Patents

Literature

36 results about "Custom made implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for design and production of a custom-fit prosthesis

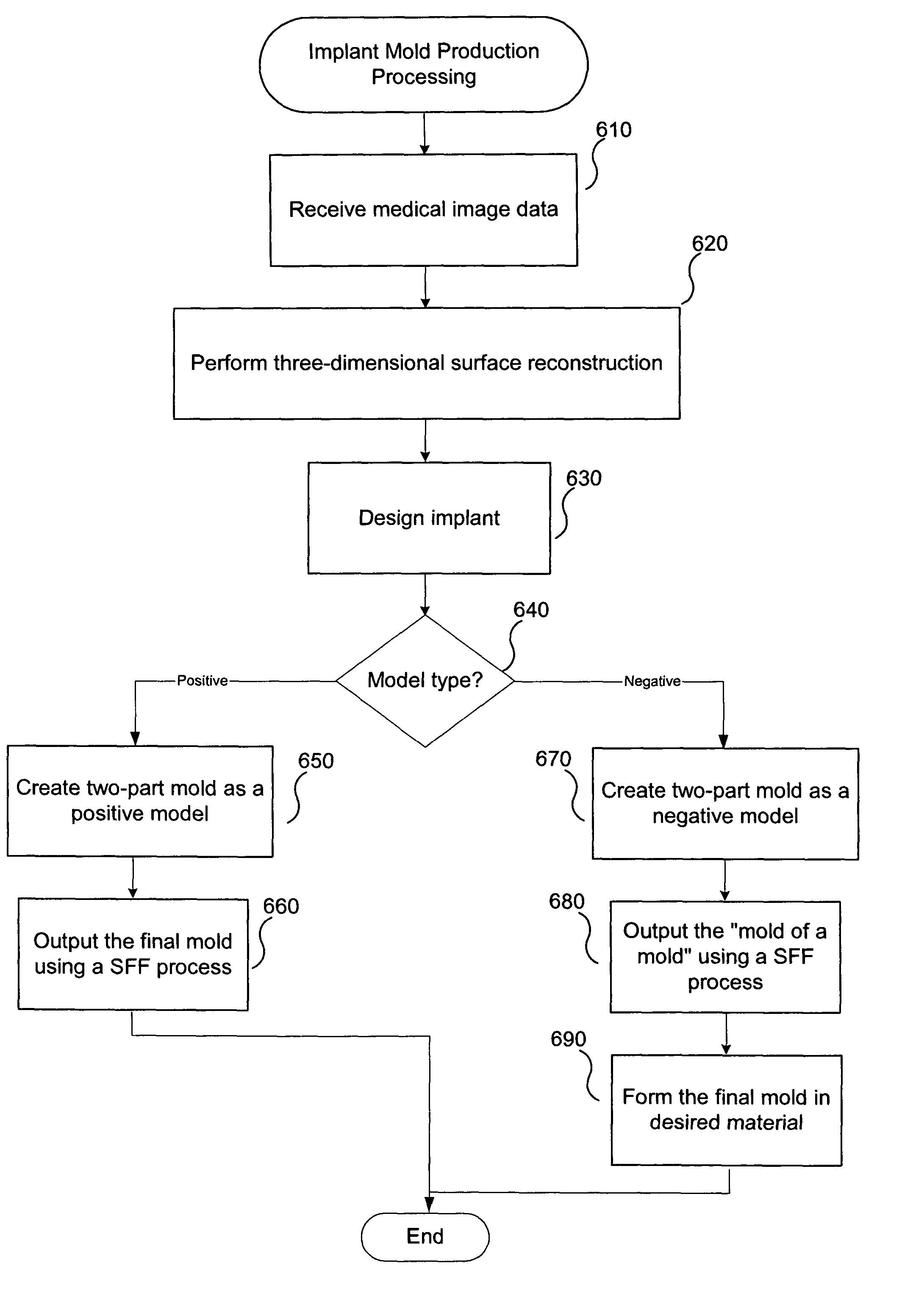

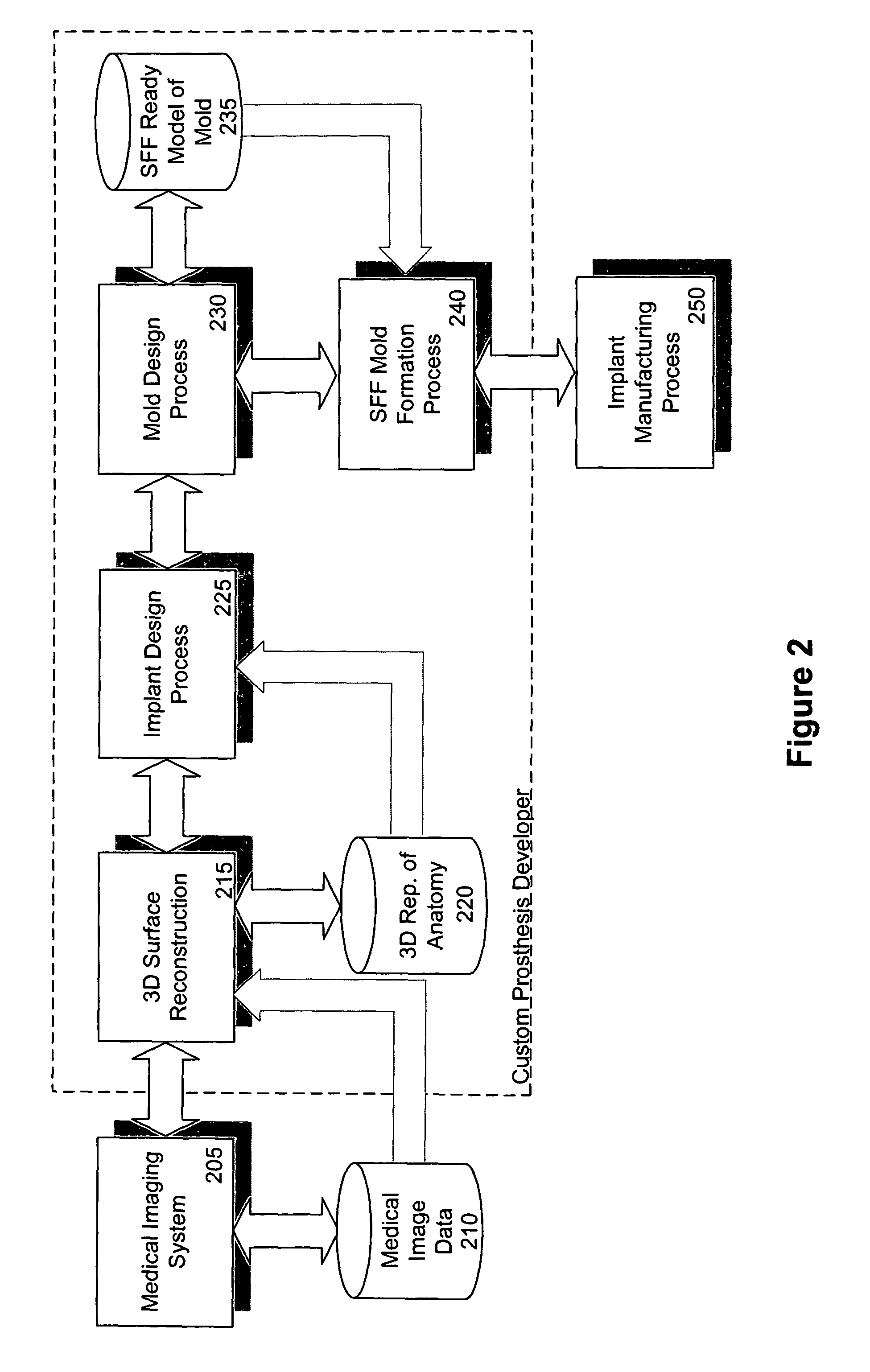

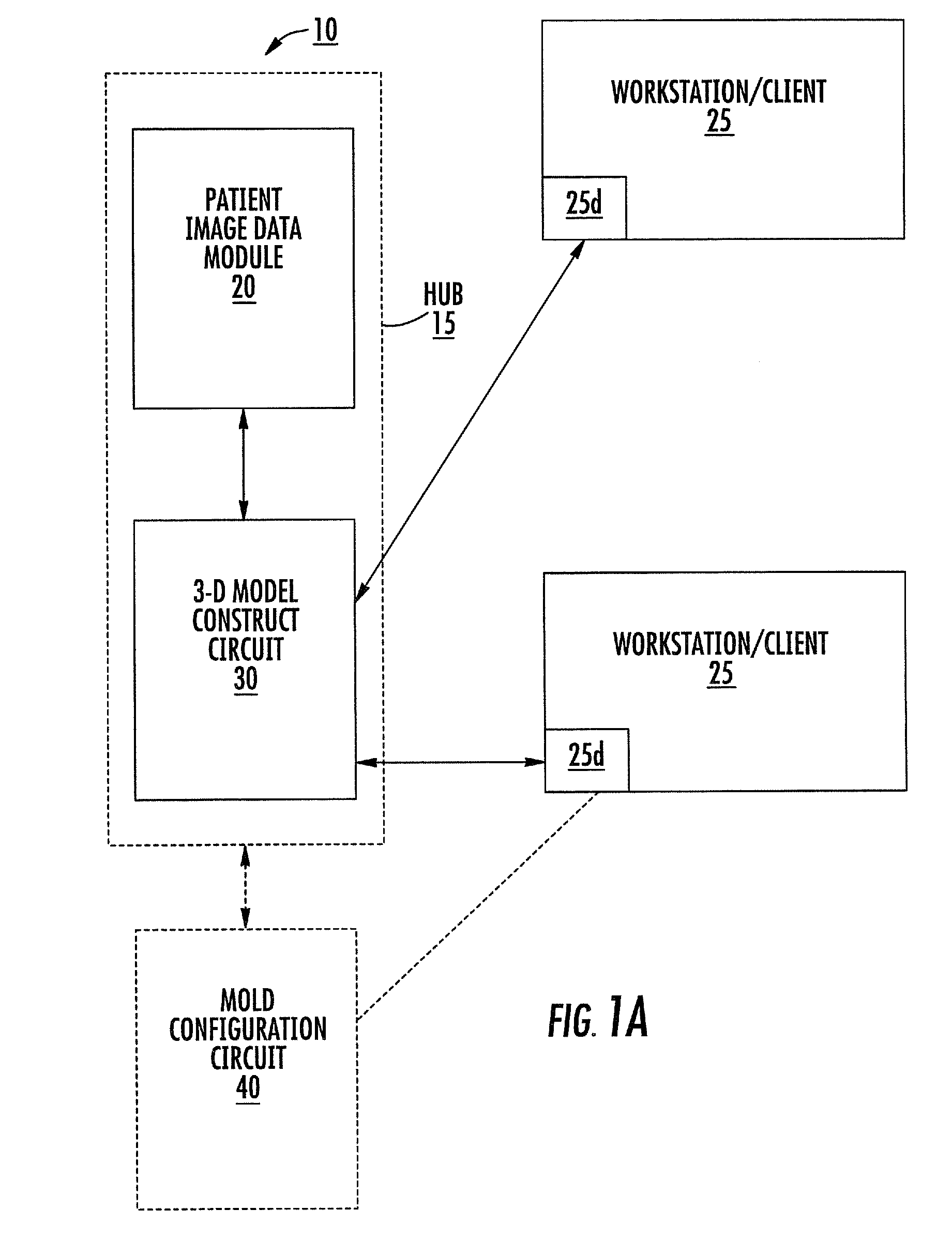

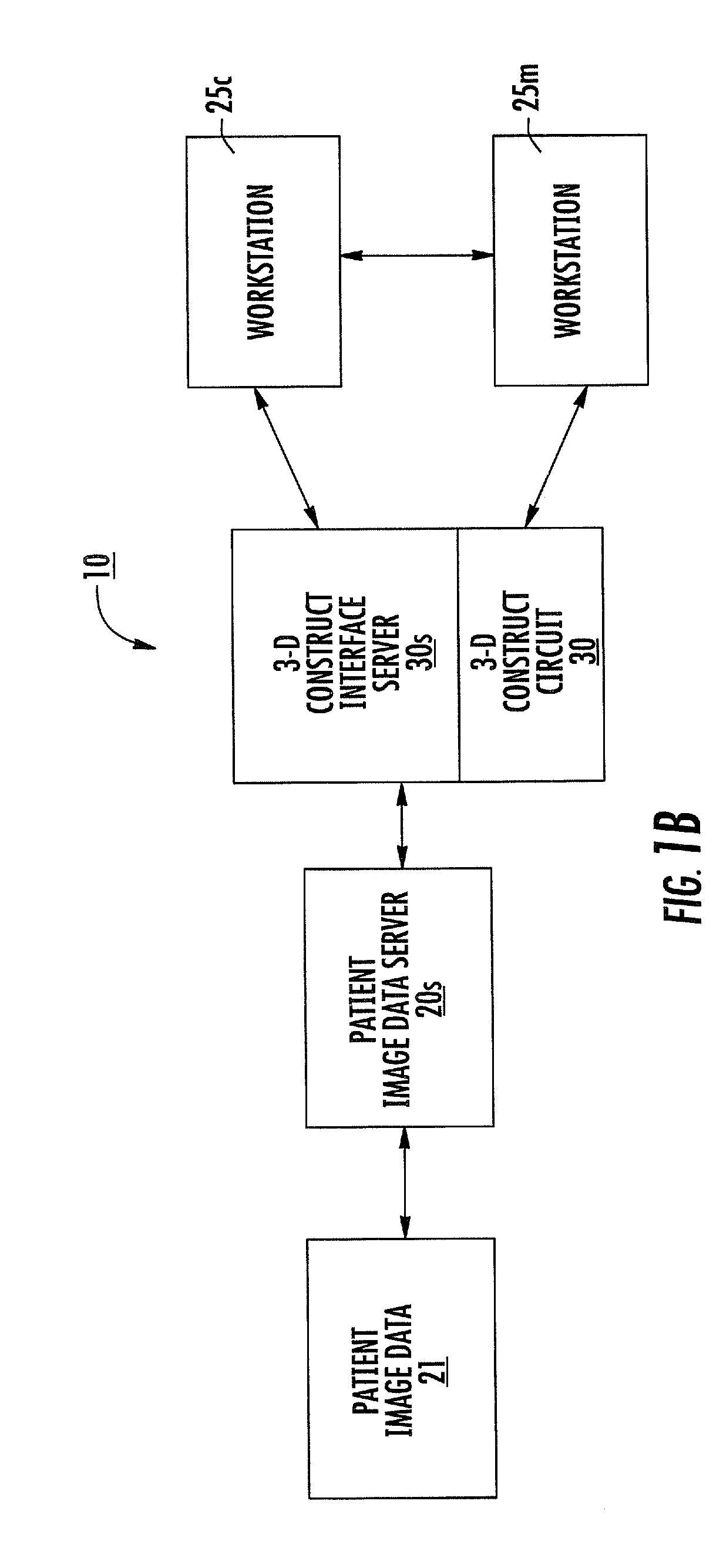

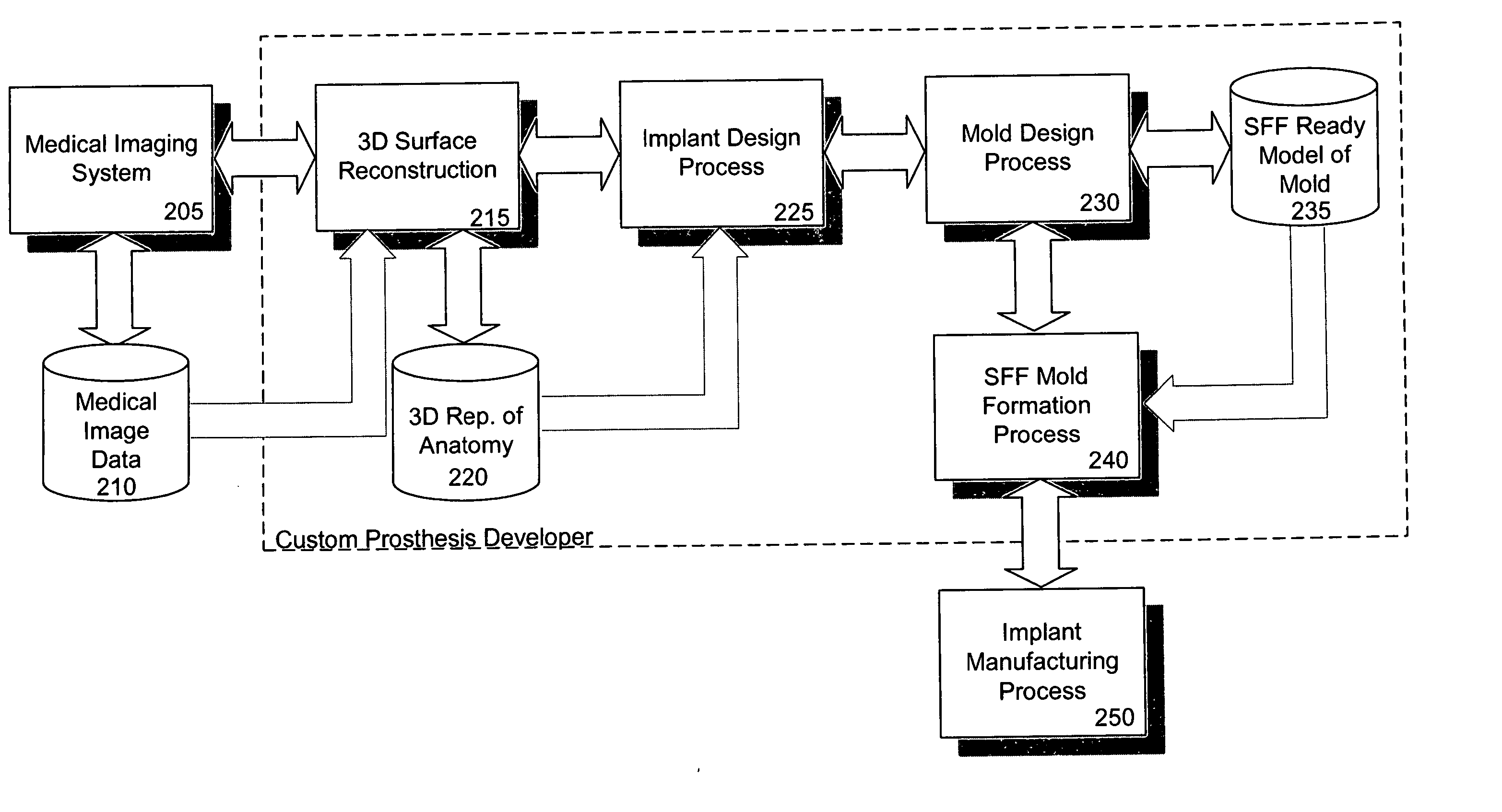

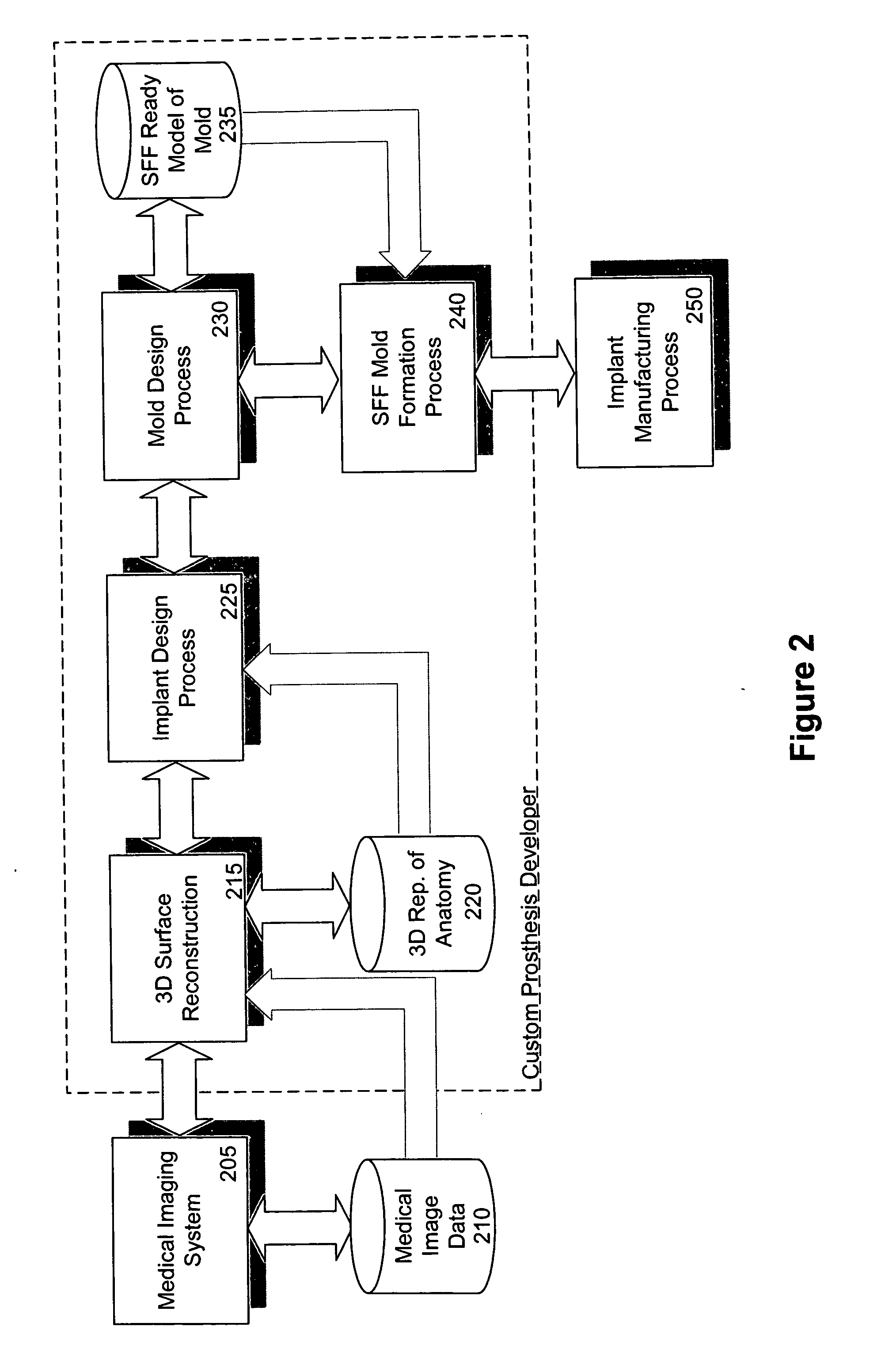

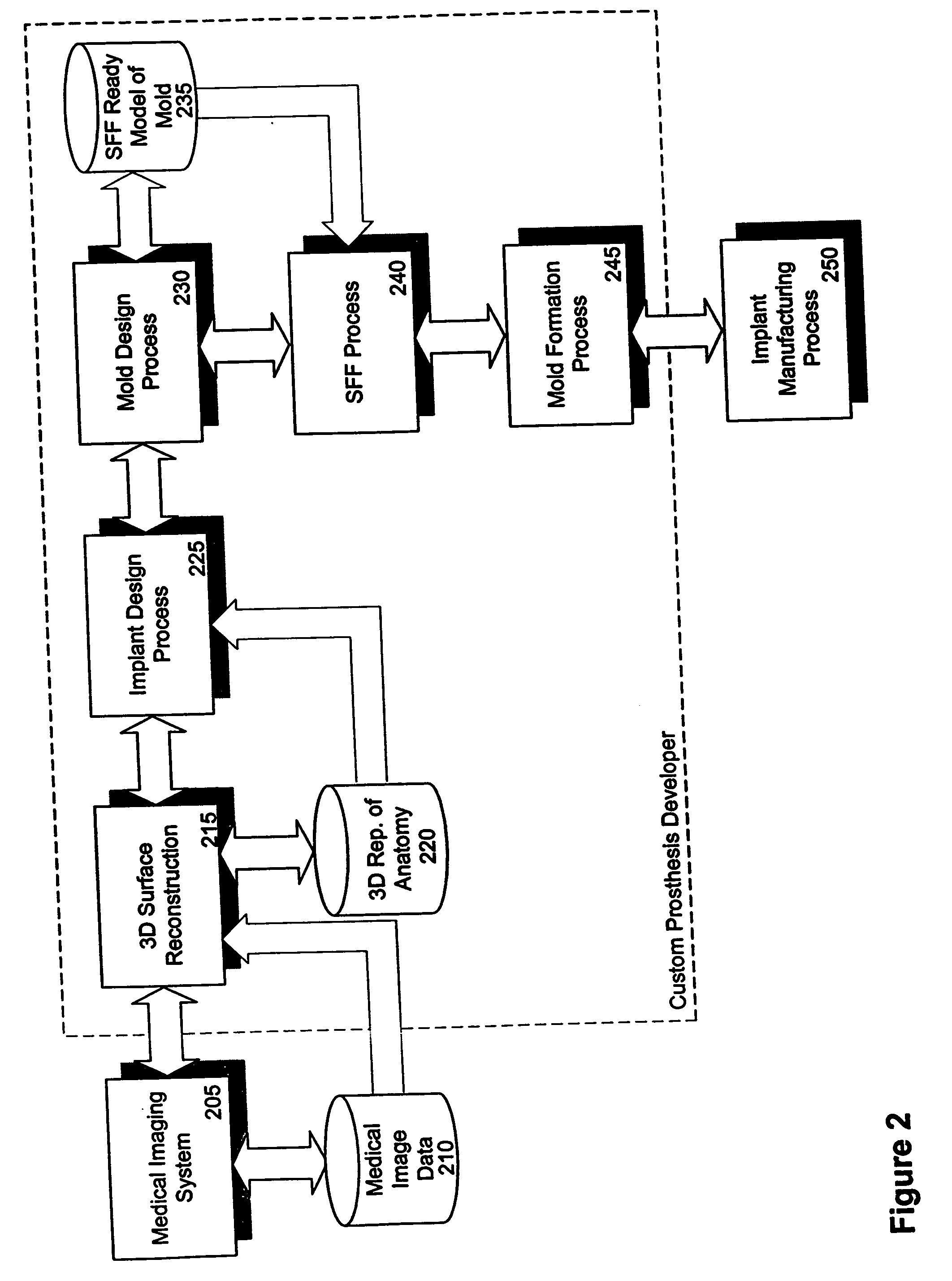

Systems and methods are provided for designing and producing a custom-fit prosthesis. According to one embodiment, a mold is produced from which a custom-fit implant may be directly or indirectly manufactured. Medical image data representing surrounding portions of a patient's anatomy to be repaired by surgical implantation of the custom-fit implant are received. Then, three-dimensional surface reconstruction is performed based on the medical image data. Next, the custom-fit implant is designed based on the three-dimensional surface reconstruction and a positive or negative representation of a two-part mold is created with a void in the shape of the custom-fit implant by subtracting a representation of the custom-fit implant from a representation of a mold. Finally, the two-part mold is output from which the custom-fit implant may be directly manufactured; or an implant is directly output. Alternatively, an intermediate mold is created from which a two-part mold may be directly manufactured.

