Large-area nanometer imaging device and large-area nanometer imaging method

A nano-pattern, large-area technology, applied in micro-structure devices, manufacturing of micro-structure devices, photo-engraving process of pattern surface, etc. The effect of good graphic consistency, large embossed graphic area and good mold release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] The present invention takes the nano-patterning of glass as an embodiment, and manufactures a large-area structure on a coating on a glass substrate.

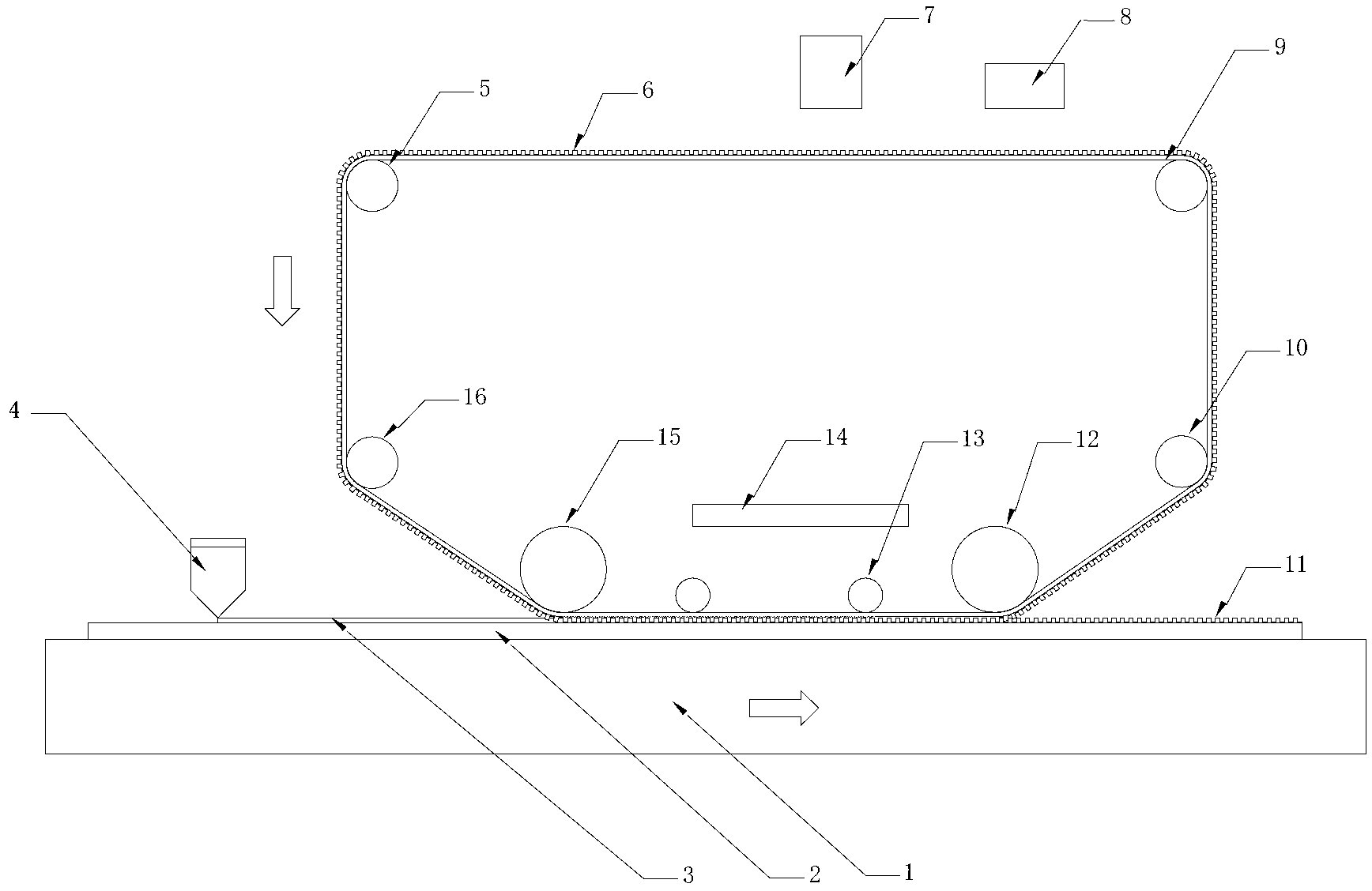

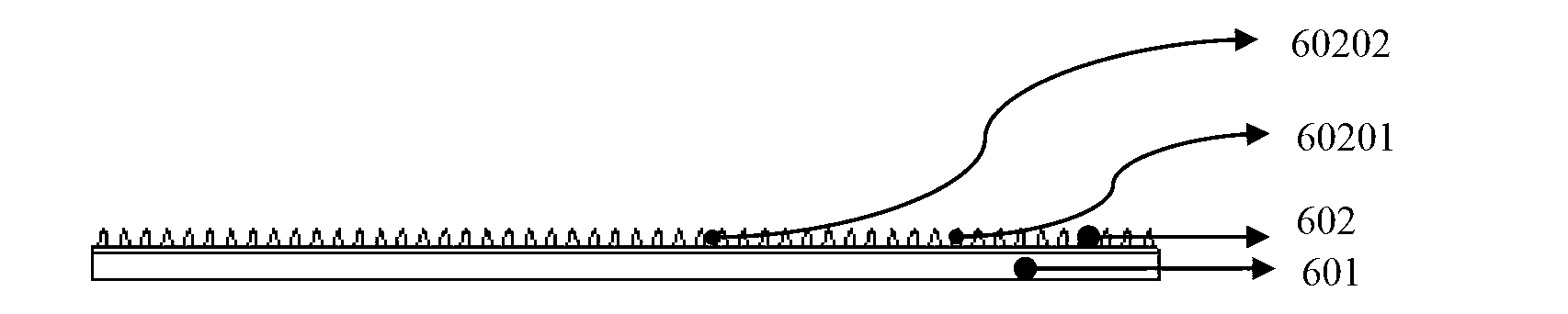

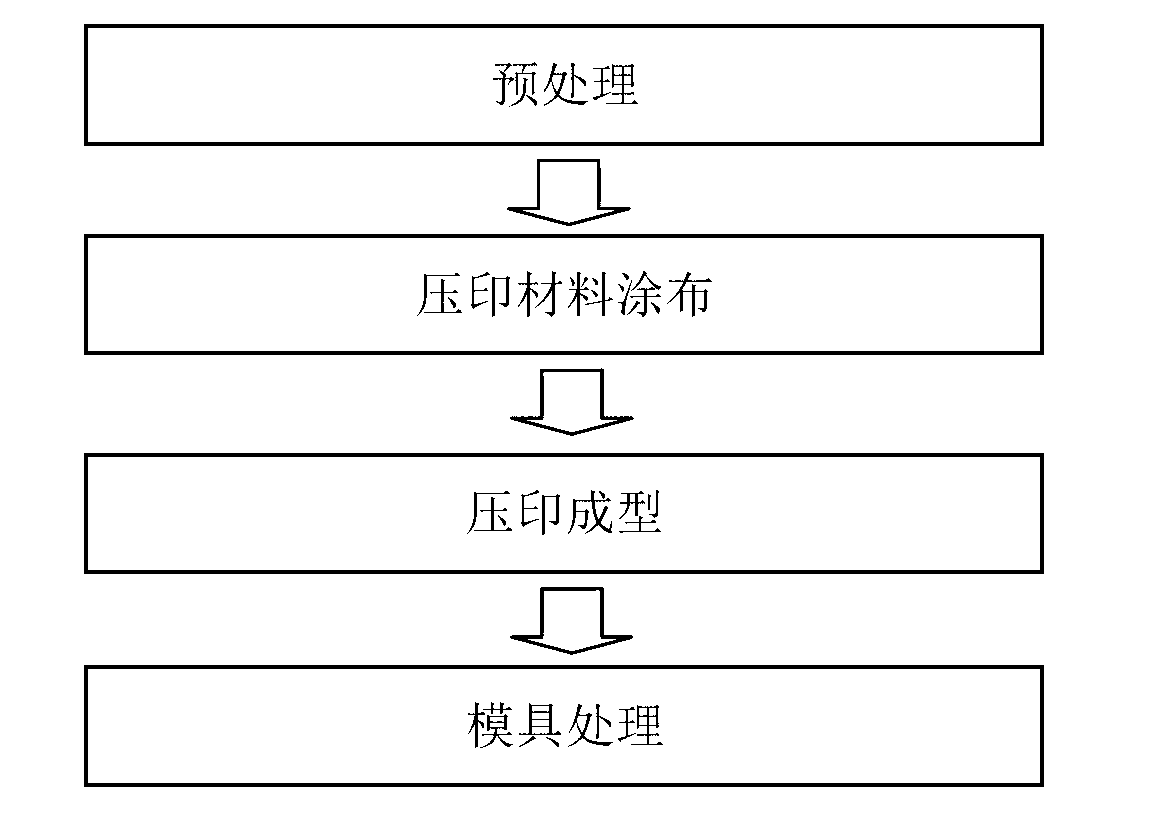

[0034] figure 1It is a schematic diagram of the structure of the large-area nano-patterning device of the present invention, which includes: a substrate 1, a substrate (glass) 2, a liquid imprinting material (transparent UV-curable polymer) 3, a coating device 4, and a mold feed Units 5 and 9, strip mold 6, release agent spraying unit 7, mold cleaning unit 8, mold guides 10 and 16, embossed features 11, stripping roller 12, auxiliary embossing unit 13, UV curing unit 14. Imprinting device 15. Wherein the substrate 2 is placed on the wafer table 1, and the liquid imprint material 3 is evenly coated on the upper surface of the substrate 2 by the coating device 4, and the belt-shaped mold 6 is woun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com