Patents

Literature

181 results about "3d design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

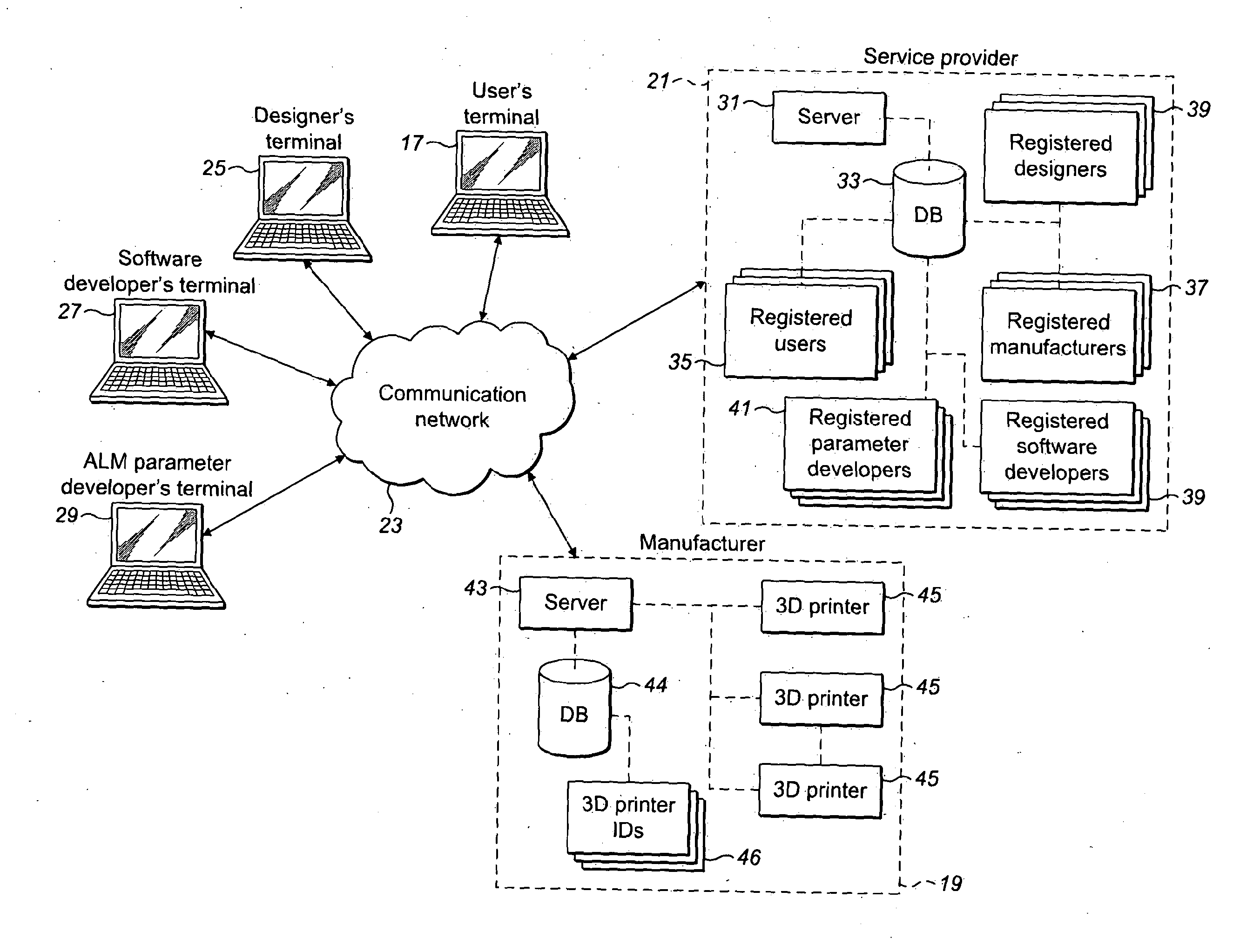

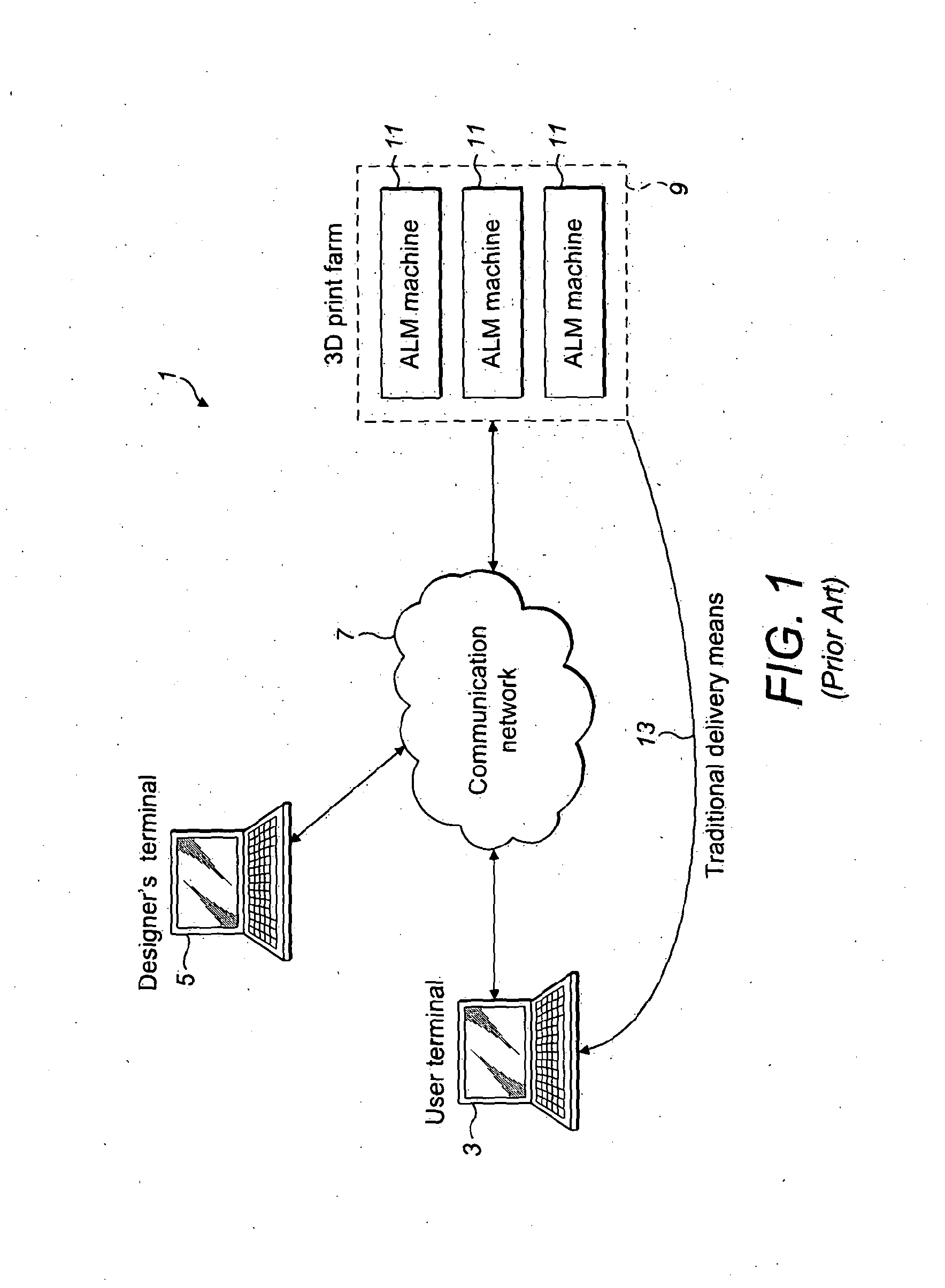

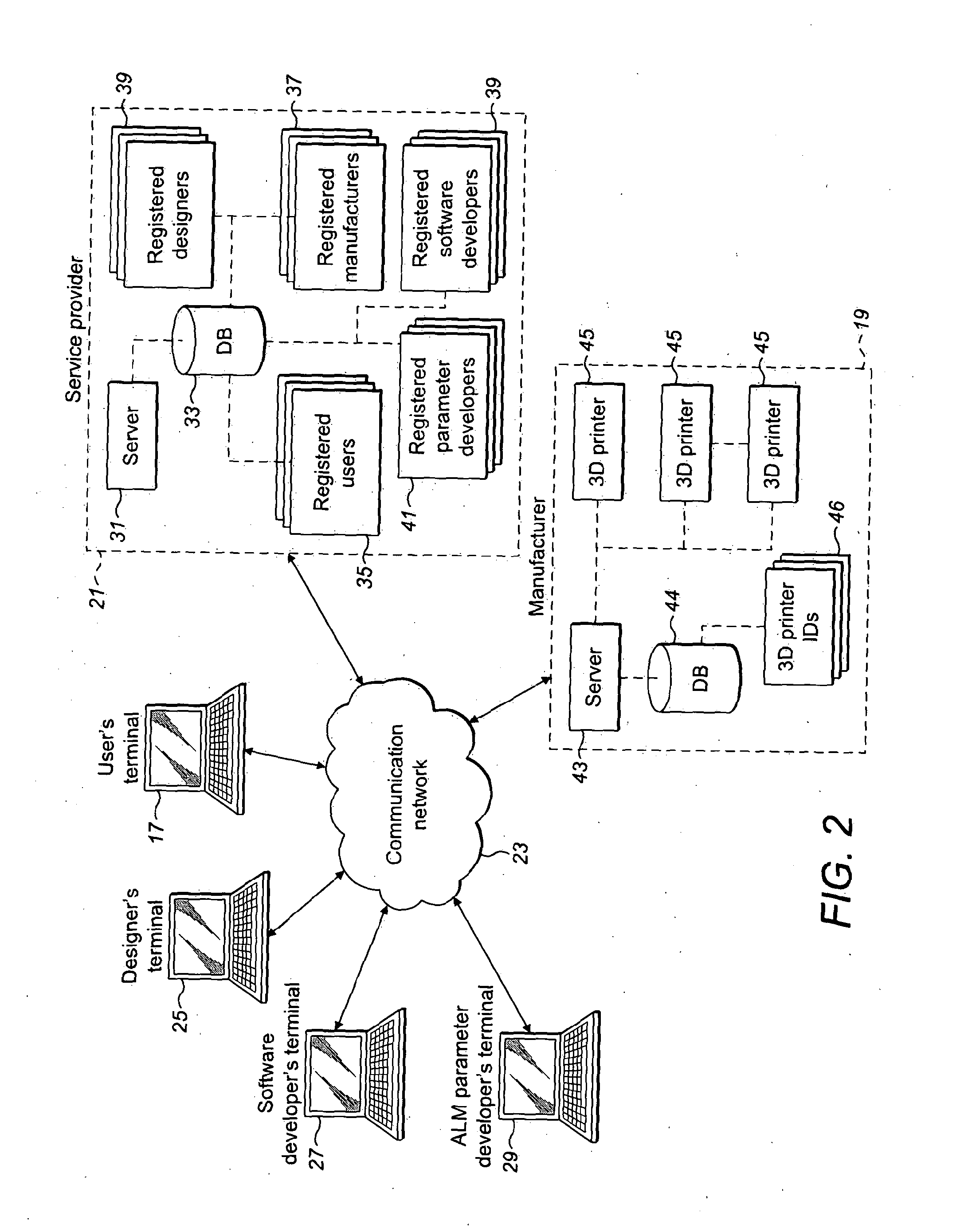

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

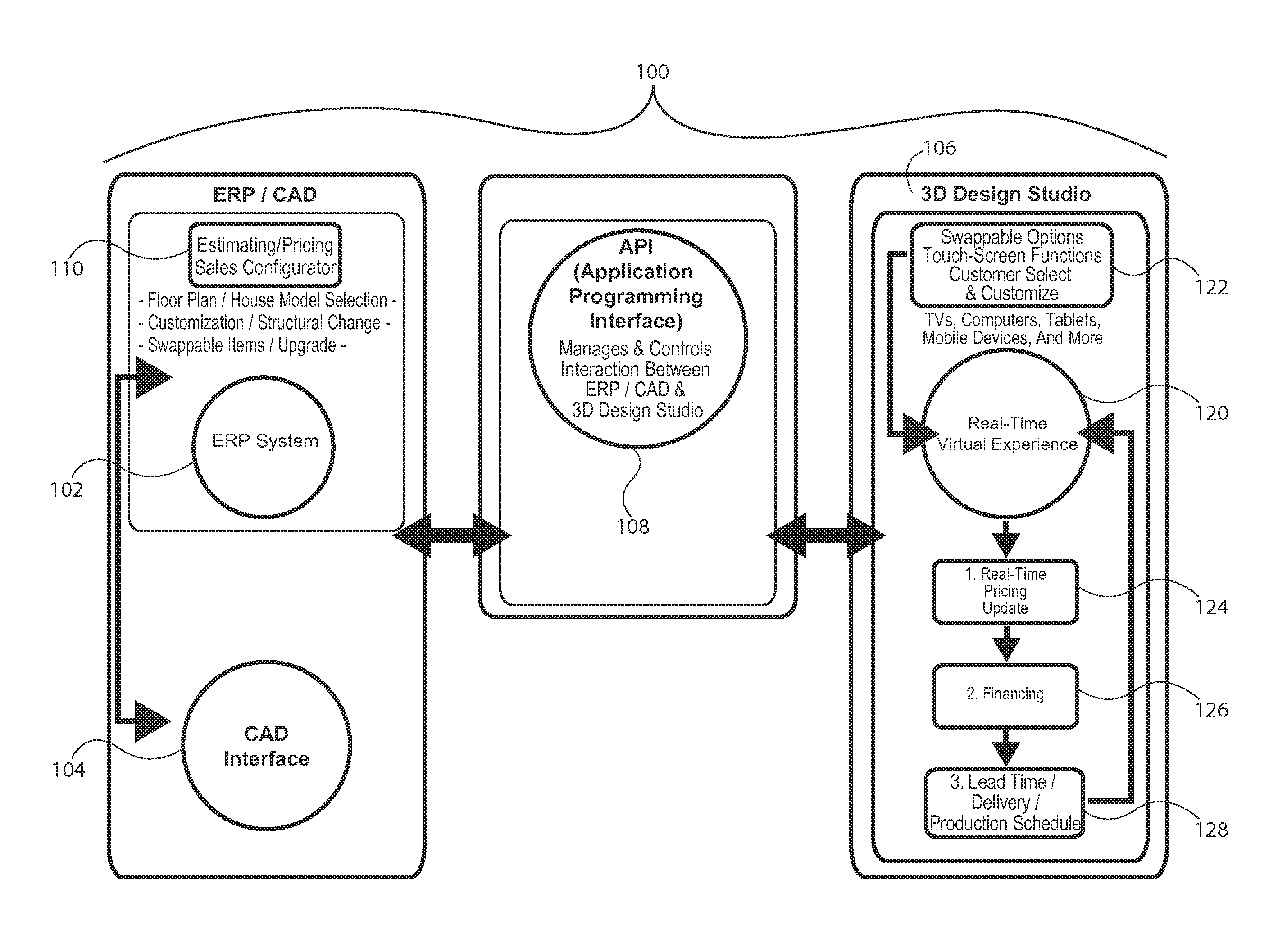

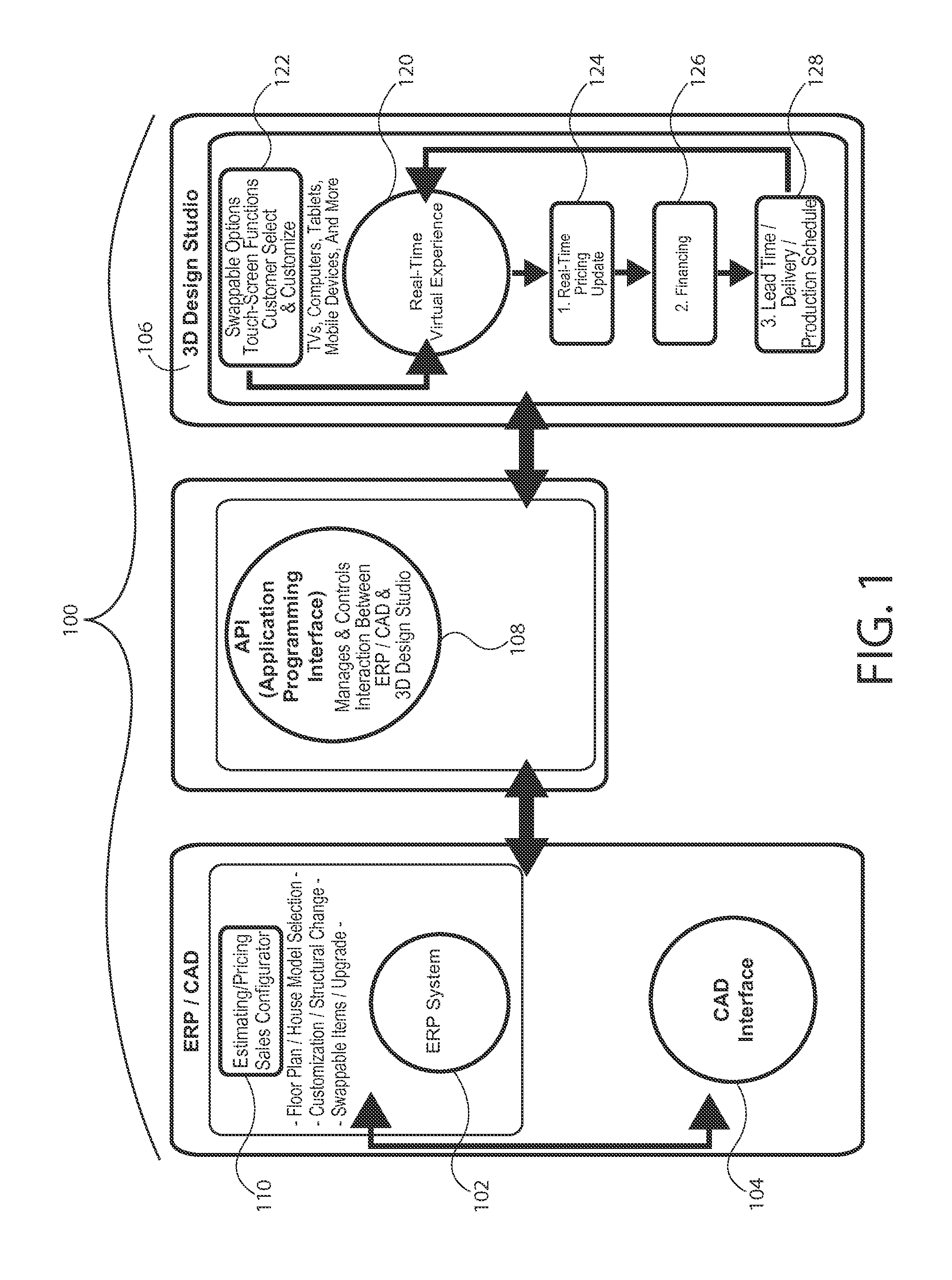

3D Interactive Construction Estimating System

InactiveUS20150324940A1Easy to customizeGeometric CADBuying/selling/leasing transactionsGraphics3d design

A 3D interactive construction estimating system is provided that includes a computerized interactive ERP / 3D design and estimating system for building construction projects and services. The computerized 3D interactive construction estimating system is real-time, visual, and transparent to both the customer and the manufacturer, and allows the customer to design and customize a home or other building with real-time integrated 3D virtual tour, pricing, scheduling, ordering, and financing options. The system includes an ERP system, a CAD system, and a graphical front end that provides the user with a virtual design experience.