Owner:3D SYST INC

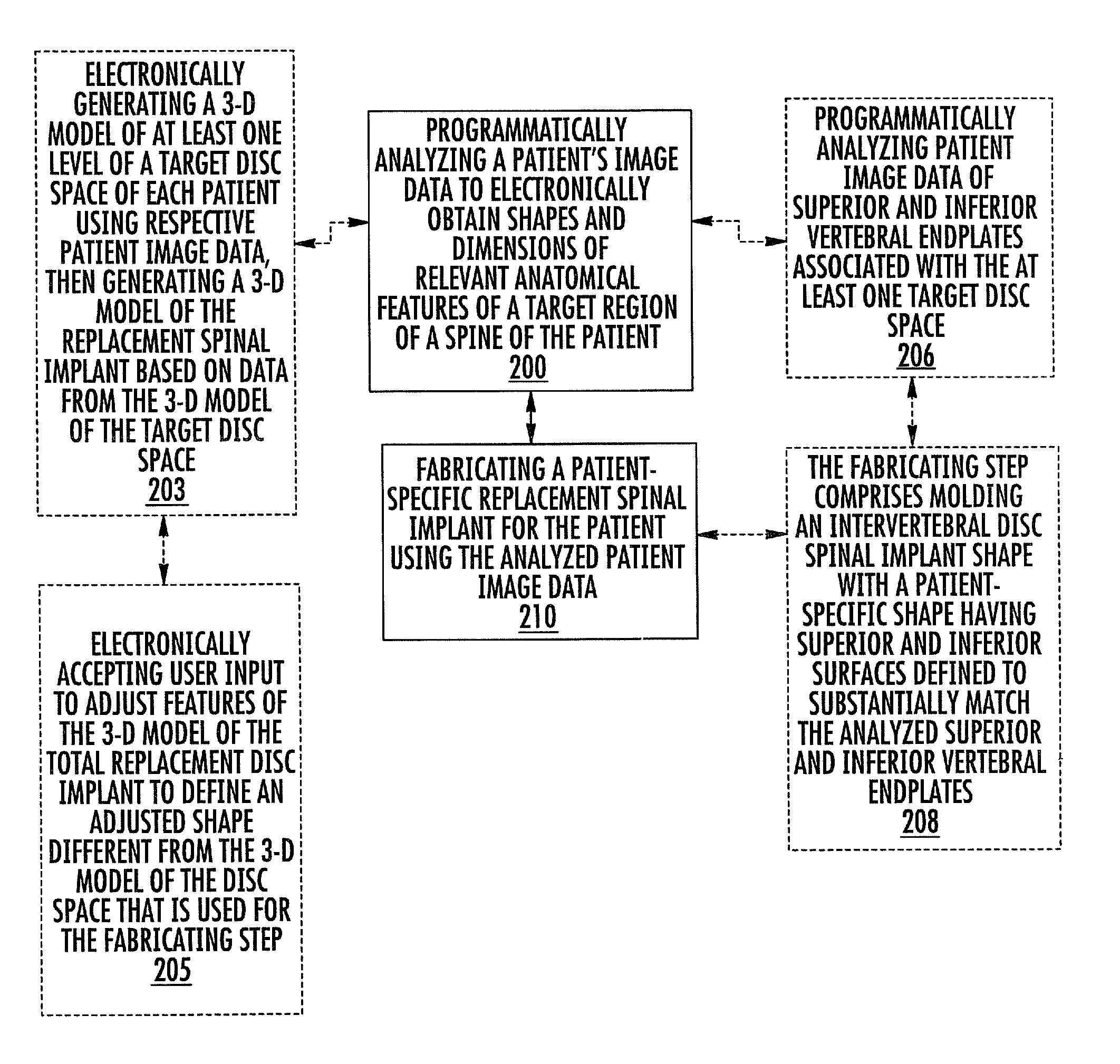

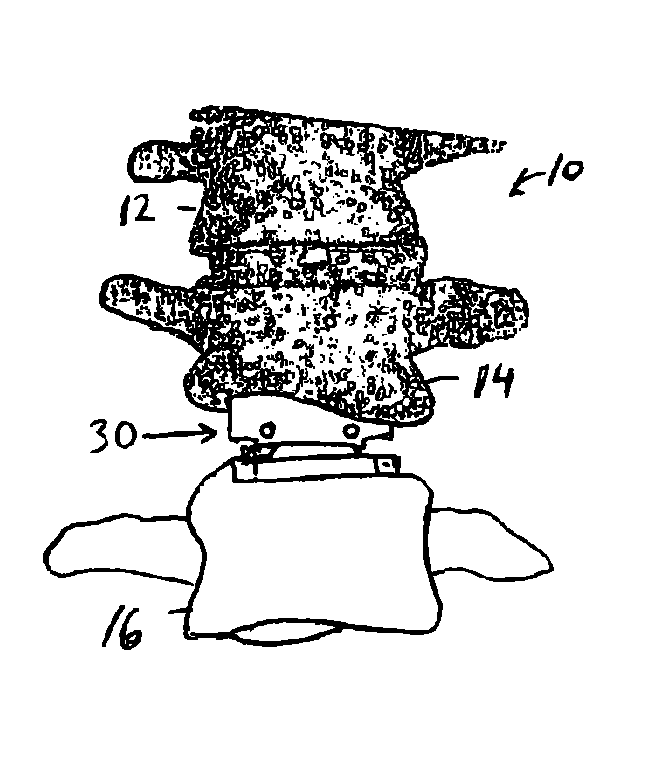

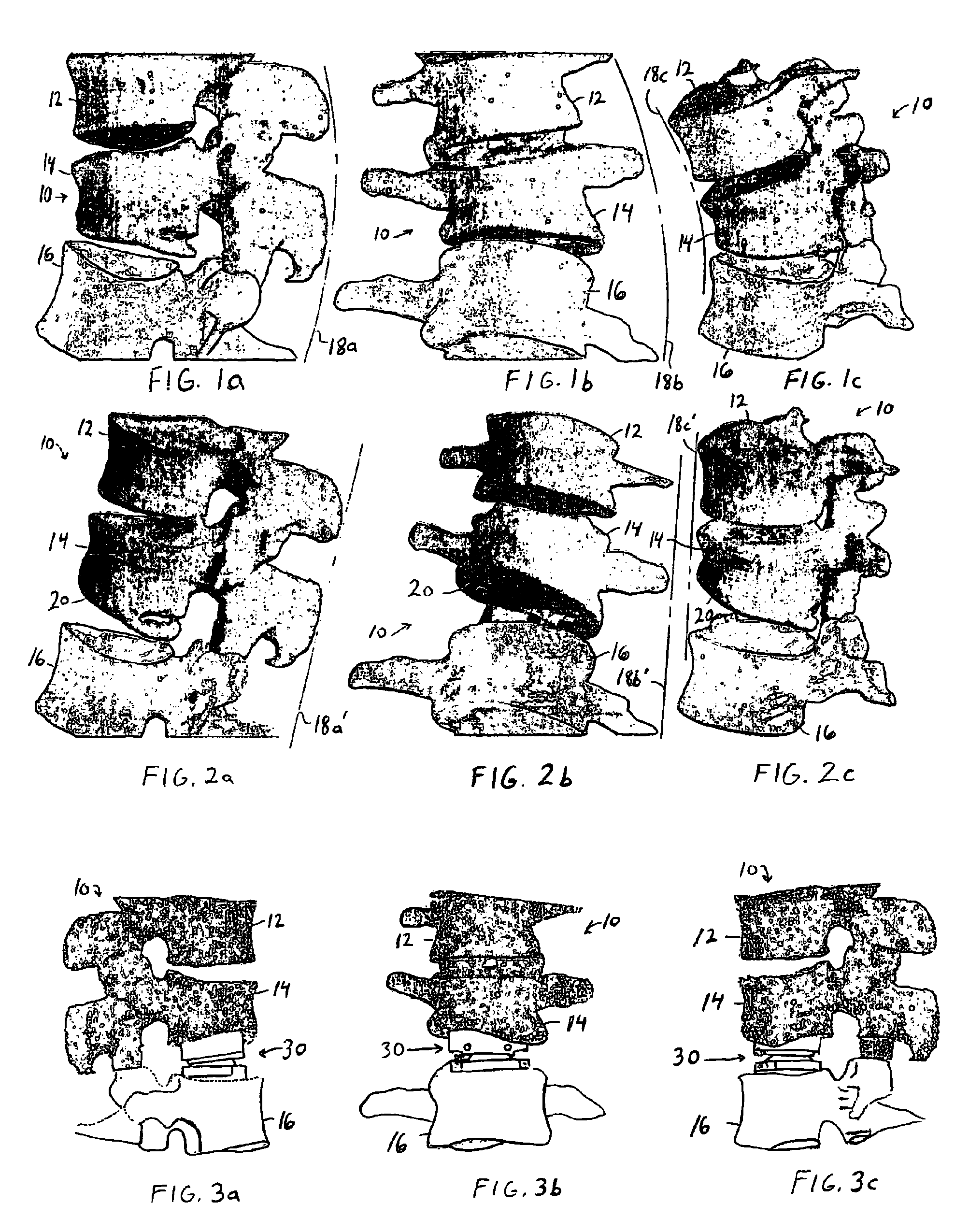

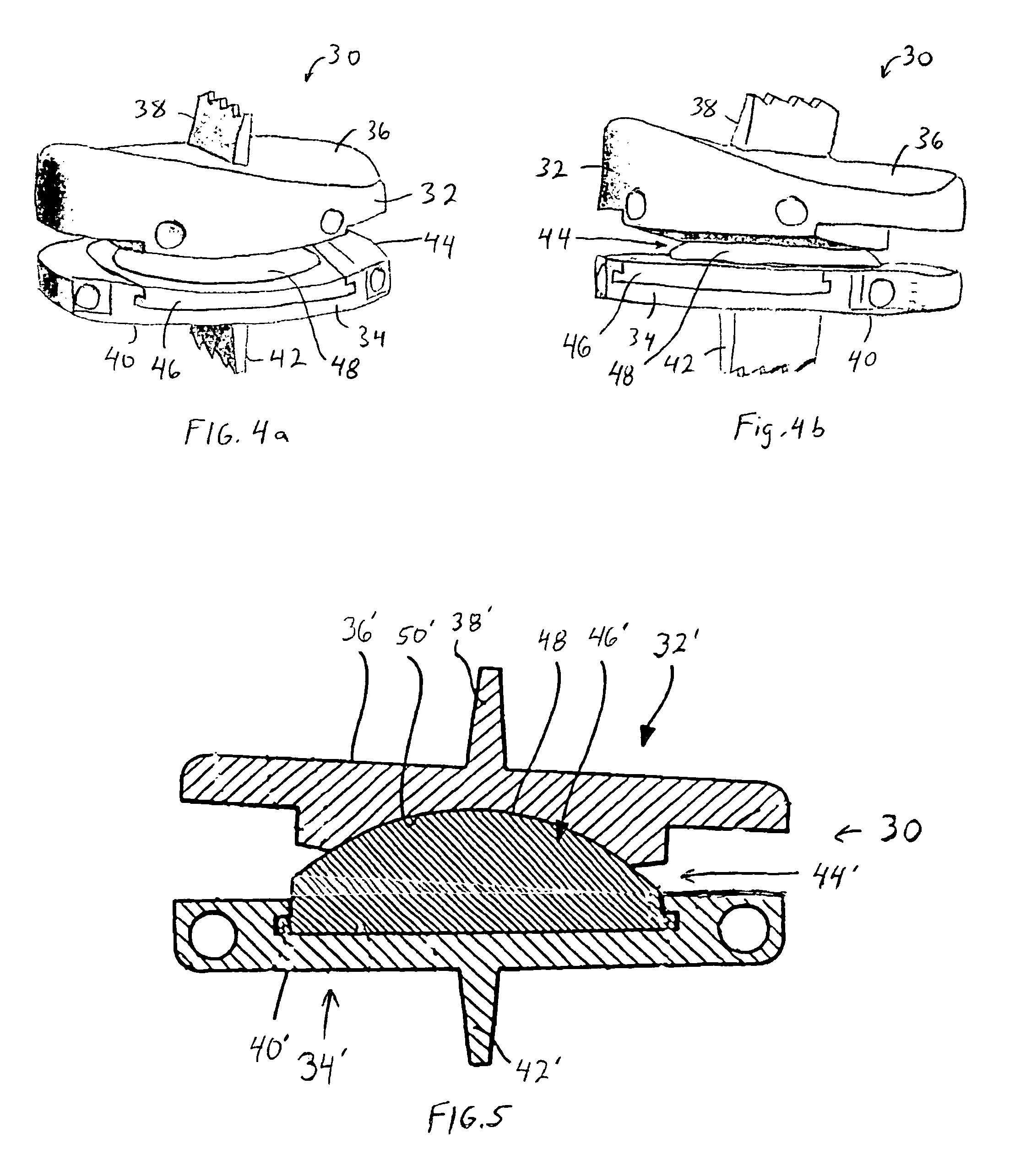

Patient-specific spinal implants and related systems and methods

InactiveUS8246680B2Easy to implantAdditive manufacturing apparatusInternal osteosythesisCustom made implantReplacement implant

Methods and systems for generating custom implants by programmatically analyzing a patient's image data to electronically obtain shapes and dimensions of relevant anatomical features of a target region of the patient; and fabricating a patient-specific replacement implant for the patient using the analyzed patient image data. Related patient-specific spinal implants are also described.

Owner:MIMEDX PROCESSING SERVICES LLC

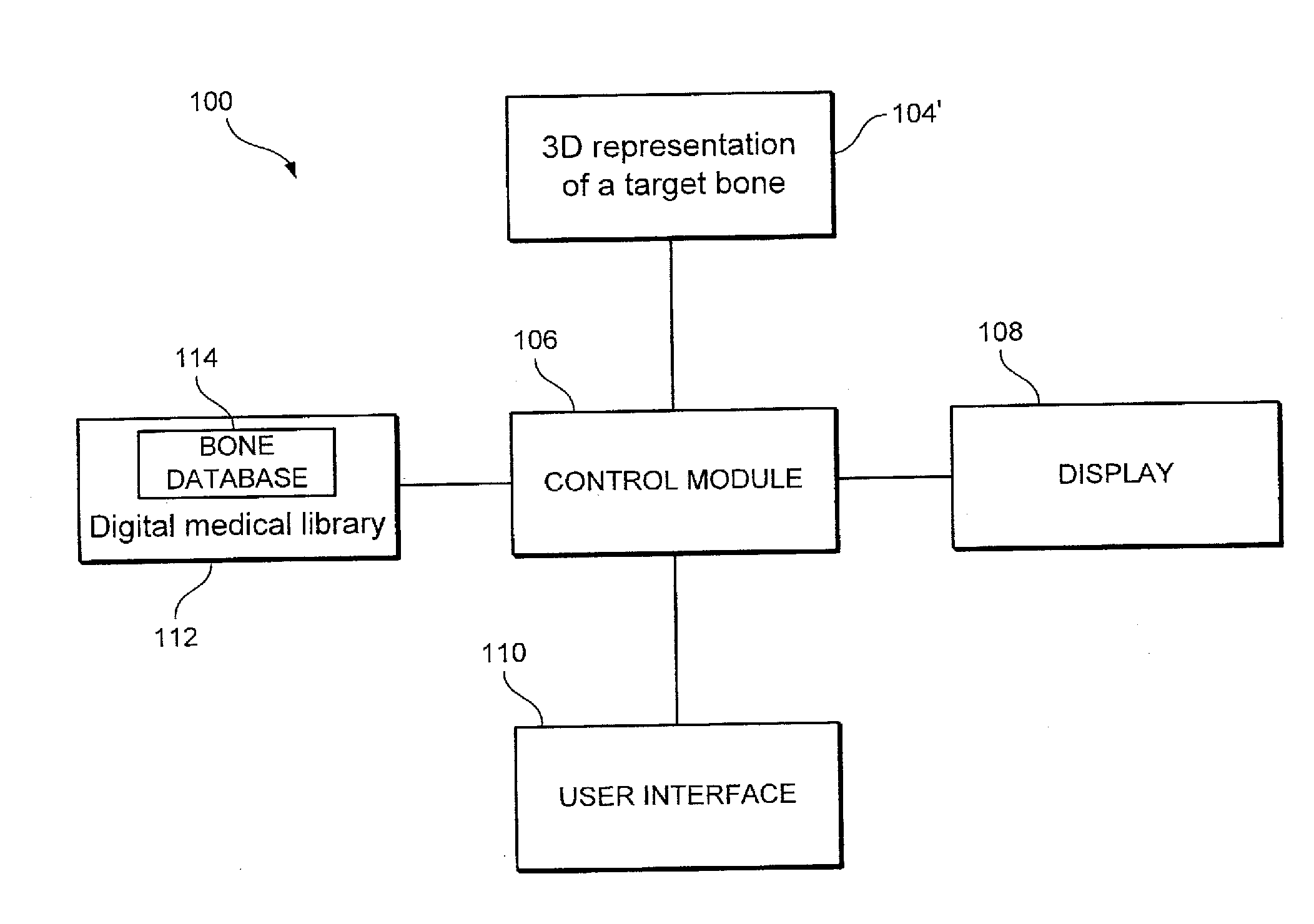

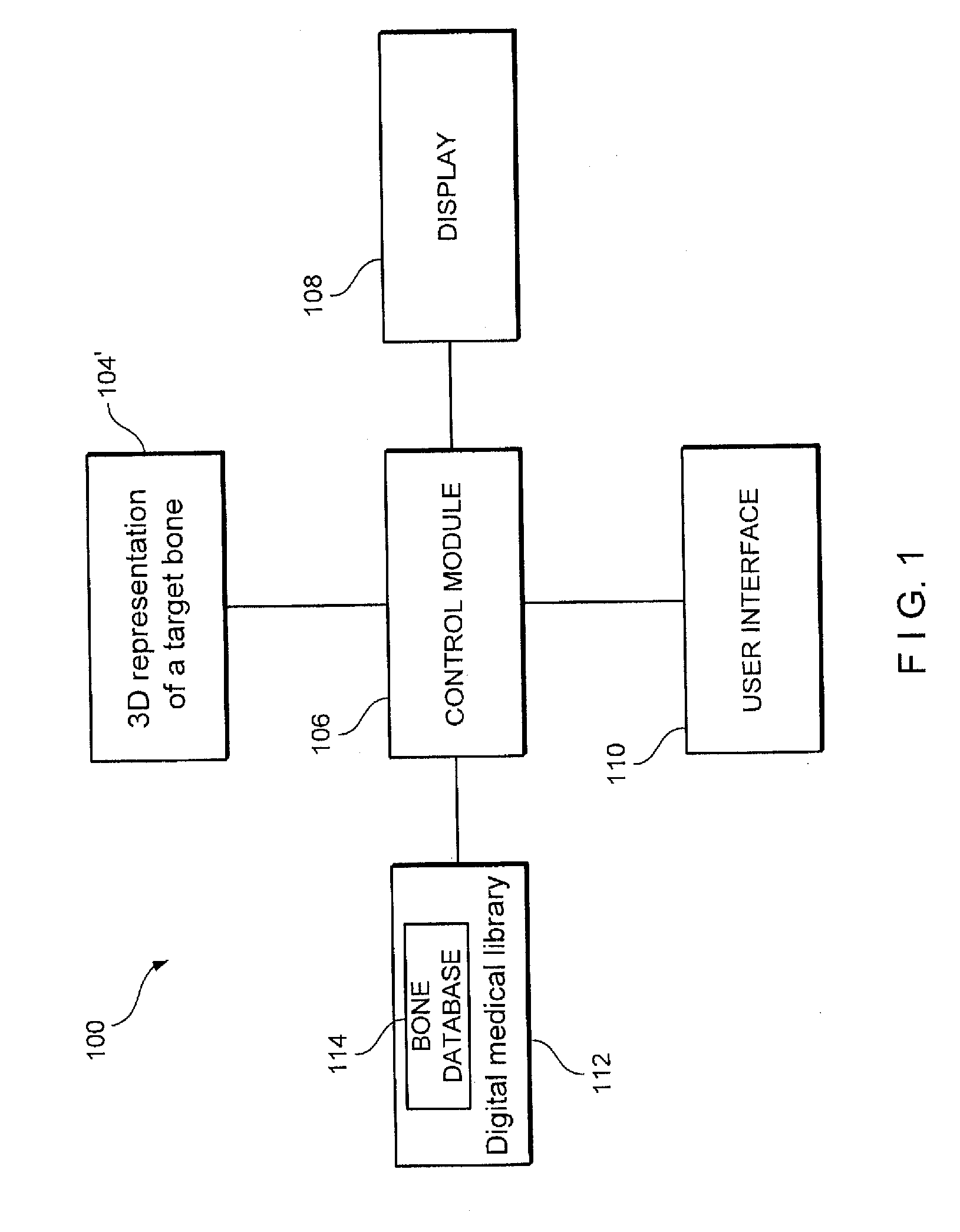

Advanced Bone Marker and Custom Implants

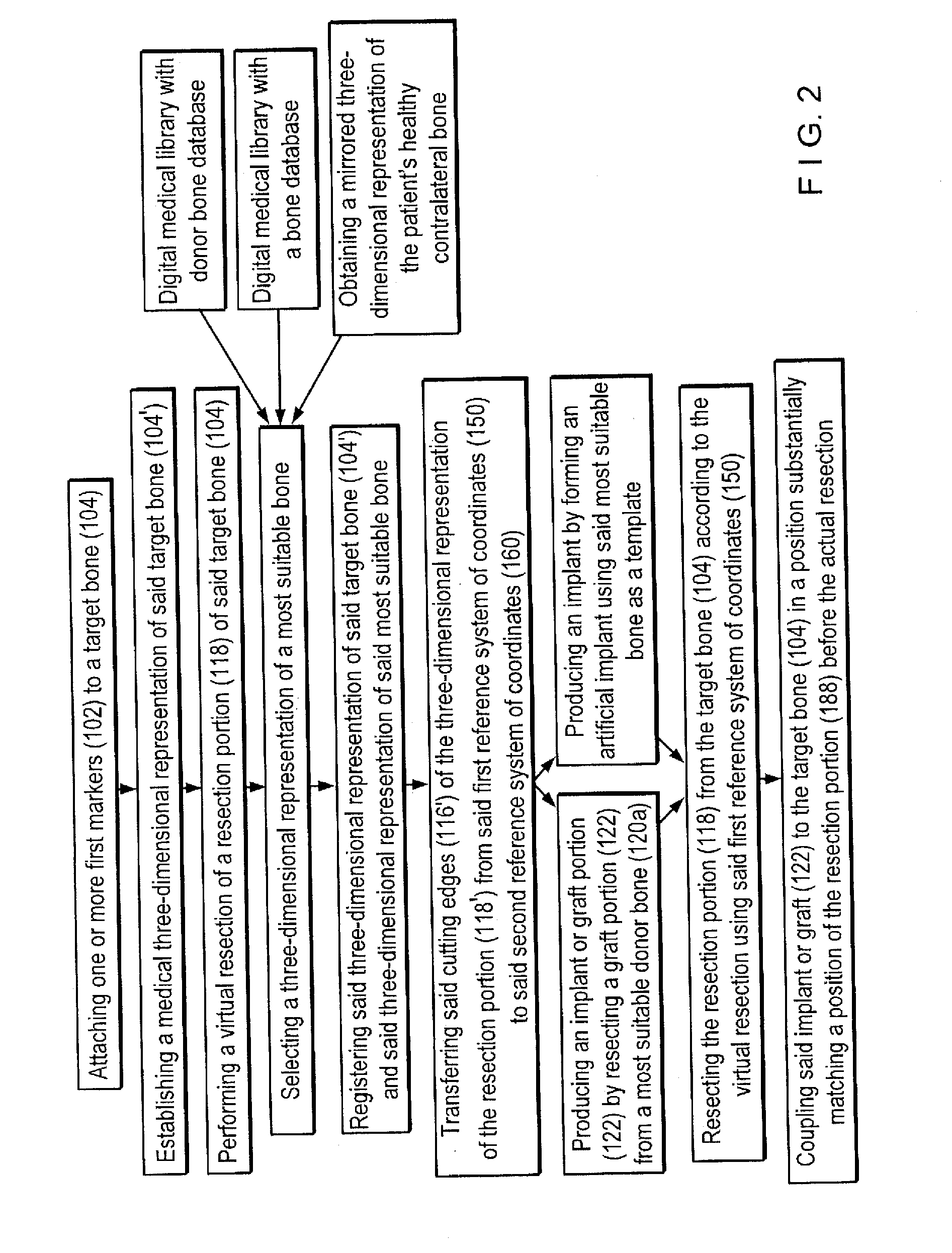

A method for replacing a portion of a target bone in a living body includes the steps of attaching one or more first markers to a target bone, establishing a medical three-dimensional representation of the target bone, performing a virtual resection of a resection portion, the virtual resection constructing a three-dimensional representation of the resection portion and a three-dimensional representation of the remaining target bone including cutting edges, providing a virtual pattern of the resection portion, obtaining an implant or graft portion for replacing the resection portion of the target bone by using the virtual pattern of the resection portion, resecting the resection portion from the target bone according to the virtual resection using the first reference system of coordinates and coupling the implant or graft portion to the target bone in a position substantially matching a position of the resection portion before the actual resection.

Owner:DEPUY SYNTHES PROD INC

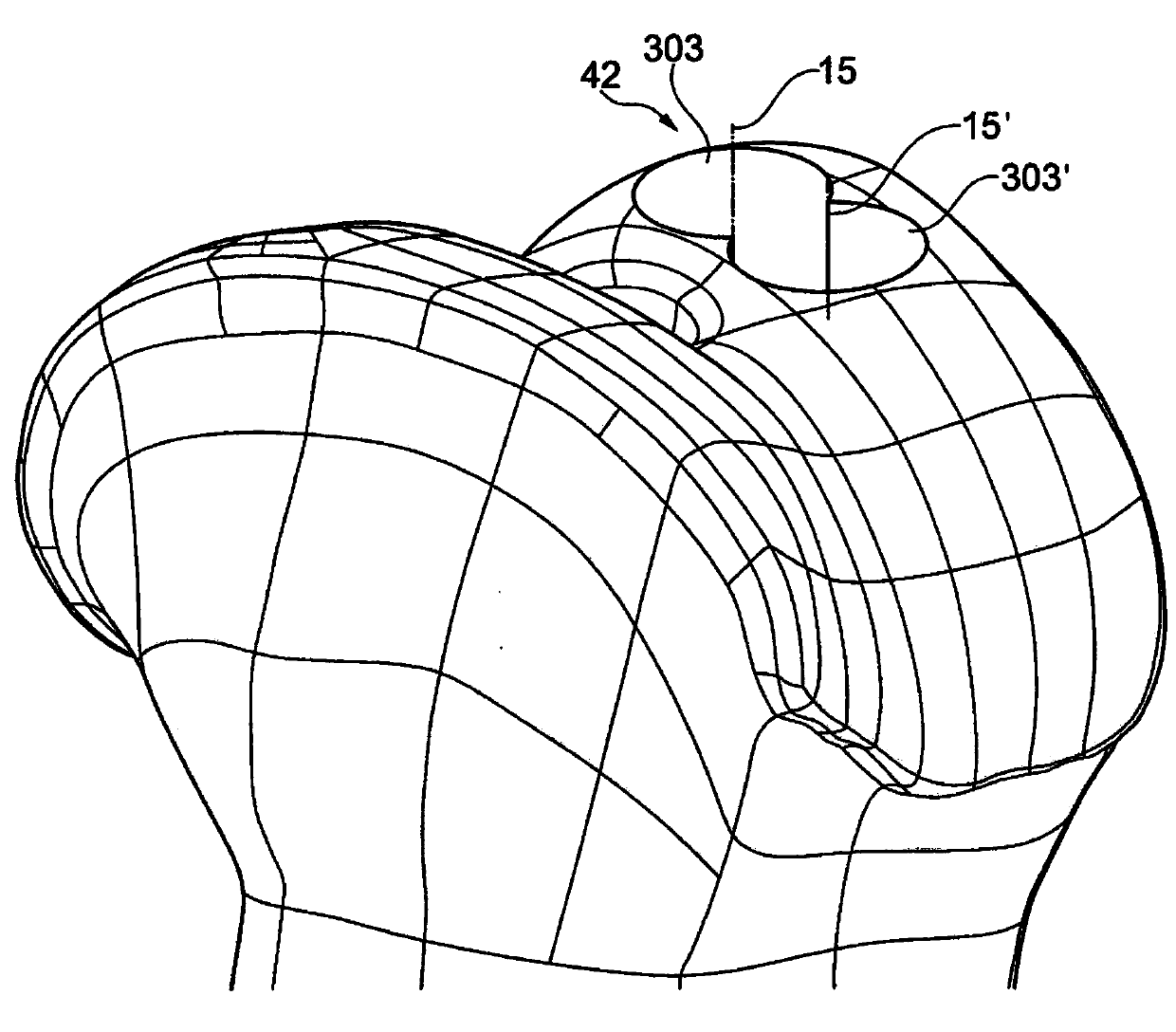

Process to design and fabricate a custom-fit implant

InactiveUS8706285B2High precisionImprove accuracyProgramme controlImage enhancementAxis of symmetryCustom made implant

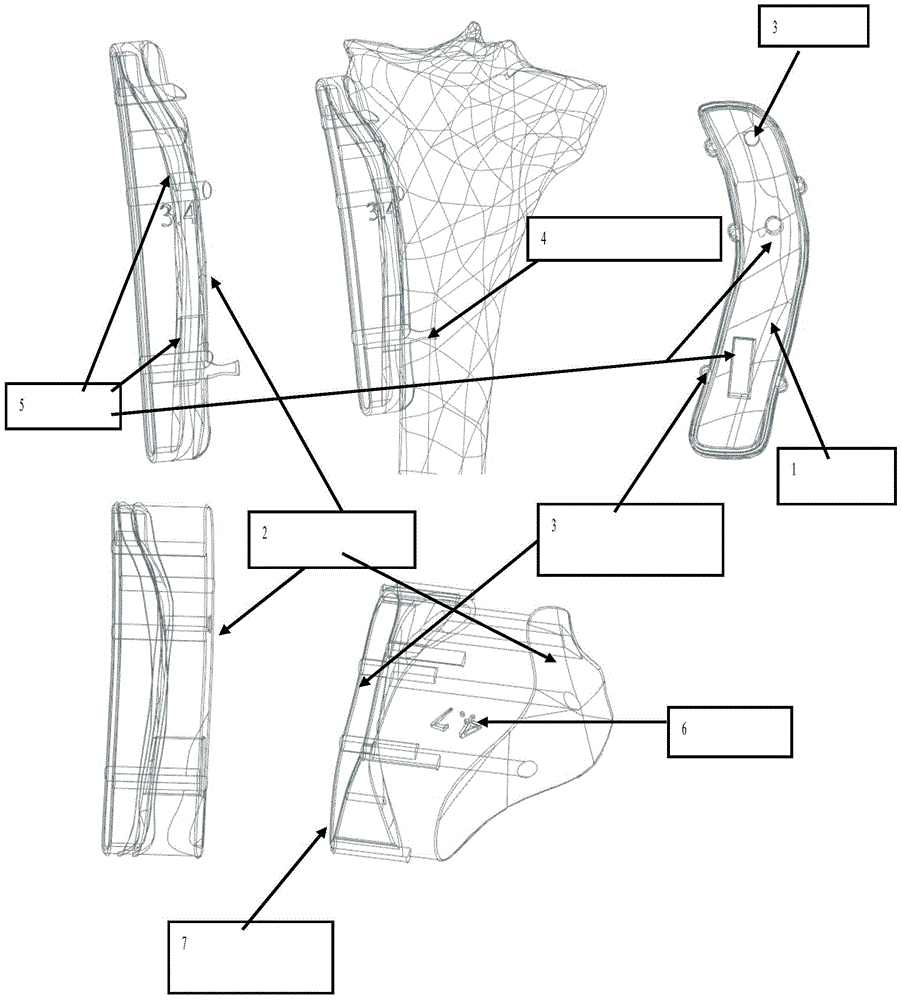

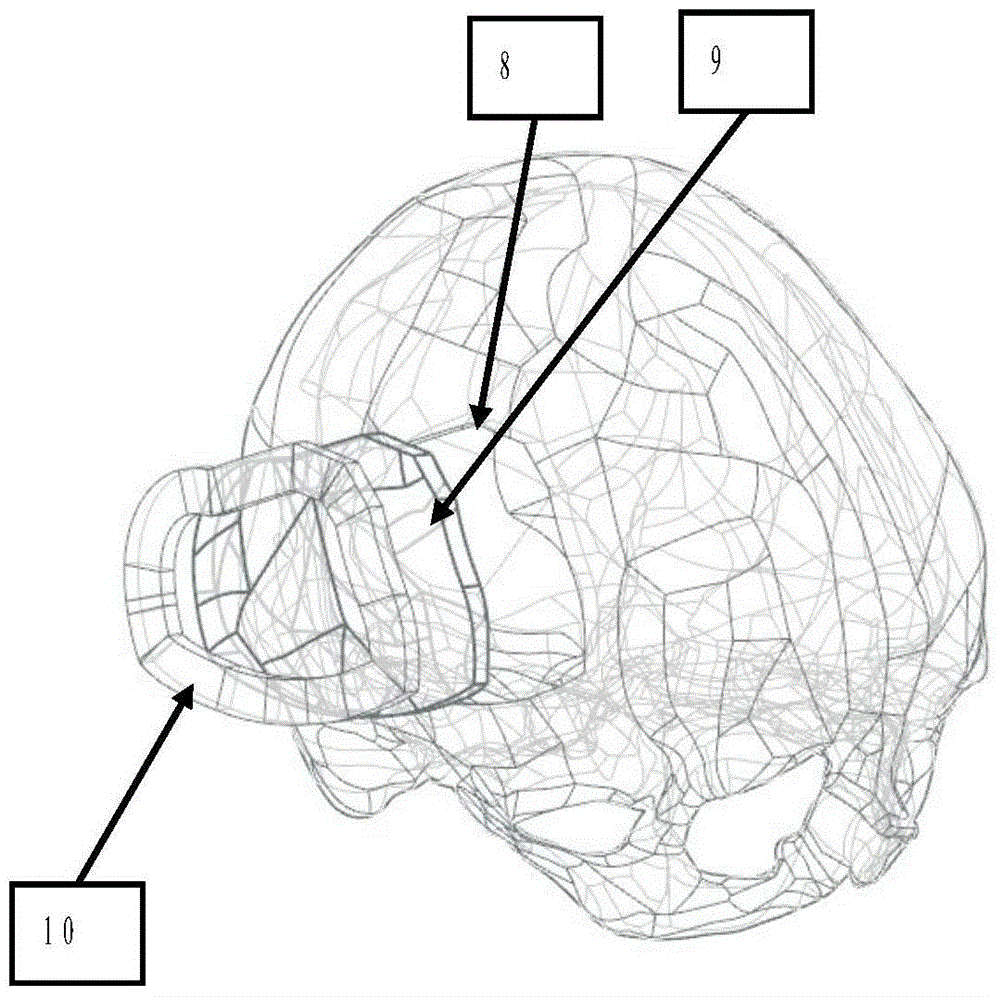

A process for designing and fabricating a custom-fit implant, comprising: a) processing medical image data of a patient's pathologically defective or anatomically deformed area having a symmetrical part to construct a three-dimensional (3D) digital model; b) forming a mirror image of the left or right side of the three-dimensional (3D) digital model based on its axis of symmetry depending on which side the pathologically defective or anatomically deformed area is; c) overlying the mirror image on the original image to form a composite image with a non-overlapping area wherein the implant will be fitted; d) generating a digital implant by cutting off the non-overlapping area of the mirror image; e) designing mounting points between the digital implant and the pathologically defective or anatomically deformed area where the implant is mounted thereon; f) building a positive and a negative mold based on the digital implant to fabricate a custom-fit implant.

