Method for producing a tailor-made implant

A manufacturing method and implant technology, applied in the direction of joint implants, joint implants, general control systems, etc., can solve the problems of insufficient transmission force, unsatisfactory, and not allowing practitioners joint freedom, etc. To achieve the effect of ensuring healthy distribution, saving bone mass and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0171] First, it should be noted that the drawings are not drawn to scale.

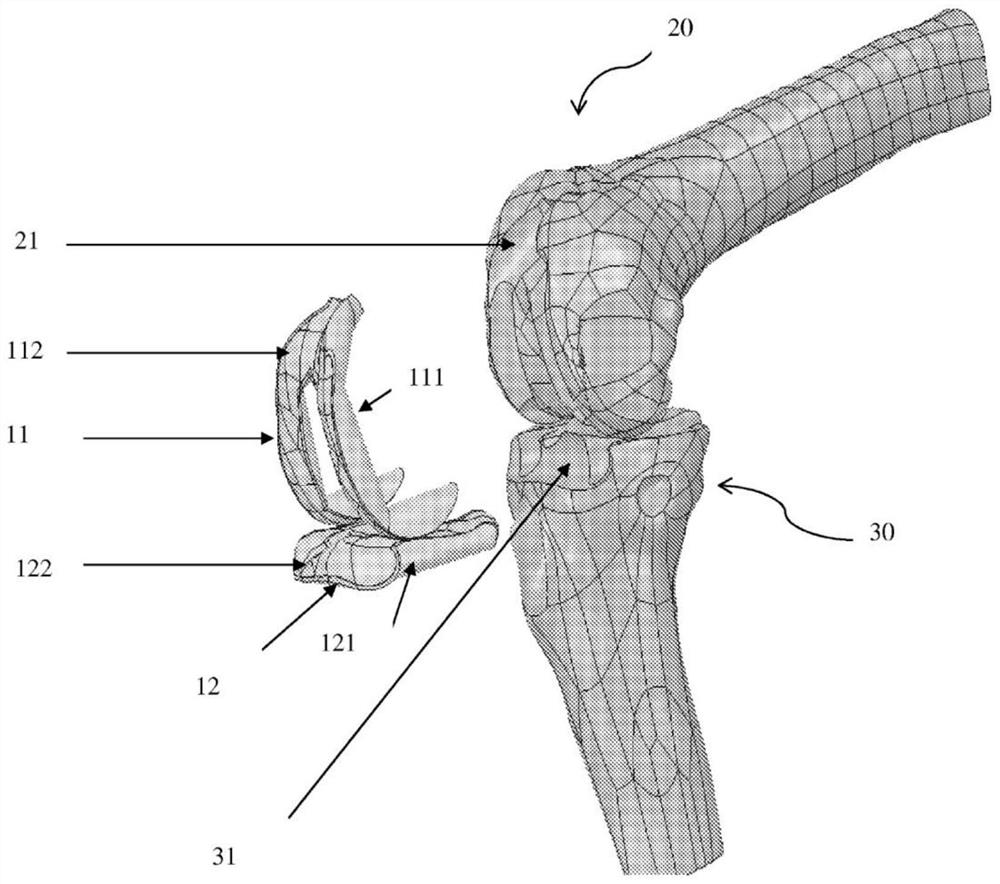

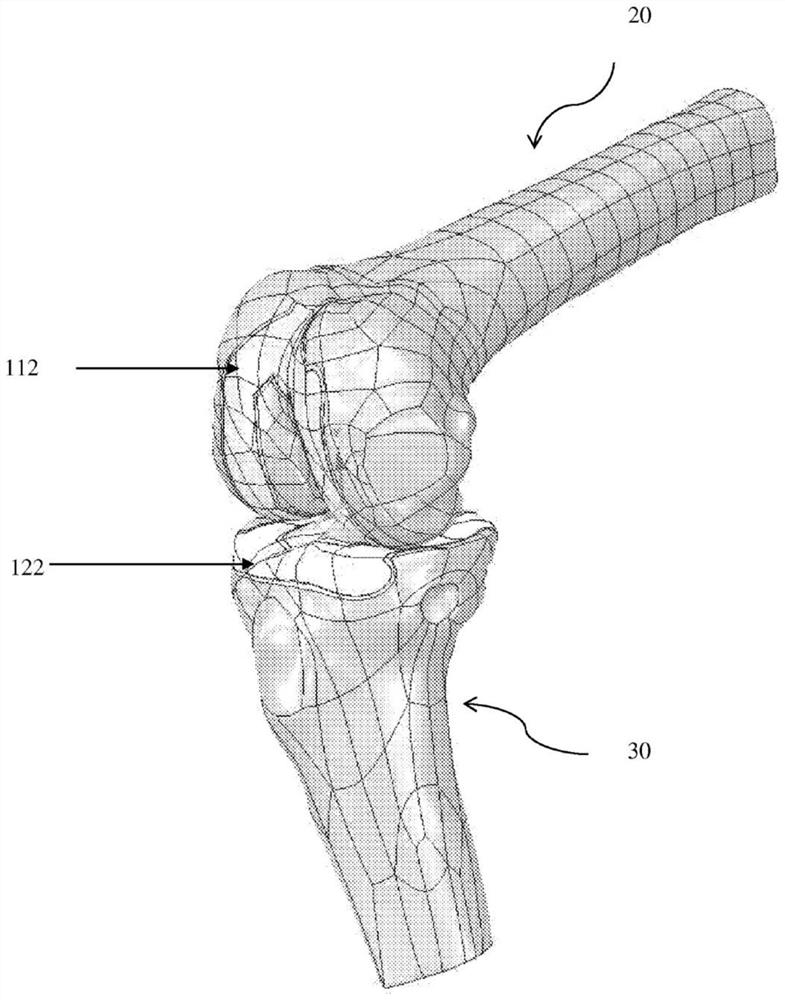

[0172] An image of the skeletal part (here the skeletal part fitting in the tibiofemoral joint) has been acquired by magnetic resonance imaging, and the image has then been segmented and 3D modeled on