Owner:MODULAR NORTH AMERICA

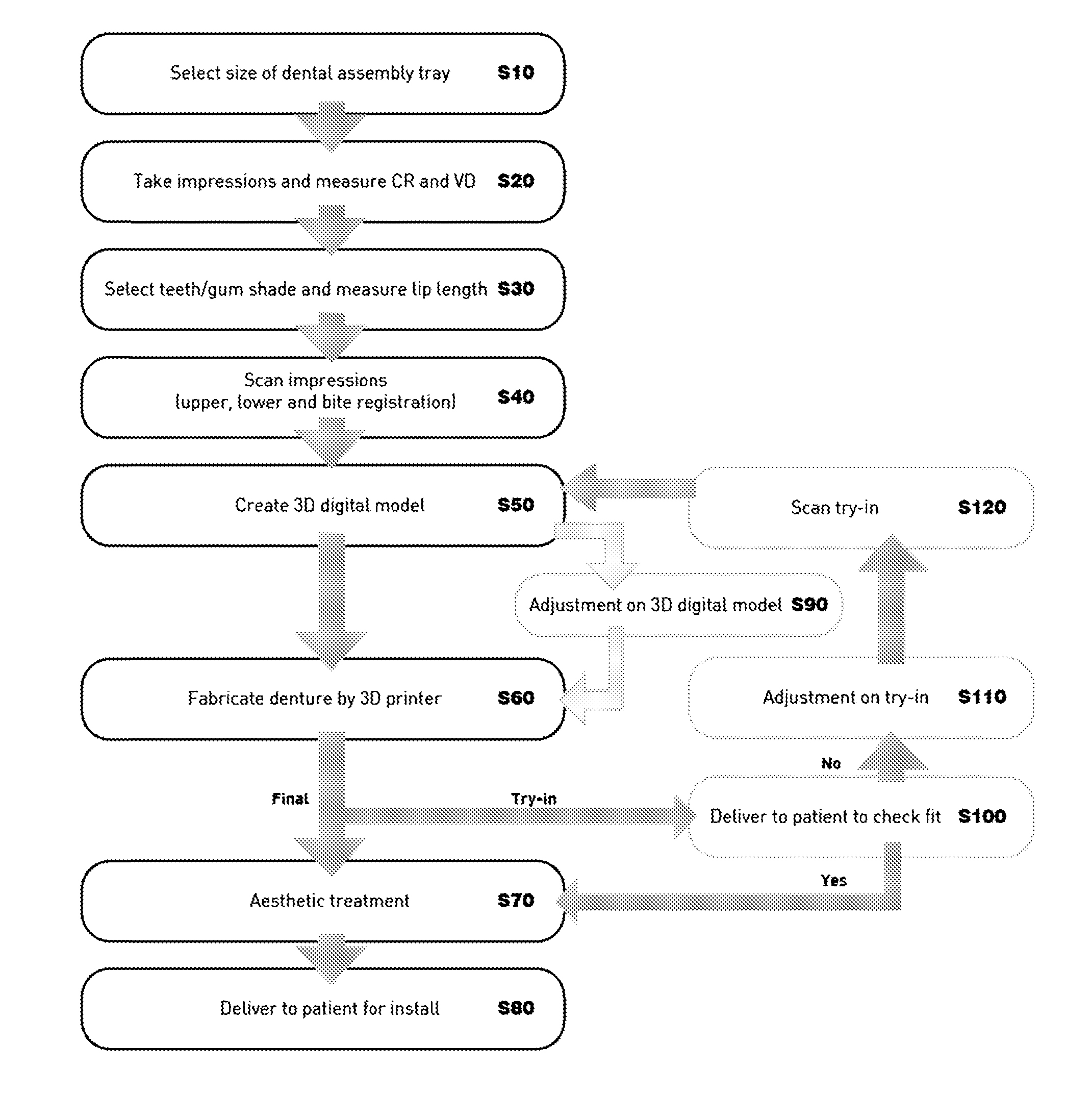

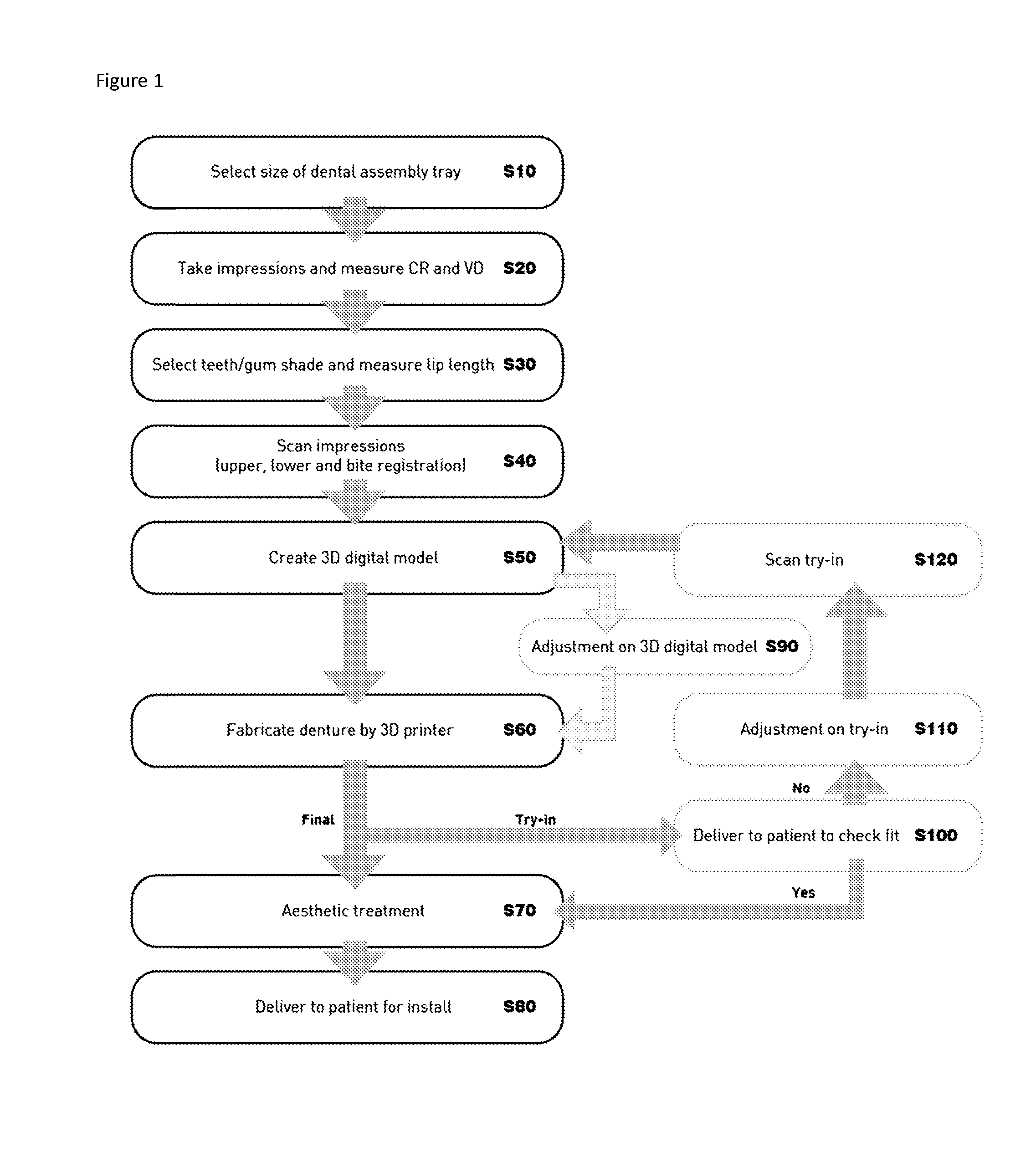

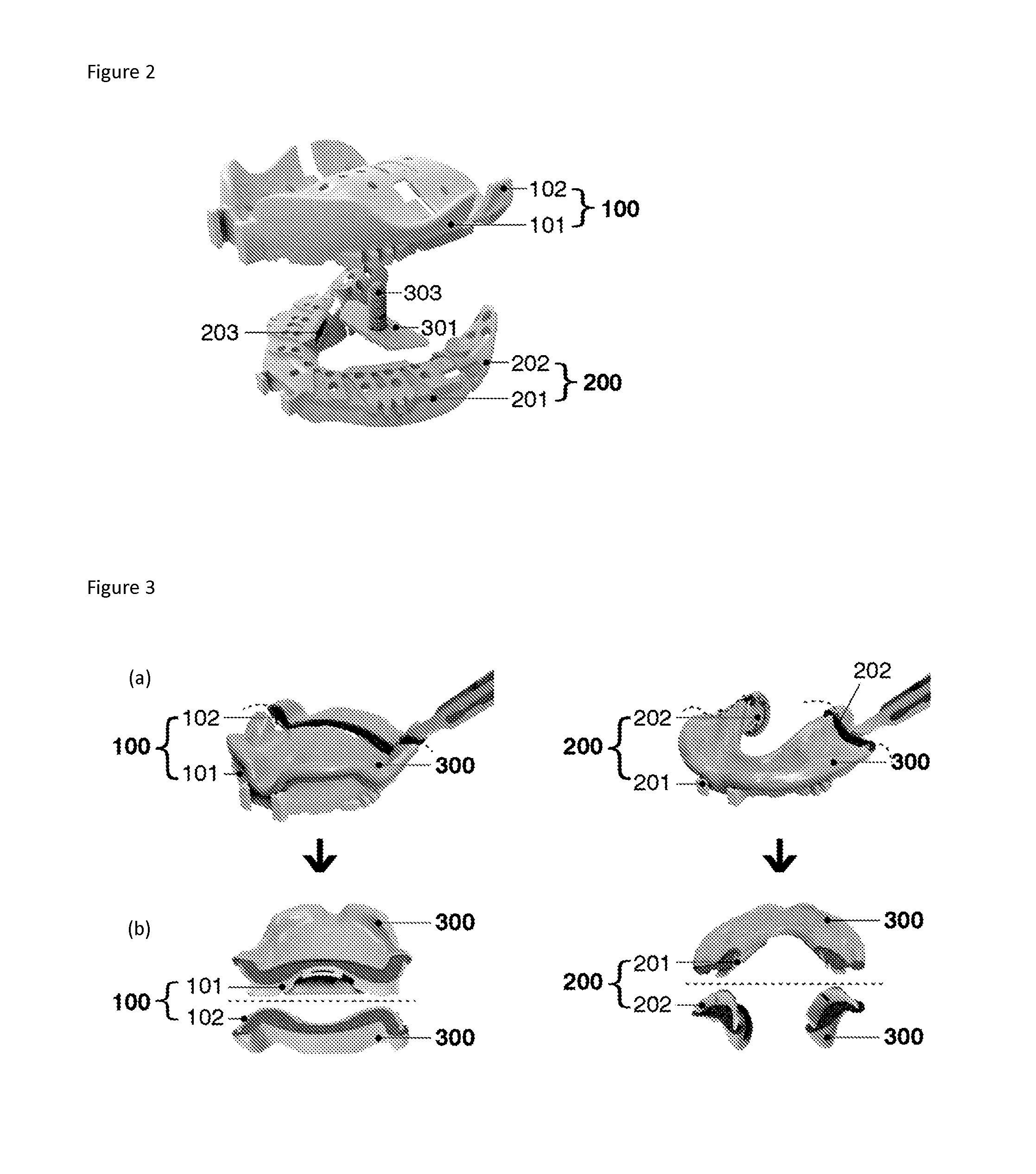

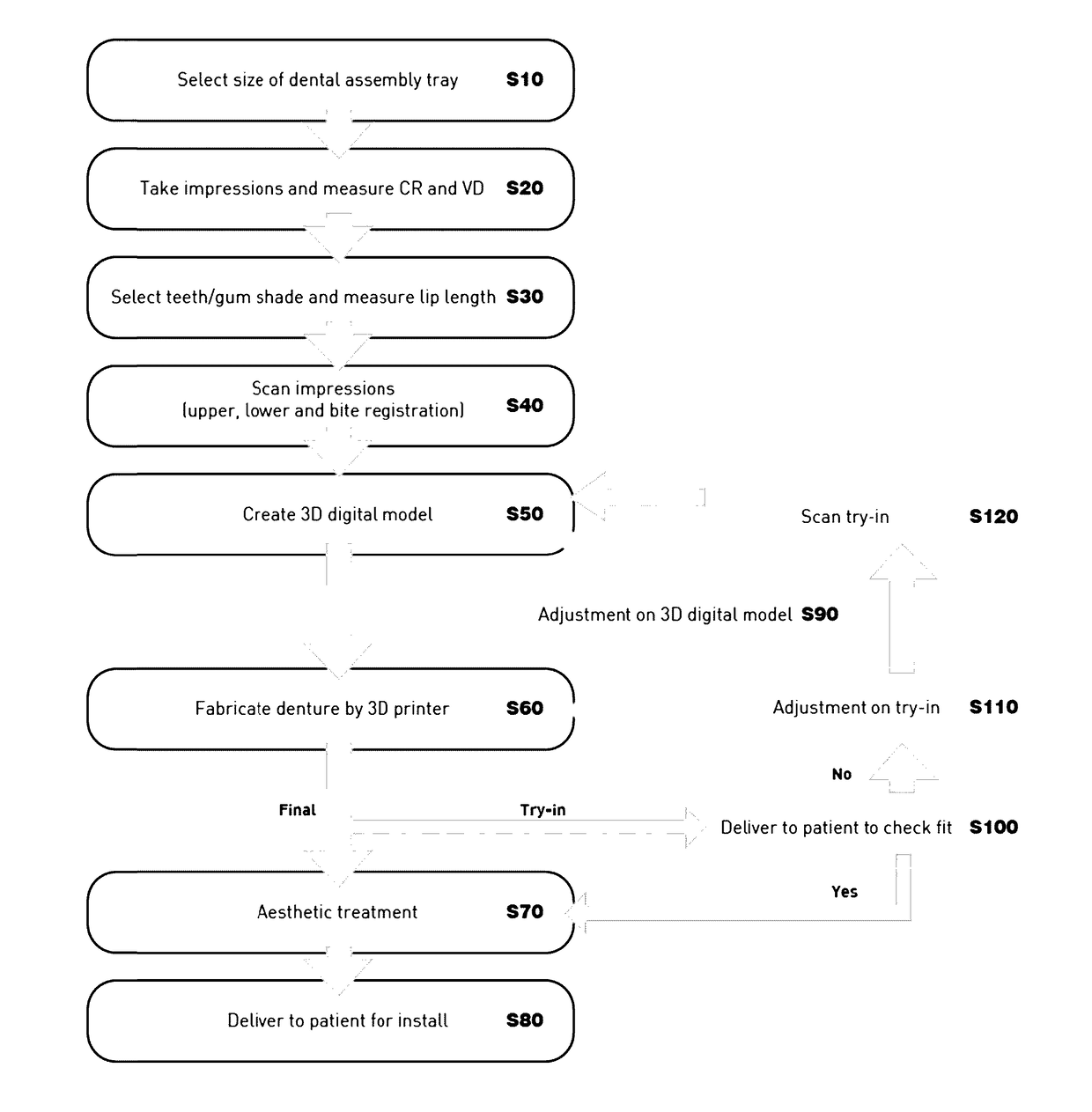

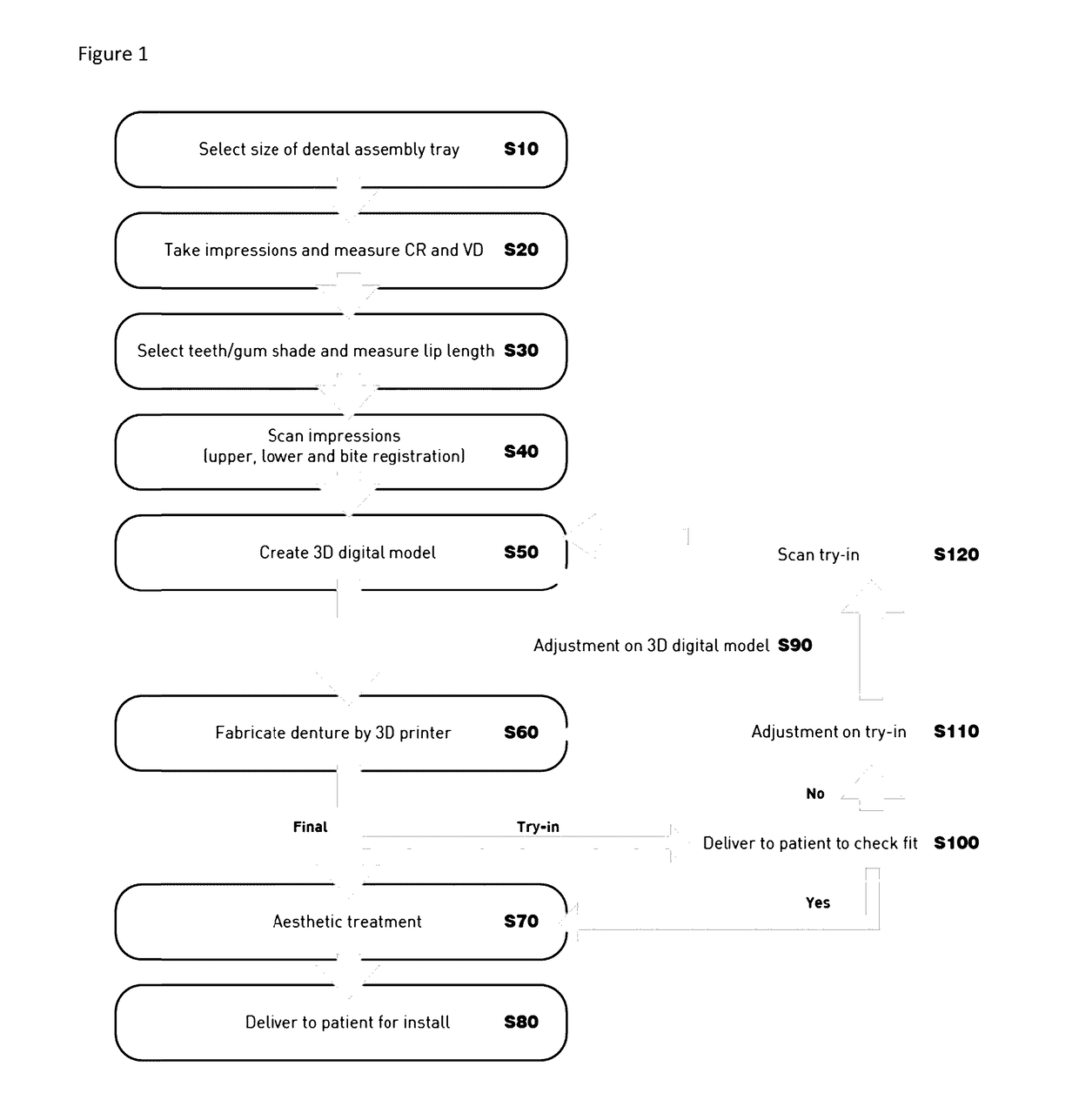

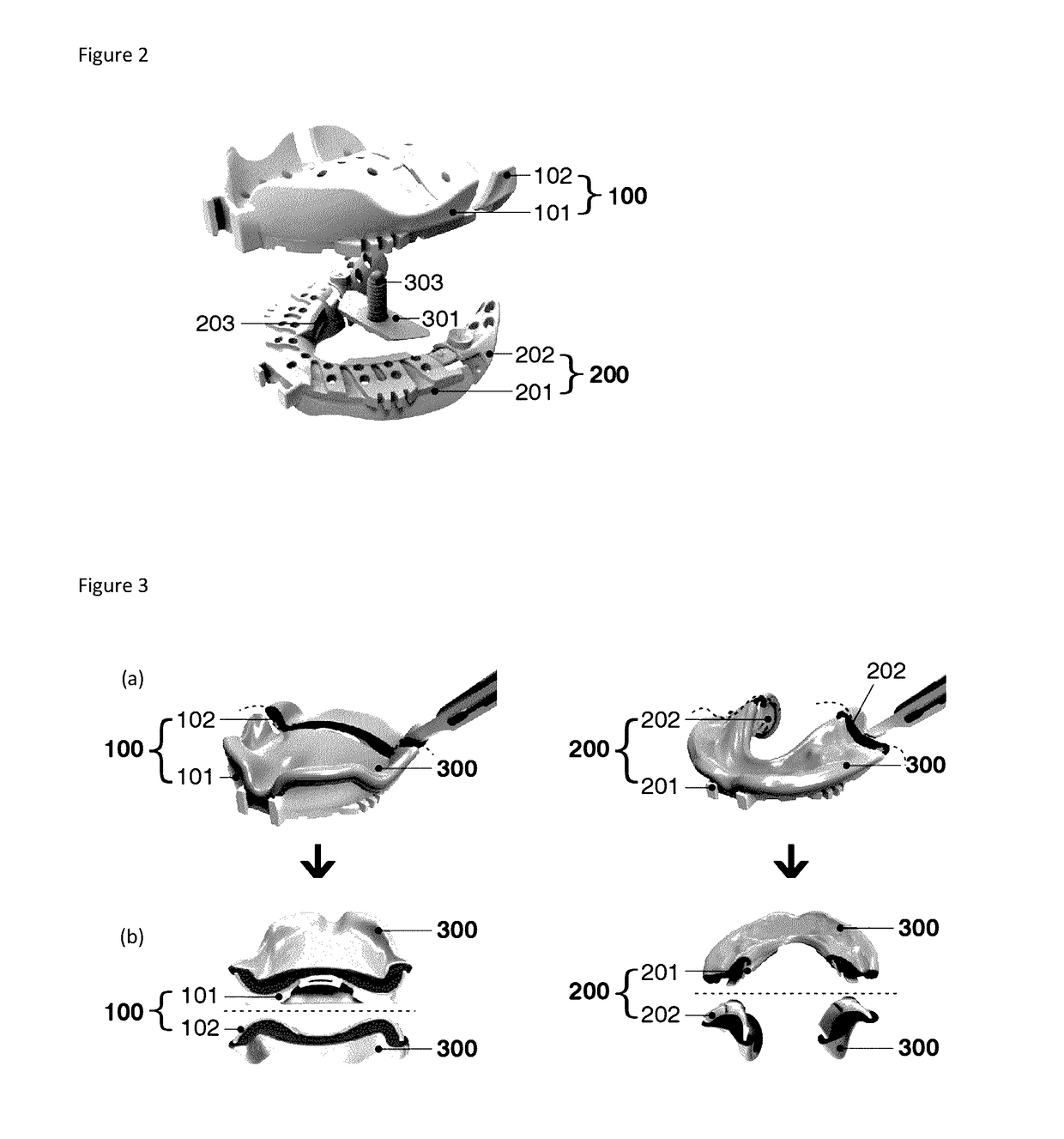

Method and apparatus for preparing removable dental prosthesis

ActiveUS20140308624A1Easy to operateAccurate manufacturing of a complete denture without intensive manual laborImpression caps3D printingSingle visit3d design

A method for manufacturing a removable dental prosthesis using a three-dimensional (3D) printer includes receiving dental impressions of a patient obtained using a dental impression tray assembly, the dental impressions including a bite registration and at least a mandibular impression or a maxillary impression; receiving information related to the patient's jaw relations obtained using the dental impression tray assembly, the jaw relations including a vertical dimension and a centric relation obtained during the patient's single visit to a dentist; scanning the received dental impressions with a 3D scanner to provide data representative of an edentulous shape of the patient; generating a 3D model of the dental prosthesis based on the data and the received information related to the patient's jaw relations using 3D design software; displaying the generated 3D model on a display, allowing customization of the 3D model; and 3D printing the dental prosthesis according to the 3D model.

Owner:DENTCA INC

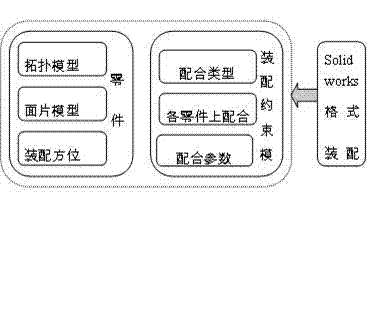

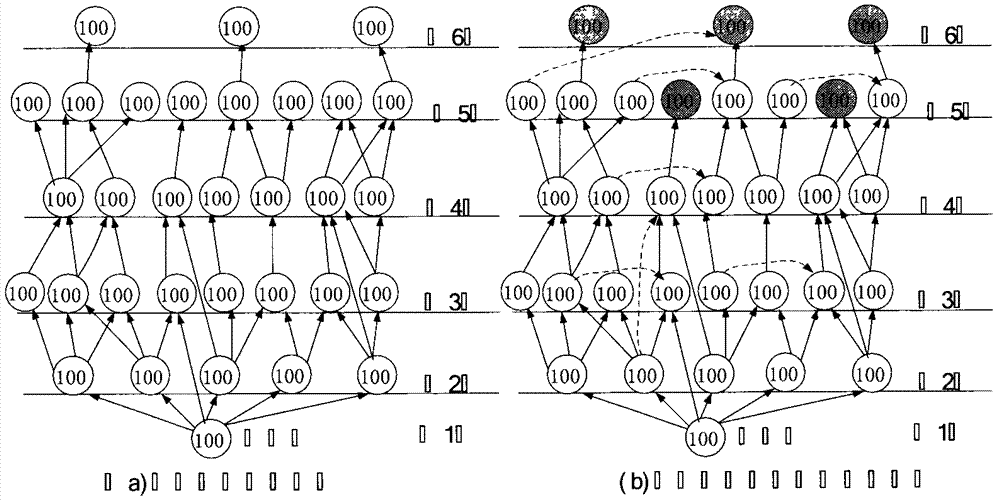

Induction method of three-dimensional (3D) online induction system for mechanical equipment dismounting

InactiveCN102789514AAugmented reality inductionImprove high universalityInput/output for user-computer interactionGraph readingInduction motor3d design

The invention discloses an induction method of a three-dimensional (3D) online induction system for mechanical equipment dismounting. The induction system comprise an eyeglass-type augmented reality helmet, a hand position tracking device and a computer, wherein the augmented reality helmet is provided with two display screens and two cameras; and wireless communication can be realized among the augmented reality helmet, the hand position tracking device and the computer. An induction method for realizing the three-dimensional online induction system for mechanical equipment dismounting comprises the following steps of: 1, transforming a virtual assembly model; 2, initializing the induction system; 3, recognizing the dismounting purpose; 4, generating induction information; 5, overlapping the induction information; and 6, repeating the steps 3-5 until the online product induction is finished. The method disclosed by the invention has the characteristics of accurate induction information, strong universal capability and convenience in carrying, and can be used for realizing the 3D online induction driven by requirements of operators, current situations of tasks and dismounting history and realizing the integration of product 3D design and dismounting induction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

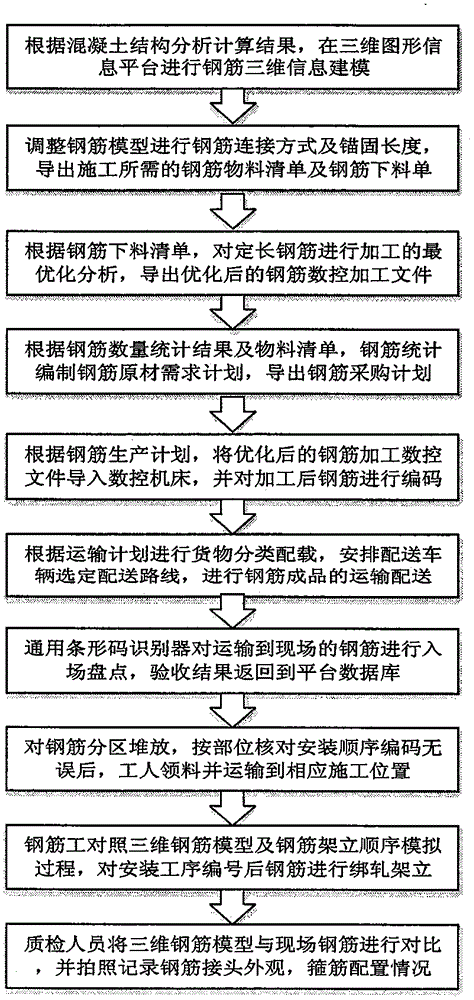

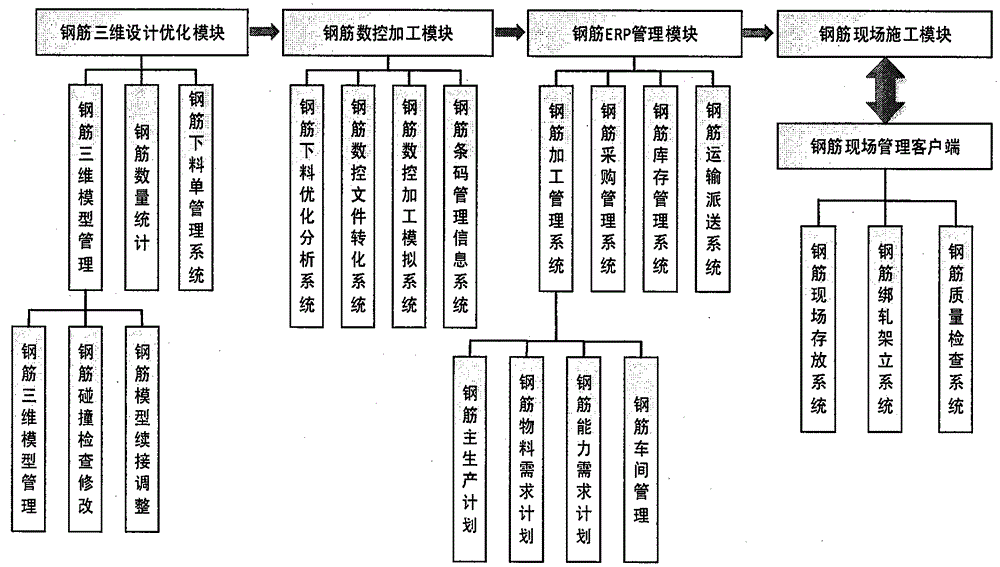

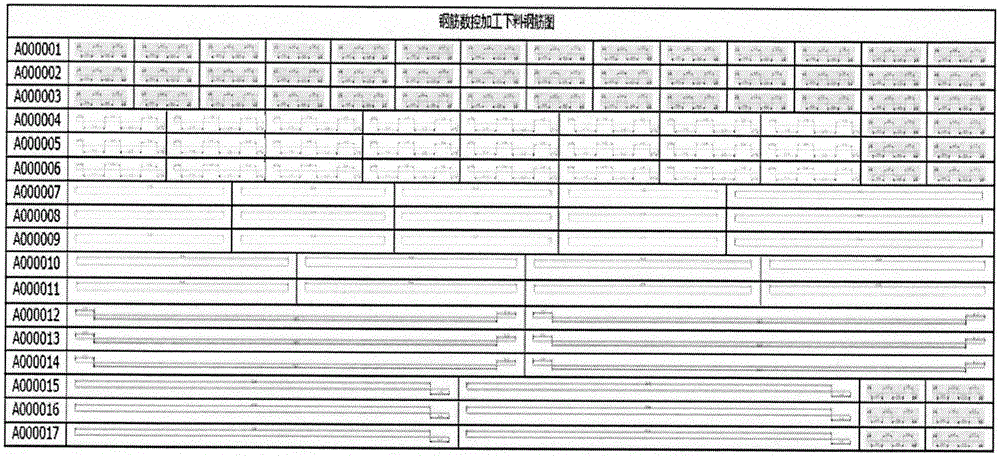

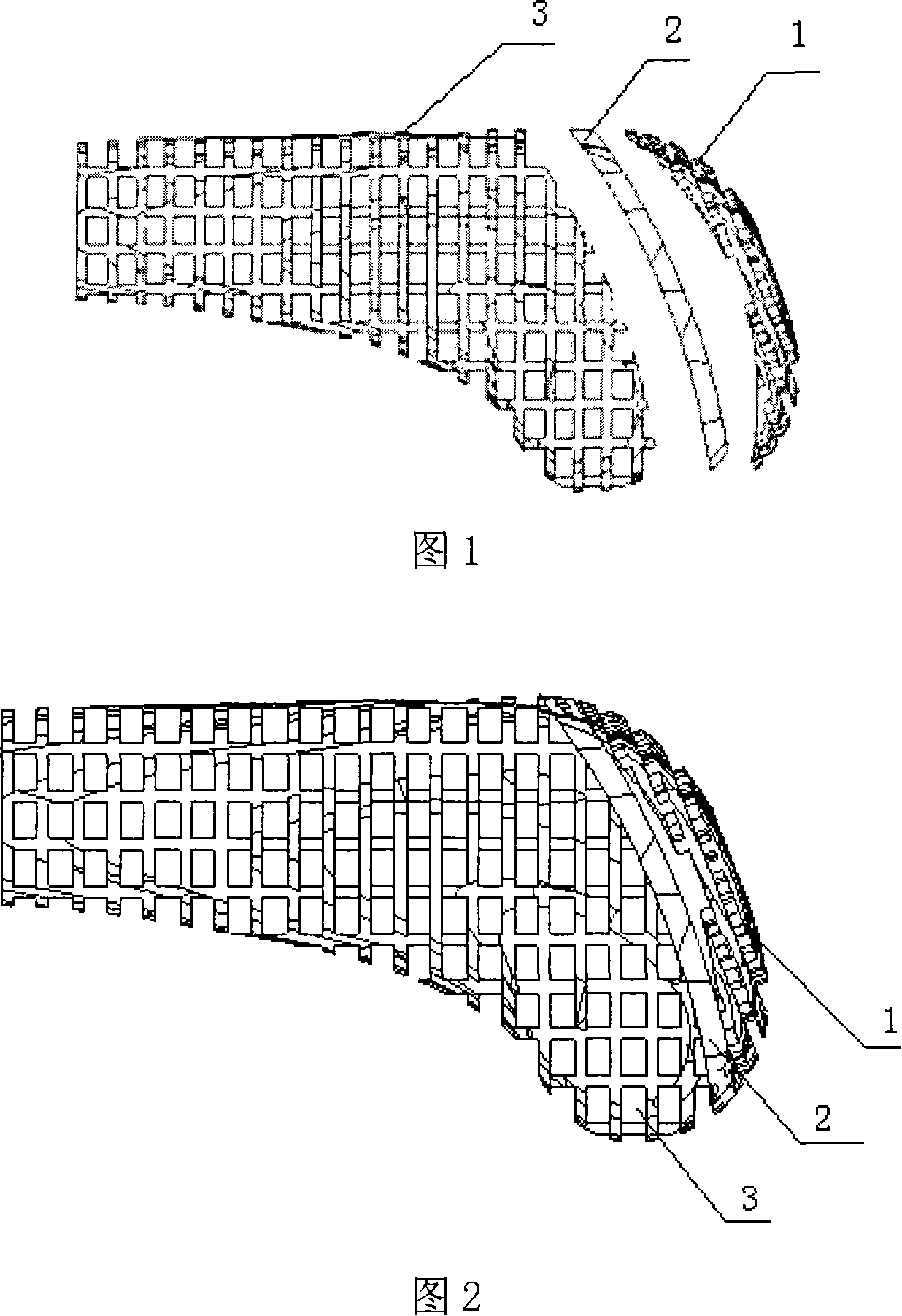

Management system and method for whole steel bar engineering process based on 3D figure information platform

The invention discloses a management system and method for the whole steel bar engineering process based on a 3D figure information platform, and provides an integrated solution for optimized design, processing, transport, stacking management and onsite construction of the steel bar engineering. The system comprises a steel bar 3D design optimization module, a steel bar numerical control processing module, a steel bar ERP management module and a steel bar onsite construction module. The method comprises the steps that a steel bar 3D information model is designed and optimized, and the amount of the steel bars is calculated; a steel bar numerical control file is led out for numerical control processing; the EPB module is used for steel bar processing and onsite information management; and the steel bar 3D information model is used to guide onsite construction and onsite steel bar quality inspection. Steel bar 3D information flows in the database platform to realize control, coordination and management for the steel bar engineering. A traditional steel bar processing model is improved, steel bars and energy are saved, the production and construction quality of the steel bars are improved, the steel bar production and construction efficiency is improved, and management for the steel bars in construction is improved.

Owner:张玉英

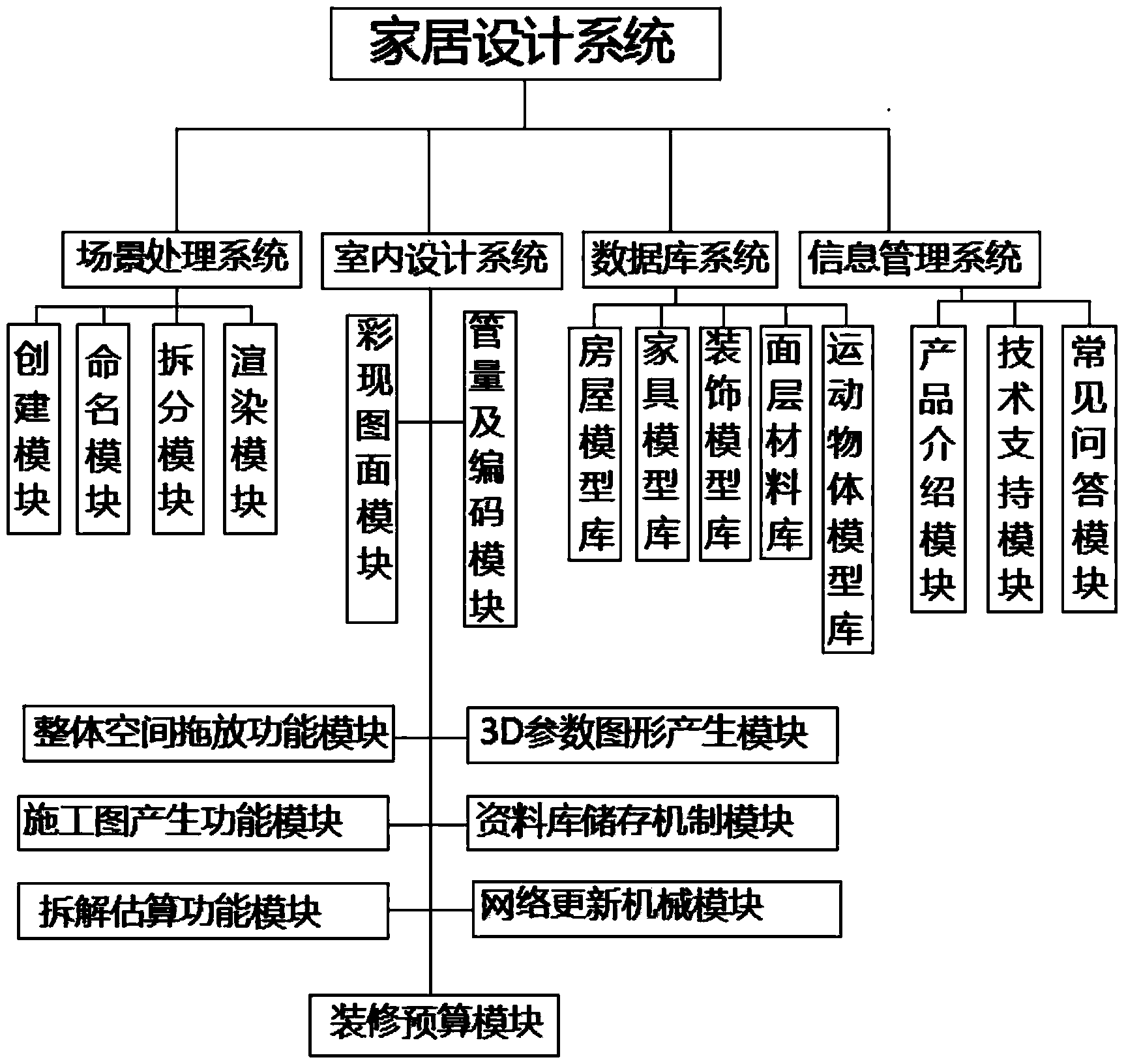

Home design system

The invention provides a home design system. The home design system comprises a database system, a scene processing system and an indoor design system, wherein the database system provides a plurality of model bases related to home design, the scene processing system is used for calling the model bases, processing the model bases and generating model bases with the 3D effect, and the indoor design system is used for calling the model bases with the 3D effect, designing the model bases with the 3D effect and generating a home design scheme. The home design system can rapidly and conveniently generate a home 3D model and pictures of different angles needed by 3D design and display, can dynamically amend the size and angles of a room according to the designed room type, and is provided with an automatic settlement module, thereby being capable of analyzing the current design scheme in real time, calculating the ground and wall surface areas, and generating a product material detailed list.

