Waste steam recovering and utilziing method for atmospheric evaporation in imine puling process

A technology of evaporative emission and waste steam recovery, which is applied in the direction of evaporation, concentration of waste liquid, separation methods, etc., can solve the problems of difficult operation, high energy consumption, pollution of the environment, etc., and achieve the effect of reasonable investment and energy consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

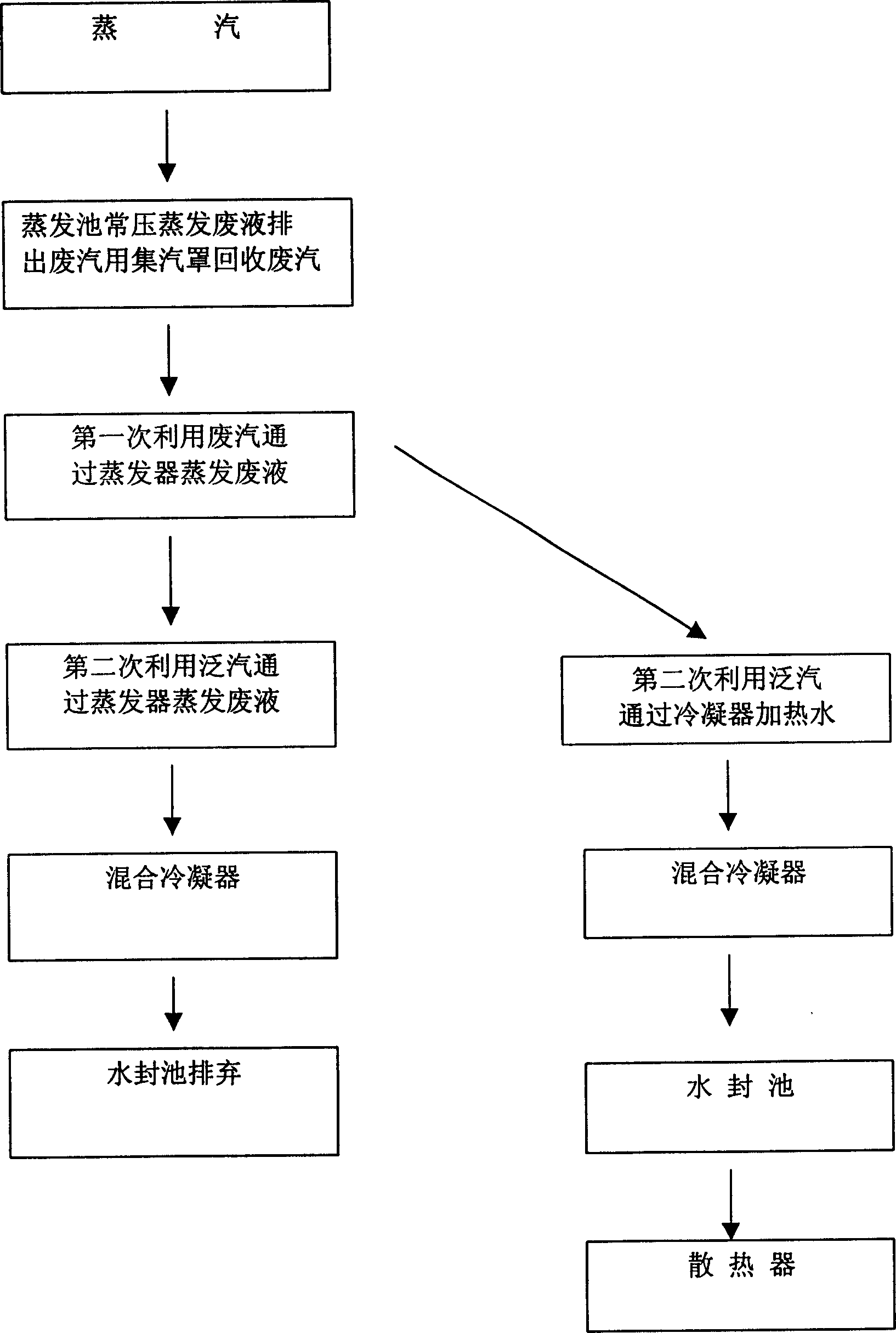

[0019] The waste steam recovery method of ammonium pulping waste liquid is evaporated at atmospheric pressure, that is, reinforced concrete is combined with a 15mm thick steel plate to make a steam collecting hood with a cone angle of 172°, and the bottom of the steel plate steam collecting hood is fixed on the 11.5m in diameter by welding On the steel ring embedded in the reinforced concrete opening groove wall. There are 4 water seal holes for people to enter and exit on the steam collecting hood. The diameter of the hole is 500mm, and the water surface of the water seal is 2mm high. The water seal cover is made of 1mm thick stainless steel plate and is worn on a steel rod. If the pressure of the evaporation pool exceeds 12mm water column due to an operation error, the water seal cover will automatically take off and exhaust quickly to ensure the safety of the gas collecting hood.

Embodiment 2

[0021] It is the first time to use the method of recycling waste steam to evaporate waste liquid, that is, to use a steel pipe with an outer diameter of 426mm and a wall thickness of 6mm to connect the steam collecting hood with a normal spray-film horizontal evaporator. The evaporator is equipped with a heater and an evaporation chamber for evaporation. Install TQ3701 demister on the chamber. The outer diameter of the heat transfer tube is 38mm, the wall thickness of the tube is 1.2mm, and the length of the steel tube is 3000mm. The distance between each side and the center is 48mm. The temperature of the atmospheric waste steam is 100°C, the temperature of the evaporation chamber is 76°C, and the concentration of the waste liquid entering the evaporator is 10.7% (by weight). 80m with normal lift 2 / H, the SBG100-200 centrifugal circulating pump with a lift of 8m water column sprays waste liquid to the heat transfer tube. The concentration of waste liquid at the inlet of the...

Embodiment 3

[0023] The method of using flashing steam to heat water is to use the recovered waste steam to evaporate the waste liquid for the first time to heat the water with flashing steam at 76°C. After the flashing steam passes through the TQ3701 demister on the evaporation chamber to separate water droplets, it enters the condensation through the steel pipe. Condenser, the inlet pressure of the condenser is 0.06Mpa, the steam enters the condenser and mixes with water to condense into water, its volume is 4000m 3 / t water cooling shrinks to 1m 3 / t water, a vacuum is formed, and the steam automatically flows from the evaporator into the mixed condenser. The non-condensable gas in the condenser is pumped out by a water ring vacuum pump, and the condenser is installed on a shelf with a height of 10m. The temperature of the water from the mixing condenser discharged through the water-sealed pool reaches 60°C. It is used for heating in winter, and the hot water is cooled by the pond in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com