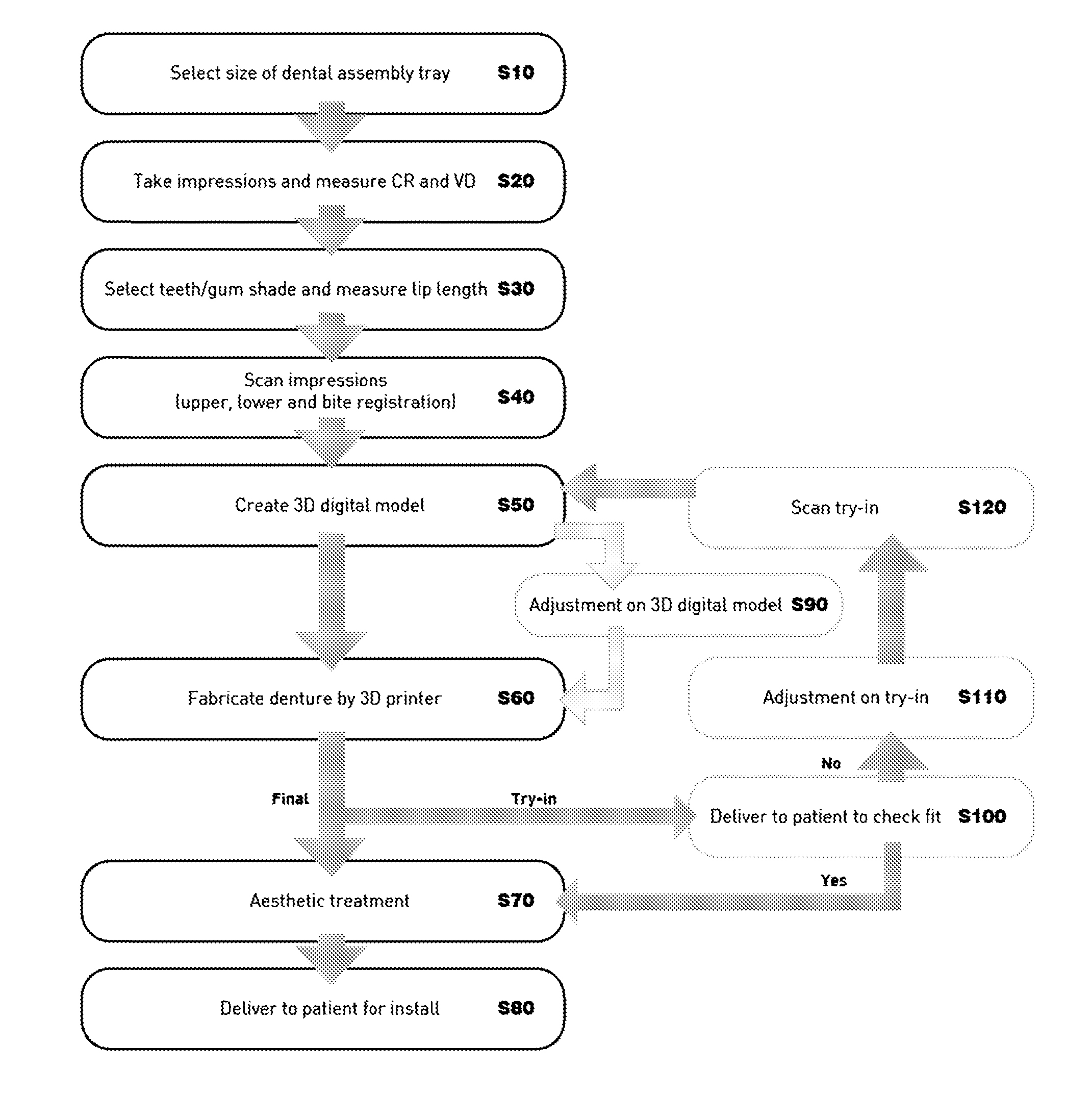

System for producing a dental implant and method

A system and method for producing a dental fixture are provided. A laser digitizer imaging system creates a visual three-dimensional image of a dental item such as a tooth or a dental impression. The three-dimensional image may be displayed and the size and shape of the image may be selectively modified by the user of the system. Digital data associated with the three-dimensional image of the dental item is sent to an implant production device. A dental implant is produced in response to receipt of the data associated with the three-dimensional image such that the implant is insertable into a socket of the jawbone from where a tooth was extracted.

Owner:D4D TECH LP

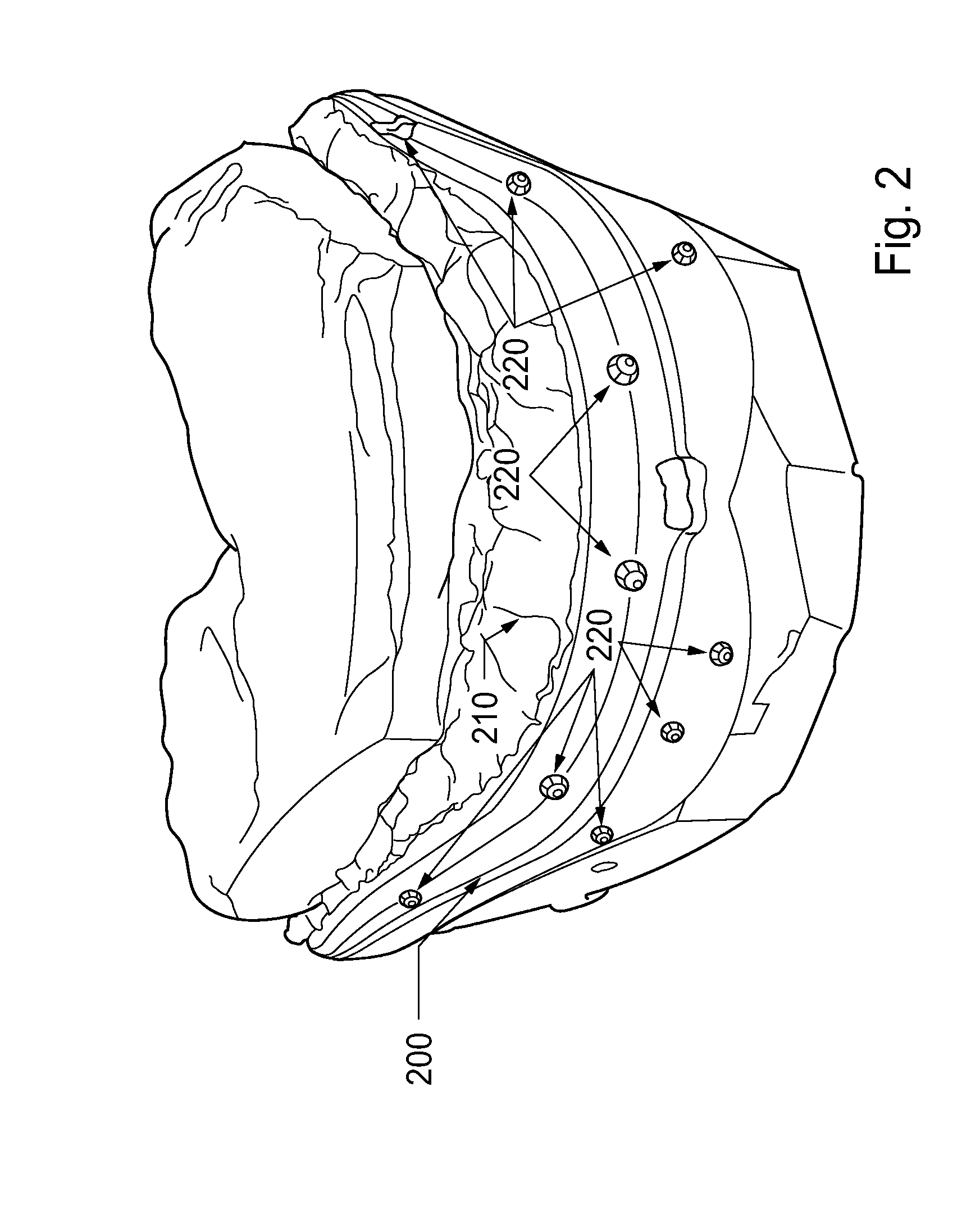

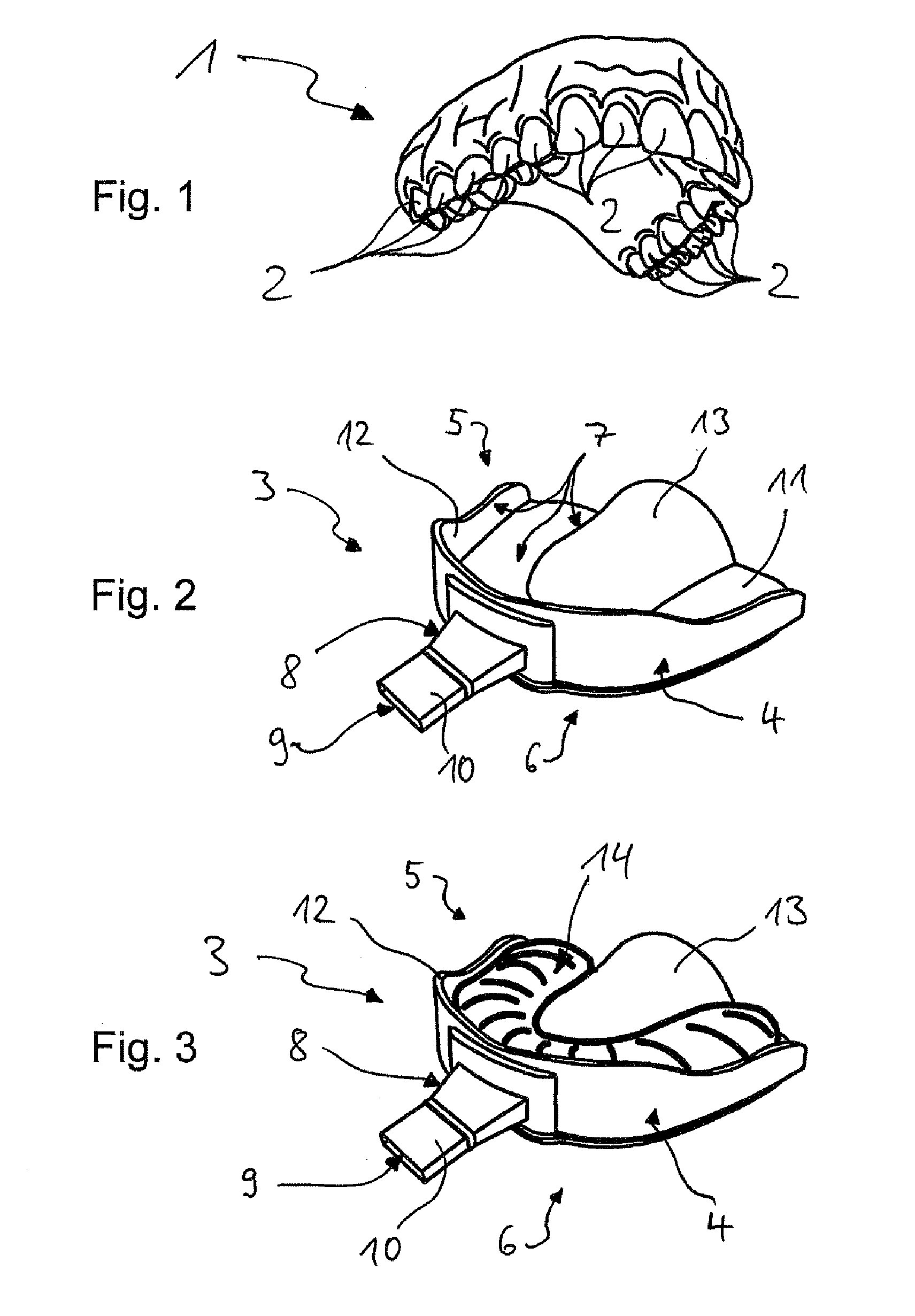

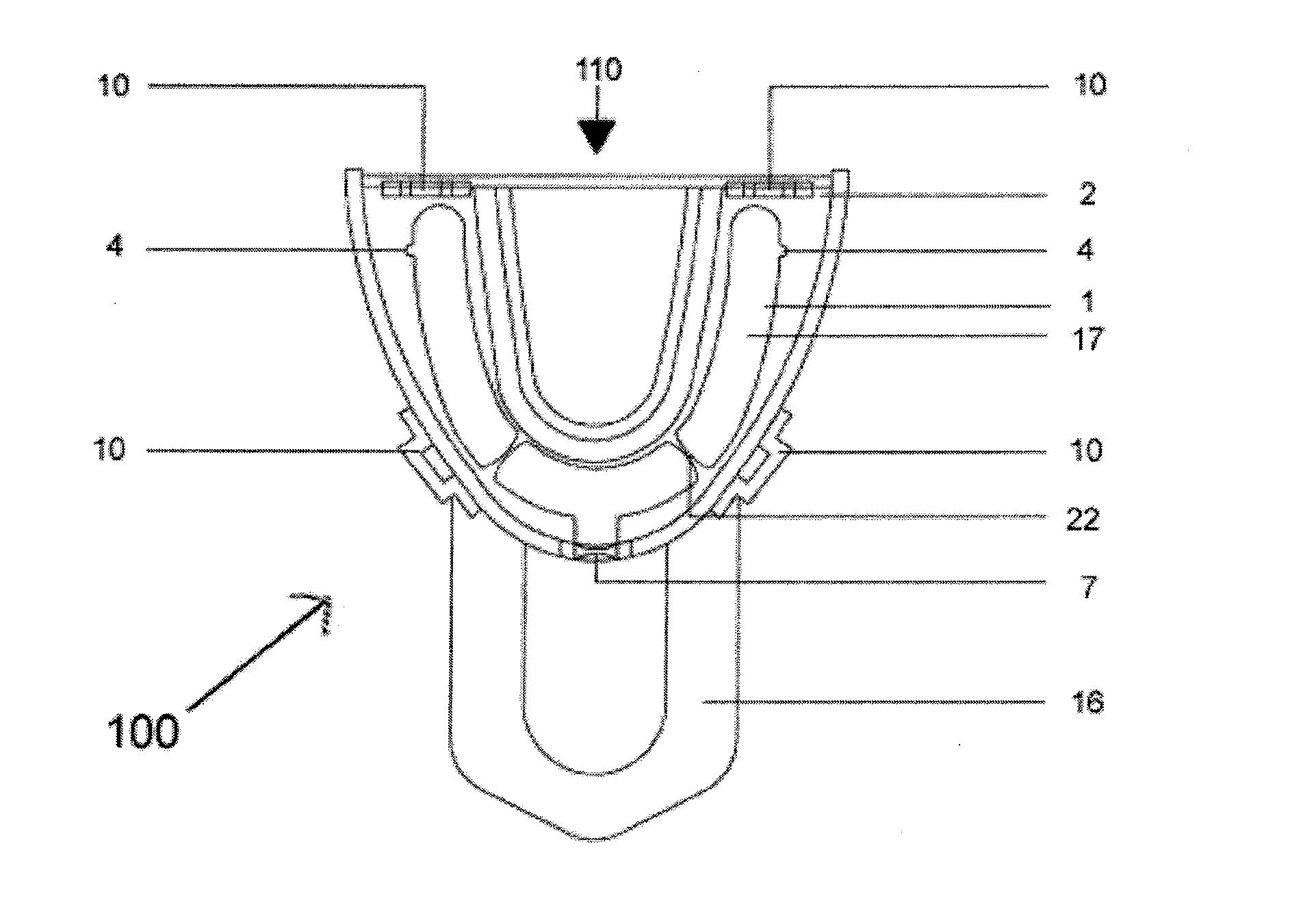

Impression tray, and method for capturing structures, arrangements or shapes, in particular in the mouth or human body

InactiveUS20120064477A1Easy, dependable and accurateImpression capsTeeth fillingSpatially resolvedHuman body

The invention relates to an impression tray, such as in particular a dental impression tray, which carries a deformable impression mass in order to prepare an impression of arrangements, shapes and / or dimensions, in particular in or on the human body, preferably in the mouth, and further preferred an impression of at least part of a tooth or of dental structures, wherein furthermore sensor devices are present, by means of which a change of at least one physical property and / or variable of the impression mass can be captured in a spatially resolved manner when preparing an impression and can be provided in a form that is suited for electronic data processing. The invention further relates to a method for capturing structures, arrangements or shapes, such as preferably for capturing dental structures, arrangements or shapes in the mouth or in the human body, whereby a deformable impression compound is brought onto or into the structures, arrangements or shapes in particular, is introduced, into the mouth or body and a change of at least one physical property and / or variable of the impression compound is transmitted there in a spatially resolved manner directly to sensor devices when preparing an impression and is captured by the sensor devices and, furthermore, provided in a form that is suitable for electronic data processing.