Owner:JIANGSU ZHONGYOU PETROLEUM MACHINERY SCI & TECH CO LTD

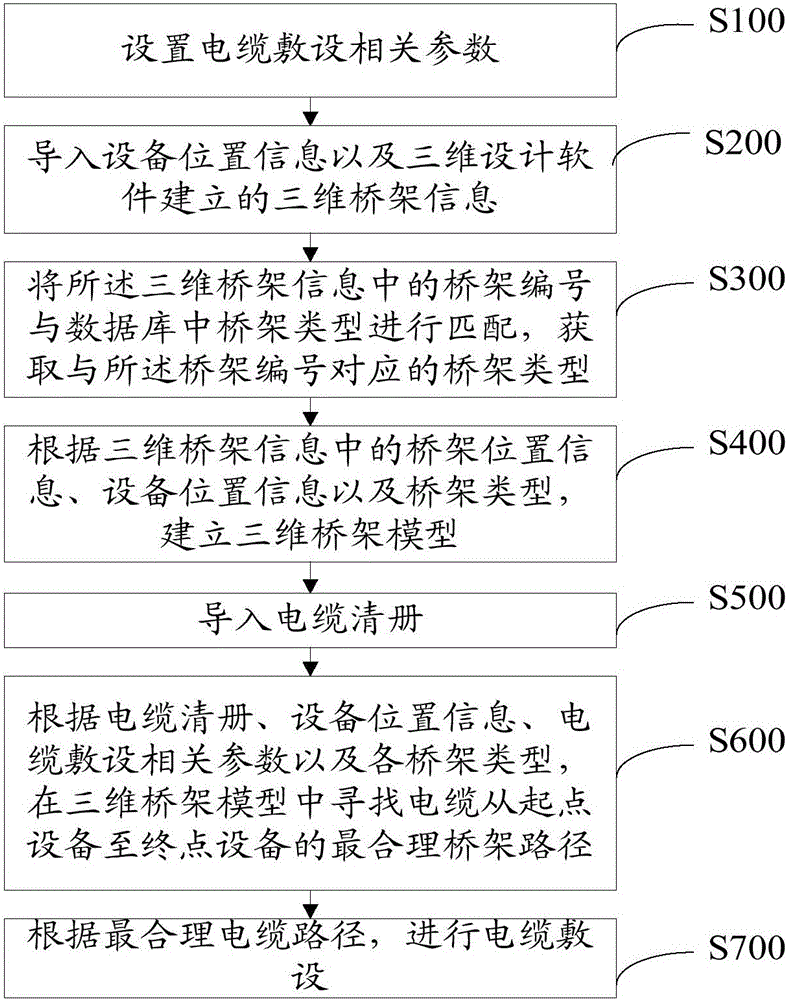

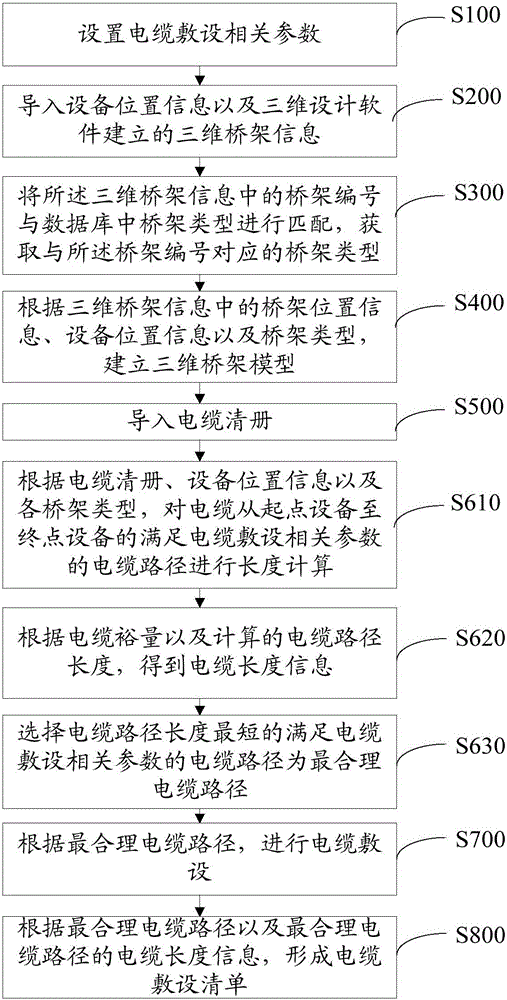

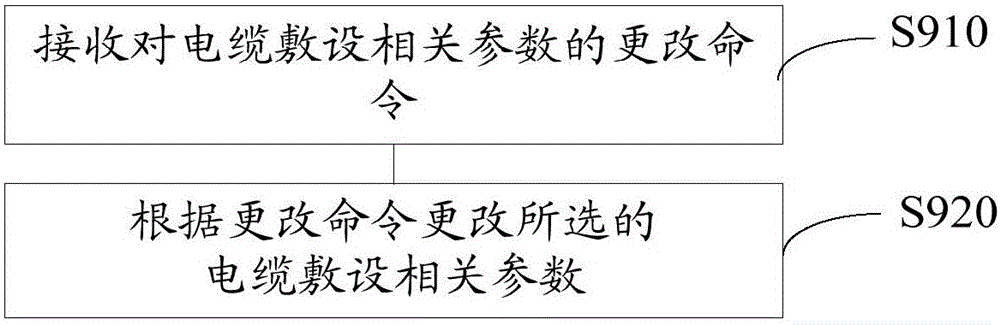

Cable laying method and system

ActiveCN105005659AImprove laying efficiencyImprove efficiencyForecastingSpecial data processing applicationsBridging positionBridge type

The invention relates to a cable laying method and system. The cable laying method comprises the following steps of: acquiring three-dimensional (3D) bridge information built by 3D design software; matching a bridge number in the 3D bridge information with a bridge type in a database to find the bridge type corresponding to the bridge number and realize the conversion of the bridge number to the bridge type; and forming a 3D bridge mode according to imported bridge position information, device position information and the bridge type in the 3D bridge information. By the cable laying method, the bridge position information, the device position information and the bridge type are unnecessarily reset in the cable laying system to build the 3D bridge model; through information matching, the bridge number in the 3D bridge information built by the 3D design software is converted into information required for cable laying, namely the bridge type, the bridge type is unnecessarily set, and thus the laying efficiency is improved; and the most reasonable cable path is searched according to parameters related to cable laying, rapidness and accuracy are achieved, manual labor is not needed to search the path, and the laying efficiency is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

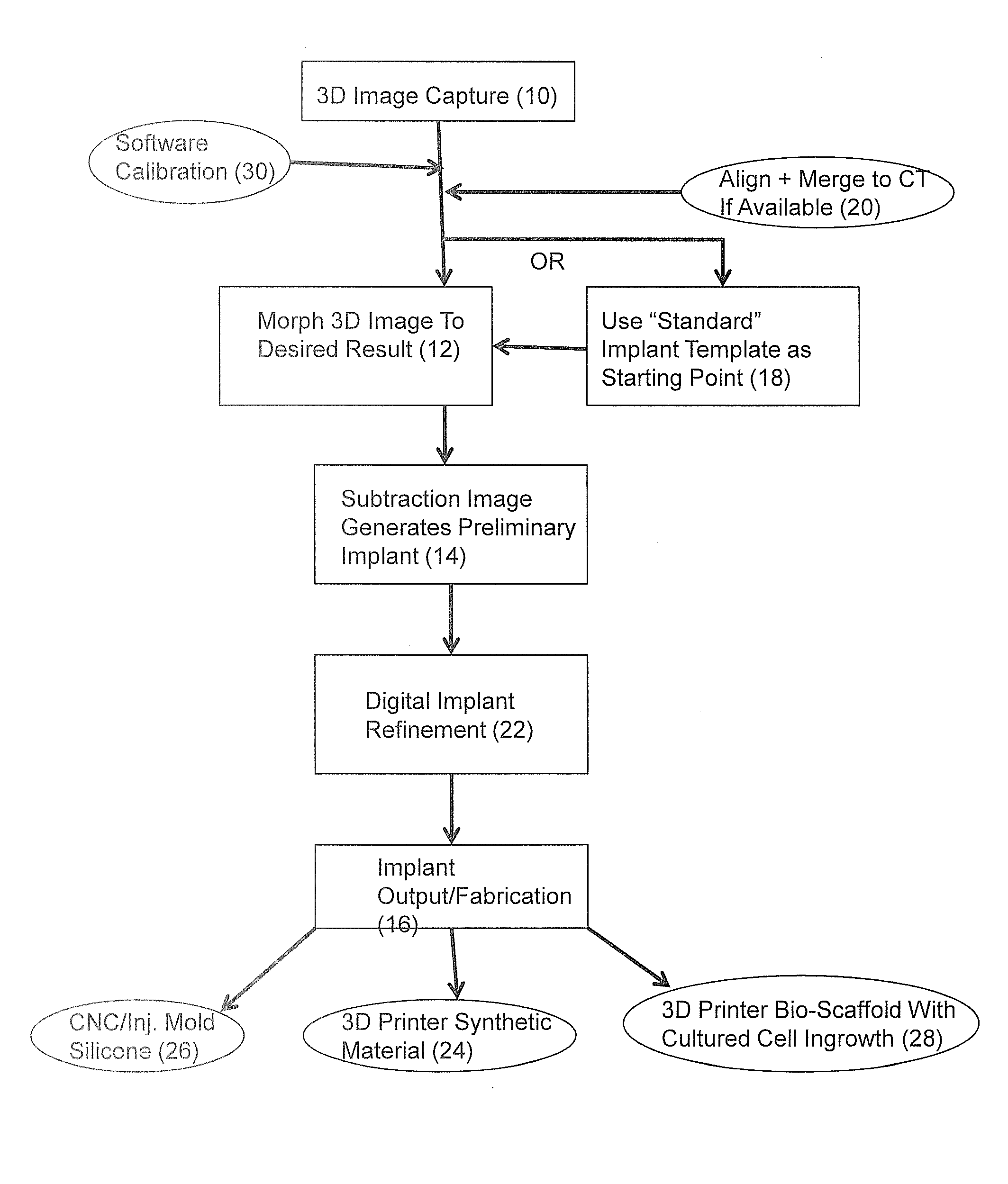

3D design and fabrication system for implants

ActiveUS20130238096A1Details involving processing stepsAdditive manufacturing apparatusCustom made implantIntervertebral disc

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, and fabricating a real 3D implant. A method of implanting a custom implant in a patient, by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, fabricating a real 3D implant, and implanting the implant in the patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. The present invention also provides for an implant fabricated by this method.

Owner:KOTLUS BRETT

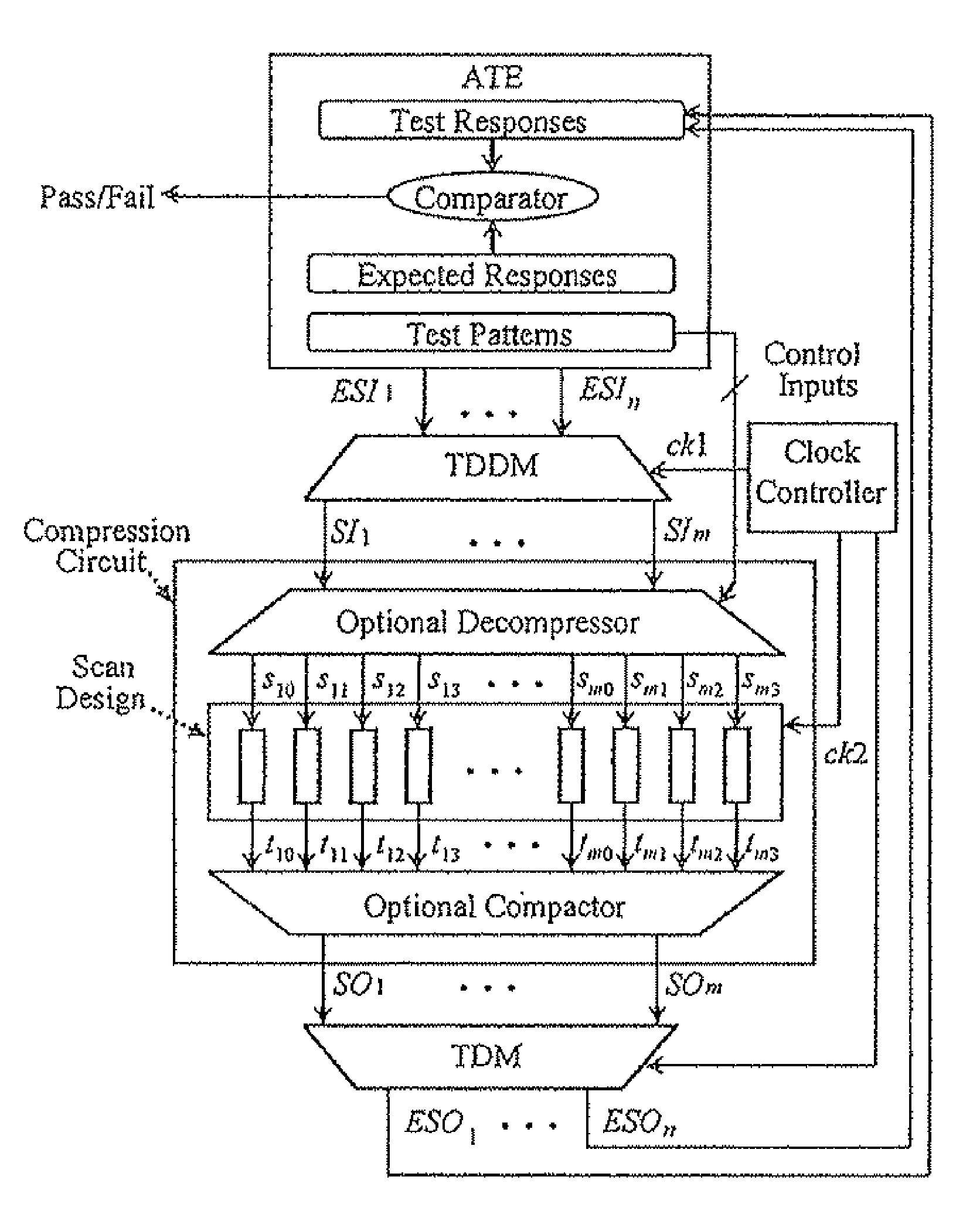

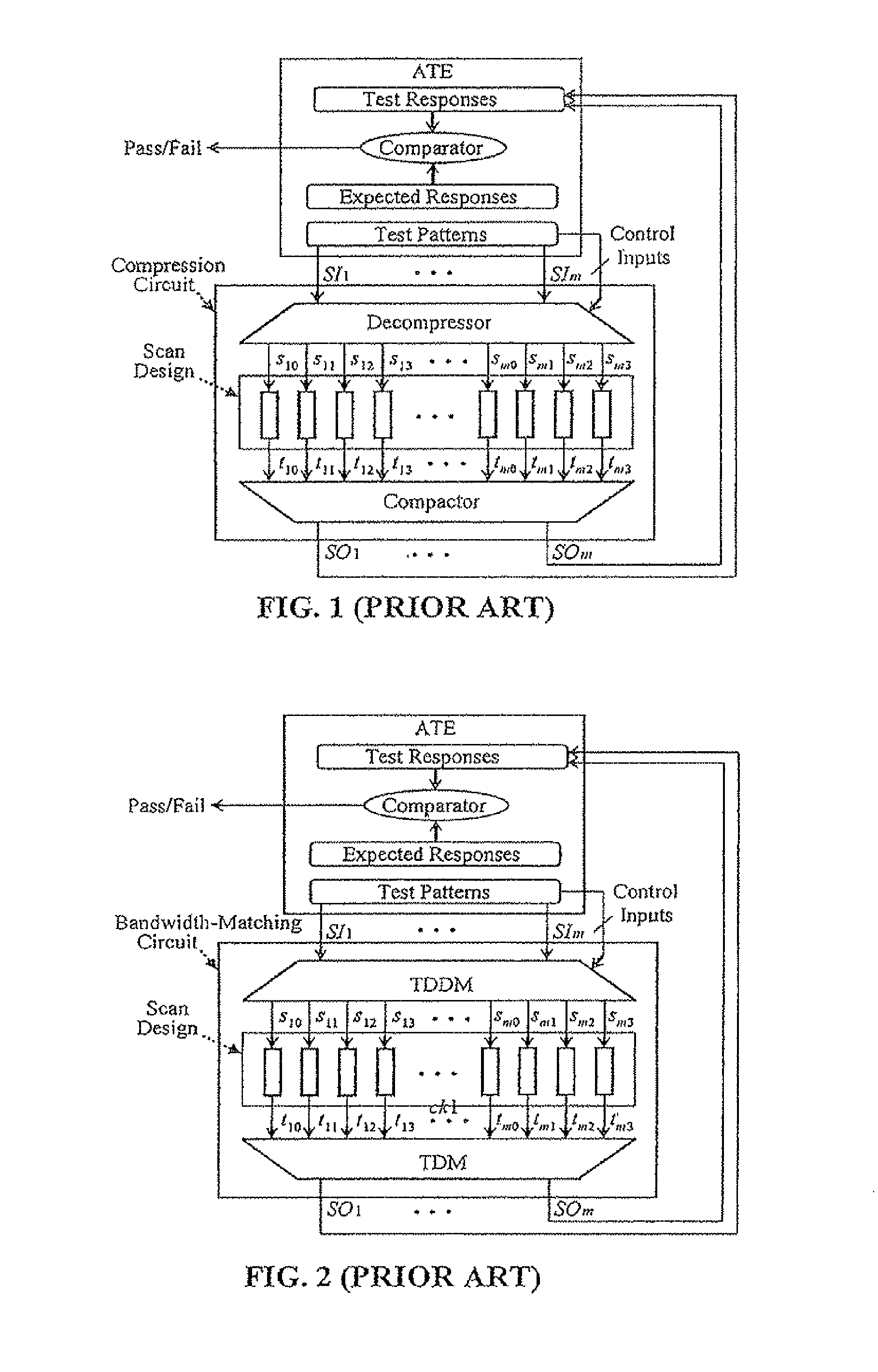

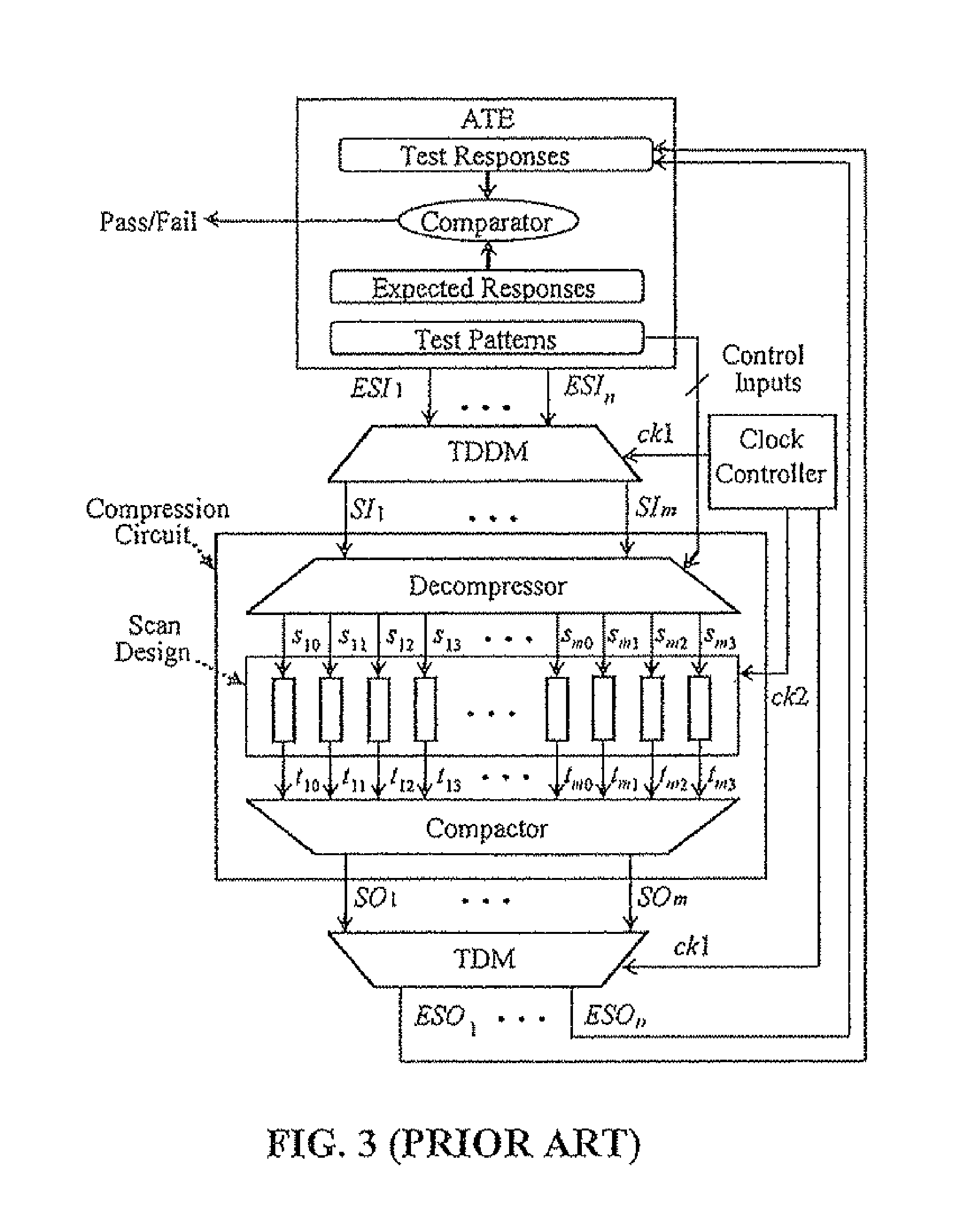

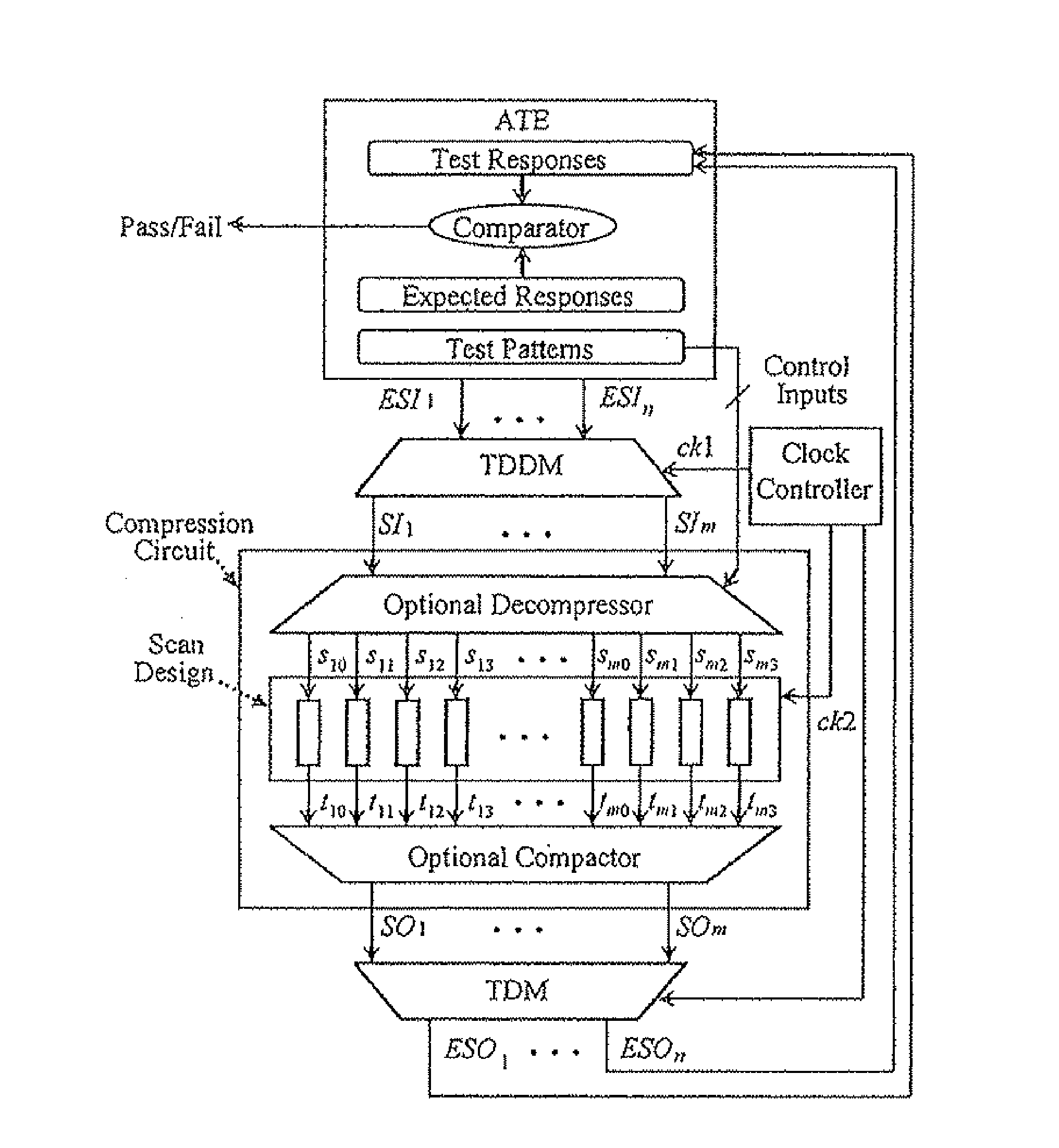

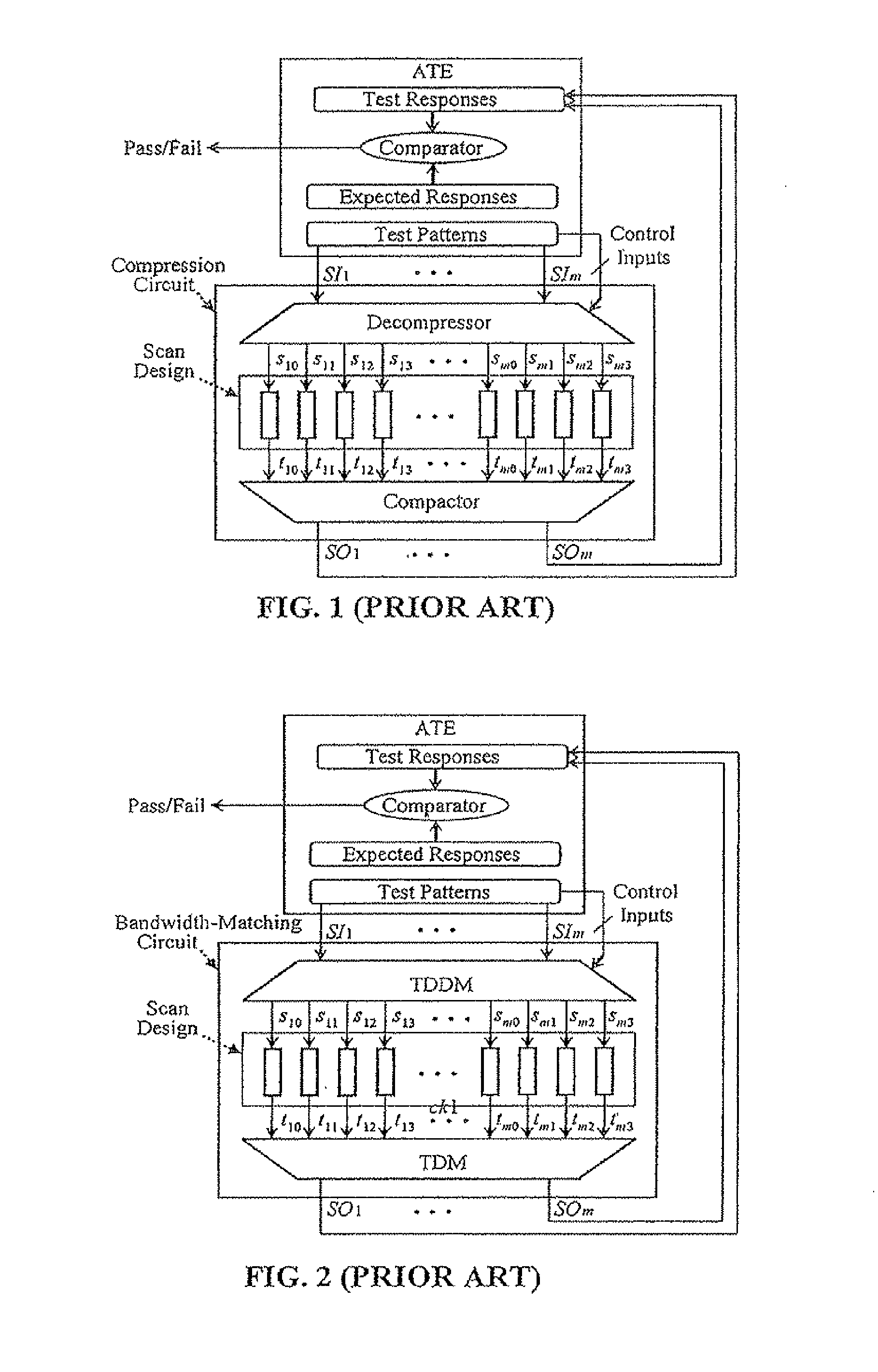

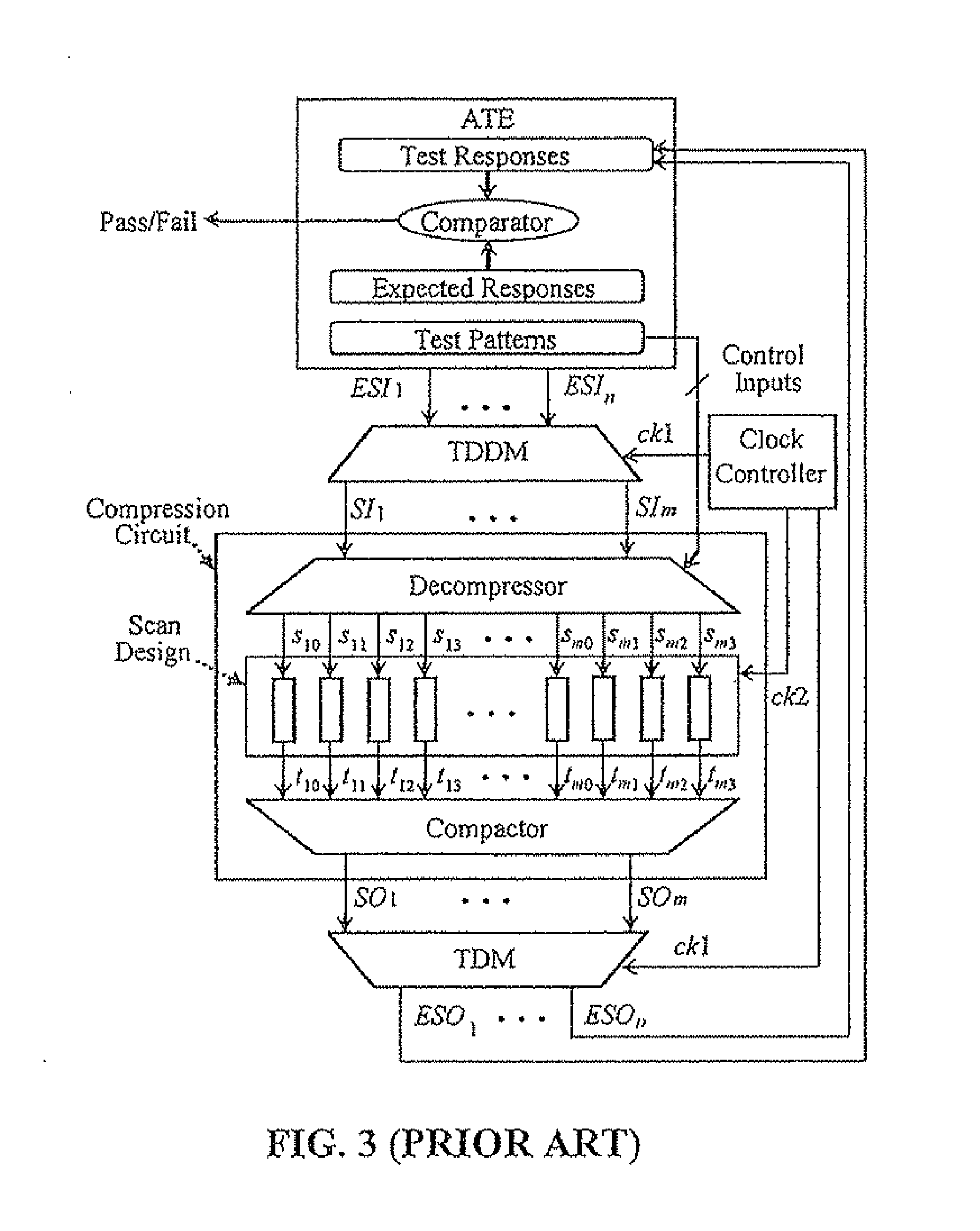

Method and apparatus for testing 3D integrated circuits

InactiveUS8522096B2Reduce testing costsIncrease data rateElectronic circuit testingFault coverageEngineering

A method and apparatus for testing a scan-based 3D integrated circuit (3DIC) using time-division demultiplexing / multiplexing allowing for high-data-rate scan patterns applied at input / output pads converting into low-data-rate scan patterns applied to each embeddded module in the 3DIC. A set of 3D design guidelines is proposed to reduce the number of test times and the number of through-silicon vias (TSVs) required for both pre-bond testing and post-bond testing. The technique allows reuse of scan patterns developed for pre-bond testing of each die (layer) for post-bond testing of the whole 3DIC. It further reduces test application time without concerns for I / O pad count limit and risks for fault coverage loss.

Owner:SYNTEST TECH

3D design and fabrication system for implants

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects the volumetric changes of the site, and fabricating a real 3D implant that includes the volumetric changes. A method of designing, presenting, generating, and implanting custom implants by obtaining a three-dimensional (3D) image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects volumetric changes of the site, and injecting or infusing a gel or semi-solid implant into a patient to effect the volumetric changes. A method of implanting a custom implant in a patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. An implant fabricated by this method.

Owner:KOTLUS BRETT

3D design and fabrication system for implants

ActiveUS9056017B2Details involving processing stepsAdditive manufacturing apparatusCustom made implant3d design

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, and fabricating a real 3D implant. A method of implanting a custom implant in a patient, by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, fabricating a real 3D implant, and implanting the implant in the patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. The present invention also provides for an implant fabricated by this method.

