Management system and method for whole steel bar engineering process based on 3D figure information platform

A technology of steel bar engineering and graphic information, which is used in data processing applications, electrical digital data processing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

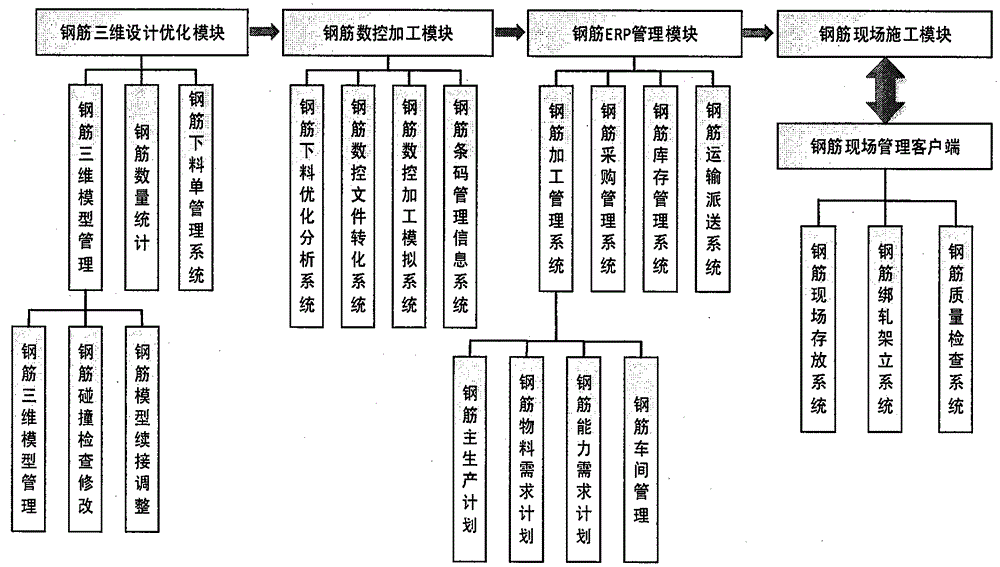

[0040] The purpose of the present invention is to solve the above-mentioned technical problems, and provide a set of solutions based on a three-dimensional graphics information platform for reinforced concrete structures.

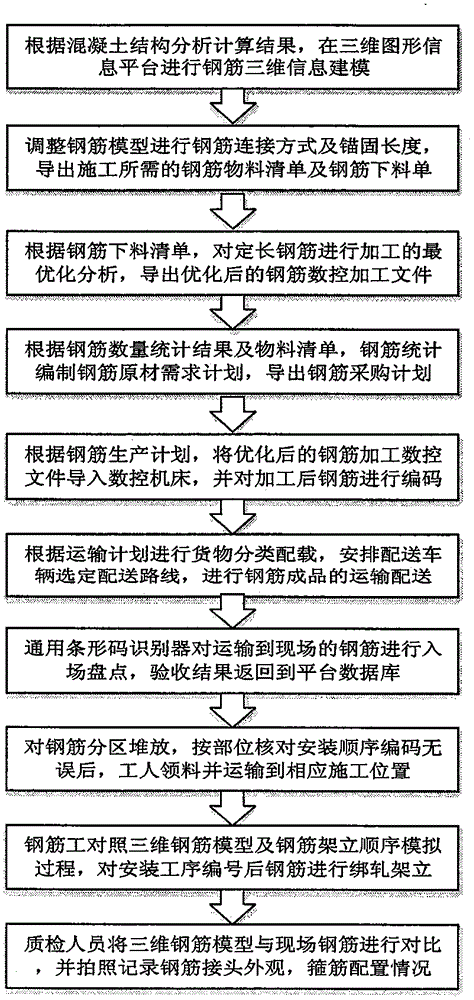

[0041] step one

[0042] According to the structural analysis and calculation results of reinforced concrete structures, secondary modeling of steel bars is carried out on steel bar calculation books, CAD drawings or BIM models of steel bar calculations, and the three-dimensional information of steel bars with engineering information is completed through the rapid modeling tool of the three-dimensional graphic information platform developed by the present invention Model.

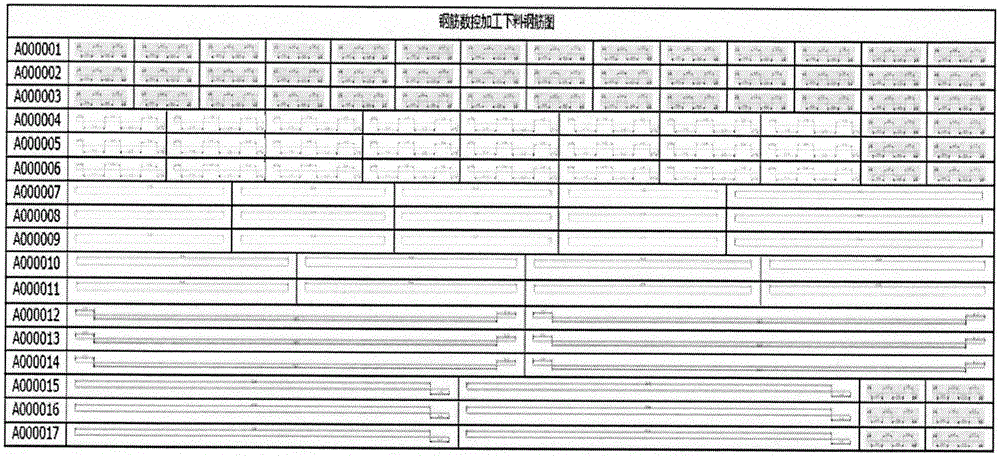

[0043] 1. Obtain the reinforcement calculation book and CAD two-dimensional reinforcement drawings through the structural analysis software, and complete the three-dimensional modeling of the reinforcement through the reinforcement layout rules and the 3D graphic information platform. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com