Owner:UNIVERSITI MALAYA

Method for design and production of a custom-fit prosthesis

Systems and methods are provided for designing and producing a custom-fit prosthesis. According to one embodiment, a mold is produced from which a custom-fit implant may be directly or indirectly manufactured. Medical image data representing surrounding portions of a patient's anatomy to be repaired by surgical implantation of the custom-fit implant are received. Then, three-dimensional surface reconstruction is performed based on the medical image data. Next, the custom-fit implant is designed based on the three-dimensional surface reconstruction and a positive or negative representation of a two-part mold is created with a void in the shape of the custom-fit implant by subtracting a representation of the custom-fit implant from a representation of a mold. Finally, the two-part mold is output from which the custom-fit implant may be directly manufactured; or an implant is directly output. Alternatively, an intermediate mold is created from which a two-part mold may be directly manufactured.

Owner:3D SYST INC

Method for design and production of custom-fit prosthesis

Systems and methods are provided for designing and producing custom-fit prosthesis. According to one embodiment, a mold is produced from which a custom-fit implant may be directly manufactured. Medical image data representing surrounding portions of a patient's anatomy to be repaired by surgical implantation of the custom-fit implant are received. Then, three-dimensional surface reconstruction is performed based on the medical image data. Next, the custom-fit implant is designed based on the three-dimensional surface reconstruction and a two-part mold is created with a void in the shape of the custom-fit implant by subtracting a representation of the custom-fit implant from a representation of a mold. Finally, the two-part mold is output from which the custom-fit implant may be directly manufactured.

Owner:MEDICAL MODELING

Tracked cartilage repair system

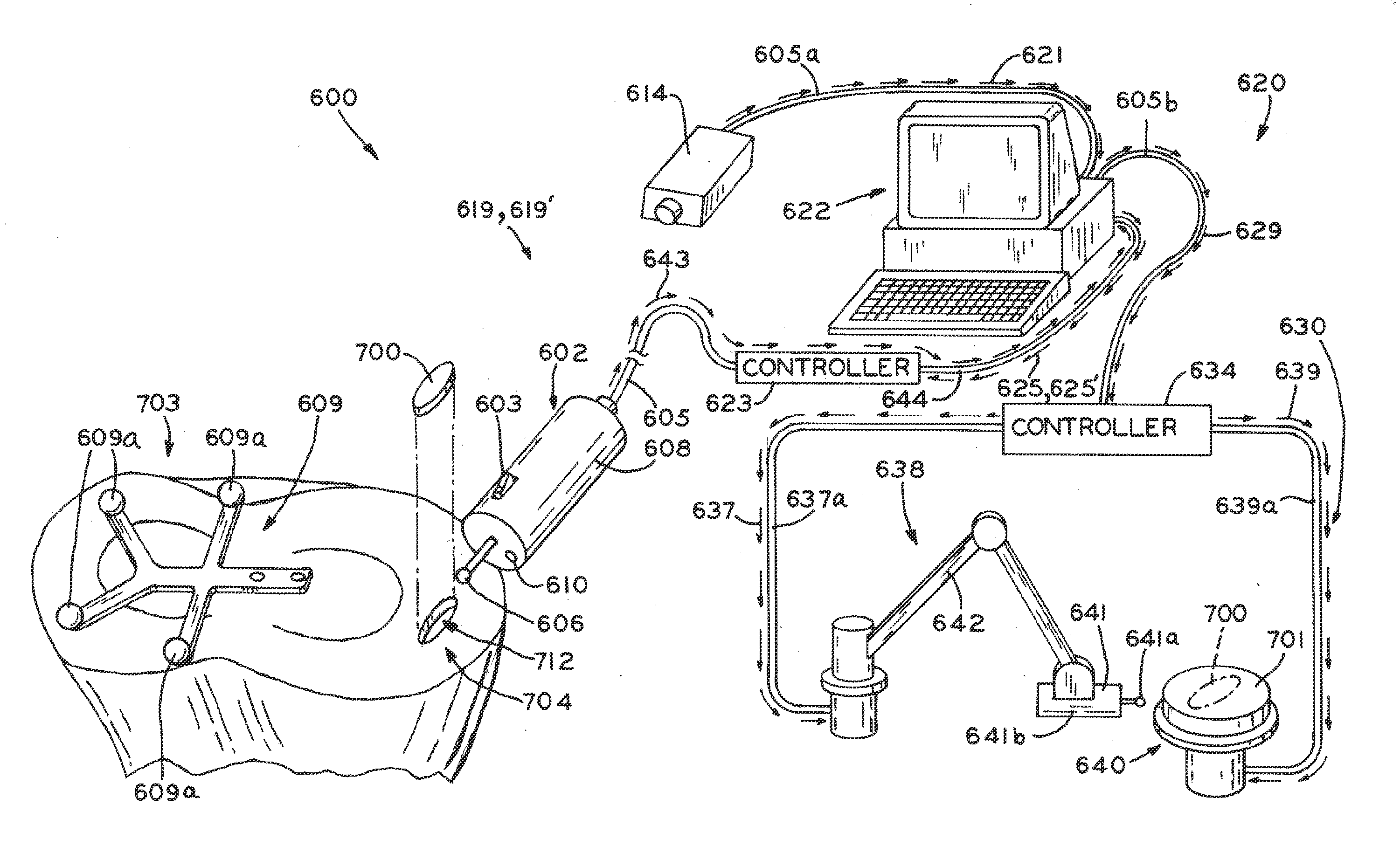

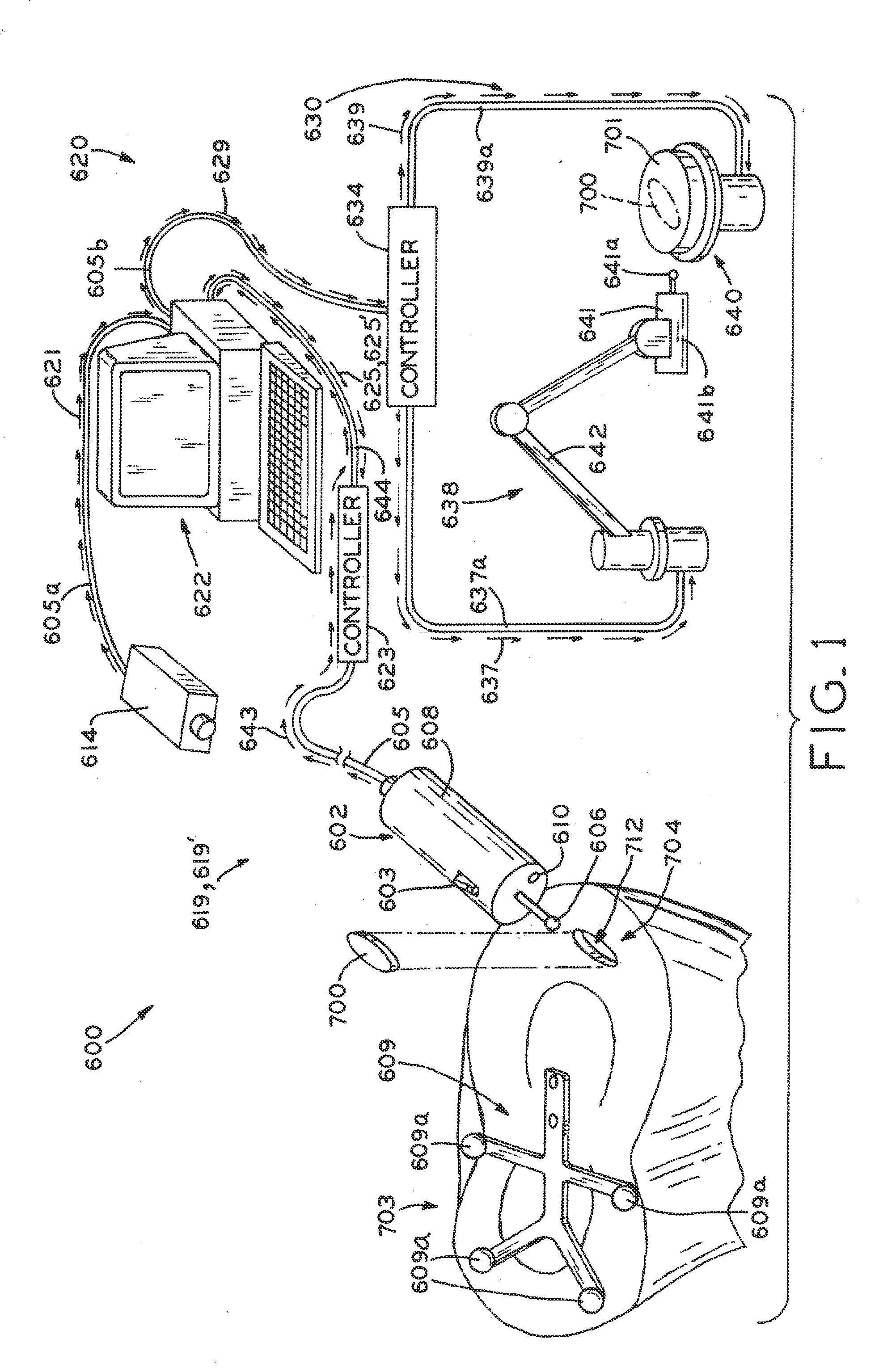

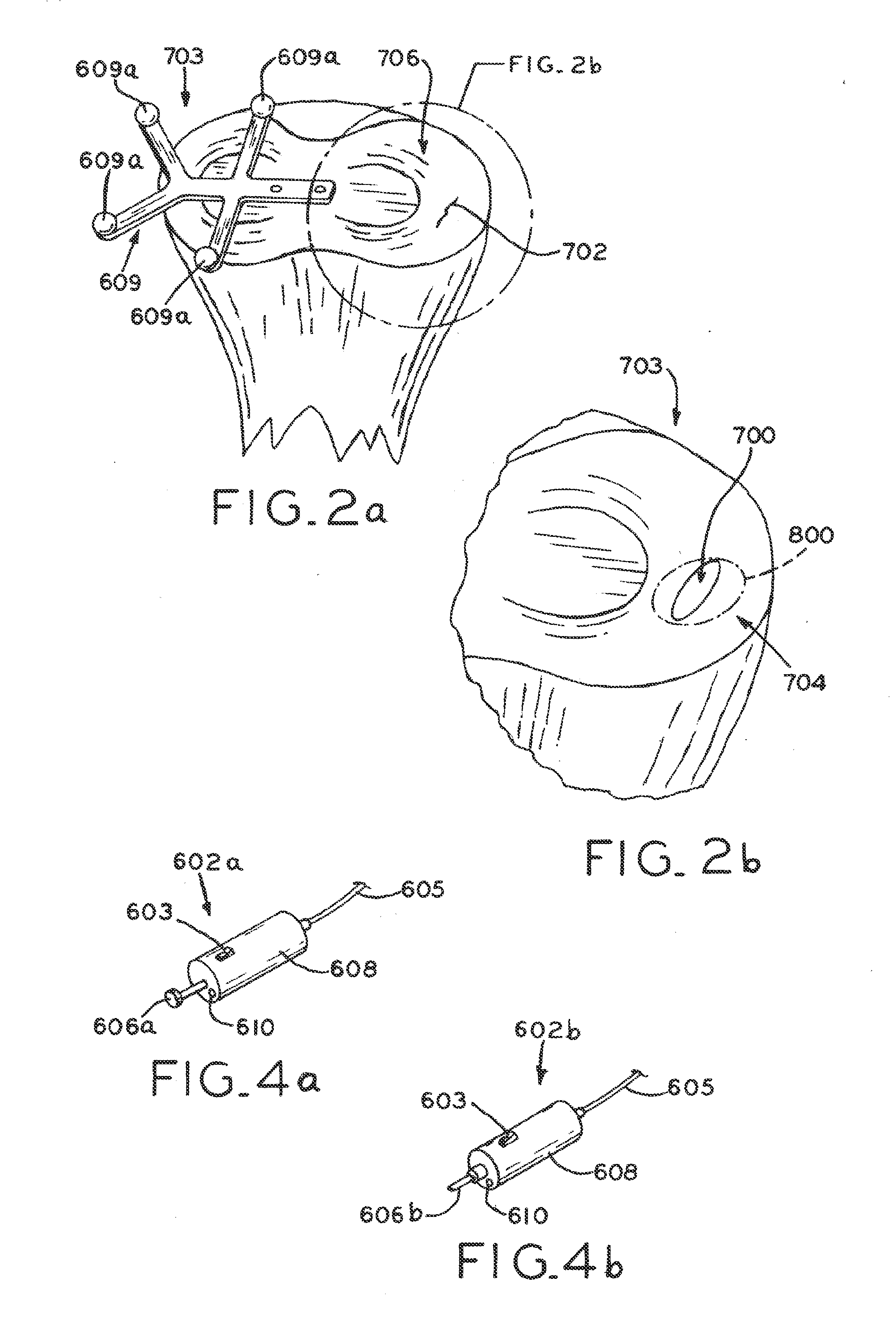

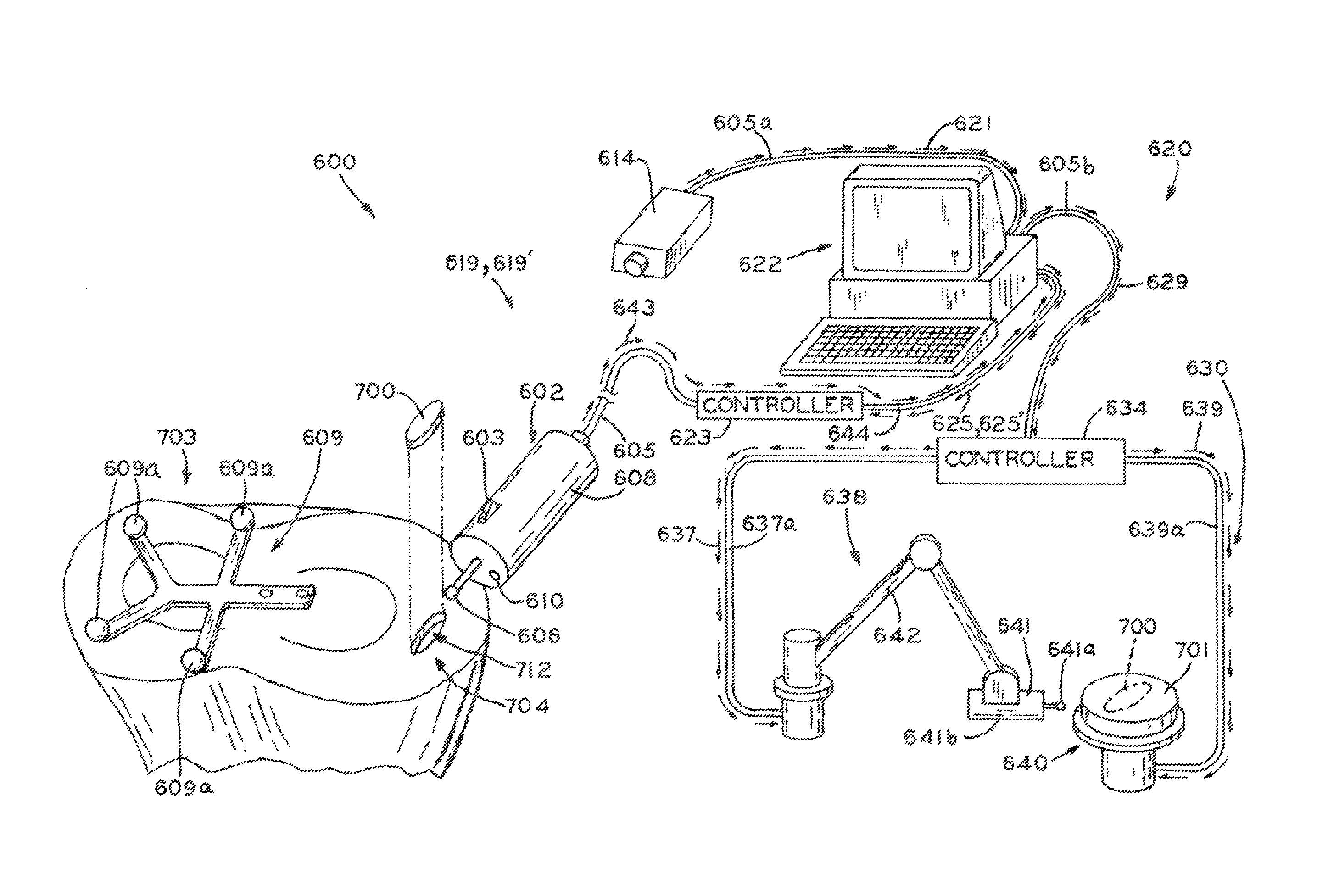

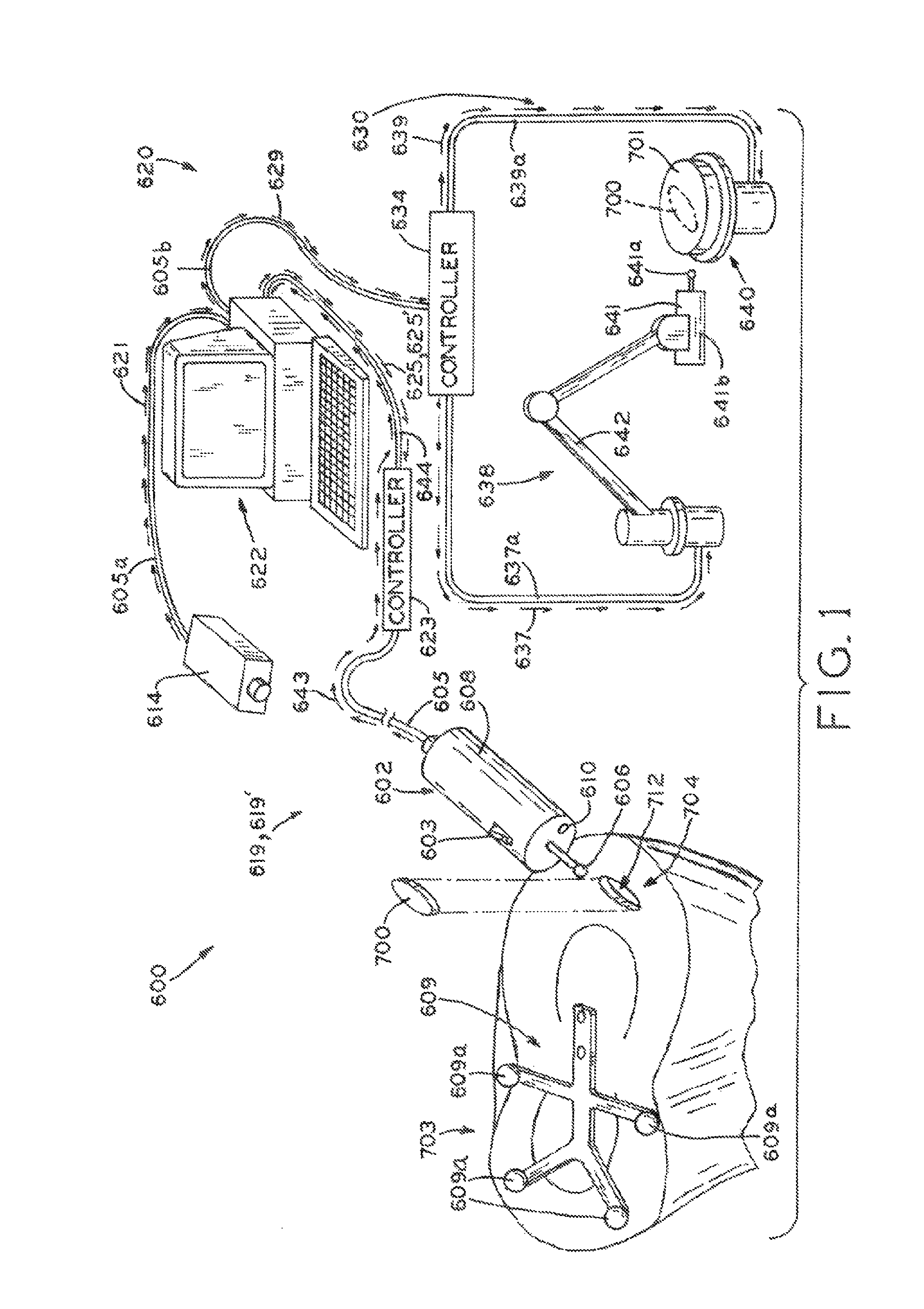

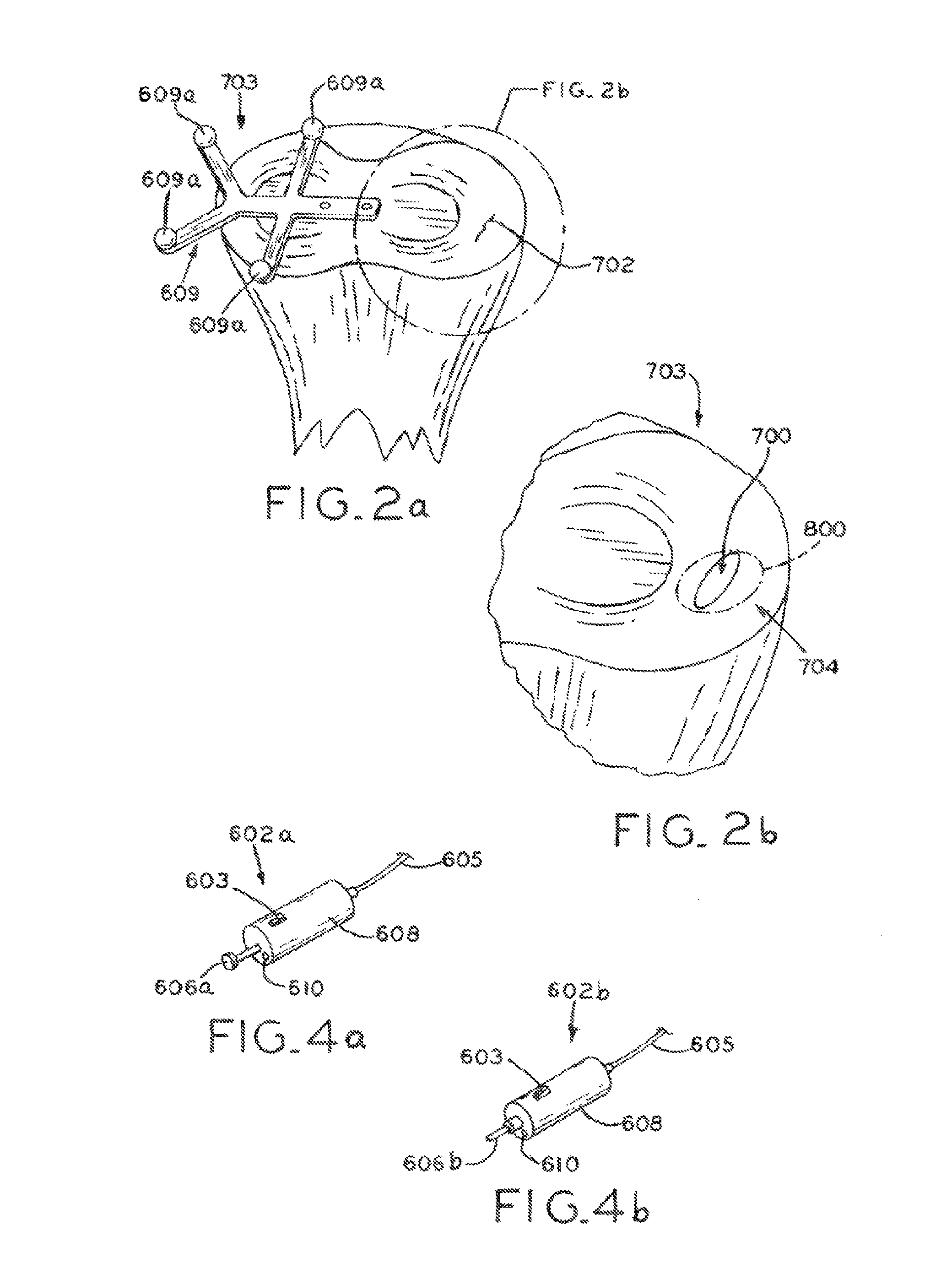

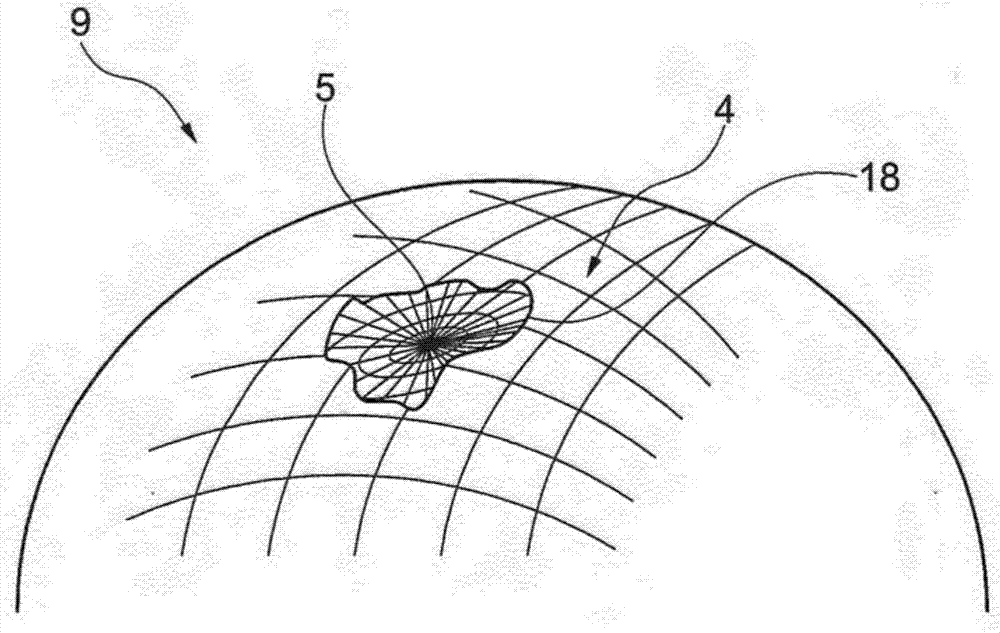

ActiveUS20110208256A1Reduce removalAdditive manufacturing apparatusDiagnosticsData setCustom made implant