Owner:KOTLUS BRETT

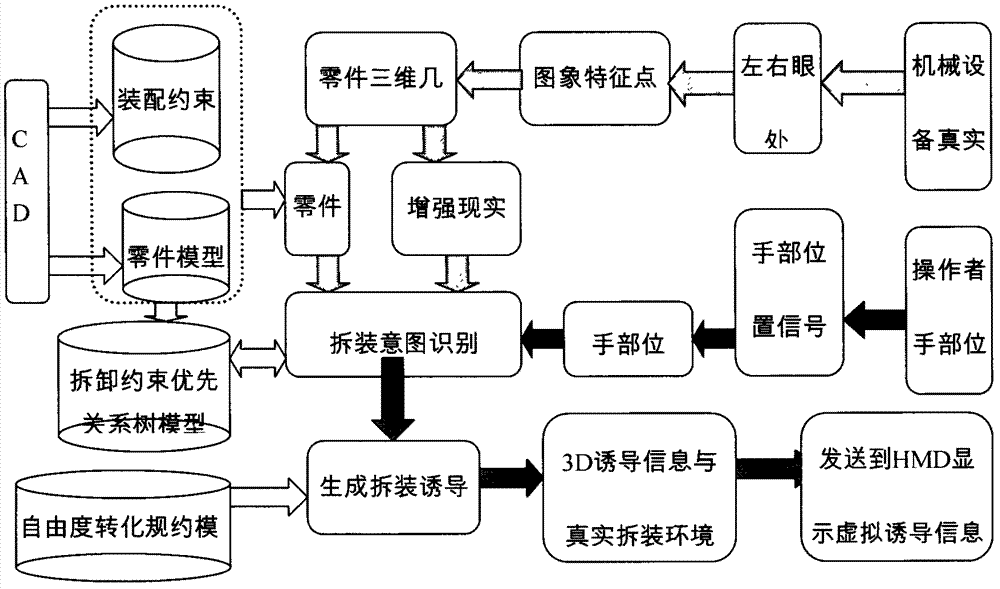

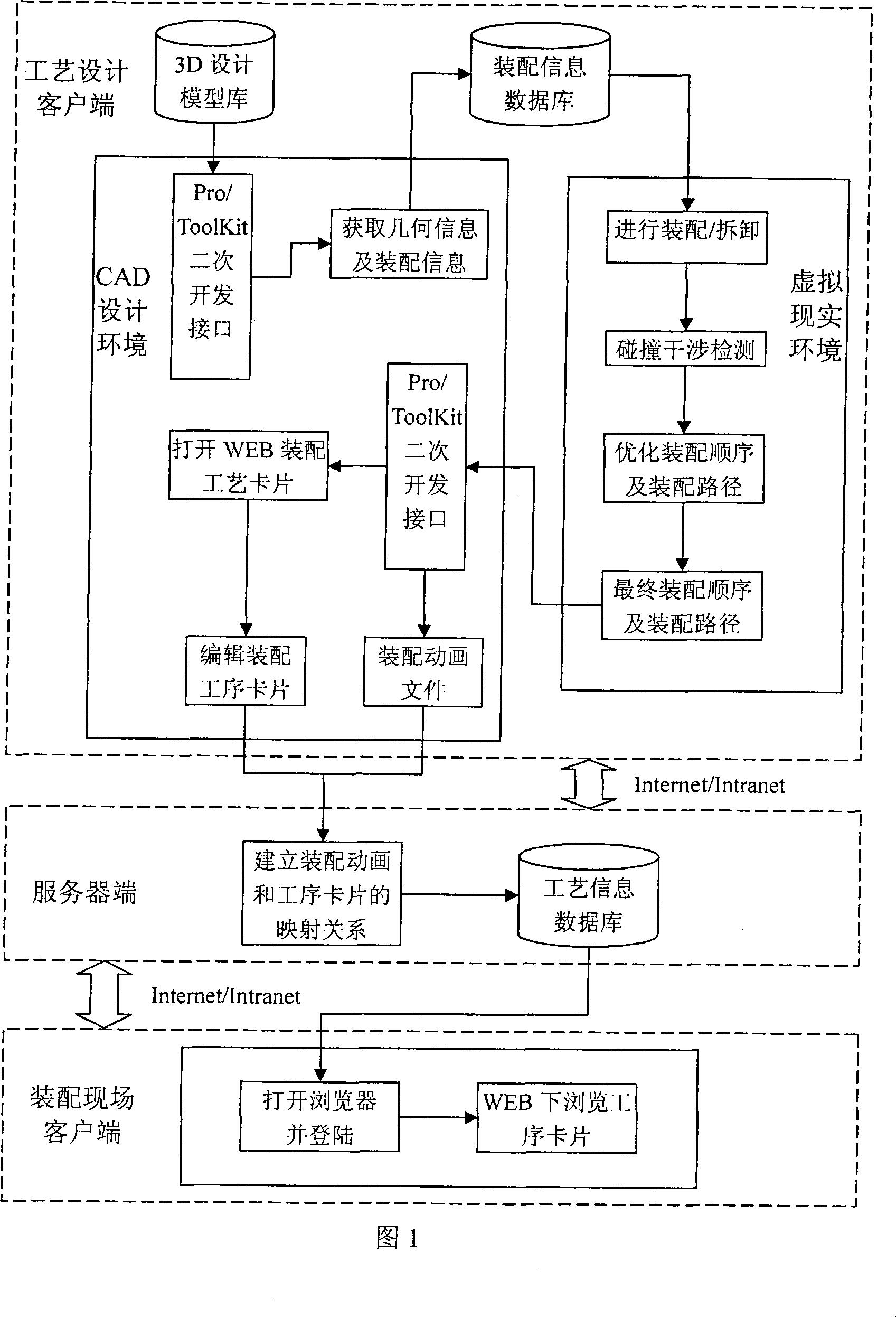

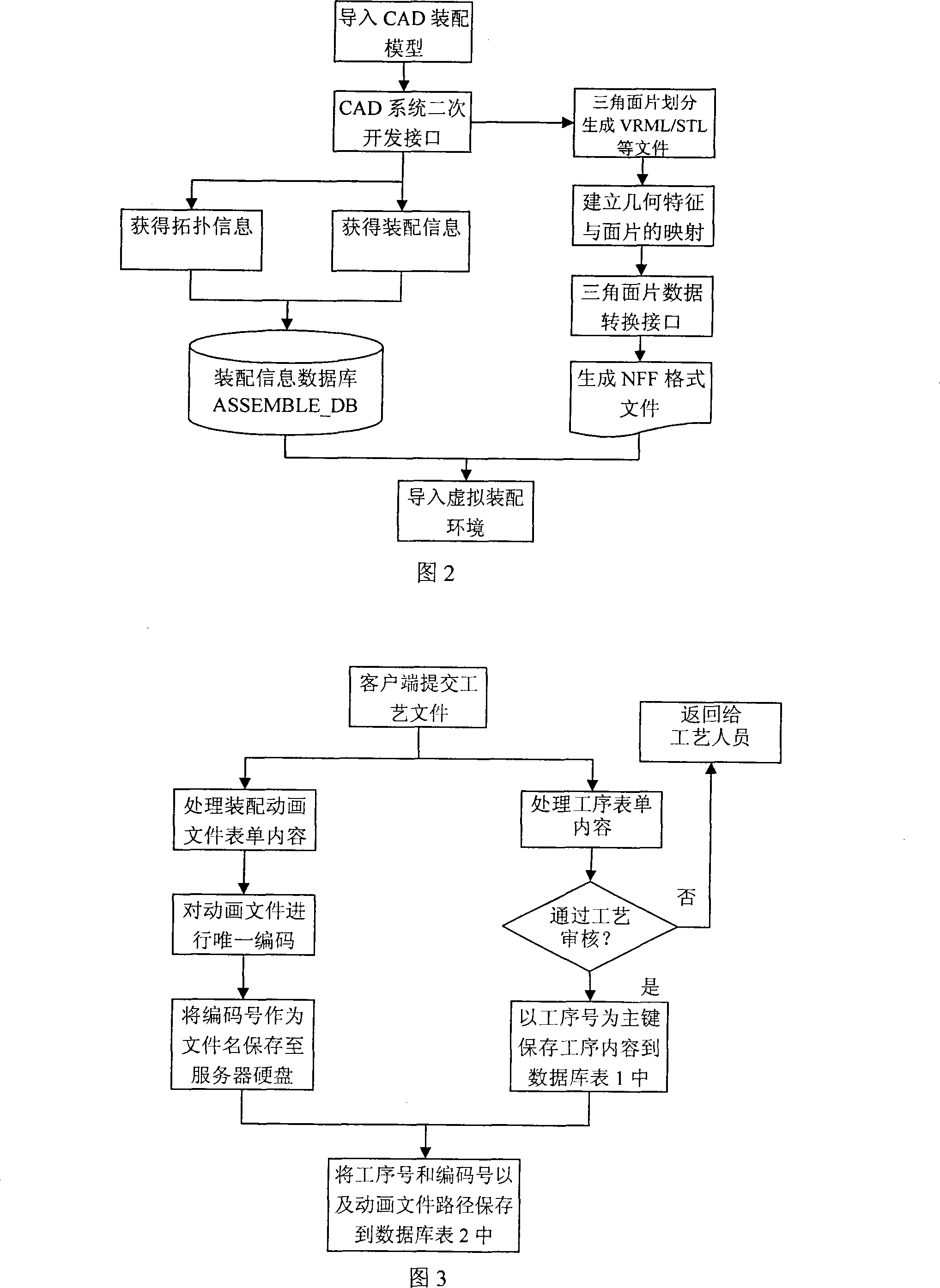

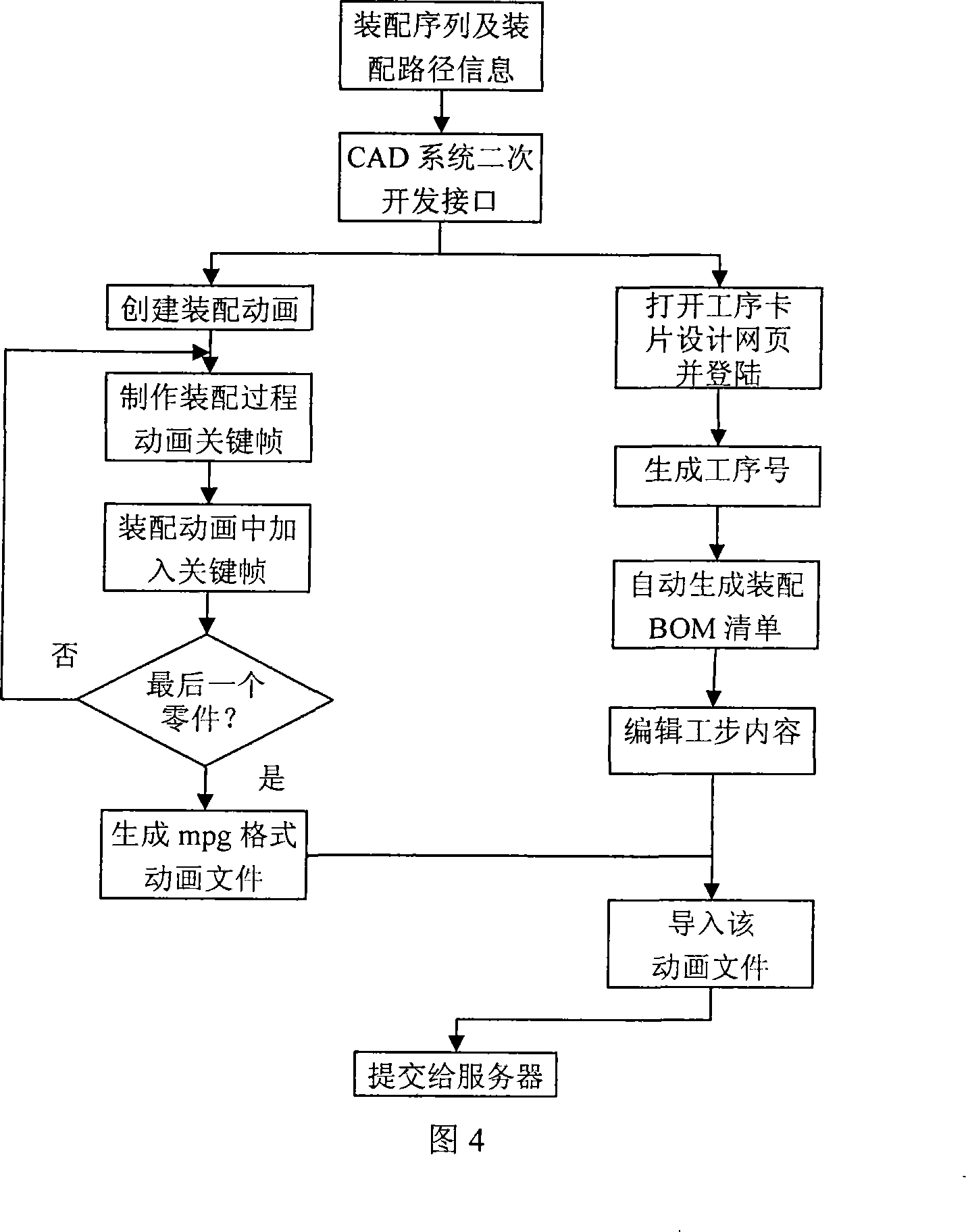

Method for implementing three-dimensional assembly technique file and on-site teaching based on WEB

The invention relates to a generation method of product assembly process based on WEB and a realization method of field teaching demonstration, aiming at design problems of prior 3D assembly process. The method integrates advantages of 3D CAD software design, virtual reality technique and network application, solves problems that prior assembly process is disjoint with 3D design module, 2D paper process is not helpful for operational persons' comprehension and usage, and the generated process files are not helpful for management. The method of the invention is characterized by good convenience, vivacity and interaction, so that technicians can conveniently compile 3D assembly process files and assembly cartoons through the method and by use of browsers through Internet or Intranet, and the method can also facilitate field teaching demonstration for field assembly persons with convenience and vivacity. The method can greatly improve products assembly and design efficiency and can reduce products field assembly period.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

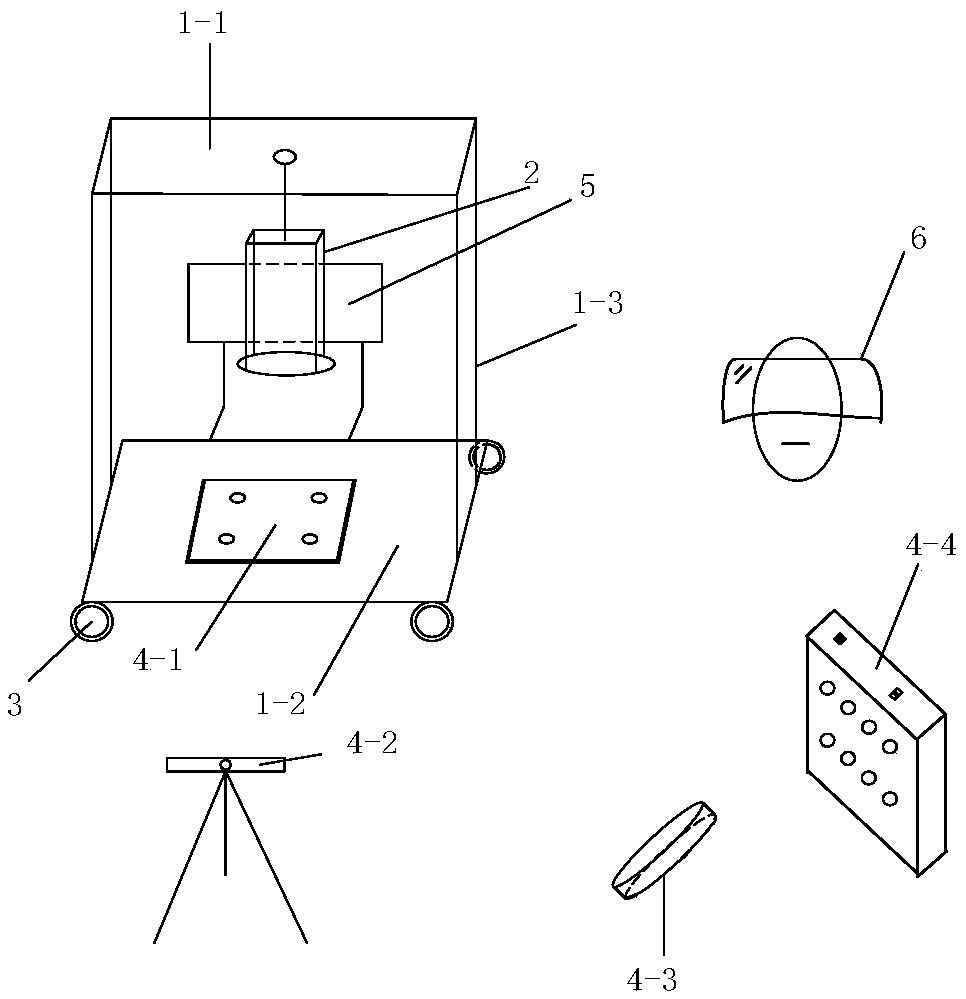

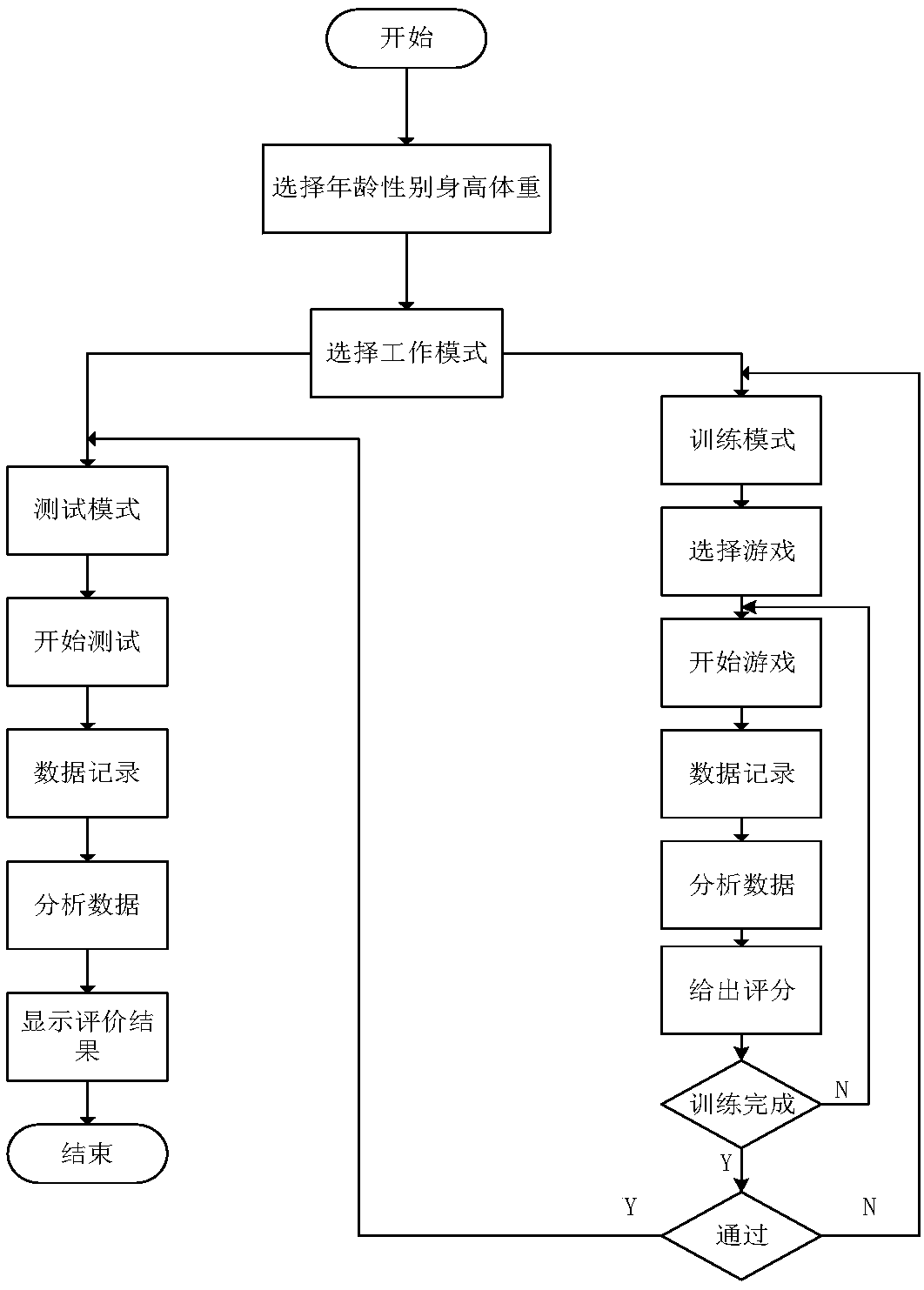

Omni-mobile balance capacity assessing and training system of stroke patients

PendingCN109276237AAchieving Fun Balance TrainingImprove recovery efficiencyEvaluation of blood vesselsSensorsHuman bodyDisplay device

The invention discloses an omni-mobile balance capacity assessing and training system of stroke patients. The omni-mobile balance capacity assessing and training system structurally comprises a fixingdevice, a safe device, a moving device, a data collecting device, a data processing and displaying device and a visual interference device; on the basis of multi-mode signal collecting and processingand by combining friendly human-computer interaction between voice prompt and the tested persons, a human body balance capacity assessing virtual task based on the Unity 3D design is completed by thestroke patients, information such as age, gender, stature, weight, pressure center path, heart rate, blood pressure, electromyographic signal and joint angle of the stroke patients are obtained accurately, and balance capacity assessing results of the stroke patients are comprehensively given; the system can further automatically formulate a corresponding training scheme according to the assessing results, and balance capacity training of the stroke patients is achieved by combining a balance capacity training game in VR glasses; and the omni-mobile balance capacity assessing and training system is simple in structure, easy and convenient to operate, capable of moving omni-directionally and high in reliability, and has good promotional value.

Owner:ZHENGZHOU UNIV

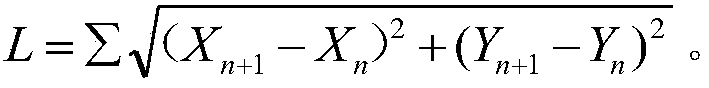

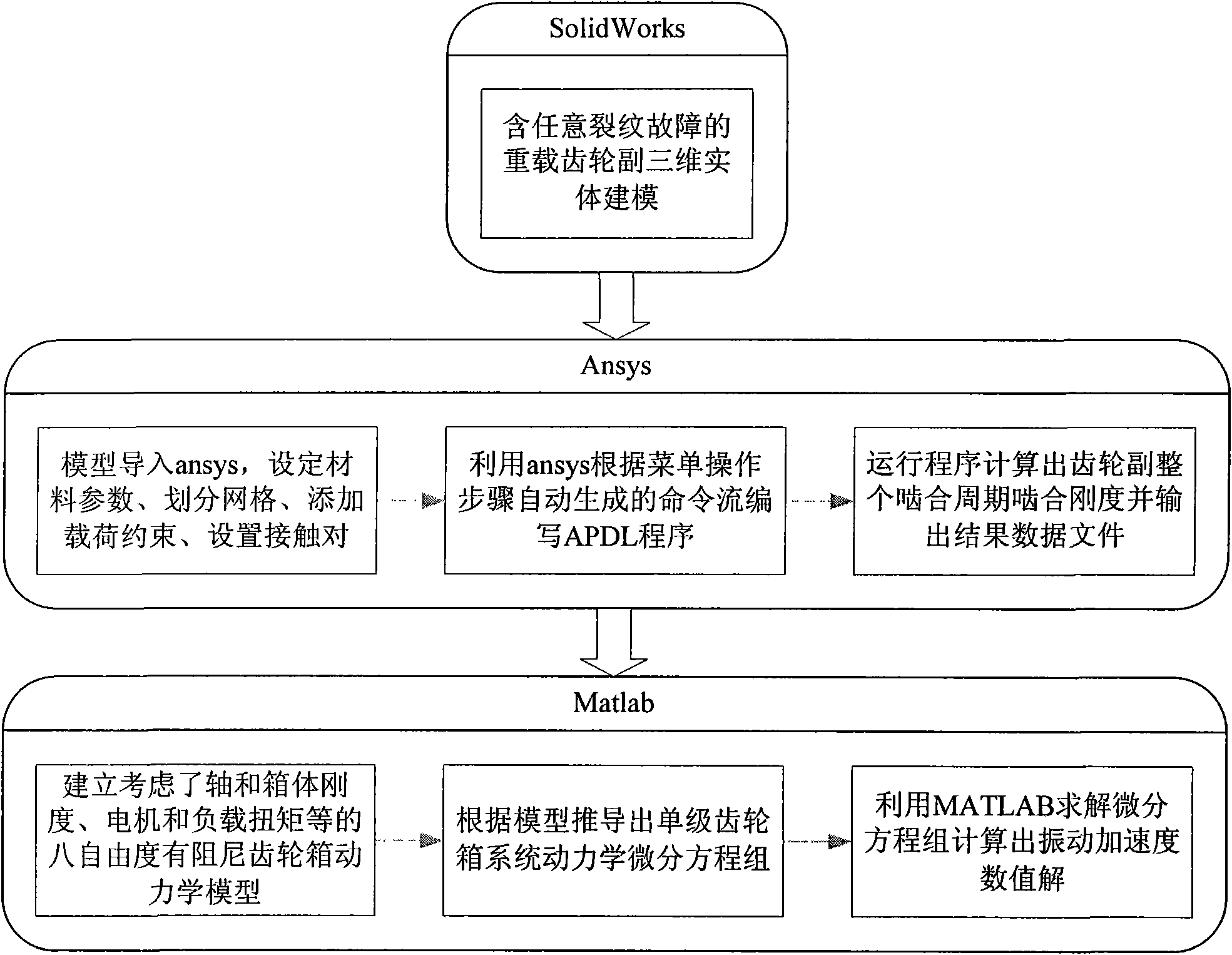

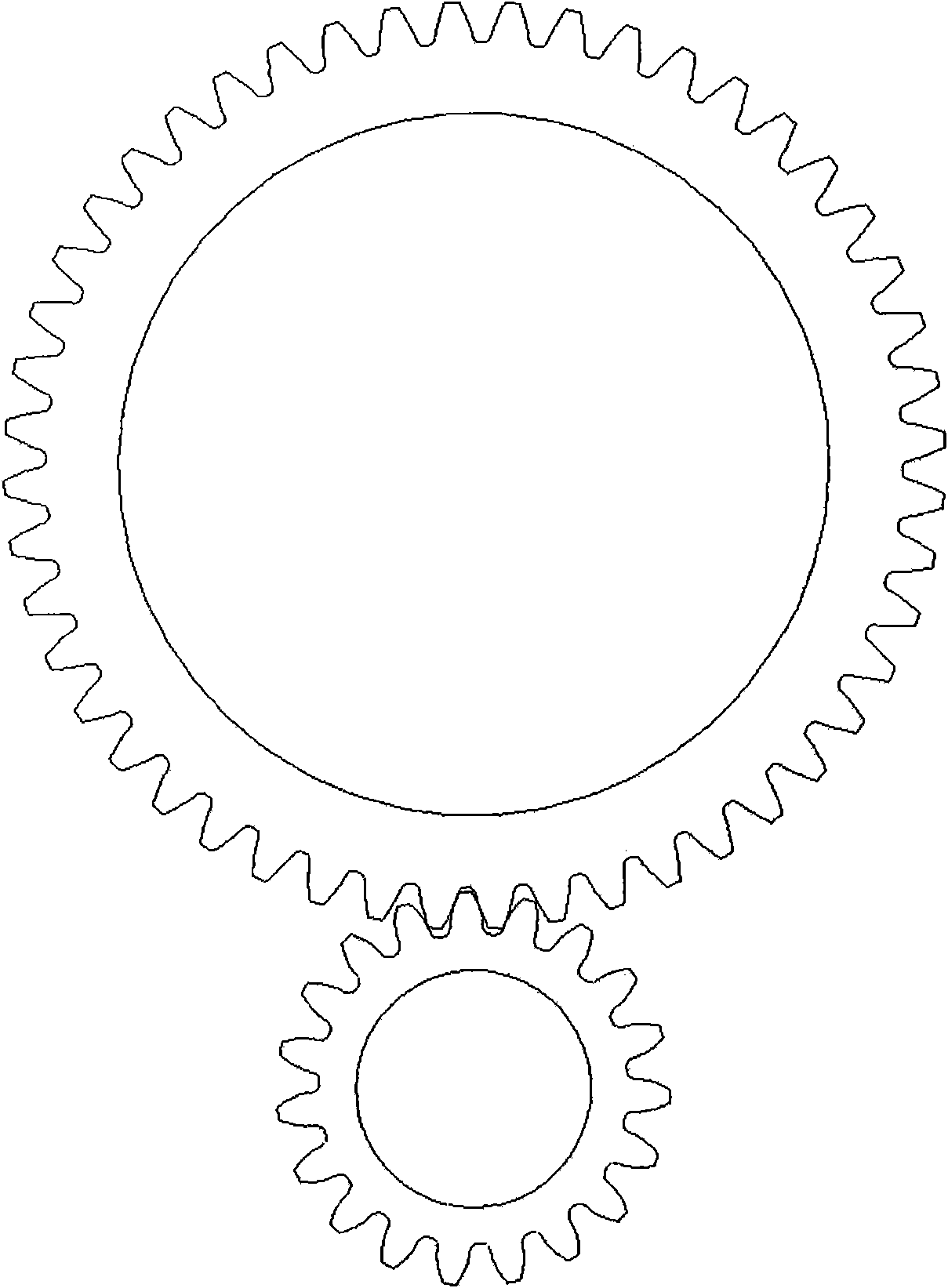

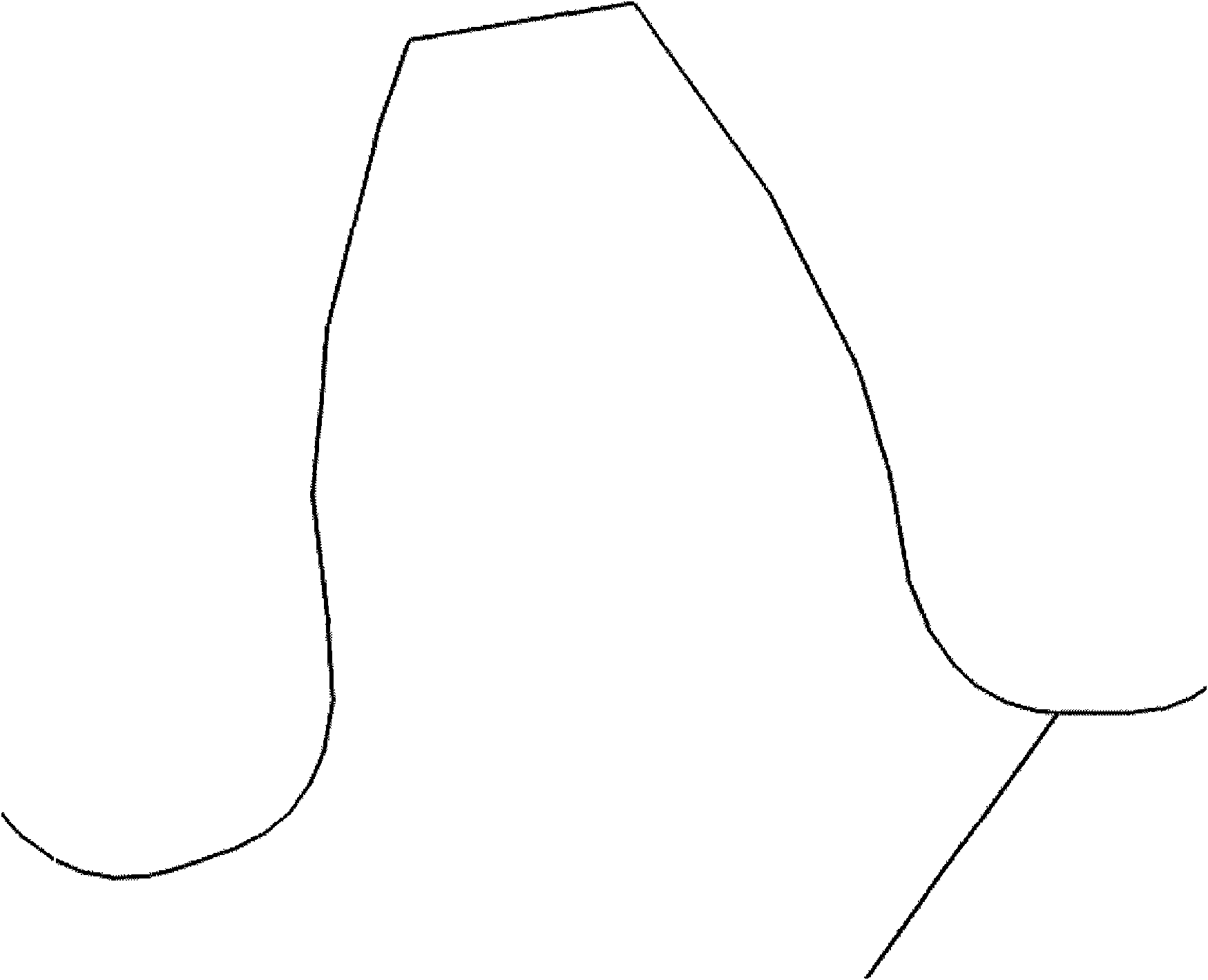

Simulation analysis method of vibratory response of variable working condition single-stage heavy gear case containing crackle fault

InactiveCN101625710AEasy to drawDrawn preciselyMachine gearing/transmission testingSpecial data processing applicationsLoad torqueSystem dynamics model

The invention relates to a simulation analysis method of the vibratory response of a variable working condition single-stage heavy gear case containing a crackle fault, which comprises the following steps: establishing a gear pair 3D solid model containing a crackle fault on the basis of 3D design software SolidWorks; leading the model into finite element analysis software ansys, programming a program capable of calculating the gear meshing rigidity of any meshing positions by combining menu operations of the ansys and APDL languages and outputting a result data file of the meshing rigidity; establishing a damping gear case system kinetic model of 8 degrees-of-freedom and kinetic simultaneous differential equations considering factors of the rigidity and the damping of a shaft and the case, an input torque and a load torque of a motor, and the like and utilizing MATLAB to solve the equations so as to simulate the system vibratory response of the single-stage heavy gear case containing a crackle fault. The invention integrates the advantages of the SolidWorks, the ansys and the MATLAB and can quickly and accurately simulate the vibratory responses of variable working condition heavy single-stage heavy gear cases containing various different forms of crackle faults.