Owner:MEDENTIC

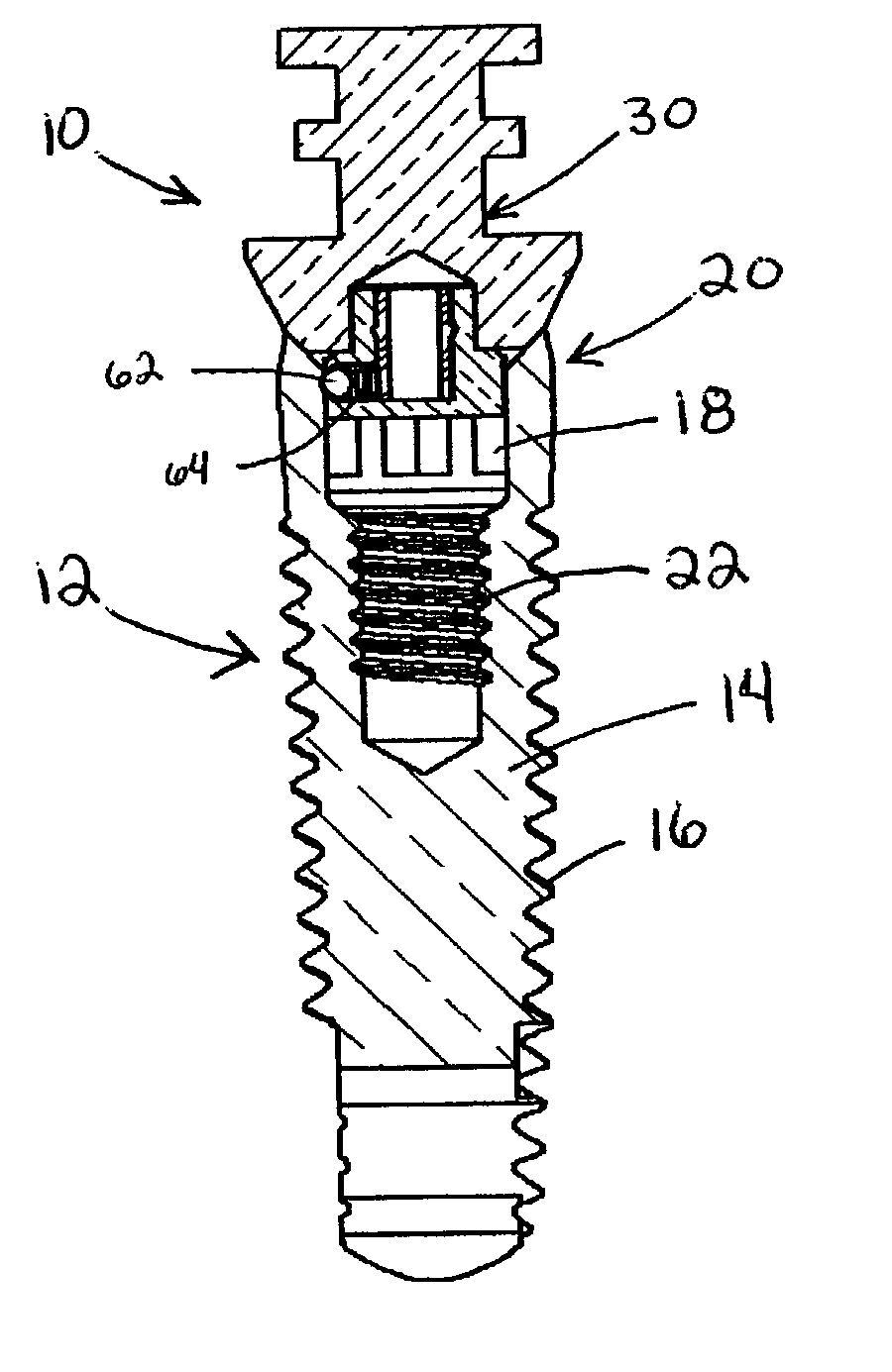

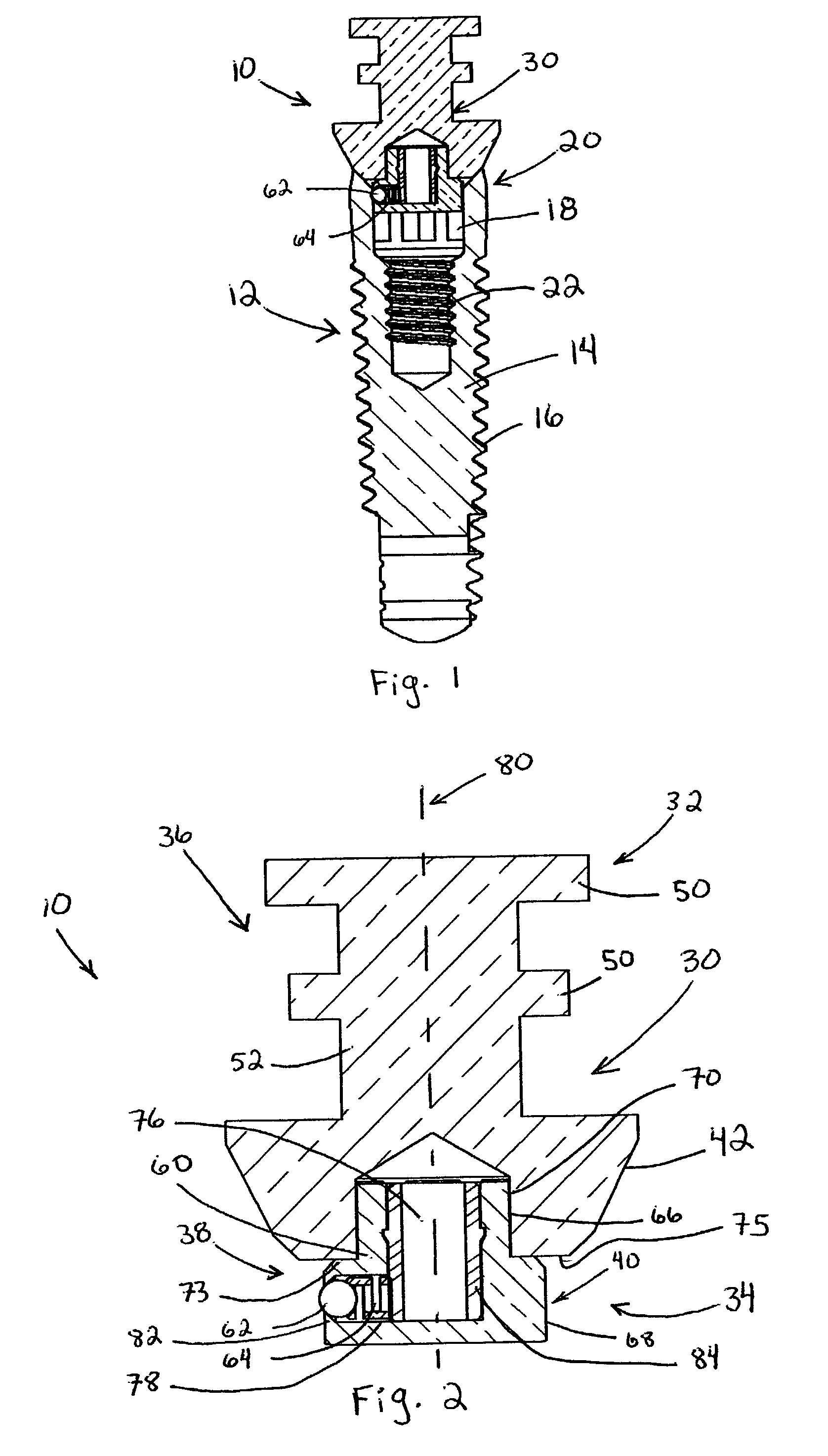

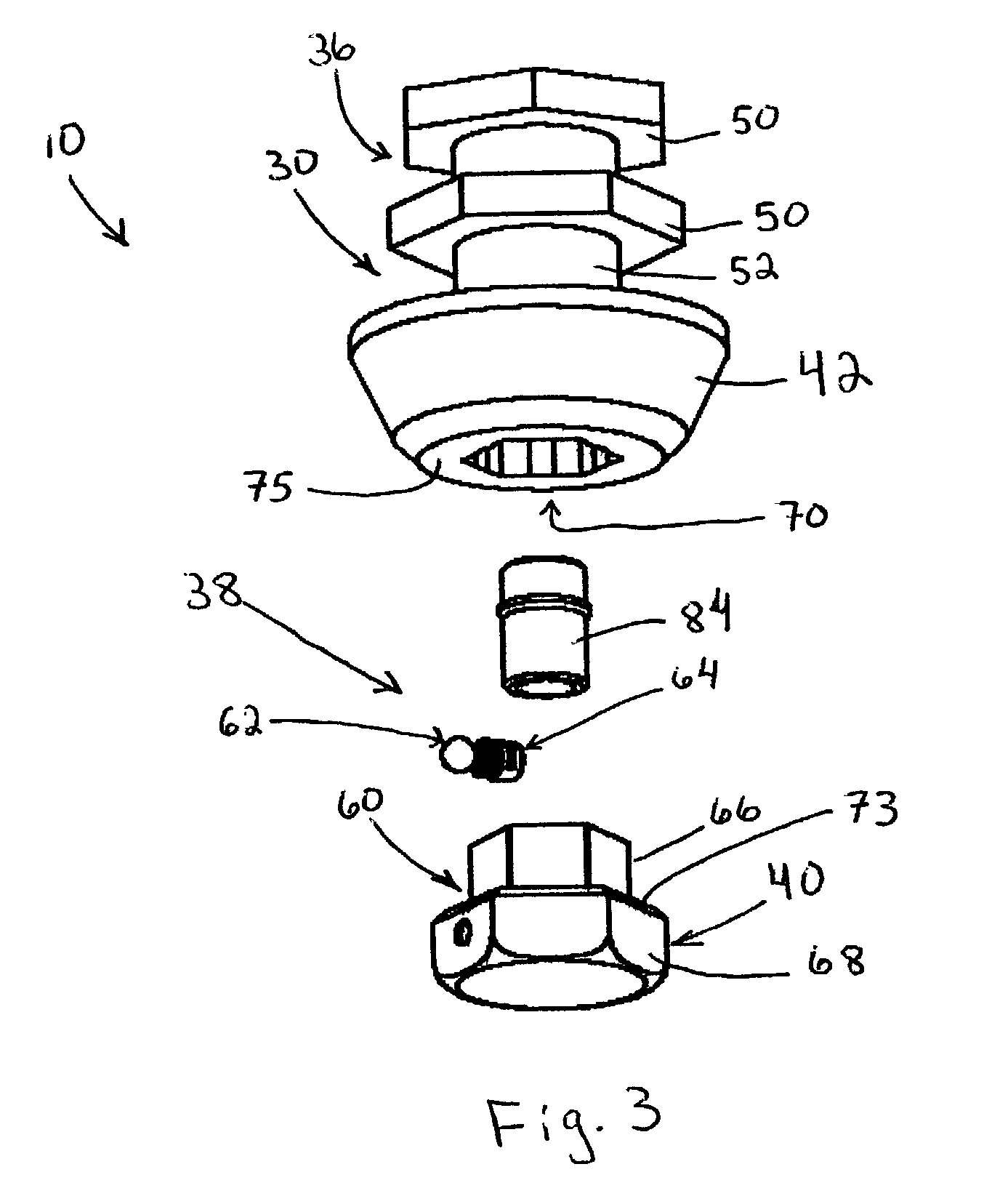

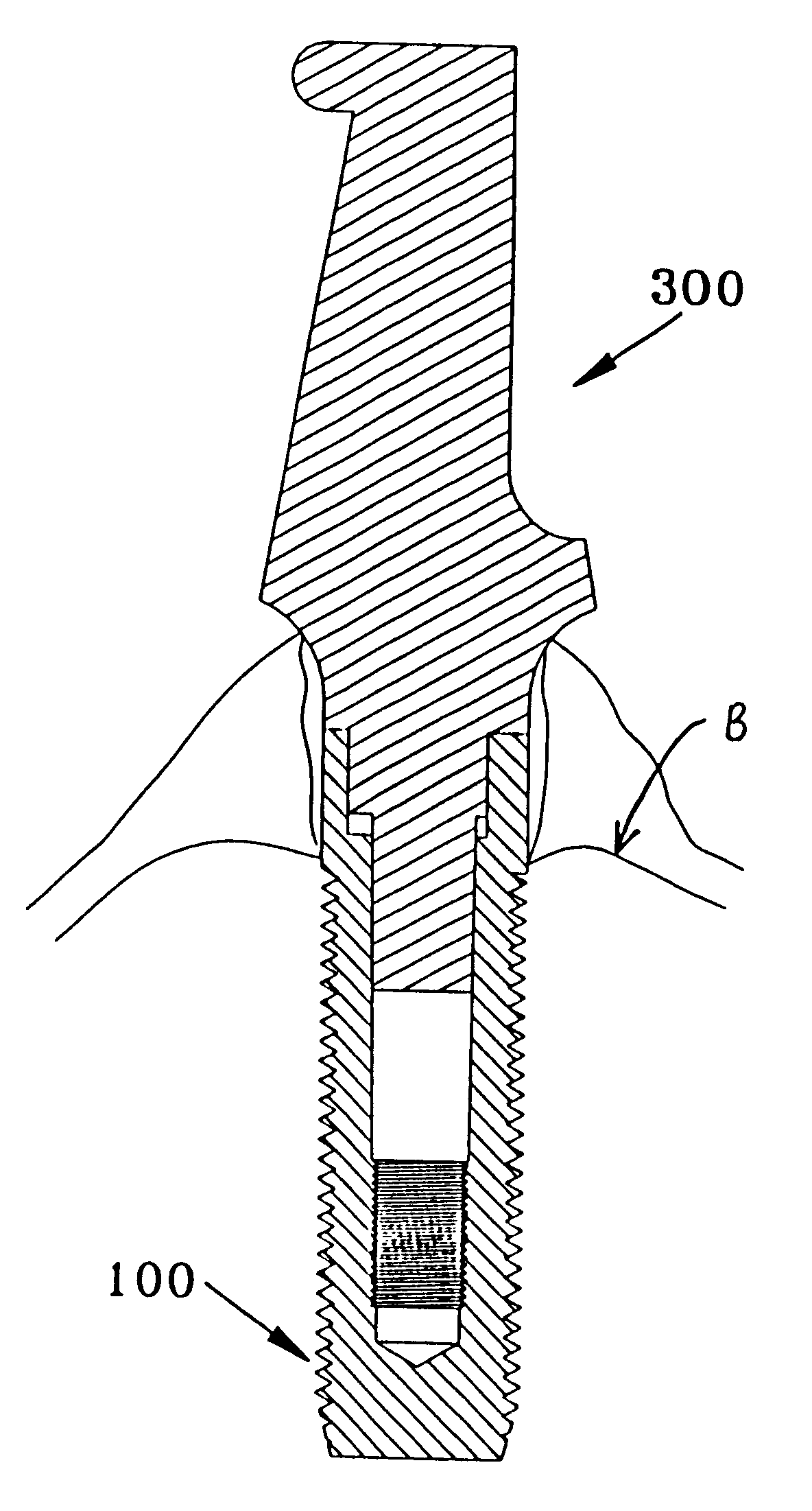

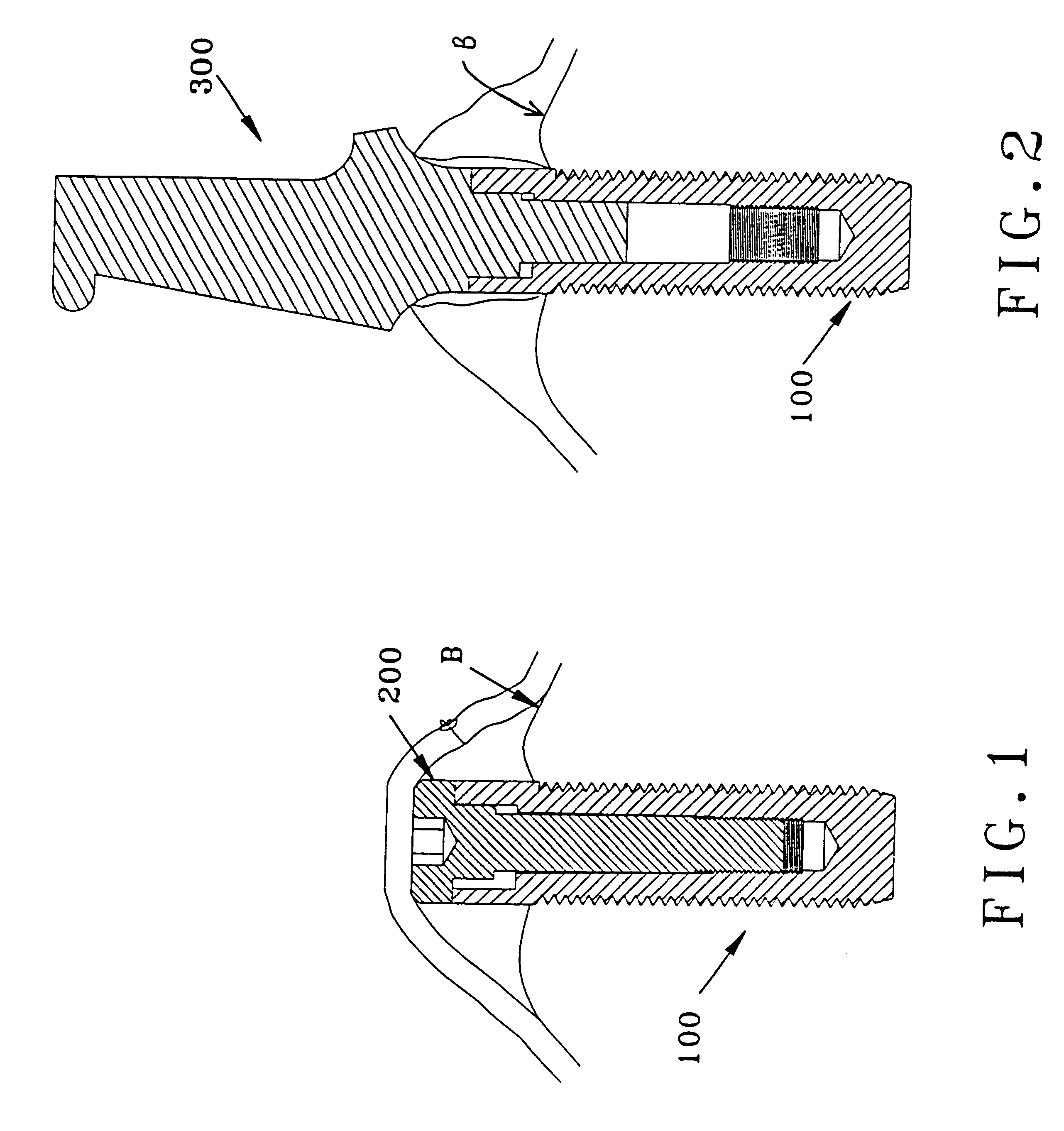

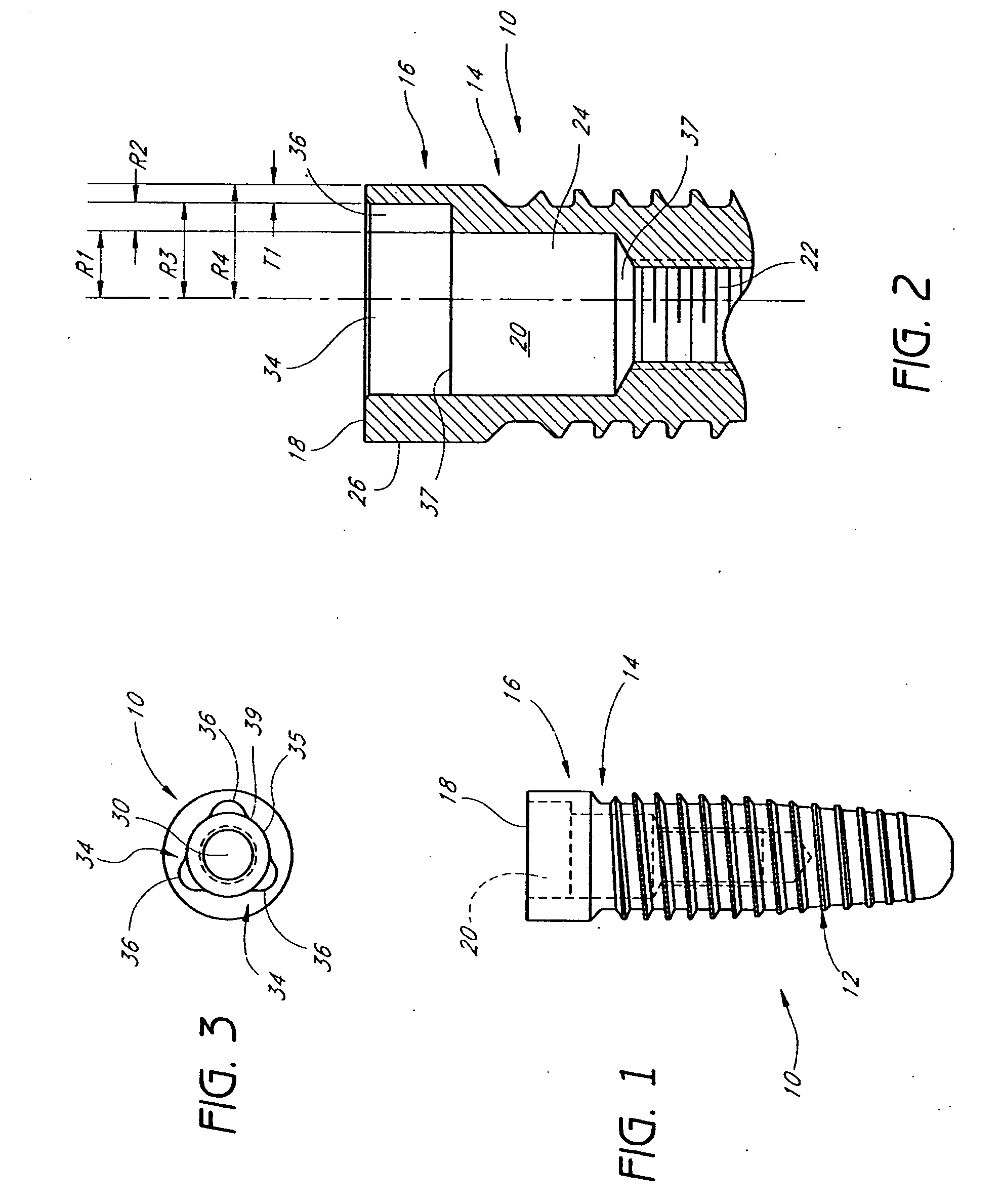

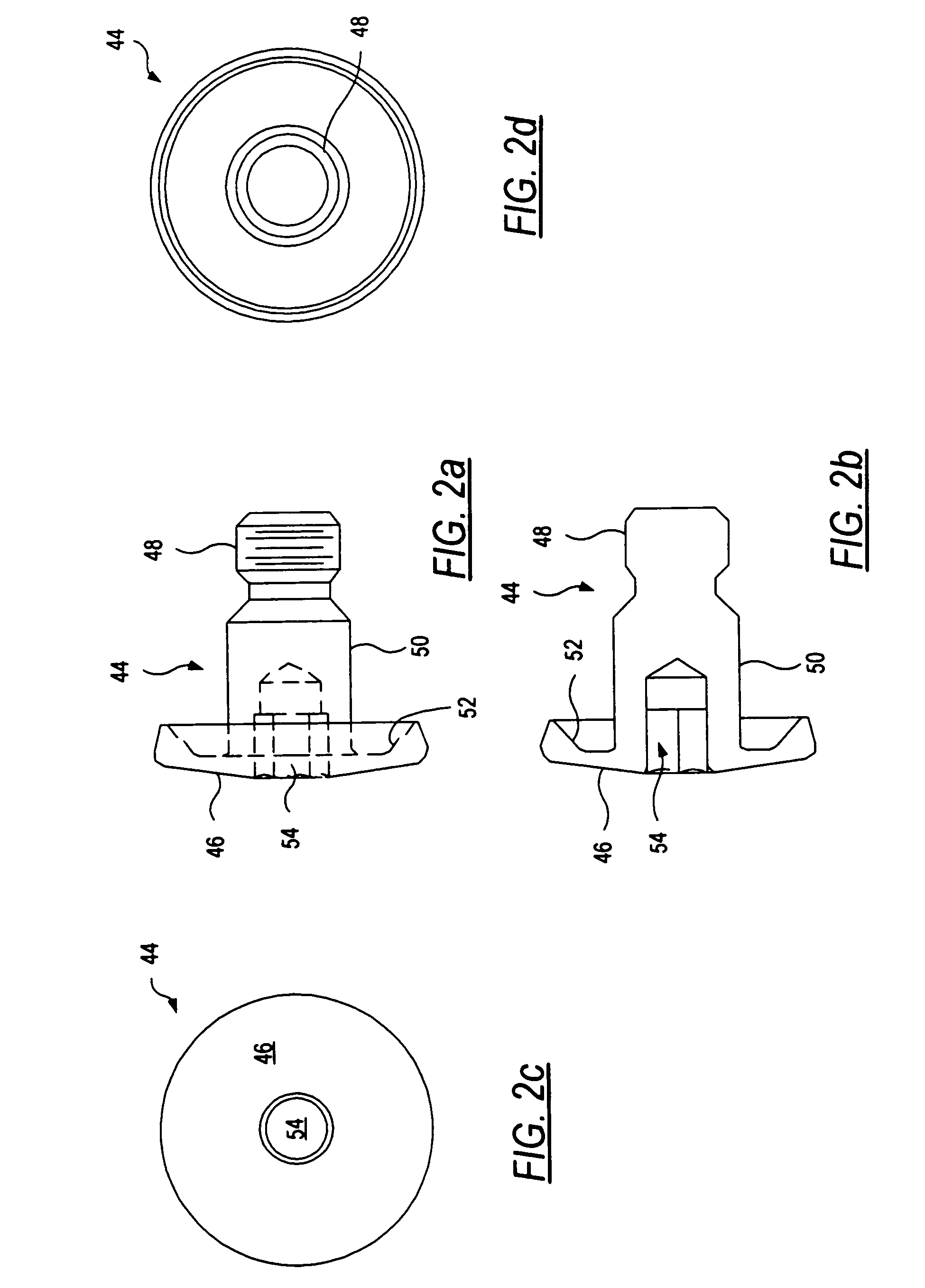

Dental impression coping with retention

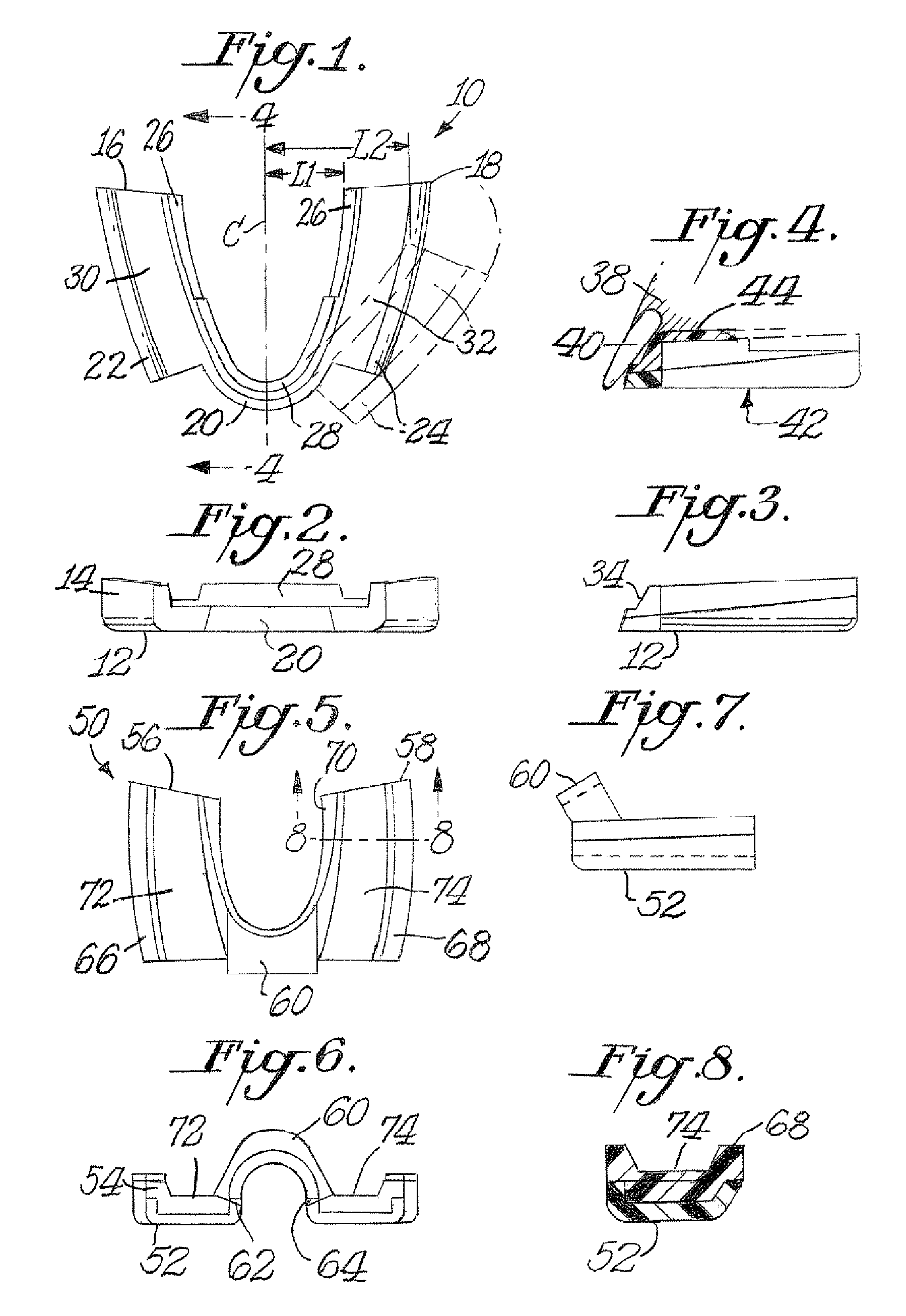

InactiveUS7066736B2Precious timeLow costDental implantsFastening prosthesisDistal portionEngineering

An impression coping for taking an impression of a dental implant installed in the jawbone of a patient. The impression coping has a proximal end with an impression portion adapted to be embedded in impression material and a distal portion with a retention mechanism. The retention mechanism includes a housing having a locking member and biasing member. The locking member is biased to slideably move in the housing and engage the dental implant.

Owner:ZIMMER DENTAL INC

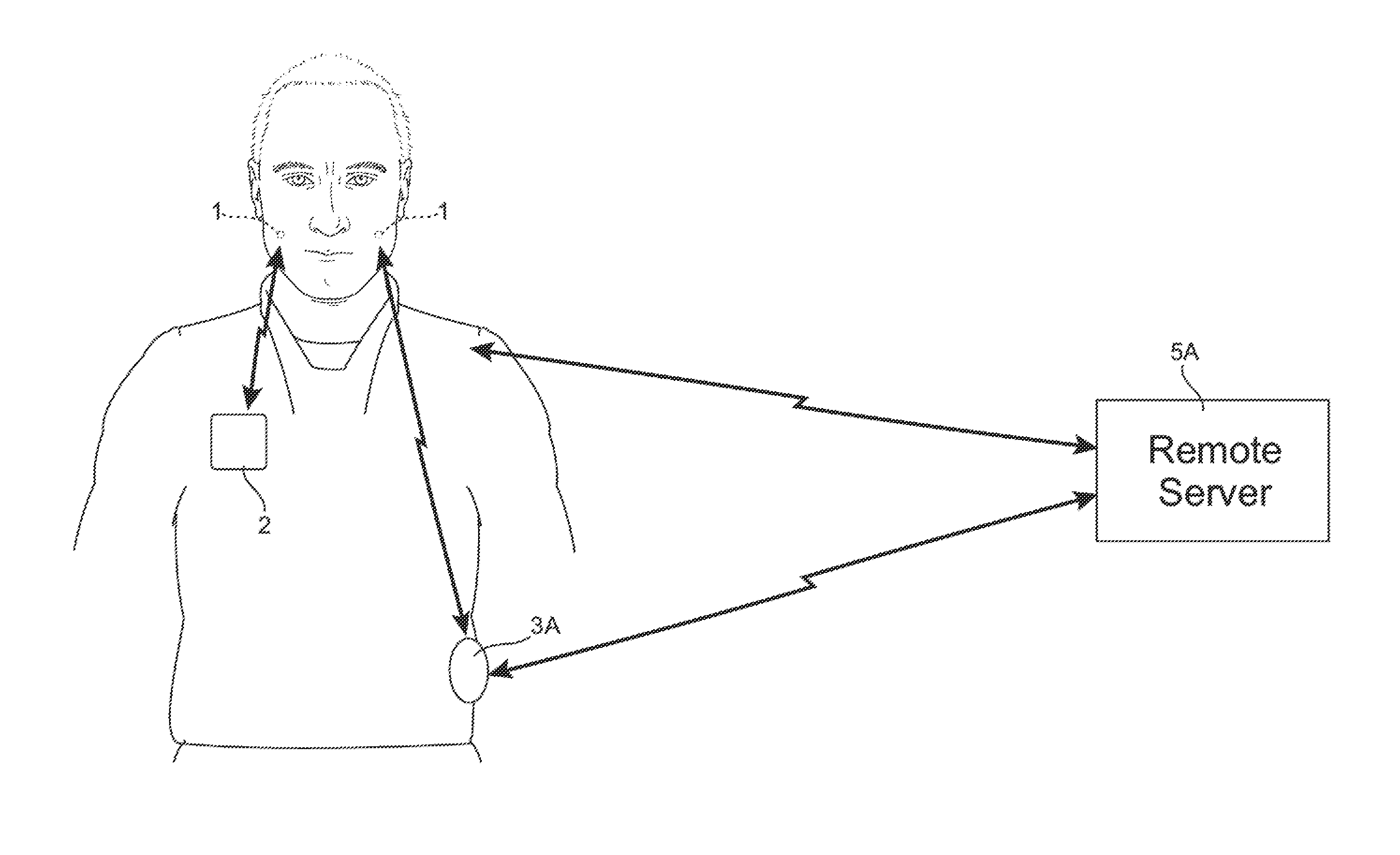

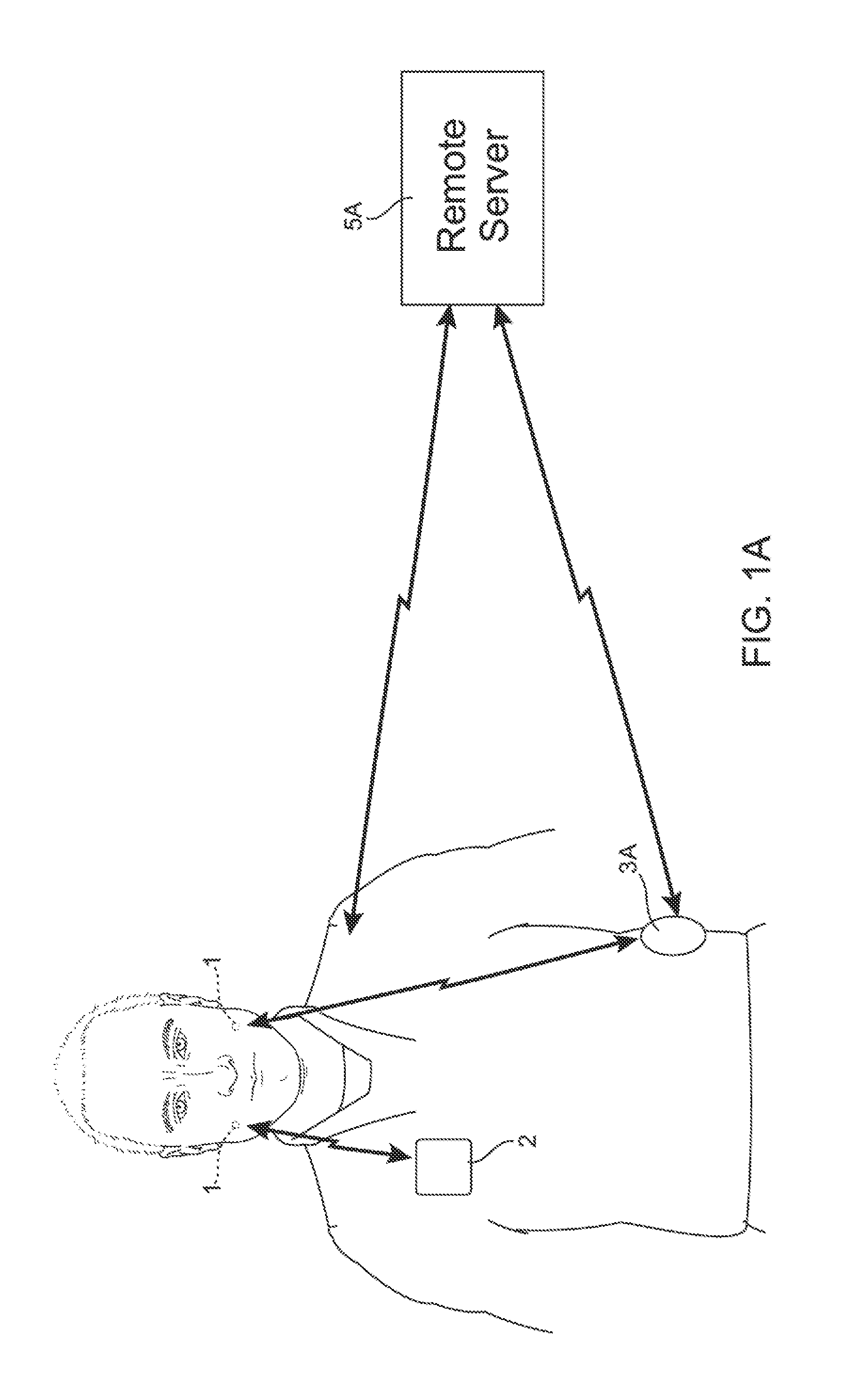

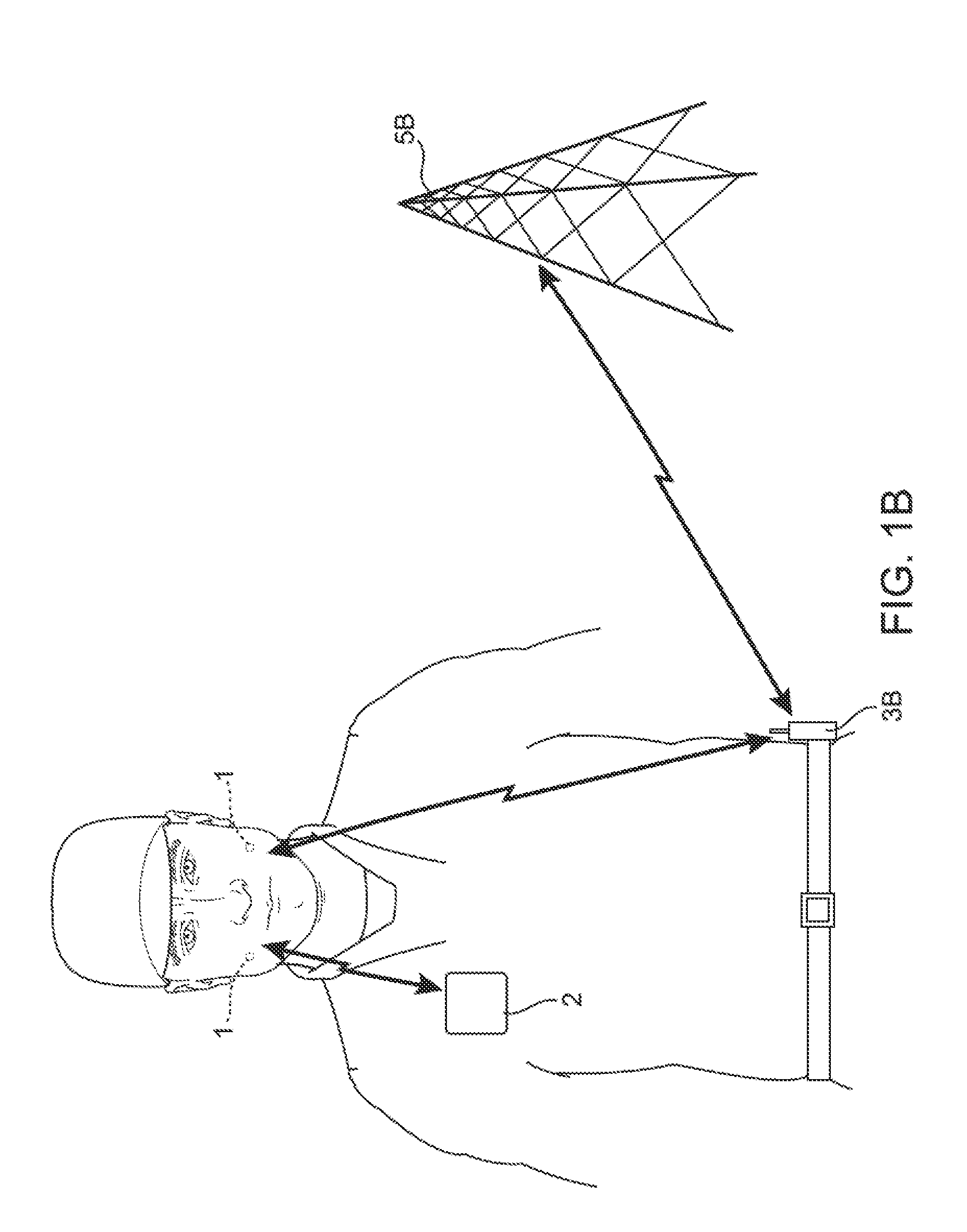

Systems and methods to provide communication and monitoring of user status

InactiveUS20140081091A1Reduce paperworkImprove responsivenessAdditive manufacturing apparatusDiagnostic signal processingBone structureTransducer

An electronic and transducer device can be attached, adhered, or otherwise embedded into or upon a removable oral appliance or other oral device to form a two-way communication assembly. The device contains a motion sensor to detect external forces imposed on the user such as an explosion, for example. The information is stored for medical treatment, among others. In another embodiment, the device provides an electronic and transducer device that can be attached, adhered, or otherwise embedded into or upon a removable oral appliance or other oral device to form a medical tag containing patient identifiable information. Such an oral appliance may be a custom-made device fabricated from a thermal forming process utilizing a replicate model of a dental structure obtained by conventional dental impression methods. The electronic and transducer assembly may receive incoming sounds either directly or through a receiver to process and amplify the signals and transmit the processed sounds via a vibrating transducer element coupled to a tooth or other bone structure, such as the maxillary, mandibular, or palatine bone structure.

Owner:SOUNDMED LLC

Dental implant system and method for effecting a dental restoration using the same

A dental implant system and method for effecting a dental restoration using the same. The dental implant system having an implant fixture adapted to be deployed in a bone; an impression coping adapted to be selectively deployed on the implant fixture and in a dental impression; a laboratory analog adapted to be selectively deployed on the impression coping and in a dental cast; a spherical abutment adapted to be selectively deployed on the laboratory analog; and a multiaxis abutment adapted to be adjustably deployed on the spherical abutment; wherein the spherical abutment and the multiaxis abutment are used to generate a cast permanent abutment which may be received by the laboratory analog and the implant fixture.

Owner:LUSTIG L PAUL +2

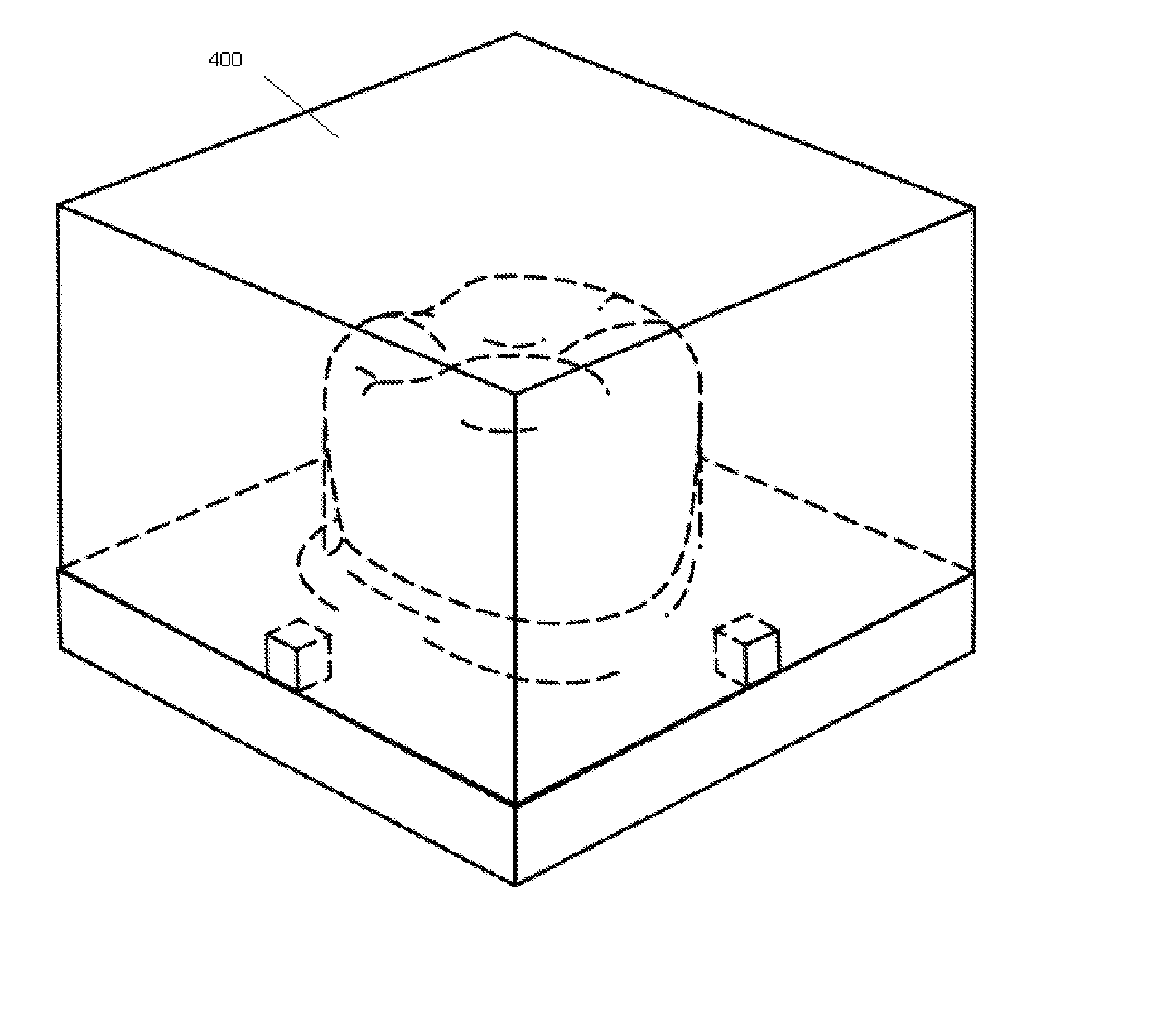

Digital impression for remote manufacturing of dental impressions

A “digital impression” is provided in lieu of a physical “dental” impression. A 3D digitizer is used to capture the digital impression, e.g., by scanning in a patient's oral cavity. A digital impression “data set” is formed using a computer-implemented method. The method begins by generating a three dimensional (3D) restoration model. Then, a bounding volume of the restoration model is computed. The bounding volume is defined as at least a minimum 3D volume that contains the 3D model. Thereafter, a lower solid 3D model, and an upper solid 3D model are created; these lower and upper models have a predetermined relationship with one another. In particular, when superimposed upon one another within the bounding volume, the lower and upper 3D models define a cavity into which the restoration model is adapted to fit. The restoration model, the lower solid 3D model and the upper solid 3D model are then aggregated into the data set to form the digital impression. Typically, the digital impression is generated at a first location, i.e., a dental office, and then transmitted to a second location, a dental laboratory, remote from the first location. Such transmission is conveniently done over a network, such as a TCP / IP network (e.g., the Internet). A dental item is then manufactured at the second location. Thus, for example, the lower solid 3D model may be used to build a coping, or the restoration model itself used to build a restoration. In the latter case, information in the data set may be used to check a fit of the restoration.