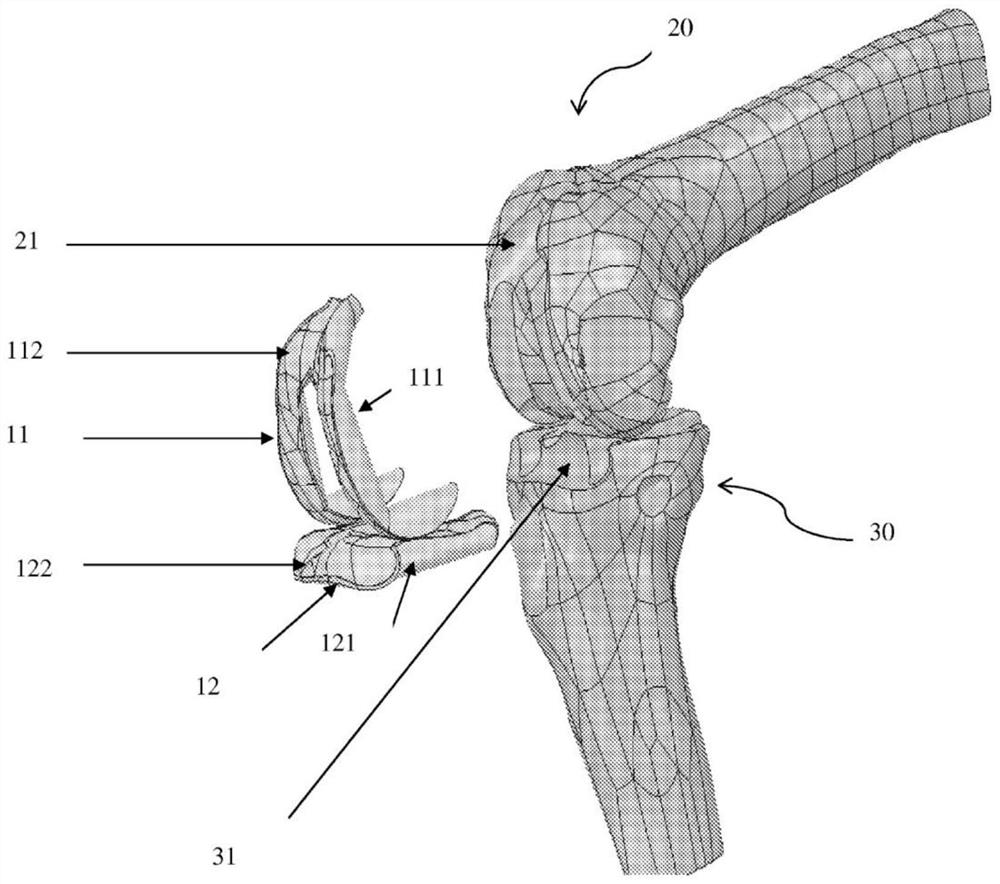

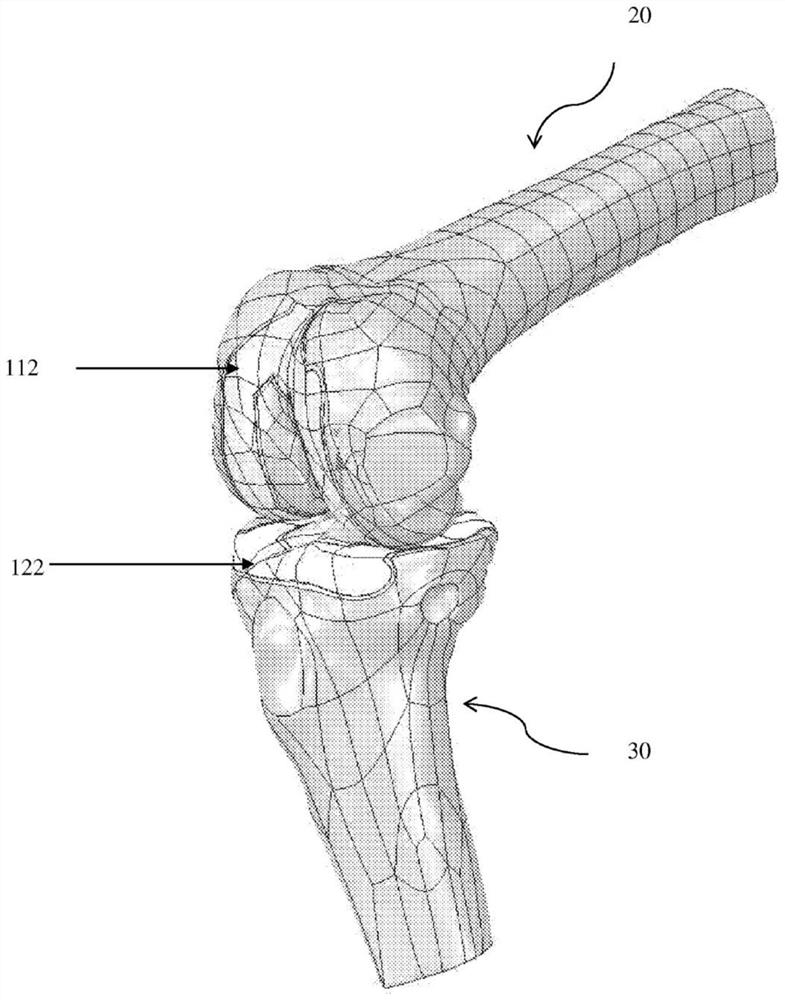

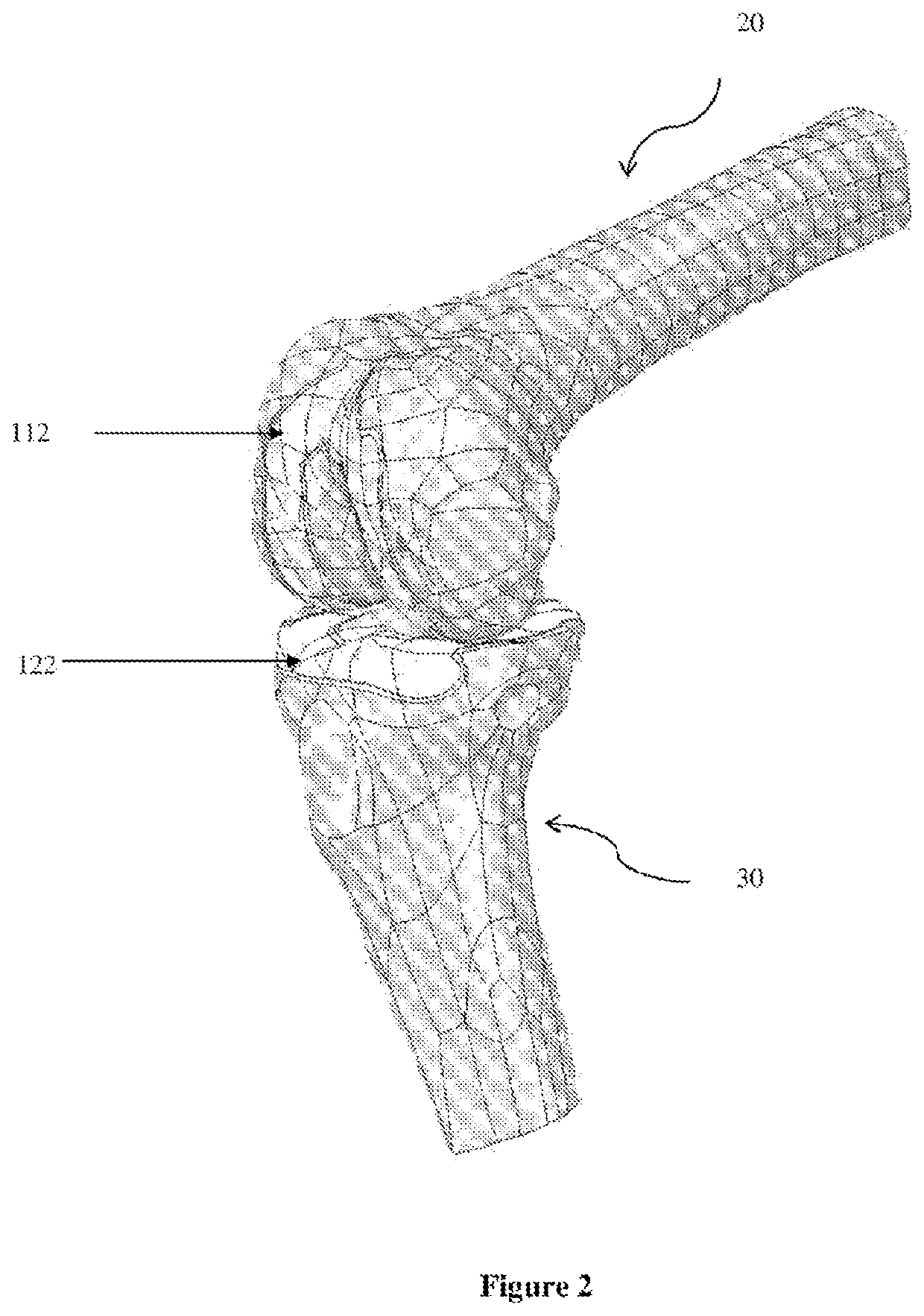

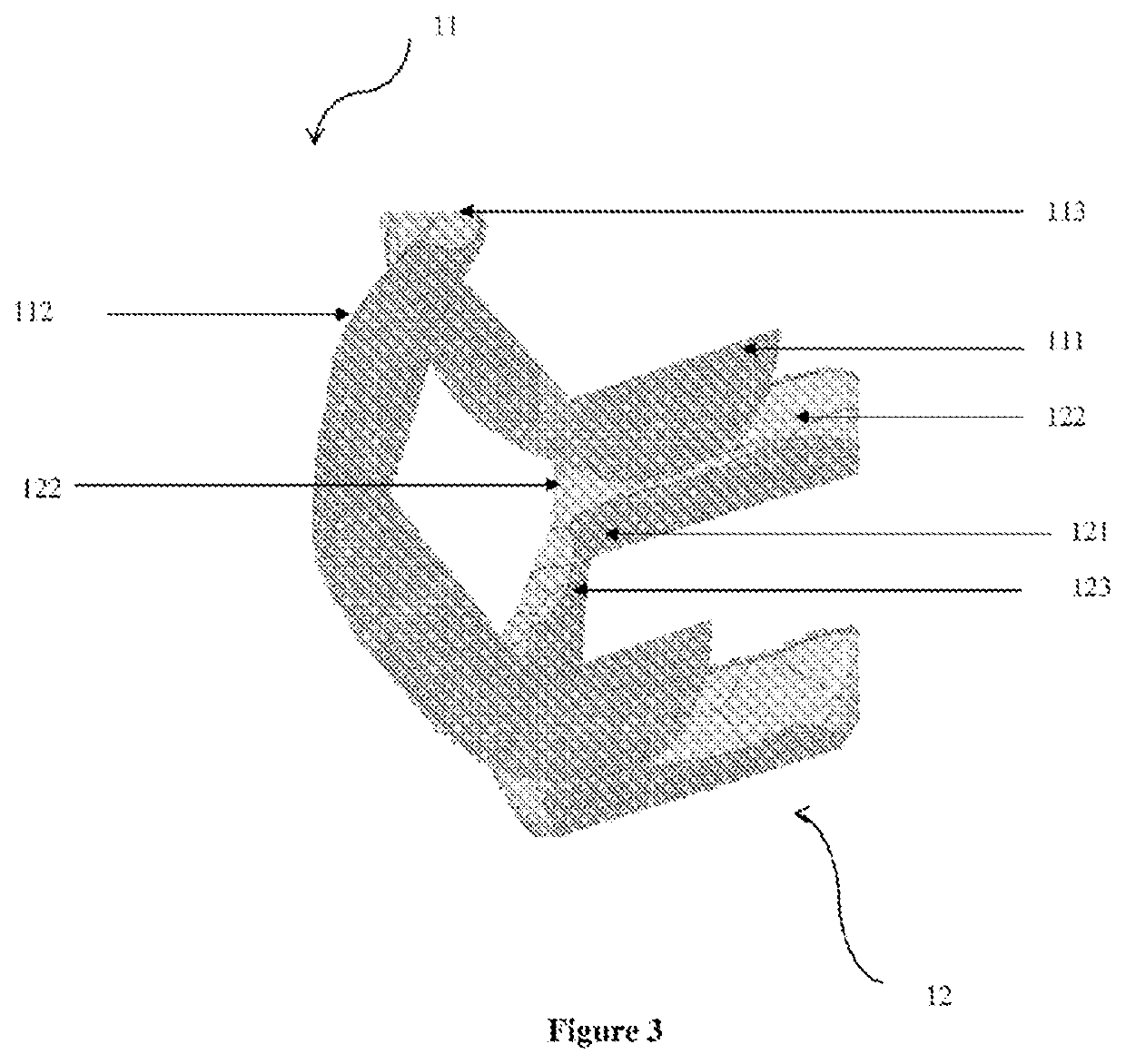

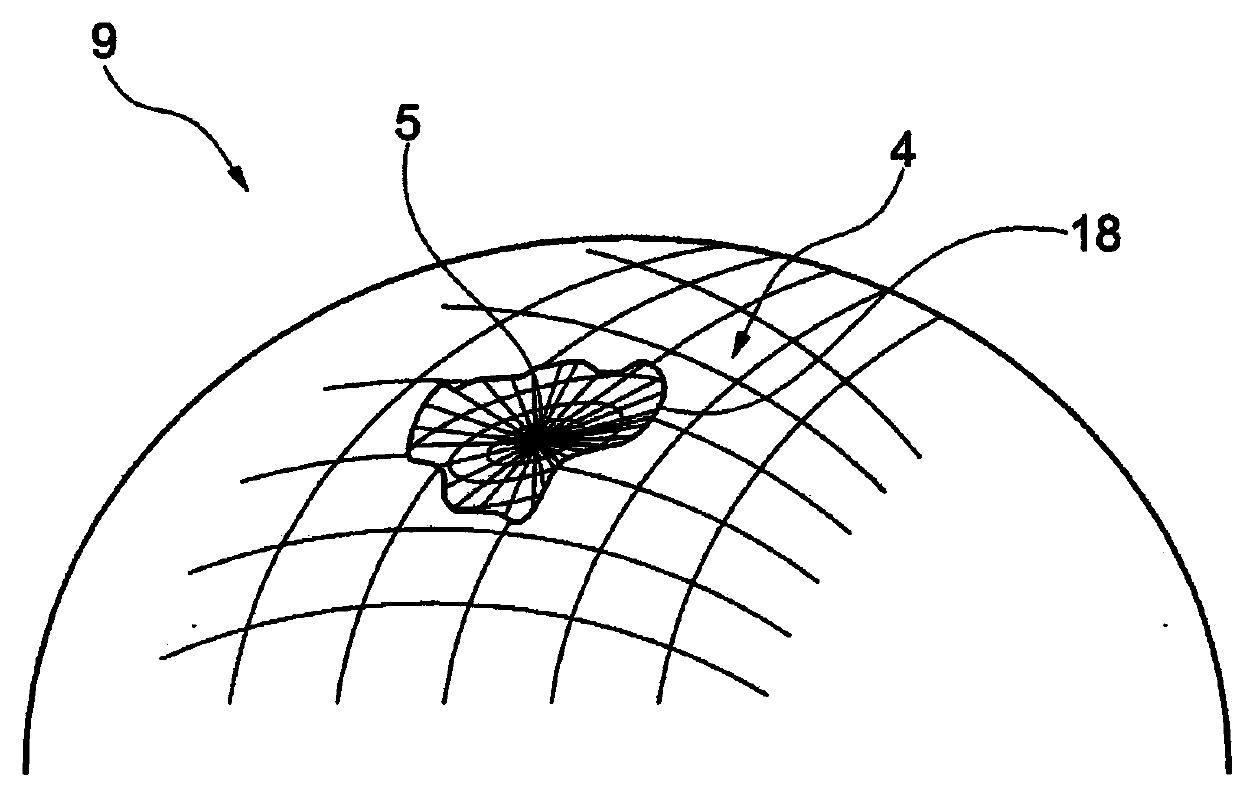

A system and method for repairing an area of defective tissue reduces the removal of healthy tissue at the margins of the defect. During excision of diseased or damaged tissue, the system tracks the movement and function of a tissue resection tool within a monitored surgical space. This movement is continuously recorded to create a three-dimensional set of data points representative of the excised volume of tissue. This data set is then communicated to a custom implant forming device which creates a custom implant sized to fit the void created by the excision. The system and method of the present disclosure allows a surgeon to exercise intraoperative control over the specific shape, volume and geometry of the excised area. Moreover, the surgeon may utilize a “freehand” resection method to excise only that tissue deemed to be diseased and / or damaged, because the custom-formed implant will accommodate an irregularly-shaped resection volume.

Owner:ZIMMER INC

Customized implants for bone replacement

InactiveUS20110144752A1Reduce the chance of solidificationLow process temperatureImpression capsAdditive manufacturing apparatusNatural boneCustom made implant

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

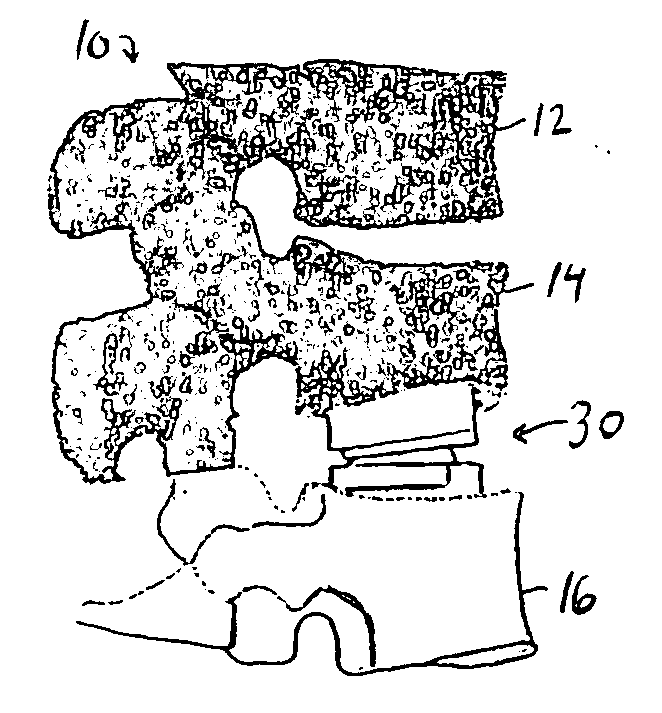

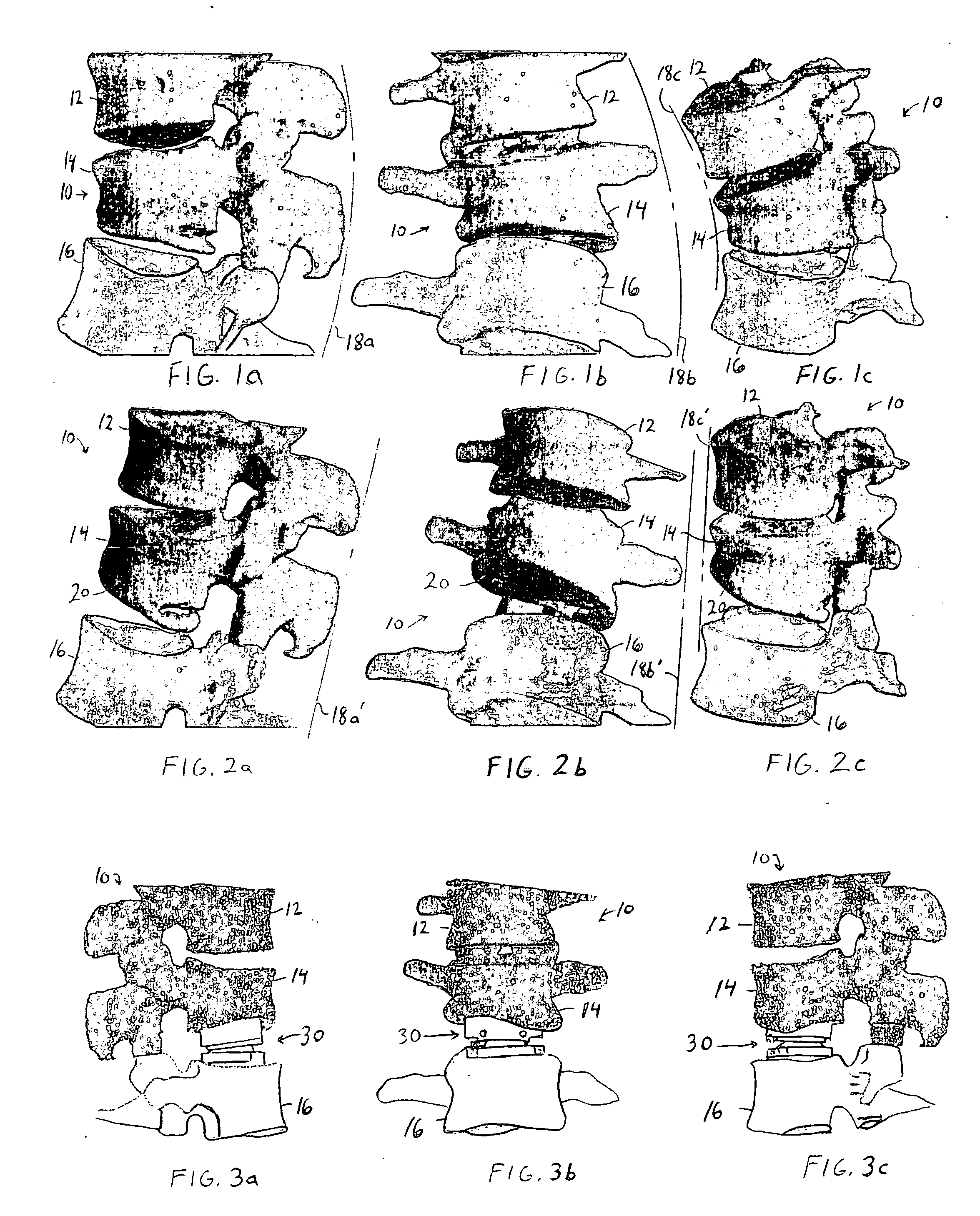

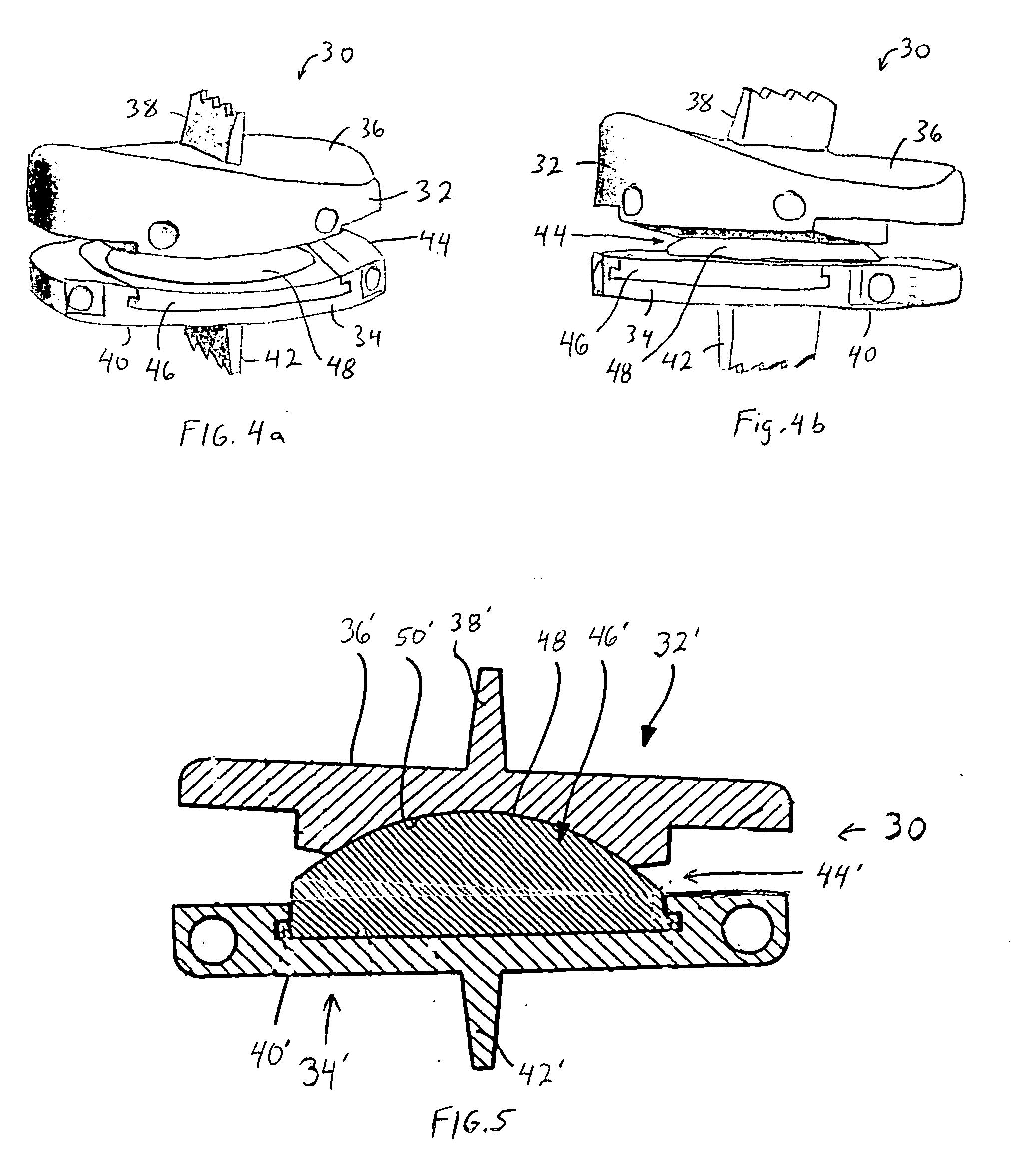

Customizing an intervertebral implant

ActiveUS20060282020A1Eliminate as farPerson identificationSpinal implantsCustom made implant3d anatomy