Owner:BEIJING UNIV OF TECH

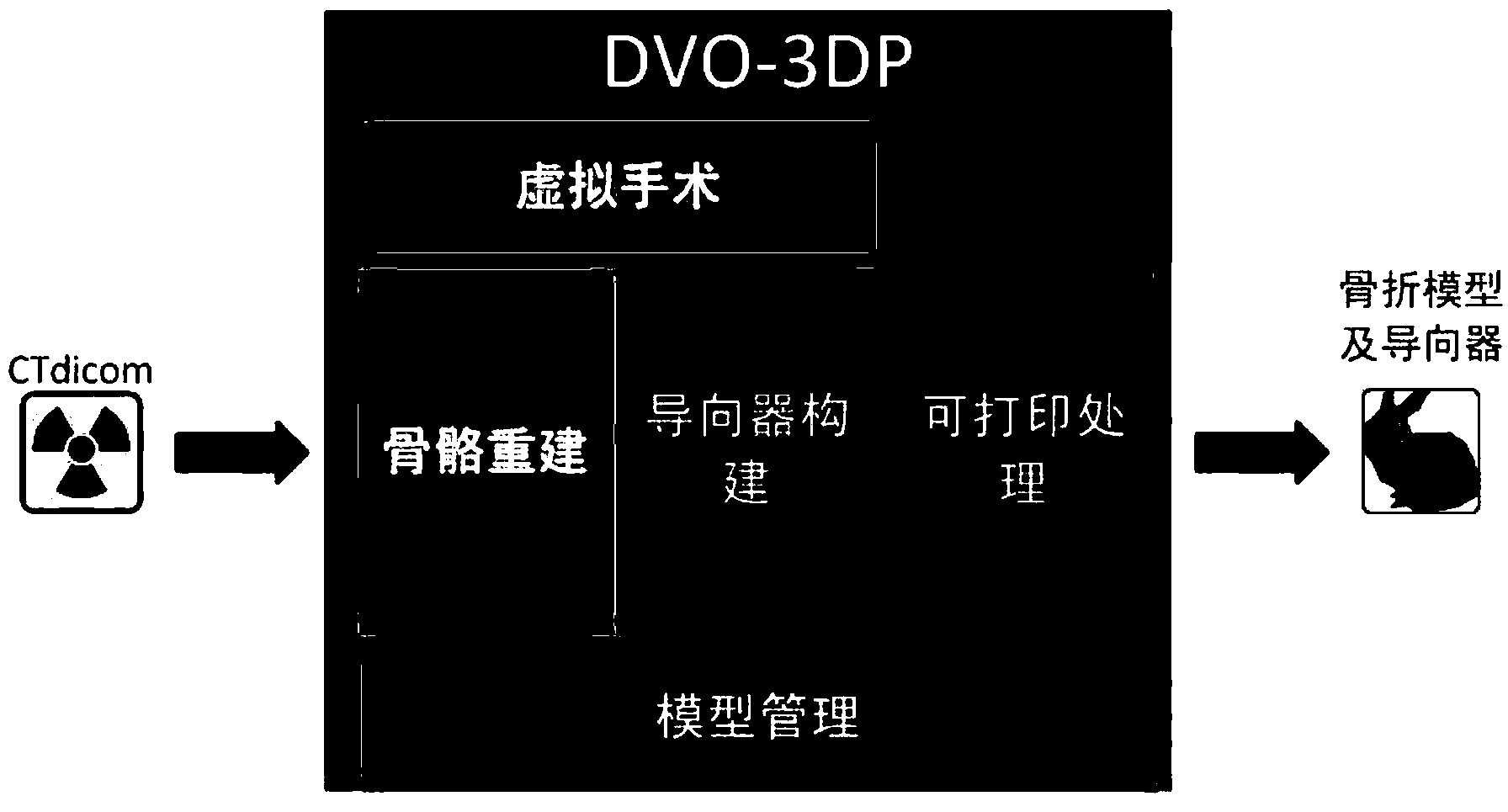

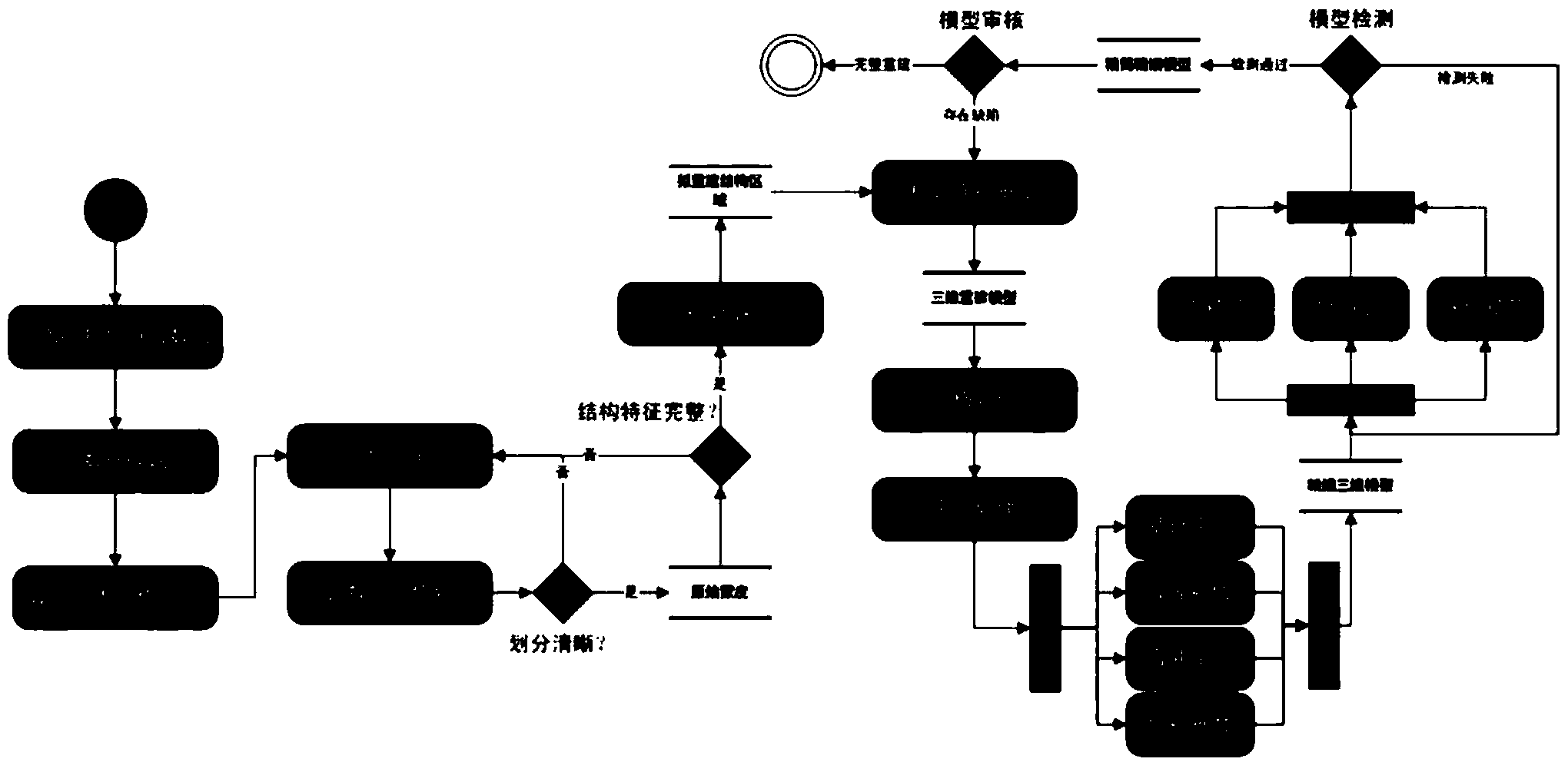

Atlantoaxial pedicle screw guide and preparation method therefor

InactiveCN104306061AImprove surgical precisionReduce surgical riskOsteosynthesis devices3d designComputing tomography

The invention provides an atlantoaxial pedicle screw guide and a preparation method therefor. The method is that a hospital PACS (picture archiving and communication system) system obtains atlantoaxial fracture data or CT (computed tomography) scan data of cervical dislocation of a patient; based on the data, and a 3D design and print work platform of digital visualized orthopedics is used for designing and preparing the atlantoaxial pedicle screw guide. The atlantoaxial pedicle screw guide and the preparation method therefor has the advantages of being high in accuracy, easy to operate and low in cost. Furthermore, the atlantoaxial pedicle screw guide and the preparation method therefor is capable of making complex and high-risk atlantoaxial fixation surgery accurate, safe and easy to operate under the accurate guide of the guide, surgery accuracy is greatly improved, and the risk of the surgery is reduced.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

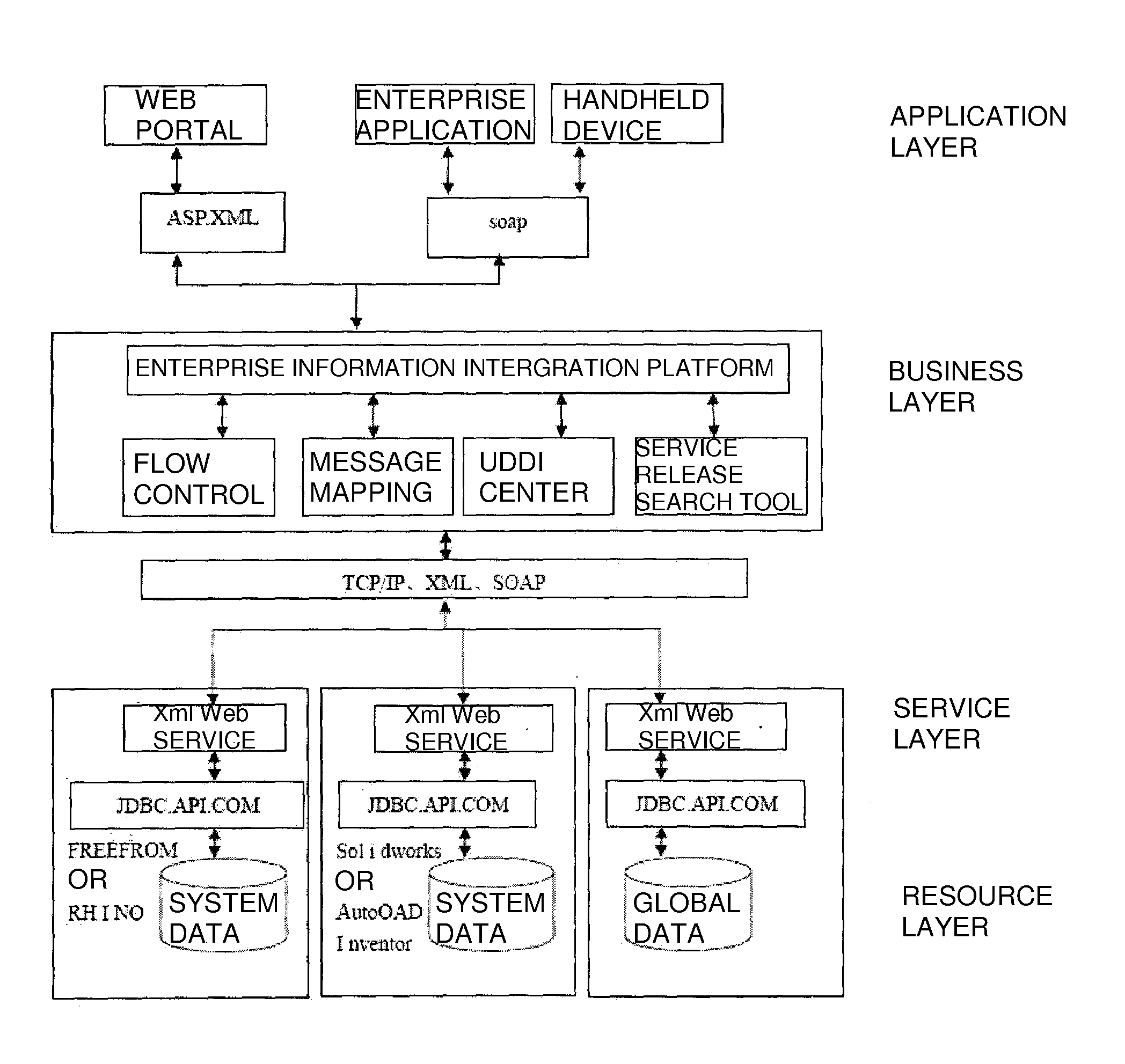

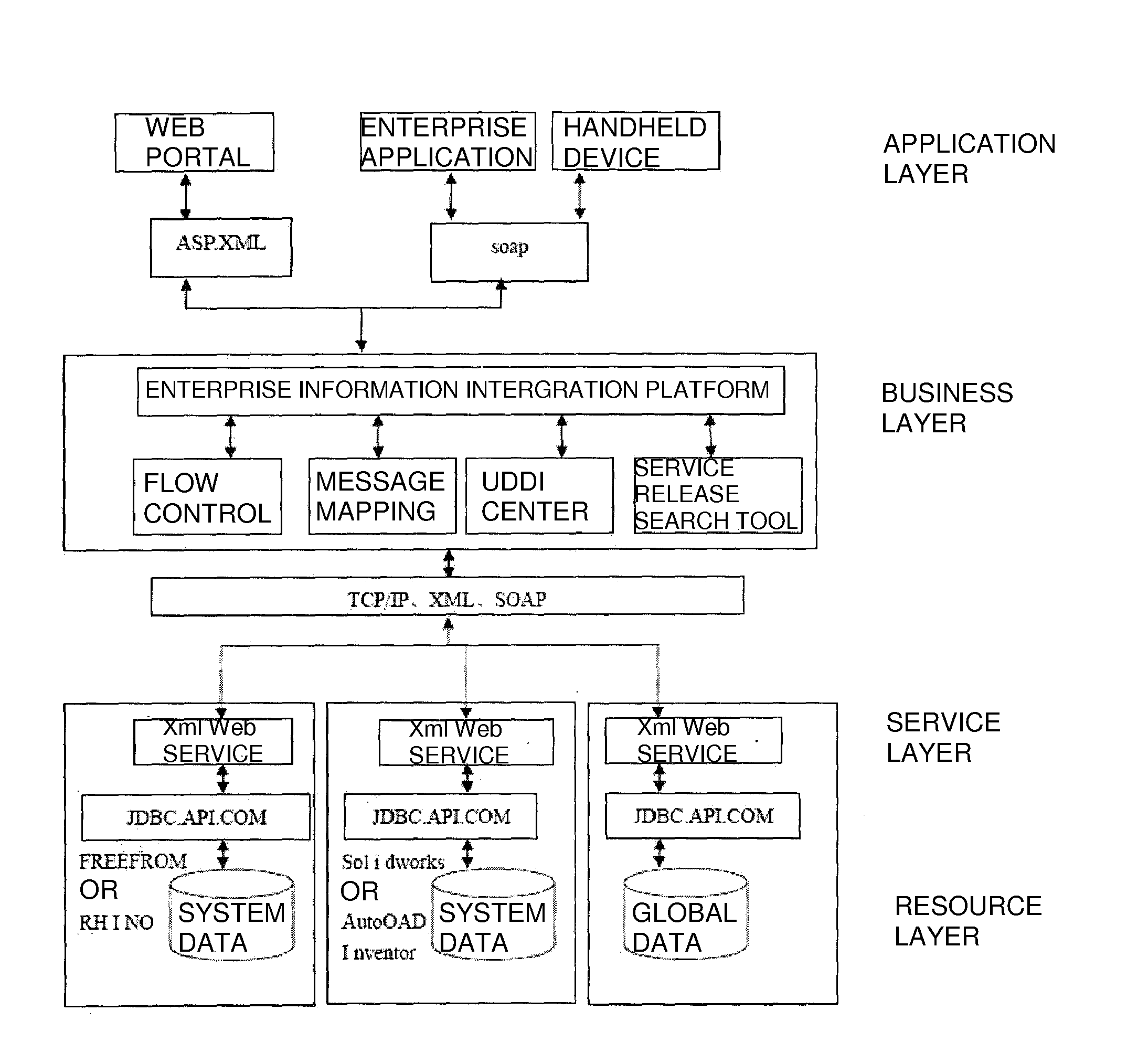

SOA-based Integration Method and System for 3D Design System

InactiveUS20130283228A1Improve efficiencyHighly standardizedSoftware designImage data processingThird partyWeb service

The present invention provides an SOA-based integration method for a 3D design system. The method comprises the following steps: 1) constructing an SOA integration development system platform, comprising four structural layers connected to each other, communicating with each other, and being, from top to bottom, an application layer, a business layer, a service layer, and a resource layer; 2) setting at least one global model data server at the resource layer, and setting a design information integration platform at the business layer; 3) setting multiple pieces of third-party 3D model design system software at the resource layer, encapsulating them into a WEB service through an API program thereof, and setting the WEB service at the service layer; 4) setting database systems of the multiple pieces of third-party 3D model design system software at the resource layer, connecting the database systems to the global model data server through a data bus for mutual communication; and 5) setting an integration web portal at the application layer, wherein the portal is integrated with sign-in links of the third-party 3D model design system software. The present invention further provides a system for implementing the above method.

Owner:DONGGUAN GOSCIEN ELECTRICAL & MECHANICAL TECH SERVICES

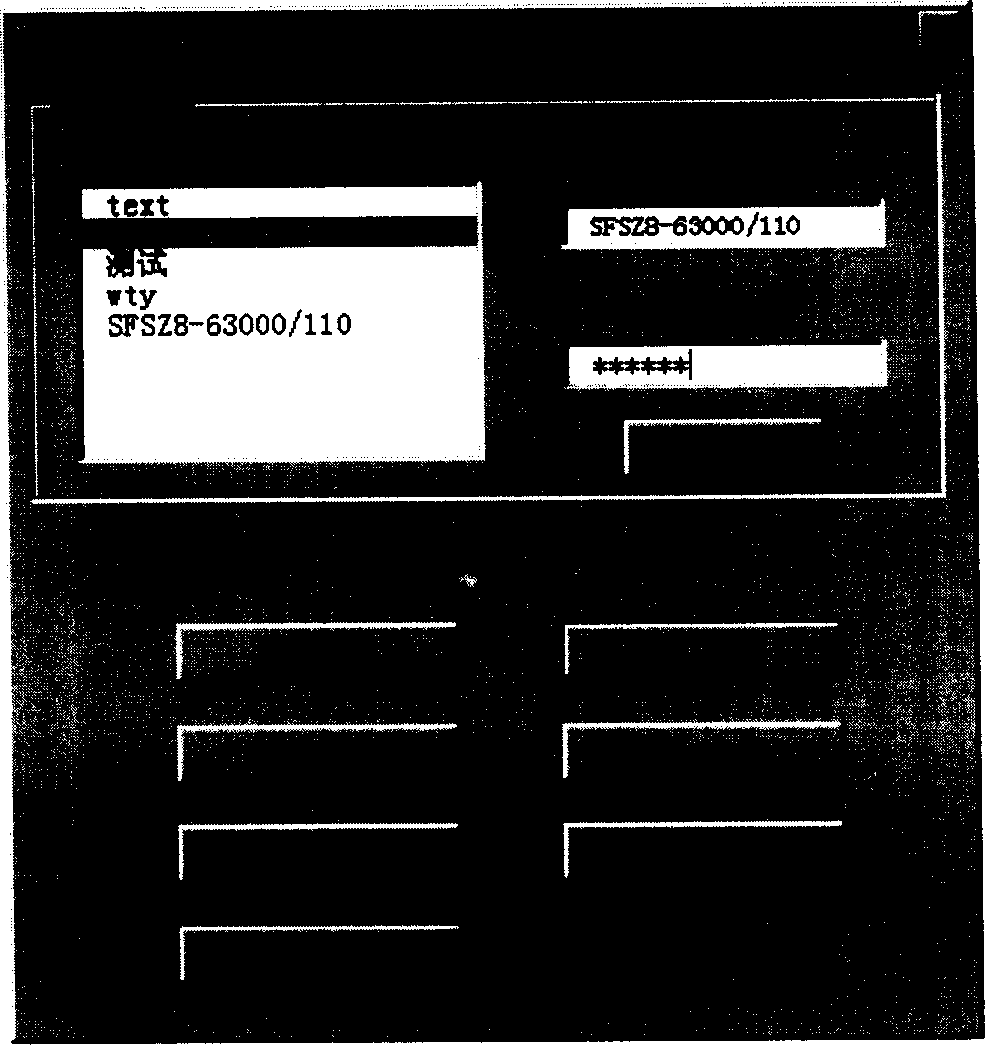

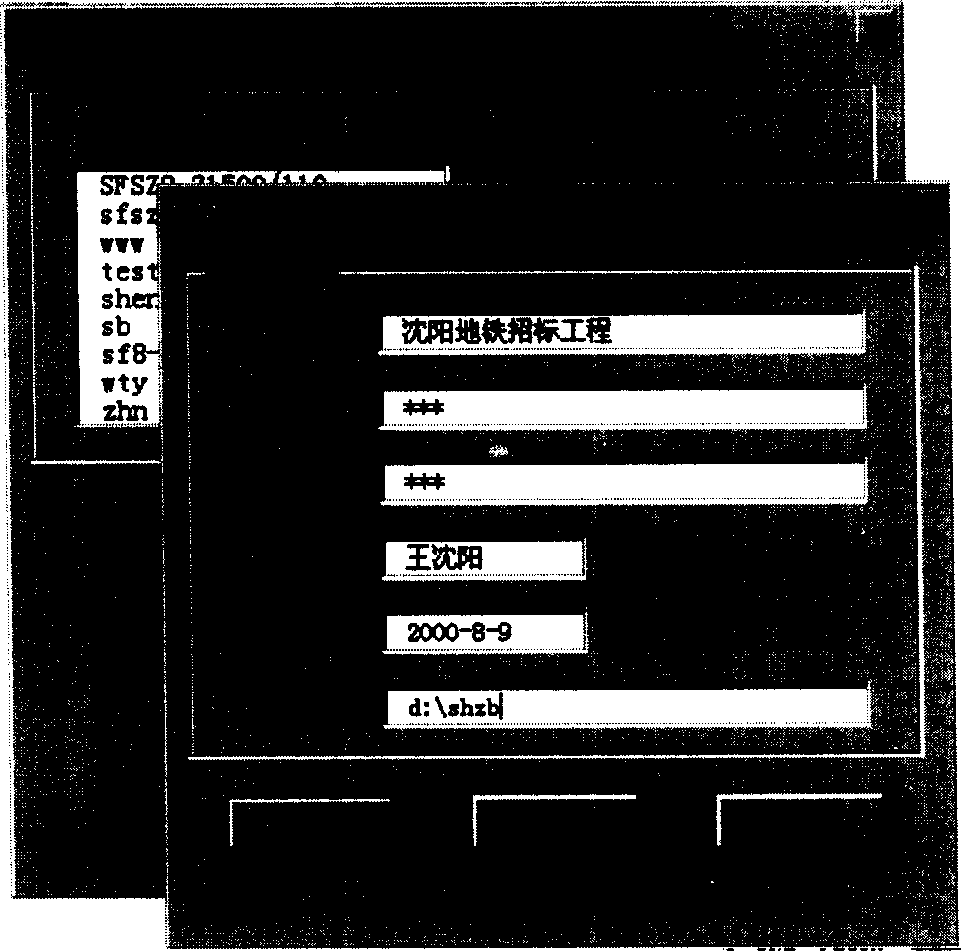

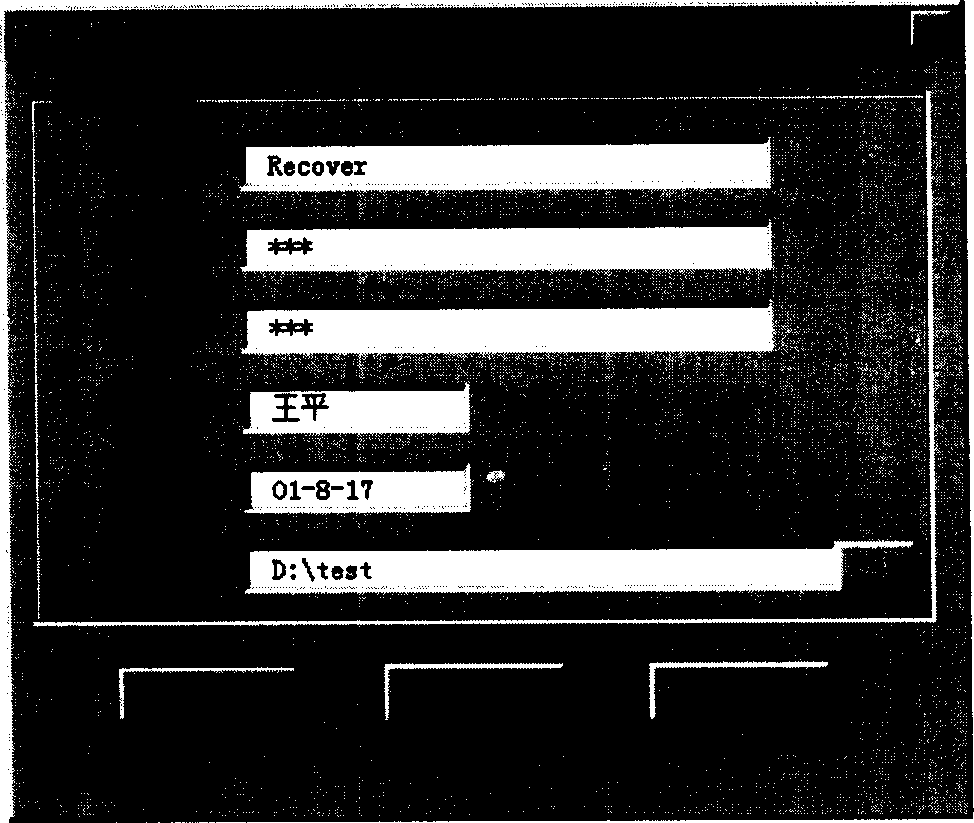

3D design system for transformer

InactiveCN1670874AProtection of rights and interestsInductances/transformers/magnets manufactureSpecial data processing applicationsOff design3d design

This invention provides three-D shaping software, which can simulate the complete assembling process of transformer in screen, produce the three-D products model same with the real products in shape, reflect the fitting information of parts and make the designer modifying the design before production, which is operated in MDT three-D software platform and adapted to the power transformer equal to or lower than 110 kv type.

Owner:沈阳变压器研究院有限公司

Method and apparatus for testing 3D integrated circuits

InactiveUS20120110402A1Reduce testing costsIncrease data rateElectronic circuit testingLogical operation testingFault coverageEngineering

A method and apparatus for testing a scan-based 3D integrated circuit (3DIC) using time-division demultiplexing / multiplexing allowing for high-data-rate scan patterns applied at input / output pads converting into low-data-rate scan patterns applied to each embeddded module in the 3DIC. A set of 3D design guidelines is proposed to reduce the number of test times and the number of through-silicon vias (TSVs) required for both pre-bond testing and post-bond testing. The technique allows reuse of scan patterns developed for pre-bond testing of each die (layer) for post-bond testing of the whole 3DIC. It further reduces test application time without concerns for I / O pad count limit and risks for fault coverage loss.

Owner:SYNTEST TECH

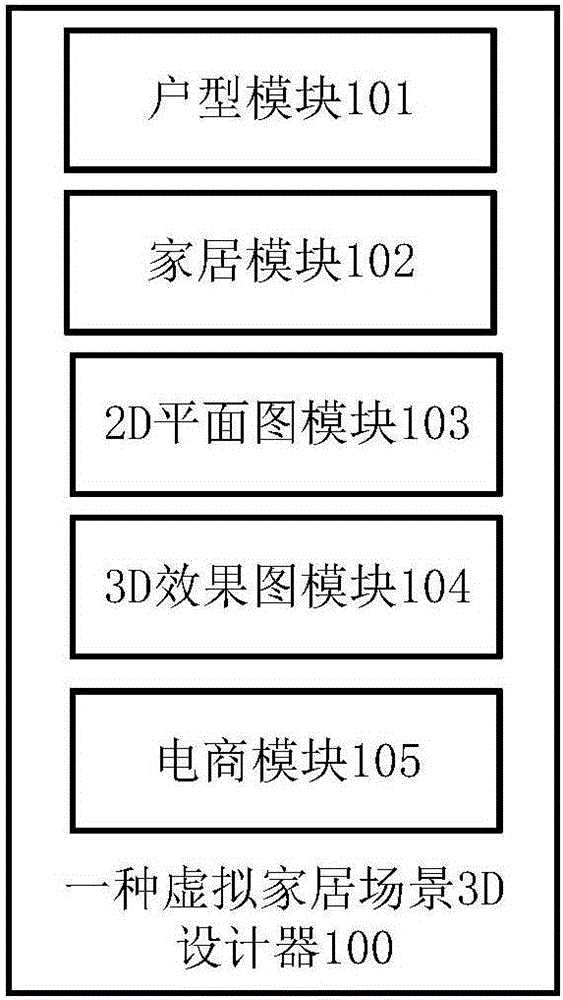

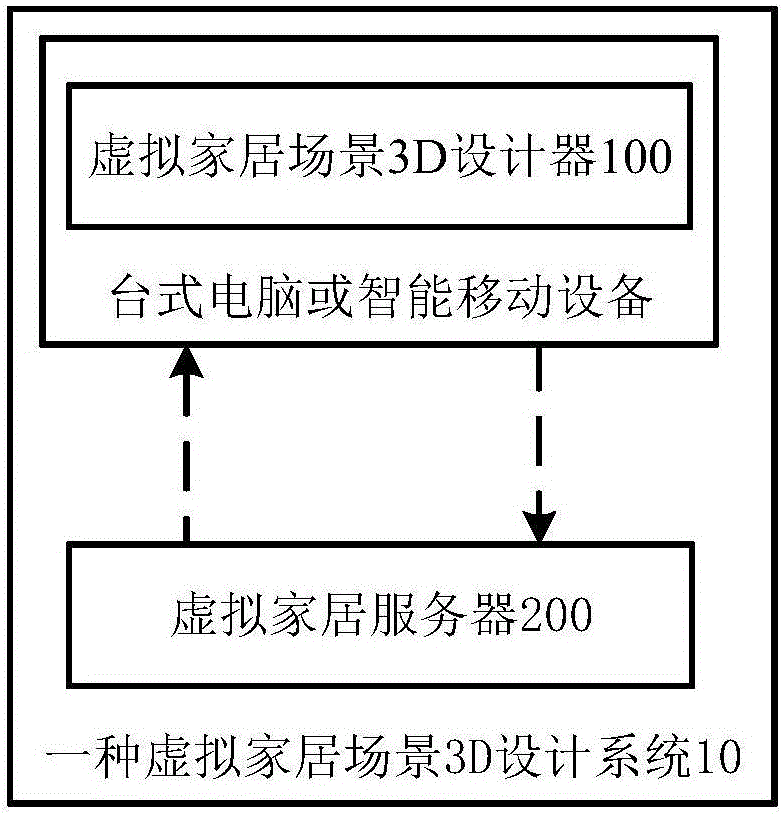

Virtual home scene 3D designer and virtual home scene 3D design system

InactiveCN106652005AEasy to buyMeet the needs of personalized household product customization2D-image generationTransmission3d designComputer graphics (images)

The invention relates to a virtual home scene 3D designer and a virtual home scene 3D design system. The designer is installed in a desktop computer or in a smart mobile device. The desktop computer or in the smart mobile device is wirelessly connected with a virtual home server. The virtual home scene 3D designer comprises a house type module, a home module, a 2D floor plan module which is used for generating a 2D virtual home scene according to a house type picture selected by a user from the house type module so the user can select a visual home model from the home module and drag the visual home model to an appropriate position of the 2D virtual home scene, and a 3D effect picture module which is used for generating a 3D home stereogram according to the 2D virtual home scene output by the 2D floor plan module and the visual home model therein and displaying the 3D home stereogram on a user interface. Through the technical scheme provided by the invention, home products custom-made and personalized by users can be presented graphically and stereoscopically.