Owner:D4D TECH LP

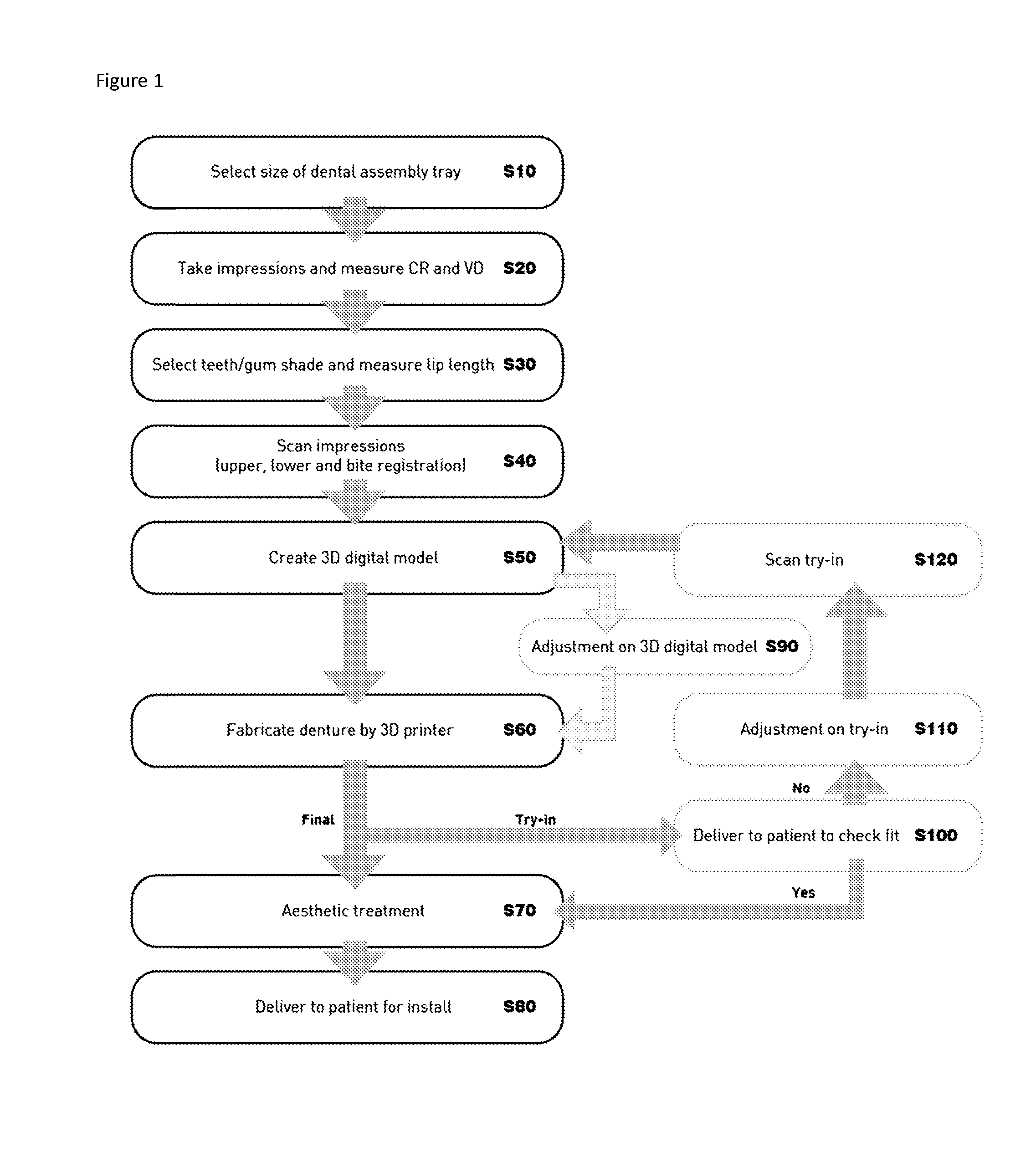

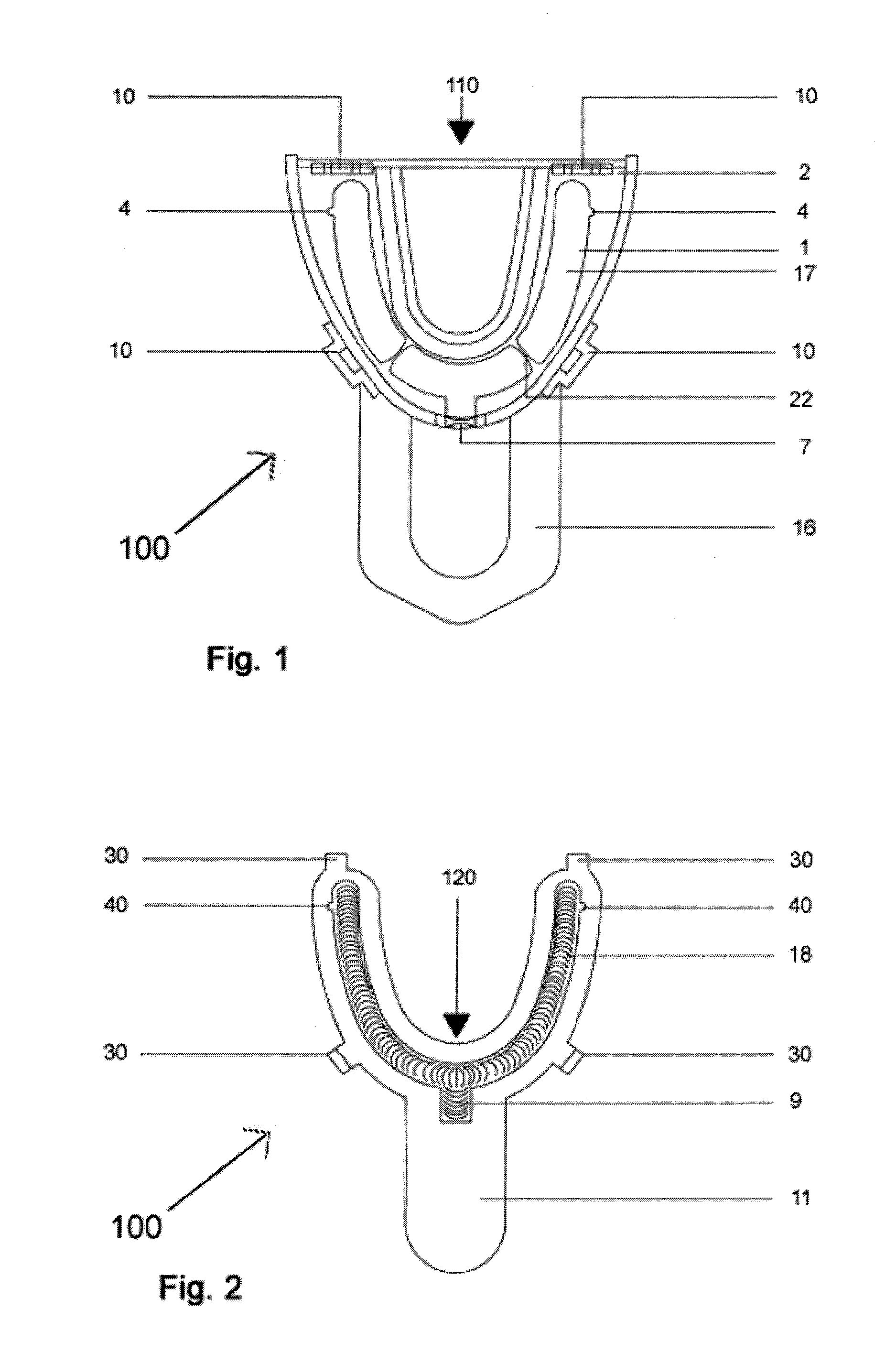

Method and apparatus for preparing removable dental prosthesis

ActiveUS20140308624A1Easy to operateAccurate manufacturing of a complete denture without intensive manual laborImpression caps3D printingSingle visit3d design

A method for manufacturing a removable dental prosthesis using a three-dimensional (3D) printer includes receiving dental impressions of a patient obtained using a dental impression tray assembly, the dental impressions including a bite registration and at least a mandibular impression or a maxillary impression; receiving information related to the patient's jaw relations obtained using the dental impression tray assembly, the jaw relations including a vertical dimension and a centric relation obtained during the patient's single visit to a dentist; scanning the received dental impressions with a 3D scanner to provide data representative of an edentulous shape of the patient; generating a 3D model of the dental prosthesis based on the data and the received information related to the patient's jaw relations using 3D design software; displaying the generated 3D model on a display, allowing customization of the 3D model; and 3D printing the dental prosthesis according to the 3D model.

Owner:DENTCA INC

Apparatus for Producing Dental Impressions

Owner:NEUSCHAFER GERD

Dental impression composition on functionalized polyethers

A dental impression composition comprises a polyether derivative functionalized via the hydroxyl groups of a polyether polyol with groups such as aziridine, epoxide and unsaturated substituents including (meth)acrylic, allyl, vinyl, vinyl ether or maleate groups, wherein the level of cyclic oligomeric polyethers is less than 5.0 weight percent.

Owner:3M DEUTLAND

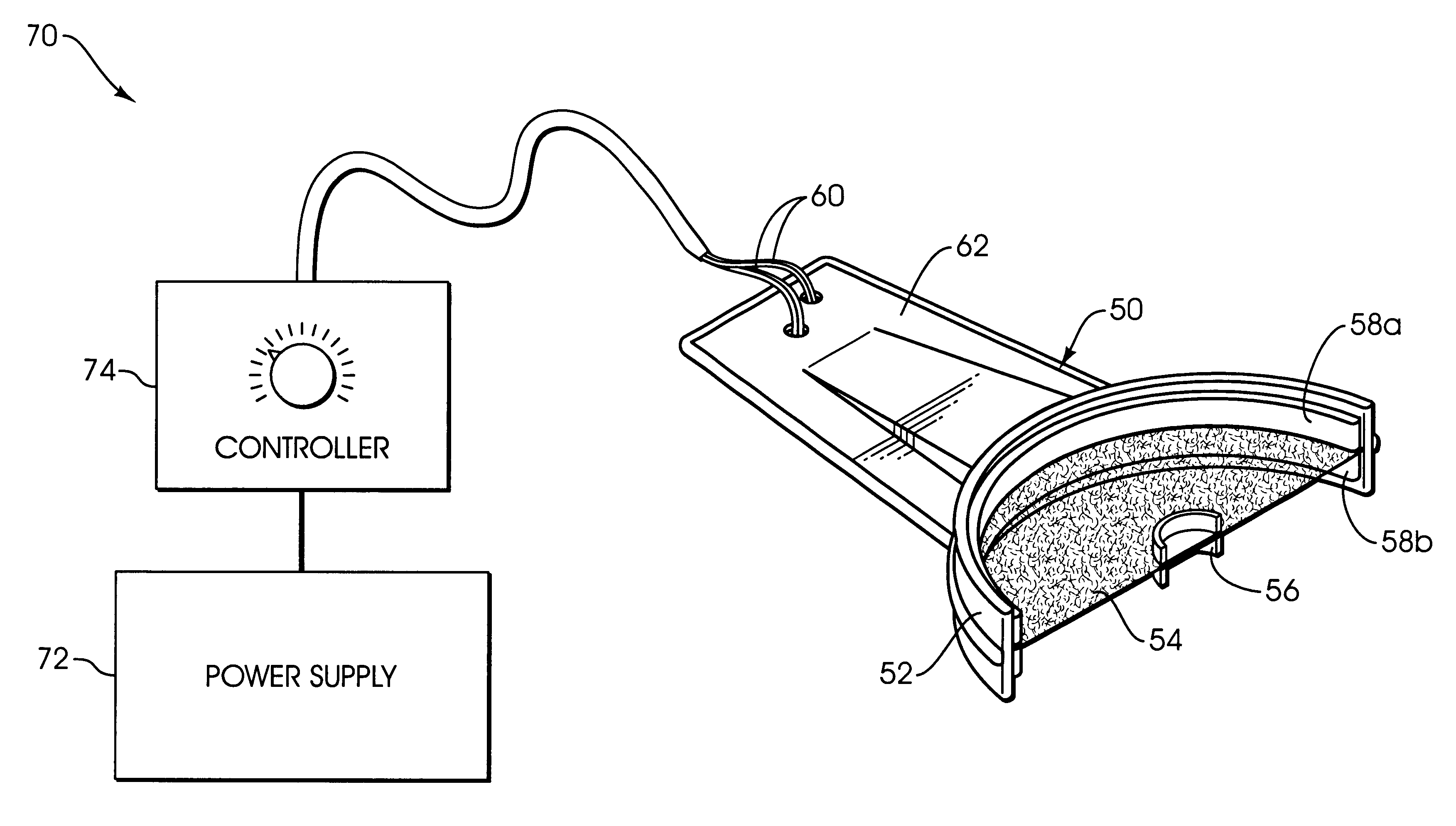

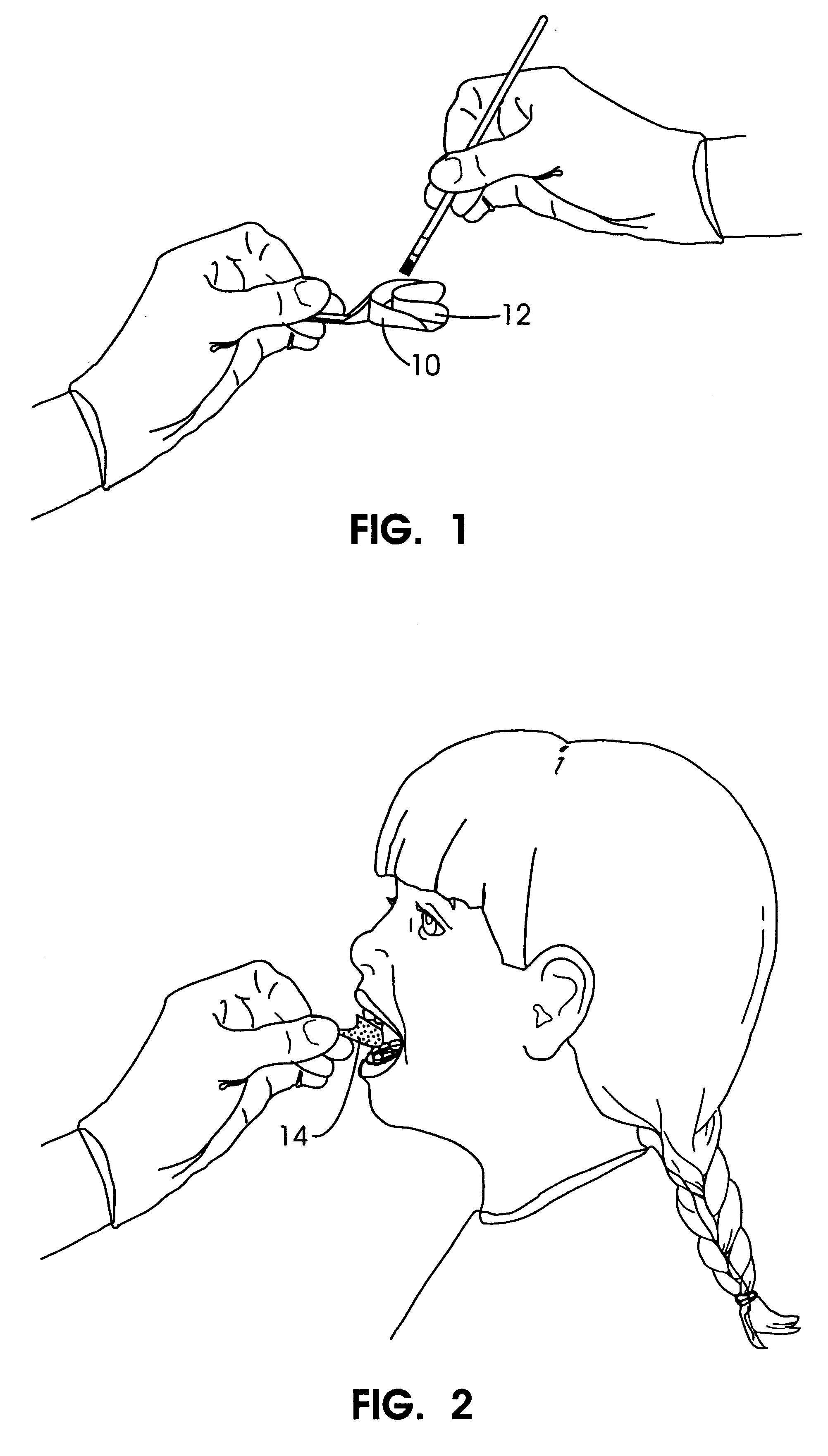

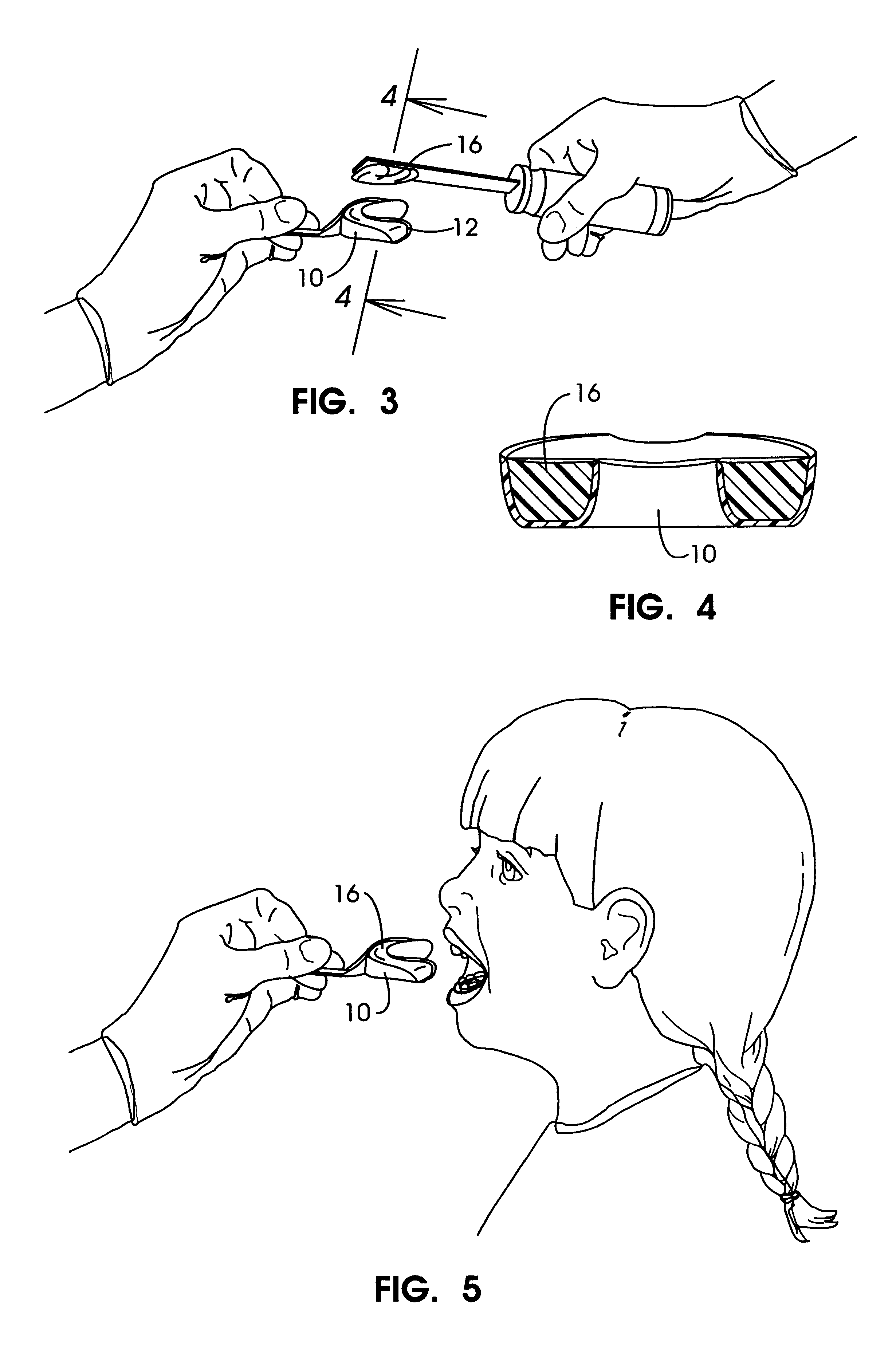

Apparatus and methods for accelerating dental treatments

InactiveUS6382979B2High activityIncrease ratingsImpression capsTeeth fillingElectrical resistance and conductancePotassium nitrate

Apparatus, kits and methods for providing accelerated treatment of a patient's teeth. The apparatus, kits and methods involve the use of a dental impression tray that includes a patient dentition impression formed from a dental impression material such as an alginate. The impression tray advantageously includes heating means for heating and maintaining the formed patient dentition impression at a temperature greater than about 105° F. The heated dental trays may be used to accelerate the activity of dental bleaching agents (e.g., peroxides), desensitizing agents (e.g., potassium nitrate), remineralizing agents (e.g., fluoride salts), and the like. A dental office procedure for treating teeth involves the basic steps of: (1) coating a specially-prepared patient dentition impression with a dental composition such as a bleaching, desensitizing or remineralizing composition; (2) placing the coated patient dentition impression into the patient's mouth; (3) heating the patient dentition impression and dental composition to a temperature of at least about 105° F.; and (4) retaining the patient dentition impression in position for period of time in a range of about 1 minute to about 60 minutes. The procedure can be adapted to microwave heating, electrical resistance heating, or hot fluid heating of the patient dentition impression.

Owner:LINDQUIST SHERRILL F DDS +1

Transfer coping for dental implants

An impression coping is provided for taking an impression of an implant installed in a patient's mouth. The impression coping comprises an engagement portion, a cover and an impression portion. The engagement portion is adapted to be inserted within an internal cavity of the implant. The engagement portion has a plurality of axially extending protrusions positioned around the periphery for engaging corresponding channels within the internal cavity of the implant. The engagement shaft is thus configured to register the internal orientation of the implant within a patient's jaw. The impression portion of the coping includes one or more embedment features adapted to be embedded in a dental impression material for taking a dental impression thereof.

Owner:NOBEL BIOCARE SERVICES AG

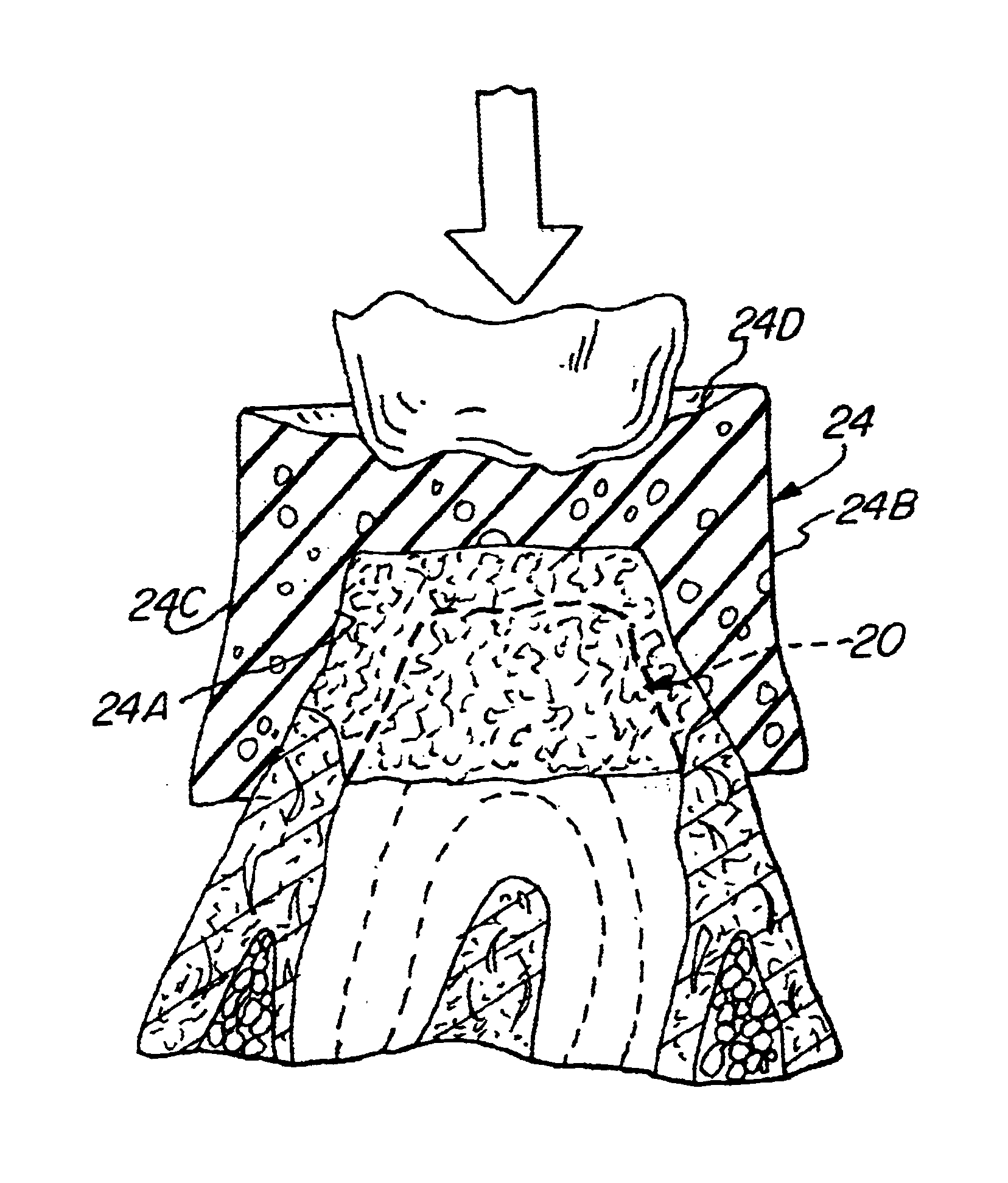

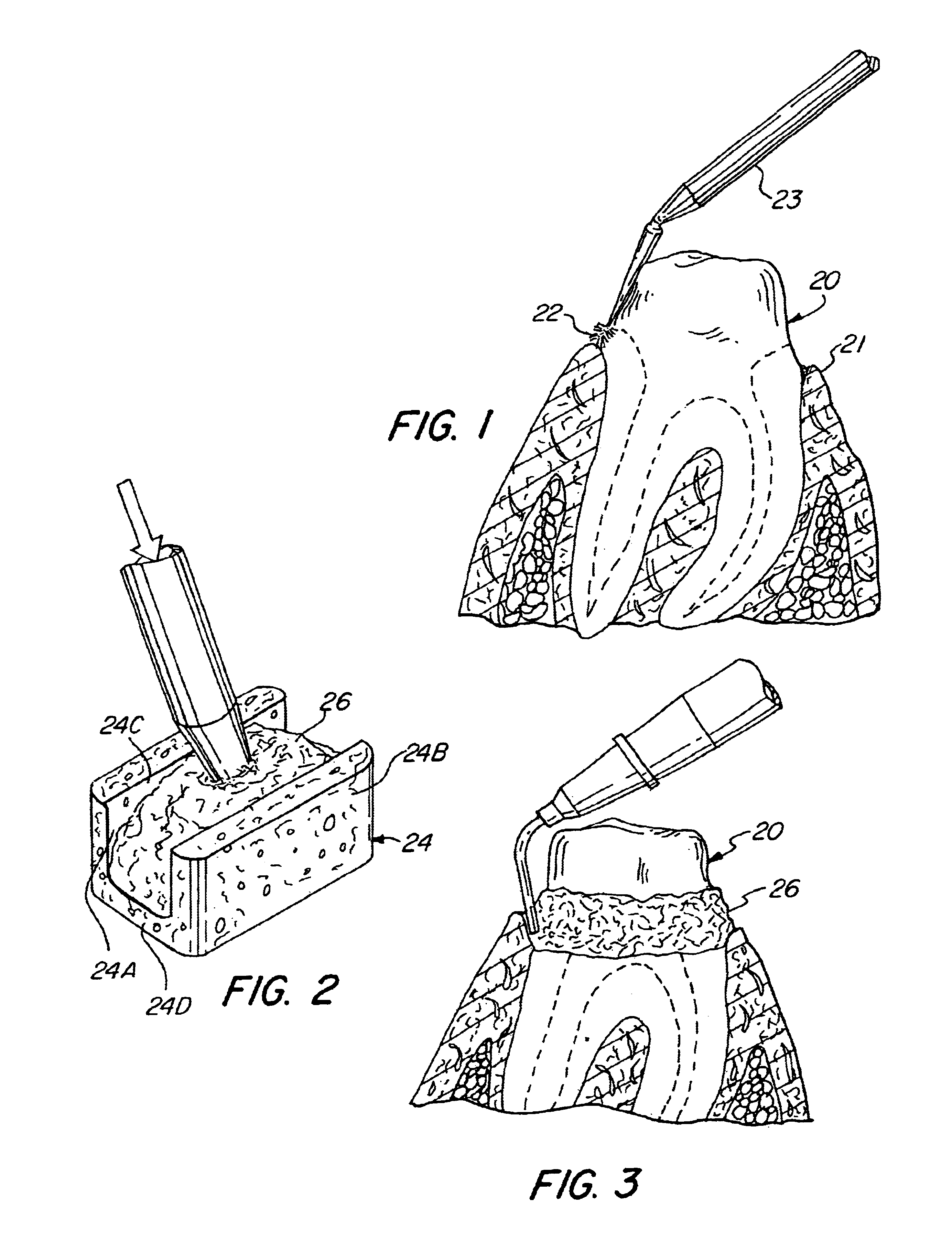

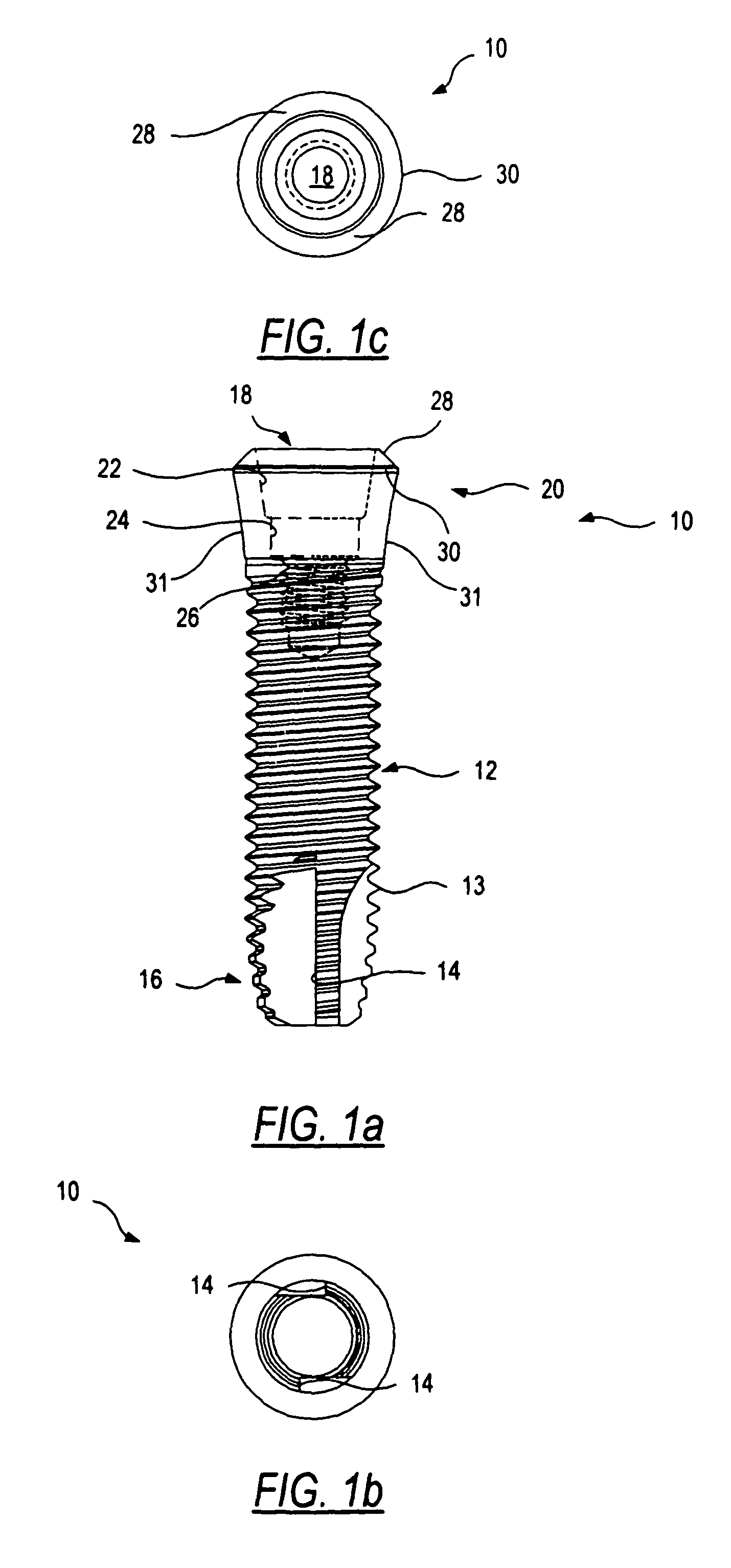

Method and device for the retraction and hemostasis of tissue during crown and bridge procedures

InactiveUS6890177B2Positive in operationEasy to operateImpression capsDental aidsBite force quotientGingival space

A method and a device for effecting the cordless retraction of the gingival sulcus tissue prior to the taking of an impression of a tooth for making a crown or bridge which is attained by controlling any bleeding in the gingival sulcus area, and utilizing a dental dam preferably formed of a sponge or foam like material to contain an astringent fortified silicone impression material embedded about the prepared tooth, and using the patient's biting force to apply the necessary pressure onto the dam until the silicone impression material sets and adheres to the dam to enhance easy removal of the set impression material from the tooth. The dam is formed to accommodate either the posterior teeth or the anterior teeth.