a computer, which is transferred in STL format. Thus, a 3D image of the tibiofemoral joint (i.e. of the proximal end 30 of the tibia and the distal end 20 of the femur) has been acquired, and e.g. figure 1 As shown, the image is located in a functional position.

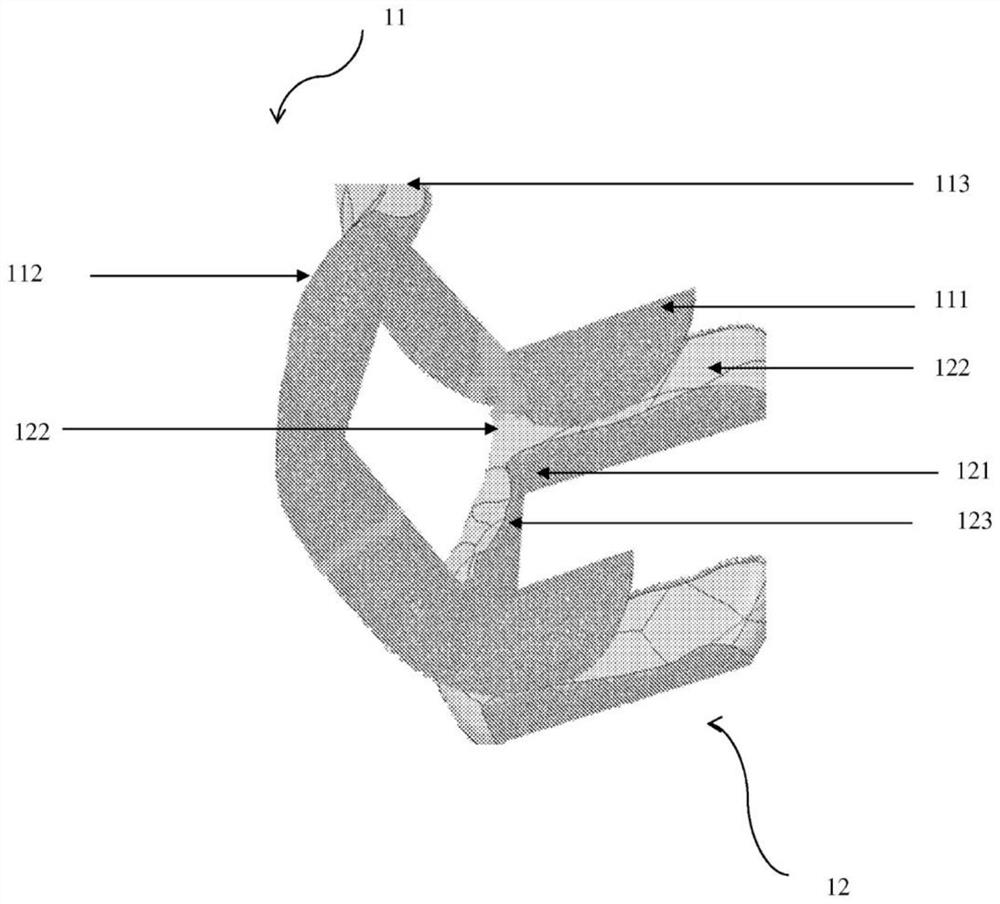

[0173] On the basis of the 3D image of the tibiofemoral joint in functional position, the recesses required to accommodate the custom implants 11, 12 have been made on the 3D image of the tibiofemoral joint in order to locally modify the proximal tibial end 30 and Distal femoral end 20 .

[0174] A recess 21 has been formed on the distal femoral end 20 and a recess 31 has been formed on the proximal tibial end 30 .

[0175] By means of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com