Owner:成都盈同乐家信息技术有限公司

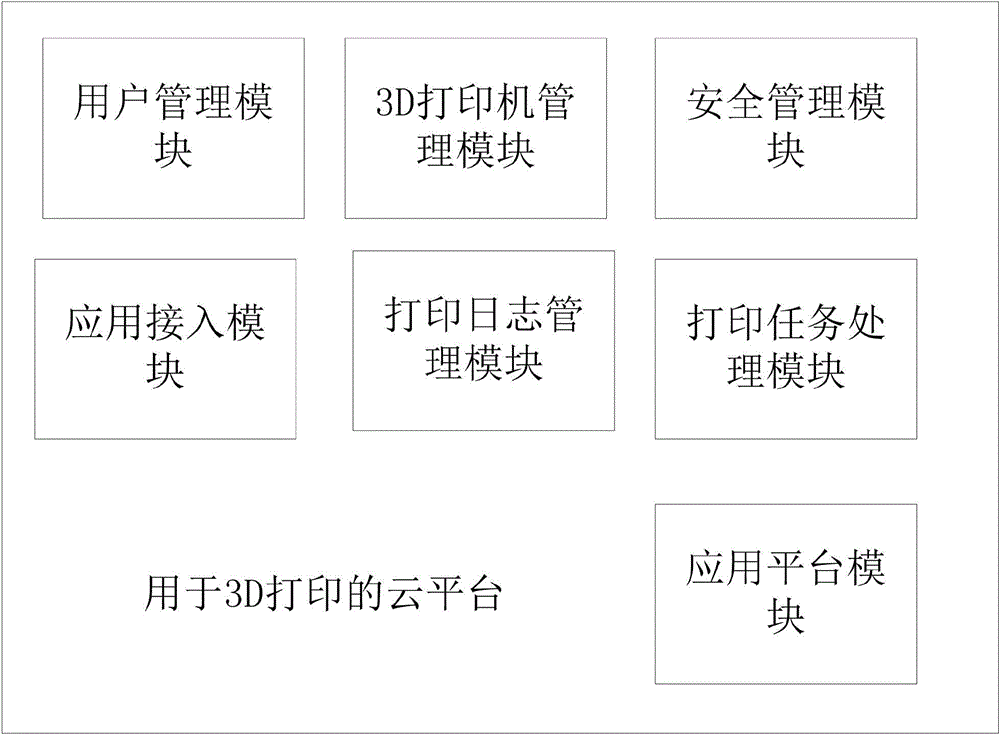

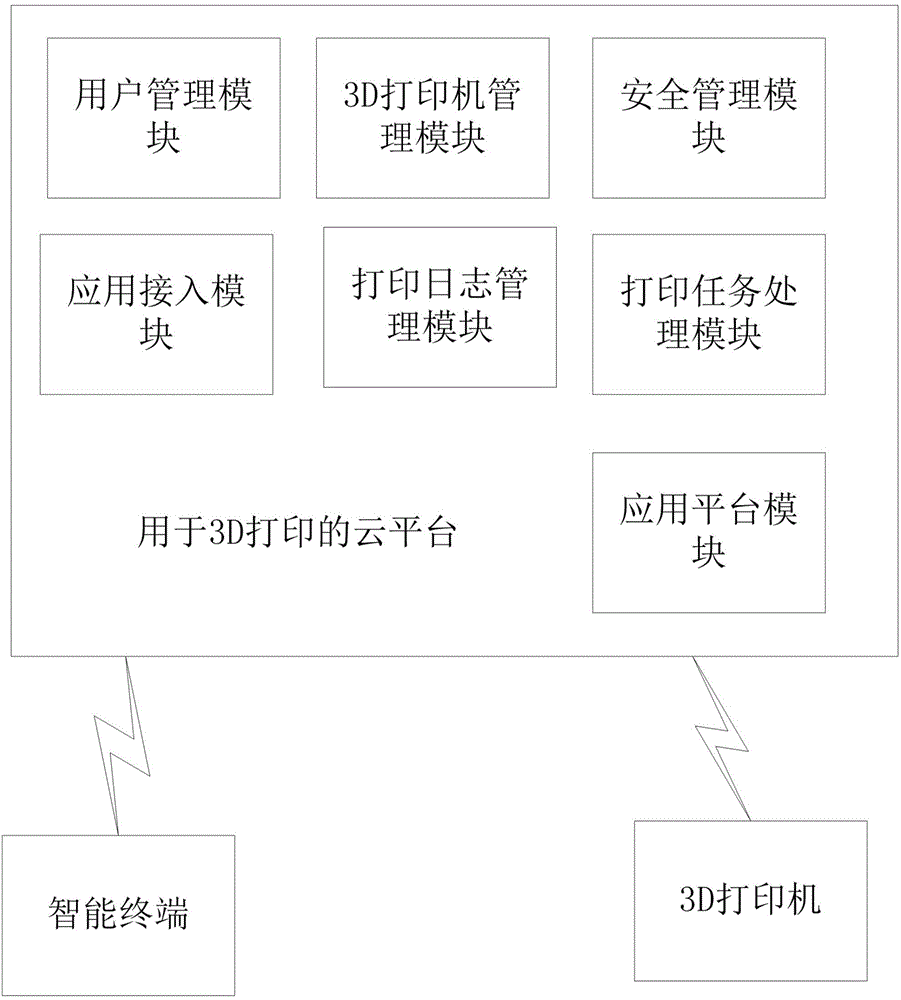

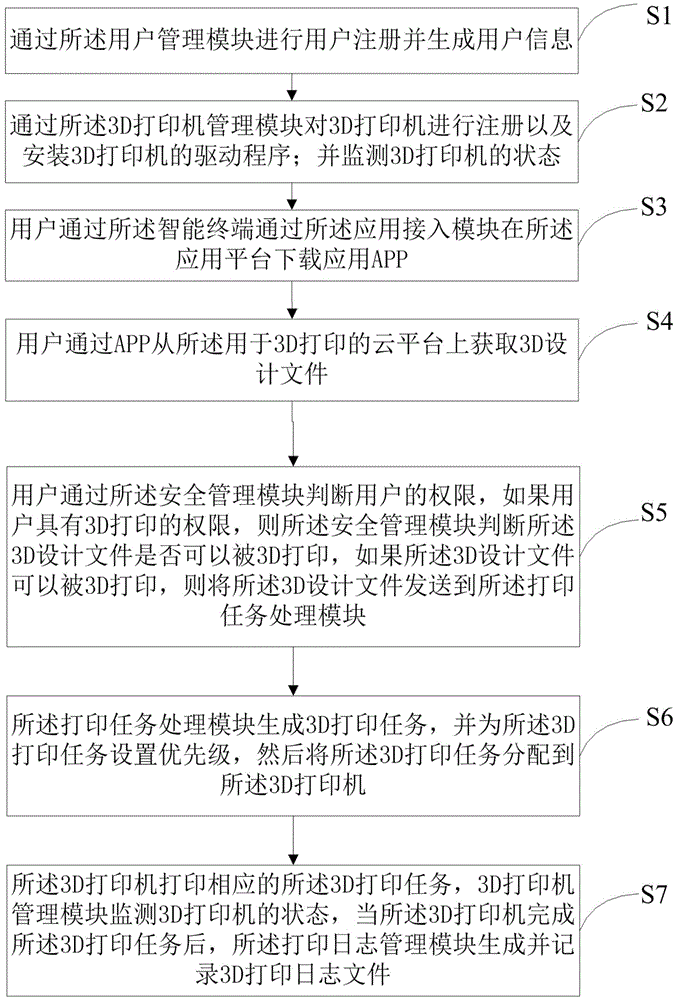

Cloud platform used for 3D printing, 3D printing system and method

The invention discloses a cloud platform used for 3D printing. The cloud platform comprises a user managing module used for managing registers of users and user information; a 3D printer managing module used for managing real-time communication with a 3D printer, managing the registers and driving programs of the 3D printer, monitoring the state of the 3D printer and further used for a user to configure the 3D printer on a remote end; a safety managing module used for managing the user right and further managing the verification of printing tasks; a printing task processing module used for managing the priority of printing tasks, distributing the printing tasks and detecting the printing task finishing states; a printing log managing module used for generating and recording 3D printing log files; an application access module used for providing an API interface for the cloud platform; and an application platform used for providing applications APP and 3D design files for the cloud platform. By means of the platform, the 3D printer can be remotely controlled through a mobile terminal.

Owner:苏州速先三维科技有限公司

Method and apparatus for preparing removable dental prosthesis

ActiveUS9675432B2Easy to operateAccurate manufacturing of a complete denture without intensive manual laborImpression caps3D printingSingle visit3d design

A method for manufacturing a removable dental prosthesis using a three-dimensional (3D) printer includes receiving dental impressions of a patient obtained using a dental impression tray assembly, the dental impressions including a bite registration and at least a mandibular impression or a maxillary impression; receiving information related to the patient's jaw relations obtained using the dental impression tray assembly, the jaw relations including a vertical dimension and a centric relation obtained during the patient's single visit to a dentist; scanning the received dental impressions with a 3D scanner to provide data representative of an edentulous shape of the patient; generating a 3D model of the dental prosthesis based on the data and the received information related to the patient's jaw relations using 3D design software; displaying the generated 3D model on a display, allowing customization of the 3D model; and 3D printing the dental prosthesis according to the 3D model.

Owner:DENTCA INC

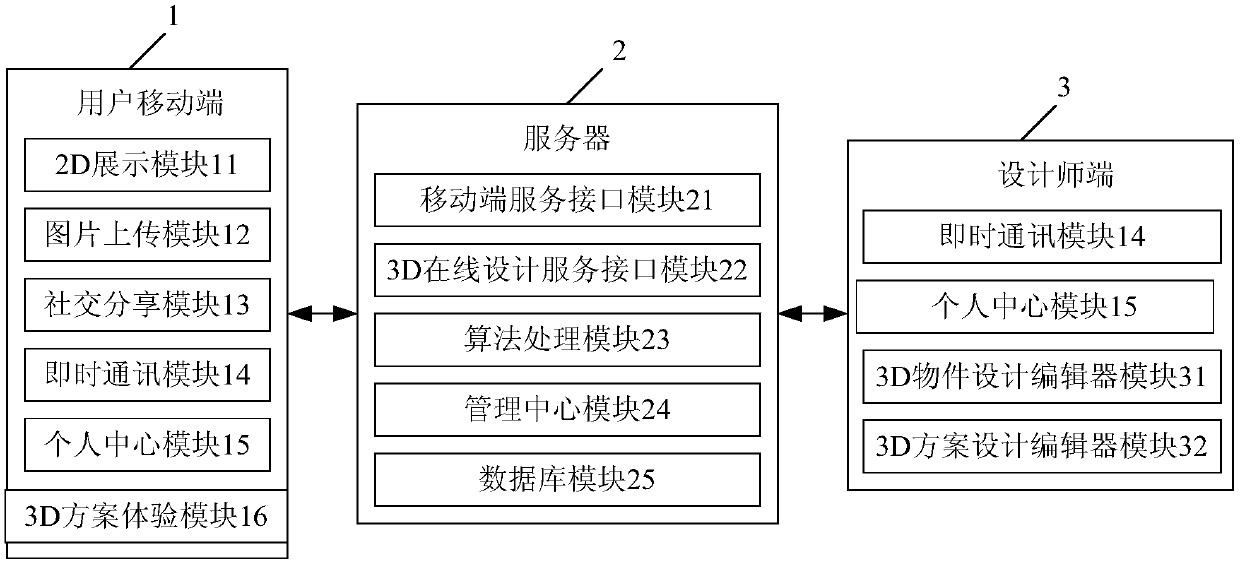

Bionic artificial semi- joint body and manufacturing technique thereof

InactiveCN101108145APrecise thickness controlPrecisely control the areaJoint implantsPolyurethane elastomerManufacturing technology

A simulation manual semi-joint body and fabrication technics are provided, which forms a shell model through reverse engineering and 3D design software and the divides the bone layer into three parts, namely upper, middle and lower layer; then designing the internal pipe column negative structure according to the funvtions of each layer and finally combining the model of each layer and the shell model to form the negetive model. The invention shapes the false body model by adopting the speedy shaping and exact photocureable forming machine, fills the ceramics slurry into the false body model and solidifies it in vacuum high temperature stove and then places the solidified ceramics body in polyurethane solution module; then pumping the vacuum, placing the module still and then taking out the ceramics after the polyurethane fully solidified; shaping it, thus achieving the bone layer material serving as the ceramics part; the soft bone layer elastomer is made of manual semi-joint body of the polyurethane elastomer. The invention reduces the rubbing damage for side joints and strengthens the activity capacity of the joints when the soft bone layer contacting the side joints.

Owner:XI AN JIAOTONG UNIV

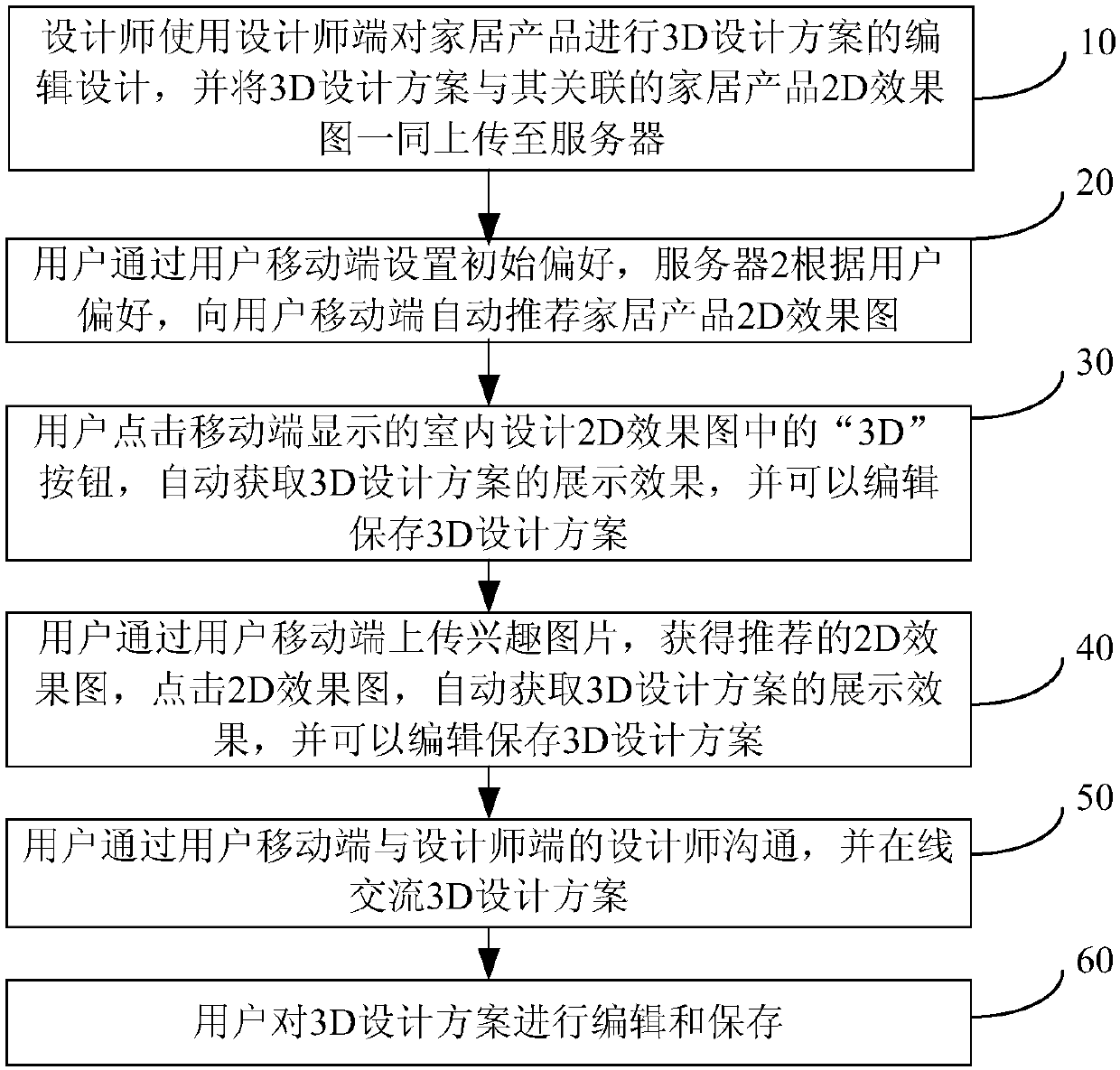

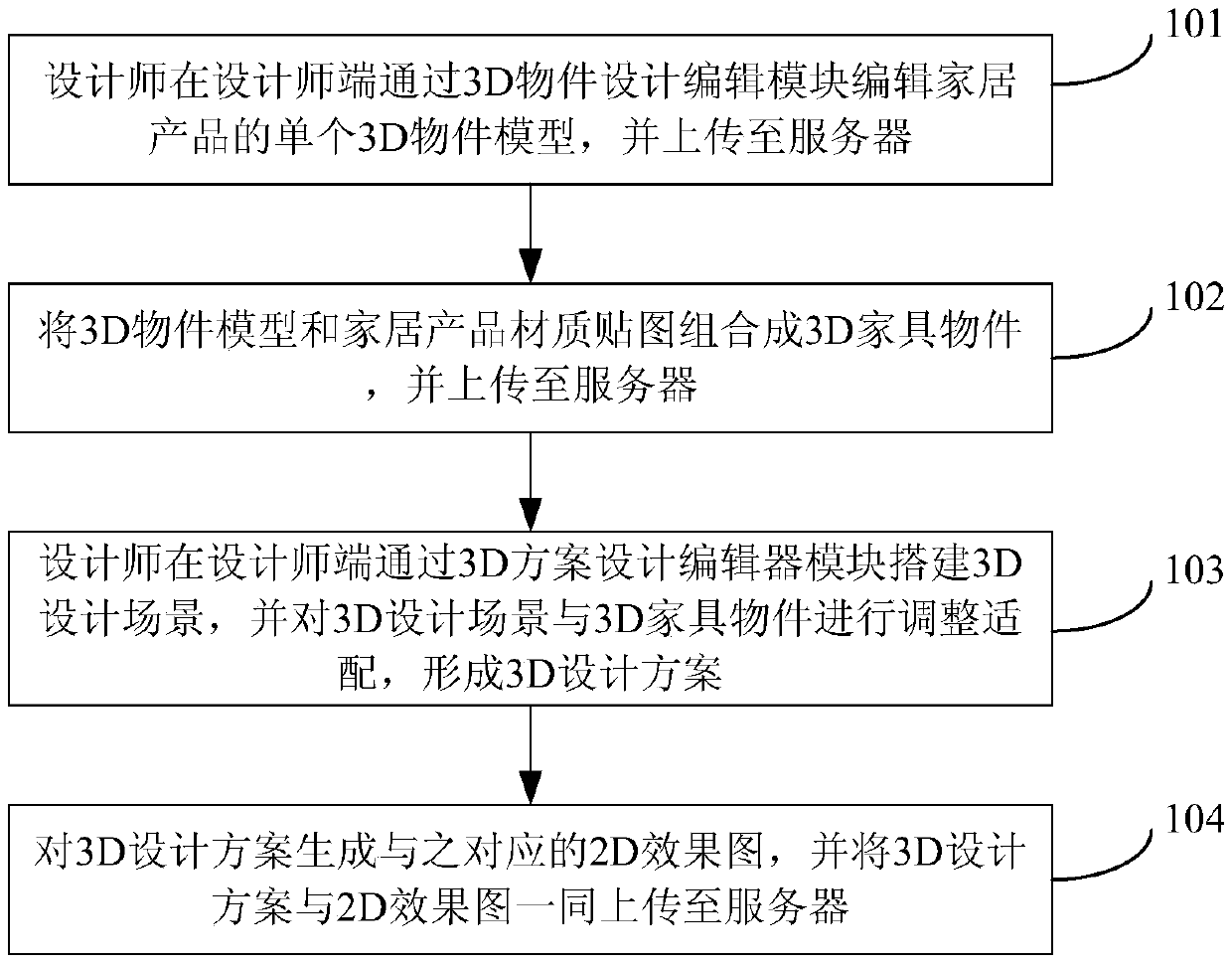

Interior-design method and system based on user interest preference

ActiveCN107944124ALearn about interestsRealize automatic recommendationGeometric CADBuying/selling/leasing transactions3d designMobile end

The embodiment of the invention discloses an interior-design method and system based on user interest preference. The method includes: carrying out editing design of 3D design schemes by a designer for interior design, and uploading the 3D design schemes and interior-design 2D effect drawings, which are associated therewith, to a server; setting initial preference by a user, automatically recommending interior-design 2D effect drawings to a user mobile-end by the server according to the user preference; uploading an interest picture by the user to acquire 2D effect drawings associated with theinterest image and corresponding 3D design schemes; clicking an interior-design 2D effect drawing by the user to automatically acquire a presentation effect of a 3D design scheme; and communicating with the designer by the user to communicate the 3D design scheme online. According to the method, user attributes, browsed-content attributes and operation behaviors of the user in the system are simultaneously investigated, the user interest preference is effectively understood, automatic recommendation of the design schemes is realized, the user and the designer can simultaneously and jointly participate in scheme design online, communication costs are reduced, and efficiency of communication between the designer and the customer is improved.