Owner:CENTRIX

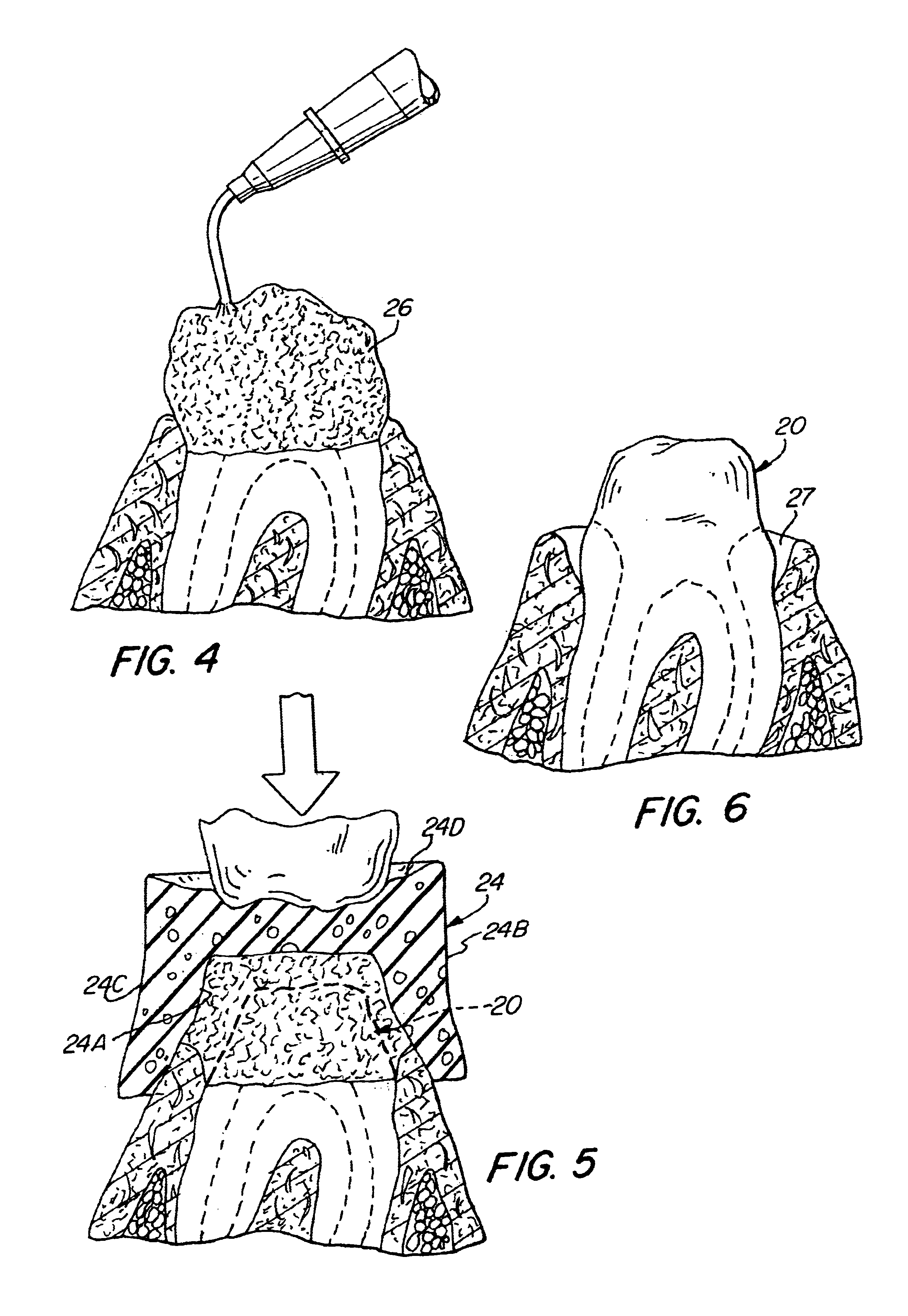

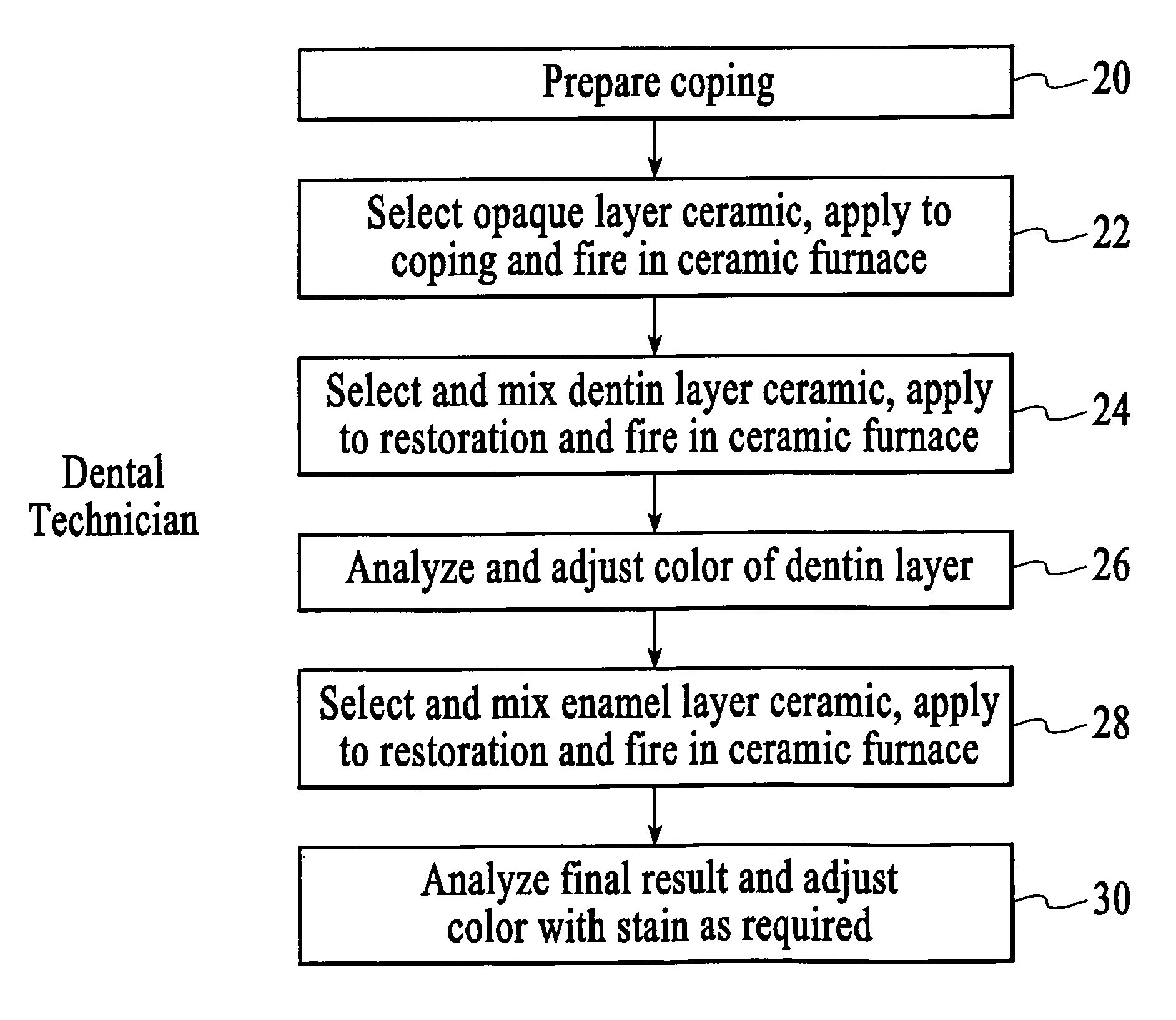

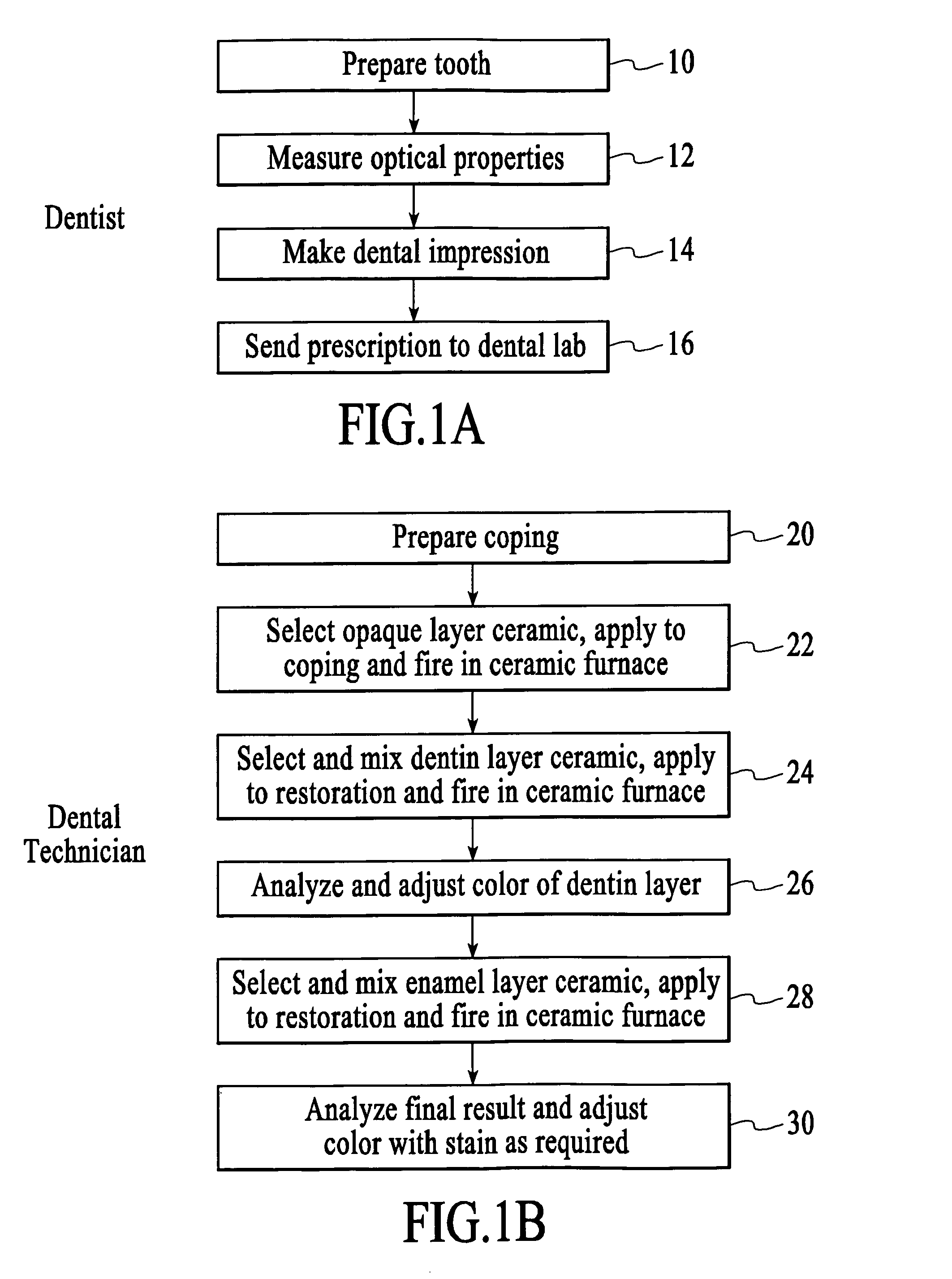

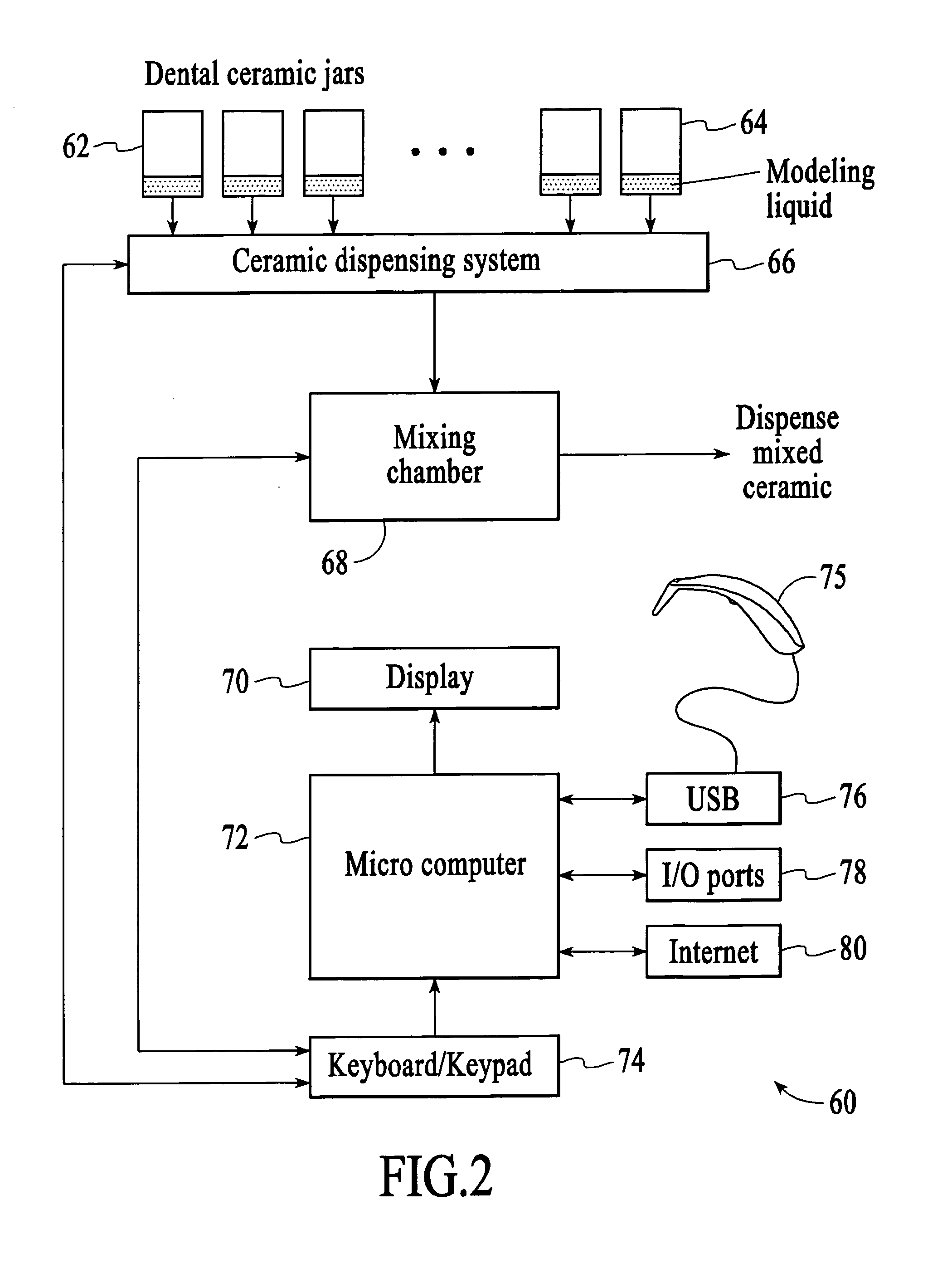

Systems and methods for preparing dental restorations

InactiveUS20070212667A1Reduce in quantityMinimal numberMechanical/radiation/invasive therapiesTooth crownsMeasuring instrumentData file

Improved systems and methods for producing dental restorations and ceramic materials for such restorations are disclosed. Optical properties, preferably including color and translucence characteristics, of a tooth or teeth of a patient are measured with a shade measuring instrument. The tooth to be restored is prepared, and a physical or virtual dental impression is created. A prescription for the restoration, which typically includes color, translucence and thickness information, is sent to the restoration fabrication facility either electronically or physically. A recipe and / or a mixture of ceramics are generated for the restoration, with multiple layers being specified, based on the measured optical properties. The recipe algorithm may adapt, or process checks may be performed, based on measurements of fabricated layers. Preferably, dental ceramics are specified to bracket the region of color space relevant to human teeth, and a reduced set of ceramic materials are manufactured and distributed. Based on measured optical characteristics of the ceramic materials, recipes and / or material mixtures are specified or prepared for the restoration. A virtual impression data file may be transmitted to the laboratory instead of a physical impression.

Owner:JJL TECH

Adjustable dental impression tray and methods for using same

An adjustable dental impression tray includes a first and second arcuate member movably attached at a proximal end of each arcuate member. The adjustable dental impression tray includes a handle to facilitate removal of the tray from a person's mouth. The dental impression tray also includes an adjustment mechanism which allows the user to position the first arcuate member relative to the second arcuate member to form a U-shaped channel which approximates the patients dentition. The dental impression is further configured with a locking member to receive and retain impression material into the tray.

Owner:SKINNER GREGORY C

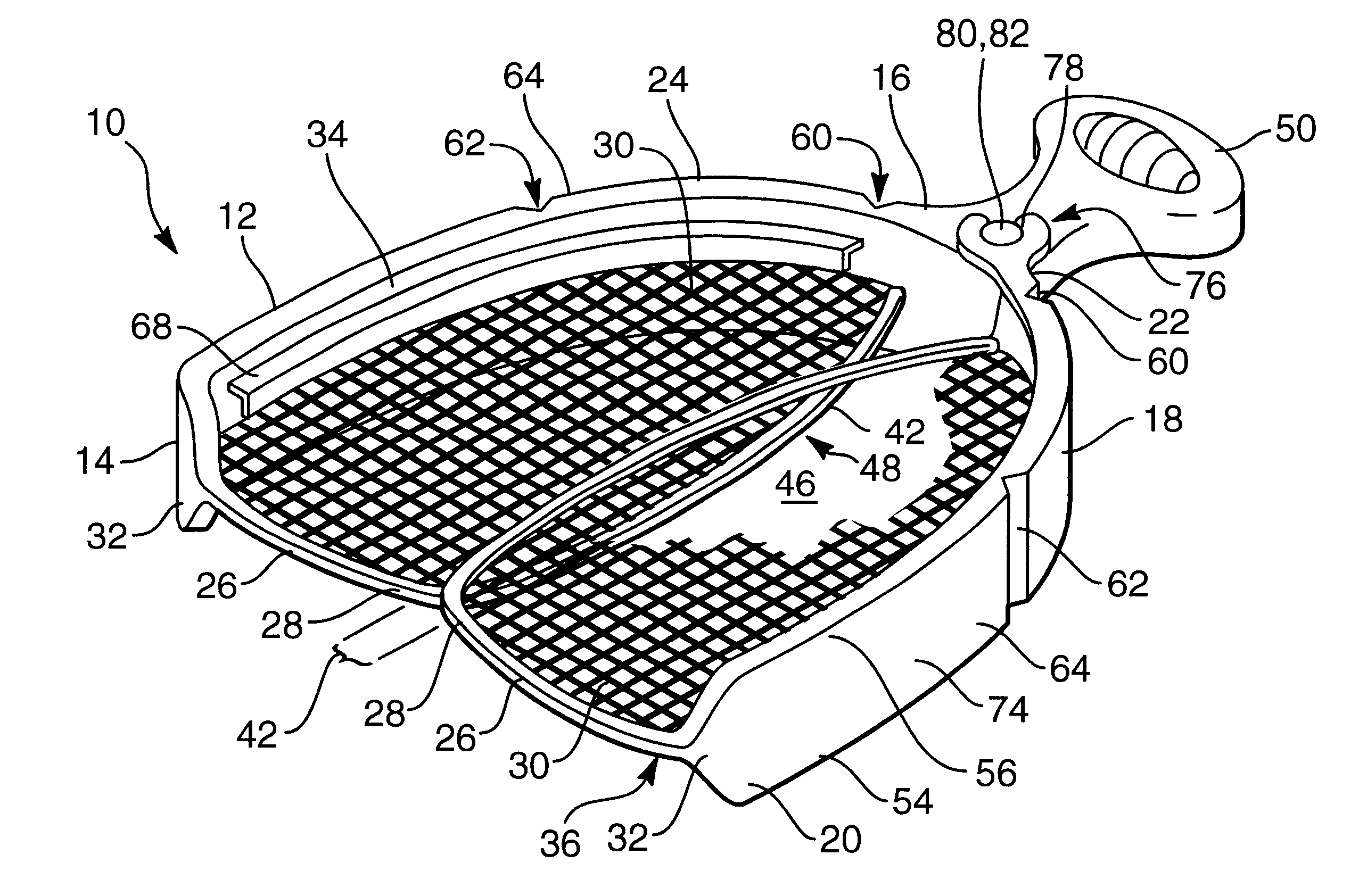

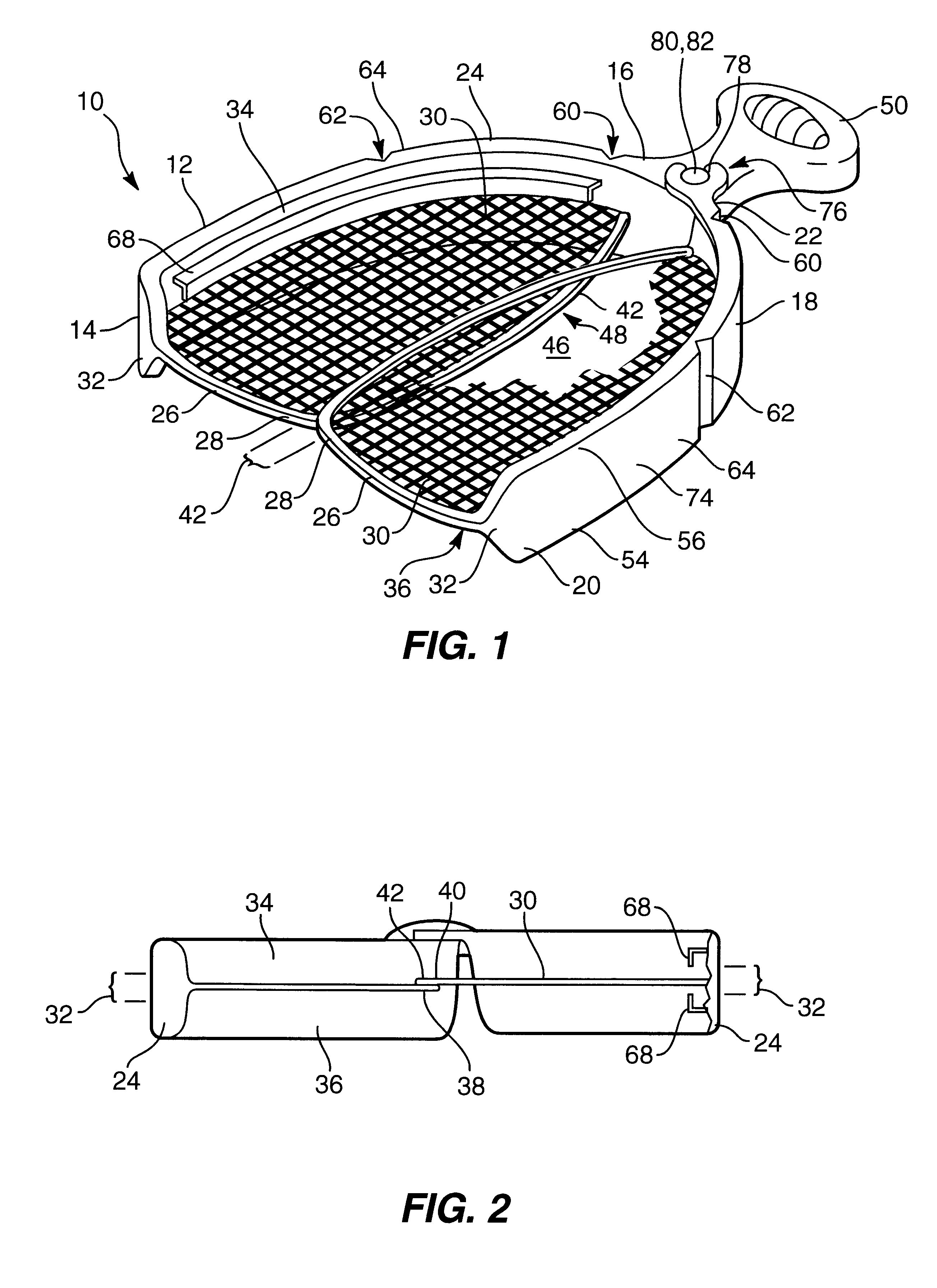

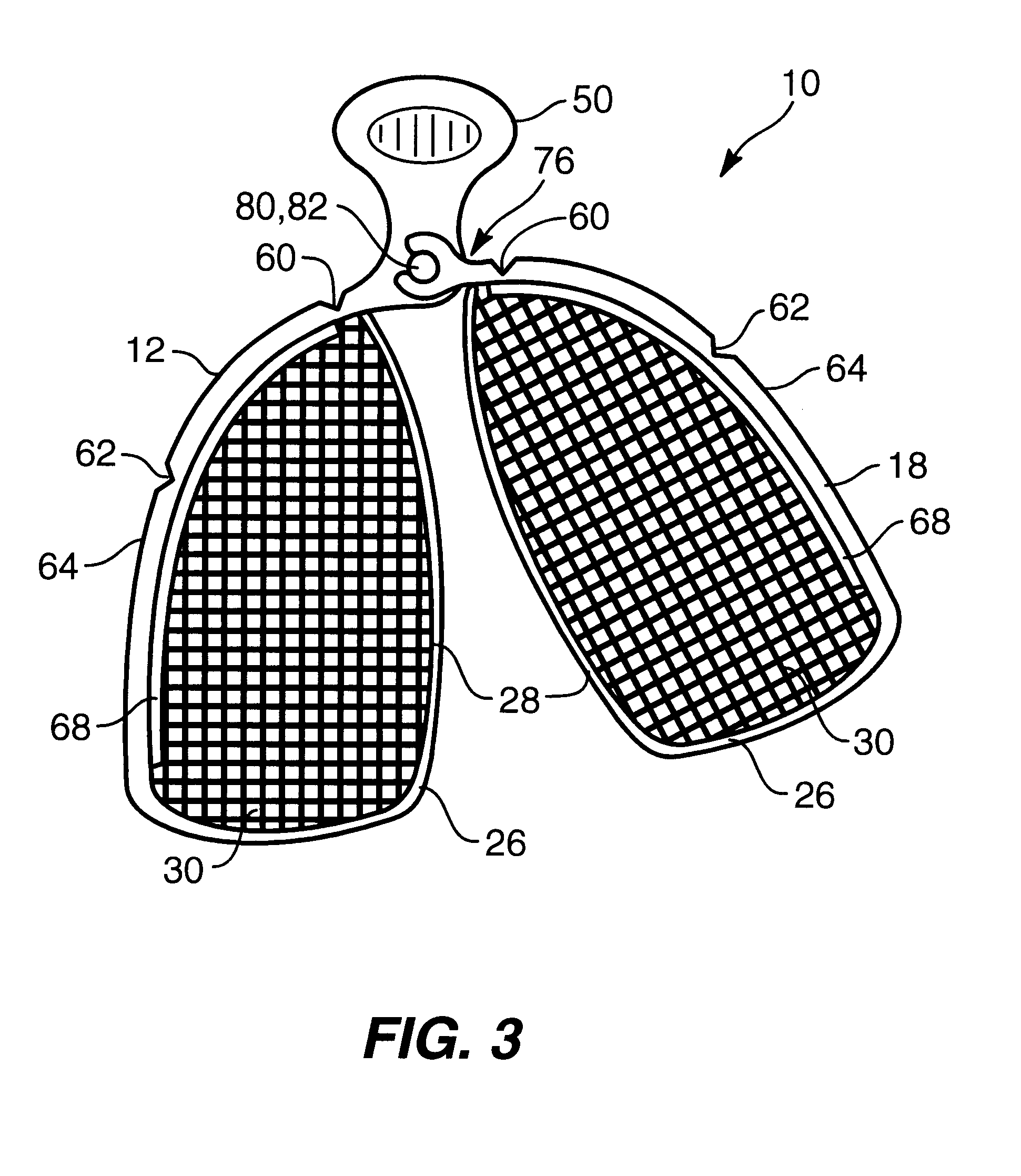

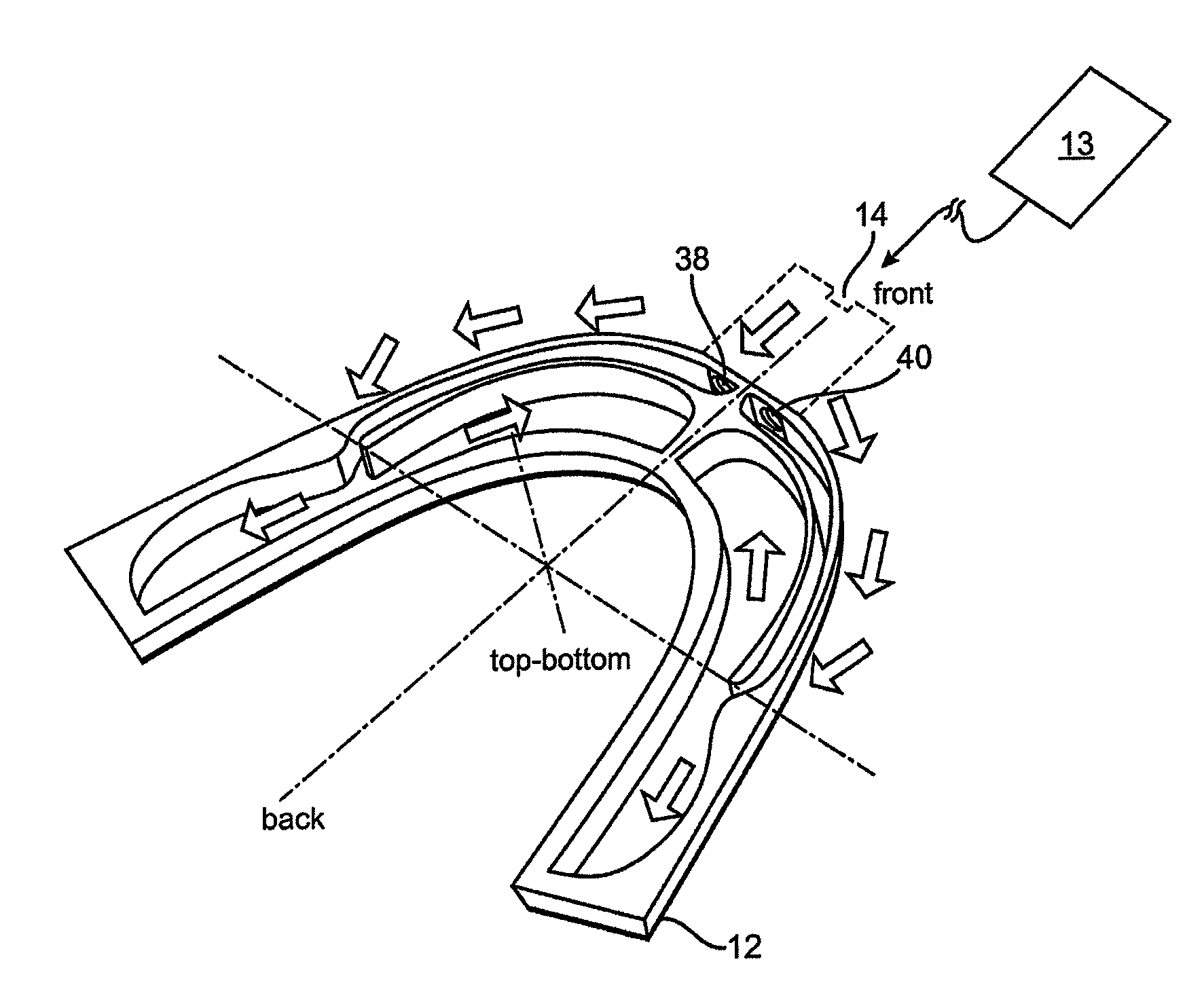

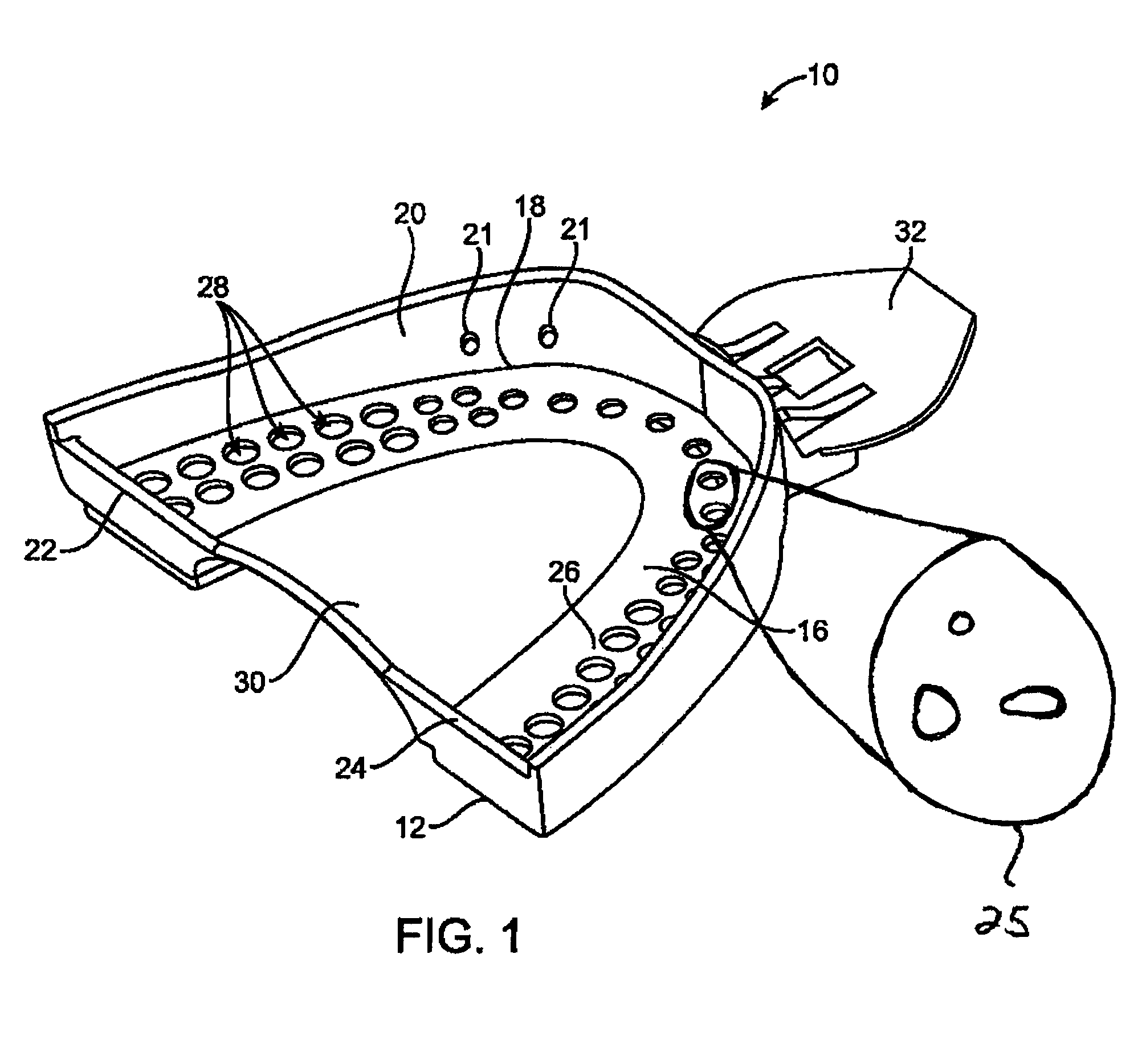

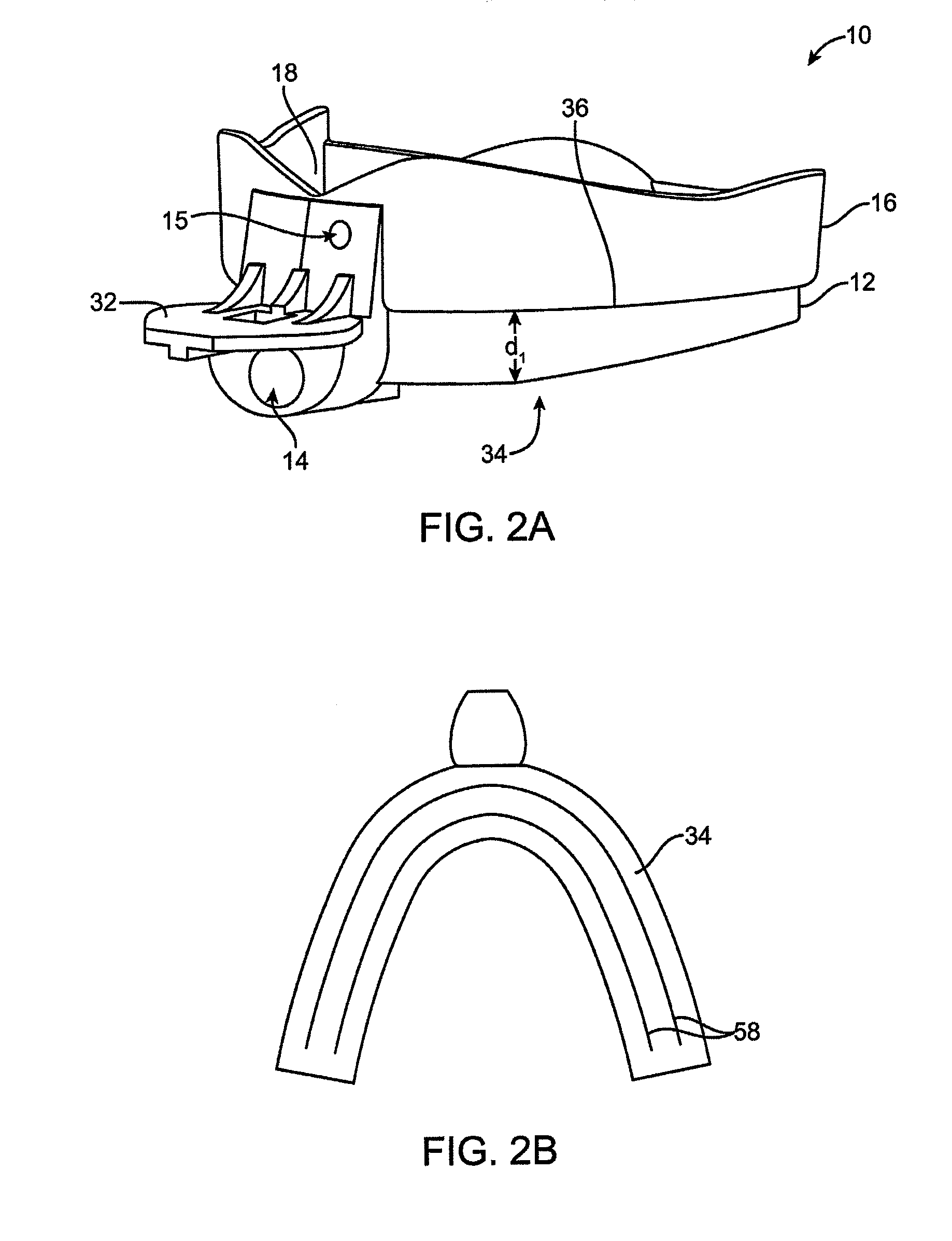

Injection impression tray

The present invention relates to an improved dental impression tray and related methods. In one embodiment, a dental impression tray includes a first portion for receiving impression material from a source and a second portion is configured for receiving a patient's upper or lower teeth and will at least partial define a cavity shaped to receive the teeth during use. In use, impression material introduced into the first portion can pass through openings and into the second portion and around a patient's teeth.