Owner:DEPUY SYNTHES PROD INC

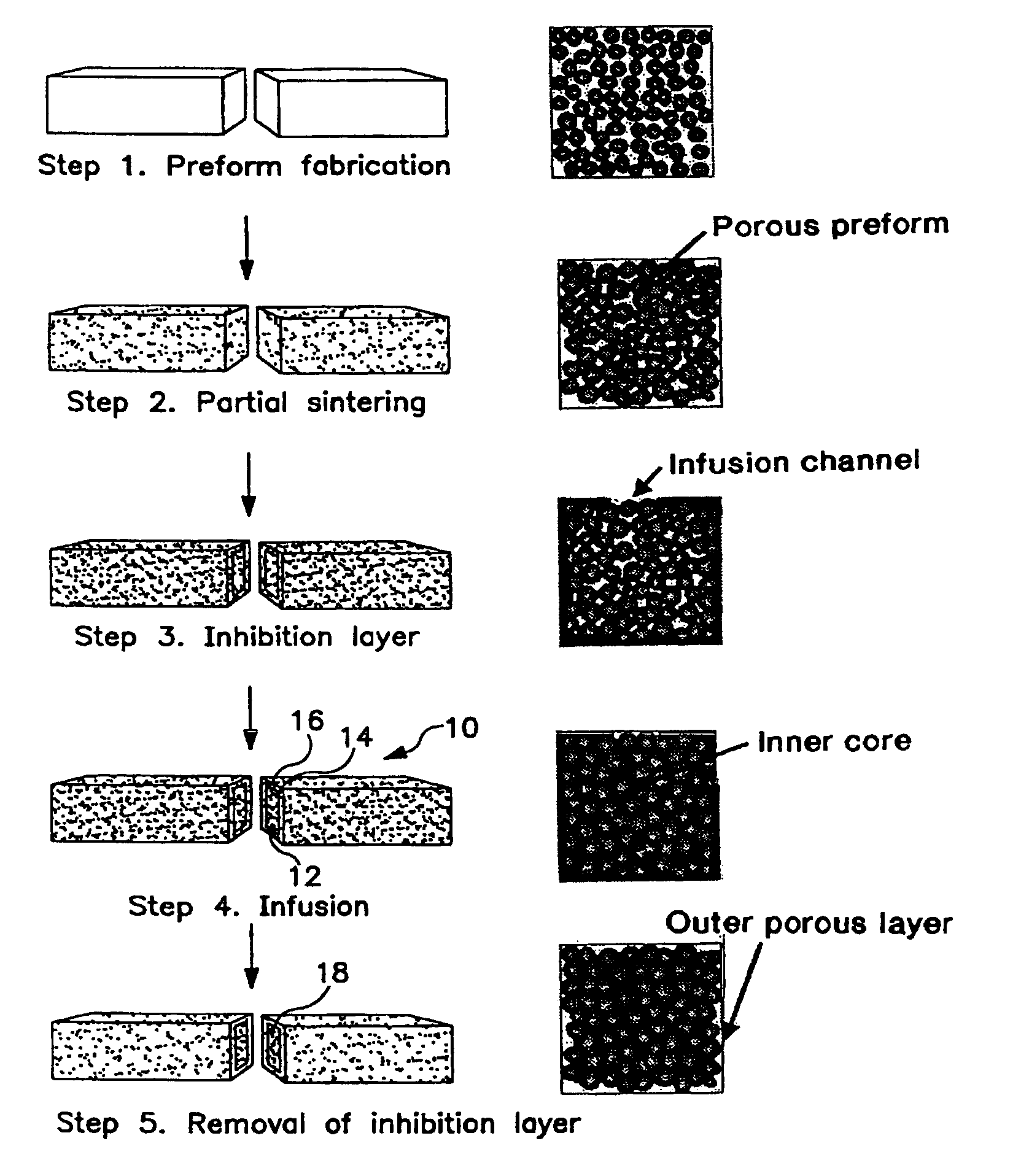

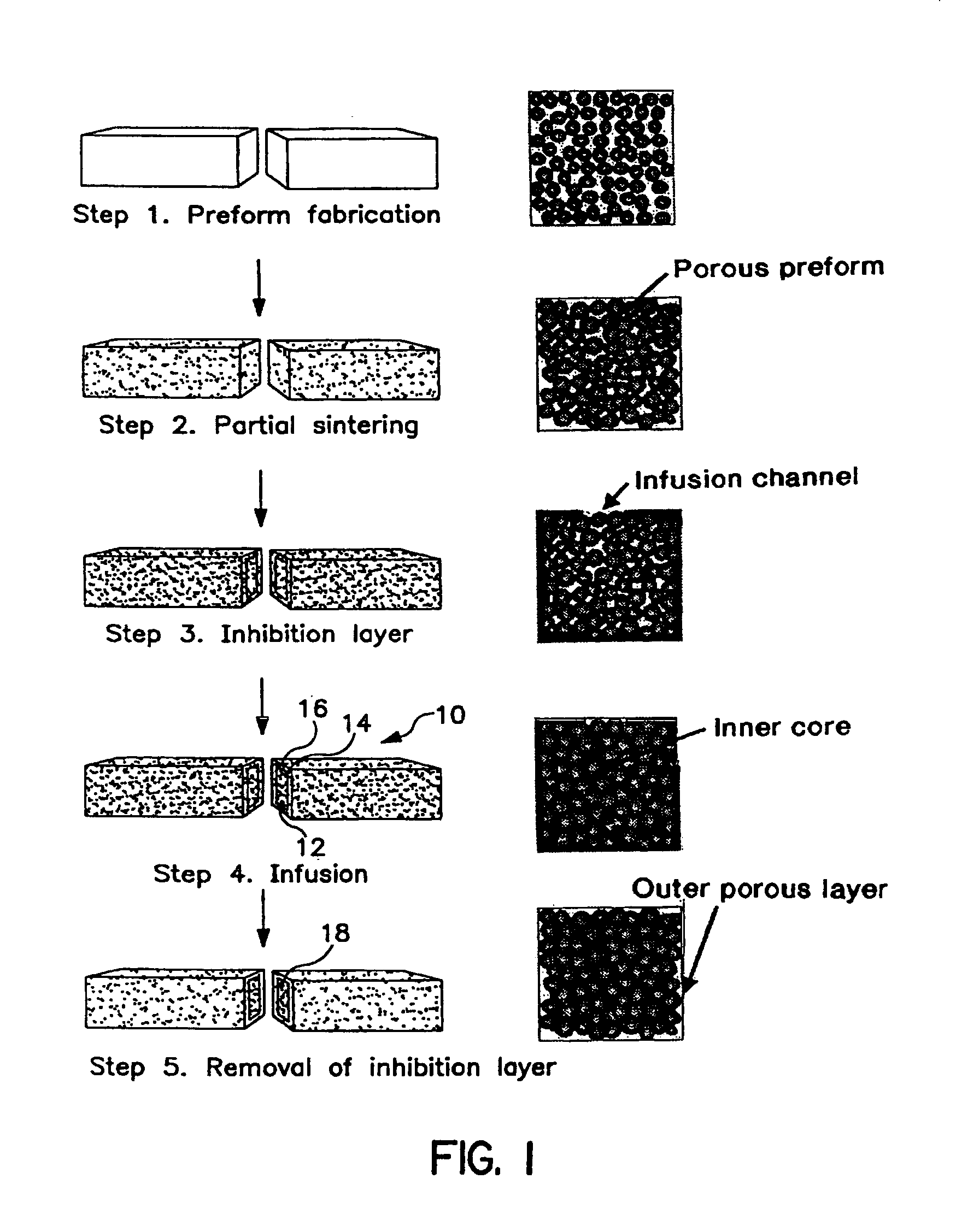

Polymer re-inforced anatomically accurate bioactive protheses

InactiveUS7052710B2Improve mechanical propertiesImprove abilitiesPowder deliveryImpression capsHigh fractureCustom made implant

Customized implants for use in reconstructive bone surgeries where anatomical accuracy and bone adaptation are important, such as plastic and craniomaxillofacial reconstructions. This implant comprises a porous surface layer and a tough inner core of interpenetrating phase composite. The porous surface layer enhances the biocompatibility, tissue ingrowth, and implant stability. The tough inner core improves the mechanical properties of the implant with a high fracture toughness and a low modulus. The anatomical accuracy of the implants will minimize the intra-operative manipulation required to maintain a stable host bone-implant interface.

Owner:TRUSTEES OF BOSTON UNIV

Customizing an intervertebral implant

Owner:DEPUY SYNTHES PROD INC

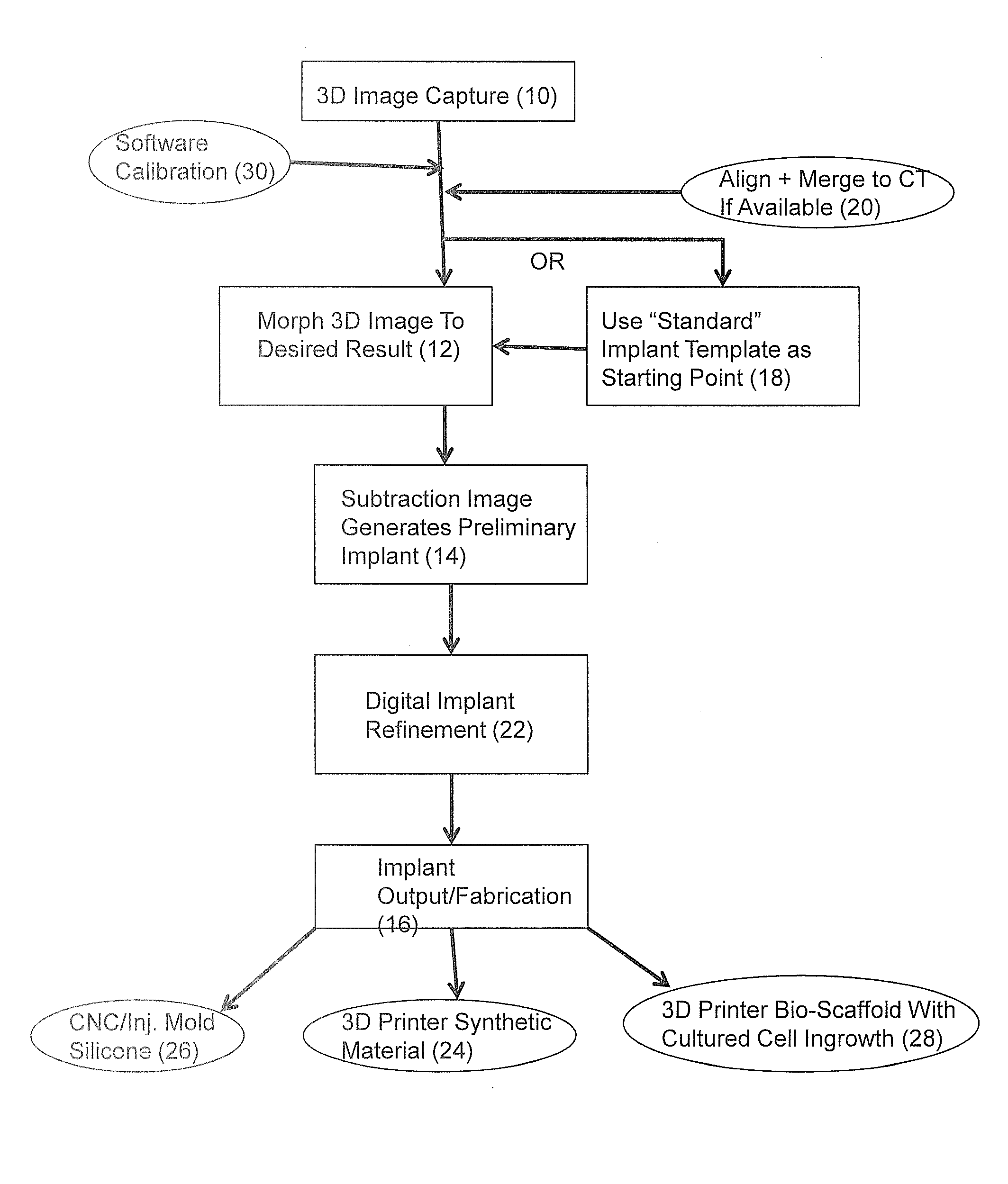

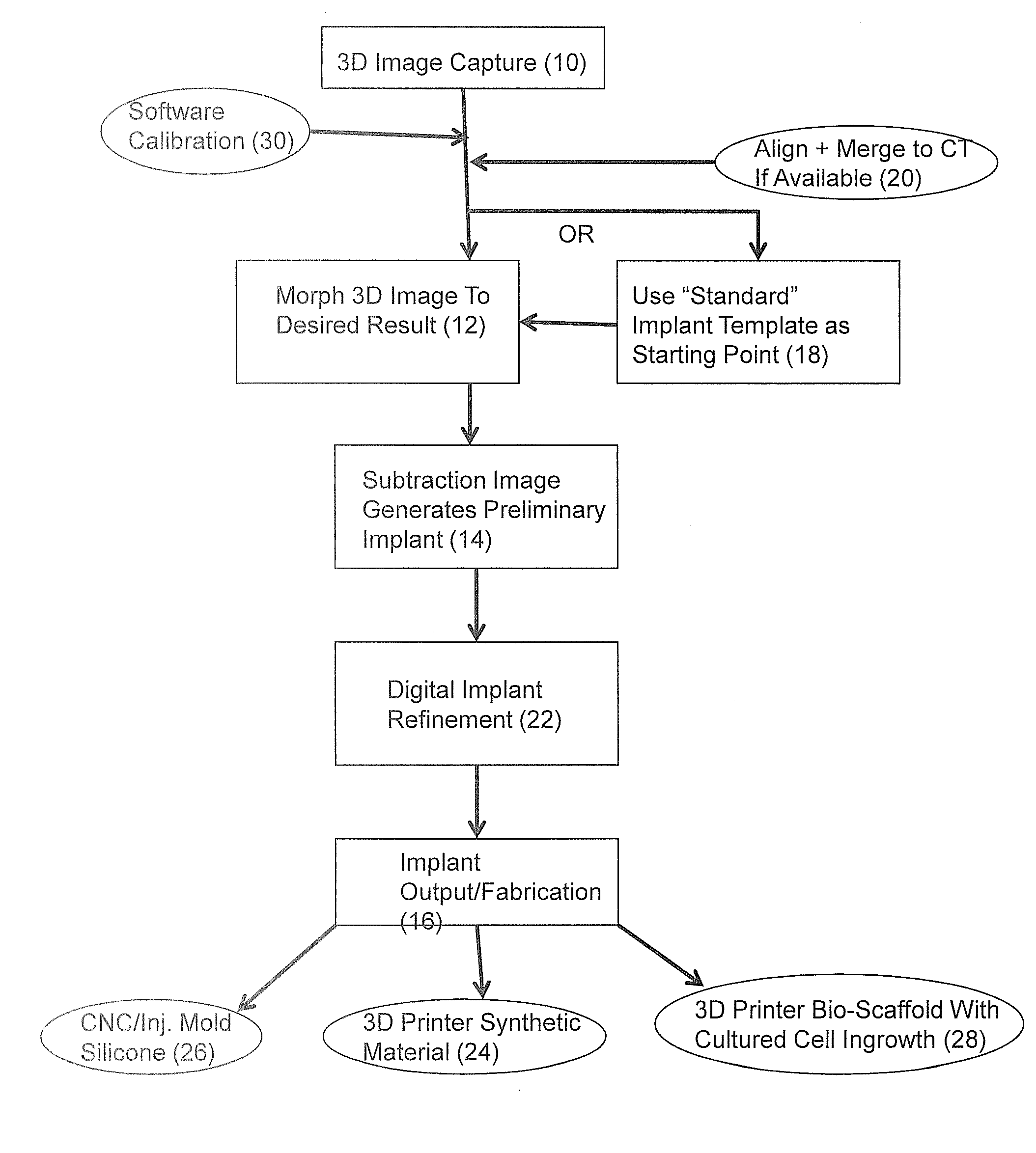

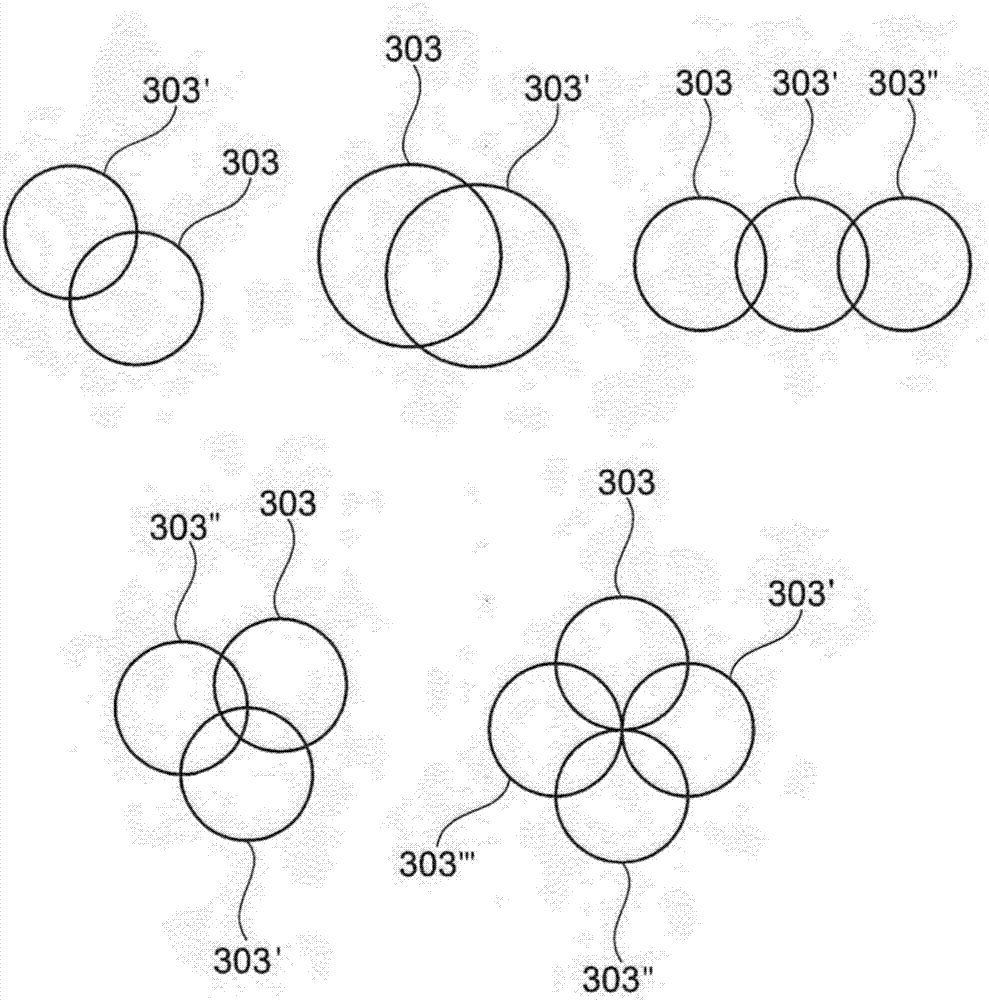

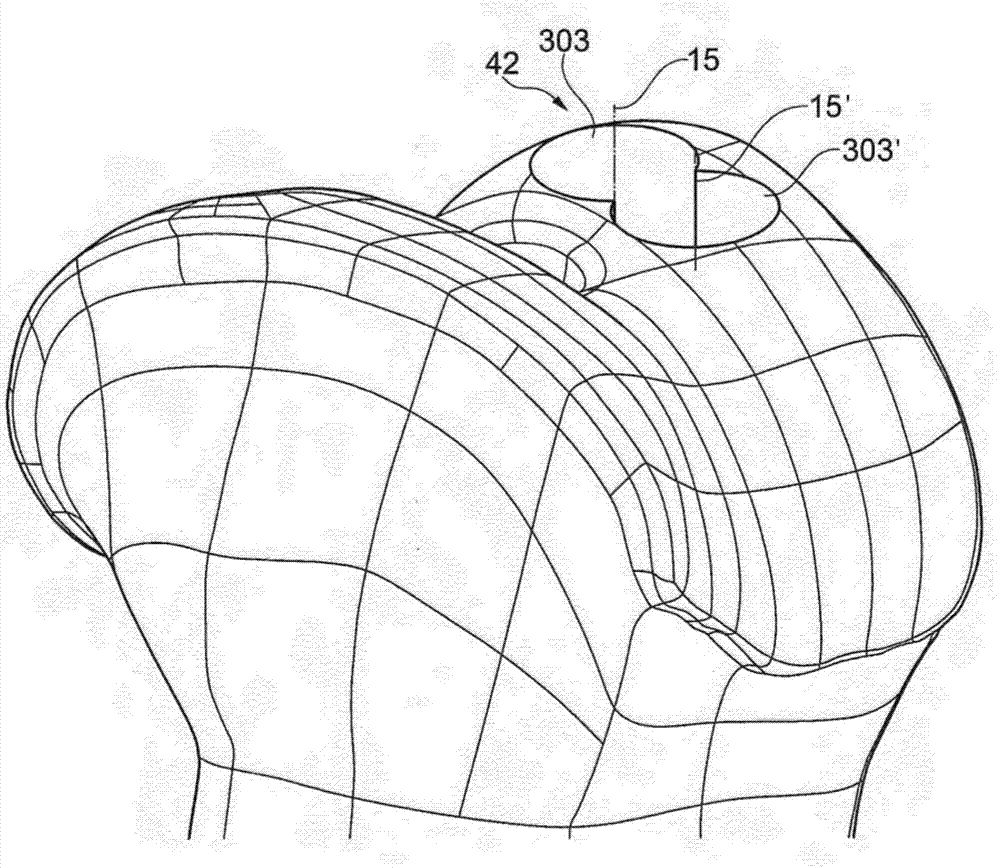

3D design and fabrication system for implants

ActiveUS20130238096A1Details involving processing stepsAdditive manufacturing apparatusCustom made implantIntervertebral disc

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, and fabricating a real 3D implant. A method of implanting a custom implant in a patient, by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, fabricating a real 3D implant, and implanting the implant in the patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. The present invention also provides for an implant fabricated by this method.

Owner:KOTLUS BRETT

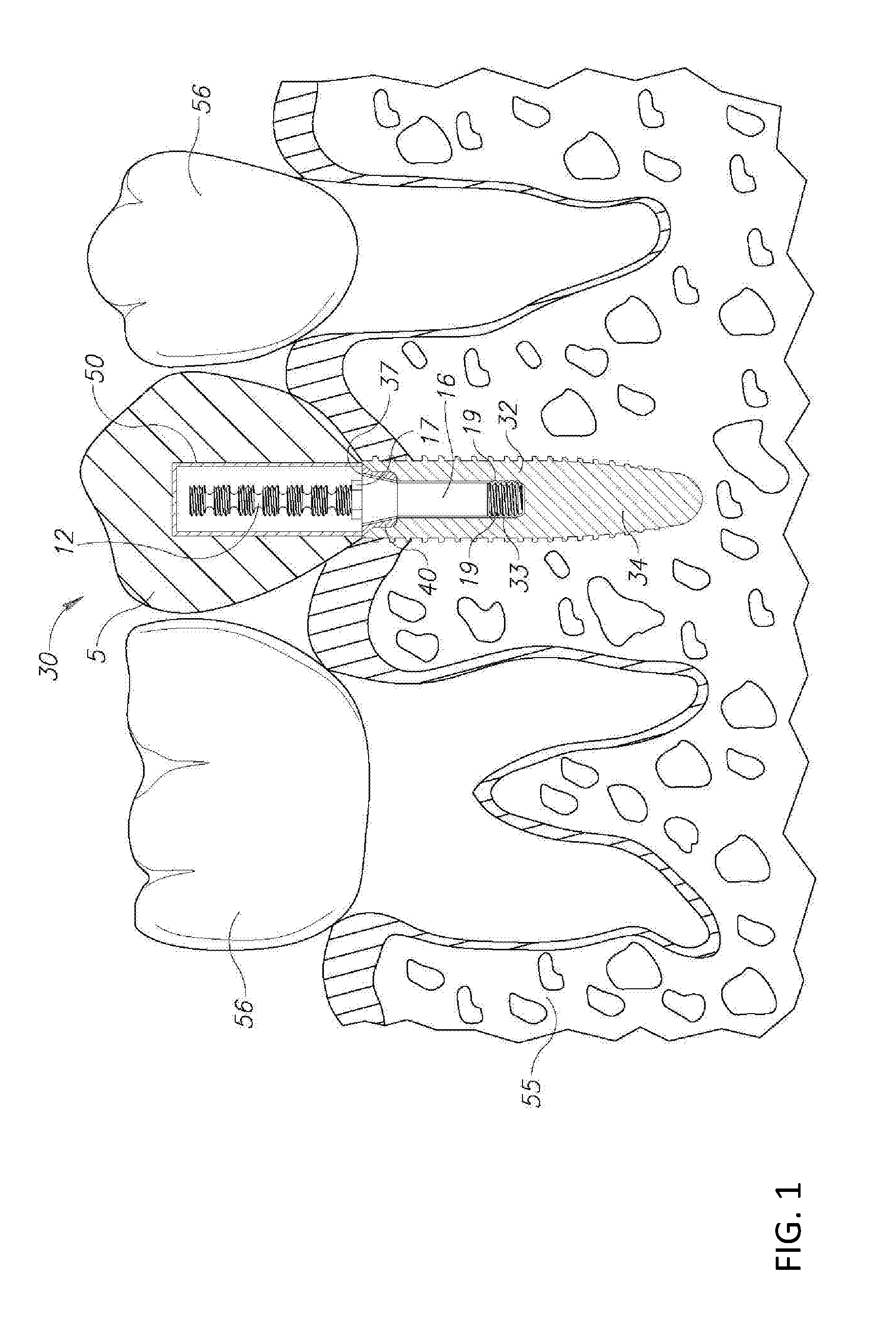

Tracked cartilage repair system

ActiveUS8652148B2Reduce removalAdditive manufacturing apparatusSurgical navigation systemsDamages tissueCustom made implant

A system and method for repairing an area of defective tissue reduces the removal of healthy tissue at the margins of the defect. During excision of diseased or damaged tissue, the system tracks the movement and function of a tissue resection tool within a monitored surgical space. This movement is continuously recorded to create a three-dimensional set of data points representative of the excised volume of tissue. This data set is then communicated to a custom implant forming device which creates a custom implant sized to fit the void created by the excision. The system and method of the present disclosure allows a surgeon to exercise intraoperative control over the specific shape, volume and geometry of the excised area. Moreover, the surgeon may utilize a “freehand” resection method to excise only that tissue deemed to be diseased and / or damaged, because the custom-formed implant will accommodate an irregularly-shaped resection volume.

Owner:ZIMMER INC

3D design and fabrication system for implants

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects the volumetric changes of the site, and fabricating a real 3D implant that includes the volumetric changes. A method of designing, presenting, generating, and implanting custom implants by obtaining a three-dimensional (3D) image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects volumetric changes of the site, and injecting or infusing a gel or semi-solid implant into a patient to effect the volumetric changes. A method of implanting a custom implant in a patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. An implant fabricated by this method.

Owner:KOTLUS BRETT

3D design and fabrication system for implants

ActiveUS9056017B2Details involving processing stepsAdditive manufacturing apparatusCustom made implant3d design

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, and fabricating a real 3D implant. A method of implanting a custom implant in a patient, by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant, fabricating a real 3D implant, and implanting the implant in the patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. The present invention also provides for an implant fabricated by this method.

Owner:KOTLUS BRETT

Customized Implants For Bone Replacement

ActiveUS20150351915A1Reduce the chance of solidificationLow process temperatureAdditive manufacturing apparatusBone implantCustom made implantNatural bone

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

Individualized customized implantation material shaping device for 3D printing and manufacturing method thereof

ActiveCN105726168ARelieve painEasy to acceptAdditive manufacturing apparatusBone implantCustom made implantTissue defect

The invention discloses an individualized customized implantation material shaping device for 3D printing and a manufacturing method thereof. The individualized customized implantation material shaping device is characterized in that the shaping devices are divided into three types: a guide plate or mold with the skeleton surface as a basis after a most ideal digital reset, para-position and alignment skeleton model is established, a guide plate or mold with establishment of a digital most-ideally installed most-ideal implantation material model of an implantation material as basic design and a shaping device mainly used for a tissue defect repairing implantation material and a prosthesis implantation material. The manufacturing method comprises the steps that firstly, the digital skeleton model is obtained through modeling based on a reverse engineering technology; secondly, reset or osteotomy shape-correcting operation is conducted on the skeleton model according to the operation purpose to make skeleton model reach a final ideal state required by an operation, and material obtaining is performed on the basis to establish various characteristics gradually. The individualized customized implantation material shaping device has the advantages of saving operation time, relieving the suffering of patients, more facilitating the operation, being low in access threshold and the like.

Owner:佛山市三水区人民医院

A method for manufacturing a customized implant

InactiveUS20160346091A1Fast and cost-effective methodImprove accuracyProgramme controlAdditive manufacturing apparatusCustom made implantManufacturing technology

The present invention relates to a method for manufacturing a customized implant comprising the steps of obtaining a plurality of medical images of a bone region with a defect area; converting the medical images into a three-dimensional data; designing a mould customized for the defect area based on the three-dimensional data to produce a customized mould; and fabricating a customized implant from a biocompatible plate using the customized mould via an additive manufacturing technique.