Owner:上海得见计算机科技有限公司

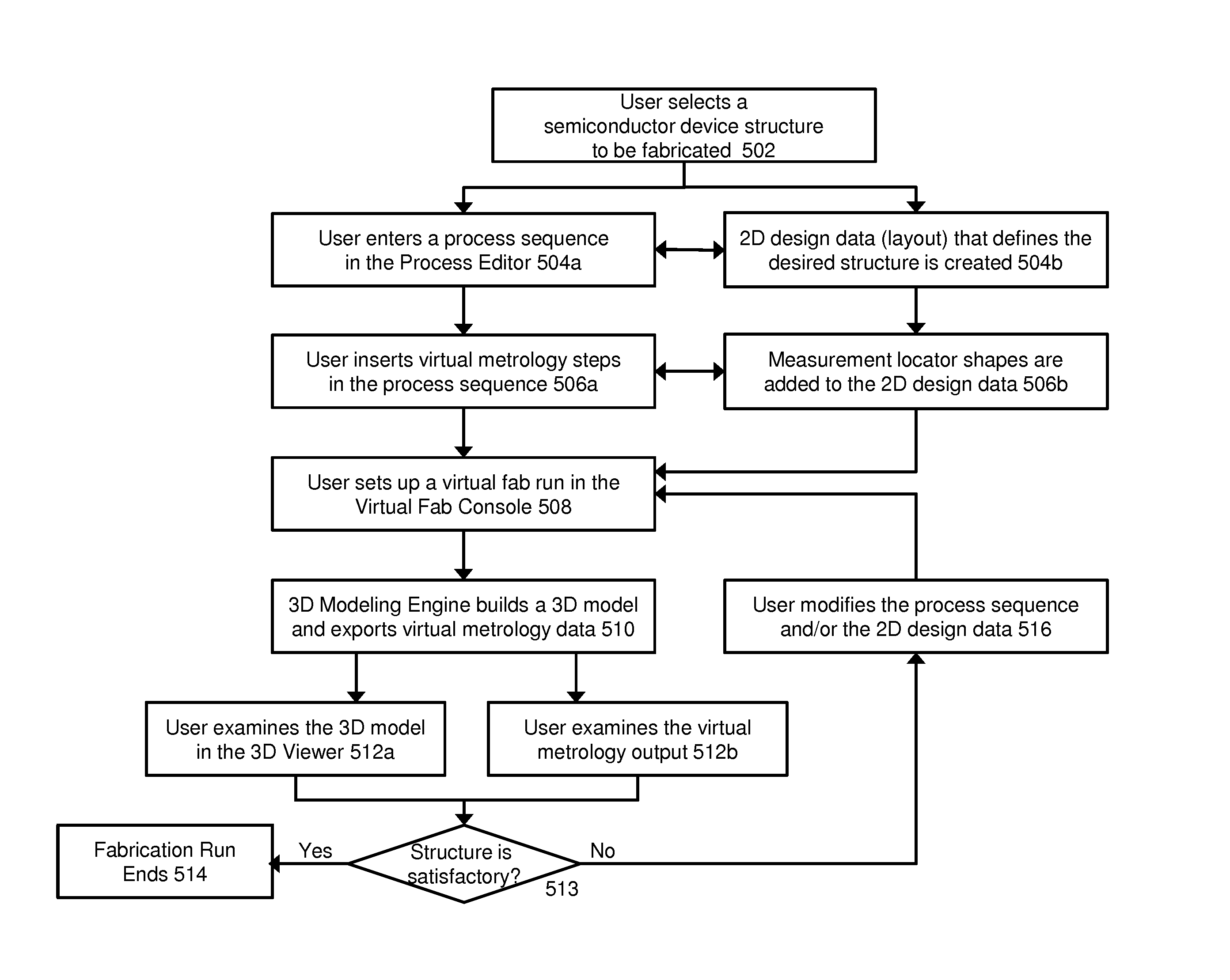

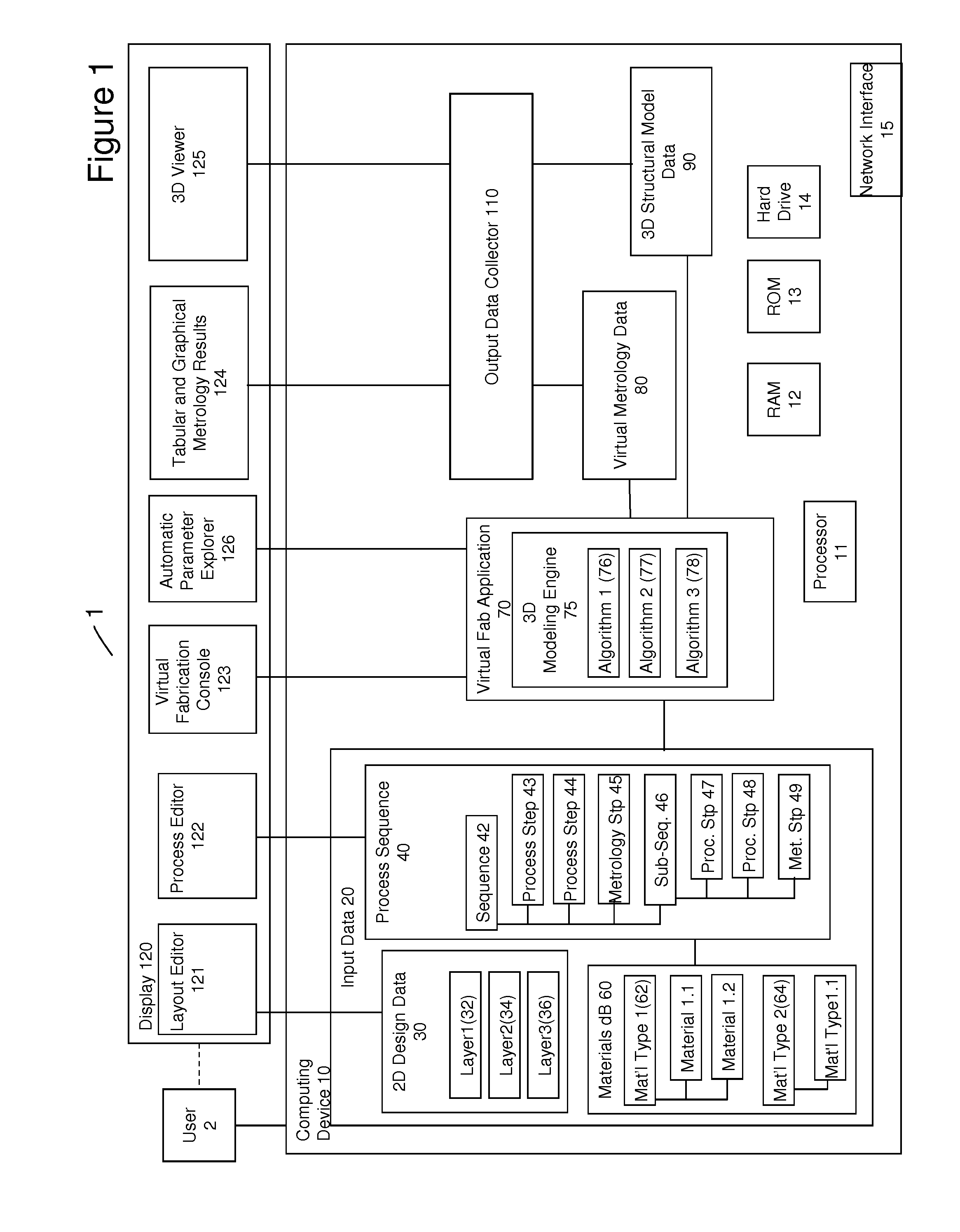

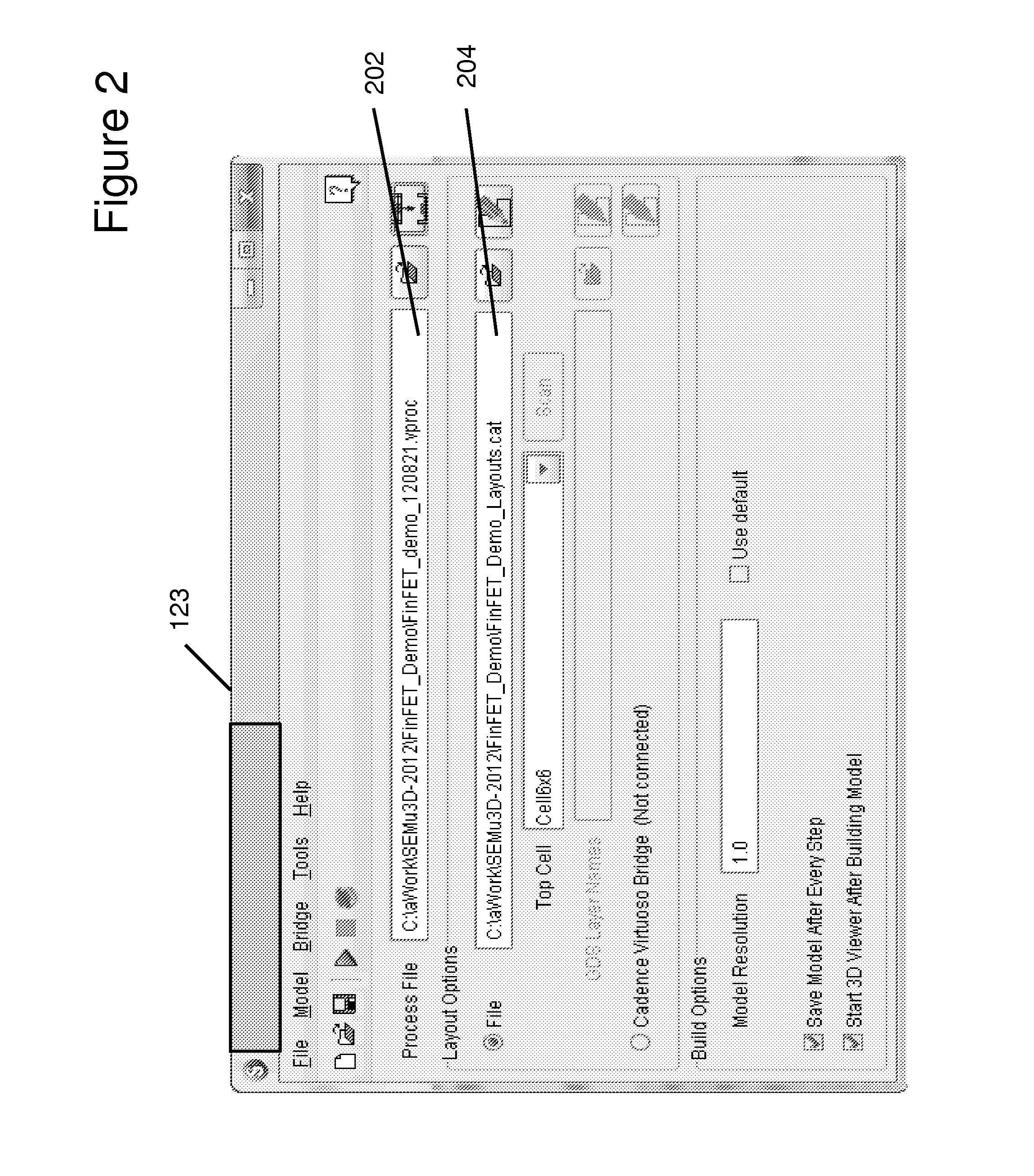

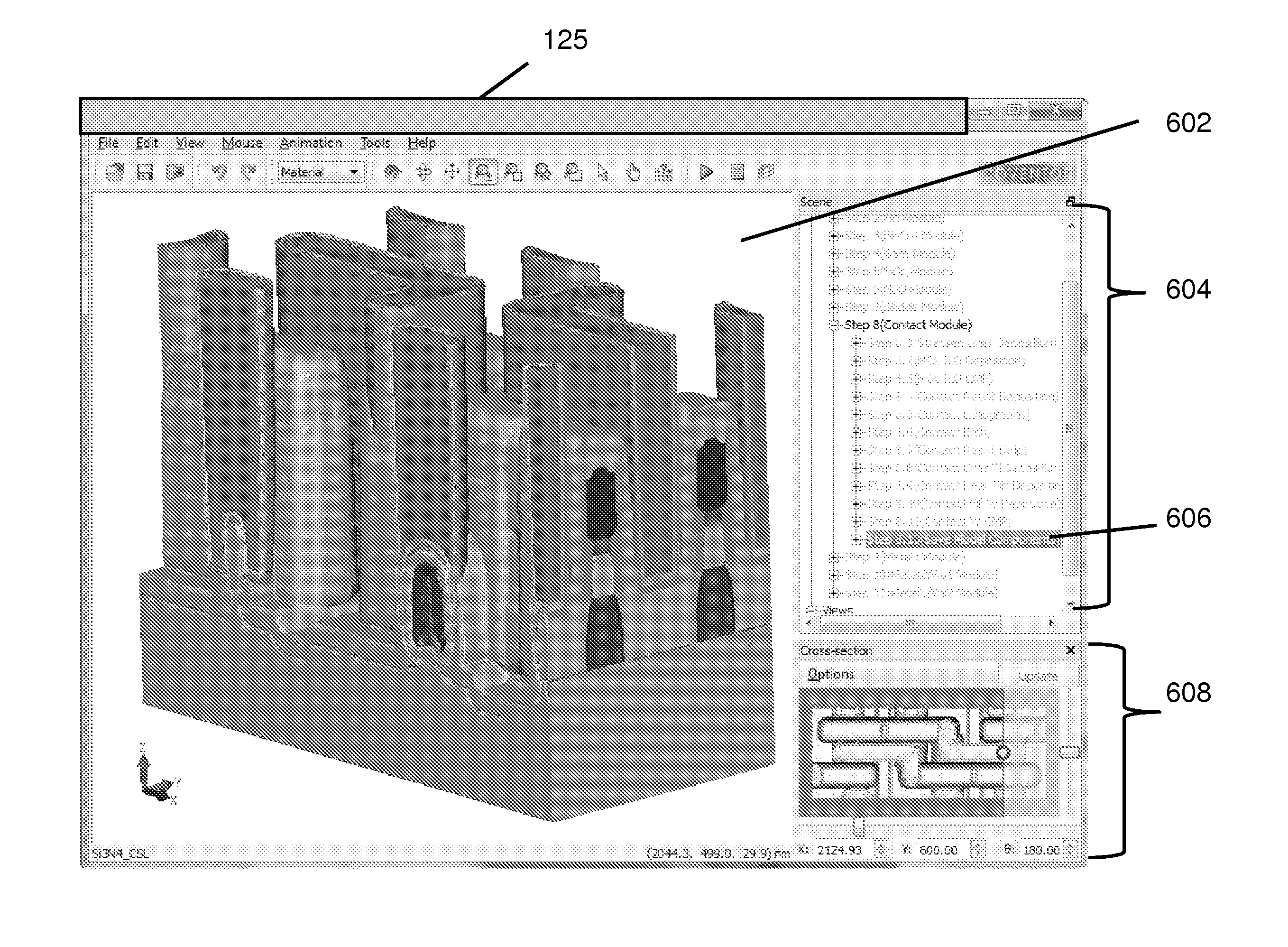

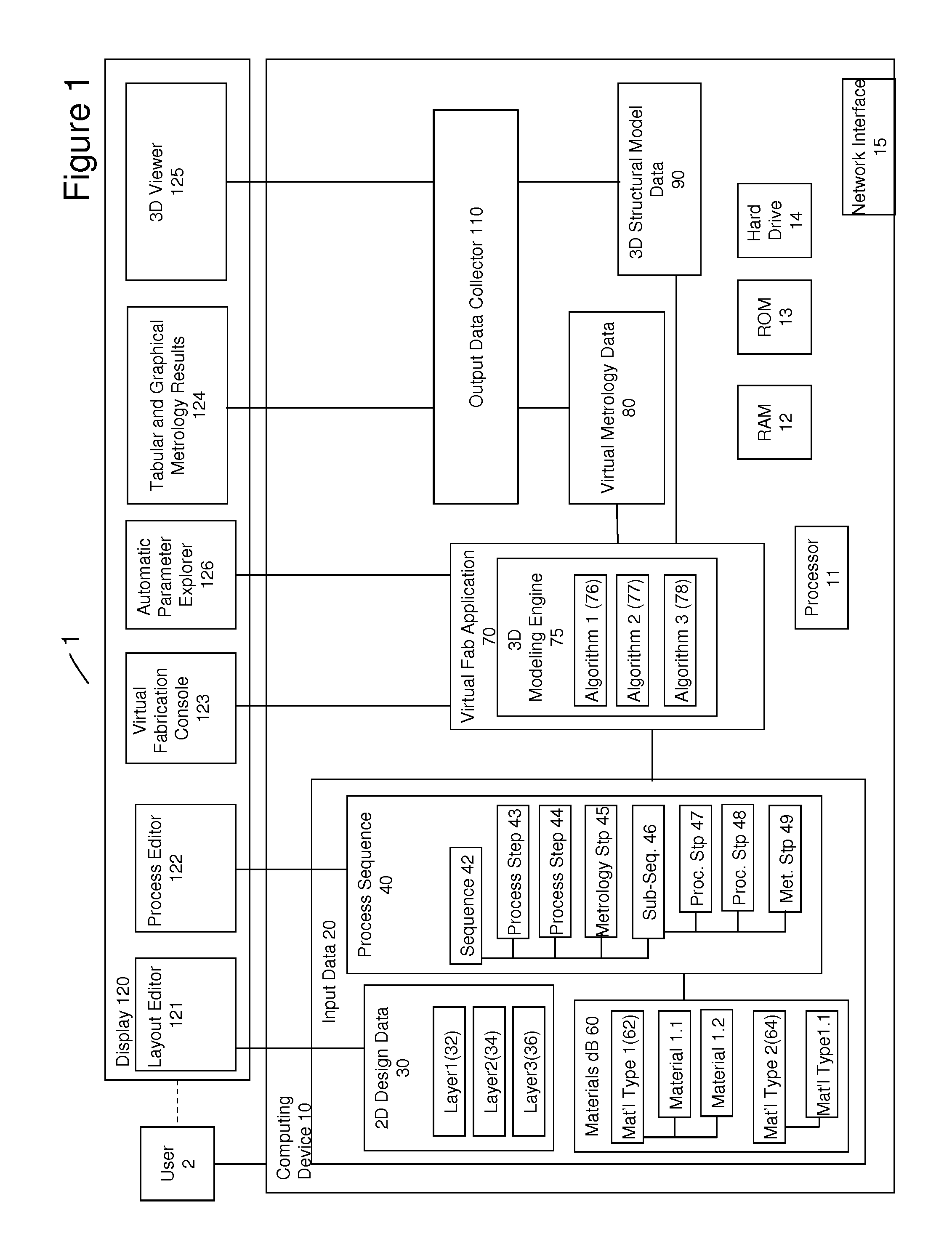

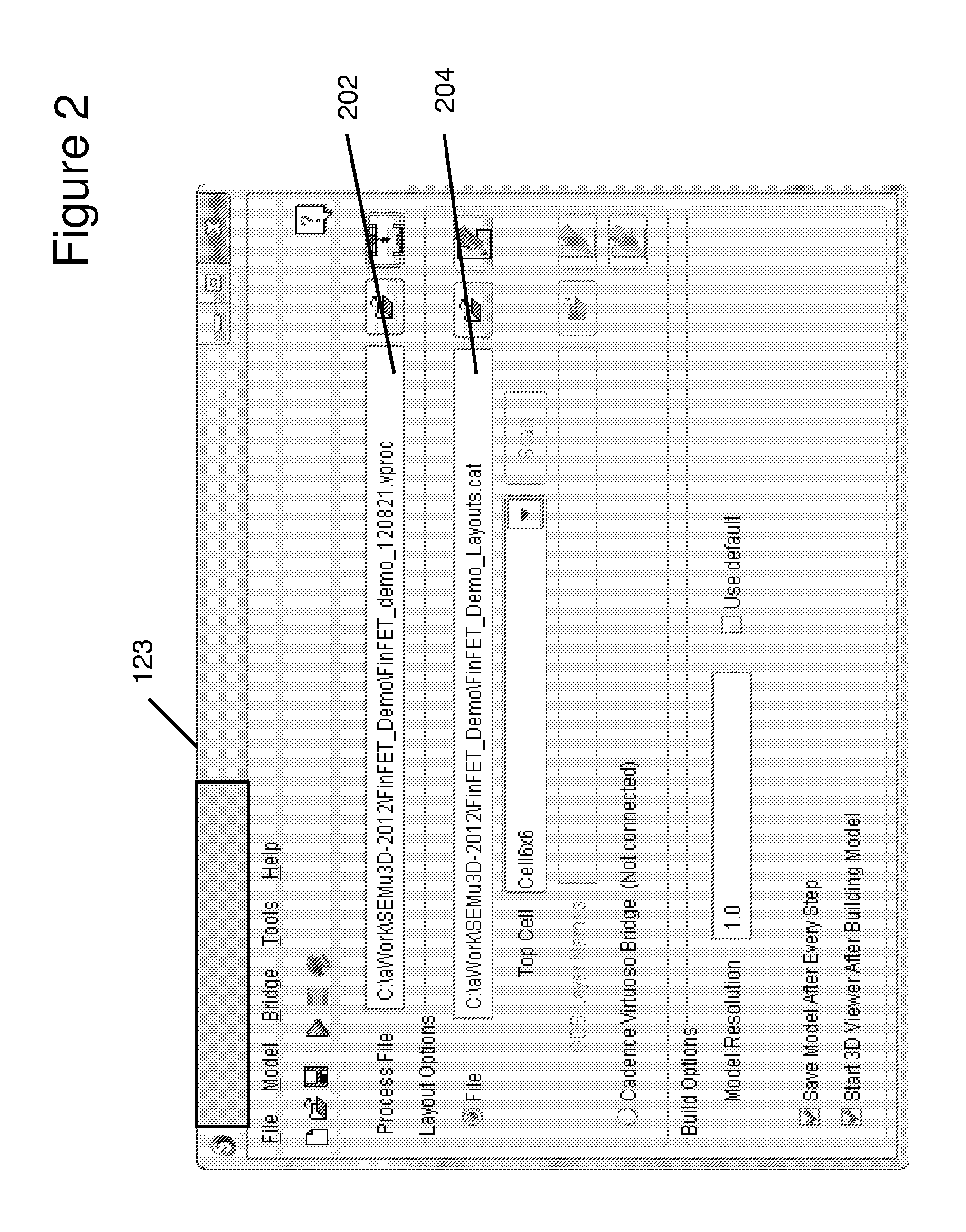

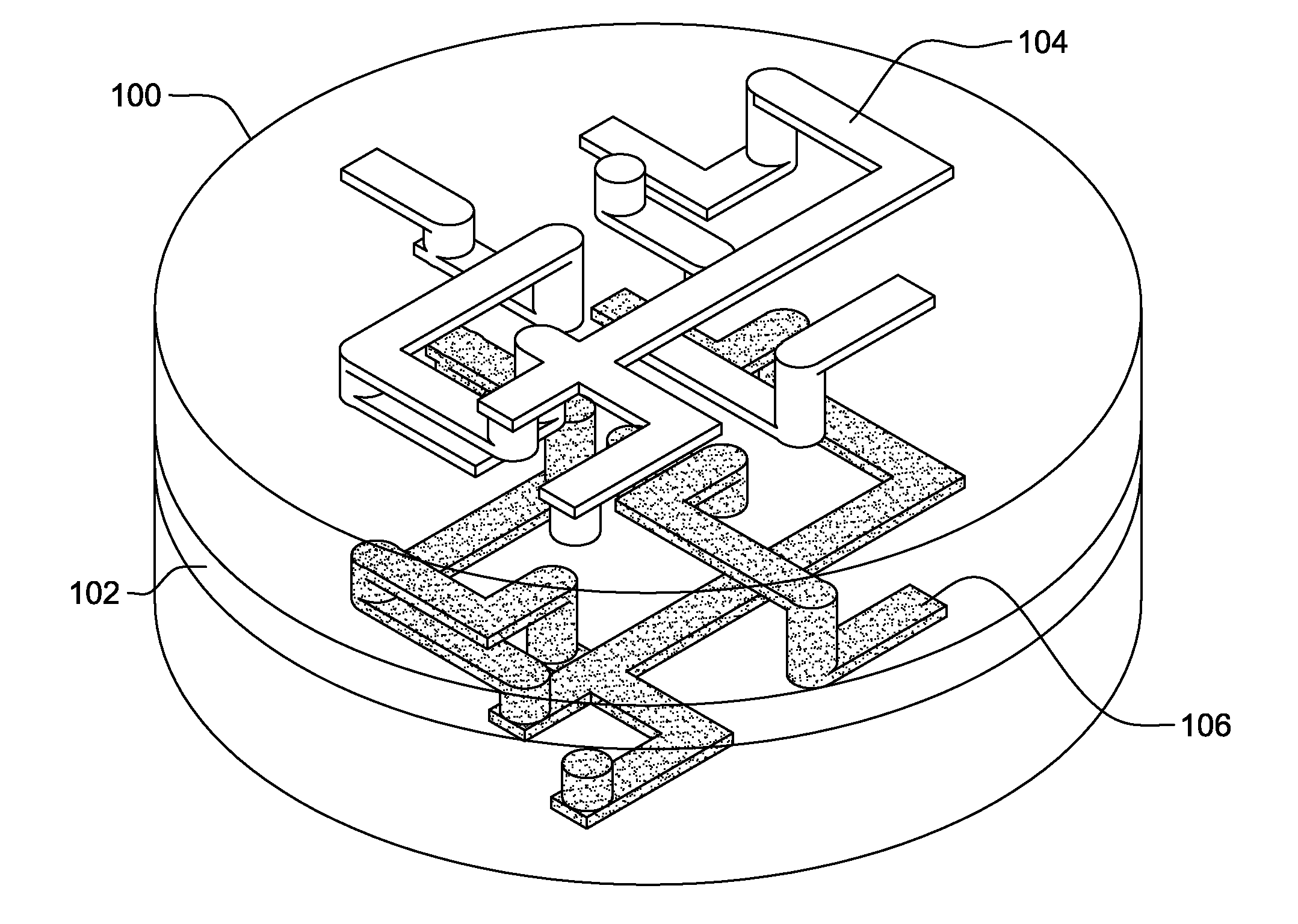

Rule checks in 3-D virtual fabrication environment

ActiveUS8832620B1Requirement for numberComputer aided designSpecial data processing applications3d designEngineering

A virtual fabrication environment that enables 3D Design Rule Checks (DRCs) or Optical Rule Checks (ORCs) on 3D structural models of semiconductor devices to be performed is discussed. The virtual fabrication environment may perform 3D design rule checks, such as minimum line width, minimum space between features, and minimum contact area between adjacent materials, directly in 3D without making assumptions about the translation from 2D design data to a 3D structure effected by an integrated process flow for semiconductor devices. The required number of 3D design rule checks may therefore be significantly reduced from the number of design rule checks required in 2D environments. Embodiments may also perform the 3D design rule checks for a range of statistical variations in process and design parameters.

Owner:COVENTOR

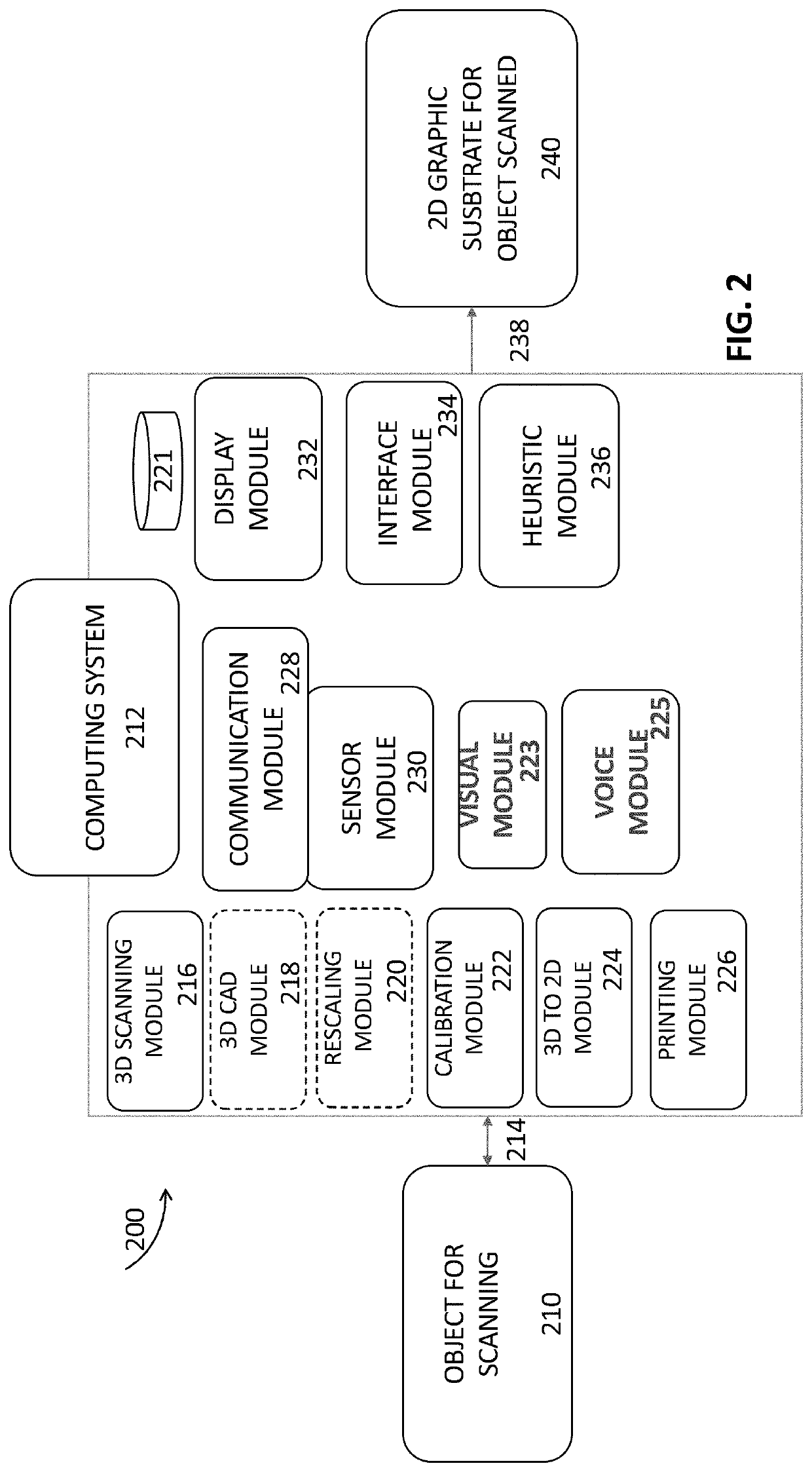

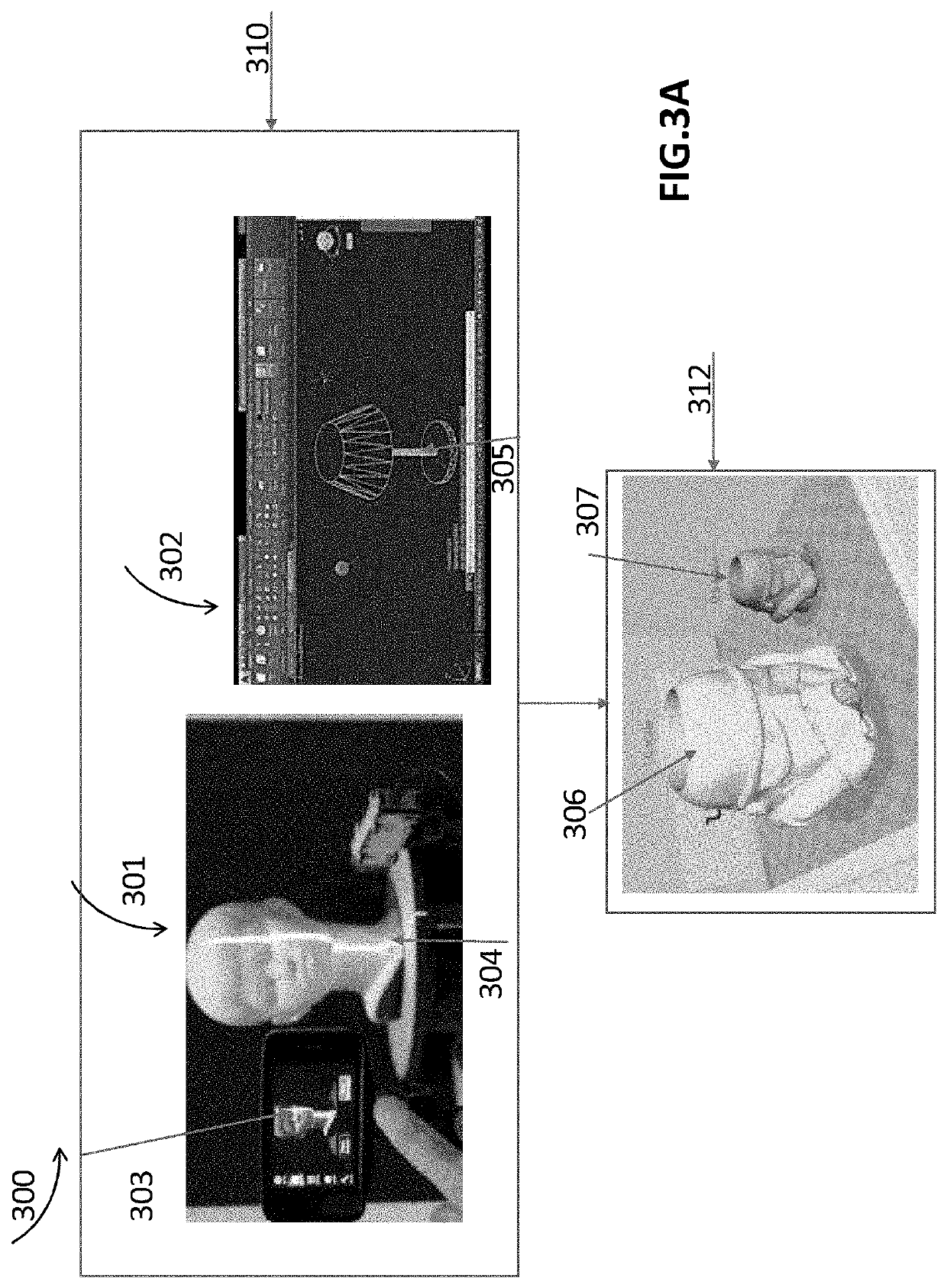

Method and System for the 3D Design and Calibration of 2D Substrates

A system, program product, and method including scanning an object or entity with a three-dimensional (3D) scanning module of a computing system; providing at least one of a three-dimensional (3D) image model and a 3D mesh model from the scanned, rendered, created, or uploaded object or entity; retopologizing at least one of the three-dimensional (3D) image model and 3D mesh model; applying a UV mapping process to at least one of the retopologized three-dimensional (3D) image model and 3D mesh model, where the “U” and “V” of the UV are a two-dimensional axes of a UVW coordinate plane; projecting a two-dimensional (2D) image to at least one of the three-dimensional (3D) image model and 3D mesh model to visualize or determine if the two-dimensional (2D) image has the correct size relative to at least one of the three-dimensional (3D) image model and 3D mesh model.

Owner:PAULSON ETHAN BRYCE +1

Design rule checks in 3-d virtual fabrication environment

ActiveUS20140282328A1Requirement for numberComputer aided designSoftware simulation/interpretation/emulation3d designEngineering

A virtual fabrication environment that enables 3D Design Rule Checks (DRCs) or Optical Rule Checks (ORCs) on 3D structural models of semiconductor devices to be performed is discussed. The virtual fabrication environment may perform 3D design rule checks, such as minimum line width, minimum space between features, and minimum contact area between adjacent materials, directly in 3D without making assumptions about the translation from 2D design data to a 3D structure effected by an integrated process flow for semiconductor devices. The required number of 3D design rule checks may therefore be significantly reduced from the number of design rule checks required in 2D environments. Embodiments may also perform the 3D design rule checks for a range of statistical variations in process and design parameters.