Owner:ALIGN TECH

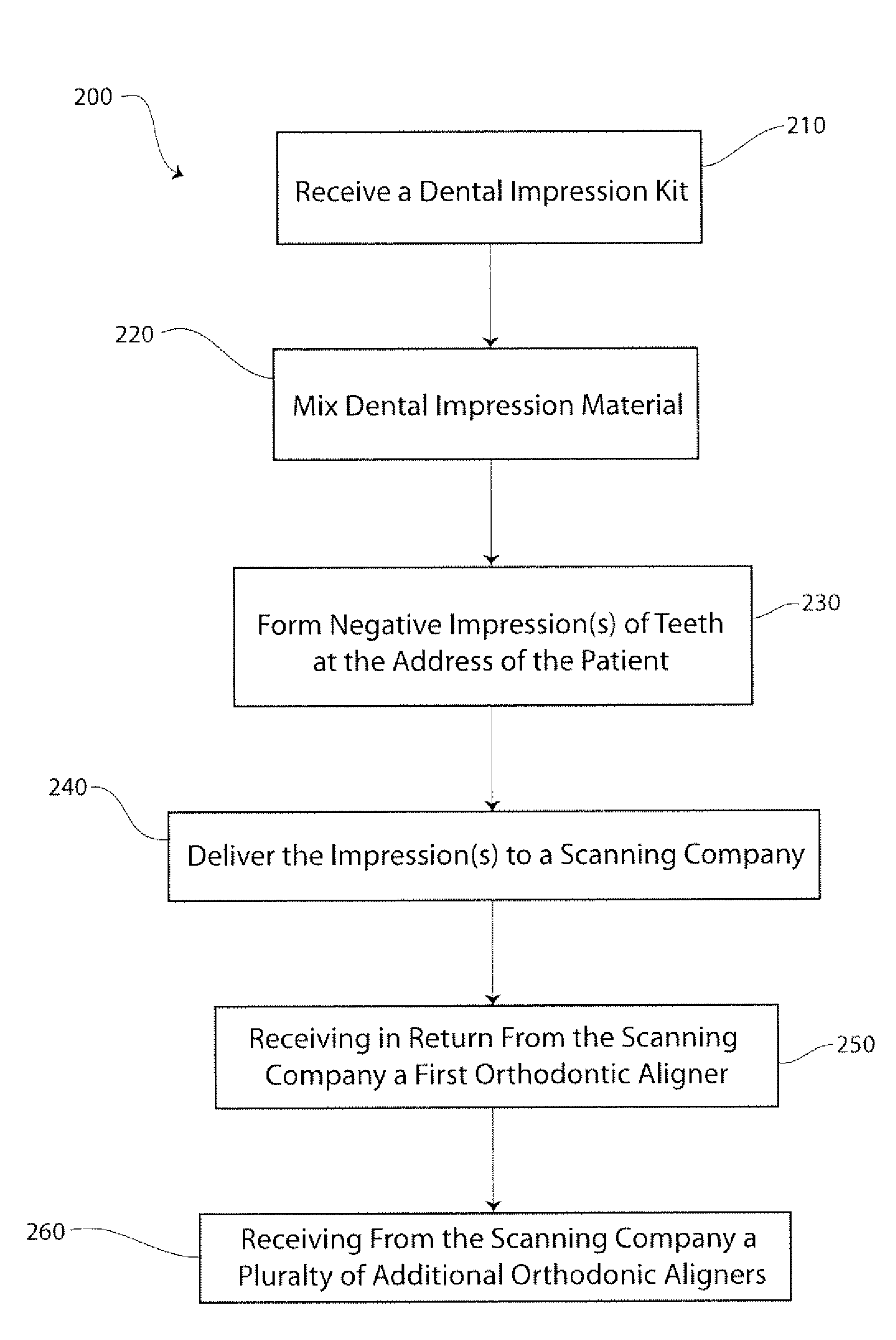

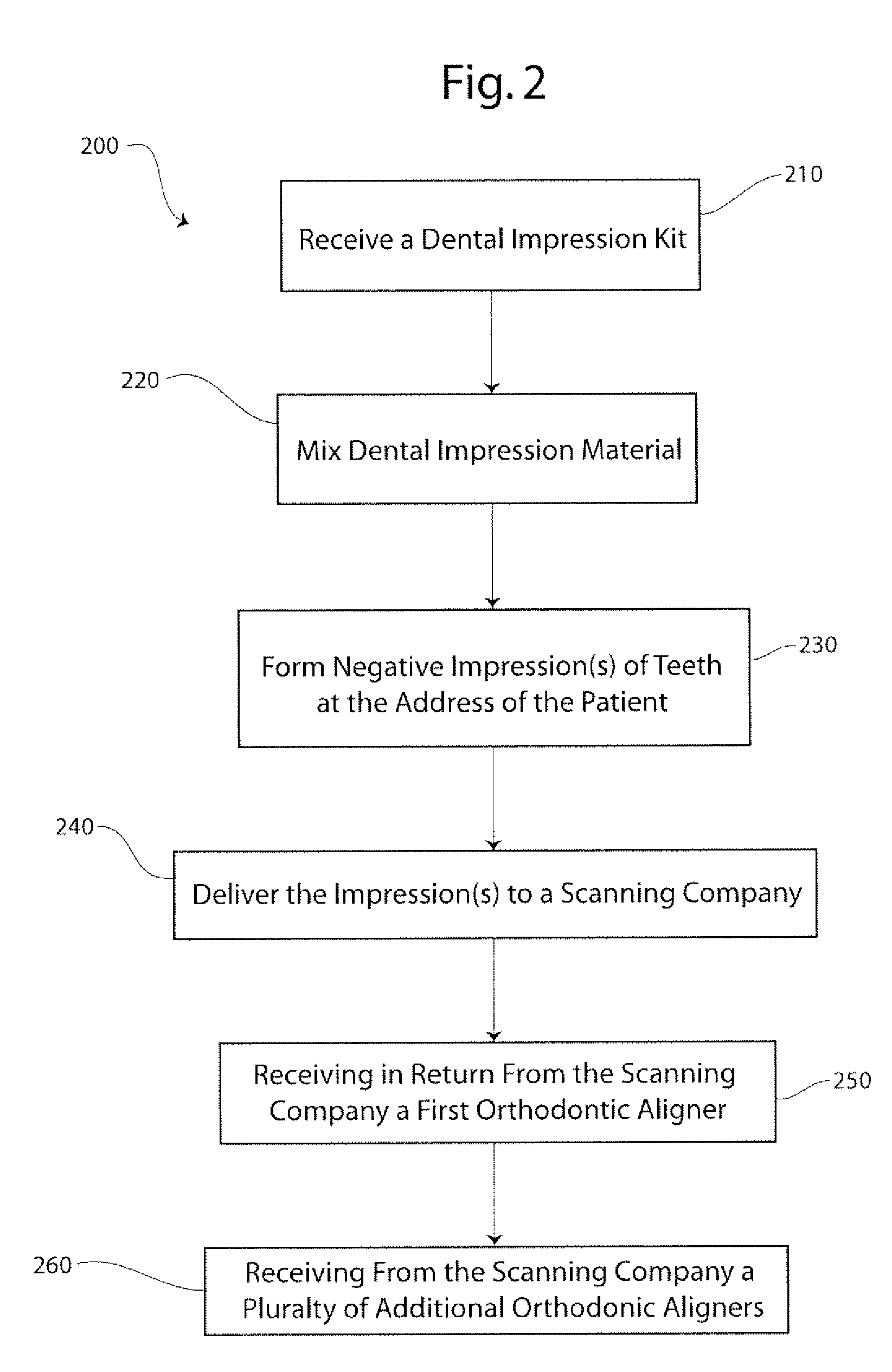

Method for Repositioning Teeth

A method for positioning teeth is provided. The method includes receiving a dental impression kit at an address of the dental patient. The dental impression kit includes a first dental impression tray, a mixable dental impression material, and instructions for taking an impression of the patient's teeth. The method also includes the steps of mixing the mixable dental impression material to form a settable dental impression material, and then placing the settable dental impression material into the first dental impression tray. A dental impression of the patient is made at the address of the patient. The method then includes delivering the impression to a scanning company, and in return, receiving a first orthodontic aligner from the scanning company. A plurality of additional aligners may also be received for the purpose of moving the patient's teeth to a final desired position. Preferably, the processes take place without the intervention of a dental healthcare provider.

Owner:FISHER COLEMAN

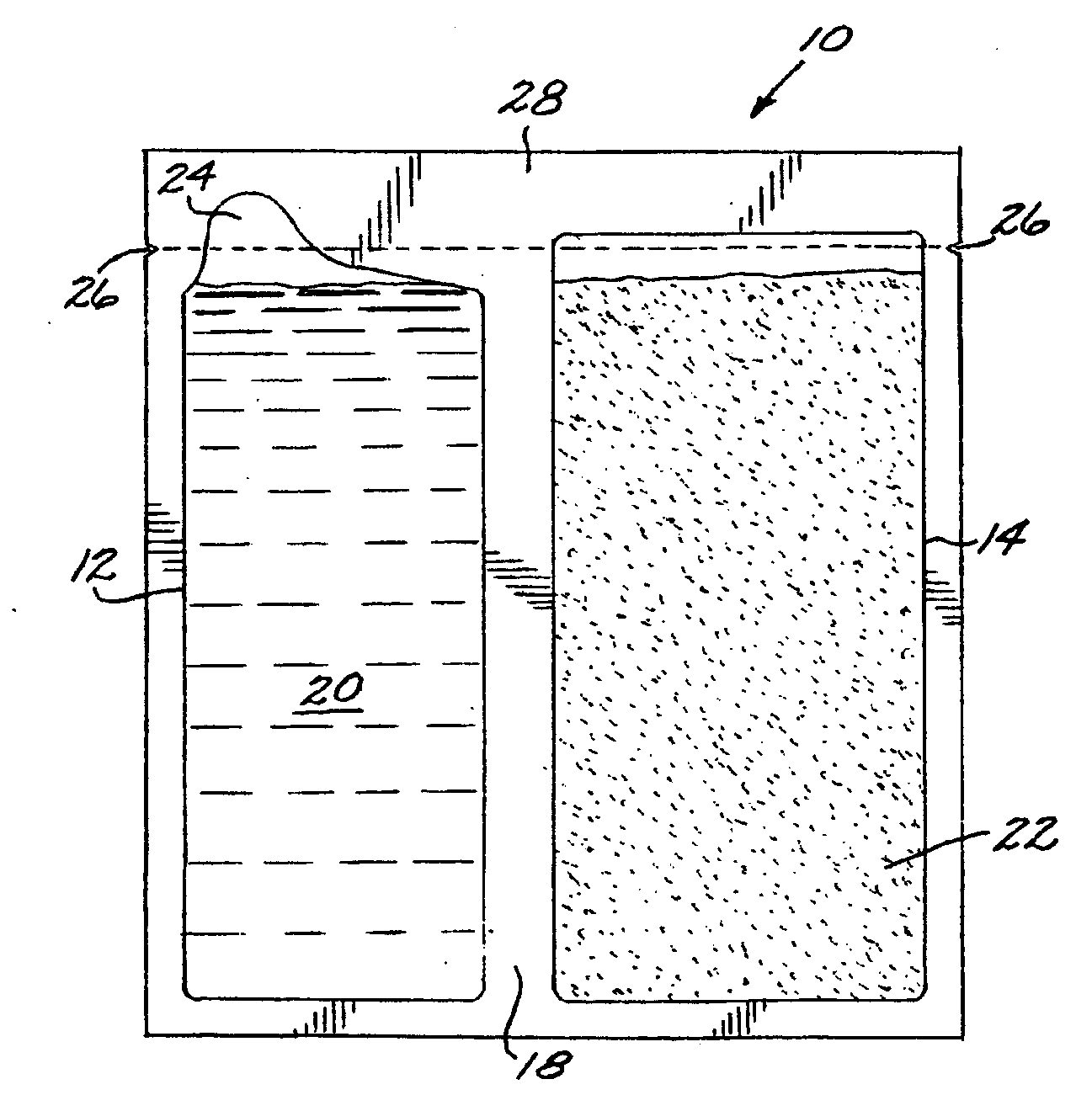

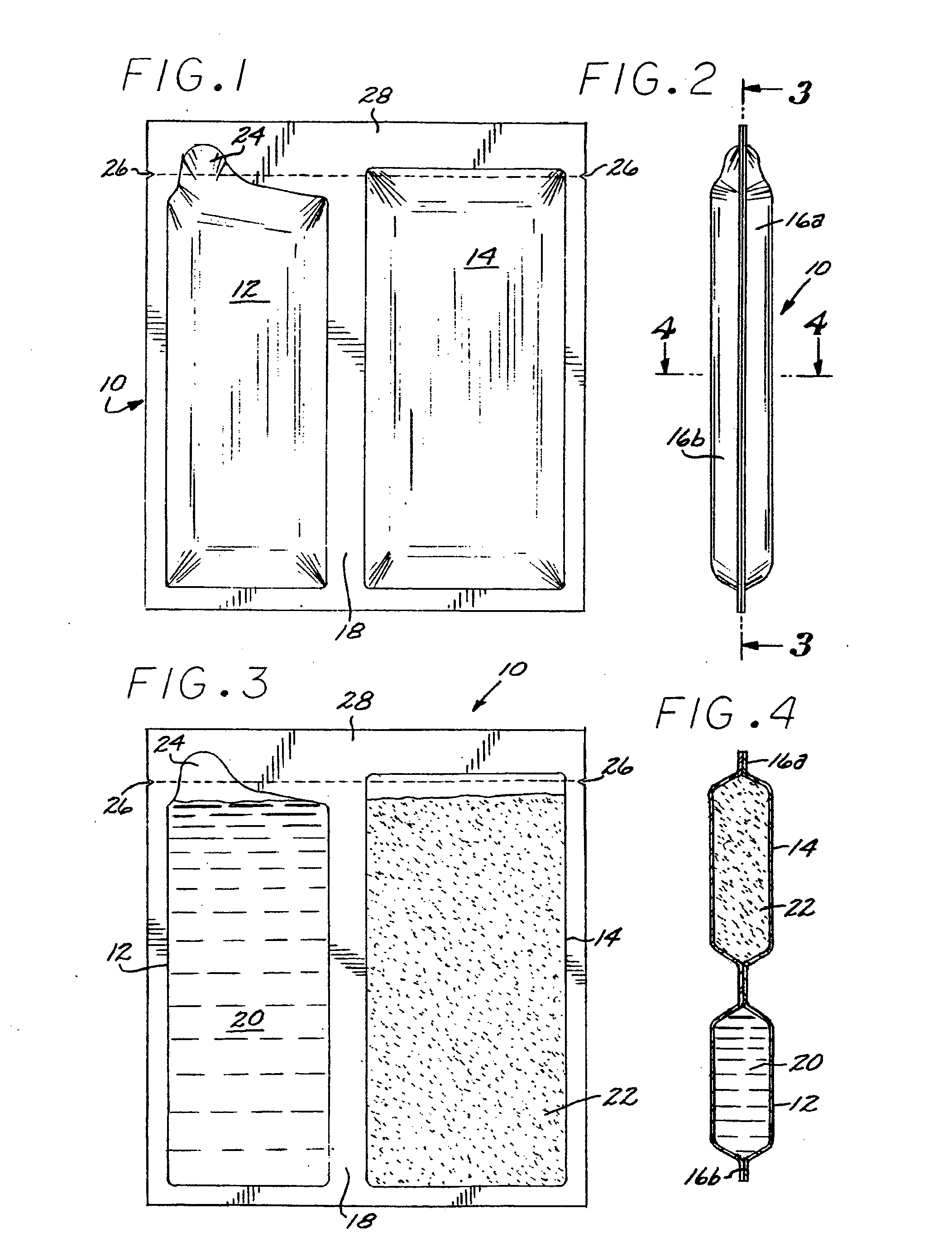

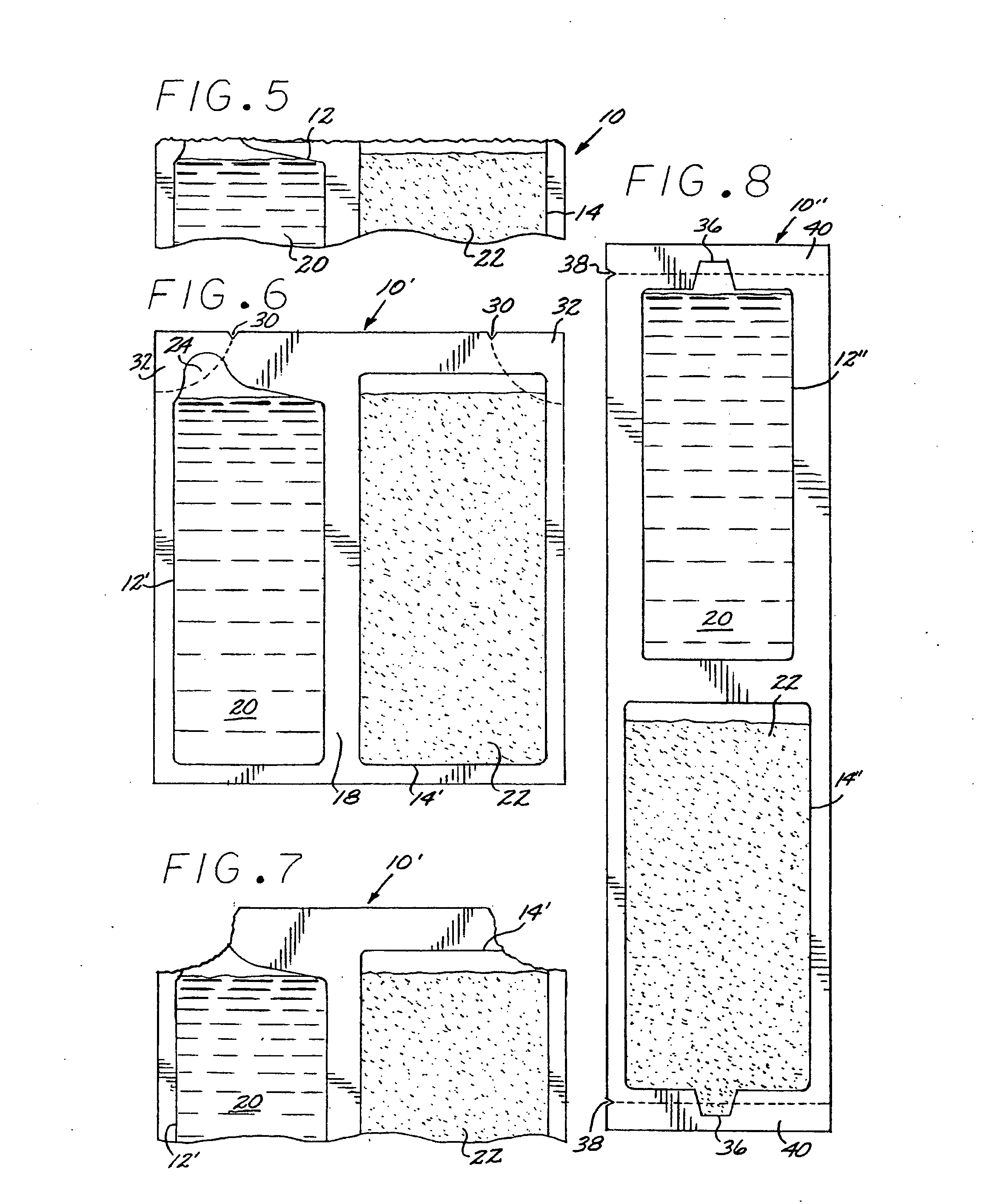

Dual-chamber package for preparing alginate impression paste

InactiveUS20080083348A1Accurate impressionGuaranteed mixImpression capsOther chemical processesDentistryImpressions materials

A dual-chamber package for the constituent materials for preparing an alginate dental impression paste includes a first chamber containing a pre-measured volume of water, and a second chamber, attached to and isolated from, the first chamber, and containing a pre-measured quantity of alginate powder, wherein the quantity of powder and the volume of water are in a pre-determined ratio for making a dental impression paste when mixed together. The powder and the water may be mixed outside of the package by dispensing the water and the powder respectively from the first and second chambers. Alternatively, the powder and water may be mixed within the second chamber by breaching a barrier between the first and second chambers to allow water to flow from the first chamber into the second chamber, after which the alginate dental impression paste is dispensed from the second chamber.

Owner:ALIGN TECH

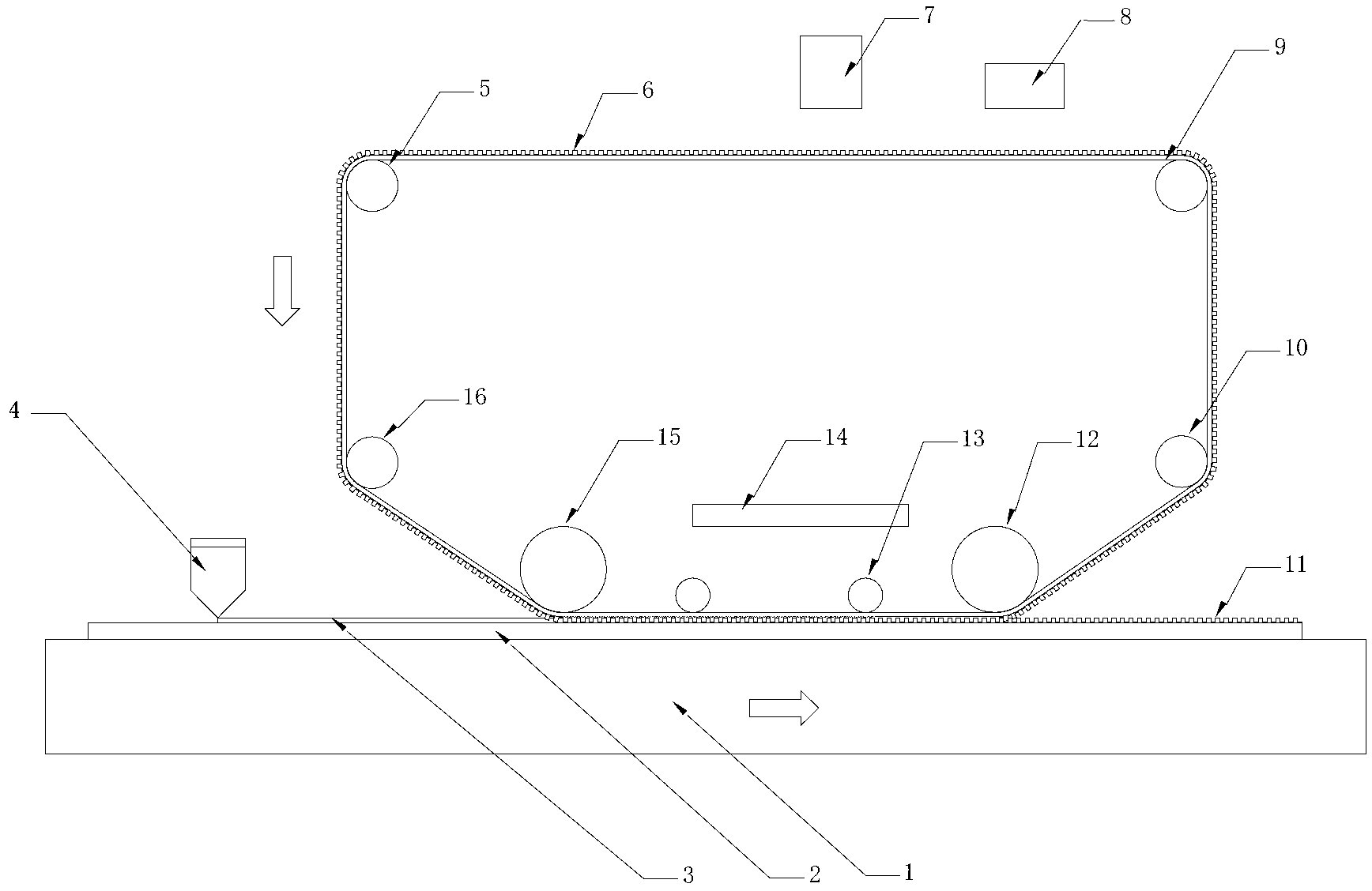

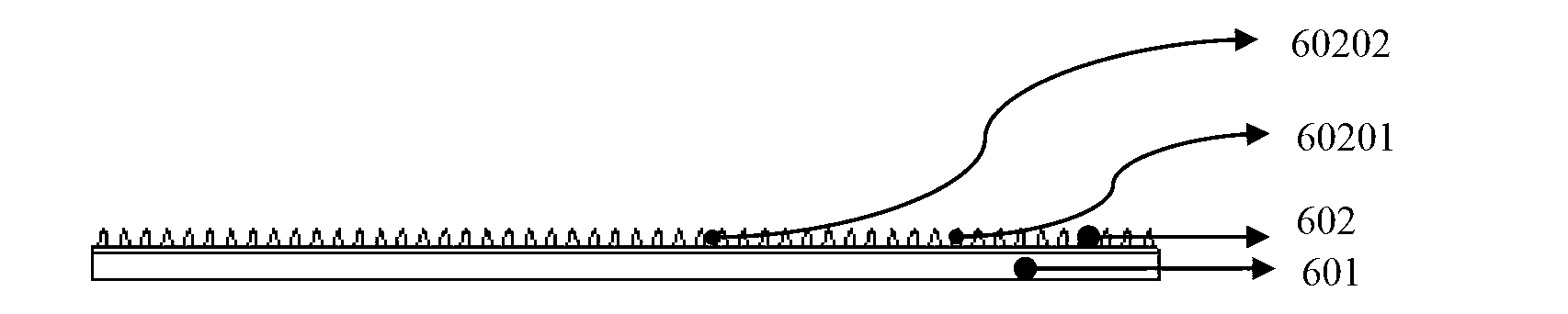

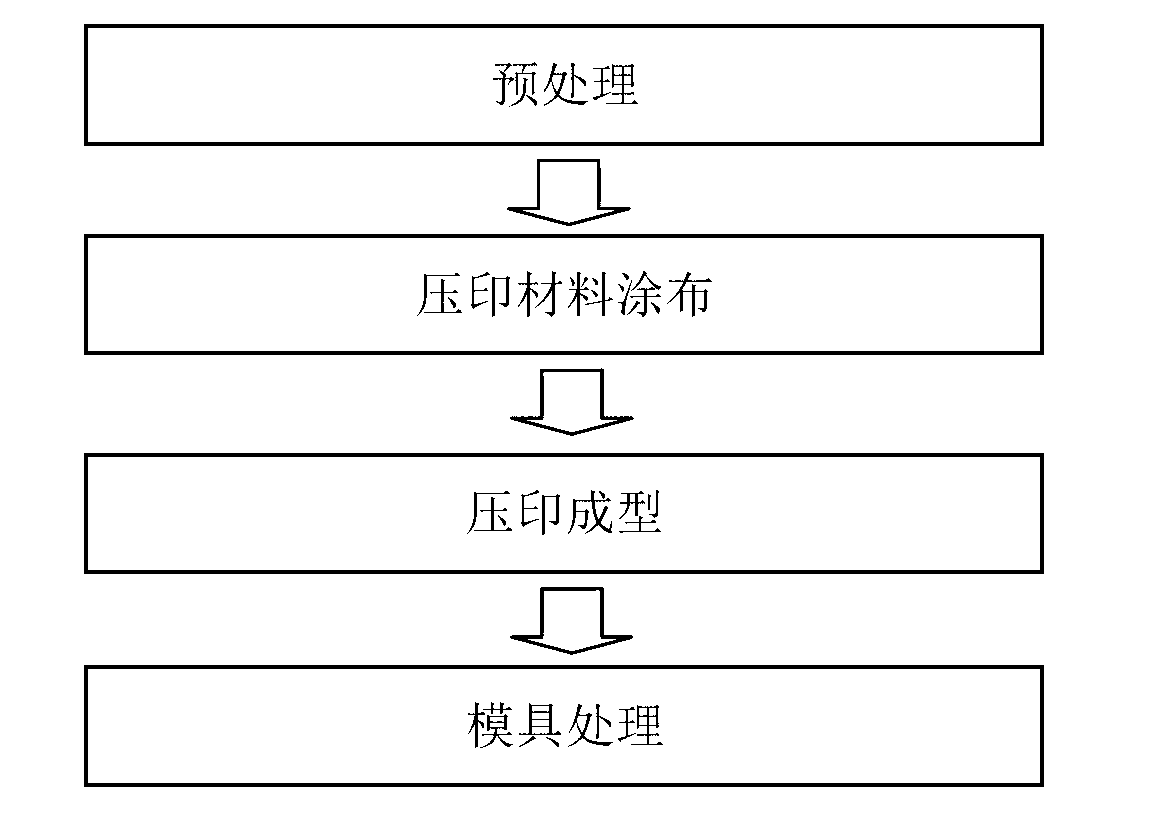

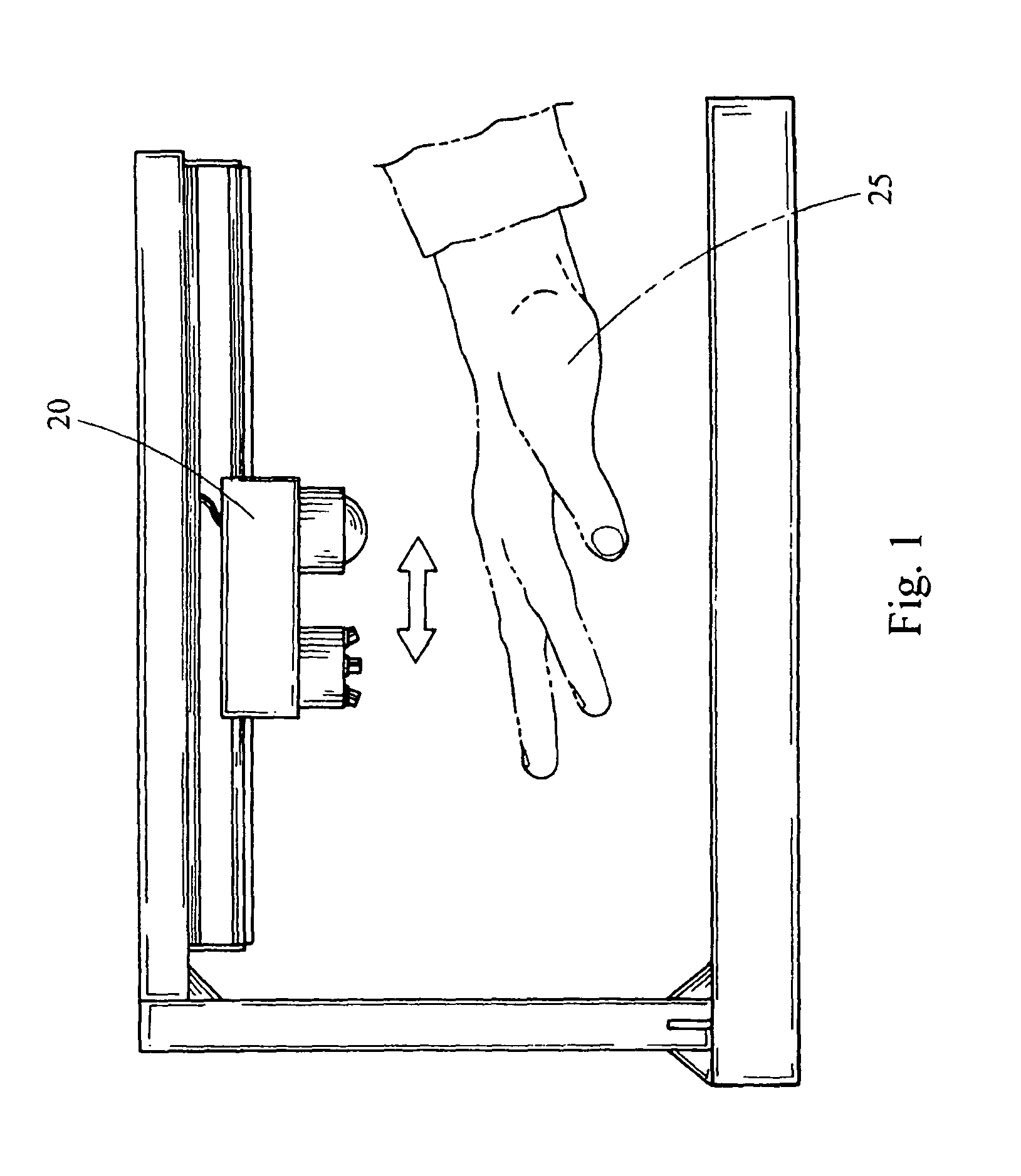

Large-area nanometer imaging device and large-area nanometer imaging method

ActiveCN103235483ASolution to short lifeEasy maintenanceDecorative surface effectsPhotomechanical apparatusUltravioletEngineering