Owner:UNIVERSITI MALAYA

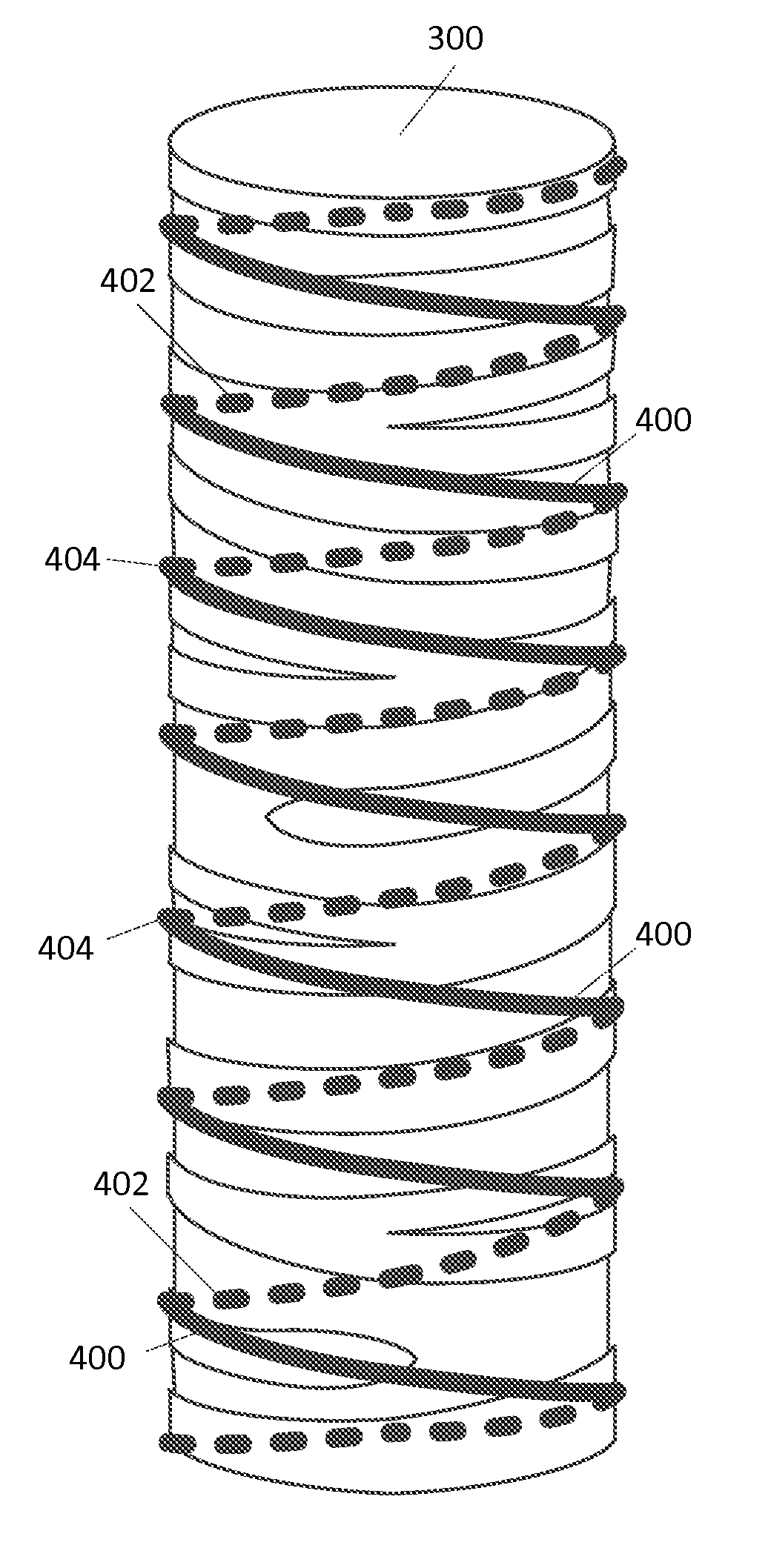

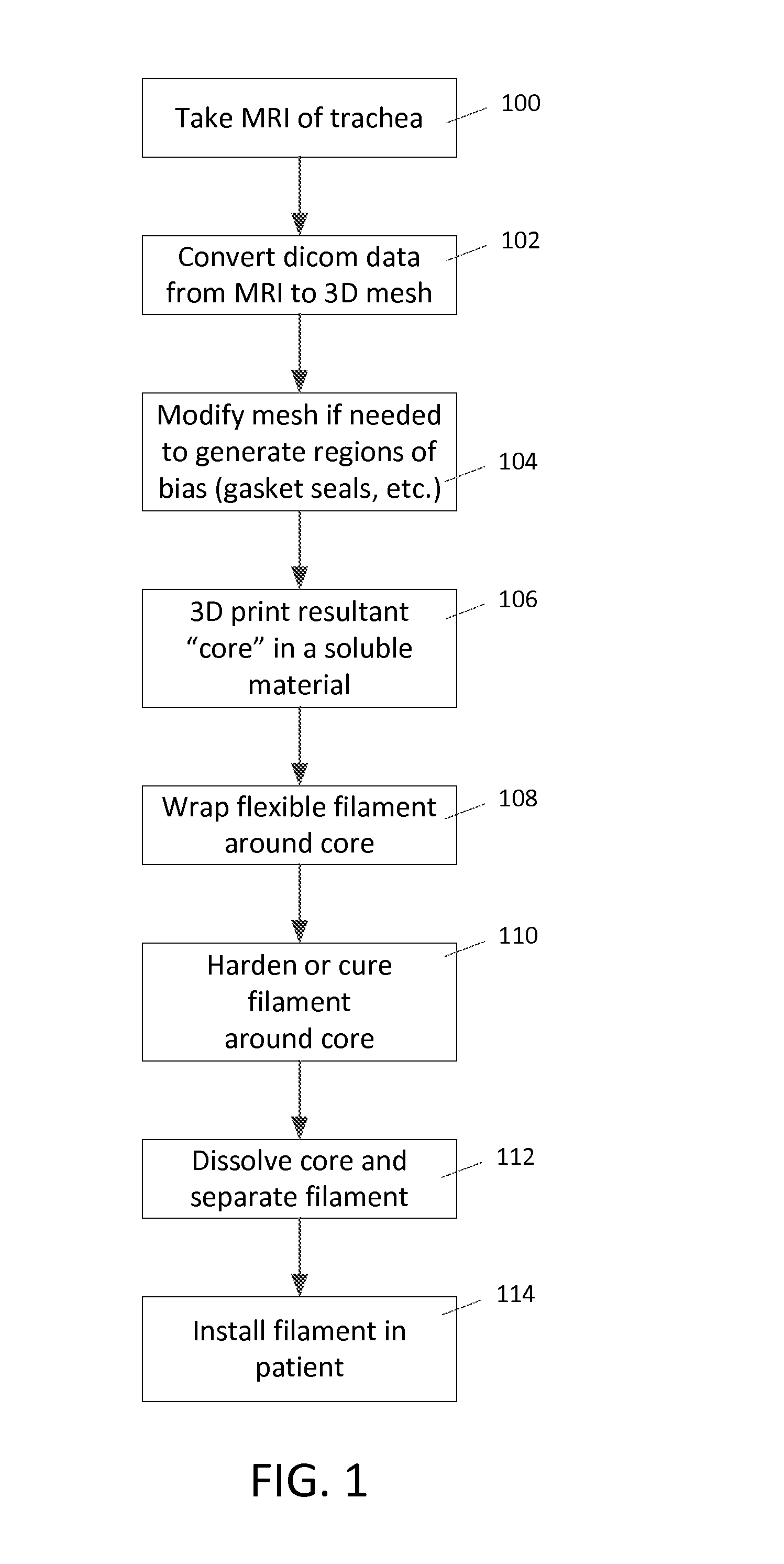

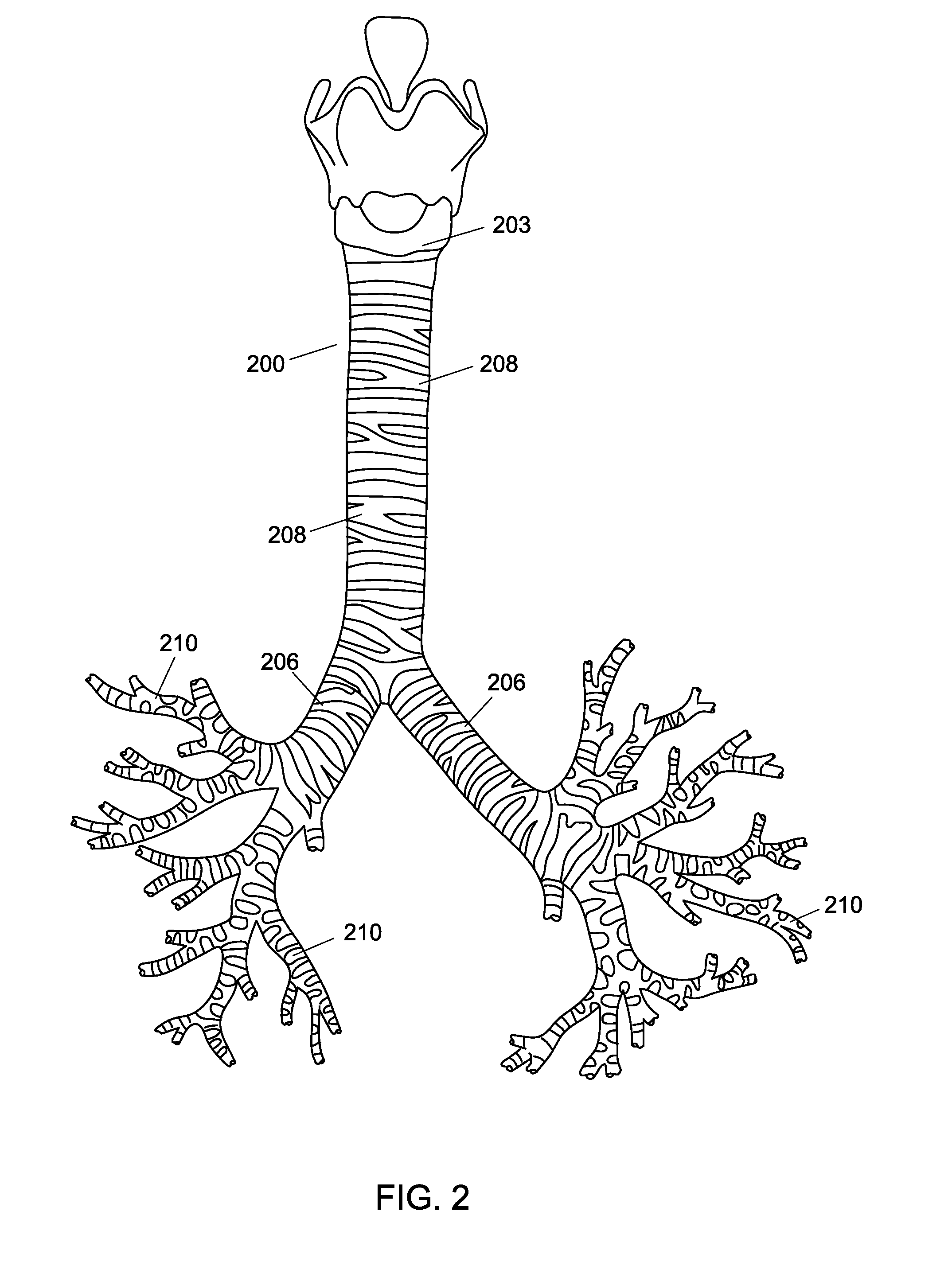

System and method for fabricating custom medical implant devices

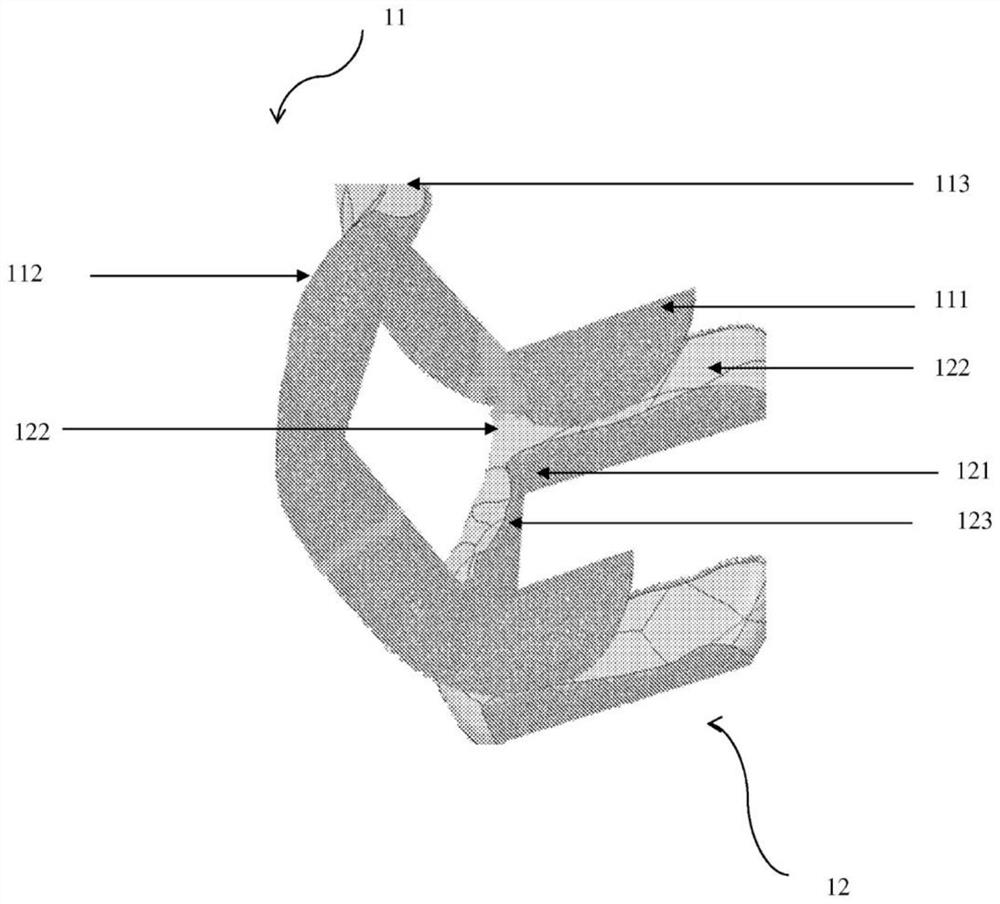

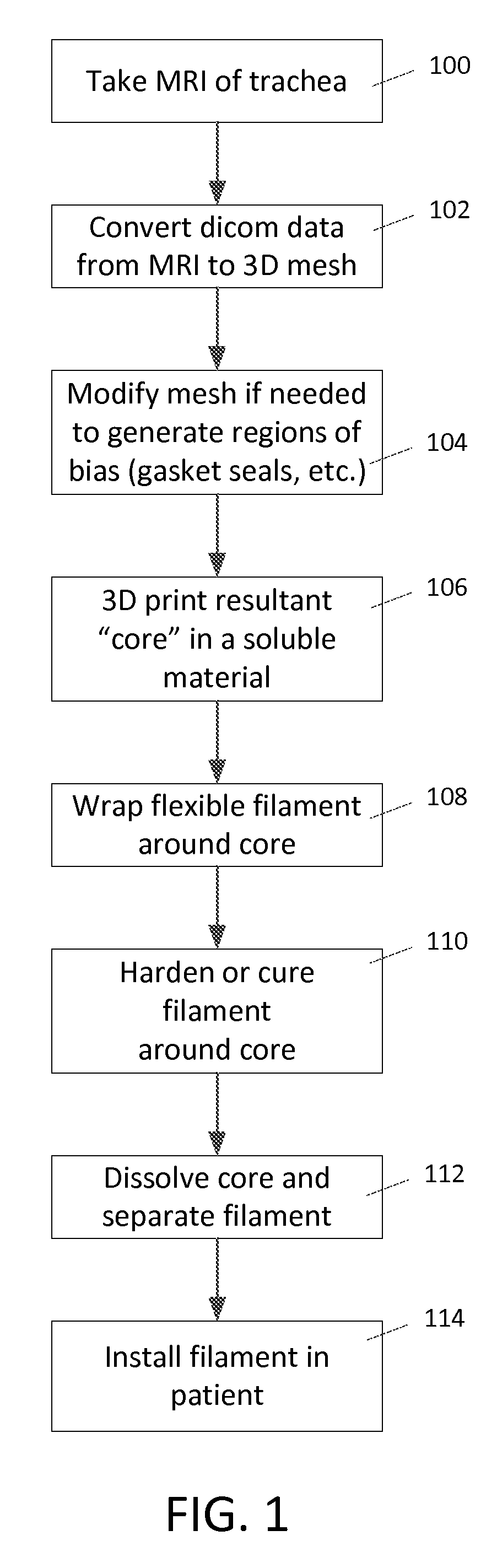

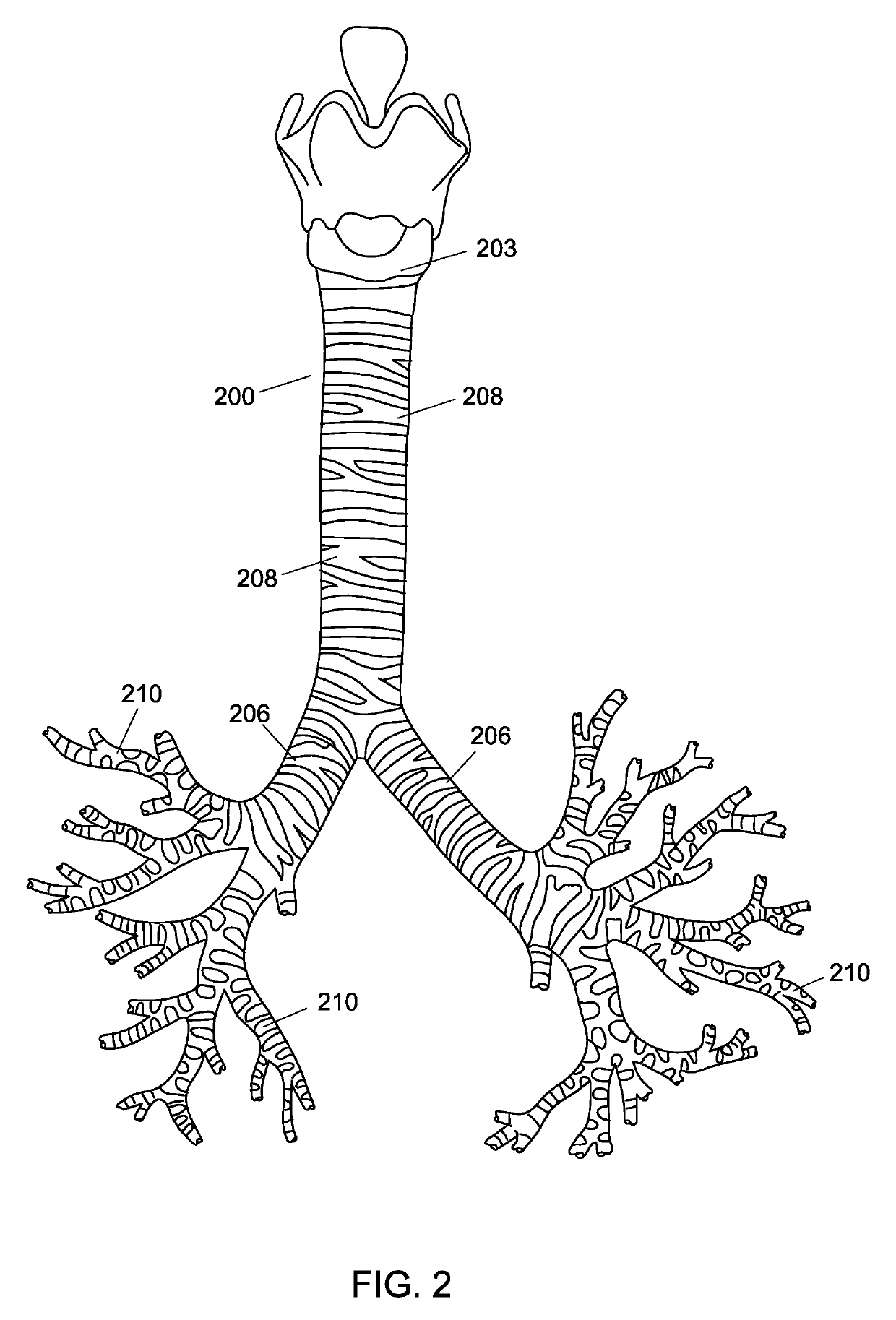

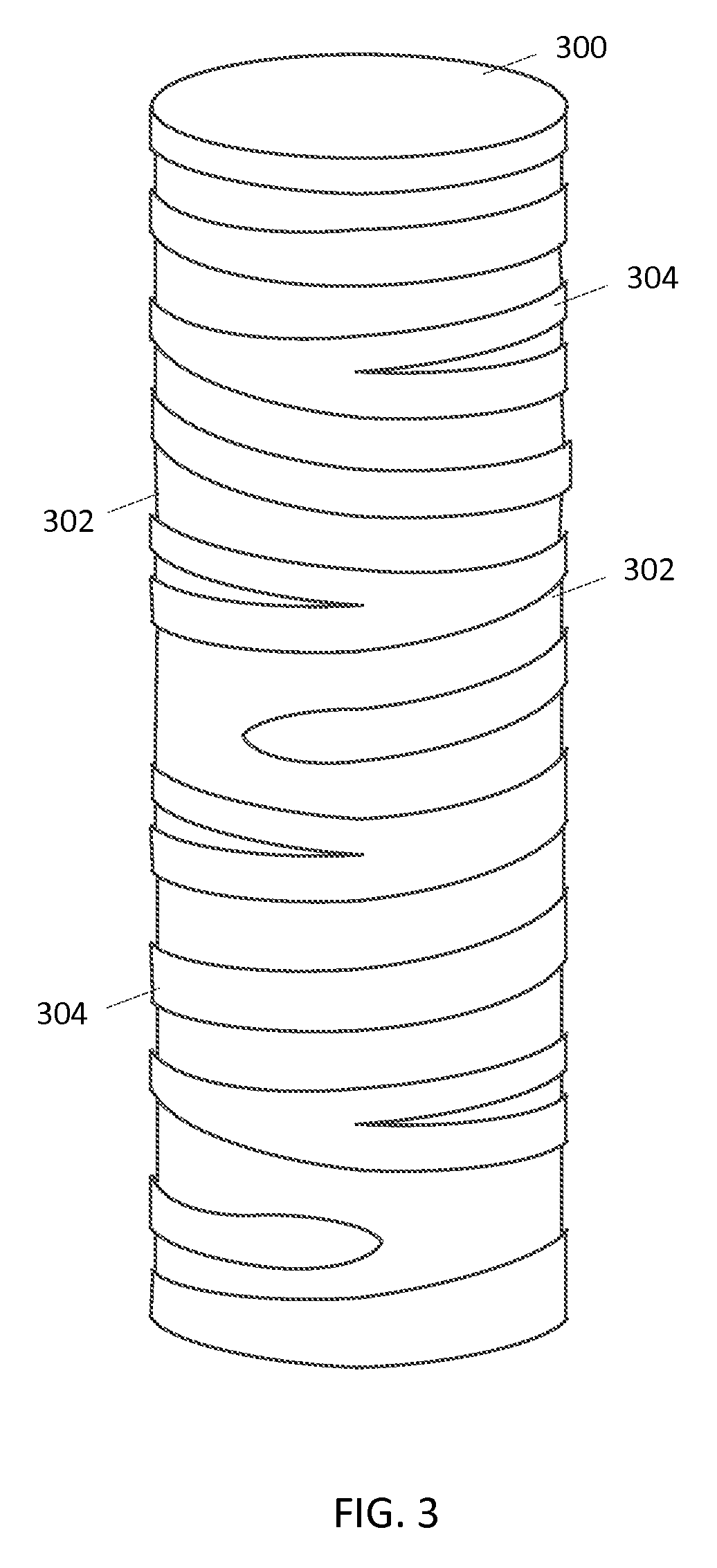

A method for creating tubular inserts is useful for creating custom fitted inserts that correspond to the anatomy of a patient and solve the problem of pressure points, wear of the implant, damage to surrounding tissue, and denting. Surface measurements of the affected portion of a patient's internal cavity are obtained. Those measurements are used to design a core. The core is 3D printed with a soluble material. The core is wrapped with a thin filament or film such that the contours from the core develop on the outer surface of the covering. The covering is hardened and the core is dissolved away, leaving a custom-made implant device that can be deposited in the patient's cavity.

Owner:3D SYST INC

3D design and fabrication system for implants

ActiveUS20150198943A1Details involving processing stepsCosmetic implantsCustom made implantBiomedical engineering

A method of designing, presenting, generating, and fabricating custom implants by obtaining a 3D image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects the volumetric changes of the site, and fabricating a real 3D implant that includes the volumetric changes. A method of designing, presenting, generating, and implanting custom implants by obtaining a three-dimensional (3D) image of a site to receive an implant, simulating volumetric changes of the site, generating a virtual 3D implant that effects volumetric changes of the site, and injecting or infusing a gel or semi-solid implant into a patient to effect the volumetric changes. A method of implanting a custom implant in a patient. A method of correcting disfigurement in a patient. A method of replacing a disc in a patient's back. An implant fabricated by this method.

Owner:KOTLUS BRETT

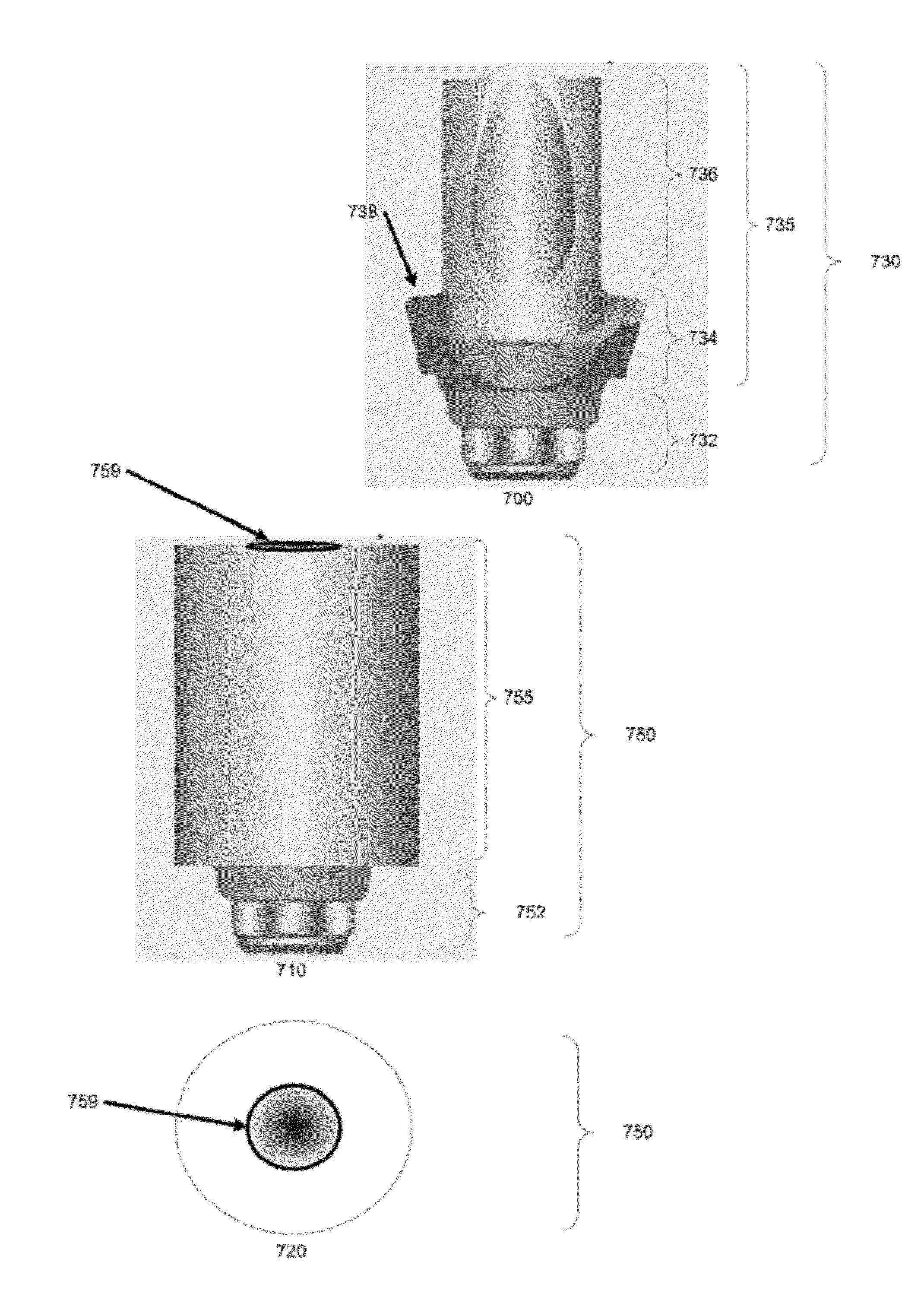

Techniques for providing custom-formed implants

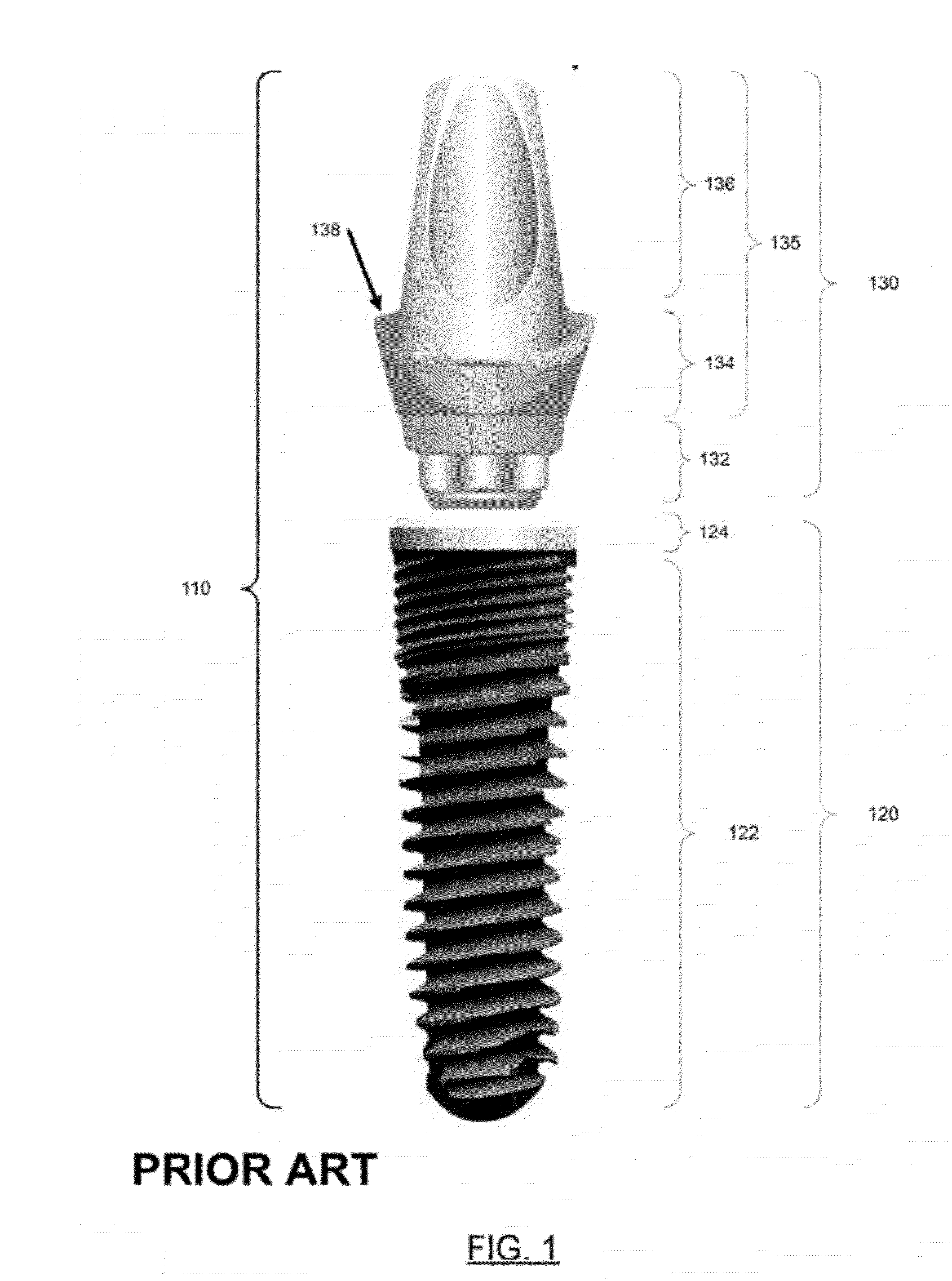

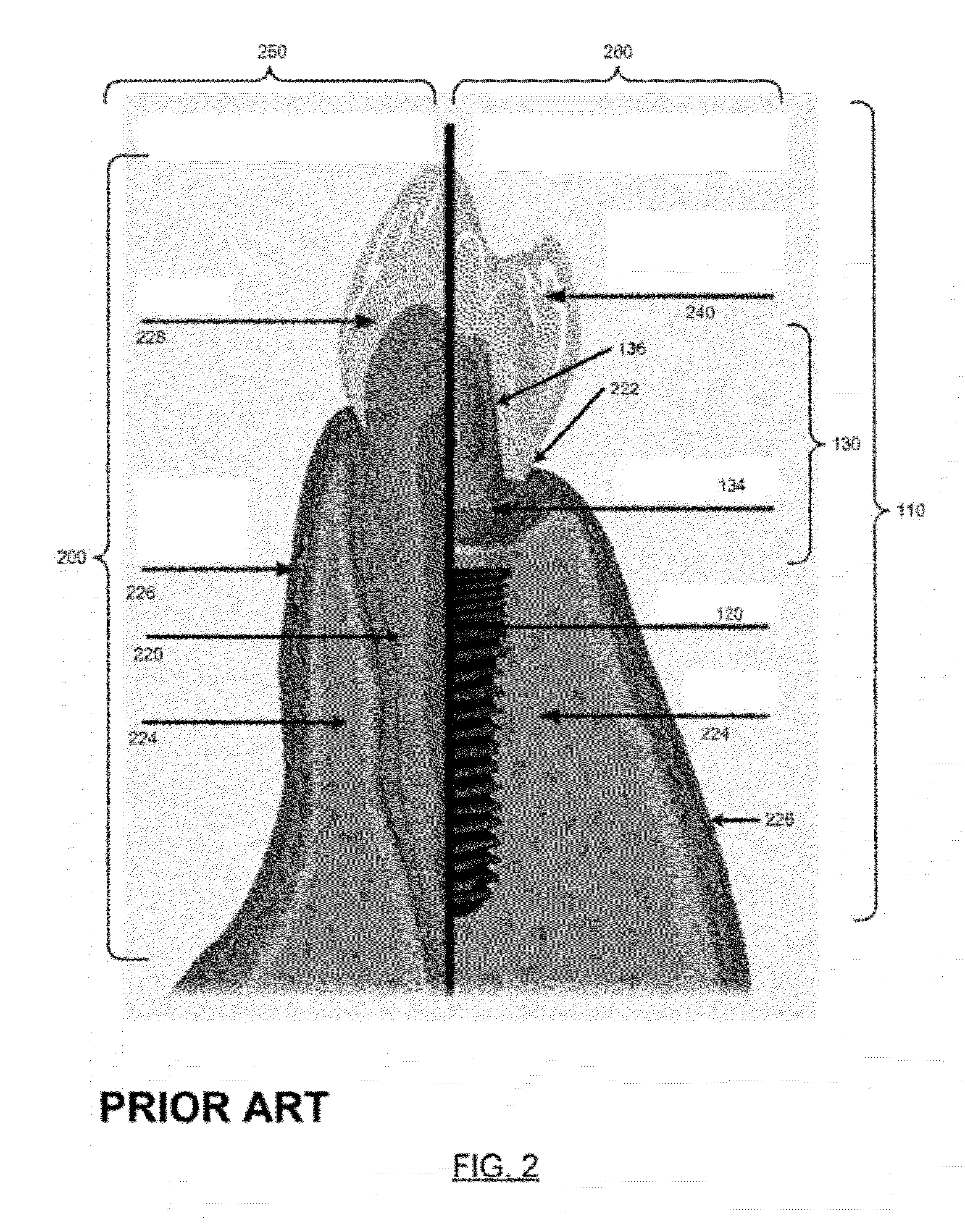

Techniques for providing medical implants that have been custom-formed for a particular patient for surface treatment to alter properties of a surface of an implant component. A dental abutment implant component, custom-formed by removing or adding material or by providing an electronic or other specification for its fabrication, is provided to a third party for a surfaced treatment to be, performed. After the abutment with surface treatment is received from the third party, it may be moved to the patient's body. One preferred kind of surface treatment employs anodization of a dental metal material such as titanium to give a pink color for improved cosmetic results. Other kinds of surface treatment including bonding may also be used. A blank implant component that has a first portion compatible with a standardized implant component, and a second portion expressly intended to be custom-formed by removing material.