Owner:COVENTOR

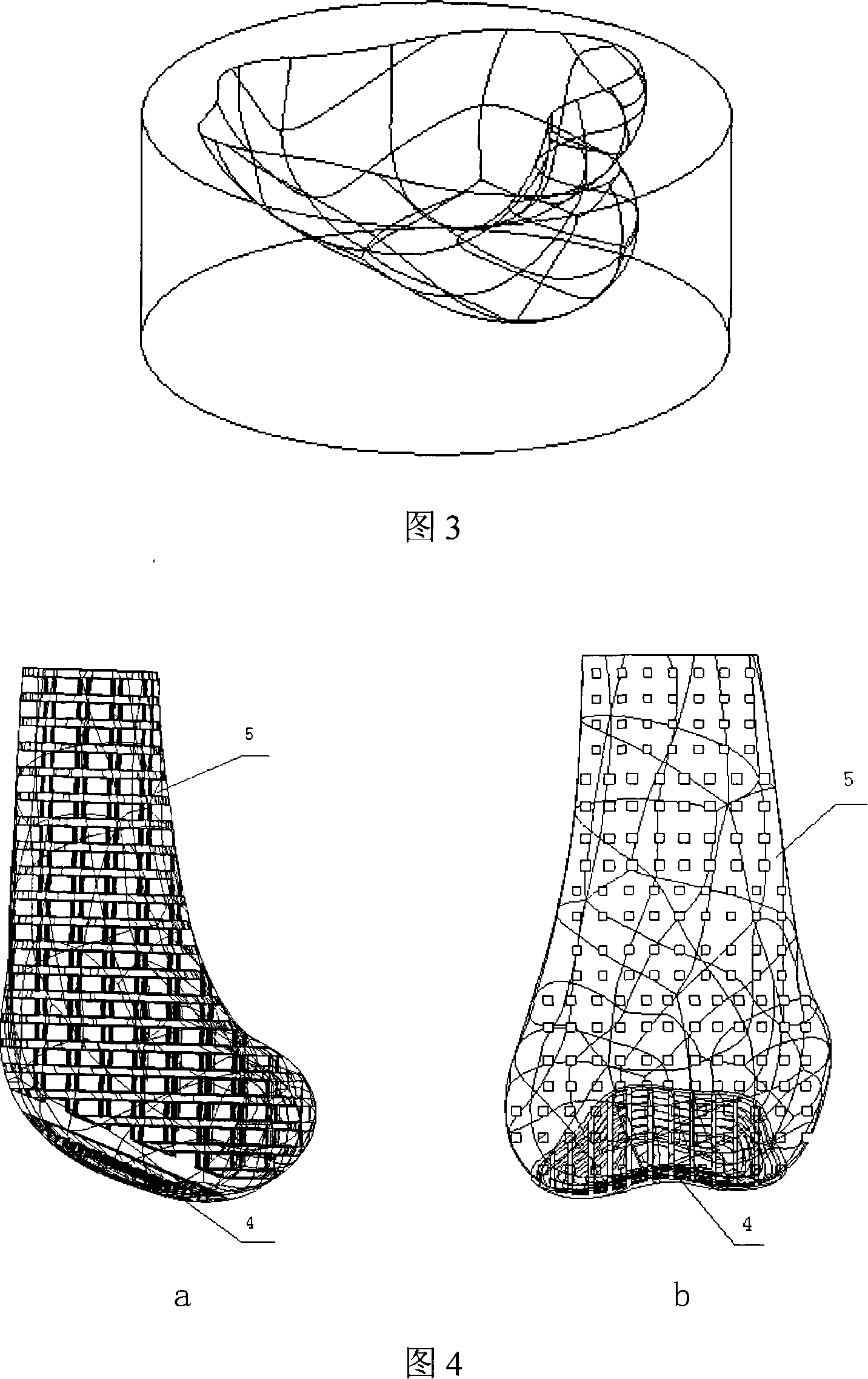

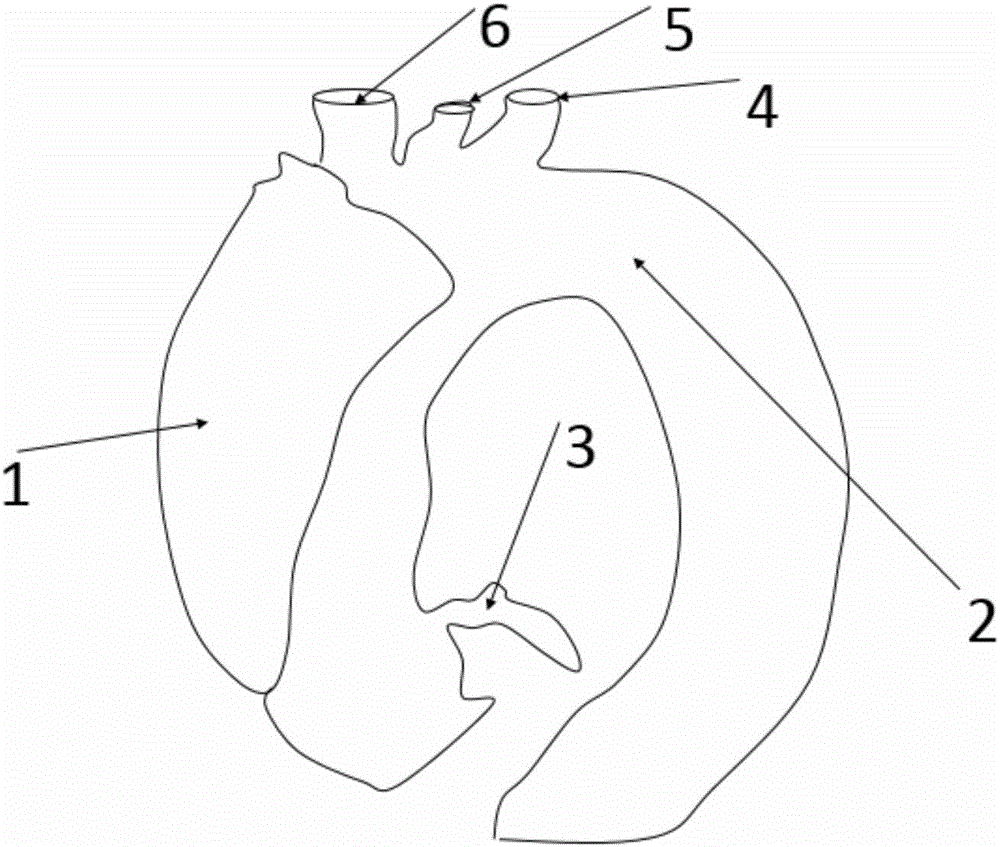

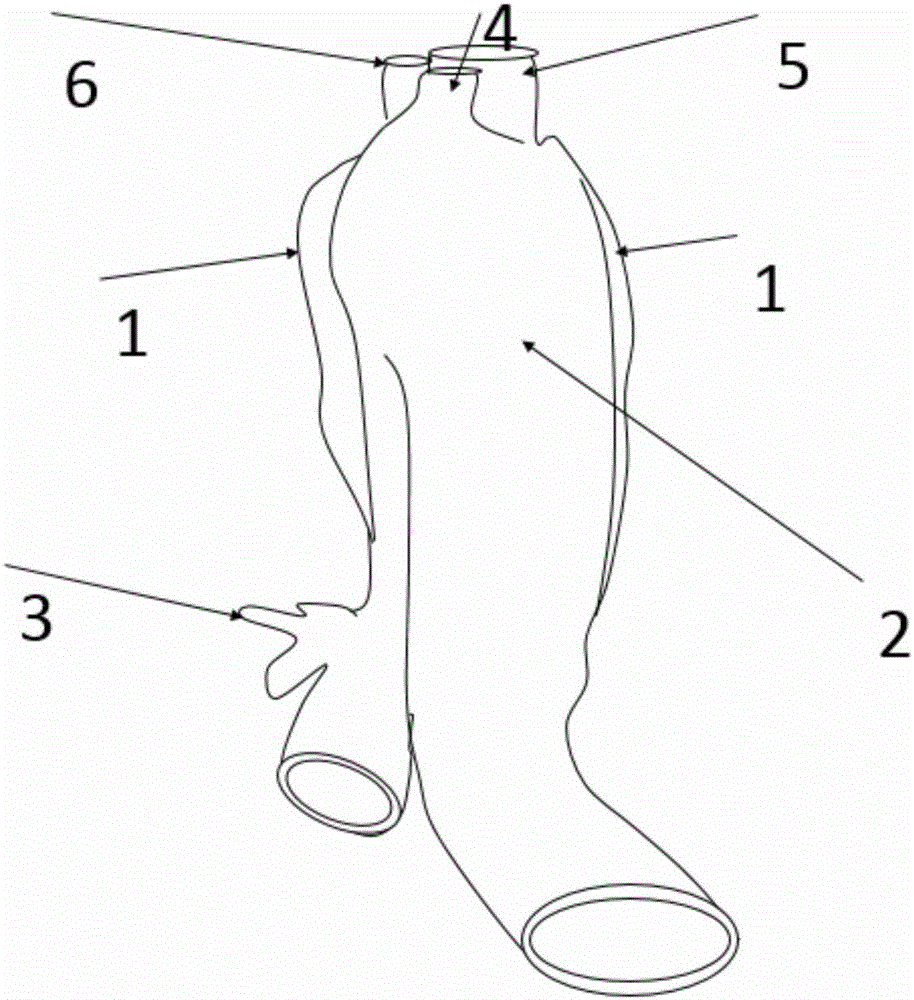

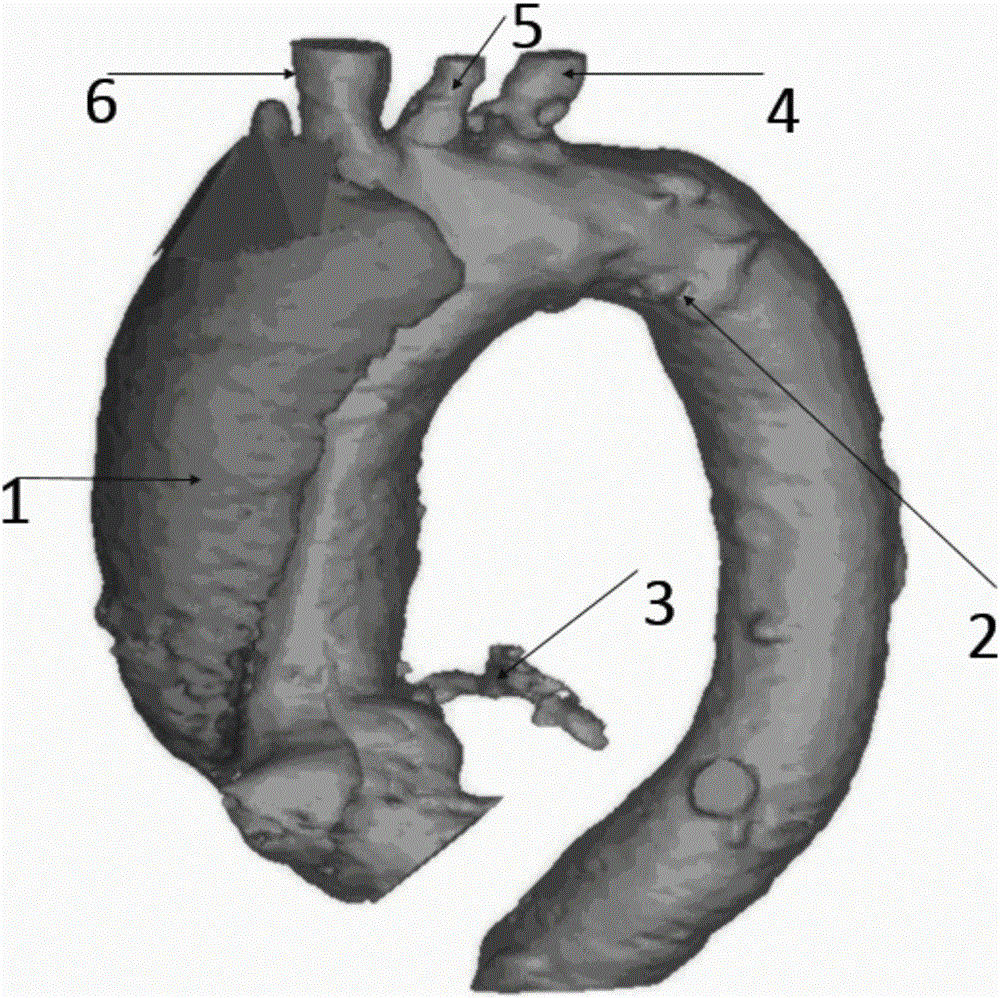

Aneurysm model based on 3D printing and manufacturing method thereof

The invention discloses an individual aneurysm model obtained through 3D printing technology and a manufacturing method thereof. The manufacturing method comprises the steps of firstly, performing high-precision layered scanning on an artery of an aneurysm patient by means of imaging equipment, thereby aneurysm image data; then performing sorting by means of inverse reconstruction software for obtaining the artery, and performing three-dimensional reconstruction; performing expansion amplification on the reconstructed artery by means of computer-aided 3D design software, then subtracting original blood vessels through Boolean operation, obtaining an empty aneurysm model and outputting a 3D printing identifiable file; and finally printing the aneurysm model by means of different materials through a 3D printer, wherein the size ratio between the aneurysm model and the aneurysm of the patient is 1:1. The aneurysm model obtained through the method can settle a defect of disease model shortage in China and can be applied in the fields of disease teaching, open heart surgery or interventional surgery training, surgery planning, etc. The aneurysm model and the manufacturing method have advantages of user-friendly customization, high accuracy, effective realizing of visuality and touchness, simple process, high forming speed and low cost.

Owner:李翔宇

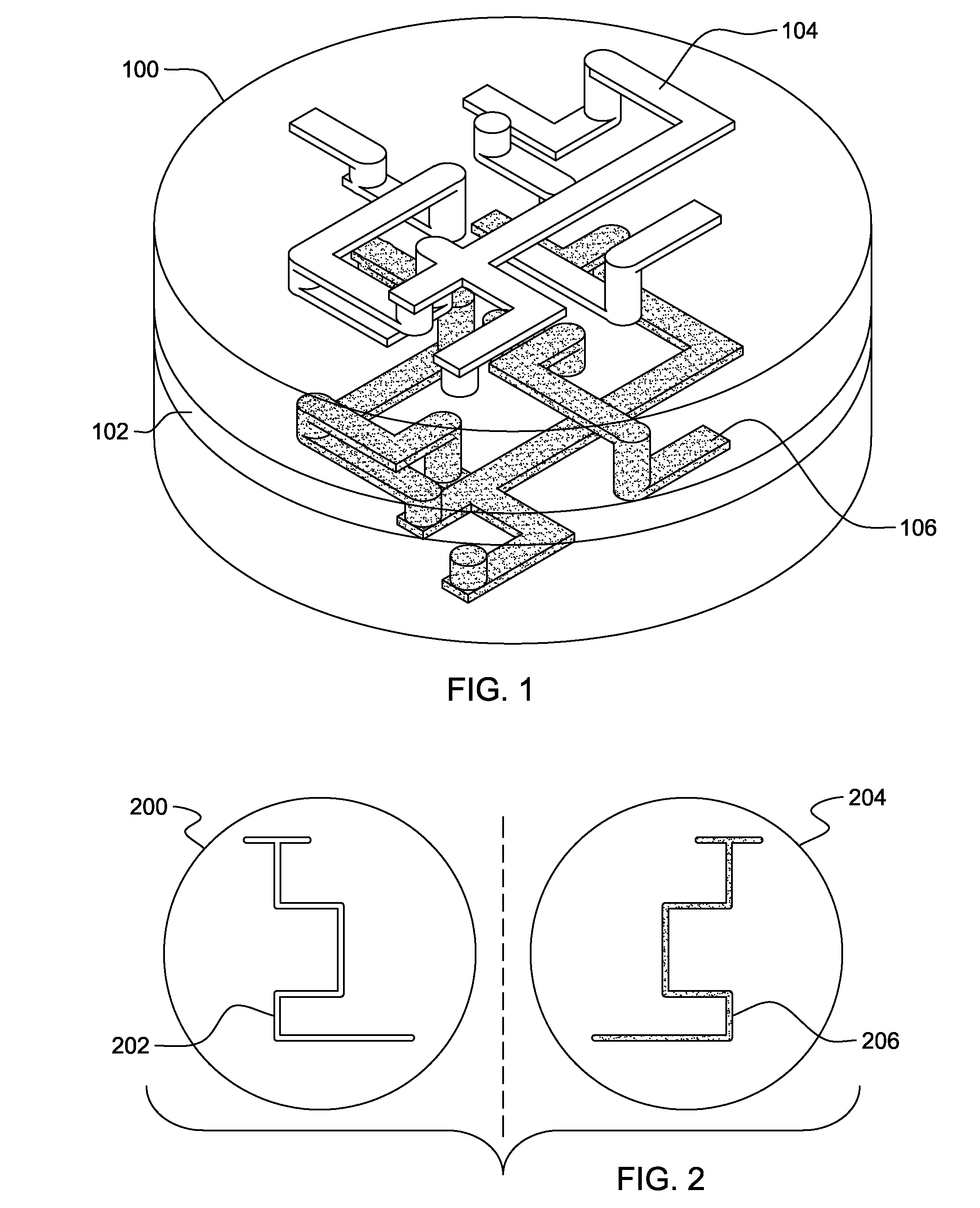

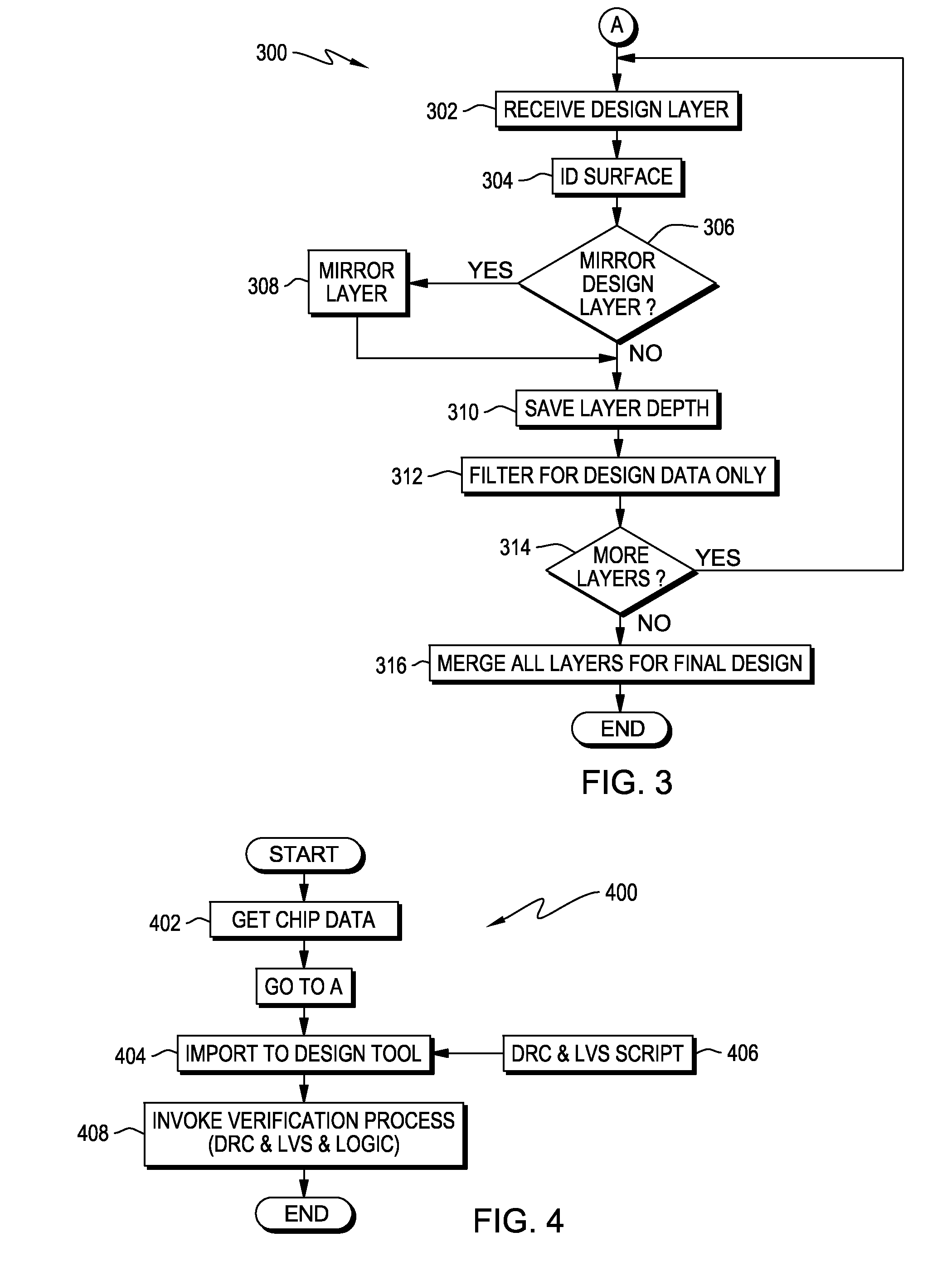

Circuit design checking for three dimensional chip technology

InactiveUS20120304138A1Detecting faulty computer hardwareComputer aided design3d designIntegrated circuit

A tool that allows three dimensional chip circuit designs to be checked subsequent to 3D design layer mirroring. The 3D chip design is converted to a corresponding 2D chip design by mirroring one or more design layers from the mirrored side of a 3D design and merging those design layers with unmirrored design layers from the unmirrored side of a 3D design. The converted circuit design can be processed by standard verification checks. The tool may also receive design layers corresponding to an integrated circuit that will pass through multiple semiconductor chips. Each design cell is examined to determine if it corresponds to a mirrored or unmirrored side of its respective semiconductor chip. If the respective design cell corresponds to the mirrored side, the design cell is mirrored. All mirrored cells are then merged with the unmirrored design cells in the correct order. The merged design is processed by standard verification checks. The tool also has the capability to create terminal metal abstracts for two adjoining chips. One of the abstracts is mirrored and then merged with the other for connectivity and alignment checking.

Owner:GLOBALFOUNDRIES INC

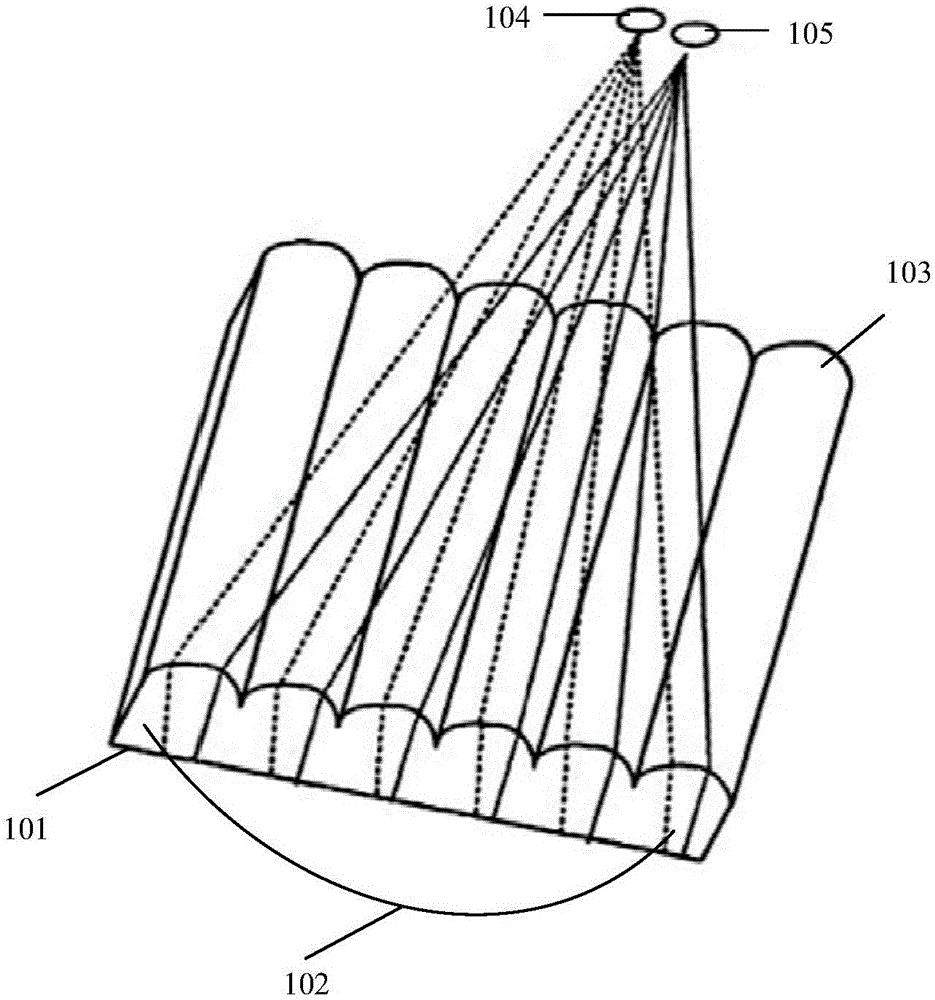

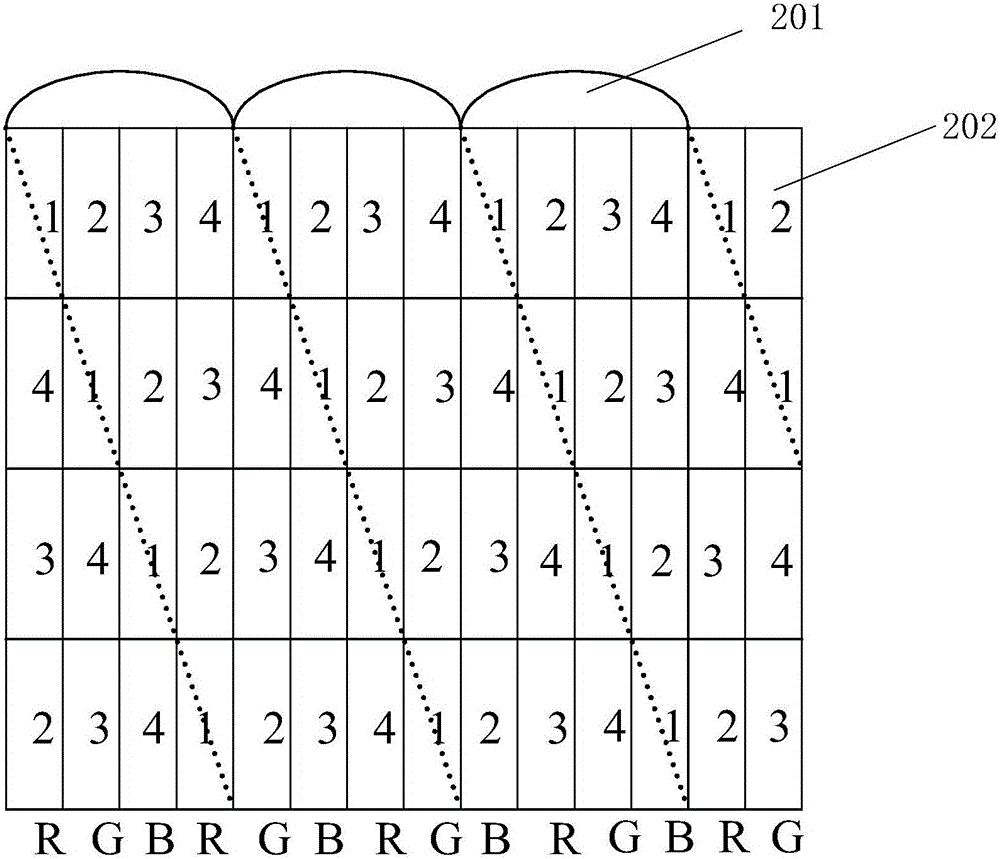

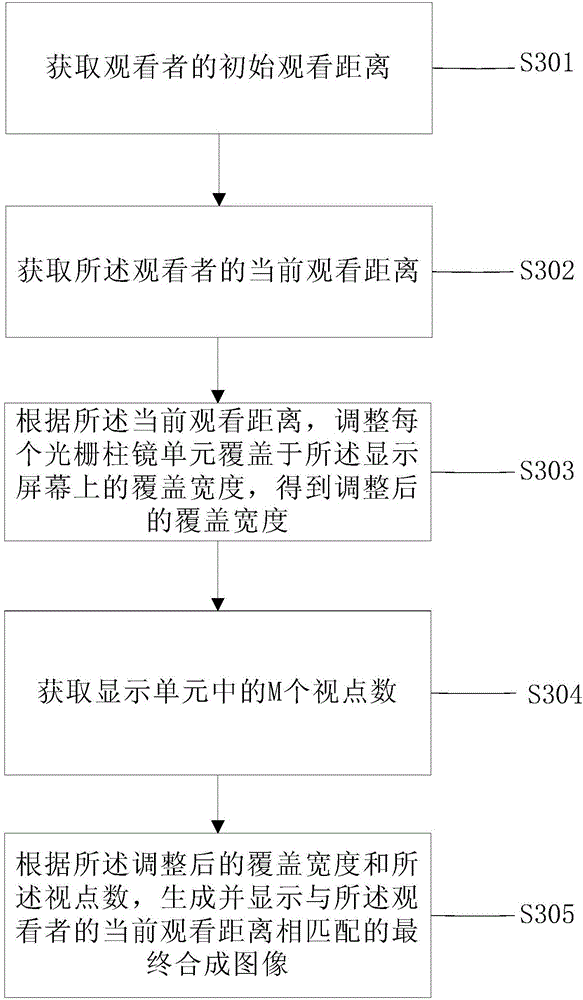

Multi-view-point liquid crystal display LCD naked-eye 3D (Three Dimensional) display method and device

ActiveCN105911712AImprove experienceIncrease flexibilityNon-linear opticsOptical elementsGratingLiquid-crystal display

The invention discloses a multi-view-point liquid crystal display LCD naked-eye 3D (Three Dimensional) display method and device, which are applied to an LCD naked-eye 3D display system or equipment with an LCD naked-eye 3D display function. The method comprises the following steps: acquiring a current observation distance from a viewer to a display; according to the current observation distance, adjusting covering width of each optical grid prism unit on a display screen of the display to obtain adjusted covering width; acquiring the quantity of view points in the display unit; and according to the adjusted covering width and the quantity of view points, generating and displaying a final composite image matched with the current observation distance of the viewer. The observation distance from the viewer to the LED can be adjusted, so that a user can obtain an optimal 3D display effect image after the observation distance is adjusted and the user experience is improved; and meanwhile, the flexibility of an optical grid 3D design is increased and the hardware cost of an LCD naked-eye 3D display system is saved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

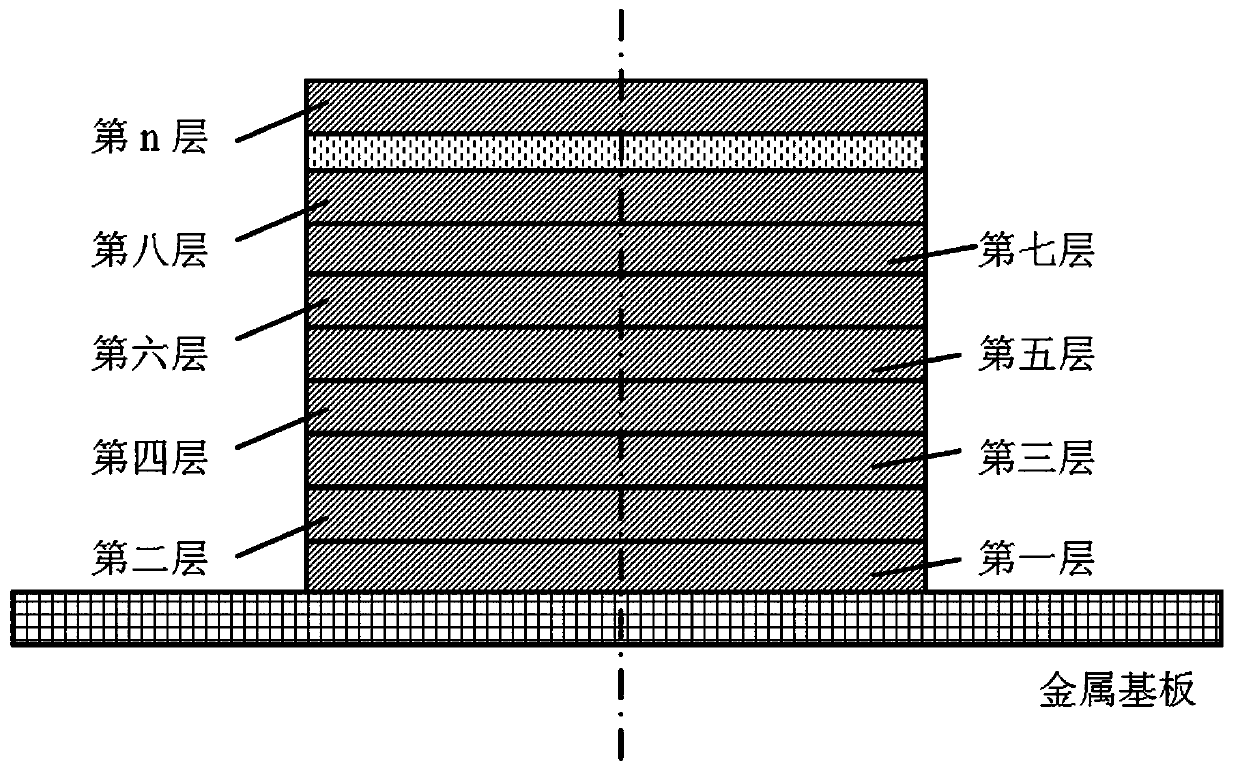

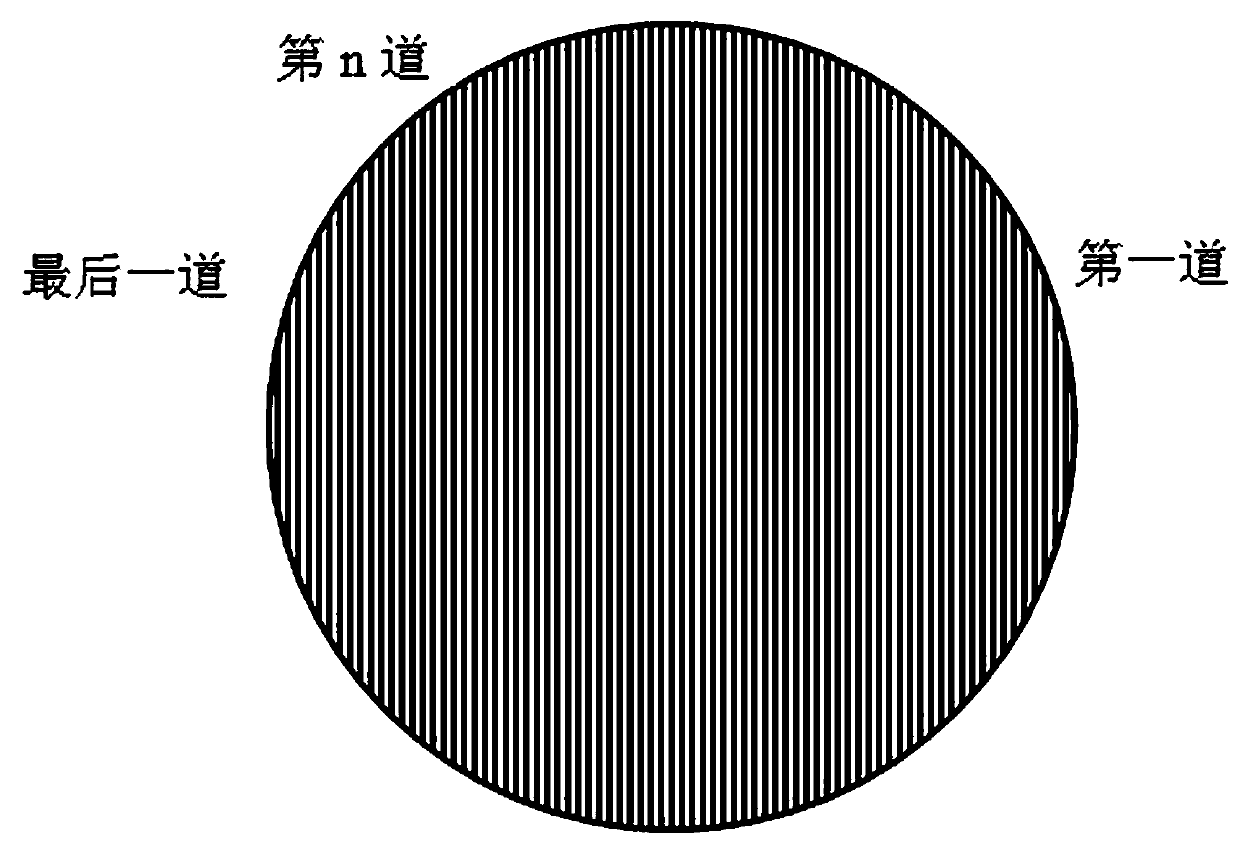

Laser 3D printing and manufacturing method of electric spark electrode

InactiveCN107891200AImprove reliabilitySimple processElectrical-based machining electrodes3d designEngineering

The invention discloses a laser 3D printing and manufacturing method of an electric spark electrode. The laser 3D printing and manufacturing method comprises the following steps: (1) machining and flattening a metal base plate; (2) setting a powder scraping amount of a scraper; (3) cutting a 3D design drawing of the electrode into multiple layers of slice layer structures in the height direction;(4) adjusting printing parameters of a laser device; (5) dividing each slice layer of the electrode into multiple regions, and controlling laser beams to perform overlapping scanning fusion covering in the regions covered with powder; (6) performing scanning fusion covering on the first layer of the electrode on the metal base plate, then repeatedly downwards moving the metal base plate by one slice layer thickness, and performing scanning fusion covering on the next layer of the electrode till the scanning fusion covering of the whole electrode is completed; (7) separating the metal base plate from the formed electrode to complete laser 3D printing and manufacturing of the electric spark electrode. According to the laser 3D printing and manufacturing method of the electric spark electrode, by use of a laser 3D printing technology, a metal-based material with a high content of ceramic components is directly subjected to 3D printing to form the electric spark electrode with a complicated structure, so that no molds are needed; the working procedures are simple, the production efficiency is high, and the cost is low; the manufactured electrode can meet requirements of electric sparkmachining and electric spark deposition technologies.

Owner:GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com