The invention discloses a large-area nanometer imaging device and a large-area nanometer imaging method. The device comprises a piece-supporting platform, a substrate, a coating device, mould feeding devices, a belt-shaped module, a release agent spraying device, a module cleaning device, an auxiliary impression device, an UV (Ultraviolet) solidifying device, an impression device and the like. The method for realizing large-area nanometer imaging based on the device comprises the following steps of: (1) pretreating; (2) coating an impression material; (3) performing impression molding; and (4) processing a mould. The large-area nanometer imaging device and the large-area nanometer imaging method, provided by the invention, have the advantages that a nanostructure on a non-smooth rigidity line with an oversized size is manufactured in an efficient and low-cost large-scale manner, an industrial-grade solution is provided for large-area nanometer imaging of a large-size rigidity substrate, and the large-area nanometer imaging device and the large-area nanometer imaging method are applied in industry large-scale manufacture such as high-performance glass, solar panels, panel displays, micro-optics devices and LEDs (light-emitting diodes).

Owner:QINGDAO BONA PHOTOELECTRIC EQUIP

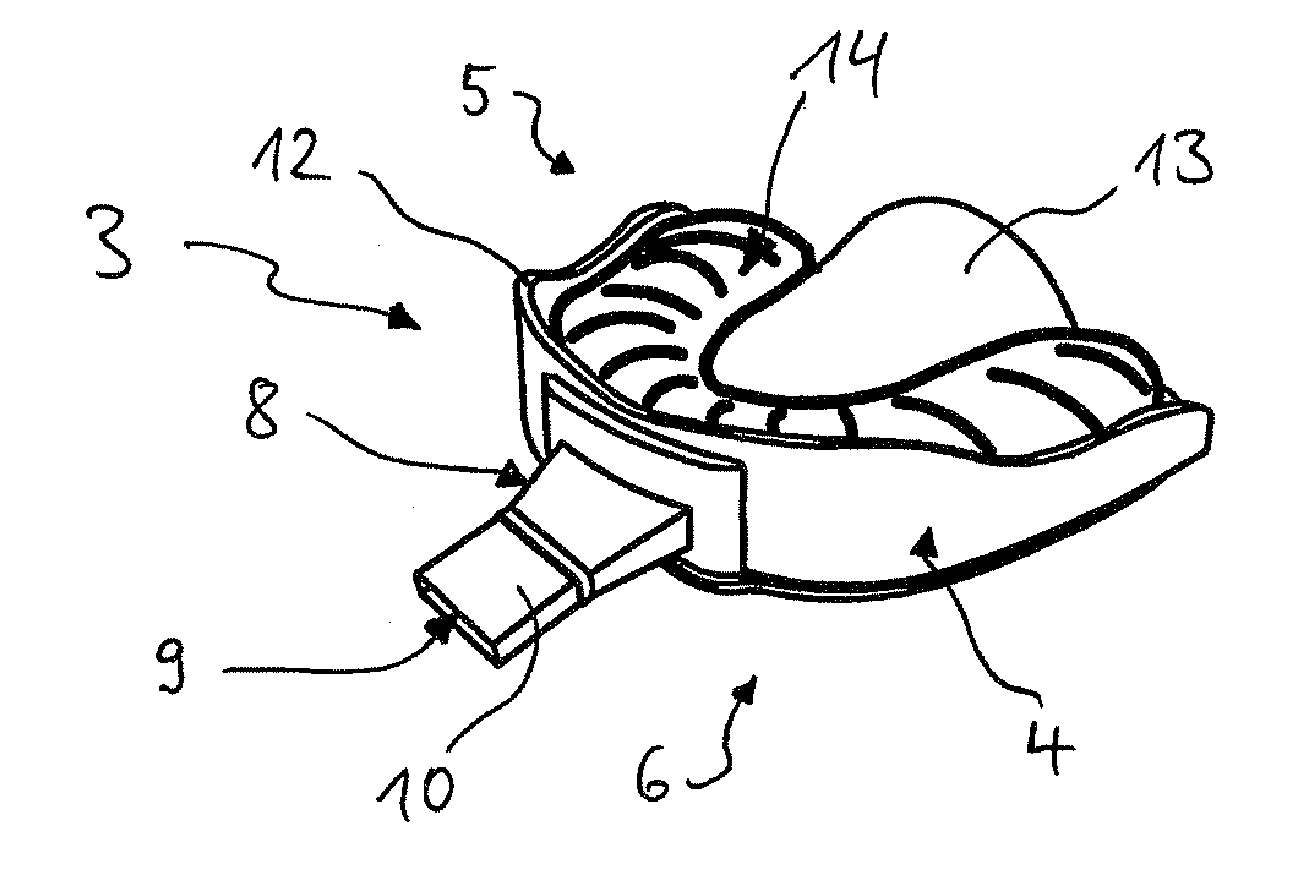

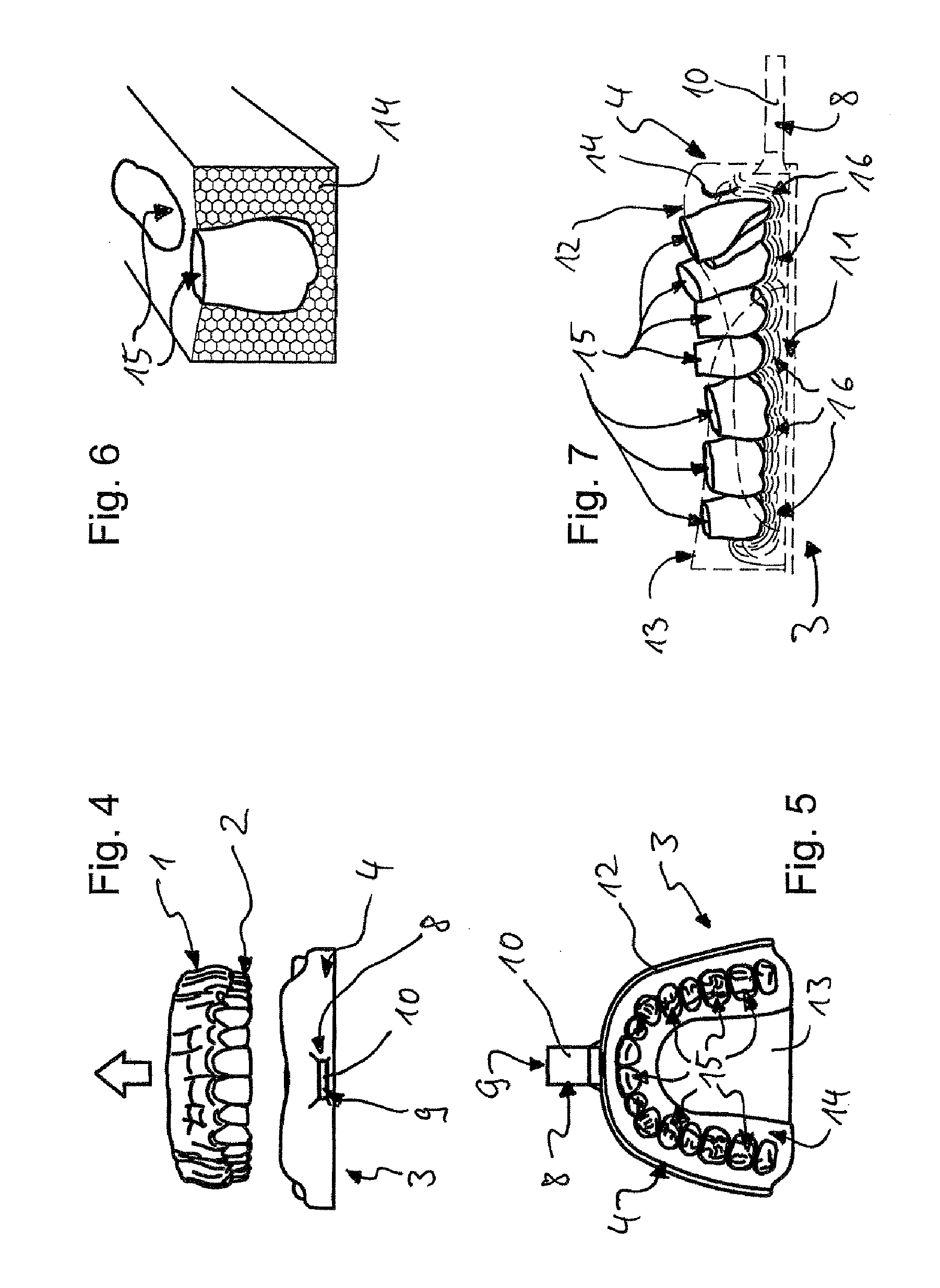

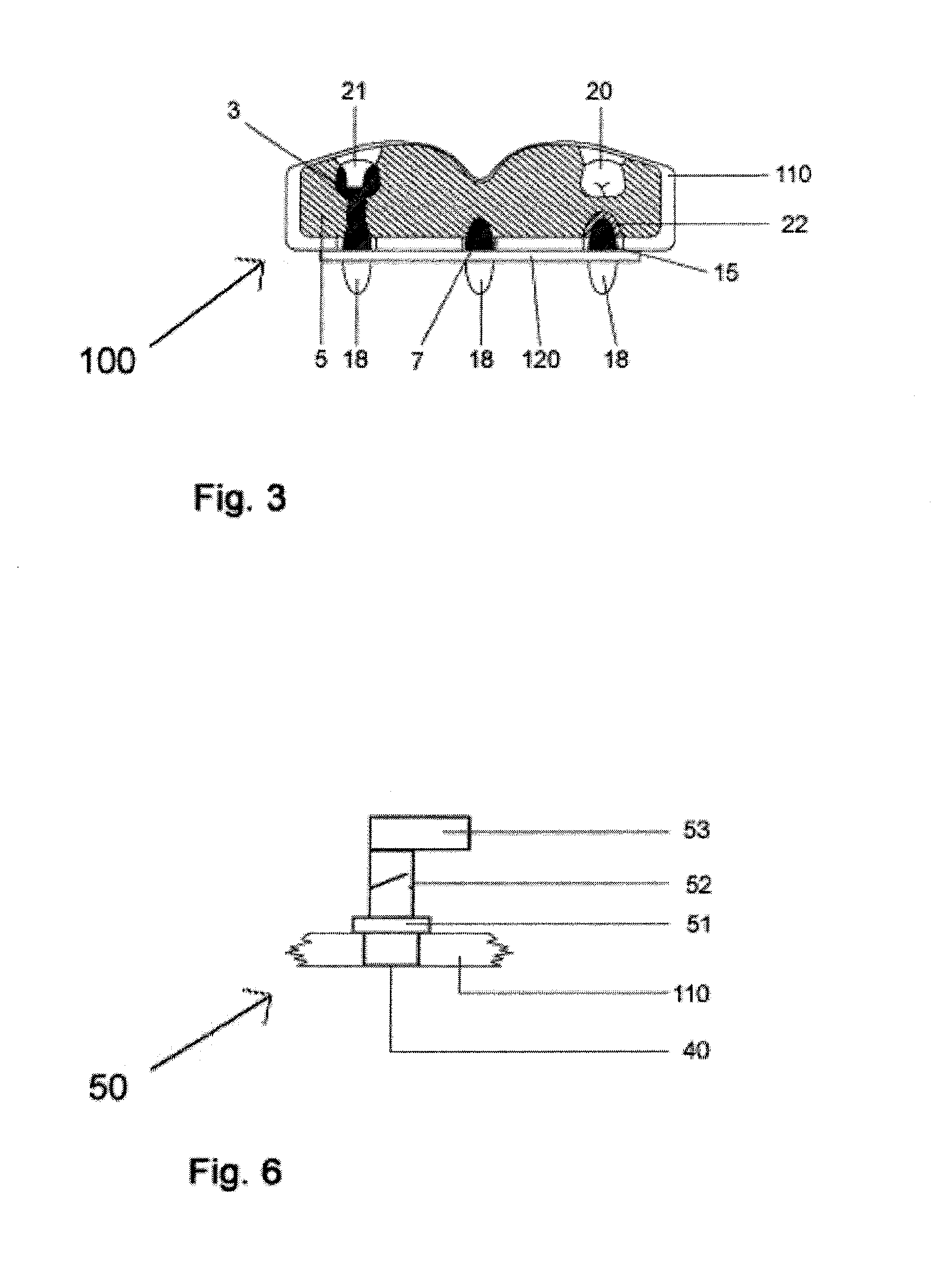

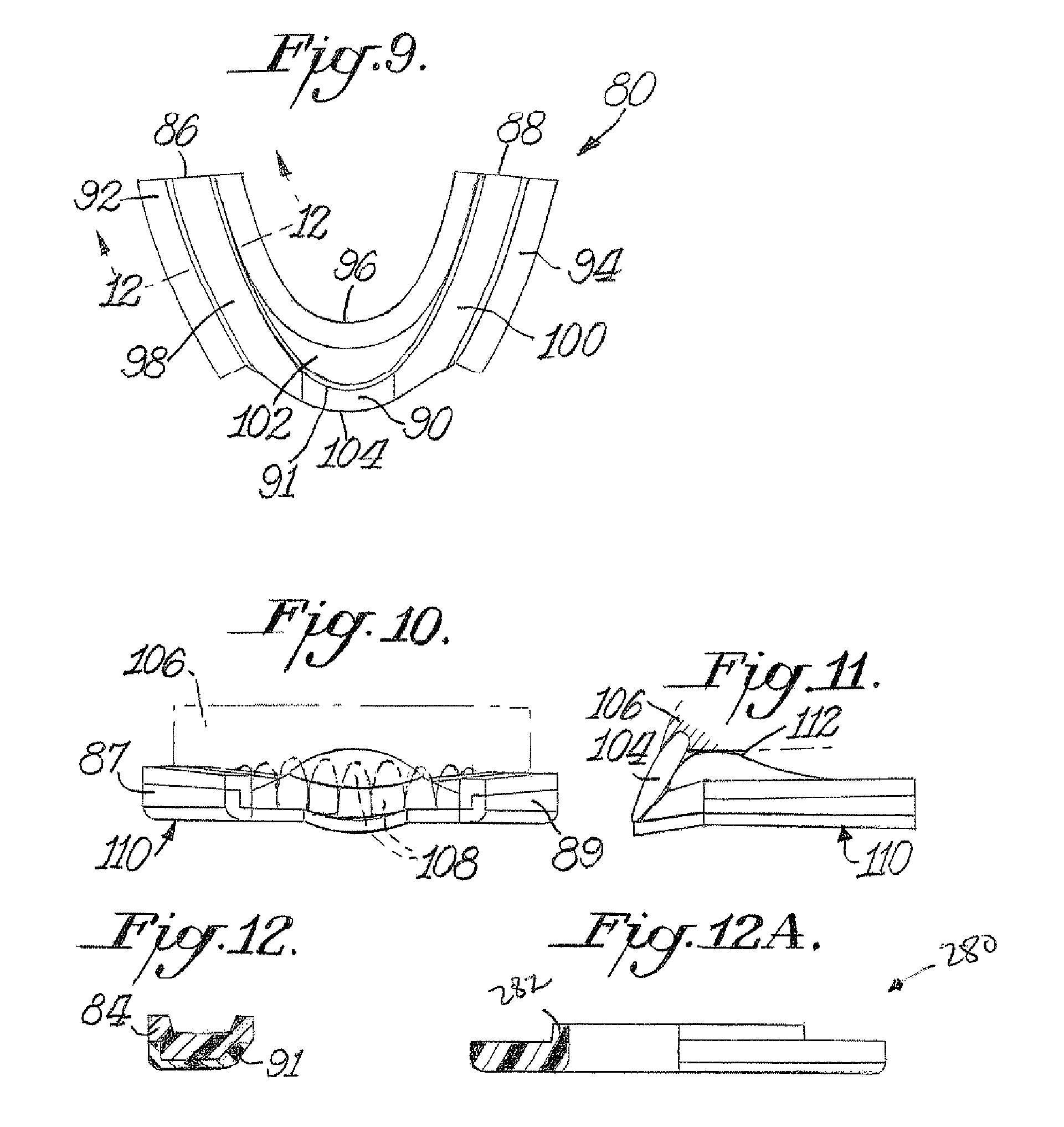

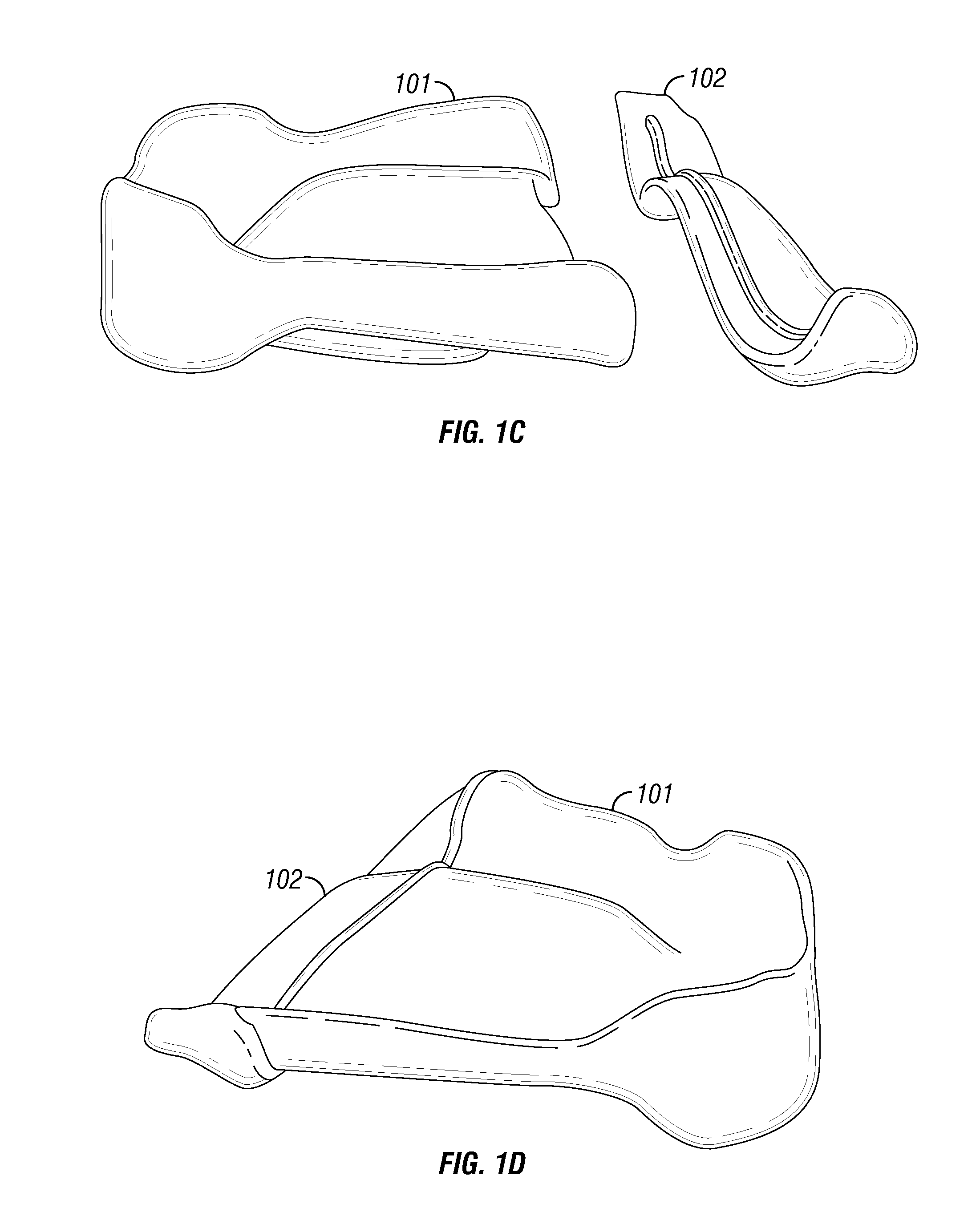

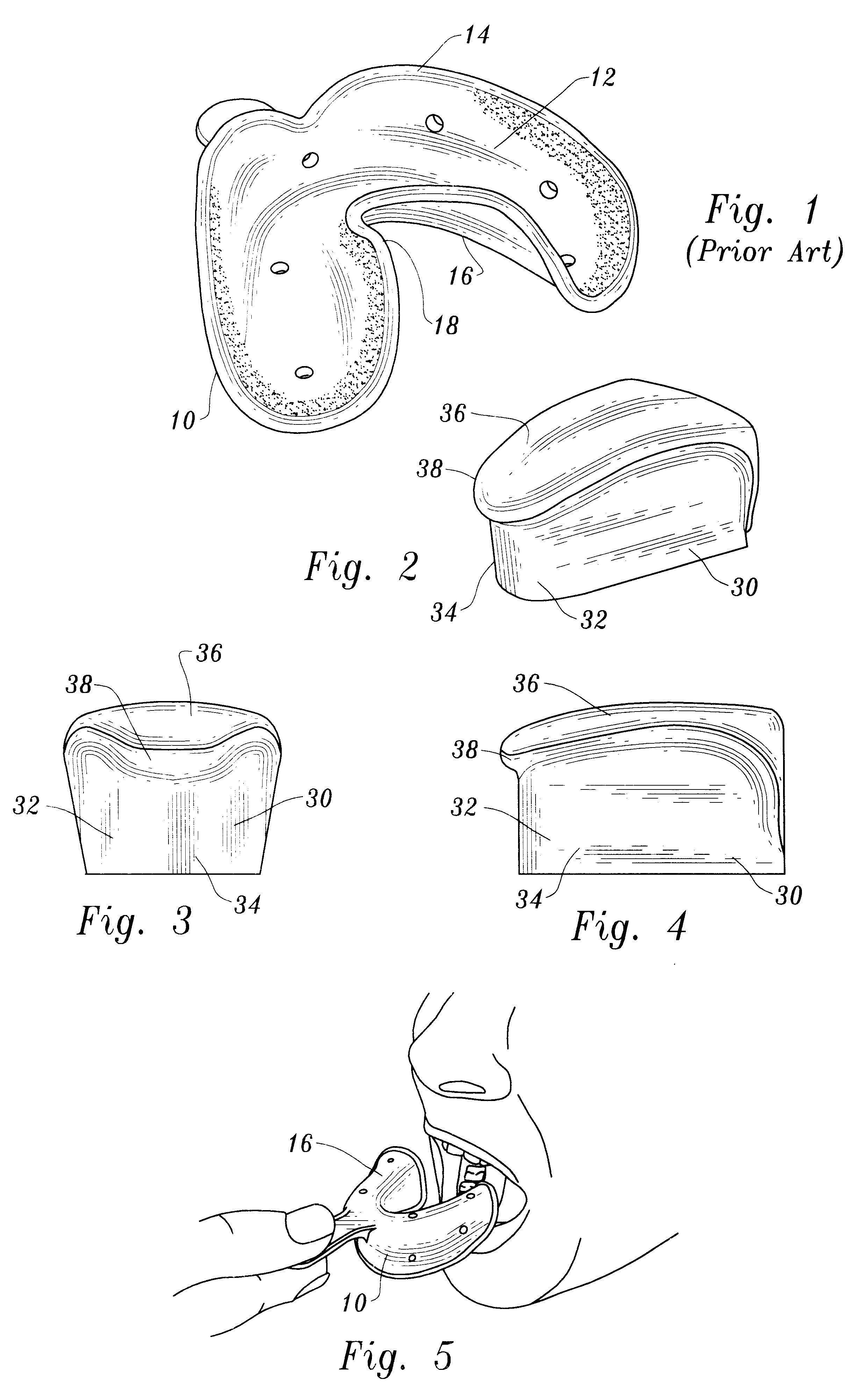

Interocclusal appliance and method

ActiveUS7658193B2Color be alteredHardness be alteredImpression capsOthrodonticsInterocclusal appliancePermlastic

An interocclusal appliance is formed from a single polymer material composition as one unitary piece or from multiple polymer material compositions as a two-piece preform. The two-piece preform includes a base material and an impression material that has a softening point lower than the base material. Teeth are received into the heat-softened impression material, so as to contour the impression material. A portion of the impression material also may contour to a portion of the user's palate. In certain embodiments, substantially no polymeric material contacts the front surfaces of the front teeth, leading to greater comfort and better air flow between front teeth. In still another embodiment, the appliance fits over front teeth only and no polymeric material contacts the maxillary molars.

Owner:HAYLOFT ENTERPRISES INC

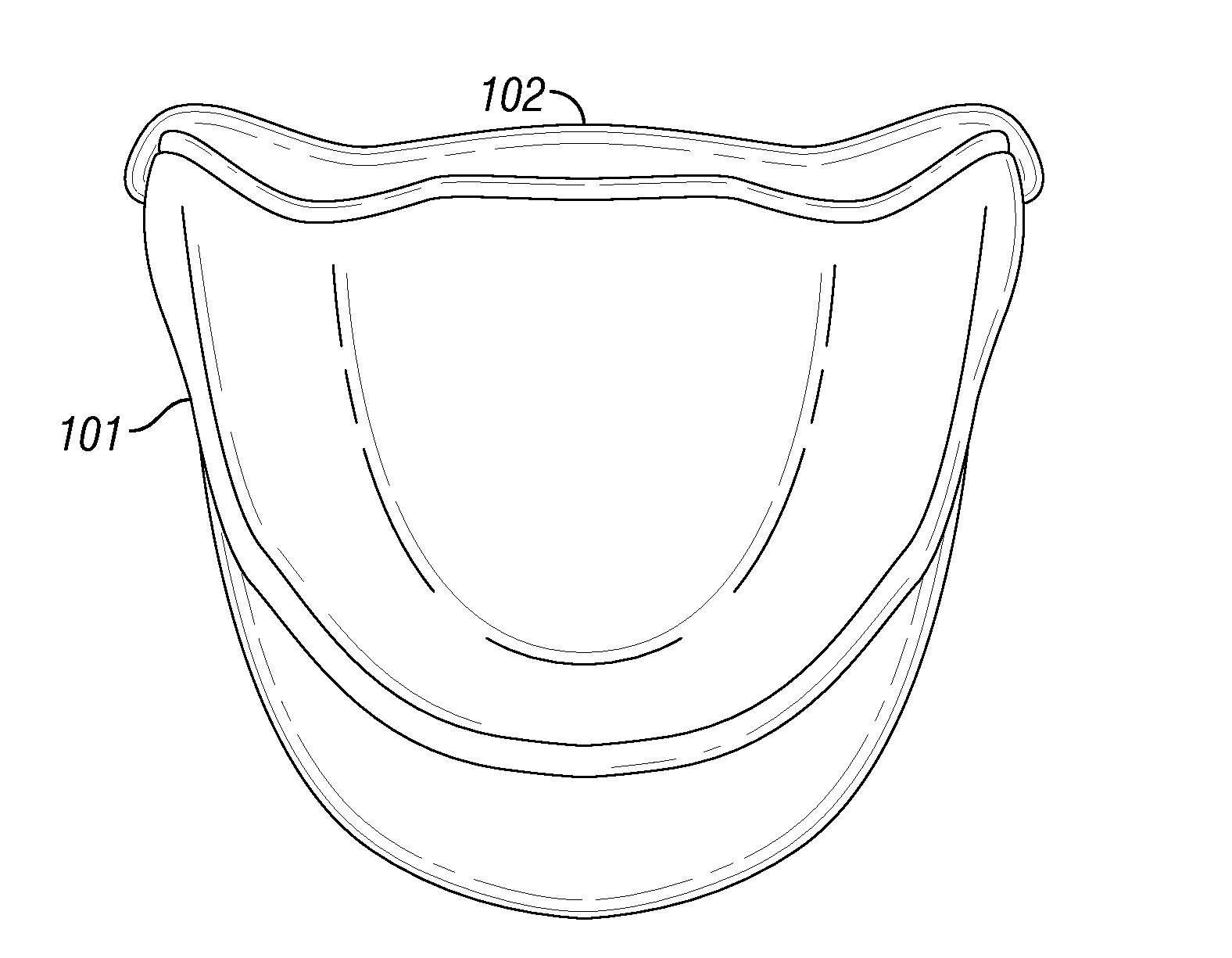

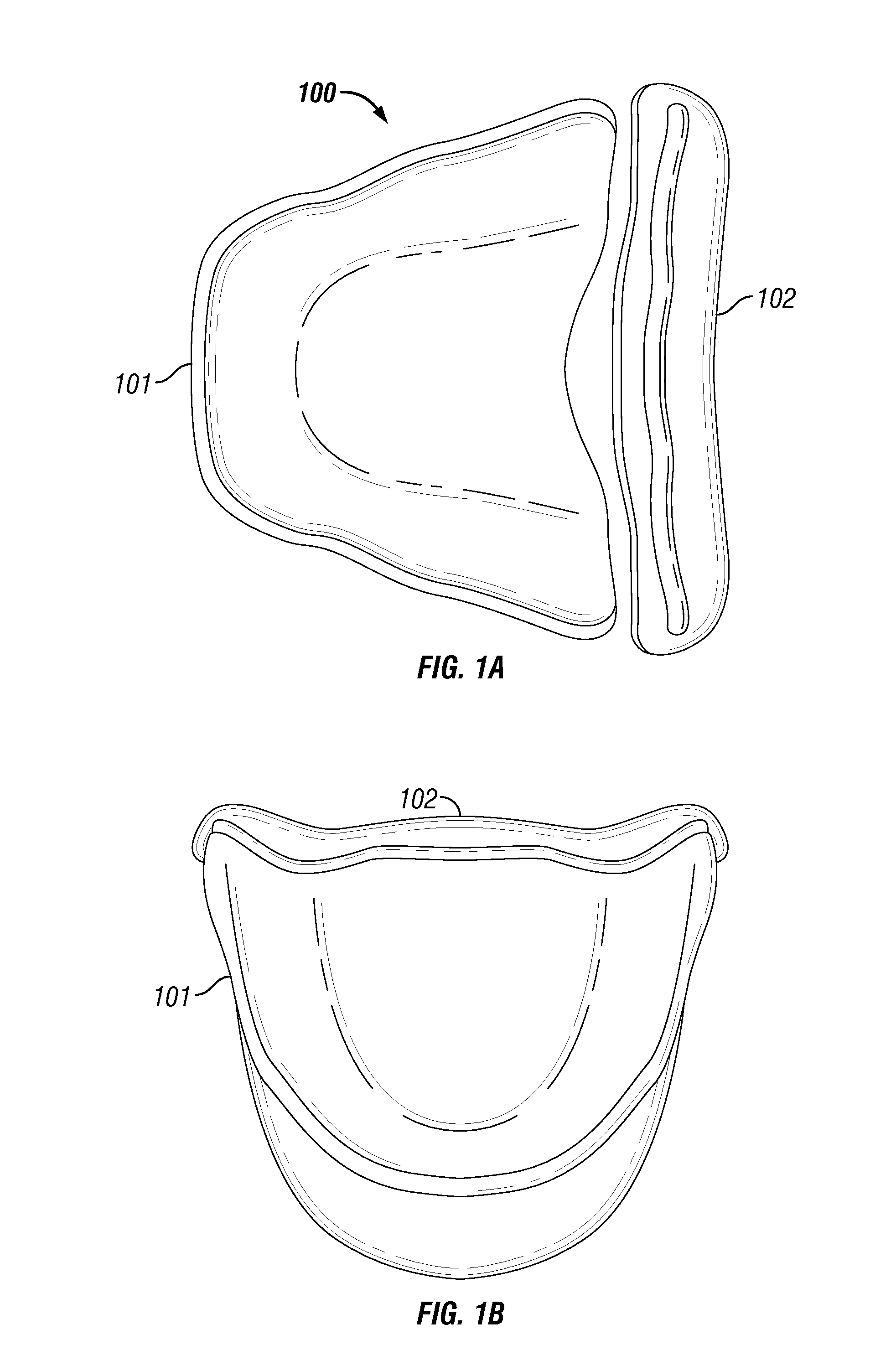

Method and apparatus for preparing denture

ActiveUS20100297572A1Made preciselyLow costImpression capsArtificial teethDenturesImpressions materials

A dental impression tray assembly includes an upper tray and a lower tray operable with the upper tray, and the lower tray includes a first piece configured to measure jaw relations of a patient's mouth and a pair of second pieces detachably attachable to the first piece. The first piece of the lower tray is inserted into the patient's mouth independently of the pair of second pieces of the lower tray to measure the jaw relations and to obtain a bite registration. After the first piece is connected to the pair of second pieces, the assembly allows a final gum impression of the patient's lower gum to be obtained.