Owner:JOSEPH MANISCALCO DDS PC

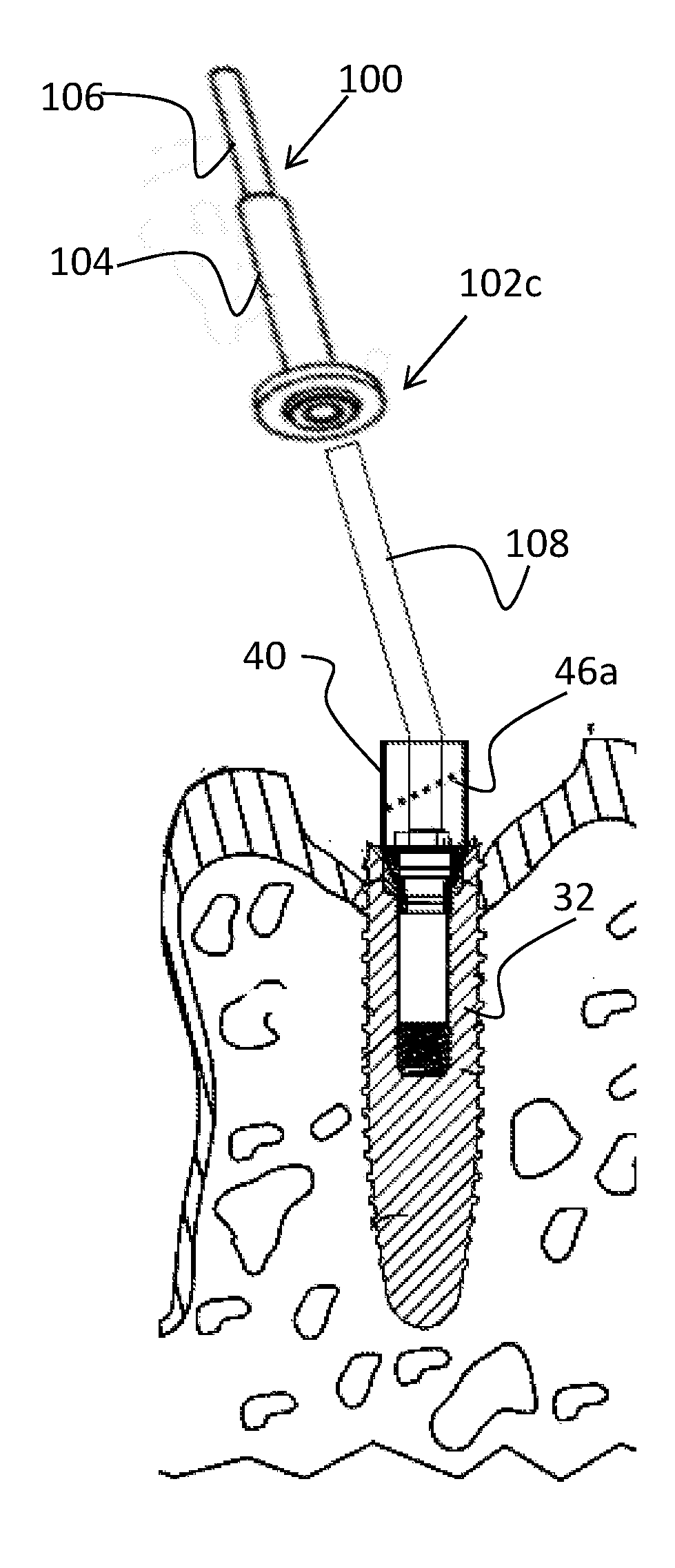

Dental Tool for Customizing Implants, System and Methods Thereof

InactiveUS20150351878A1Exact widthFit tightlyDental implantsDental toolsCustom made implantDentistry

A device, system and method providing a dental tool (100) and a guiding member (108) for customizing at least a portion of a member of a dental implant system by way of milling and / or filing.

Owner:ABRACADABRA IMPLANT LTD

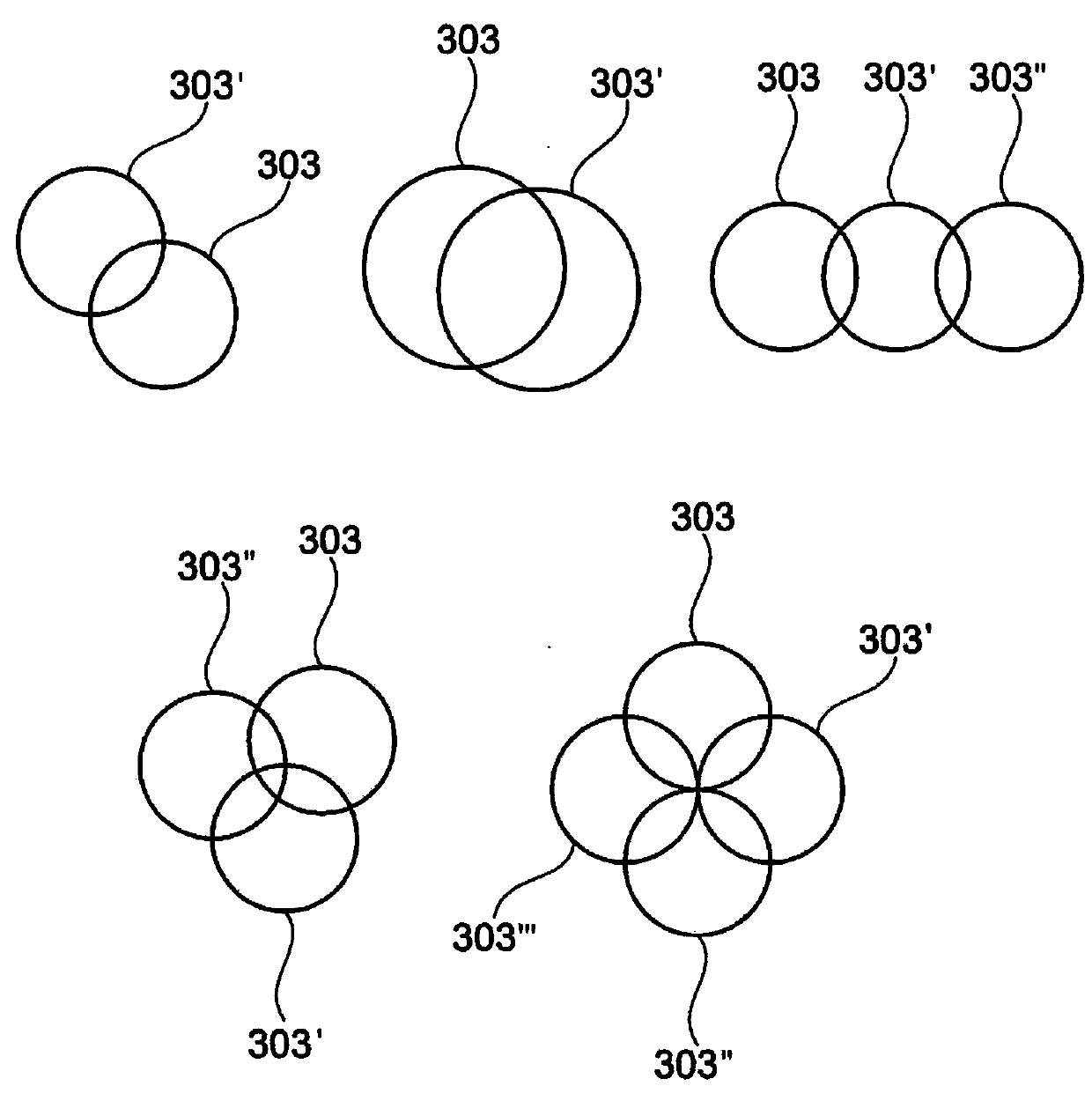

Surgical membrane

ActiveCN107072787AEasy to set upCooperate accuratelySurgeryJoint implantsCustom made implantSurgical procedure kit

A reinforced surgical membrane for supporting bone growth by shielding a bone cavity from soft tissue ingrowth comprises are a reinforcing layer (2) between a first membrane layer and a second membrane layer (4). The reinforcing layer (2) has defined therein an array of holes (3) which may connect the first and second membrane layers.

Owner:EPISURF IP MANAGEMENT

Implant made of fibre-reinforced plastic

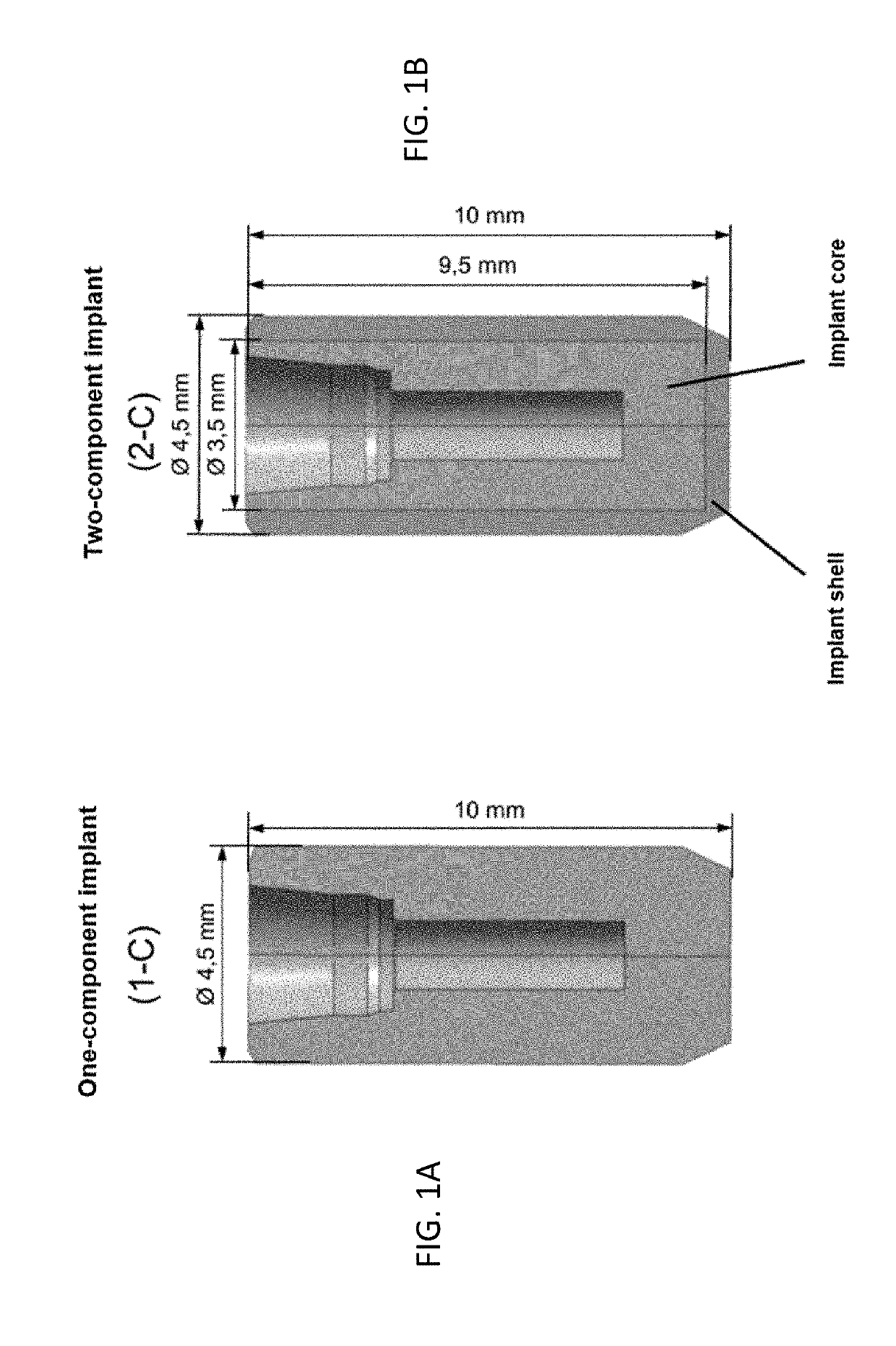

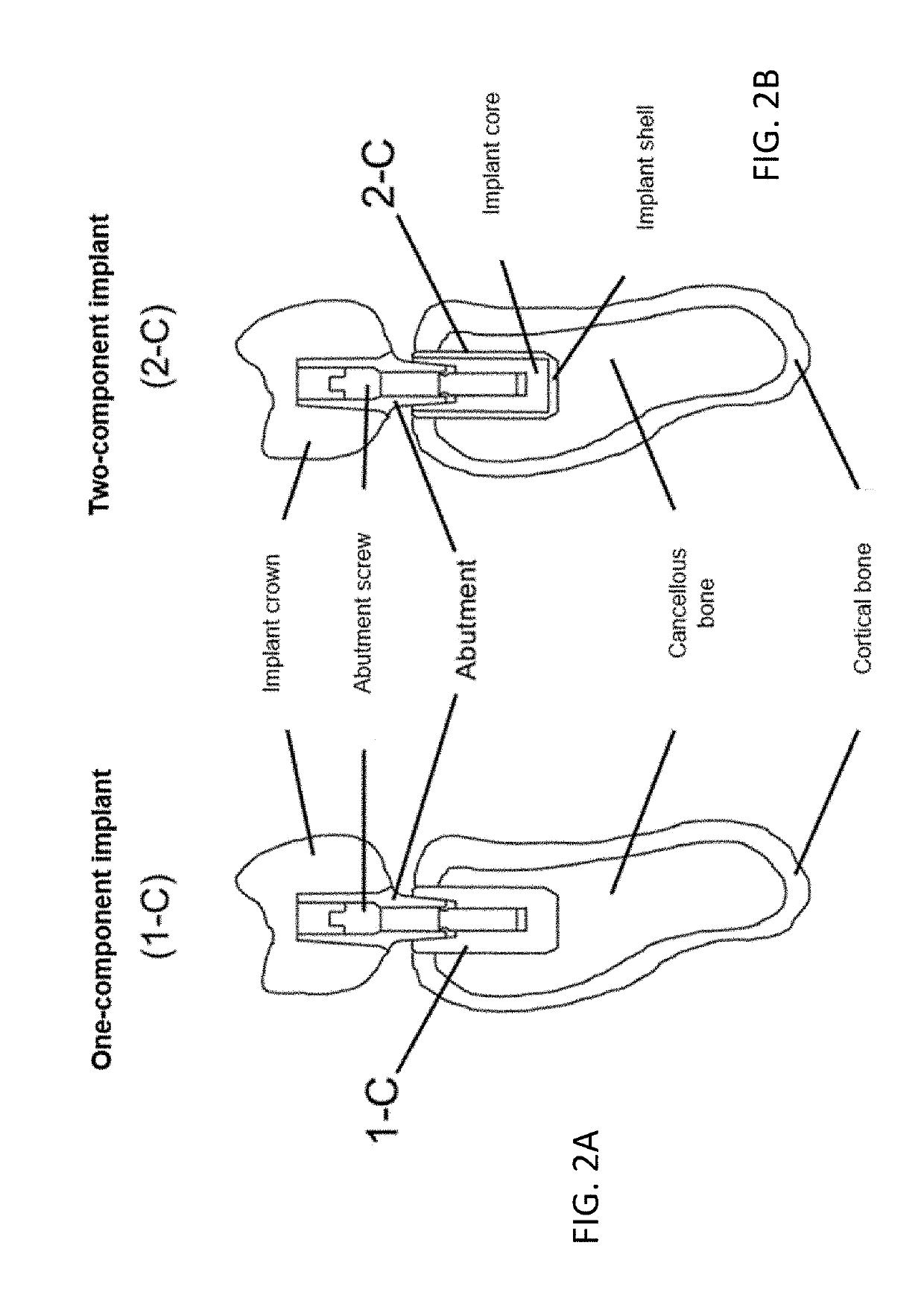

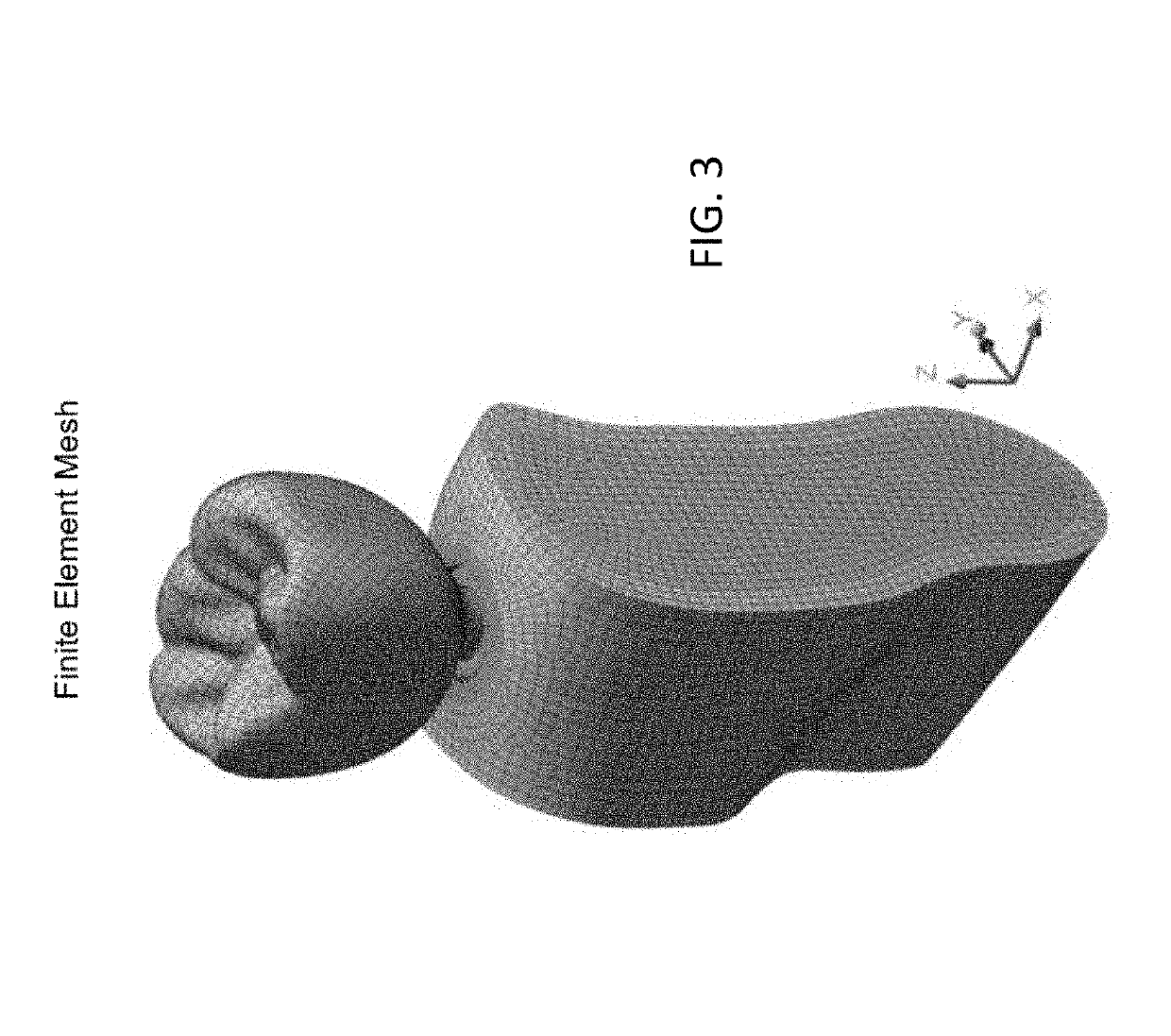

ActiveUS20190307534A1Efficient productionImprove automationDental implantsTissue regenerationThermoplasticCustom made implant

A customizable implant made of plastic including a thermoplastic which is reinforced with long fibers arranged multidirectionally in a targeted manner and has a modulus of elasticity E of 10-70 GPa is provided. A system for producing a customizable implant including a device for collecting patient data regarding the environment into which an implant is to be inserted, a computer program for creating a model for a customized implant based on the patient data collected, and a device for producing the customized implant based on the calculated model by means of 3D printing and / or laser sintering is also provided.

