Individualized customized implantation material shaping device for 3D printing and manufacturing method thereof

A 3D printing and implant technology, used in bone implants, additive processing, etc., can solve the problems of single function, not widely promoted, and high cost, achieve convenient shaping, reduce patient pain, and low entry threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

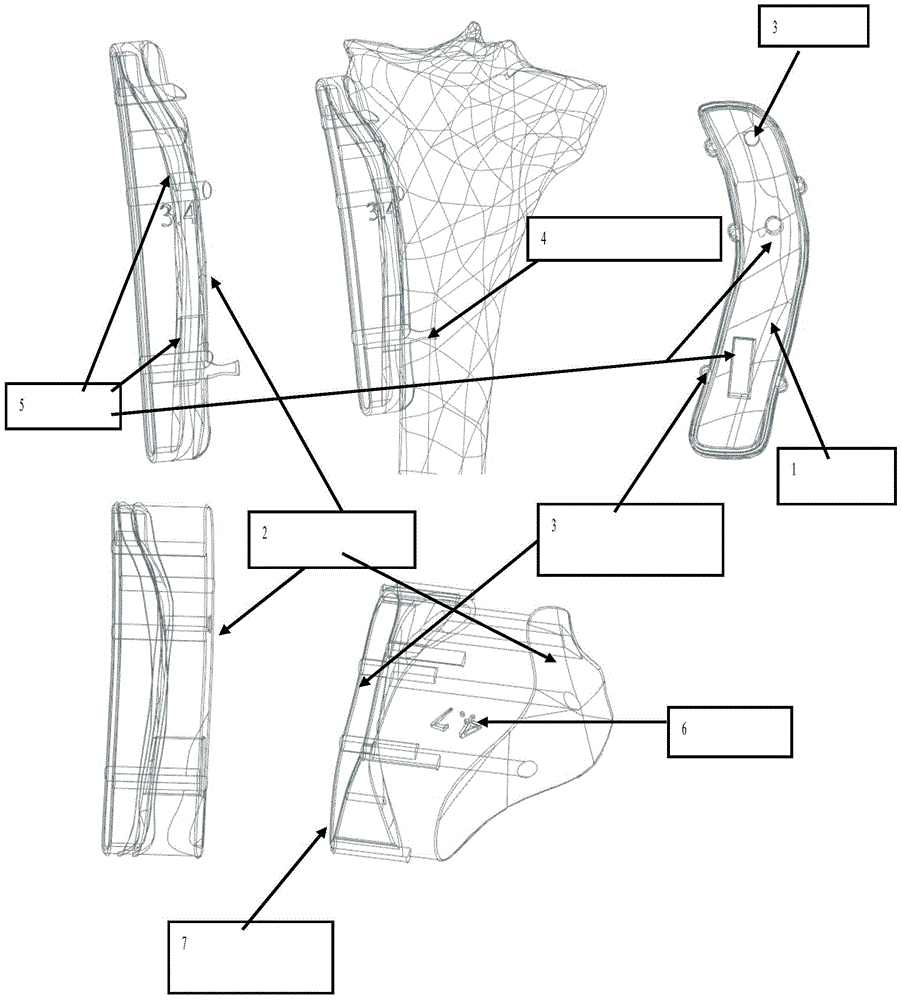

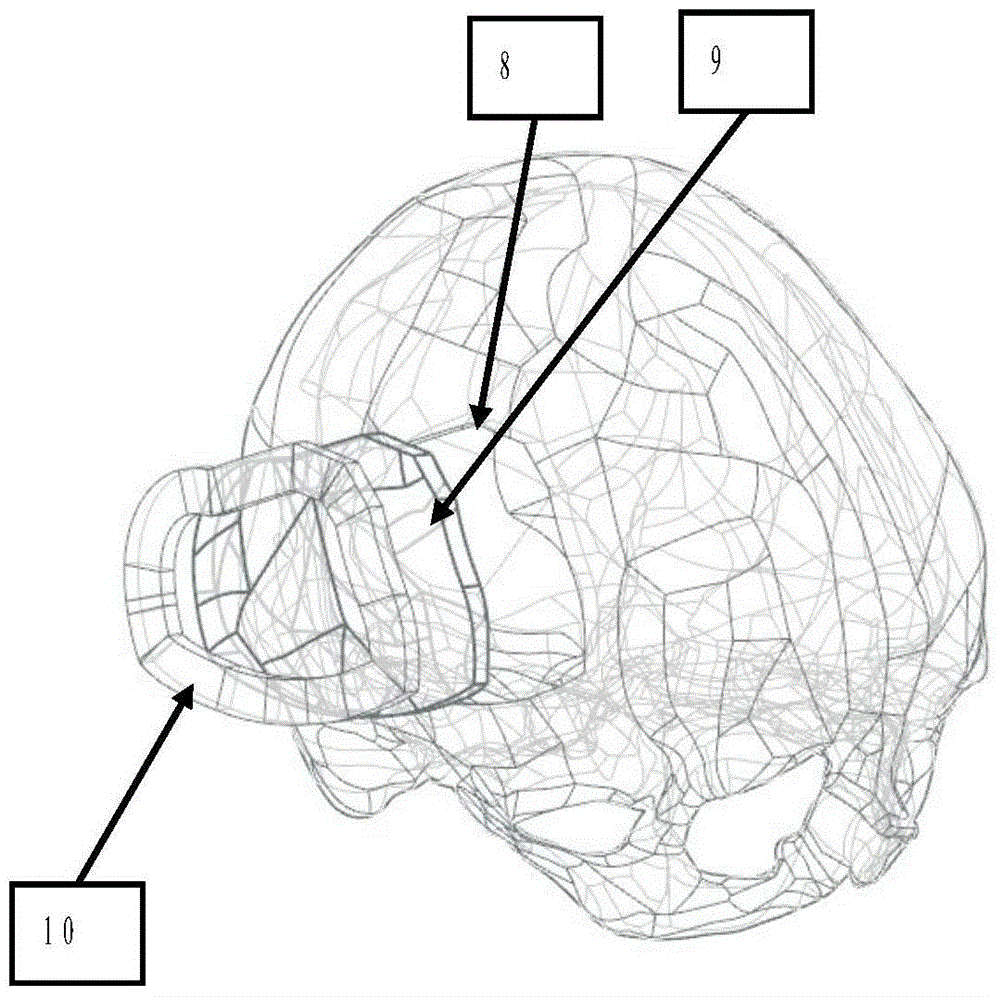

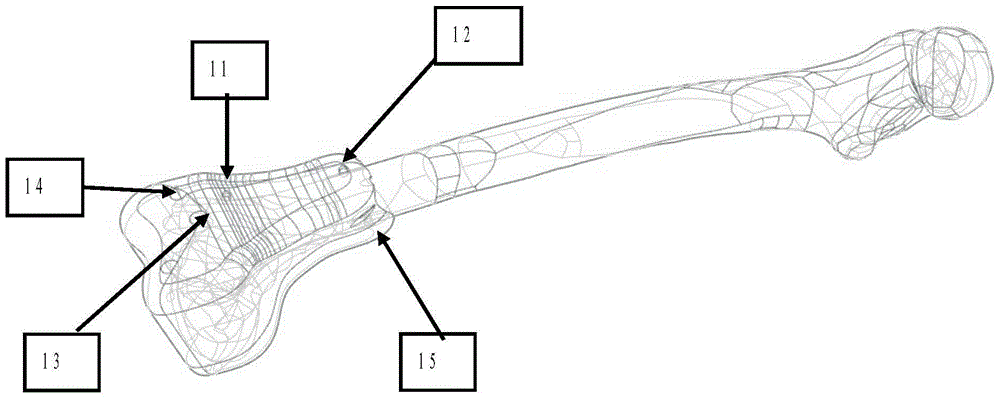

[0032] Such as Figure 1-3 As shown, the 3D printing personalized implant shaping device can be divided into three categories: one is a guide plate or mold designed based on the bone surface after the establishment of the most ideal reposition and alignment bone digital model. The other is a guide plate or mold designed based on the establishment of the most ideal installation and digital model of the implant, and the other is mainly used for tissue defect repair implants and prosthetic implants.

[0033] The first is suitable for situations where the shape of the implant is complex, the bone surface is intact or the defect is small, the bone digital model is simple to reset, or the normal side bone model is established. According to its bottom design, it is divided into 3 categories. For these three types of devices, the top surface 1 is the working surface, and the top surface 1 is consistent with the bone surface of the established digital bone model that has been optimally r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com