Owner:DENTCA

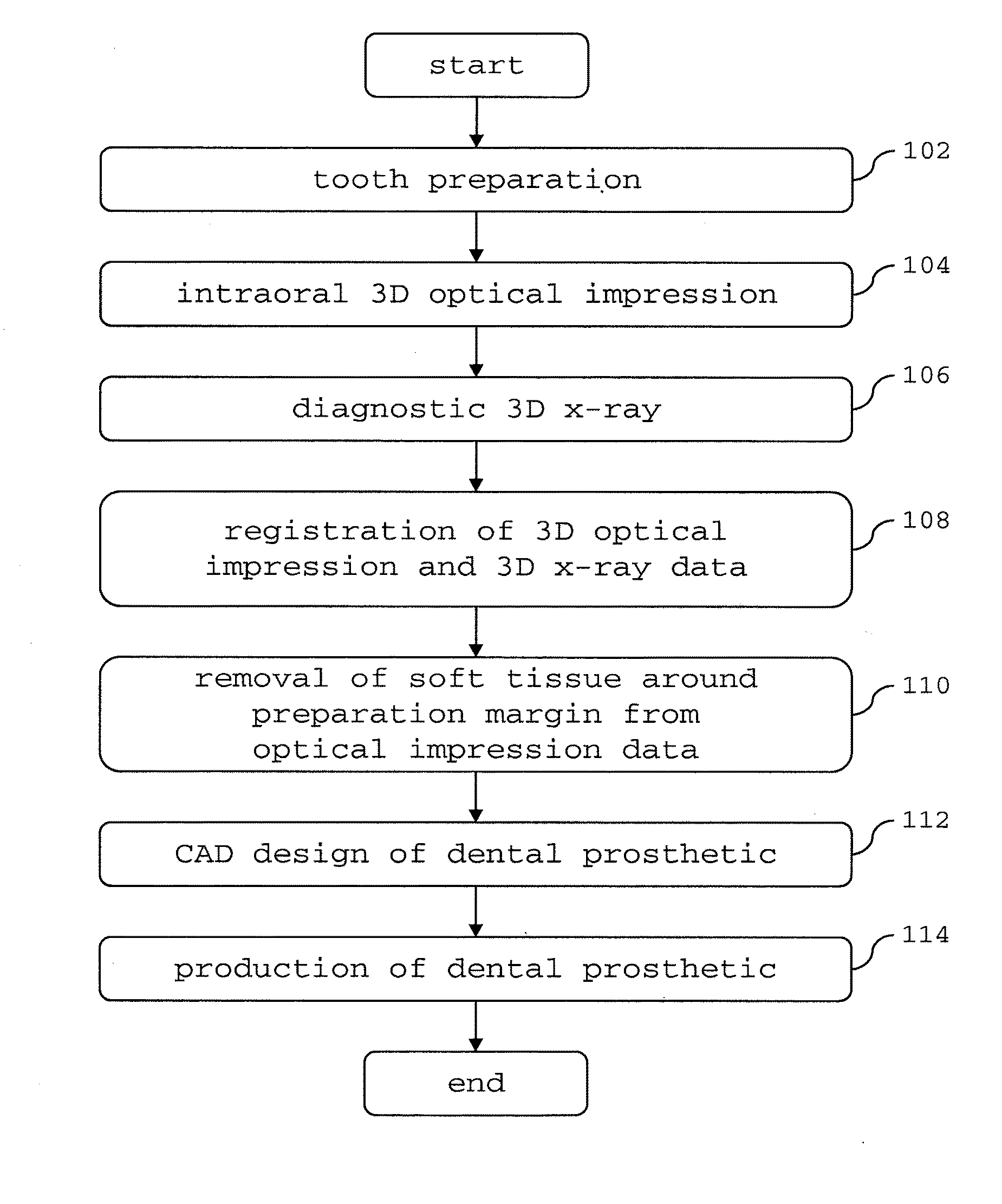

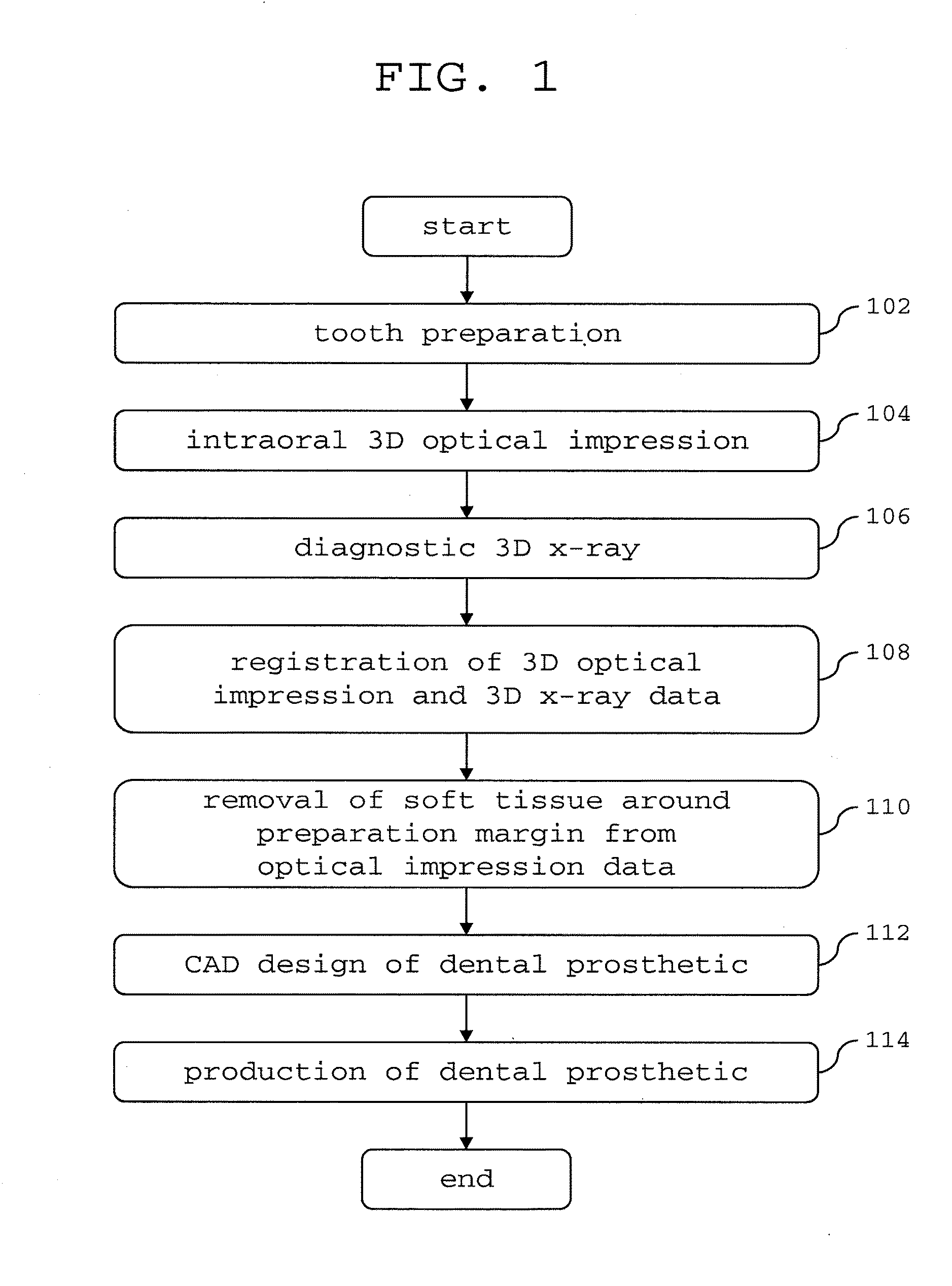

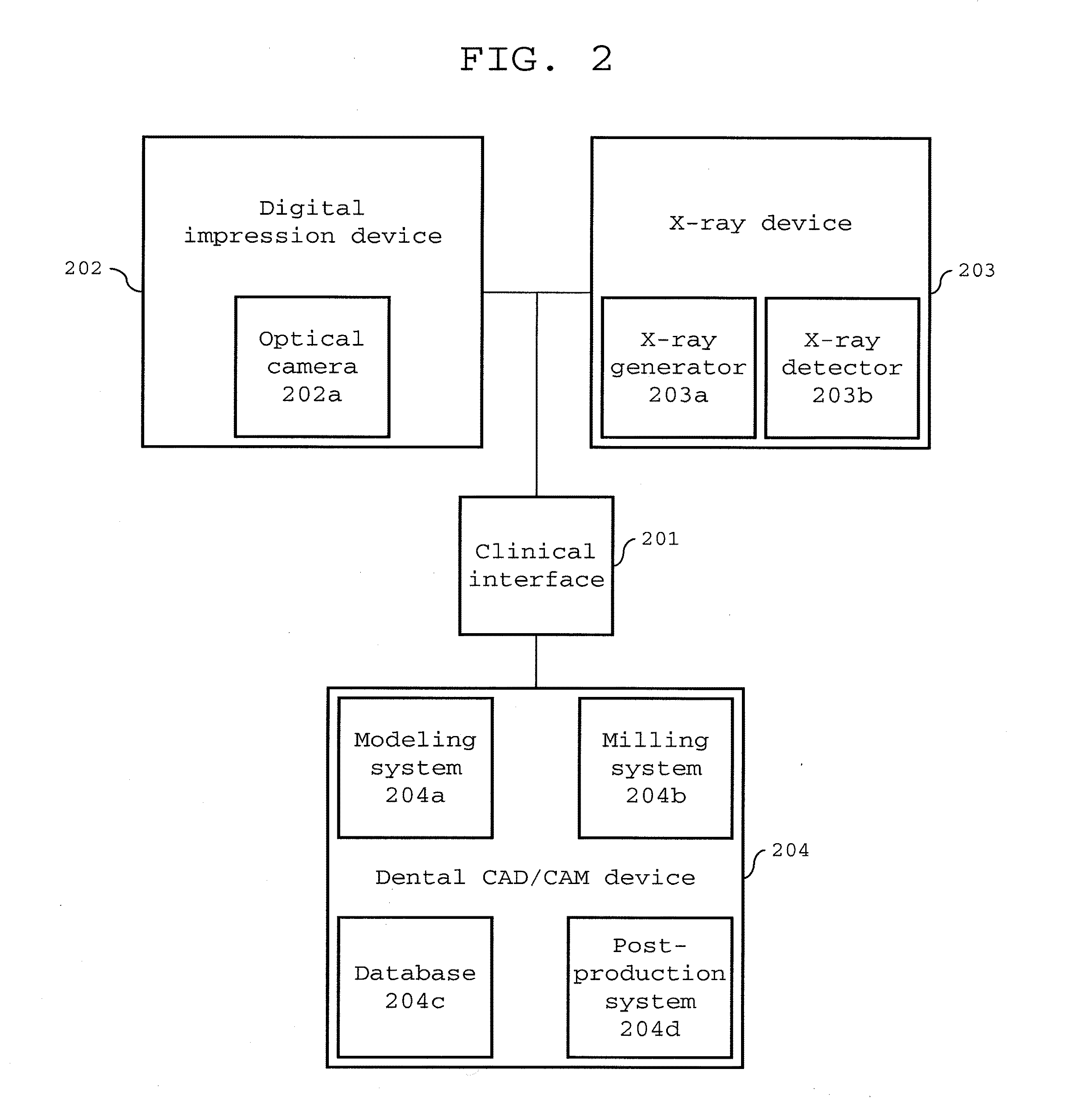

Methods, Apparatuses, Computer Programs, and Systems for Creating a Custom Dental Prosthetic Using CAD/CAM Dentistry

A procedure for creating a dental prosthetic includes registering three-dimensional (3D) dental impression image data of a tooth restoration site and 3D x-ray image data of the tooth restoration site, and removing image data corresponding to soft tissue in the tooth restoration site from the 3D dental impression image data. A system for producing a dental prosthetic includes at least one processor operable to register 3D dental impression image data of a tooth restoration site and 3D x-ray image data of the tooth restoration site and remove image data corresponding to soft tissue in the tooth restoration site from the 3D dental impression image data.

Owner:SIRONA DENTAL SYSTEMS

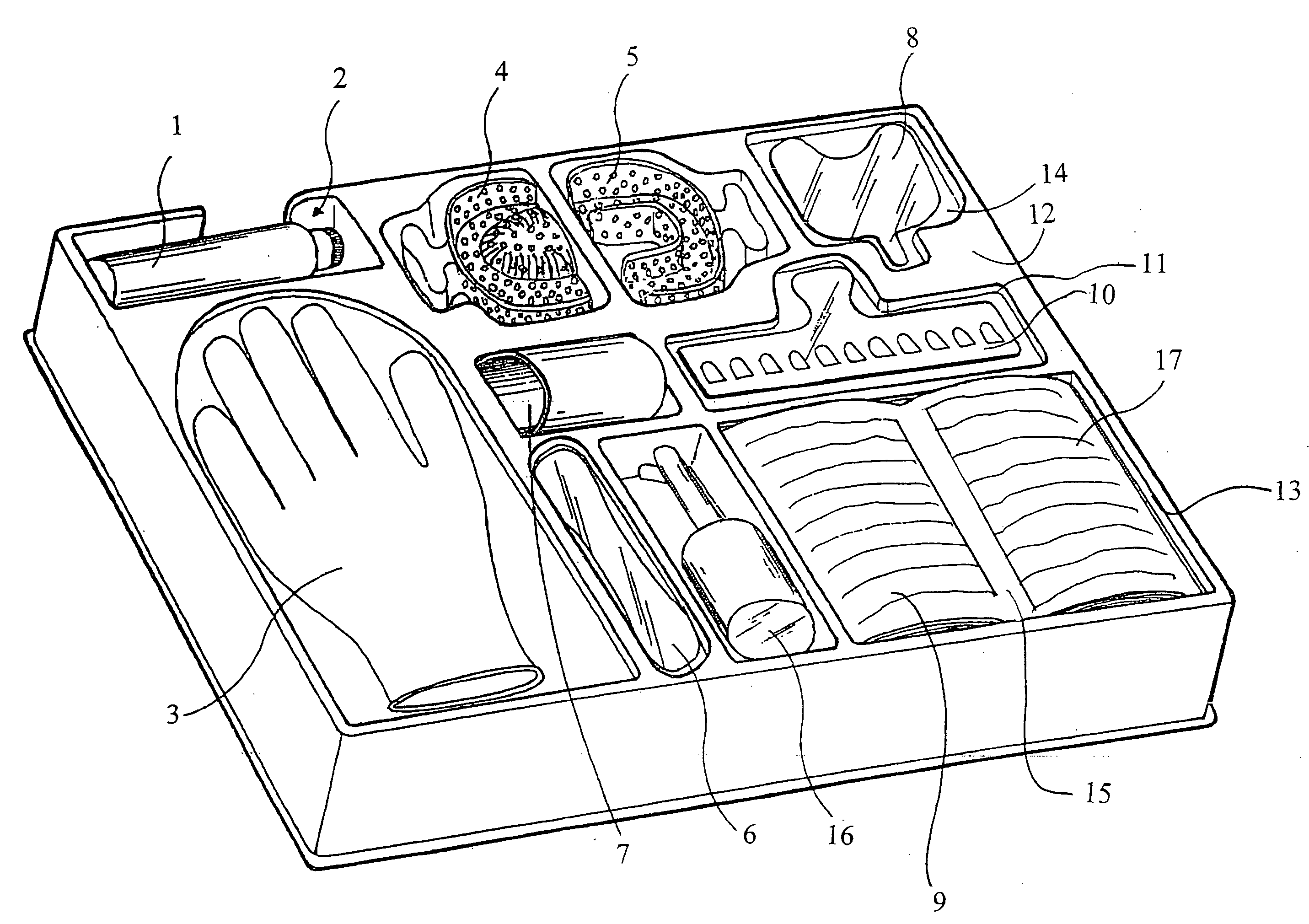

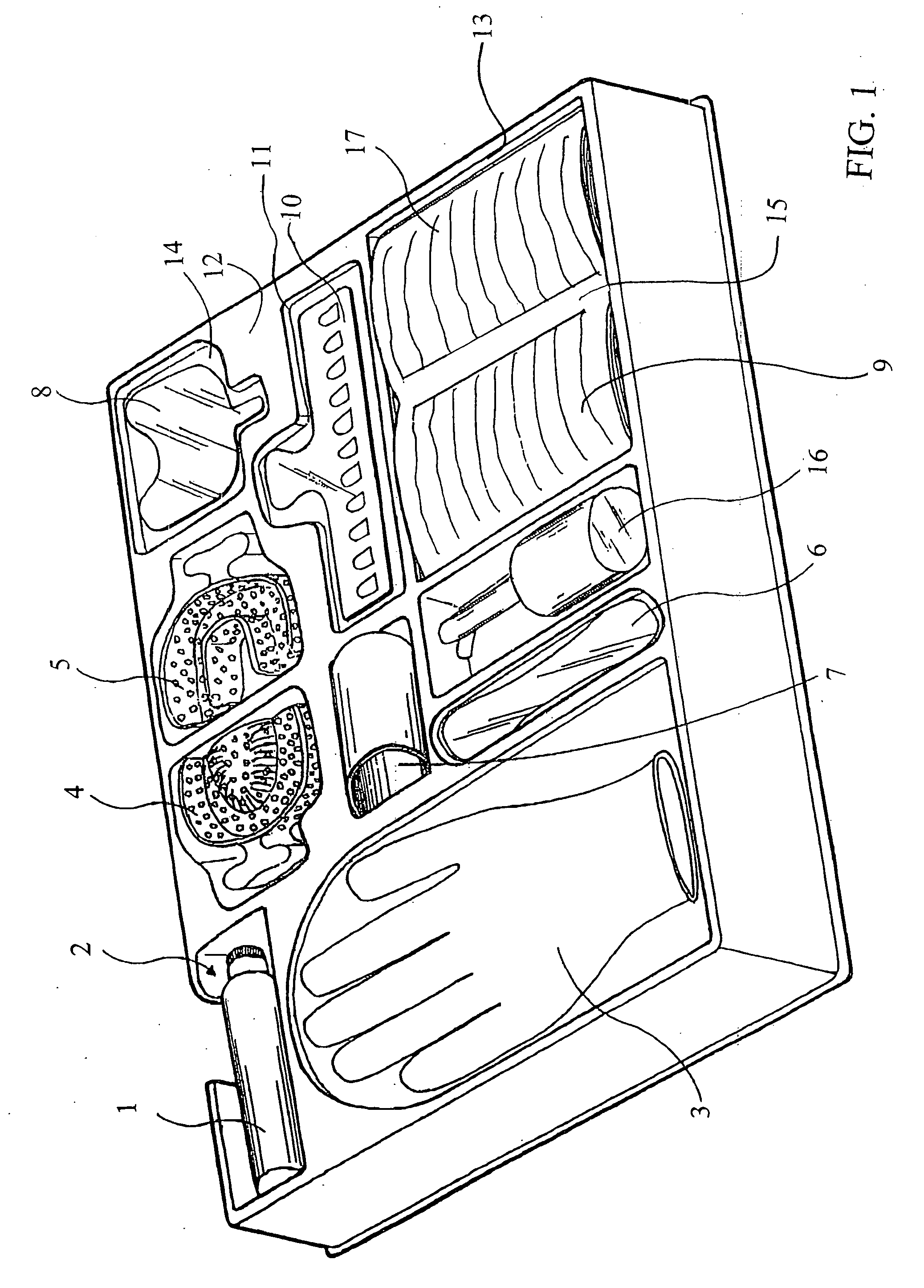

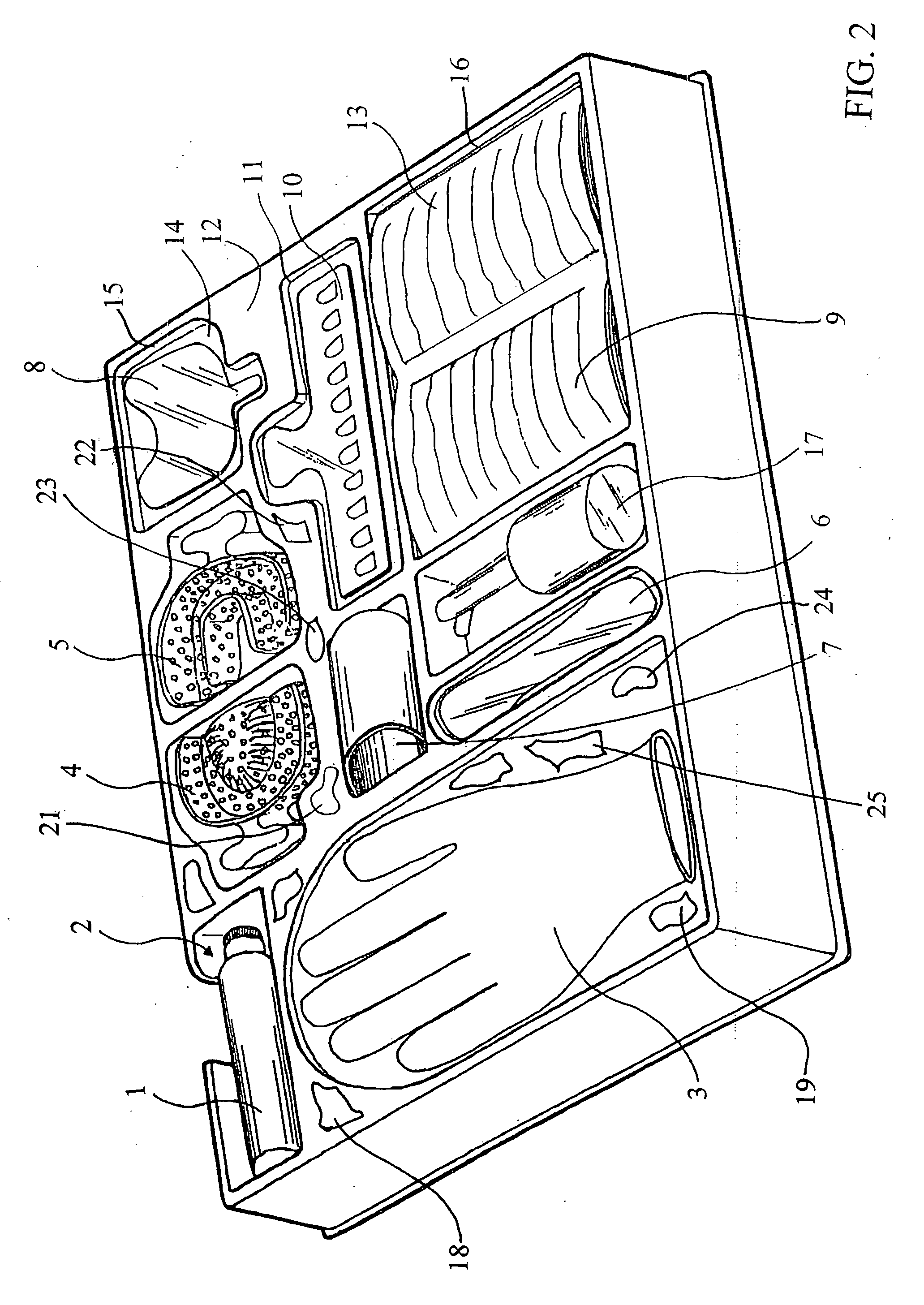

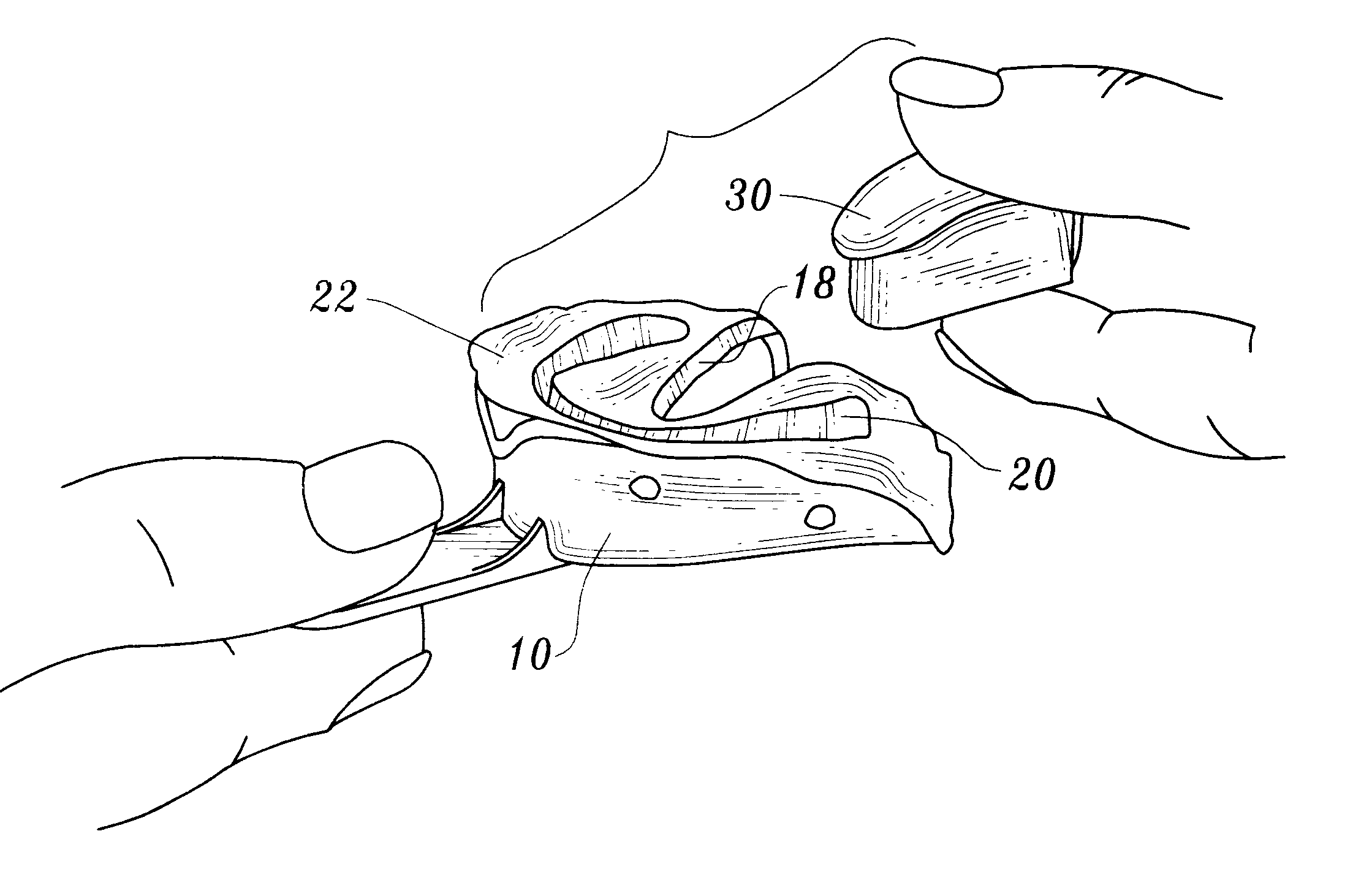

Kit for fabricating and maintaining dentures and dental apparatus and for personal professional tooth whitening by autonomous dental impression taking

InactiveUS20080308450A1Cost delayDelay in fabricationGum massageDiagnosticsDental instrumentsDentures

Owner:TCHOUANGANG LYDIE LIVOLSI

System for forming dental impressions

A block member is selectively positioned on a dental impression tray with an outer engagement surface of the block member in engagement with the tray portion defining a lingual recess to block entry of plaster or other casting material into the lingual recess.