Owner:SCHWITALLA ANDREAS +1

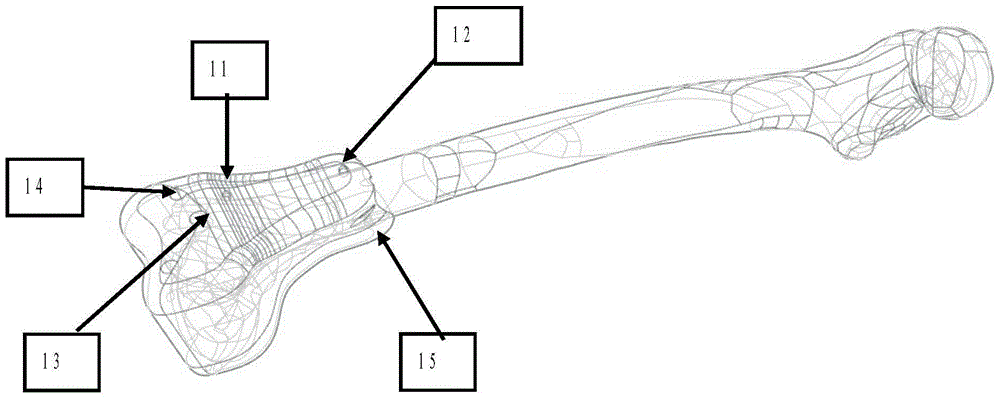

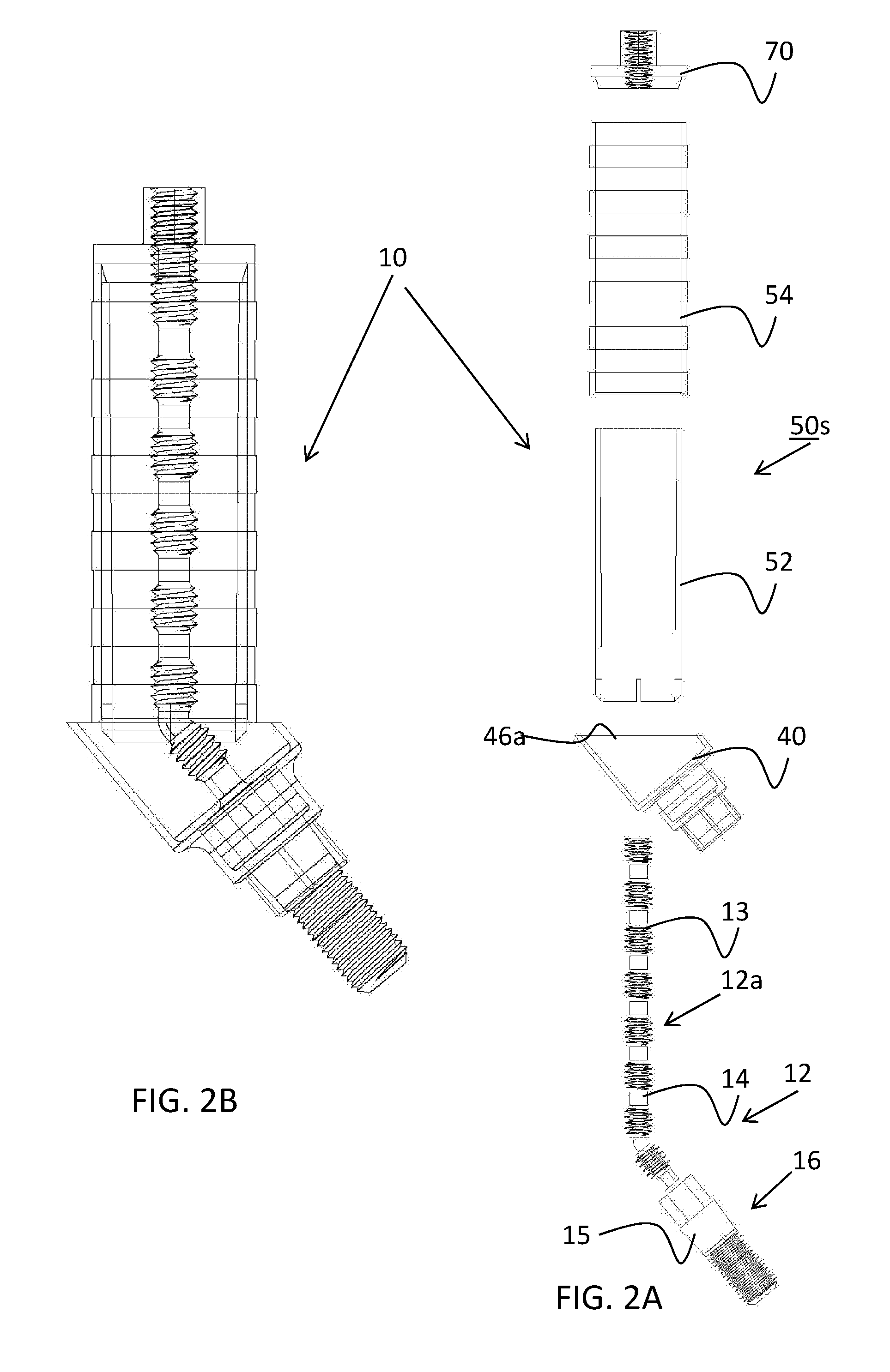

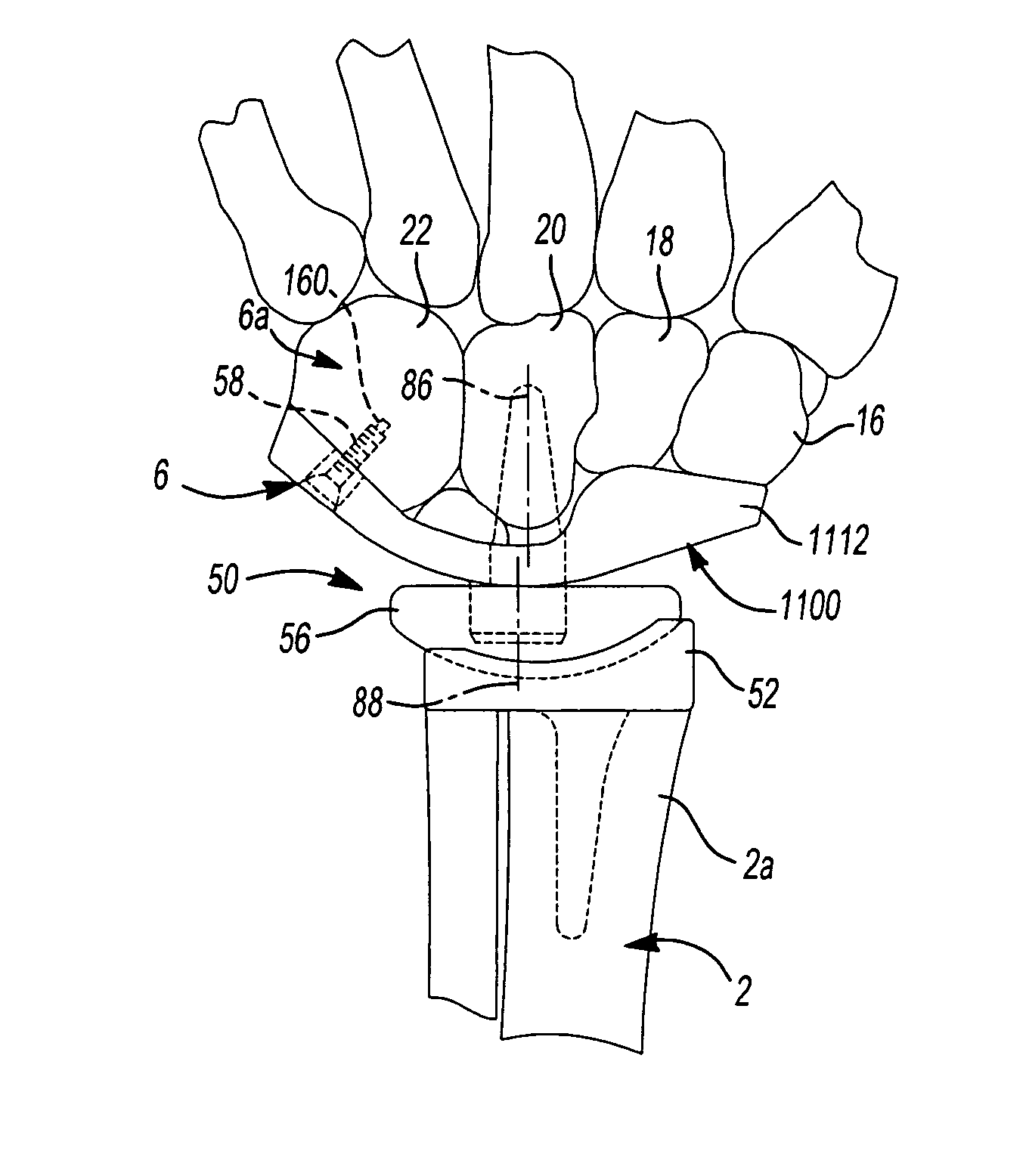

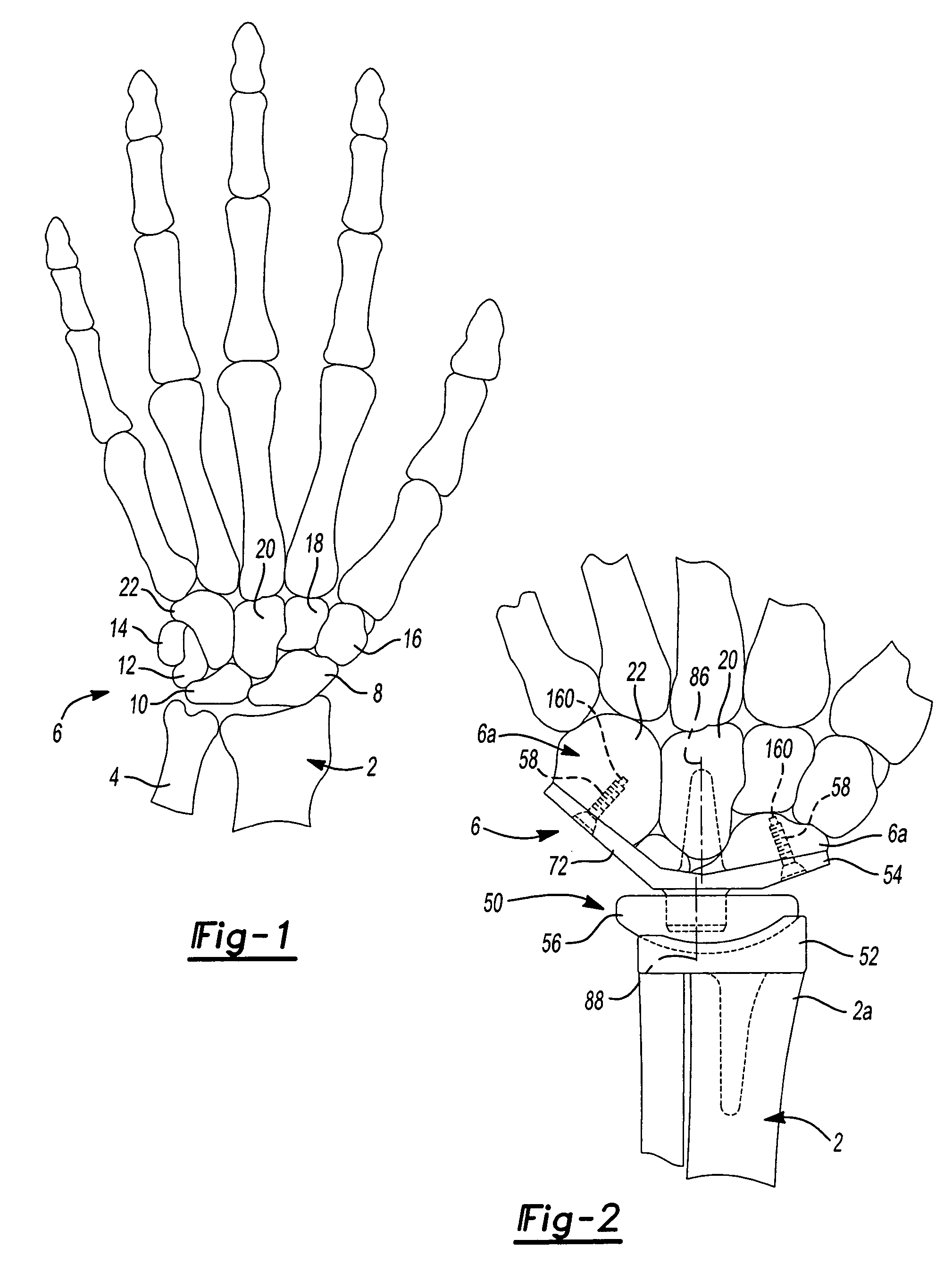

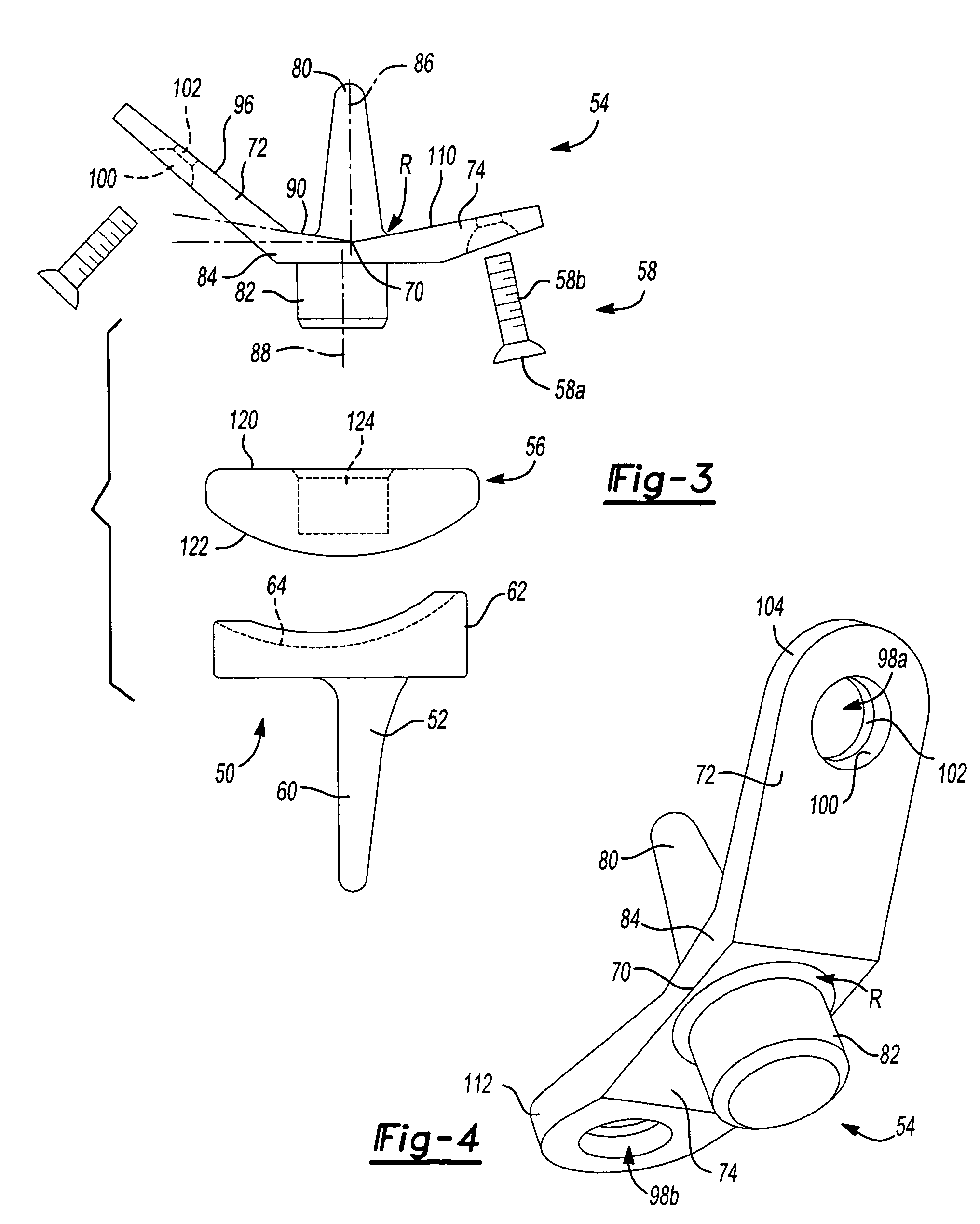

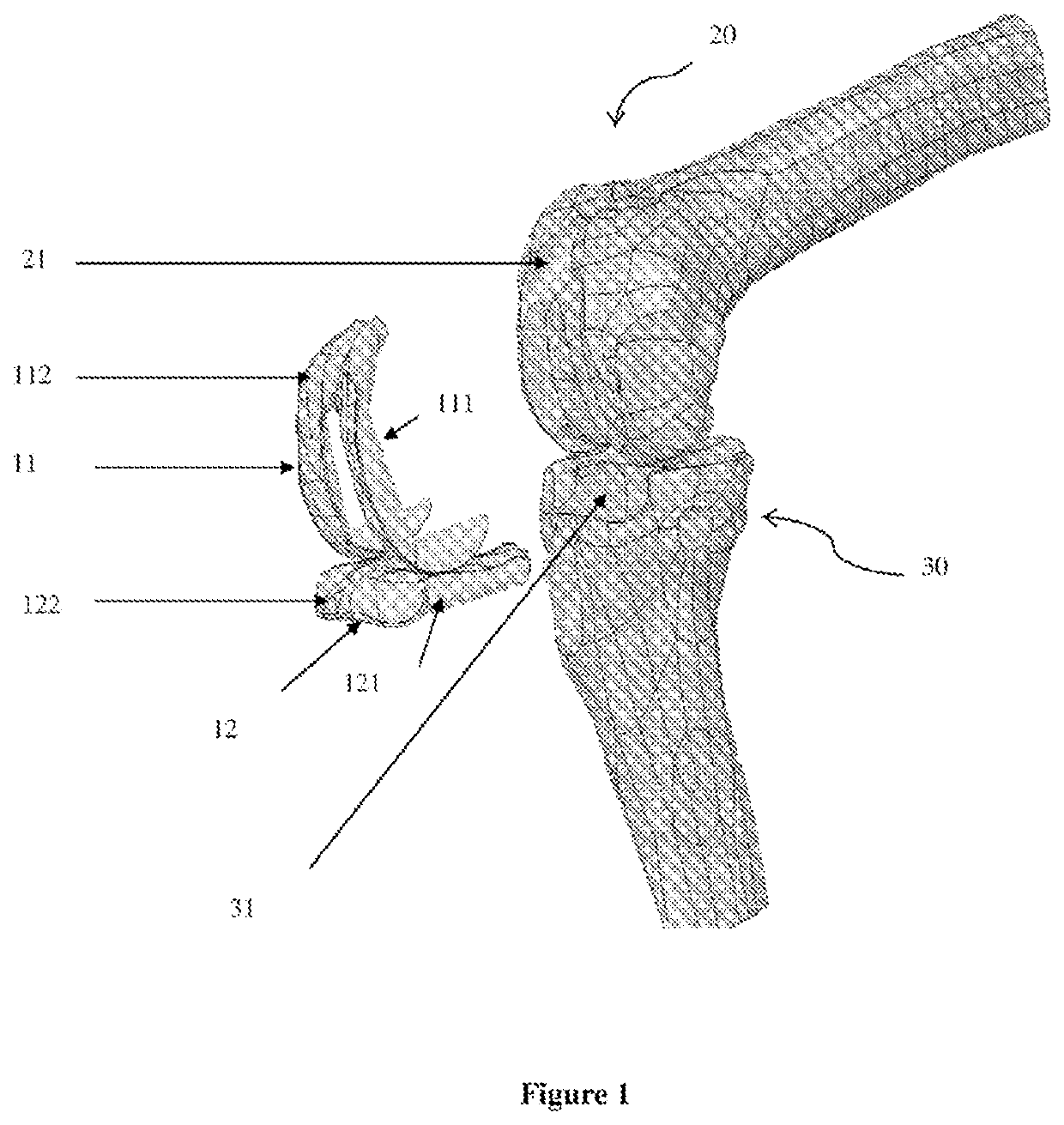

Method and apparatus for wrist arthroplasty

A prosthetic wrist having at least one of a radial insert, which is configured to be fixed to a radius of a patient, a carpal implant or a wrist bearing component. The carpal implant can include a body and a pair of flanges, each of which being skewed to the axis of the body in a manner that permits them to abut the ulnar side of the hamate bone and the radial side of the distal portion of the carpal bone complex, respectively. The radial insert may be provided with a plurality of modular portions to allow for selection and customization of an implant. Also the various portions can allow for a hemi- or total, or revision wrist arthroplasty. The modular portions can allow for intraopertative customization.

Owner:BIOMET MFG CORP

Method for producing a tailor-made implant

The present invention relates to a method for producing a tailor-made implant intended to be implanted at an implantation site of a damaged bone part, the method comprising a step in which a 3D representation of a standard implant is superposed on a 3D representation of a damaged bone part by positioning said standard implant on an implantation site of the damaged bone part, in order, if necessary, to modify the dimensions and / or to adjust the shape of said standard implant, and also, if necessary, to modify the outer surface of said standard implant, which may be either the impression or substantially the impression of the outer surface of said bone part in the state prior to superpositioning of said implant, when the geometry of the damaged bone part is intended to be retained, or a functional outer surface, when said tailor-made implant is intended to be used at the interface of two bone parts cooperating with each other.

Owner:3D MEDICAL

System and method for fabricating custom medical implant devices

A method for creating tubular inserts is useful for creating custom fitted inserts that correspond to the anatomy of a patient and solve the problem of pressure points, wear of the implant, damage to surrounding tissue, and denting. Surface measurements of the affected portion of a patient's internal cavity are obtained. Those measurements are used to design a core. The core is 3D printed with a soluble material. The core is wrapped with a thin filament or film such that the contours from the core develop on the outer surface of the covering. The covering is hardened and the core is dissolved away, leaving a custom-made implant device that can be deposited in the patient's cavity.

Owner:3D SYST INC

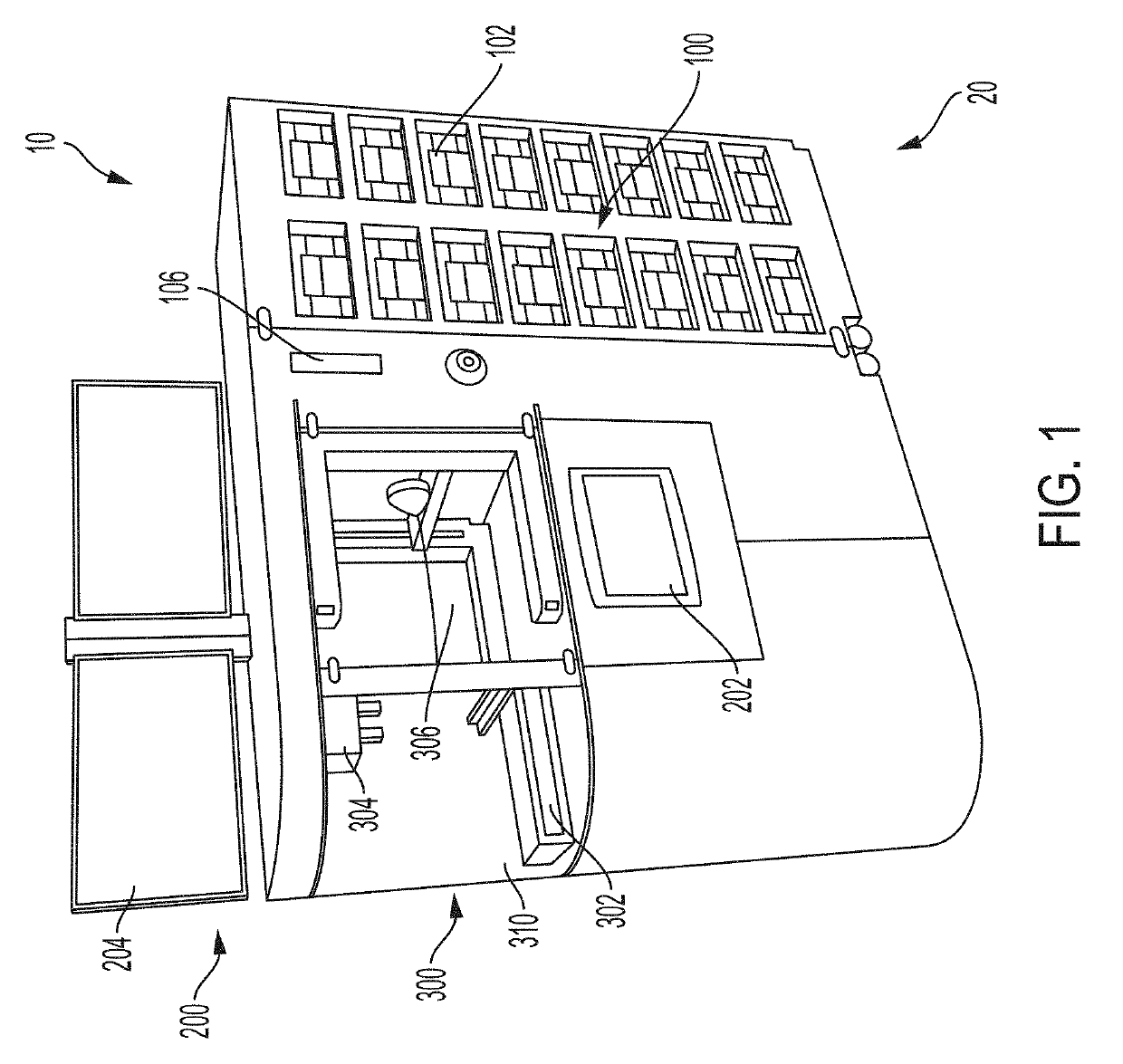

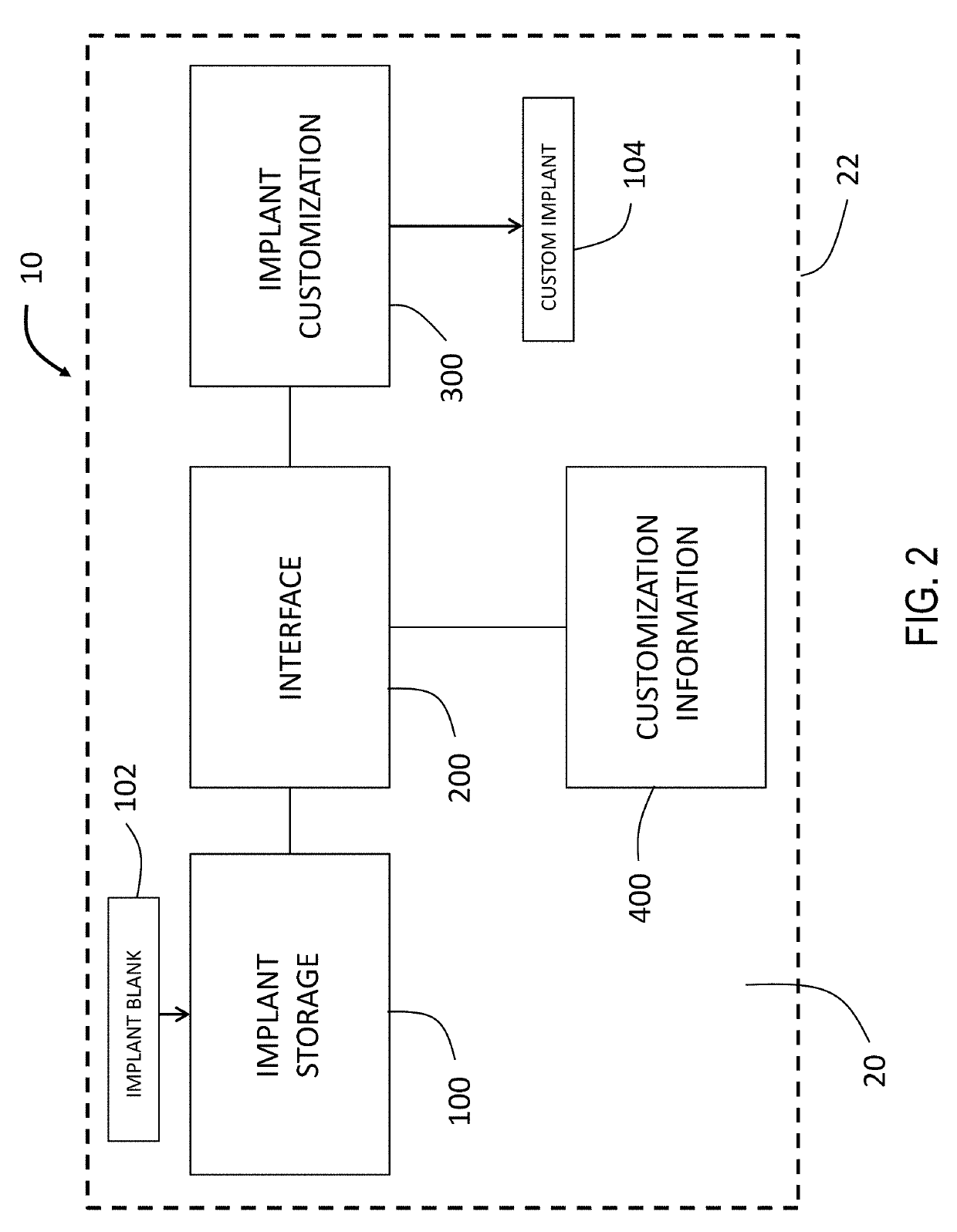

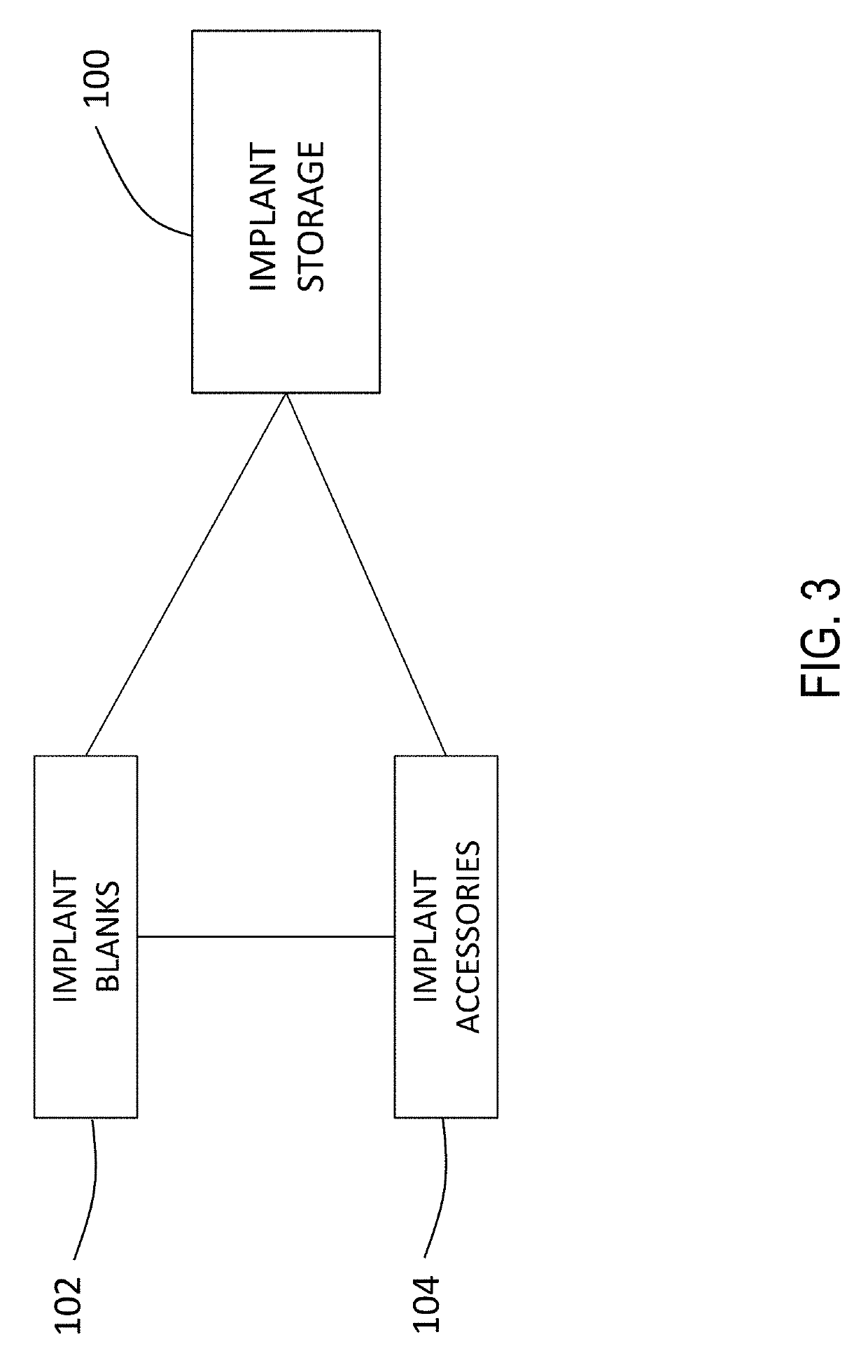

On-Demand Implant Customization In A Surgical Setting

ActiveUS20190314088A1Surgical systems user interfaceJoint implantsSterile environmentCustom made implant

Disclosed herein are apparatuses and methods for intraoperative on-demand implant customization in a surgical setting. An apparatus may include a storage portion, an implant customization portion and an interface. The storage portion may house implant blanks and implant accessories. The implant customization portion may customize the implant blanks. The interface may be configured to receive implant customization information and utilize the same to intraoperatively manipulate the implant blank to a patient-specific implant within a sterile environment. A method to customize an implant in a surgical care environment may include the steps of obtaining information related to the implant location, selecting an implant blank based on the information, and customizing the implant blank in a surgical care setting with a customization apparatus.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

Method for producing a tailor-made implant

ActiveUS20200297495A1Shorten the timeLow costImage enhancementImage analysisCustom made implantMetatarsal bone part

The present invention relates to a method for producing a tailor-made implant intended to be implanted at an implantation site of a damaged bone part, the method comprising a step in which a 3D representation of a standard implant is superposed on a 3D representation of a damaged bone part by positioning said standard implant on an implantation site of the damaged bone part, in order, if necessary, to modify the dimensions and / or to adjust the shape of said standard implant, and also, if necessary, to modify the outer surface of said standard implant, which may be either the impression or substantially the impression of the outer surface of said bone part in the state prior to superpositioning of said implant, when the geometry of the damaged bone part is intended to be retained, or a functional outer surface, when said tailor-made implant is intended to be used at the interface of two bone parts cooperating with each other.

Owner:3D MEDICAL

Surgical kit and set of tools for cartilage repair including implants

Owner:EPISURF IP MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com