Owner:MAYWEATHER GEORGE S

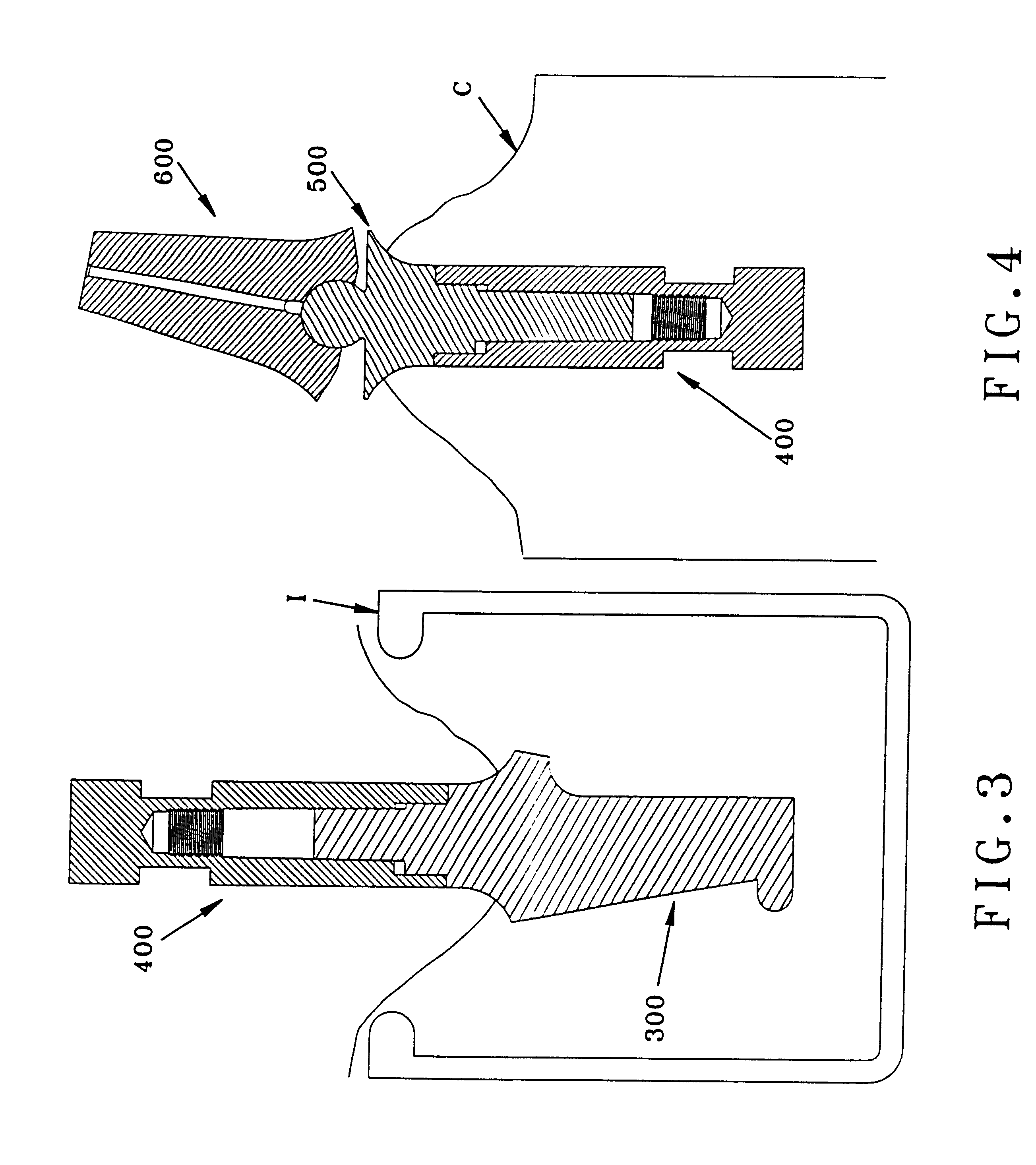

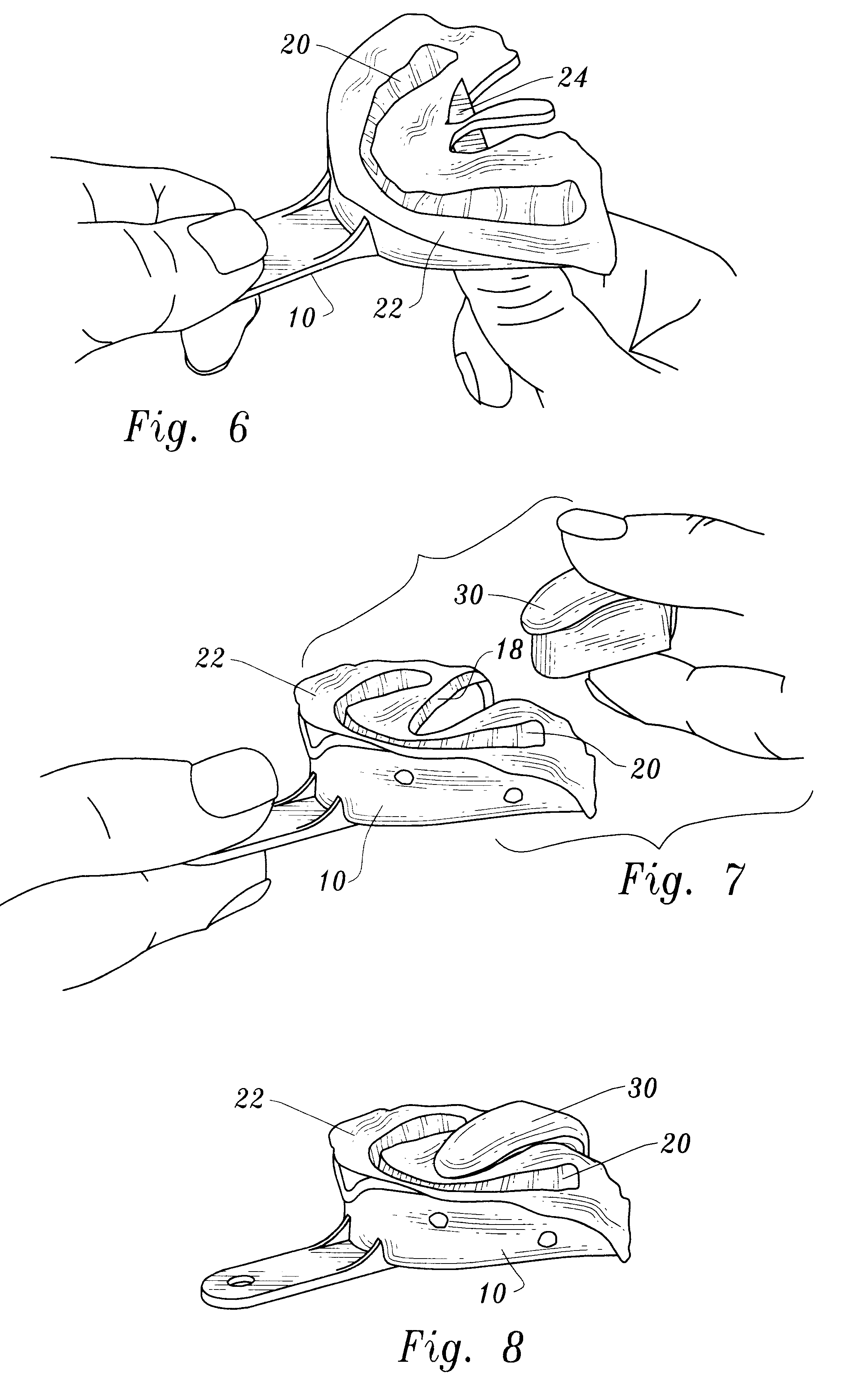

Preparation coping for creating an accurate permanent post to support a final prosthesis and method for creating the same

InactiveUS8002547B2Accurate placementAccurate shapeDental implantsImpression capsProsthesisImpressions materials

An implant comprising an internal bore having an opening at one end of the implant is initially fixed within a patient's mouth. A support post on which a final artificial prosthesis will be mounted is attached to the implant by allowing a portion of the post to extend into and attach within the bore of the implant. The post generally extends supragingivally from a base at or beneath the gum surface and contains a retention bulb to assist in registering the axial orientation of an impression cap and the final prosthesis. The impression cap is then placed over the post to assist in taking an impression of the relevant dental region. The impression cap contains means to allow to the retention bulb to snap onto the impression cap. After the impression material is placed to surround the impression cap, post and implant, the impression material and impression cap are removed. A healing cap is placed on the post and acts as a temporary tooth able to last within the patient's mouth for several months.

Owner:BIOMET 3I LLC

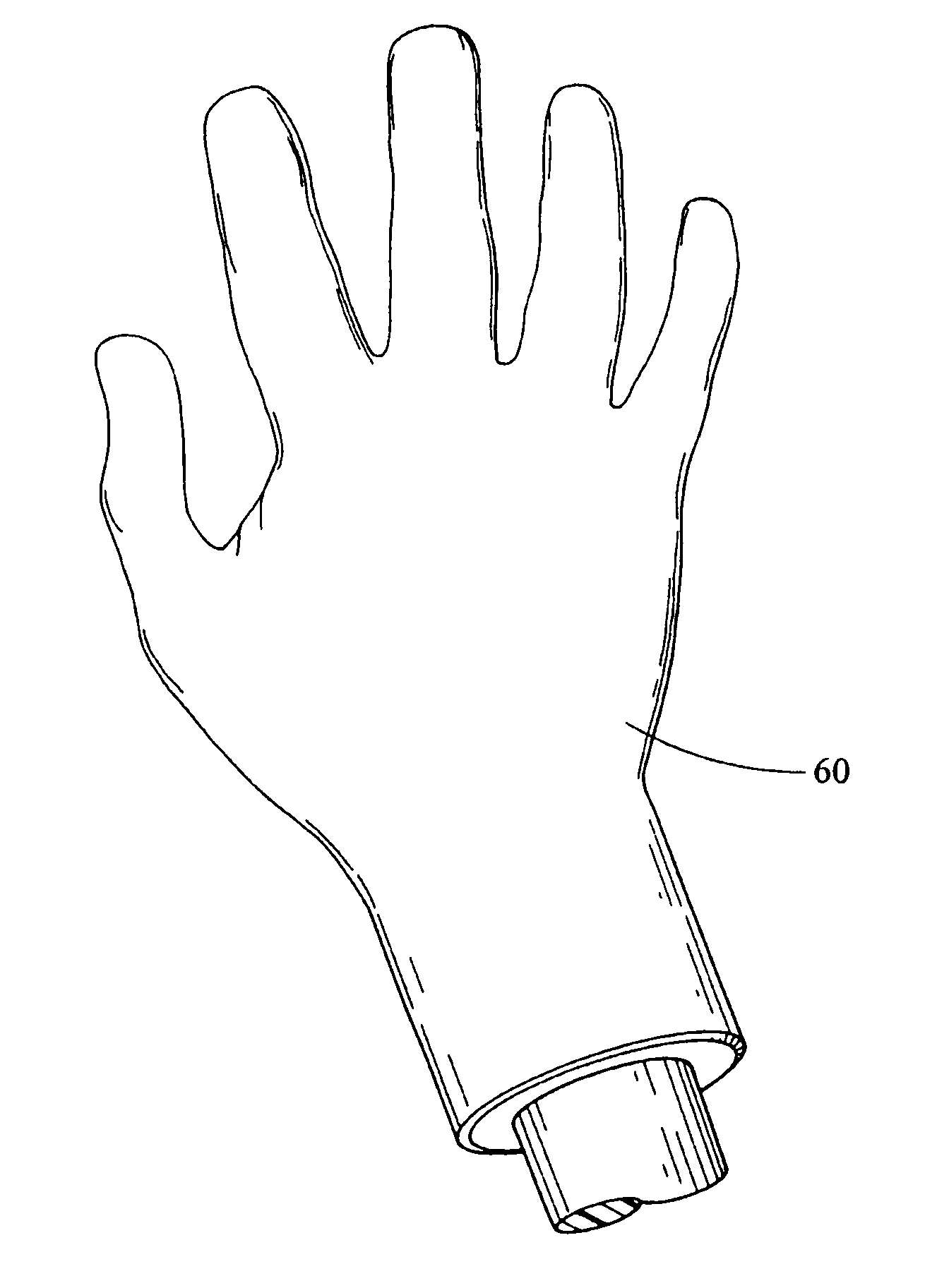

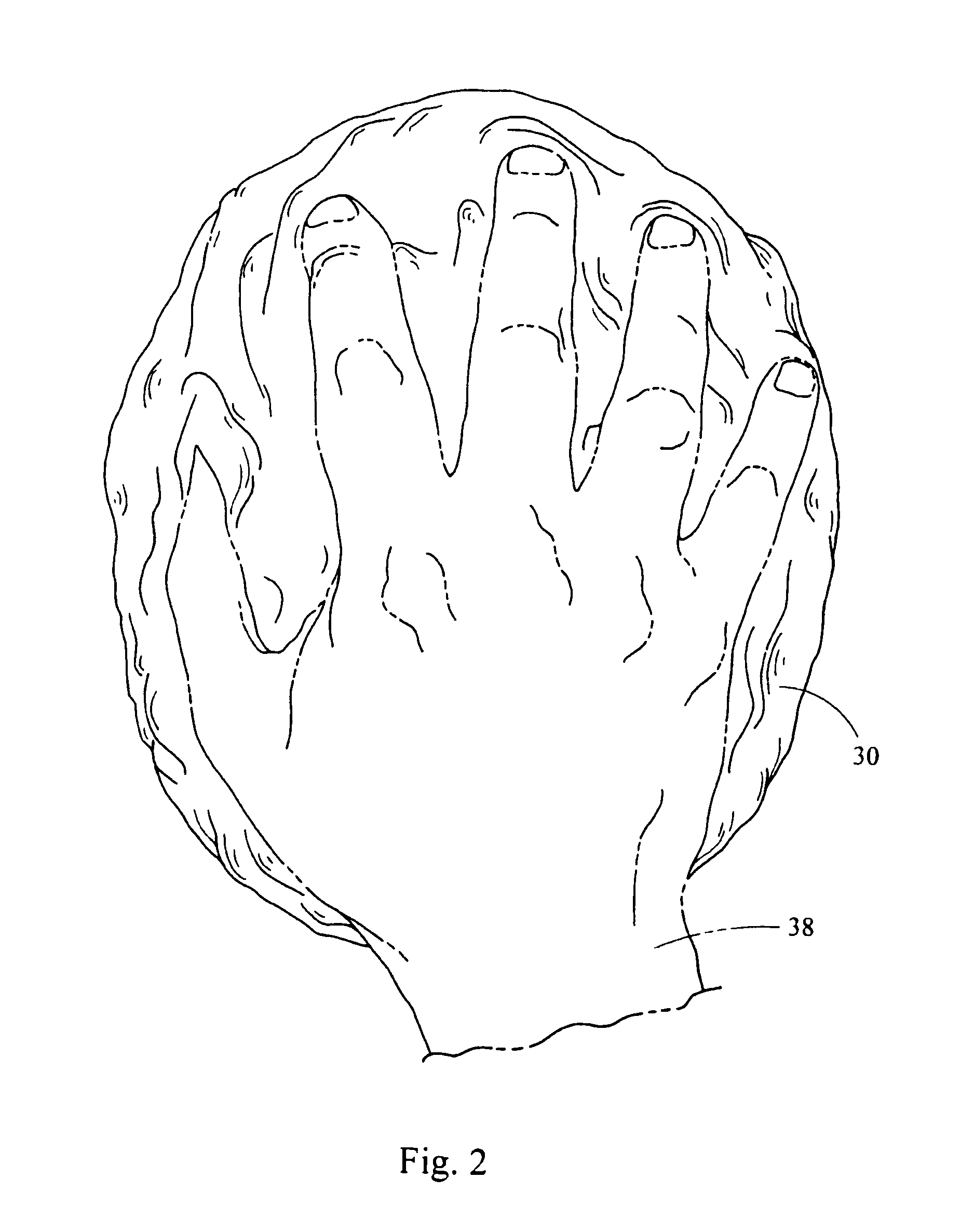

Methods for making customized gloves and formers

A method of making custom glove formers for making custom-fit disposable gloves using a three dimensional camera or laser for taking the dimensions of a user's hand and making a mold therefrom for use in making the custom glove former. Alternatively, the method includes using an impression material for taking an impression of a user's hand to make a mold for use in making the custom glove former. In further embodiments, the method includes using a combination of a three dimensional camera or laser and impression material to make a mold for use in making the custom glove former. The custom glove formers are then used for making the custom-fit disposable gloves.

Owner:MEDLINE IND LP

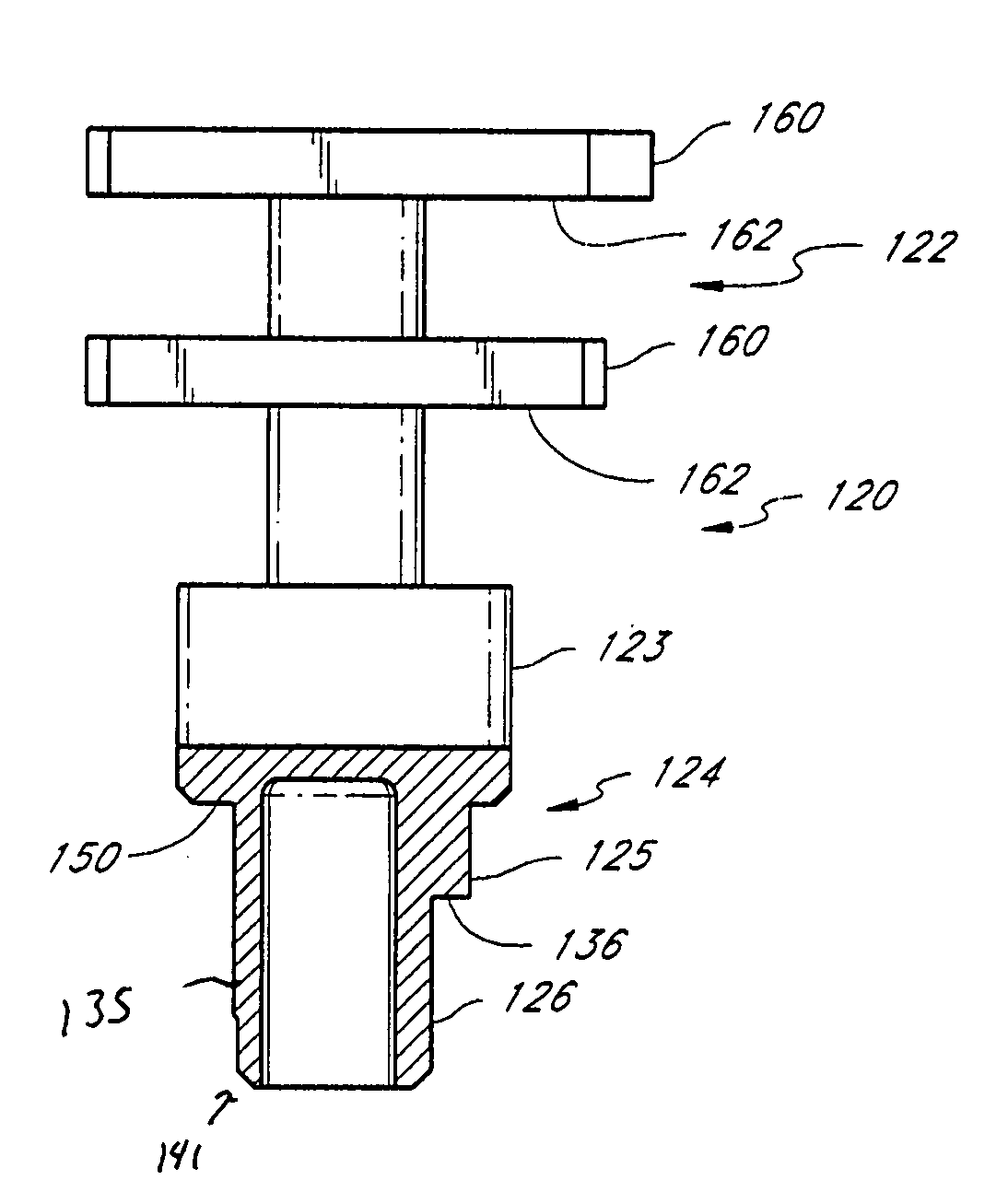

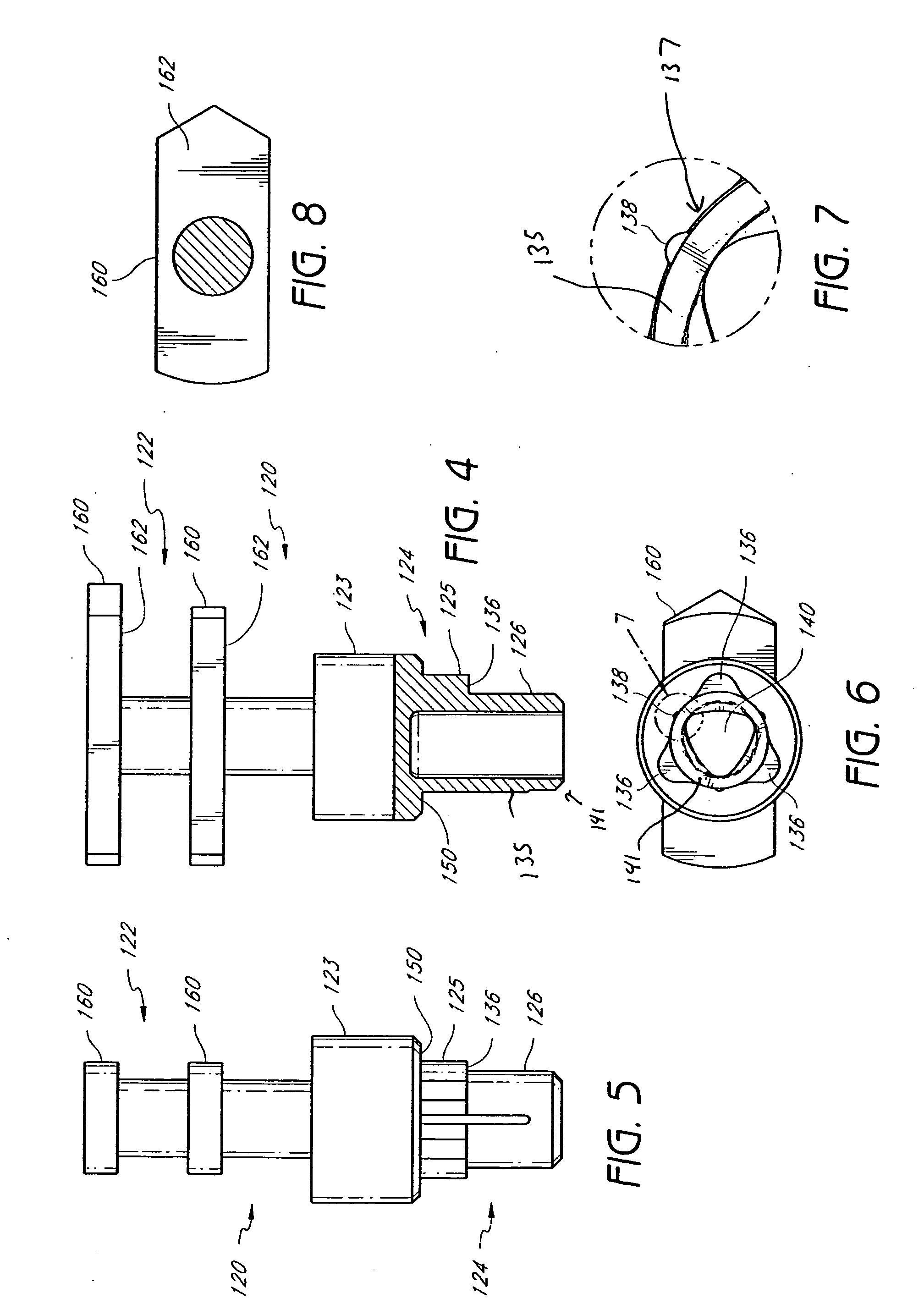

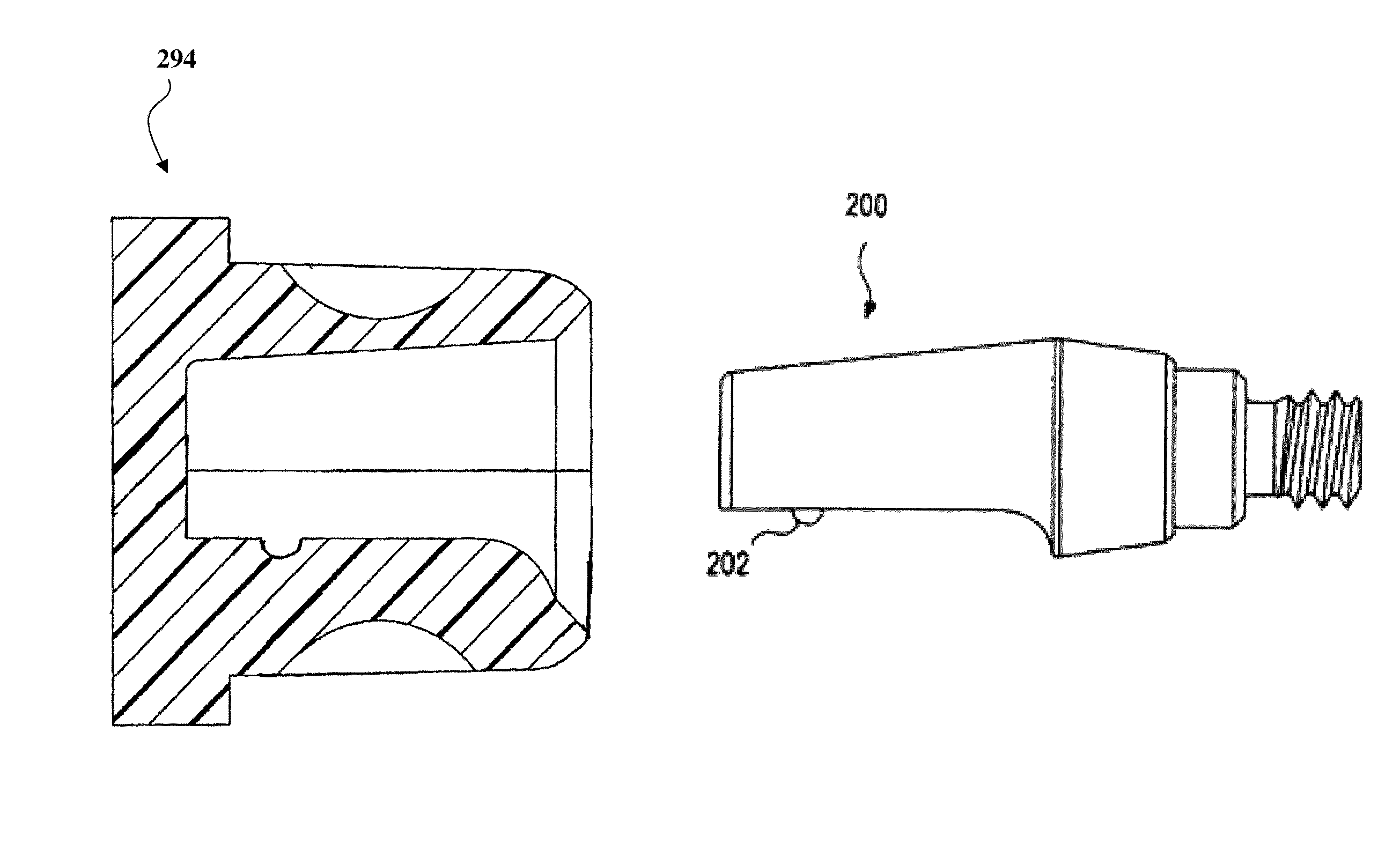

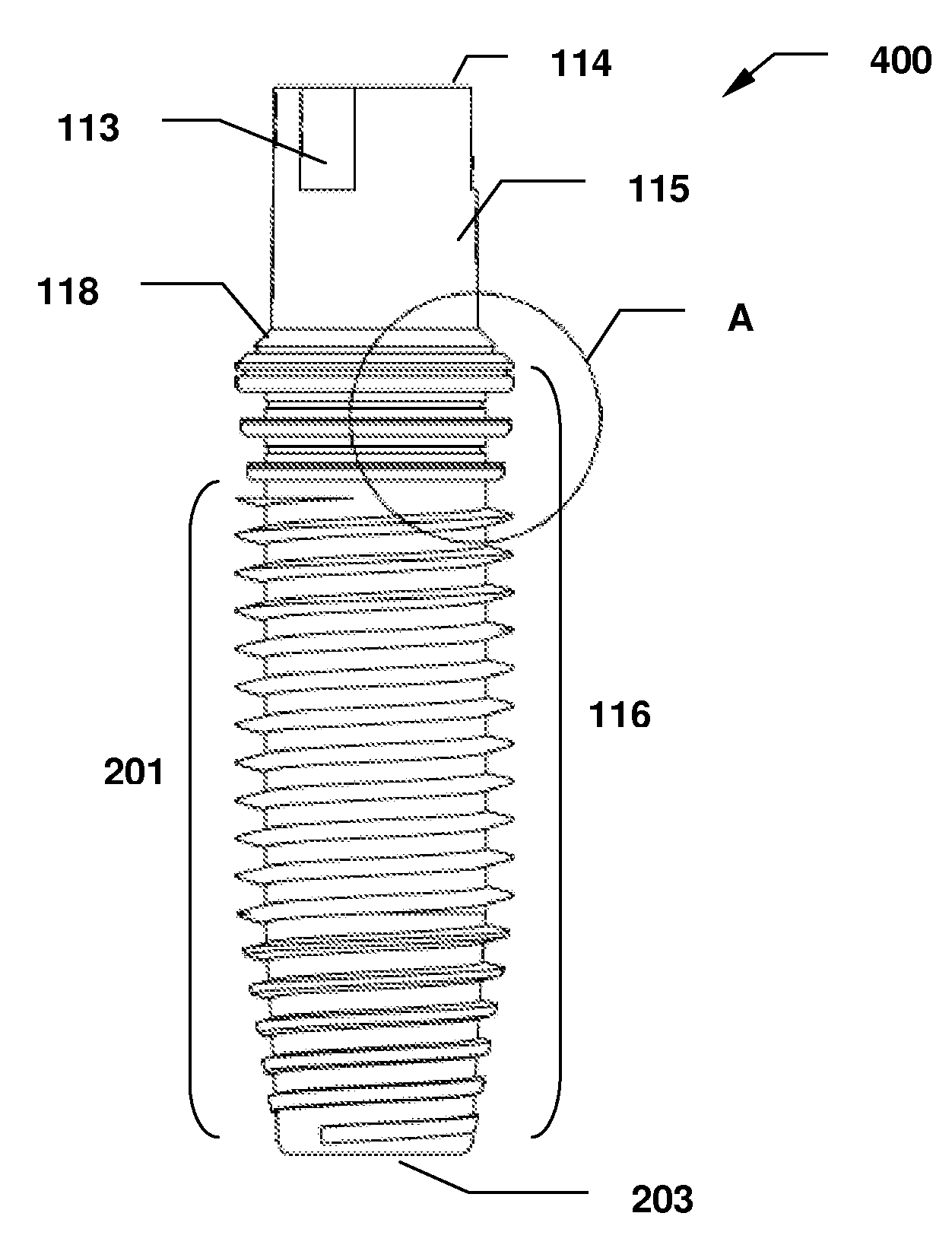

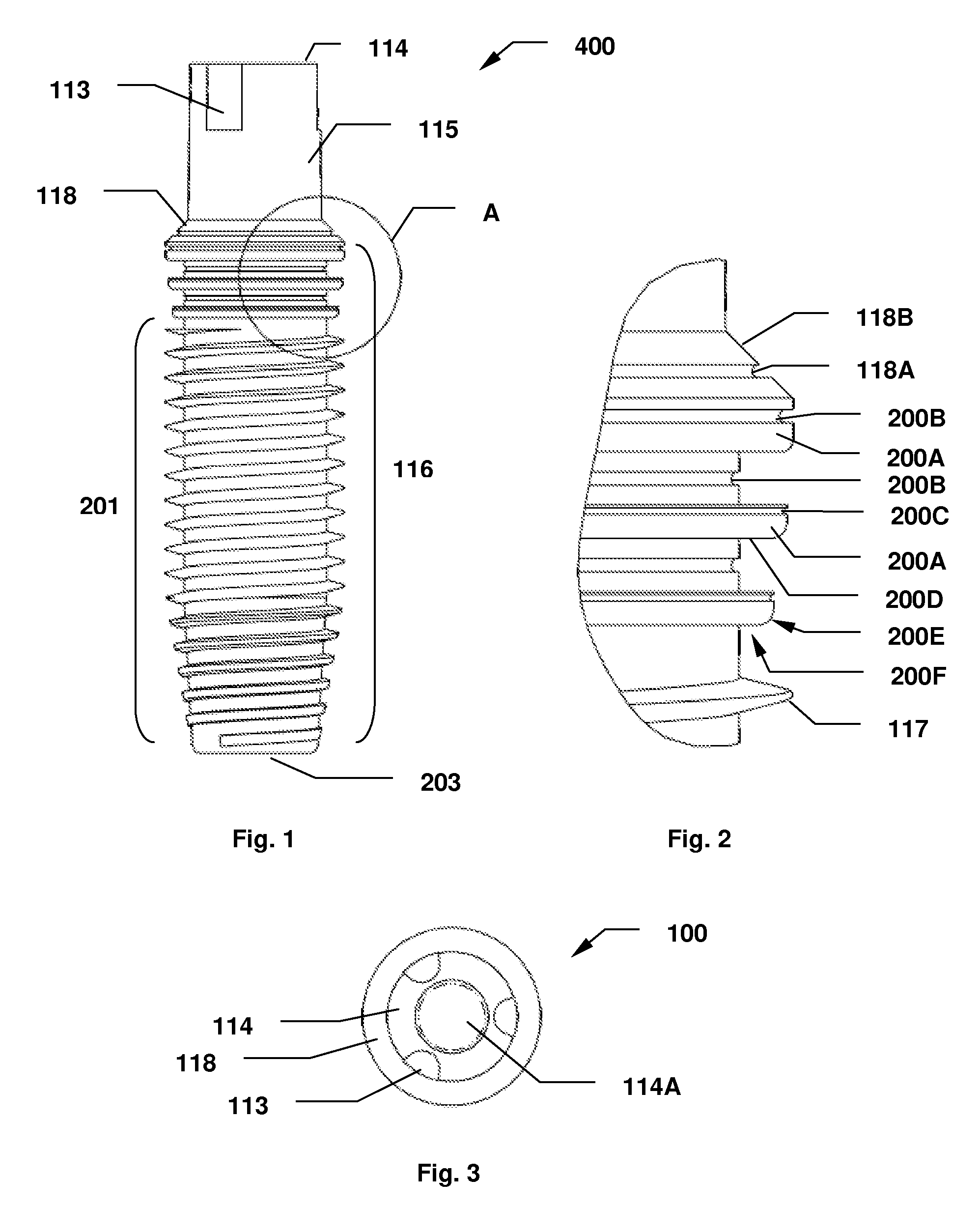

Dental Implant System and Method

ActiveUS20080254411A1Accurate placementEliminate disadvantagesDental implantsFastening prosthesisAbutmentSurgical department

A dental implant system comprising an implant member, an abutment member and a transfer key with cooperatively engaging structures for ensuring proper alignment and orientation of an abutment assembled on the implant member and for preparing an accurate dental impression and mold which represents the implantation site and its relationship to adjacent teeth structures. The abutment has the advantage of being easily removed for maintenance, repair or replacement with minimal or no discomfort to the patient. The invention also includes a dental implant with an improved bone-engaging structure for enhancing implant stability and fixation, an O-ring type abutment assembly with a reduced footprint in its assembled state when compared with similar conventional systems, a surgical screw and bone screw insertion tool, a healing abutment that need not be removed during an impression taking procedure, and an implant coding system that facilitates selection and identification of dental implants and implant analogs whose dimensional attributes will produce an accurate fit between the dental prosthesis and the dental implant. Further, dental reconstruction and abutment installation methods utilizing the dental implant system and instruments of the invention are disclosed.

Owner:BONDAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com